Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Sizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sizing or size is any one of numerous substances that is applied to, or incorporated into, other materials—especially papers and textiles—to act as a protective filler or glaze. Sizing is used in papermaking and textile manufacturing to change the absorption and wear characteristics of those materials.

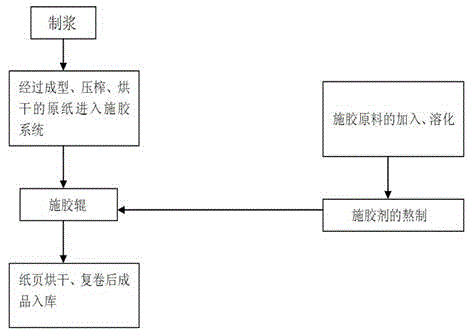

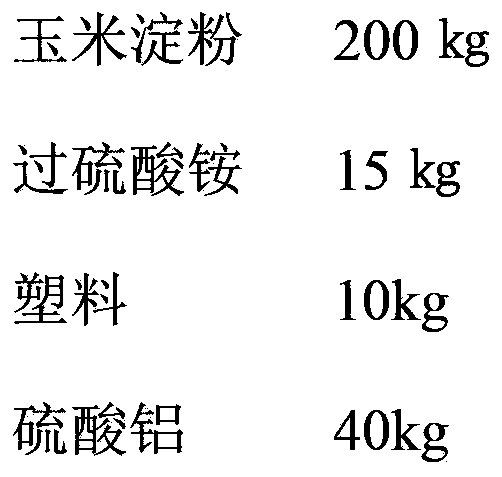

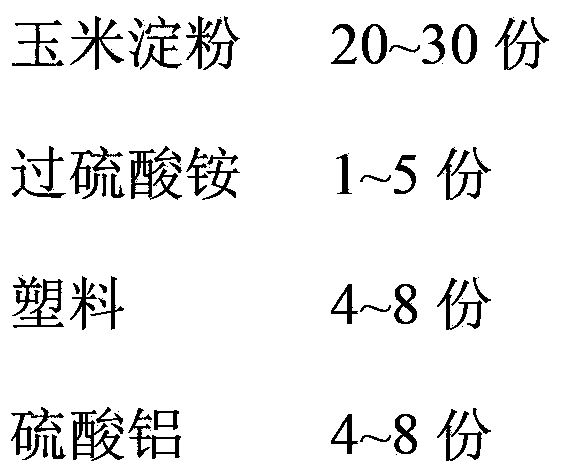

AKD emulsion and preparation method thereof

ActiveCN104499363AThe emulsification process is streamlinedLow impurity contentWater-repelling agents additionWaxStarch gelatinization

The invention discloses an AKD emulsion and a preparation method thereof. According to the preparation method of the AKD emulsion, as the process of starch gelatinization is saved, and AKD waxes and other raw materials are simultaneously added in the emulsification process, the operation is simple, and the consumed time is obviously shortened. According to the preparation method, equipment and manpower inputs are reduced, and the inventory of the raw materials are also reduced; in addition, as the prepared emulsified product can be used while being produced, the aging rate of paper leaving the machine is high, the hydrolysis degree of the AKD is greatly lowered, the sizing effect is ensured, and the economical benefit is obvious.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Production method of permanent ultraviolet protecting, moisture absorbing and sweat removing fabric

ActiveCN104799458AReduce surface tensionImprove permeabilitySingeingHeating/cooling textile fabricsFiberPolyester

The invention discloses a production method of a permanent ultraviolet protecting, moisture absorbing and sweat removing fabric. The method comprises the steps of blending and weaving; singeing; desizing-scouring-bleaching; mercerizing; sizing; dyeing; softening and tentering; pre-shrinking and arranging. The fabric manufactured by the production process is outstanding in permanent ultraviolet resisting function; the UPF is not less than 150; micro pores of CTATEX super-comfortable polyester fibers can be opened fully by the desizing-scouring-bleaching and mercerizing, holes in the fibers are smooth, the moisture absorbing and breathing performances of the fabric can be improved under the absorbing effect of hole cores, and the water drops can be absorbed within 3 seconds according to the test; the fuzzing and pilling resistance of the fabric is more than 4 grades; the advantages of wearing resistance, non-ironing, wrinkle preventing and quick drying of the polyester fibers are remained to the maximum; the fabric is particularly suitable for wearing when working and living outdoor in a hot season.

Owner:SWOTO PROTECTION & TECH CO LTD +1

Shoulder wedge composite material and manufacturing method thereof

The invention discloses a shoulder wedge composite material and a manufacturing method thereof. The shoulder wedge composite material consists of the following raw materials in part by weight: 100 parts of natural rubber, 10 to 50 parts of carbon series nano thermal conducting filler, 10 to 35 parts of coarse particle size carbon black, 2 to 6 parts of octyl phenolic resin, 2 to 4 parts of surfactant, 1 to 8 parts of silane coupling agent, 1.5 to 9 parts of vulcanizing agent and the balance of other common aids. The preparation method comprises the following steps of: plasticating the rubber in an internal mixer, adding the coarse particle size carbon black, the carbon series nano thermal conducting filler, the octyl phenolic resin, the surfactant and the other aids into the internal mixer, mixing and controlling the temperature to be between 80 and 120 DEG C; adding the silane coupling agent into the mixture, controlling the temperature to be between 120 and 160 DEG C, and discharging the sizing material; adding a master batch and the vulcanizing agent into the internal mixer and discharging products until the temperature is 80 to 120 DEG C, wherein if the other aids contain scorch retarder, the scorch retarder and the vulcanizing agent are added together. The shoulder wedge composite material provided by the invention meets the requirements of mechanical properties, and is low in themogenesis, high in thermal conductivity, and excellent in machinability.

Owner:BEIJING UNIV OF CHEM TECH +1

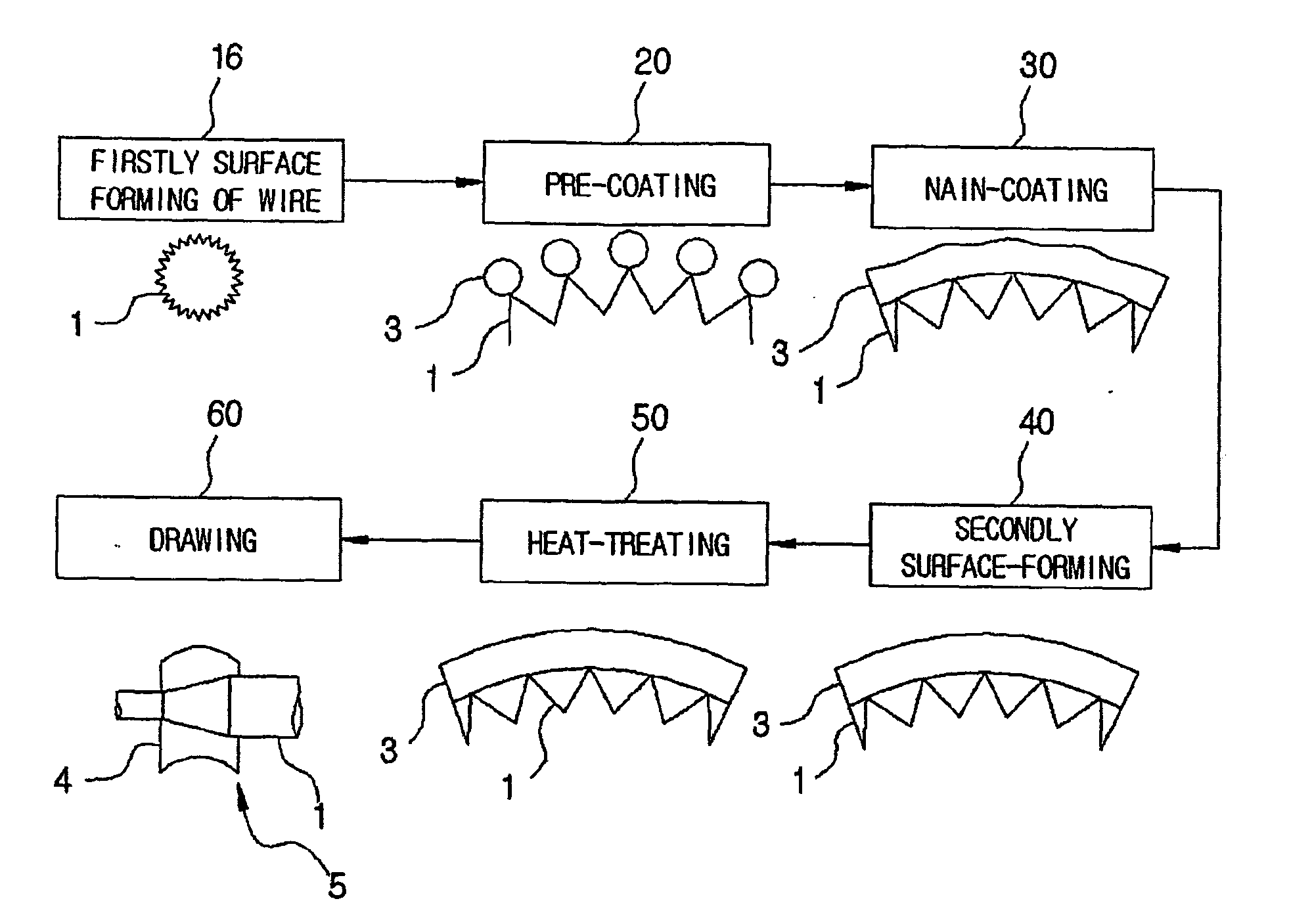

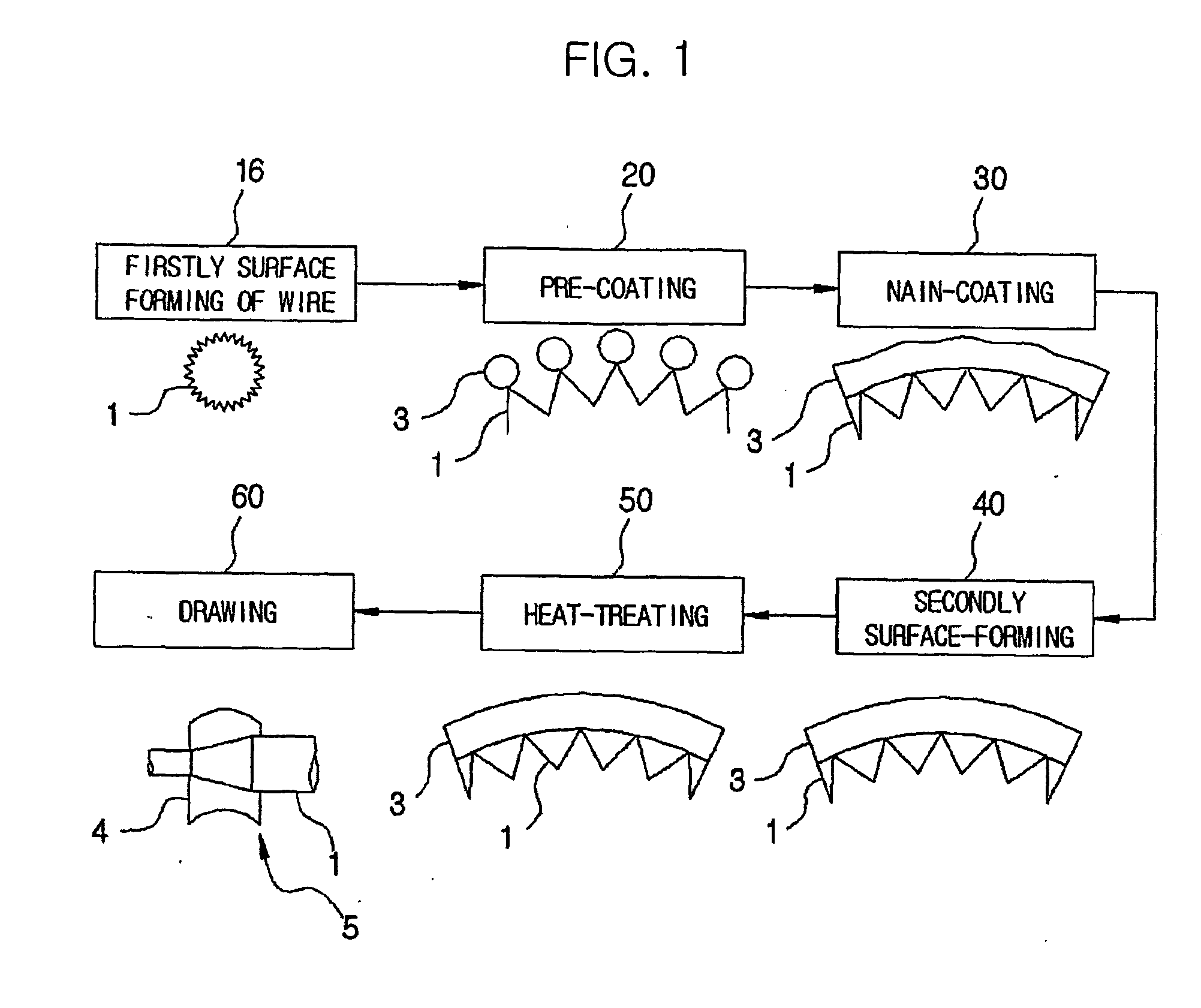

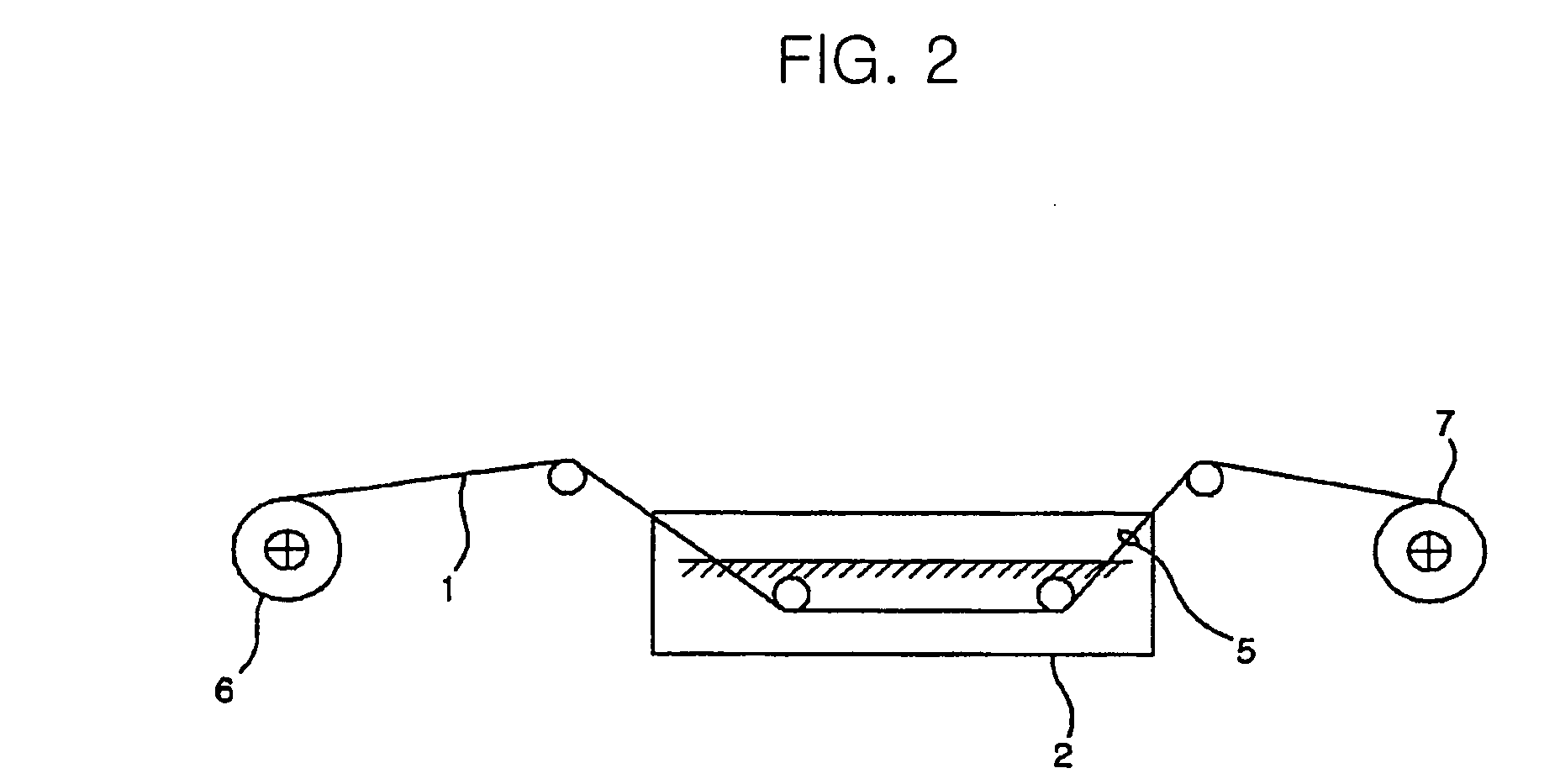

Method of manufacturing zinc-coated electrode wire for electric discharge processors using hot dip galvanizing process

InactiveUS20060138091A1Reduce manufacturing costReduce waste generationHot-dipping/immersion processesElectrical-based machining electrodesHot-dip galvanizationSizing

Owner:PUNG KUK

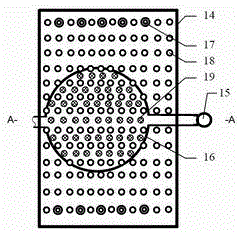

Micro-fluidic chip for preparing microspheres and using method of micro-fluidic chip

ActiveCN104588139AEasy to operateProfessionalLaboratory glasswaresMicroballoon preparationDispersityMicrosphere

Owner:重庆新赛亚生物科技有限公司

Device for expanding thermal shrinkage tube

ActiveCN101327645AExtended service lifePlay a lubricating roleTubular articlesShrinkage rateCooling effect

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

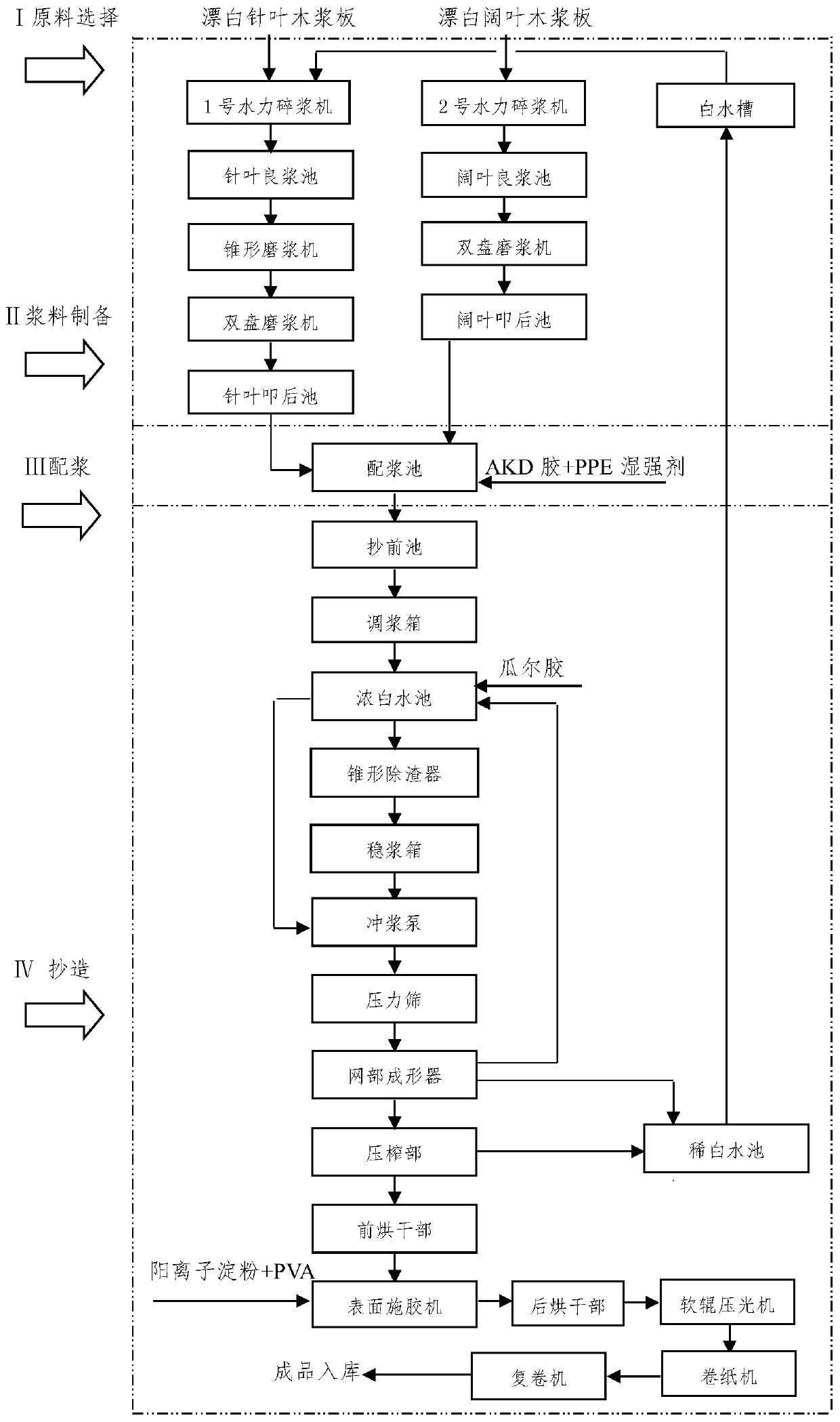

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

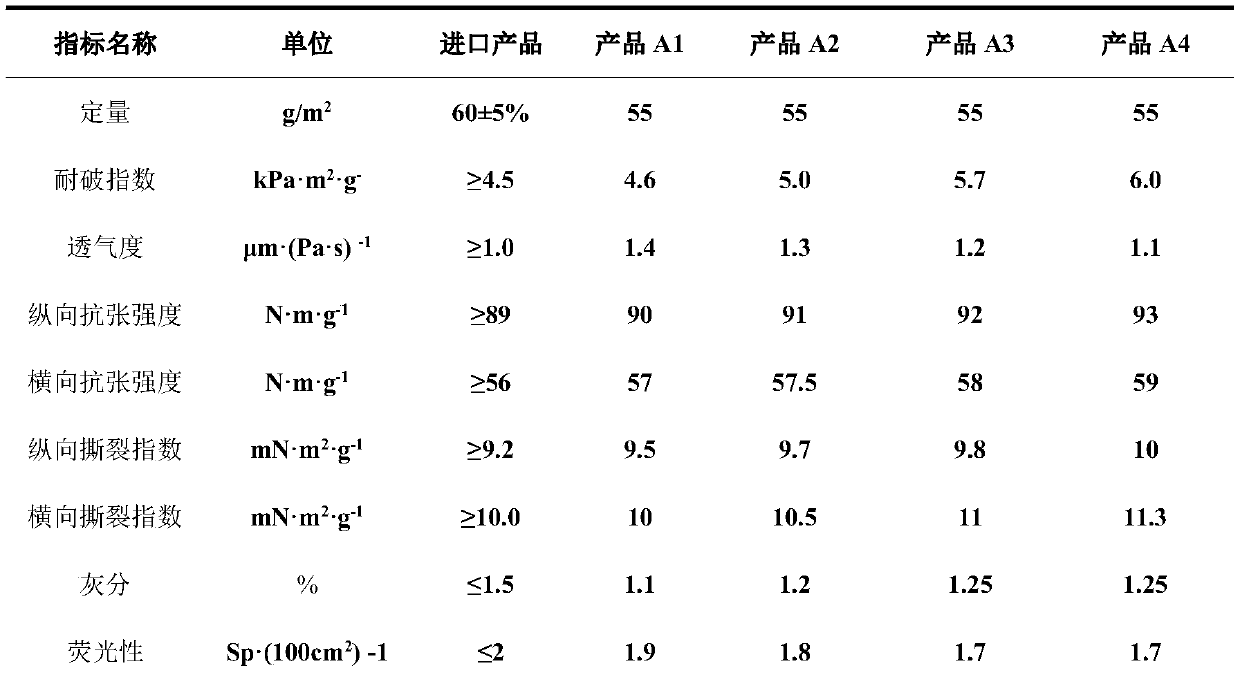

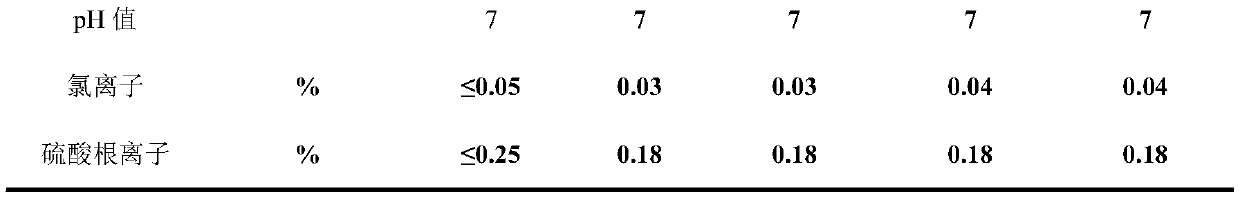

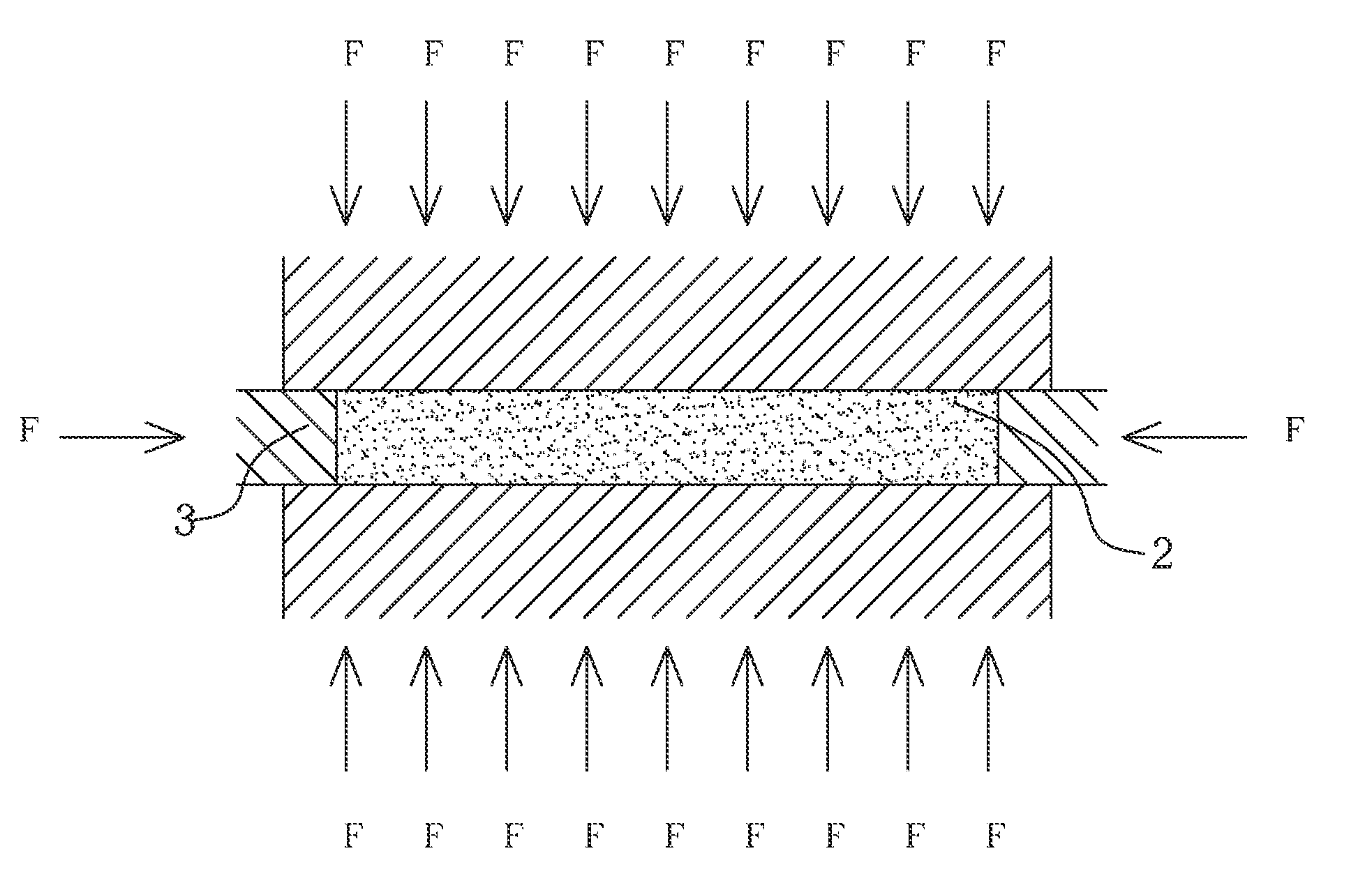

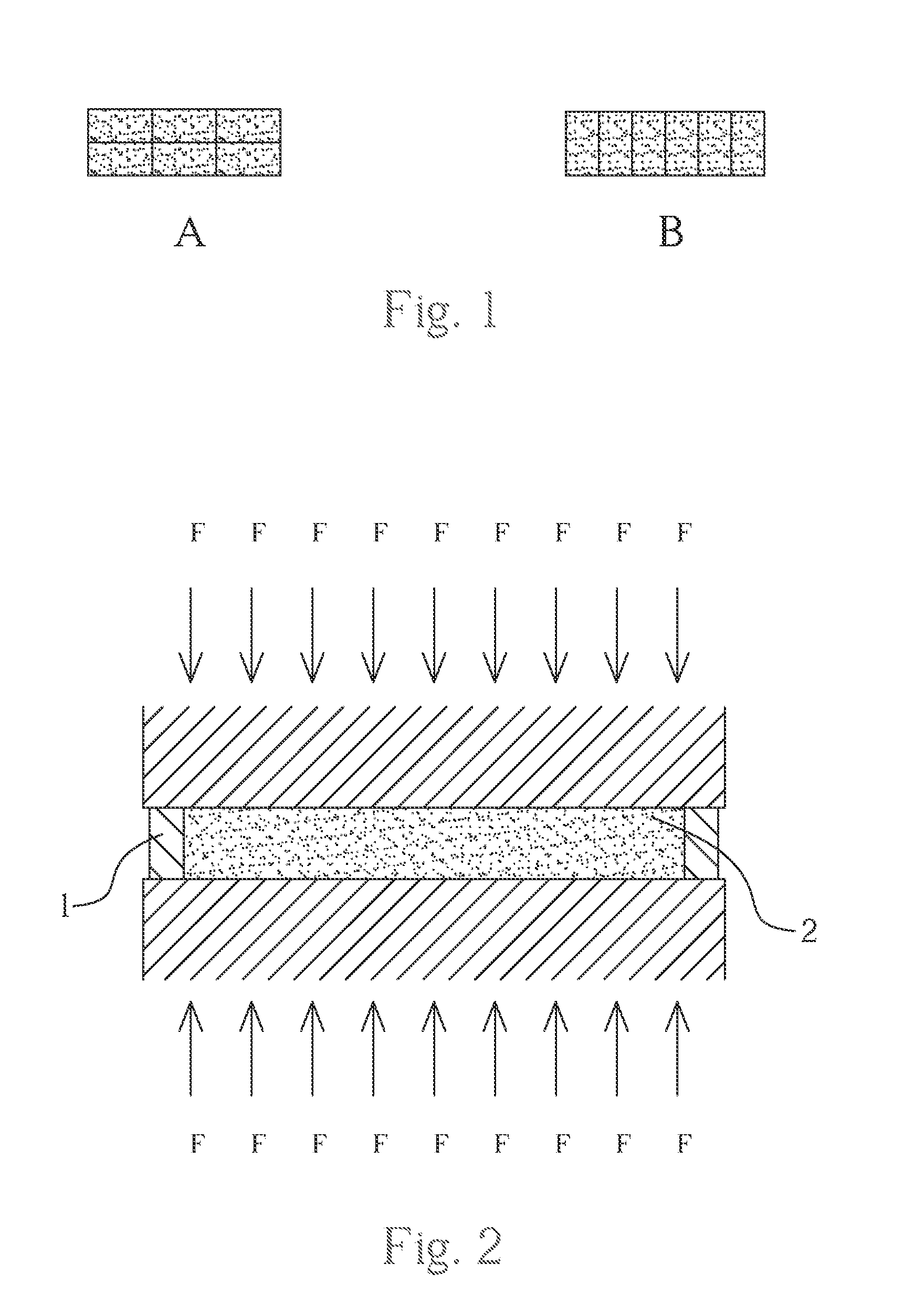

Medical dialysis body paper and production method thereof

InactiveCN109853297AHigh strengthImprove breathabilityWater-repelling agents additionSpecial paperWinding machinePulp and paper industry

Owner:NANJING FORESTRY UNIV

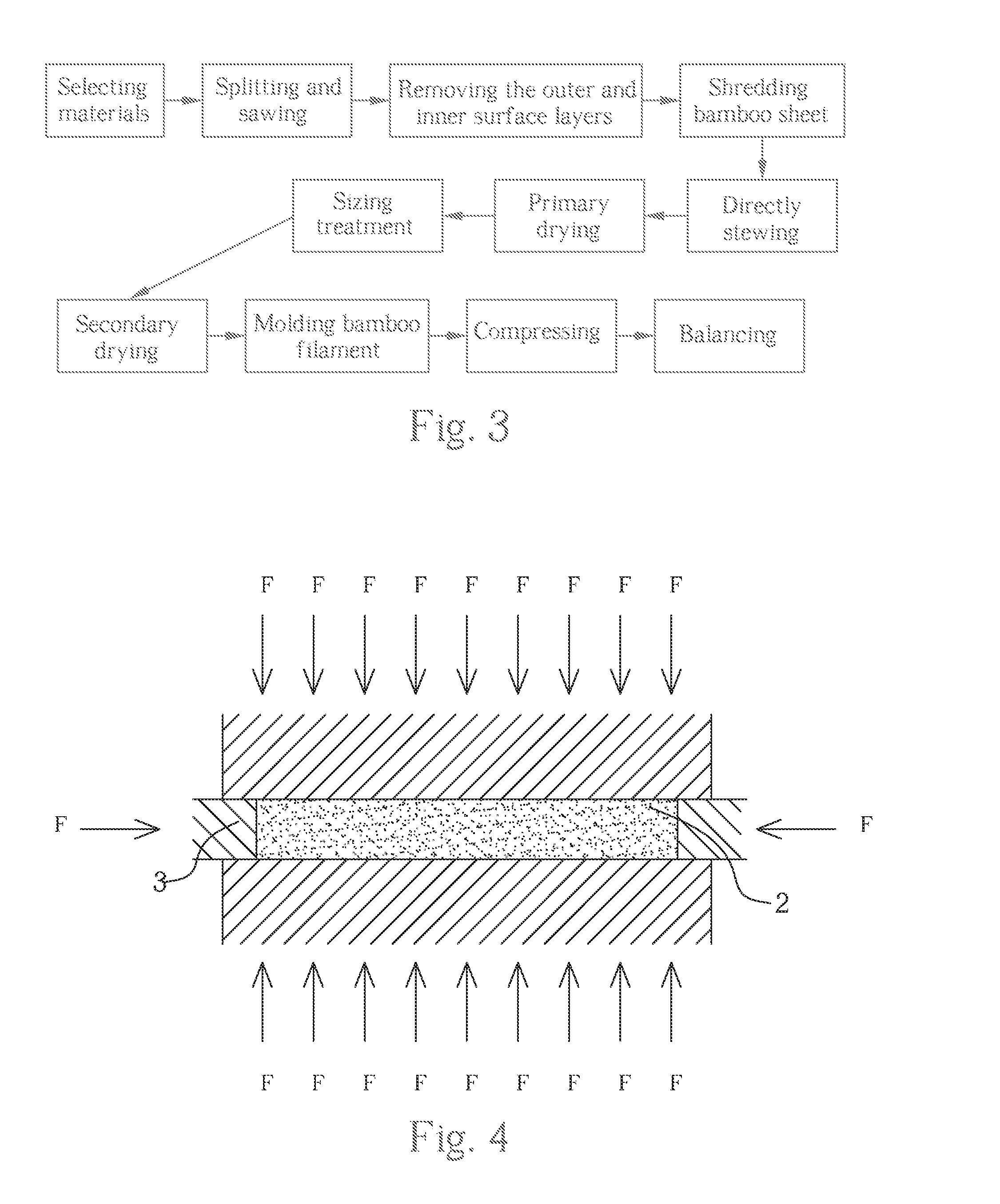

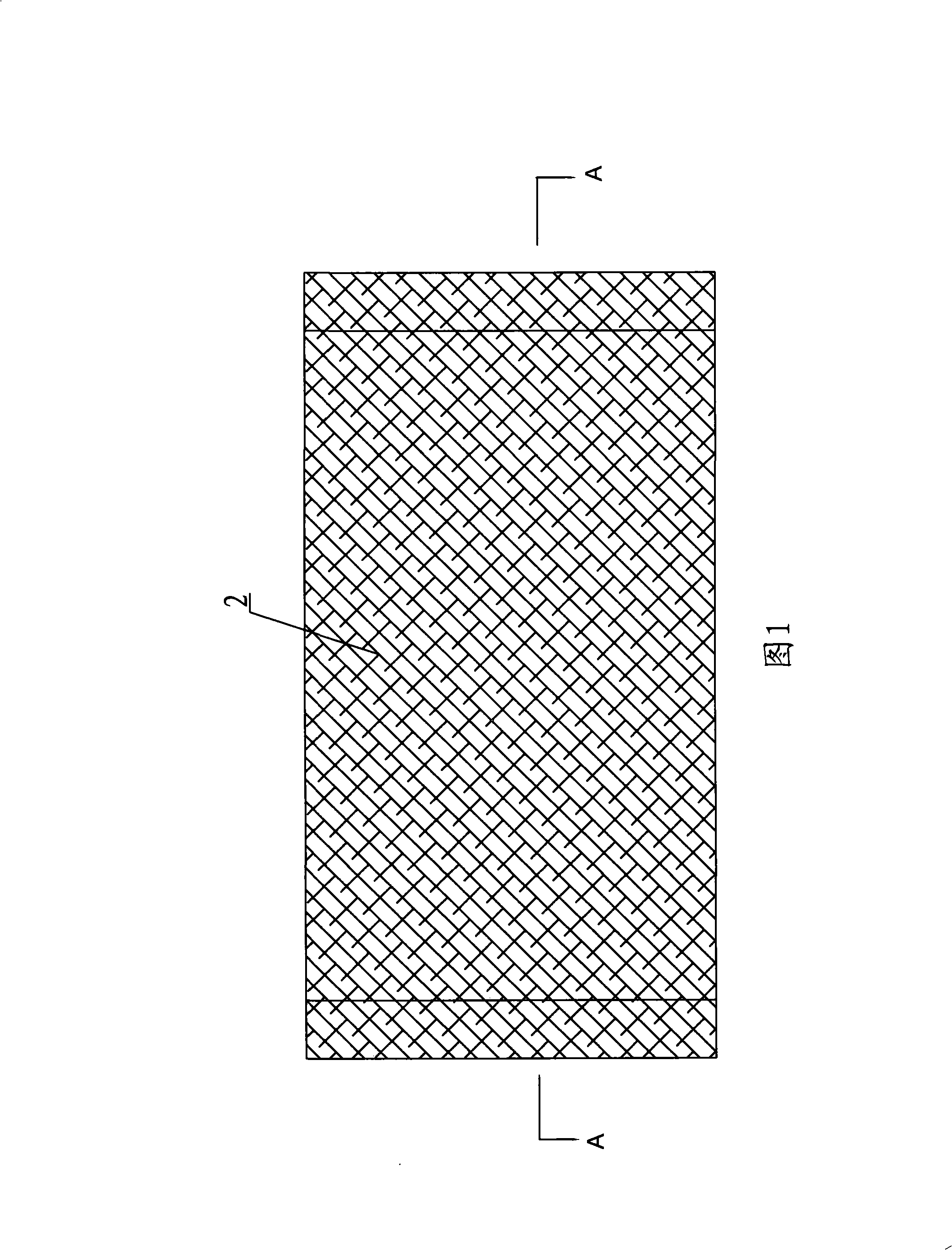

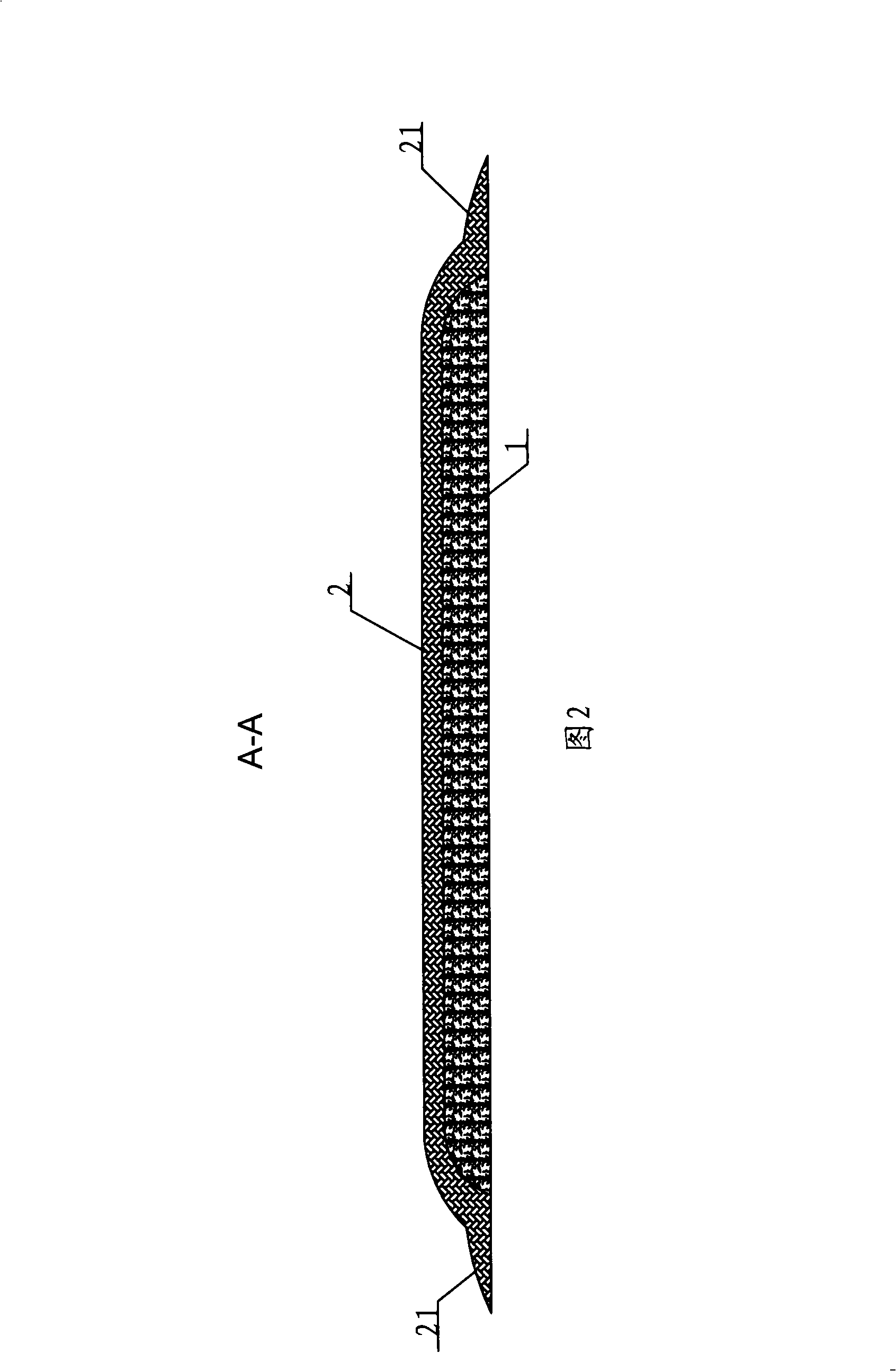

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

Method for manufacturing body paper special for lotteries

InactiveCN106894277AHigh strengthImprove smoothnessWater-repelling agents additionReinforcing agents additionSulfateUltimate tensile strength

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Combined fatigue resistant pad and manufacturing method thereof

InactiveCN101292833AReduce manufacturing costEffective protectionLayered productsDomestic articlesFoaming agentPolyvinyl chloride

Owner:TAICANG ALL MATS PLASTIC IND

Super large caliber and non-excavation-use PE pollution discharge tubular product and manufacturing method thereof

The invention relates to a super large caliber and non-excavation-use PE pollution discharge tubular product and a manufacturing method thereof, wherein, the tubular product are manufactured by the following materials which are arranged according to the following mass percentage after the steps of pelleting and extrusion molding: 60-85% of PE100 pipeline special material; 5-15% of calcium carbonate superfine powder; 7-22% of unit triplet blending modified resin; 1-3% of high molecular weight polyethylene; and 0.2-2% of fluoropolymer. The method comprises the following steps: mixing PE100 pipeline special material accounting for 20-30% of total volume of addition evenly with other components according to proportion and obtaining master batch by extrusion and pelleting; mixing the excess PE100 pipeline special material evenly with the master batch and colorant and drying the mixture for 2-4 hours at the temperature of 0-80 DEG C; and then obtaining fixed-length tubular products after the steps of extrusion, vacuum sizing, cooling and cutting. The tubular products has the characteristic of integration; hot welding is carried out on the pipelines; the pipelines have fine flexibility and scratching-and-cracking-resisting capcacity; in addition, the pipelines has more unique technological and economic advantages when applied to drag construction of non-excavation works.

Owner:ANHUI YOUYI PIPES

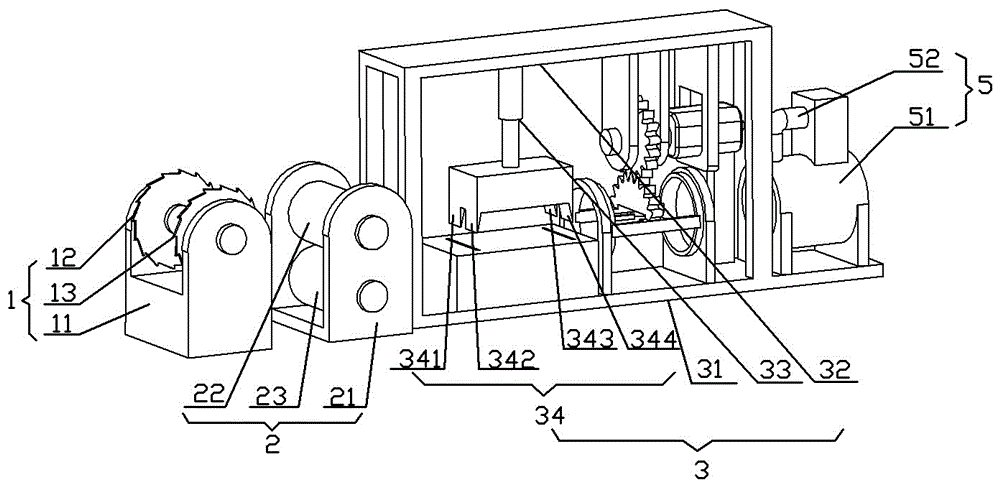

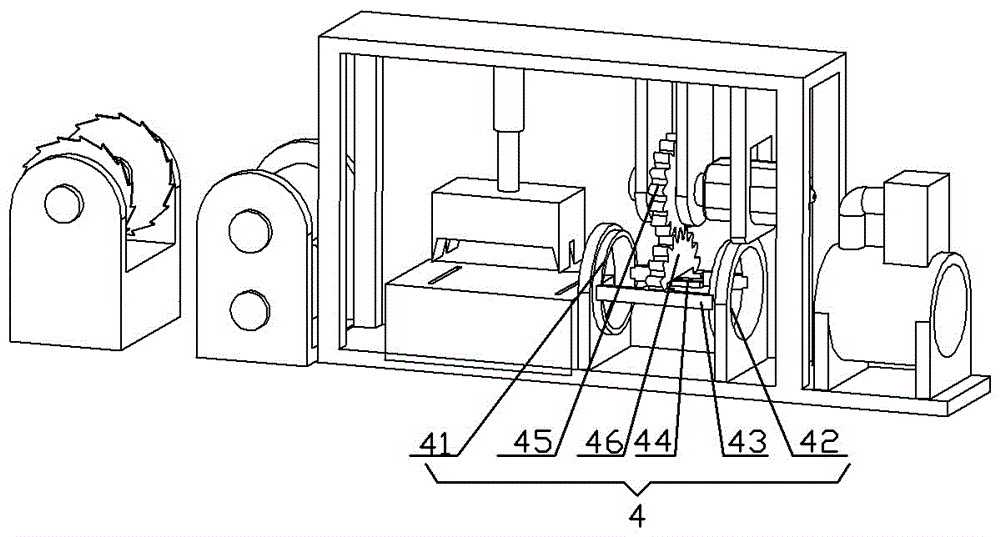

Machining process for flow spoiler bands

Owner:CHONGQING YUQING MACHINERY MFR

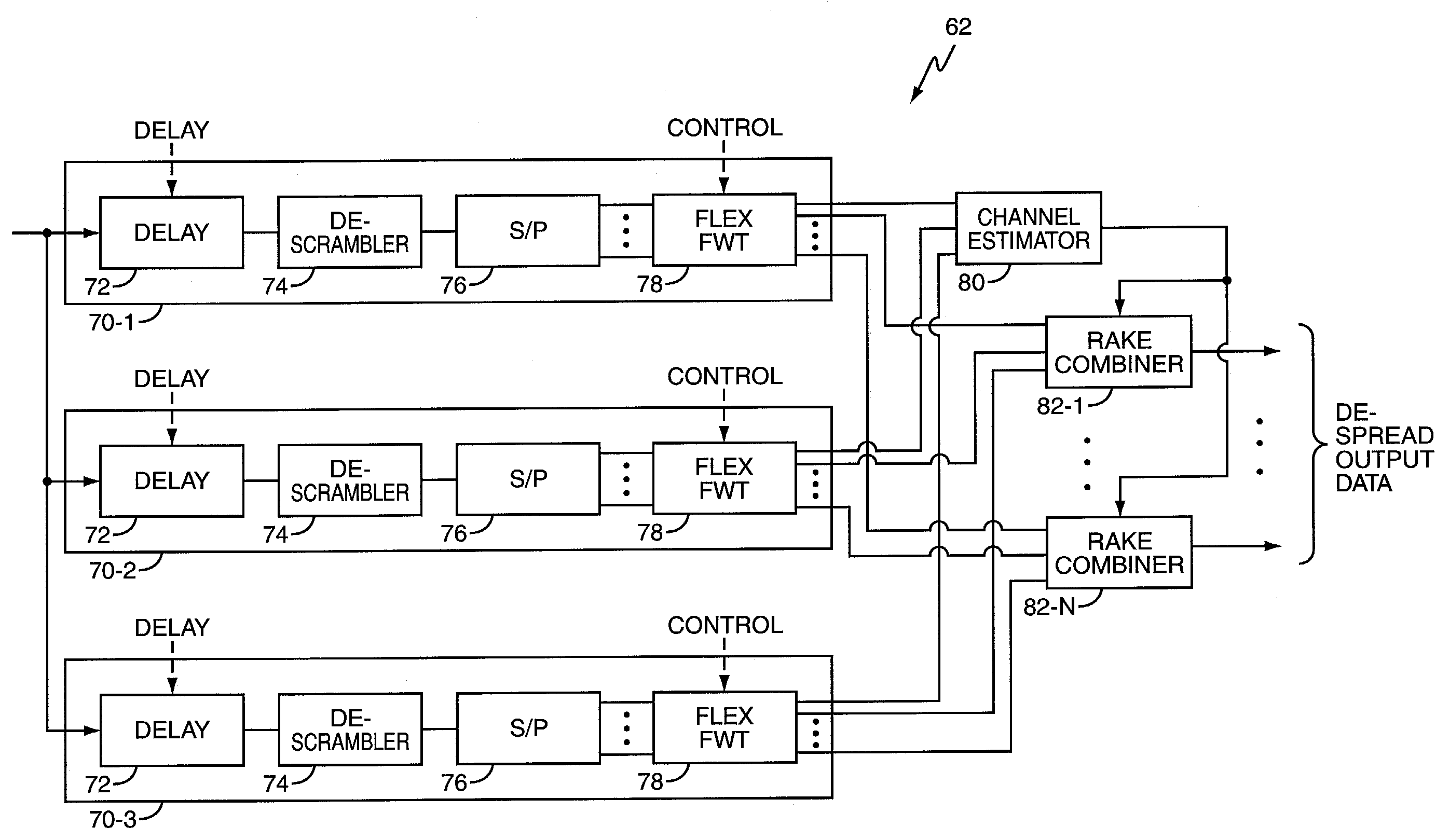

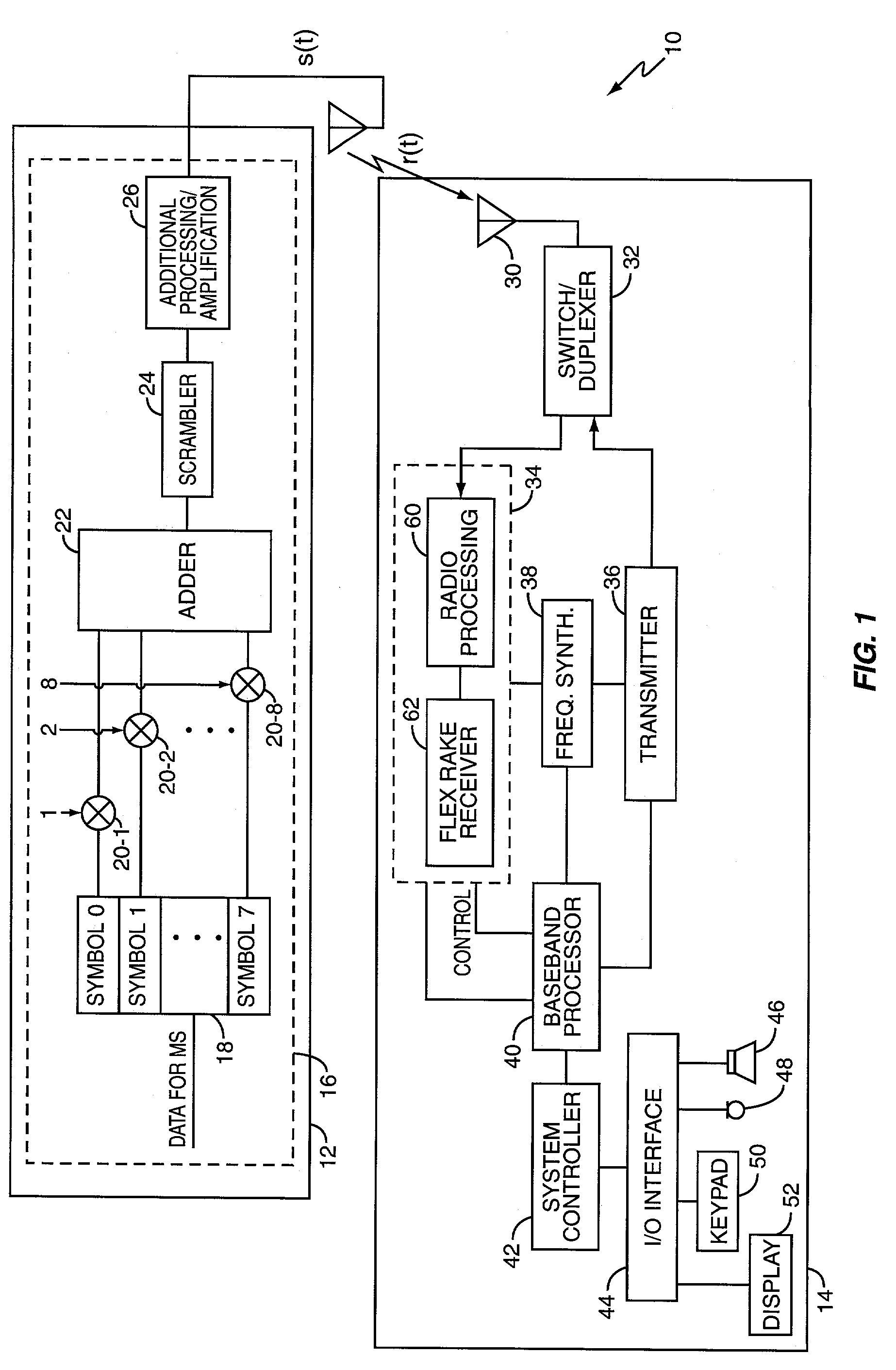

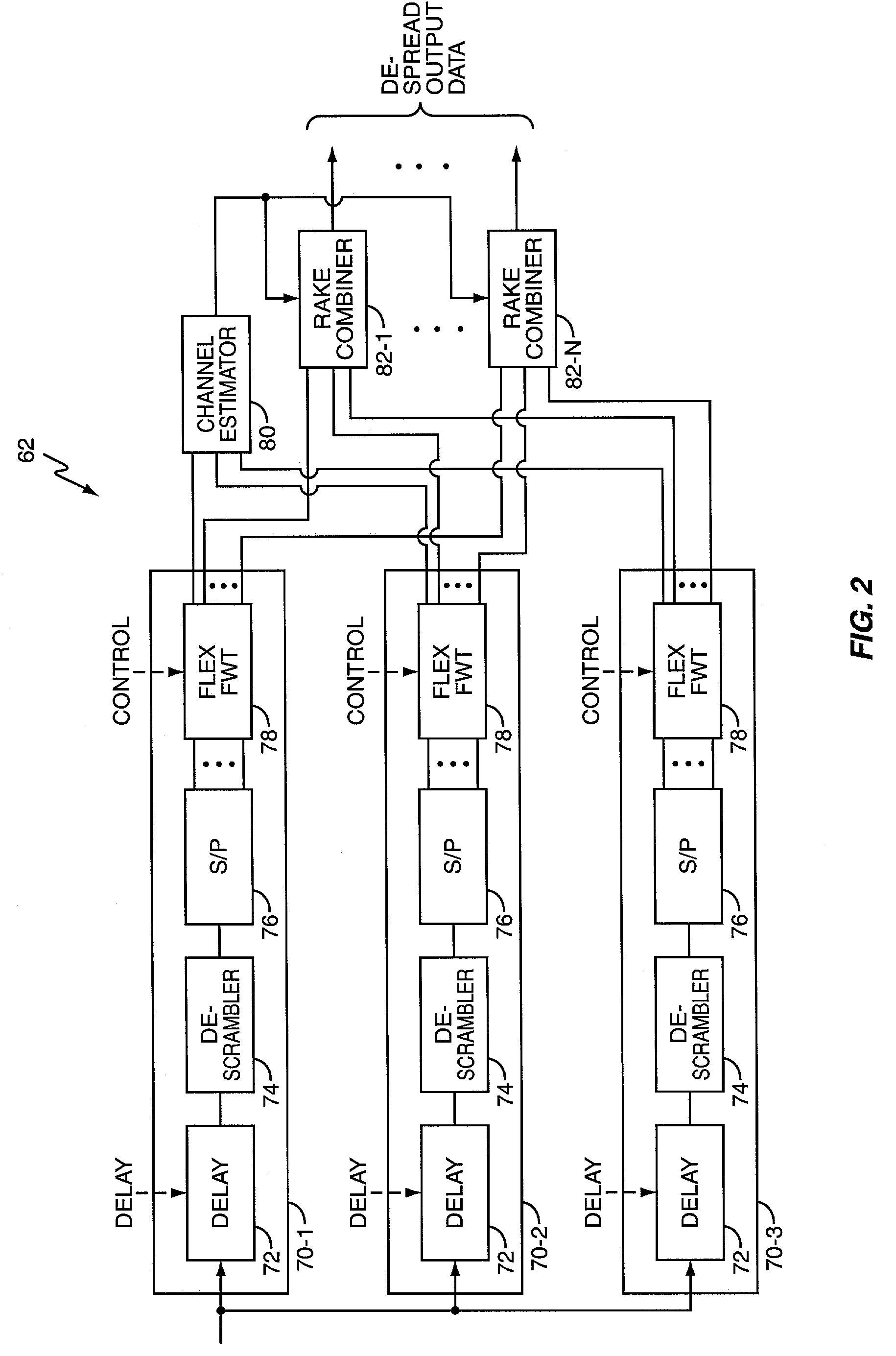

System and method for Fast Walsh Transform processing in a multi-coded signal environment

InactiveUS7308019B2Amplitude-modulated carrier systemsCode division multiplexRadio receptionRadio receiver

Owner:UNWIRED PLANET

Method for preparing insulator

Owner:STATE GRID CORP OF CHINA +1

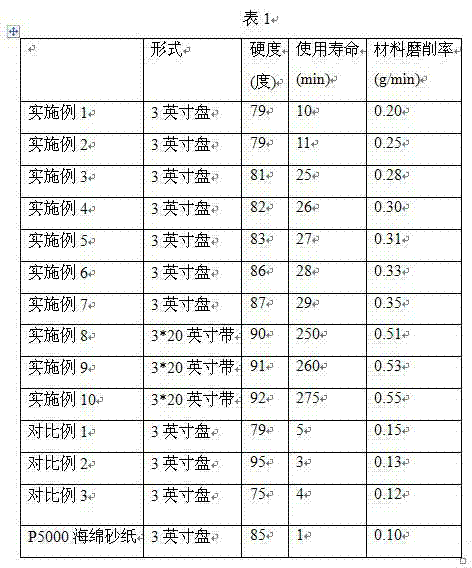

Foam coating grinding tool and preparing method thereof

Owner:ZIBO RIKEN MT COATED ABRASIVES

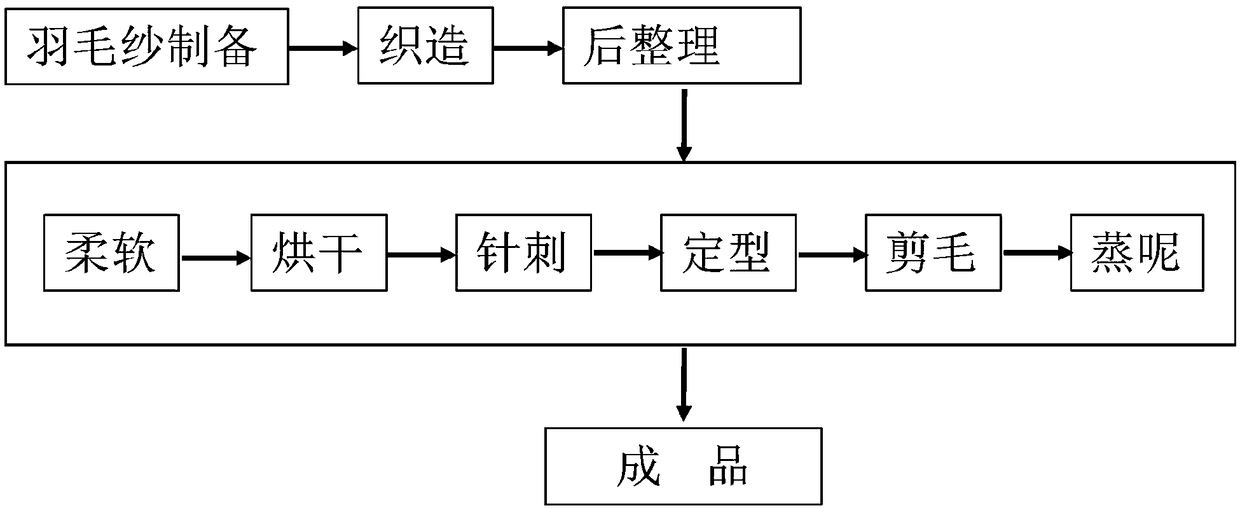

Production technology of weft-knitted flight down feather

Owner:江苏润玖纺织有限公司

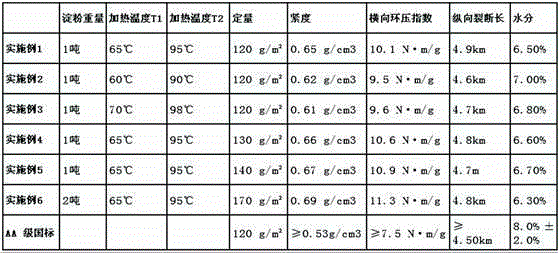

Production technology of high-strength corrugating base paper

Owner:HEZE SHANDONG HENGLI PAPER

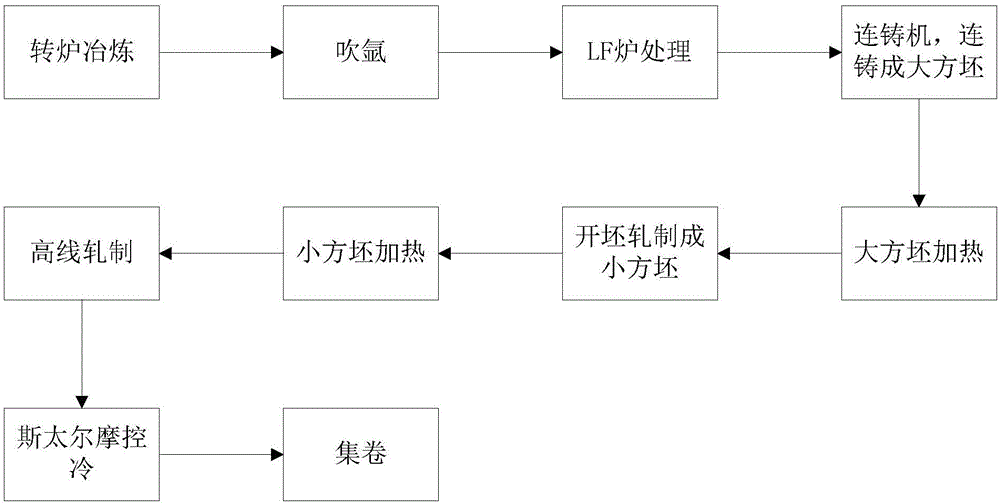

Method for relieving pattern segregation of spring steel

ActiveCN106399654ASolve the problem of resentmentReduce manufacturing costTemperature differenceSpring steel

Owner:武汉钢铁有限公司

Preparation method and preparation device for PET multi-layer composite sheet

The invention discloses a preparation method of a PET multi-layer composite sheet. The preparation method comprises the following steps: (1) treating a PET raw material and a PETG raw material respectively; (2) mixing the treated PET raw material and PETG raw material by a metering pump; (3) carrying out upper-layer and lower-layer distribution for the two types of raw materials through a material distributor; (4) obtaining a sheet from the raw materials treated by upper and lower layering through a molding die head; (5) cooling and sizing the obtained sheet by water of 30 degrees; (6) coating the sheet with a lubricating agent and an antistatic agent after intermediate sizing by a push coating device; (7) drying the sheet after being coated with the lubricating agent and the antistatic agent; (8) cutting boundary materials of the obtained sheet according to required specifications; and (9) drawing out the sheet with the boundary materials being cut, and then rolling to obtain a finished product. According to the preparation method disclosed by the invention, the PET multi-layer composite sheet can be produced by the device, and the device can be used for changing physical properties of the PET multi-layer composite sheet.

Owner:SHANGHAI KUNYUAN NEW MATERIALS CO LTD

Polymer bonding mortar and preparation method thereof

The invention discloses a polymer bonding mortar and a preparation method of the polymer bonding mortar. The bonding mortar uses a modified redispersible powder to replace the traditional sizing material, the redispersible powder modified by paraffin and micron sized silica aerogel is better in water resistance and dispersibility, the bonding strength between the redispersible powder and an aggregate is stronger, in addition, a certain amount of aramid pulp and activated carbon powder are added as the aggregate, the degree of compacting of the mortar and the internal permeability of the mortar are improved, the bonding speed of the mortar is accelerated, the uneven hydration is avoided, the solidified mortar is excellent in anti-permeability, an introduced water retention particle is a long-acting reversible product, the water retaining property of the mortar is effectively improved, and the comprehensive performance of the mortar are further improved. The prepared bonding mortar is green and environmentally friendly, is economical and efficient, and has a prominent application advantage in an external wall insulation system.

Owner:HEFEI SHENZHOU CONSTR GRP CO LTD

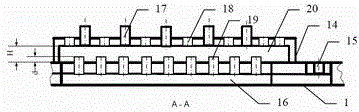

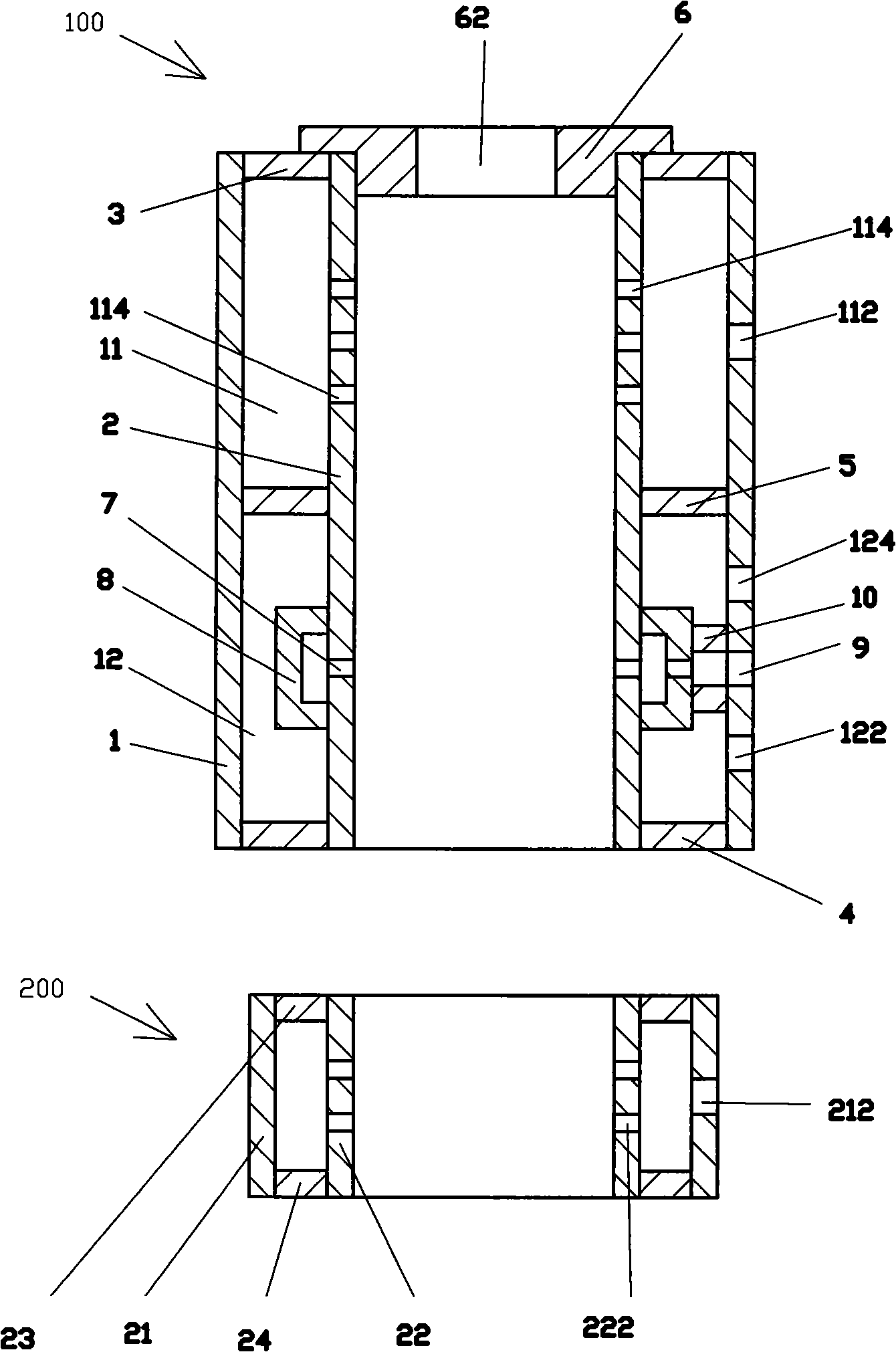

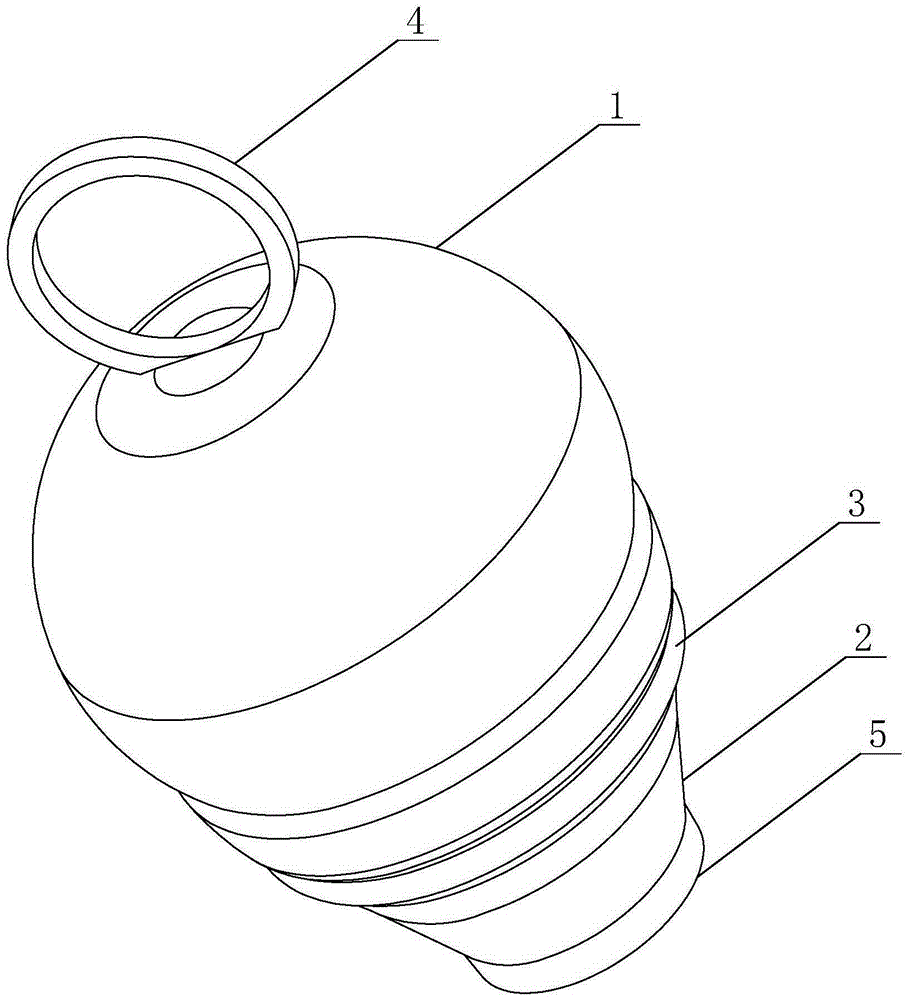

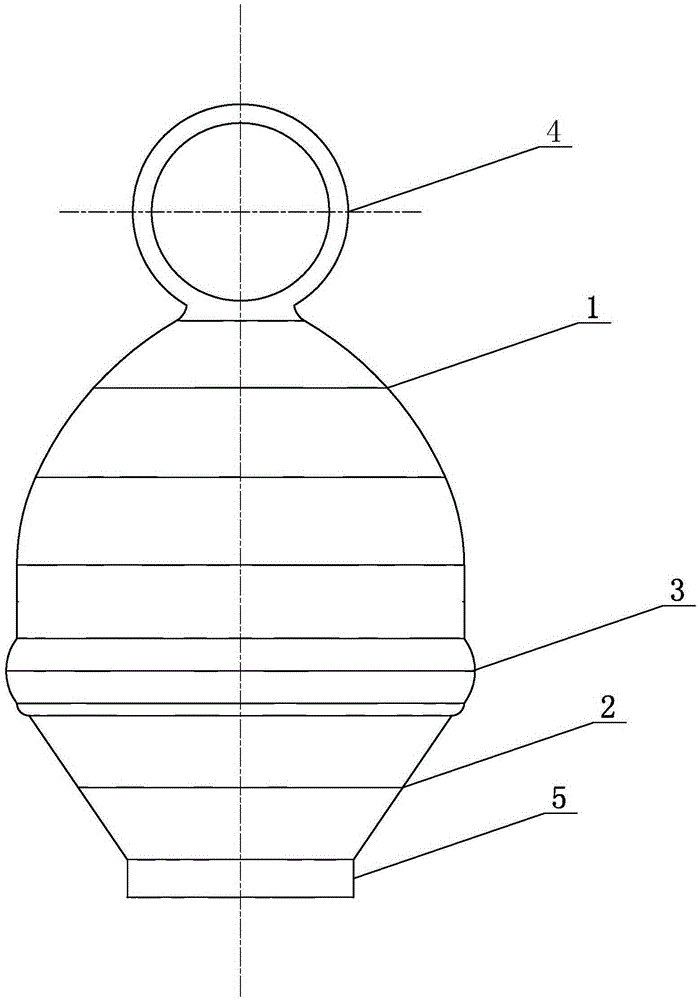

Menstrual cup

Owner:魏群巍

Method for preparing corrugated paper

InactiveCN103410039AHigh indexStrength Enhancement BoostWater-repelling agents additionPaper/cardboardPulp and paper industryHigh intensity

Owner:安徽浙源再生纸业科技有限公司

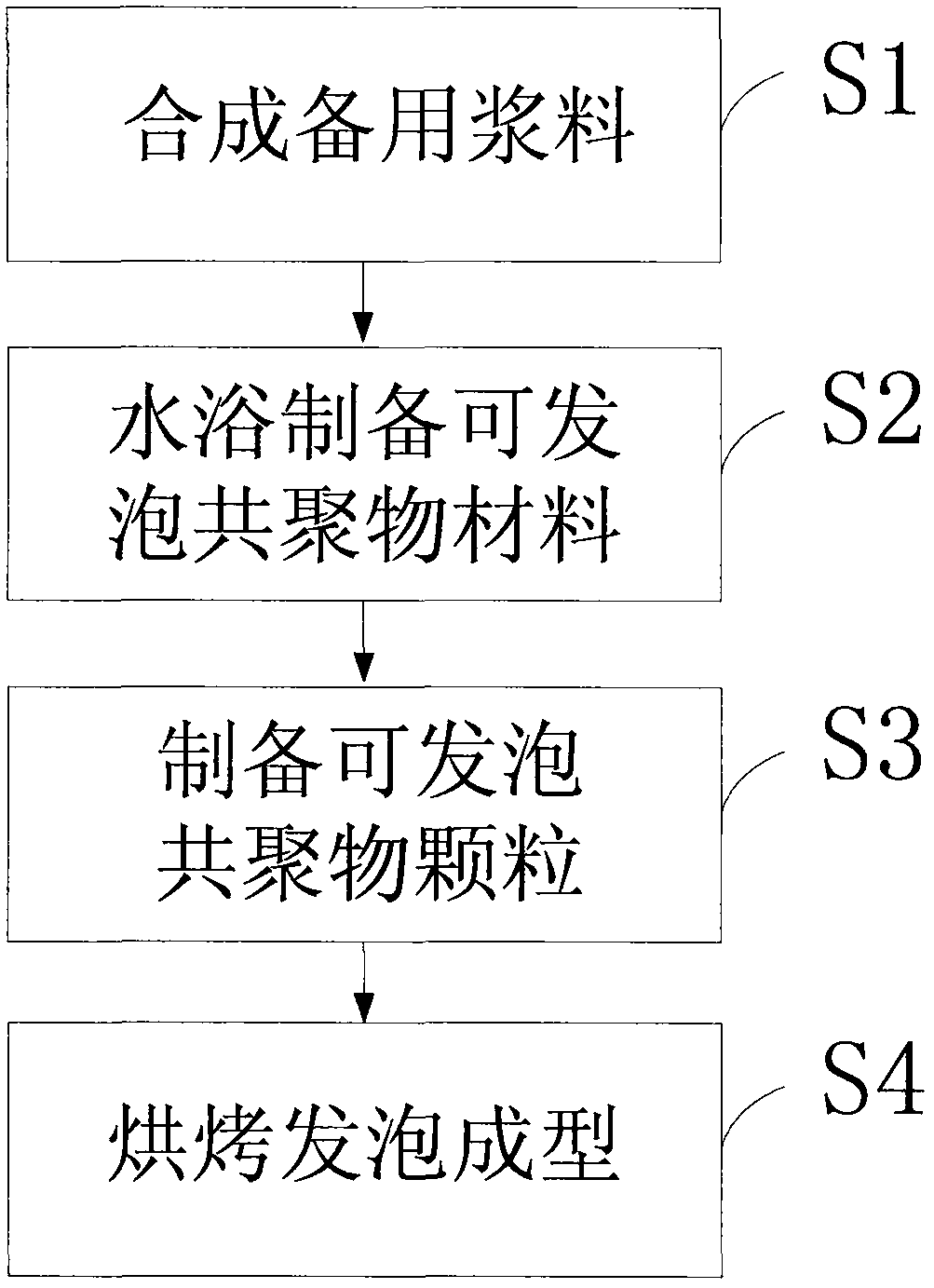

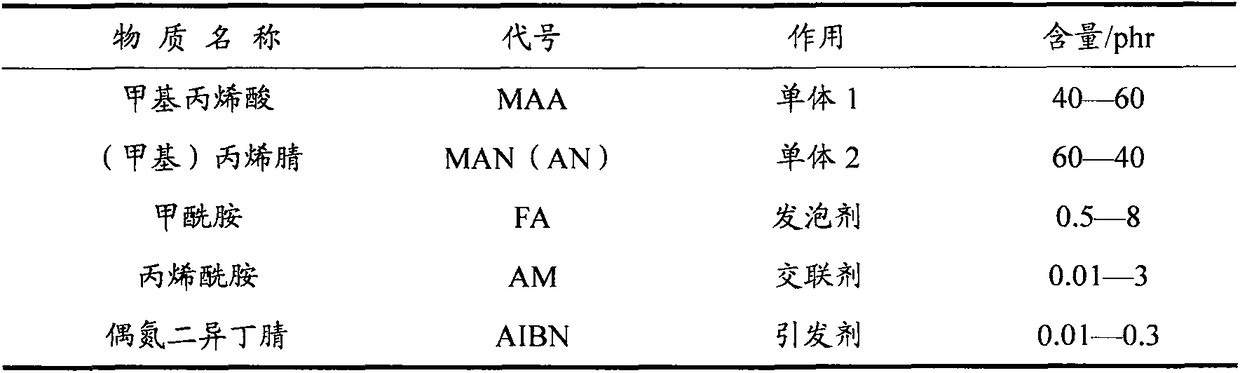

Preparation method of PMI (Polymethacrylimide) foam plastic

Owner:威海维赛新材料科技有限公司

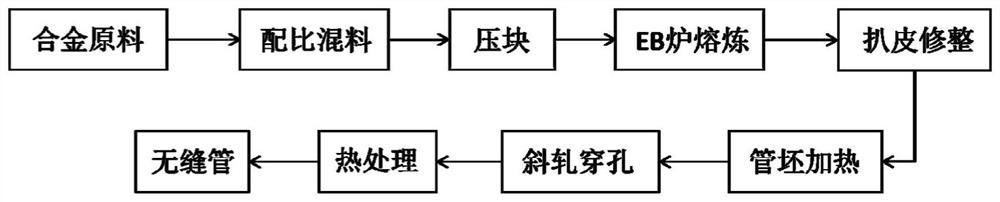

Short-process preparation method of Ti-Al-V-Fe alloy seamless tube

Owner:KUNMING UNIV OF SCI & TECH

Test method for comprehensively simulating rubber blooming

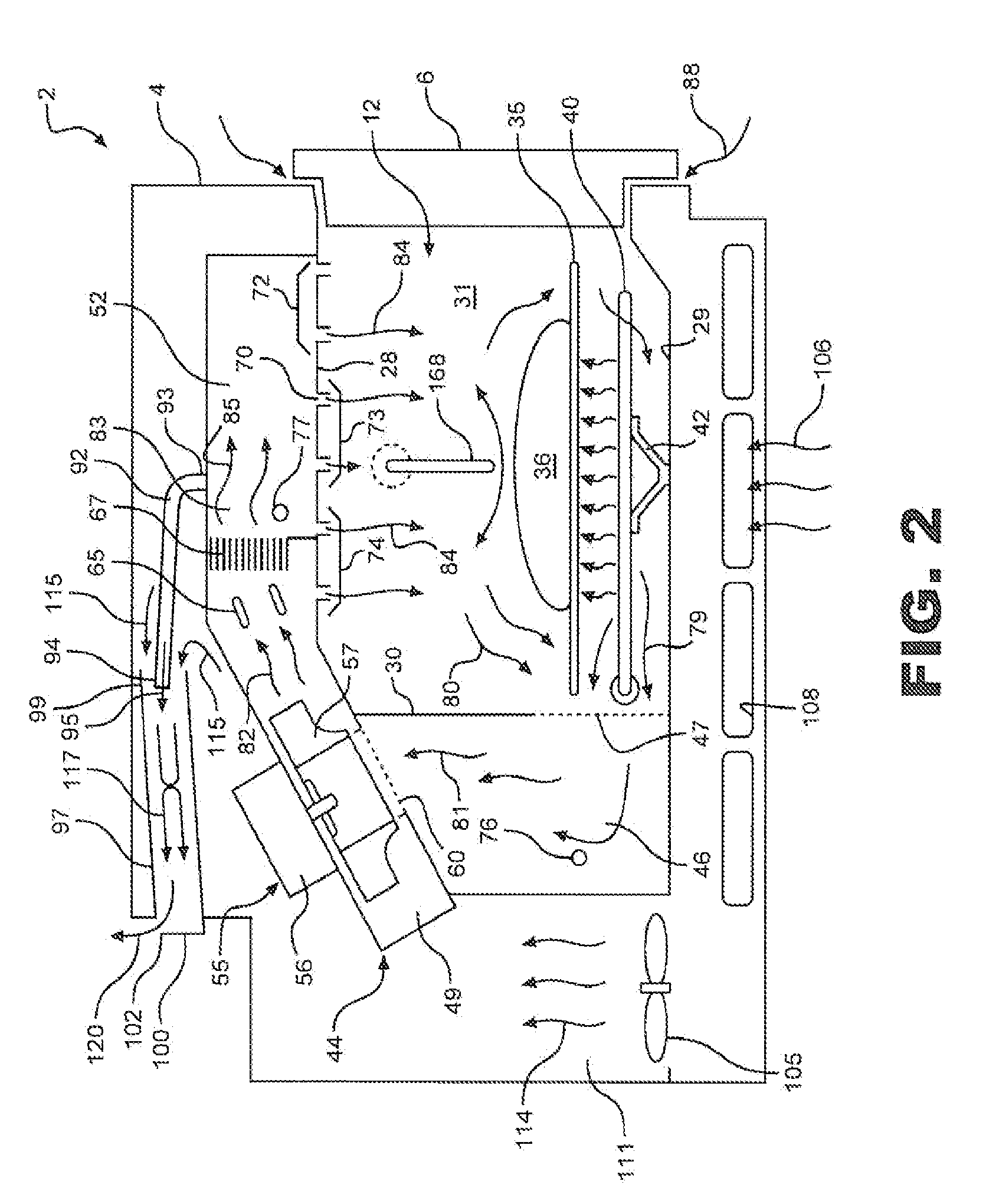

InactiveCN109959778AAccelerated agingCharacterizing Blooming PerformanceWeather/light/corrosion resistanceMaterial testing goodsVulcanizationTest chamber

Owner:ZHEJIANG JUNHE RUBBER TECH

High-efficiency low-cost textile size and sizing technology by using same

Owner:SICHUAN YUYANG TEXTILE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap