Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Oil film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

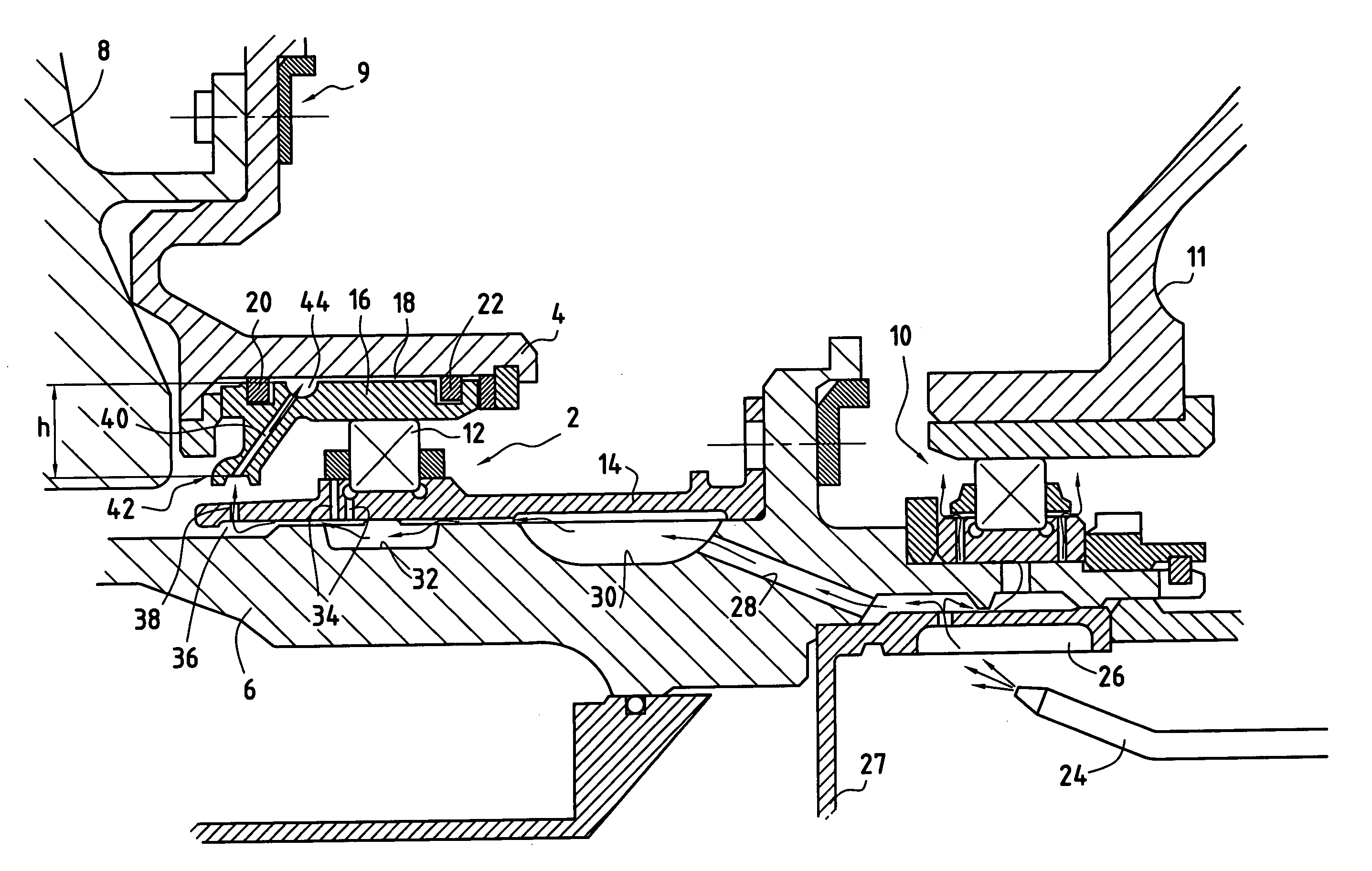

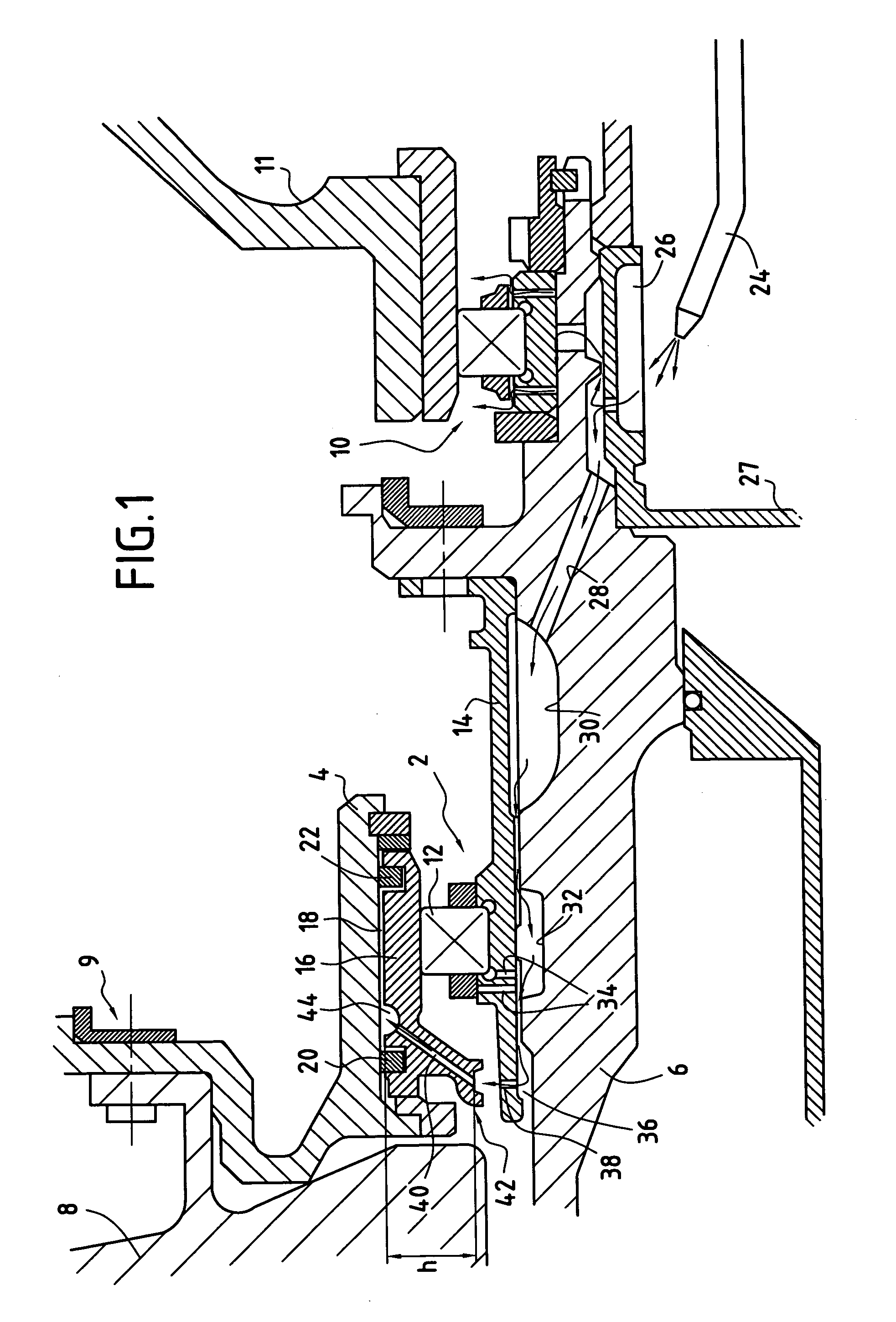

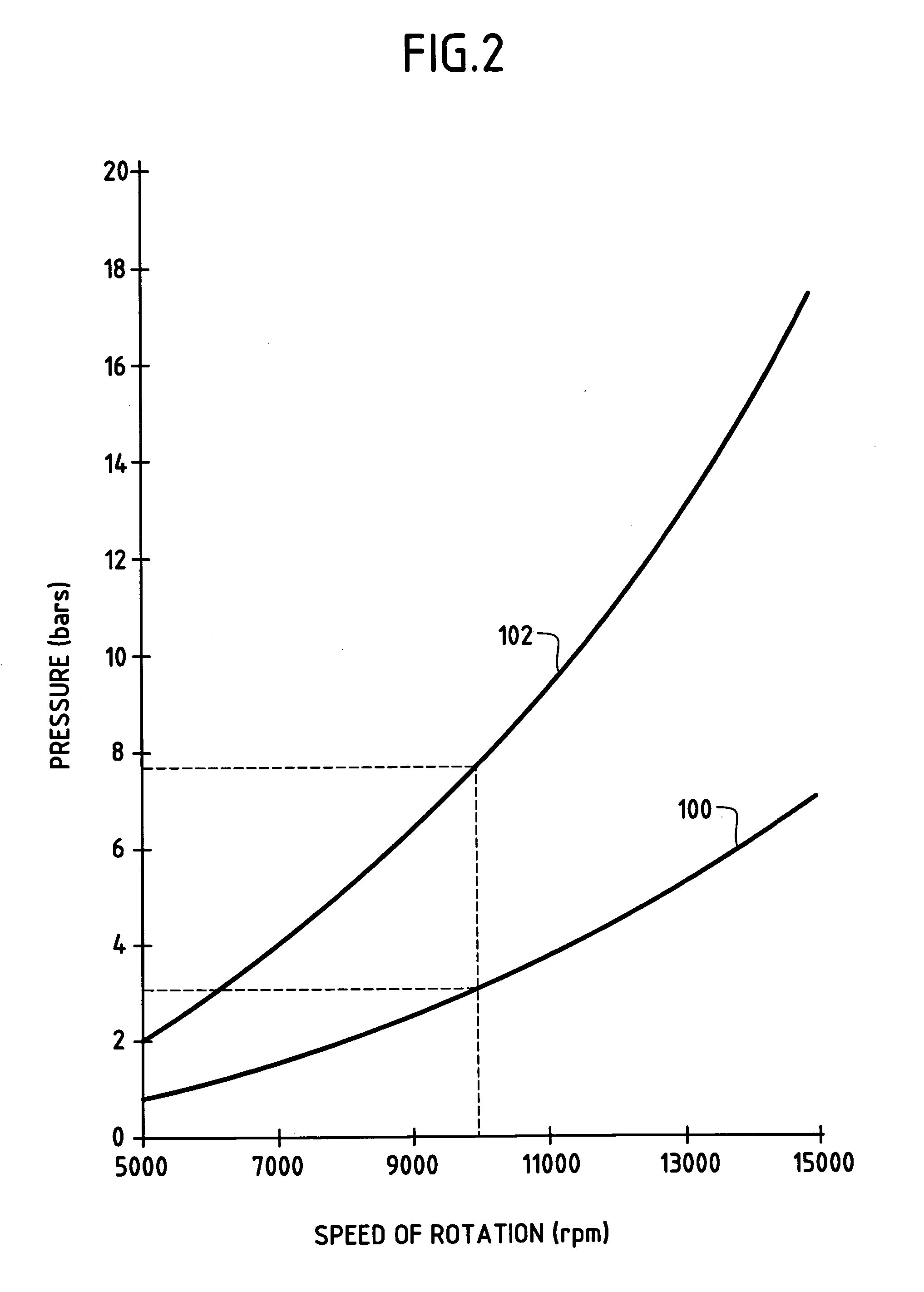

Oil-damped rolling bearing

ActiveUS20040062460A1Mitigate such drawbackRoller bearingsPump componentsRolling-element bearingEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Wooden sound insulation door

ActiveCN106761297AImprove sealingAchieve penetrationNoise insulation doors/windowsSealing arrangementsEngineeringPiston

Owner:重庆金华兴门业有限公司

Central grading lean oil premixed low-pollution combustion chamber

ActiveCN111174233ABroaden the boundaries of workPromote atomizationContinuous combustion chamberSpontaneous combustionCombustion chamber

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Thrust bearing

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

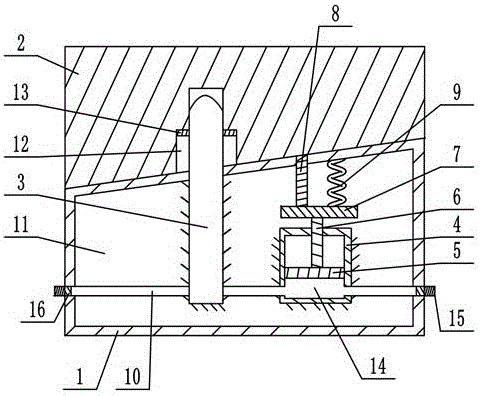

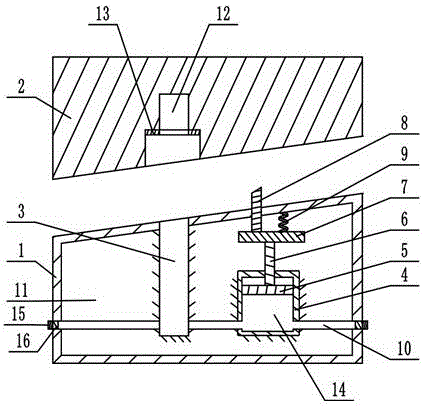

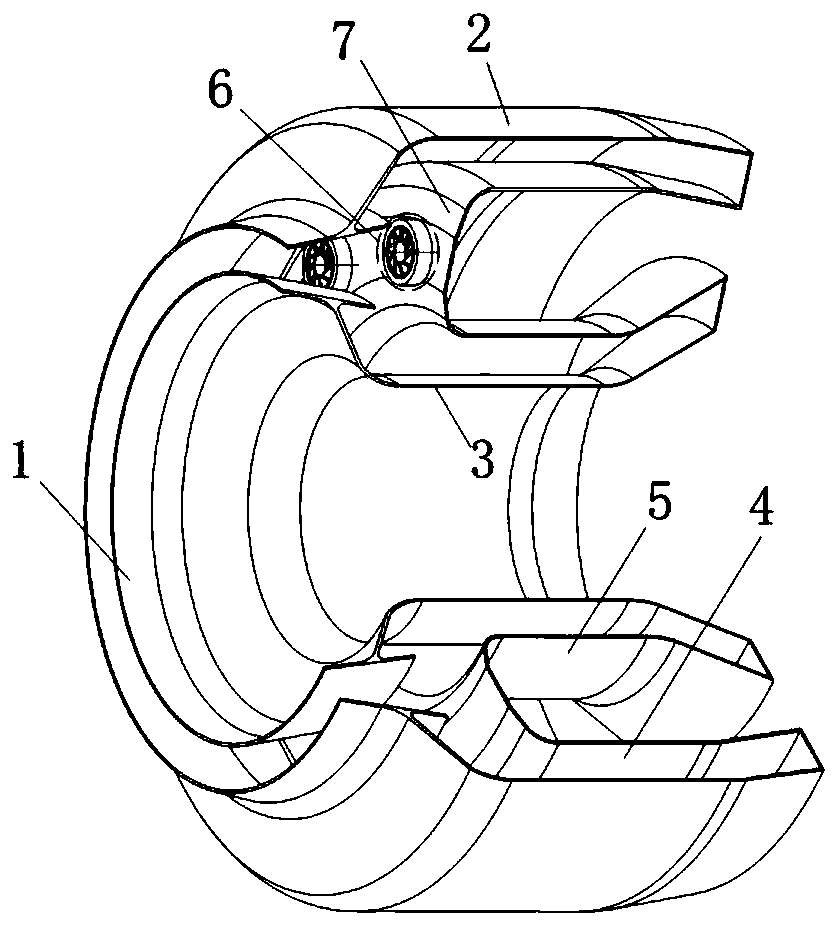

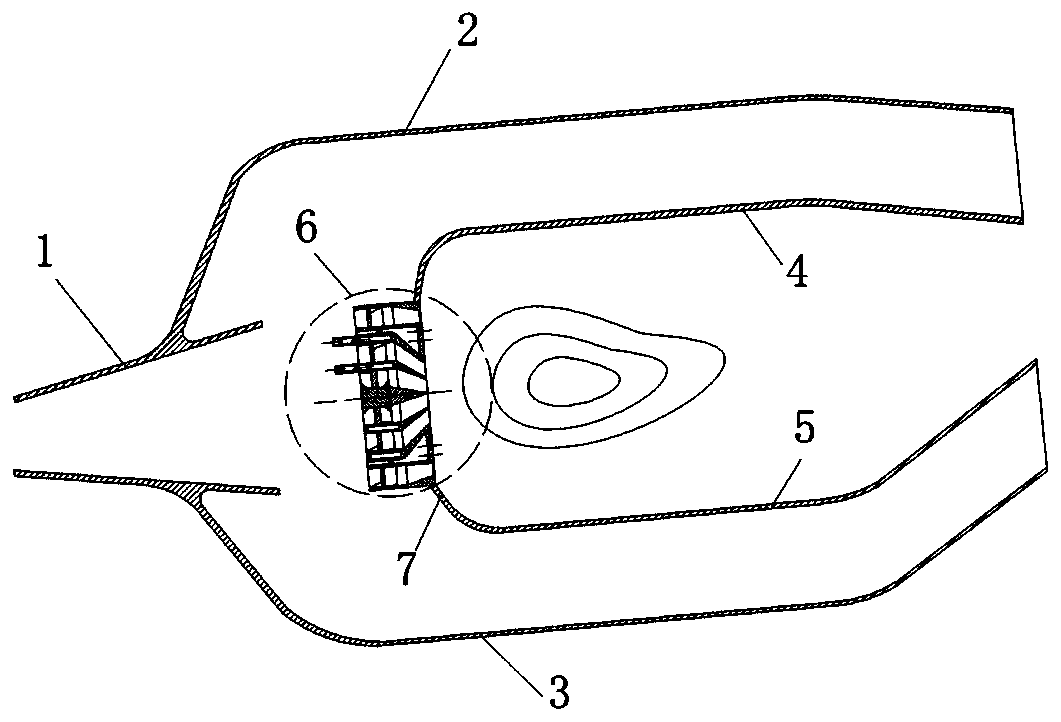

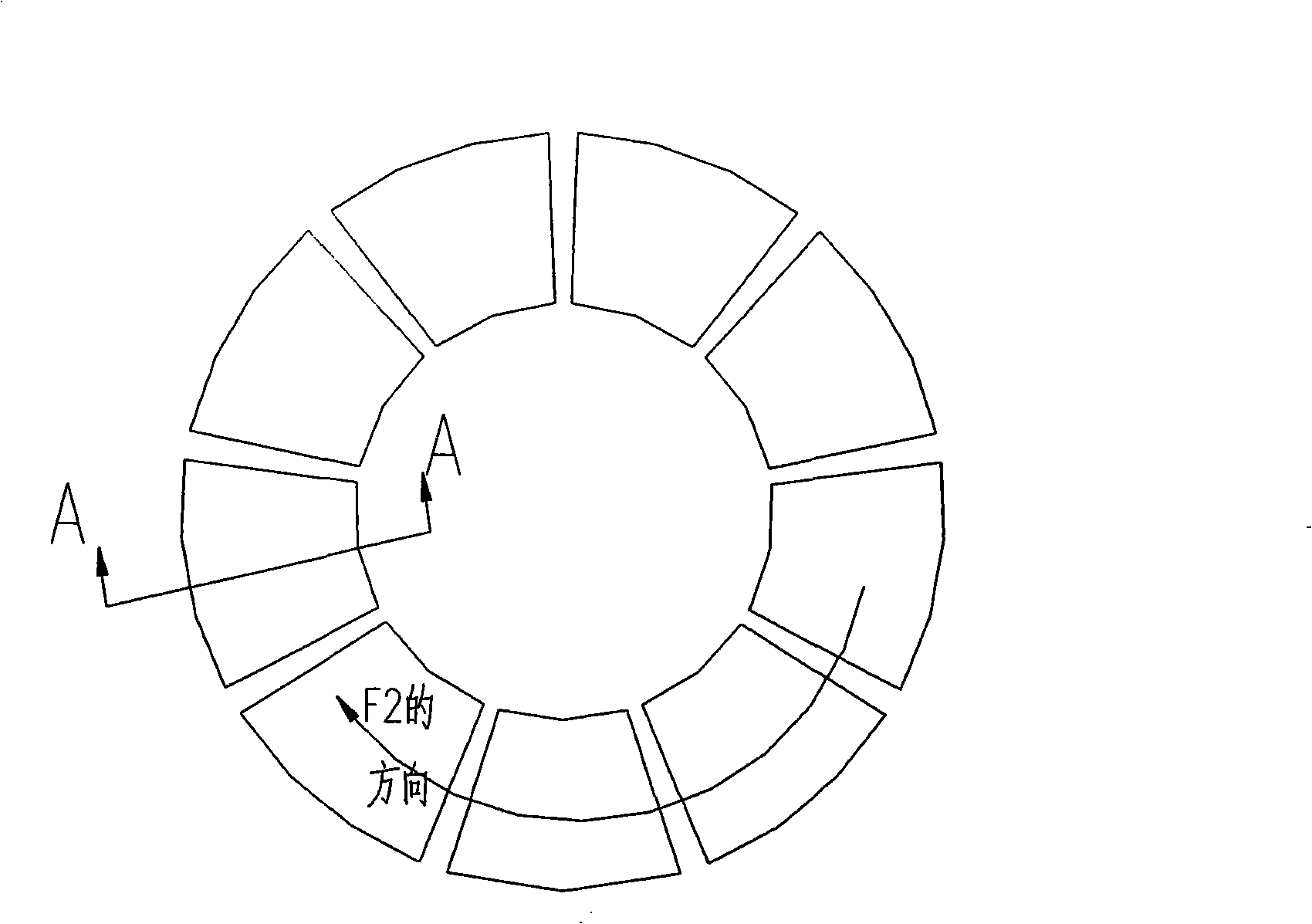

Hydrostatic thrust bearing device for reducing hot oil carrying

InactiveCN109236859AReduce carryReduce temperature riseBearingsThermal deformationThrust bearing

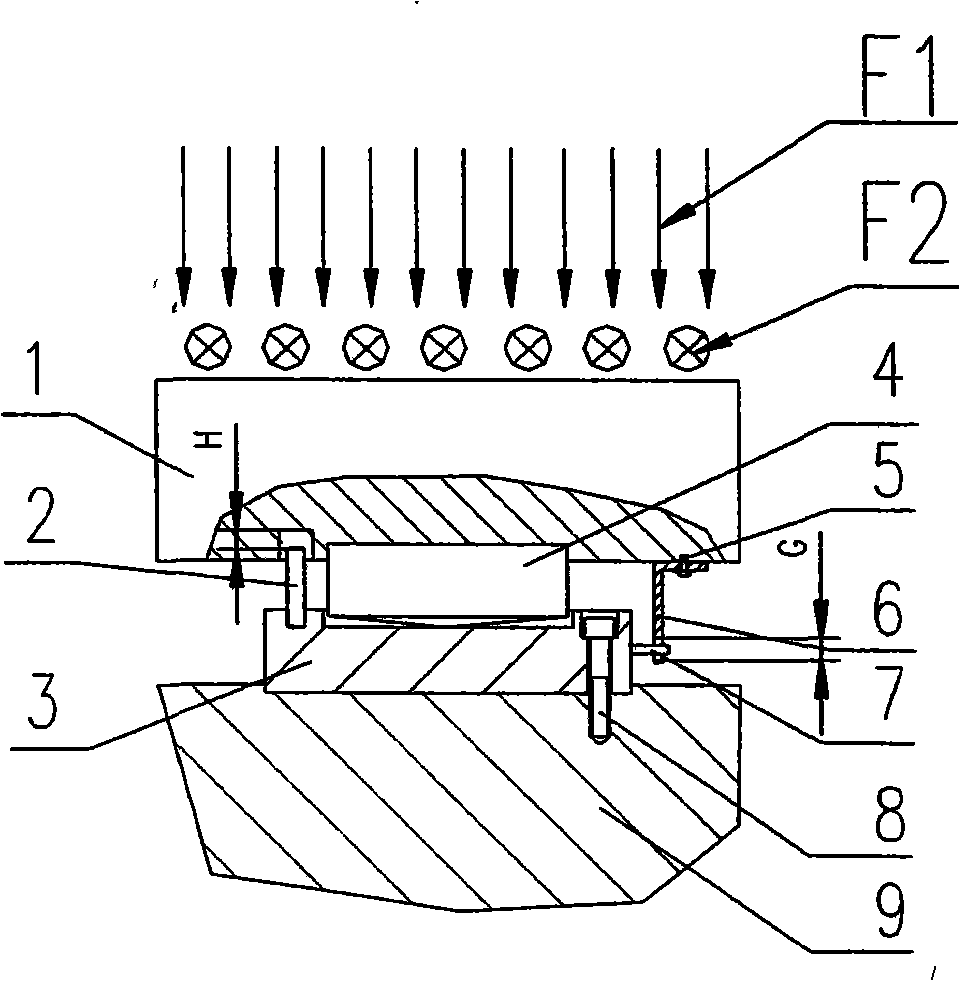

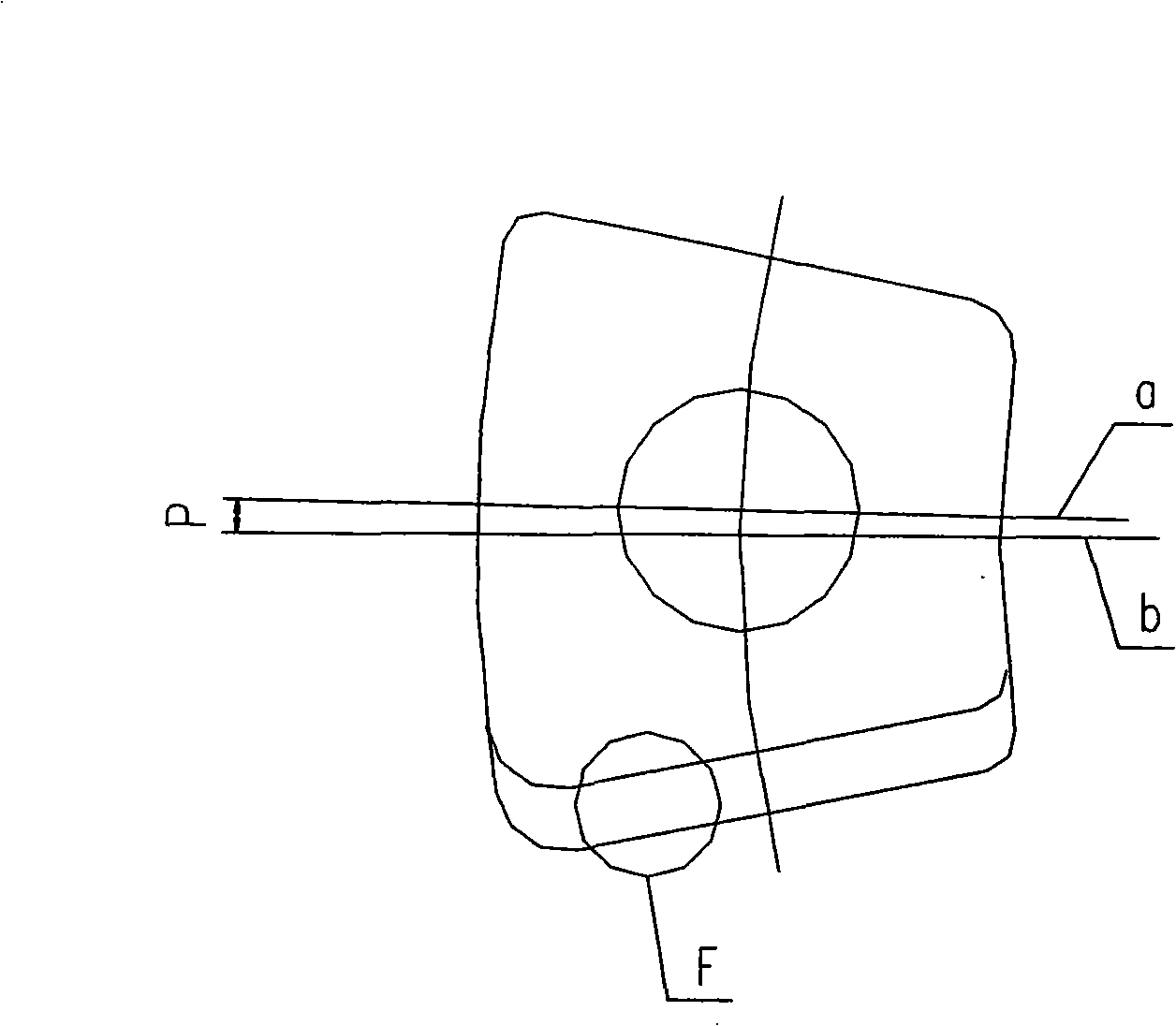

The invention discloses a hydrostatic thrust bearing device for reducing hot oil carrying. In order to solve the problem of temperature rise of an oil film caused by hot oil carrying between oil padsin a hydrostatic thrust bearing, an oil scraping plate structure easy to remove and change is mounted on a traditional hydrostatic thrust bearing base, and the traditional plane oil scraping surface is changed into a curved oil scraping surface, thus the heat dissipation area of oil liquid and the hot oil scraped by the oil scraping plate are increased, the hot oil carried between two adjacent oilpads is reduced, the temperature rise of the oil liquid is effectively relieved, and thermal deformation of a machine tool is prevented; meanwhile, the circumferential width of the left and right ends of an oil sealing edge of the oil pad is of an asymmetric structure, the side with greater circumferential width inclines downward, then a dynamic pressure is formed by use of a wedge shape betweenthe inclined plane of the oil pad and a rotary table guide rail so as to compensate for the hydrostatic loss of the lubricating oil, thus the rigidity and the bearing capacity of the oil film are improved, the problem of lubrication failure of the hydrostatic thrust bearing is solved, and high-precision and high-efficiency work of the whole machine tool is guaranteed.

Owner:HARBIN UNIV OF SCI & TECH

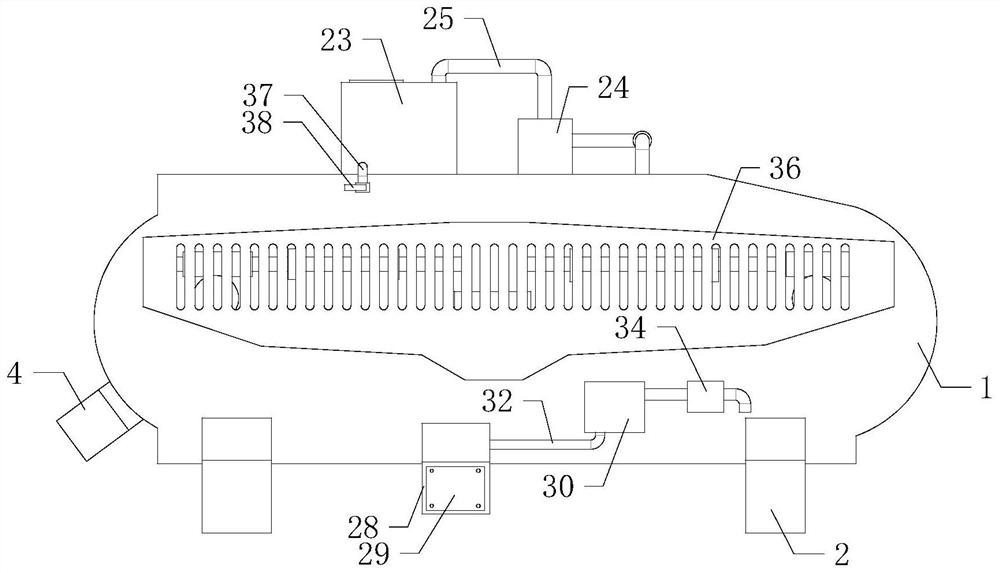

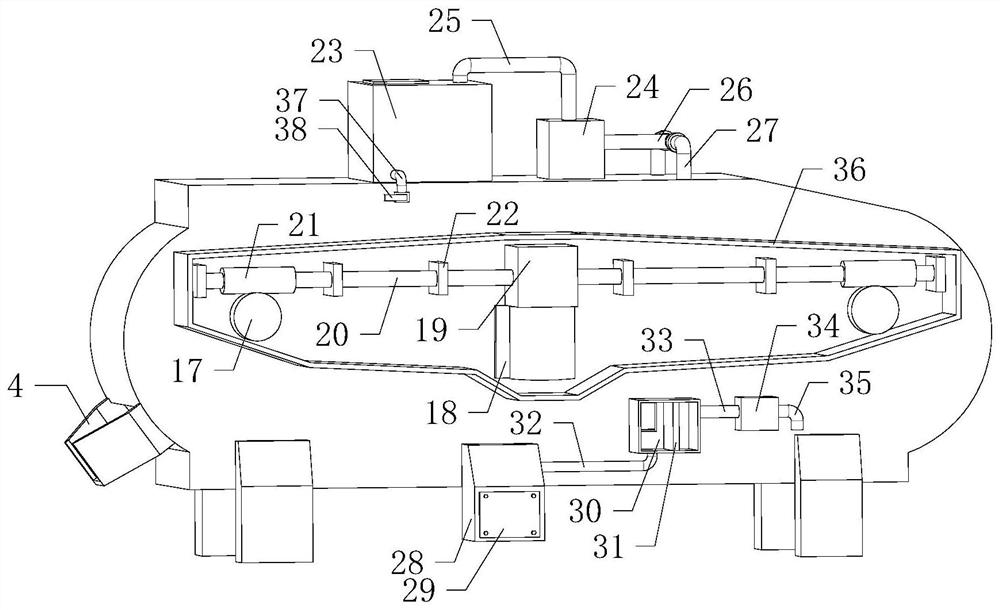

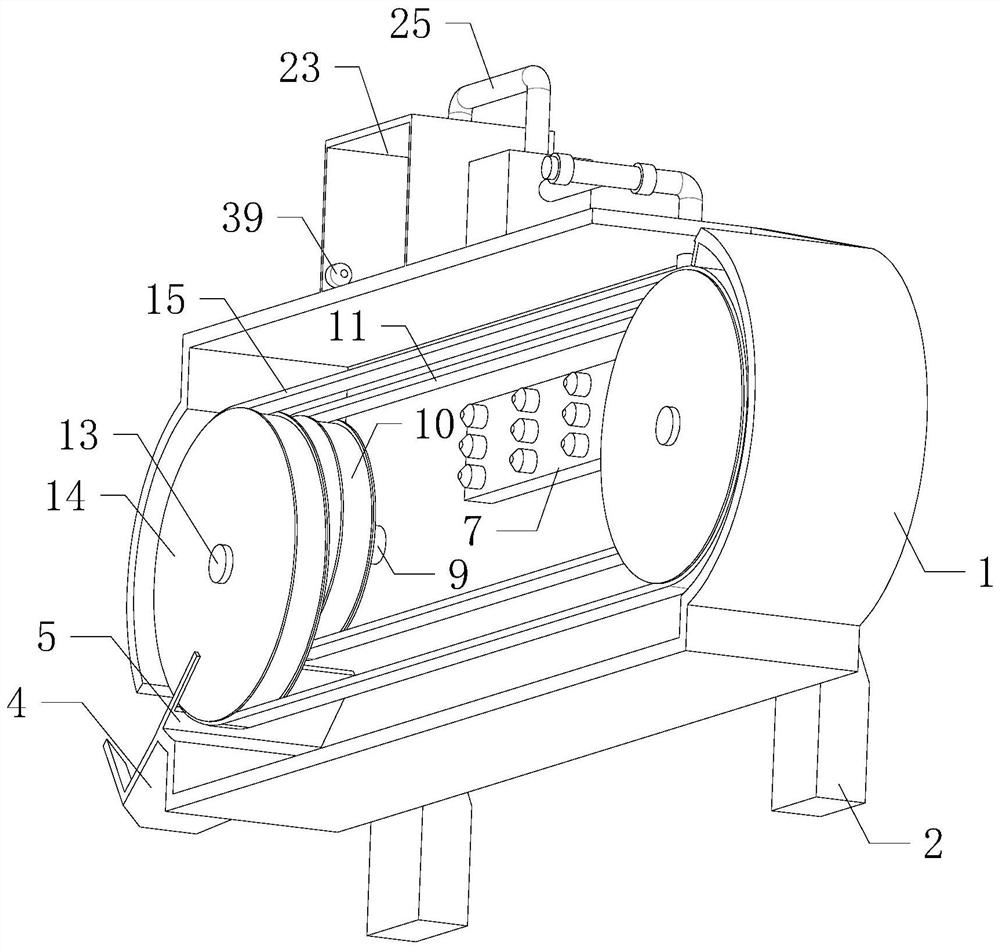

Oil film coating equipment for bolt production

ActiveCN111940198AEasy to recycleHigh recovery rateSpray boothsProcess engineeringMechanical equipment

Owner:SHANDONG GAOQIANG FASTENER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap