Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Metal sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

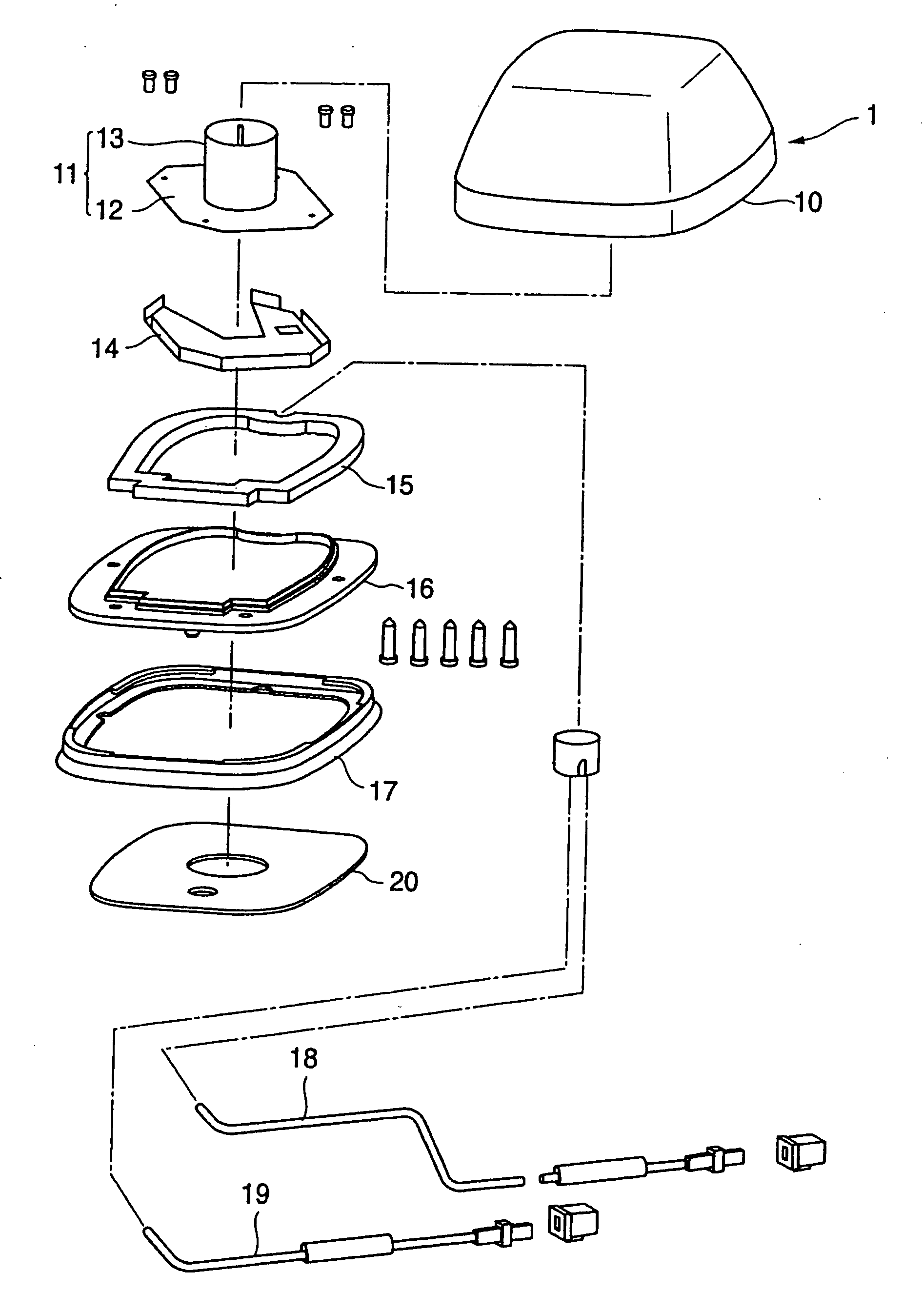

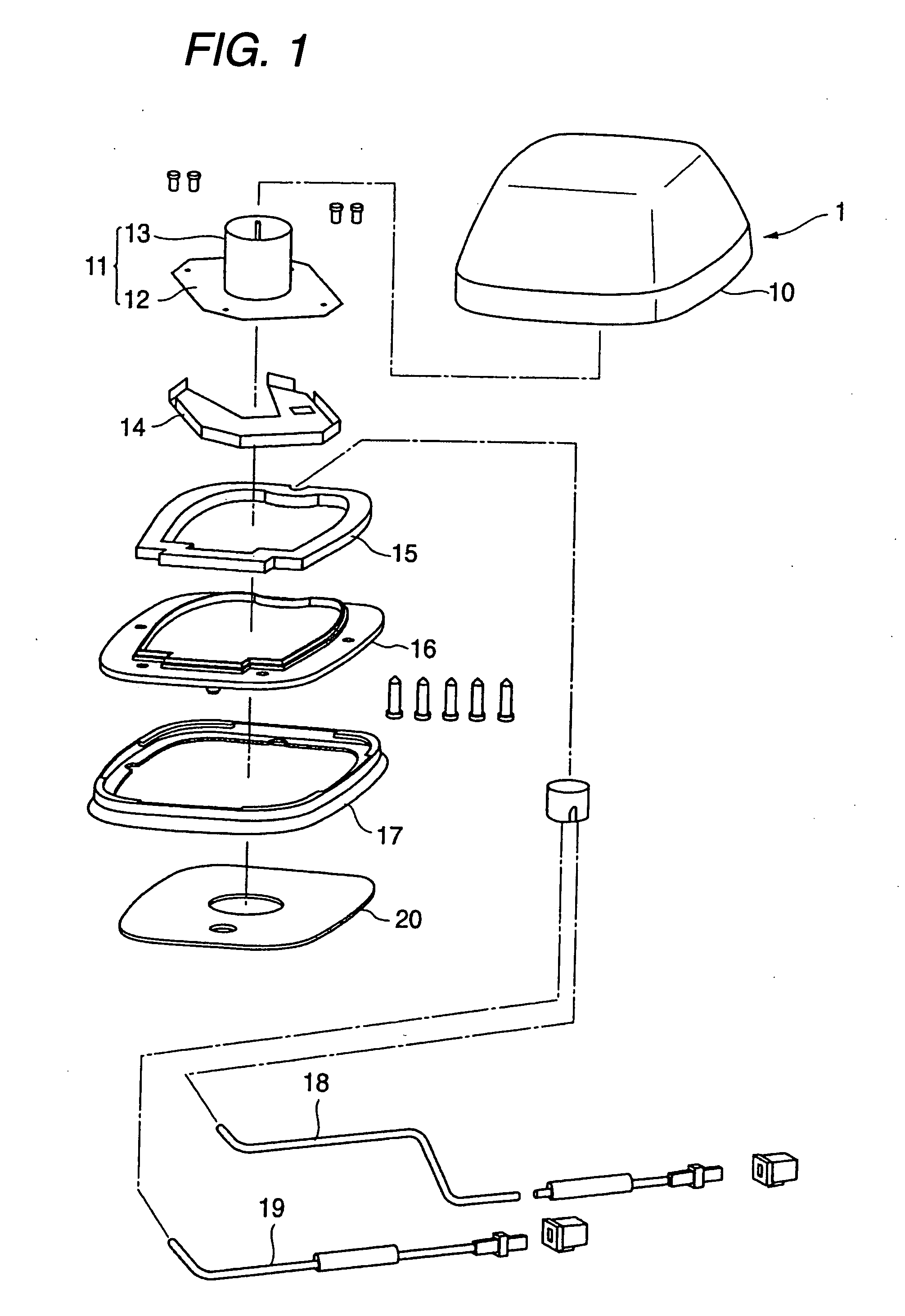

Antenna unit

InactiveUS20050225489A1Antenna supports/mountingsAntenna adaptation in movable bodiesInterior spaceMetal sheet

Owner:MITSUMI ELECTRIC CO LTD

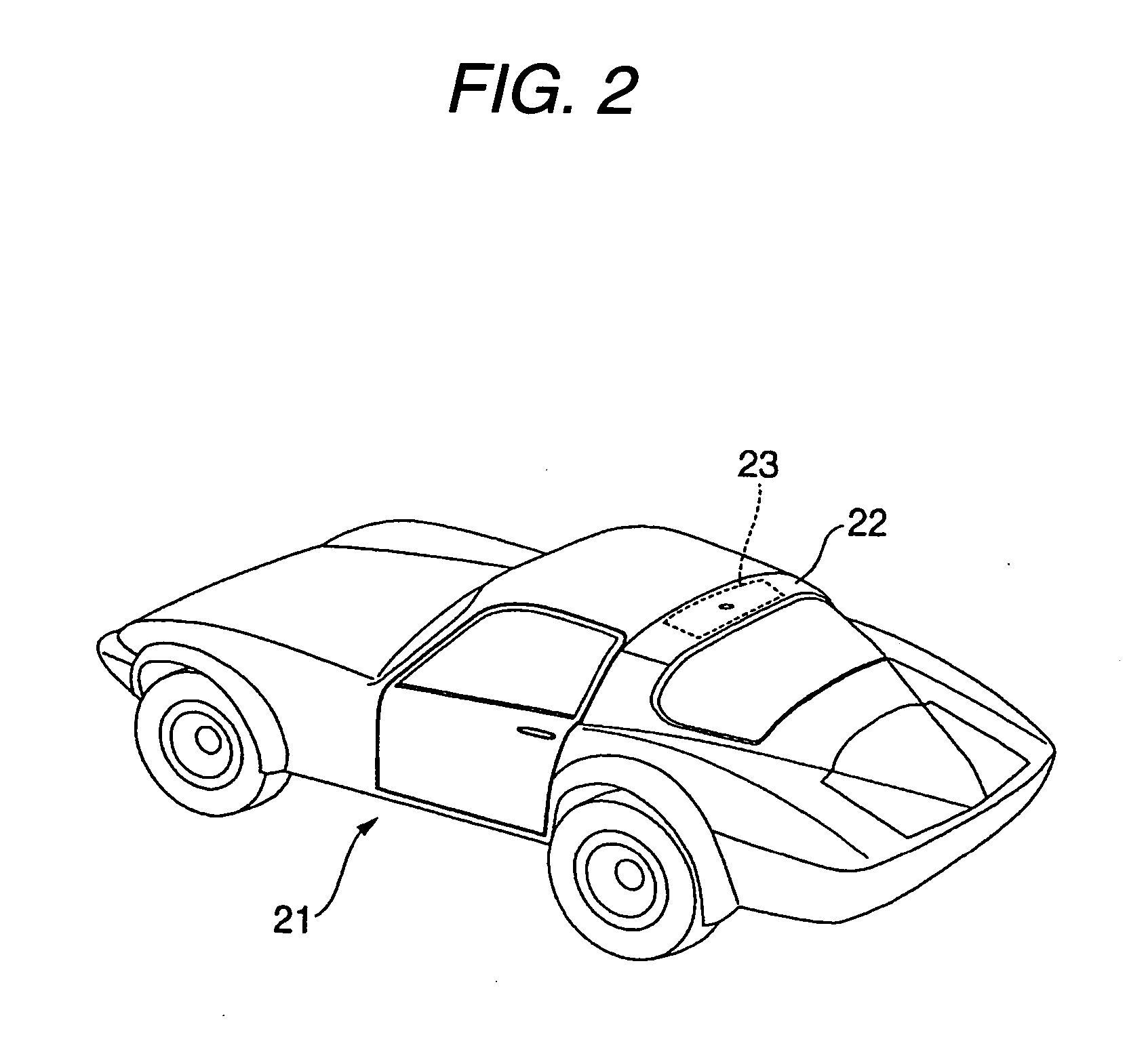

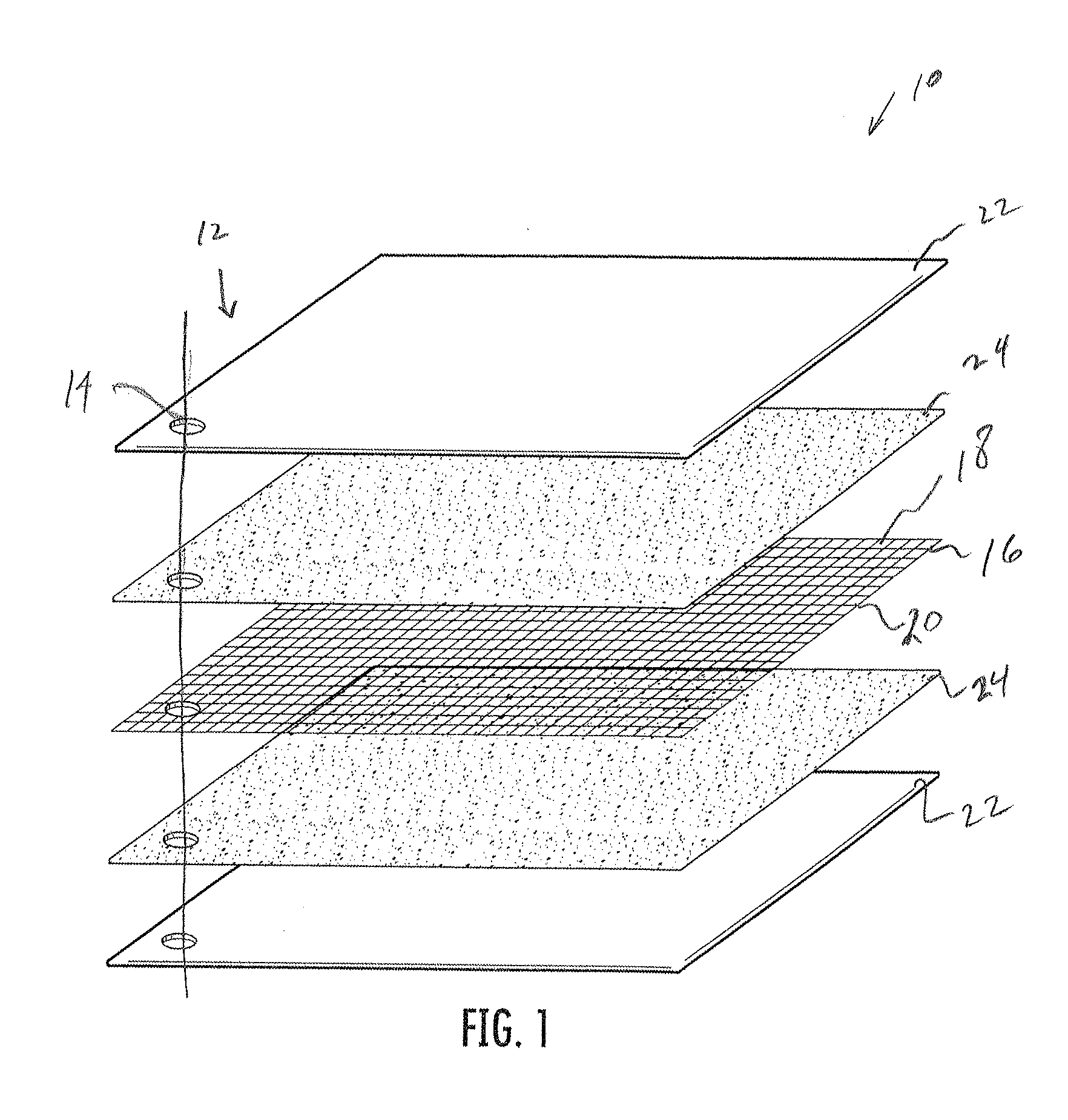

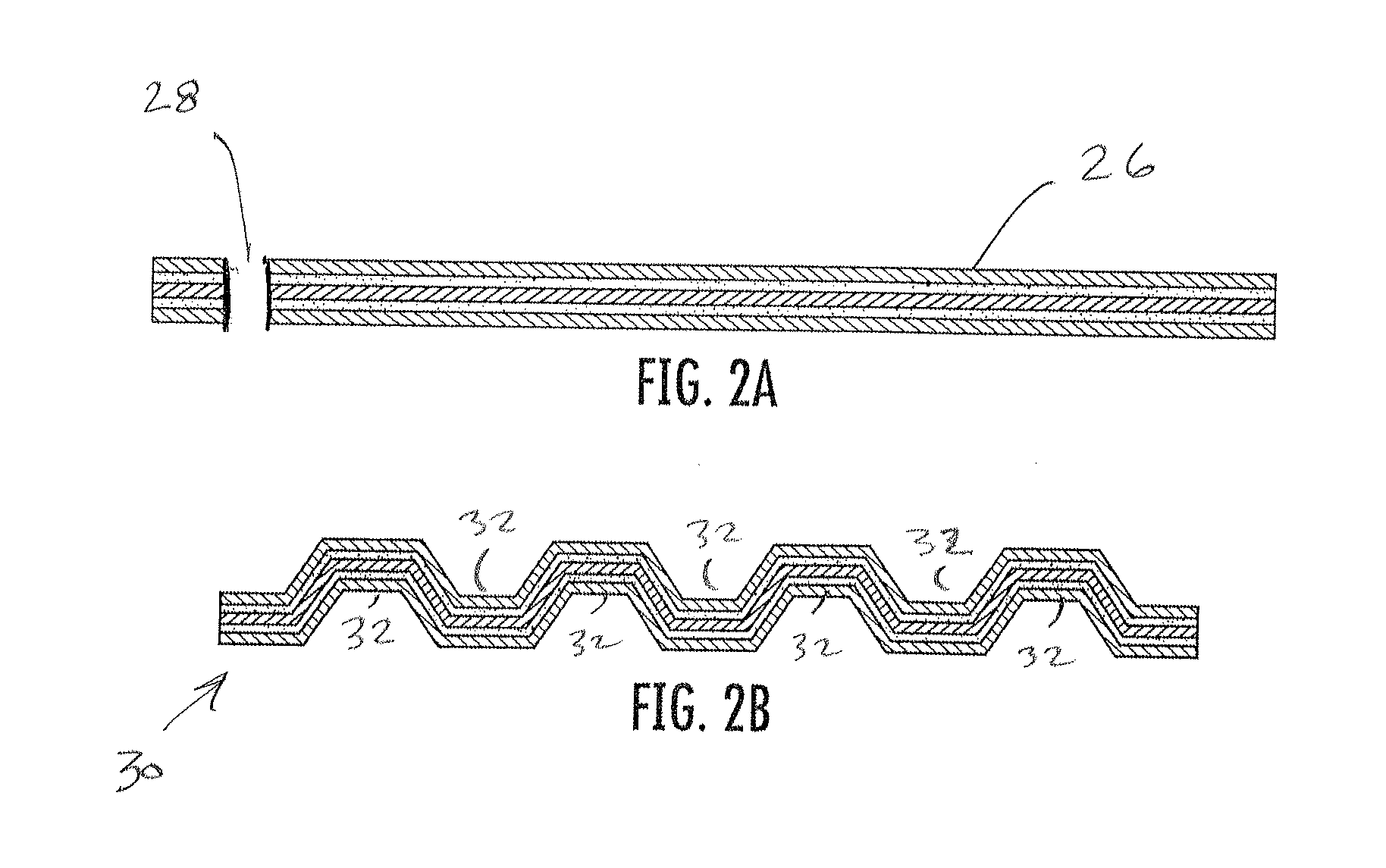

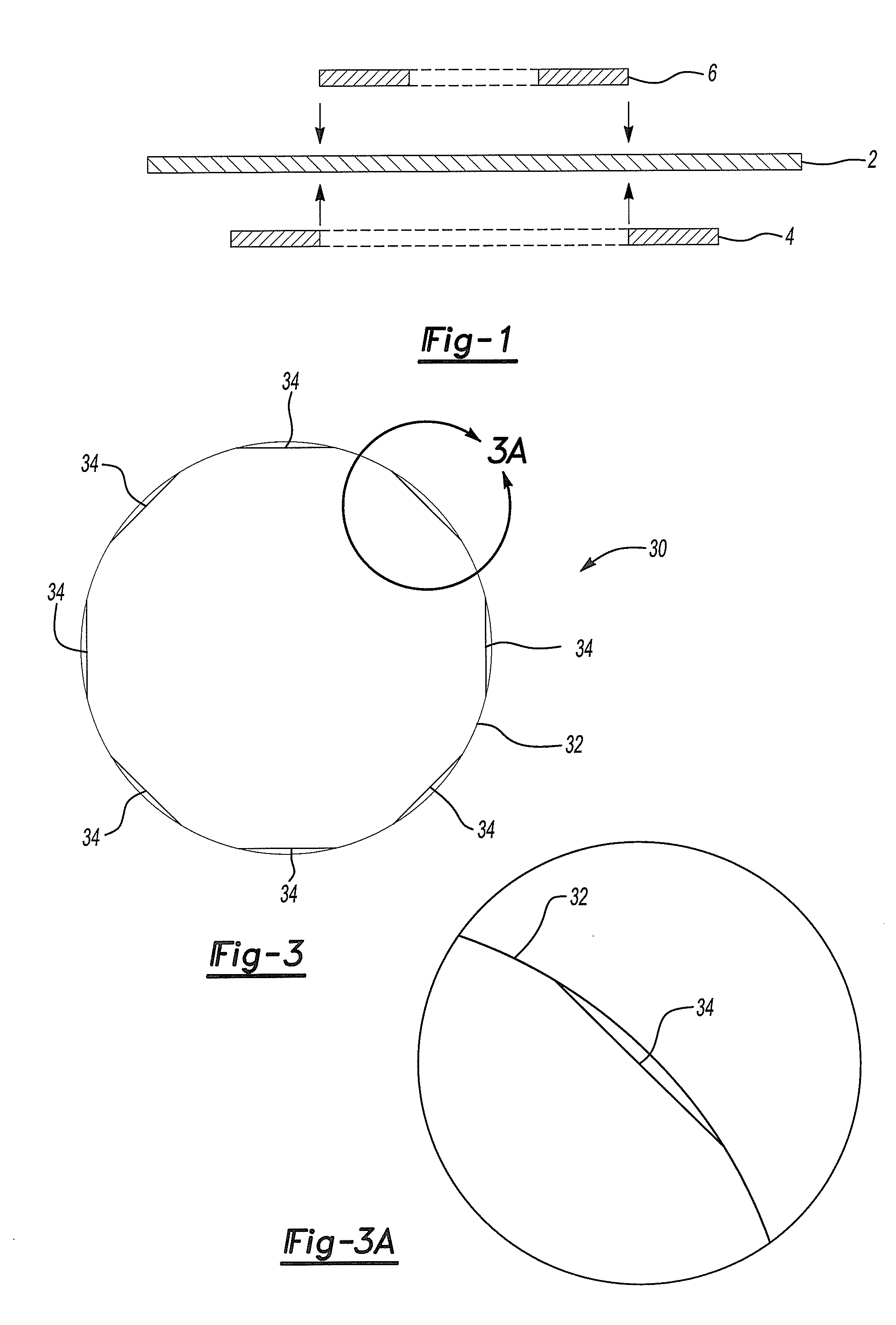

Fuel cell composite flow field element and method of forming the same

InactiveUS20110053052A1High thermalImprove conductivityElectrode manufacturing processesElectrode carriers/collectorsFuel cellsGraphite

Owner:VPJP

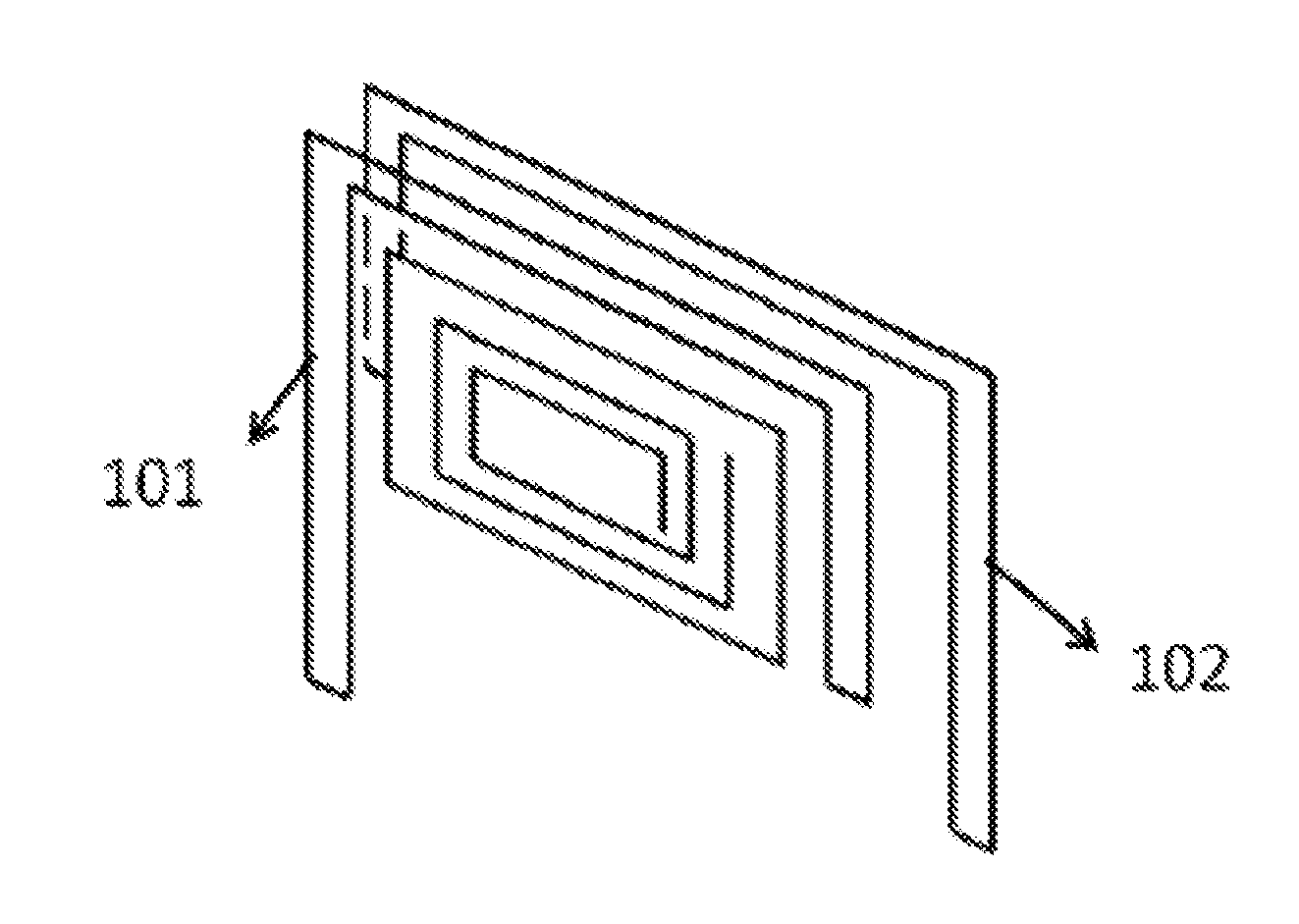

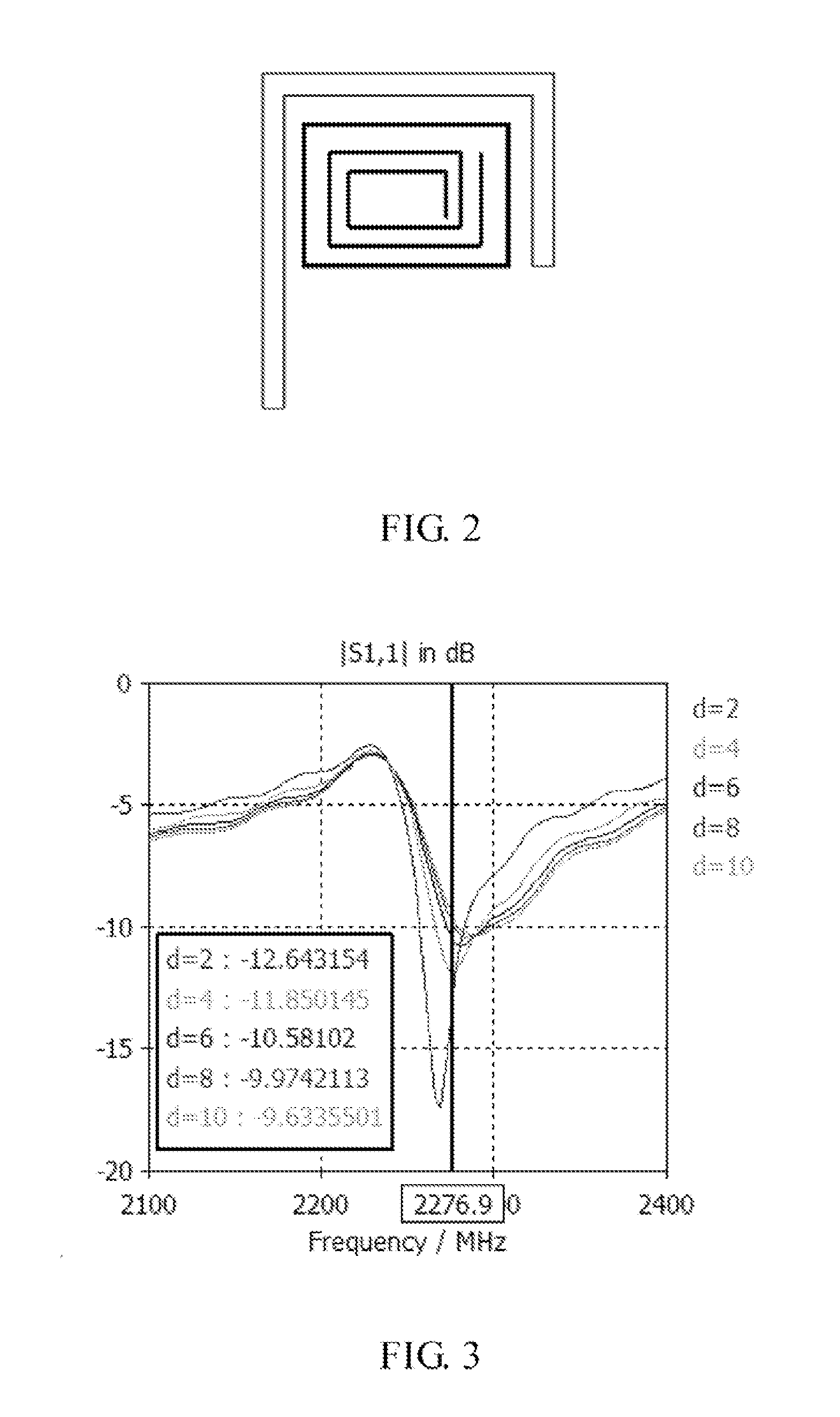

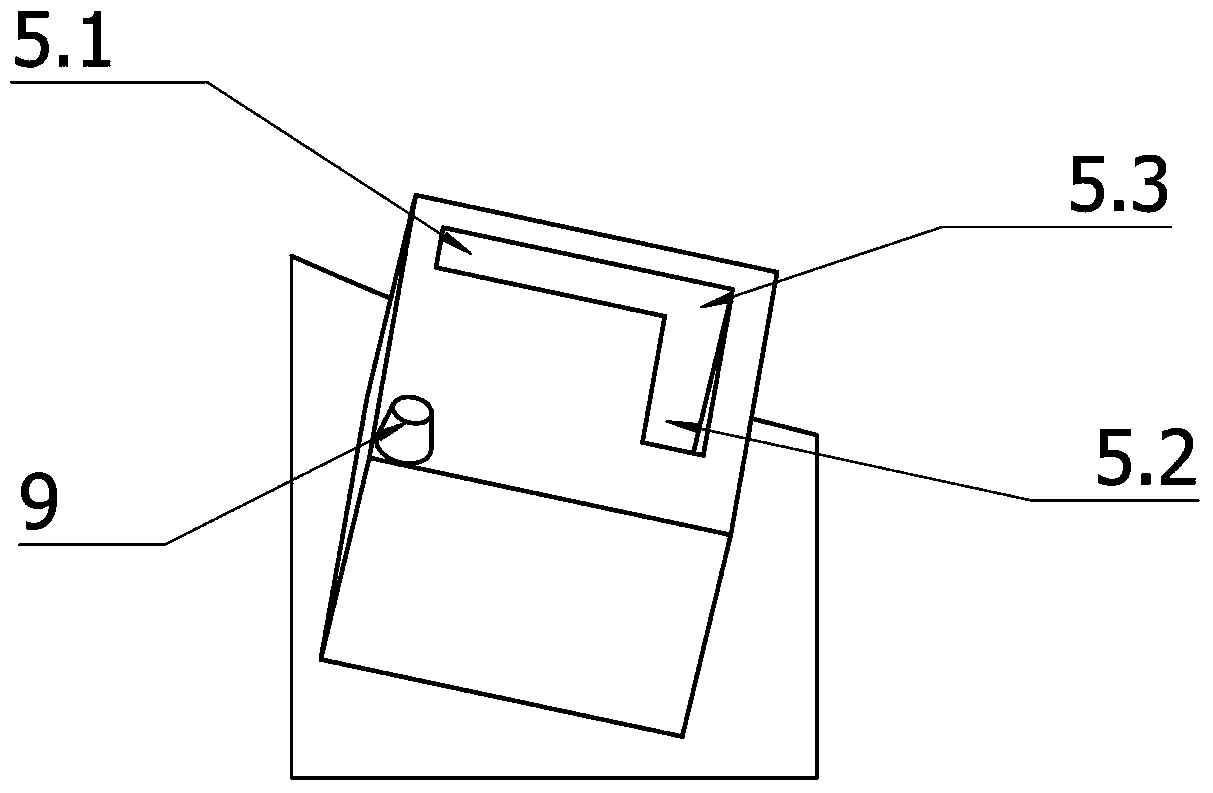

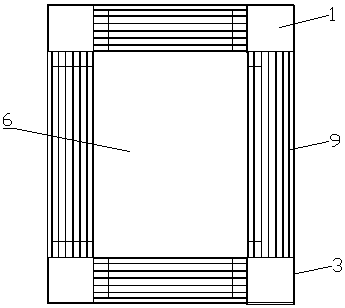

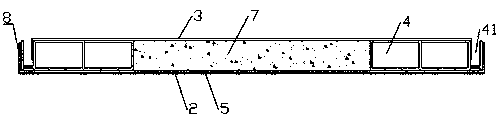

Broadband polarization insensitive meta-material wave absorber

InactiveCN103647152AAchieving Broadband TargetsChange the working frequency bandAntennasCopper foilElectromagnetic wave equation

The invention belongs to the technical field of microwave antenna engineering, and discloses a broadband polarization insensitive meta-material wave absorber, for the purpose of solving the problems of narrow working bandwidth and sensitivity of incident electric field wave polarization directions of a conventional meta-material wave absorber. The broadband polarization insensitive meta-material wave absorber comprises a top-layer resonance structure, a middle-layer medium plate and bottom-layer copper foil, wherein the resonance structure comprises an opening resonance ring and a metal sheet disposed in the ring; when electromagnetic waves are incident to the wave absorber, the resonance structure generates a magnetic field loop, the medium plate generates dielectric loss, and electromagnetic energy is converted into heat energy through loss so that loss of the electromagnetic waves is absorbed. The wave absorber has absorption effects for incoming waves from different polarization directions so that the wave absorber is insensitive to the polarization directions of the incoming waves. At the same time, the working bandwidth of the wave absorber reaches 9.20 GHz. The broadband polarization insensitive meta-material wave absorber is applied to the field of electromagnetic interference shielding and stealth technologies and the like.

Owner:HARBIN INST OF TECH

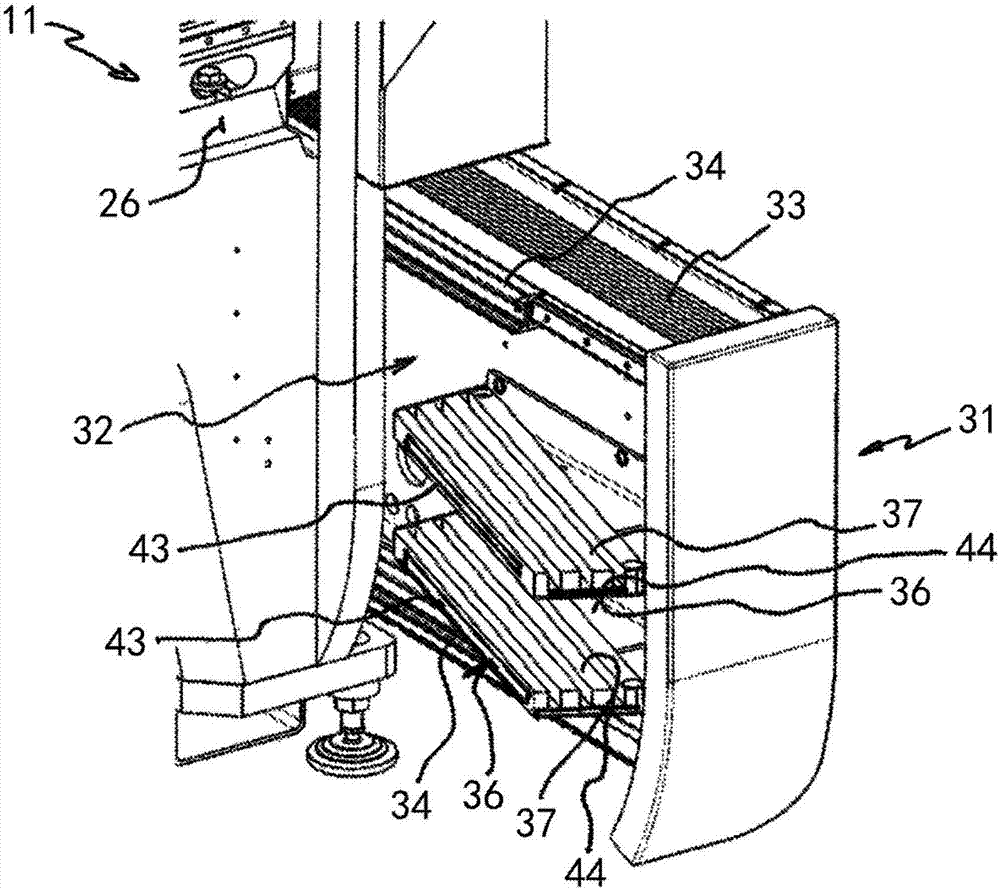

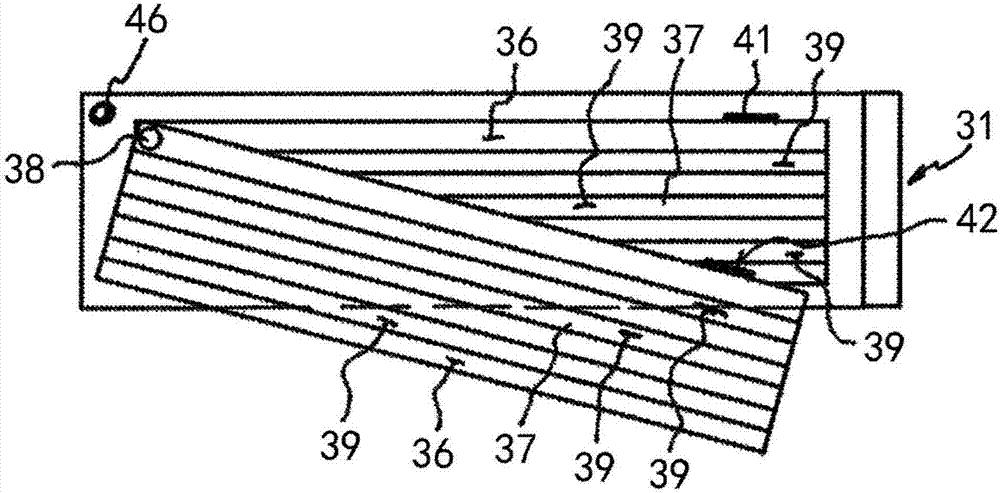

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminates the effects of thermal contact resistanceEliminate the effects ofPV power plantsEnergy industryCells panelMetal sheet

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

Microchannel-group integrated heat-pipe radiator

InactiveCN1851911ASimple preparation processSpeed up the flowDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidMetal sheet

This invention relates to a micro-slot group integrated heat-pipe radiator including a closes shell made of metal thin plates, in which, the inside cavity of the shell is vacuum filled with working fluid, a core piled up closely by multiple metal thin plates are set in the closed shell, the outer surface of the core is welded to the internal surface of the shell, gaps generating capillary force to adsorb the working fluid is set between the metal thin plates, the surface of the plate is opened with through holes, multiple piled up through holes form through holes on said core to drive the boiled fluid to flow among the slots adjacent to said metal thin plates.

Owner:杨洪武

Connection method for carbon fiber yarns and metal sheet for heating

The invention relates to a connection method for carbon fiber yarns and a metal sheet for heating, which is characterized in that the method comprises the following steps of: 1) stranding: stranding 3-10 beams of adjacent carbon fiber yarns at the end of carbon fiber cloth into one strand; 2) coating adhesive: evenly coating conductive adhesive doped with curing agent at a position at which the stranded carbon fiber yarns are in contact with the metal sheet; 3) wrapping felts: wrapping 1-2 layers of thin carbon fiber felts on the surface of the carbon fiber yarns coated with the conductive adhesive to enable the conductive adhesive to infiltrate the thin carbon fiber felts; 4) sheathing: sheathing a metal sheet clamp on the carbon fiber yarns into which the conductive adhesive infiltrates, clockwise turning a clamping knob to tightly clamp the carbon fiber yarns until the conductive adhesive flows out of the two ends of the clamp; and 5) curing: fixing the clamp, placing at room temperature and controlling curing time to be 24-72h. Compared with the prior art, the connection method has the advantages of simplicity, effectiveness, economy, durability, even and firm connection position, stable and reliable performance and the like.

Owner:JIANGSU YUEKE NEW MATERIAL

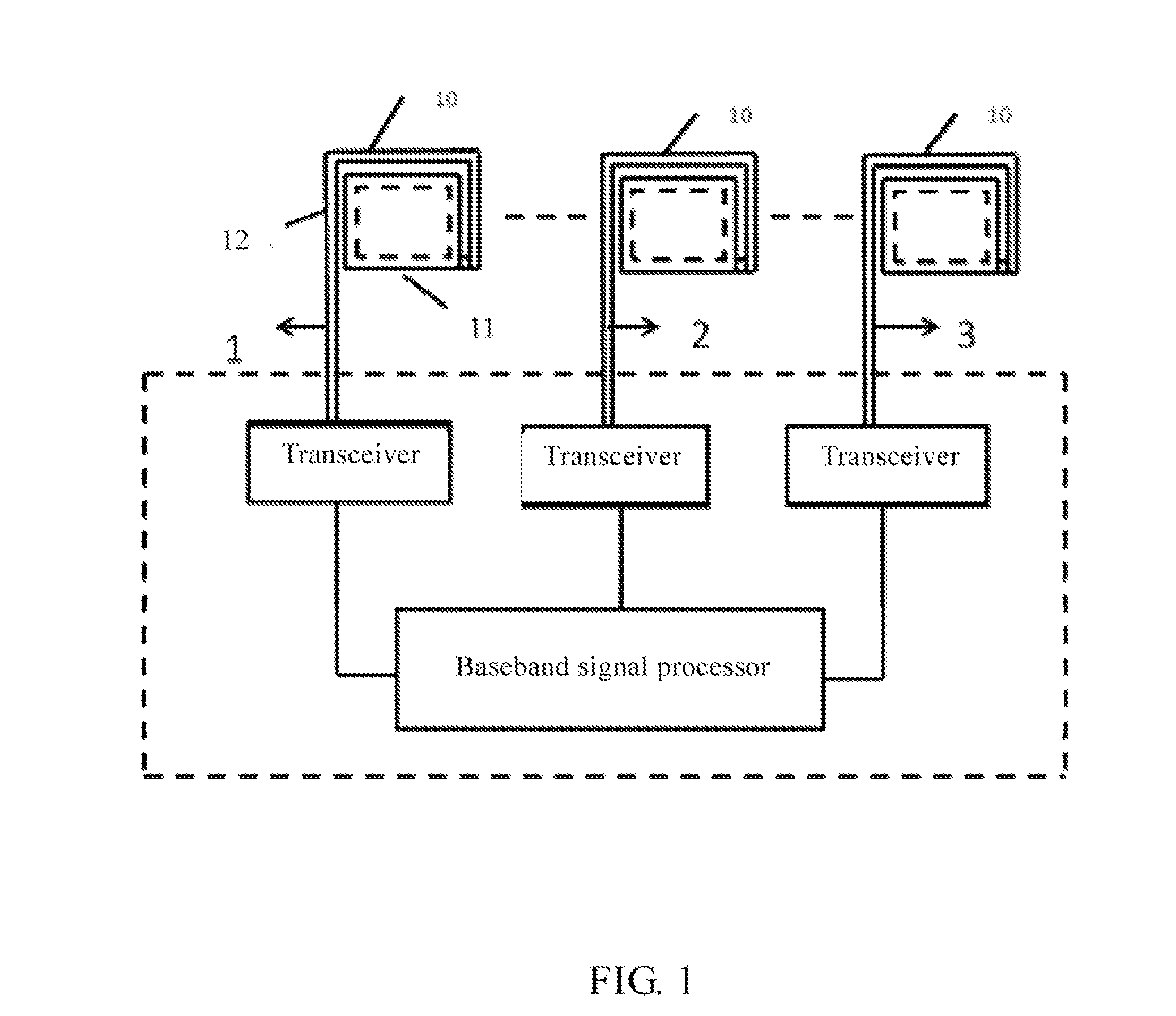

Unipolar, bipolar and hybrid MIMO antennae

InactiveUS20130082897A1Improve isolationEasy can be integrated togetherRadiating elements structural formsElongated active element feedAntenna designCommunications system

Owner:KUANG CHI INST OF ADVANCED TECH +1

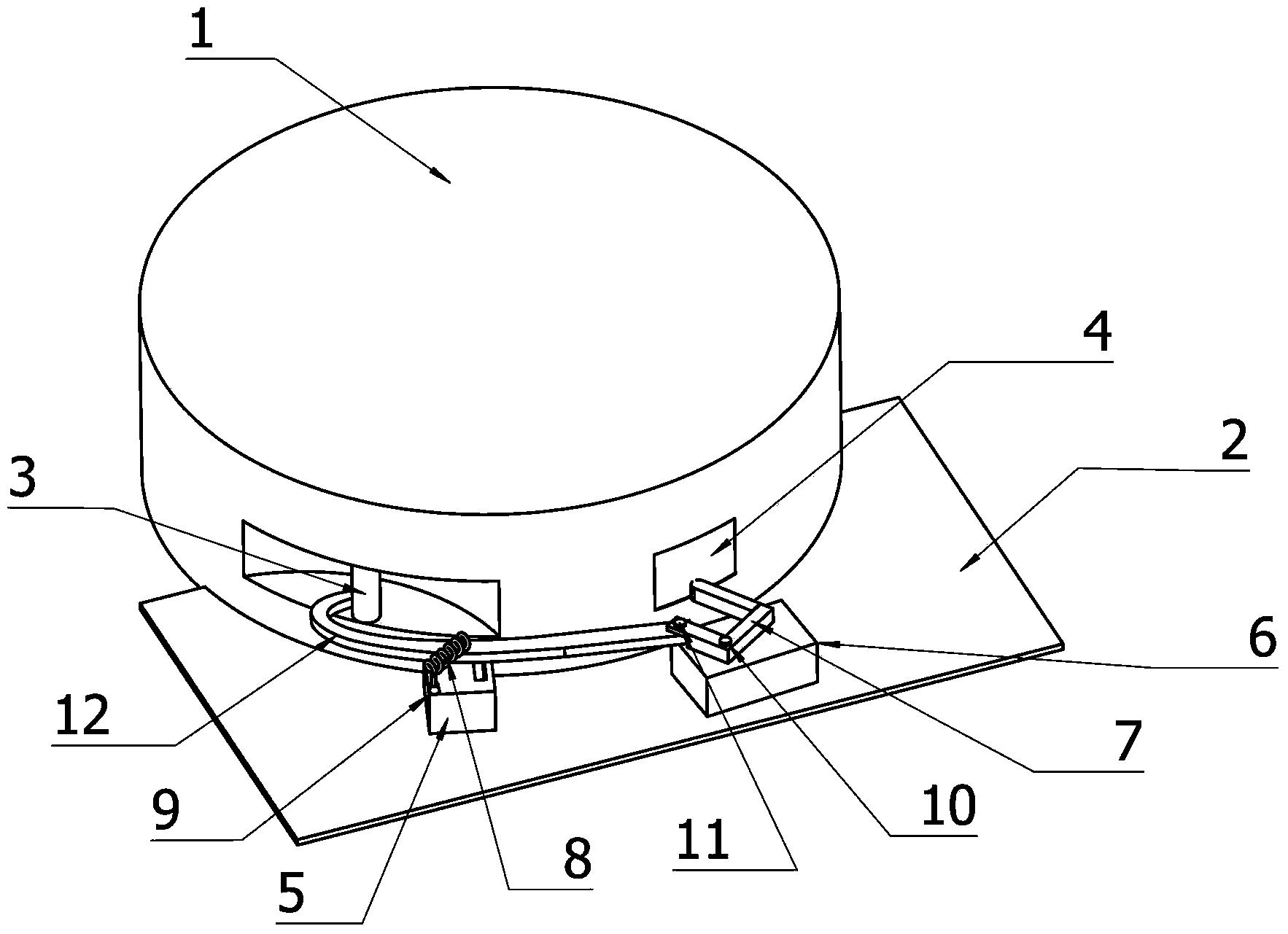

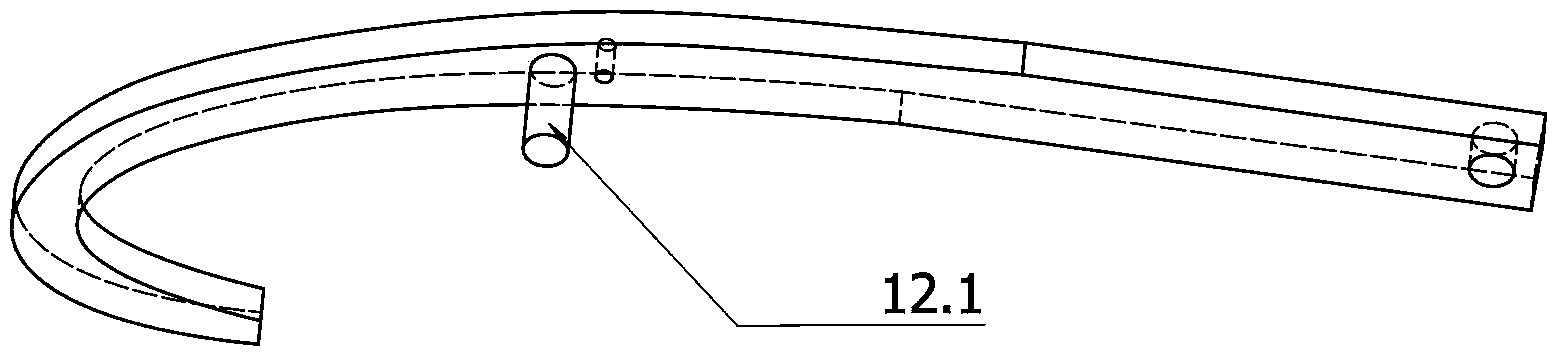

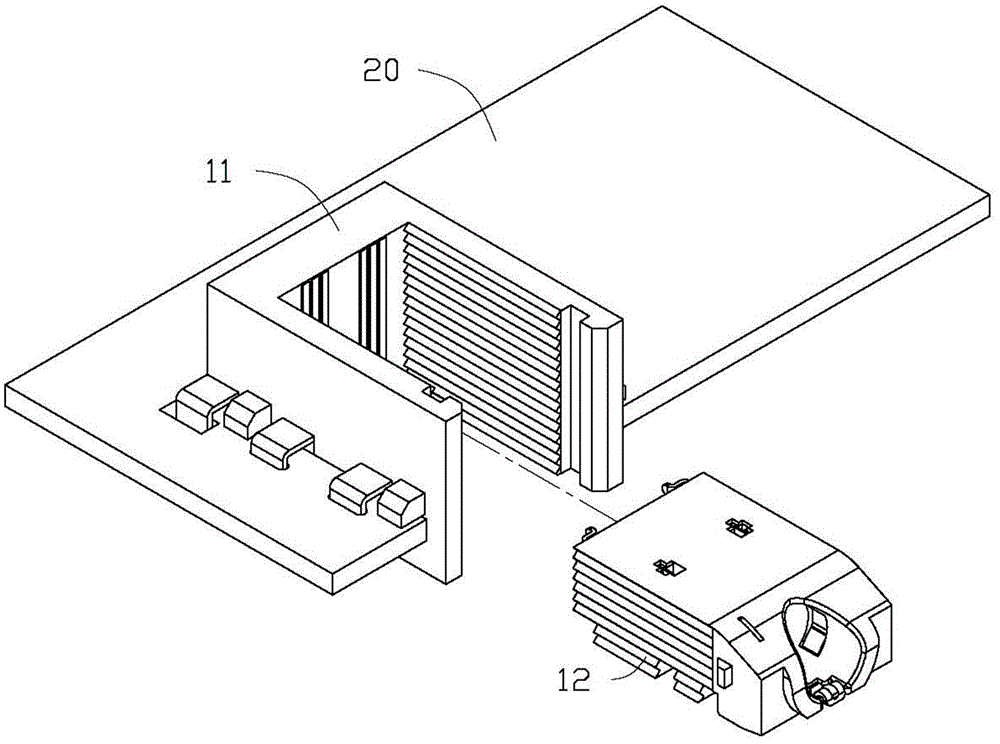

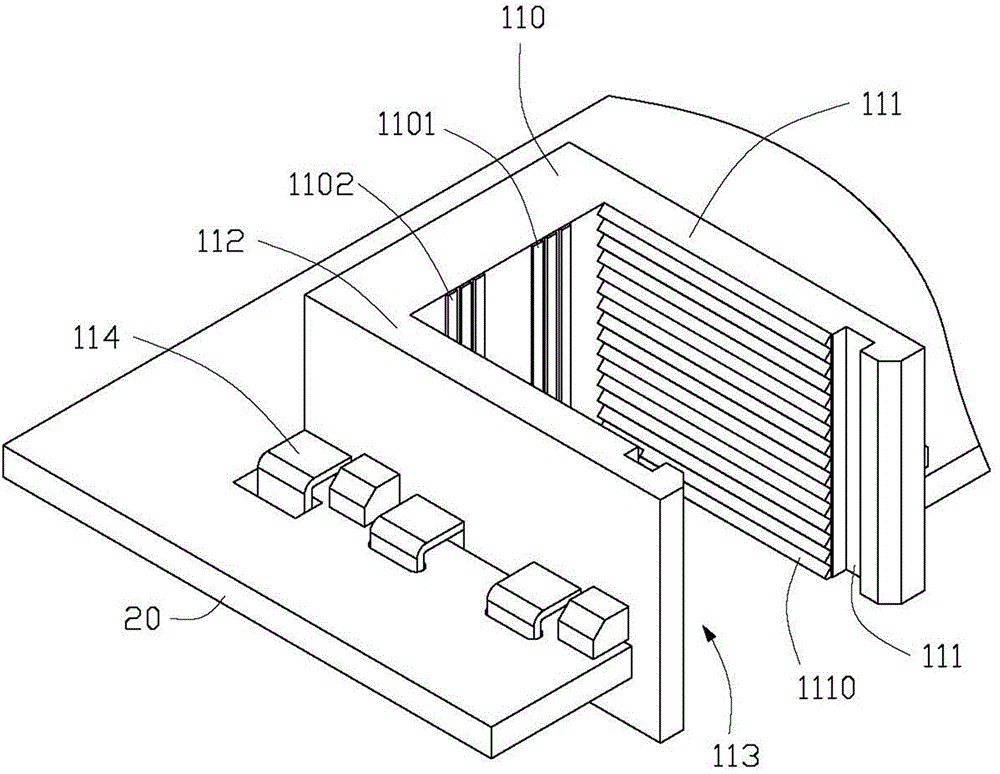

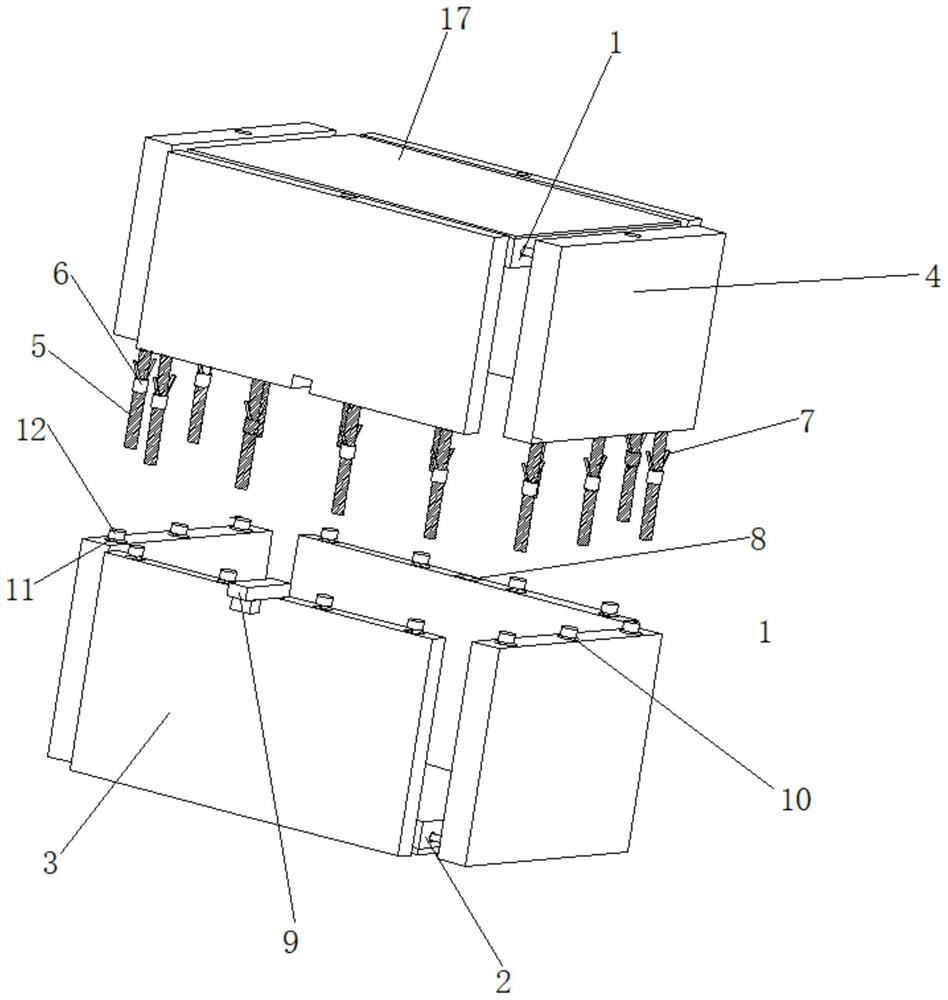

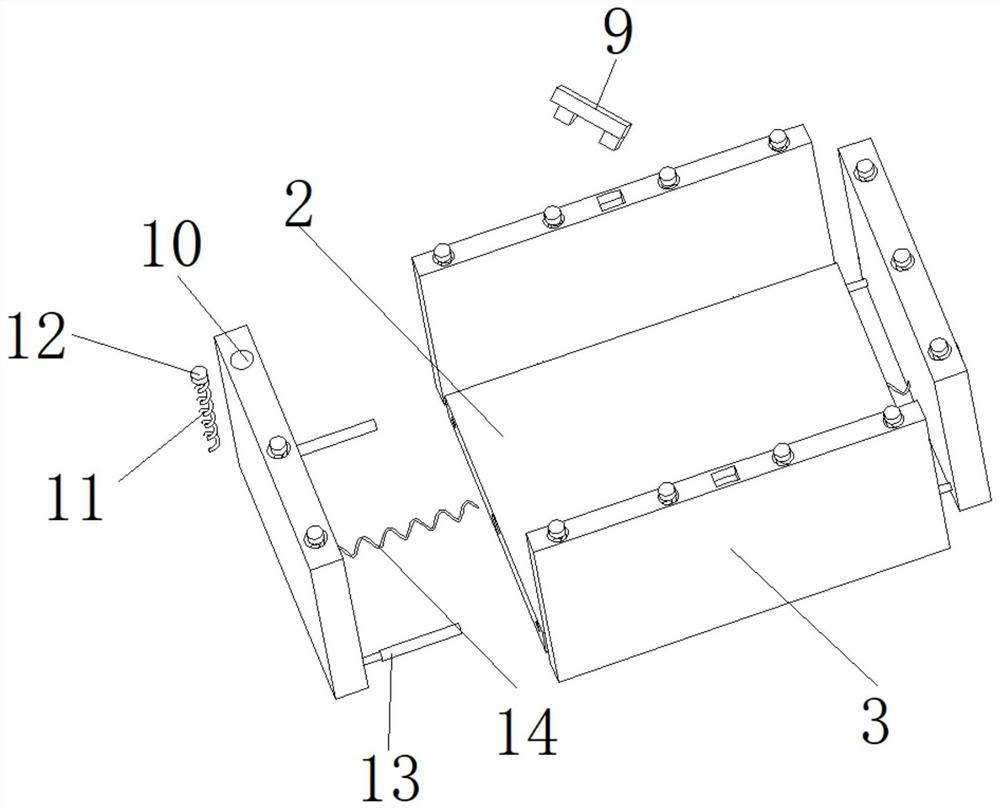

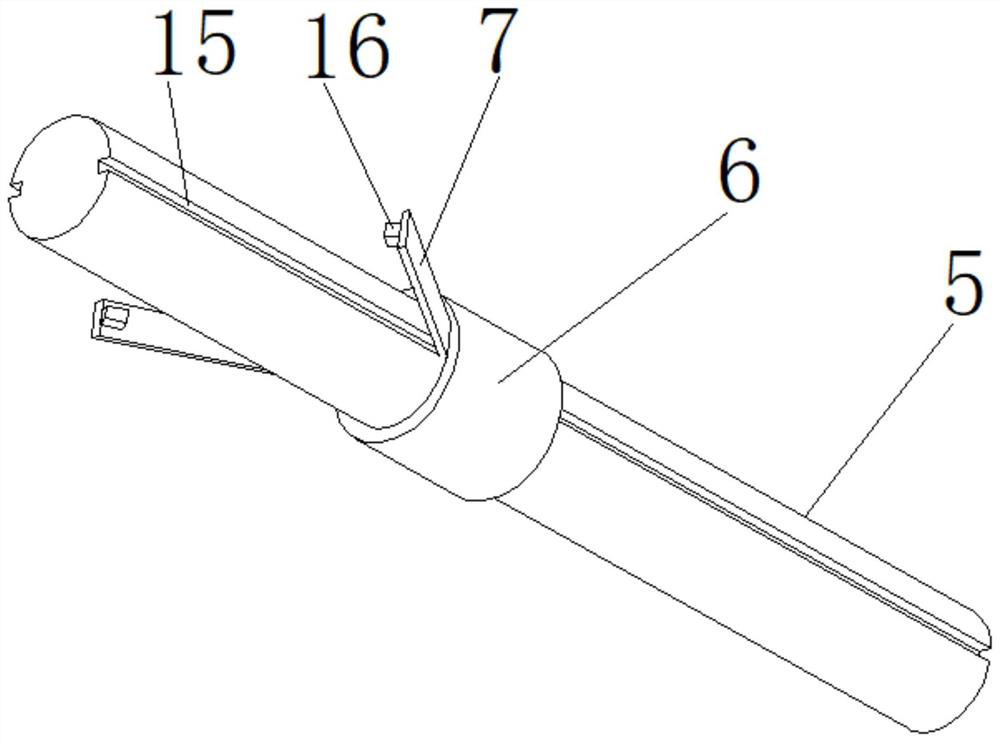

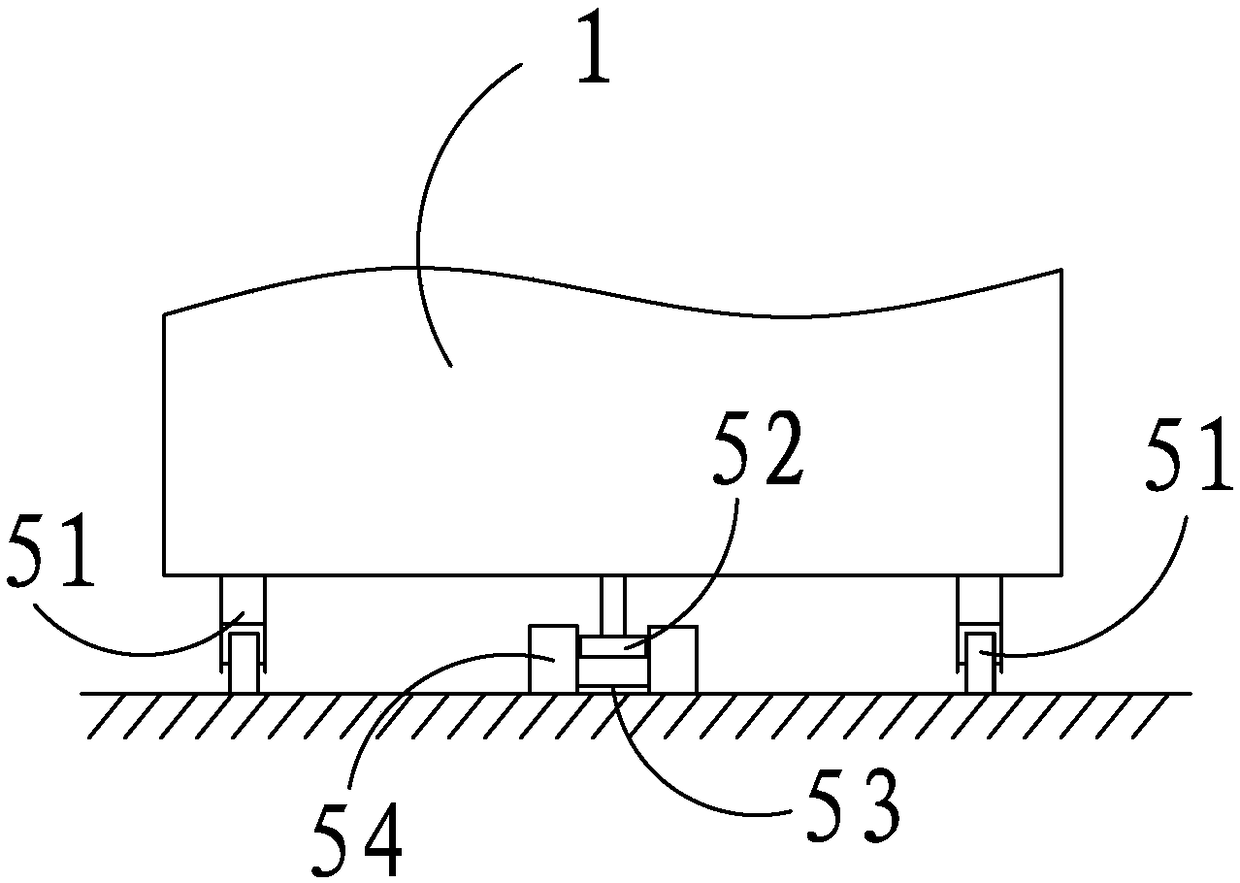

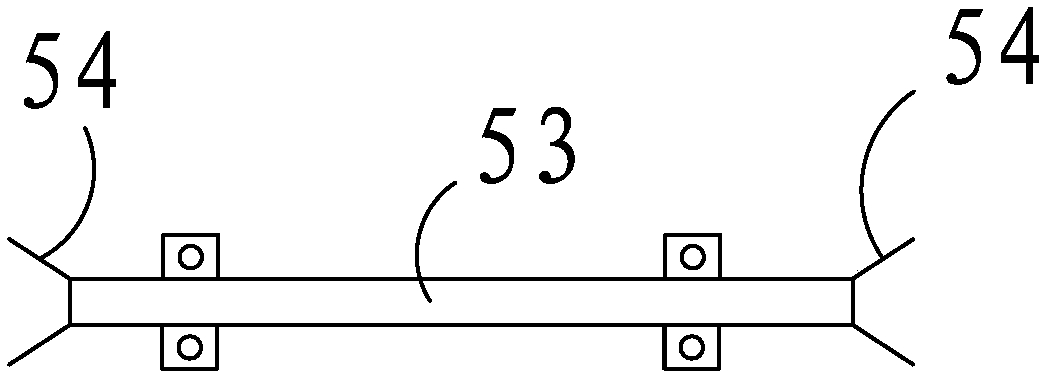

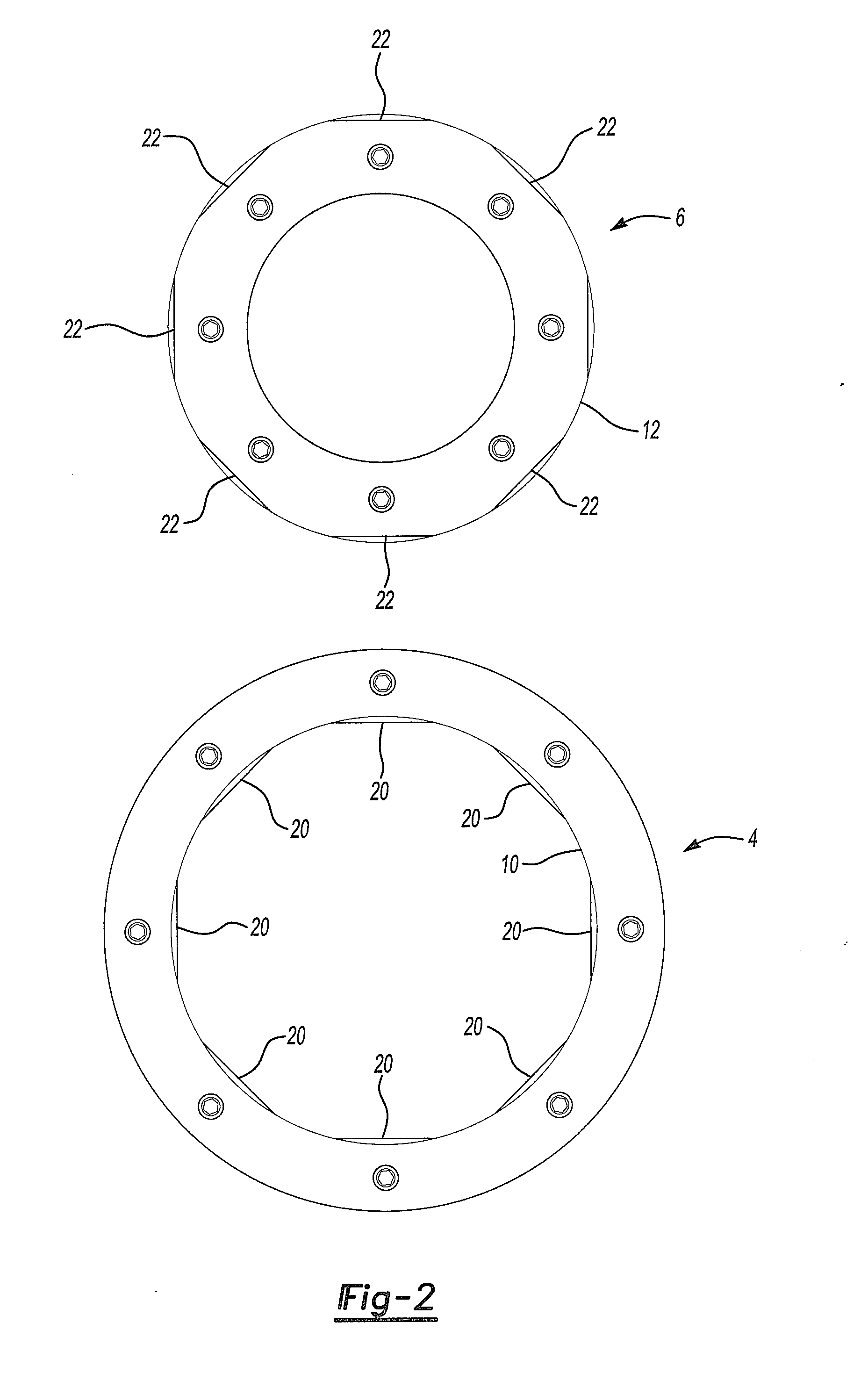

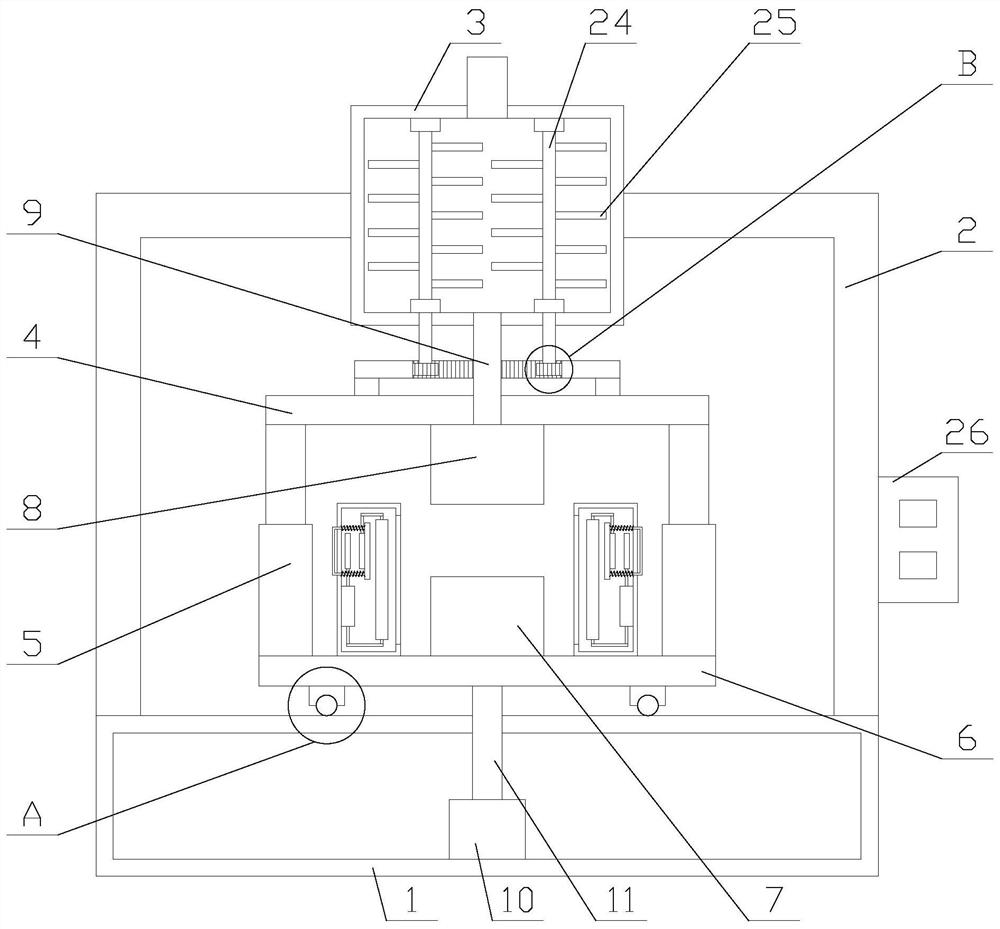

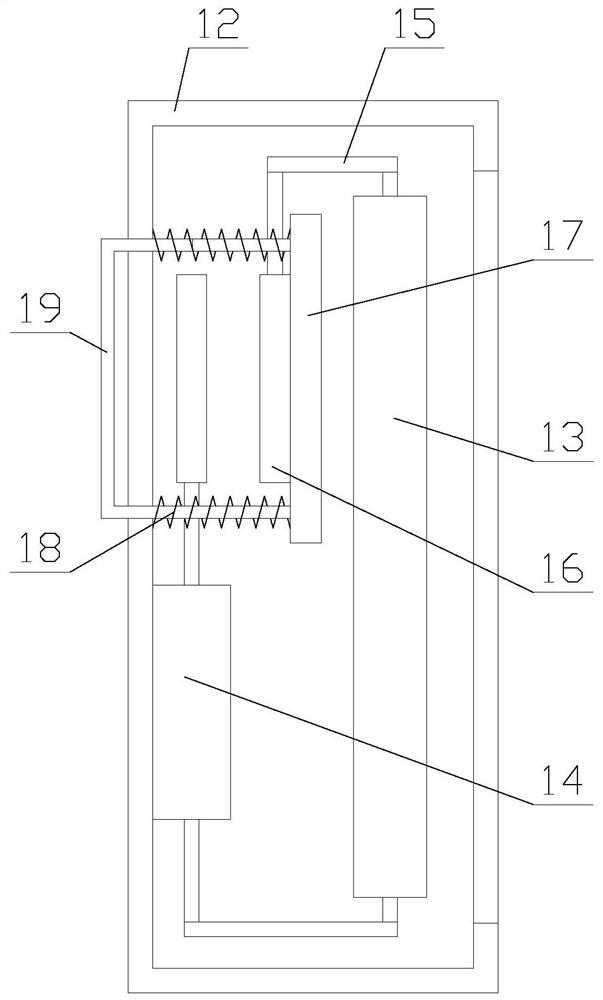

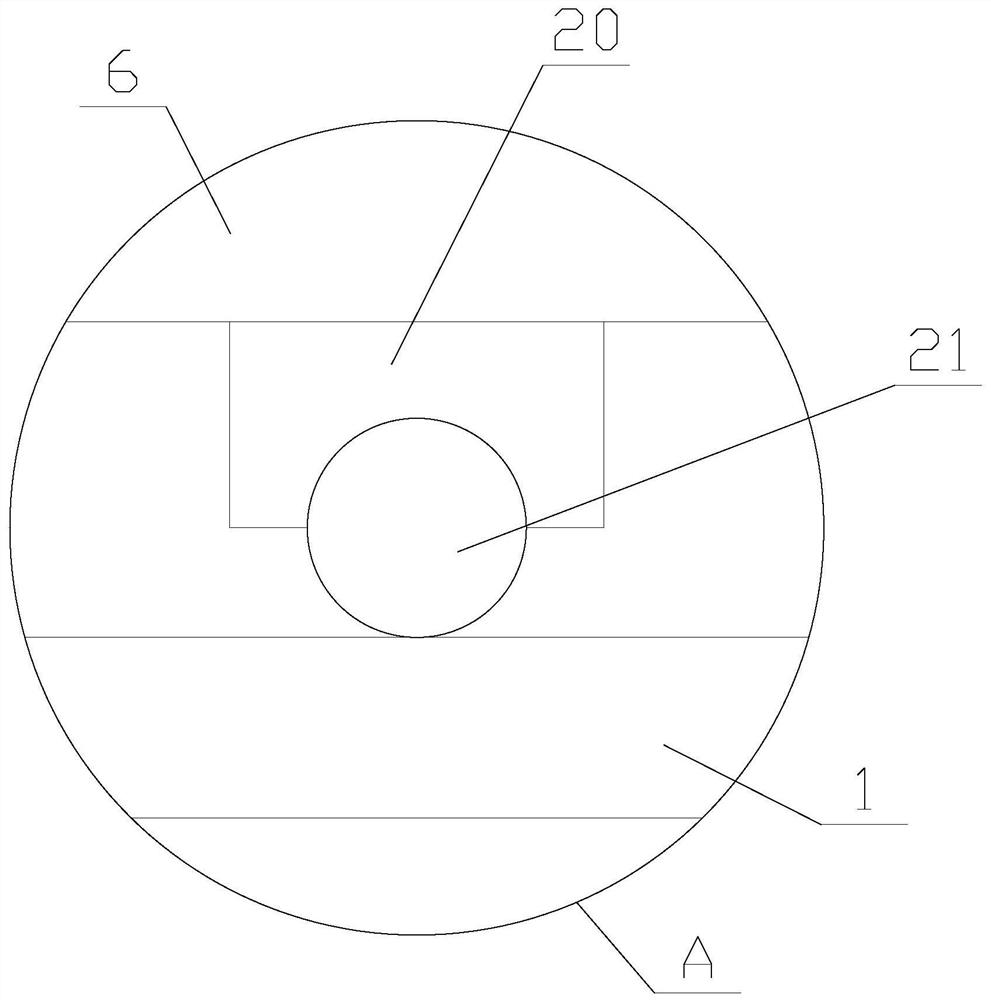

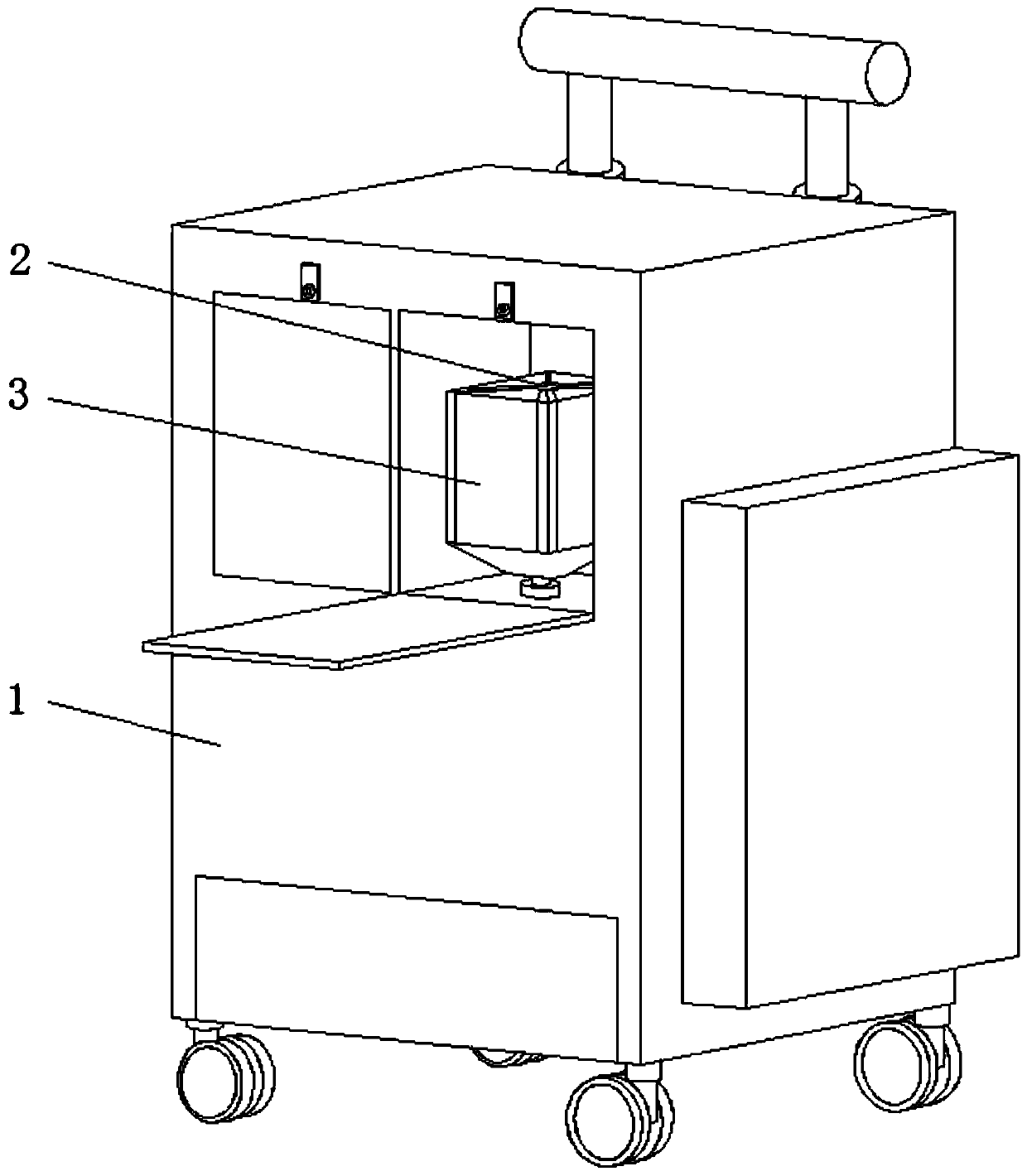

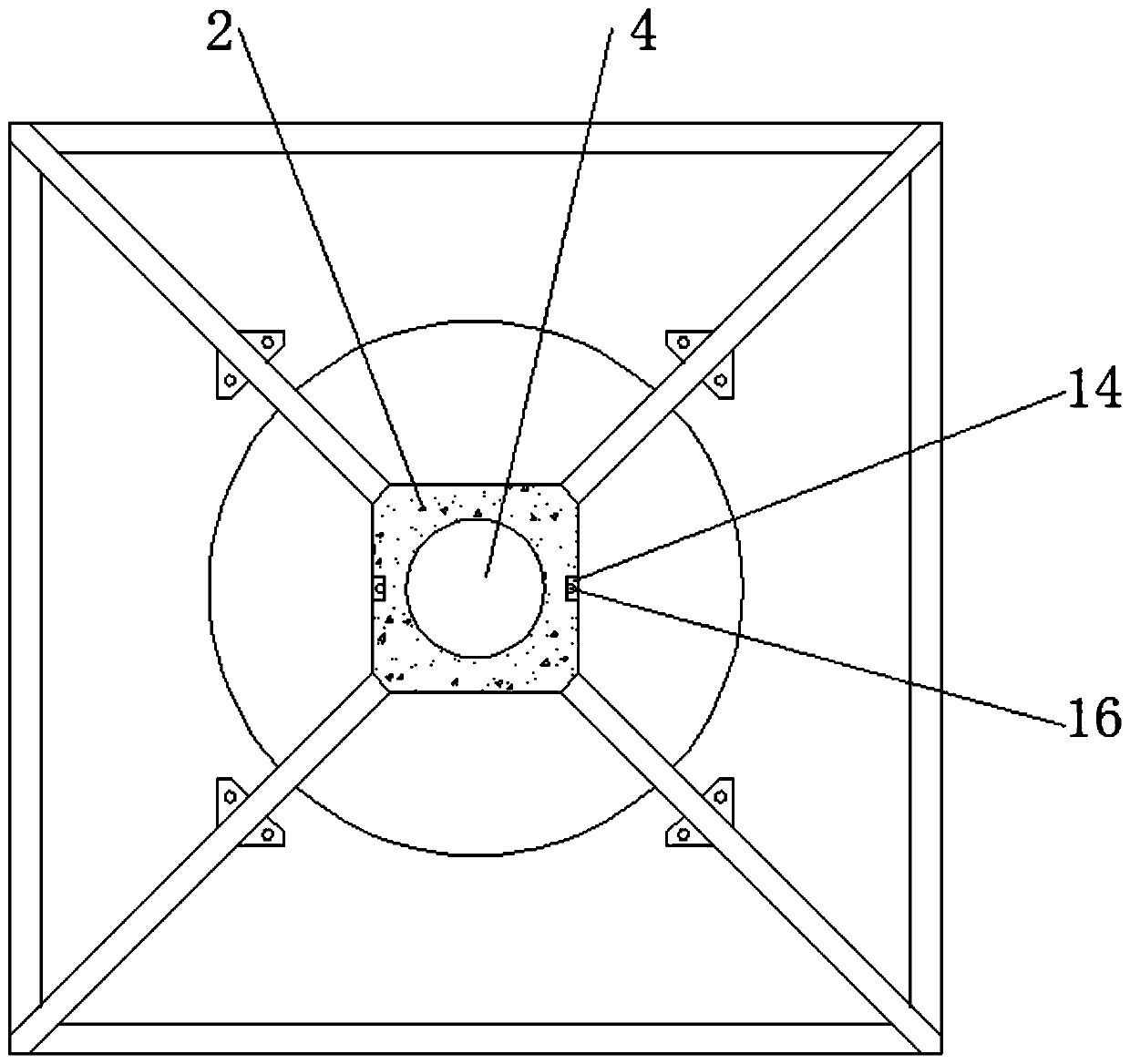

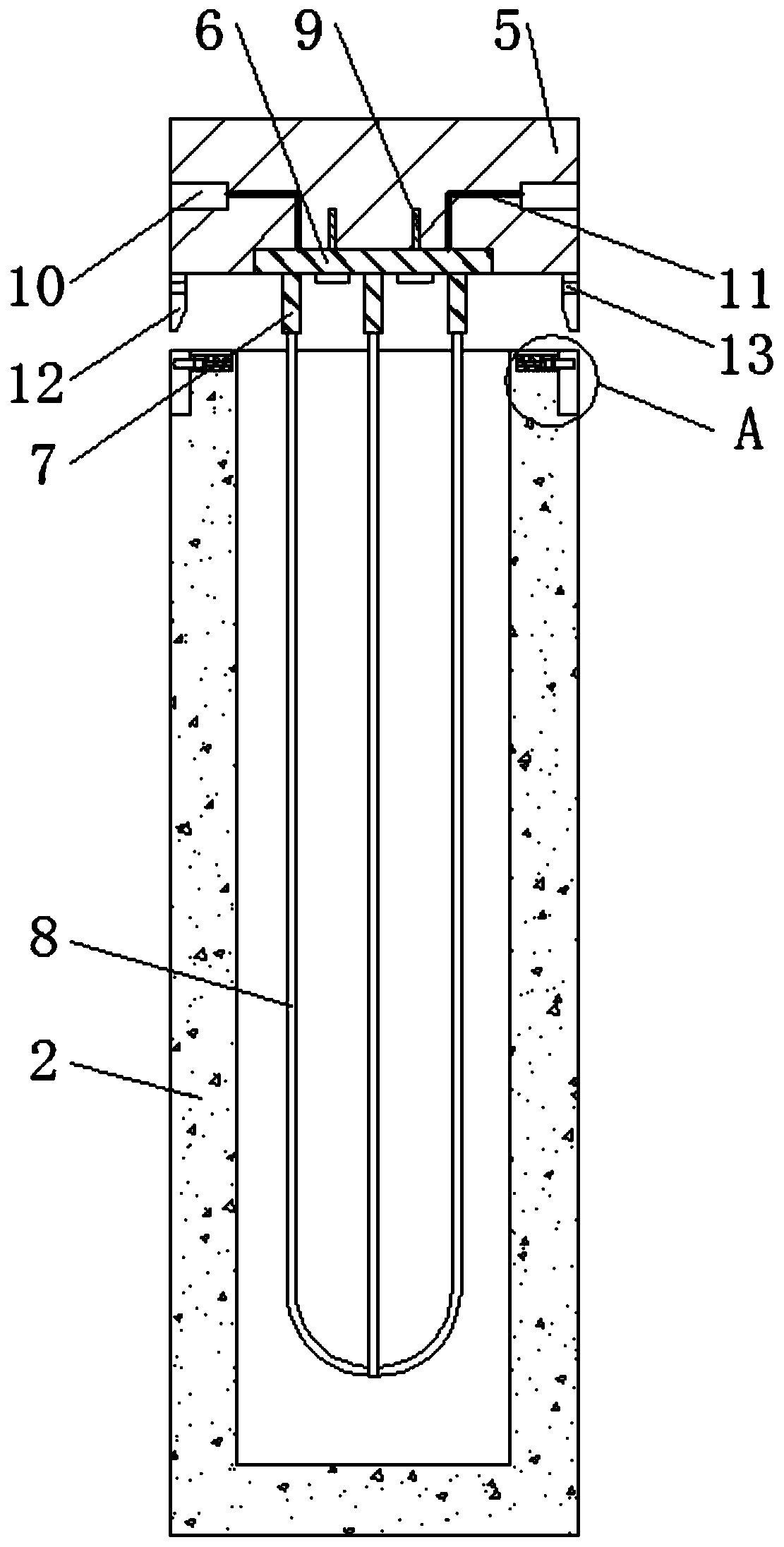

Fixing device for high-power charging of round robot

ActiveCN103944221ARealize the function of high-power chargingSimple structureBatteries circuit arrangementsElectric powerMetal sheetEngineering

Owner:BEIJING UNIV OF TECH

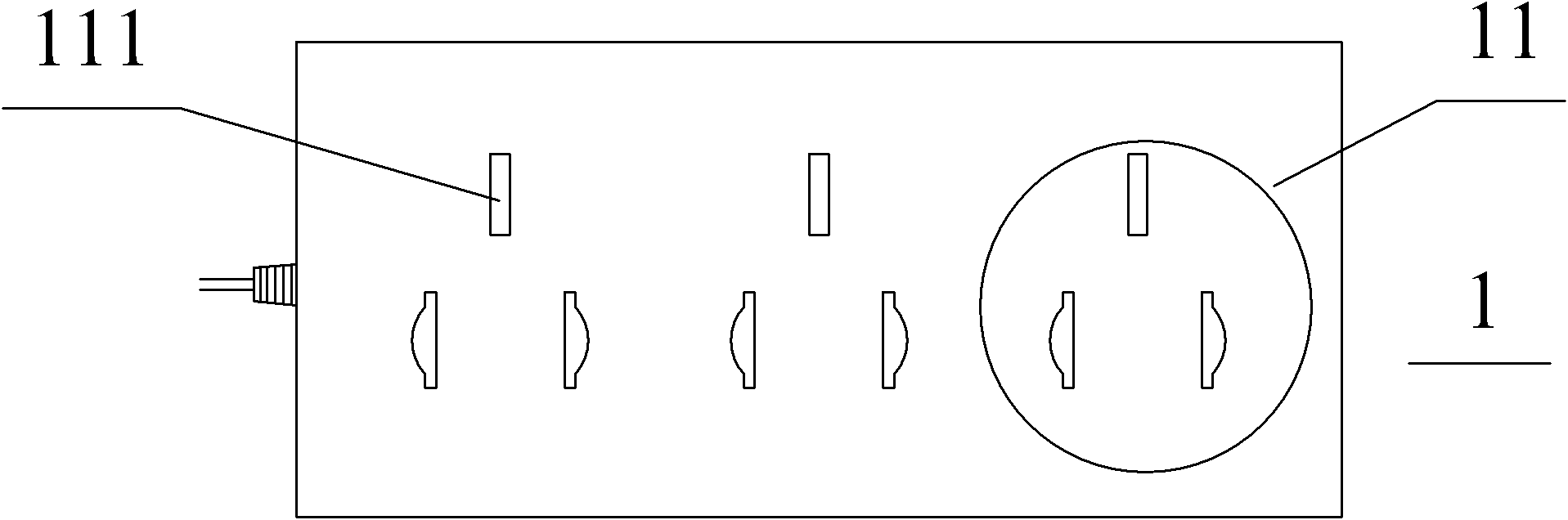

Integral safety socket made of ceramic material

InactiveCN102760998AExcellent safety and fire performanceReduce poor contactSecuring/insulating coupling contact membersCoupling contact membersMaterial consumptionMetal sheet

Owner:余乐恩

Connecting device

InactiveCN105098398AEasy to assembleShorten the development cycleCoupling contact membersFixed connectionsMetal sheetEngineering

Owner:FU TAI HUA IND SHENZHEN +1

New energy automobile power battery shell mounting method

InactiveCN112366395AImprove practicalityEasy to useAssembling battery machinesFinal product manufacturePower batteryNew energy

Owner:广州成刚科技有限公司

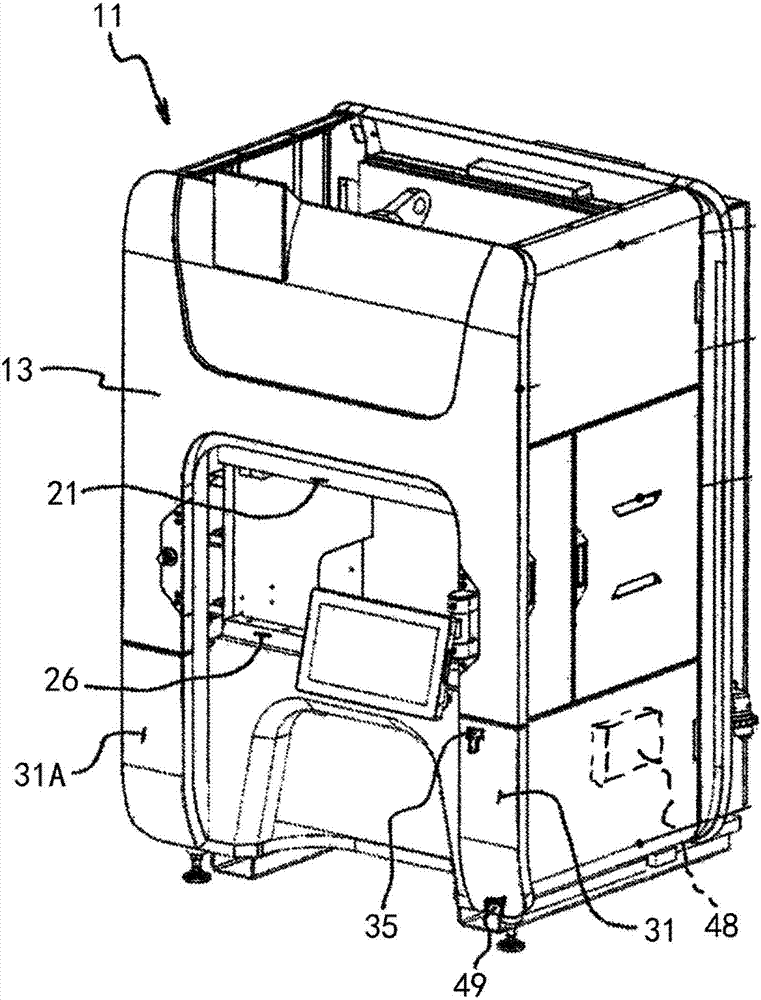

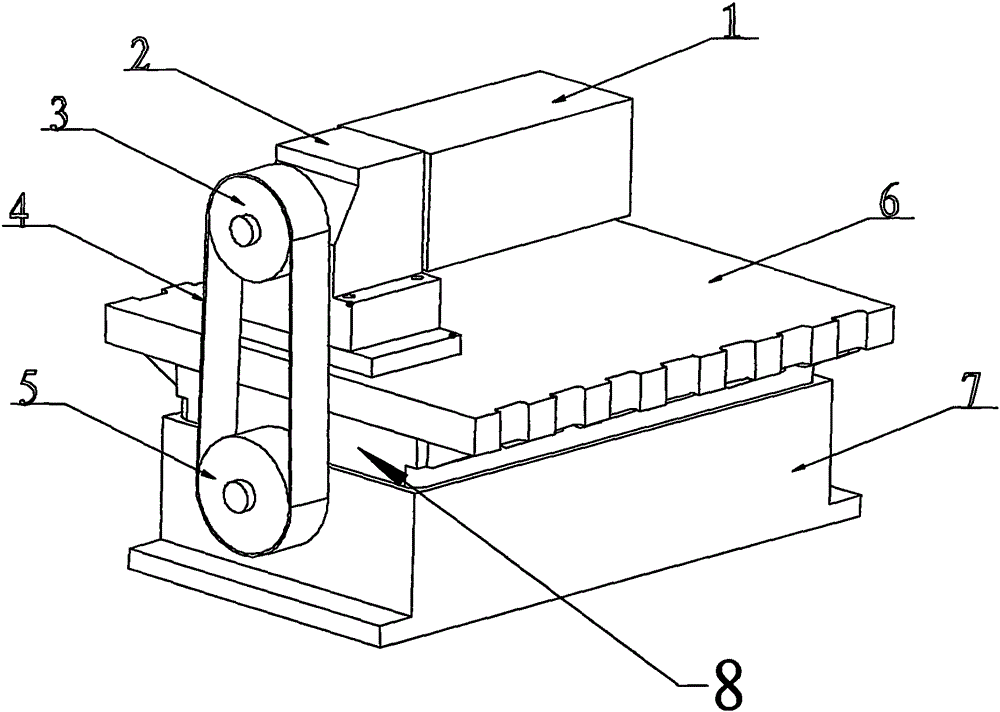

Bending press

Owner:BYSTRONIC LASER

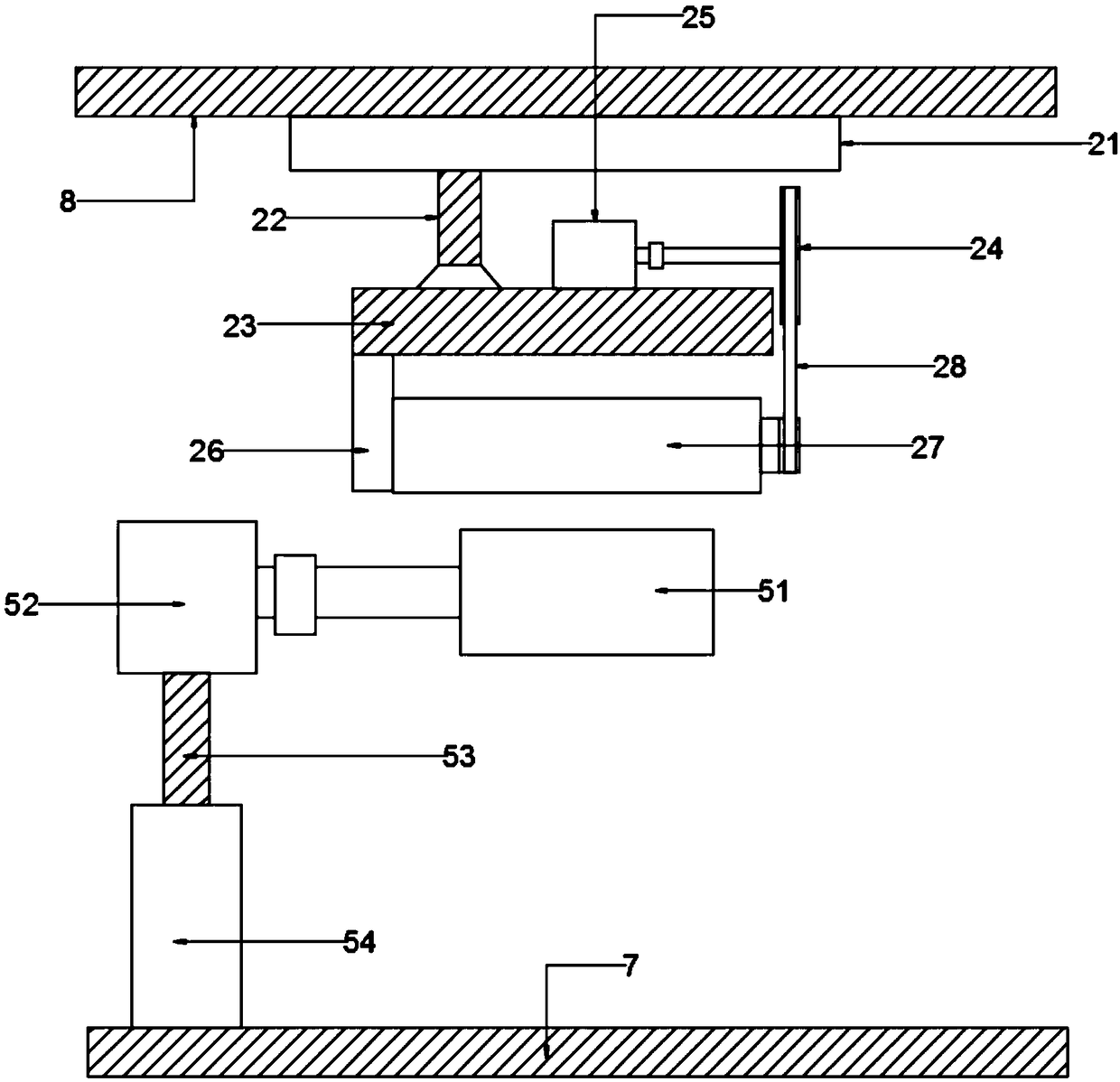

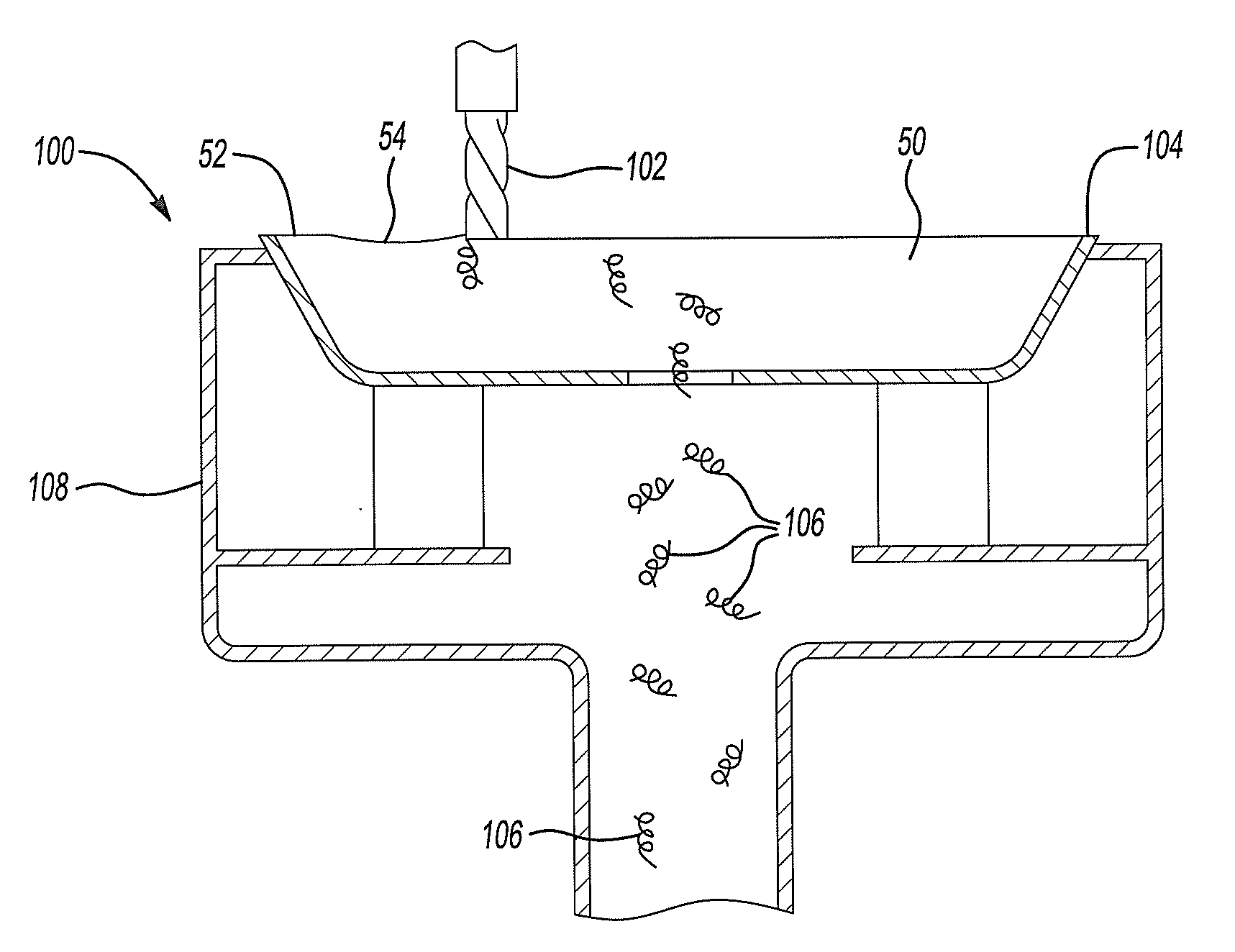

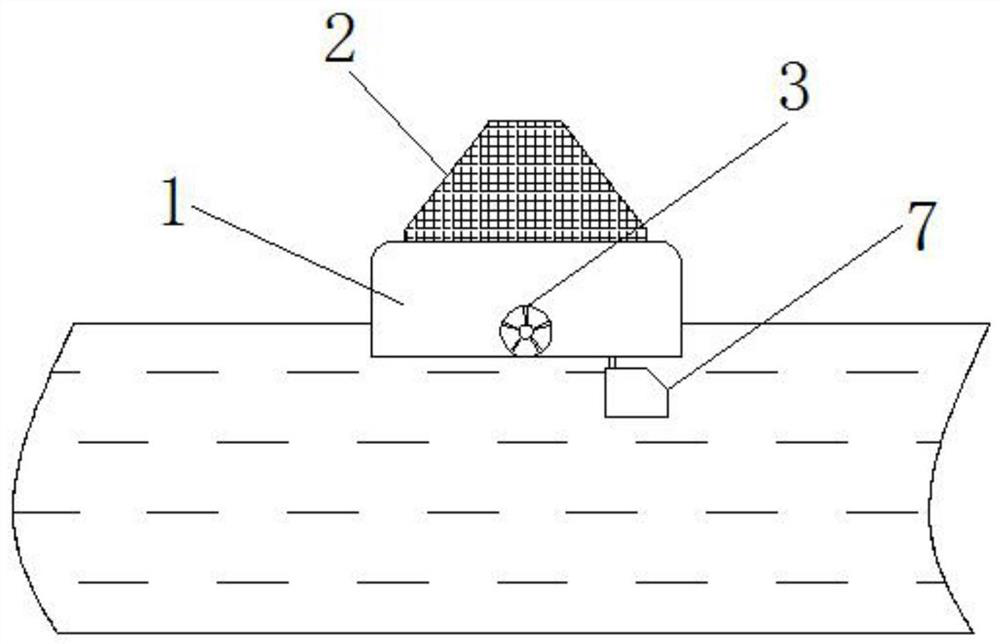

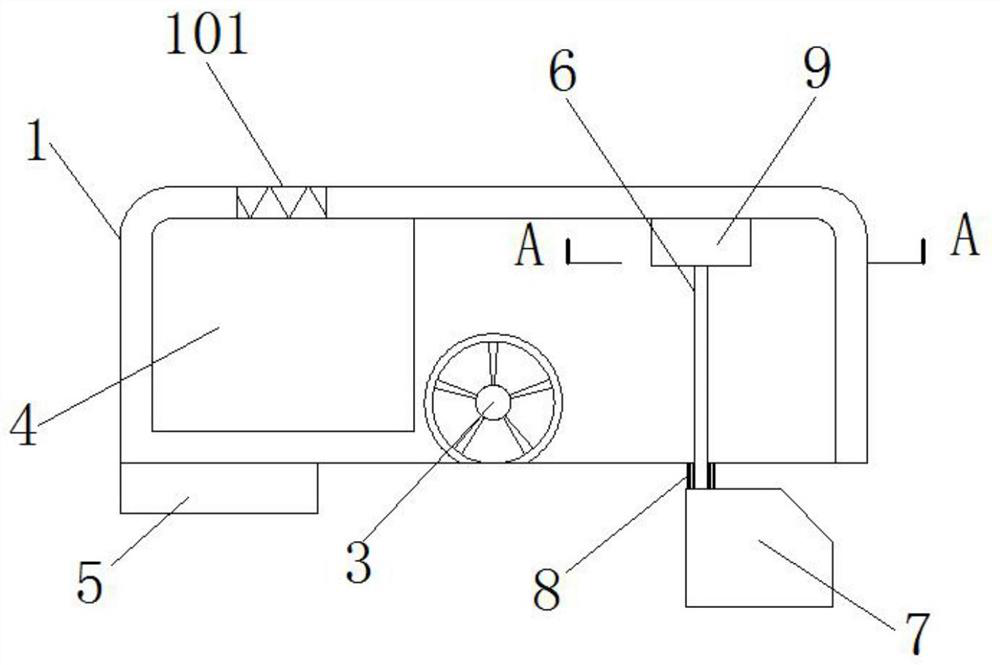

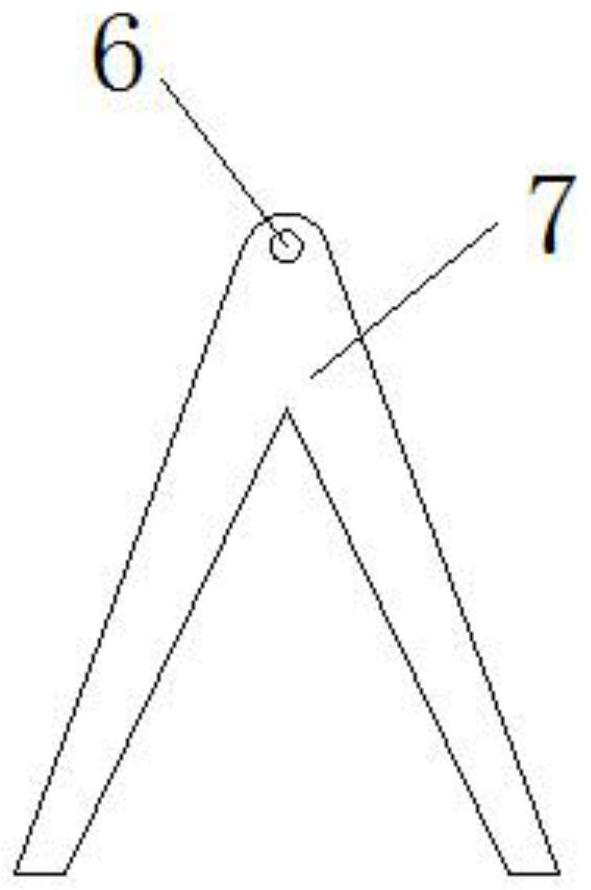

Hot dip coating device and method

ActiveCN110809633AReduced risk of damaging sheet metalHot-dipping/immersion processesMetal coatingMetal sheet

The invention relates to a hot dip coating device to provide a metal coating on a moving metal sheet, containing a liquid bath of metal coating material in use, wherein the metal coating material is to be provided on the moving metal sheet in use, comprising a container for the liquid bath, at least a guide or sink roll that is provided in the container below surface level of the liquid bath in use to guide the moving metal sheet through the bath, and a gas knife that is provided above the liquid bath in use, said gas knife having an outlet to project wiping gas on the metal coating provided on the metal sheet that in use passes along the gas knife, and wherein at least one supporting roll is provided which together with the guide or sink roll in use influence a shape of the metal sheet inits width direction at least at the location of the gas knife. According to the invention, in use the at least one supporting roll is placed above surface level of the liquid bath on a position enabling it to operate on the metal sheet before the metal sheet enters the liquid bath. The invention also relates to a method for use of the hot dip coating device.

Owner:TATA STEEL NEDERLAND TECH BV

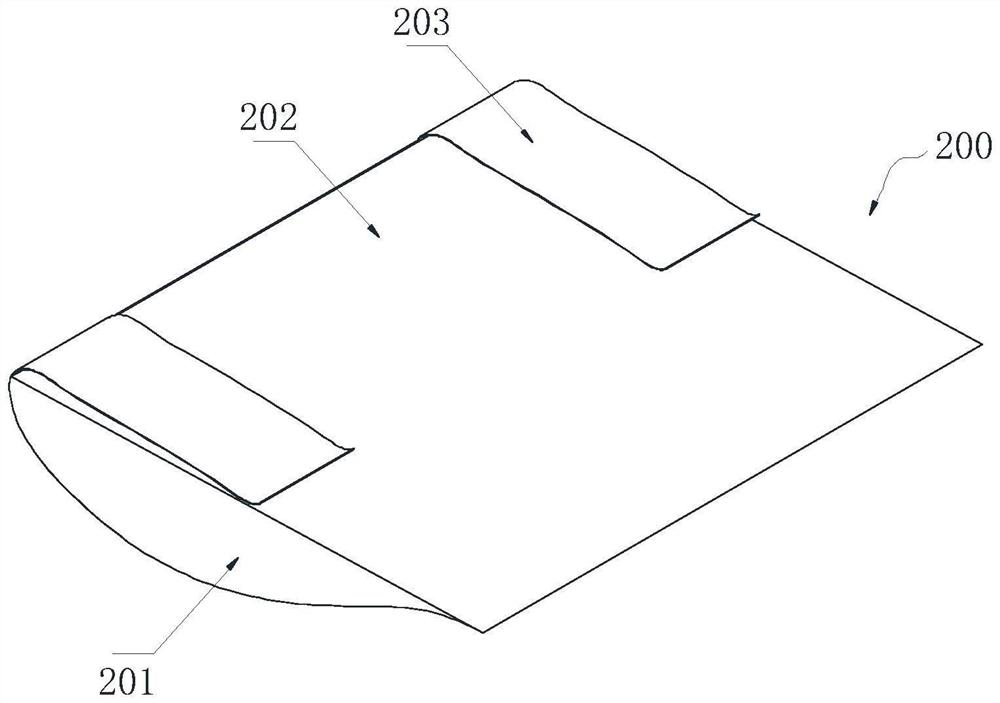

Stamping process for large-table-board stamping device of metal sheet stamping and cutting automation equipment

Owner:LUOYANG YOUNENG AUTOMATION EQUIP CO LTD

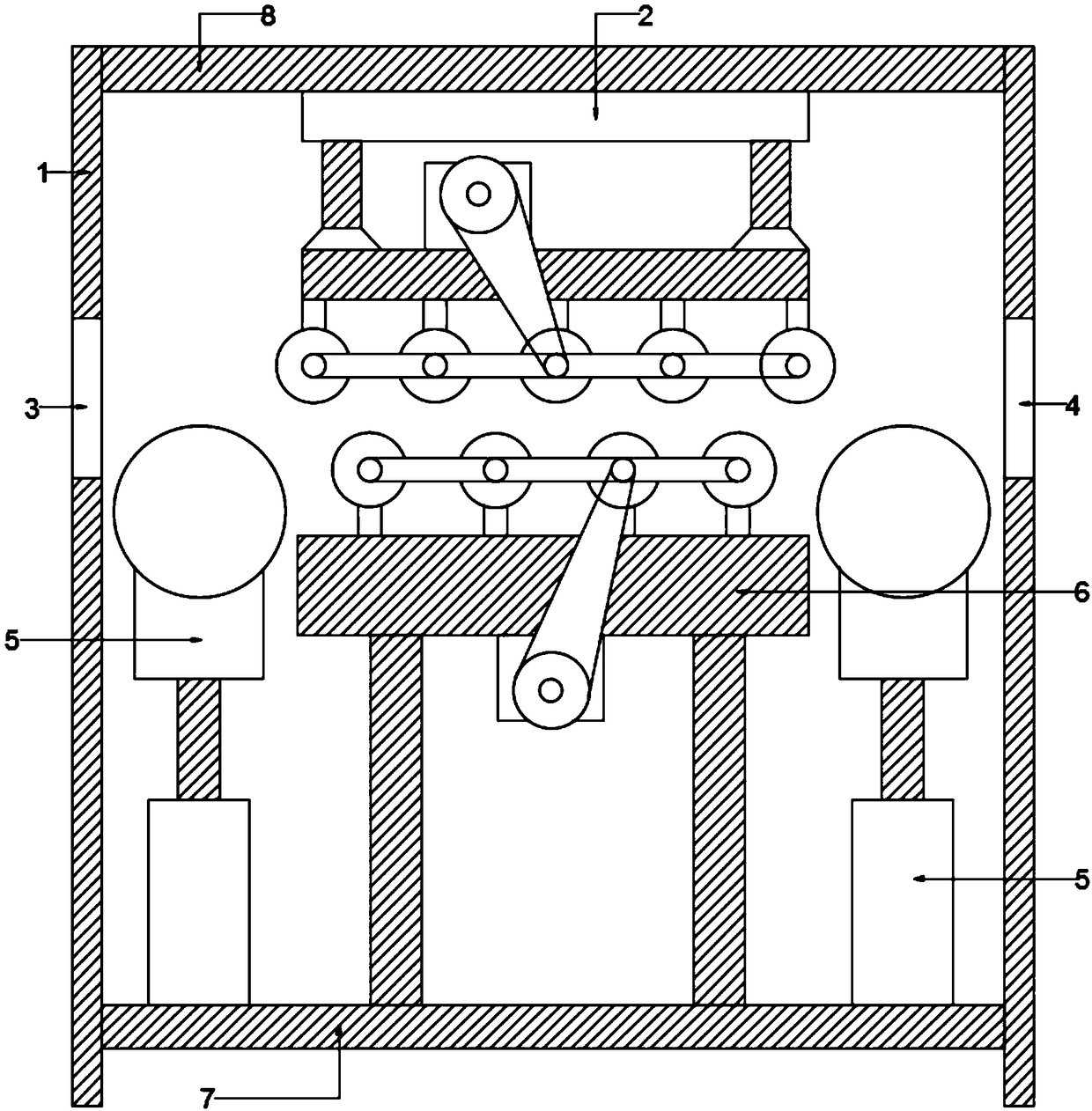

Sheet material polishing device for metal 3D printing

InactiveCN109202678AAdjustable positionAdjustable heightGrinding carriagesPolishing machinesMetal sheetMetal

Owner:广西慧思通科技有限公司

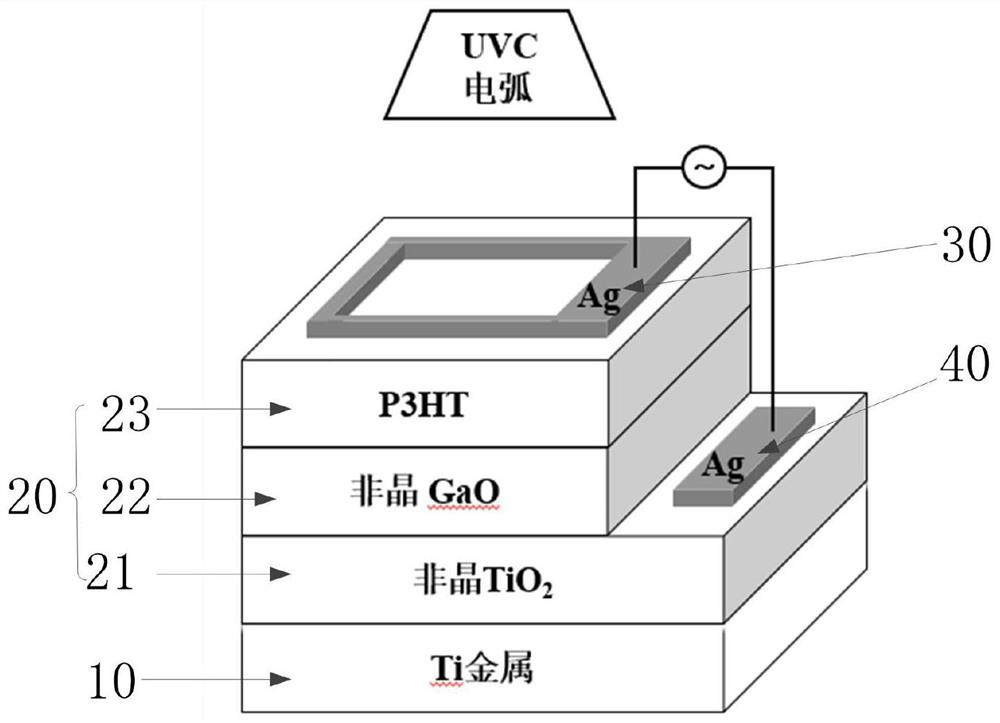

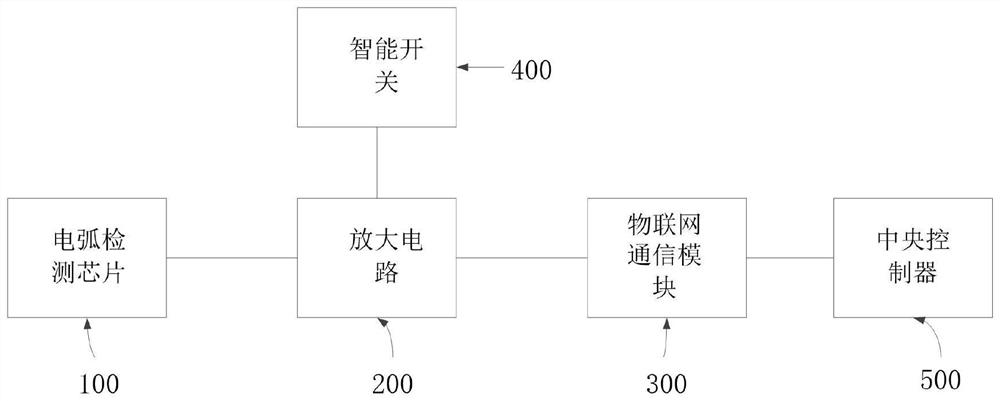

Energy storage power station arc monitoring system and preparation method

PendingCN113659707AHigh sensitivityRealization of organic-inorganic hybrid heterojunctionElectrical storage systemPhotovoltaic monitoringHeterojunctionThe Internet

Owner:杭州哲合科技有限公司

Method for debugging ironing board assembly of elastic thread ironing mechanism

ActiveCN108360111AUniform temperatureImprove thermal conductivityTextiles and paperMetal sheetElectrical and Electronics engineering

Owner:WUJIANG XINGYE TEXTILE CO LTD

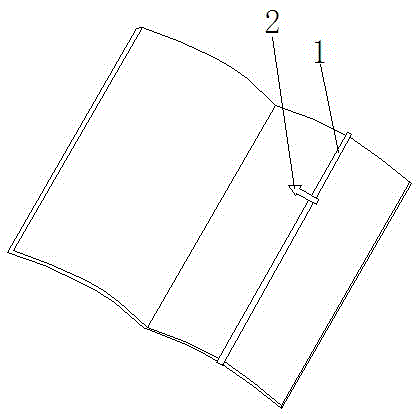

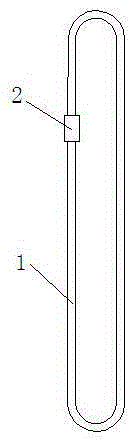

a bookmark

Owner:徐雪宜

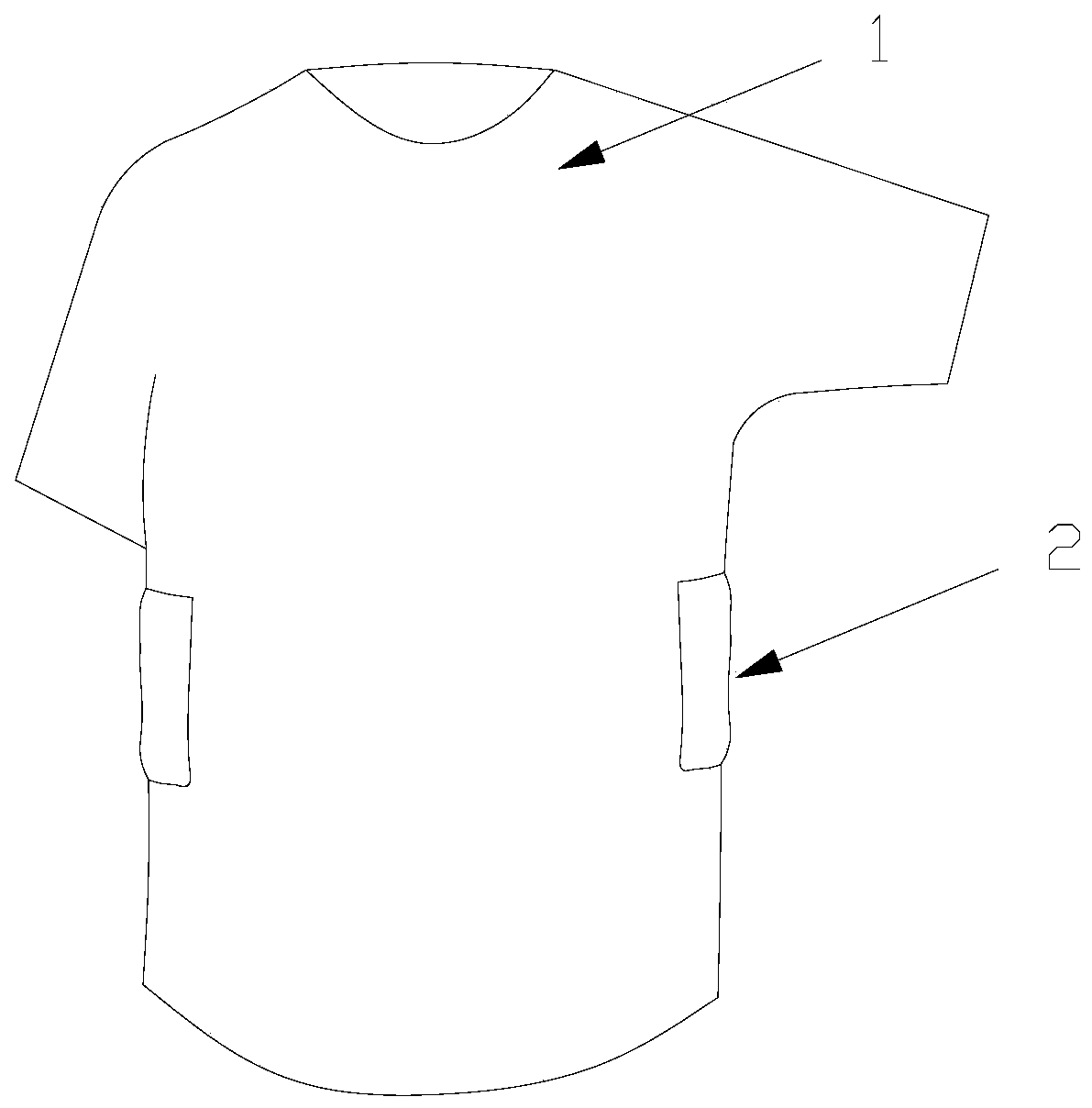

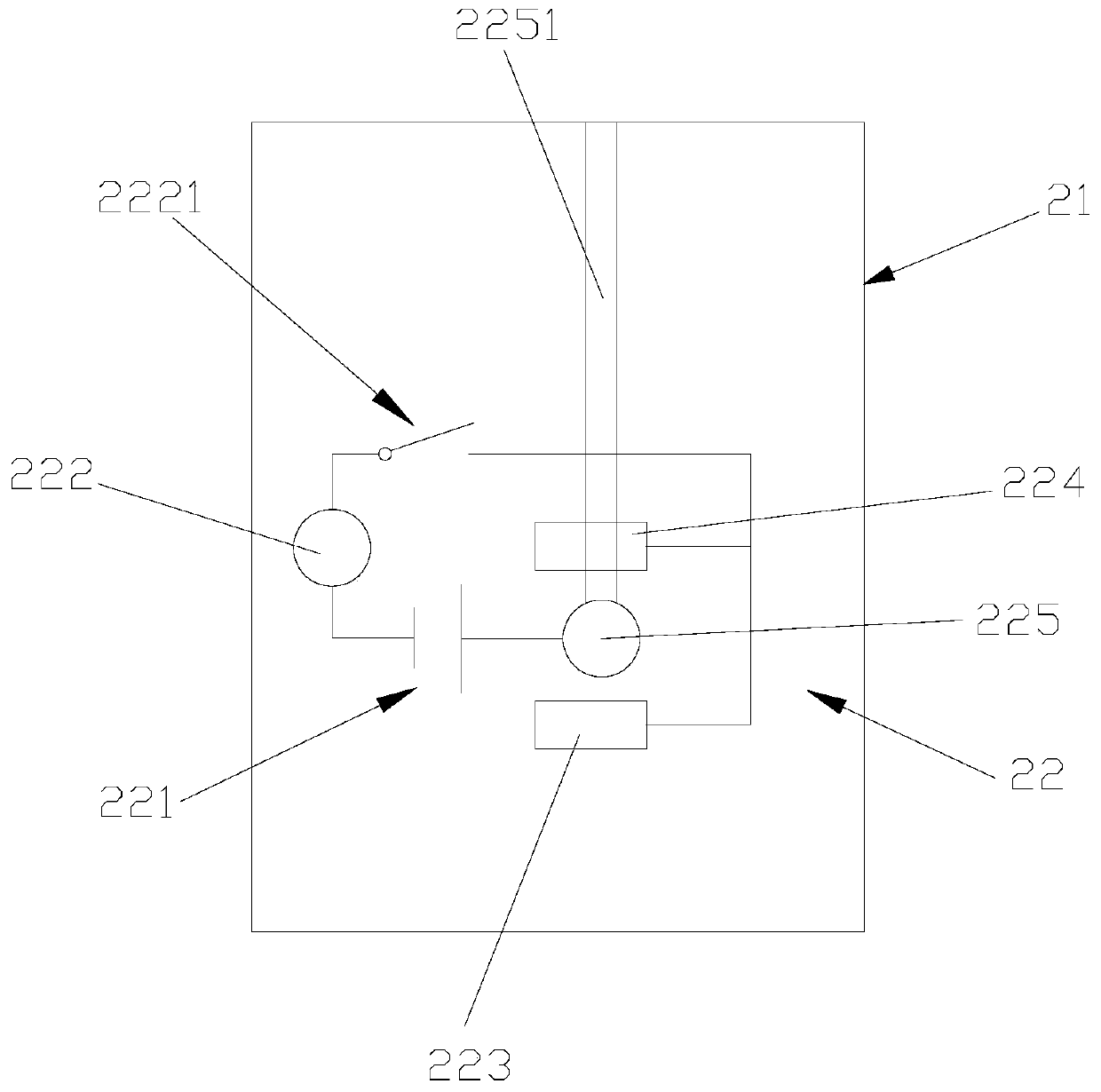

Human body posture correction underwear

InactiveCN109859440APrevent dozing offPrevent hunchbackAlarmsUndergarmentsMuscle relaxationHuman body

Owner:雷霆

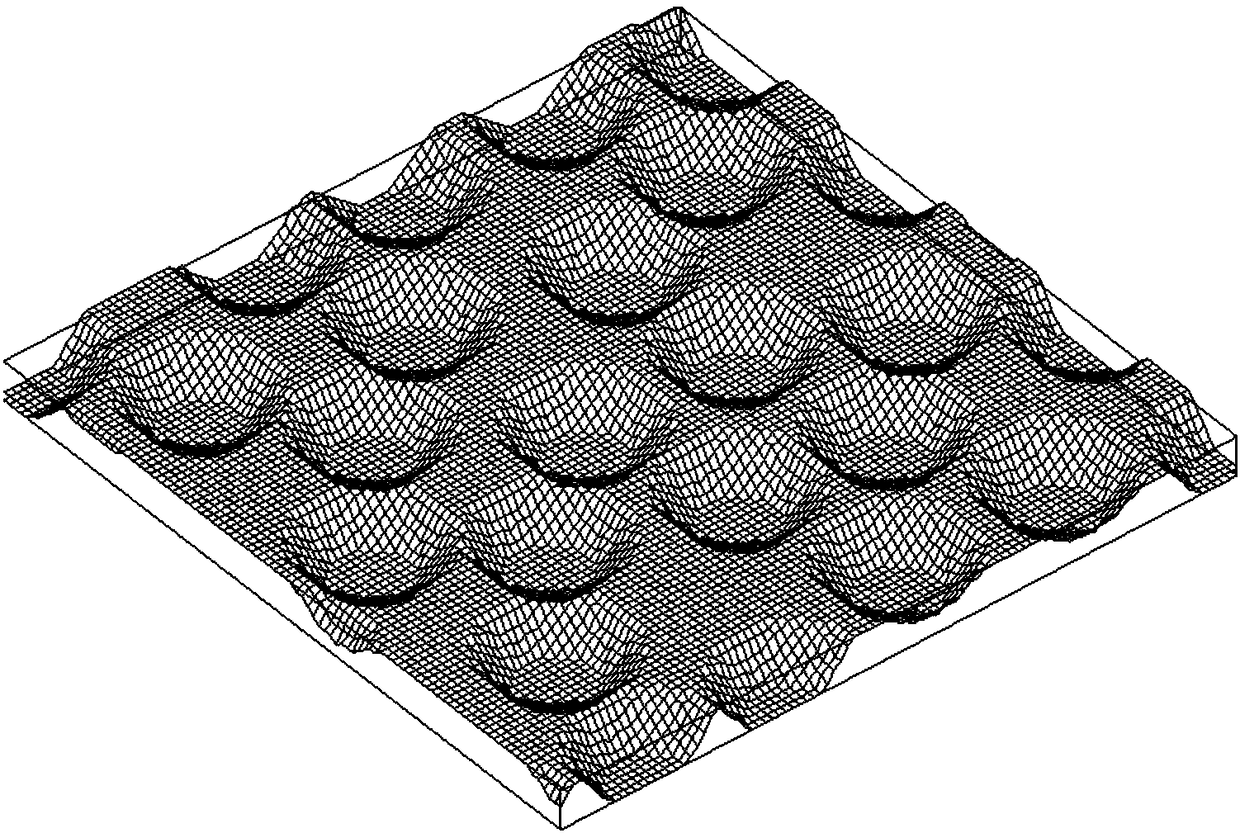

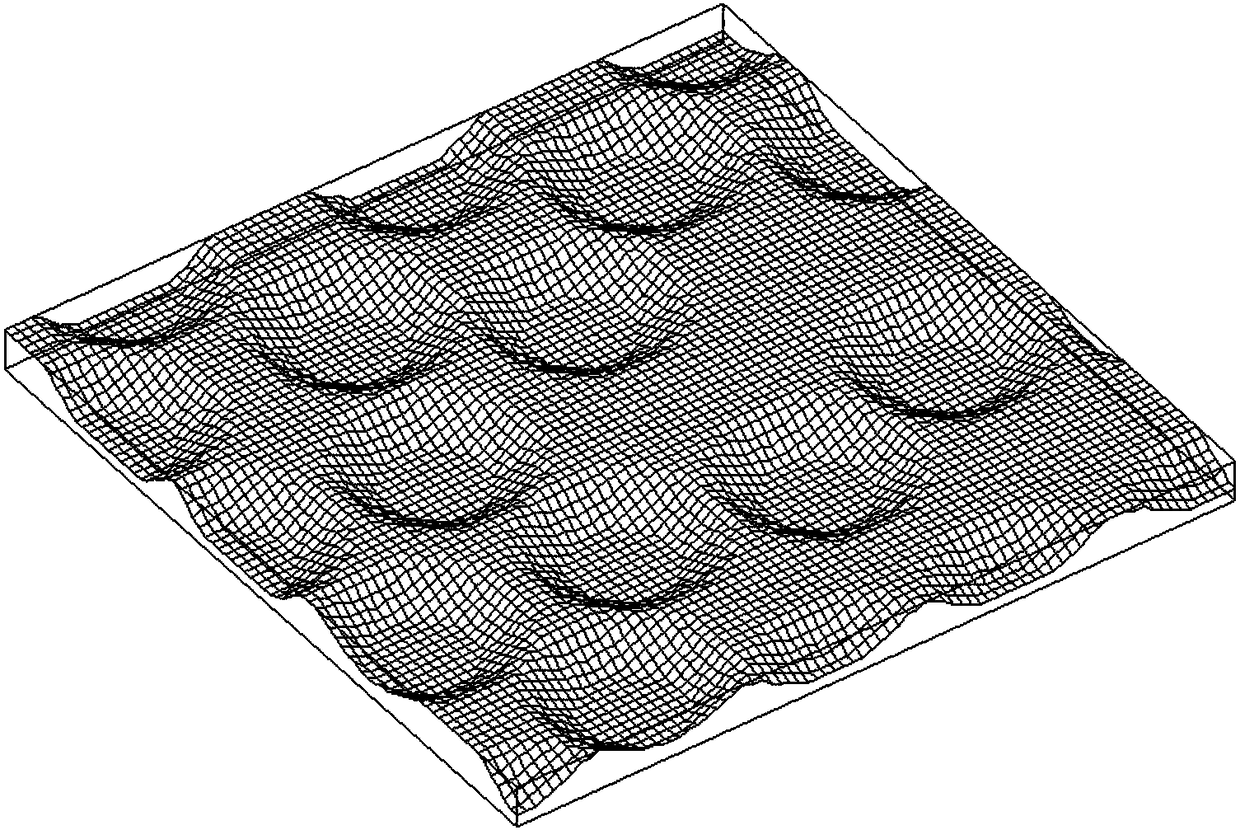

Low-friction coefficient and low-ripple degree metal sheet

ActiveCN109424844AEasy to shapeGood paint effectLayered productsSheets/panelsSquare MillimeterMetal sheet

Owner:BAOSHAN IRON & STEEL CO LTD

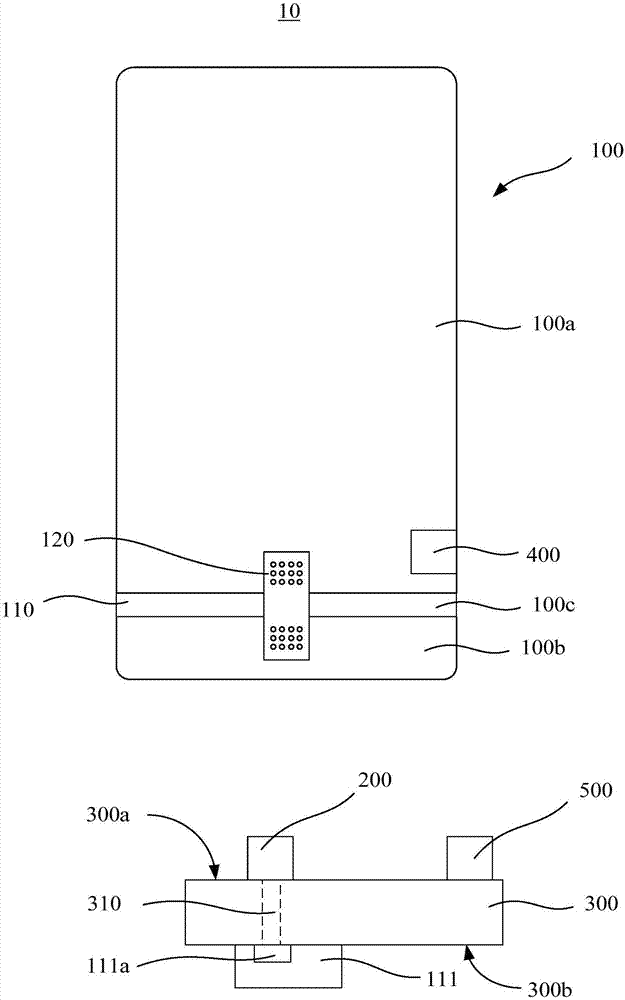

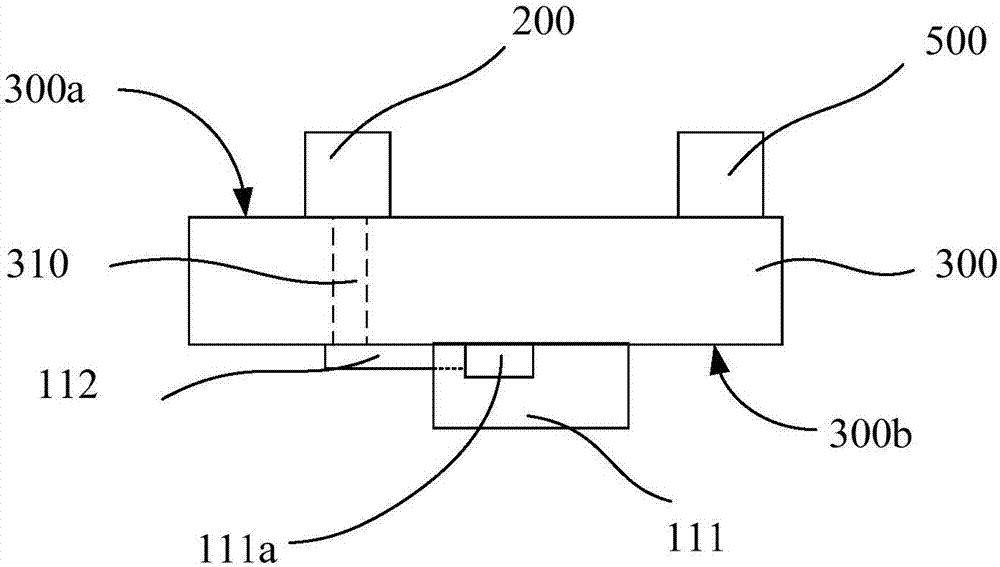

Antenna apparatus and mobile terminal

ActiveCN107887685AImprove communication qualityQuickly Eliminate Radiation SpursAntenna supports/mountingsRadiating elements structural formsElectricityEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Hanging metal surface layer wallboard

InactiveCN108179852ALower level requirementsQuality improvementCovering/liningsSurface layerEconomic benefits

Owner:SUZHOU TONGKUAI PURIFICATION TECH

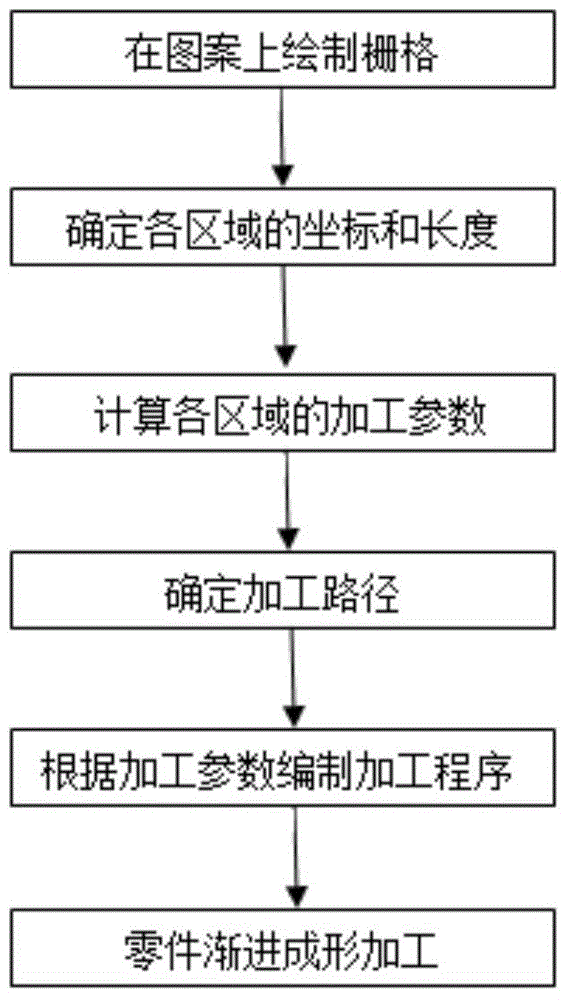

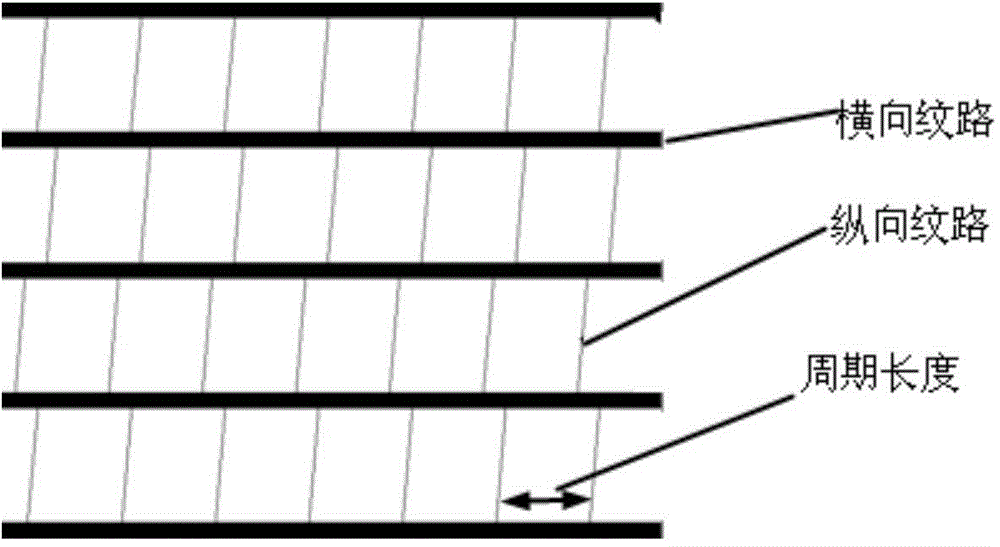

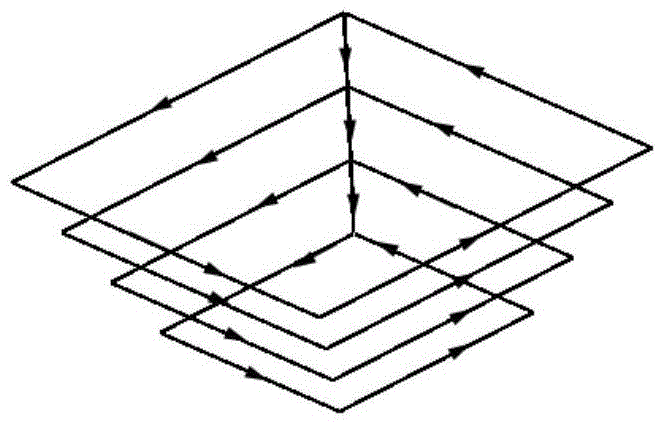

Method for manufacturing patterns on surface of metal sheet incremental forming workpiece

InactiveCN104553566AImprove processingIncrease productivityDecorative surface effectsMetal sheetEngineering

Owner:XIAN UNIV OF TECH

Mobile phone shell and injection molding technology thereof

InactiveCN107379458AInjection molding process energy saving and environmental protectionSimple methodCoatingsMetal sheetEngineering

Owner:DONGGUAN XIANGJIANGXIN HARDWARE PROD

Hydraulic casting equipment with defoaming function

Owner:广州市欧伊若科技有限公司

Multifunctional electric control cabinet intelligent door lock

PendingCN114482713AImprove securityDouble lock implementationNon-mechanical controlsIndividual entry/exit registersMaster controllerMetal sheet

The invention discloses a multifunctional electric control cabinet intelligent door lock, and belongs to the technical field of electric control cabinet door locks, the multifunctional electric control cabinet intelligent door lock comprises an electric control lock, a miniature display screen and a main controller, the electric control lock comprises a lock body and a miniature electric push rod, and the miniature electric push rod is horizontally arranged on the side face of the lock body; the miniature electric push rod is provided with a spring bolt hole at a position corresponding to the door frame of the electric control cabinet; a signal induction device is arranged in the micro display screen, the signal induction device is used for generating an unlocking trigger signal and is connected with the main controller, and the micro display screen is further used for displaying an electronic two-dimensional code; and the main controller is used for receiving the unlocking trigger signal and transmitting an unlocking execution signal to the electric control lock. According to the electric control cabinet lock, the micro electric push rod of the electric control lock is used for replacing a traditional linear metal sheet type structure, so that the electric control cabinet lock has higher safety.

Owner:刘奕 +3

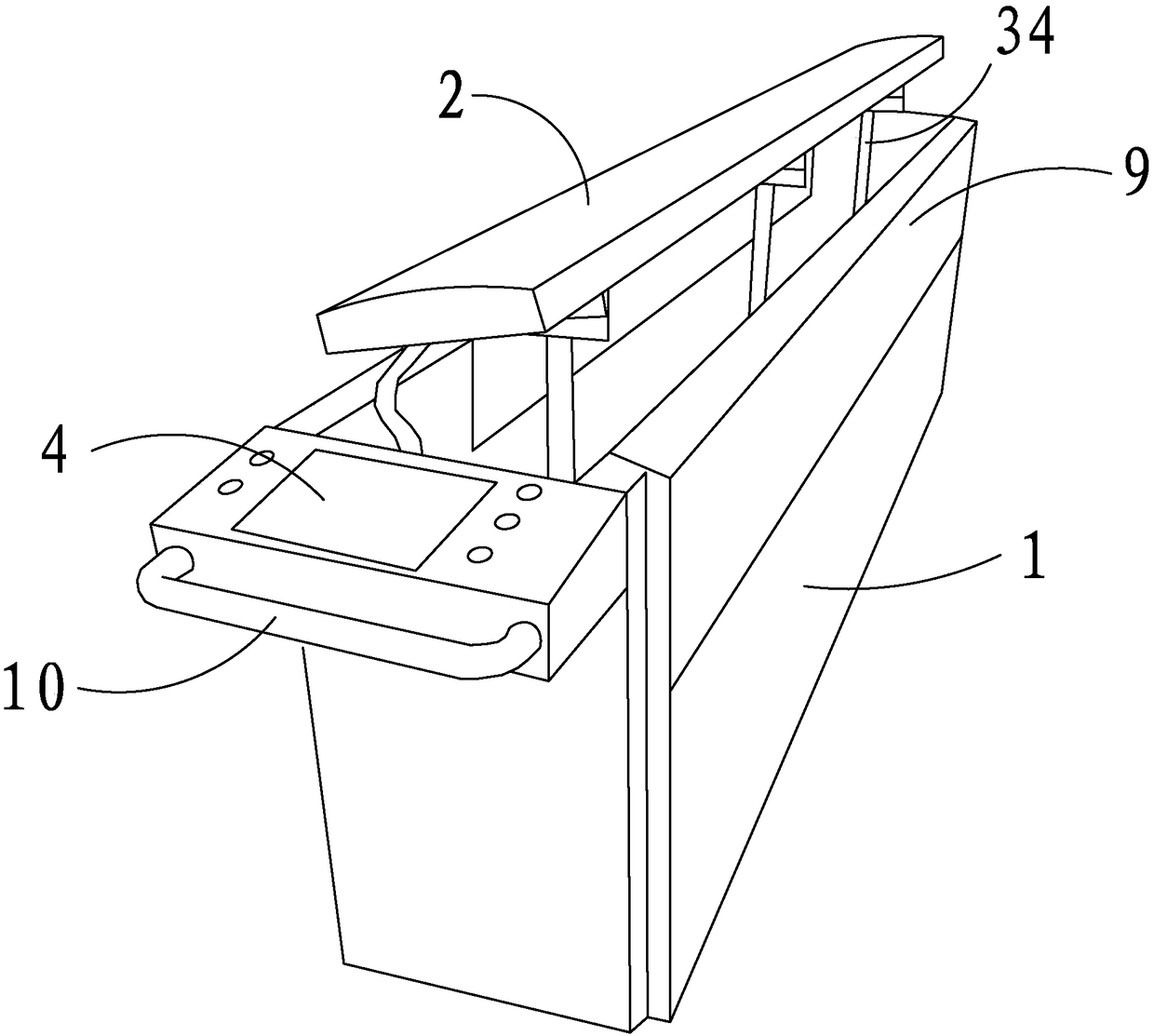

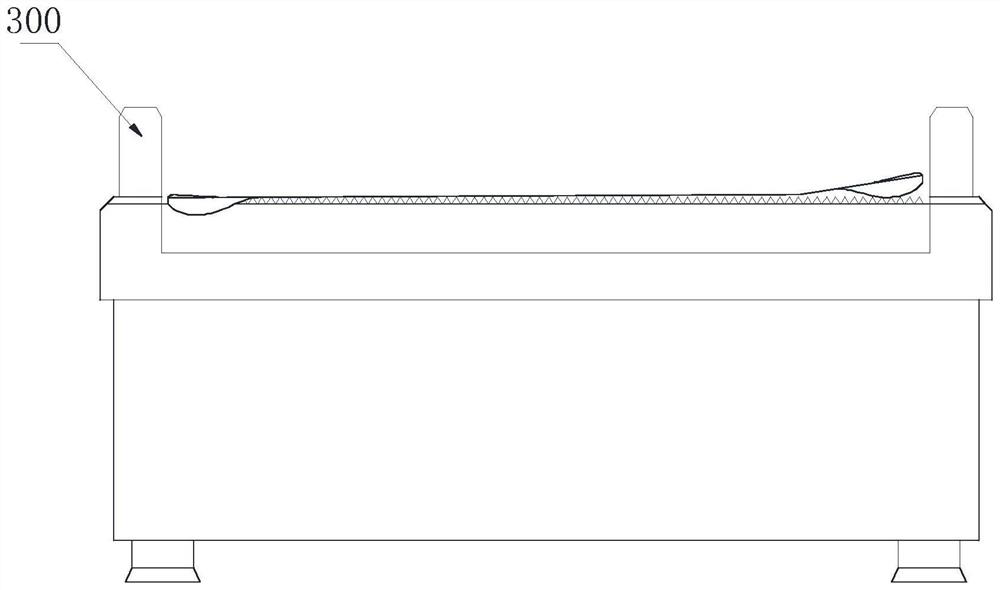

Laser cutting machine with plate fixing device

PendingCN114799505ASolve the cutting accuracySolve the problem of the yield rate of cutting finished productsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

Owner:安徽同兴科技发展有限责任公司

Guiding device for water source environment monitoring based on big data

InactiveCN111650850AQuick monitoringSolve the strength problemProgramme controlComputer controlWater sourceMetal sphere

Owner:邓红兵

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap