Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Vanadium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium is a chemical element with the symbol V and atomic number 23. It is a hard, silvery-grey, ductile, malleable transition metal. The elemental metal is rarely found in nature, but once isolated artificially, the formation of an oxide layer (passivation) somewhat stabilizes the free metal against further oxidation.

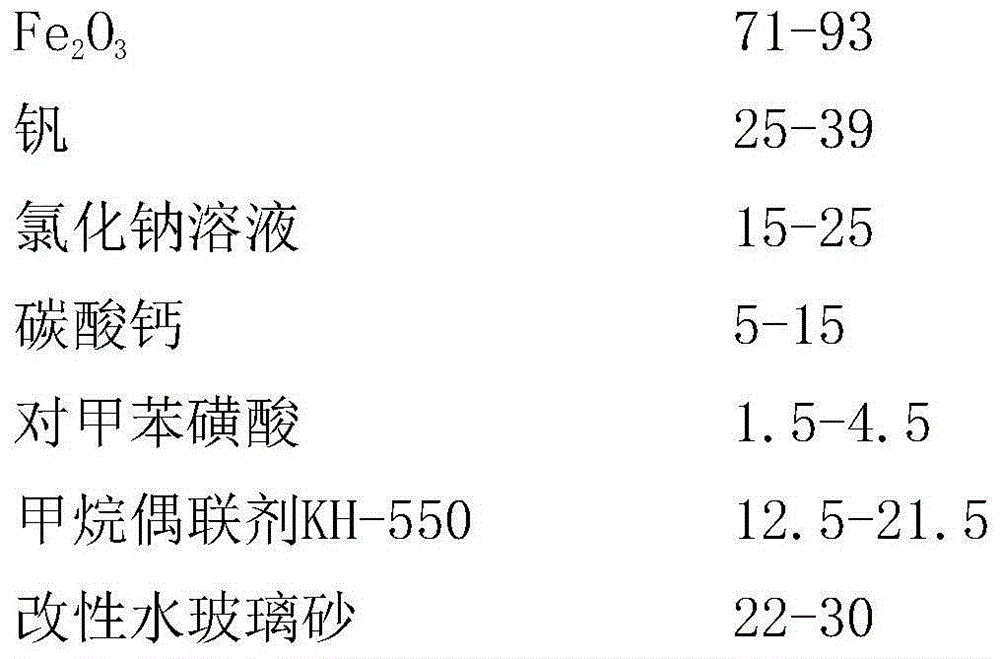

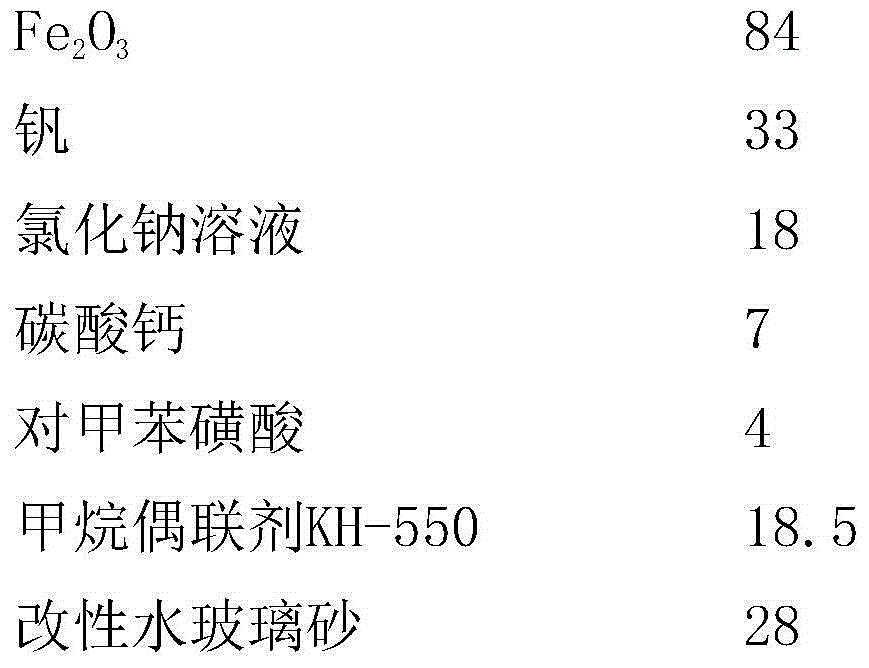

Micro-electrolytic filler containing catalyst

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

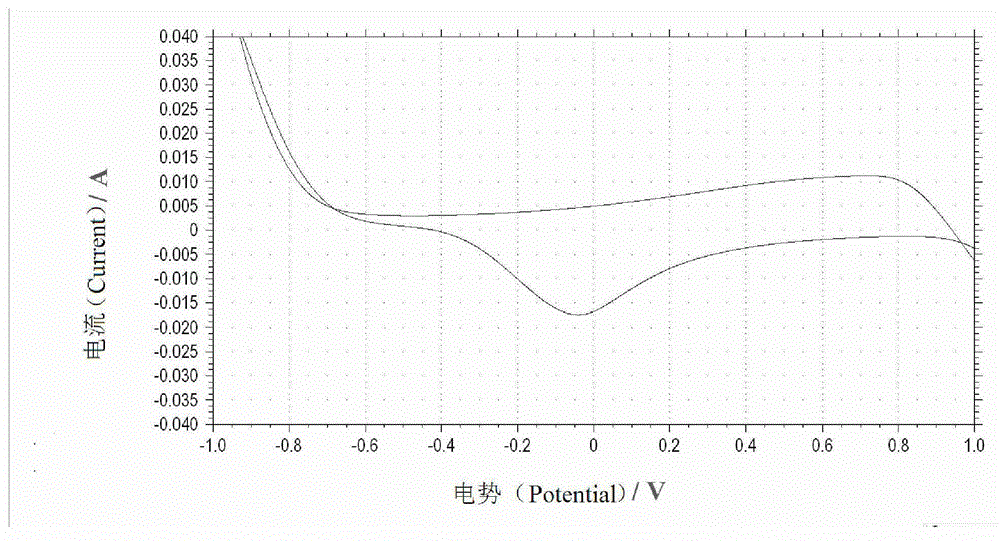

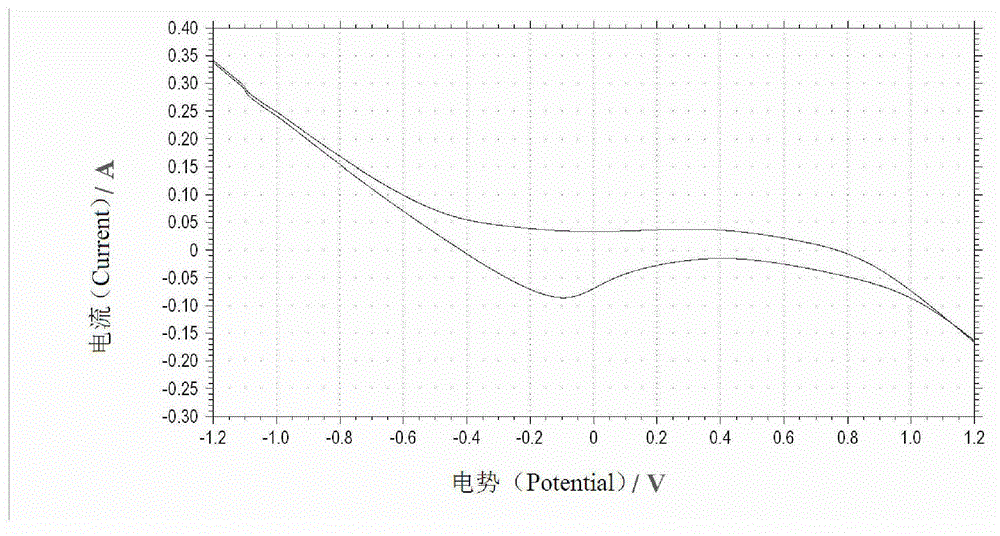

Treatment method of carbon felt for vanadium batteries

ActiveCN103066287AImprove hydrophilicityImprove the activation effectCell electrodesActivated carbonCarbon felt

Owner:承德新新钒钛储能科技有限公司 +1

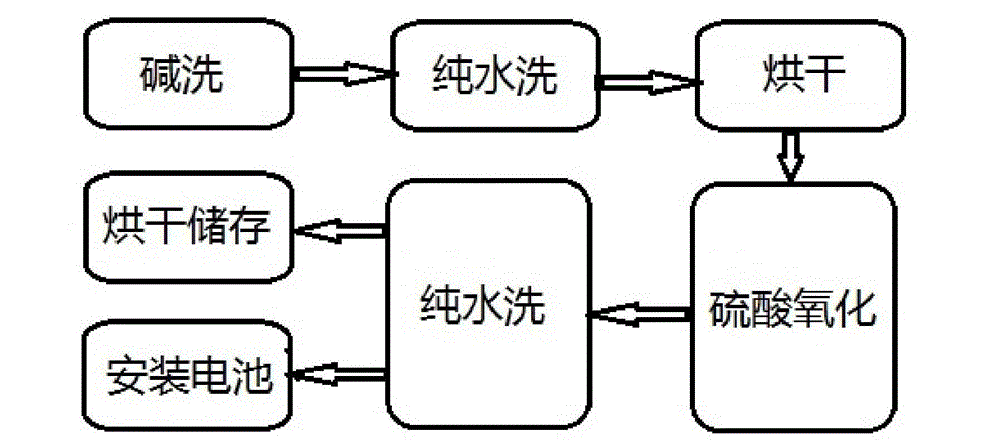

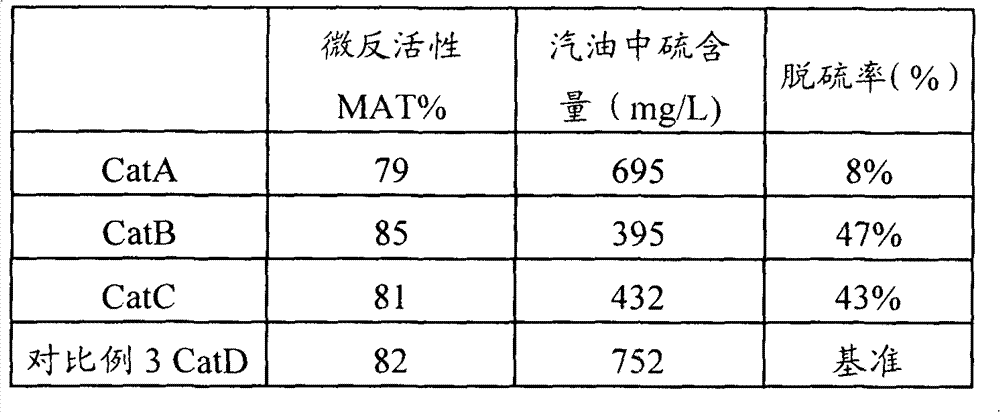

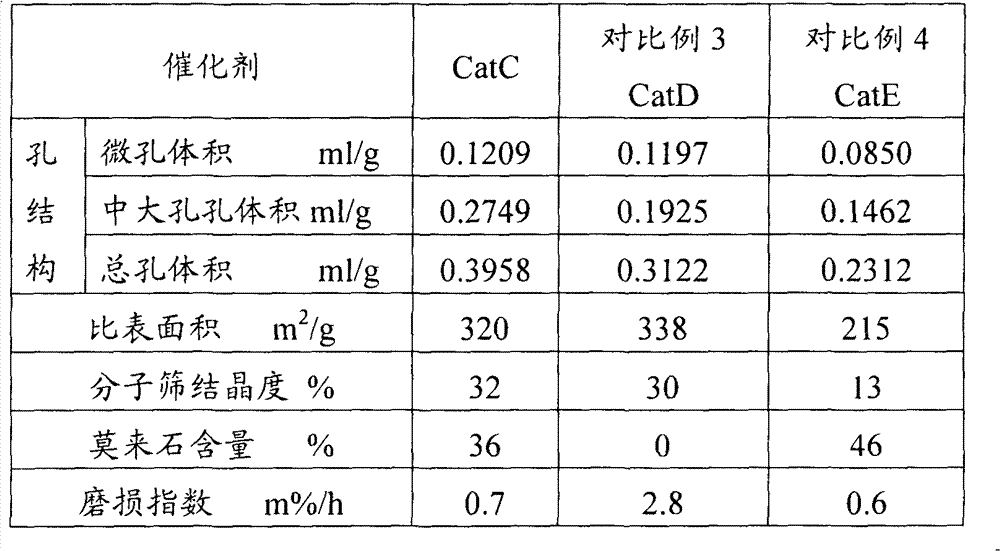

Wear-resistant heavy oil catalytic cracking catalyst capable of reducing sulfur content of gasoline and preparation method thereof

ActiveCN103028432AImprove wear resistanceHigh activityCatalytic crackingMolecular sieve catalystsMicrosphereWear resistant

Owner:EAST CHINA UNIV OF SCI & TECH +1

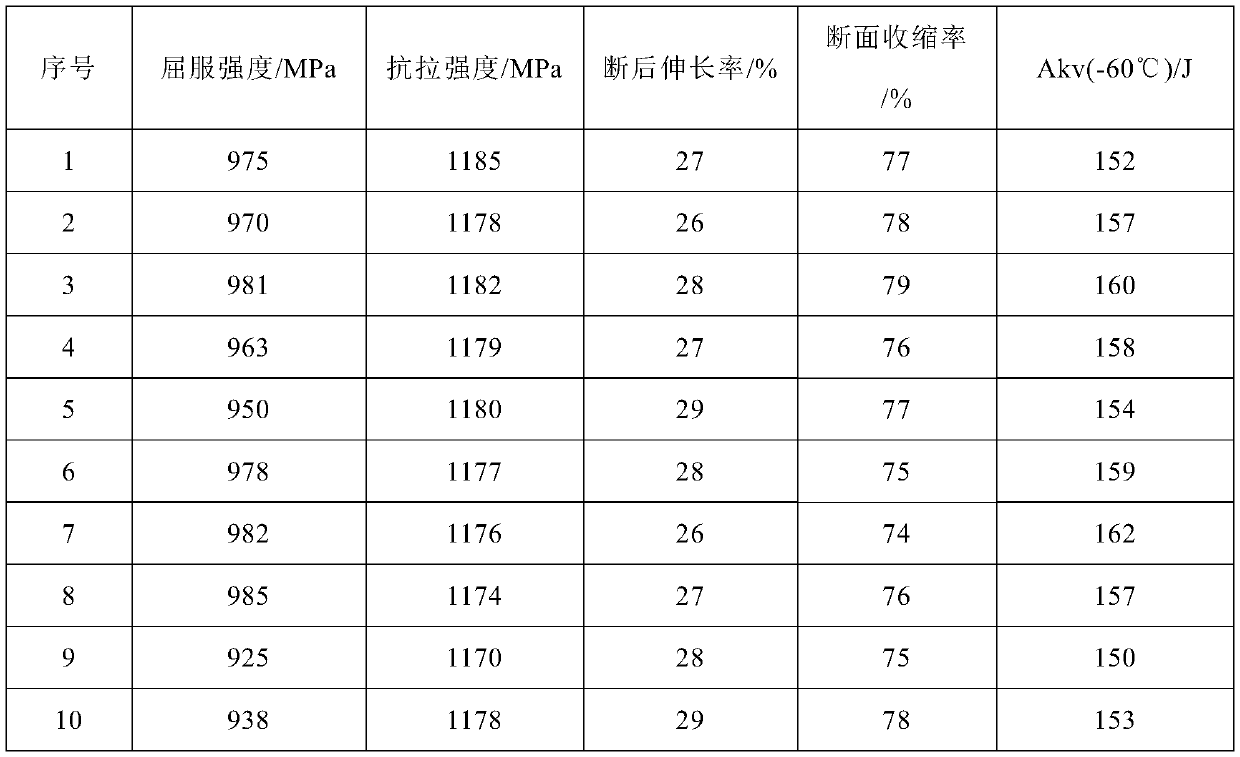

Small-dimension British standard deformed steel bar B500B and manufacturing technology thereof

The invention discloses a small-dimension British standard deformed steel bar B500B and a manufacturing technology thereof. The chemical component requirements of the small-dimension British standard deformed steel bar B500B are: C: 0.19-0.22 wt%, Si: 0.20-0.60 wt%, Mn: 0.70-0.90 wt%, Cr: 0.5-0.8%, P, S: less than or equal to 0.035 wt%, Ni, Cu: less than or equal to 0.25 wt%, Mo, Al: less than or equal to 0.10 wt%, and N: less than or equal to 0.011 wt%; the balance is Fe; carbon equivalent Ceq is less than or equal to 0.50%. The technology comprises converter or electric furnace smelting, LF refining or argon blowing refining, CCM bloom or billet continuous casting, bar controlled rolling, and controlled cooling. The component design takes chromium to replace expensive vanadium for alloying, is matched with reasonable-design controlled rolling temperature and air cooling temperature, realizes production of the small-dimension British standard deformed steel bar B500B with qualified performance in low cost, and acquires favorable economical and social benefits.

Owner:NANJING IRON & STEEL CO LTD

Preparation method of far infrared antibacterial ceramic

InactiveCN106866115AReduce manufacturing costTake advantage ofCeramic materials productionClaywaresSpray GranulationEmissivity

Owner:SICHUAN UNIV

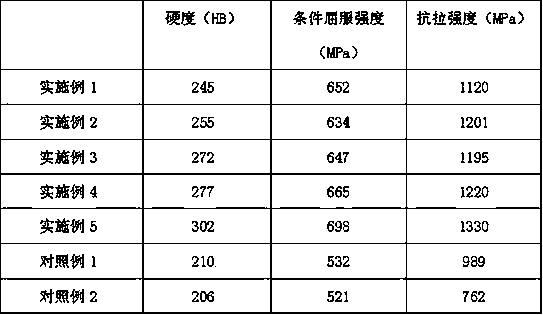

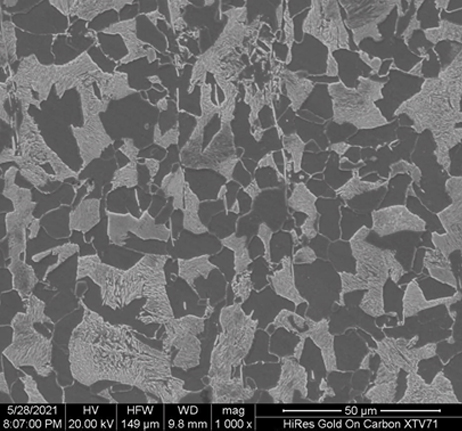

High-strength 23Mn2CrNiMnVERA steel for railway train connection and preparation method thereof

Owner:SHANDONG XIWANG SPECIAL STEEL

High-temperature-resistant high-performance rare earth permanent magnet material

InactiveCN105374488AHigh temperature resistance and high performanceImprove stabilityInorganic material magnetismRare-earth elementTemperature resistance

Owner:南通长江电器实业有限公司

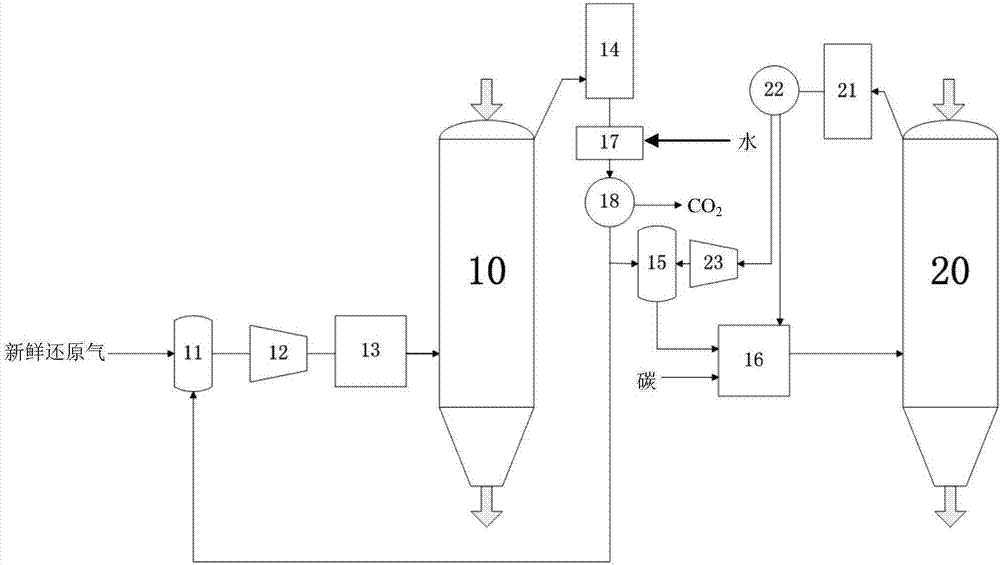

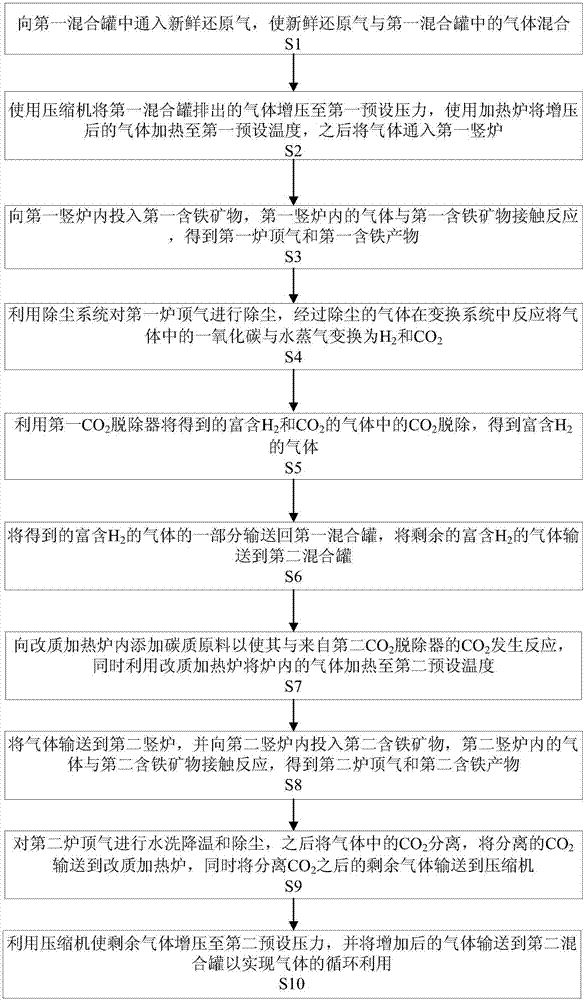

Double shaft furnace system and method for joint production

PendingCN107513596AEfficient use ofAchieve productionShaft furnaceProcess efficiency improvementShaft furnaceMixing tank

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Vanadium inhibitor, preparing method of vanadium inhibitor, vanadium inhibition composition, application of vanadium inhibition composition and preparing method of vanadium inhibition composition

The invention relates to a vanadium inhibitor, a preparing method of the vanadium inhibitor, a vanadium inhibition composition, application of the vanadium inhibition composition and a preparing method of the vanadium inhibition composition. The vanadium inhibitor comprises an active center and a wrapping layer. The active center comprises nanometer magnesium oxide. The wrapping layer comprises maleic anhydride grafted alpha-olefin, and the wrapping layer is connected with the active center through an ester bond. The vanadium inhibitor is good in oil dissolubility and strong in hydrolysis resistance.

Owner:SHENZHEN GCD PETROLEUM ADDITIVE CO

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

Continuous process for producing titanium tetrachloride

Owner:MILLENNIUM INORGANIC CHEM

Novel thermoforming reinforcer and processing method thereof

Owner:JINGJIANG XINCHENG VEHICLE PARTS

Improved coconut shell and method thereof for reducing vanadium in water body

InactiveCN107617425ALarge specific surface areaEasy to prepareOther chemical processesWater contaminantsSocial benefitsAlcohol

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

High heat input welding resistant building steel and production method thereof

ActiveCN114150228AImprove welding effectGood anti-fatigueHeat treatment process controlProcess efficiency improvementNiobiumHeat cycling

Owner:NORTHEASTERN UNIV

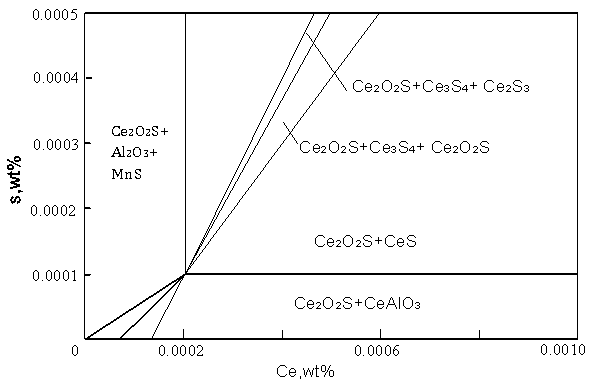

Smelting method for rare-earth microalloyed steel

Owner:内蒙古中天宏远稀土新材料股份公司

Method for increasing finished product rate of sintered ore

The invention relates to the field of iron and steel metallurgy, and discloses a method for increasing the finished product rate of sintered ore. The method for increasing the finished product rate ofthe sintered ore includes the steps that firstly, clear water is added in a sintered material and selectable return fines, first-time mixing is conducted, the amount of the return fines which are used is smaller than or equal to 30% of the weight of the sintered material, and the returned fines are vanadium-titanium sintered ore with the grain size being 5 mm or lower; secondly, second-time mixing is conducted on the mixed material obtained in the first step and mixed material reinforcement liquid; and thirdly, the mixed material obtained in the second step is subjected to material distribution, ignition and sintering, wherein the mixed material reinforcement liquid is prepared from corn starch and warm water according to the proportion being (0.05-1) : 99, and the temperature of the warmwater is 40 DEG C to 80 DEG C. By means of the method, the size composition of the mixed material can be improved, and therefore the finished product rate of the sintered ore is increased.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Alloy powder for plasma cladding

PendingCN109735842AImprove performanceGood workmanshipMetallic material coating processesWear resistantAlloy

Owner:WEIFANG UNIVERSITY

Heat treatment quenching technology for high-carbon chromium-molybdenum-vanadium powder hubbing steel precise parts

The invention discloses a heat treatment quenching technology for high-carbon chromium-molybdenum-vanadium powder hubbing steel precise parts. The technology comprises the following steps that 1, workpieces with the average thickness being 32 mm are put into a quenching furnace to be preheated twice to reach the temperature being 150 DEG C; 2, heating is conducted in the quenching furnace in two stages to reach the quenching temperature being 1,018 DEG C, and heat preservation is conducted; 3, the workpieces are subjected to discharge and air cooling till the temperature is 65 DEG C; 4, the workpieces are put into a tempering furnace twice, heat preservation and tempering are conducted at 510 DEG C, and discharge and air cooling are conducted. The workpieces with the average thickness being 32 mm are put into the quenching furnace to be preheated twice, for the first time, the temperature is raised to 100 DEG C at the heating speed smaller than 75 DEG C / hour, and for the second time, the temperature is raised to 150 DEG C at the heating speed smaller than 115 DEG C / hour. Accordingly, the excellent performances such as the extremely high abrasive wear resistance and high pressure resistance strength, good toughness and good size stability of heat treatment of the precise parts are reliably guaranteed, and the use requirements of the precise parts are met.

Owner:HUBEI ENG INST

Corrosion-resistant alloy

InactiveCN103265751ACorrosion resistant alloyLithium

The invention relates to a corrosion-resistant alloy, consisting of main components and auxiliary components, wherein the main components consist of the following components in percentage by mass: 32-38% of magnesium, 2-6% of molybdenum, 15-18% of lithium, 2-5% of cobalt, 18-23% of nickel and 2-5% of vanadium; and the auxiliary components consist of the following components in percentage by mass: 15-25% of ethylene-tetrafluoroethylene copolymer, and 1-2% of a lubricant. The corrosion-resistant alloy has good corrosion resistance.

Owner:CHUZHOU HAOYU SLIDING BEARING CO LTD

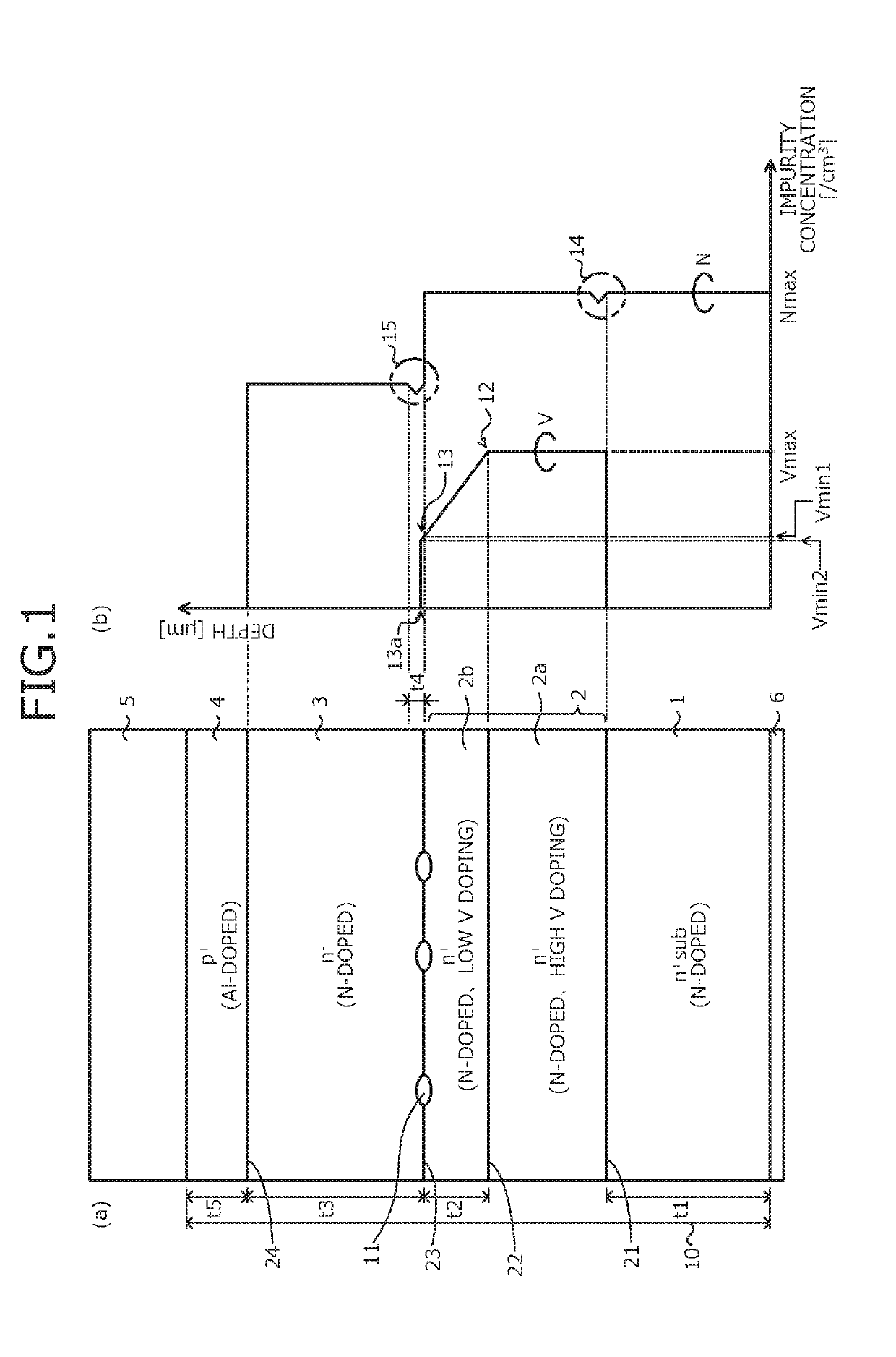

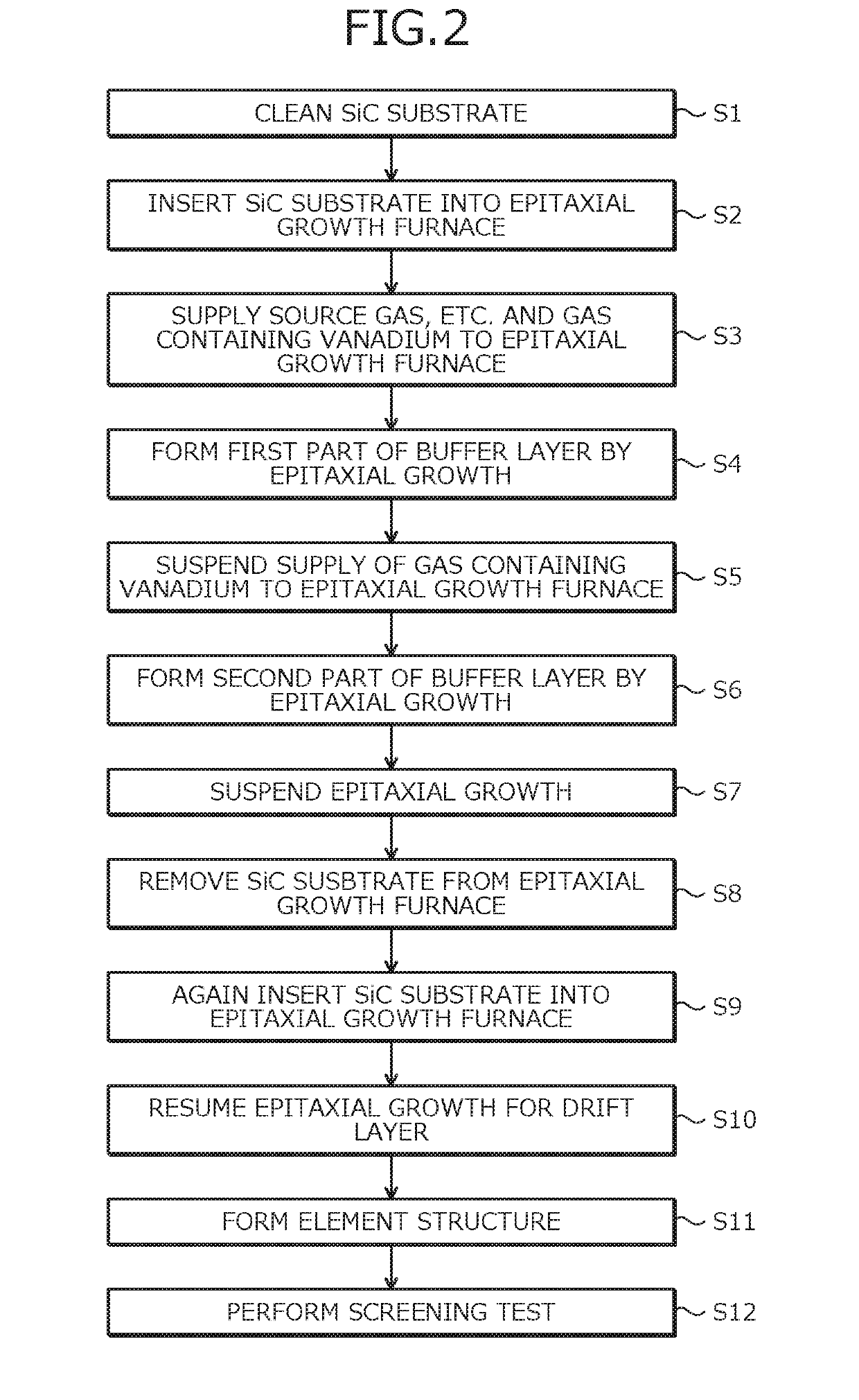

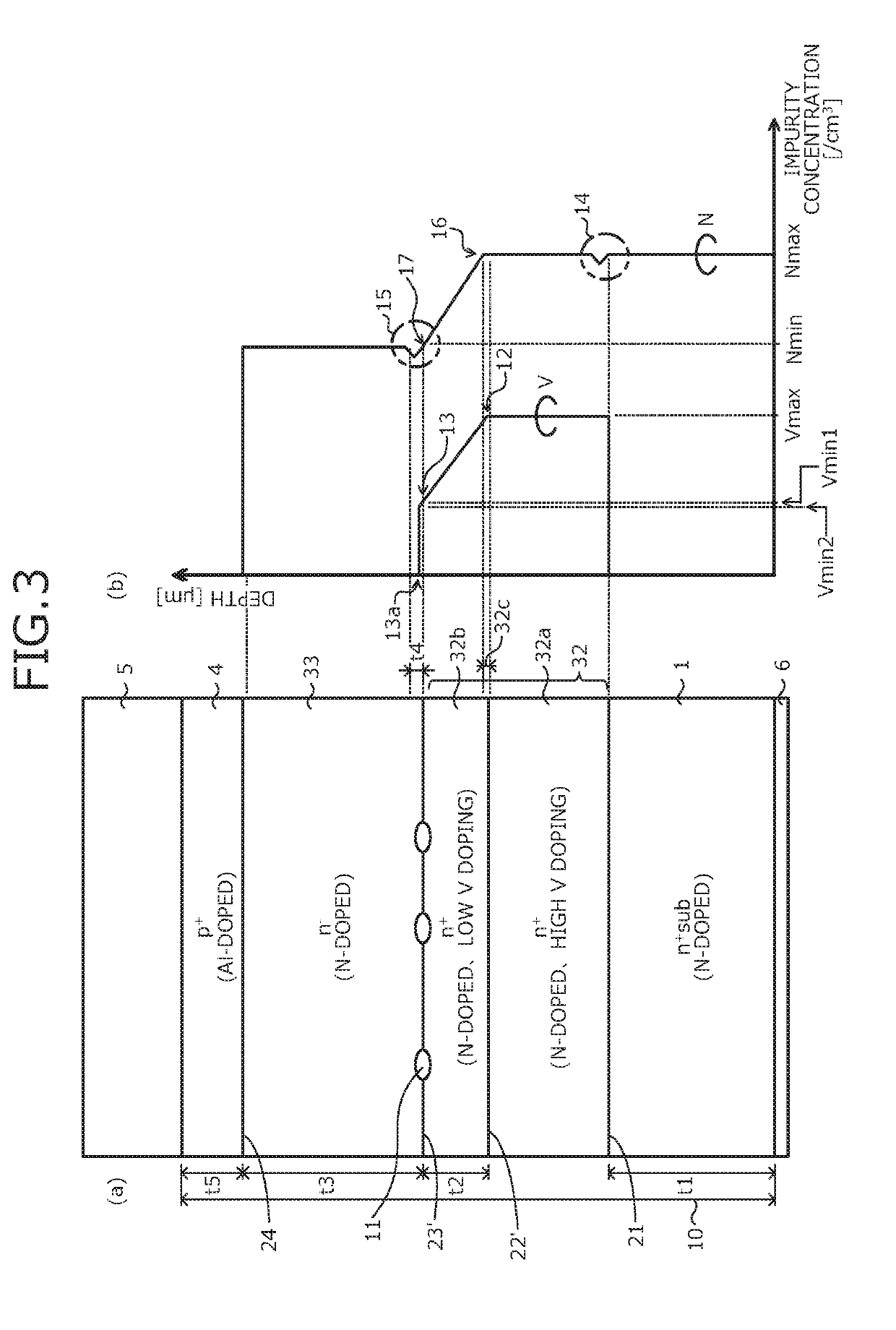

Silicon carbide semiconductor device and method of manufacturing silicon carbide semiconductor device

ActiveUS20190237547A1Semiconductor/solid-state device manufacturingSemiconductor devicesNitrogenSemiconductor

Owner:FUJI ELECTRIC CO LTD

Material formula for diamond bit

InactiveCN108746592AReduce manufacturing costHigh tensile strengthTransportation and packagingMetal-working apparatusNiobiumSilicon dioxide

Owner:如皋千骏工具有限公司

Preparation method of prestressed steel strand for cable suspension

Owner:合肥悦兰信息技术有限公司

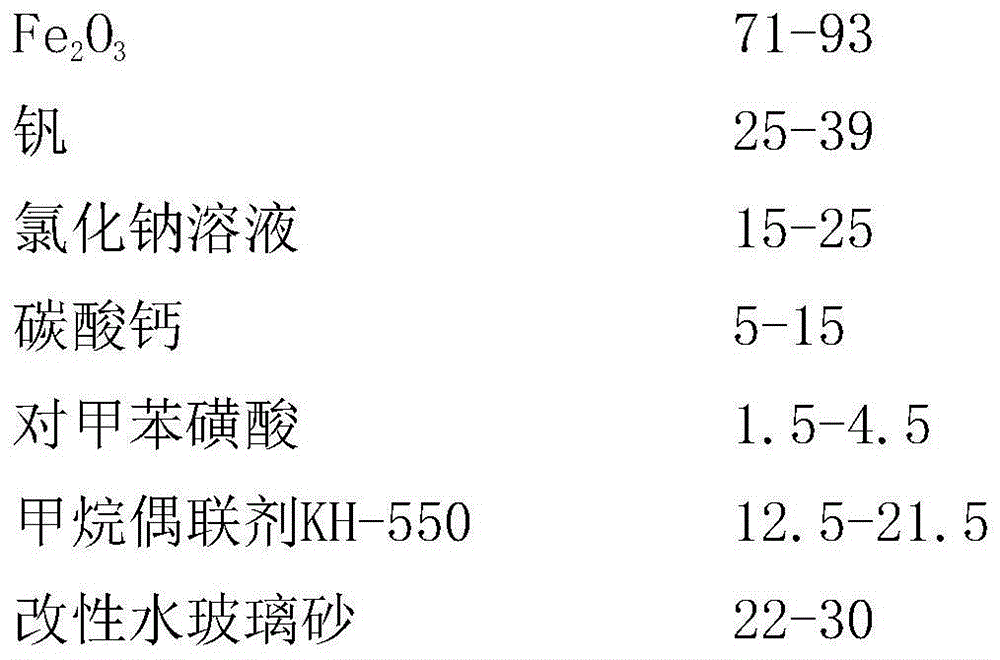

Chemical industry raw material placing barrel

InactiveCN104911433AImprove chemical performanceLow pricePackaging corrosive chemicalsChemical industryCoupling

Owner:含山县宏记精工铸造厂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap