Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

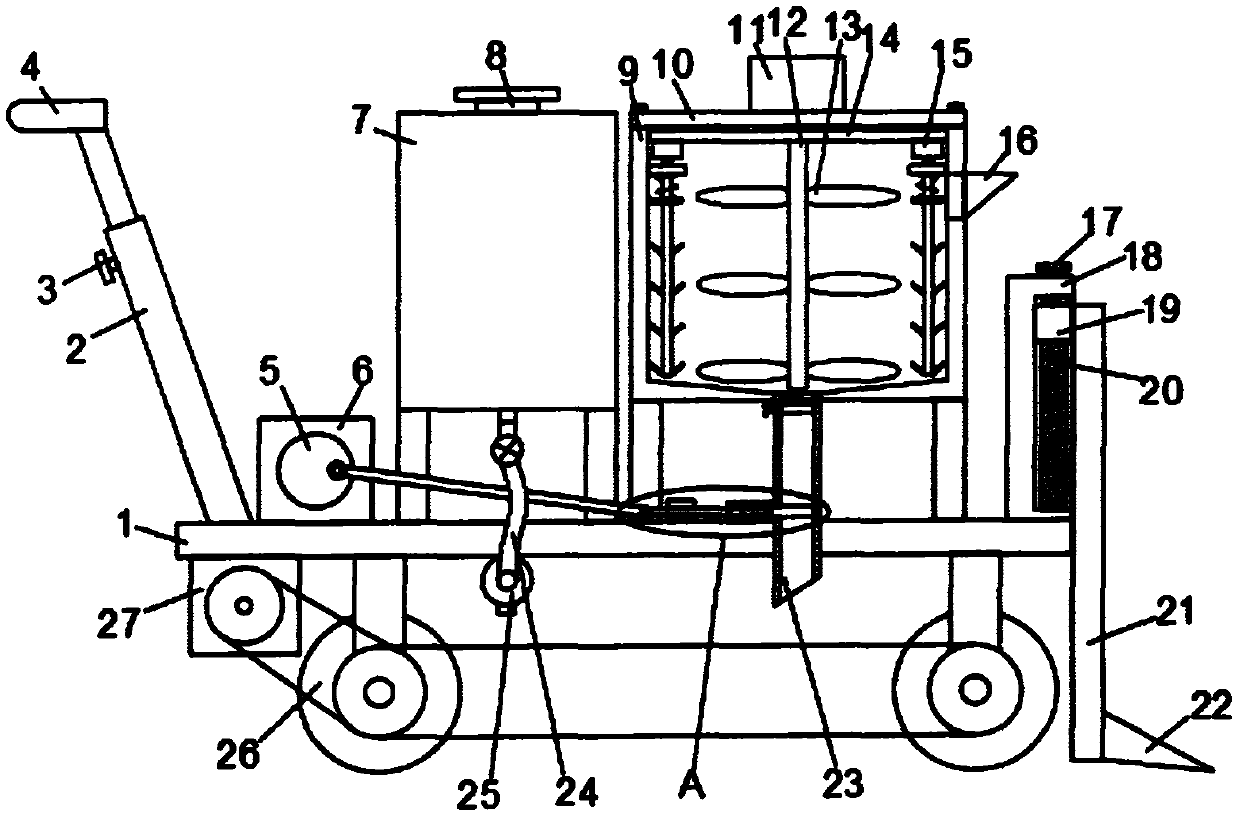

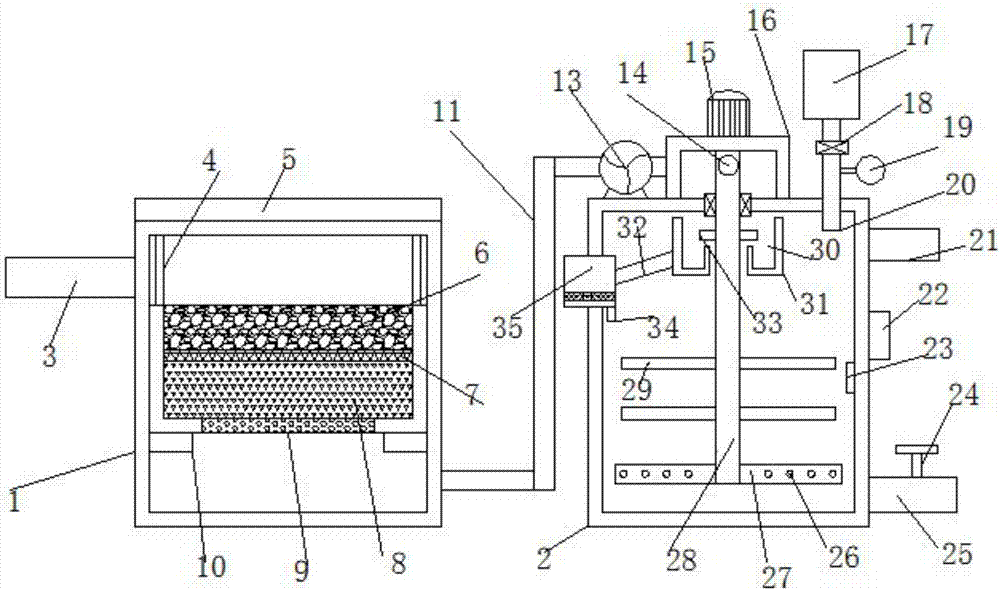

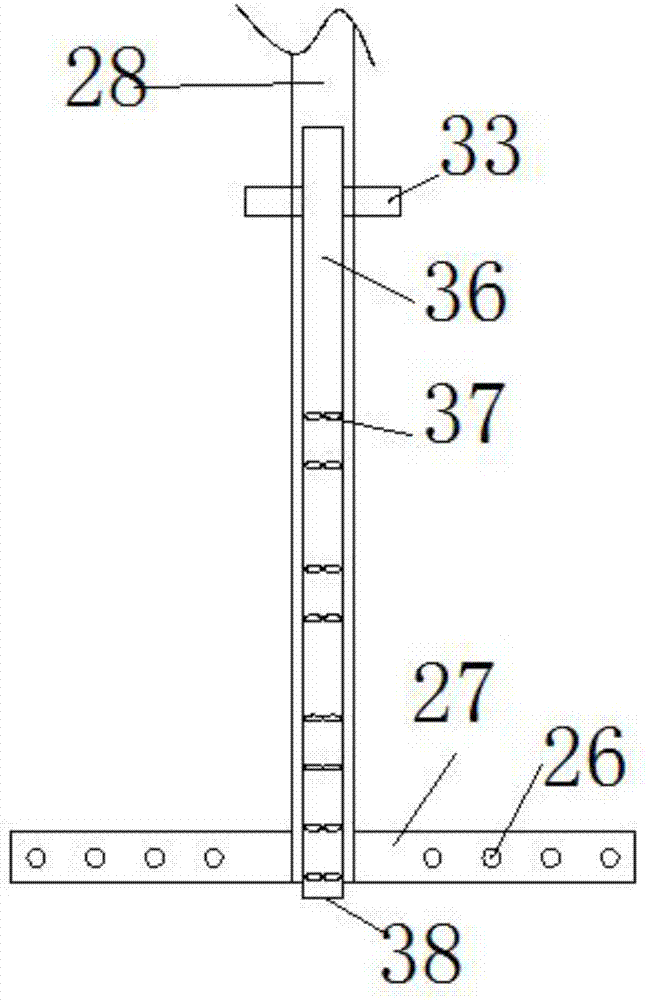

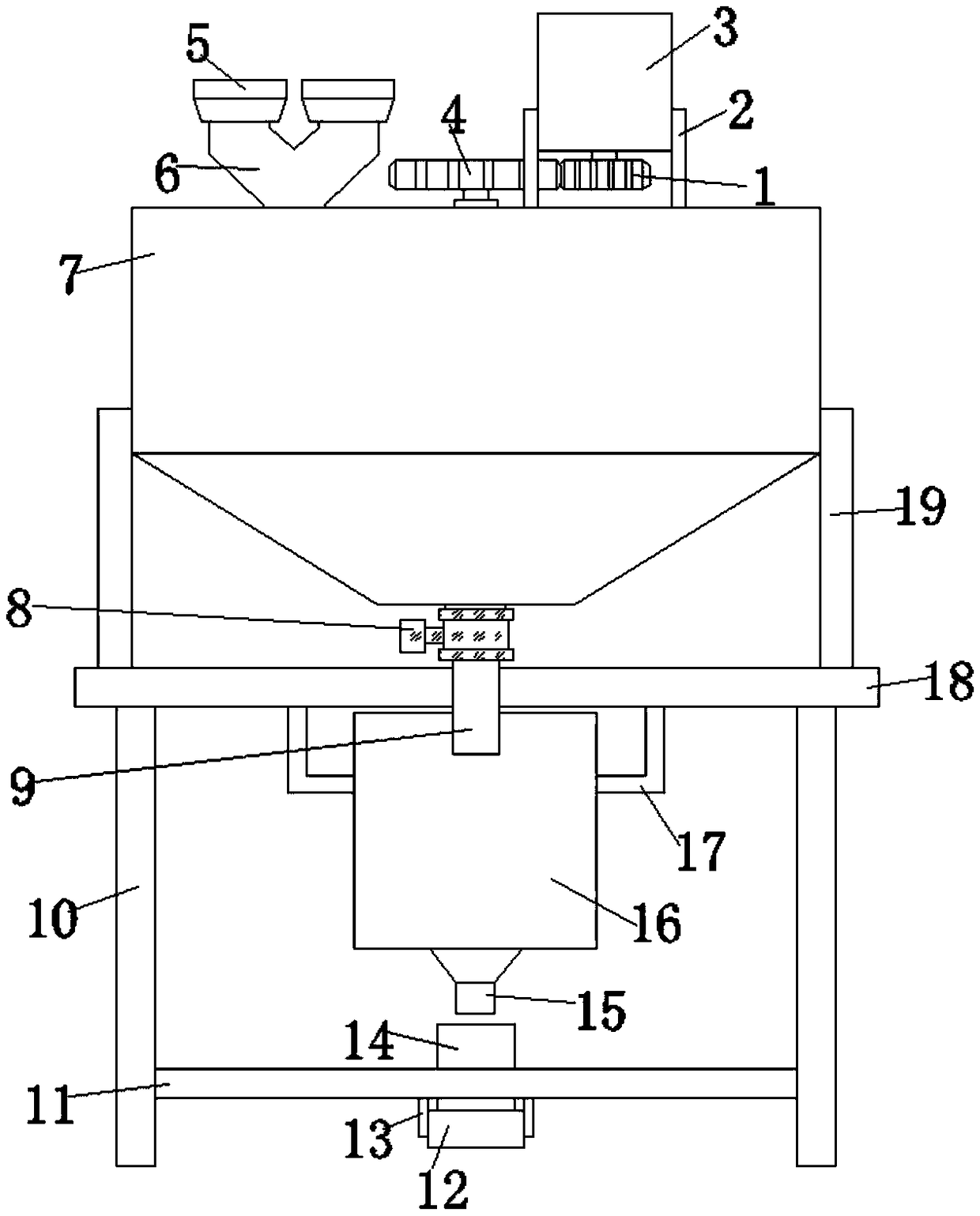

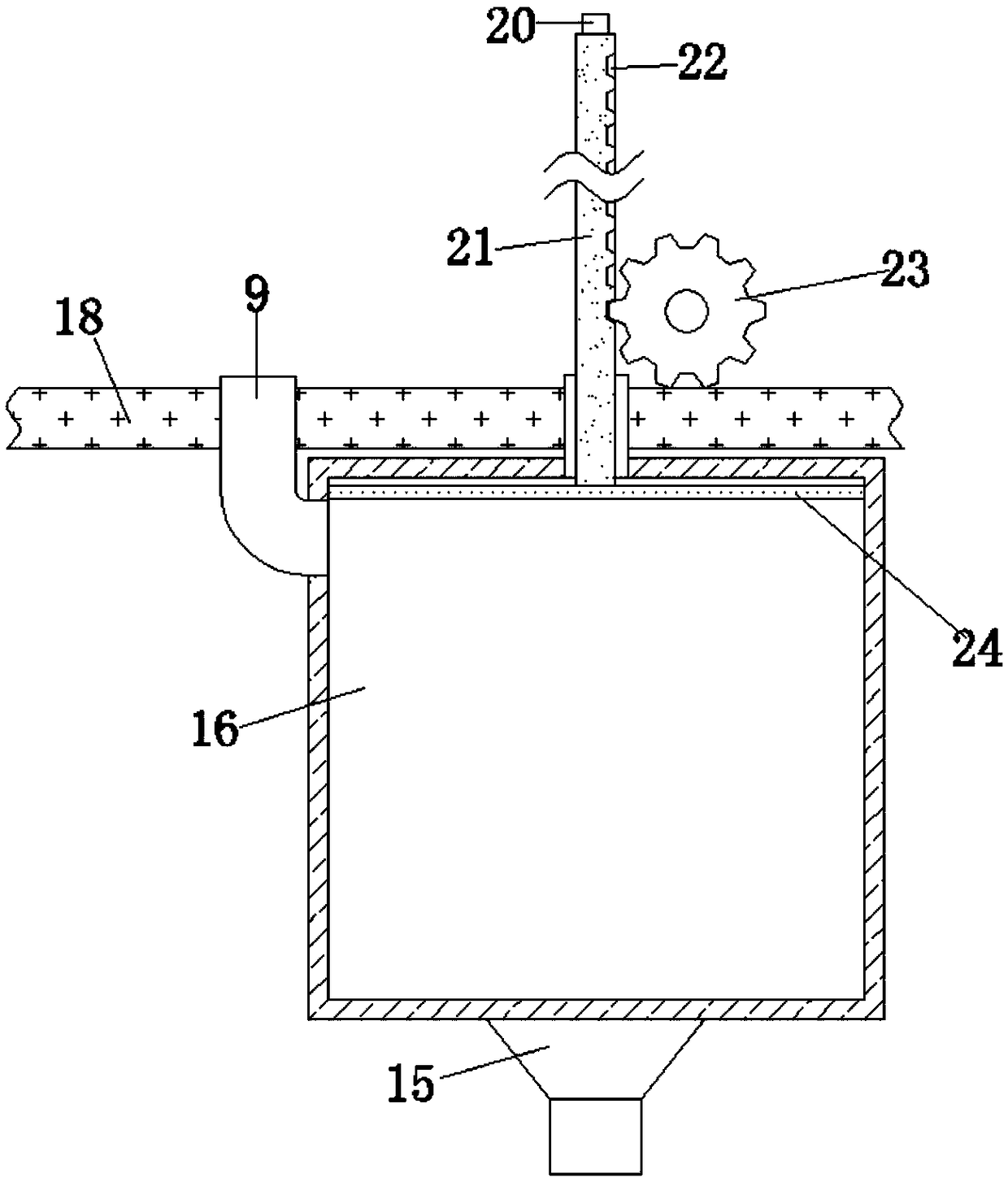

Automatic fertilization device for agriculture science and technology

InactiveCN110178509AImprove mixing uniformityImprove stirring efficiencyRotary stirring mixersTransportation and packagingEngineeringMixing effect

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

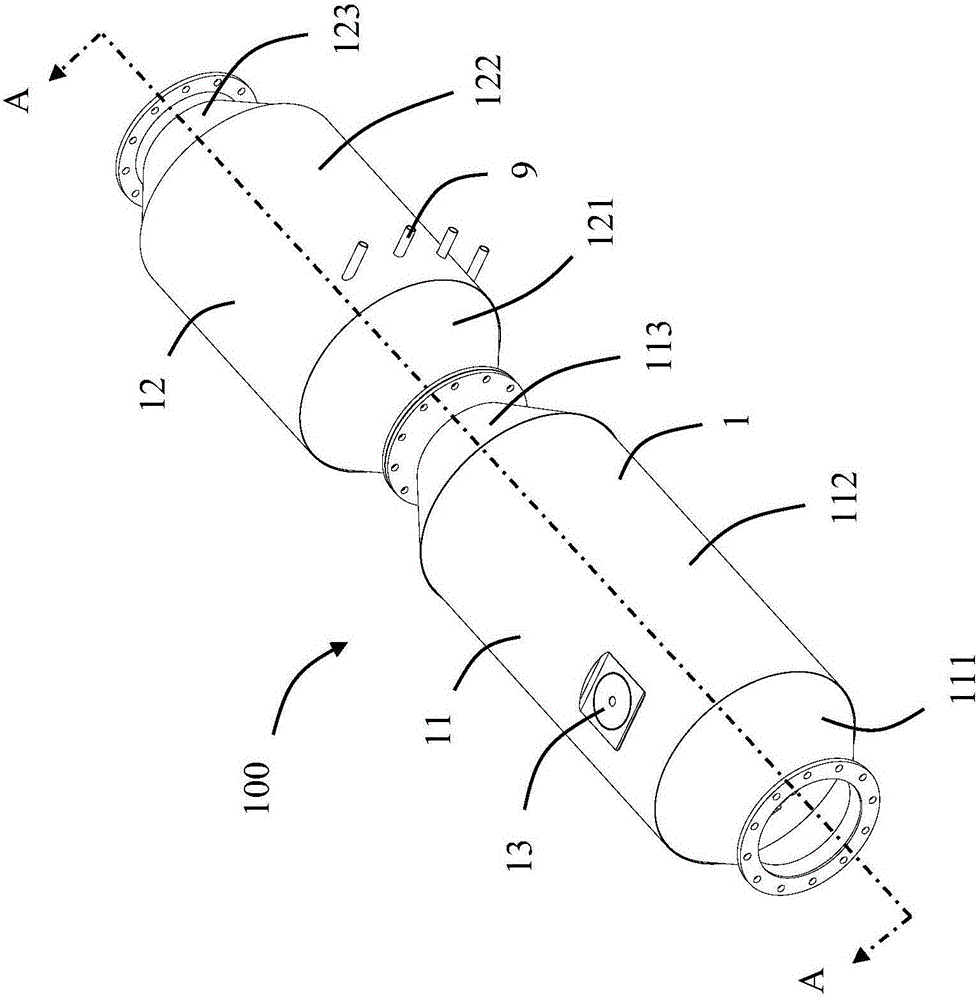

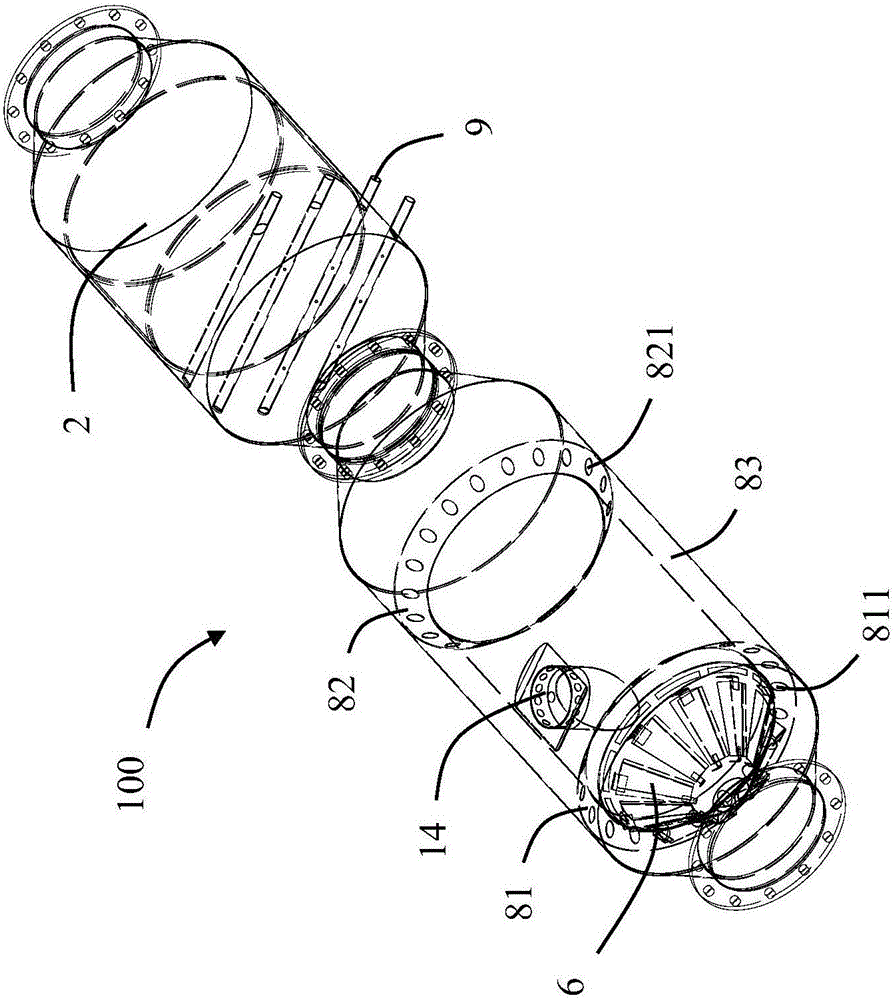

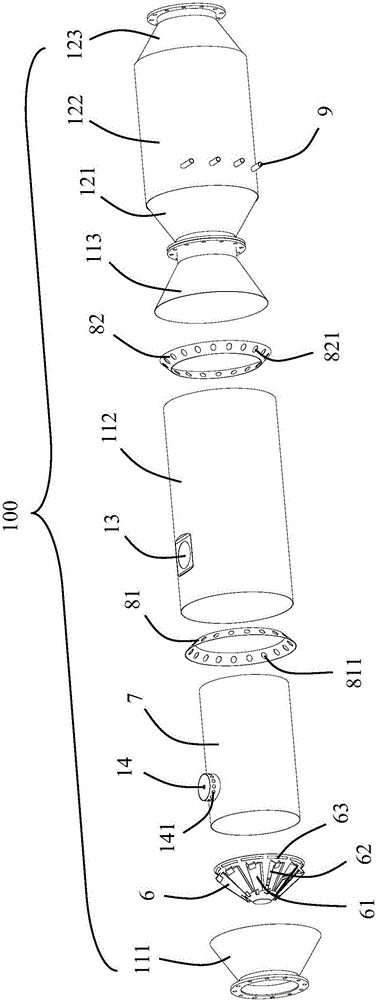

Exhaust gas treatment device

ActiveCN105804840AIncrease evaporation areaExtended stayExhaust apparatusSilencing apparatusEvaporationEngineering

Owner:TENNECO SUZHOU EMISSION SYST

Ship waste gas desulfuration device and method

ActiveCN107998761AImprove the mixing effectFully purifiedGas treatmentDispersed particle filtrationActivated carbonMixing effect

Owner:唐山伟德船用设备有限公司

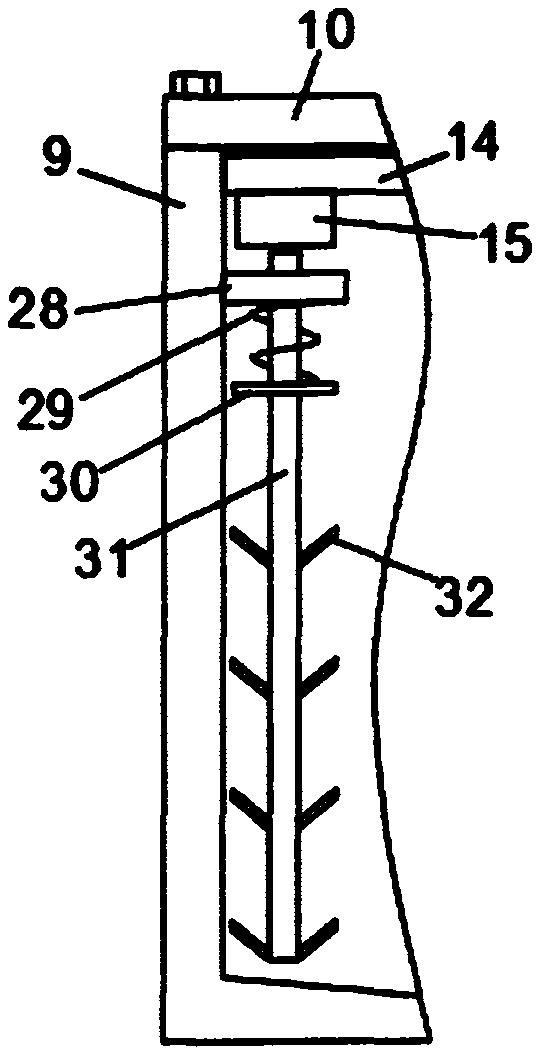

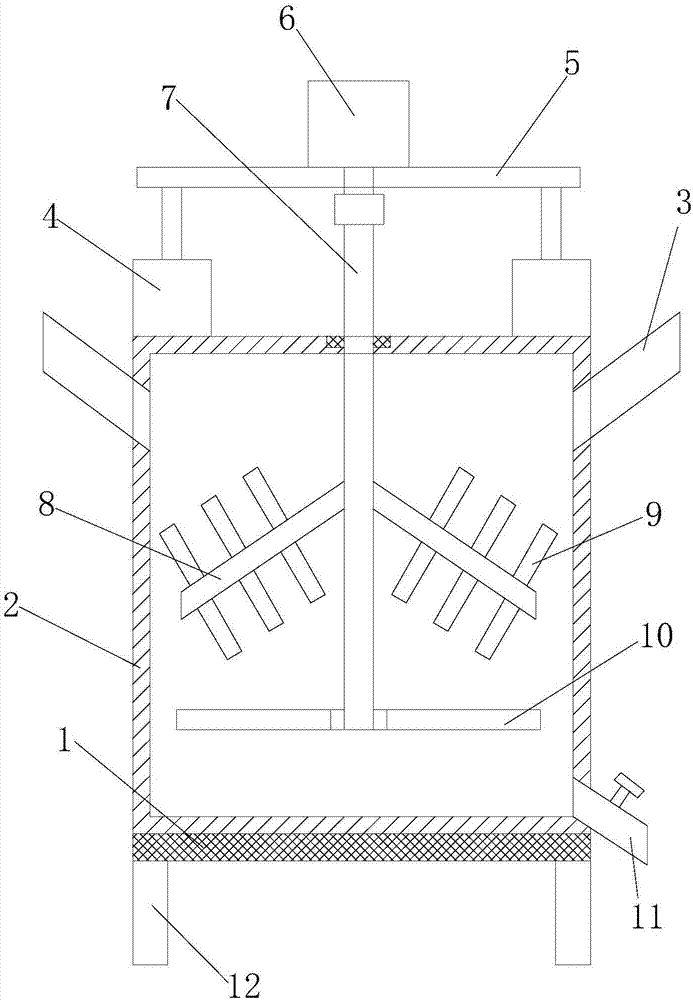

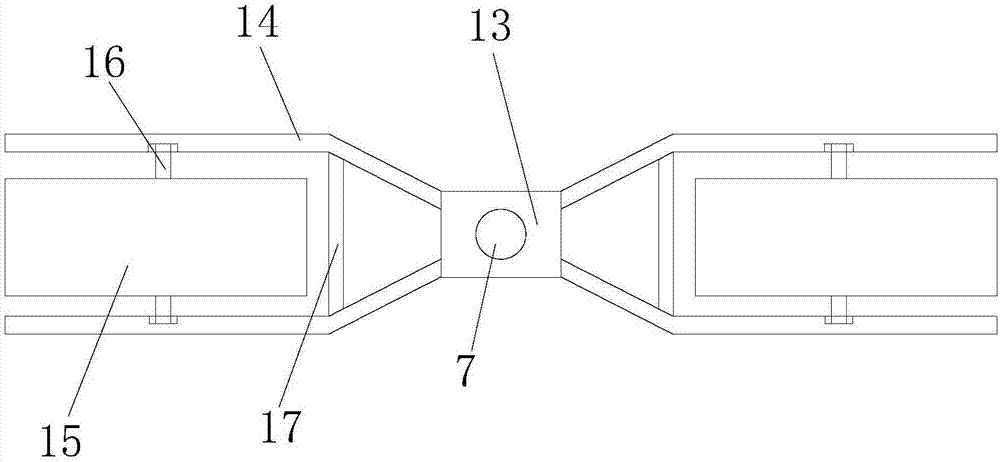

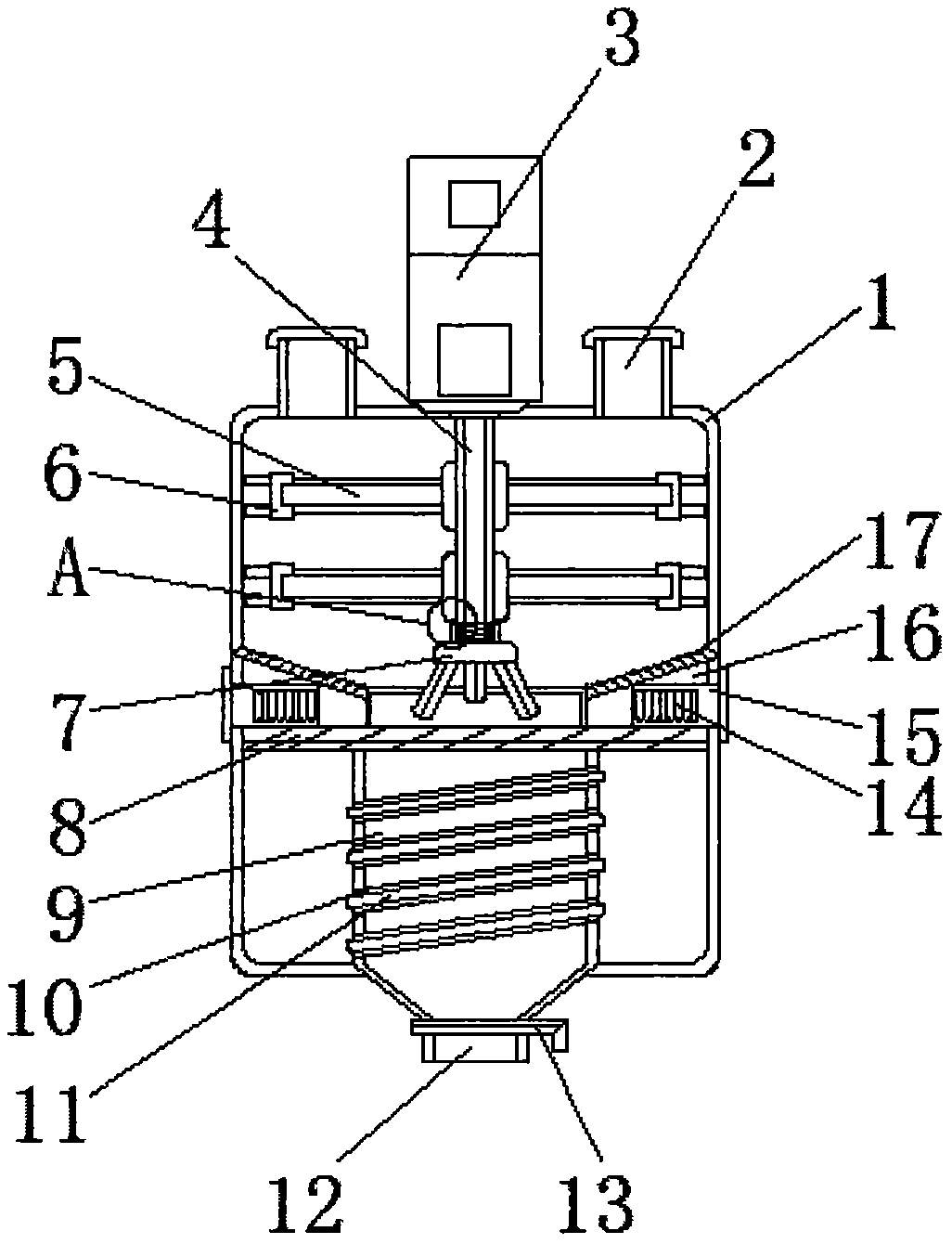

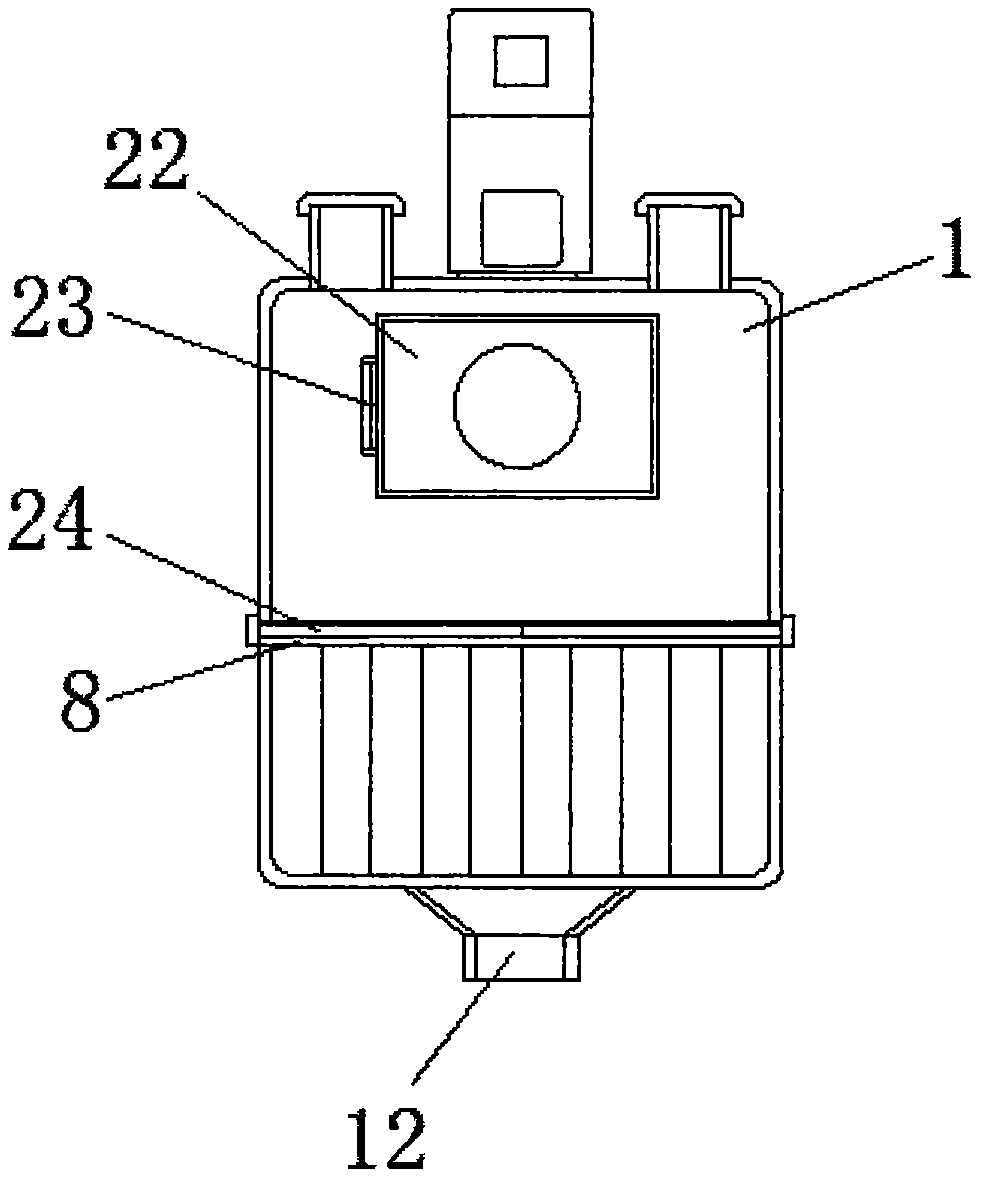

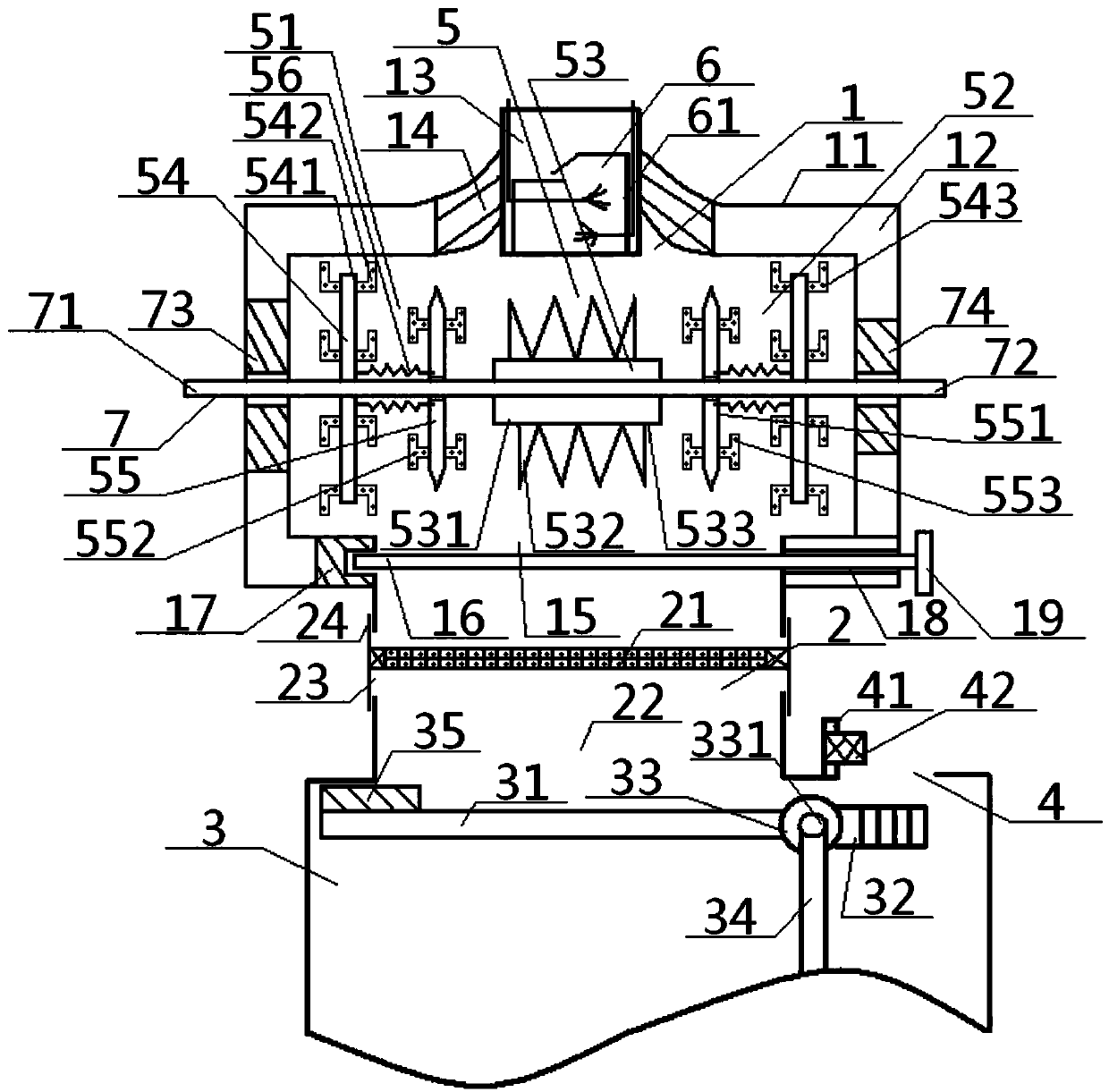

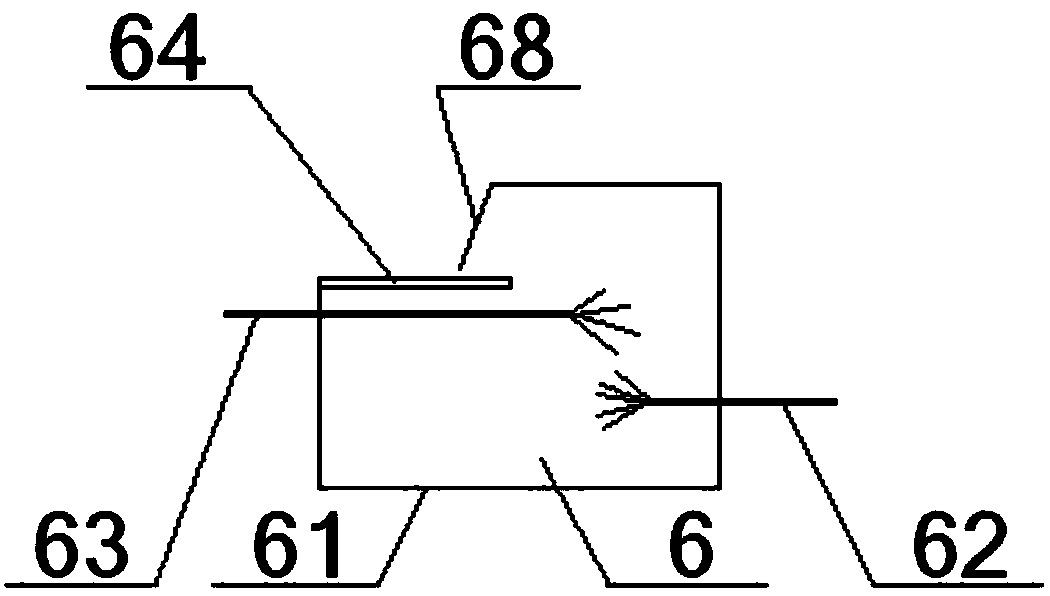

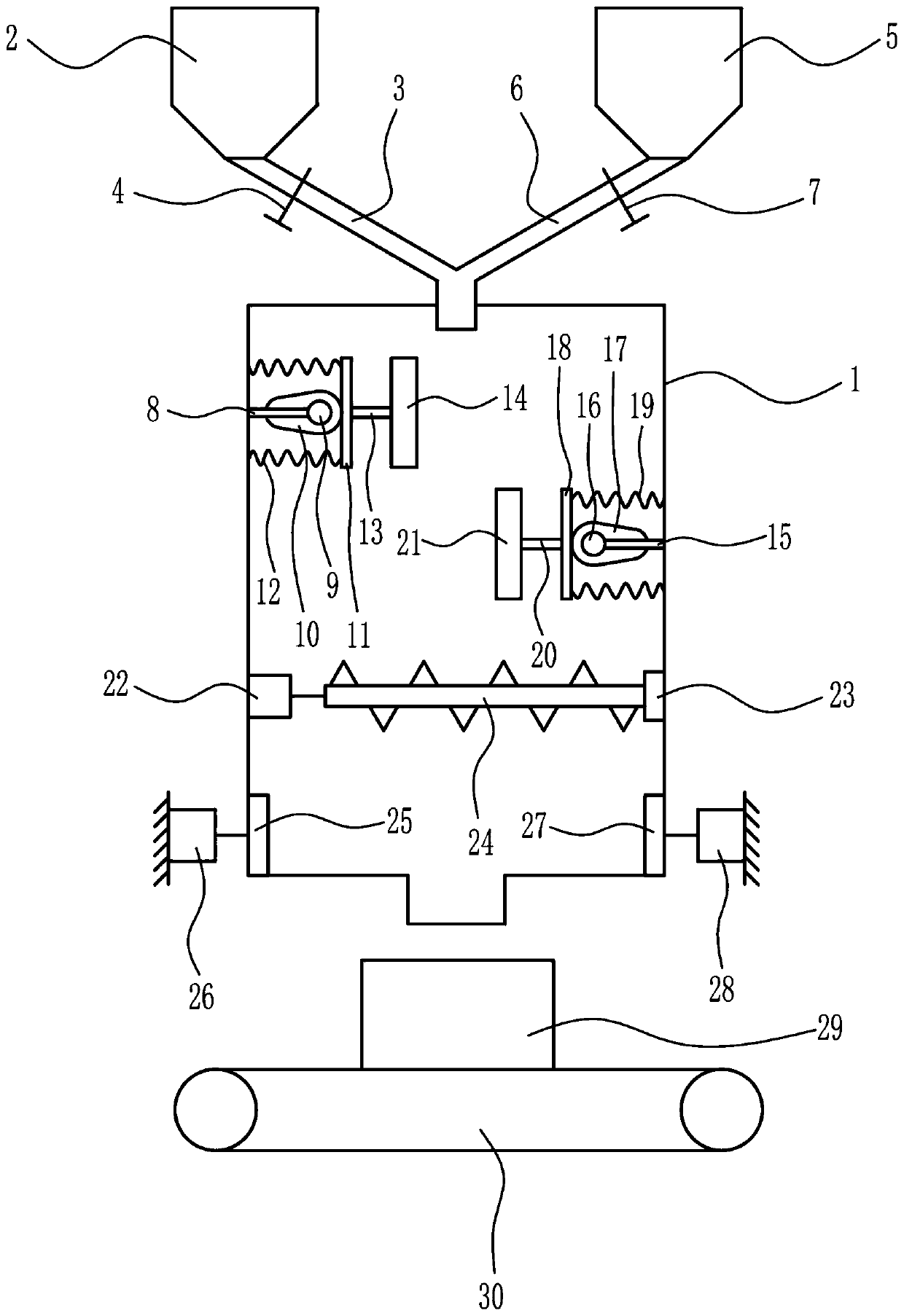

Left/right swinging type feed mixing equipment

InactiveCN107970819AImprove the mixing effectExpand the mixing rangeFeeding-stuffRotary stirring mixersEngineeringCentrifugal force

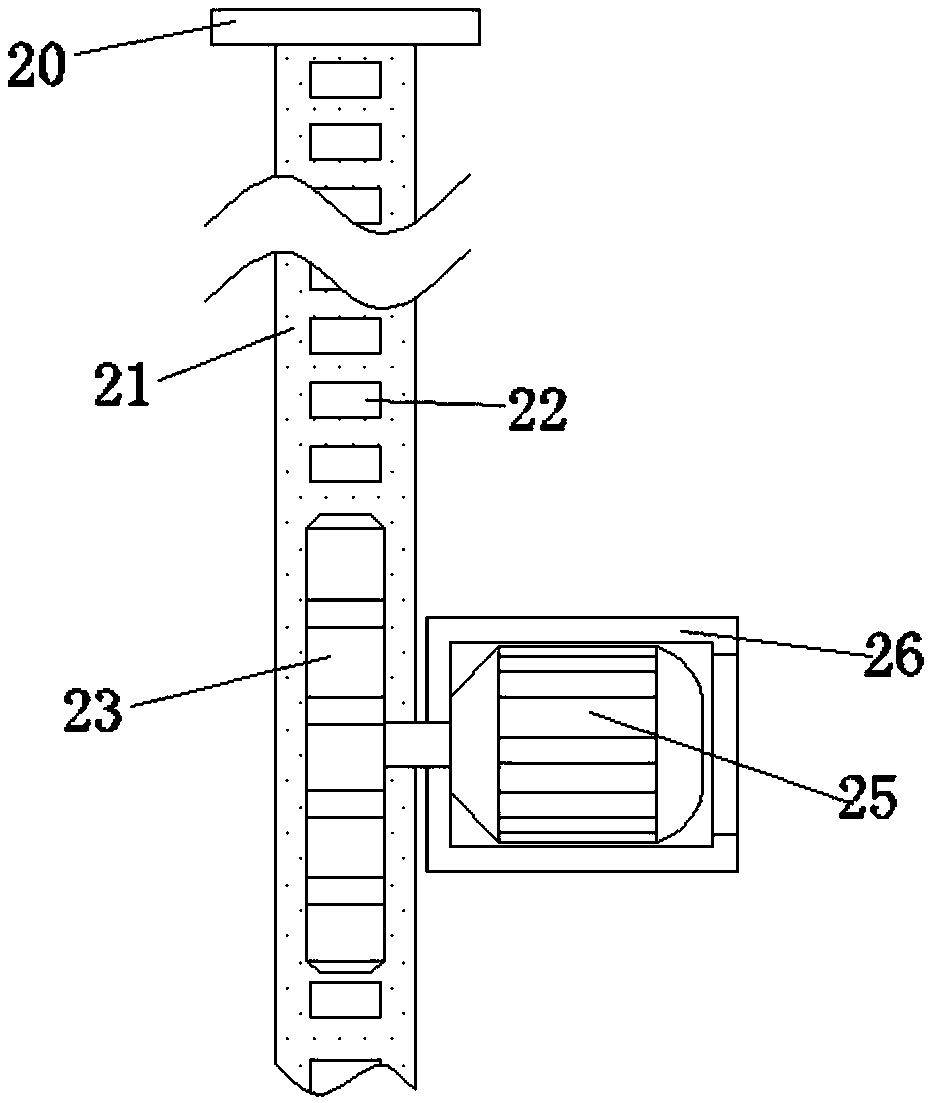

The invention discloses left / right swinging type feed mixing equipment which comprises a shell, wherein mounting bases are symmetrically and fixedly connected with the outer side wall of the shell; support columns are fixedly connected with the mounting bases; support plates are fixedly connected with top ends of the support columns; support bases are fixedly connected with the middle parts of thelower sides of the support plates; swinging columns are moveably hinged with the support bases; first motors are fixedly connected with the bottom ends of the swinging columns; first rotating shaftsare fixedly connected with output shafts of the first motors; two stirring devices are fixedly and symmetrically connected with bottom ends of the first rotating shafts; the stirring devices comprisehorizontal rods. The equipment has the beneficial effects that moving blocks on the stirring devices are moved away from the first rotating shafts because of a centrifugal force, at the same time thefirst springs are compressed, and then stirring bulges are driven by the moving blocks to change the stirring range; with the combination of pull devices and second springs, the stirring devices are swung leftwards and rightwards, so that the stirring range is effectively increased, and the feed mixing effect is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Mixing machine for powder materials

InactiveCN107096427AWell mixedImprove stabilityRotary stirring mixersTransportation and packagingEngineeringMixing effect

Owner:LIANGXI XUZHONG GENERAL MACHINERY DESIGN STUDIO

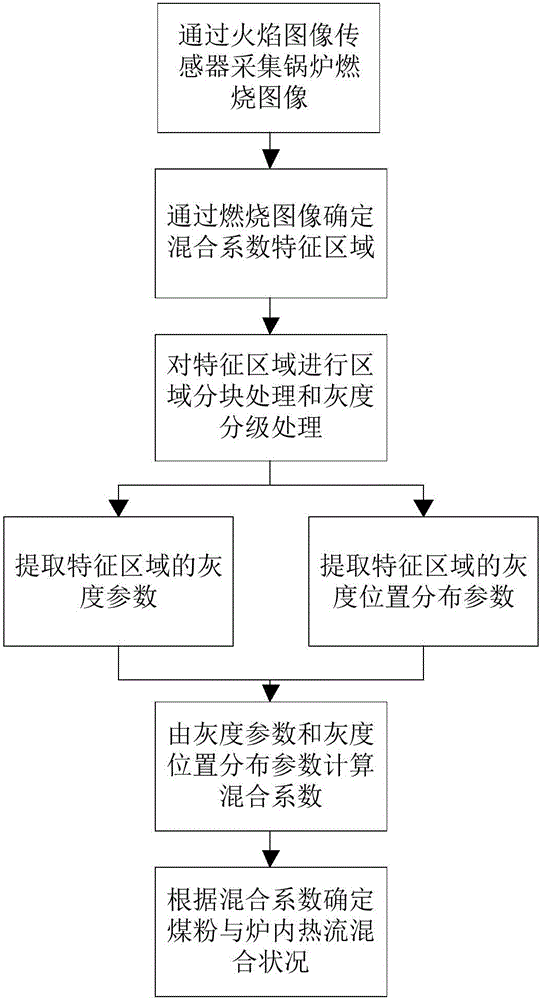

Measurement method of coal dust and in-furnace heat flow mixing effect on the basis of combustion image

InactiveCN105912872ARealize online monitoringAccurate calculationImage analysisInformaticsImaging processingHeat flow

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

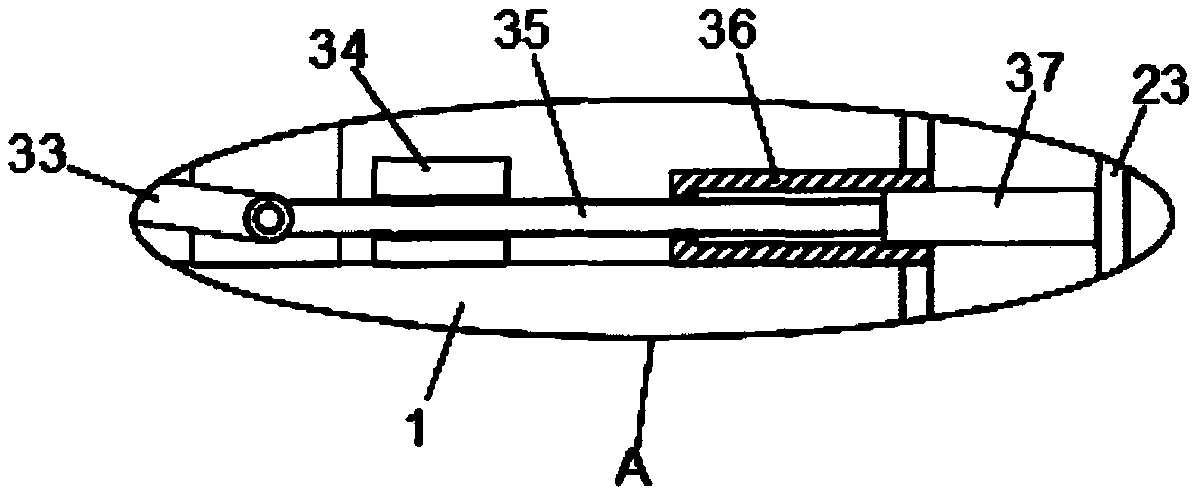

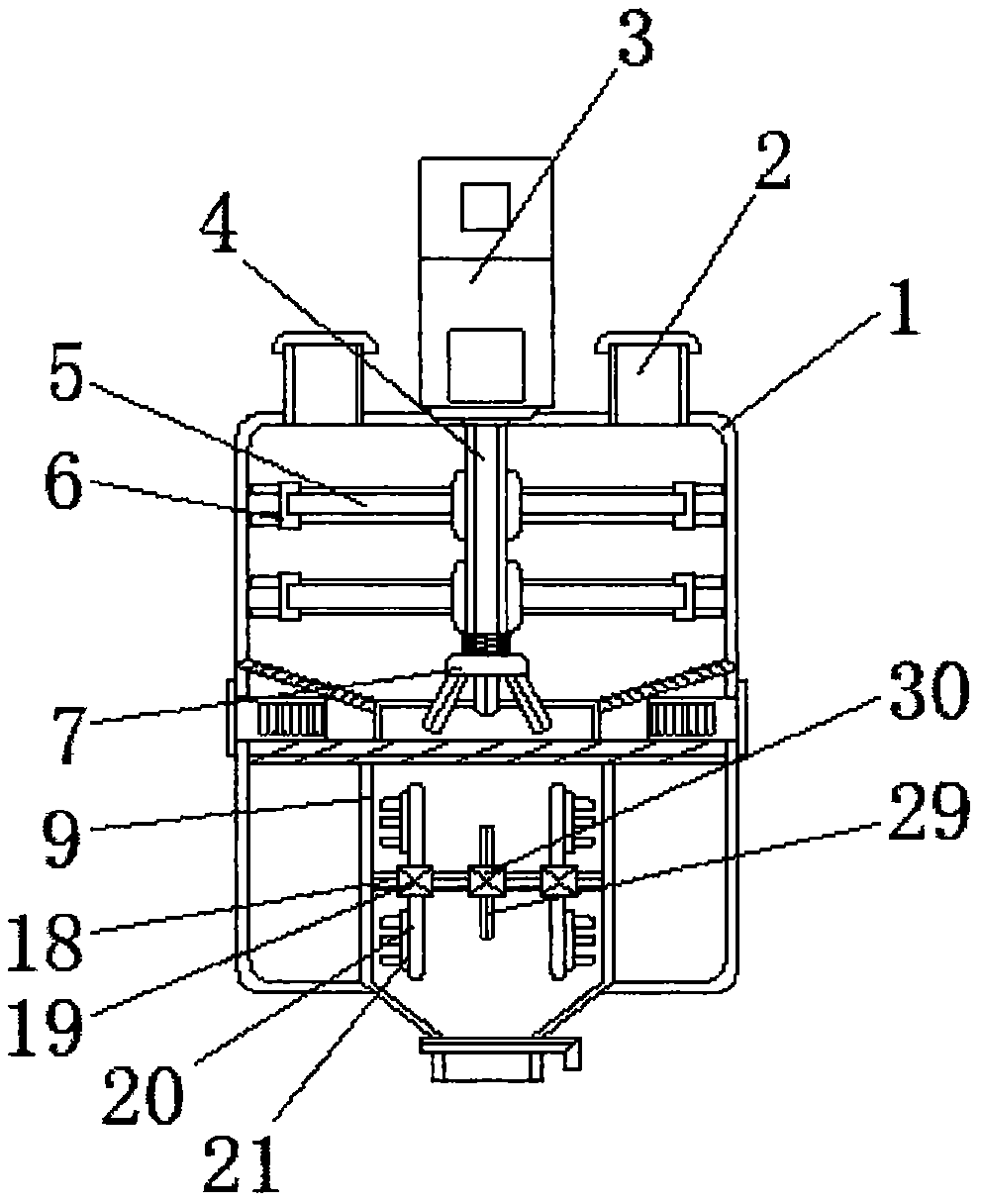

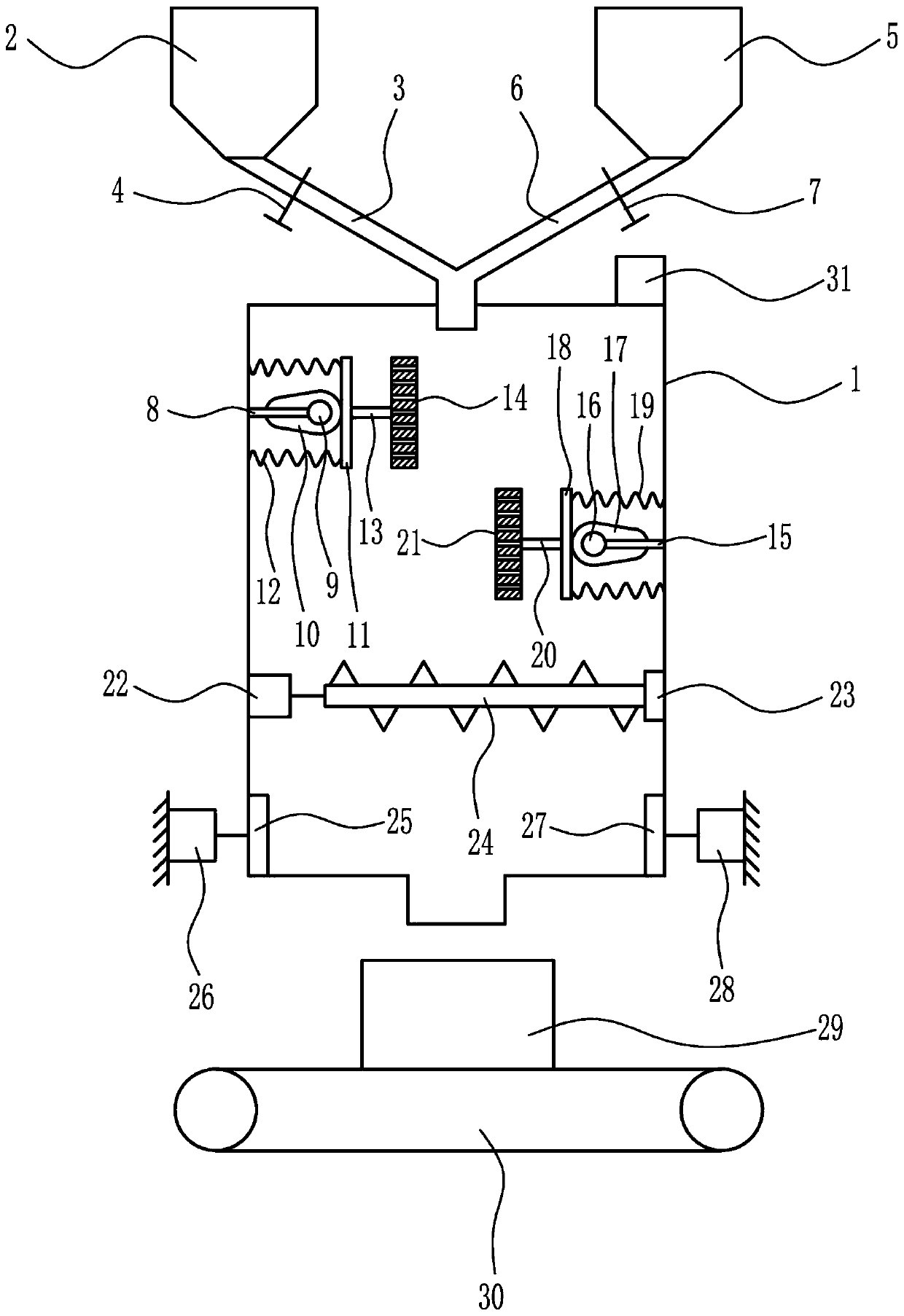

Culture medium device for super-strong repair of reductase

InactiveCN112812962AIncrease productivityWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyReciprocating motion

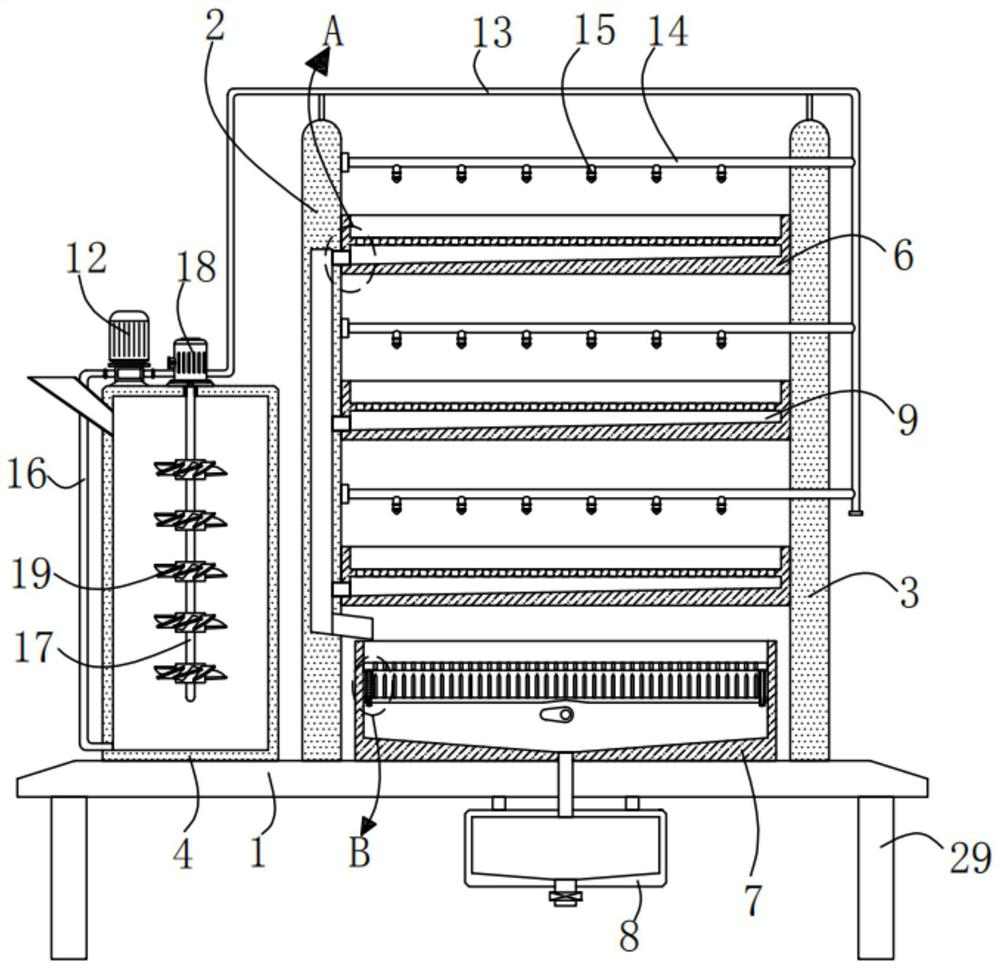

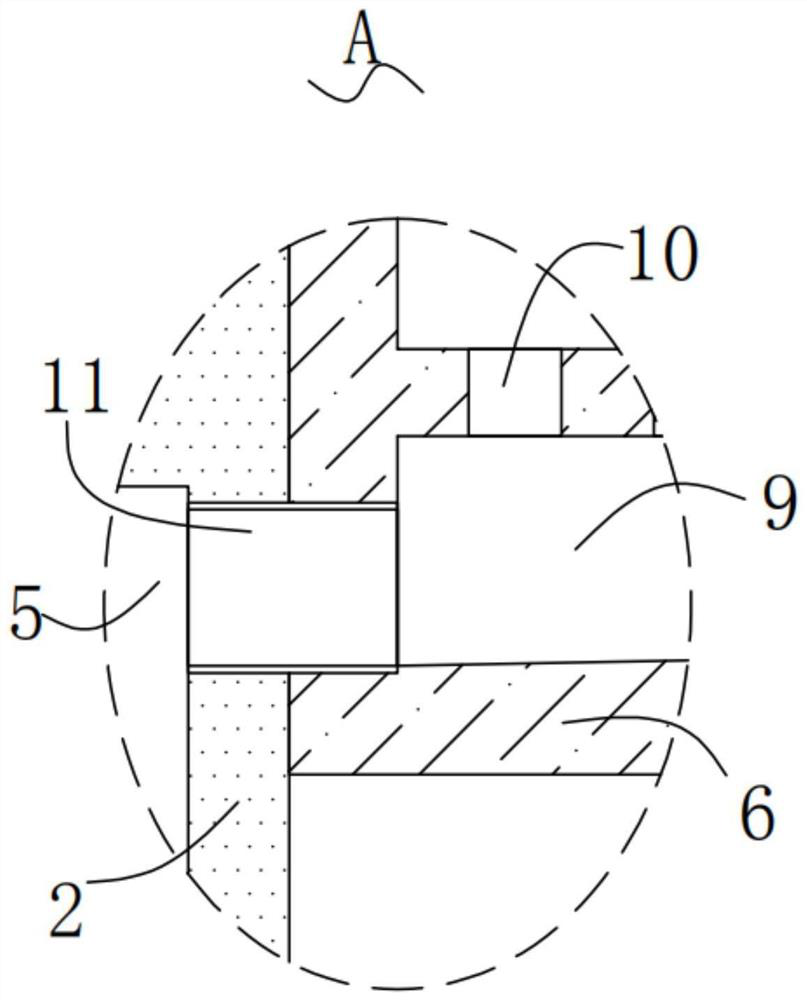

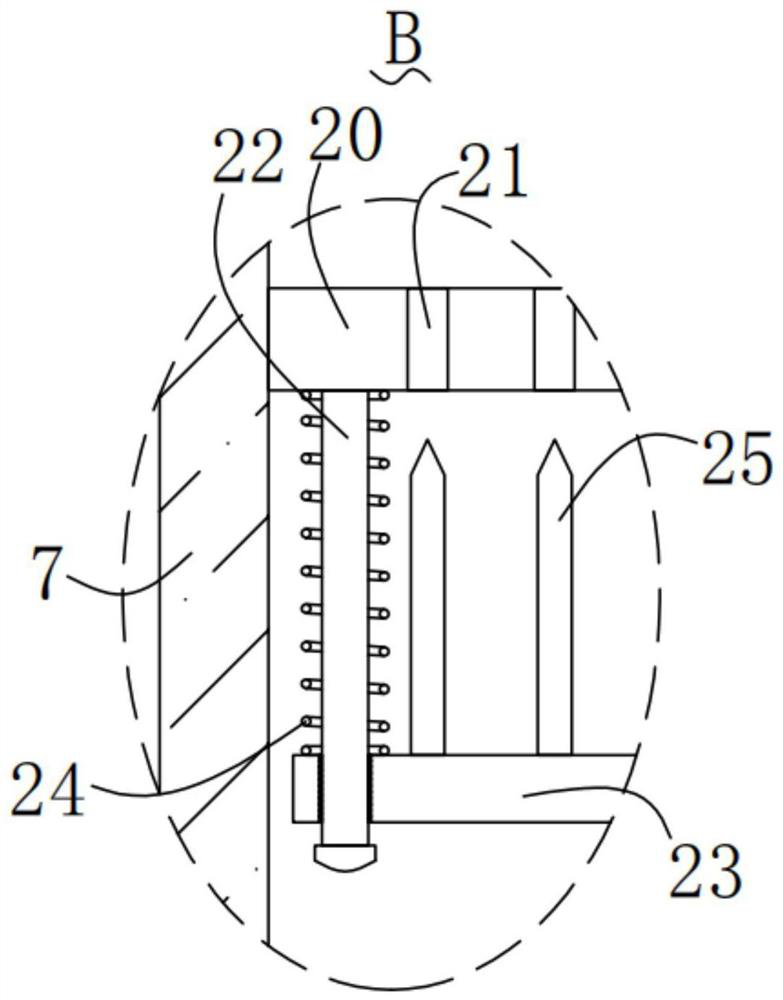

The invention discloses a culture medium device for super-strong repair of reductase, belongs to the technical field of culture media, and solves the problem of low production efficiency of an existing culture medium device. The culture medium device is characterized by comprising an incubator; and raw materials for preparing a culture medium are placed in the incubator, a water pump operates to extract liquid for heating, the liquid is sprayed out from a through hole in a hollow pipe, a first motor operates, stirring blades rotate, so that the mixing effect of the raw materials is good, the liquid enters a first box body, a second motor operates, reciprocating motion of the first box body is realized, so that the stirring blades on a threaded sleeve rod are driven to rotate in a reciprocating manner, a third motor operates, a heating pipe and a temperature sensor are used for controlling the temperature, so that the culture medium is at a proper concentration, valves on a first connecting pipe and a second connecting pipe are opened, a fourth motor operates, so that the liquid in a second box body is quantitatively discharged from the second connecting pipe, a conveying mechanism conveys the culture medium to carry out multi-position connection of the liquid, and the culture medium device has the advantage of high production efficiency.

Owner:SHIZI HEDE (HANGZHOU) HEALTH MANAGEMENT CO LTD

Mixing and stirring device capable of uniformly heating for producing calcium silicate board

InactiveCN109012481AMixing Works ExcellentSpeed up the mixingRotary stirring mixersTransportation and packagingCalcium silicateEngineering

Owner:湖南长乐建材有限公司

Granulated arabinose preparation method and device

PendingCN107987109AHigh hardnessHigh densitySugar derivativesSugar derivatives preparationMolten stateCooling chamber

Owner:山东绿健生物技术有限公司

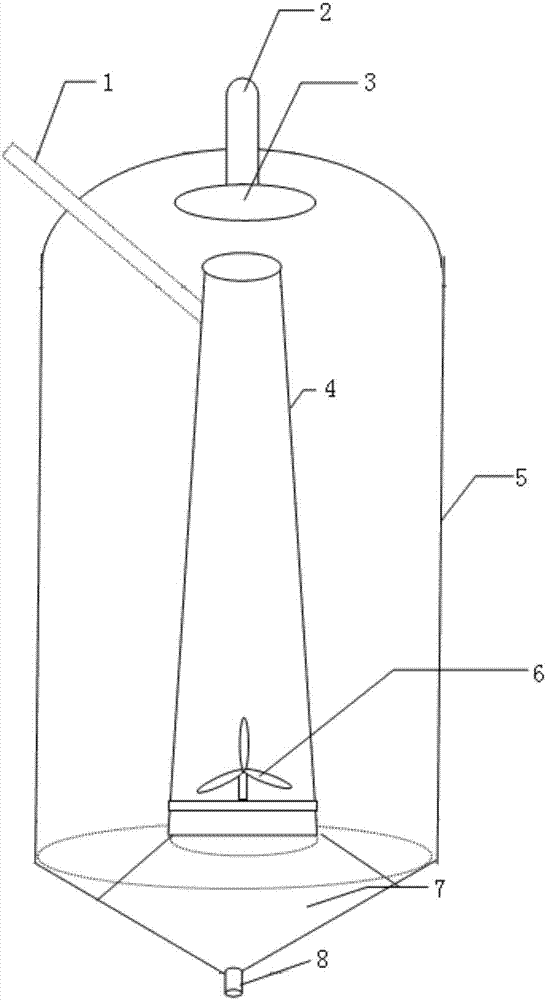

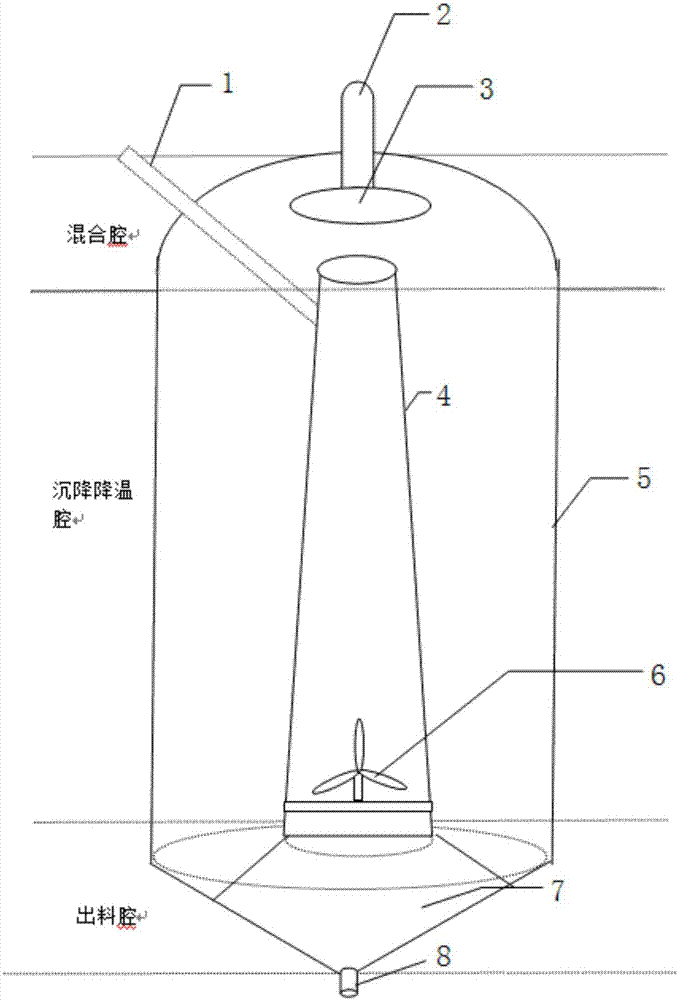

Pretreatment system of crop fermentation raw materials

InactiveCN109825421AIncrease temperatureReduce volumeBioreactor/fermenter combinationsBiological substance pretreatmentsLowering plantsEngineering

Owner:胡方柯

Mixing device for manufacturing high-reliability cable

InactiveCN110368863AOvercoming structural complexityOvercoming automationTransportation and packagingMixer accessoriesEngineeringMaterial resources

Owner:KINGSIGNAL OPTICAL FIBER & CABLE GANZHOU CO LTD

Preparation method of bed sheet capable of releasing negative oxygen ions

Owner:四川圣达高环保科技有限公司

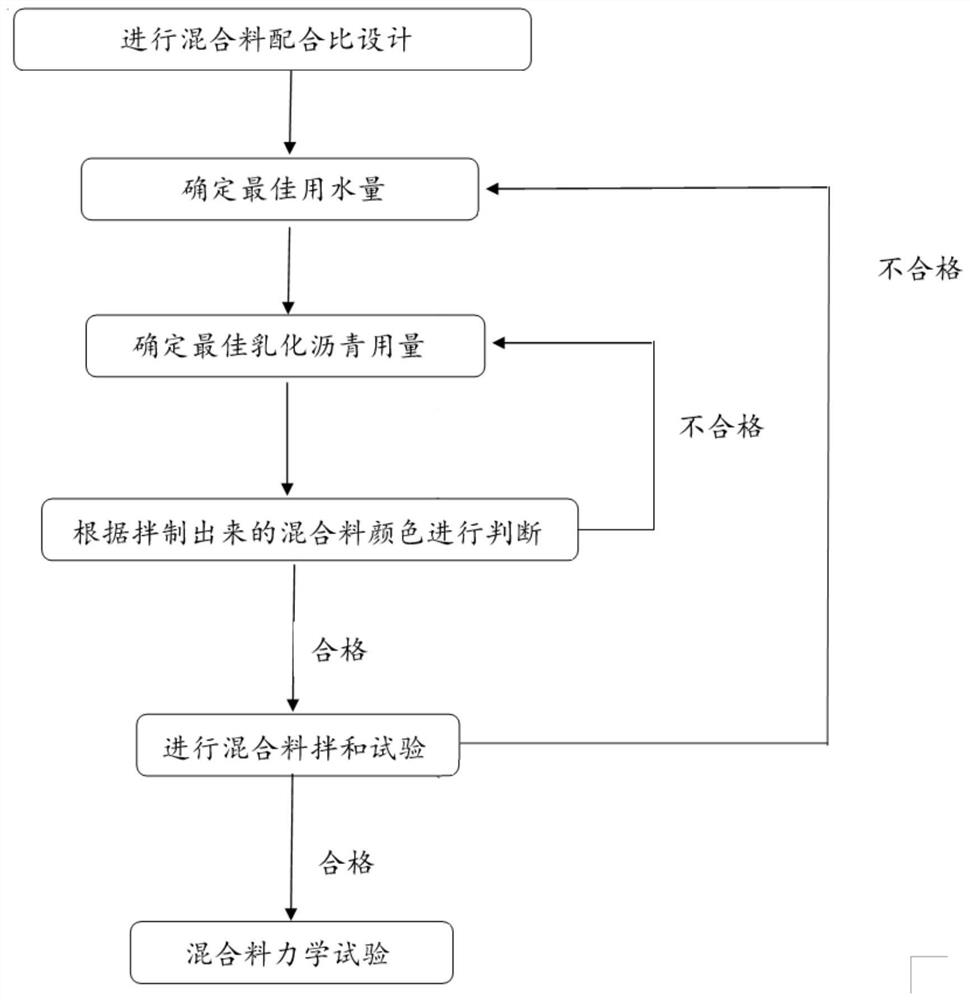

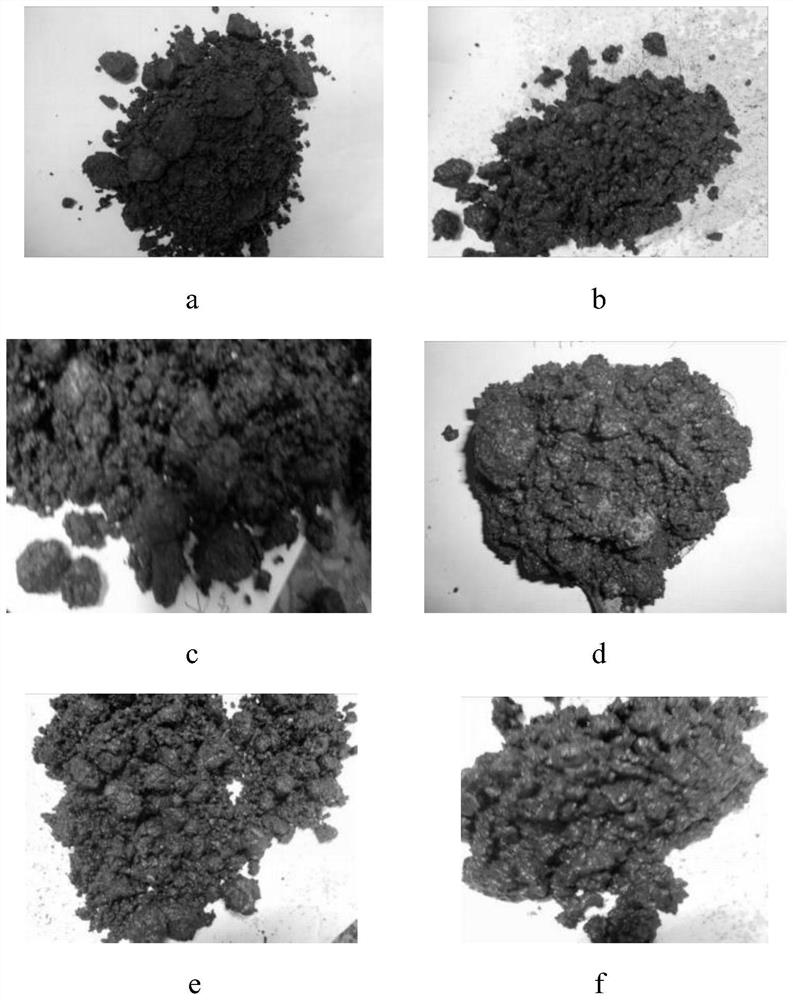

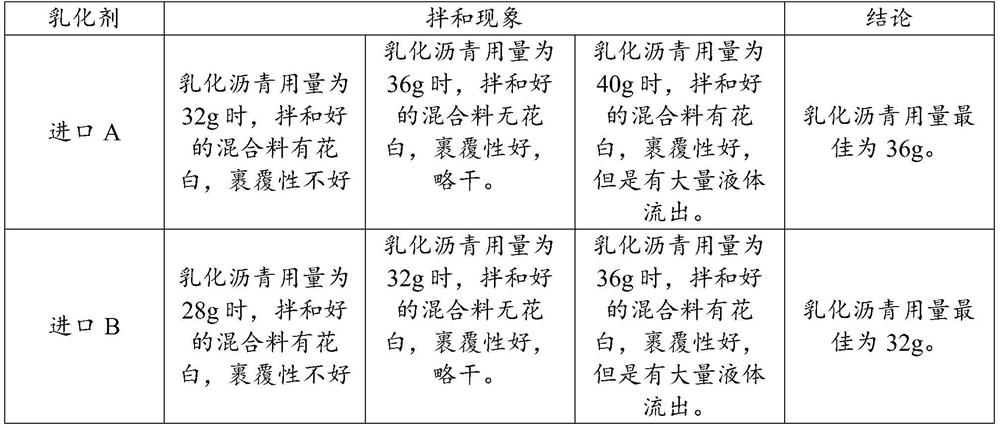

Indoor detection method for mixing effect of emulsified asphalt cold-recycled mixture

PendingCN114527263AAdequate shipping timeSufficient construction timeSolid waste managementPreparing sample for investigationBitumen emulsionProcess engineering

Owner:XIAN HIGHWAY INST +1

Uniform-discharging double-color filling device for cosmetic production

ActiveCN109335053ASpeed up the fallImprove the leveling effectLarge containersLiquid materialDrive shaftEngineering

Owner:辽宁珂思美化妆品有限公司

Agricultural planting and cultivating device

InactiveCN112640699ARotary stirring mixersTransportation and packagingAgricultural scienceAgricultural engineering

Owner:HEBEI UNIV OF ENG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap