Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "High density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

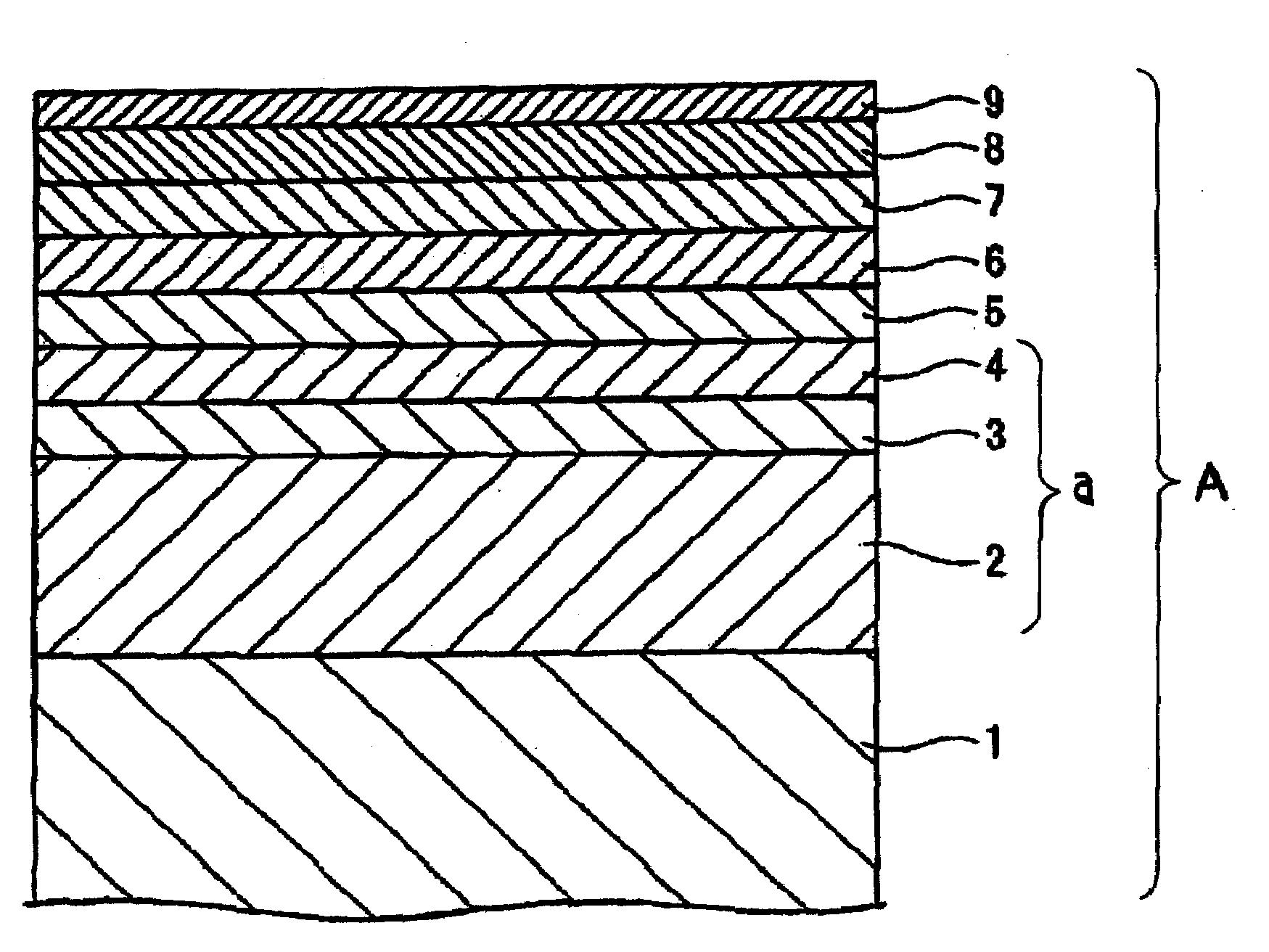

Electronics module having high density interconnect structures incorporating an improved dielectric lamination adhesive

InactiveUS6294741B1Improve electrical performanceAdequate processing propertyInsulating substrate metal adhesion improvementPrinted electric component incorporationComposite filmHigh density

A multi-chip electronics module is provided which utilizes benzocyclobutene as a laminate adhesive for bonding the upper dielectric films in a high density interconnect structure. The benzocyclobutene thermosetting polymer is spin coated on a polyimide film, and baked at low temperature to remove any solvent to leave a B-staged coating on the polyimide film. The composite film can be laminated to an underlying electrical structure using a vacuum laminator and heat. As the heat is applied, the BCB layer softens, flows and then cures to bond the polyimide film to the underlying electrical structure.

Owner:LOCKHEED MARTIN CORP

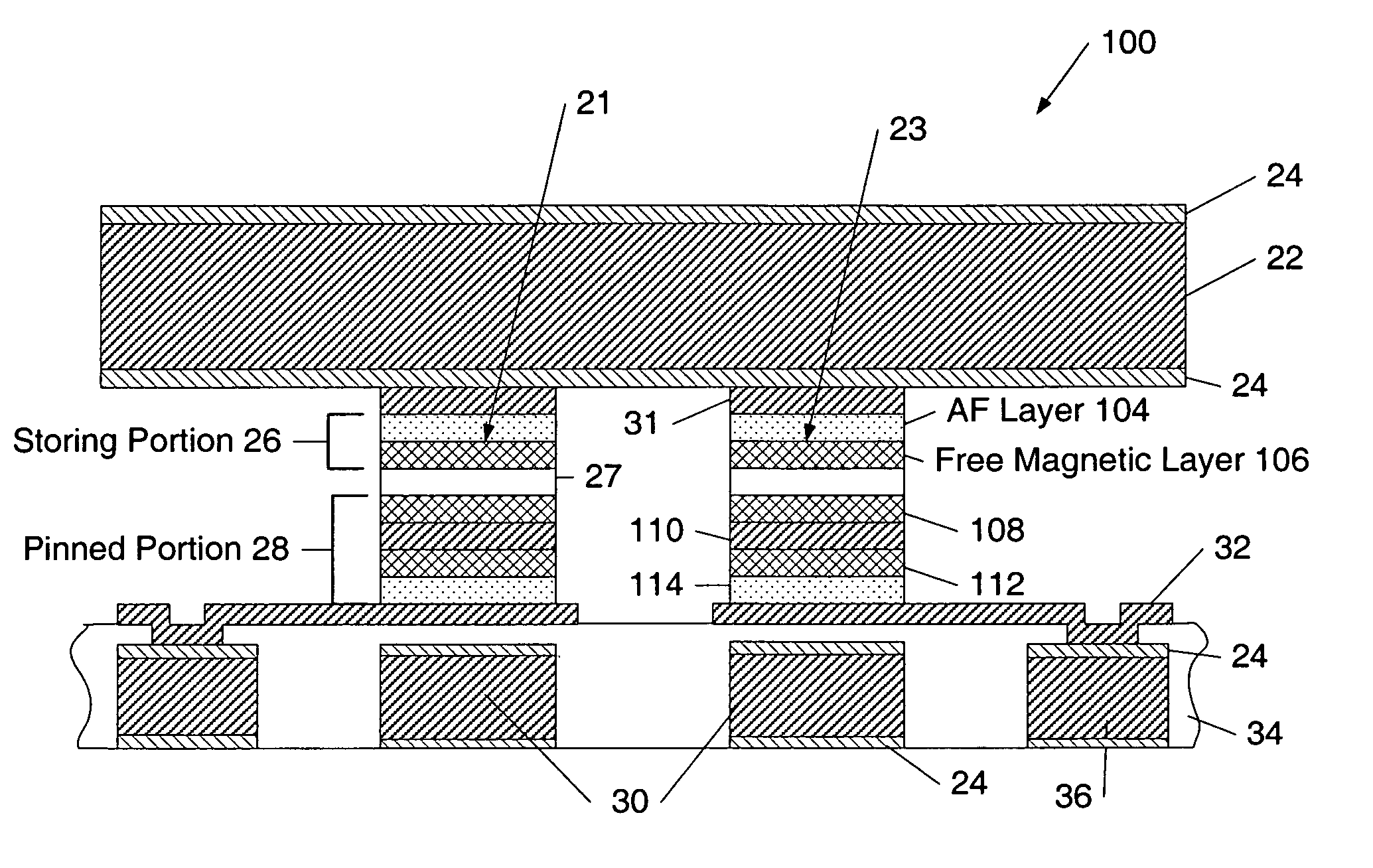

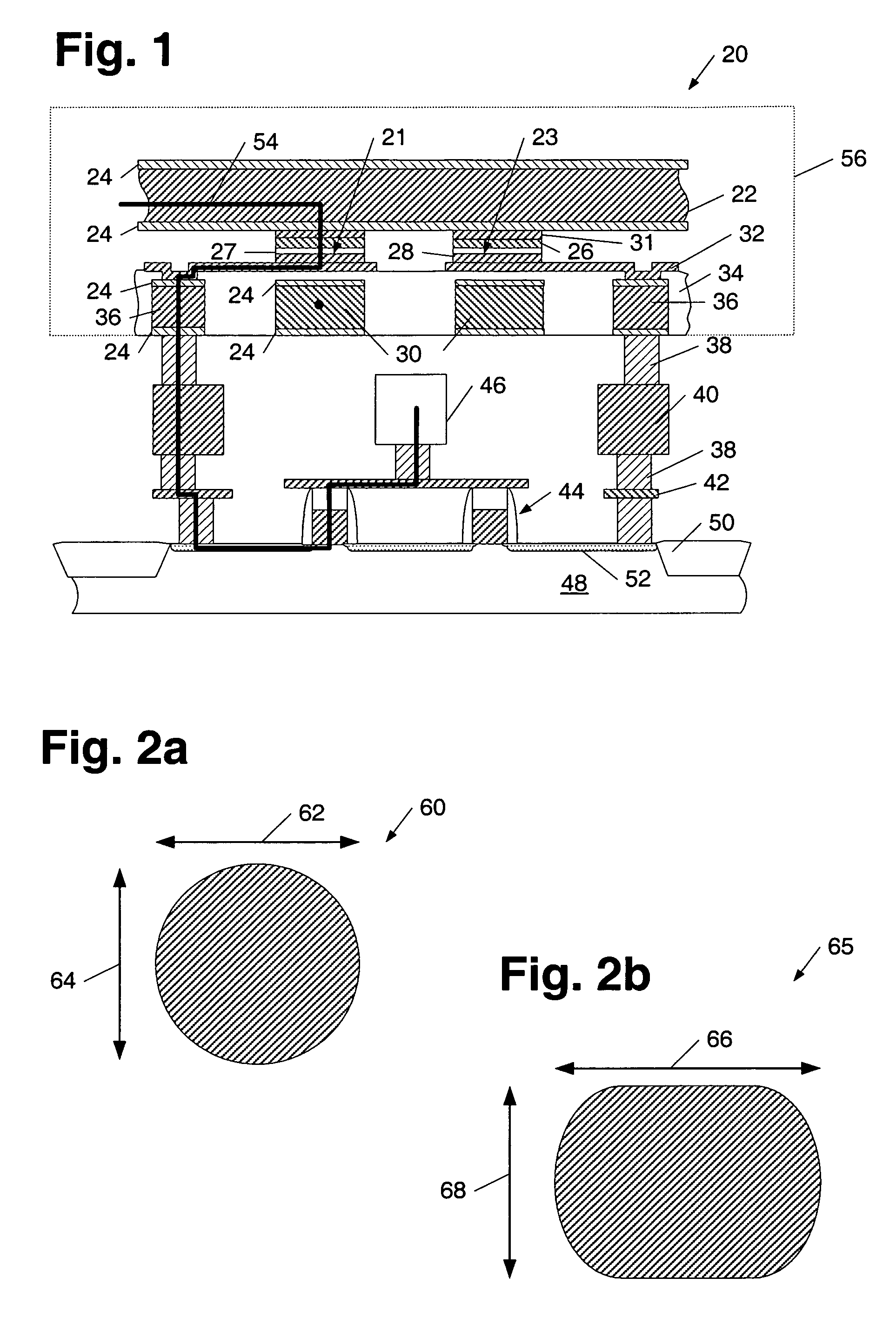

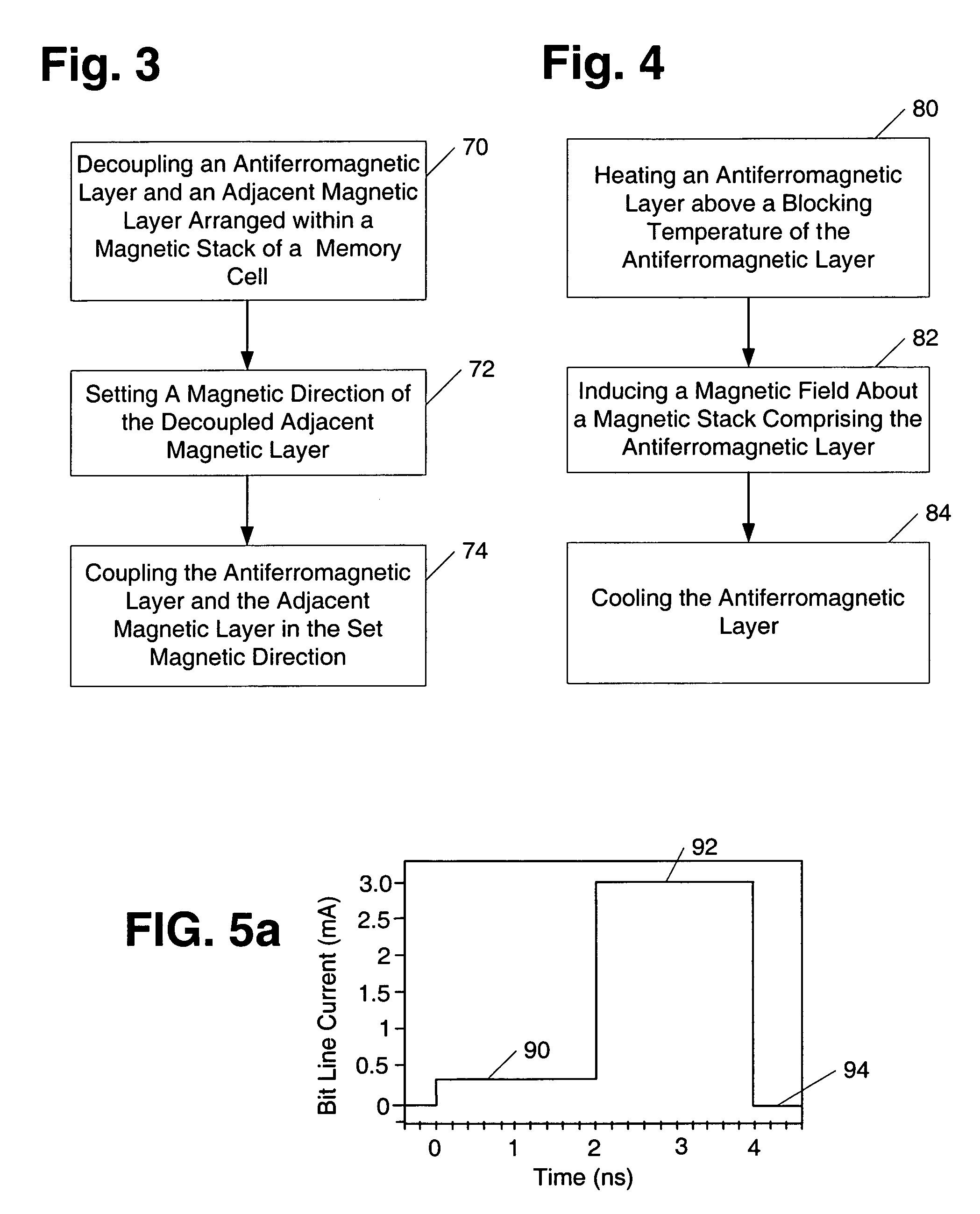

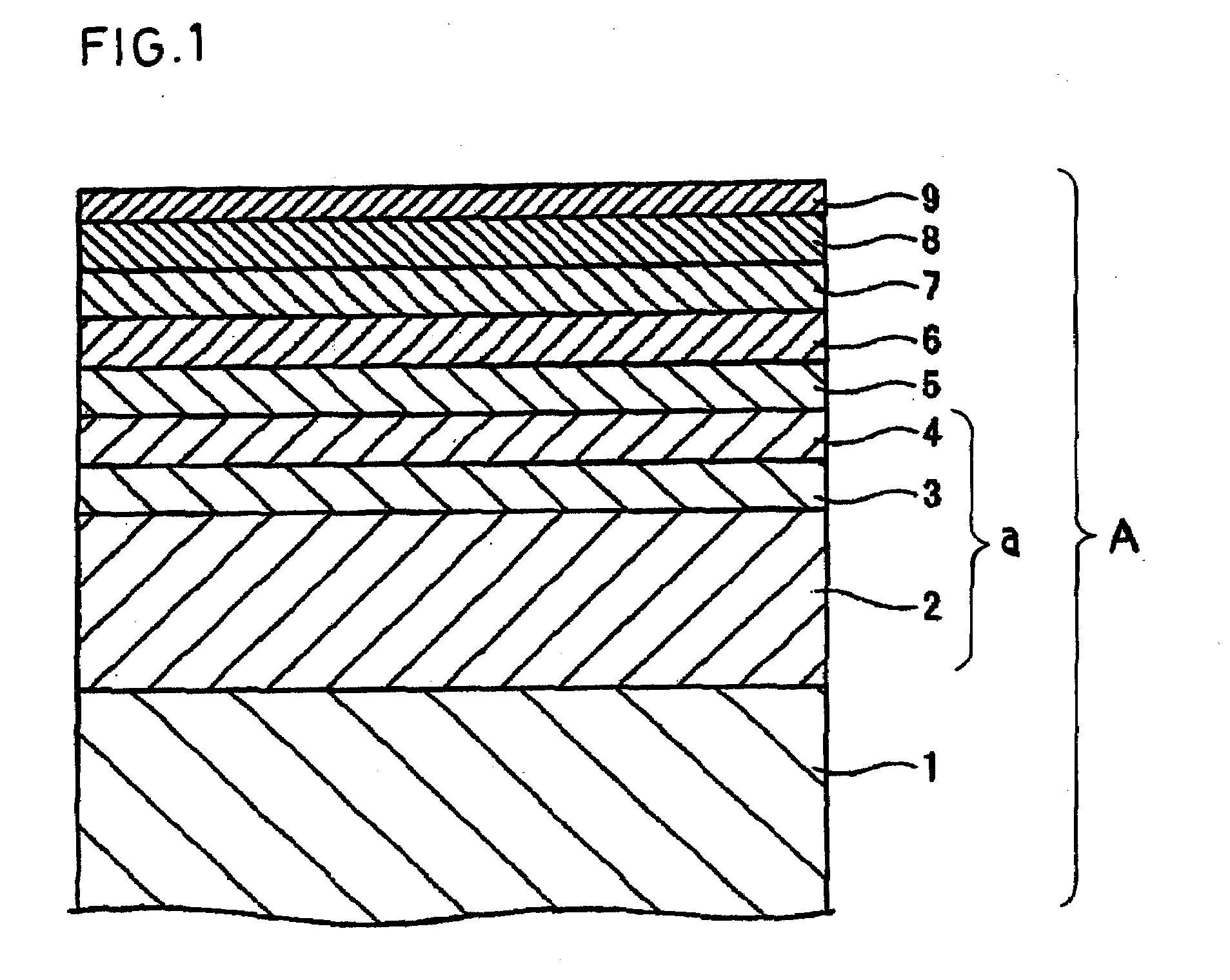

High density MRAM using thermal writing

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Technique for perfecting the active regions of wide bandgap semiconductor nitride devices

InactiveUS20050164475A1Lower average currentHigh densityPolycrystalline material growthFrom solid stateEngineeringNitride

This invention pertains to e lectronic / optoelectronic devices with reduced extended defects and to a method for making it. The method includes the steps of depositing a dielectric thin film mask material on a semiconductor substrate surface; patterning the mask material to form openings therein extending to the substrate surface; growing active material in the openings; removing the mask material to form the device with reduced extended defect density; and depositing electrical contacts on the device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Non-volatile, resistive memory cell based on metal oxide nanoparticles, process for manufacturing the same and memory cell arrangement of the same

ActiveUS20070045704A1Improve storage densityLow costMaterial nanotechnologySolid-state devicesMetal oxide nanoparticlesContact position

Disclosed is a non-volatile memory cell including a first conductive electrode region, a second conductive electrode region and a memory region disposed therebetween. The memory region includes one or a plurality of metal oxide nanoparticles, which contact and electrically connect the first and the second electrode region via contact locations and which exhibit a bistable resistance properties when applying an external voltage.

Owner:POLARIS INNOVATIONS LTD

Fender assembly and mounting clamp therefor

Owner:STREETCAREC SLOAN

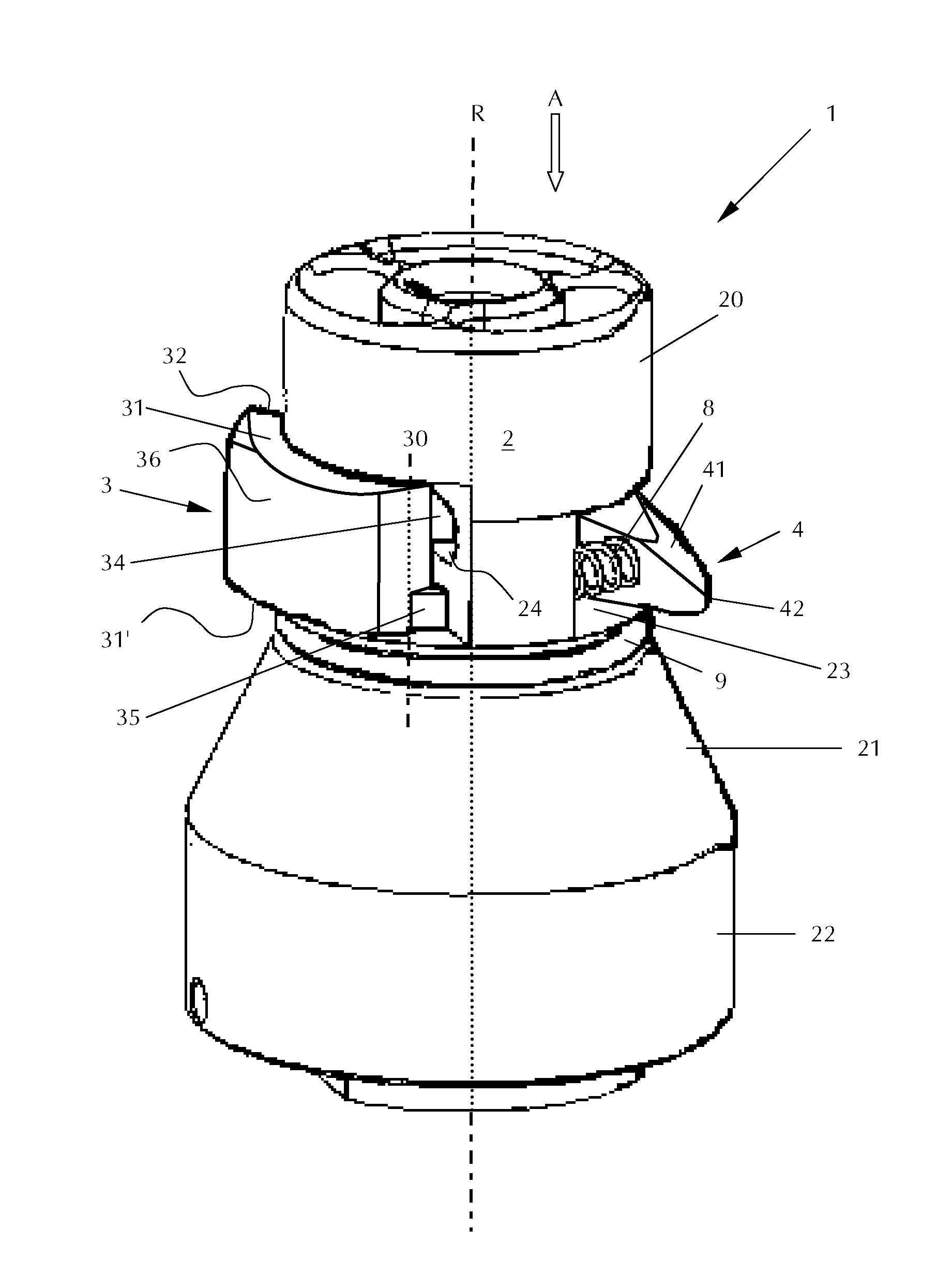

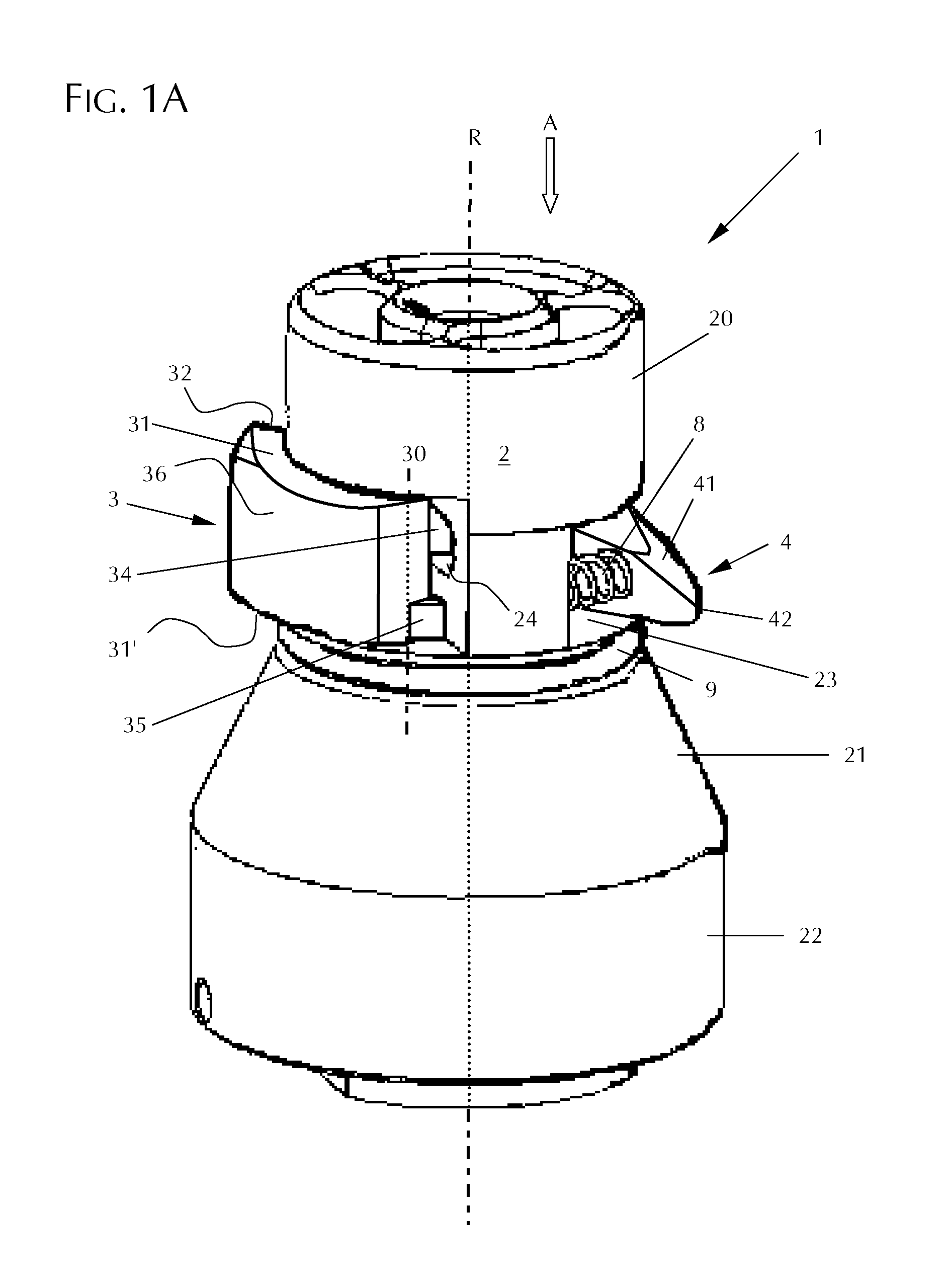

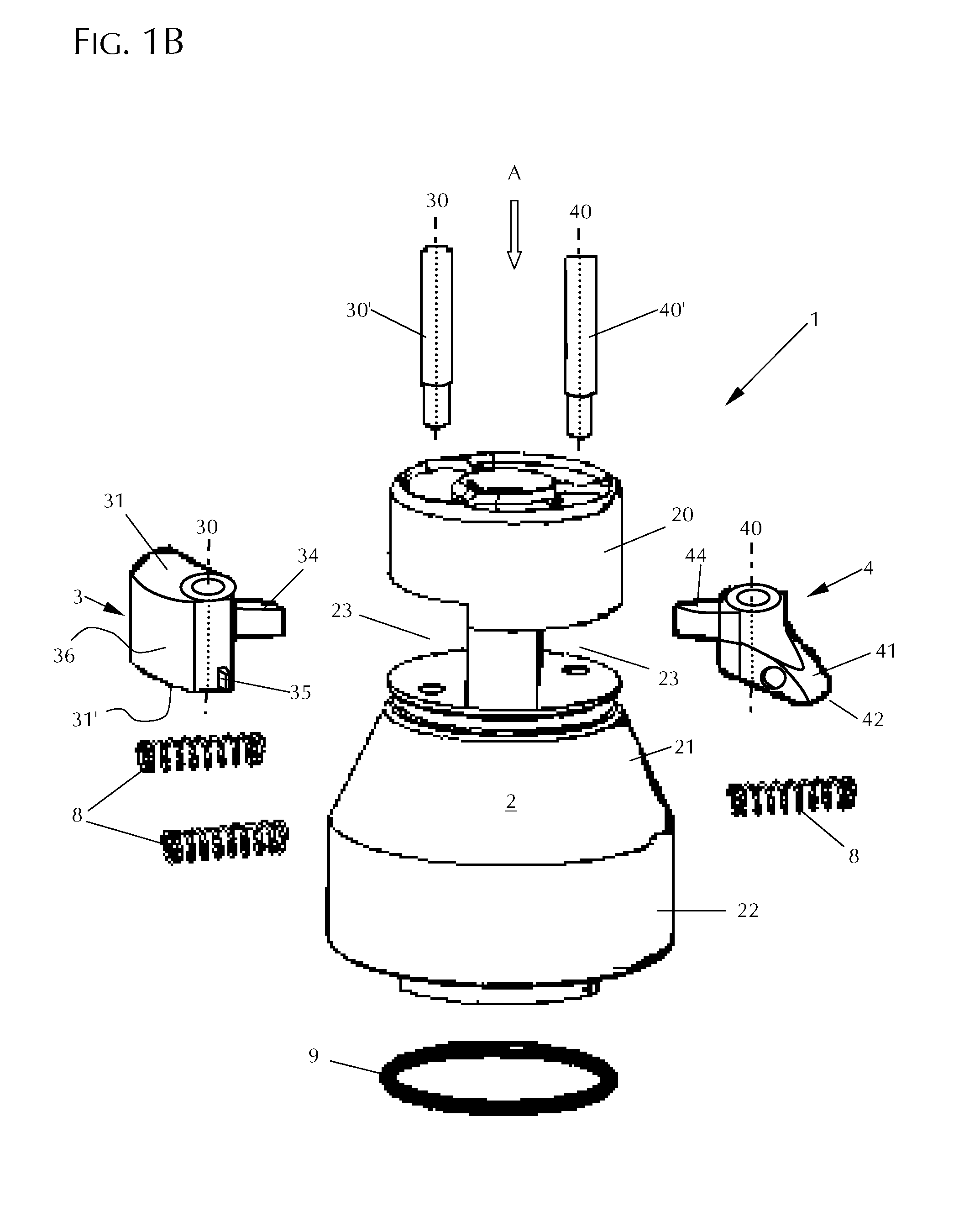

Centrifuge Drive Head For Releasably Connecting A Driving System To A Rotor Of A Centrifuge, A Set And A Centrifuge Comprising The Drive Head

ActiveUS20130331253A1High densityHigh strengthCentrifugesCouplings for rigid shaftsCentrifugeCoupling

Owner:QIAGEN

Wastegate valve position correction

InactiveUS20150082788A1Increase airflowHigh densityInternal combustion piston enginesEngine controllersWastegatePower flow

Various methods for compensating a deflected linkage in a wastegate arrangement are provided. In one example, current is applied to an actuator to move a wastegate valve coupled through a linkage to the actuator for diverting gasses from a turbocharger. The position of the actuator is indicated, and a correction to said indicated actuator position is applied compensating for deflection of the linkage based at least on said applied current. Said applied current is adjusted when said corrected actuator position reaches a position corresponding to a desired valve position.

Owner:FORD GLOBAL TECH LLC

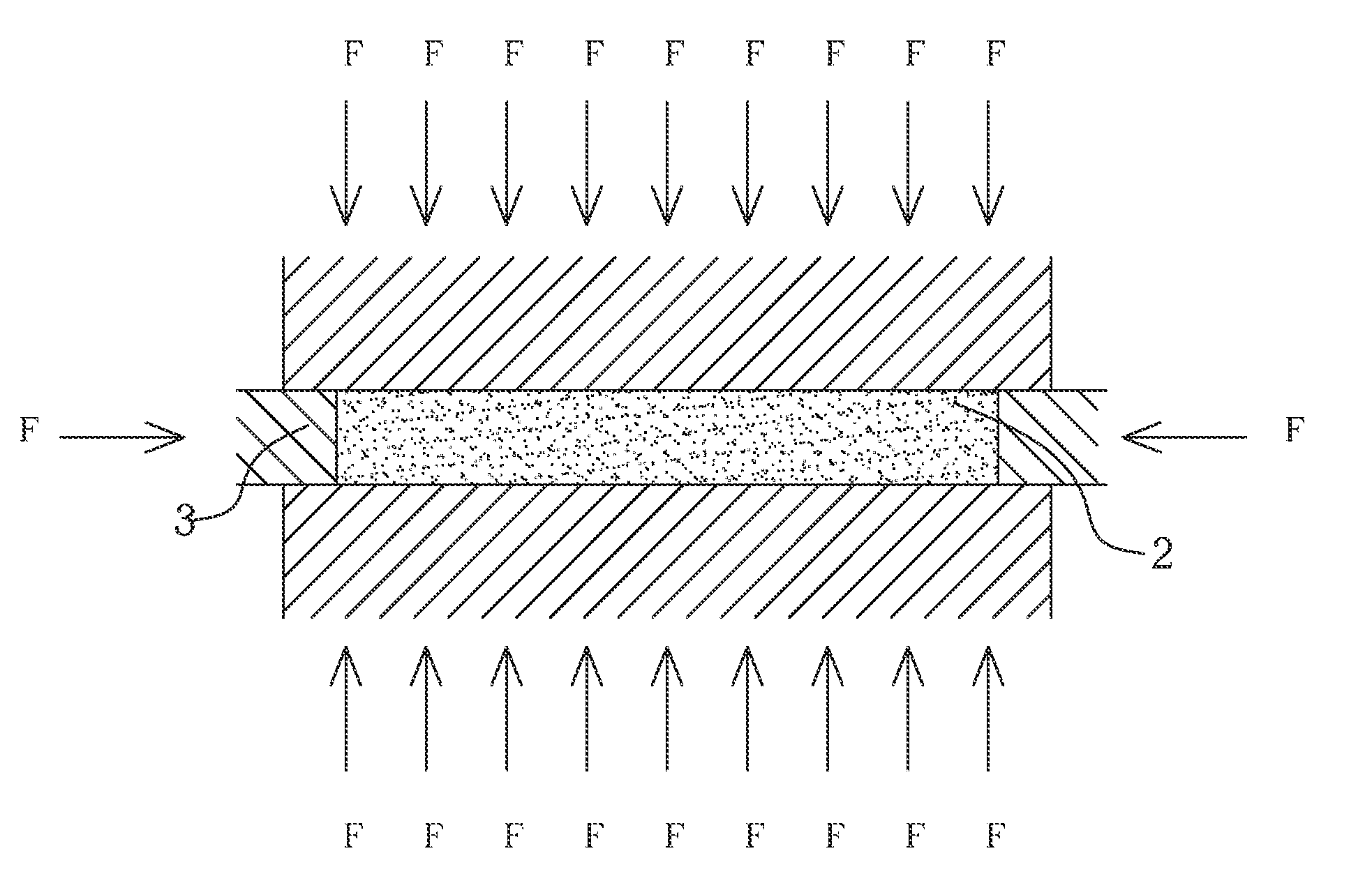

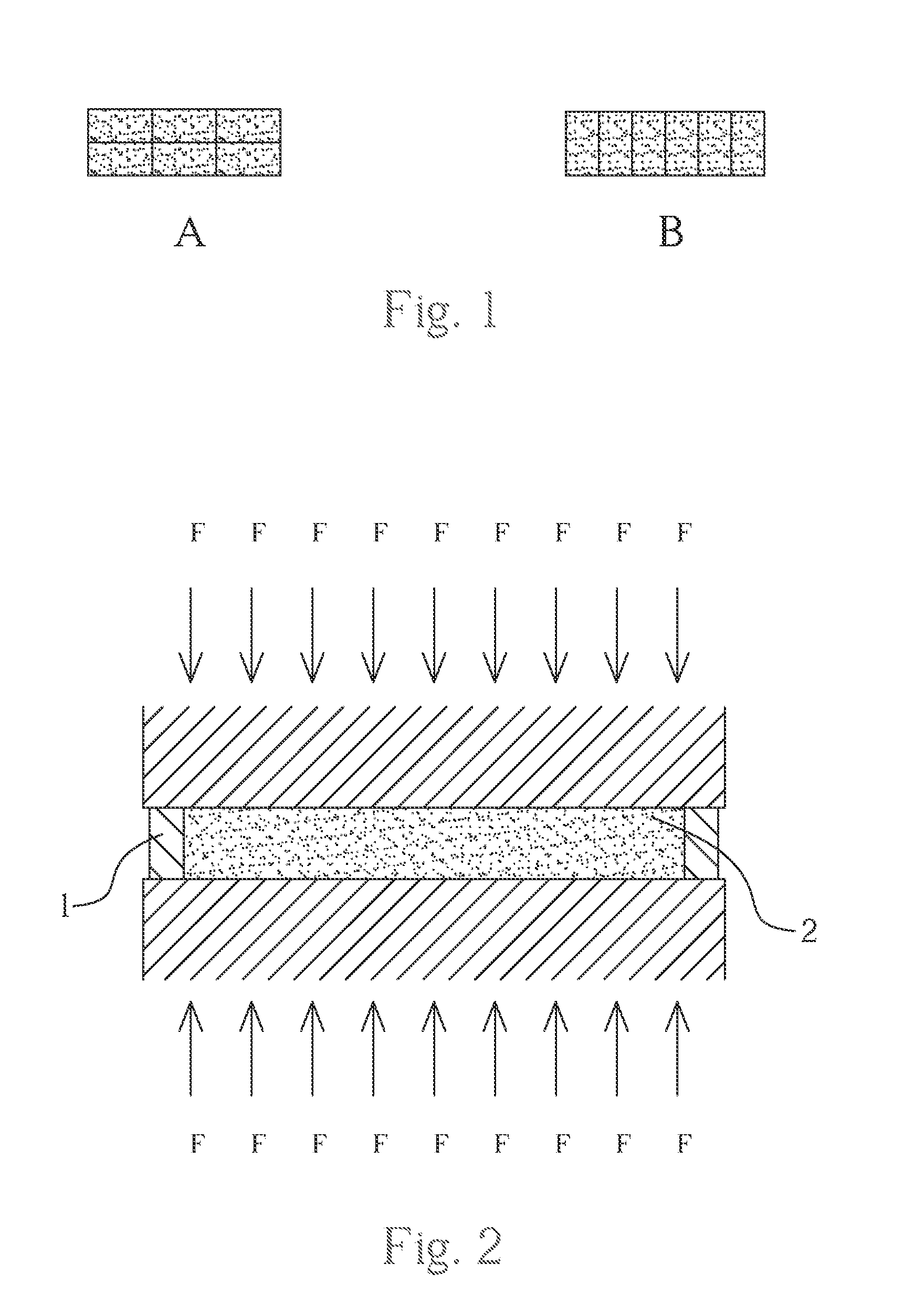

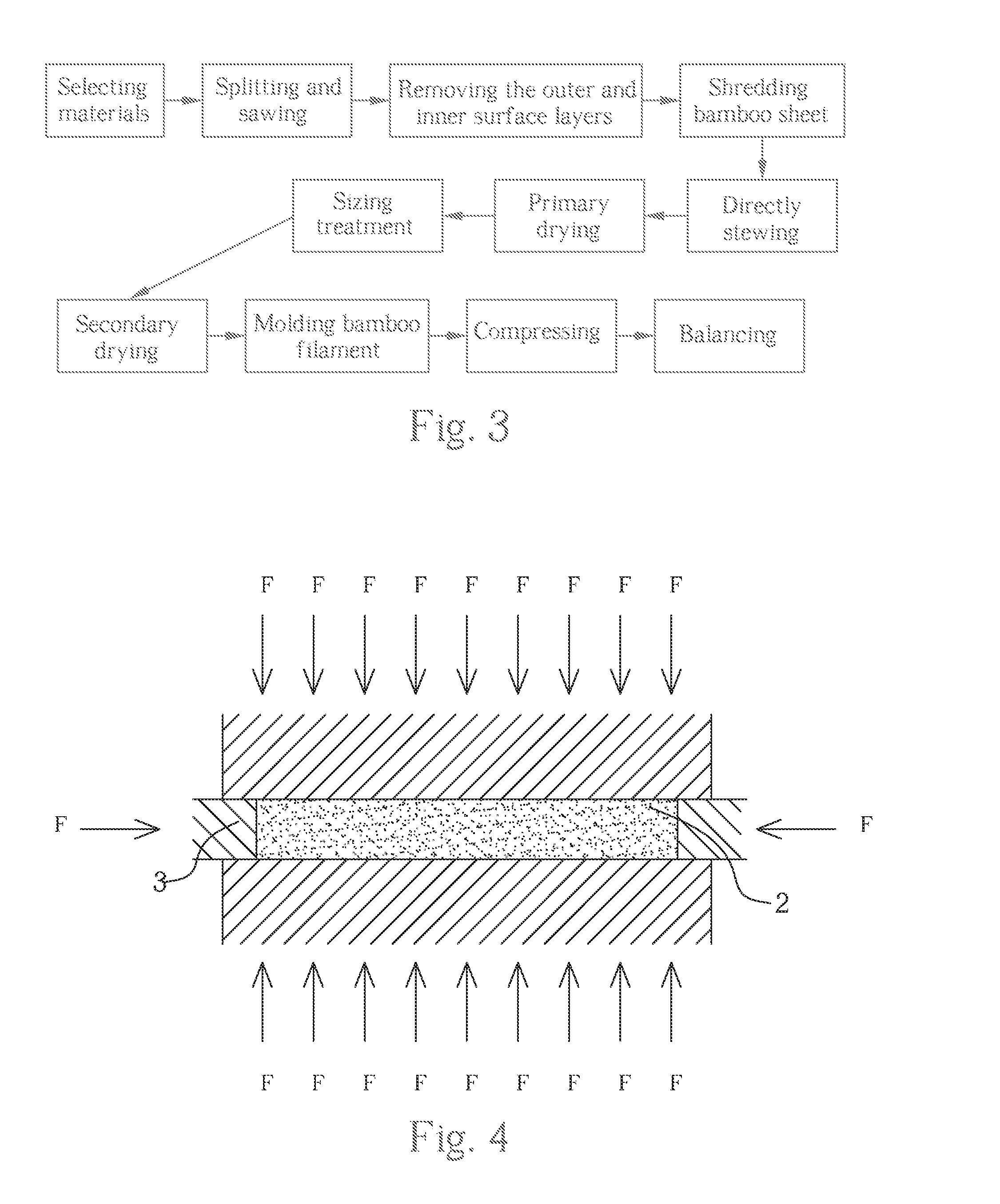

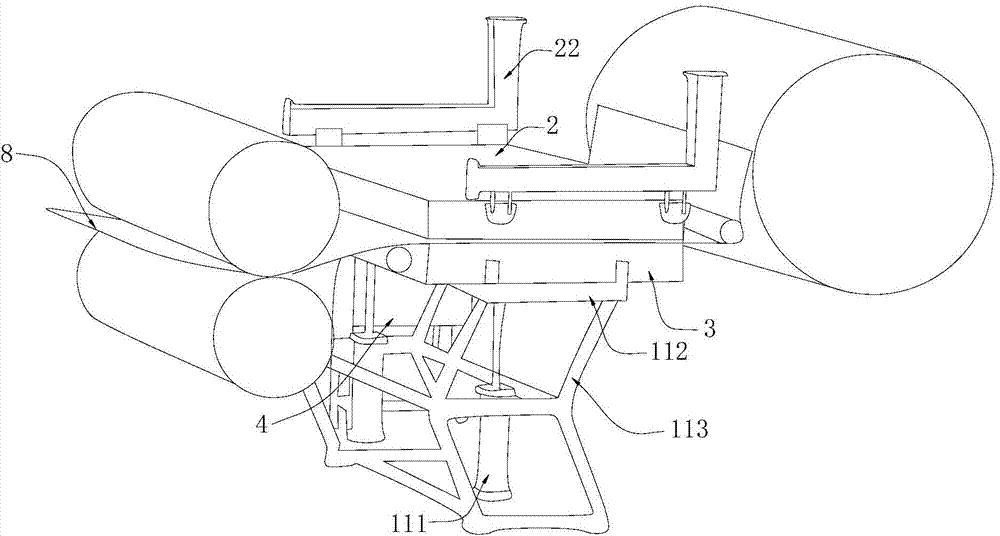

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

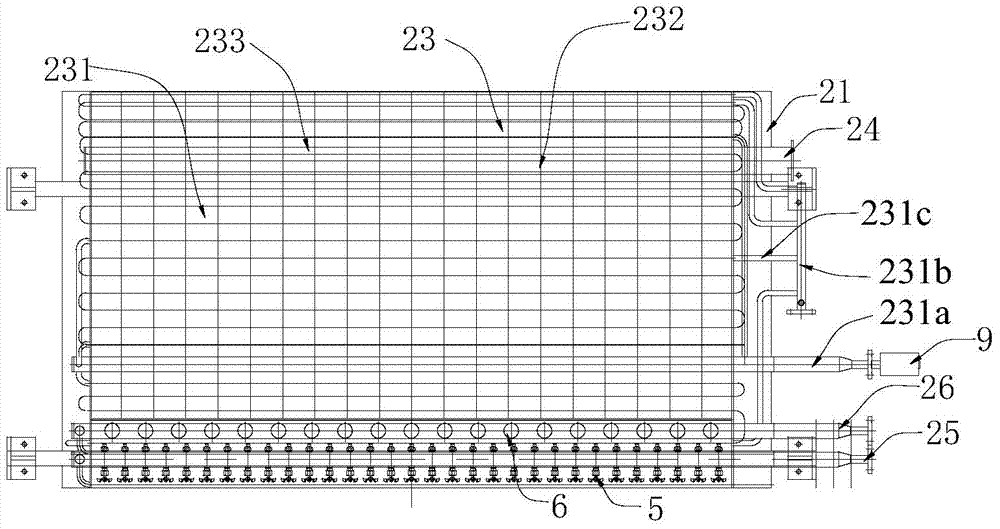

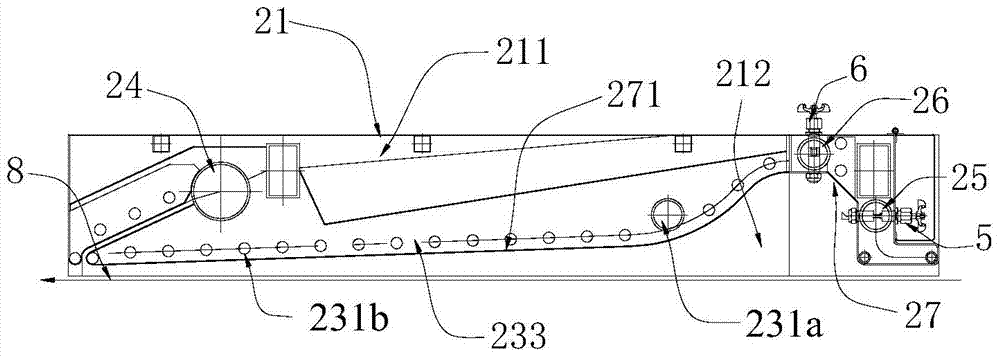

Paper humidifying device on paper making machine

The invention relates to the field of paper making devices, in particular to a paper humidifying device on a paper making machine. The paper humidifying device comprises an upper humidifying box. The upper humidifying box comprises a box body, a heat exchanger, a separation plate and a steam pipeline. The heat exchanger, the separation plate and the steam pipeline are arranged in the box body. The heat exchanger comprises a steam inlet and a steam outlet. The steam pipeline is communicated with the steam outlet in the heat exchanger, the box body is arranged on paper conveyed by a roll shaft, the separation plate divides the box body into an upper part and a lower part, an installation room is arranged in the upper part, and a humidifying room is arranged between the separation plate and the paper. The heat exchanger and the steam pipeline both are arranged in the installation room, the heat exchanger is connected with the separation plate through heat conduction, a steam valve is arranged on the steam pipeline, and a nozzle on the steam valve is located in the humidifying room. The surface density and the printing effect of paper processed by the paper humidifying device on the paper making machine are greatly improved, and smoothness is achieved, and warping is avoided.

Owner:浙江汉普新材料技术有限公司

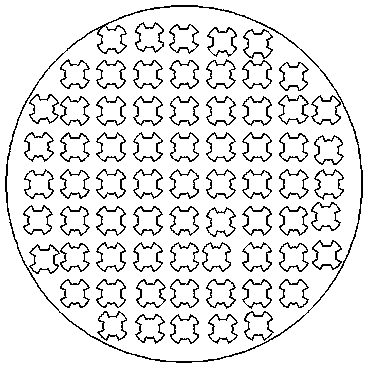

Diamond micro-channel Cu-based CVD diamond heat sink sheet and preparation method thereof

ActiveCN110557936AThermal limitationsHigh densityModifications by conduction heat transferHeat sinkNucleation

The invention discloses a diamond micro-channel Cu-based CVD diamond heat sink sheet and a preparation method thereof. The diamond micro-channel Cu-based CVD diamond heat sink sheet sequentially comprises a Cu substrate, a micro-through-hole template and a CVD diamond film from bottom to top, wherein the Cu substrate and the micro-through-hole template are provided with nano-diamond particles therebetween, the Cu substrate is embedded with a diamond micro-channel array, the diameter of each diamond micro-channel ranges from 0.3mm to 0.5mm, and the distance between every two micro-channels ranges from 2mm to 3mm. The heat dissipation effect of the heat sink sheet is superior to that of traditional heat sink sheets such as Ag, Cu and Al; the heat dissipation performance of the micro-channelCu-based diamond heat sink sheet is better; the nucleation density and the growth rate of diamond in the micro-through-hole are greatly improved; and the CVD selective growth of the diamond film is realized in the micro-through holes.

Owner:SHAANXI UNIV OF SCI & TECH

Magnetic recording medium and magnetic recording and reproducing device using the magnetic recording medium

ActiveUS20090296276A1Excellent productivityHigh densityMagnetic recordingRecord information storageAlloyHigh density

Owner:SHOWA DENKO KK

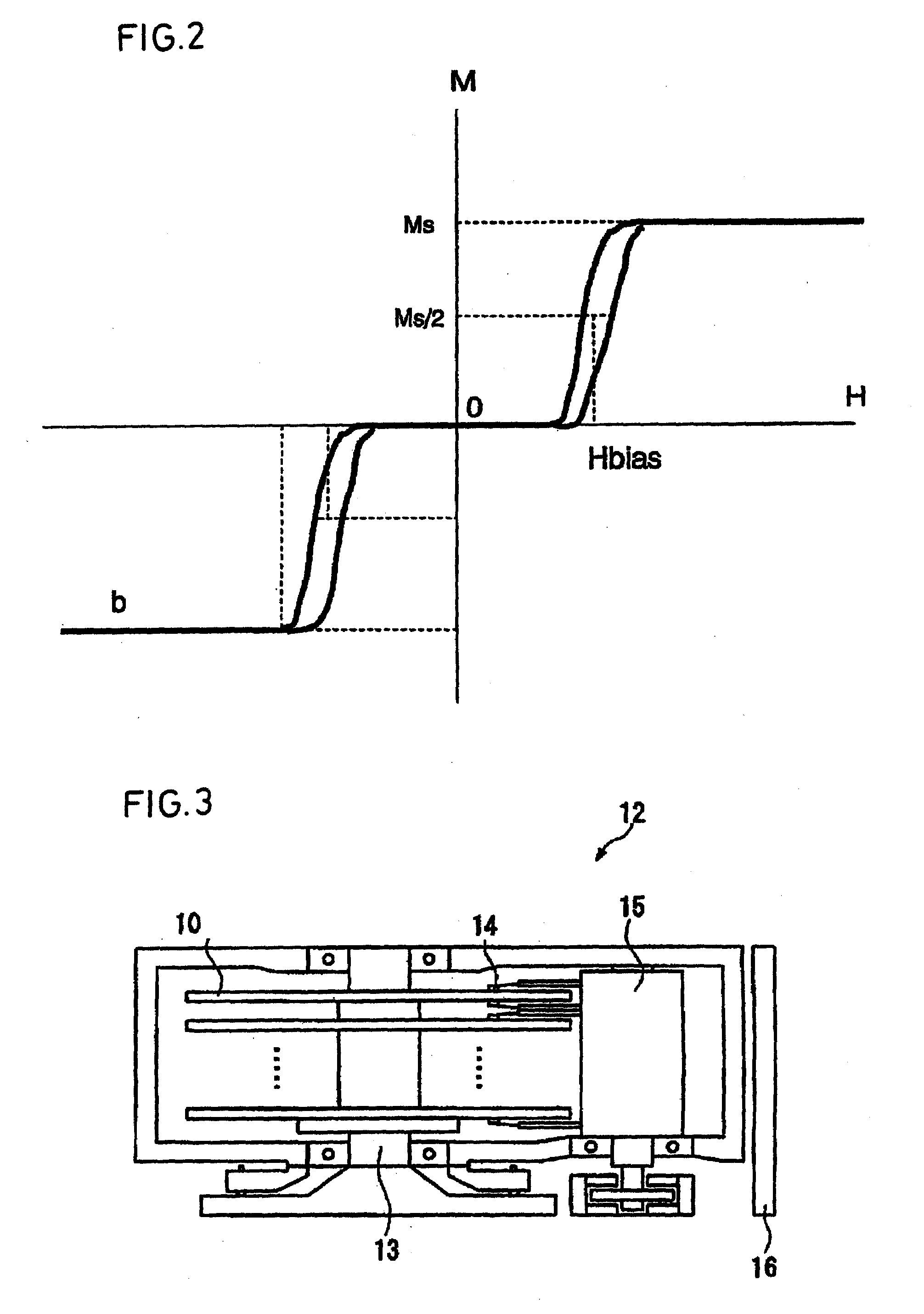

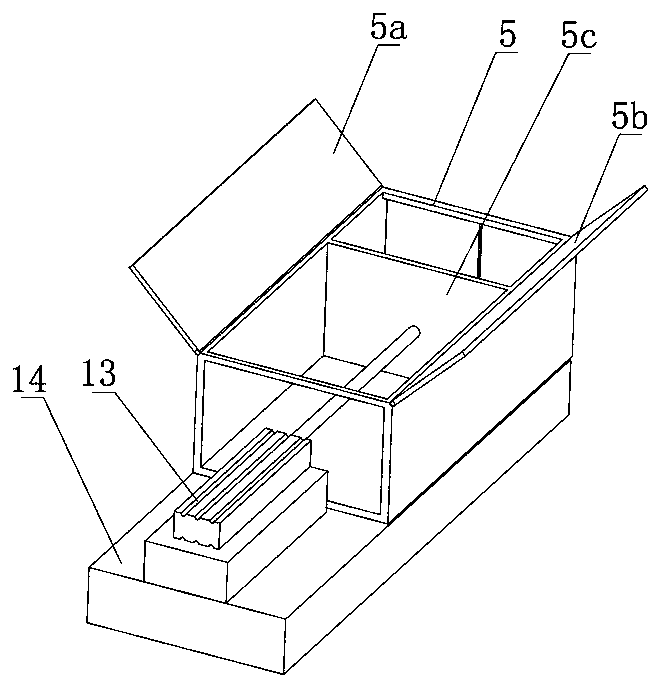

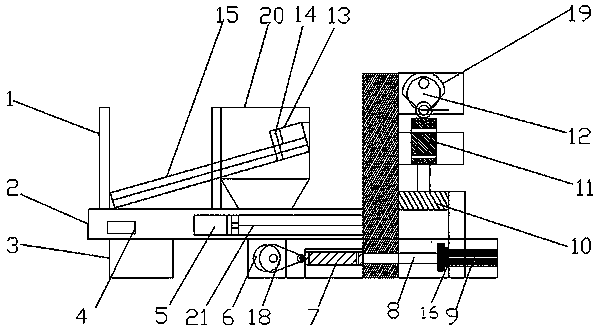

Horizontal cut tobacco boxing system and boxing method

ActiveCN108910131AHigh densityImprove work efficiencyPackagingTransfer mechanismAgricultural engineering

Owner:CHINA TOBACCO HENAN IND

Regeneration production method of scrap rubber

Owner:NANTONG HUILI RUBBER

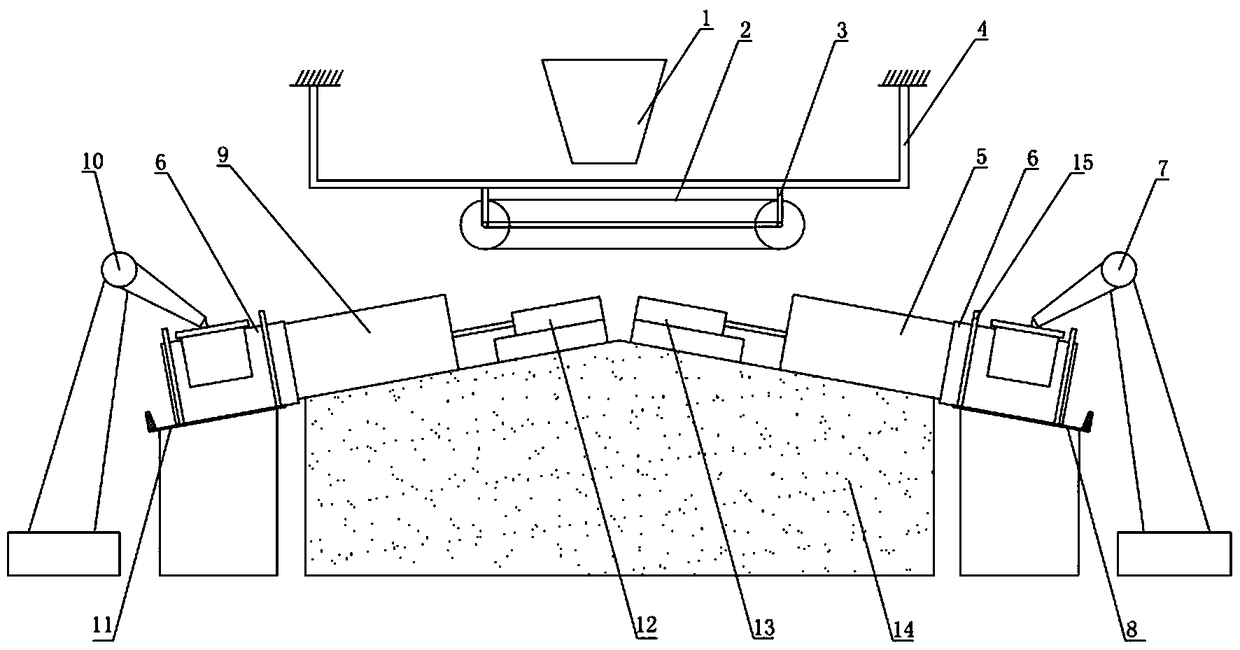

Biomass fuel solidification molding preparation machine

InactiveCN108773102AEasy to collect packagingHigh densityShaping pressBiomass feedstockBiomass fuels

Owner:泰州市明德科技服务有限公司

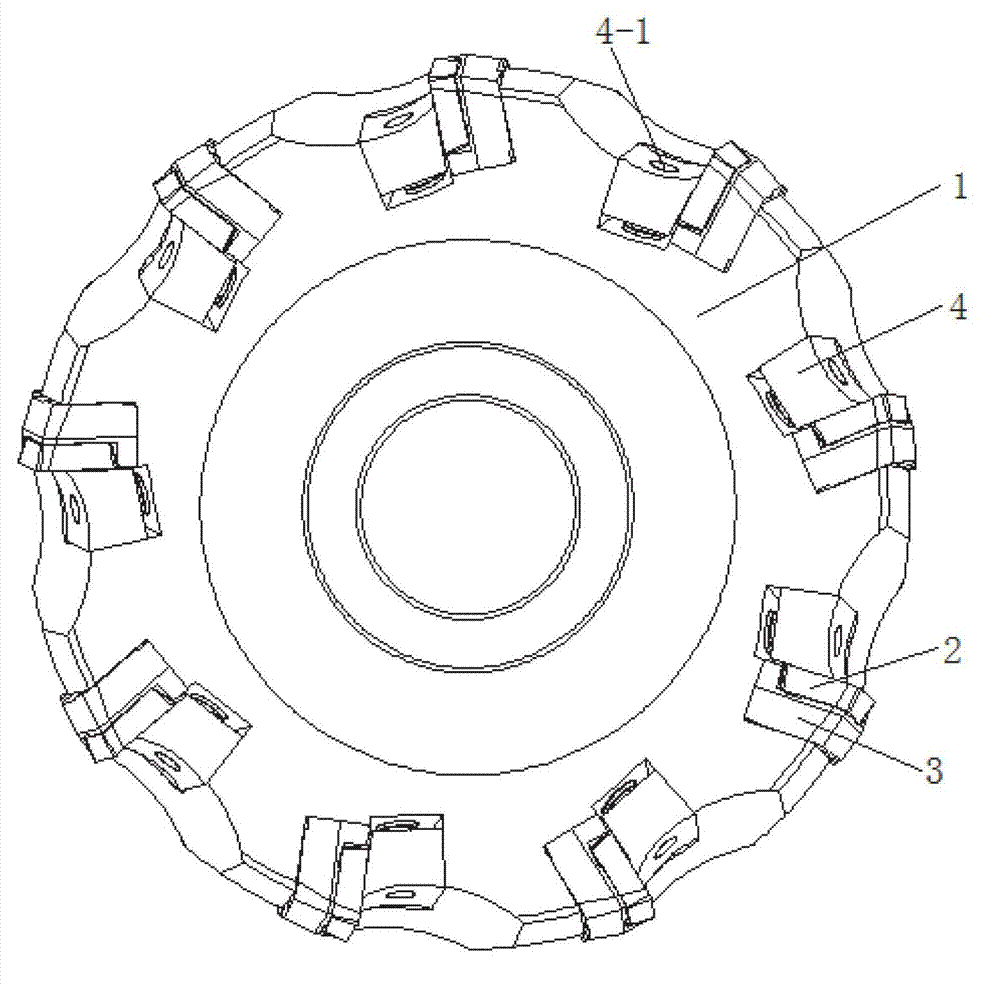

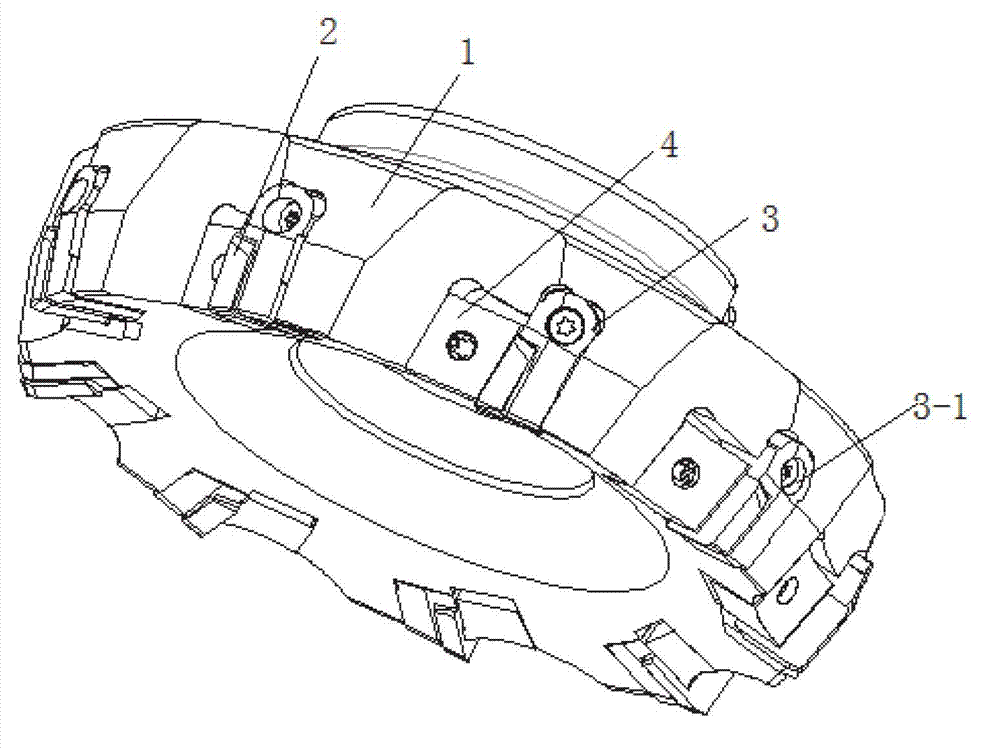

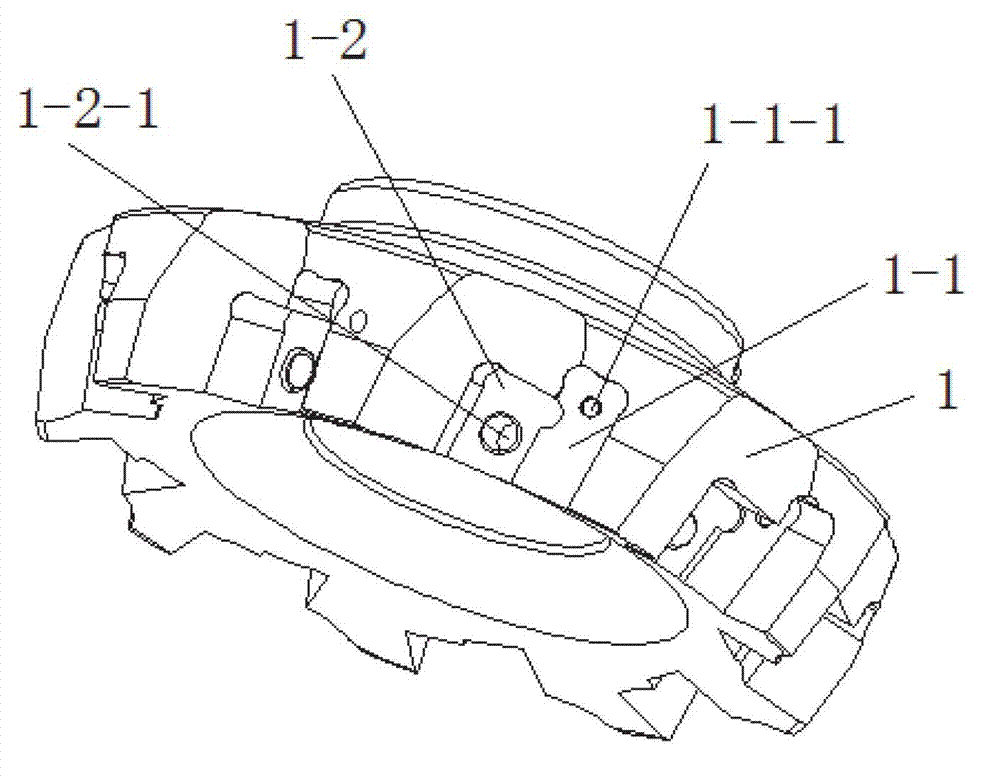

Face milling cutter with indexable inserts and knife pads thereof

The invention discloses a face milling cutter with indexable inserts and knife pads thereof. Each knife pad is provided with a knife pad screw hole and a step groove. The step groove comprises a blade bottom contact face, a blade axial locating face and a blade radial locating face which are connected with each other. A notch with three sides opening is formed in each knife pad. Due to the design of the unique knife pads, blades are not in direct contact with a cutter body, the rigidity of the cutter body is greatly strengthened, the abrasion of the cutter body is reduced, the service life of the cutter is prolonged on the whole, and meanwhile the blades are enabled to be located without the need of being in contact with the cutter body, and the accuracy of repeated locating is high. The service life of the cutter is longer than face milling cutters of other types by more than 50%, the accuracy of processing workpieces is improved by more than one accuracy level, the replacement of the blades is convenient, and the processing cost is reduced greatly.

Owner:常州瑞诺切数控刀具有限公司

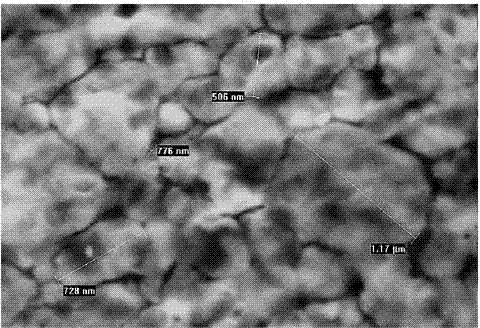

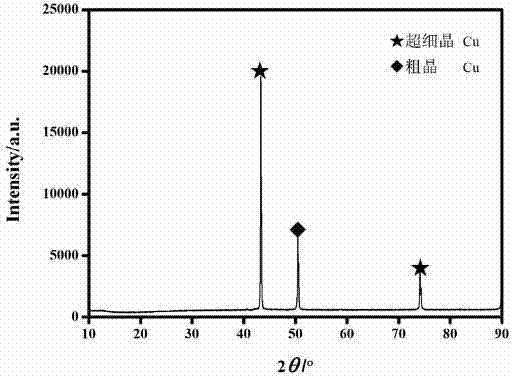

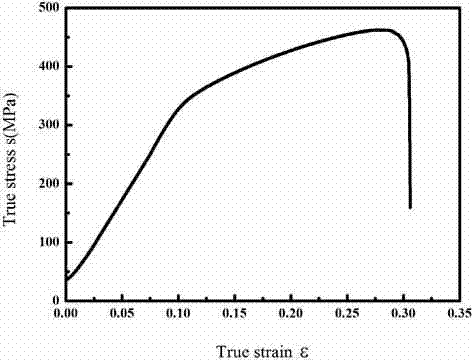

Super-fine grain twin-peak copper preparing method

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

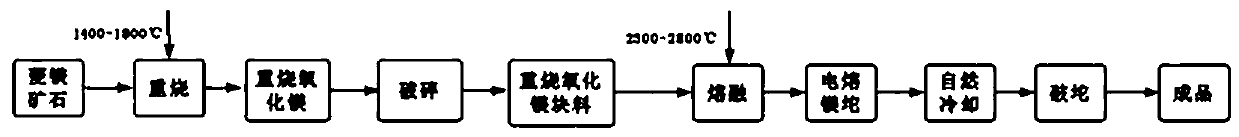

Method for preparing high-density fused magnesite by reburning electric smelting composite process

Owner:HAICHENG CITY ZHONGHAO MAGNESIUM CO LTD

Nano multi-layer composite solid lubricating film layer with long service life under space irradiation and preparation thereof

ActiveCN112760607AAchieve self-lubricationReduce coefficient of frictionVacuum evaporation coatingSputtering coatingSputteringAlloy substrate

The invention discloses a nano multi-layer composite solid lubricating film layer with a long service life under space irradiation and preparation thereof. The nano multi-layer composite solid lubricating film layer composed of a Ti binding layer, a TiN bearing layer and an AgTiNi / MoS2Ti nano multi-layer lubricating functional layer is deposited on a titanium alloy substrate, an aluminum alloy substrate, a stainless steel substrate, a bearing steel substrate and the like by adopting a closed magnetic field unbalanced magnetron sputtering technology. The nano multi-layer composite film layer can reliably serve for a long time in strong space irradiation environments such as low-orbit high atomic oxygen density, medium-high-orbit high electron proton density and high ultraviolet irradiation dose, and is high in bearing capacity and low in friction coefficient, thus, the service life of a moving part of a spacecraft exposed in the space irradiation environments can be greatly prolonged, and the reliability of the moving part is improved. In addition, the preparation method has the characteristics that the process is environment-friendly and flexible, the film thickness is uniform, the compactness is good, the preparation process of the film layer is controlled in a programmed manner, the modulation period of the film layer is easy to regulate and control, and batch treatment can be realized, industrial production is easy to realize, and the good application prospect is achieved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Method and Apparatus for Application of Mortar

ActiveUS20120199668A1Durability and performance increaseHigh densityCorrosion preventionLiquid spraying apparatusDry powderHead position

Owner:PURIS

Method for manufacturing cross winding bobbin

To produce a cross wound bobbin (11), at the workstation (2) of a bobbin winder (1), the yarn (30) is wound at the start of a winding cycle at a crossing angle to increase the density of the bobbin core. The crossing angle is increased significantly during the winding cycle, so that the density of the wound bobbin is reduced progressively outwards. The increased crossing angle acts against the yarn laying width, and the stroke movement of the reciprocating yarn guide (29) has a defined increase.

Owner:SAURER GERMANY GMBH & CO KG

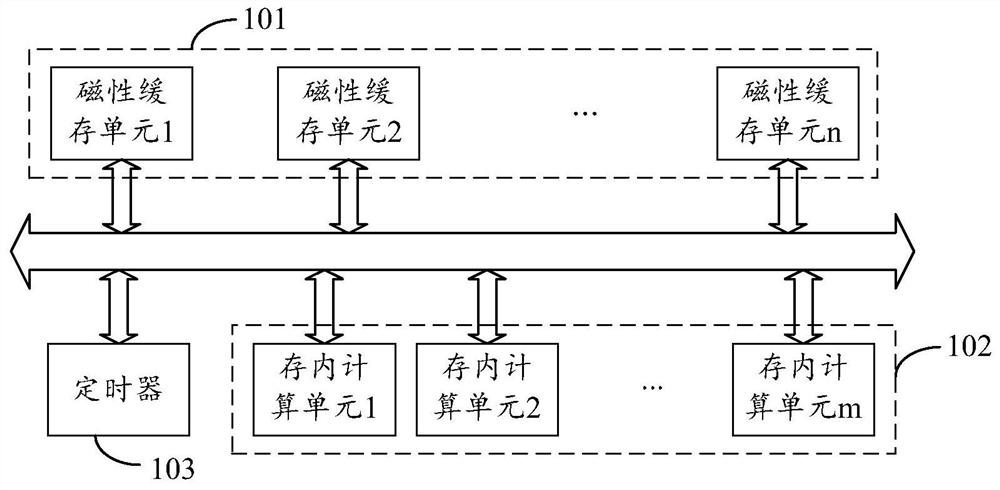

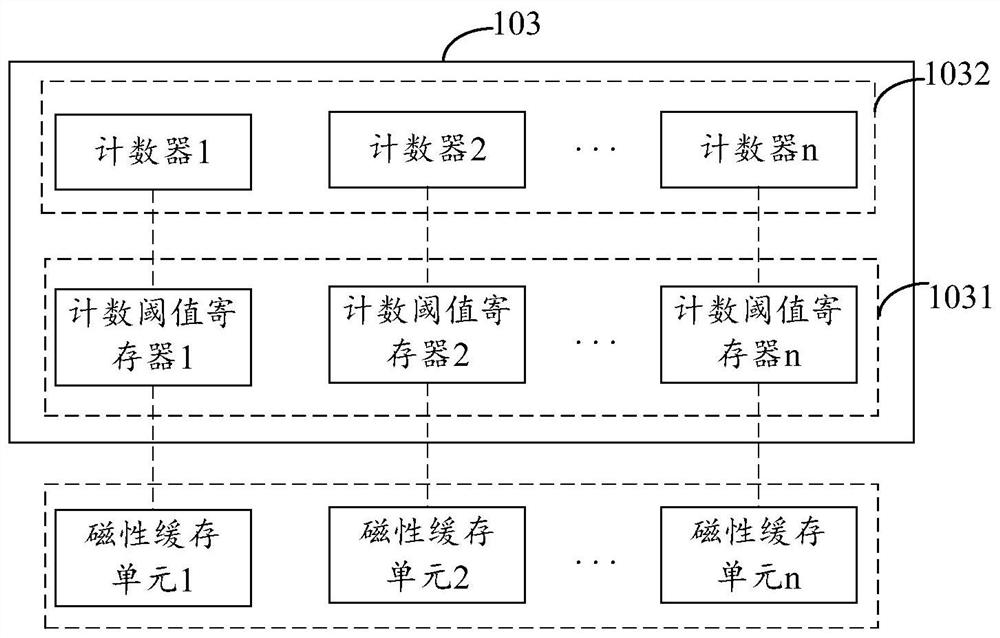

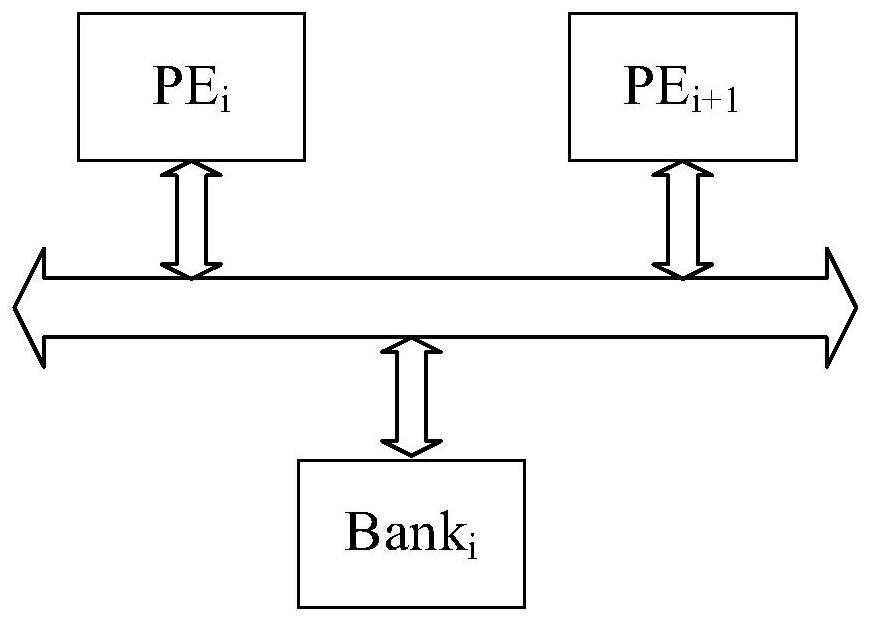

In-memory computing circuit chip based on magnetic cache and computing device

PendingCN113539318AIncrease capacityLarge capacityDigital storageNeural architecturesData needsEngineering

The embodiment of the invention discloses an in-memory computing circuit based on a magnetic cache, and the circuit comprises at least one magnetic cache unit, at least one in-memory computing unit, and a timer. The magnetic cache unit in the at least one magnetic cache unit is used for caching data output by the corresponding in-memory computing unit as to-be-processed data within the corresponding data retention time; the timer is used for respectively setting data retention time for the at least one magnetic cache unit; and the in-memory computing unit in the at least one in-memory computing unit is used for extracting the data to be processed from the corresponding magnetic cache unit for calculation and outputting the computed data to other magnetic cache units. According to the embodiment of the invention, the invention achieves the flexible adjustment of the data retention time of the magnetic cache unit in various in-memory calculation scenes, and achieves the provision of a high-capacity cache for the data needed by in-memory computing under the lower power consumption.

Owner:NANJING HOUMO TECH CO LTD

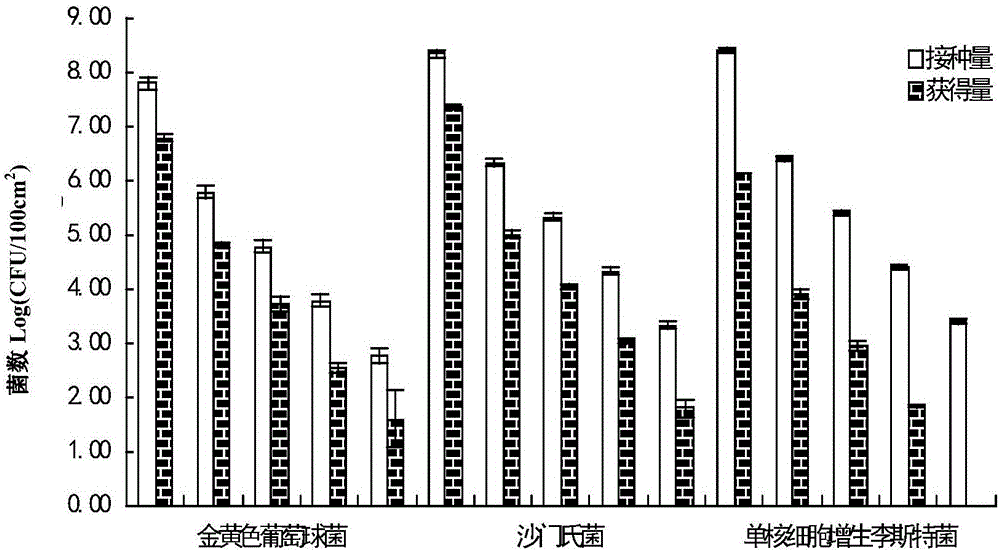

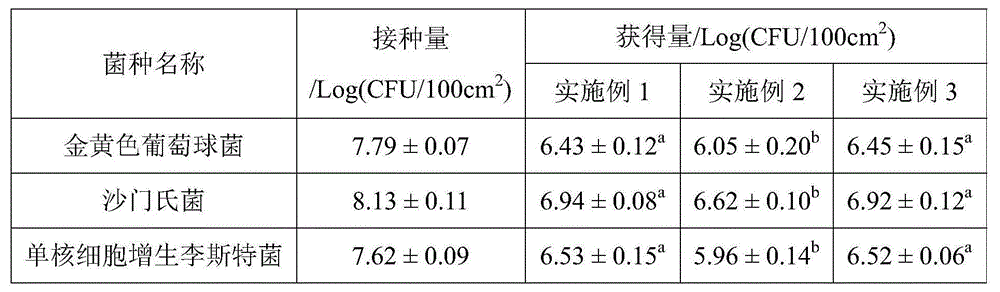

Methods for sampling and detecting microorganisms on contact surface

InactiveCN105087753ASimple and fast operationImprove sampling effectMicrobiological testing/measurementWettingFilter paper

The invention discloses methods for sampling and detecting microorganisms on a contact surface and belongs to the technical field of microbiological detection. The sampling method comprises the following steps: 1), sterile filter paper is placed in a sterile wetting liquid containing peptone, a surfactant and sodium chloride for wetting; 2), a to-be-detected surface is covered with the wetted filter paper, and the filter paper is retained for sampling. The detection method further comprises the following steps: the filter paper after sampling is arranged in a phosphate buffer, uniform mixing, sampling and counting are performed, and the quantity of microorganisms on unit detected surface is obtained through calculation. The sampling method is simple to operate and high in sampling efficiency, causes little mechanical damage to the microorganisms on the contact surface, is particularly suitable for batch sampling of the microorganisms on table board type contact surfaces and can improve the sampling efficiency substantially. Meanwhile, the detection precision and accuracy of the detection method are high, and the detection efficiency can be improved substantially.

Owner:HENAN AGRICULTURAL UNIVERSITY

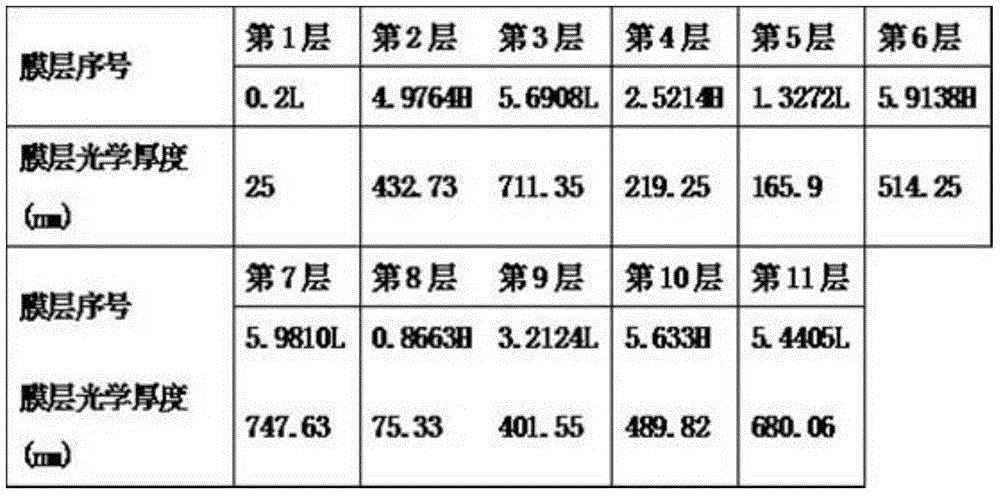

Preparation method of antireflection film allowing wide-angle incidence of infrared optical waveband in silicon or germanium base

InactiveCN104561907AHigh densityHigh film firmness and high densityIon implantation coatingSputtering coatingCoatingEvaporation

Owner:SOUTH WEST INST OF TECHN PHYSICS

Method for preparing laser thermal composite induction nanoparticle reinforcement laminated film

InactiveCN103103523AEliminate heat damageHigh densityMetallic material coating processesAutomationHigh pressure

Owner:JIANGSU UNIV

Transistor and formation method thereof

ActiveCN104299994AFlat and uniform thicknessHigh densitySemiconductor/solid-state device manufacturingTransistorDielectric layerGate dielectric

Owner:SEMICON MFG INT (SHANGHAI) CORP

New cleaning method, apparatus and use

ActiveUS20170267949A1High densityDetergent materialsDetergent mixture composition preparationChemistryCleaning methods

Owner:XEROS LTD

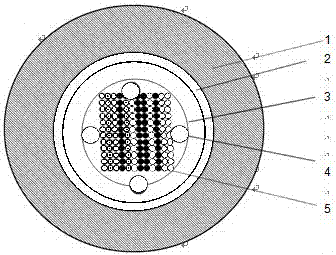

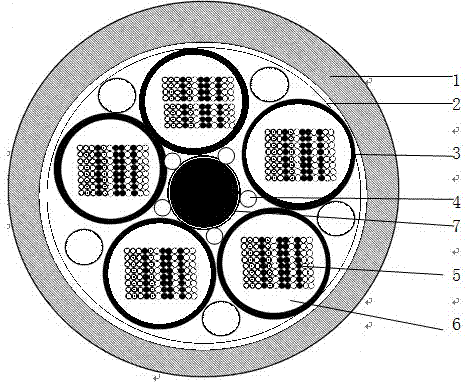

Anti-ant large-core-number fiber ribbon cable

InactiveCN107479158AAvoid infringementGuarantee statusFibre mechanical structuresEngineeringFiber density

The invention relates to an anti-ant large-core-number fiber ribbon cable comprising a cable core and an outer sheath. The cable core includes loose tubes; and fiber ribbons are sleeved inside the loose tubes. The outer sheath is an outer nylon sheath; and a non-metallic reinforcement layer is arranged between the outer sheath and the cable core. According to the anti-ant large-core-number fiber ribbon cable provided by the invention, with the outer nylon sheath, ants can not bite the sheath, so that the damages on the optical cable by ant biting in a pipe at an area with a serious anti problem are prevented, the normal state of the cable is ensured, and the application region of the cable is extended. The cable based on a simple and reasonable structure has advantages of small cable diameter, high fiber density, large fiber capacity, and low duty ratio and can be laid in a pipe conveniently; and the bending performance is good. During branched connection, 4 to 24 fibers can be melted once, so that the construction time is saved and the manpower cost is lowered, and the construction efficiency is improved. On the basis of the full drying type dielectric structure, branched connection is realized conveniently and usage becomes convenient.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Nuclear power plant containment concrete

ActiveCN108059405AIncreased durabilityReduce porosityNuclear energy generationContainmentFiberCrack resistance

The invention relates to nuclear power plant containment concrete. The concrete consists of the following components in parts by mass: 130-200 parts of cement with strength of 52.5 or 42.5, 60-120 parts of slag, 50-100 parts of metakaolin, 50-150 parts of boron glass sand, 600-800 parts of nickel slag, 600-800 parts of barite, 200-400 parts of limonite, 100-300 parts of ceramsite, 20-50 parts of lead fibers, 130-160 parts of water, 4-6 parts of a water reducing agent and 4-6 parts of an early strength agent. After 28 days of curing of the concrete, the inner surface of the concrete is coated with a layer of anti-radiation coating. The nuclear power plant containment concrete provided by the invention has a good anti-radiation property, can well shield alpha, beta and gamma rays and neutronrays, and has good crack resistance, high-temperature resistance and durability, and simultaneously solid wastes such as nickel slag, glass powder and the like are utilized, so that the problems of resource waste and environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

Dynamic filter

InactiveCN1772334AImprove filtering effectHigh densityDispersed particle separationEngineeringFan blade

The dynamic filter has combined dynamic plate structure to filter out light matter under rotating force, and is used mainly for filtering out harmful matter in fume, dusty air, air, etc. The dynamic filter consists of large belt wheel, small belt wheel, driving belt, positioning bearing, motor, casing, blowdown port, detergent liquid inlet, blowdown channel, driving plate, detergent liquid nozzle, filtered matter inlet, filtered matter outlet, fan blade, baffle, dry filtering layer, main shaft and blowdown blade combined together.

Owner:黎凡

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap