Automatic steel bar bundling position identification method

An identification method and steel bar technology, applied in the field of steel bar binding, can solve the problems of high cost of safety facilities, large personal safety hazards, and quality hidden dangers, and achieve the effect of avoiding safety hazards and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to illustrate the embodiments of the present invention more clearly, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

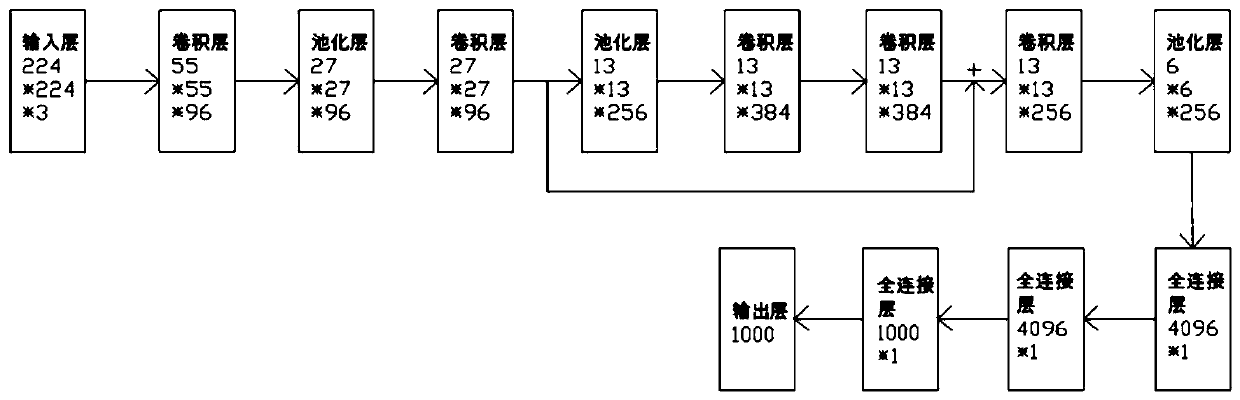

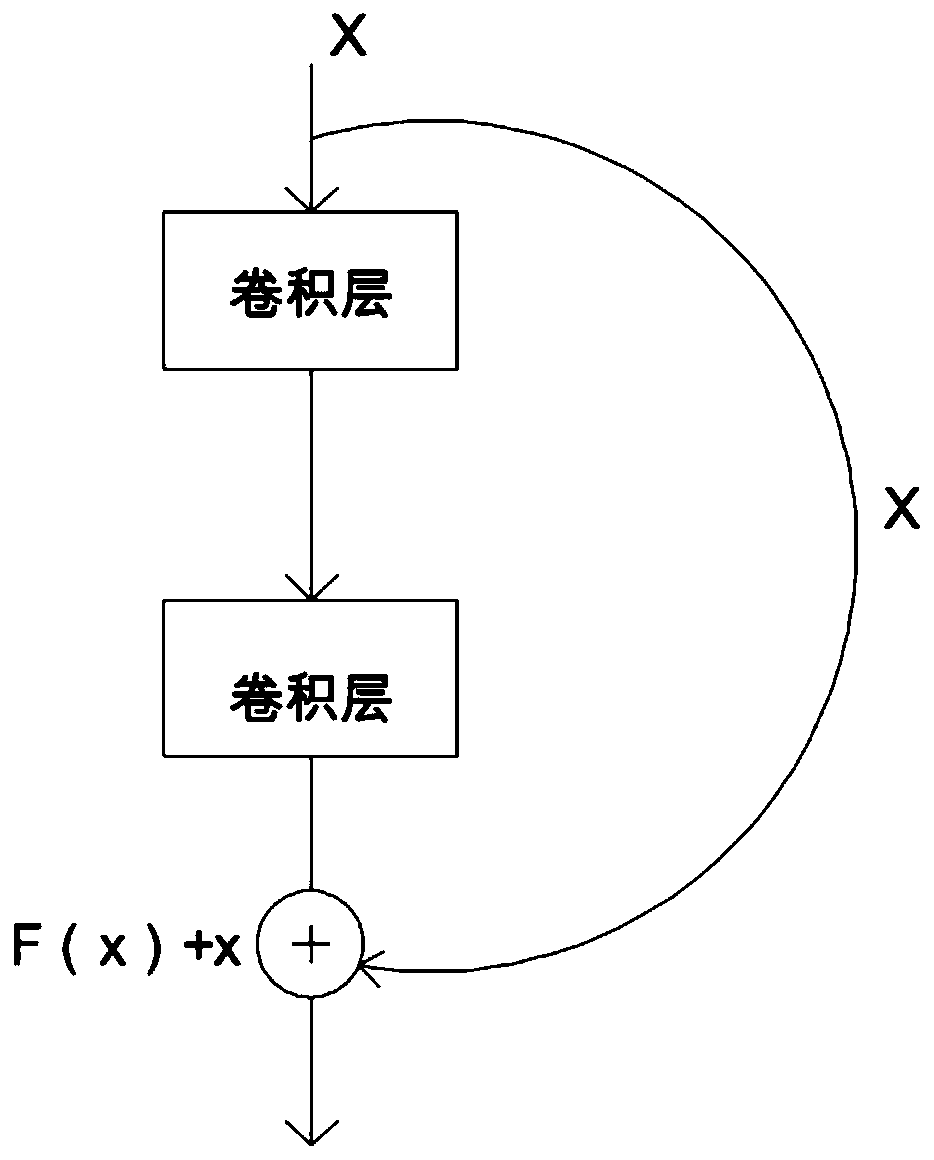

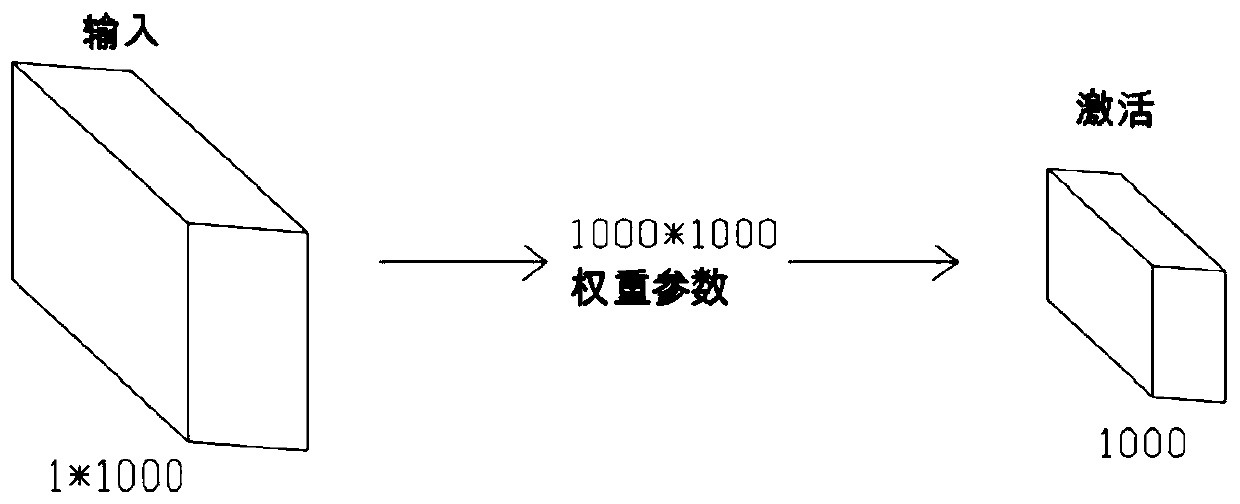

[0052] The automatic steel bar binding position recognition method of the embodiment of the present invention is applied to a system framework including a computer and a network camera. Specifically, the computer vision-based automatic steel bar binding position recognition method includes the following steps:

[0053] S1. Preprocess the positive sample pictures with steel bar binding objects and the negative sample pictures without steel bar binding objects respectively, and then generate a sample model by training the classifi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap