Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D printing modified polyamino acid material and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI

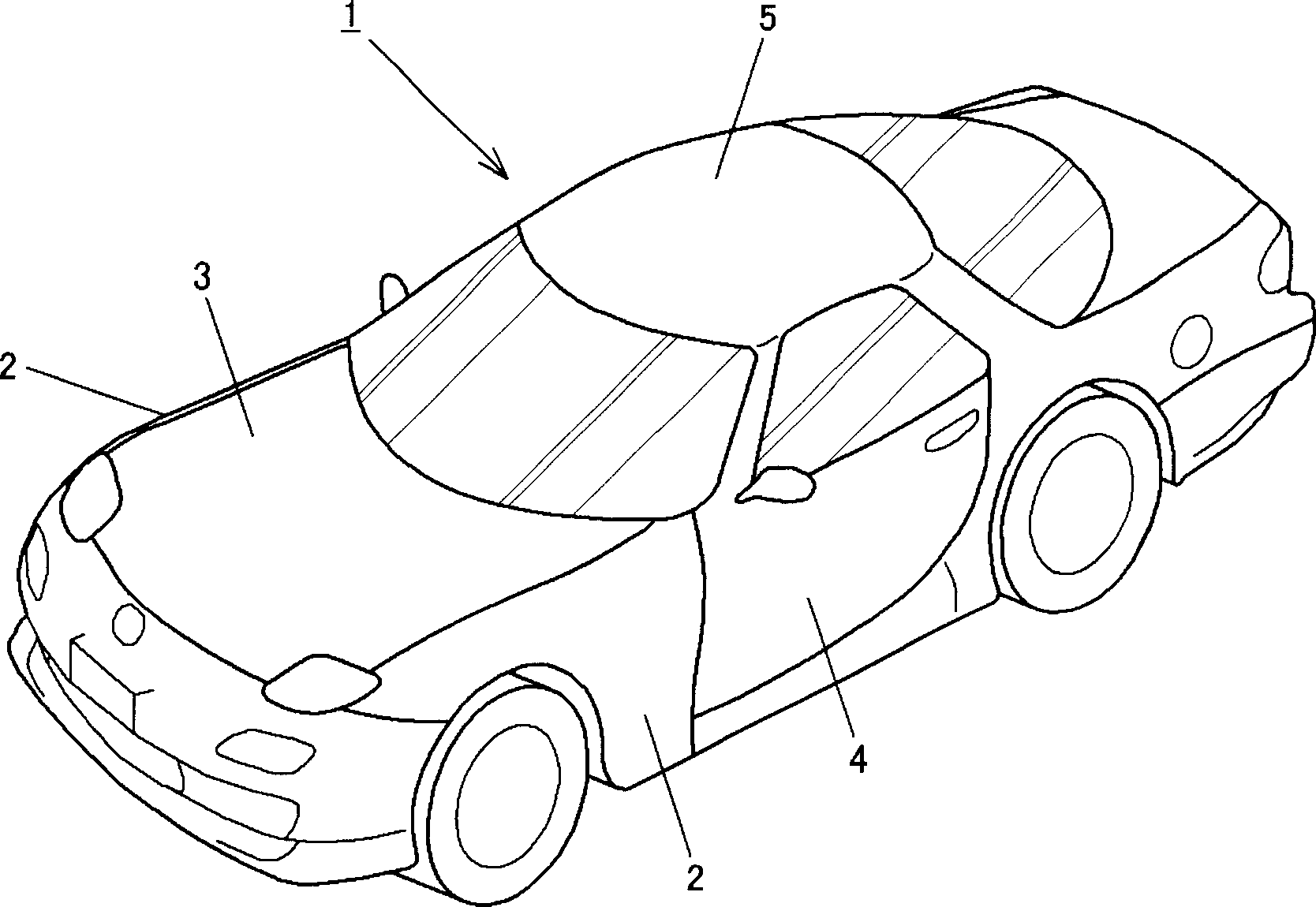

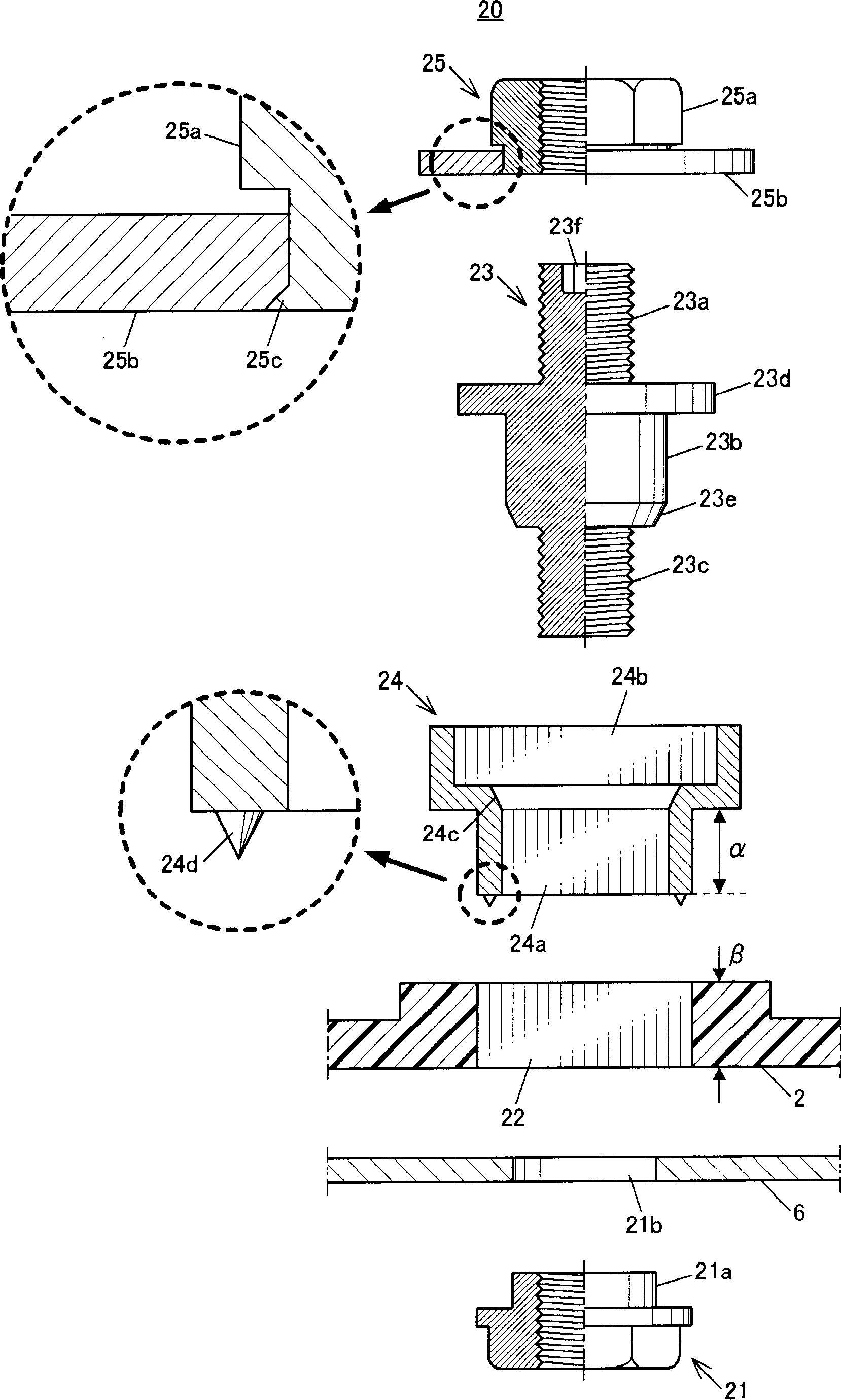

Mounting structure and mounting method for resin vehicle panel

InactiveCN1892055AAvoid deformationAvoid damageSuperstructure connectionsDowelsThermal deformationEngineering

Owner:MAZDA MOTOR CORP

Low-Nd anisotropic Nd2Fe14B/alpha-Fe composite nanocrystalline magnet and preparation method thereof

InactiveCN101593591AInorganic material magnetismInductances/transformers/magnets manufactureMagnetic anisotropyThermal deformation

Owner:YANSHAN UNIV

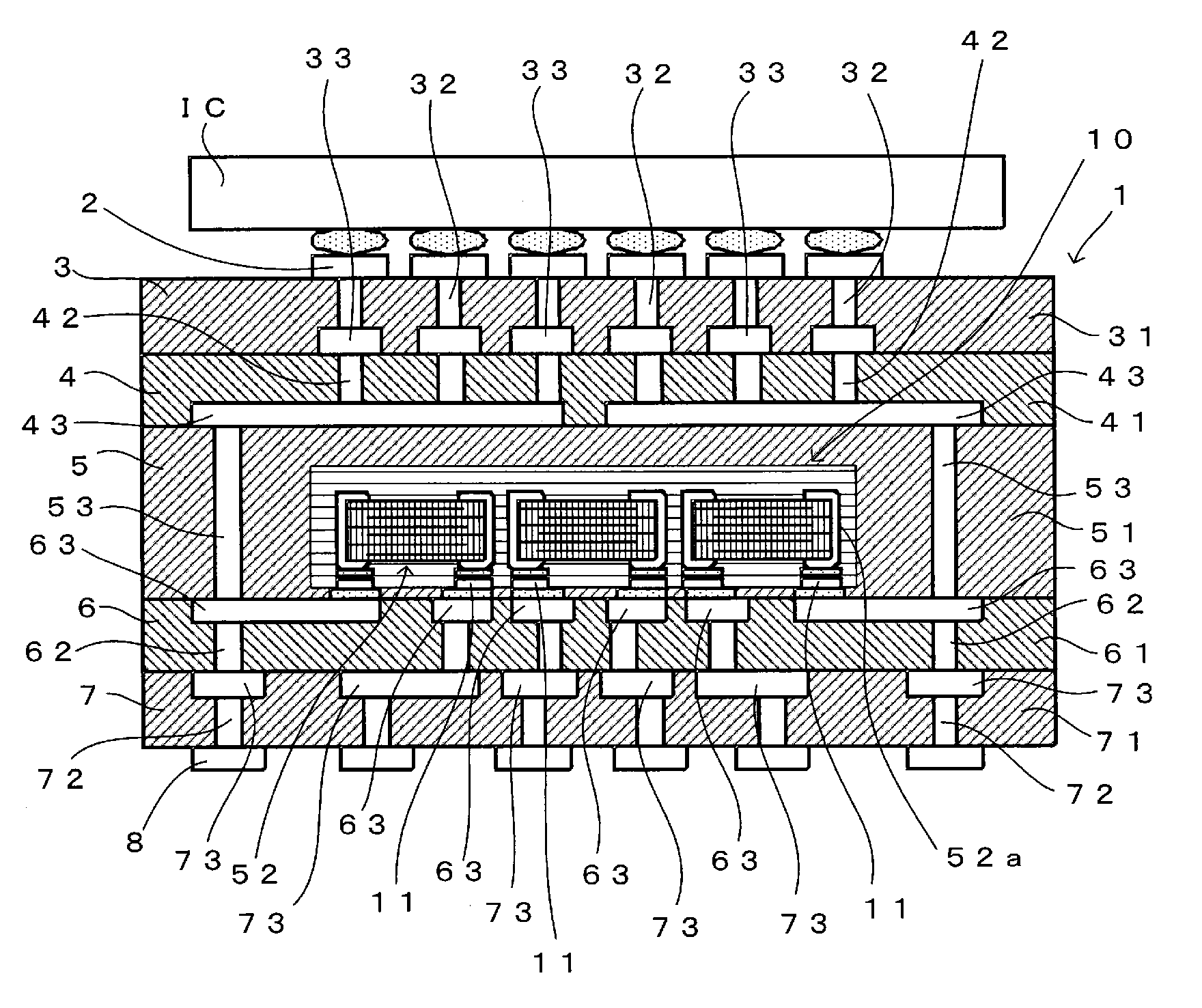

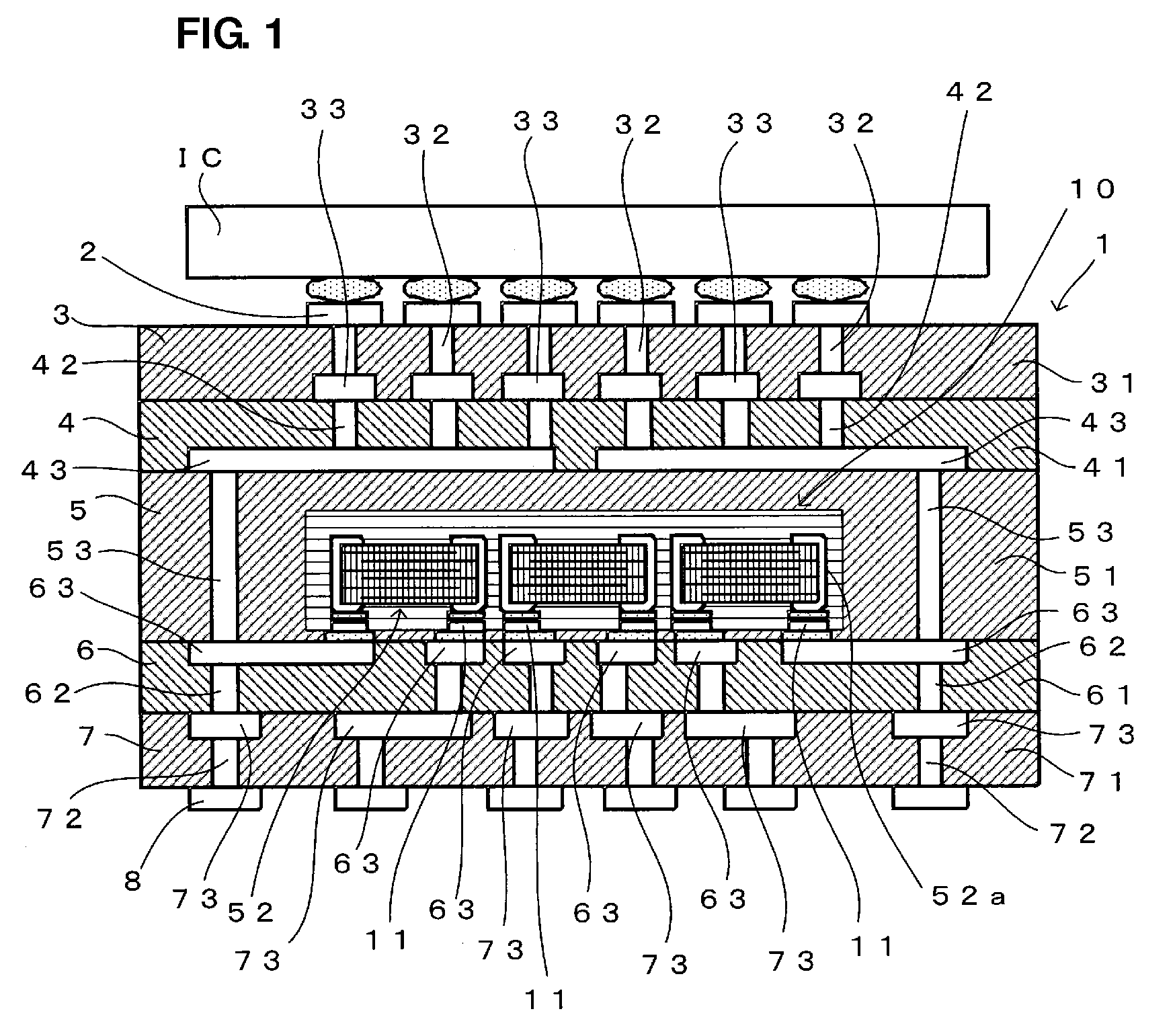

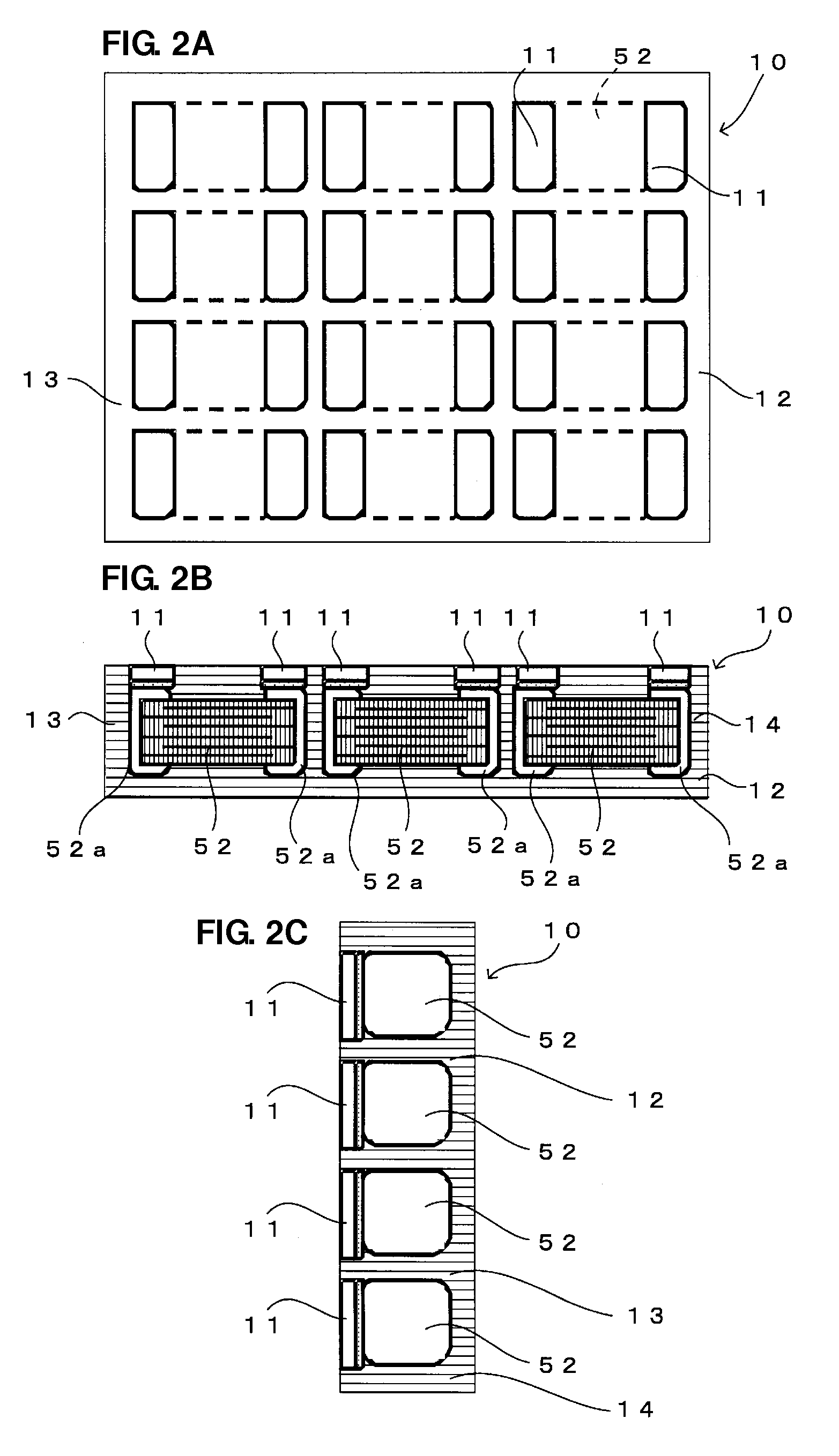

Component assembly

ActiveUS20130242517A1Well formedDistanceSemiconductor/solid-state device detailsFinal product manufactureThermal deformationEngineering

Owner:MURATA MFG CO LTD

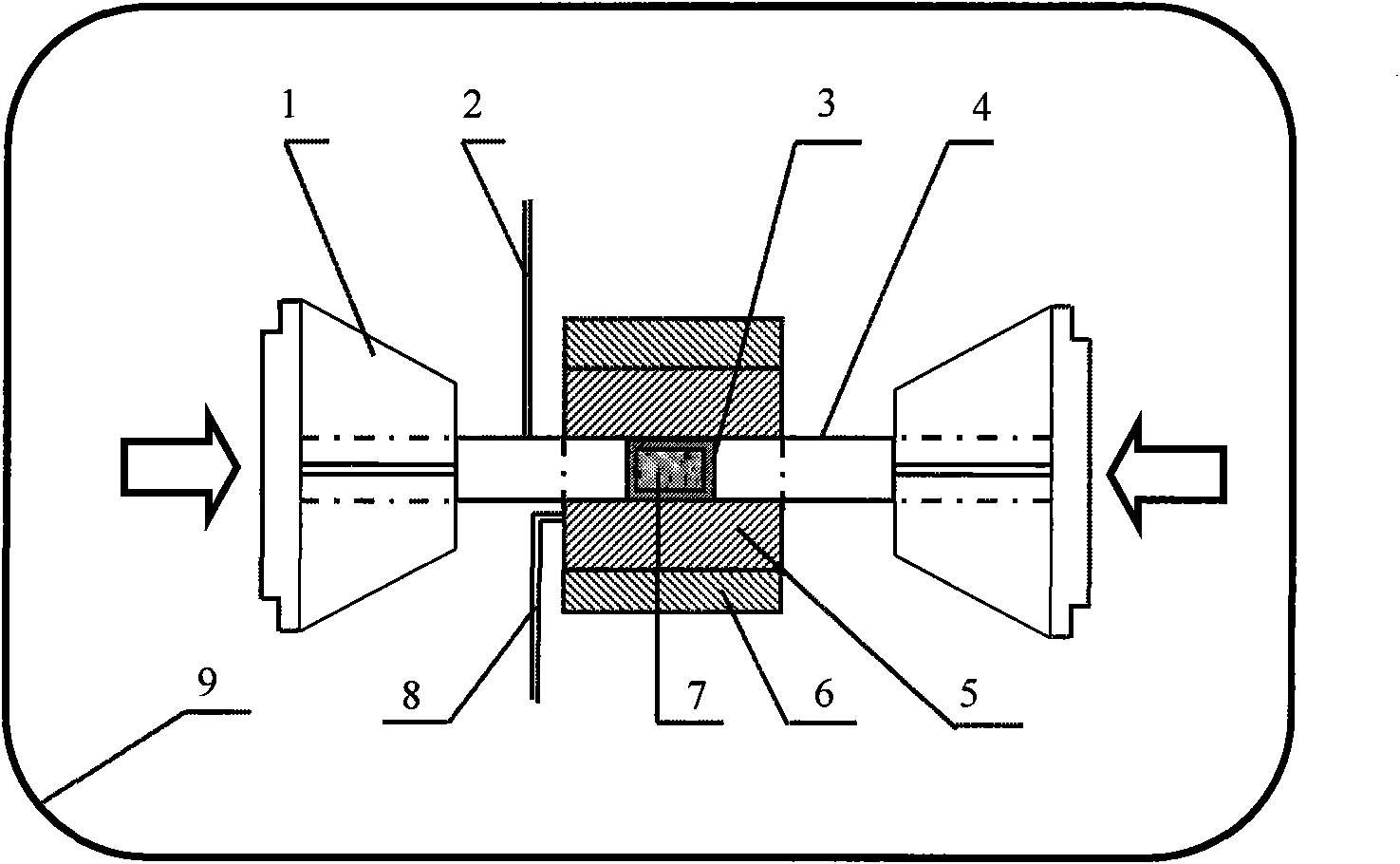

Welding method, welding system and welding jig

InactiveUS20060151572A1Reduce impactAvoid crackingElectric heatingWelding/cutting auxillary devicesFuel tankThermal deformation

A plurality of attachments having springs hold the outer plate of a fuel tank, and an inner jig positions the inner plate. The attachments are attached to clamp arms which are opened / closed by cylinders. When the overlap portion between the outer and inner plates is welded, the thermal deformation caused by welding is accommodated by the springs. The attachments are spaced from the fuel tank in the order in which the welding point is approached.

Owner:HONDA MOTOR CO LTD

Grain boundary diffusion method suitable for large rare earth permanent magnet material

ActiveCN111063536AMagnetic materialsInductances/transformers/magnets manufacturePhysicsThermal deformation

Owner:ZHEJIANG UNIV +1

Oil conveying pipeline shaping machine

The invention provides an oil conveying pipeline shaping machine and relates to the technical field of bent pipe machining. The oil conveying pipeline shaping machine comprises a fixing part, a pushing part, an inclined plate pressing part, thermal deformation assemblies, a driving assembly, a shaping part and a grinding control part and has the beneficial technical effects that a port of a pipeline can be closed, and the left end of the pipeline is pressed into a closed cross-shaped pattern. The pushing part is connected to the middle of the fixing part in a matched mode, the inclined plate pressing part is arranged at one end of the fixing part, the four thermal deformation assemblies are evenly arranged on the inclined plate pressing part in a surrounding mode, the driving assembly is fixedly connected to the other end of the fixing part, the shaping part is connected to the driving assembly in a matched mode, and the grinding control part is arranged on the shaping part, and the grinding control part drives the shaping part to rotate.

Owner:金爱兰

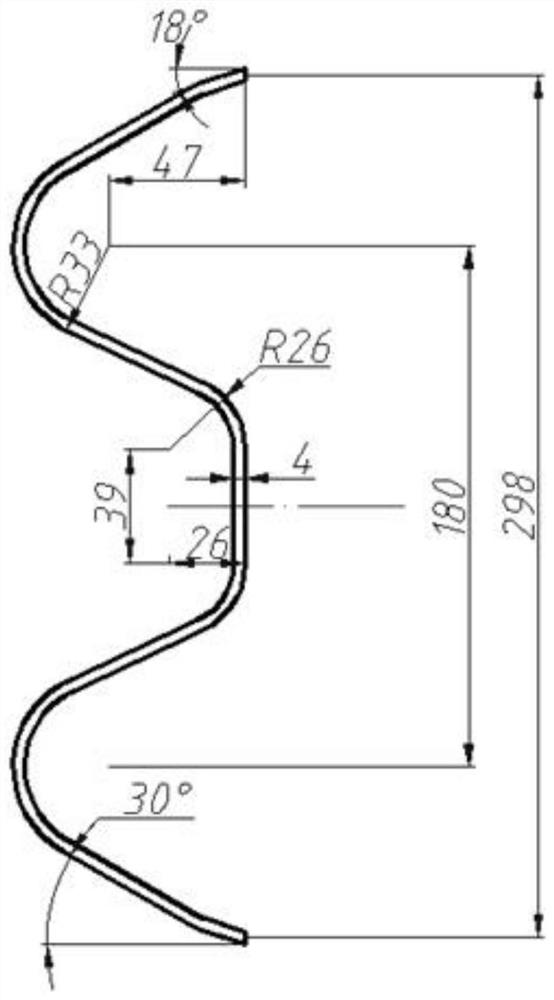

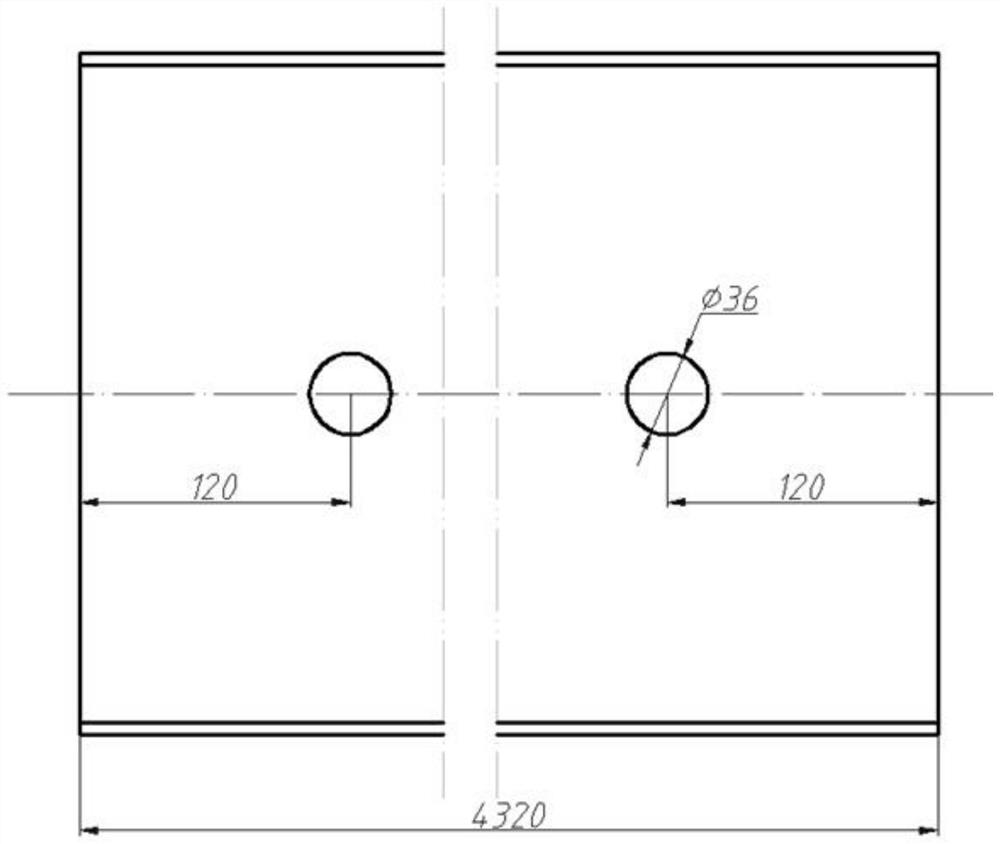

Hydrostatic thrust bearing device for reducing hot oil carrying

InactiveCN109236859AReduce carryReduce temperature riseBearingsThermal deformationThrust bearing

The invention discloses a hydrostatic thrust bearing device for reducing hot oil carrying. In order to solve the problem of temperature rise of an oil film caused by hot oil carrying between oil padsin a hydrostatic thrust bearing, an oil scraping plate structure easy to remove and change is mounted on a traditional hydrostatic thrust bearing base, and the traditional plane oil scraping surface is changed into a curved oil scraping surface, thus the heat dissipation area of oil liquid and the hot oil scraped by the oil scraping plate are increased, the hot oil carried between two adjacent oilpads is reduced, the temperature rise of the oil liquid is effectively relieved, and thermal deformation of a machine tool is prevented; meanwhile, the circumferential width of the left and right ends of an oil sealing edge of the oil pad is of an asymmetric structure, the side with greater circumferential width inclines downward, then a dynamic pressure is formed by use of a wedge shape betweenthe inclined plane of the oil pad and a rotary table guide rail so as to compensate for the hydrostatic loss of the lubricating oil, thus the rigidity and the bearing capacity of the oil film are improved, the problem of lubrication failure of the hydrostatic thrust bearing is solved, and high-precision and high-efficiency work of the whole machine tool is guaranteed.

Owner:HARBIN UNIV OF SCI & TECH

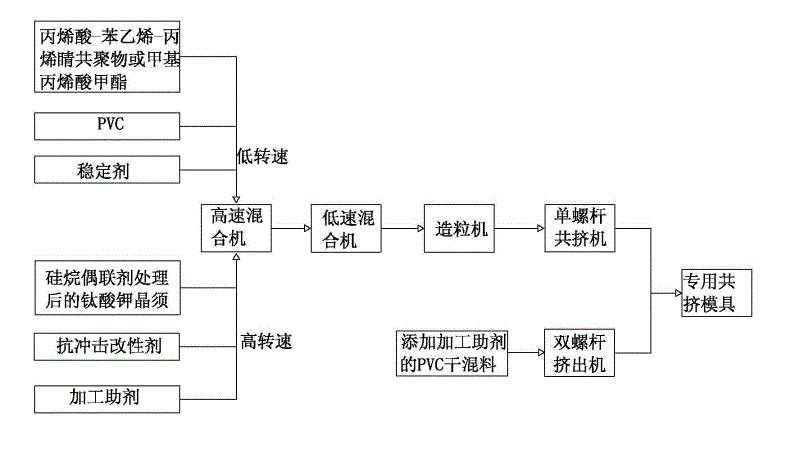

Color bending-resistant co-extruded section bar reflecting infrared rays and preparation method thereof

ActiveCN102617962AWith reflective infrared functionWith heat insulation functionInfraredPolyvinyl chloride

Owner:新疆蓝山屯河型材有限公司

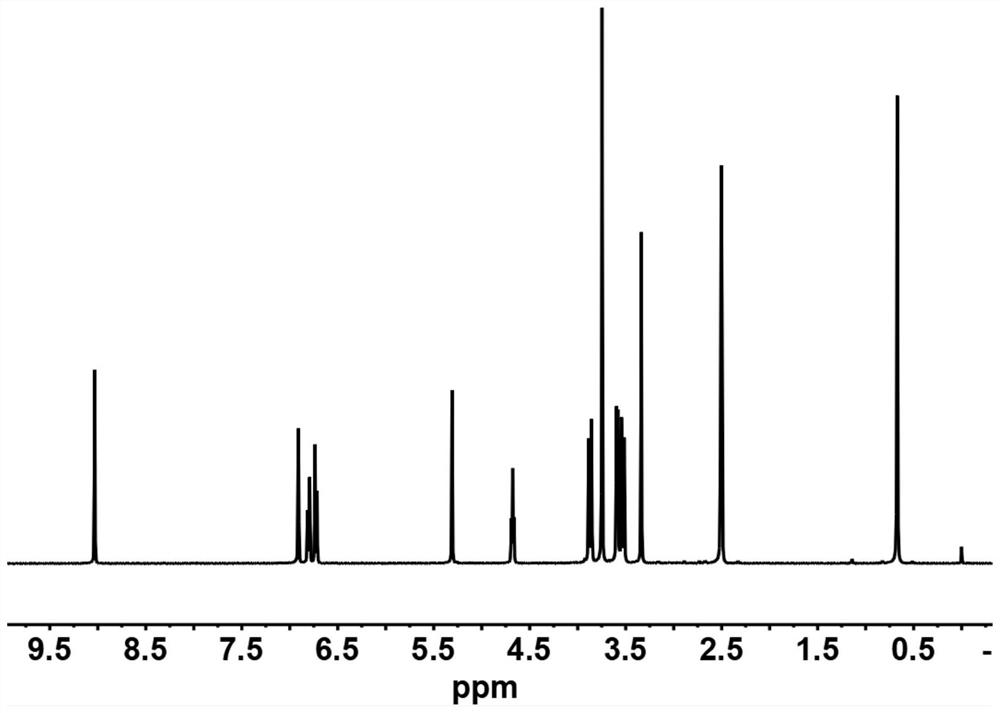

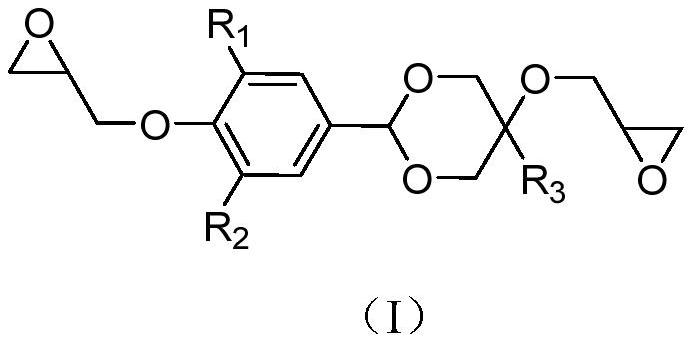

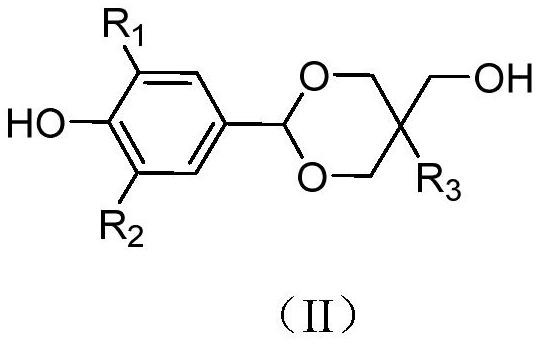

Epoxy monomer based on acetal structure as well as preparation method and application thereof

ActiveCN111704711AImprove mechanical propertiesImprove heat resistanceOrganic chemistryEpoxyHeat deflection temperature

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Joint calculation method for strength of transverse stationary blade and cylinder body of steam turbine based on finite elements

The invention discloses a joint calculation method for strength of a transverse stationary blade and a cylinder body of a steam turbine based on finite elements, and belongs to the field of steam turbine design. The invention aims to solve the safety problem caused by the fact that only steam stress is considered and thermal deformation and thermal stress of a cylinder caused by temperature are not considered in the existing design. The method comprises the following steps: a calculation method can accurately solve an equivalent stress of a transverse stationary blade under the influence of a thermal deformation of a cylinder, and a basis is provided for the design of the transverse stationary blade of a steam turbine; finite element solution is conducted on the coupling of the transverse stationary blade with a cylinder body structure, temperature-stress-strain distribution of all nodes is obtained, and a CEEQ criterion is used to check whether the structure is invalid or not; the stress-strain value obtained through the calculation method can be used for evaluating the safety of the turbine transverse stationary blade during a steady-state operation, and a reliable calculation method is provided for calculation of the stress-strain field of the transverse stationary blade of the steam turbine under the thermosetting coupling condition. The method is mainly used for calculating the equivalent stress, a maximum stress and an equivalent creep strain of the transverse stationary blade and the cylinder.

Owner:HARBIN TURBINE +1

Protective guard

Owner:河北省高速公路京衡管理处

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap