Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Thrust bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thrust bearing is a particular type of rotary bearing. Like other bearings they permit rotation between parts, but they are designed to support a predominantly axial load. Thrust bearings come in several varieties.

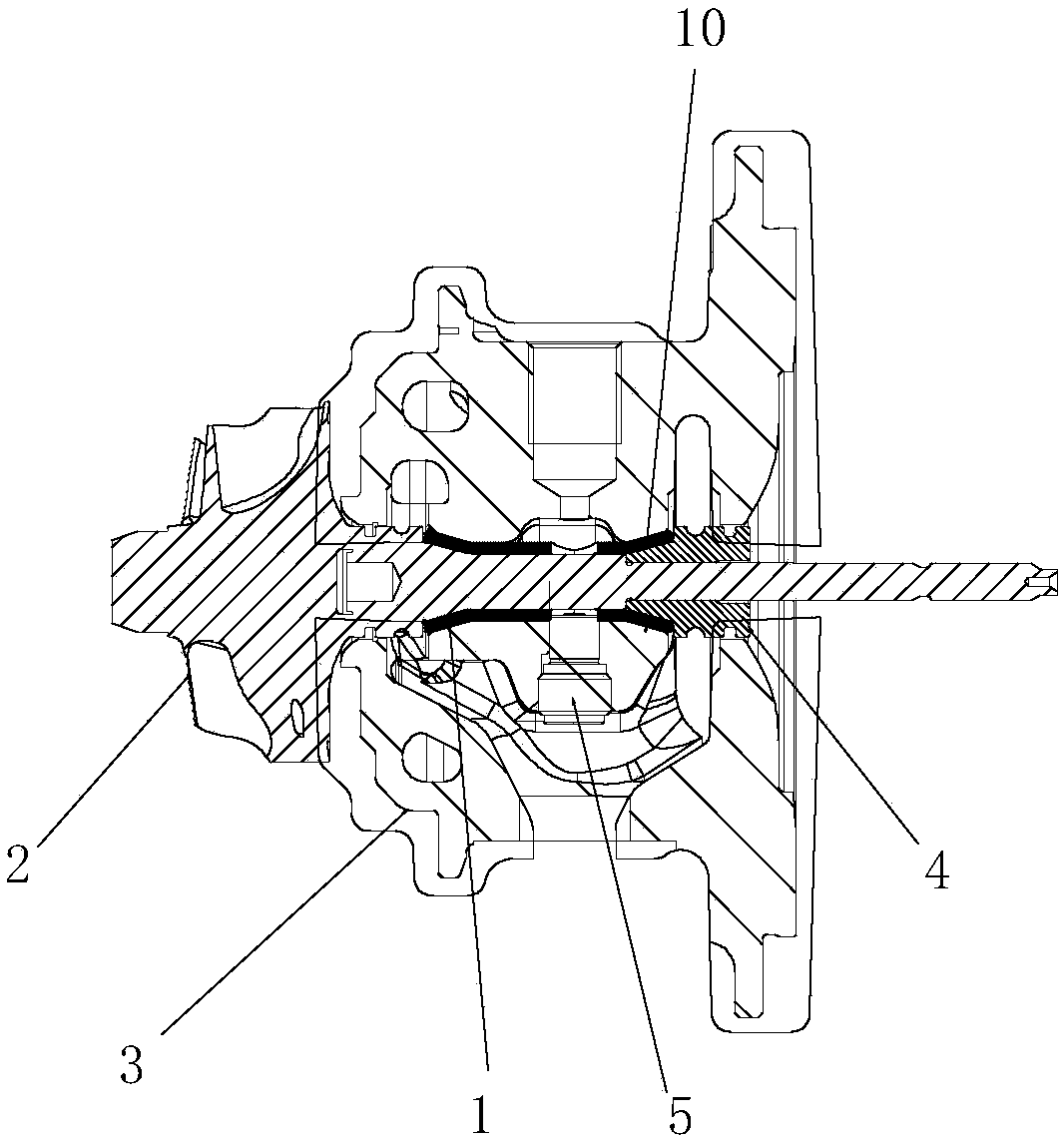

Scroll compressor

ActiveUS20080050260A1Avoid seizuresEngine of arcuate-engagement typeOscillating piston enginesThrust bearingEngineering

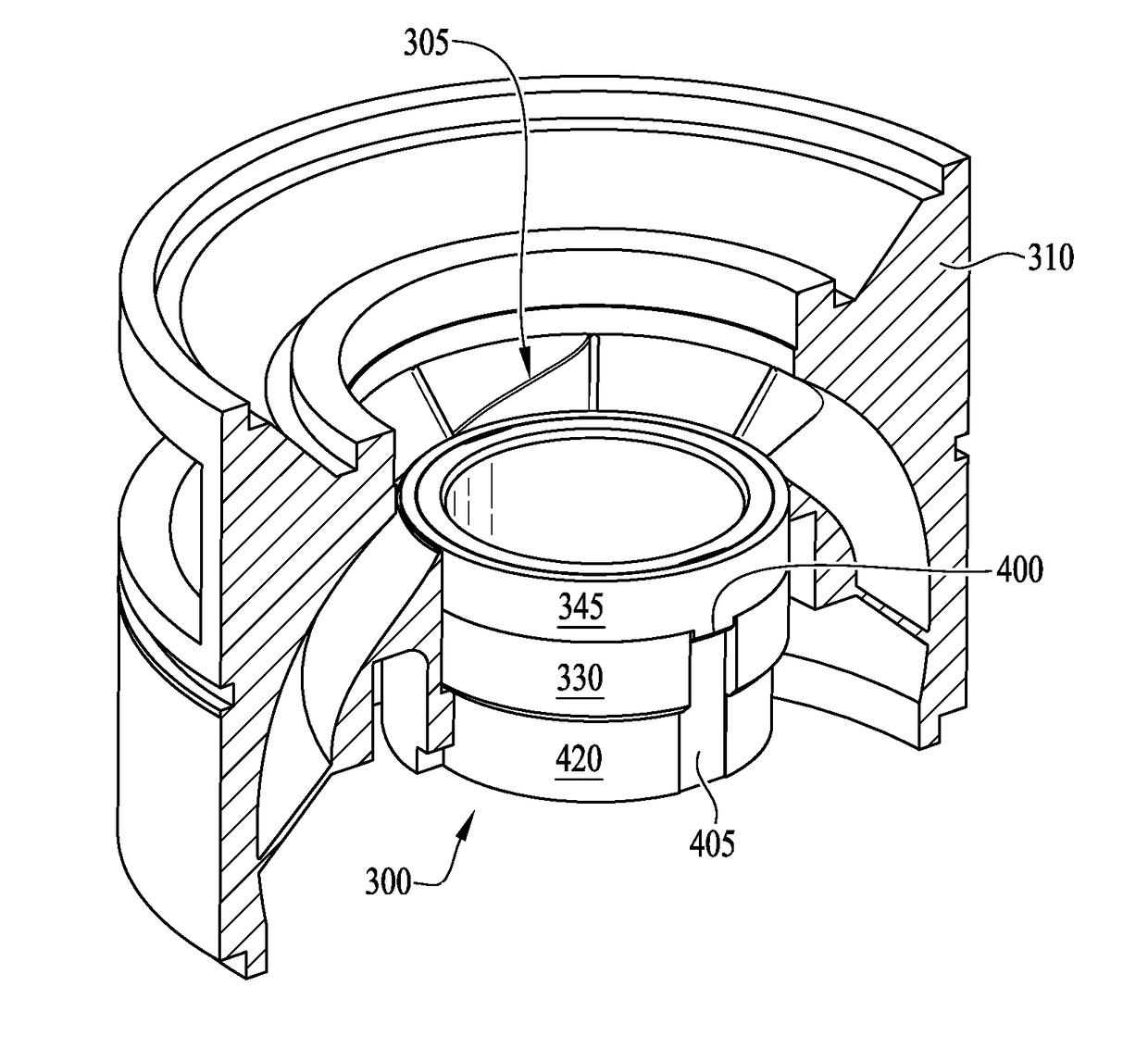

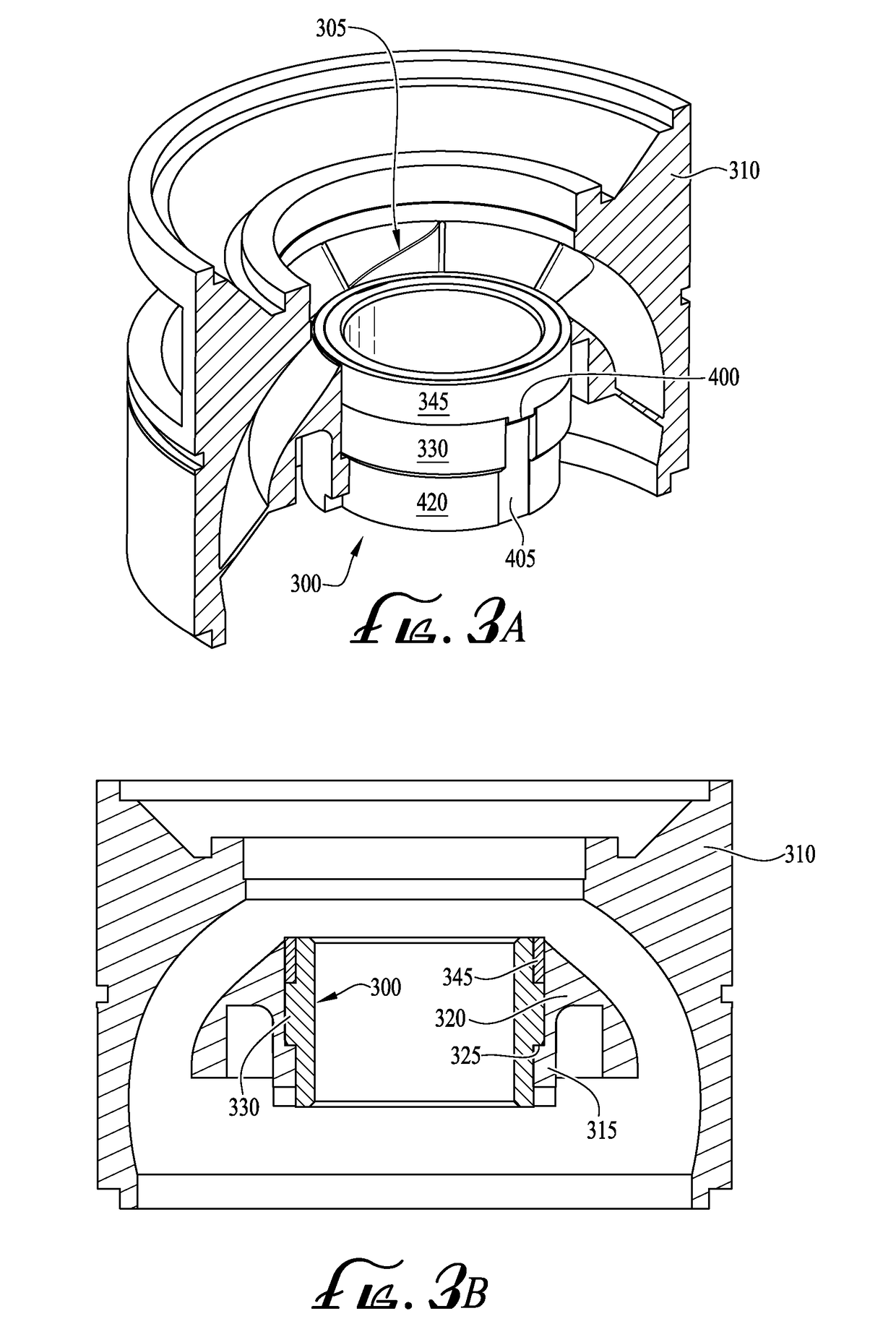

A scroll compressor is disclosed. A plurality of grooves (85) communicating with each other are formed on a sliding surface of a thrust bearing (53) subjected to the axial force received by a movable scroll (32). The areas surrounded by the plurality of the grooves (85) make up a plurality of insular pressure receiving portions (83) independent of each other. The pressure receiving portions (83) represent at least one half of the area of the sliding surface.

Owner:NIPPON SOKEN

Plasticizing apparatus

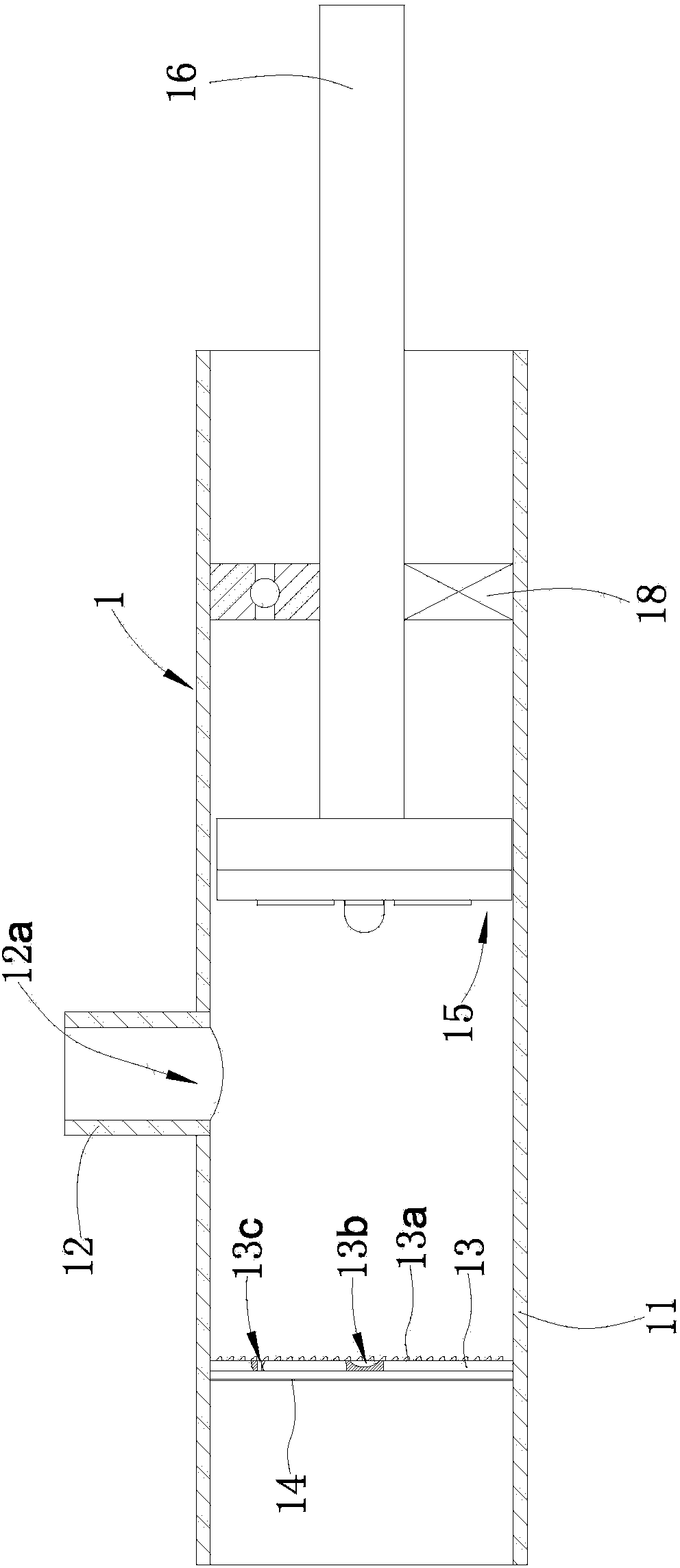

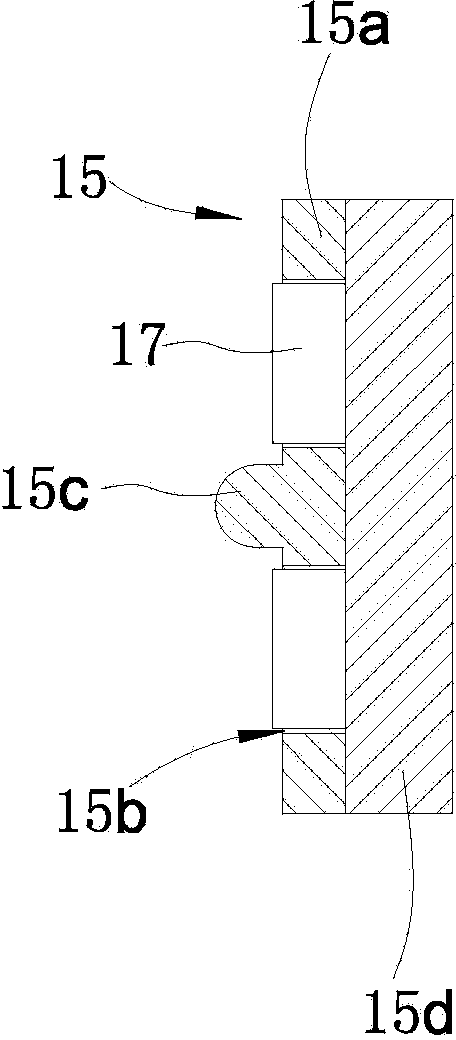

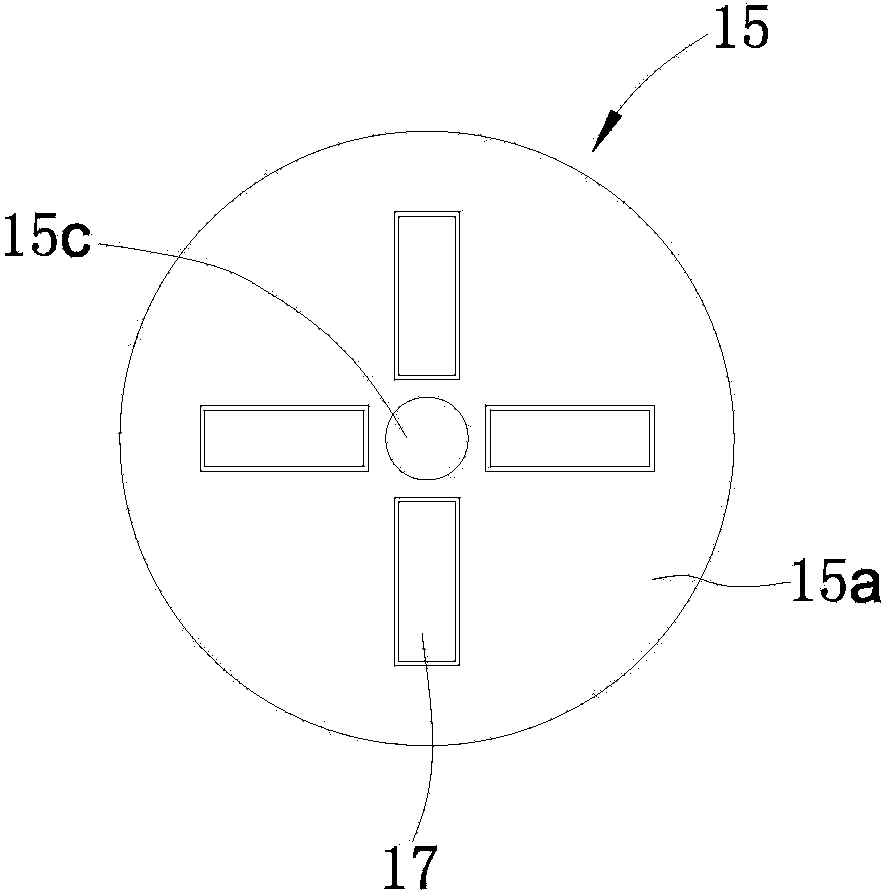

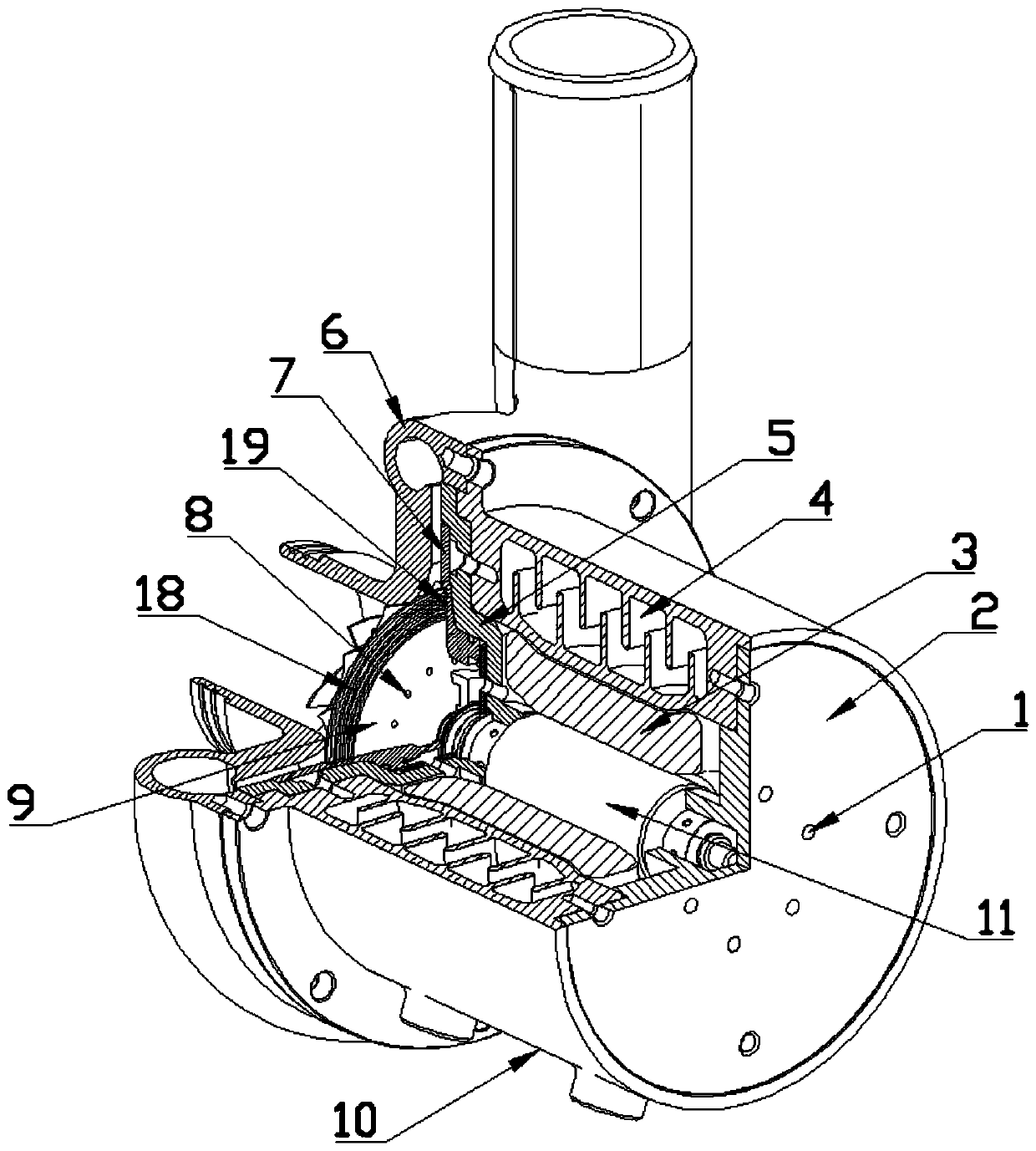

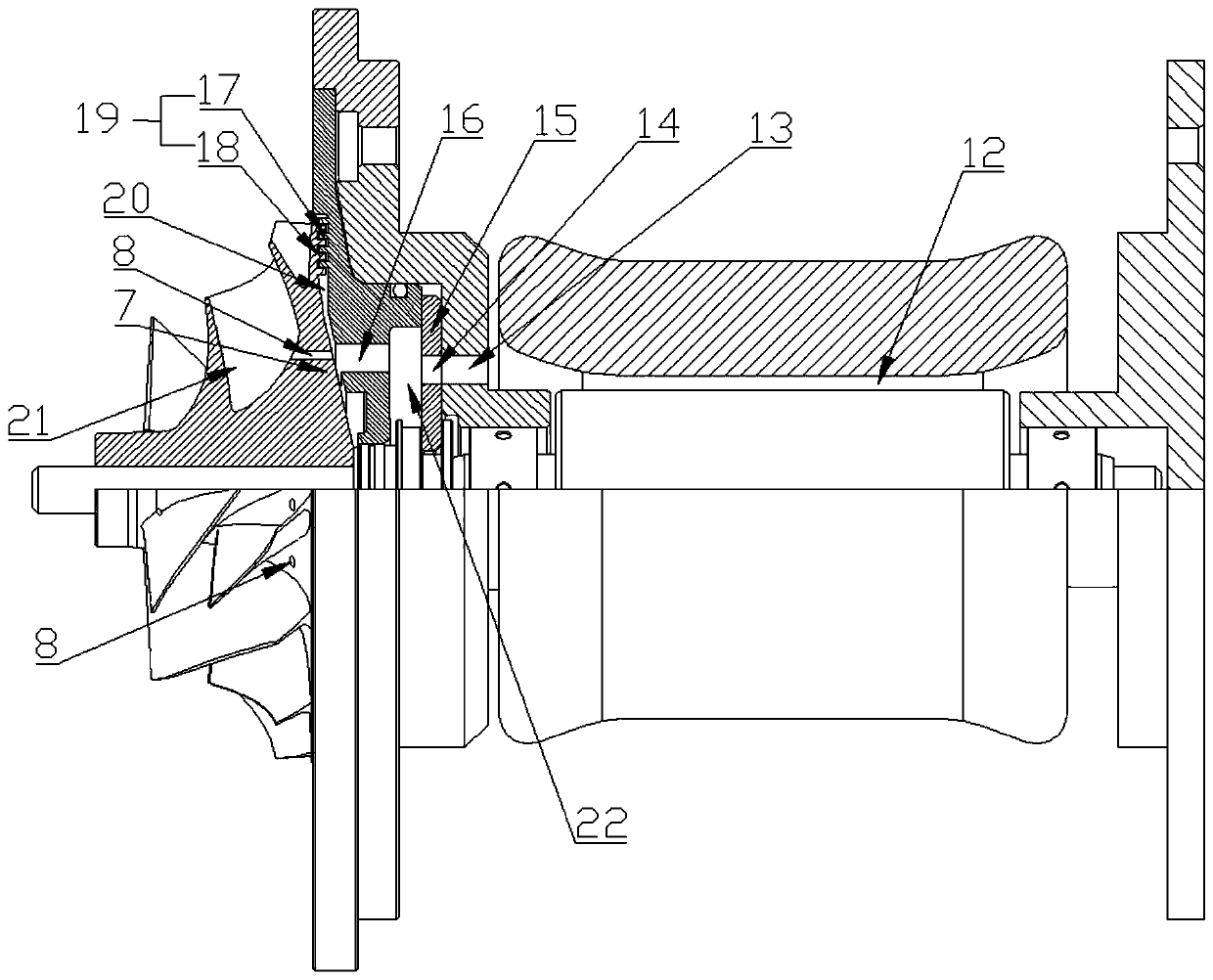

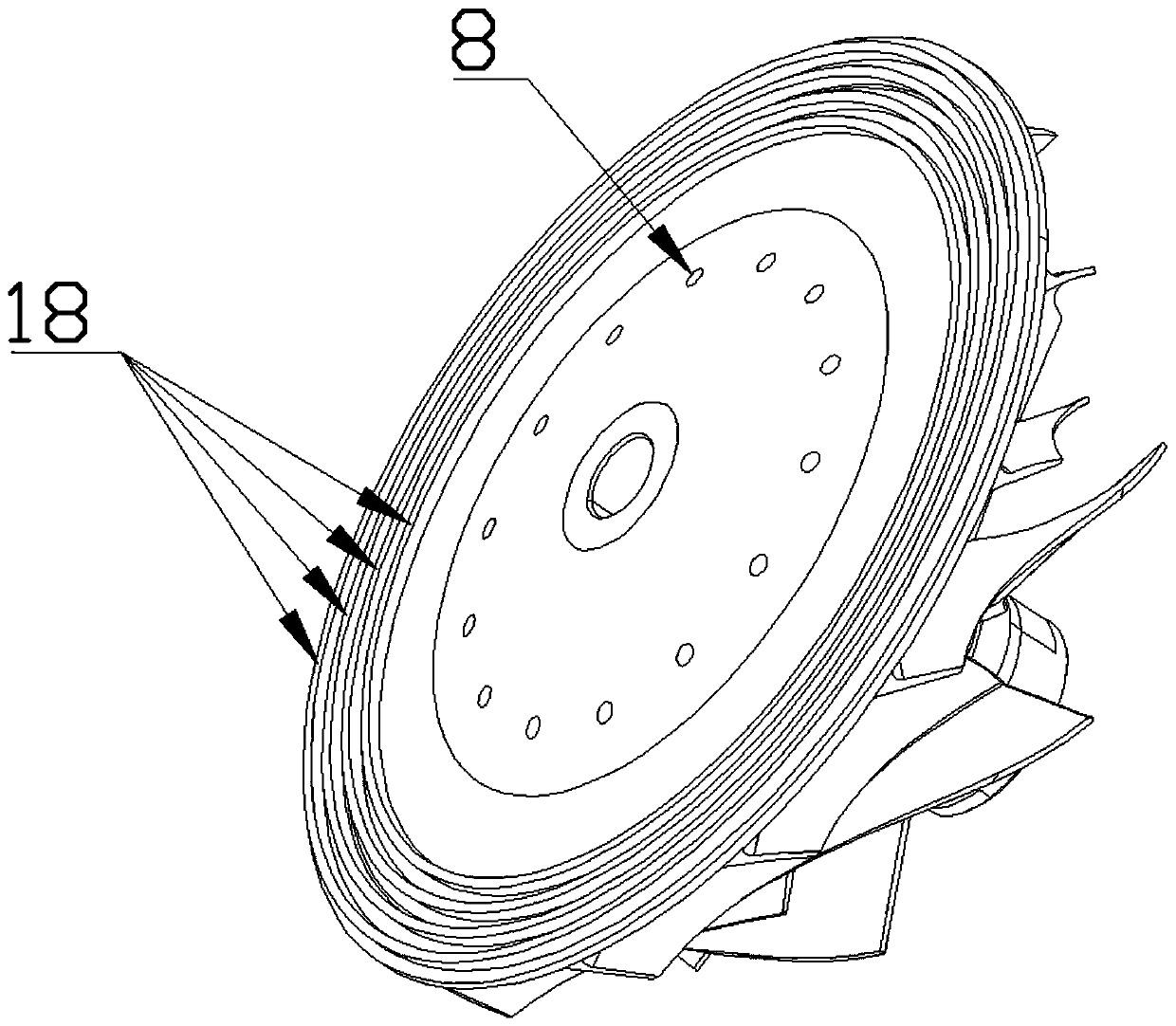

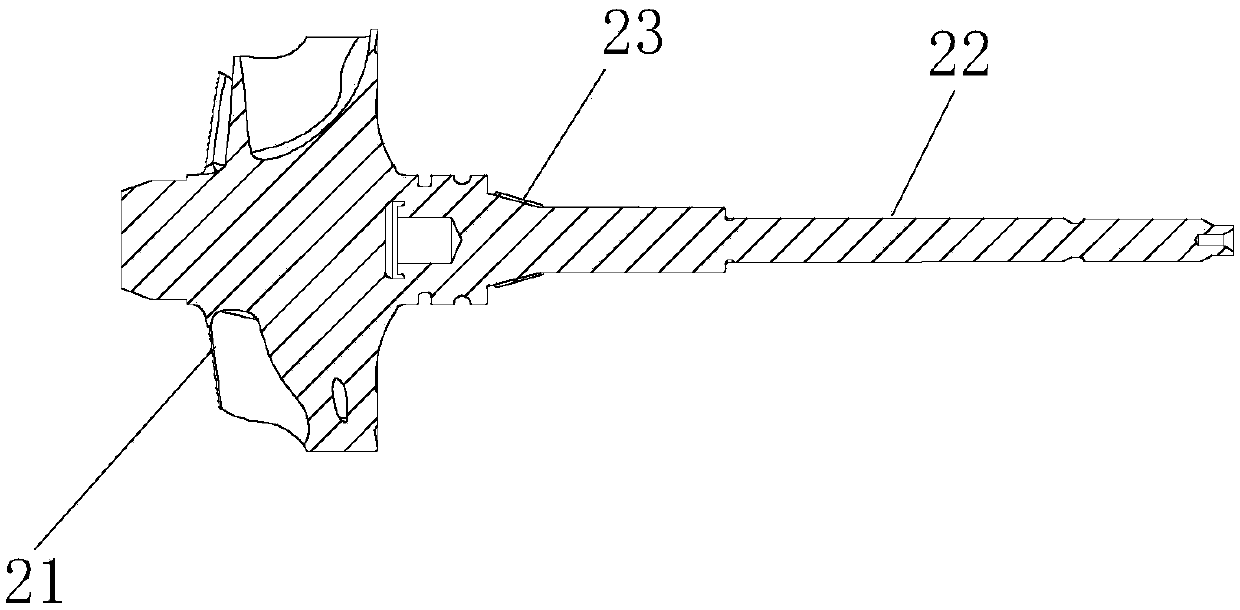

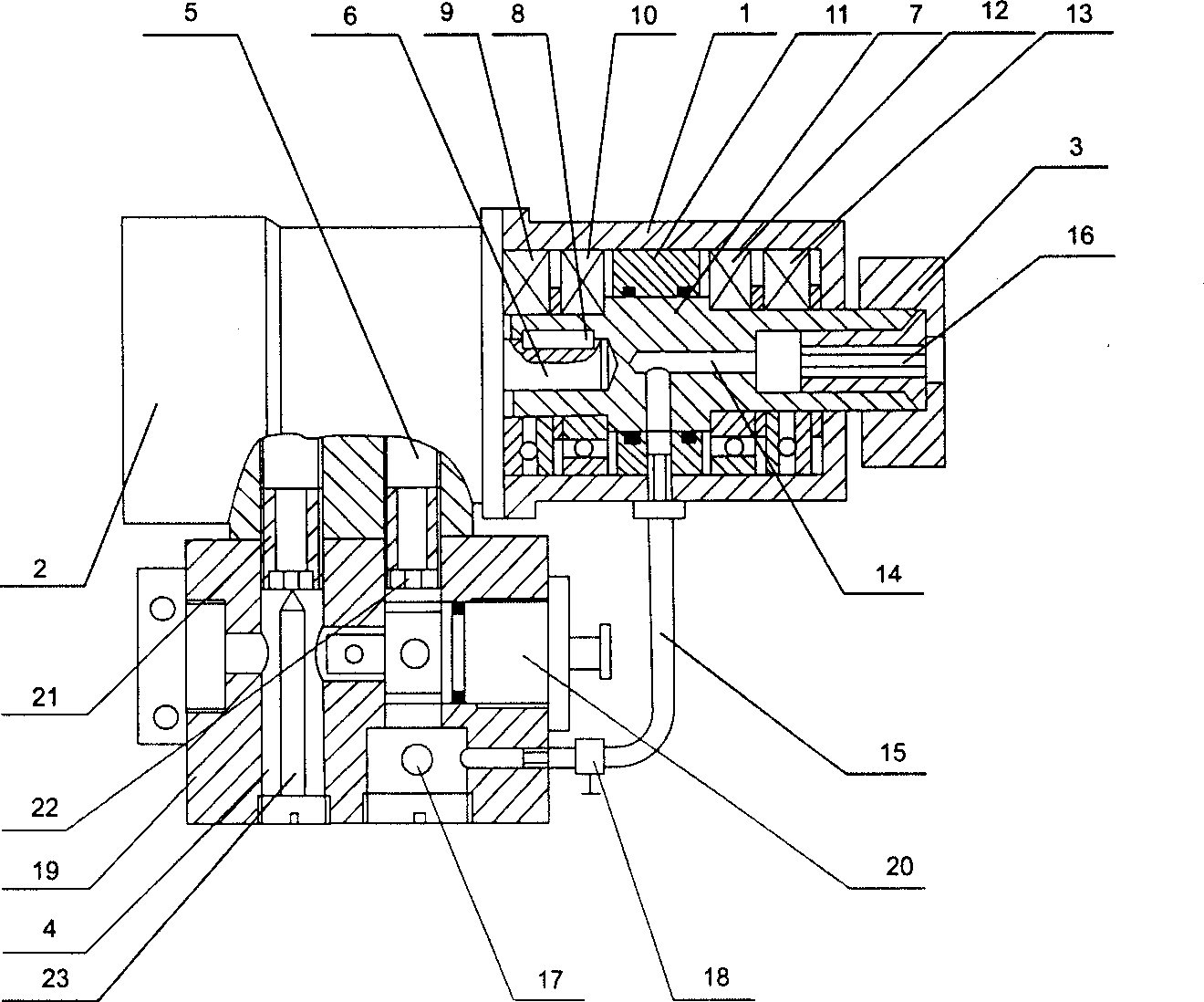

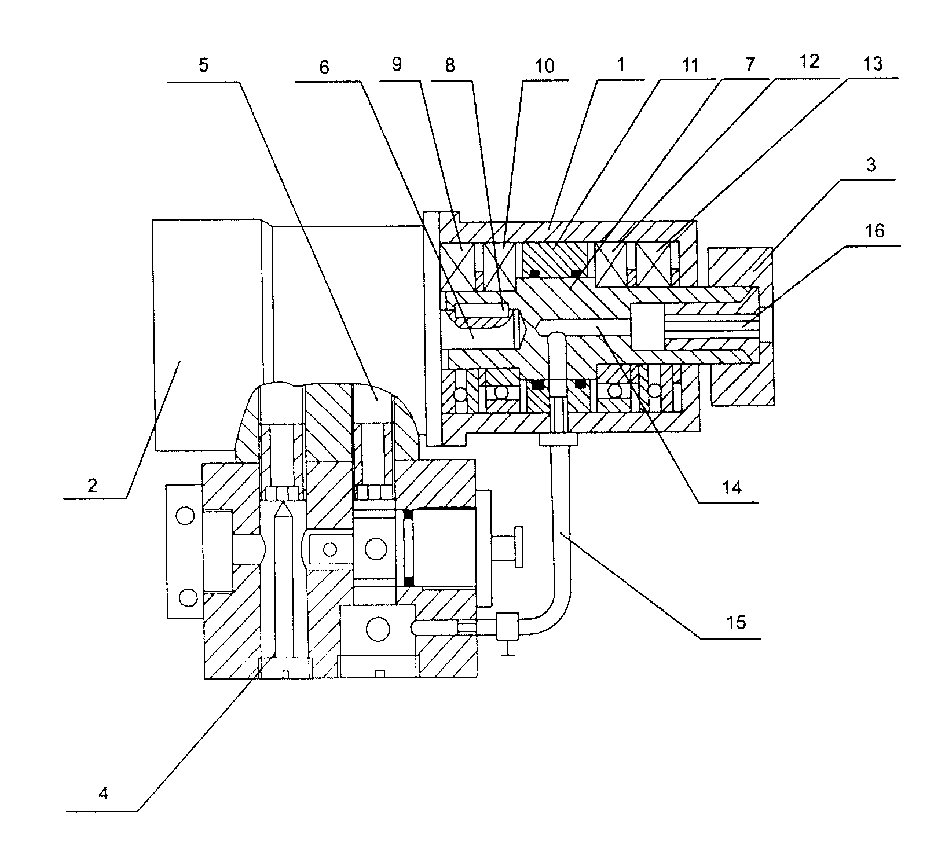

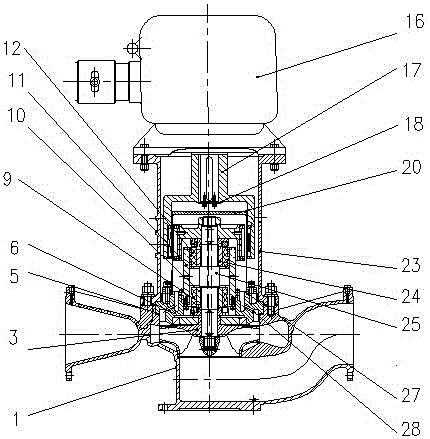

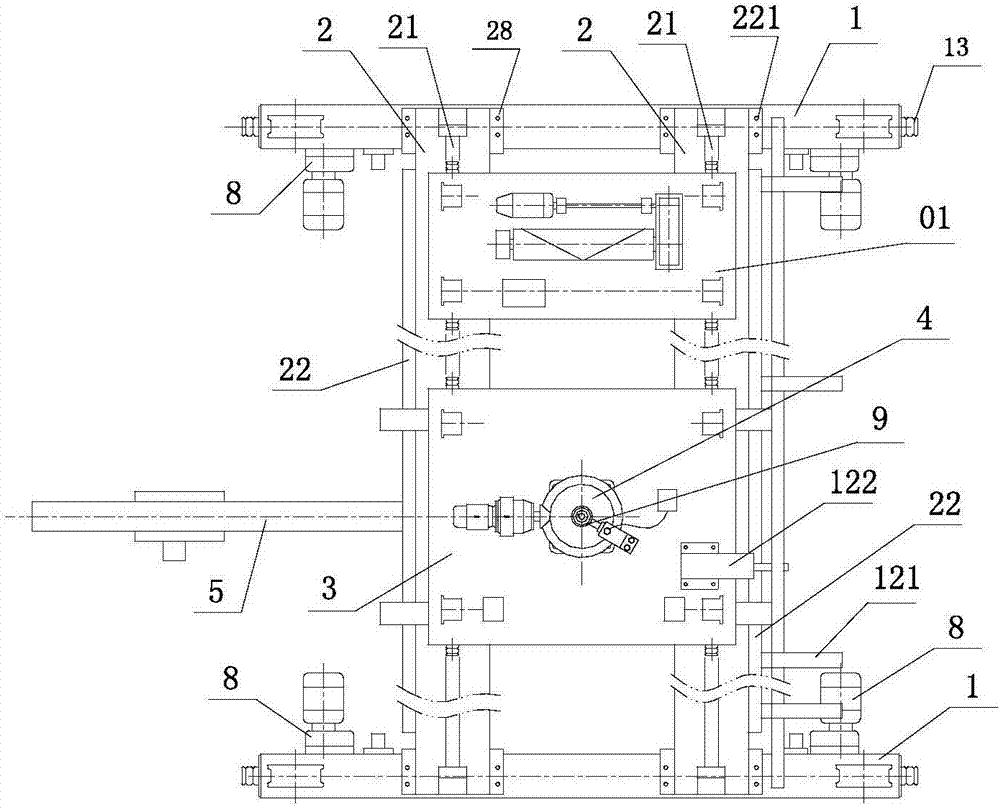

The invention discloses a plasticizing apparatus. The apparatus comprises a motor, a driving device, a driving shaft, a plasticizing front board supported at the front end of the driving shaft through a deep groove ball bearing, and a plasticizing backboard supported at the back end of the driving shaft through an aligning roller bearing, the plasticizing backboard is upwardly provided with a motor fixing board for fixedly mounting the motor, a positioning projection used for fixation is arranged at the front end of the motor, the motor fixing board is provided with a positioning hole for the penetration of the positioning projection, the driving device comprises a small belt wheel fixedly mounted on the output shaft of the motor, a large belt wheel fixedly mounted on the driving shaft, and a synchronous belt connecting the small belt wheel with the large belt wheel, the central portion of the back end of the driving shaft is in threaded connection with a screw, the screw penetrates through the plasticizing backboard, and a thrust ball bearing is arranged between the head portion of the screw and the plasticizing backboard. The plasticizing apparatus adopting the motor to drive has the characteristics of small energy consumption, small noise, stable output torque, simple structure, low cost, small inertia and good performances.

Owner:NINGBO HAIZHOU MASCH CO LTD

Grinding filter component and bone slurry machine

Owner:润桐(苏州)技术服务有限公司

Press-fit thrust bearing system and apparatus

ActiveUS20180291917A1Avoid displacementPrevent rotationPump componentsBearing assemblyDrive shaftThrust bearing

Owner:HALLIBURTON ENERGY SERVICES INC

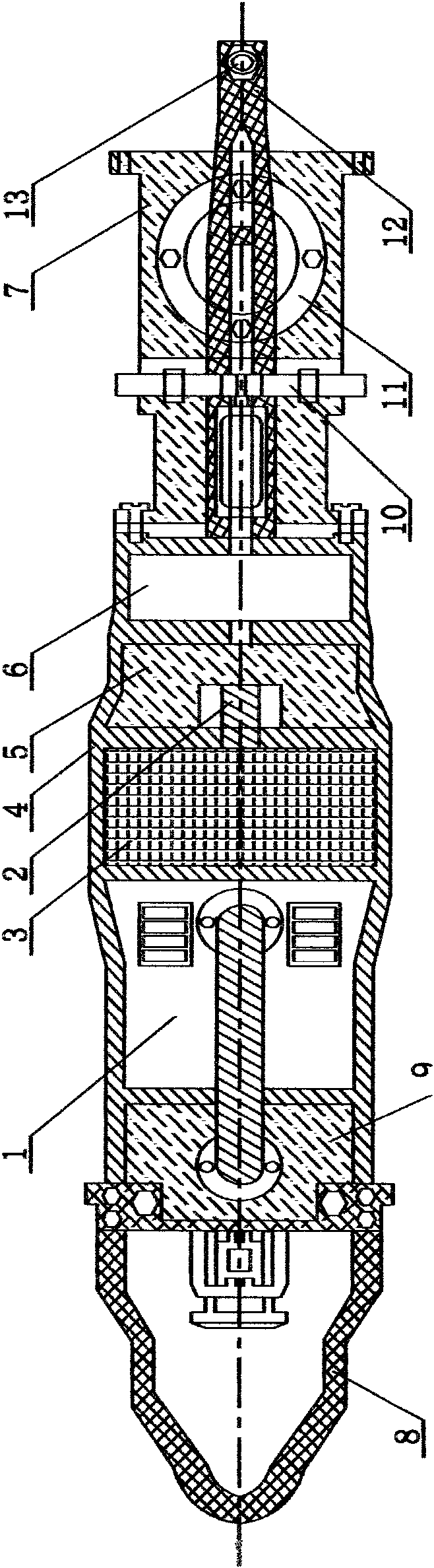

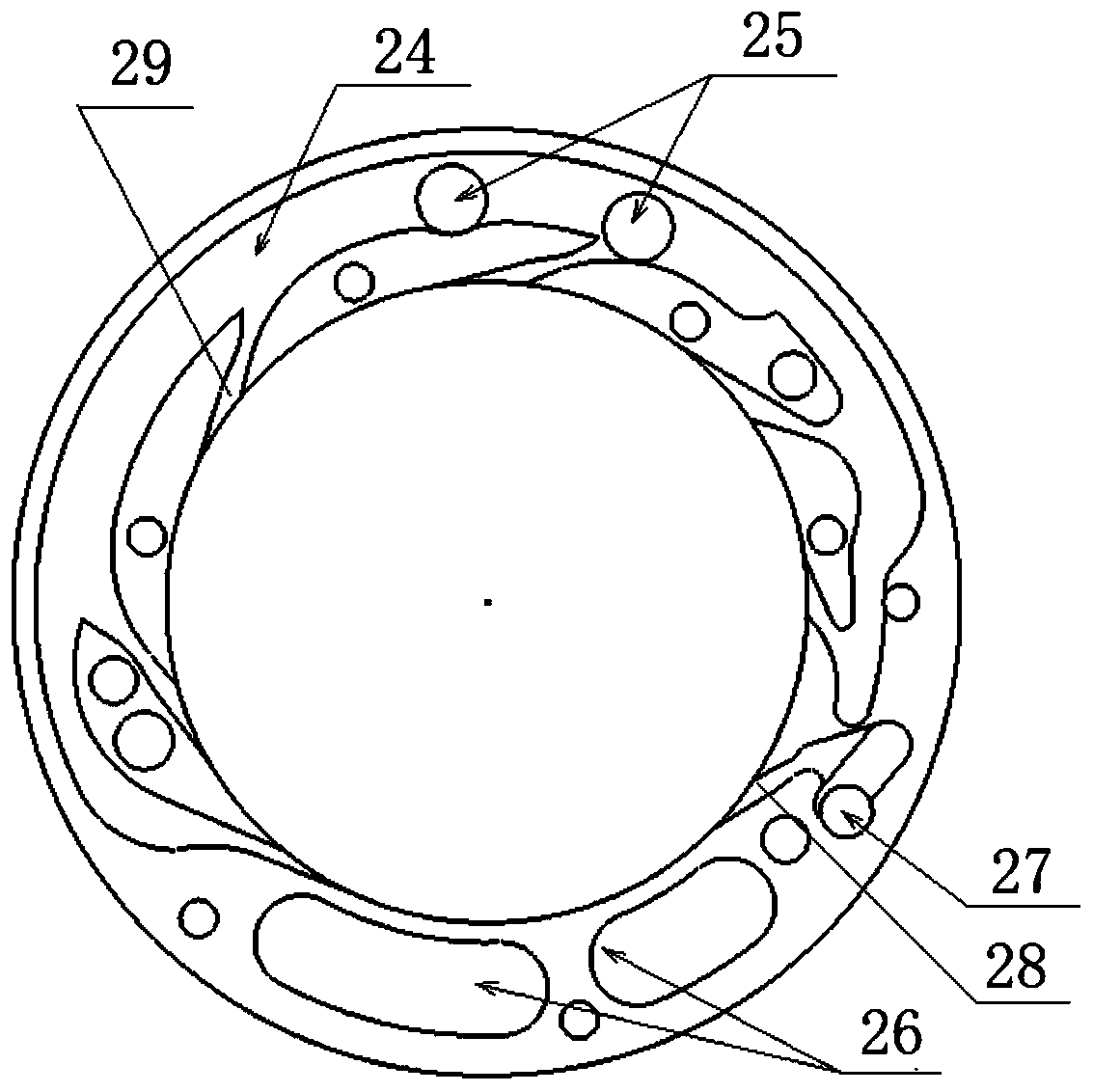

Hydrostatic thrust bearing device for reducing hot oil carrying

InactiveCN109236859AReduce carryReduce temperature riseBearingsThermal deformationThrust bearing

The invention discloses a hydrostatic thrust bearing device for reducing hot oil carrying. In order to solve the problem of temperature rise of an oil film caused by hot oil carrying between oil padsin a hydrostatic thrust bearing, an oil scraping plate structure easy to remove and change is mounted on a traditional hydrostatic thrust bearing base, and the traditional plane oil scraping surface is changed into a curved oil scraping surface, thus the heat dissipation area of oil liquid and the hot oil scraped by the oil scraping plate are increased, the hot oil carried between two adjacent oilpads is reduced, the temperature rise of the oil liquid is effectively relieved, and thermal deformation of a machine tool is prevented; meanwhile, the circumferential width of the left and right ends of an oil sealing edge of the oil pad is of an asymmetric structure, the side with greater circumferential width inclines downward, then a dynamic pressure is formed by use of a wedge shape betweenthe inclined plane of the oil pad and a rotary table guide rail so as to compensate for the hydrostatic loss of the lubricating oil, thus the rigidity and the bearing capacity of the oil film are improved, the problem of lubrication failure of the hydrostatic thrust bearing is solved, and high-precision and high-efficiency work of the whole machine tool is guaranteed.

Owner:HARBIN UNIV OF SCI & TECH

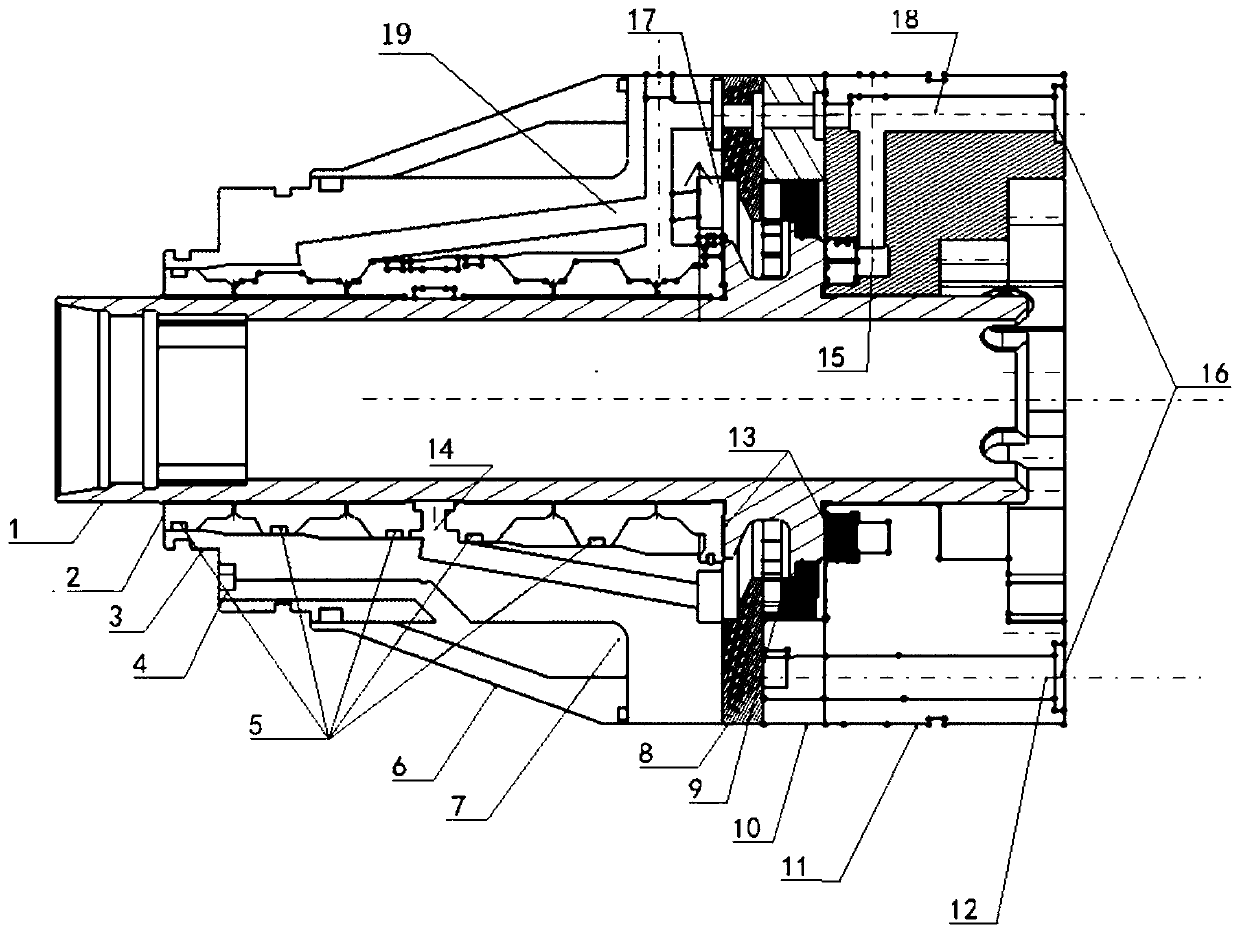

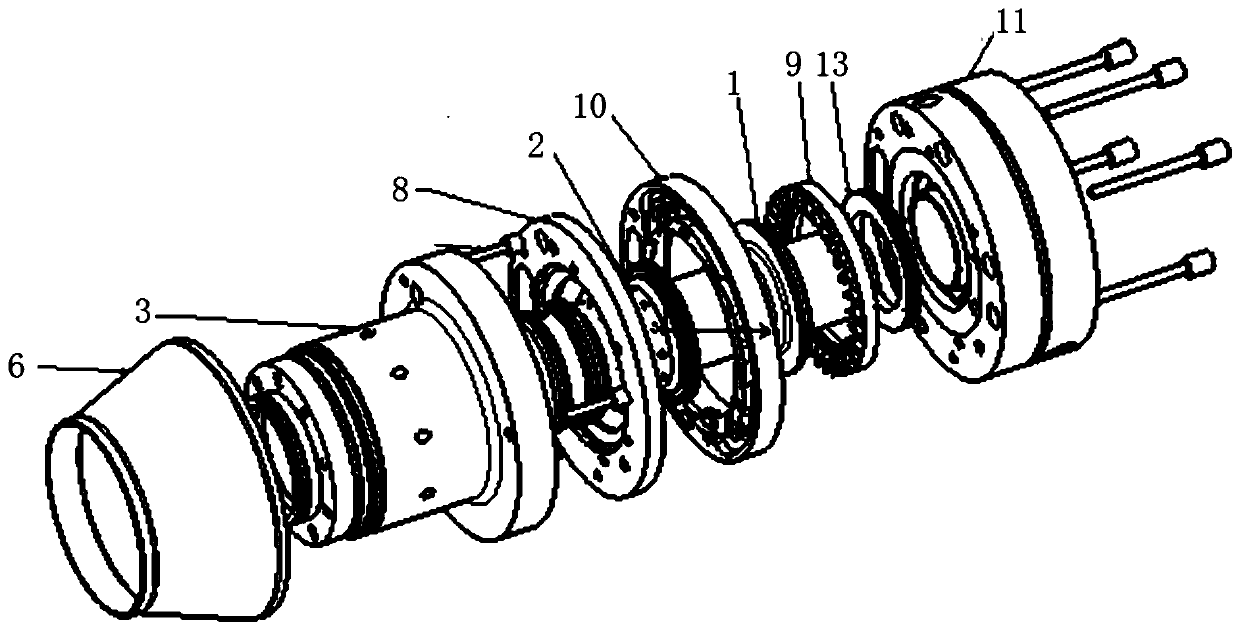

Electric air compressor with motor rotor cooling system

InactiveCN110145479AAchieve self-coolingReduce manufacturing costPump componentsPump installationsImpellerThrust bearing

Owner:DALIAN MARITIME UNIVERSITY

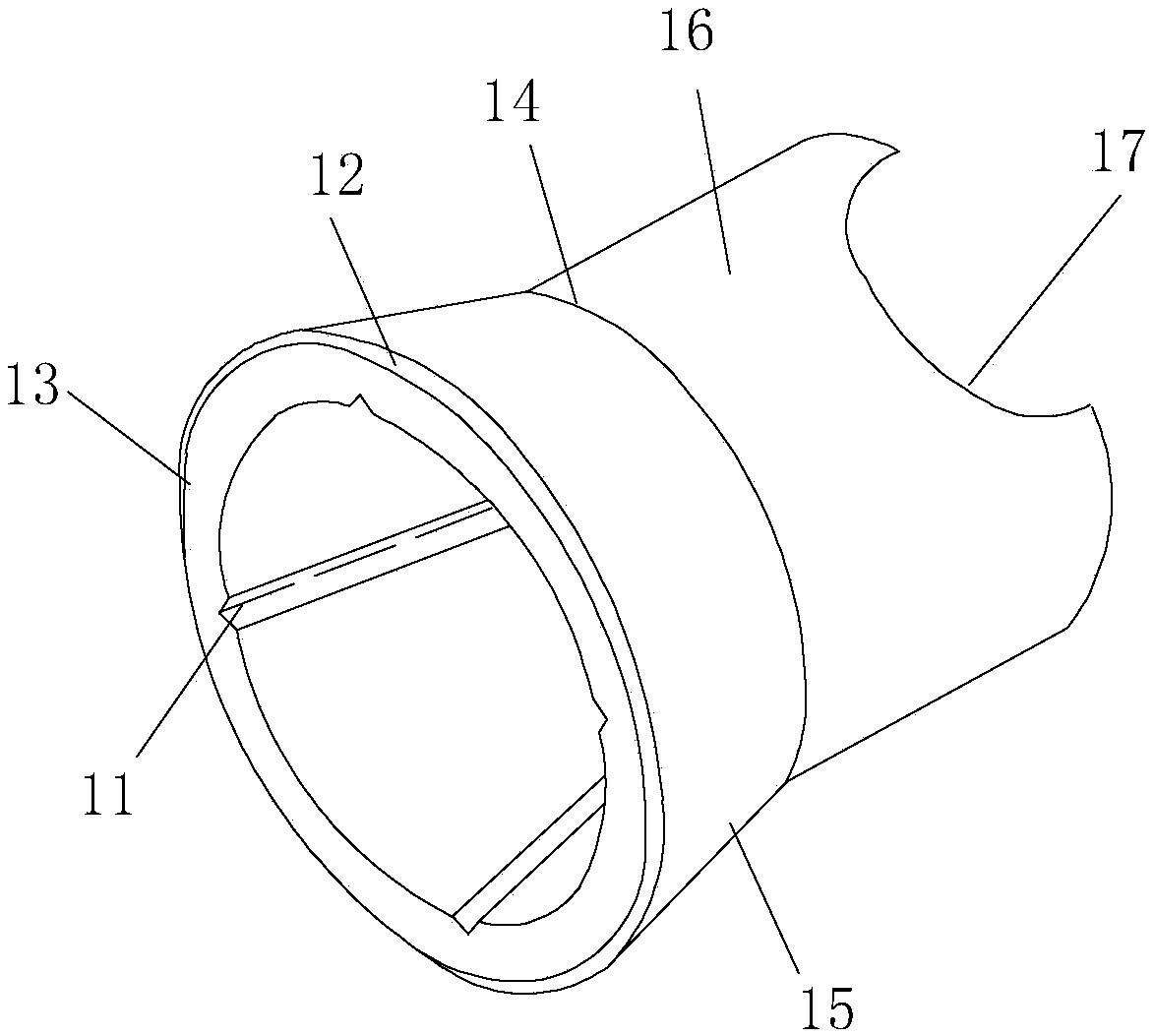

Bottle cap assembly dislocation auxiliary device

The invention provides a bottle cap assembly dislocation auxiliary device which comprises an assembling machine working table and an upper fixed plate, wherein an principle axis is arranged on the working table, a driven wheel is arranged at the lower end of the principle axis and meshed with a driving wheel, a large guide sleeve body, a small guide sleeve body and a tray are arranged on the principle axis, a lower guide sleeve is arranged on the large guide sleeve body, an upper guide sleeve and an internal plastic piece drive plate are arranged on the small guide sleeve body, reciprocating levers are arranged on the upper guide sleeve and the lower guide sleeve, rollers are arranged at the lower ends of the reciprocating levers, cams are arranged at the lower ends of the rollers and fixedly arranged on the working table, the tray is provided with a piece supporting tray and an upper drive plate, a guide seat is arranged on the tray and internally provided with a lifting lever and a thrust bearing, a spring is arranged on the lifting lever, a soft sleeve is arranged at the lower end of the lifting lever, and a steel ball is arranged in a groove at the upper end of the guide seat and contacted with a tooth surface cam plate. The bottle cap assembly dislocation auxiliary device solves the problem that raised teeth of a plastic inner assembly and positioning grooves of an outer cover can not accurately correspond to one another when an automatic assembling machine is in assembling, improves the production efficiency and lowers the production cost.

Owner:LIPENG PACKING YANTAI CITY

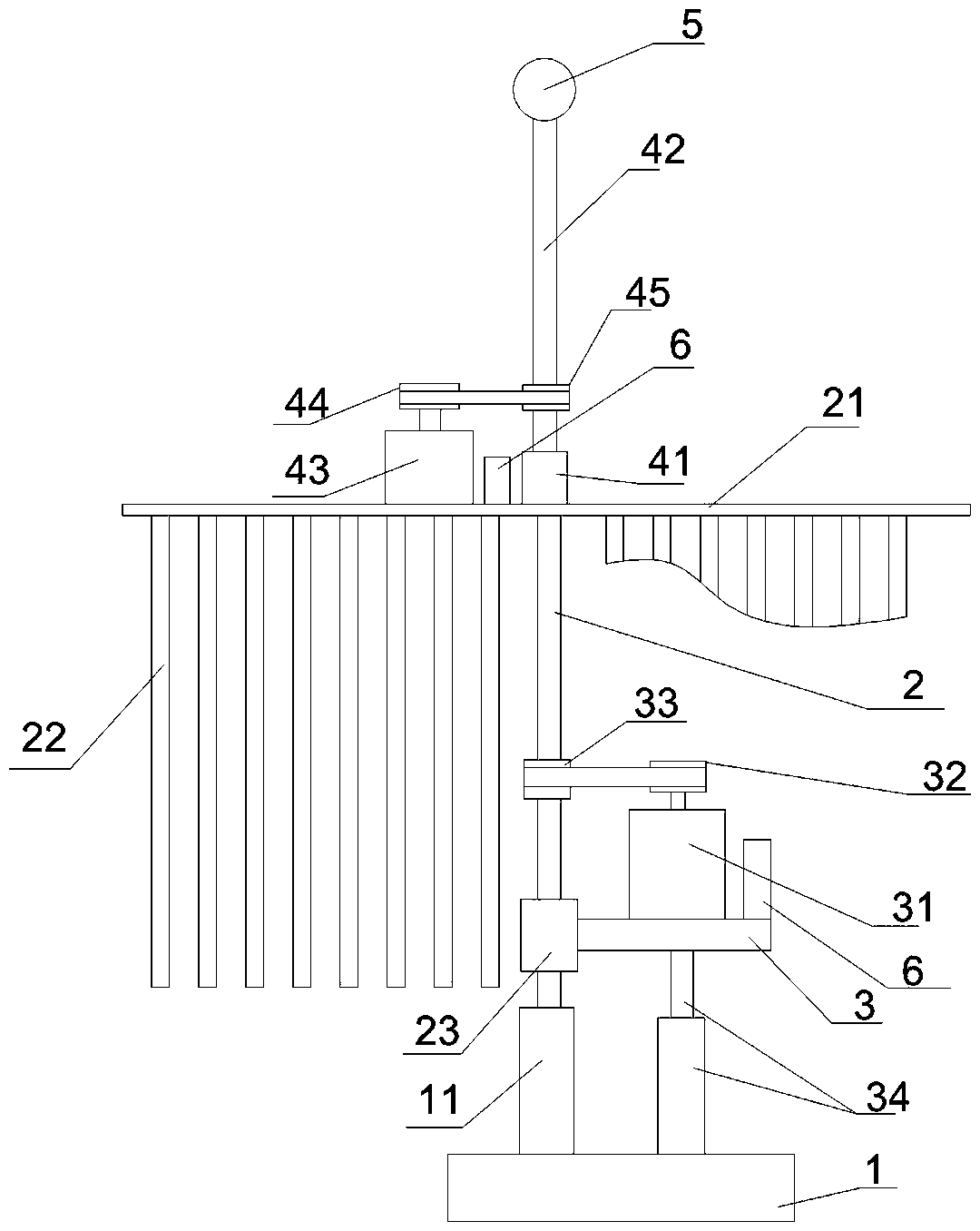

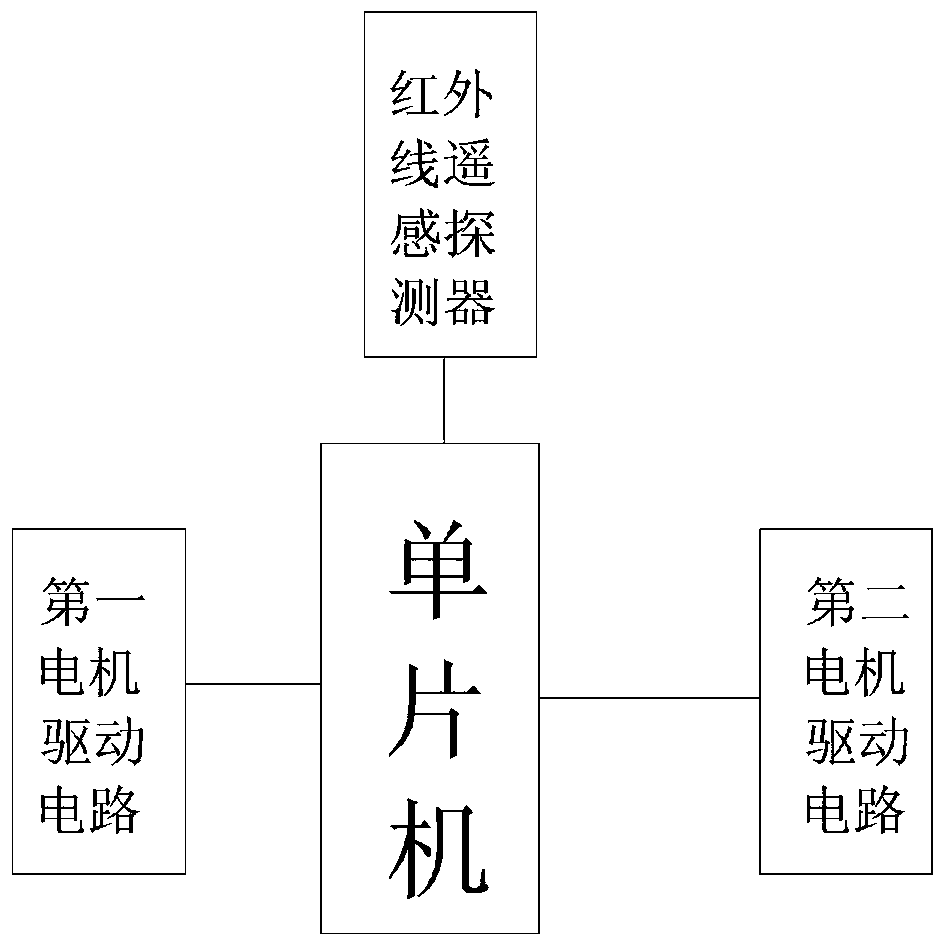

Bird repelling device for farm

InactiveCN108651435AEffective sensingDrive away quicklyOptical detectionAnimal repellantsDrive wheelThrust bearing

Owner:登封市绿奥农林科技有限公司

Semi-floating combined thrust bearing assembly and assembling method thereof

InactiveCN109869201APrevent jumpingPrevent axial movementMachines/enginesEngine componentsThrust bearingTurbine

Owner:汉捷机械部件(常州)有限公司

Hydraulic wet drill

Owner:戴永杰

Magnetically driven pipeline type centrifugal pump

InactiveCN106122036ANo leak functionImprove general performanceSpecific fluid pumpsPump componentsThrust bearingEngineering

Owner:CHANGJIANG PUMP & VALVE MFG JINGJIANG

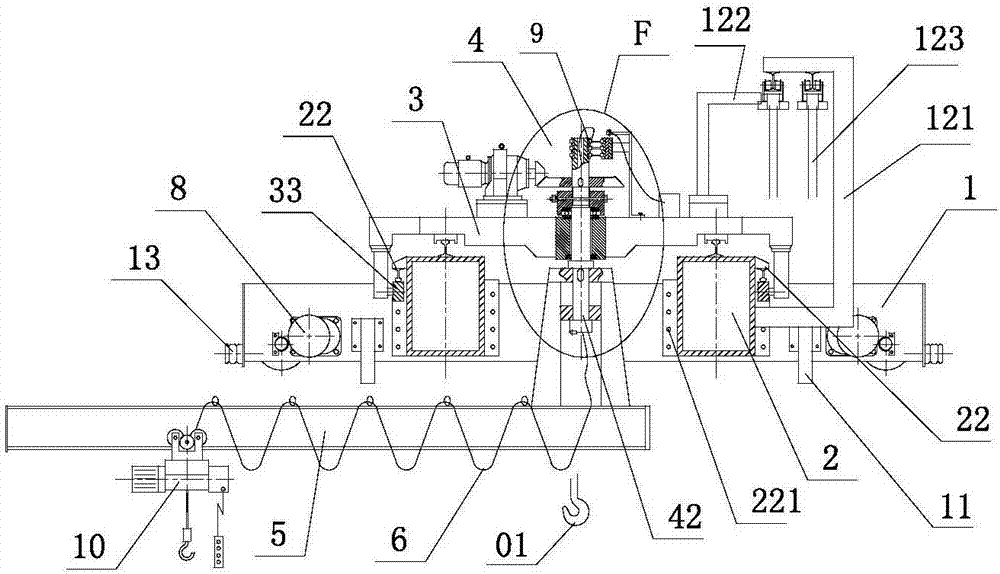

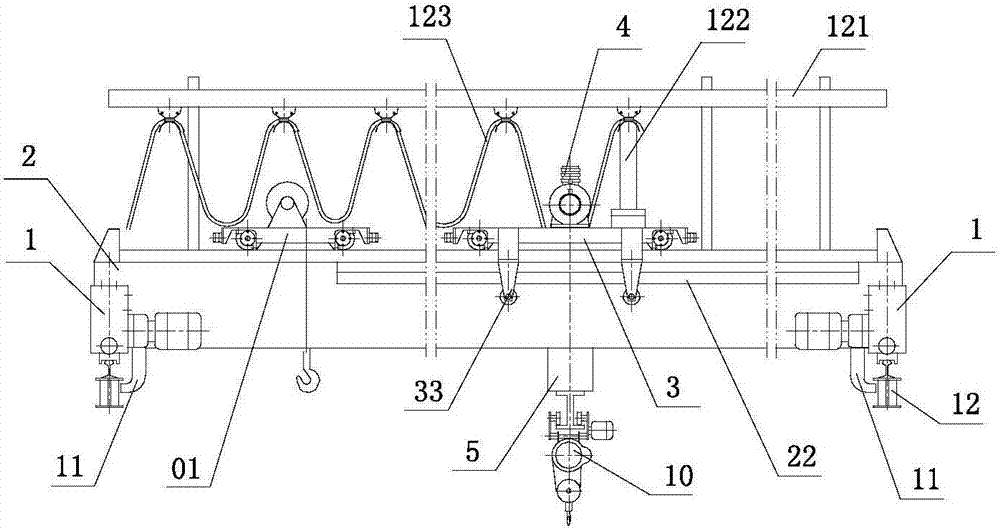

Cantilever crane provided with lifting trolley, reversed rolling wheel trolley and safety hook

InactiveCN107954337AEasy to liftAccurate requirements for rotational speedTravelling cranesTravelling gearRolloverThrust bearing

Owner:福州市鼓楼区奇韵通自动化设备有限公司

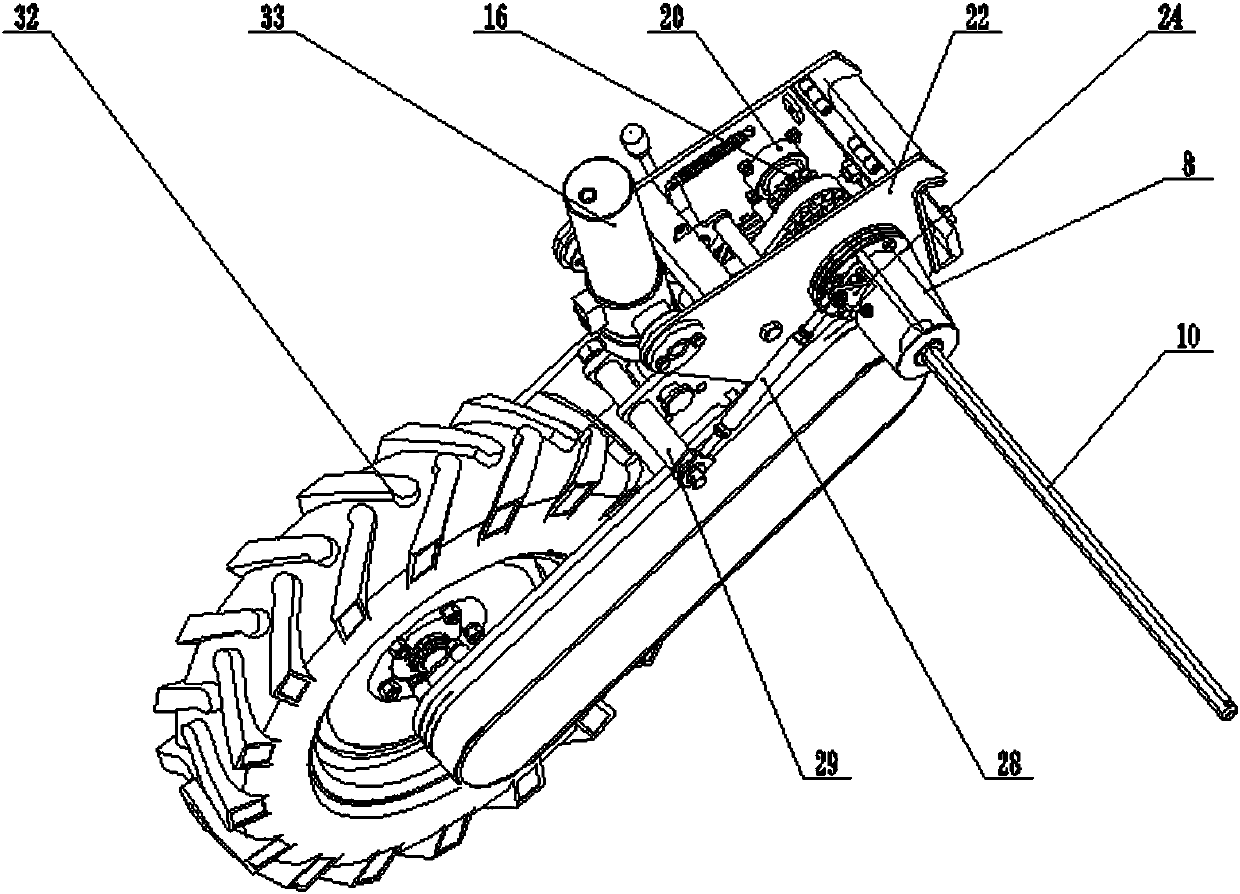

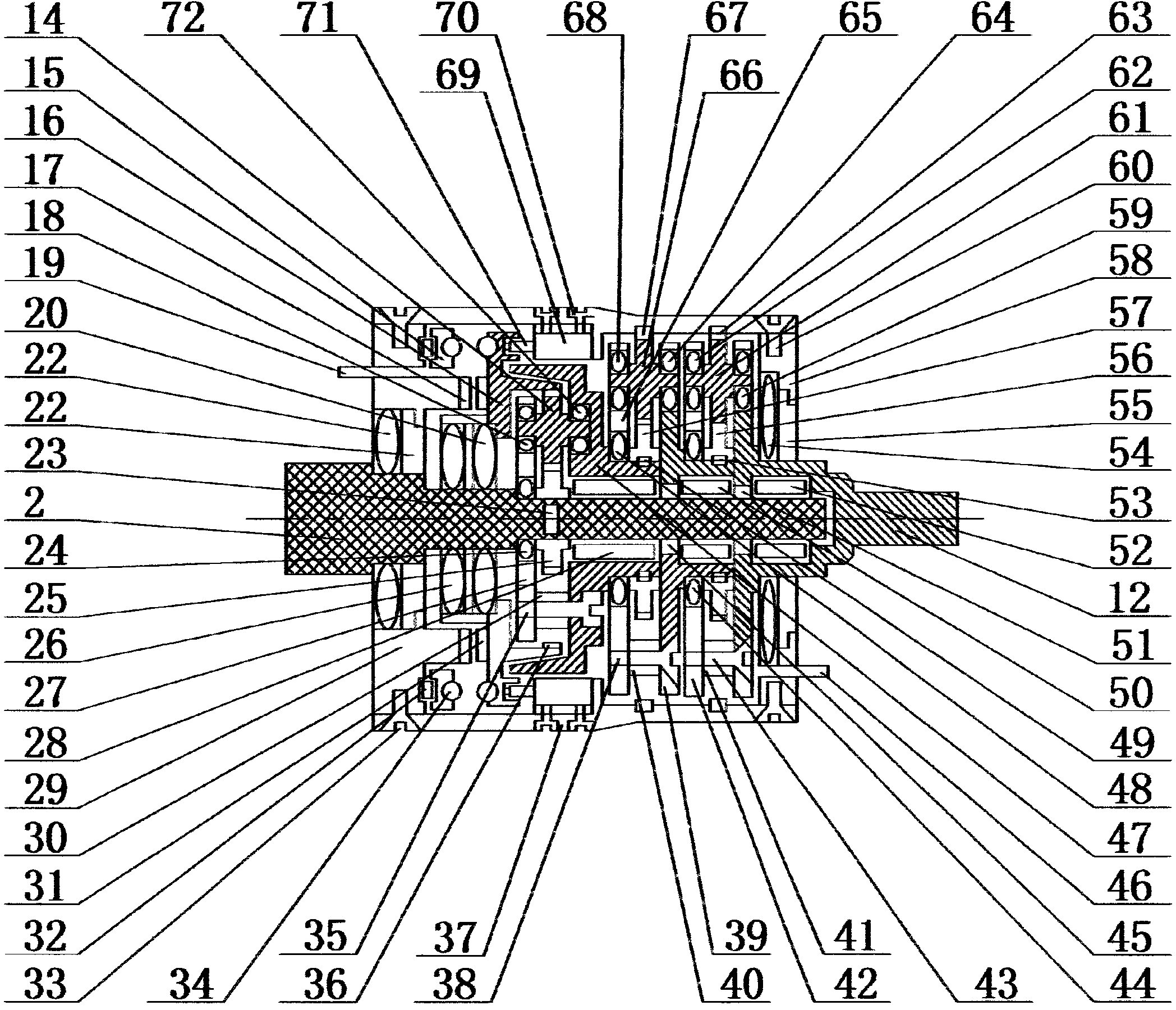

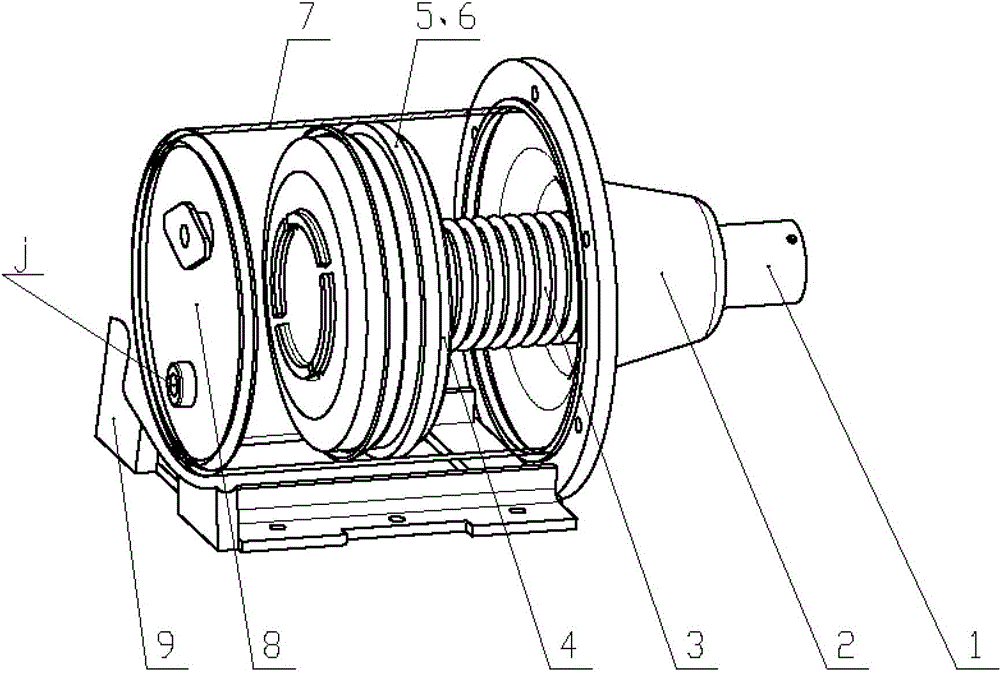

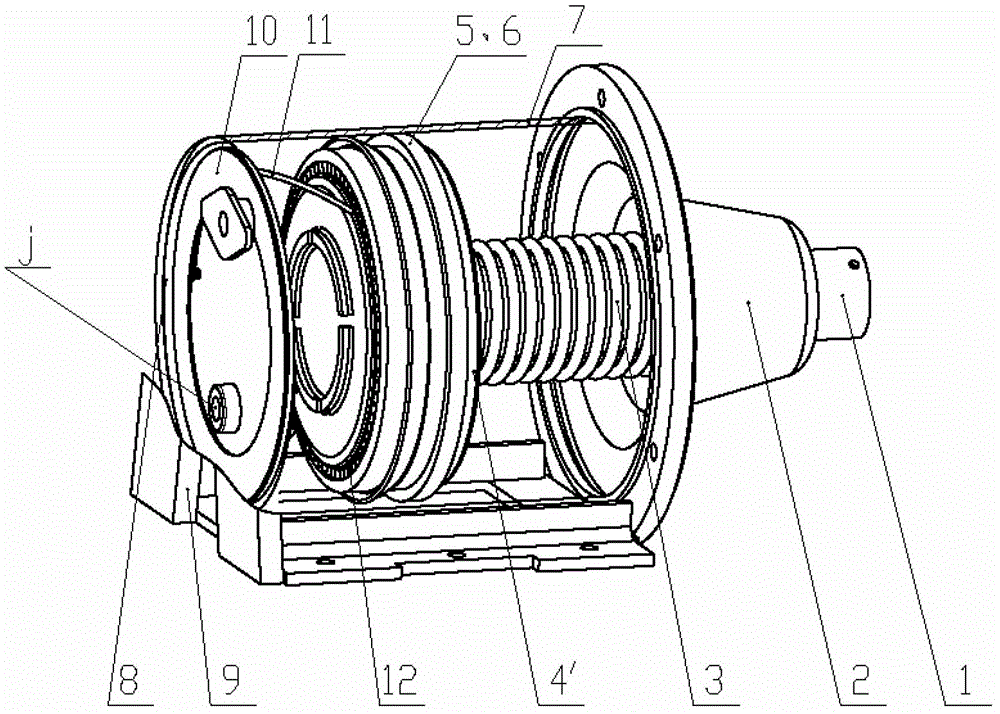

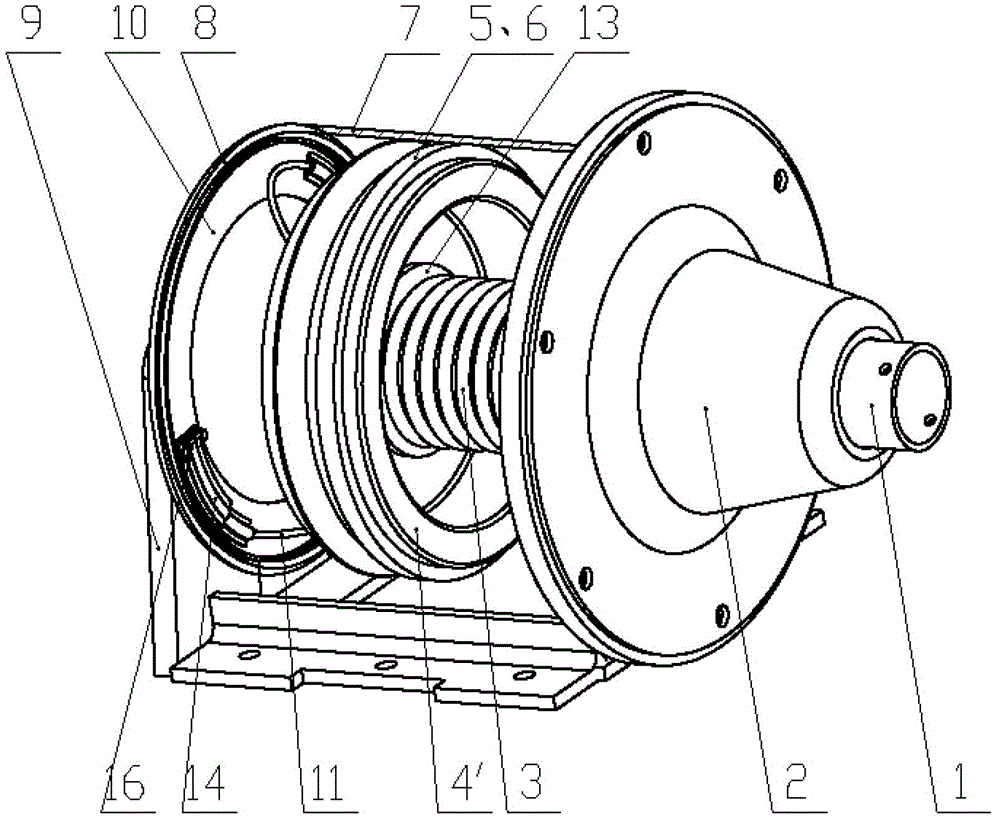

Main transmission clutch of non-tillage precise sowing machine

PendingCN107830078ACompact structureEasy to installFluid actuated clutchesBogieAgricultural engineering

Owner:瓦房店明运农机装备有限公司

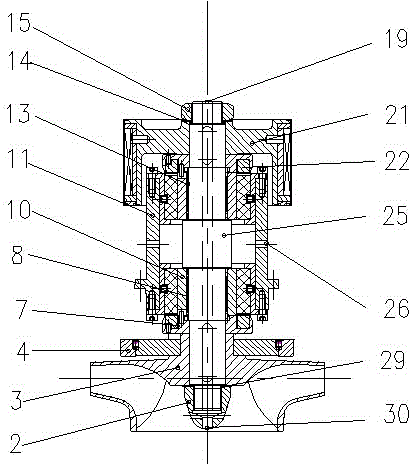

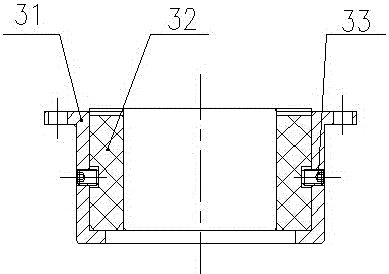

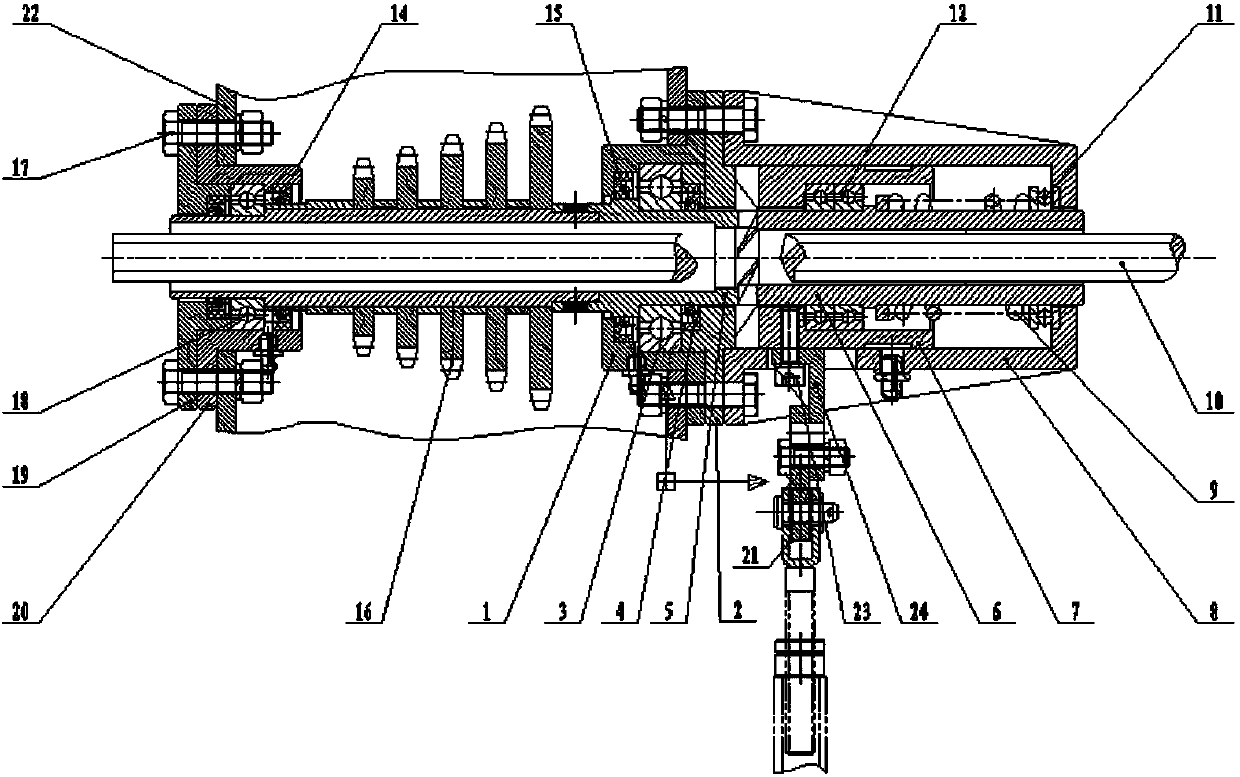

Servo mechanical transmission special for top drive drilling machine

InactiveCN103670265ATightly boundStrong output torqueConstructionsToothed gearingsElectric machineThrust bearing

Owner:河北格洛斯节能设备科技股份有限公司

Pneumatic motor with pressure-feed air bearing

ActiveCN110410153AIncrease stiffnessReasonable gas supply layoutStatorsSafety/regulatory devicesImpellerAir bearing

Owner:北京德丰六禾科技发展有限公司

Device capable of enabling rotary-extrusion type brake cylinder to rotate for lubrication

ActiveCN103148133BEvenly lubricatedAvoid dry frictionBrake actuating mechanismsActuatorsThrust bearingContact position

Owner:太原融盛科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap