Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106 results about "Textile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

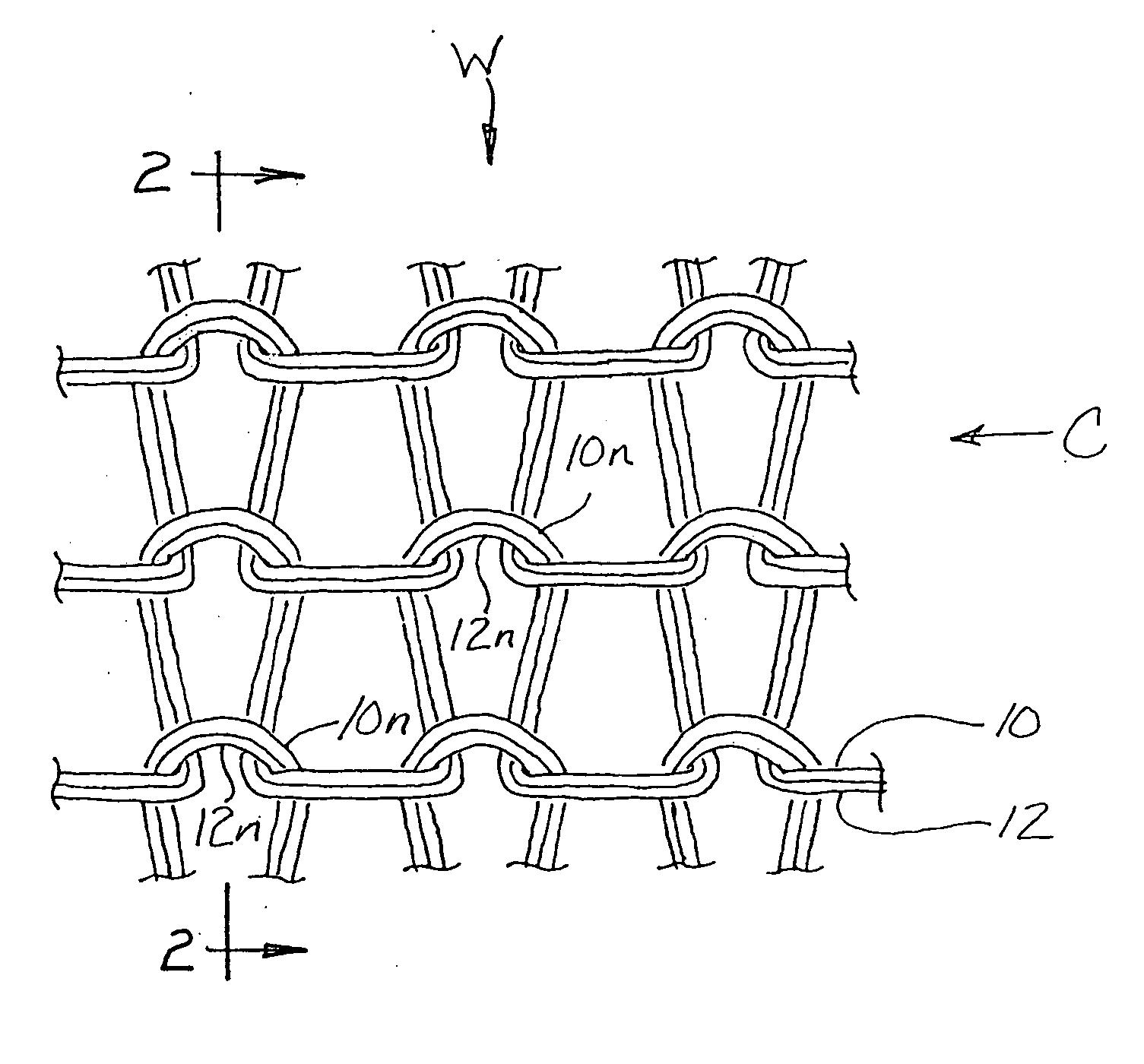

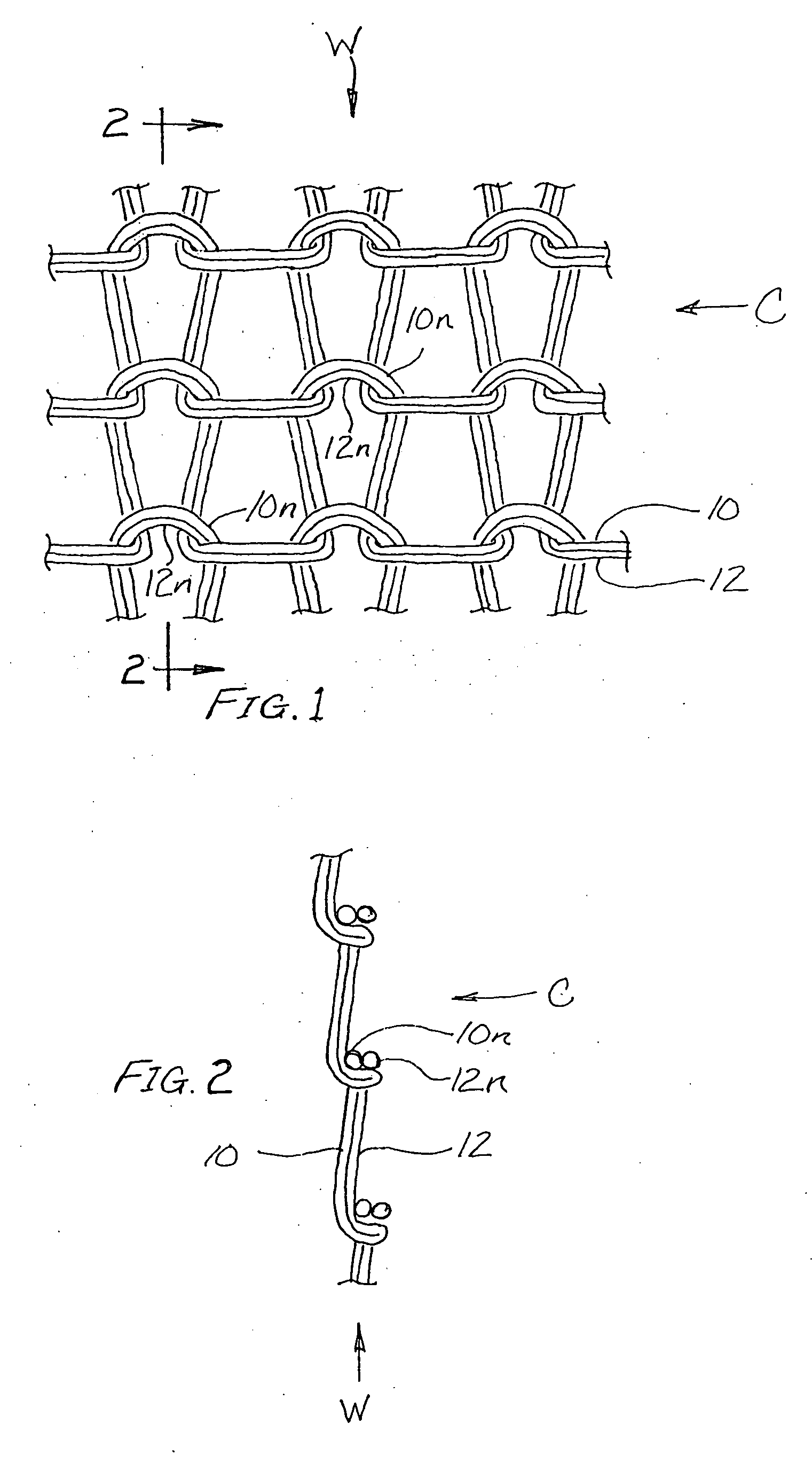

A textile is a flexible material consisting of a network of natural or artificial fibers (yarn or thread). Yarn is produced by spinning raw fibres of wool, flax, cotton, hemp, or other materials to produce long strands. Textiles are formed by weaving, knitting, crocheting, knotting or tatting, felting, or braiding.

Ultra-high temperature high pressure dyeing method for aramid fiber textile

InactiveCN101235598AHigh color fastnessBright colorPhysical treatmentDyeing processColour fastnessAtmospheric pressure

The invention discloses a method for dying kevlar fabrics under ultrahigh temperature and high pressure, which comprises: a preprocessing procedure under the ultrahigh temperature and the high pressure and a dying procedure under the ultrahigh temperature and the high pressure, wherein in the preprocessing procedure under the ultrahigh temperature and the high pressure, atmospheric pressure plasmas are used to process the kevlar fabrics for 1-5min, the processing temperature is 100-150DEG C, while in the dying procedure under the ultrahigh temperature and the high pressure, the temperature is 160DEG C-190DEG C, and the pressure intensity is 0.8-0.9MPa, wherein the plasma preprocessing procedure is an important procedure before the dying procedure under the ultrahigh temperature and the high pressure, since the processing for the plasma produces a plurality of active groups on the kevlar fabrics, which enables carriers to be better absorbed on the kevlar baric and thereby is beneficial for dying dye on the kevlar fabrics, simultaneously, the kevlar fabrics after dying under the ultrahigh temperature and the high pressure has high fastness, fresh color and soft hand feeling, and the washing color fastness and the abrasion color fastness of the kevlar fabrics are improved better.

Owner:ZHEJIANG SCI-TECH UNIV

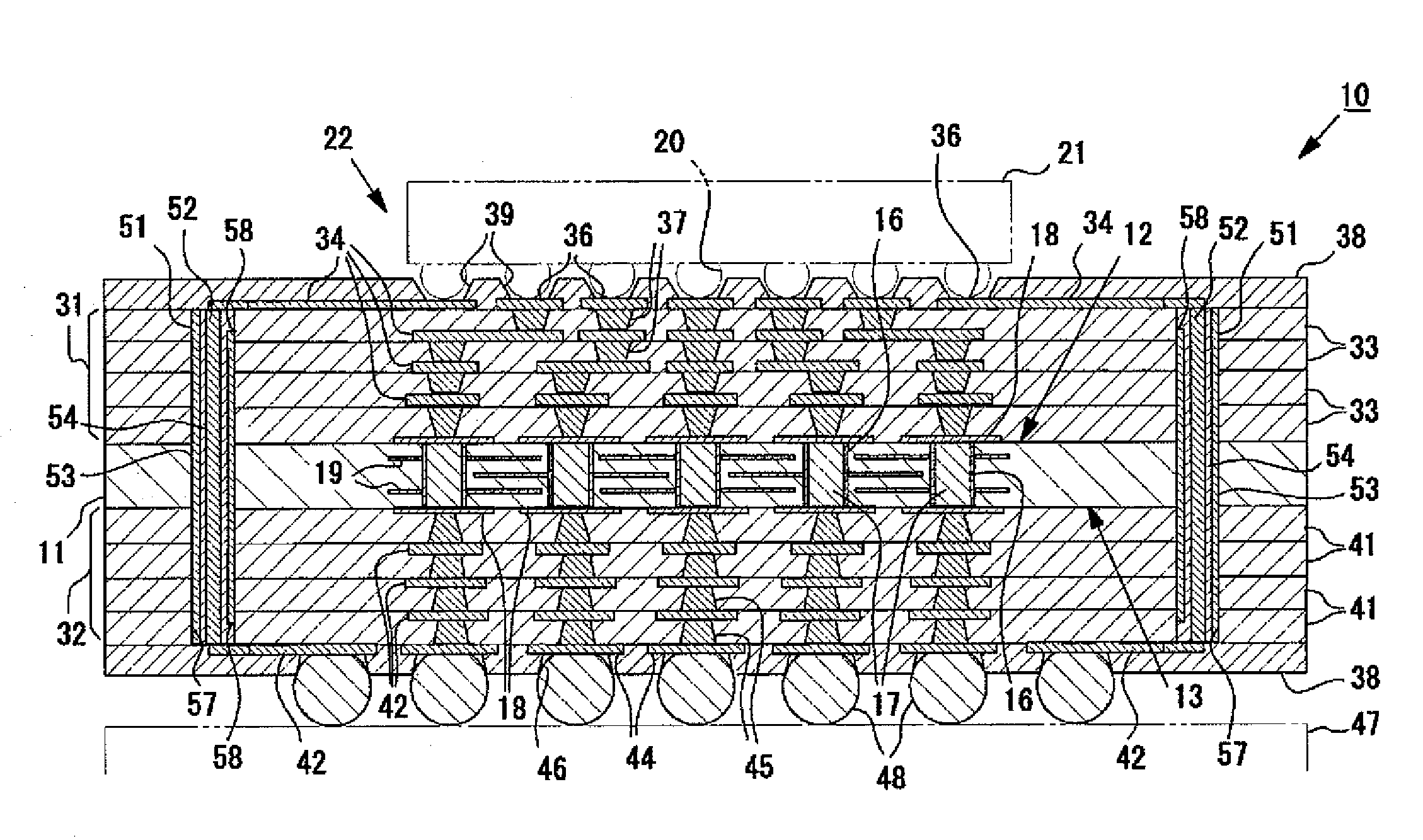

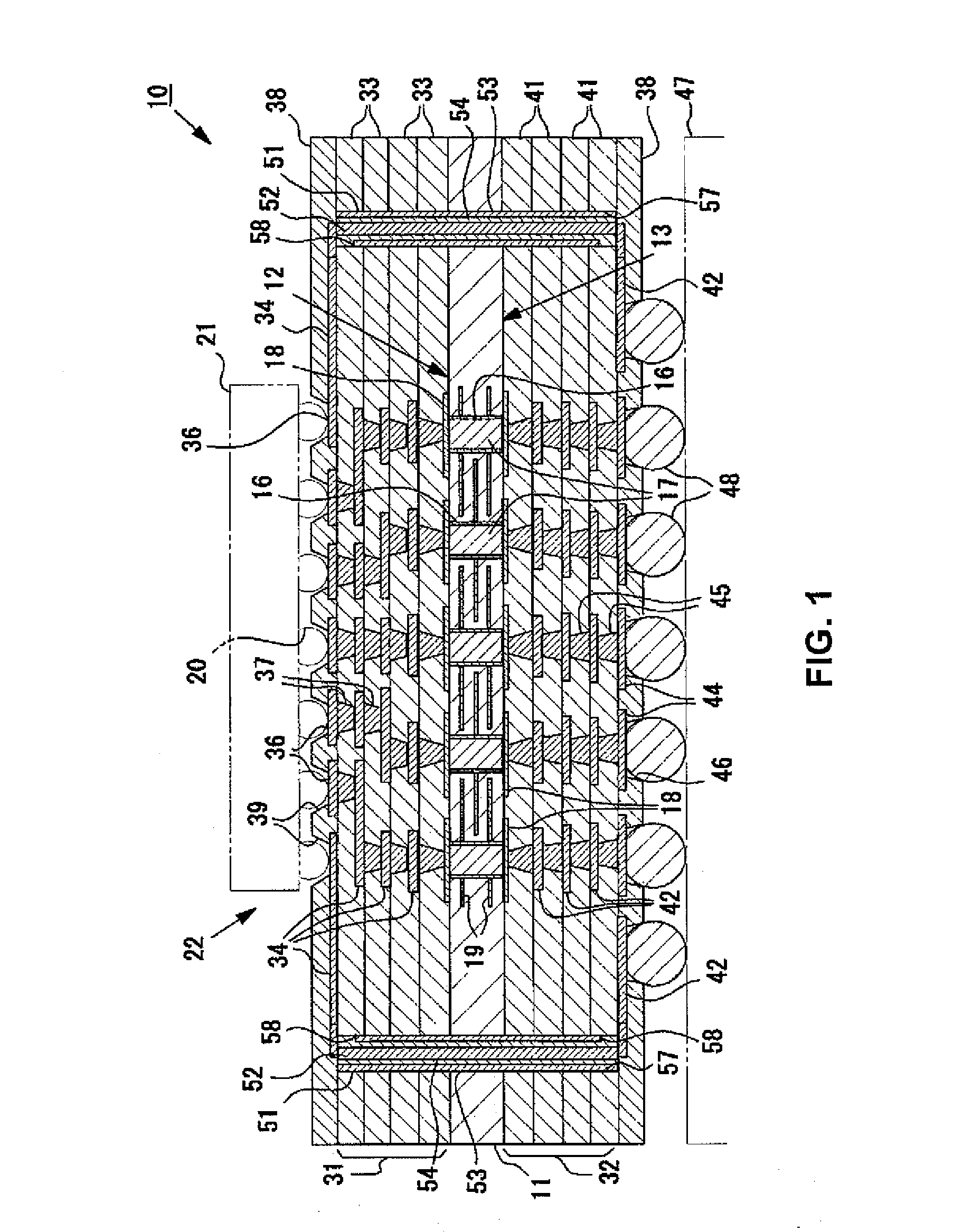

Multilayer wiring board and power supply structure to be embedded in multilayer wiring board

InactiveUS20080149384A1Lower resistanceHigh currentPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringCopper

Owner:NGK SPARK PLUG CO LTD

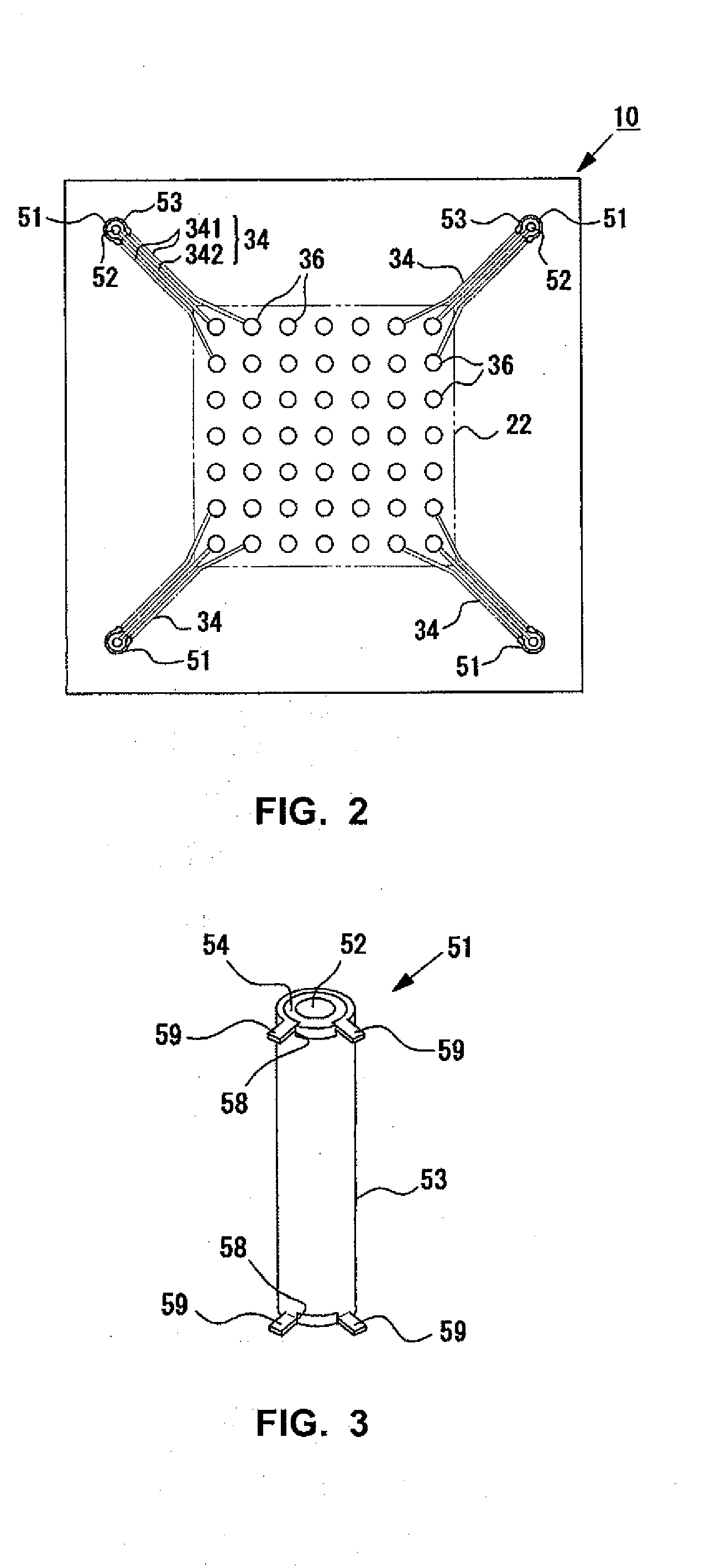

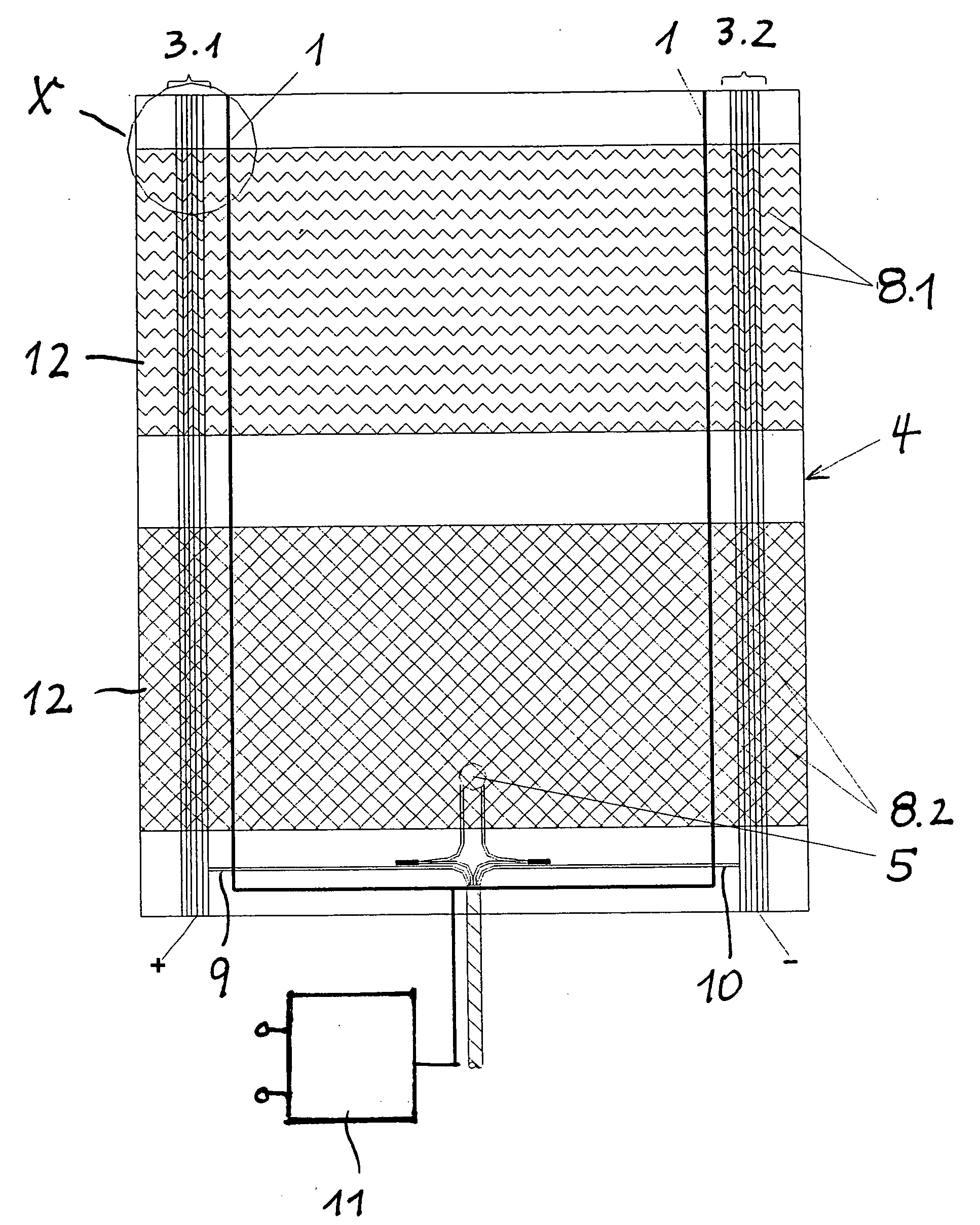

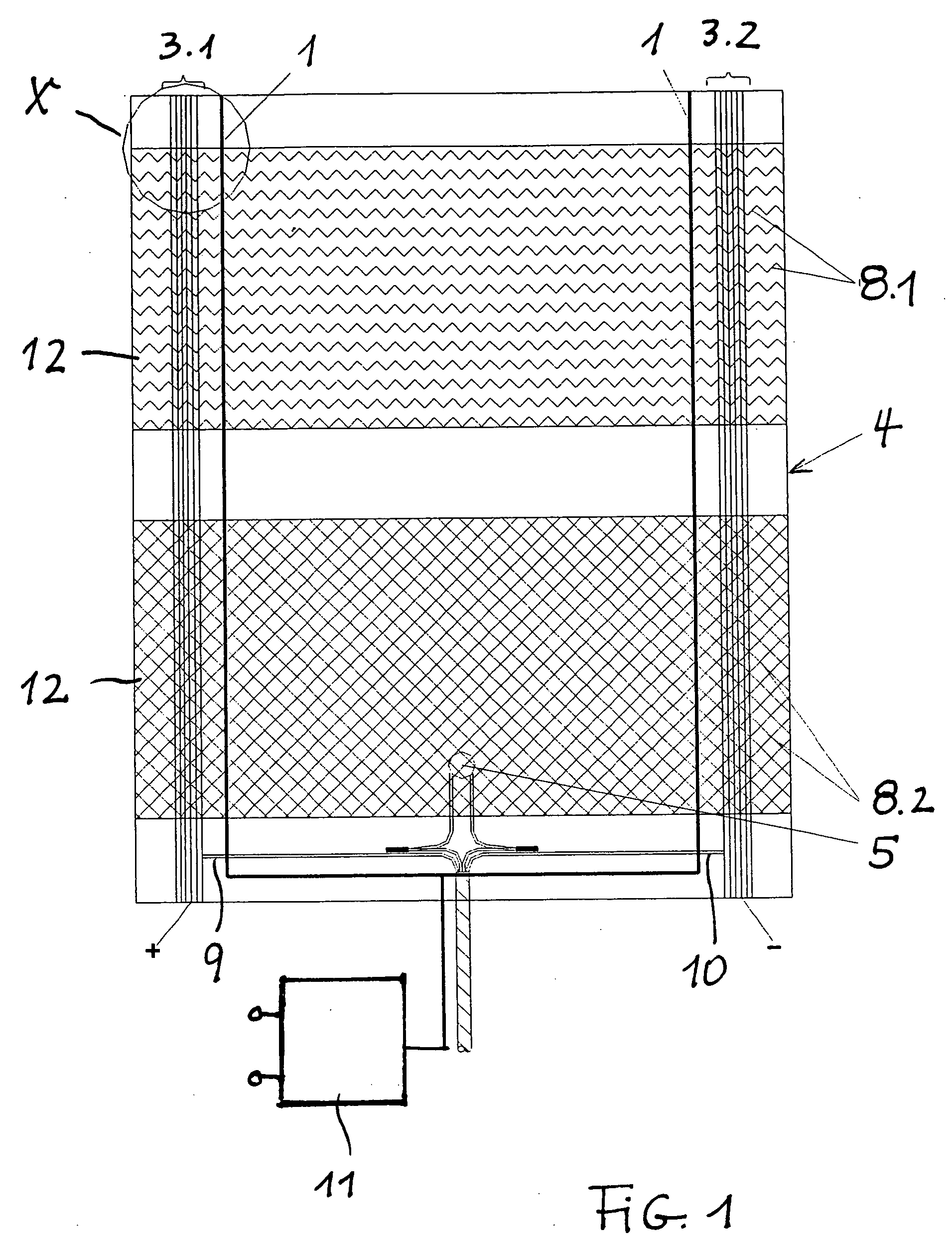

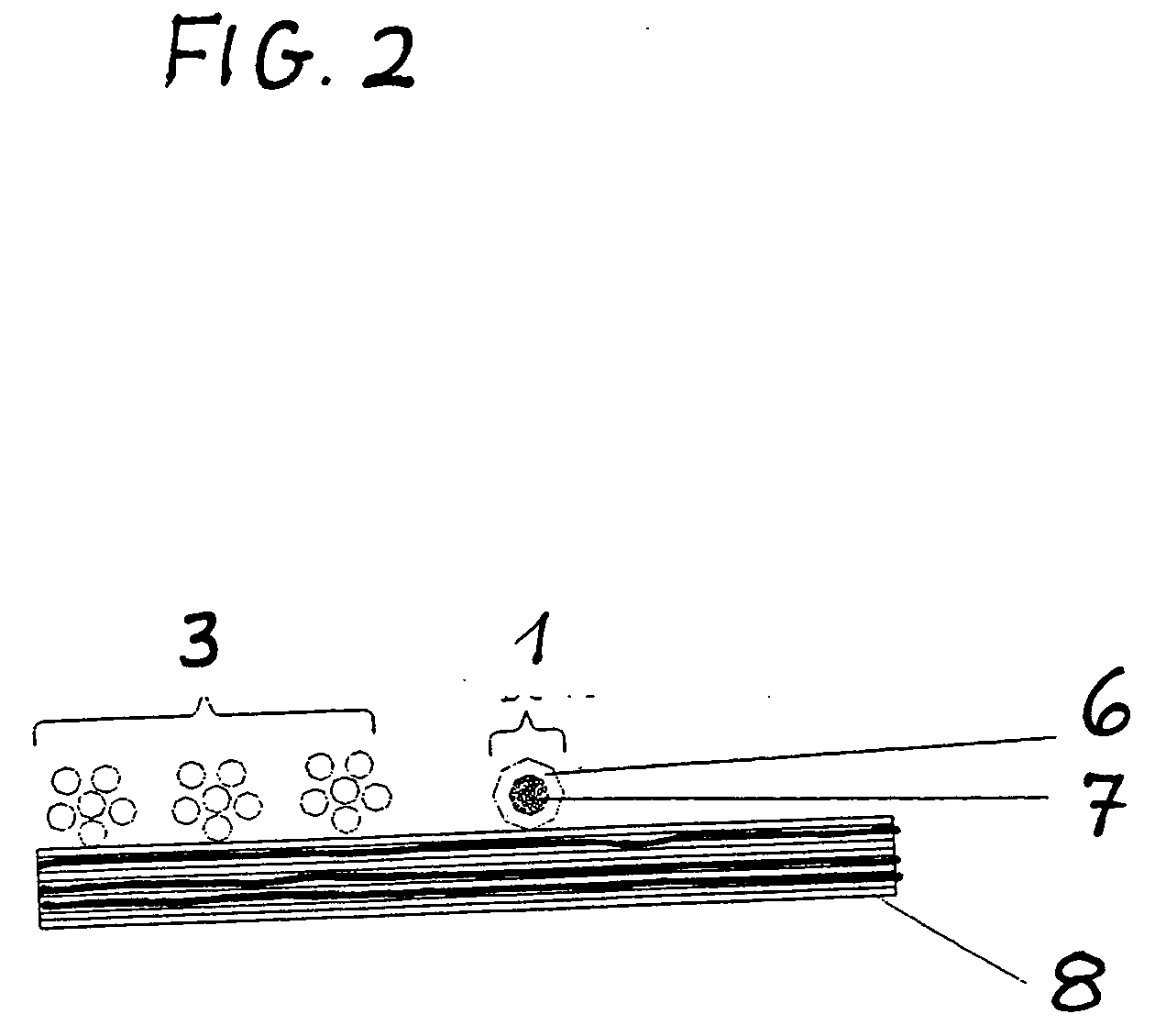

Textile arrangement and method for manufacturing

InactiveUS20130160183A1The process is simple and fastCost-effective manufacturingGlovesLaminating printed circuit boardsFlexible circuitsEngineering

Owner:CLOTHING PLUS MBU

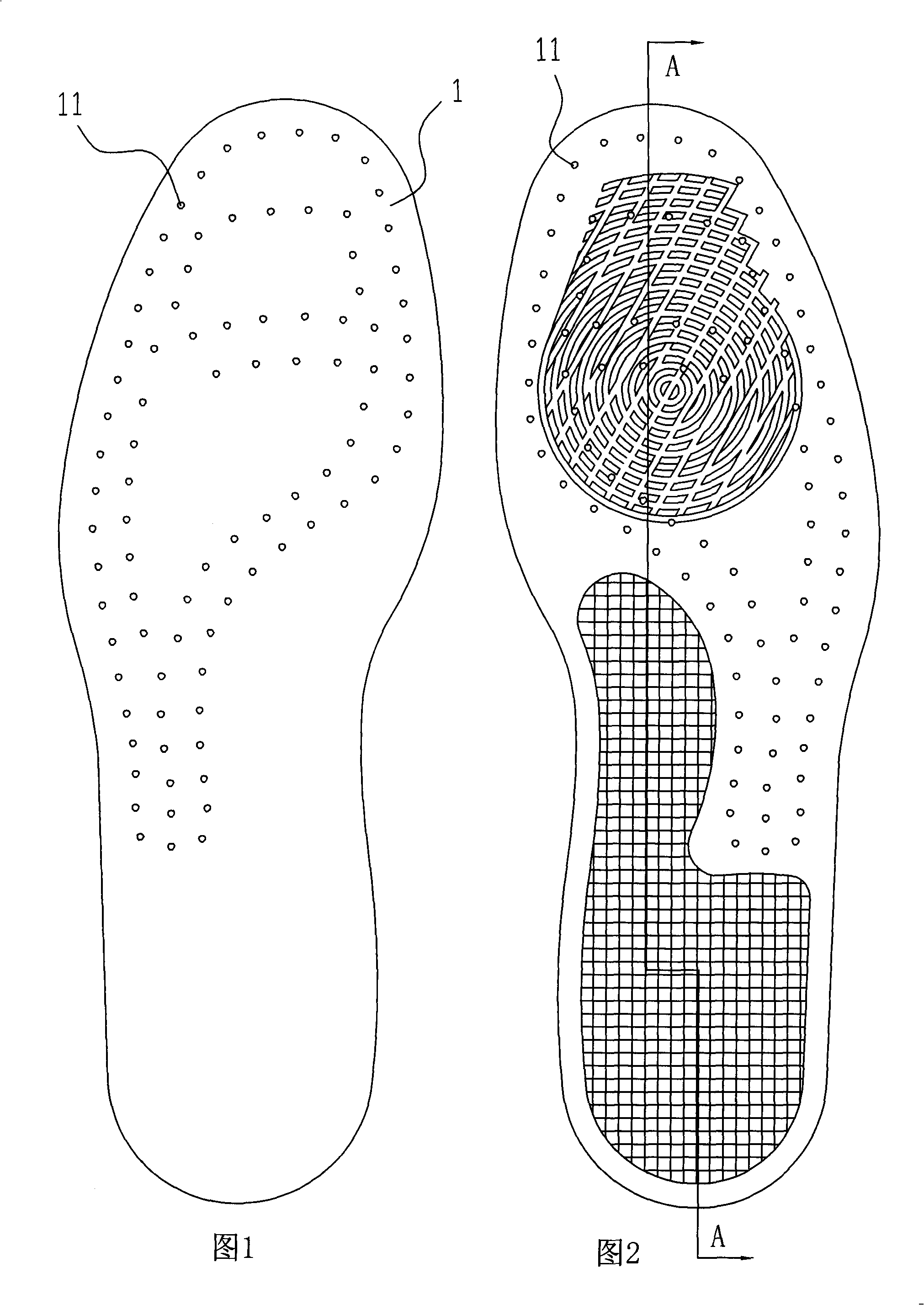

Method for making shoe-pad

InactiveCN101352905AEliminates the problem of slippery insolesAnti-vibration is goodDomestic articlesMetal working apparatusMembrane surfaceEngineering

Owner:汪士抗

Multifunctional textile lining

InactiveCN101173487AStrong reductionStrong oxidation abilityFibre treatmentMagnetic/electric field screeningNanometreHot-melt adhesive

Owner:SHENGHONG GRP CO LTD

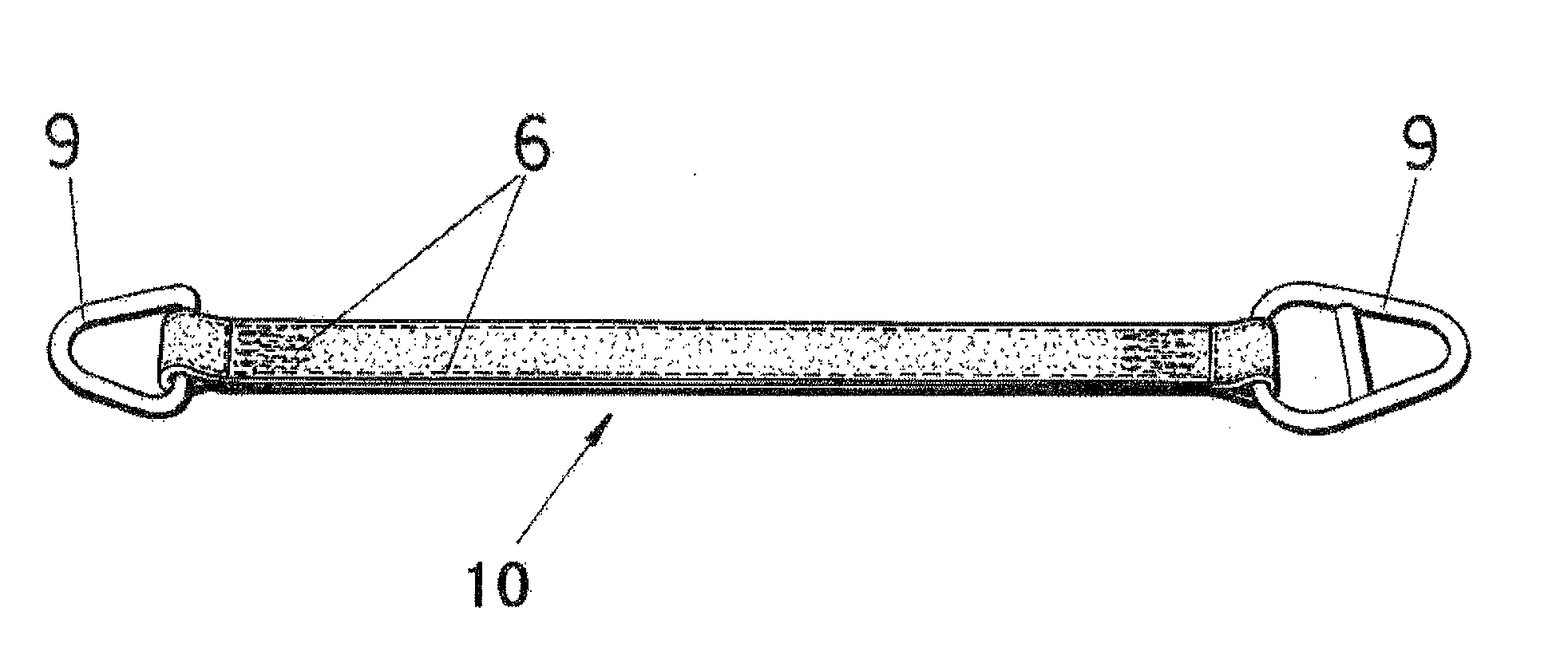

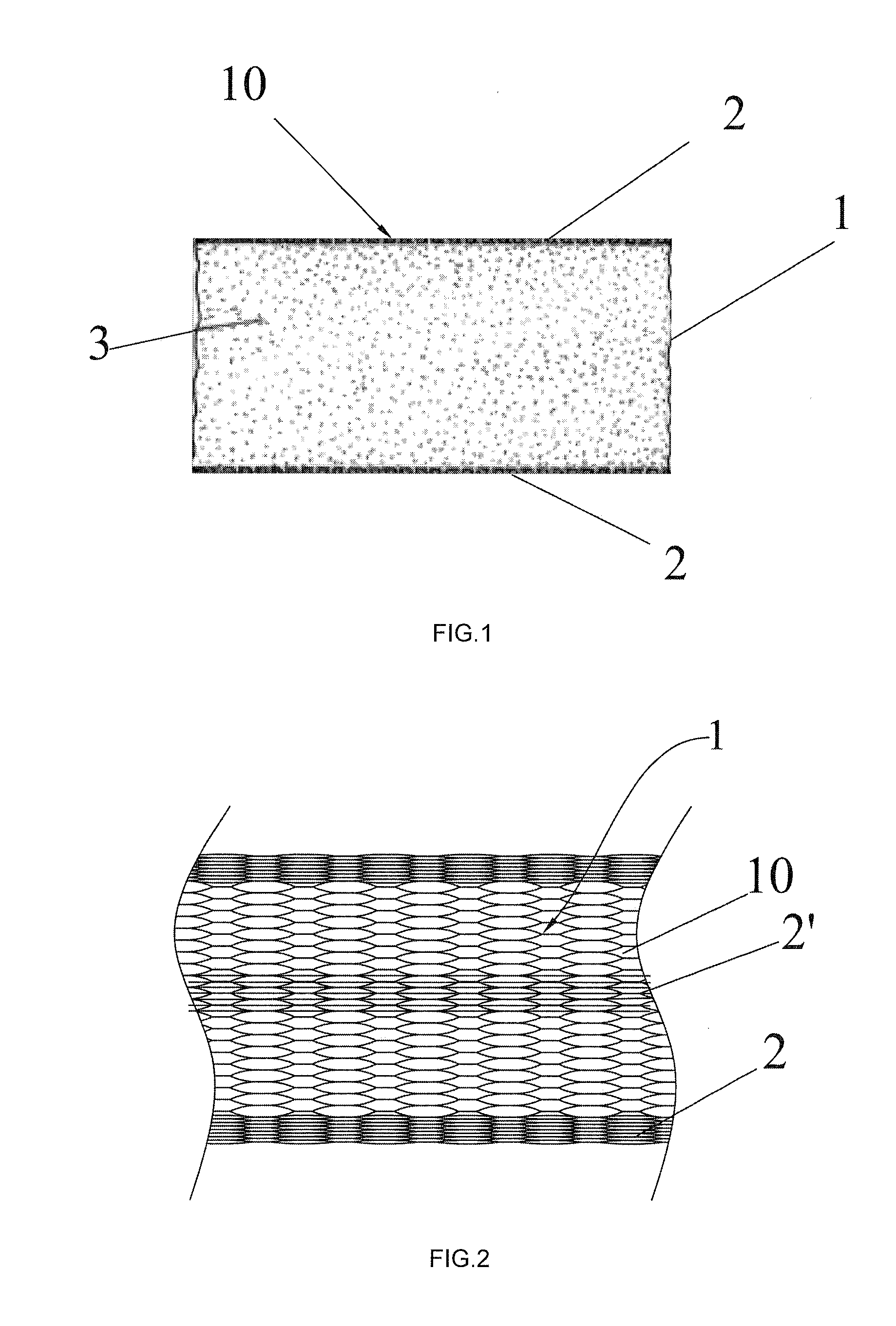

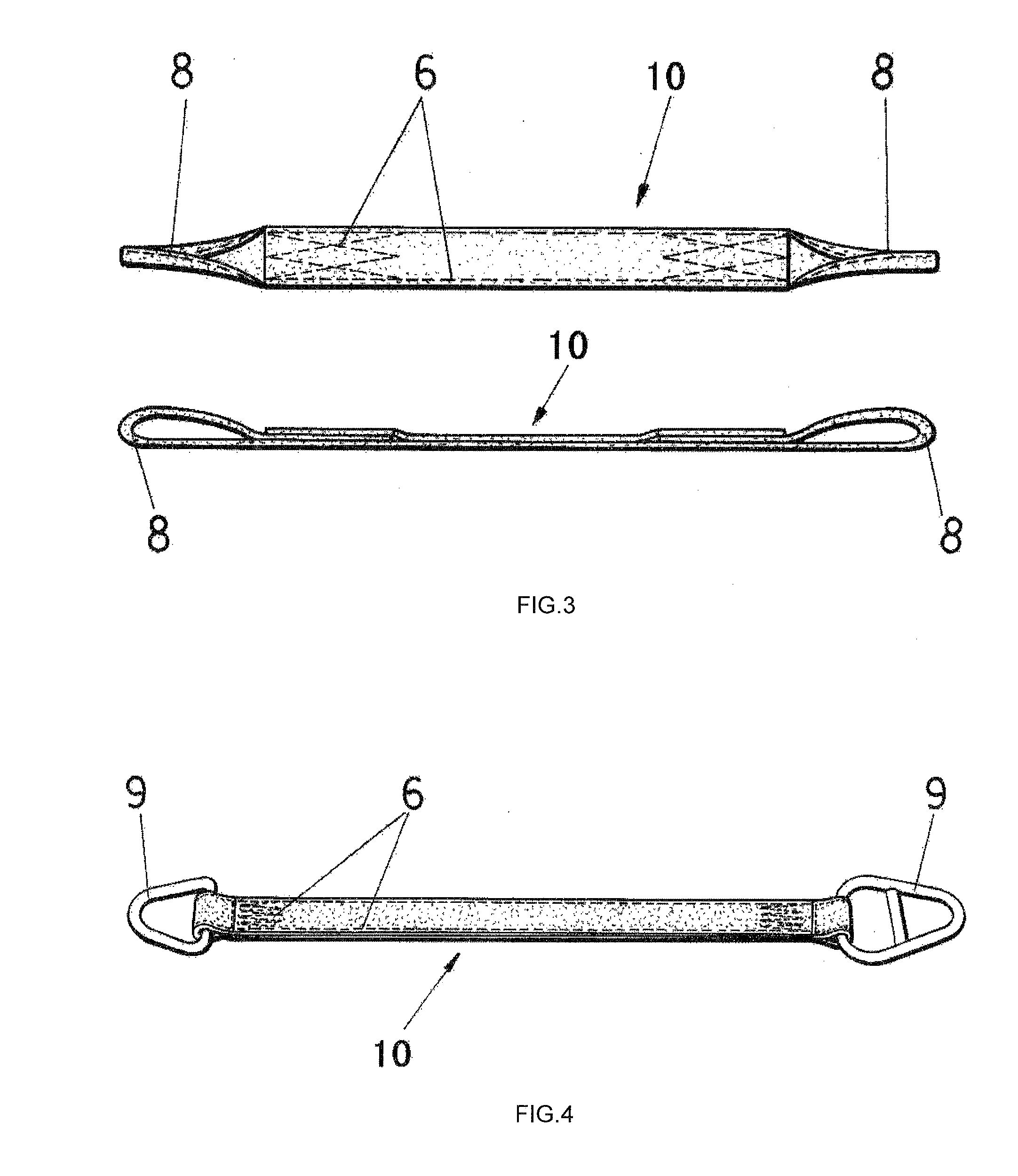

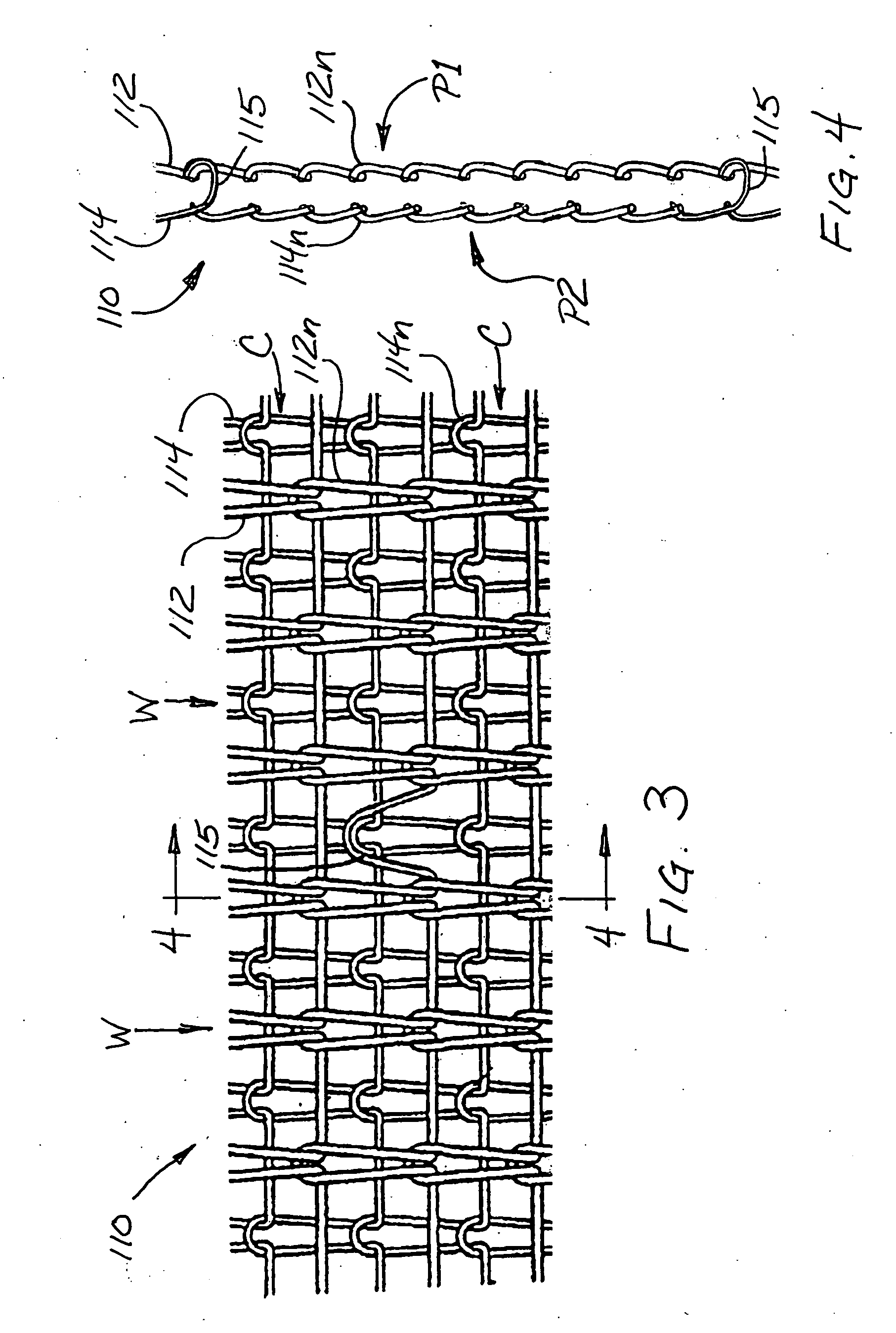

Textile sling and method of manufacturing same

InactiveUS20100327615A1Tough to abrasionTough to cutLoomsDrying machines with progressive movementsYarnPolyurethane dispersion

Owner:DONGGUAN PONSA TEXTILE

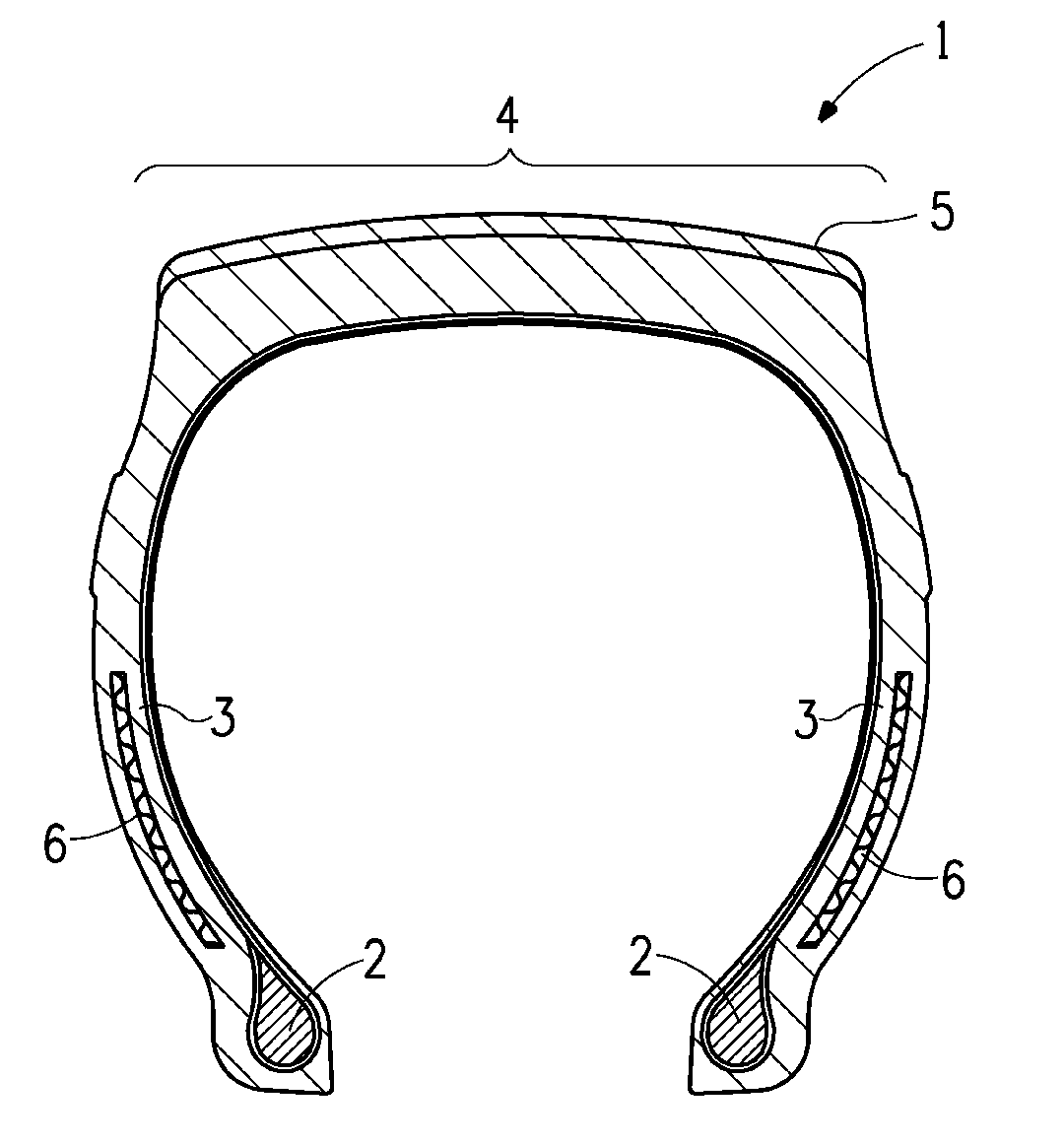

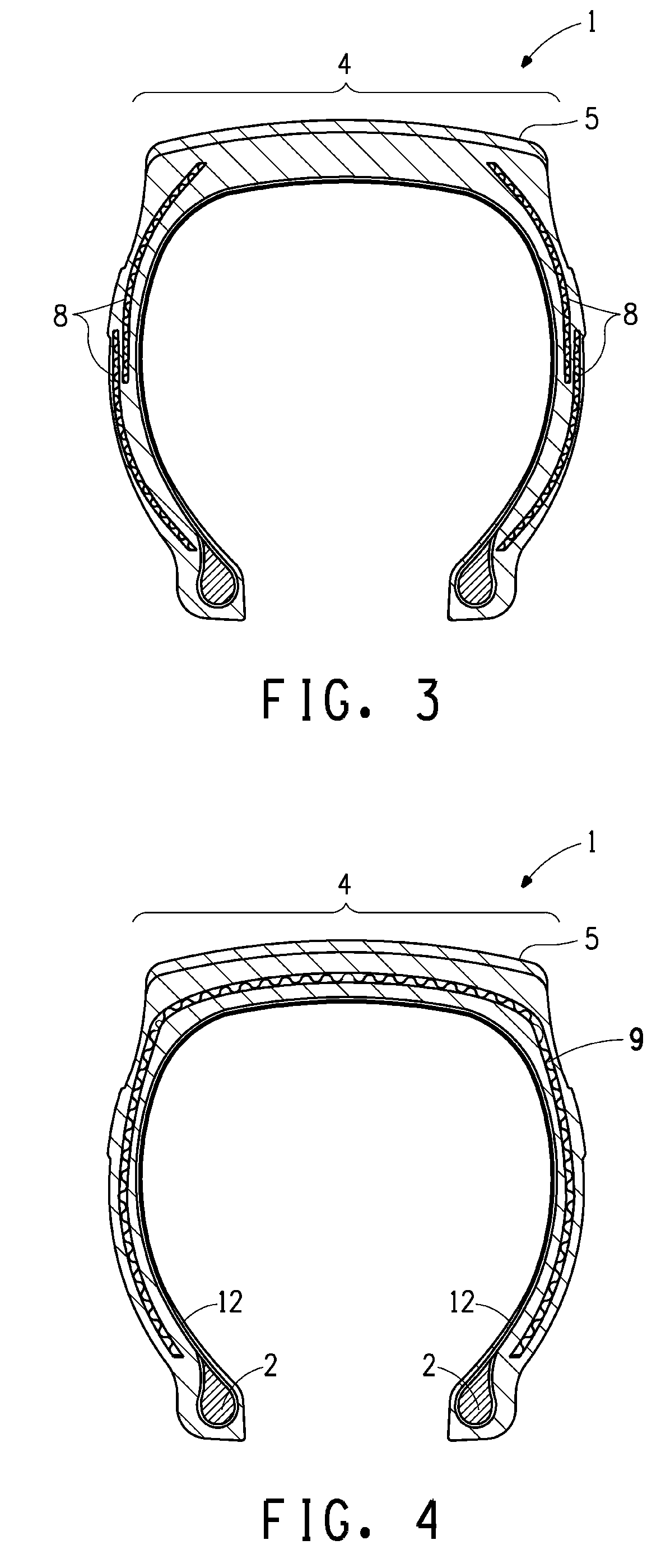

Extensible non-load bearing cut resistant tire side-wall component cotaining elastomeric filament, tire containing said component, and processes for making same

InactiveUS20100108218A1Improved adhesion of fabricLayered productsPneumatic tyre reinforcementsYarnFiber

Owner:EI DU PONT DE NEMOURS & CO +1

Textile with flame retardancy and water repellency, and production method thereof

The invention discloses a textile with flame retardancy and water repellency, and a production method thereof. The textile with flame retardancy and water repellency contains flame-retardant polyester fibers. Bromine element content of the textile with flame retardancy and water repellency is less than or equal to 5 micrograms per gram. Fluorine element content of the textile with flame retardancy and water repellency is less than or equal to 5 micrograms per gram. One or more non-halogen flame-retardant treating agents and one or more non-fluorine water-repellent treating agents are prepared into the textile with flame retardancy and water repellency through functional finishing. The textile with flame retardancy and water repellency is safe and environmentally friendly. After the textile with flame retardancy and water repellency is washed 5 times, the necessary frequency of exposure under flame for burning is great than or equal to 3 and the water repellency reaches or exceeds a second level. The textile with flame retardancy and water repellency can be utilized for preparation of shower curtains, tents, window curtains, outdoor gym suits and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Continuous cold-rolling and steaming dyeing process and equipment of active dyestuff

PendingCN106638038AReduce consumptionReduce pollutionSucessive textile treatmentsTextile treatment machine arrangementsYarnAcid washing

Owner:杨立新

Rainwater collection device for garden irrigation

InactiveCN107366328AEasy to irrigatePrevent waterloggingGeneral water supply conservationWatering devicesImpellerRainwater harvesting

Owner:SOUTHWEST FORESTRY UNIVERSITY

Automatic cleaning billboard

InactiveCN107159611AEasy to cleanSimple structureCleaning using toolsDisplay boardDistributed structure

Owner:SICHUAN MARK VISION NETWORK TECH CO LTD

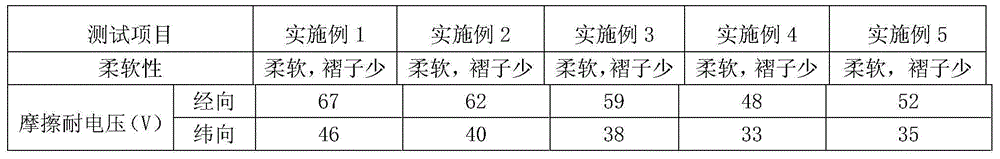

Method for producing double-color short pile fabric

The invention provides a production method of a two-color short plush fabric, which belongs to the technical field of textile fabrics. It includes the following steps: step (1), select the yarn to be used, the type of yarn used is polyester semi-gloss FDY, polyester semi-gloss light net DTY, cationic FDY; step (2), use warping machine for warping; Step (3), use the warp knitting machine for weaving; step (4), arrange and change the weaving process according to the designed production process sheet; step (5), check; step (6), blank inspection; step (7) , stacking blanks; step (8), setting the shape, setting the fabric; step (9), napping; step (10), dyeing, dyeing the shaped fabric; step (11), post-processing, after Post-processing creates a two-tone short plush fabric. The invention realizes the production of the fabric similar to the wavy pattern, forms the two-color short plush fabric, has a simple production method and high production efficiency.

Owner:TONGXIANG LONGXIANG TEXTILE

Monitoring device for flexible heating elements

Owner:I G BAUERHIN GMBH

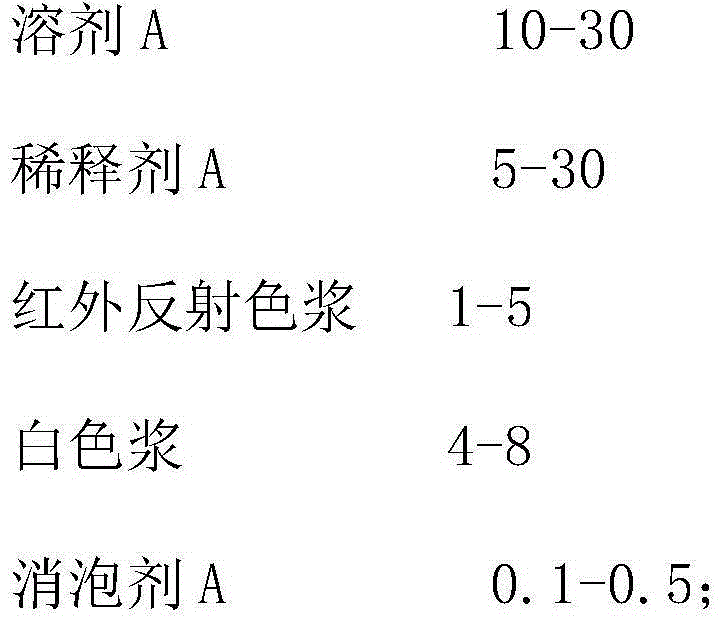

Infrared stealth textile coating fabric

ActiveCN105034523ALow infrared reflectanceImprove stealth performanceSynthetic resin layered productsCross-linkPolymer science

Owner:CTA HI TECH TEXTILES

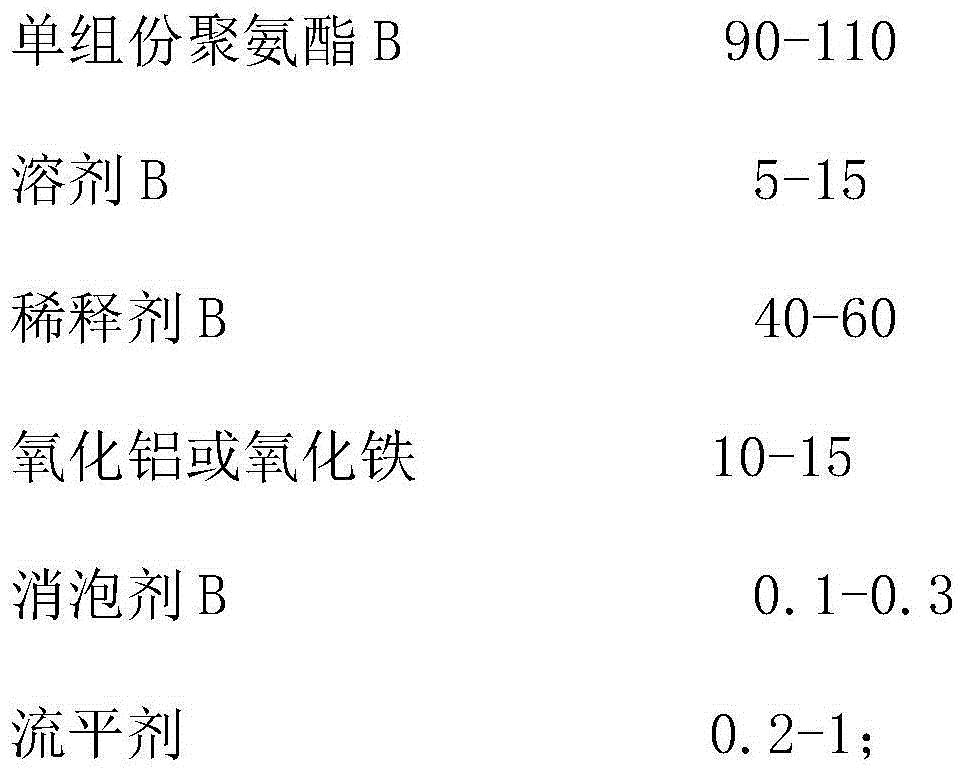

Dedusting apparatus

InactiveCN105597465AImplement coarse filteringFast absorptionCombination devicesBrickWater storage tank

Owner:ANHUI NINGHUO NEW MATERIAL

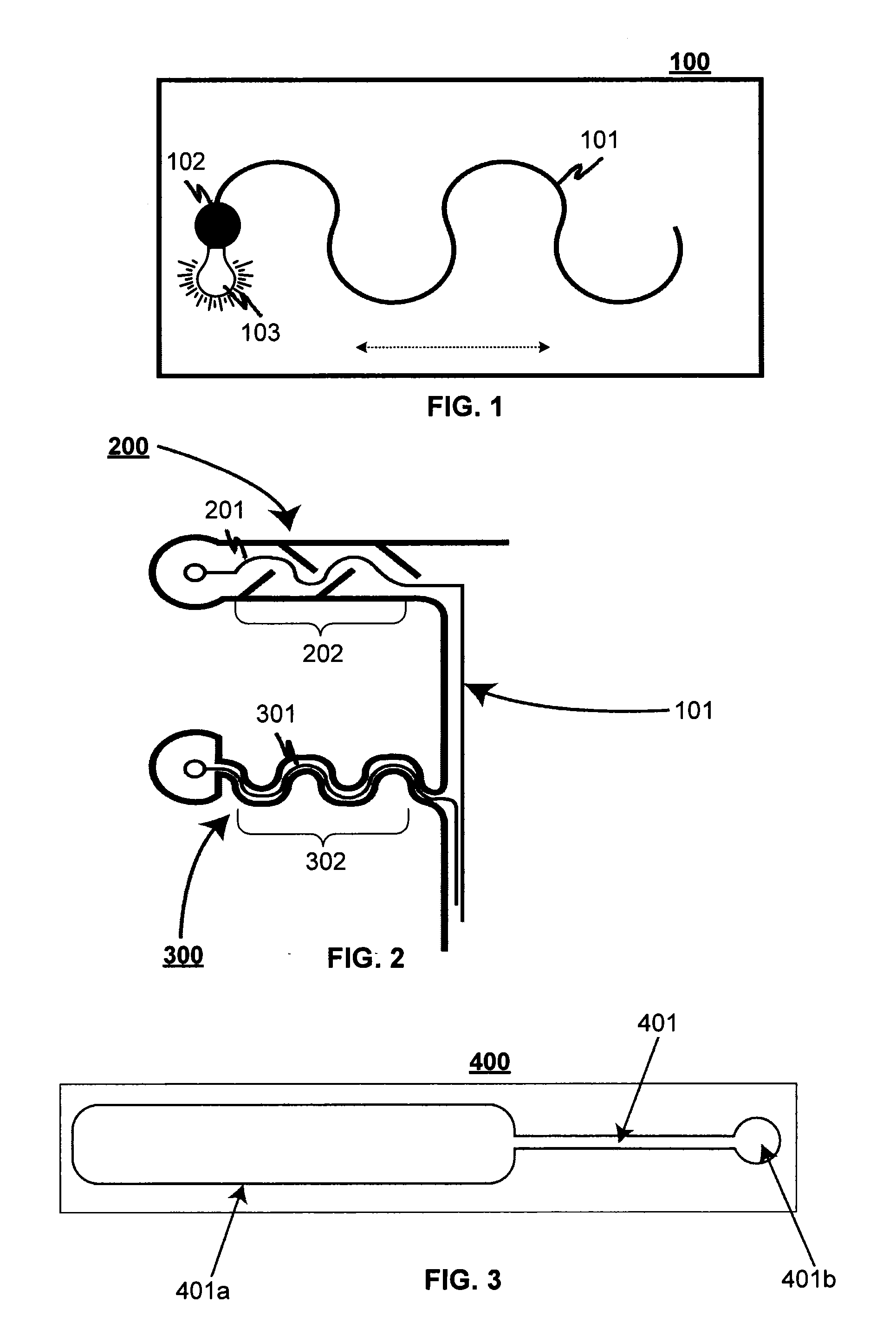

Divided Conduit

A divided conduit containing a thermoplastic conduit and at least one strip-shaped textile. The strip-shaped substrate may be a strip-shaped textile or a strip-shaped film and has a first longitudinal edge and a second longitudinal edge which are adhered to or embedded into the inner surface of the conduit forming at least two flexible, longitudinal channels for enveloping cables or other elongated structures.

Owner:MILLIKEN & CO

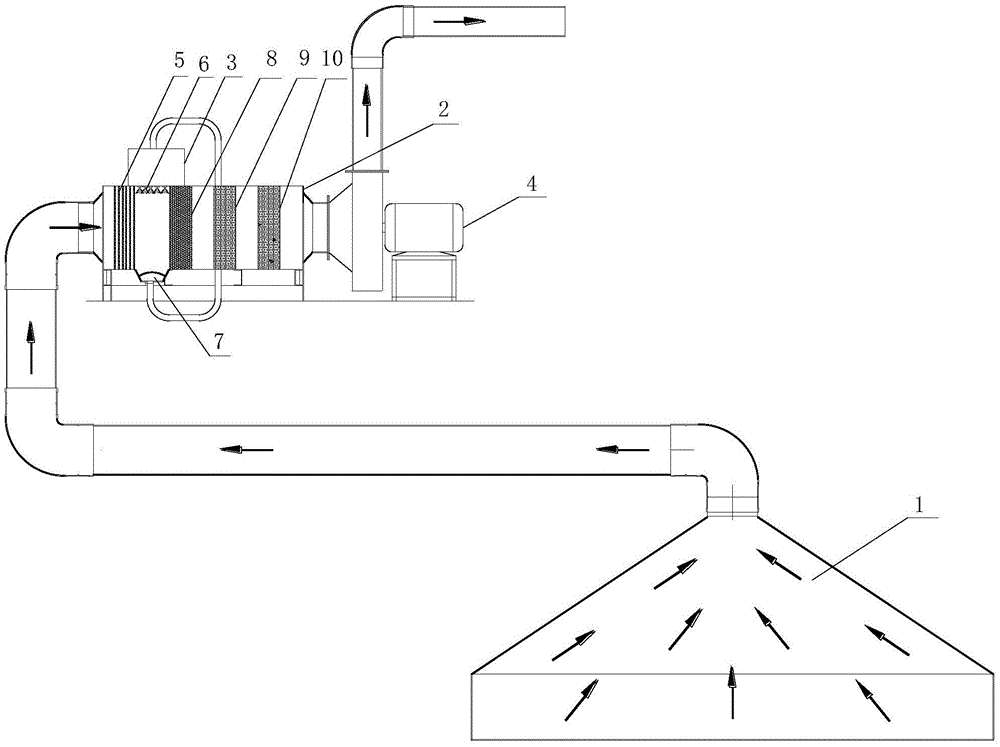

Novel electrostatic removal agent for textile materials and preparation method of novel electrostatic removal agent

InactiveCN104532572AEasy to dissolve and disperseImprove stabilityFibre treatmentAcetic acidPolyvinyl alcohol

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

Testing method for wettability of glass fiber cloth

Owner:SHENGYI TECH SUZHOU

Method for making coated filter cloth through wet process

InactiveCN103952914AHigh porosityHigh Solids RetentionFibre treatmentFiltration separationPorosityYarn

Owner:刘冠利

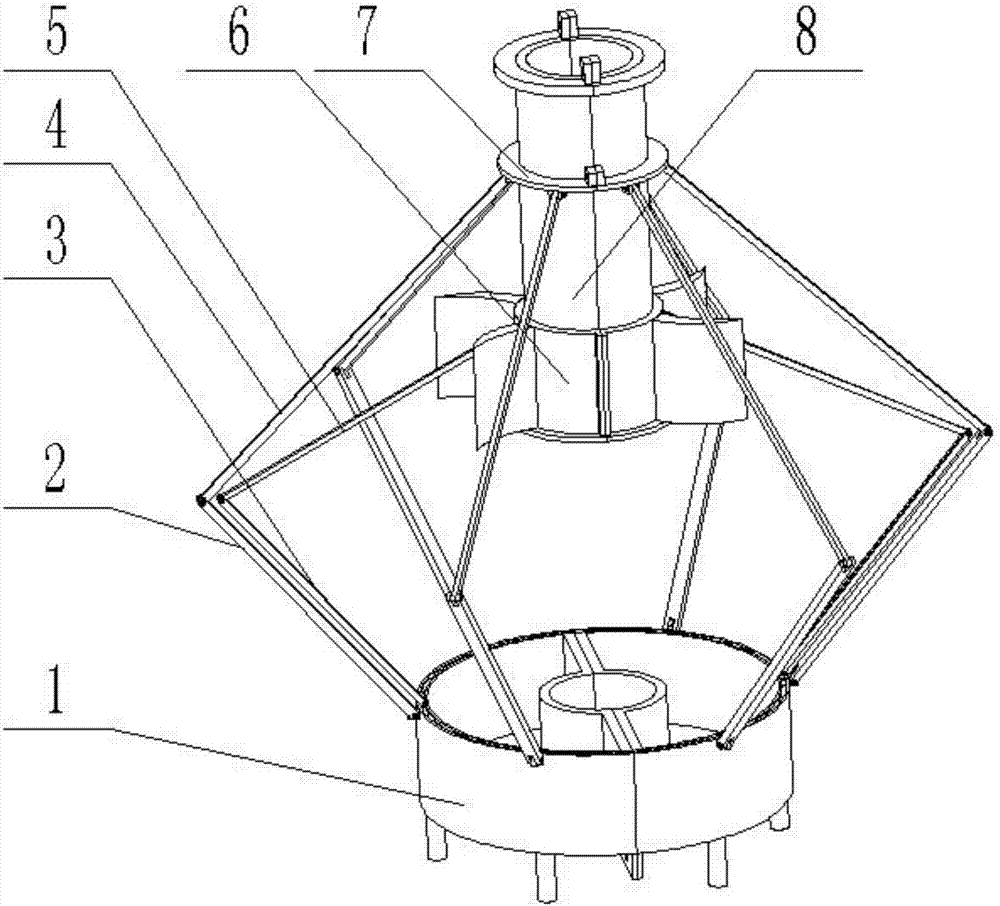

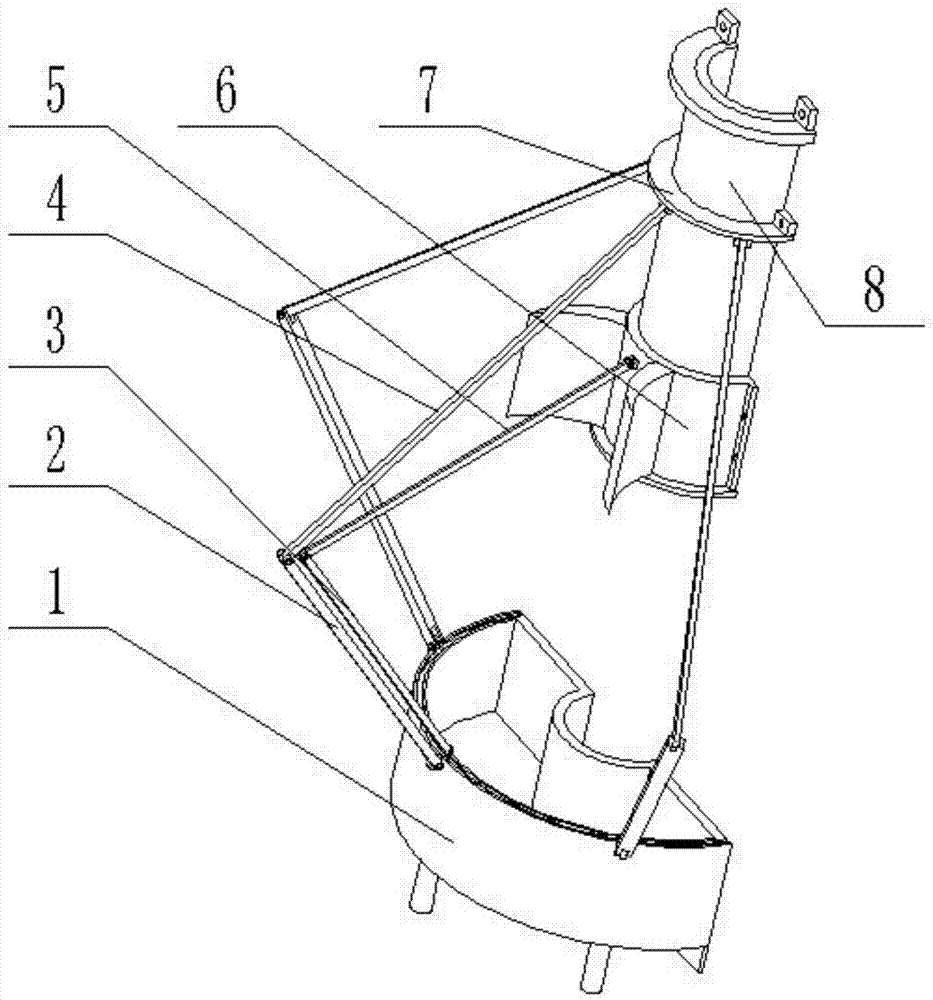

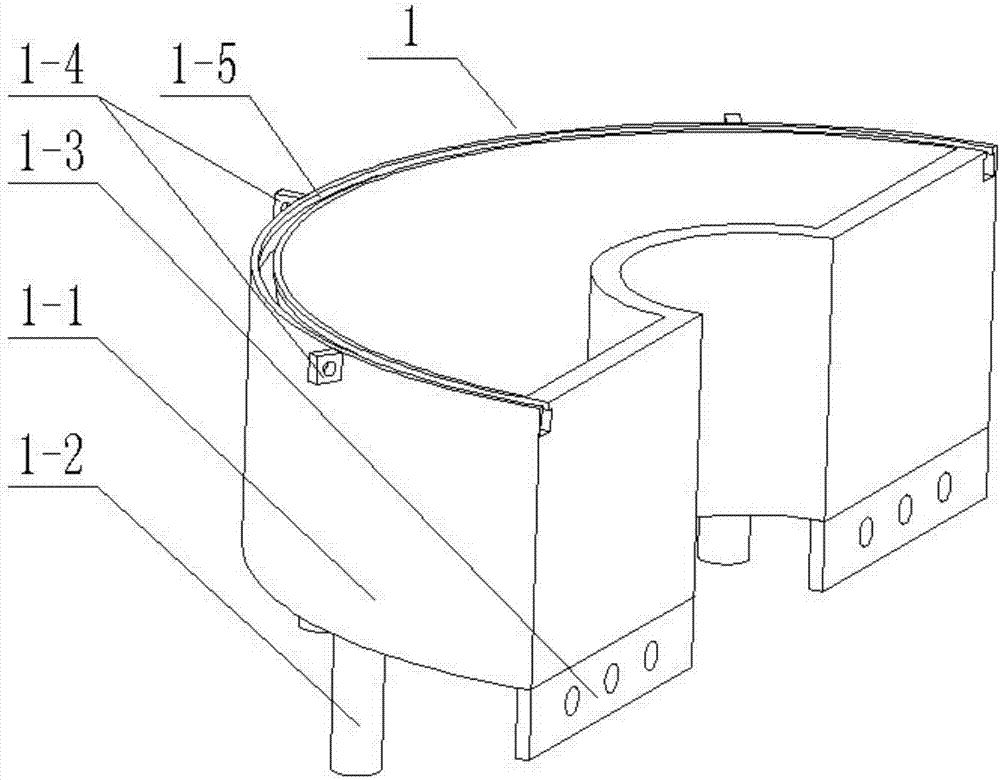

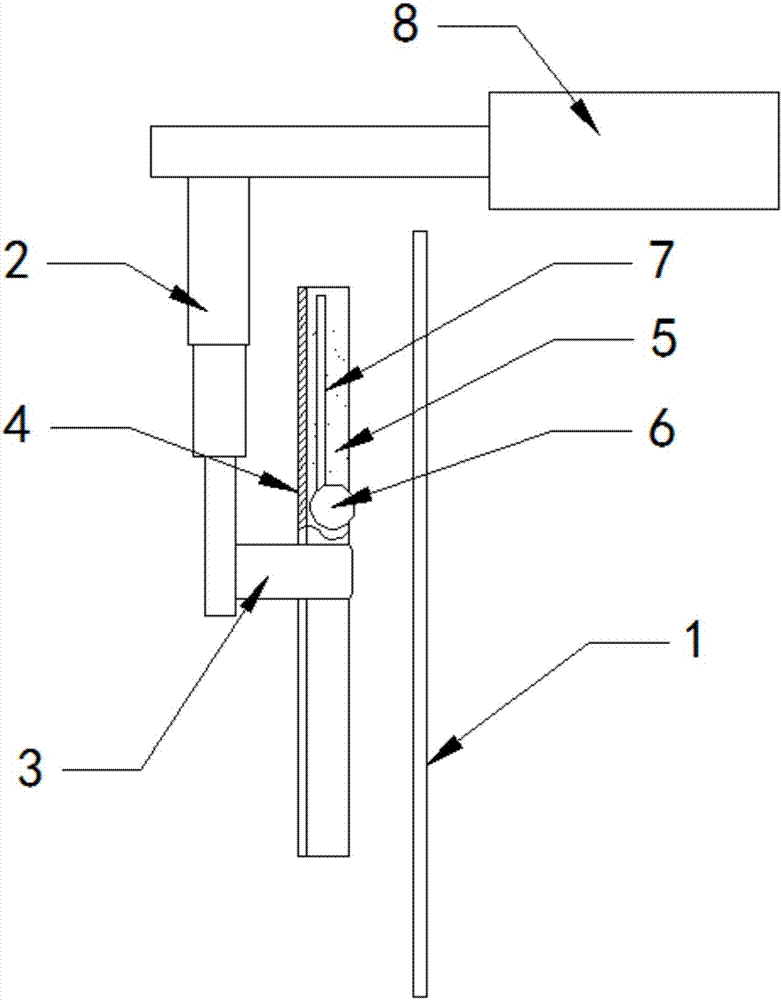

Grinding filter component and bone slurry machine

Owner:润桐(苏州)技术服务有限公司

Textile rack

InactiveCN106929987AEasy to usePlay the role of reinforcementLoomsAuxillary apparatusVertical tubeArchitectural engineering

Owner:嵊州市裕宝纺织机械有限公司

Automobile trim material combined with non-woven fabric and woven fabric

InactiveCN105034535ASignificant advantage effectLow priceSynthetic resin layered productsLaminationSodium bicarbonateWarm water

Owner:湖北南泽汽车复合材料有限公司

Doll

A doll has a figure of a human or an animal and an outer layer of a flexible gelatinous compound covering the figure so as to provide a skin-like characteristic. The figure may have a part that is made of a soft resilient material and in covering that part the gelatinous compound is bonded to a stretchy elastic textile.

Owner:T K WONG & ASSOCS

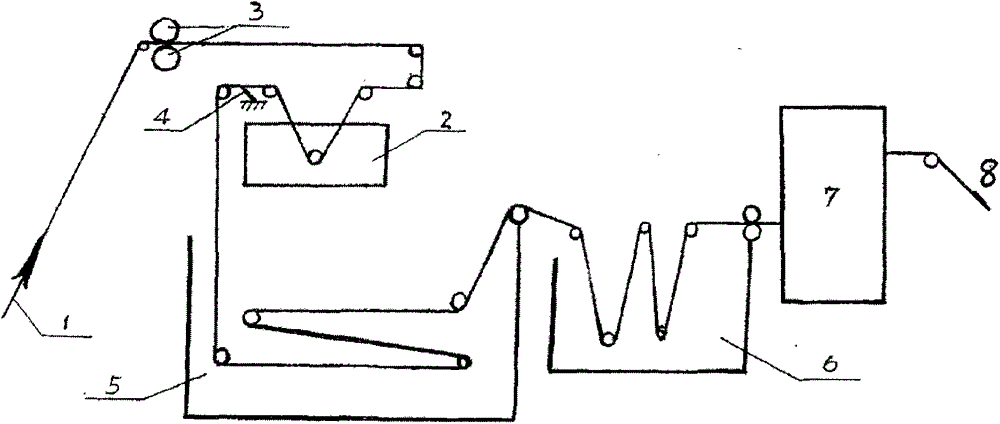

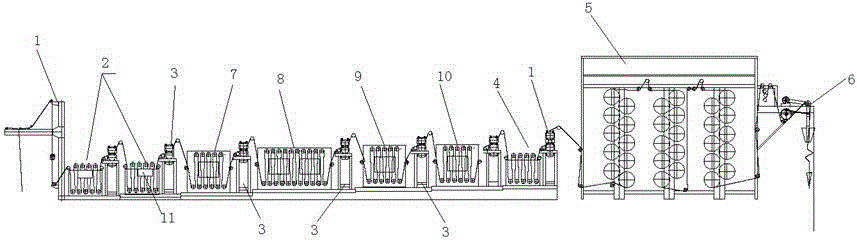

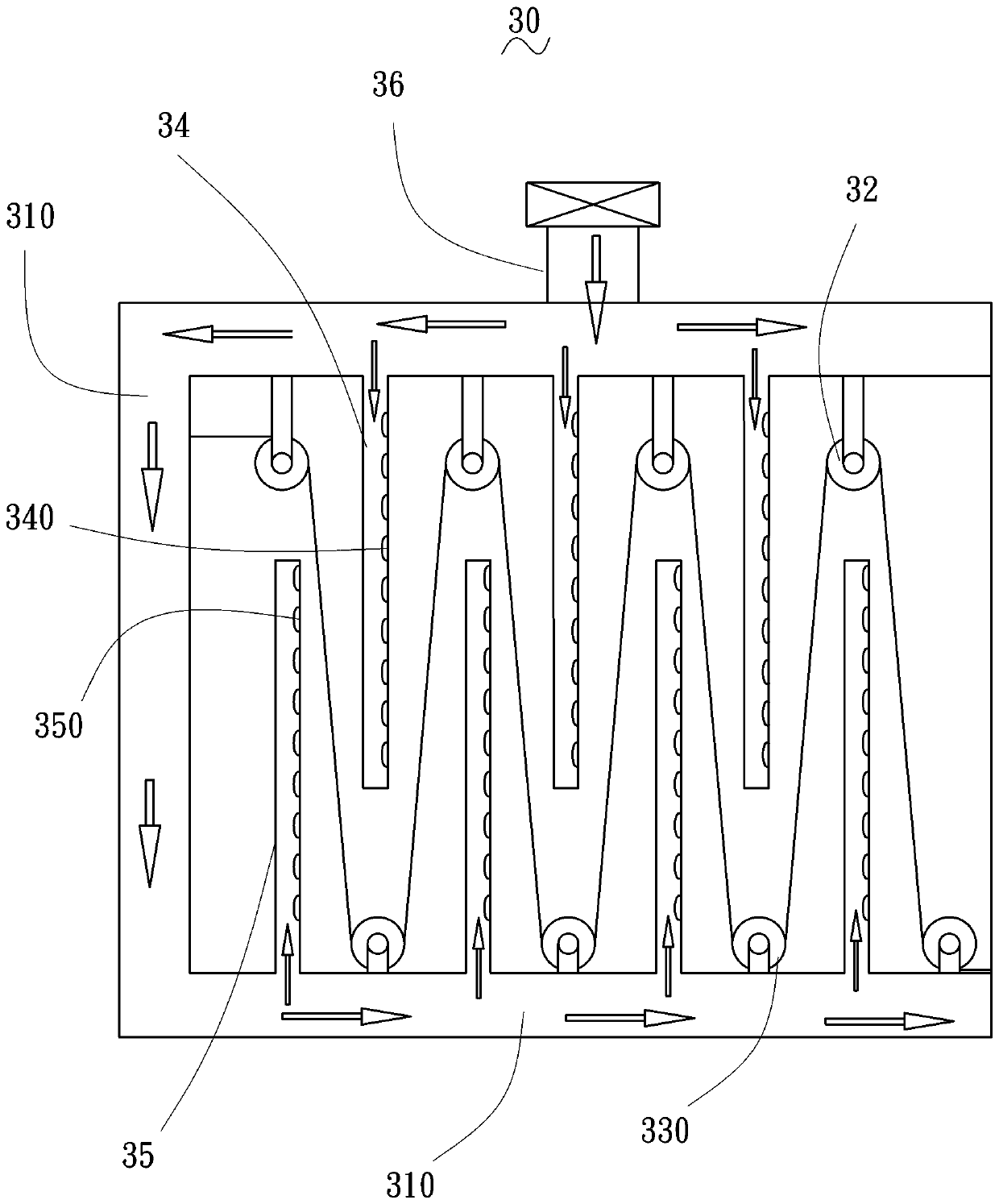

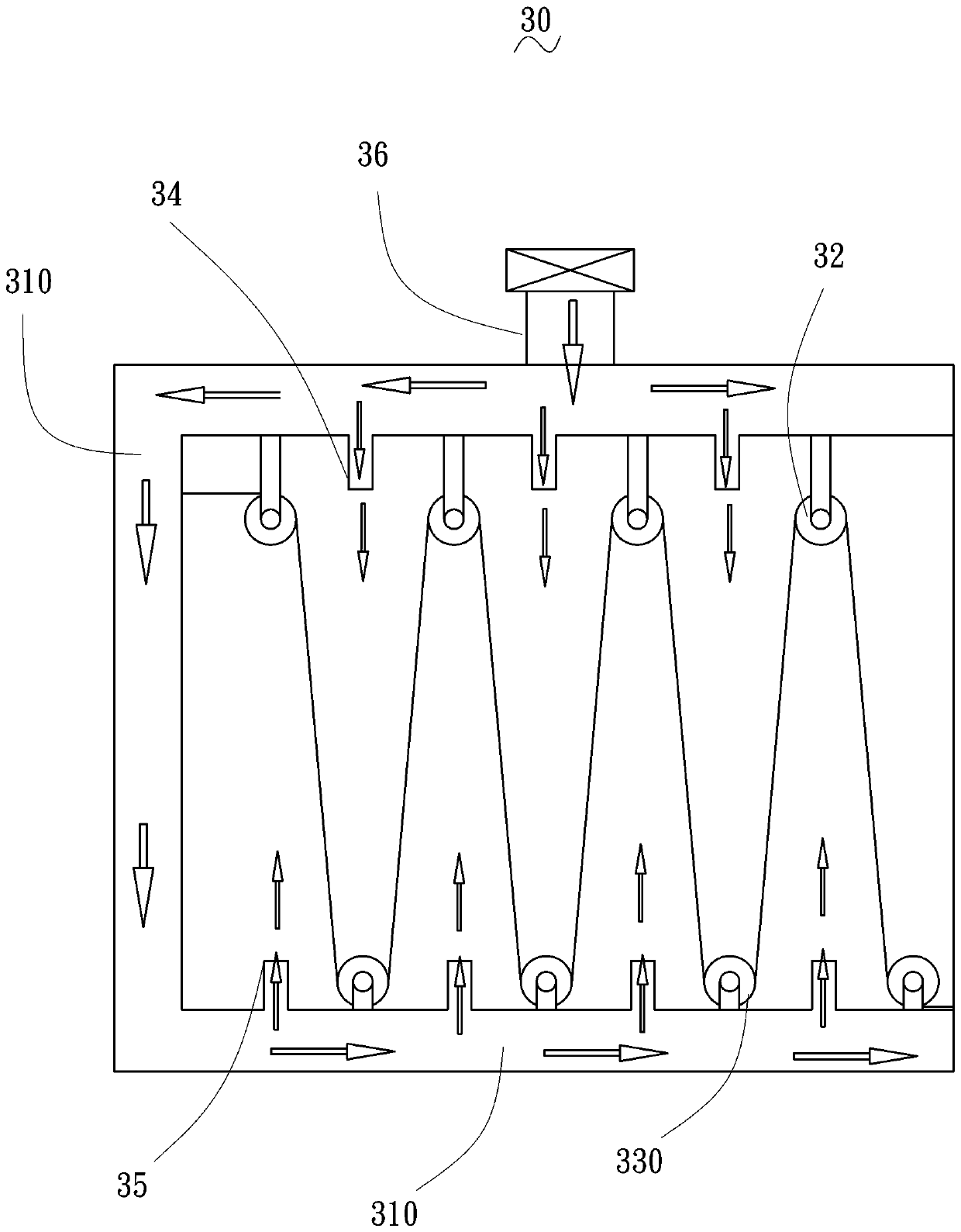

Woven fabric and jean desizing and boiling-off combined machine

InactiveCN104947339ASoft and comfortableSucessive textile treatmentsTextile treatment containersFiberDenim

Owner:扬州市江都区东盛印染机械厂

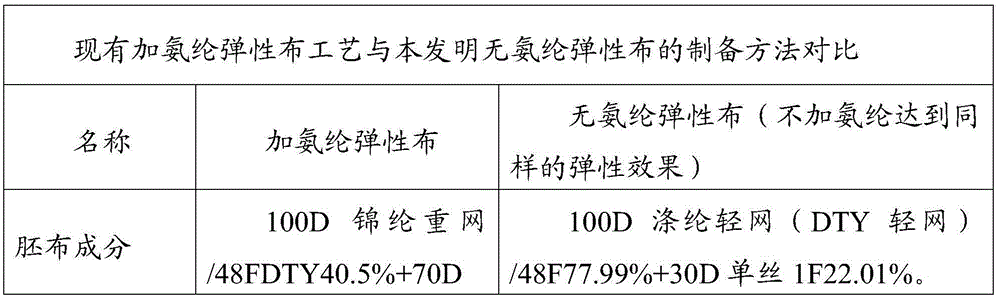

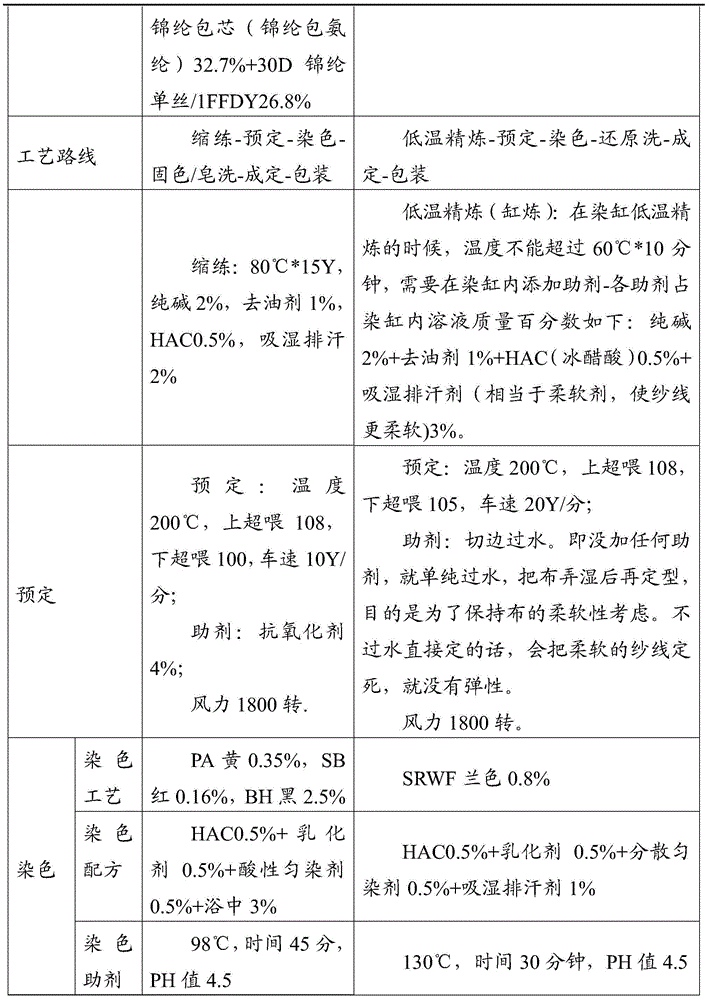

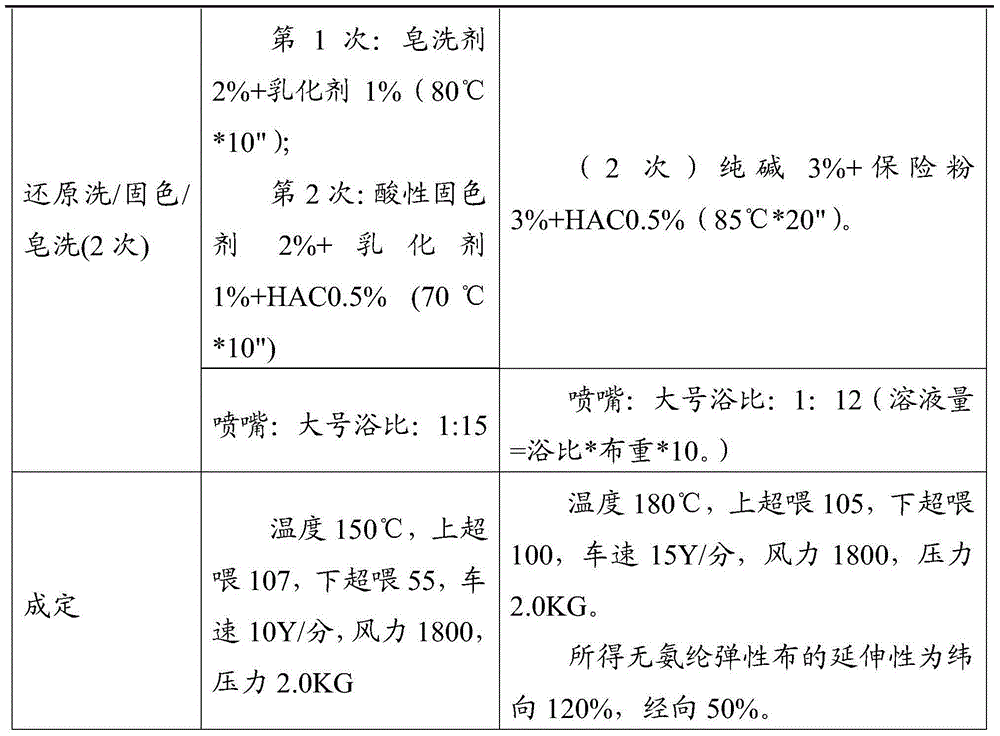

Preparation method of spandex-free elastic cloth

InactiveCN105274878APrevent color spillBleeding does not occurFibre typesHeating/cooling textile fabricsPolyesterYarn

Owner:PUTIAN HUAFENG IND & TRADE CO LTD

PVC composite material for biogas digester and preparation method of PVC composite material

ActiveCN104553171AImprove flame retardant performanceHigh smoke suppression effectLiquid surface applicatorsSynthetic resin layered productsPolyesterAging resistance

Owner:思嘉环保材料科技(上海)有限公司

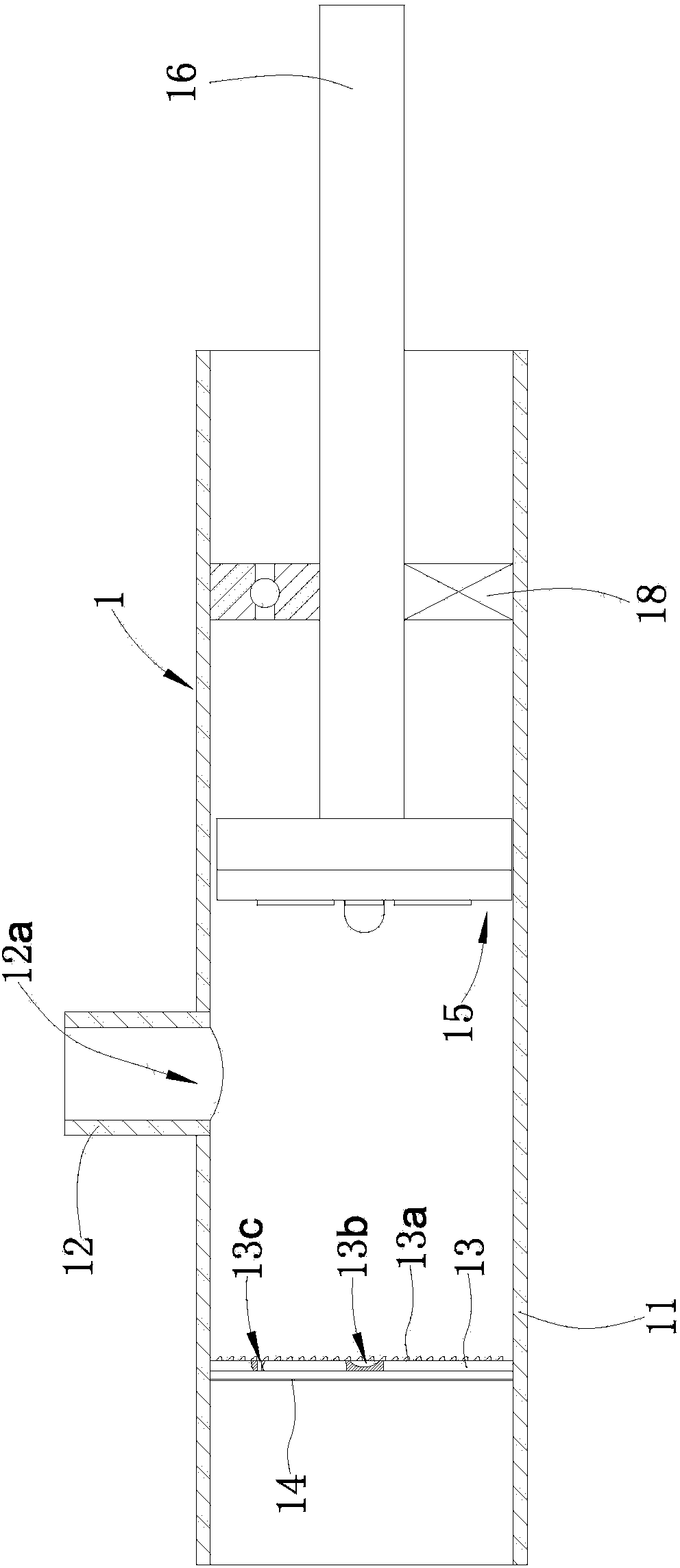

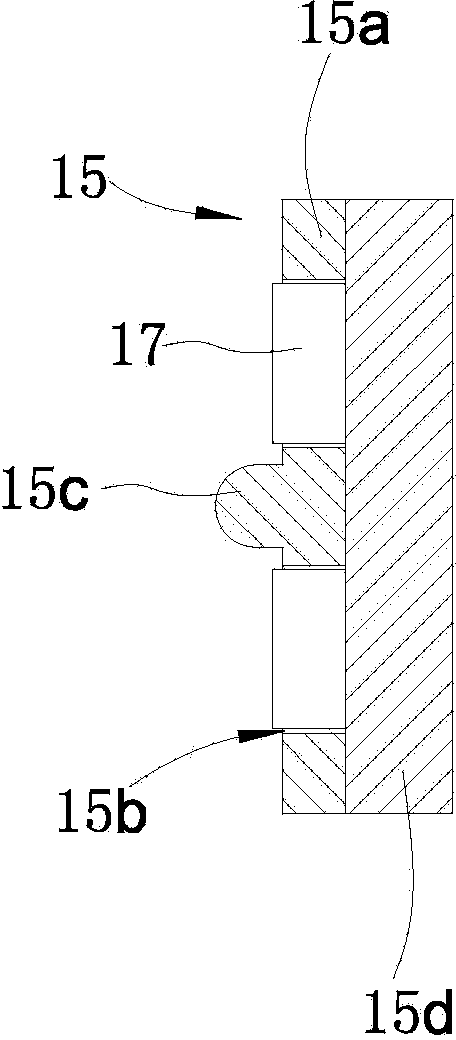

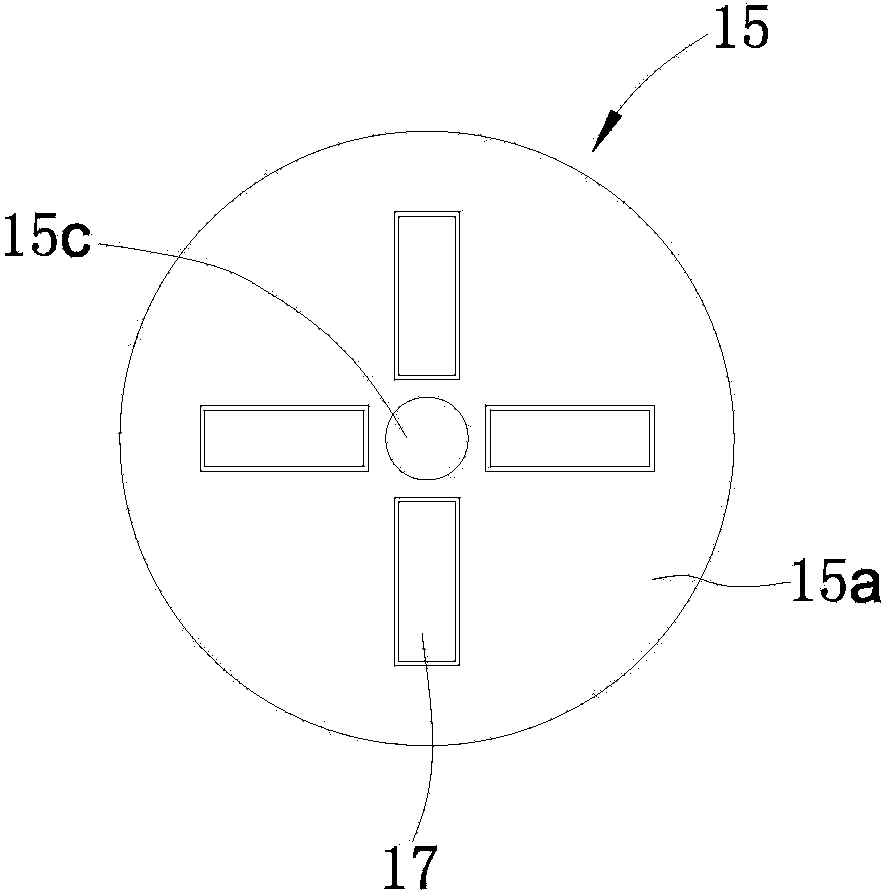

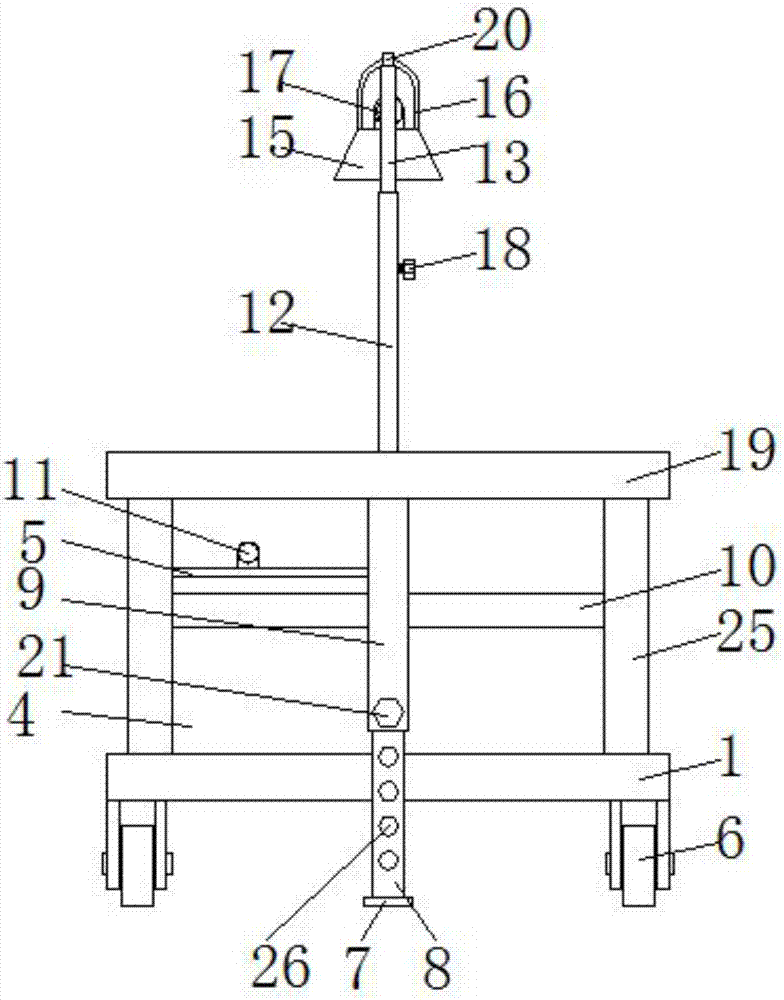

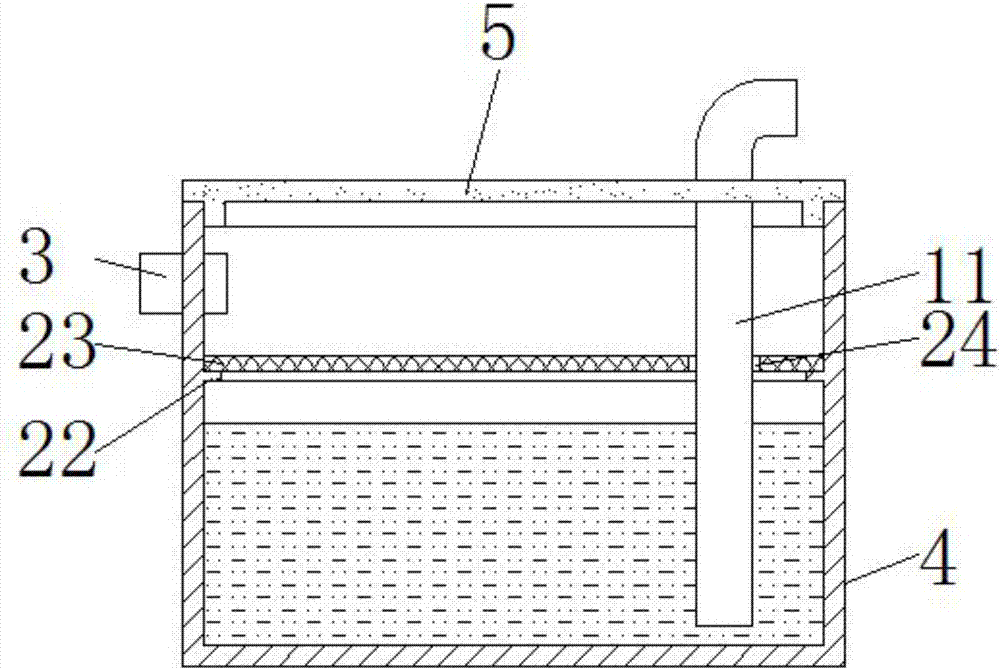

Textile drying box

InactiveCN108826912AImprove drying efficiencyEvenly heatedDrying solid materials without heatDrying gas arrangementsEngineeringSliding contact

The invention discloses a textile drying box, comprising a box body, wherein a plurality of exhaust holes are formed in the top of the box body, a multi-layer drying frame and a heating main pipe forproviding heat for the drying frame are arranged in the axial direction of the box body, and the multi-layer drying frame is driven by a rotating shaft to rotate; the drying rack comprises supportingnets fixedly sleeving the rotating shaft, the edges of the supporting nets are in sliding contact with the inner wall of the box body, a plurality of agitating blocks are arranged on each supporting net in a sliding contact manner, the agitating blocks are arranged in a ring shape around the rotating shaft, one ends of the agitating blocks are fixedly connected with the inner wall of the box body,and the same sides of the agitating blocks are smooth arc surfaces. Compared with the prior art, the supporting nets are driven by the rotating shaft to rotate, and the supporting nets and the agitating blocks cooperate with each other, so that the textile fabric is continuously rolled and agitated in the drying process, and the fabric on the supporting nets is heated uniformly, thereby improvingthe drying efficiency of the textile fabric.

Owner:HUBEI FUXING TEXTILE CO LTD

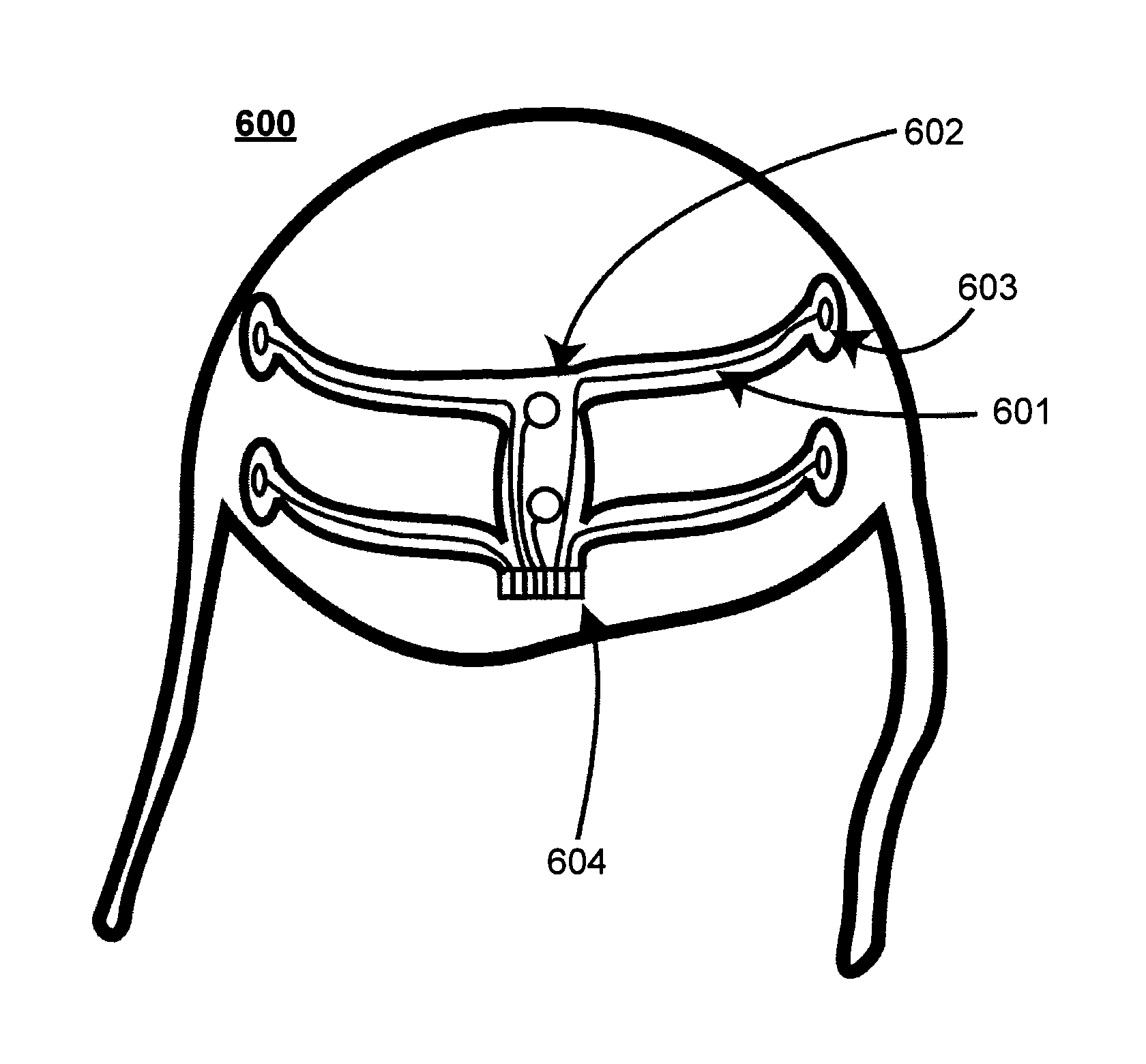

Surgical limb positioning apparatus

Owner:SMITH & NEPHEW INC

Flame-resistant high visibility textile fabric for use in safety apparel

ActiveUS20100003880A1Improve visibilityFlame resistanceWeft knittingOrnamental textile articlesVisibilityYarn

Owner:INNOVATIVE TEXTILES LLC

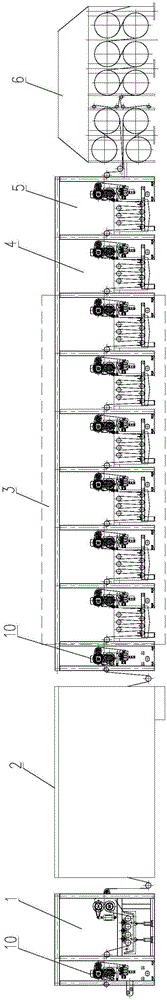

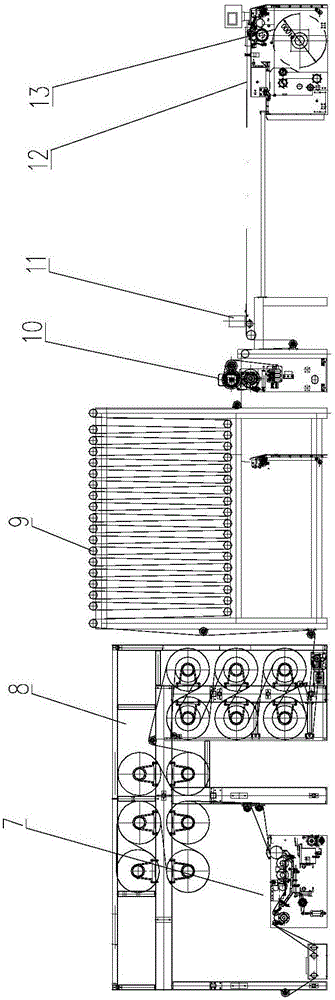

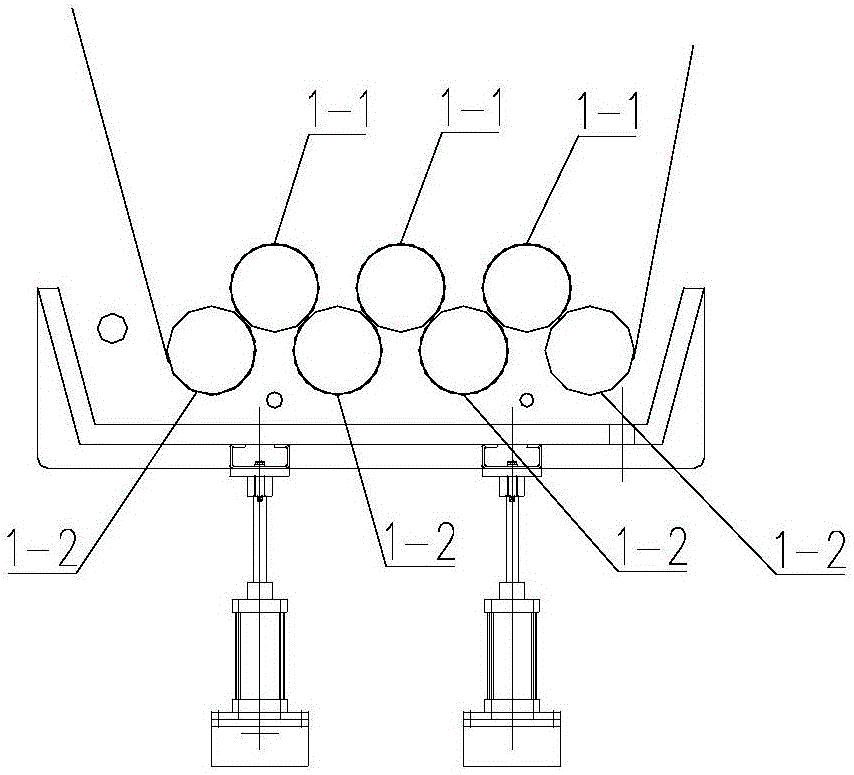

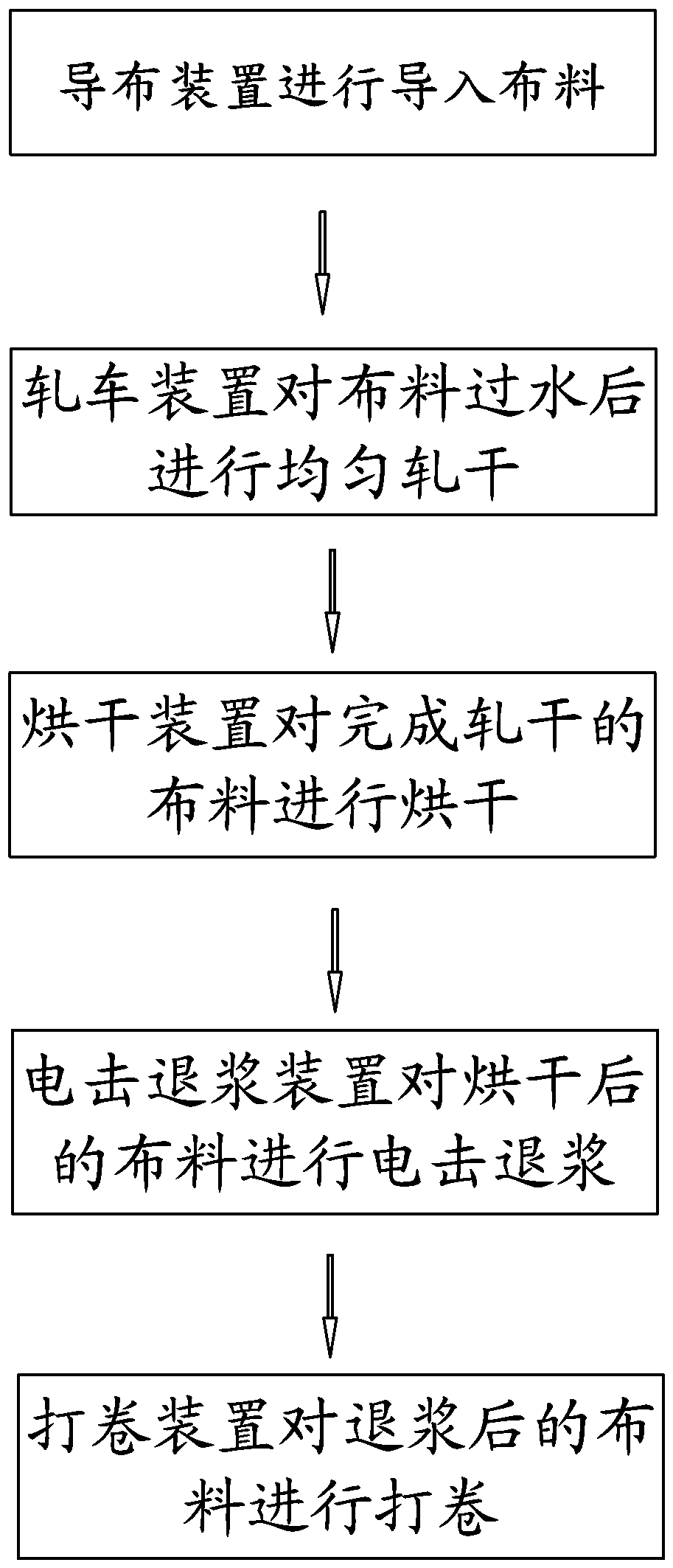

Cloth dyeing pretreatment assembly line and treatment method thereof

PendingCN107841840AHigh color fastnessHigh lusterLiquid/gas/vapor removal by squeezing rollersUltrasonic/sonic fibre treatmentAssembly linePulp and paper industry

Owner:浙江佳茂环保科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap