Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Improve product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lithium iron phosphate/carbon composite material of lithium ion battery

InactiveCN102013477AImprove performanceImprove conductivityCell electrodesSecondary cellsLithium electrodeCarbon composites

The invention relates to a method for preparing a lithium iron phosphate / carbon composite material of a lithium ion battery, which belongs to the technical field of lithium ion batteries. The method for preparing the lithium iron phosphate / carbon composite material of the lithium ion battery comprises the following steps of: 1) preparing a suspending graphene-dispersed aqueous solution system, namely, crushing graphite to 1 to 5 microns, adding the crushed graphite into distilled water or purified water, adding 0.1 to 5 percent of surfactant, heating with stirring the mixed solution to 180 to 250 DEG C in a sealing way, performing stirring for 2 to 6 hours and reducing the temperature; 2) crushing lithium iron phosphate to the particle size of 1 to 5 microns, adding the crushed lithium iron phosphate into the distilled water or the purified water, adding with stirring 0.01 to 1 percent of coupling agent, performing uniform stirring, adding the graphene-dispersed aqueous solution, and performing stirring and filtration; and 3) vacuum-drying solid powder obtained by the filtration, and calcinating the dried solid powder for 2 to 12 hours to obtain the graphene-coated lithium iron phosphate cathode material. The method has the advantages of simple process, high material performance, high conductivity, high bulk density, high compacted density and the like.

Owner:HEBEI LITAO BATTERY MATERIAL

Mold/non-mode combined pulling process and device

InactiveCN102133582AImproving the process conditions of drawing formingReduce consumptionDrawing profiling toolsEngineeringMechanical engineering

The invention belongs to the technical field of metal plastic processing, and particularly provides a mold / non-mold combined pulling process and a device. The device is characterized in that a pulling mold is directly installed between a heater and a cooling machine of a non-mold pulling device, the waste heat of non-mold pulling is utilized fully, so that the mold puling and sizing with temperature can be completed before the non-mold pulling is molded, and the surface quality is improved. In the invention, the pulling force is reduced greatly, the intermediate heat treatment or heating process of the traditional process is saved, the mold consumption is reduced, the energy resource is saved, the production cost is lowered, a high-quality metal product can be pulled and molded in short flow range, and the advantages that the deformation amount of the non-mold pulling is large, the precise of the mold pulling size is high and the like can be realized.

Owner:UNIV OF SCI & TECH BEIJING

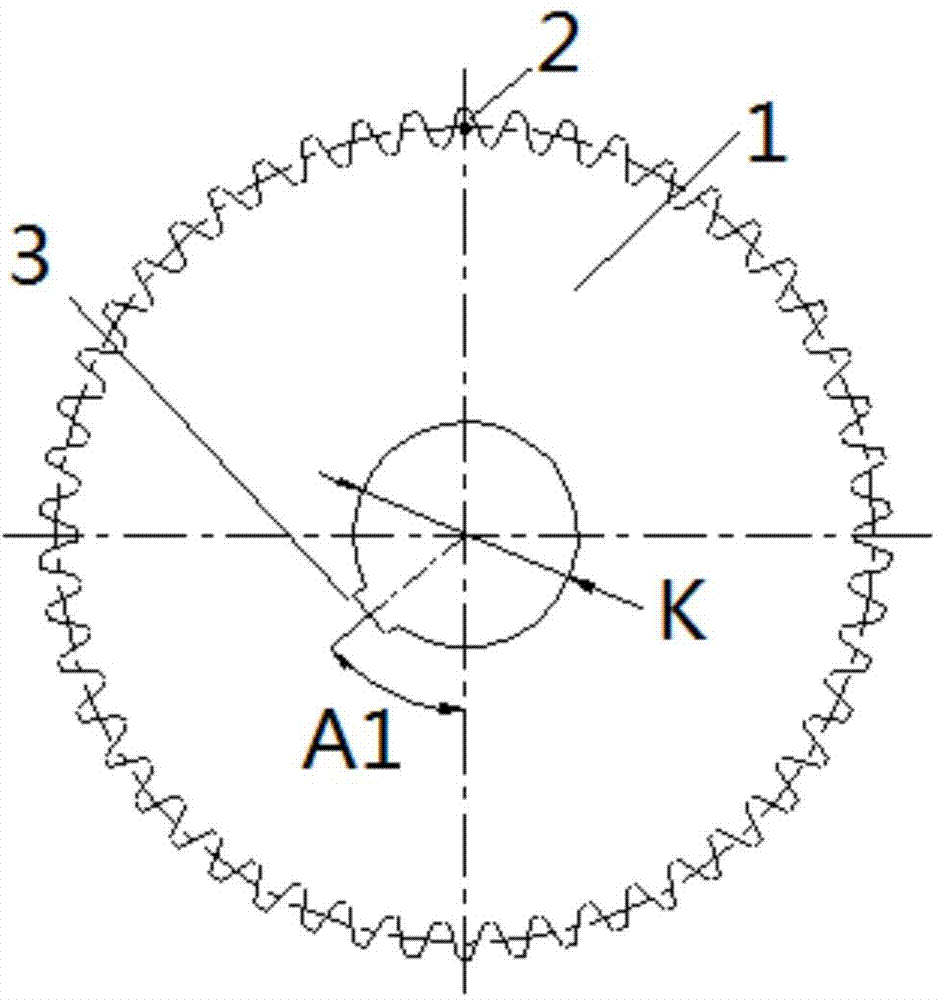

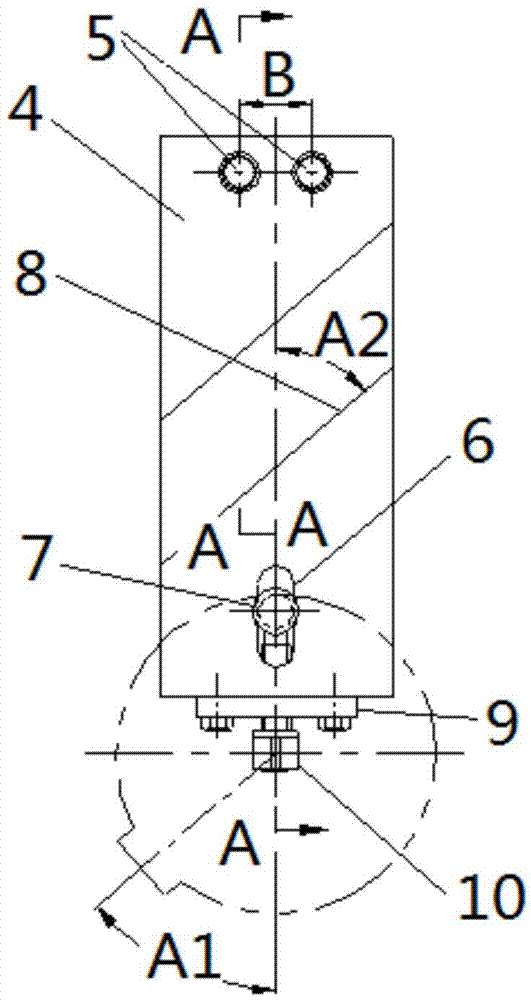

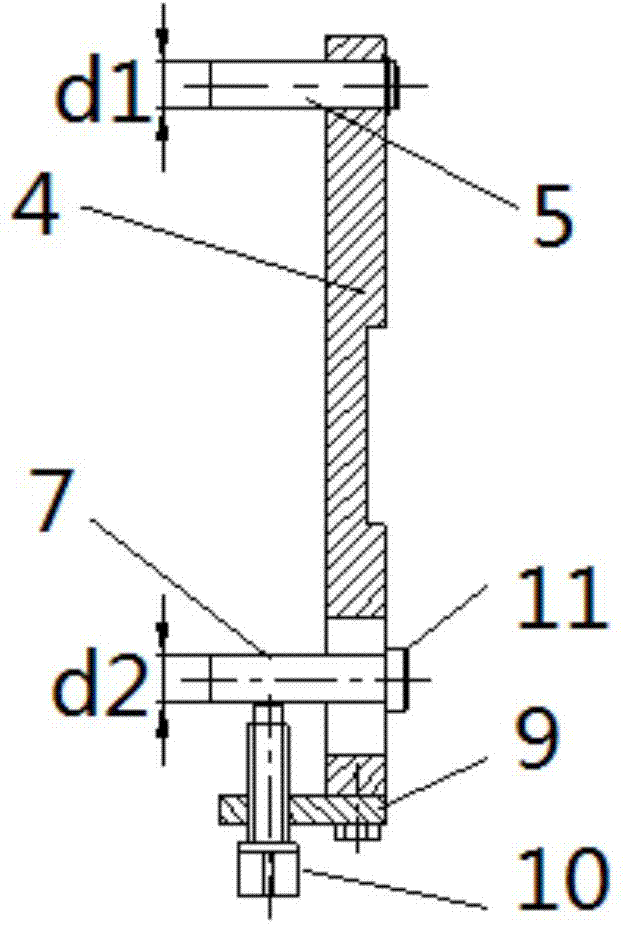

Alignment device and method for machining strict phase-position key groove of gear inner hole

ActiveCN103894861ASimple methodEasy to operatePositioning apparatusMetal-working holdersEngineeringPerpendicular direction

The invention discloses an alignment device for machining a strict phase-position key groove of a gear inner hole. The alignment device is characterized in that two symmetrical installation holes are formed in the inner edge of the outer end of a locating plate along the center line, and a fixed pin is installed in each installation hole; long grooves are machined in the inner edge of the inner end of the locating plate along the center line, movable pins are movably arranged in the long grooves, and the moveable pin ends of the movable pins are hooked on the upper edges of the long grooves; a baffle in the perpendicular direction is fixedly installed on the inner end face of the locating plate, the baffle and the locating plate are buckled through a bolt, an abutting screw is installed in a screw hole formed in the position, corresponding to the center line of the locating plate, of the baffle, and the abutting screw is in contact with the movable pins in an abutting-against mode; an alignment face is machined on the locating plate. The invention further discloses an alignment method for machining the strict phase-position key groove of the gear inner hole. The alignment device and method are simple in structure, easy to operate and high in accuracy.

Owner:MCC SFRE HEAVY IND EQUIP

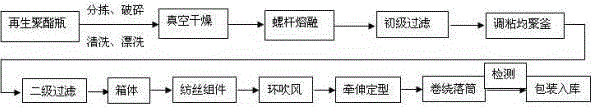

Method for producing fine denier and micro-fine denier flat regenerated polyester filaments by means of regenerated polyester bottle pieces

ActiveCN105177743AGood product qualityImprove product qualityArtificial thread manufacturing machinesMelt spinning methodsBottleChemistry

Owner:ZHEJIANG HAILI ENVIRONMENTAL TECH CO LTD

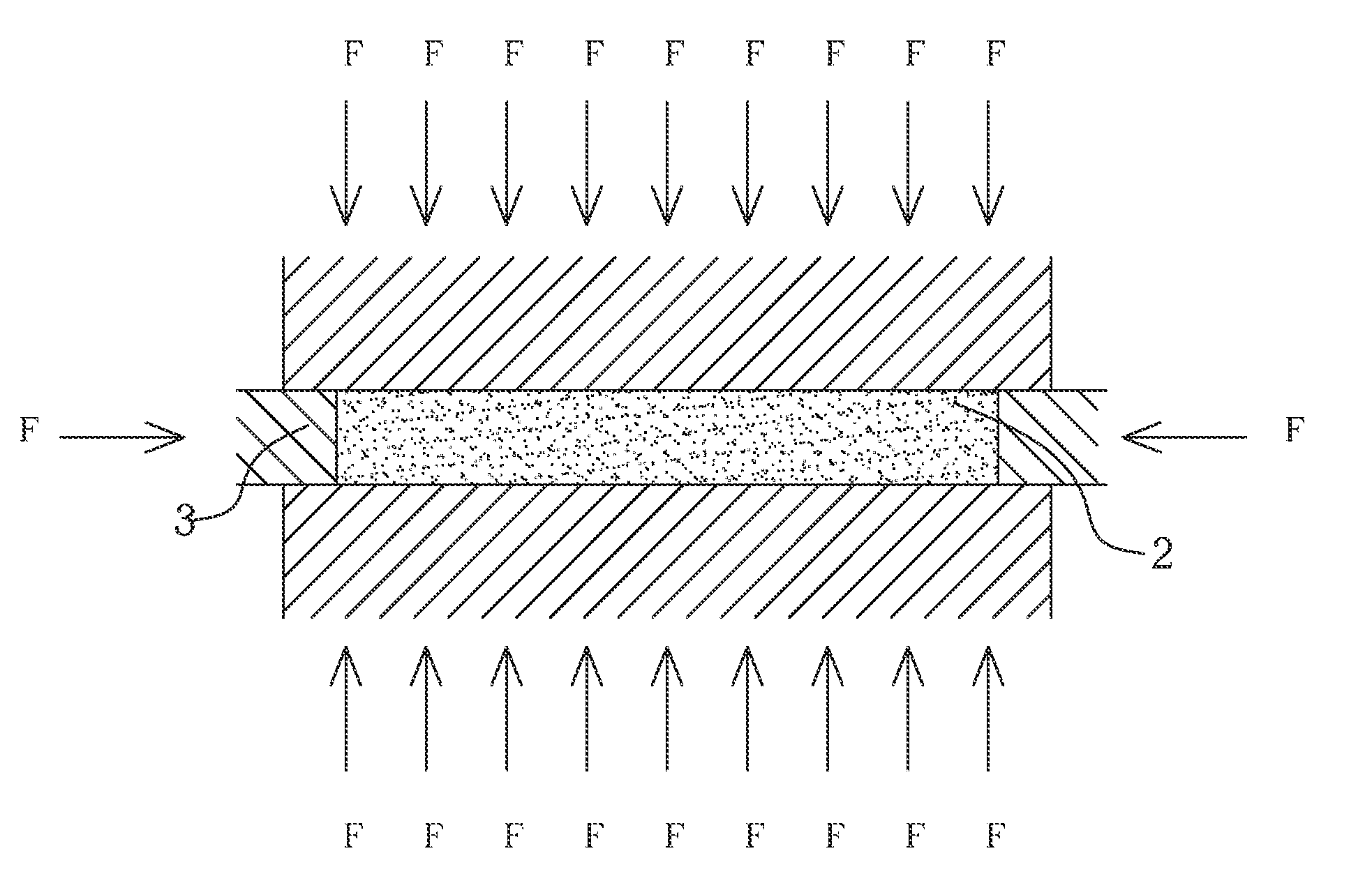

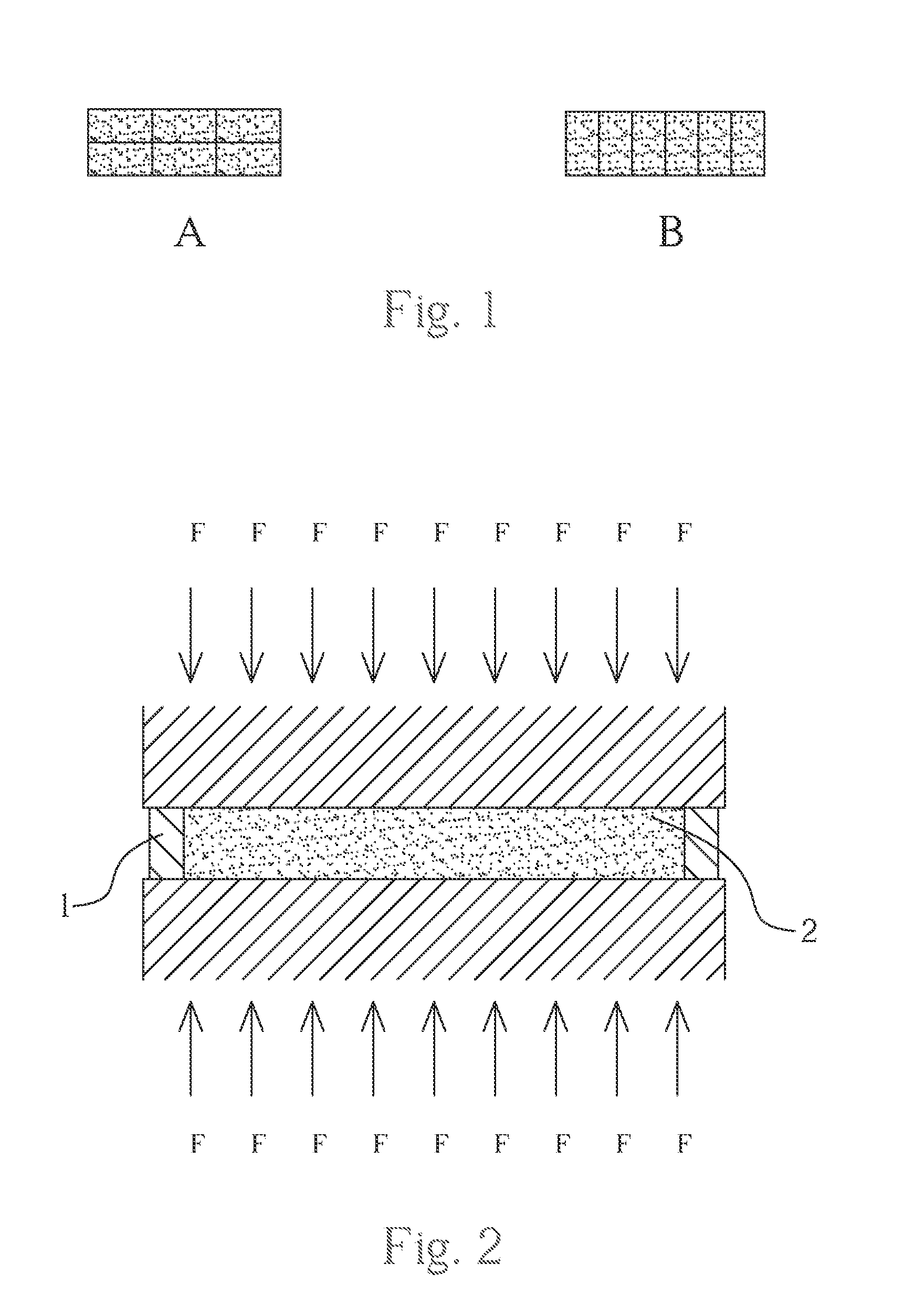

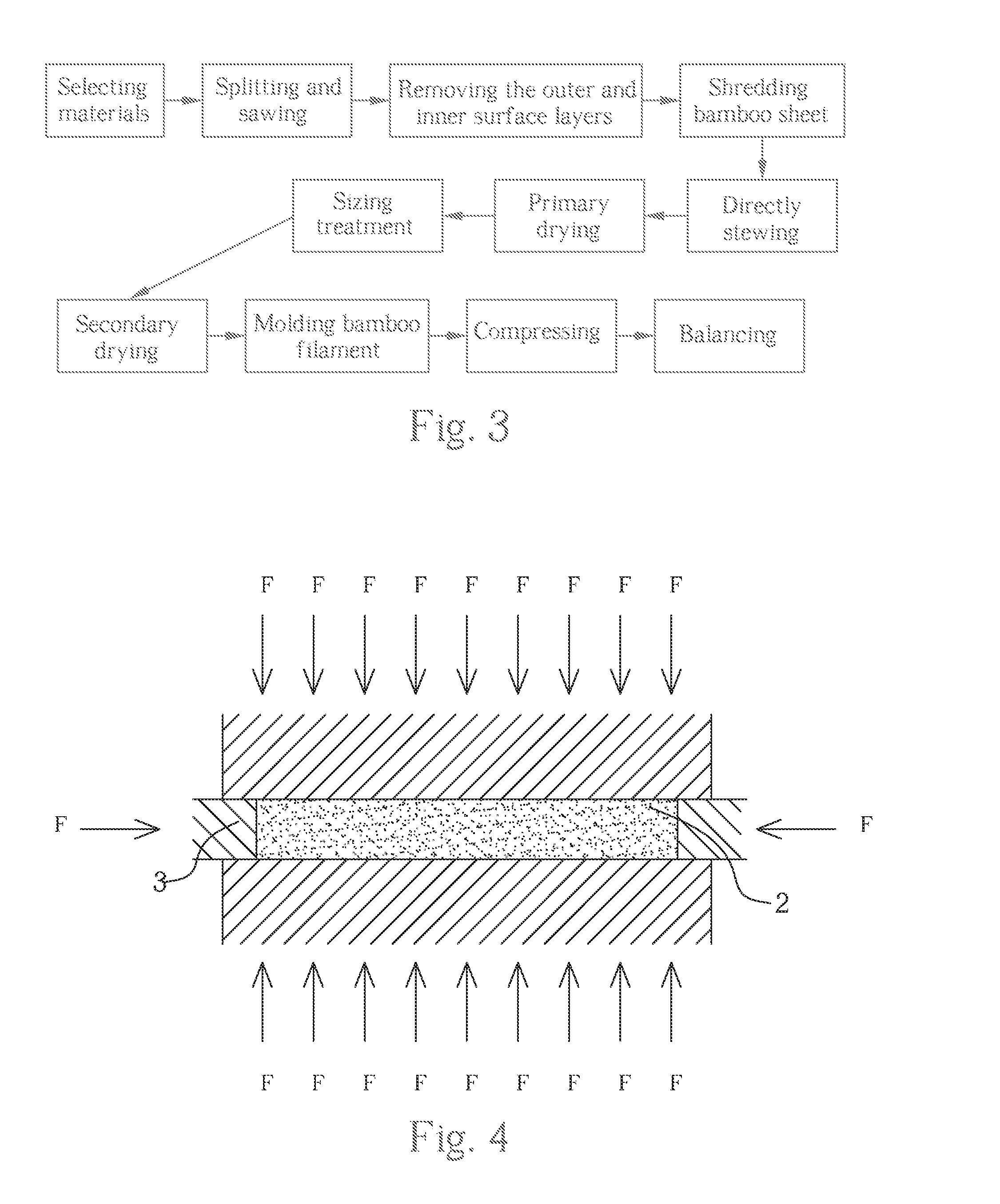

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

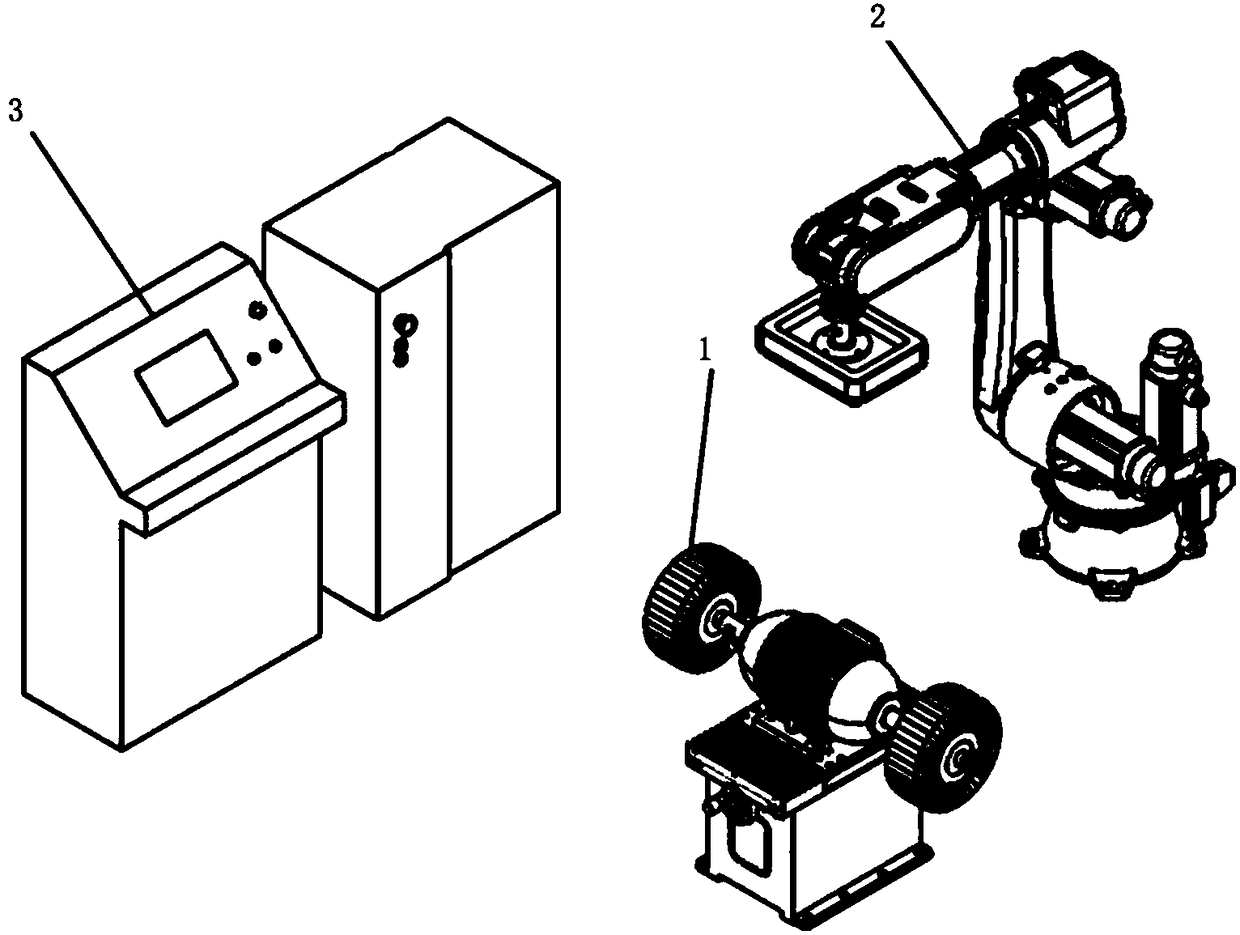

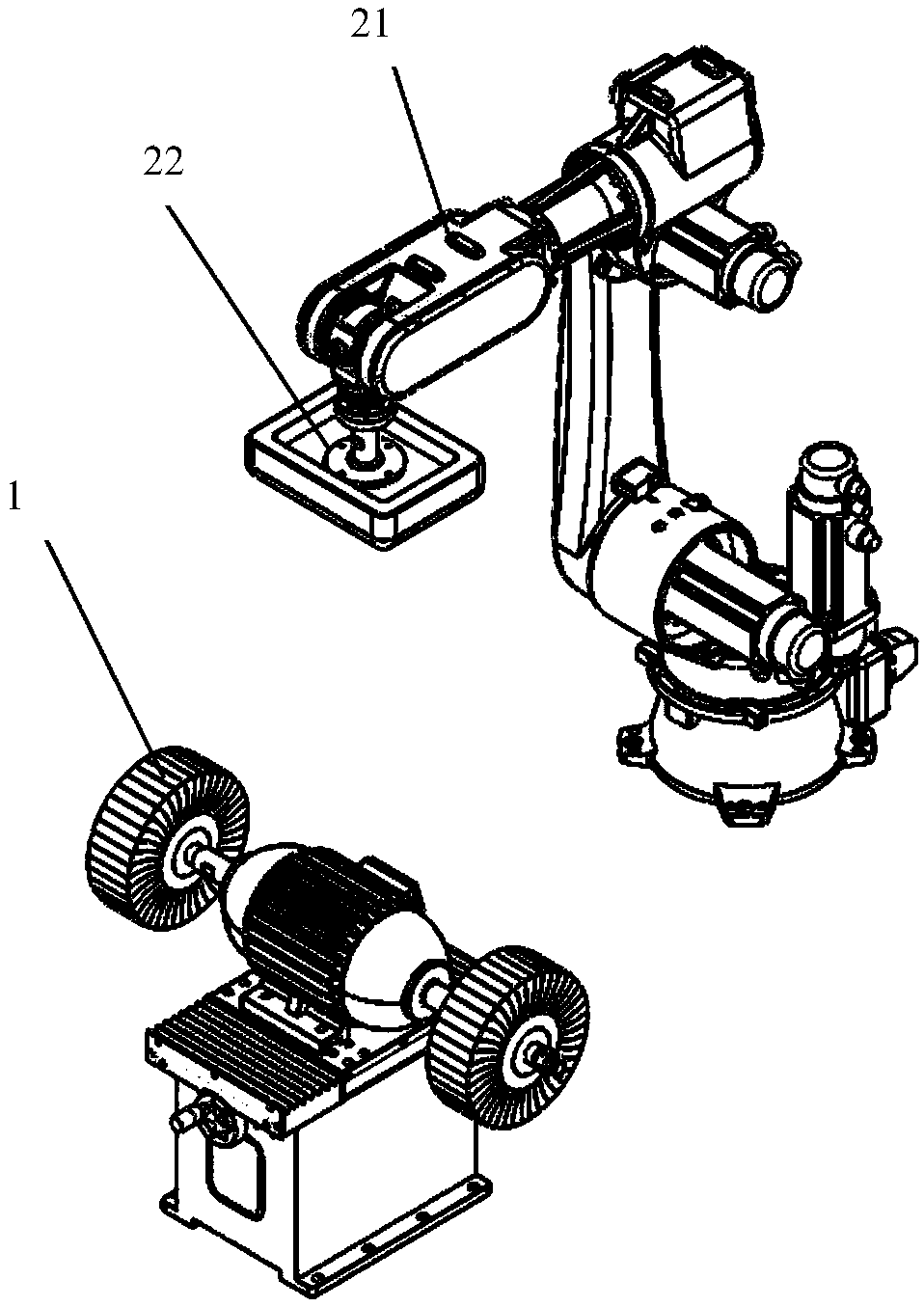

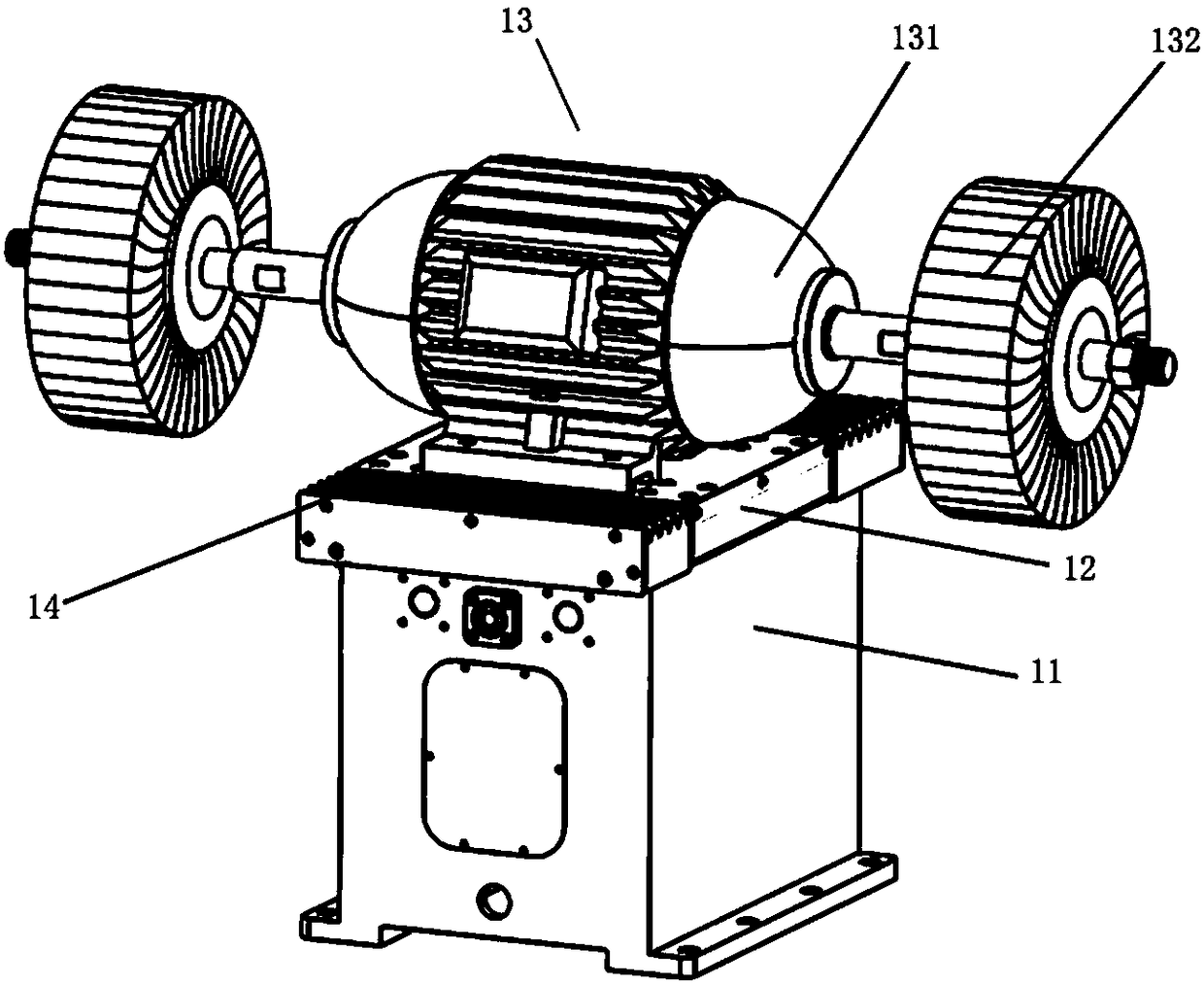

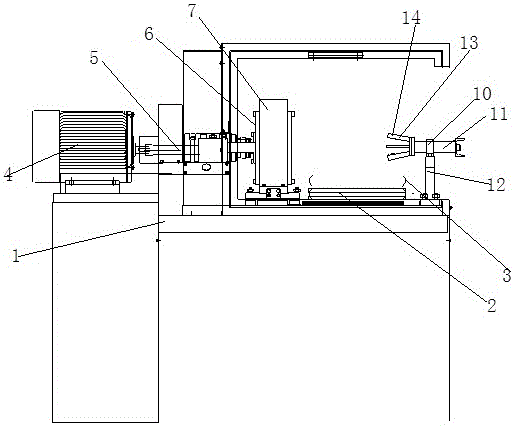

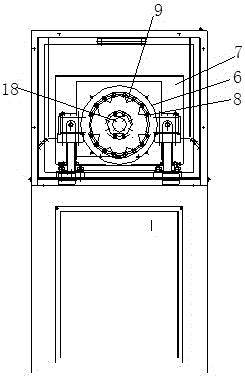

Pressure-controllable industrial robot grinding and polishing system and grinding and polishing method

PendingCN108296962AImprove grinding and polishing effectImprove production efficiency and product qualityPolishing machinesGrinding drivesPulp and paper industryIndustrial robot

The invention provides a pressure-controllable industrial robot grinding and polishing system. The pressure-controllable industrial robot grinding and polishing system is characterized by comprising apolishing device, a feeding device and a controller, and the polishing device comprises a fixed base, a mounting seat, a polishing mechanism, first slide rails, a position adjusting mechanism and a cylinder. The cylinder is connected with the mounting seat, and the mounting seat is slidably connected with the first slide rails to realize that the cylinder pushes the mounting seat to move in the length direction of the first slide rails to drive the polishing mechanism to move. The cylinder is connected with the controller to enable the controller to control the cylinder to control grinding pressure between the polishing mechanism and a workpiece. The cylinder is disposed on the fixed base through the position adjusting mechanism. The pressure-controllable industrial robot grinding and polishing system can improve grinding and polishing effects and improve production efficiency and product quality. The invention further provides an industrial robot grinding and polishing method which is capable of realizing constant grinding pressure between the polishing mechanism and the workpiece, effectively improving the grinding and polishing effects and improving the production efficiency and the product quality.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

Far infrared Nixing pottery product and preparation method thereof

The invention discloses a far infrared Nixing pottery product and a preparation method thereof. The far infrared Nixing pottery finished product, far infrared Nixing pottery powder and far infrared Nixing pottery slurry is prepared by adding the metal oxides Cr2O3, MgO, MnO2 and ZrO2 and other compounds serving as auxiliary raw materials into Nixing pottery which is made in Qinzhou, Guangxi, and has the advantages of more cheap chemical components, high content and high quality and serves as a main raw material and roasting the mixture at the temperature of between 1,000 and 1,200 DEG C in a high-temperature electric furnace or a high-temperature roasting furnace or a high-temperature burning kiln according to the pottery. The far infrared Nixing pottery product transmits a far infrared ray with the wavelength of 6 to 23 mu m at the normal temperature and can be applied to the industry, medical care and living goods in the fields such as medical care, energy conservation and environment protection, building materials, heat insulating materials, water quality improvement, paper making plastic, fiber weaving, food preservation, food roasting, wine making industry, pharmaceutical industry and the like. The preparation method has the advantages of simple process, low energy consumption, low cost, high benefit and good product quality.

Owner:李建洪

Etimicin sulfate preparation and its preparing method

InactiveCN1569010ASufficient solubilityImprove the bactericidal effectOrganic active ingredientsAntipyreticEtimicin sulfateChemistry

The invention discloses etimicin sulfate preparation and its preparing method which comprises, charging acids or alkali as pH conditioning agent so as to increase the dissolving degree of the etimicin, charging right amount of isoosmotic adjustment agent, thus resulting the action of quick sterilization.

Owner:ZHEJIANG UNIV

Preparation process of vanadium-nitrogen alloy

The invention discloses a preparation process of a vanadium-nitrogen alloy. The preparation process comprises the steps that a vanadium-containing compound is subjected to mechanical activation treatment at first, a reaction promoter, graphene and a binder are added to obtain qualified mixed materials, the mixed materials are subjected to aging treatment and fed into a calcining kiln to be calcined, a drying stage, a carbonization stage, a nitridation stage and a cooling stage are sequentially carried out, a product is discharged from the kiln, and the vanadium-nitrogen alloy finished productwith the vanadium content larger than or equal to 77.0% is obtained. According to the preparation process, quality is good, product quality is stable, the production process is stable, and the production cost is low.

Owner:涂绪洋

Cooling fin size and flatness online automatic measurement device and measurement method thereof

InactiveCN108759678AImprove product qualityIncrease productivityUsing optical meansAutomatic testingElectron

Owner:广州富唯电子科技有限公司

A pvc plastic extruder variable diameter screen changing device

Owner:XINLE HUABAO PLASTIC PROD

Cefmetazole sodium proliposome preparation

ActiveCN101623264AThe encapsulation efficiency has not decreasedImprove stabilityOrganic active ingredientsAntibacterial agentsCholesterolPhospholipid

The invention provides a cefmetazole sodium proliposome preparation which comprises the following components by weight part: 1 part of cefmetazole sodium, 3-15 parts of liposome carrier and 2-10 parts of proppant, wherein the liposome carrier comprises polyene phosphatidyl choline, cholesterol and oleinic acid according to a weight ratio of (4-20):(1-5):1. The cefmetazole sodium proliposome preparation has good preparation stability and cannot crack because of dewatering, fusion, ice crystal generation, and the like in a freeze-drying process; and after hydrated re-dissolution, the cefmetazole sodium proliposome preparation still can maintain good entrapment rate.

Owner:HAINAN LINGKANG PHARMA CO LTD

Halogen-free flame-retardant copper-plastic composite belt and preparation thereof

InactiveCN103165237AHas an ultra-thin structureReduce manufacturing costConductive layers on insulating-supportsLaminationPolyesterEngineering

The invention relates to the field of cable belts, in particular to a copper-plastic composite belt suitable for a communication cable and an optical cable and preparation thereof. The copper-plastic composite belt is coated on the outer surface of the communication cable or the optical cable and sequentially comprises a red copper layer (1), an adhesive layer (2) and a polyester film layer (3), wherein the red copper layer (1), the adhesive layer (2) and the polyester film layer (3) are bonded and heated to form a composite structure. The tensile strength of the copper-plastic composite belt is larger than or equal to 180MPa, the elongation at break of the copper-plastic composite belt is larger than or equal to 15%, the interlayer peeling strength between a copper belt and a plastic layer is larger than or equal to 15N / cm, the conductivity of the copper-plastic composite belt is larger than or equal to 90% IACS, and no punchthrough happens on the single side of the copper-plastic composite belt 1 kvd.c,1min.

Owner:JIUXING HLDG GRP

Polyamide toughening agent as well as preparation method and use thereof

InactiveCN104177825AImprove impact resistanceImprove low temperature impact resistanceElastomerPolyolefin

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

Flanging hot-die apparatus for automobile plafond

The invention relates to a vehicle ceiling flanged edge hot die device which is applied to the hot pressing technique for front edges and back edges of a ceiling and flanged edges around a sky light of a vehicle. According to the technical proposal provided by the invention, the device comprises a lifting cylinder which is fixedly arranged on a stand; a piston rod of the lifting cylinder is extended upward; the top end part of the piston rod of the lifting cylinder is fixedly provided with a shift cylinder, a piston rod of the shift cylinder is transversely extended; the end parts of the piston rod of the shift cylinder is fixedly connected with a connecting plate vertically extended upward; the top end part of the connecting part is fixedly connected with a pressing die head, and a working face of the pressing die head which is arranged downward is the same as the shape of the ceiling surface. The device has the advantages of simple, compact and reasonable structure, suitability for various products, high flexibility, high automaticity, guarantee of smooth flanged edges around the vehicle ceiling, accurate positioning of a work piece, quick process rhythm, high production efficiency, reduction of the labor intensity of a worker and manufacturing cost of the product and high product quality.

Owner:WUXI GISSING AUTO PARTS CO LTD

Core shooter

Owner:NINGGUO ZHICHENG MACHINERY MFG

Method and system for treating human excrement

InactiveCN108218480AAvoid pollutionLimit churnBio-organic fraction processingClimate change adaptationHuman wasteLiquid storage tank

The invention discloses a method for treating human excrement. The method comprises the steps as follows: (1) a liquid in the human excrement is discharged into an original liquid storage tank, and solids are dehydrated; (2) solids obtained after dehydration treatment in the step (1) are subjected to aerobic fermentation after being crushed; (3) secondary fermentation is performed; (4) materials obtained after the secondary fermentation are used as solid fertilizer. The invention also discloses a system adopting the method. The system comprises impurity removal equipment A, a dewatering deviceA, the original liquid storage tank, a crusher A, a distributor A, a full-closed fermentation tank A, an oxygen generator and the like. The method and the system for treating the human excrement havethe advantages as follows: a complete production process is provided for recycling of human excrement, a scheme is provided for urban emission reduction and sewage treatment plant pressure reduction,waste can be reused, and sustainable development can be realized really.

Owner:石伟

Processing technique of liquid crystal television metal frame

ActiveCN101332483ASmall Bend Edge Fillet RadiusReduce shockShaping toolsEngineeringMachining process

The invention discloses a processing technology of a metal face frame of a liquid crystal television, and the processing technology comprises a processing procedure of folding edges and a processing procedure of ambient round angles. The processing technology is characterized in that an aluminum sheet with a cut in the middle is fixed between a concave pattern plate and a fixing plate in the processing procedure of folding edges, wherein the edge of a concave pattern cavity of the concave pattern plate is added with a ring of pressed rib pressed into the aluminum sheet, and the inner edge of the aluminum sheet is pressed by a convex pattern plate to form the folding edge; in the processing procedure of ambient round angles, three pairs of concave-convex pattern insert block components are adopted to bend, punch and shape the four round angles at the connecting places of the four straight edges on the folding edges in three steps, and the radiuses of the arc surfaces on the three convex pattern insert blocks of the concave-convex pattern insert block components are decreased sequentially. The processing technology of the invention can press the folding edges with smaller round angle radius and the four round angles at the connecting places of the four straight edges on the folding edges, and effectively prevent rupture at the four round angles in the processing course, which improves the product quality greatly.

Owner:SUZHOU VICTORY PRECISION MFG

Rapid analysis method for sodium hydroxide and ammonia content in sodium cyanide reaction solution and its liquid products

InactiveCN102269753AReduce consumptionAvoid interferenceChemical analysis using titrationLiquid productSodium cyanide

The invention discloses a rapid analysis method for sodium hydroxide and ammonia content in sodium cyanide reaction solution and its liquid products, which uses excess formaldehyde and ammonia to react to generate hexamethylenetetramine, and then divides into two groups of titration with hydrochloric acid, Obtain two sets of values of ammonia-containing acid consumption and ammonia-removing acid consumption, and then calculate the content of sodium hydroxide and ammonia in the sample through data measurement, thereby effectively reducing the interference of free ammonia on the analysis of sodium hydroxide content, and quickly and accurately analyzing cyanide. Sodium hydroxide content and ammonia content in sodium chloride reaction liquid and its liquid products. The method of the invention is fast and effective, has obvious mutations in analysis and titration, accurate and reliable measured values, simple and convenient operation and easy mastery.

Owner:ANQING NEW SHUGUANG FINE CHEM CO LTD

Testing tool and display panel detection method

ActiveCN107132184AImprove accuracyImprove product qualityMaterial analysisUsing mechanical meansEngineeringSurface plate

Owner:HKC CORP LTD +1

Drum type screening device

InactiveCN105537097AImprove product qualityMeet process specificationsScreeningSievingEngineeringMechanical engineering

Owner:JIANGSU HENGSEN TOBACCO MACHINERY +5

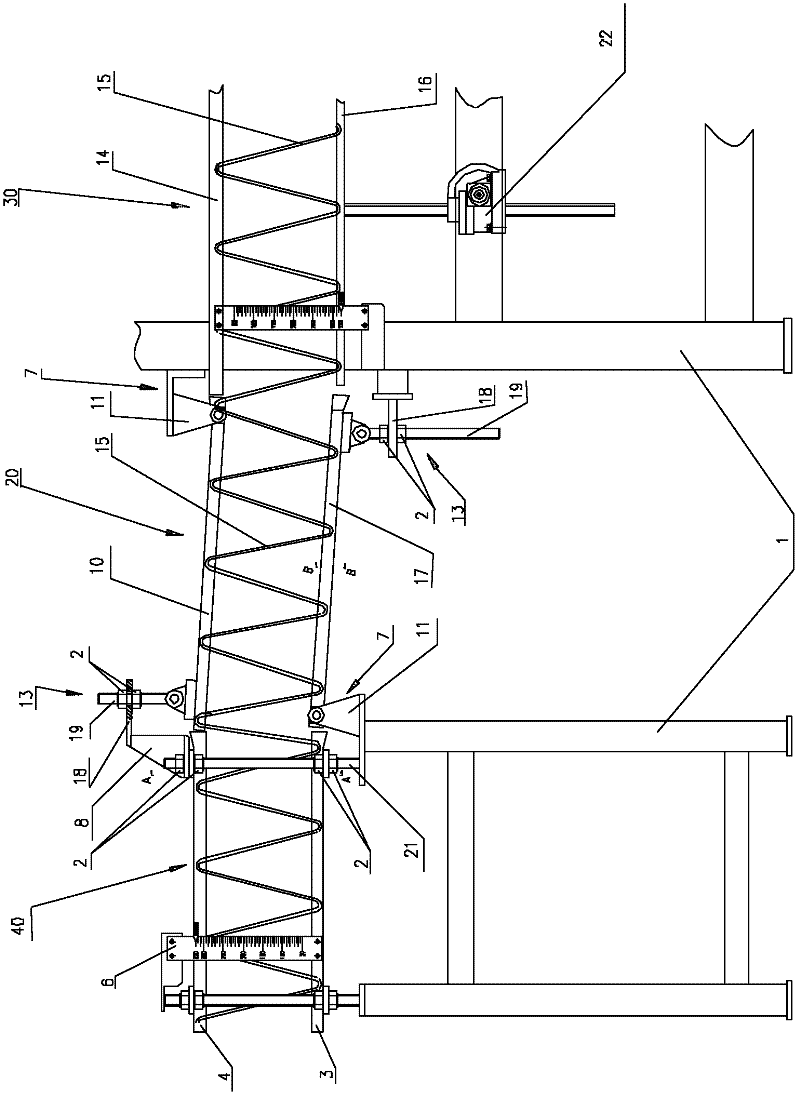

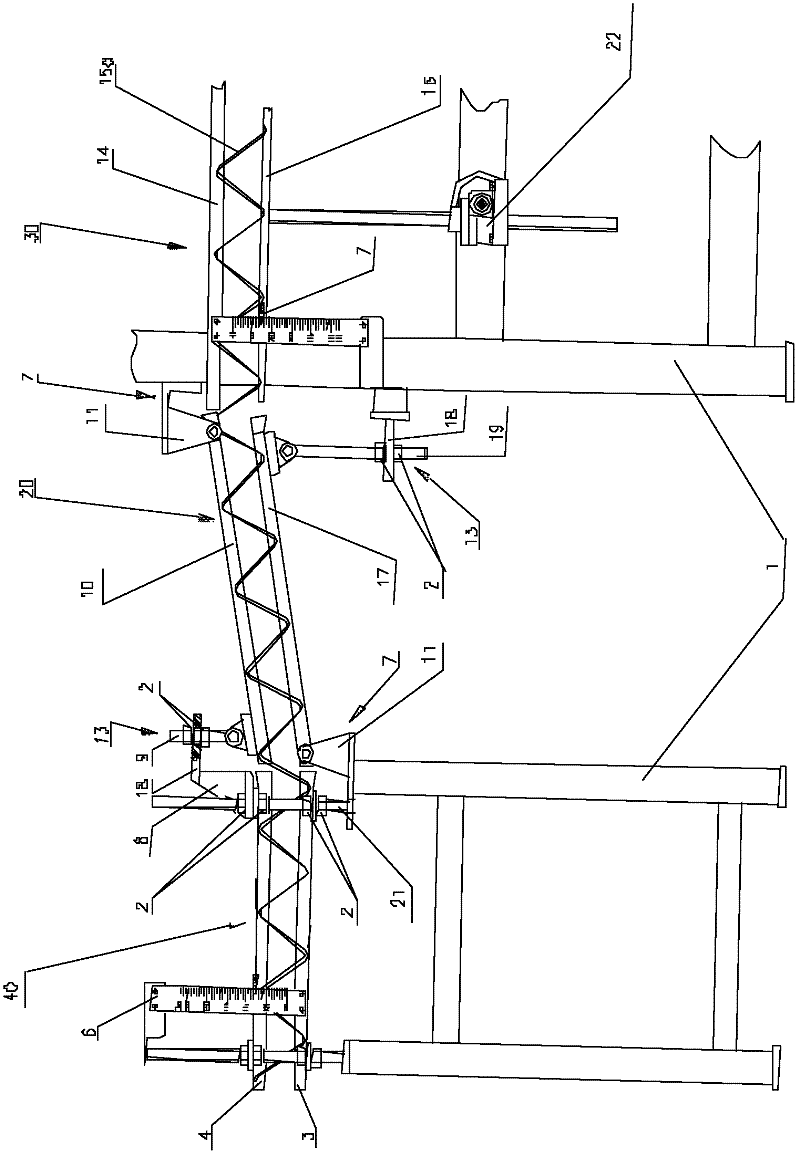

Adjustable side reinforcement support device mounted on triangular truss production line

ActiveCN102248336AImprove product qualityIncrease productivityAuxillary welding devicesSoldering auxillary devicesProduction line

Owner:TJK MACHINERY TIANJIN

Compact injection molding method of injection molding part with wire

Owner:上海飞乐汽车控制系统有限公司

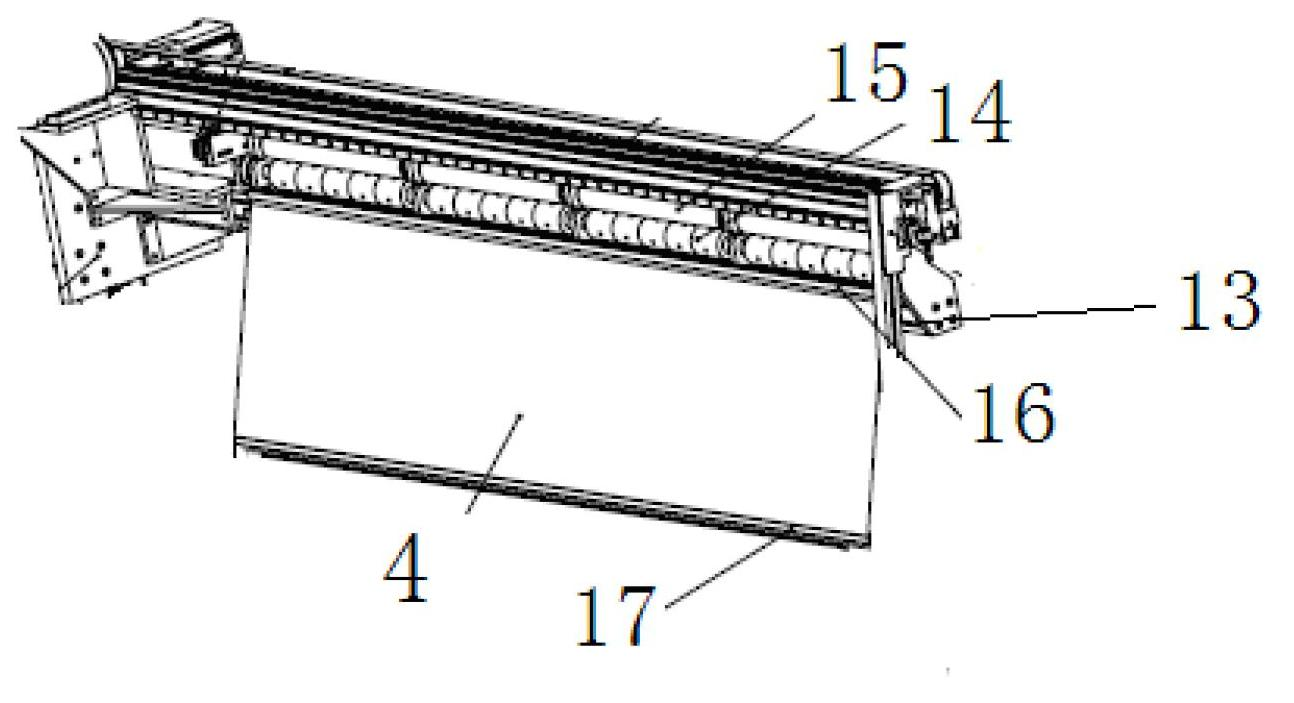

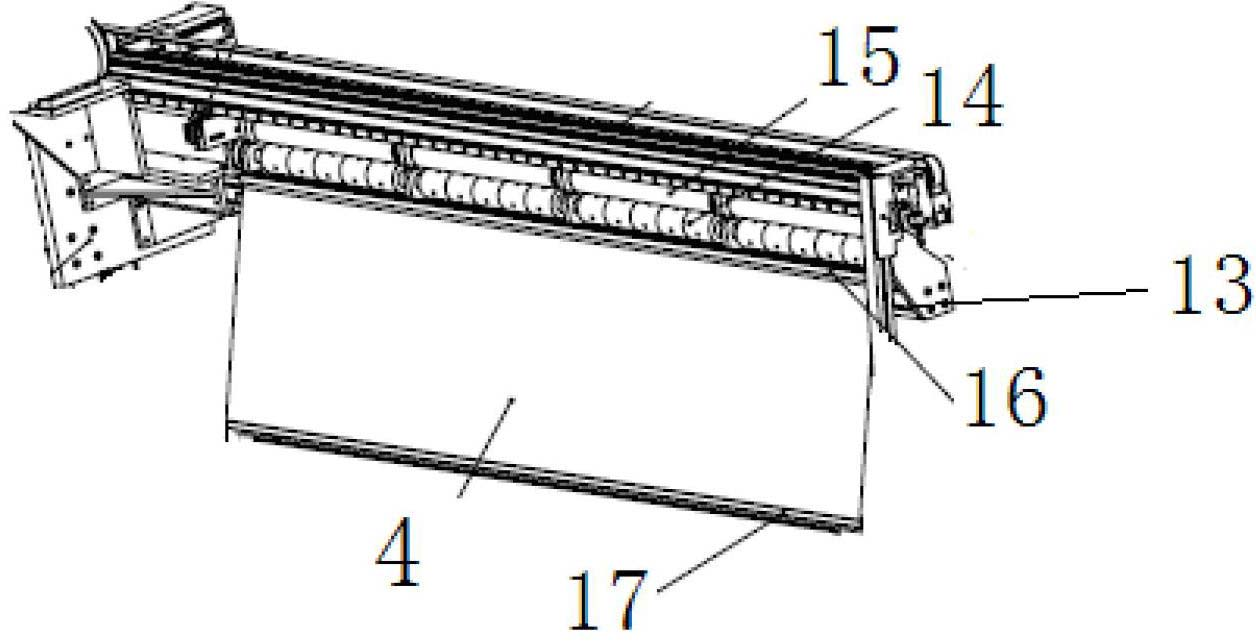

Automatic paper feeder

ActiveCN102674068AHigh product consistencyImprove product qualityArticle deliveryFeed driveHigh volume manufacturing

Owner:芜湖金三氏数控科技有限公司

Durian shell thorn passivating device

ActiveCN106666789AImprove logistics qualityImprove product qualityFood treatmentEngineeringLogistic process

Owner:徐剑英

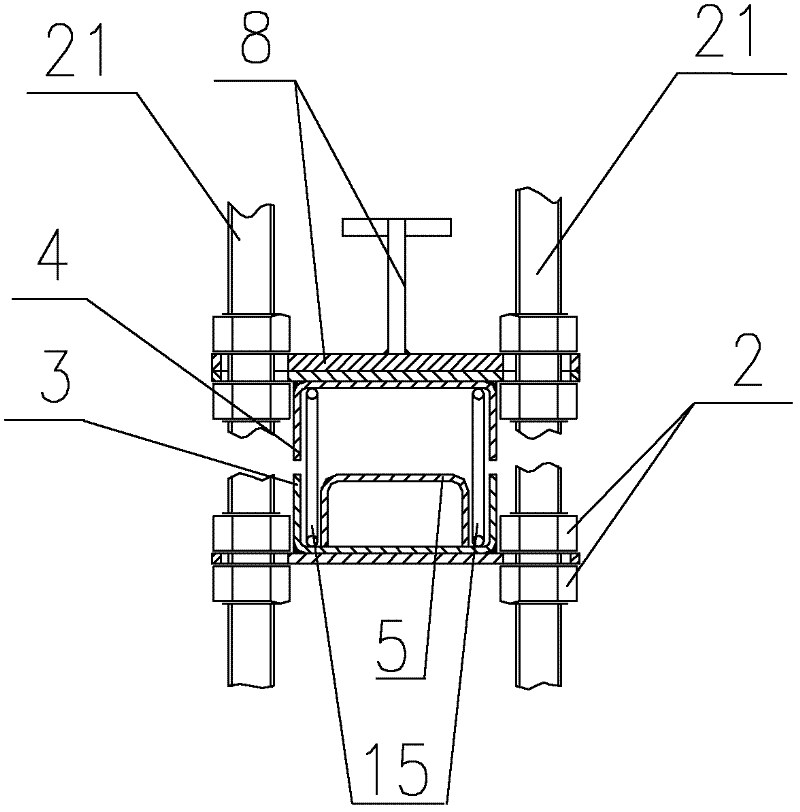

Clamping mechanism and electric eye aligning spot welder thereof

ActiveCN102343478AAccurate and reliable spot welding position controlImprove product qualityAuxillary welding devicesNon-electric welding apparatusAutonomationElectrical and Electronics engineering

Owner:SHENZHEN XINSAI AUTOMATION EQUIP

High-quality ceramic stone machining system

InactiveCN107913778AAvoid unmanageable problemsImprove product qualityMagnetic separationGrain treatmentsIron removalStone particle

The invention discloses a high-quality ceramic stone machining system. The high-quality ceramic stone machining system comprises a slurry inlet pipe, a grinding mechanism for grinding slurry, a filtering mechanism for filtering the slurry, a drying mechanism for drying ceramic stone particles, and an iron removal mechanism for removing iron in the ceramic stone particles. The high-quality ceramicstone machining system has the beneficial effects that the slurry can be subjected to adsorbing impurity removal after being dried and formed, iron scraps in the slurry are reduced, and the problem that due to the fact that impurity removal is carried out before an overall process, the iron scraps mixed in the work process cannot be treated is avoided; the product quality is improved, a continuousproduction mode of grinding, filtering and screening, drying and iron removing can be formed, and machining efficiency is greatly improved; and the overall structure is simple, and very good market generalization performance is achieved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Continuous production equipment and process for hexafluoropropylene oxide oligomer

PendingCN111530383AContinuous operationReduce consumptionChemical recyclingCarboxylic acid halides preparationOligomerPtru catalyst

The invention provides continuous production equipment and a continuous production process for a hexafluoropropylene oxide oligomer. The continuous production equipment comprises a stirring kettle anda liquid phase separation kettle, wherein a stirrer is arranged in the stirring kettle; a discharge pipe is arranged at the bottom of the stirring kettle; a discharge pipe is arranged at the bottom of the liquid phase separation kettle; the discharging pipe is communicated with the discharge pipe through a feeding pipe; the feeding pipe is provided with a conveying pump; the top of the stirring kettle is communicated with the top of the liquid-phase separation kettle through a liquid-phase circulating pipe and a gas-phase circulating pipe respectively; the liquid-phase circulating pipe is provided with a circulating pump; the gas-phase circulating pipe is provided with a condenser; one end of the liquid-phase circulating pipe, which is positioned at the liquid-phase separation kettle, extends into the lower part of the liquid-phase separation kettle; and one end of the liquid-phase circulating pipe, which is positioned at the stirring kettle, is connected with a nozzle. The equipmentand the process have the advantages of continuous production, simplicity in operation, high production efficiency, stable product quality and the like, meanwhile, the catalyst, the solvent and byproducts can be recycled, and the process is low in cost and environmentally friendly.

Owner:JIUDING FLUORIN CHEM CO LTDZHANGPING FUJIAN

Special pH value buffering agent for soilless culture nutrient solution and preparation method thereof

PendingCN112409087AImprove product qualityLow costAgriculture gas emission reductionCultivating equipmentsBuffering agentCrop

Owner:山东沃尔美肥业有限公司

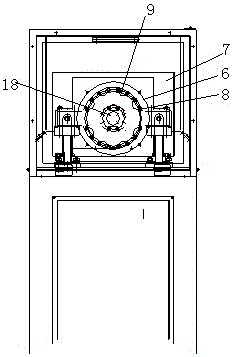

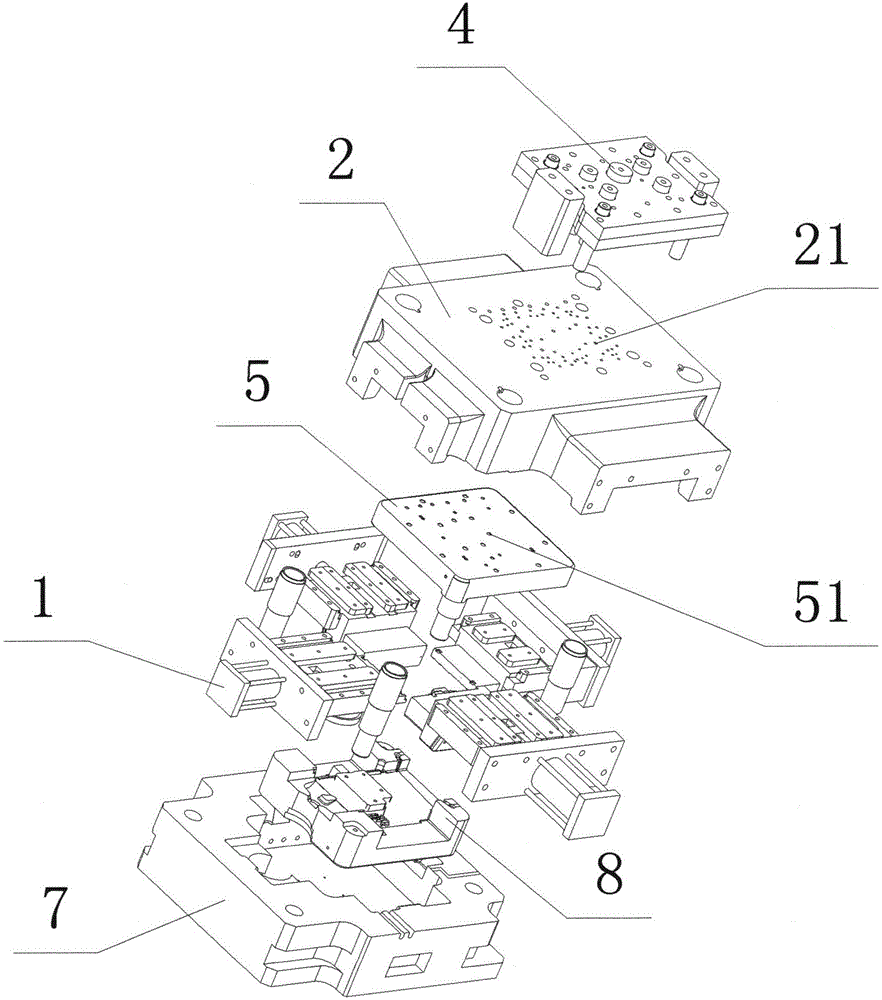

Automobile balance block die-casting mould

The invention provides an automobile balance block die-casting mould, which comprises a push cylinder, an upper mould base, an upper mould, a lower mould and a lower mould base, wherein the upper mould is arranged on the lower end of the upper mould base; the lower mould is arranged on the upper end of the lower mould base; the upper mould base is connected to the upper end of the lower mould base through a guide pillar; cooling holes are formed in the upper end face and the lower end face of the upper mould base in a penetrating way; a guide sleeve is connected onto each cooling hole. According to the automobile balance block die-casting mould, each cooling channel is communicated with a blind hole, each blind hole is communicated with a cooling hole, and each guide sleeve is arranged on the corresponding cooling hole, so that the mould can be cooled conveniently and quickly through injecting cooling water in the guide sleeves; the cooling channels are arranged at equal distances and in parallel, so that cooling is uniform, the cooling effect can be further improved, and the product quality is improved; the automobile balance block die-casting mould is simple in structure, convenient to operate, and good in cooling effect.

Owner:宁波培源股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap