Device for expanding thermal shrinkage tube

A technology of expansion device and heat-shrinkable tube, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of short service life, poor cooling effect, and low expansion efficiency of sizing tubes, so as to improve service life, Improve cooling effect and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

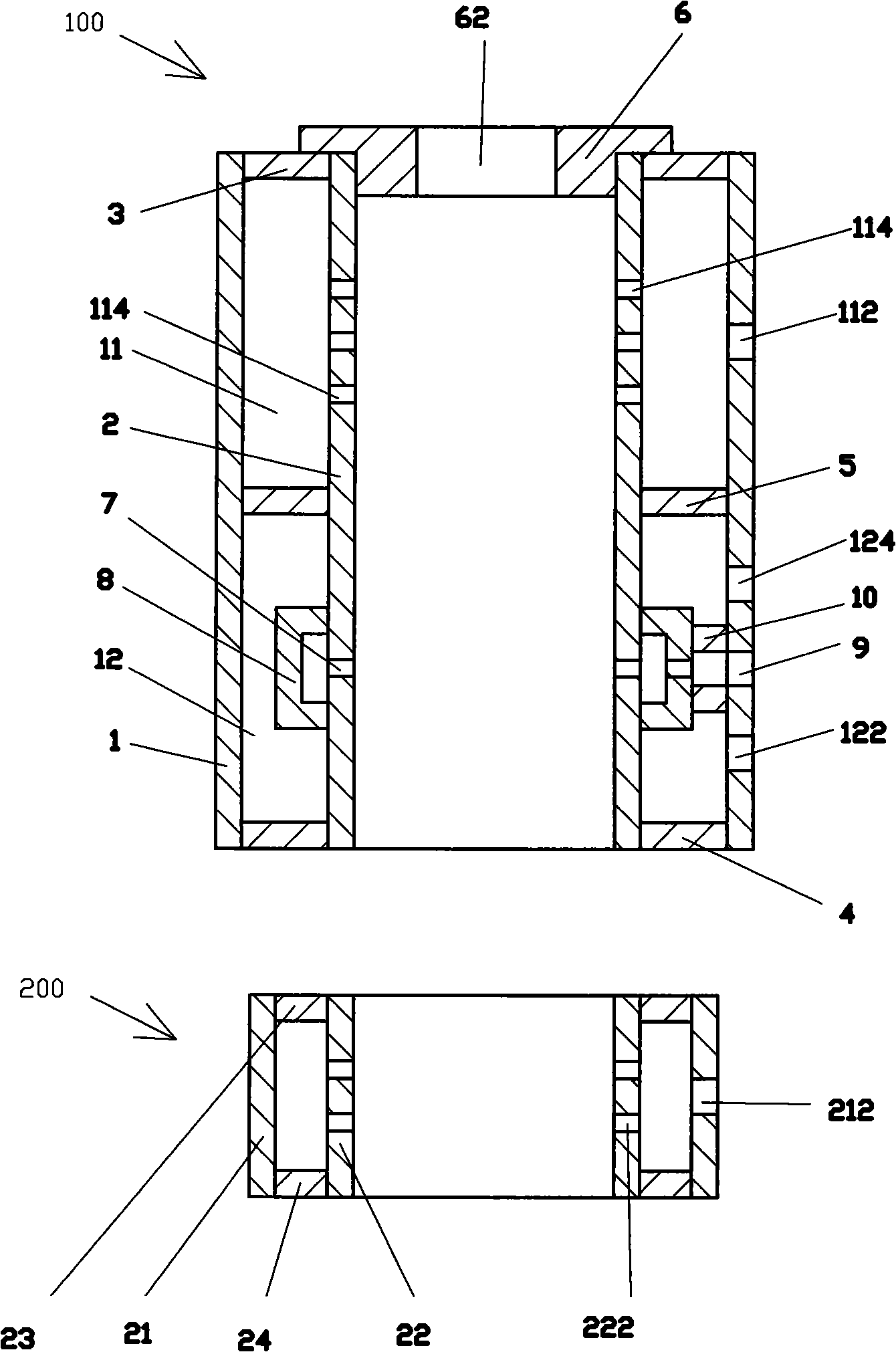

[0017] see figure 1 , a heat shrink tube expansion device, which includes an expansion mold 100, a water absorber 200.

[0018] The expansion die 100 includes a jacket 1, a fixed diameter pipe 2, a front sealing plate 3, a rear sealing plate 4, a partition 5, a die mouth 6, several water inlet holes 7, a water inlet jacket 8, a fixed diameter Pipe water inlet 9, a connecting pipe 10.

[0019] The jacket 1 is a body with two ends open.

[0020] The sizing pipe 2 is a straight cylinder made of bronze or stainless steel with two ends open. The sizing pipe 2 is installed inside the casing 1 . The inner diameter of the sizing tube 2 is the same as or slightly larger than the outer diameter of the expanded heat-shrinkable tube (not shown).

[0021] The front sealing plate 3 is fixedly installed between the outer cover 1 and the front end of the sizing tube 2 (that is, the end where the heat-shrinkable tube to be expanded (not shown) enters the sizing tube 2), and the outer cover 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap