Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Steel bar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steel bar, also called slide, play bar and bottleneck, is a musical apparatus which is used to play on steel guitars. The steel bar can be wound around the fingers or just held in the hand. Instead of pressuring the strings on the neck of the guitar, the steel bar slides over the strings, which produces a glissando effect.

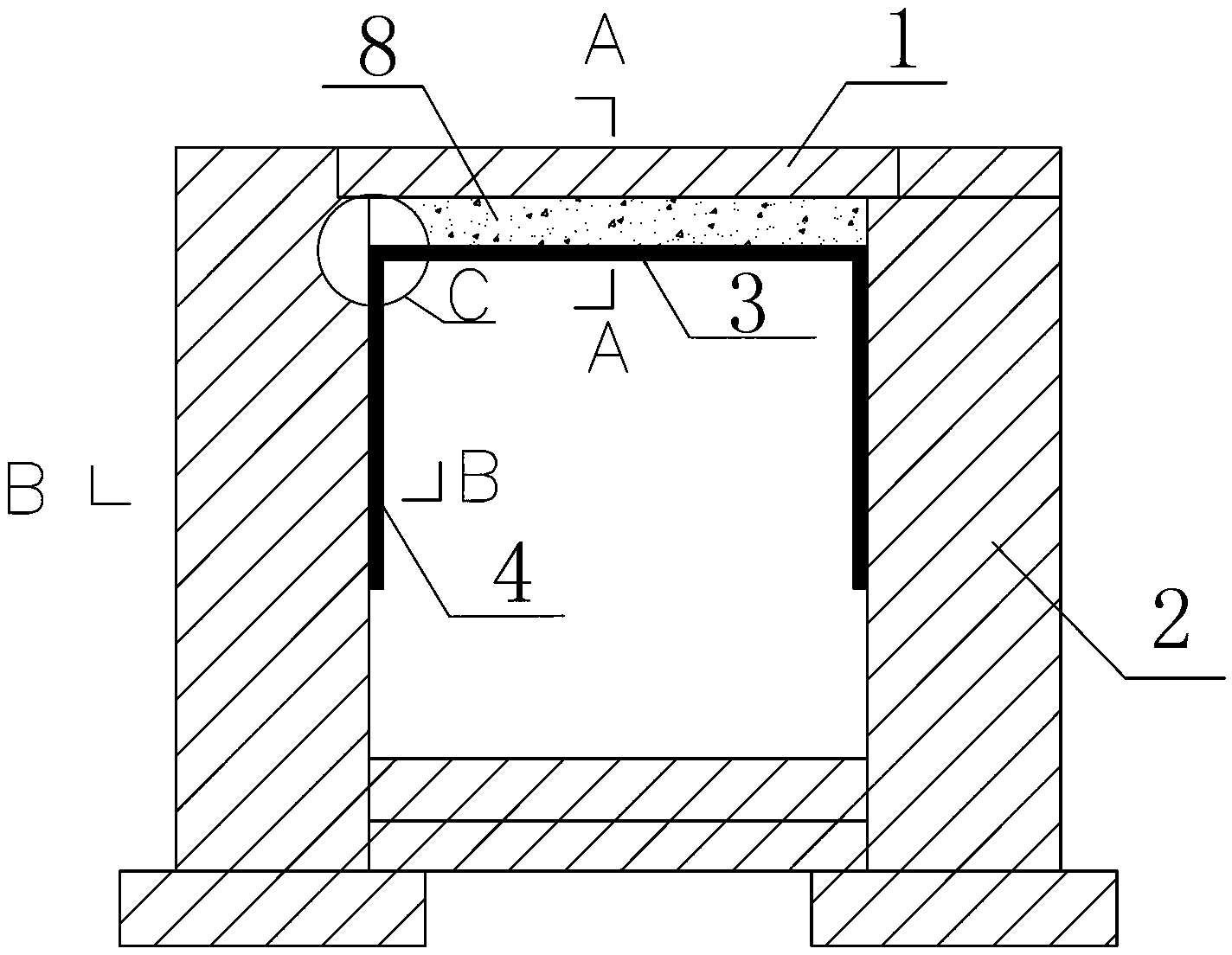

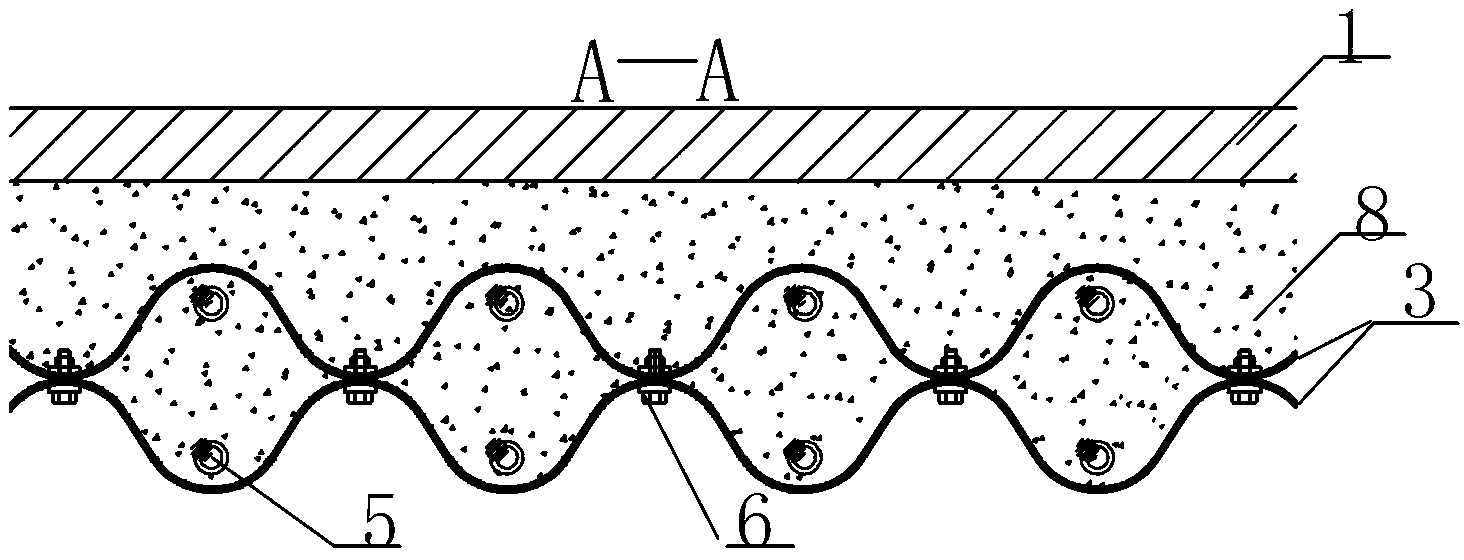

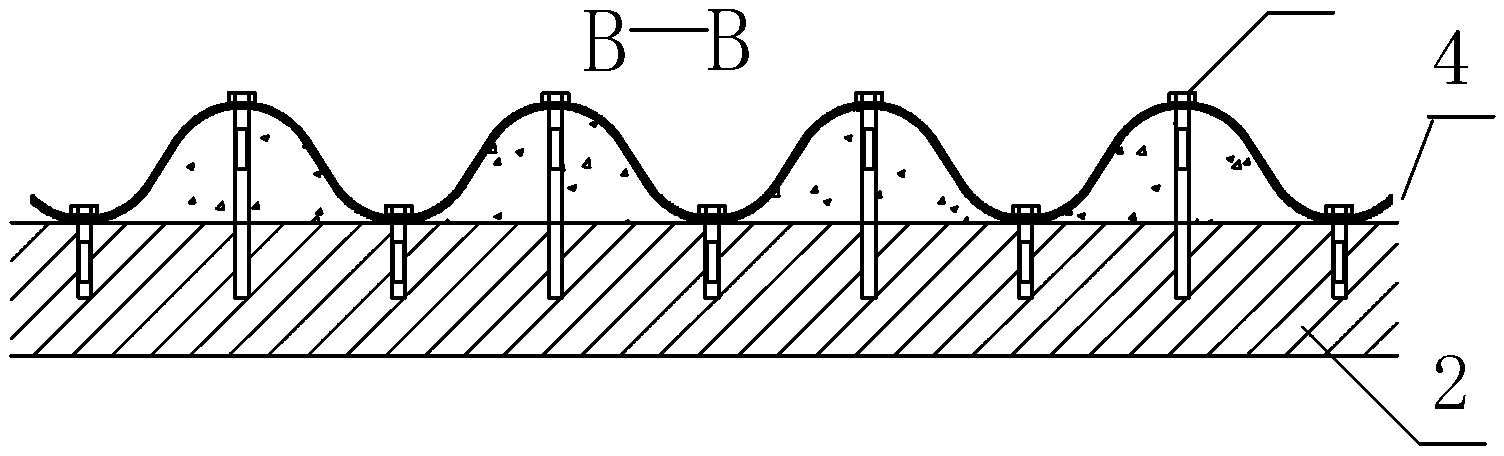

Wavelike steel plate and concrete combined shear wall

InactiveCN101922187AEffective energy dissipationHigh resistance to lateral forceConstruction materialWallsSheet steelWave shape

The invention discloses a wavelike steel plate and concrete combined shear wall, which belongs to the technical field of structural engineering. The wavelike steel plate and concrete combined shear wall is characterized by consisting of a wavelike steel plate, concrete, a reinforcing fabric, shear-resistant studs and connecting plates, wherein the shear wall is embedded into an edge frame; the connection modes of the wavelike steel plate and the edge frame are divided into two modes that: if the edge frame is a steel frame, the wavelike steel plate is welded with the edge steel frame at the periphery; and if the edge frame is a concrete frame, the wavelike steel plate is first welded with the four connecting plates at the periphery and then connected with the edge frame through the shear-resistant studs on the connecting plates. The outer surface of the wavelike steel plate on the side with concrete is provided with the shear-resistant studs, and the concrete is poured after the reinforcing fabric is arranged, so that the wavelike steel plate and concrete combined shear wall can be obtained.

Owner:TSINGHUA UNIV

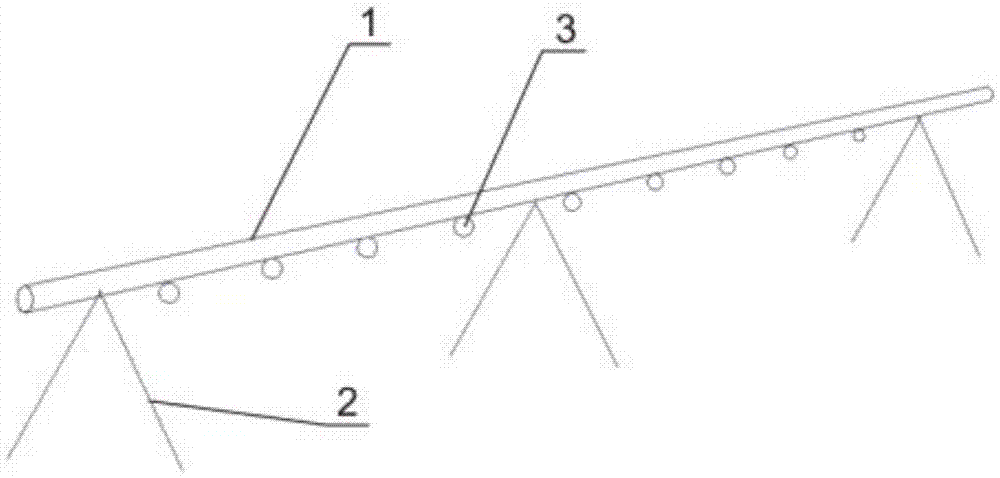

Hollow floor system filled with an air-filling bag and construction method thereof

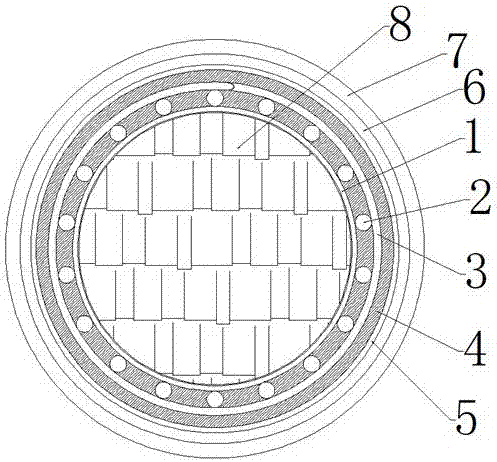

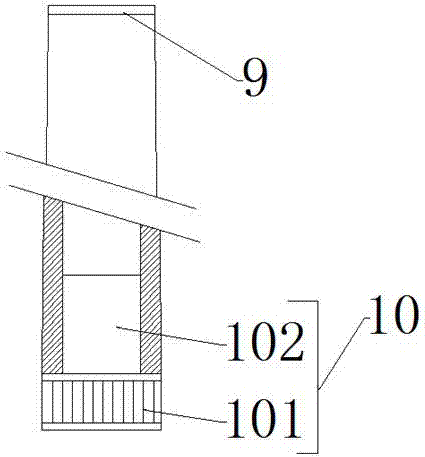

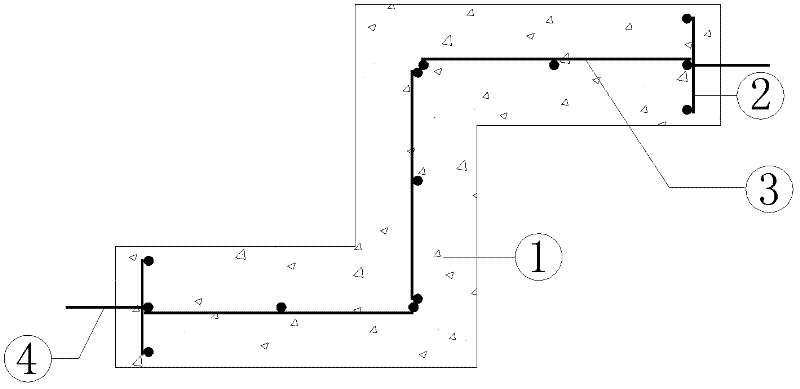

InactiveCN101793070ALight shock and vibration resistanceGood shock and vibration resistanceFloorsEarthquake resistanceCrack resistance

The invention relates to a hollow floor system filled with an air-filling bag and a construction method thereof, belonging to the field of the structure of the common building. The hollow floor system consists of the air-filling bag (1), upper steel bars (2), lower steel bars (3), hidden girder steel bars (4) and concrete (5), wherein the air-filling bag (1) is positioned among the upper steel bars (2), the lower steel bars (3) and the hidden girder steel bars (4); a bag wall (8) of the air-filling bag (1) consists of four side walls (9), an upper wall (10) and a lower wall (11); the shapes of at least two side walls (9) adjacent to the hidden girder steel bars (4) in the air-filling bag (1) are planes; the shapes of the upper wall (10) and the lower wall (11) are heaved-outward arc surfaces; and positioning pieces (12) are arranged among the inner sides of the side walls (9) so as to ensure that the two side walls (9) are parallel mutually. The hollow floor system has large span, better reliability, earthquake resistance and crack resistance, and good economy and applicability.

Owner:徐焱

Reinforced culvert

Owner:NANJING LIANZHONG CONSTR ENG TECH

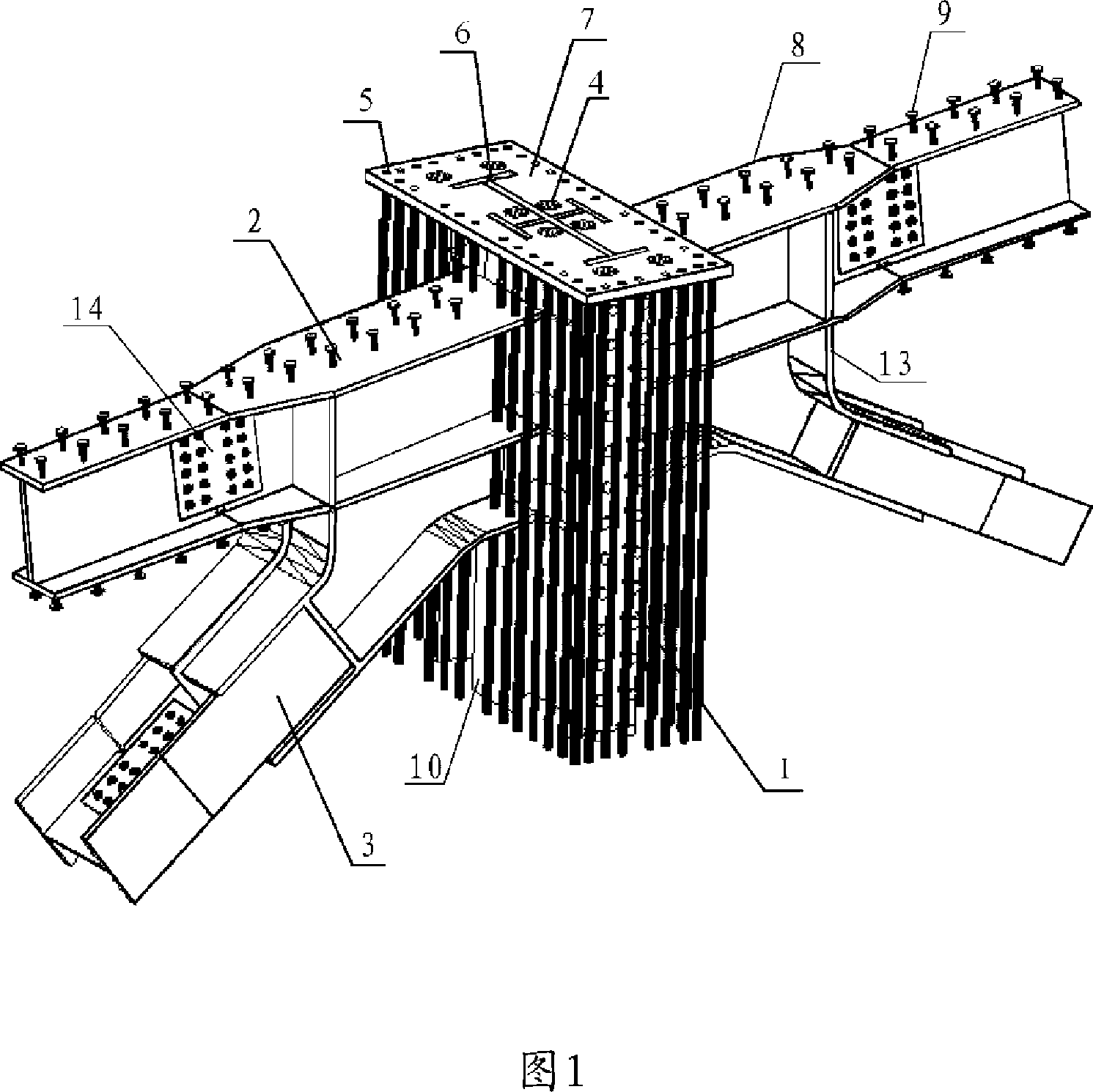

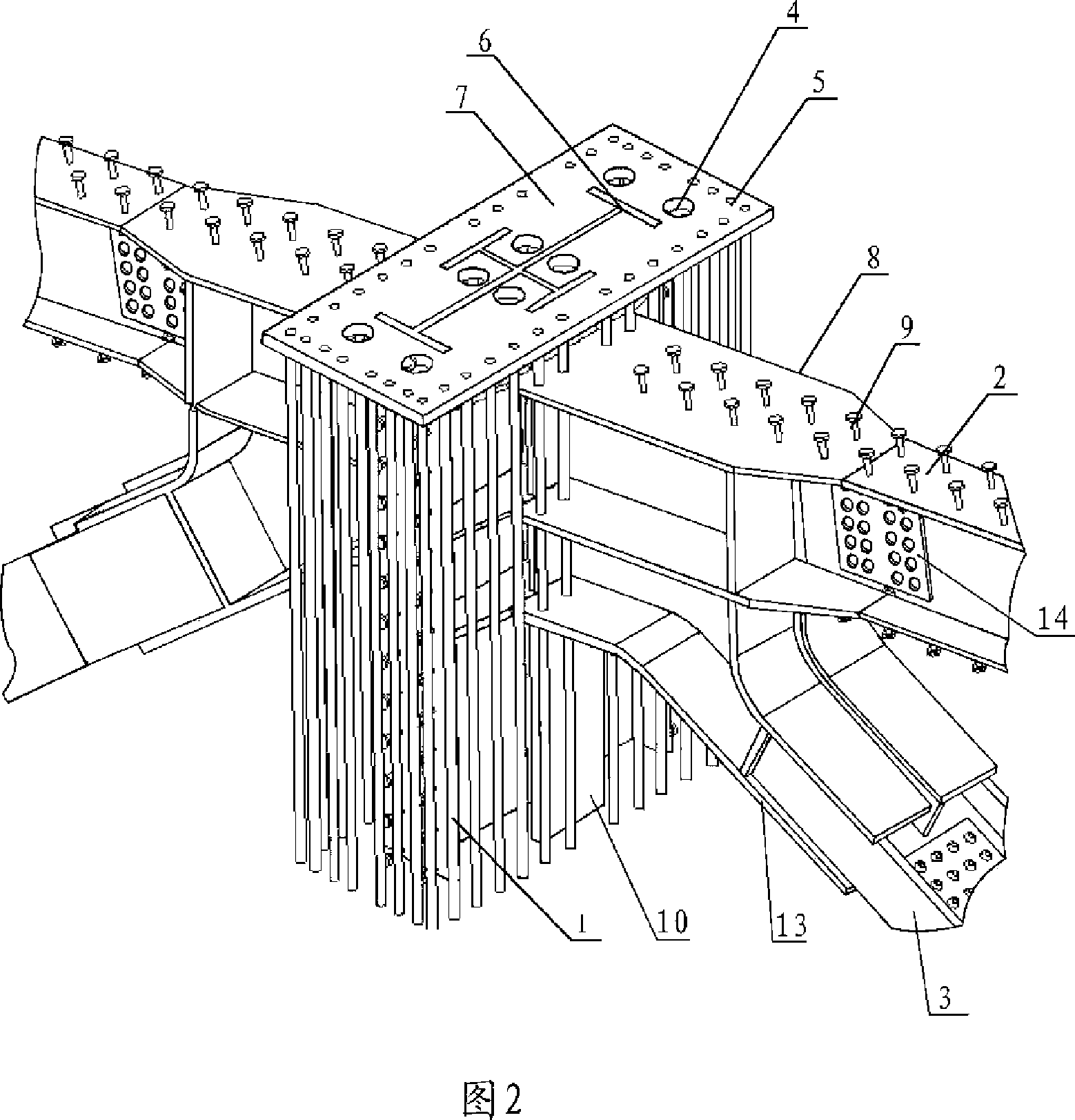

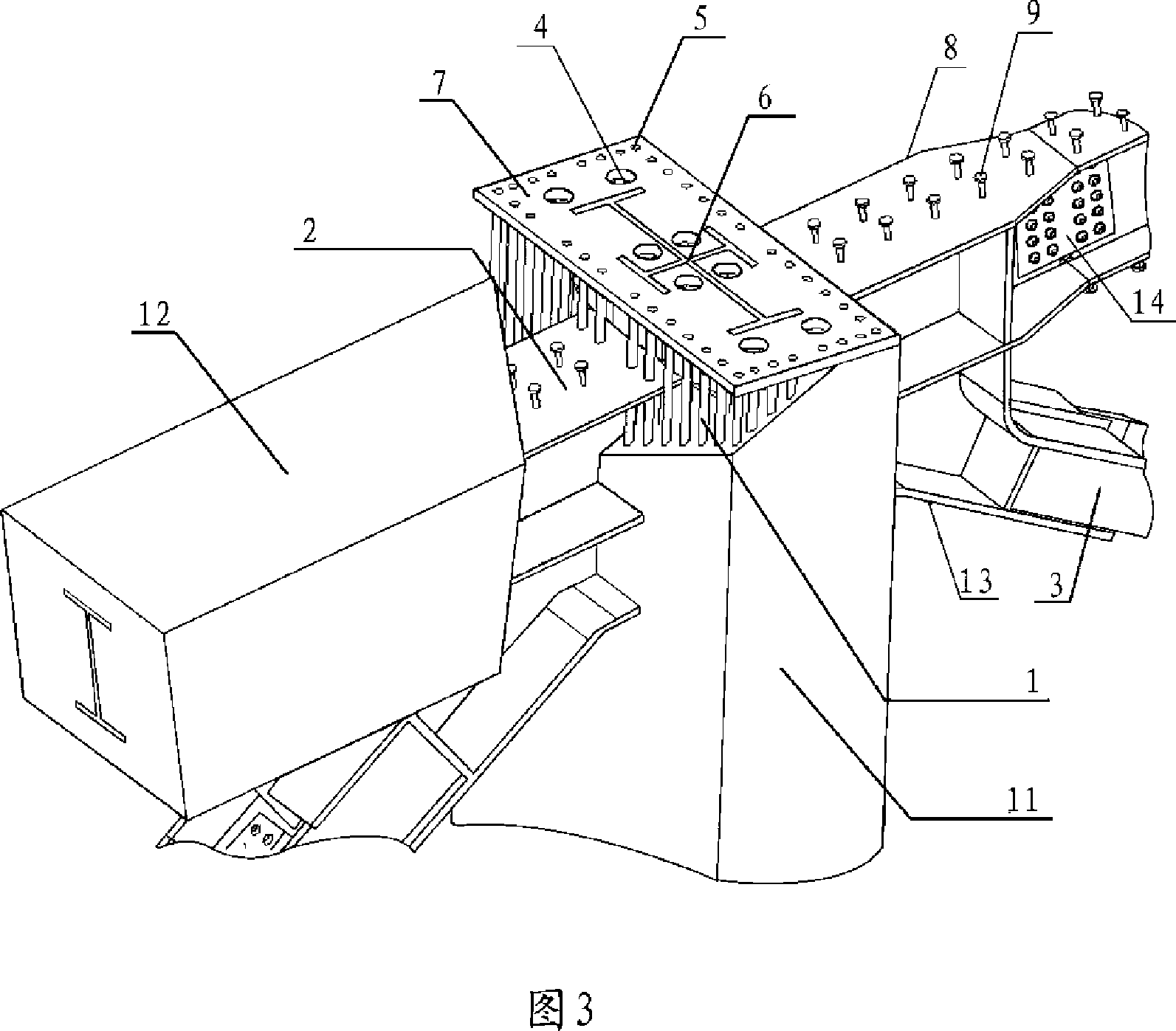

Shaped-steel concrete frame-steel supporting structure type steel column preconstraint node

ActiveCN101024974AImprove integritySafe and reliable connectionBuilding constructionsSheet steelSteel bar

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

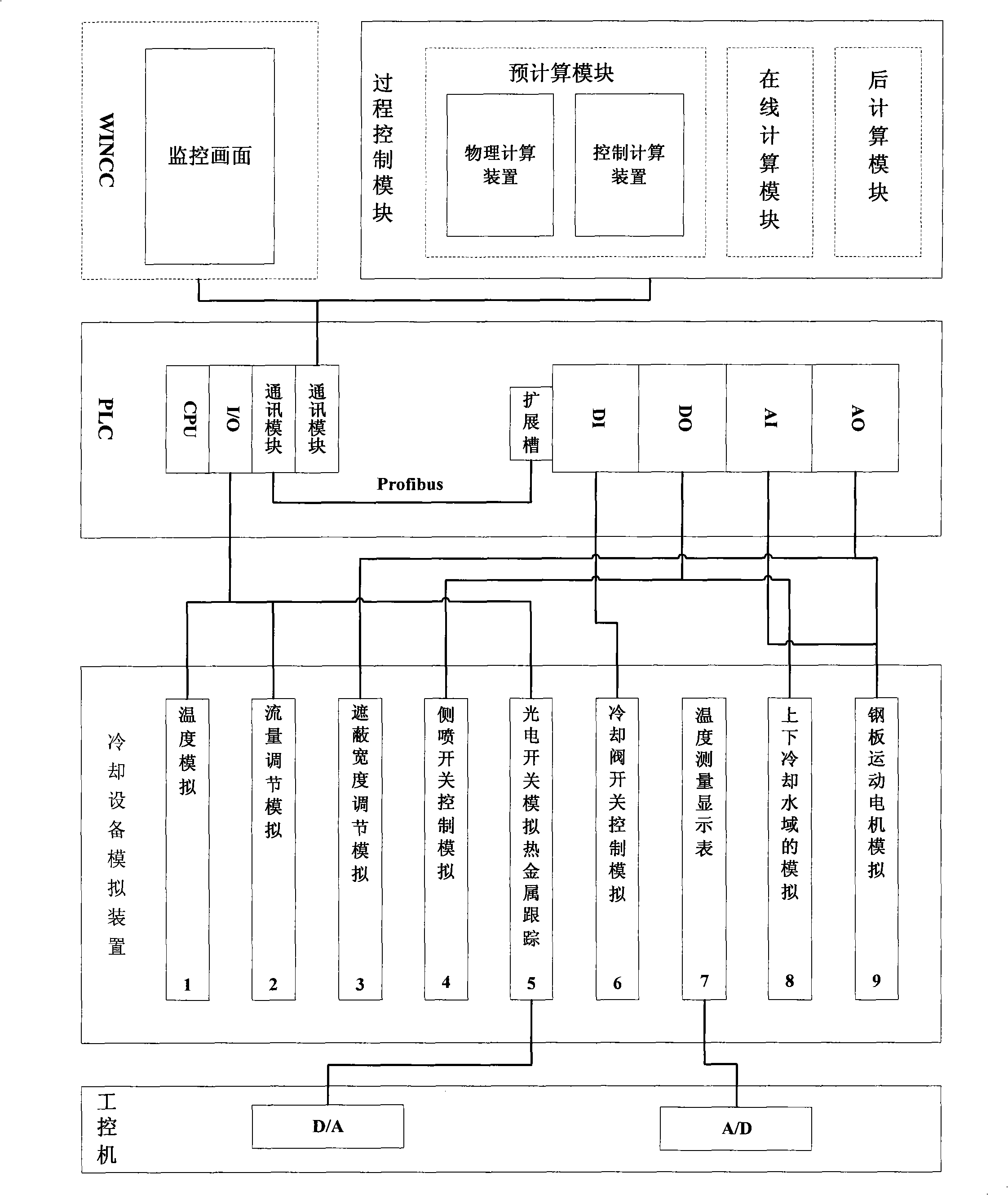

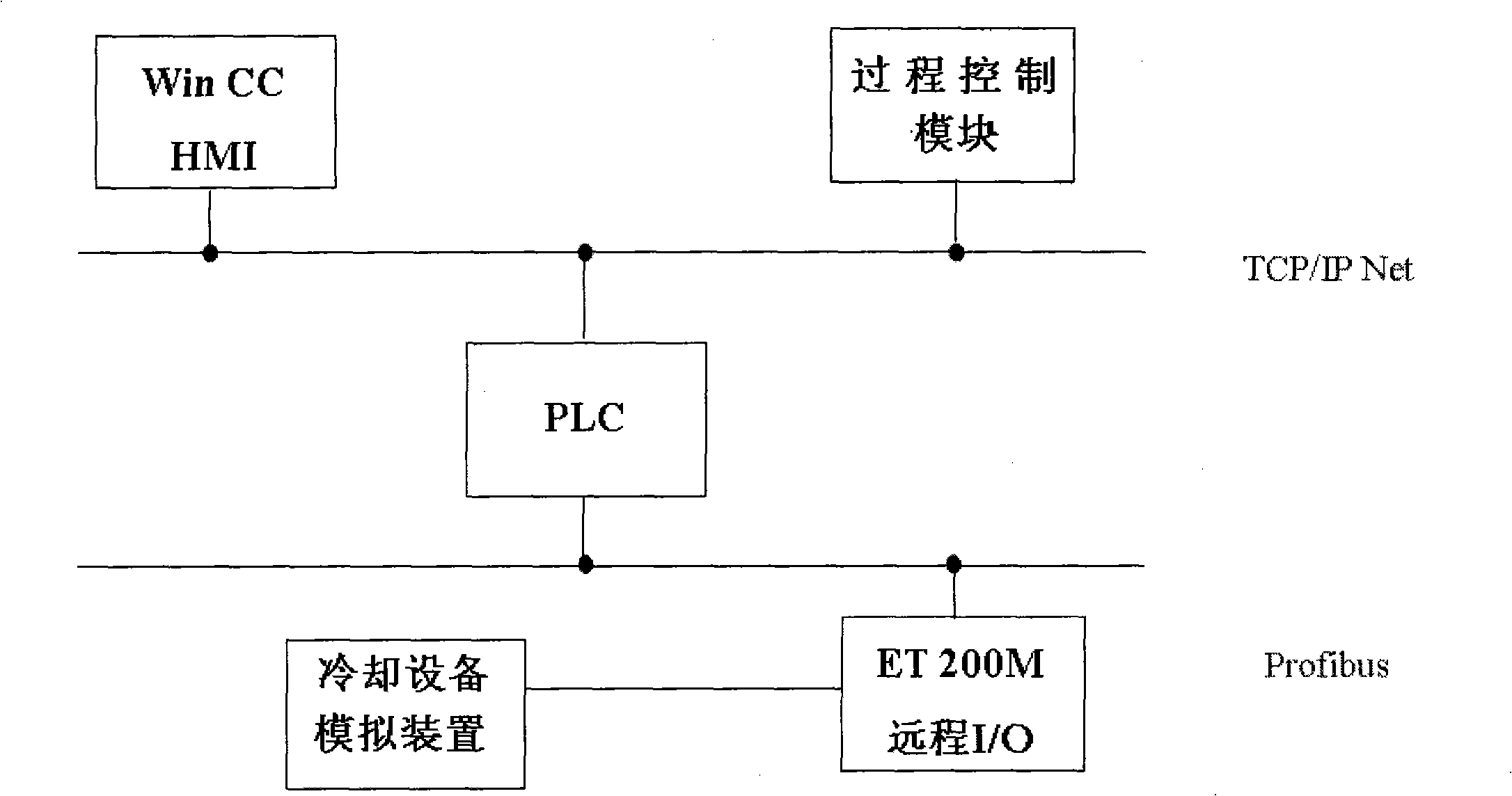

Steel plate cooling control analog system and method

ActiveCN101276209AGood simulation environmentSave time during in-circuit debuggingSimulator controlWork treatment devicesProcess systemsDevice simulation

Owner:BAOSHAN IRON & STEEL CO LTD

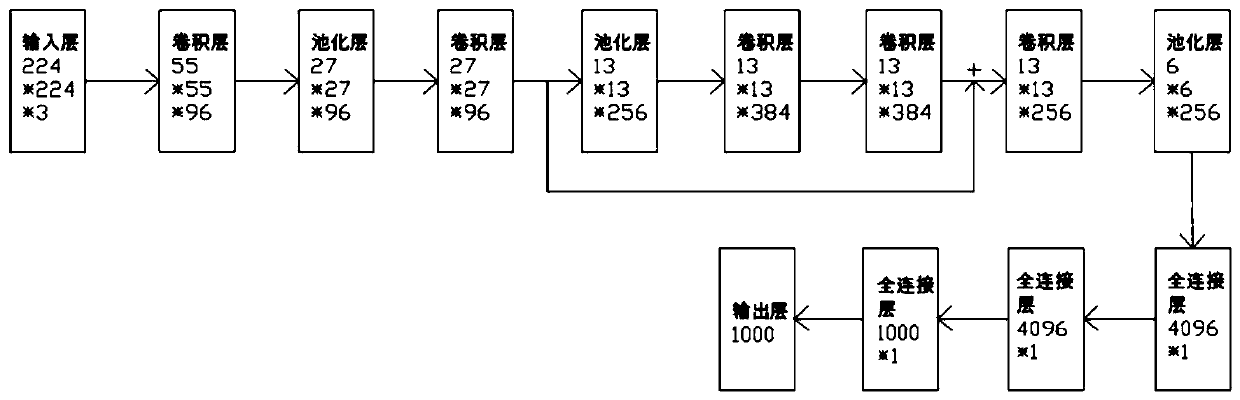

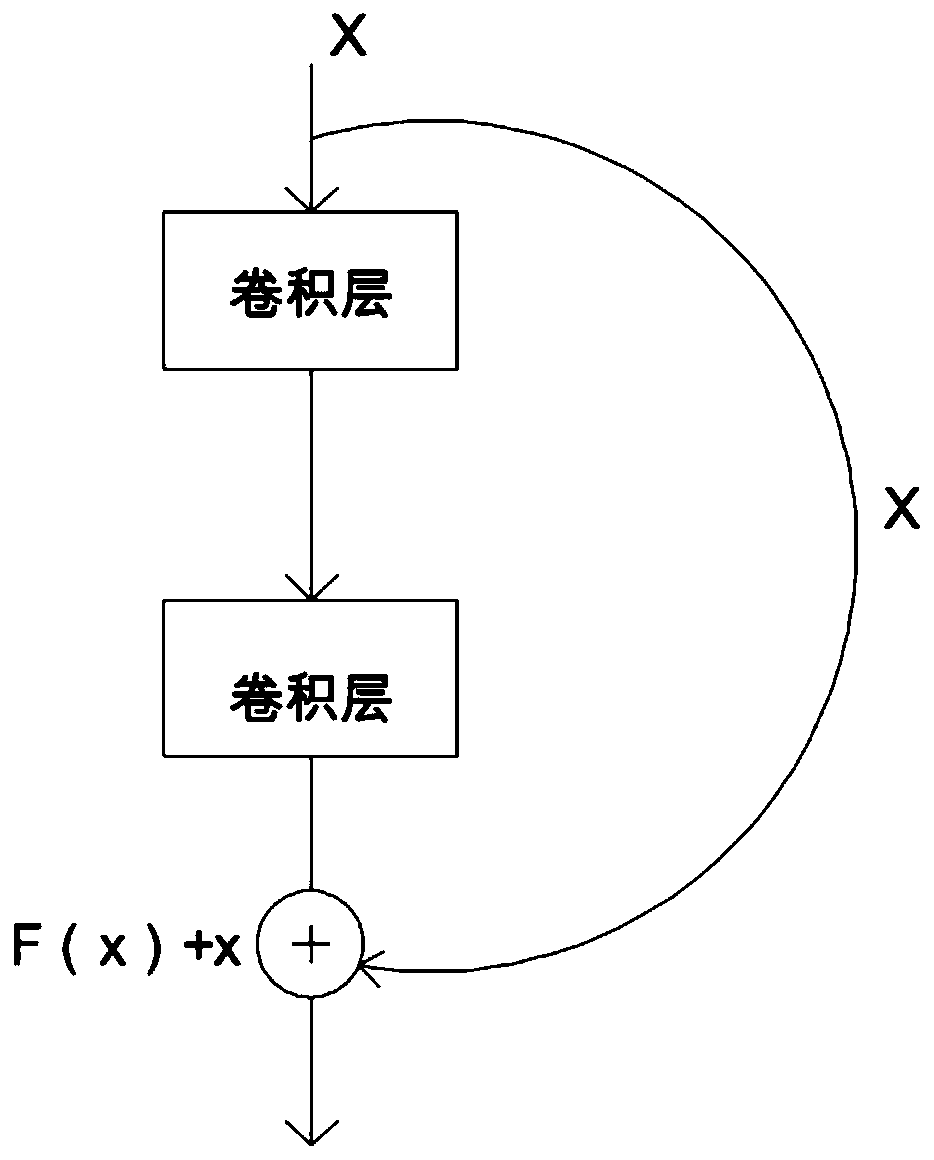

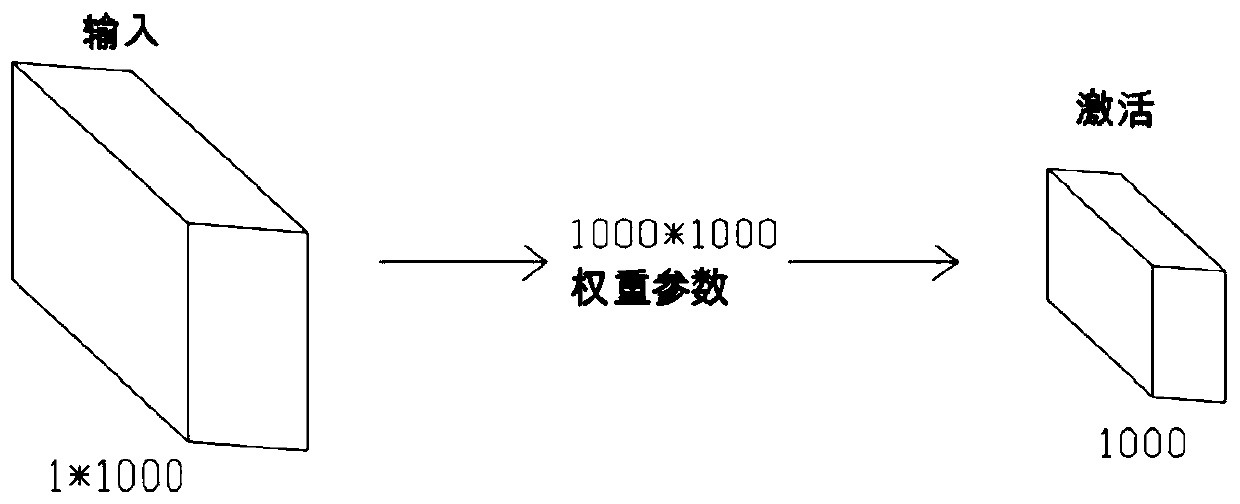

Automatic steel bar bundling position identification method

ActiveCN110097087AQuality improvementAvoid safety hazardsCharacter and pattern recognitionNeural architecturesPositive sampleSteel bar

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Small-dimension British standard deformed steel bar B500B and manufacturing technology thereof

The invention discloses a small-dimension British standard deformed steel bar B500B and a manufacturing technology thereof. The chemical component requirements of the small-dimension British standard deformed steel bar B500B are: C: 0.19-0.22 wt%, Si: 0.20-0.60 wt%, Mn: 0.70-0.90 wt%, Cr: 0.5-0.8%, P, S: less than or equal to 0.035 wt%, Ni, Cu: less than or equal to 0.25 wt%, Mo, Al: less than or equal to 0.10 wt%, and N: less than or equal to 0.011 wt%; the balance is Fe; carbon equivalent Ceq is less than or equal to 0.50%. The technology comprises converter or electric furnace smelting, LF refining or argon blowing refining, CCM bloom or billet continuous casting, bar controlled rolling, and controlled cooling. The component design takes chromium to replace expensive vanadium for alloying, is matched with reasonable-design controlled rolling temperature and air cooling temperature, realizes production of the small-dimension British standard deformed steel bar B500B with qualified performance in low cost, and acquires favorable economical and social benefits.

Owner:NANJING IRON & STEEL CO LTD

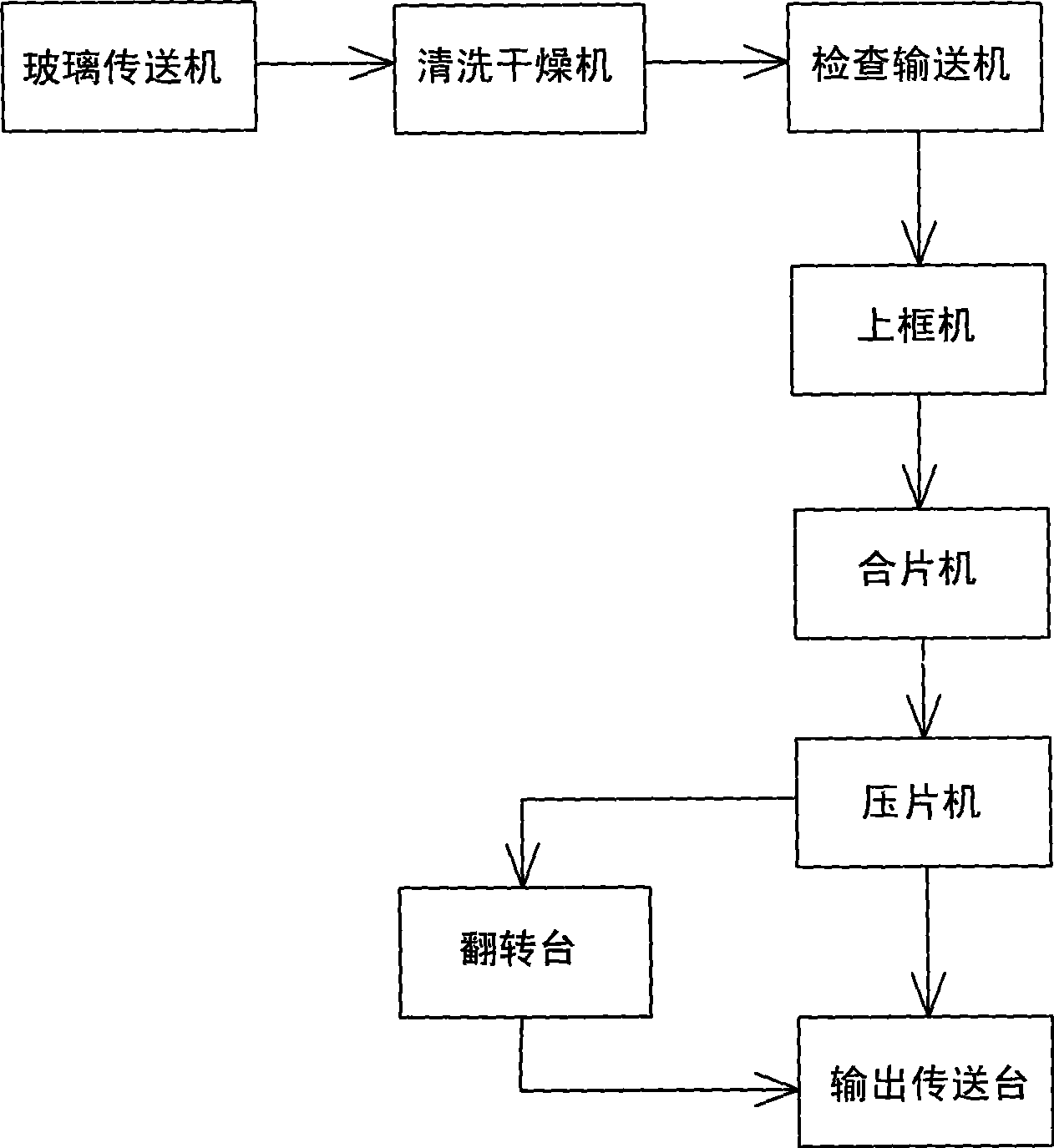

Production process of hollow glass

Owner:北京韩江自动化玻璃机械设备有限公司

Autoclaved aerated concrete and reinforcement hollow pipe bar plate

PendingCN108661233ANo increase in reinforcementExtended service lifeConstruction materialPolyesterSteel bar

Owner:大连唐家现代建材有限公司

Construction method of long steel bar stool cast-in-situ floor

InactiveCN105442735AControl thickness deviationEasy constructionFloorsBuilding reinforcementsFloor slabSurface level

Owner:广西华业建筑工程有限公司

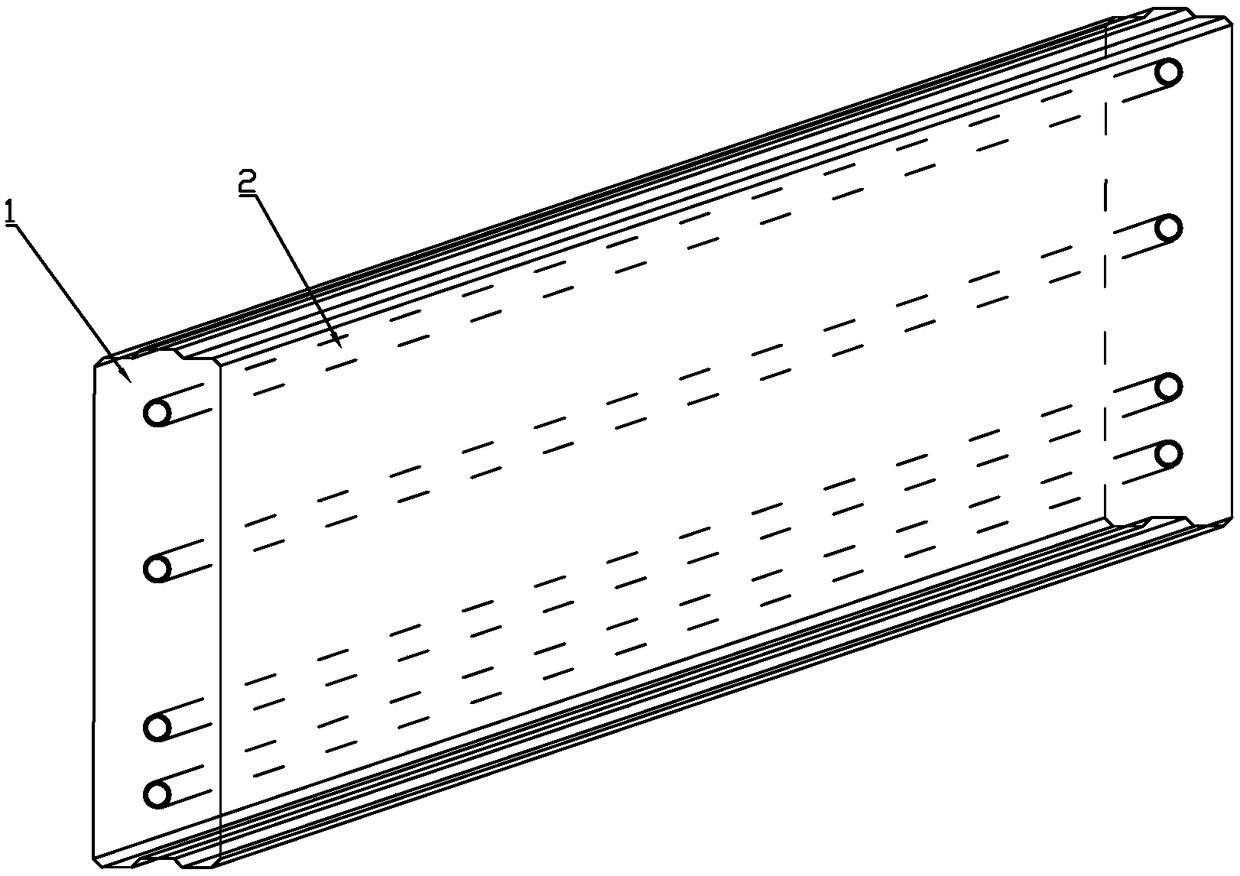

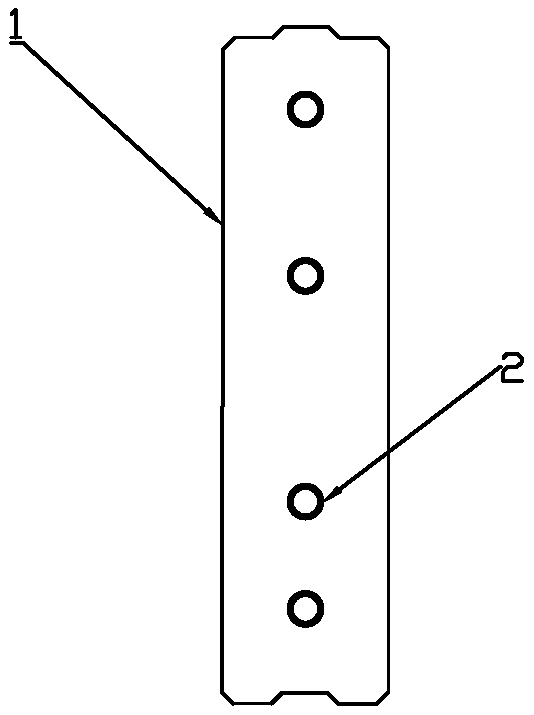

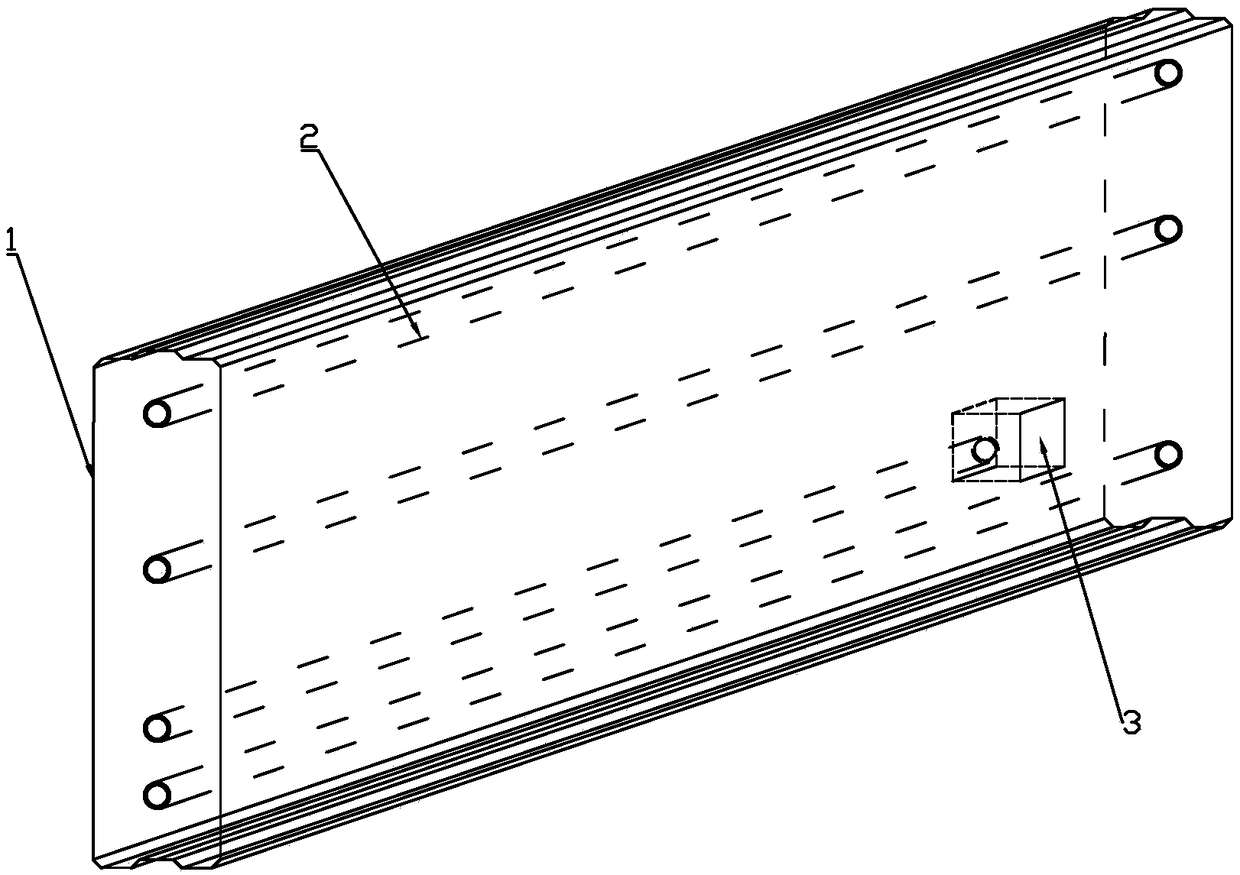

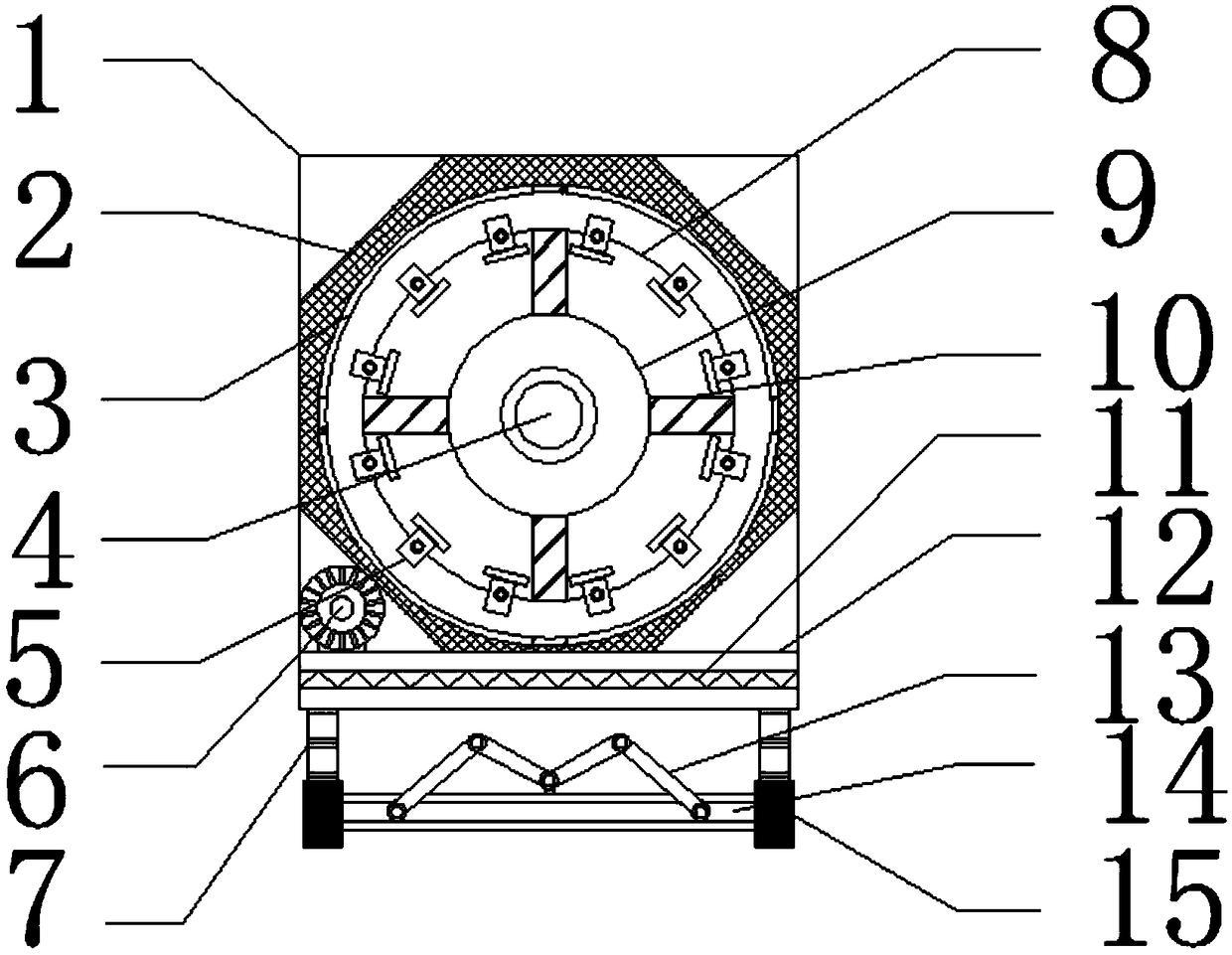

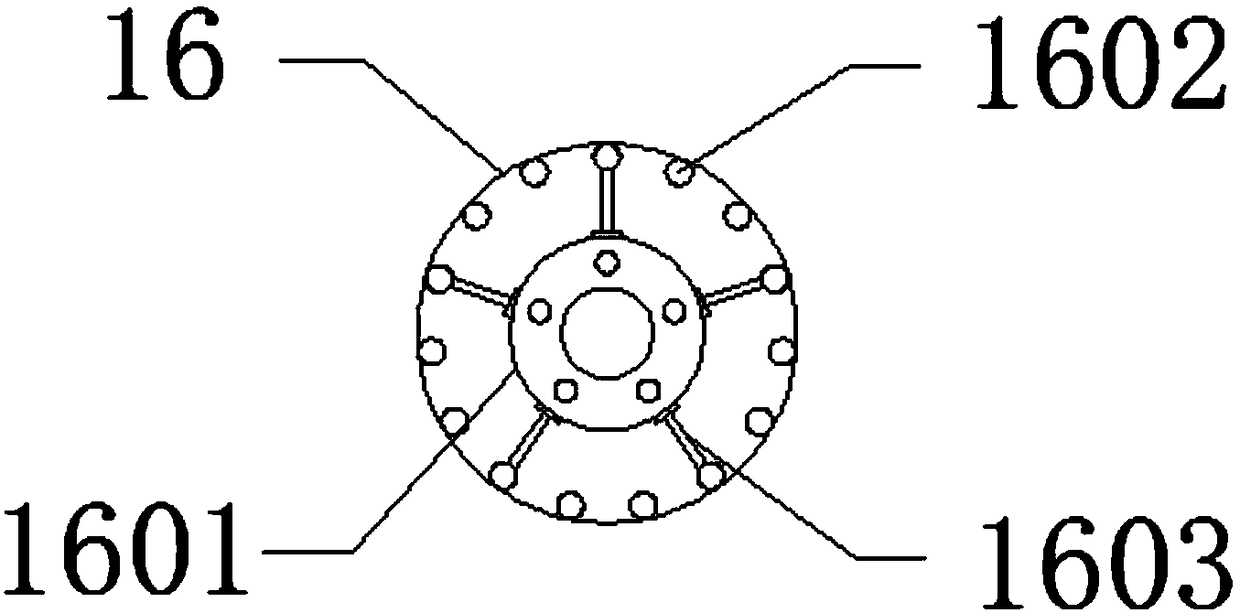

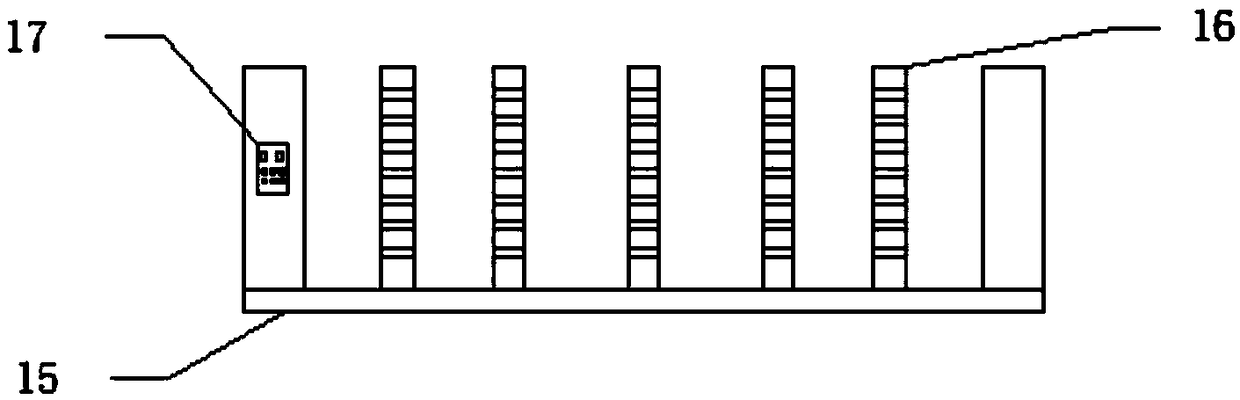

Folding car carrier structure of movable parking device

The invention discloses a folding car carrier structure of a movable parking device. The folding car carrier structure comprises a bottom steel frame and a rectangular steel frame, wherein a car carrying plate is mounted on the bottom steel frame, a group of parallel first steel bars is mounted on the rectangular steel frame, a group of parallel second steel bars intersecting with the first steel bars is mounted in the rectangular steel frame, the first steel bars are connected with the second steel bars through screws, the upper frame and the lower frame of the rectangular steel frame both are composed of a group of third steel bars, a fixed joint is mounted at the angle of the top end of the rectangular steel frame, a control box is mounted on the top end of the rectangular steel frame, driving shafts are mounted on the bottom end of the car carrying plate through rotating shafts and connected with one another through shrinkage rods, pulleys are connected to the lower ends of the driving shafts through connecting rods, and pulley guide rails are arranged on the bottom ends of the pulleys. The folding car carrier structure of the movable parking device is simple in structure, convenient to operate, and foldable, and therefore, the space usage of the car carrier is reduced and the volume of the movable parking device is reduced.

Owner:XIAN BOYU GREEN ENERGY

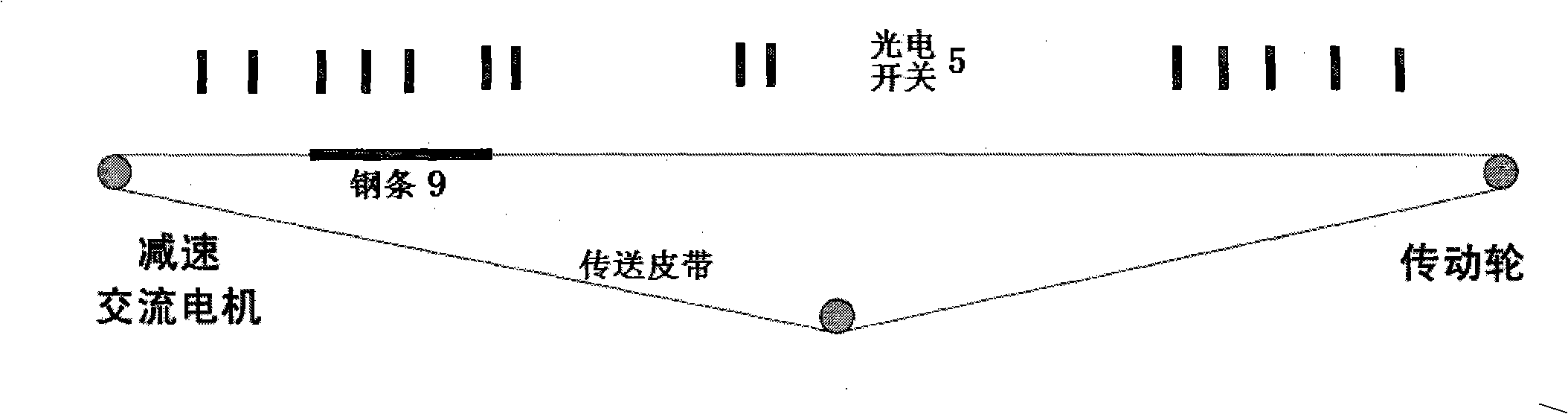

Main bar feeding mechanism of steel bar framework seam welder

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Portable type steel bar telegraph pole

InactiveCN107191052AImprove mechanical propertiesPlay an insulating roleTowersYarnMoisture resistance

Owner:HEFEI HAIYIN TOWER

Latticed single-row reinforced Z-shaped sectional concrete column and making method

InactiveCN102561594AReduce dosageImprove shear resistanceStrutsBuilding reinforcementsBrickSteel bar

Owner:BEIJING UNIV OF TECH

Flying Tail Cuff

Owner:KACOYANIS JASON NICHOLAS +1

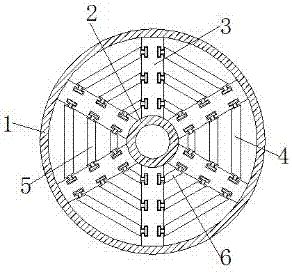

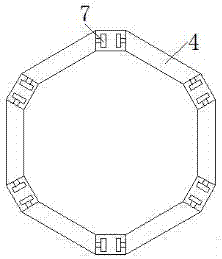

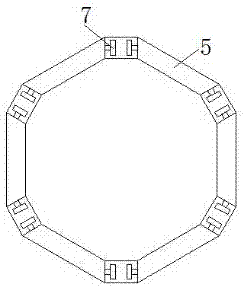

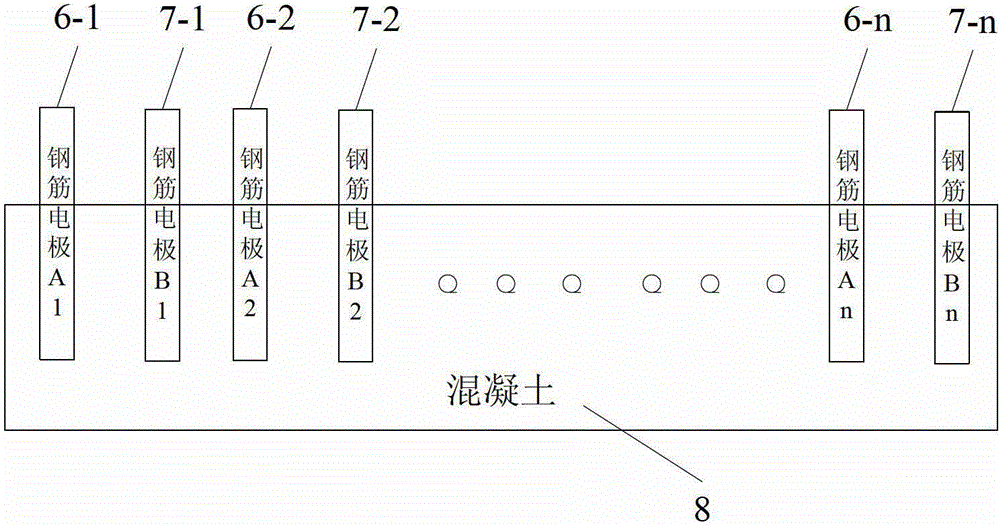

Concrete monitoring detector taking reinforcing steel bars as electrodes as well as monitoring and detection method of concrete monitoring detector

InactiveCN103105418BPerfectly compatibleEasy to useMaterial impedanceCommunication interfaceState of health

Owner:SICHUAN UNIV

Filling and off-loading box component cast-in-situ reinforced concrete slab

The invention belongs to the field of a cast-in-situ slab used for building, and more particularly relates to a site cast steel reinforced concrete slab filled with off-loading box components. The site cast steel reinforced concrete slab has fine stress section as well as convenient transportation and flexible arrangement of the off-loading components of the site cast steel reinforced concrete slab, and comprises a single body filled with an off-loading box, reinforcing steel bars and concrete, wherein, the single body filled with the off-loading box is an opening box comprising a box crest slab and a box side wall plate which are integrated into a whole, the edge around the bottom of the box side wall plate is a convex edge, the single body is placed with a downward opening, and the convex edge is at the same plane together with the lower surface of the slab. The site cast steel reinforced concrete slab filled with the off-loading box components can combine and distribute the single bodies of the box according to different stress requirements; furthermore, the single bodies of the box are convenient for combination and distribution, and the combination modes are flexible and diverse. Meanwhile, the single body filled with the off-loading box adopts an integral structure, can be sheathed, is convenient for transportation, has lighter weight and further saves the transportation cost.

Owner:王军艇

Component for cast-in-place concrete

InactiveCN1869361ARich varietyEasy to chooseFloorsForms/shuttering/falseworksSteel barMaterials science

The invention relates to a one side section for combining present casting steel bar concrete component. The feature is that: joining section is setting on the one side section or / and baffle and setting at least a baffle along the portrait. While the two one side sections buckling and forming a present casting steel bar concrete component by the joining component, the baffle would seal the end section of the component. It could be suitable for casting hollow roof, roof, basic bottom board, wall and hollow bridge.

Owner:HUNAN QIUZEYOUZHUANLIZHANLVE PLANNING CO LTD

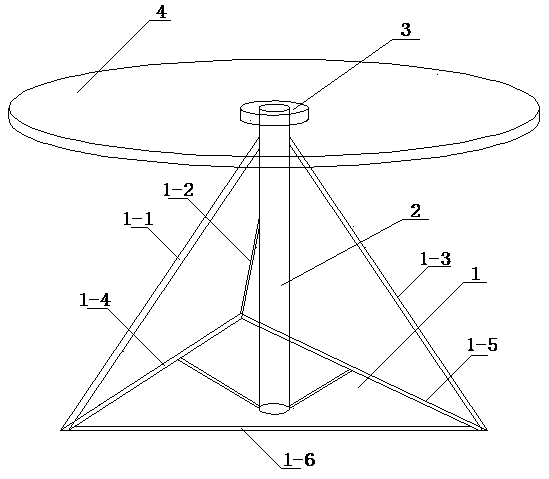

Auxiliary device for punching plate

An auxiliary device for punching a plate relates to the technical field of machine manufacturing. The device is characterized by comprising a steel structure triangular seat, a ball bearing mounting column, a ball bearing and a disc, wherein the steel structure triangular seat comprises a first steel bar, a second steel bar, a third steel bar, a fourth steel bar, a fifth steel bar and a sixth steel bar, the fourth steel bar, the fifth steel bar and the third steel bar are connected from the front to end to form the bottom surface of the steel structure triangular base, the bottom end of the first steel bar, second steel bar and third steel bar are connected with the bottom surface of the steel structure triangular base, the upper end is connected with the upper end of the ball bearing mounting column, the bottom end of the ball bearing mounting post is fixed on the fourth steel bar and the fifth steel bar through a strip-shaped steel; the ball bearing is arranged at the top end of theball bearing mounting column; and the disc is arranged on the ball bearing. The device has the advantages of simple structure, convenience and practicability, labor cost saving and increasing work safety coefficient and the like.

Owner:合肥翔威机电科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap