Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Evenly heated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

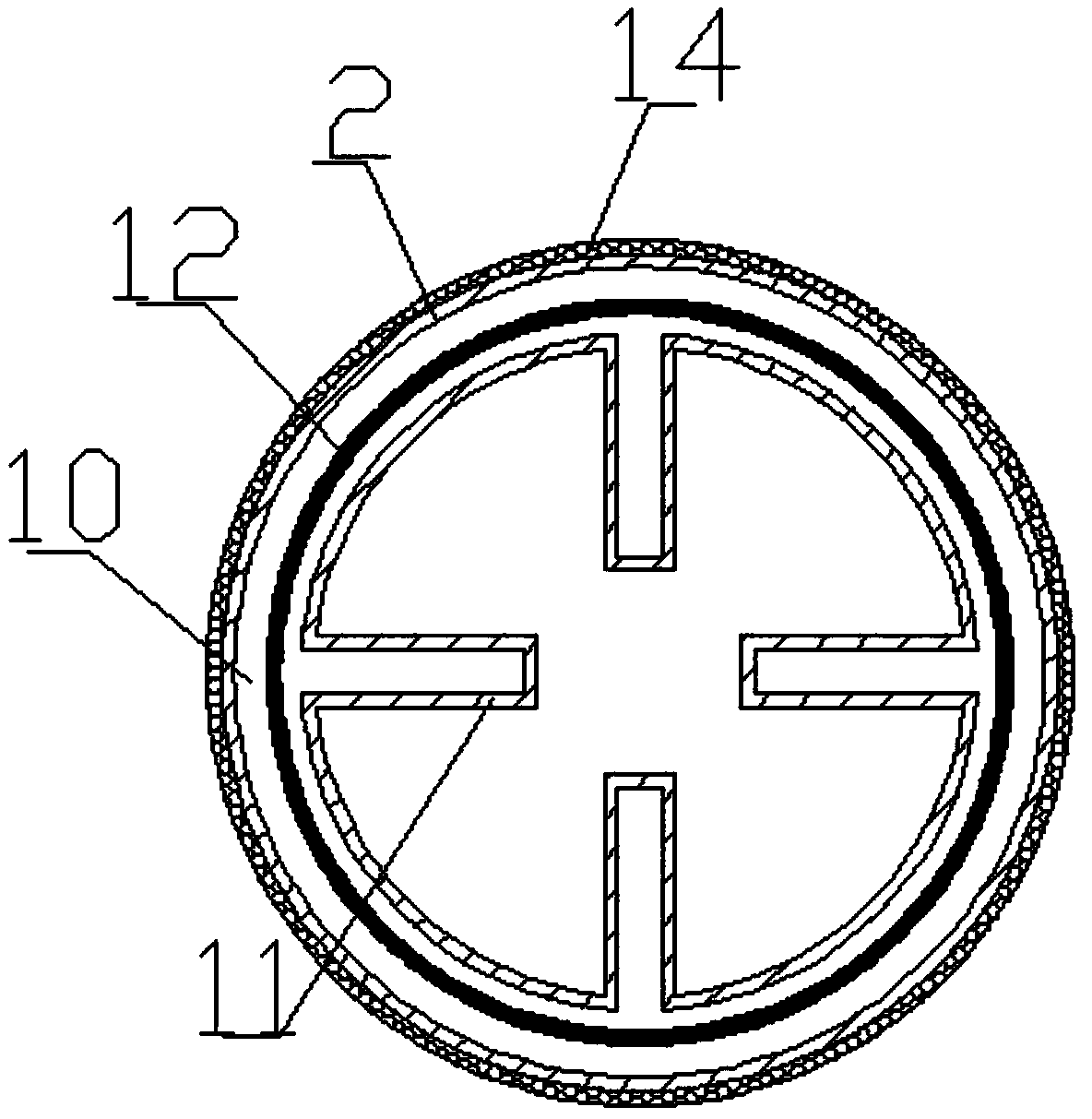

Asphalt mixture regenerating heating stirring roller

The invention discloses an asphalt mixture regenerative heating rod and mixing roller, and belongs to the concrete stirring technical field. The invention has a tilted roller supporting frame, a rolling ring, a roller and a roller driving device, wherein, the rolling ring is sleeved on the roller and supported by a rolling wheel arranged on the roller supporting frame, a burner is arranged at the lower end of the roller, a material outlet is arranged on the roller at the lower part of the burner, a material inlet is arranged at the other end of the roller, and a smoke outlet is arranged on the roller; wherein, an inner screening tube is sleeved inside the roller positioned at the material inlet end, and the inner screening tube is connected with the roller, the outer peripheral wall of the inner screening tube is composed of a screening mesh, a circular filtering mesh is sealed at the end part on the inner side of the inner screening tube, the material inlet is communicated with the inner screening tube, and an asphalt nozzle is arranged inside the roller positioned below the burner at the outlet end. The invention has compact and rational structure and high heat exchange efficiency, does not require secondary breakup of the waste asphalt mixture, can directly heat the block shape waste asphalt mixture for recycling; and the regenerated asphalt mixture can be directly utilized.

Owner:HENAN ROADY ROAD MACHINERY

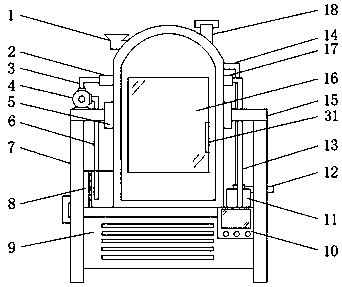

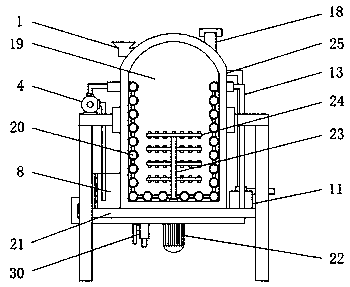

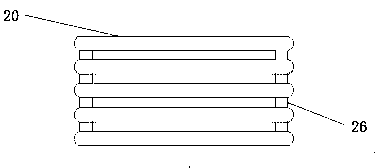

Rice steaming device and method

PendingCN107296202AEvenly heatedImprove the quality of finished riceFood scienceScreeningAgricultural engineeringBroken rice

Owner:福建生物工程职业技术学院

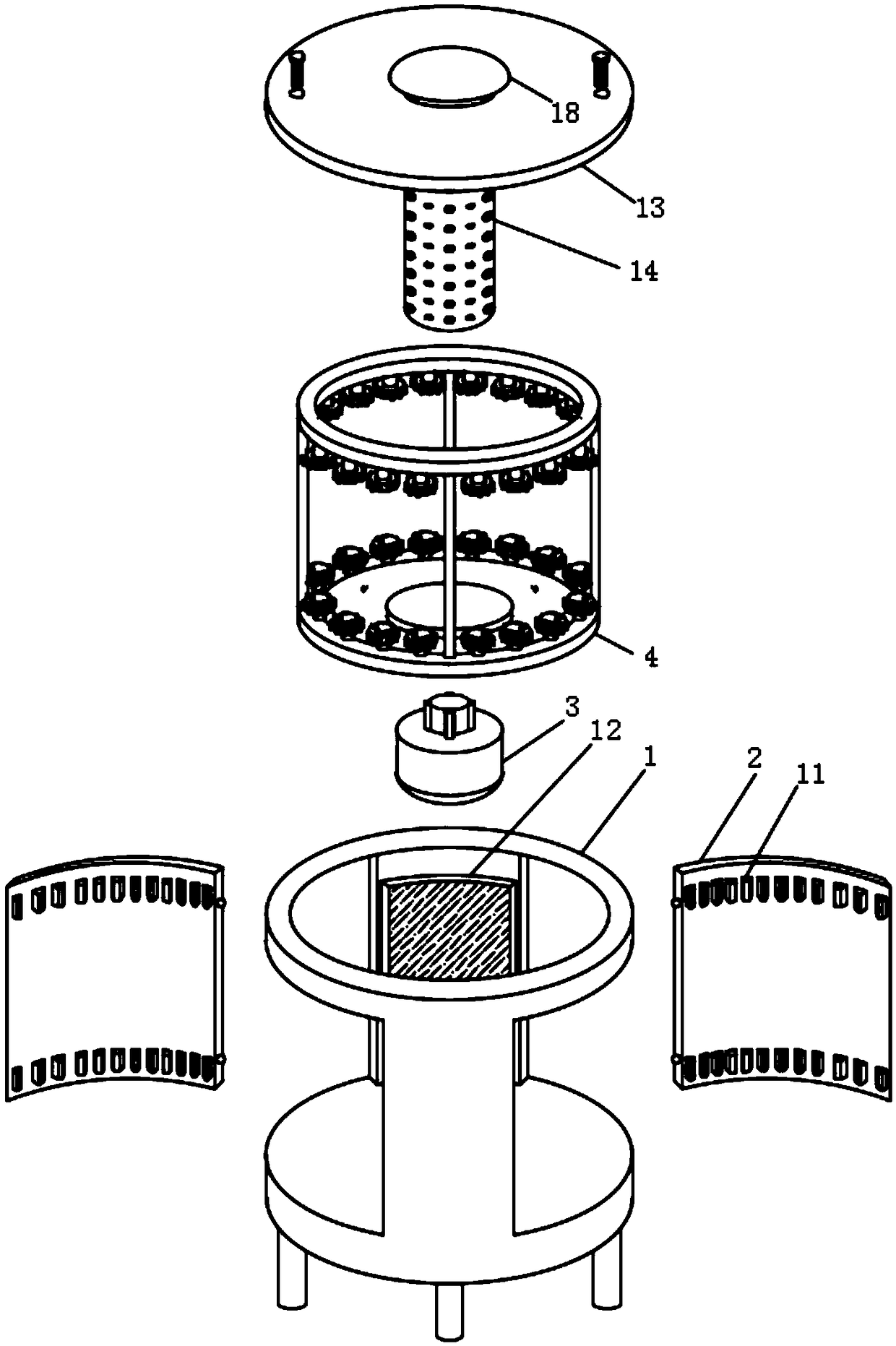

High-quality high-efficiency medicine roaster

ActiveCN112370351AEvenly heatedImprove frying efficiencyDomestic articlesPharmaceutical product form changeElectric machineryEngineering

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Cylinder-moving conveying type packaging bag drier

InactiveCN106564662AEasy to moveEasy to installDrying gas arrangementsDrying machines with progressive movementsEngineering

The invention discloses a cylinder-moving conveying type packaging bag drier which comprises a rack and a main board. A transverse moving through groove is formed in the middle of a top plate of the rack, rodless cylinders are fixed to the bottom face of the top plate of the rack, and guiding connection plates are fixed to sliding blocks of the rodless cylinders. Each guiding connection plate upwards stretches out of the transverse moving through groove, and an upper horizontal plate is fixed to each guiding connection plate. Guiding slide blocks are fixed to the left side and the right side of the bottom face of each upper horizontal plate, guiding rails are fixed to the left side and the right side of the top face of the top plate of the rack, sliding grooves are formed in the top faces of the guiding rails, and the guiding slide blocks are inserted into the sliding grooves. Movable connecting blocks are fixed to the left ends and the right ends of the front and back sides of the main board. The rodless cylinders push the upper horizontal plates to move rapidly and stably; meanwhile, heating pipes are fixed to the main board, the main board can move up and down to adjust the vertical positions of the heating pipes, so that heat is adjusted; and the heating pipes are fixed in an insertion mode through mounting blocks and limiting blocks, and the heating pipes are convenient to dismount and mount.

Owner:SHAOXING LITAI TEXTILE TECH CO LTD

Reciprocating oven for food processing

ActiveCN110811354AAvoid temperature differenceEvenly heatedRoasters/grillsRoasting apparatusElectric machineFood item

Owner:中山市博恩电器有限公司

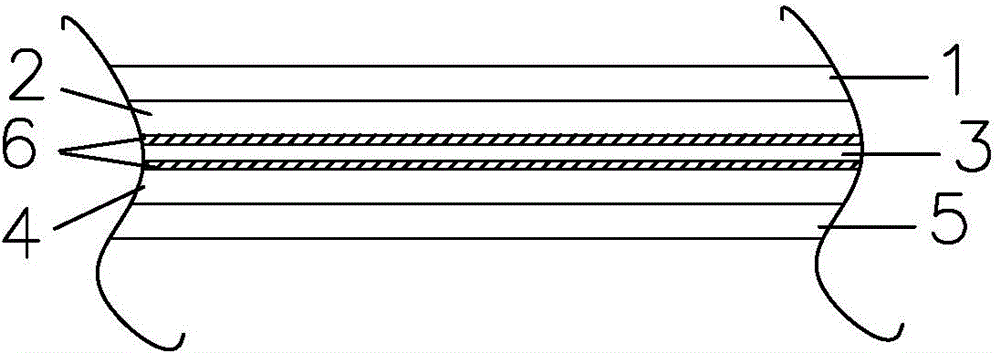

Fresnel solar and wind power complementation type heat collection tube

ActiveCN104154667AAvoid localized phase transitionsEvenly heatedSolar heat collectors with working fluidsSolar heat devicesCoatingElectric energy

Owner:BEIJING HENGJU CHEM GRP +1

Flat tea processing method and device

ActiveCN110178925AEvenly heatedGood contactPre-extraction tea treatmentTea extractionComputer engineeringEngineering

Owner:旺苍县高阳碧峰茶业有限公司

Induction quenching device and heat treatment system

ActiveCN105969955AAvoid soft band problemsEvenly heatedFurnace typesHeat treatment furnacesHeat treatedInduction heating

Owner:SANY ELECTRIC CO LTD

Apparatus and process for preparing high-molecular-weight polyester by ring-opening polymerization of cyclic ester

Owner:PUJING CHEM IND SHA

Vertical metal smelting device for alloy steel forging and casting

The invention discloses a vertical metal smelting device for alloy steel forging and casting. The vertical metal smelting device for alloy steel forging and casting comprises a high-temperature-resistant shell, wherein a first connector and a second connector are arranged in the middle of a connecting pipe; clamping slots are symmetrically formed in the outer sides of the first connector and the second connector; a filter screen is jointly arranged in the first connector and the second connector; an outer seal ring is jointly arranged on the outer sides of the first connector and the second connector; clamping blocks corresponding to the clamping slots are arranged on the inner side of the outer seal ring; and an inner seal ring corresponding to the filter screen is arranged on the inner side of the outer seal ring. According to the vertical metal smelting device for alloy steel forging and casting provided by the invention, through arranging the filter screen, metal particles in smokedust can be prevented from being discharged to cause the resource waste; and in addition, through taking off the outer seal ring and the inner seal ring on the outer sides of the first connector andthe second connector, the filter screen can be conveniently taken out so as to be conveniently cleaned and prevented from being blocked.

Owner:NANTONG JUXING CASTING & FORGING CO LTD

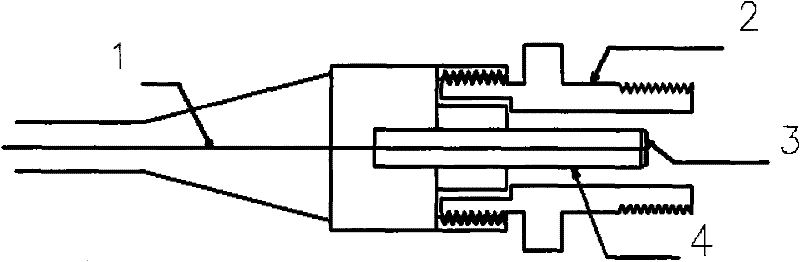

Bypass type passive pneumatic vectoring spraying pipe provided with sliding-type switch and design method for sliding-type switch

ActiveCN107387260AEvenly heatedUniform thermal deformationGeometric CADJet propulsion plantsDesign methodsLambda

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Drying box with vibration material cylinders for evenly shaking materials

InactiveCN107421294AEvenly heatedConvenience to workDrying machines with non-progressive movementsDrying solid materialsEngineeringFan blade

The invention discloses a drying box equipped with a vibrating material cylinder for shaking materials evenly, which comprises a box body. The inside of the box body is provided with a lifting mechanism. The lifting mechanism is arranged at the bottom end of the box body. The upper end of the mechanism is provided with a rotating motor, and the rotating motor leads vertically upward to the rotating shaft rod. The upper end of the rotating shaft rod is provided with fan blades. There is an interval between them, a spring is provided at the center of the upper end of the pole, one end of the spring is fixedly connected to the upper surface of the pole, the other end of the spring is provided with a barrel, and the barrel The upper end of the barrel is hingedly connected with a cover, one end of the barrel is provided with a folding handle, the inside of the barrel is a cavity, the outer end surface of the barrel is uniformly provided with ventilation holes, the inner wall There are several heating tubes. Through the above method, the present invention can shake the material evenly through the vibration of the material cylinder, so that the material is heated evenly.

Owner:WUXI TAISHUN FLOCKING MACHINERY FACTORY

Textile drying box

InactiveCN108826912AImprove drying efficiencyEvenly heatedDrying solid materials without heatDrying gas arrangementsEngineeringSliding contact

The invention discloses a textile drying box, comprising a box body, wherein a plurality of exhaust holes are formed in the top of the box body, a multi-layer drying frame and a heating main pipe forproviding heat for the drying frame are arranged in the axial direction of the box body, and the multi-layer drying frame is driven by a rotating shaft to rotate; the drying rack comprises supportingnets fixedly sleeving the rotating shaft, the edges of the supporting nets are in sliding contact with the inner wall of the box body, a plurality of agitating blocks are arranged on each supporting net in a sliding contact manner, the agitating blocks are arranged in a ring shape around the rotating shaft, one ends of the agitating blocks are fixedly connected with the inner wall of the box body,and the same sides of the agitating blocks are smooth arc surfaces. Compared with the prior art, the supporting nets are driven by the rotating shaft to rotate, and the supporting nets and the agitating blocks cooperate with each other, so that the textile fabric is continuously rolled and agitated in the drying process, and the fabric on the supporting nets is heated uniformly, thereby improvingthe drying efficiency of the textile fabric.

Owner:HUBEI FUXING TEXTILE CO LTD

Method and device for preparing Chao-flavor type baijiu

PendingCN113308325AImprove contact efficiencyImprove crushing efficiencyDigestive systemAlcoholic beverage preparationBiotechnologyEngineering

The invention relates to the field of baijiu brewing equipment, and especially relates to a method and a device for preparing Chao-flavor type baijiu. The device comprises a crushing part, a driving rotating shaft is mounted at the middle end in the crushing part, a moving plate is mounted on the outer side of the upper end of the driving rotating shaft, a mixed cooking part is connected below the crushing part, feeding boxes are connected to two sides of the mixed cooking part, a stirring rod is mounted in the mixed cooking part, driving turntables are connected to the two sides of the stirring rod, triangular convex blocks are arranged on one sides of the driving turntables, and convex blocks which are the same as convex blocks on the driving turntables are arranged on the two sides of the mixed cooking part, when the stirring rod rotates, the convex blocks on the driving turntables can be driven to be in contact with the convex blocks on the mixed cooking part, and the stirring rod can move left and right while rotating, so that the stirring effect is improved; and meanwhile, the two ends of the stirring rod are attached to the inner side of the liquid cavity, water and juice in a Chao-flavor mixture can be pressed into the mixing cooking part from the liquid cavity, the intensity of pressure in the mixed cooking part is improved, and the mixing effect of wine brewing raw materials and aroma enhancement materials is improved.

Owner:LIAONING YONGCHUN LIQUOR CO LTD

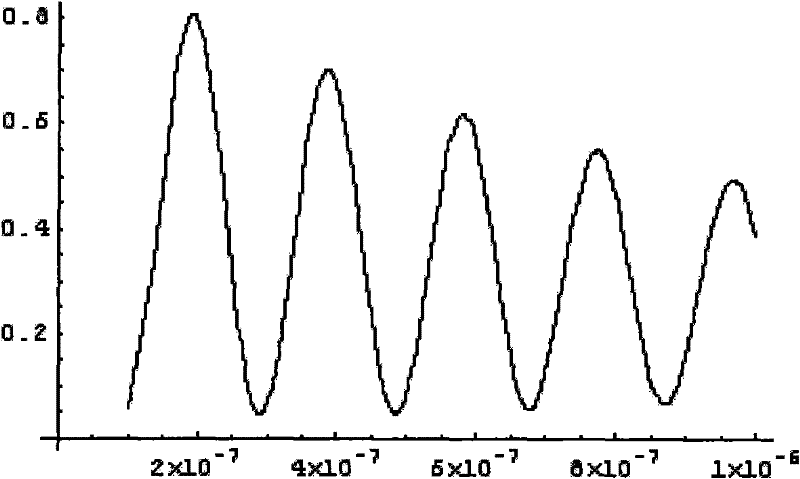

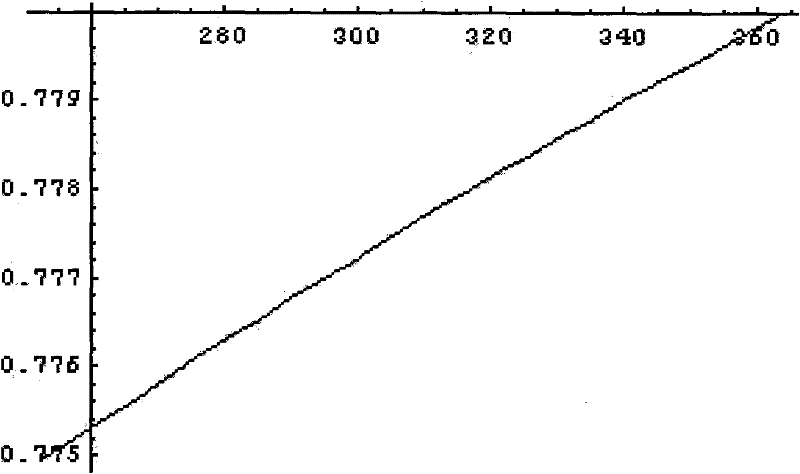

Semiconductor reflection type optical fiber temperature sensor

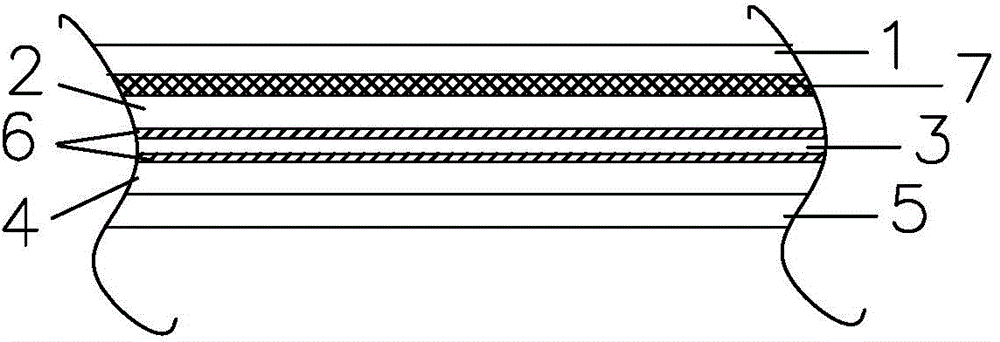

InactiveCN102235919AIncreased end face areaEvenly heatedThermometers using physical/chemical changesSemiconductor

The invention discloses a temperature sensor, and particularly relates to a semiconductor reflection type optical fiber temperature sensor. The optical fiber temperature sensor comprises an optical fiber, a semiconductor film and a ceramic pin, wherein the optical fiber core is inserted into the ceramic pin to ensure that the end face of the fiber core and the end face of the ceramic pin are in the same plane; the semiconductor film is coated to the plane by adopting a film coating technology, the film coating technology ensures that the semiconductor film and the optical fiber are closely connected, and the refractive rate of the semiconductor is not influenced by external pressure, vibration and the like, so that the temperature measurement accuracy is greatly improved; the ceramic pin can fix the optical fiber core, and increase the area of the semiconductor film, so that the semiconductor film and the optical fiber are closely contacted; and a ceramic sleeve is encapsulated outside the film coated ceramic pin, can protect the coated film, and form a temperature detection cavity with the semiconductor film surface, and when the temperature of the external environment is changed, the semiconductor film is heated uniformly, and the detected temperature is accurate.

Owner:SHANGHAI BOOM FIBER SENSING TECH

Drying device for food processing

InactiveCN111879073AHigh speedFully heatedDrying gas arrangementsDrying solid materialsElectric machineProcess engineering

The invention discloses a drying device for food processing, relates to the technical field of food processing, and mainly aims to solve the problem that existing raw materials are easy to accumulate.The drying device comprises a box body and a drying unit, a plurality of electric heating elements are installed on the two side walls of the box body, the drying unit comprises a dispersing assemblyused for dispersing materials and an air spraying assembly used for spraying hot air for drying, and the dispersing assembly comprises a supporting net, a first motor, a disc and a driving rod; the air spraying assembly comprises an air heater, a hollow rotating shaft, a driving mechanism used for driving the hollow rotating shaft to rotate, a hard air pipe, a sliding sleeve and a sliding block,the dispersing assembly is mounted, the supporting net is rapidly pulled outwards through the rapid return characteristic, raw materials on the supporting net are made to fly off upwards at a high speed and are fully and evenly heated, and the drying efficiency is improved; and the air spraying assembly is arranged, upward cyclone is formed, the drying effect is good, the air spraying angle is continuously changed, the drying range is enlarged, and the efficiency is improved.

Owner:马迎锋

Essence condiment containing black fungus and radix pseudostellariae, as well as preparation method thereof

Owner:食品行业生产力促进中心

Multi-element composite titanium pot and manufacturing process

Owner:SUZHOU XINJINGYI TITANIUM PROD

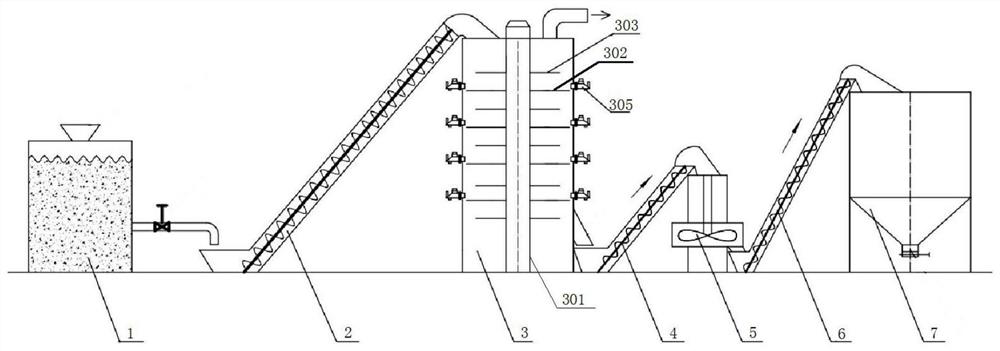

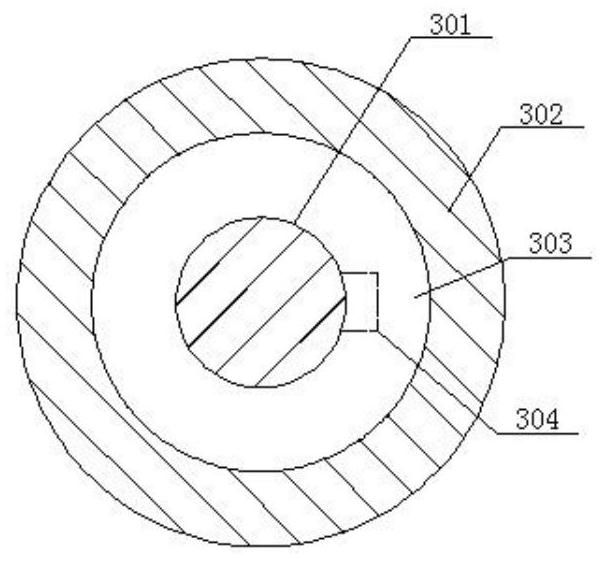

Internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method

ActiveCN105505422AEfficient dehydrationImprove thermal distillation efficiencyIndirect and direct heating destructive distillationSpecial form destructive distillationThermodynamicsCombustion chamber

The invention discloses an internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method. The system comprises a spiral pushing medium and low temperature external heating dry distillation device and a low temperature internal heating rotary kiln dry distillation device, wherein a spiral pushing dry distillation chamber in the spiral pushing medium and low temperature external heating dry distillation device is arranged in a combustion chamber of the spiral pushing medium and low temperature external heating dry distillation device, combustion smoke in the combustion chamber is directly supplied to the interior of a rotary kiln cylinder, and solid materials in the rotary kiln cylinder are supplied to the interior of the spiral pushing dry distillation chamber. Dry distillation of coal is divided into two or more phases according to temperature and is achieved through organic combination of the internal heating rotary kiln dry distillation device and the spiral pushing external heating dry distillation device, winnowing and dust removal, preheating and drying and dehydration are conducted on raw coal by means of a rotary kiln, high-efficiency medium and low temperature dry distillation and high-calorific-value raw gas and tar product precipitation are achieved by means of the spiral pushing external heating dry distillation device, the advantages of the internal heating dry distillation device and the external heating dry distillation are fully combined, dry distillation efficiency, heat utilization efficiency and the quality of dry distillation products are improved greatly, and marketing prospects are broad.

Owner:王崇峰

Novel intelligent battery piece welding lamp cover

InactiveCN108436328AWeldedSmall footprintFinal product manufactureWelding/cutting auxillary devicesEngineeringQuartz

The invention discloses a novel intelligent battery piece welding lamp cover. The novel intelligent battery piece welding lamp cover comprises a box; the box comprises a peripheral protecting plate, and a top plate bracket and a bottom quartz glass surface connected to the peripheral protecting plate; the top plate bracket comprises multiple upper and lower adjusting lamp tube brackets uniformly arranged; the upper and lower adjusting lamp tube brackets are connected with U-shaped lamp tubes through arrangement of adjustable columns; the U-shaped lamp tubes are accommodated in internal space of the box; air hole tables are connected to the two sides of the box, and are provided with air holes; and the air holes communicate with the internal of the box. All the U-shaped lamp tubes are mounted in closed space; U-shaped short lamp tubes capable of locally adjusting the temperature are adopted; and air is blown and sucked for the closed space to form an uniform-temperature heating field, so that battery pieces are uniformly heated to achieve better welding.

Owner:SUZHOU CHENZHENG SOLAR ENERGY EQUIP CO LTD

Variable-temperature drying integrated honeysuckle processing equipment

PendingCN114659350AEvenly heatedImprove drying efficiencyDrying chambers/containersDrying gas arrangementsEngineeringEnvironmental geology

Owner:江西赣盛农业发展有限公司

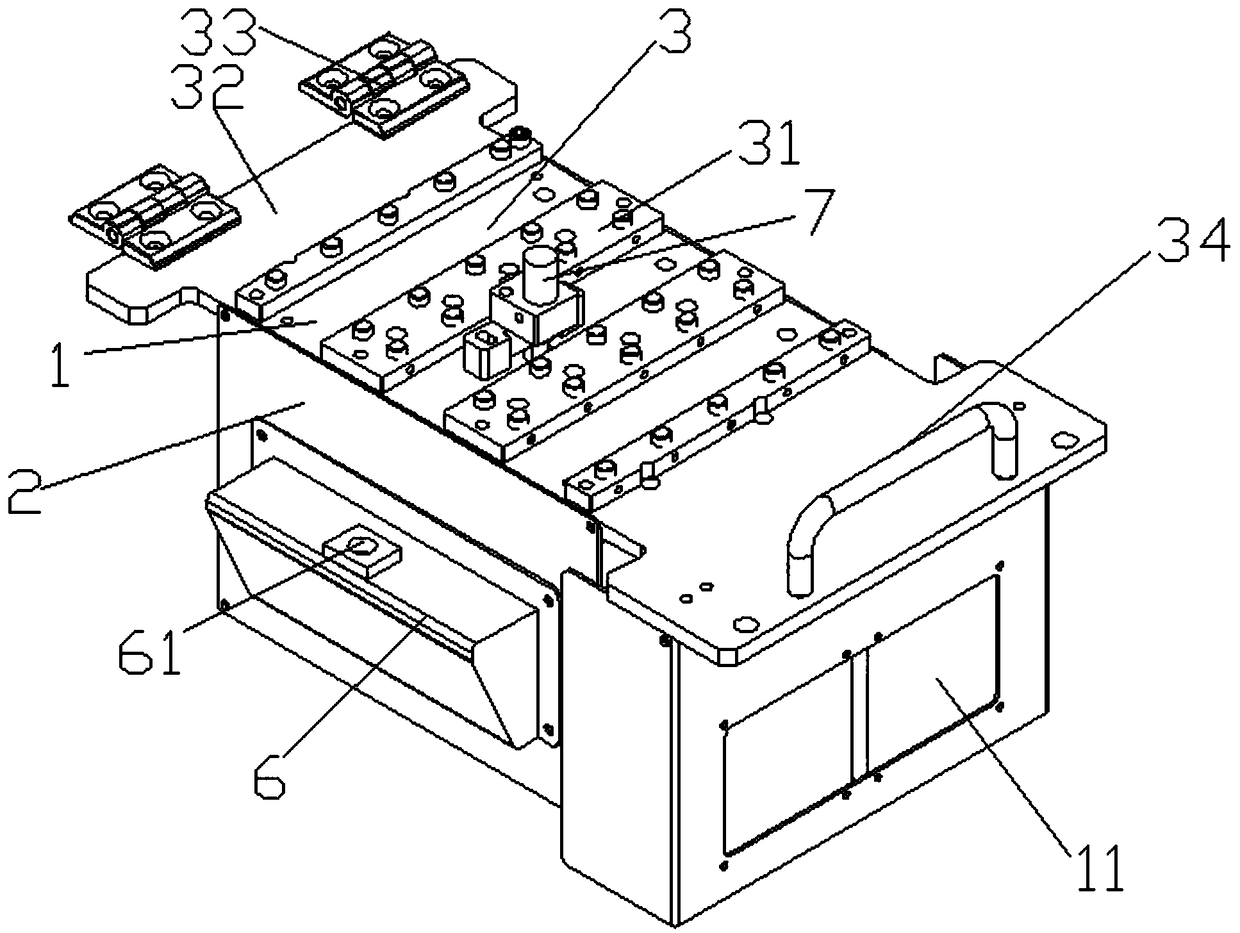

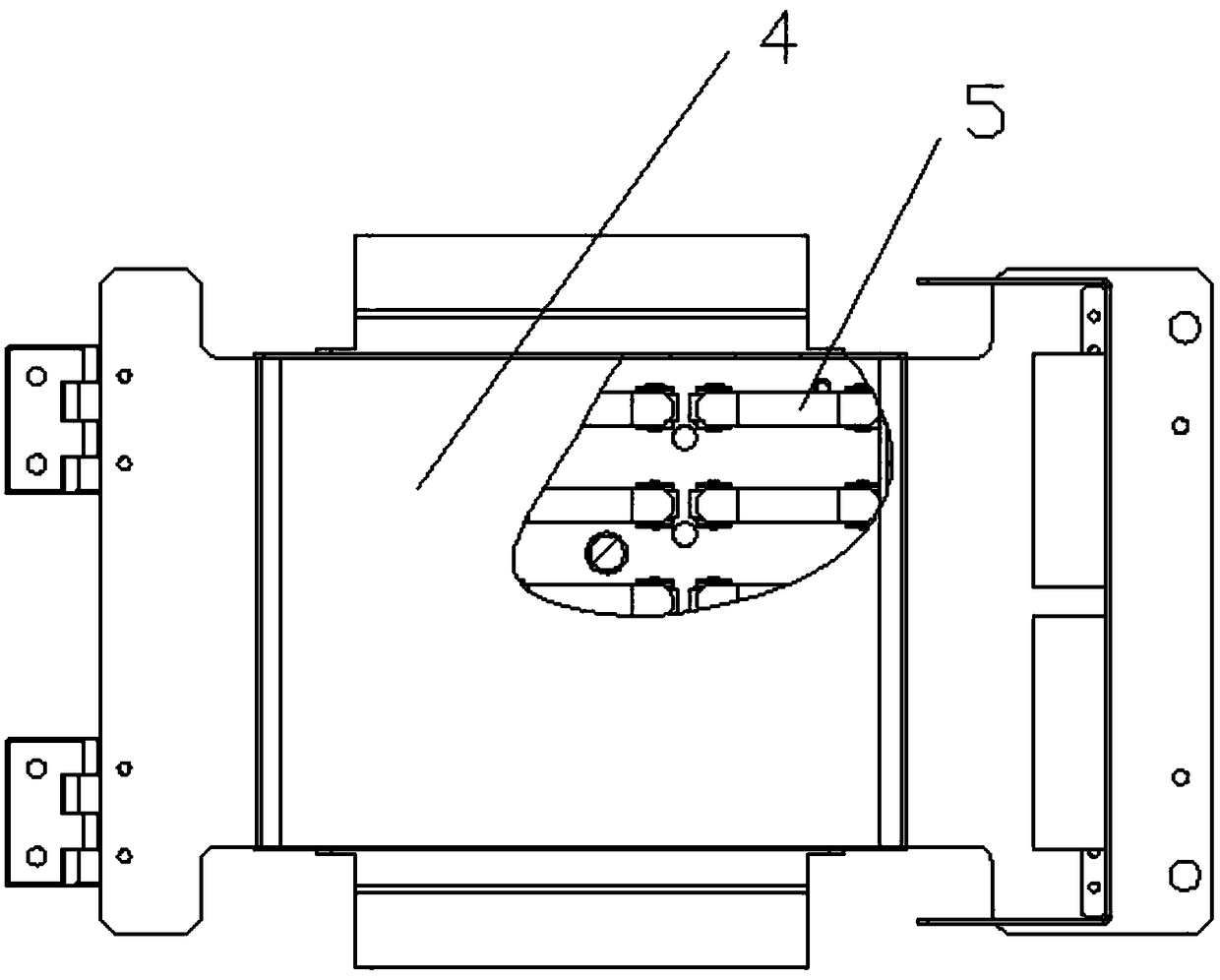

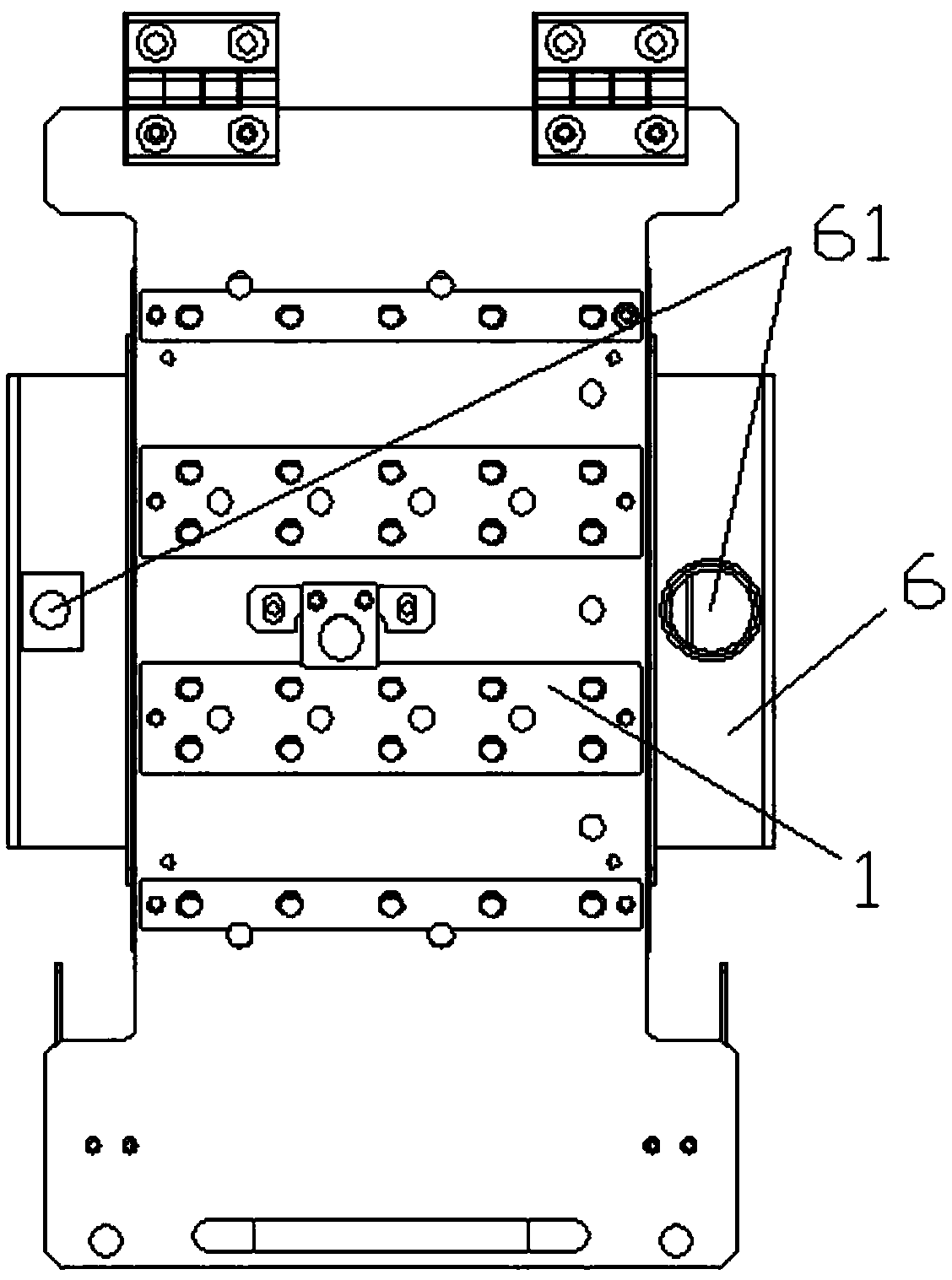

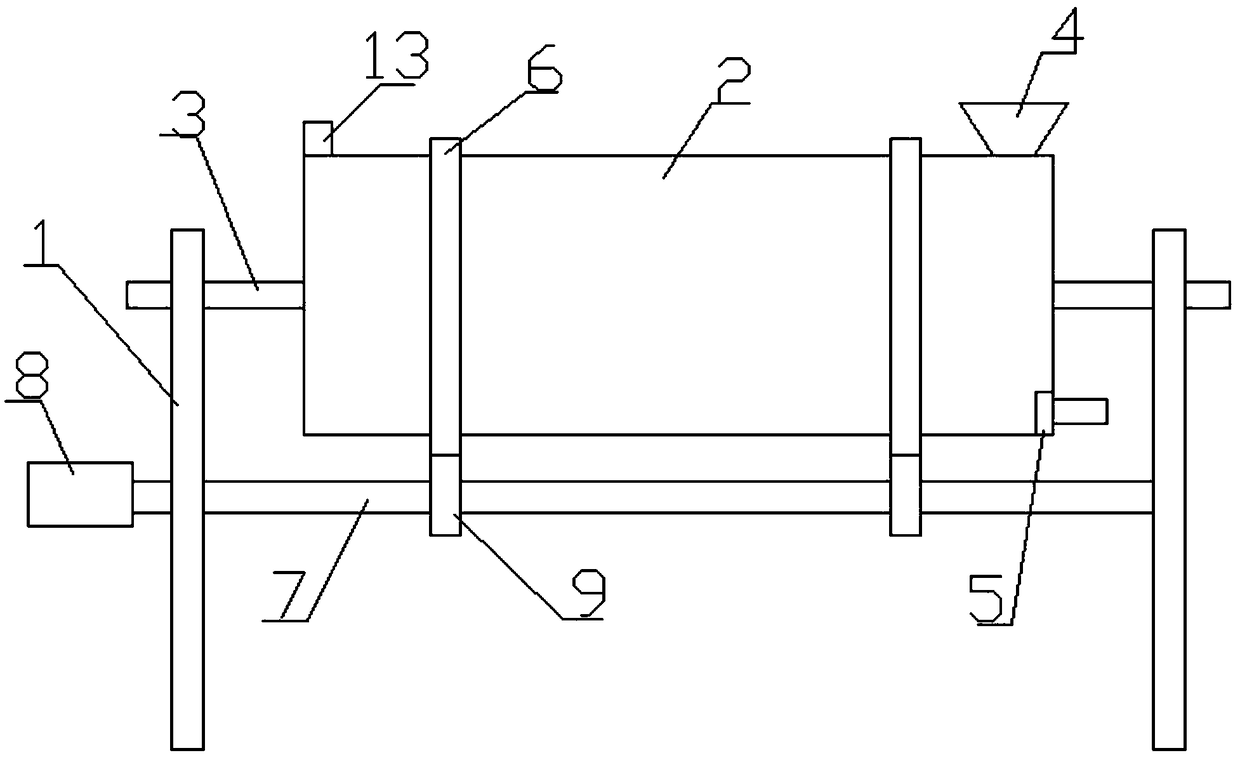

Extrusion equipment for producing multi-color master batches

The invention discloses extrusion equipment for producing multi-color master batches. The extrusion equipment comprises an extrusion equipment assembly, and the extrusion equipment assembly comprisesan internal mixing device, a material control device, a reserved transition device, an extrusion die head and a transmission extrusion mechanism. The internal mixing device, the material control device, the reserved transition device and the extrusion die head form a communication barrel body. During use, various raw materials can be mixed and stirred during discharging, so that the raw materialscan be uniformly stirred, the quality of a master batch finished product is further improved, the problem of powder blockage is avoided by adopting a stepless discharging manner, the powder can be discharged more uniformly, firstly, by adopting a stirring manner of a stirring shaft, the raw materials can be uniformly preheated, the phenomenon that hard particles exist in the master batches after the master batches are produced due to non-uniform heating of the raw materials caused by a heating blind area of the powder is avoided, gas in the master batches can be reduced in the secondary process, and the problem that air bubbles exist in the master batches is avoided.

Owner:ANHUI JIHONG MATERIAL TECH

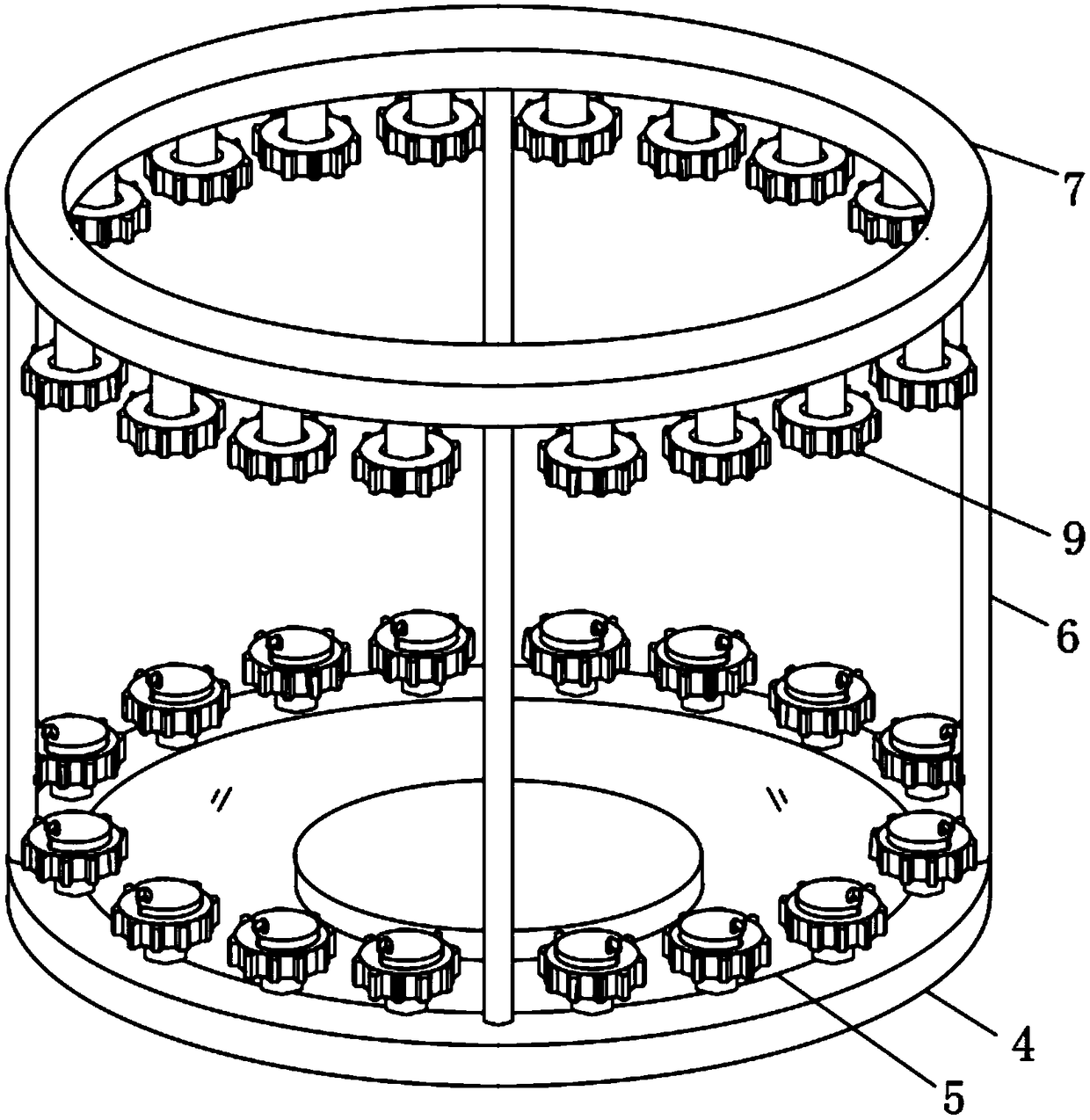

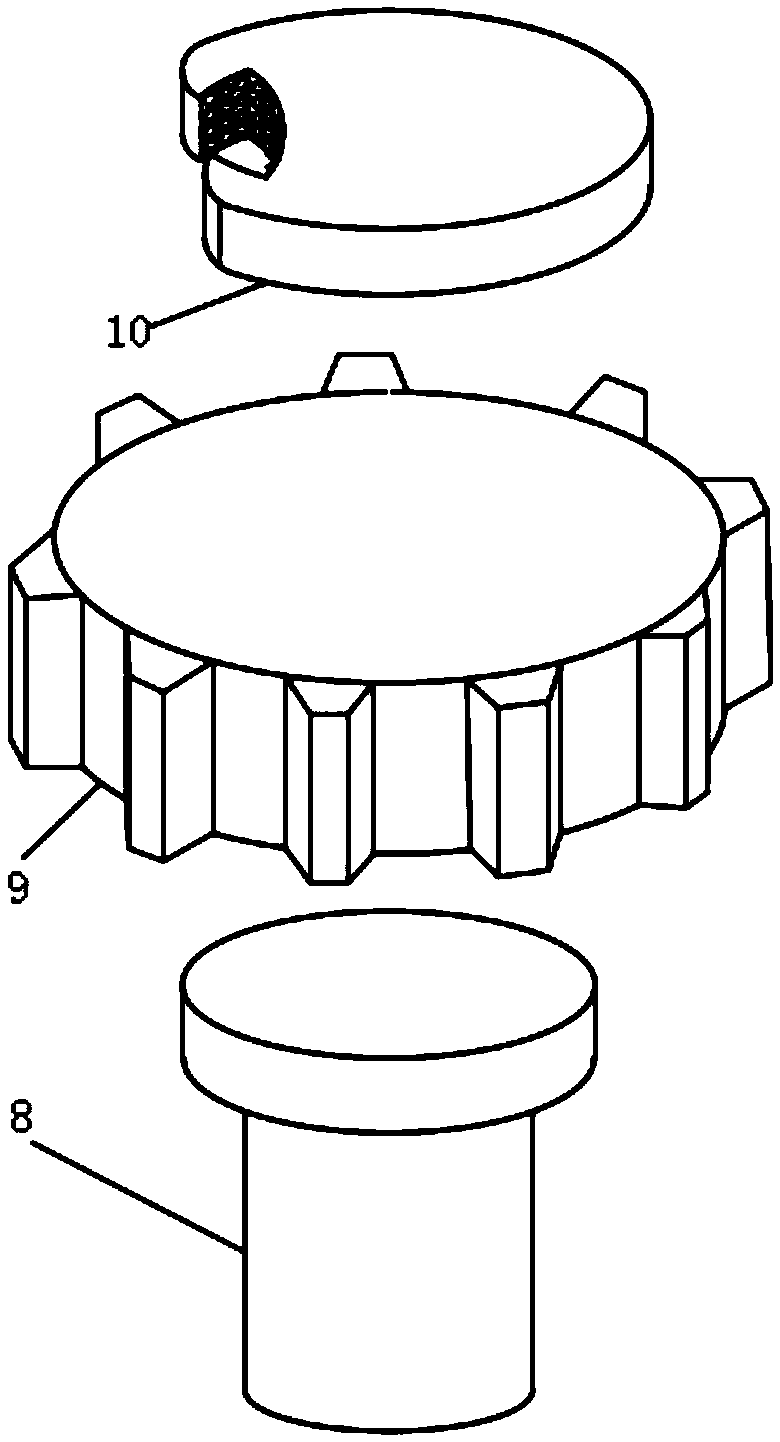

Rotor iron core baking oven support component convenient for adjusting and used for building mixing motor

InactiveCN107294320AEasy to useEvenly heatedManufacturing dynamo-electric machinesDegreasingEngineering

Owner:徐得强

High-efficiency tea water-removing machine

Owner:赤水市桫龙虫茶饮品有限责任公司

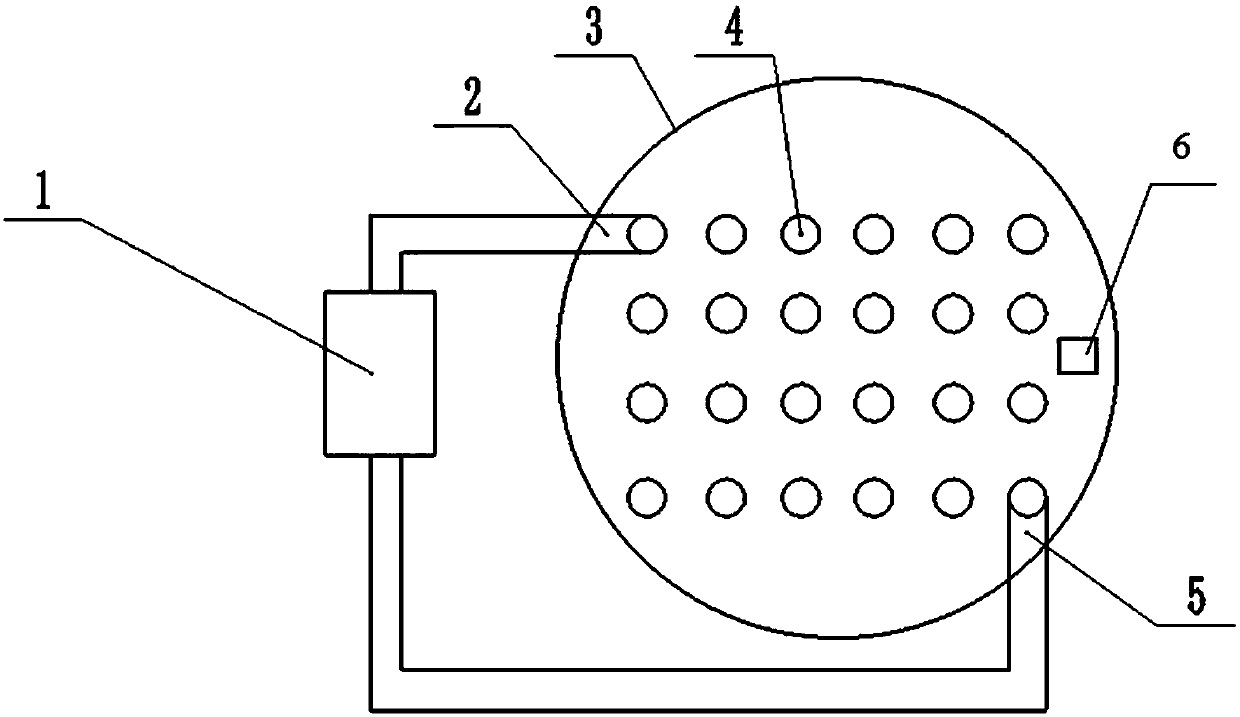

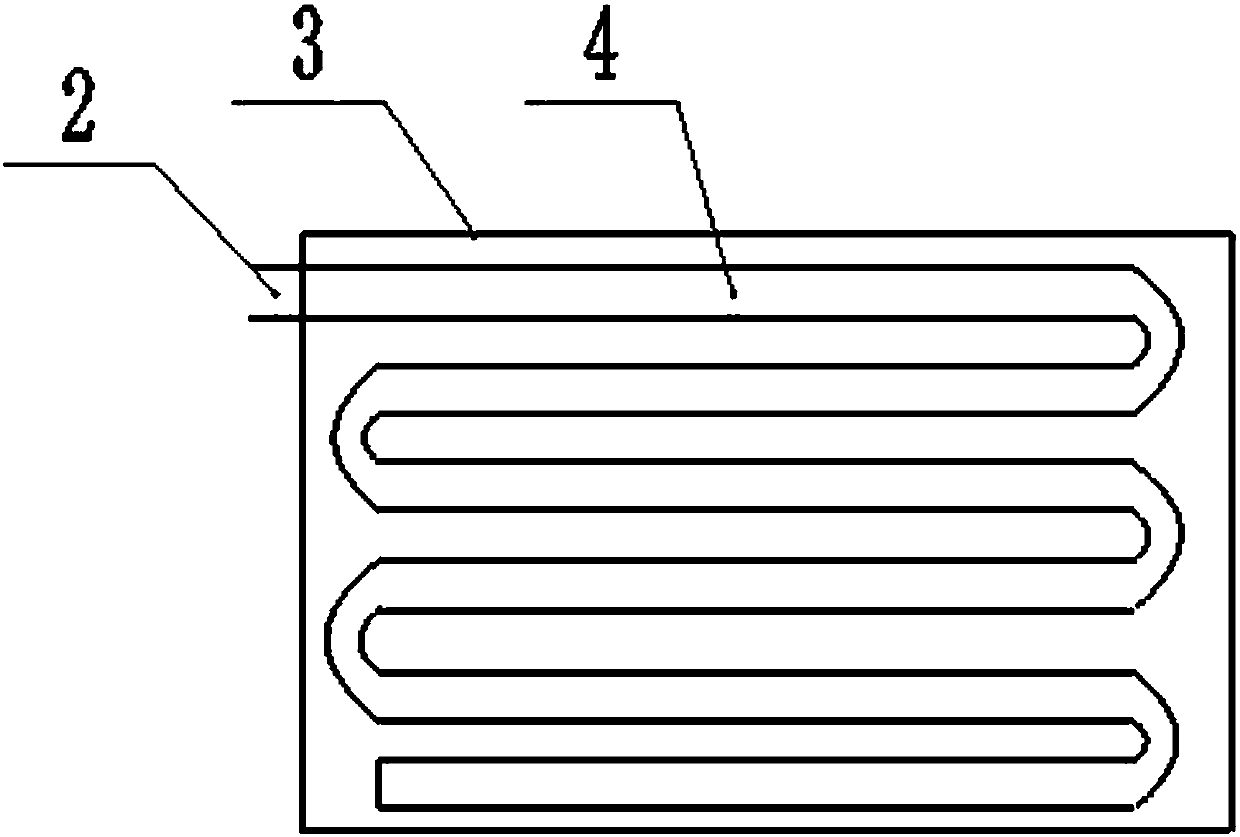

Liquid chlorine vaporizer for buprofezin preparation

InactiveCN109237297AEvenly heatedShorten the gasification timeStationary tubular conduit assembliesPressure vesselsBuprofezinLiquid chlorine

Owner:JIANGSU JIANGU CHEM

Round steel controlled rolling and controlled cooling integrated device

InactiveCN109647907AIncrease temperatureReduce the temperatureTemperature control deviceWork heating devicesEngineeringMechanical engineering

Owner:JINGYE STEEL CO LTD

Novel heater

InactiveCN107655353AEvenly heatedFast heatingHeat exchange apparatusStationary conduit assembliesEngineeringHeating system

Owner:兴安县瑞鑫天然香料有限责任公司

Organic solid waste microwave pyrolysis process and device

PendingCN112592017AEvenly heatedExpand the scope of resource utilizationByproduct vaporizationIndirect heating destructive distillationFixed carbonHazardous substance

Owner:湖南隆泰环保能源科技有限公司

Medicinal bath bed for treatment of hyperplasia of mammary glands

The invention discloses a medicinal bath bed for treatment of hyperplasia of mammary glands. The medicinal bath bed comprises a bed surface having a hollowed-out structure, a medicinal bath bed body used for supporting the bed surface, partition plates used for dividing a cabin structure into multiple chambers and second through holes used for being connected with a medicinal bath pot. The portions, close to the front end, of the bed surface are provided with first through holes into which breasts extend, the bed surface is a double-layer non-woven fabric provided with multiple spaced throughholes, and the middle of the double-layer non-woven fabric is filled with sand; the medicinal bath bed body is of the cabin structure with an opening in the top, and the bed surface is detachably fixed to the top of the medicinal bath bed body; the partition plates are arranged in the cross-sectional direction of the cabin structure; the second through holes run through the side wall of the cabinstructure. The medicinal bath bed not only can be used for treatment of the disease of hyperplasia of the mammary glands targetedly but also has uniform temperature and a remarkable medicinal bath effect.

Owner:徐中喜

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap