Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Si substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Si Substrate. Si substrates are promising materials for the heteroepitaxial growth of diamond due to their scalability, coefficient of thermal expansion, and cost.

Semiconductor device and method of manufacturing the same, circuit board and electronic instrument

InactiveUS6841849B2Not easily oxidizedSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A depression is formed from a first surface of a semiconductor substrate on which is formed an integrated circuit. An insulating layer is provided on the inner surface of the depression. A first conductive portion is provided on the inside of the insulating layer. A second conductive portion is formed on the inside of the insulating layer and over the first conductive portion, of a different material from the first conductive portion. The first conductive portion is exposed from a second surface of the semiconductor substrate opposite to the first surface.

Owner:ADVANCED INTERCONNECT SYST LTD

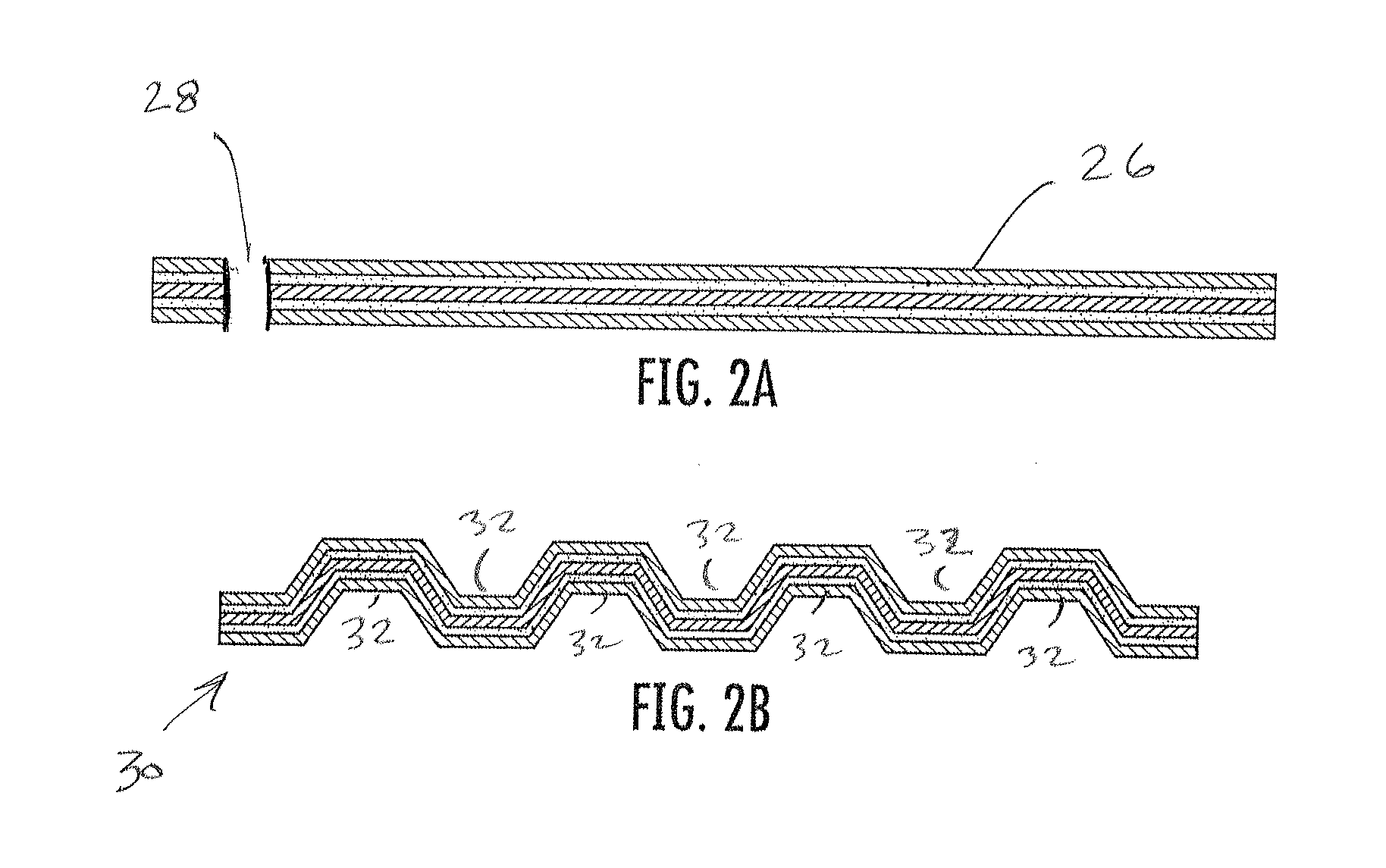

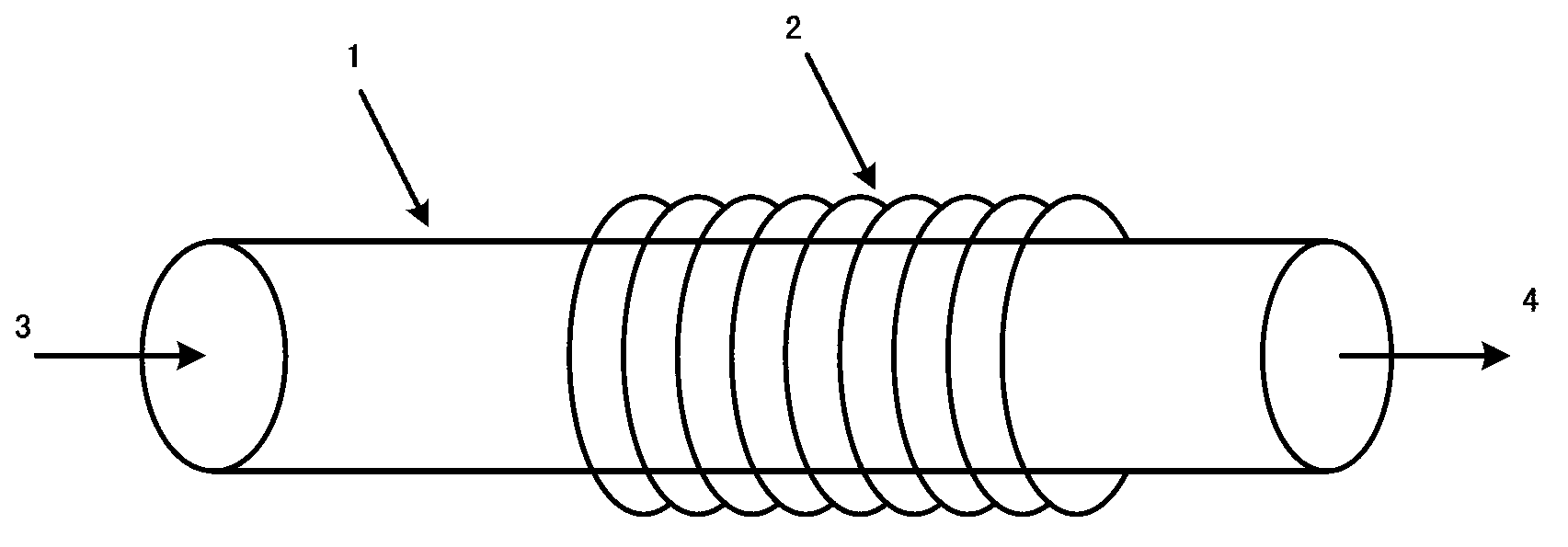

Fuel cell composite flow field element and method of forming the same

InactiveUS20110053052A1High thermalImprove conductivityElectrode manufacturing processesElectrode carriers/collectorsFuel cellsGraphite

Owner:VPJP

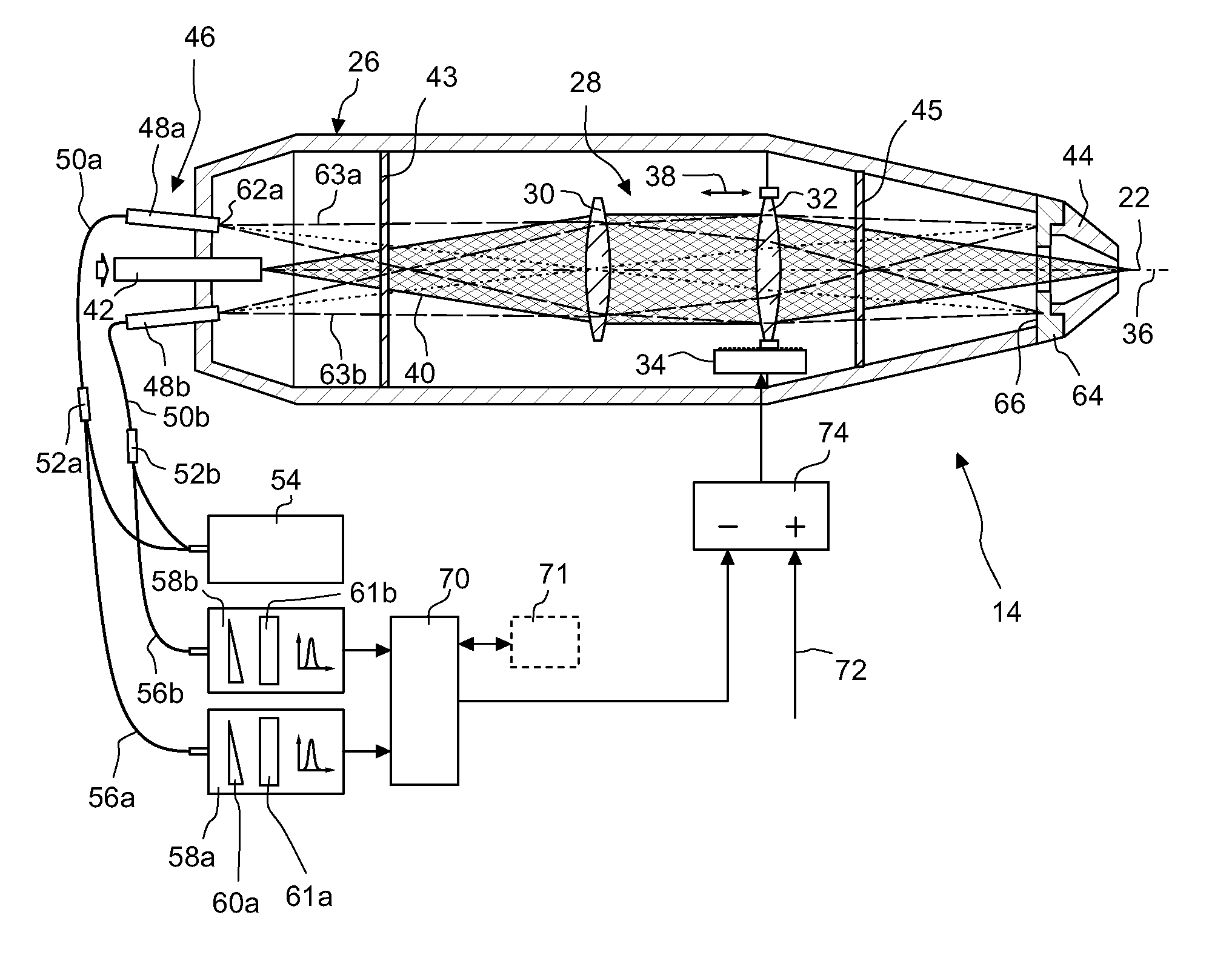

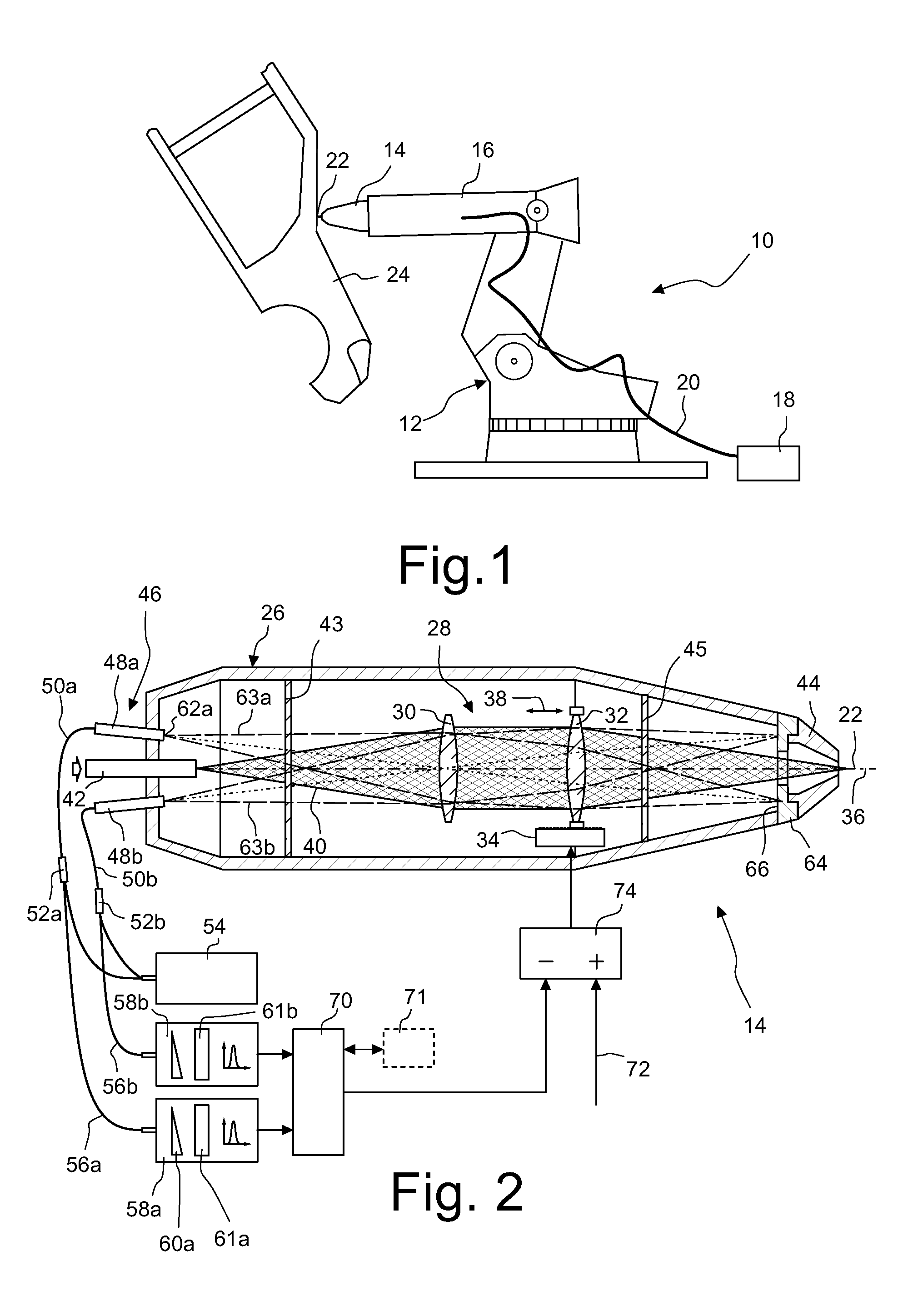

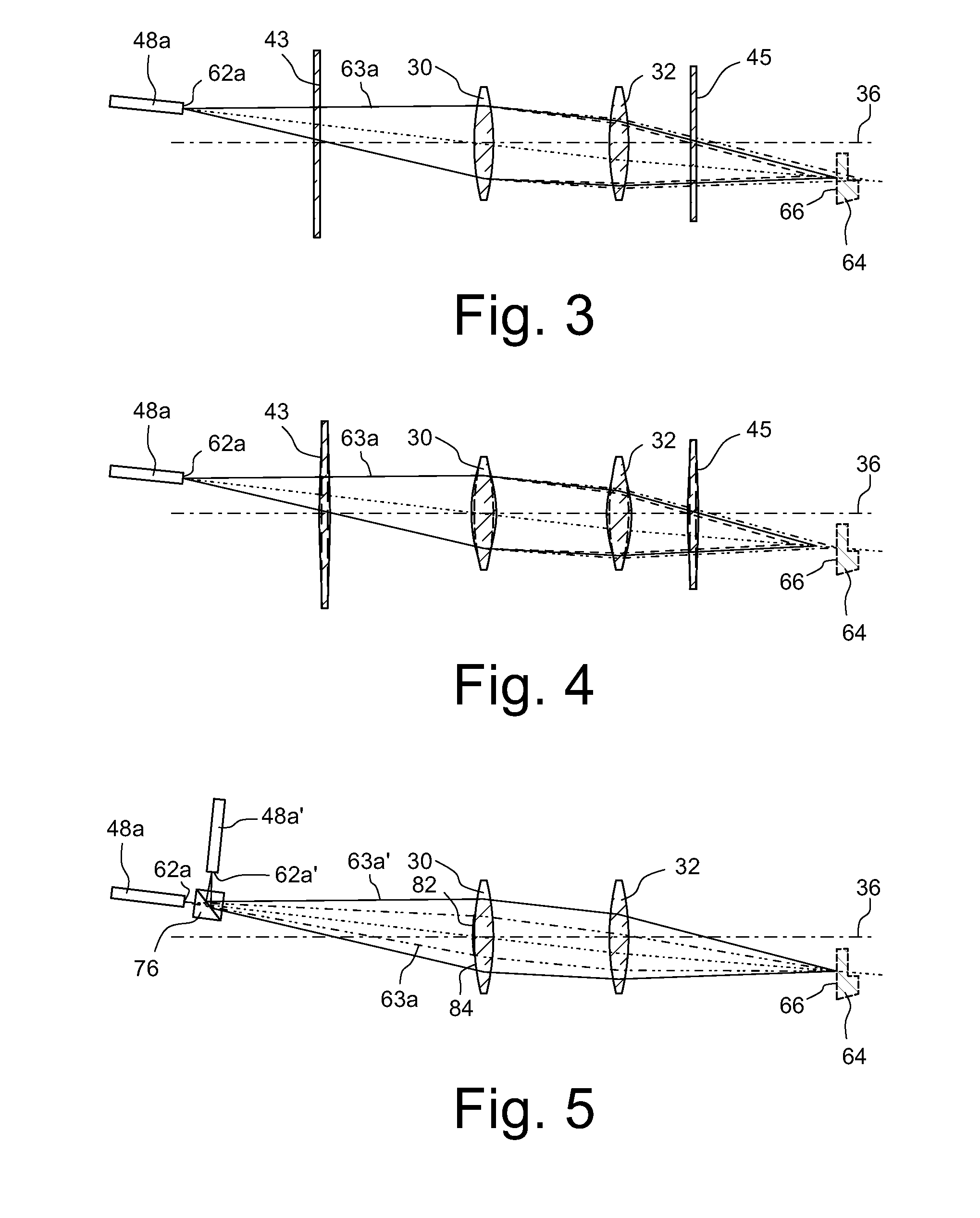

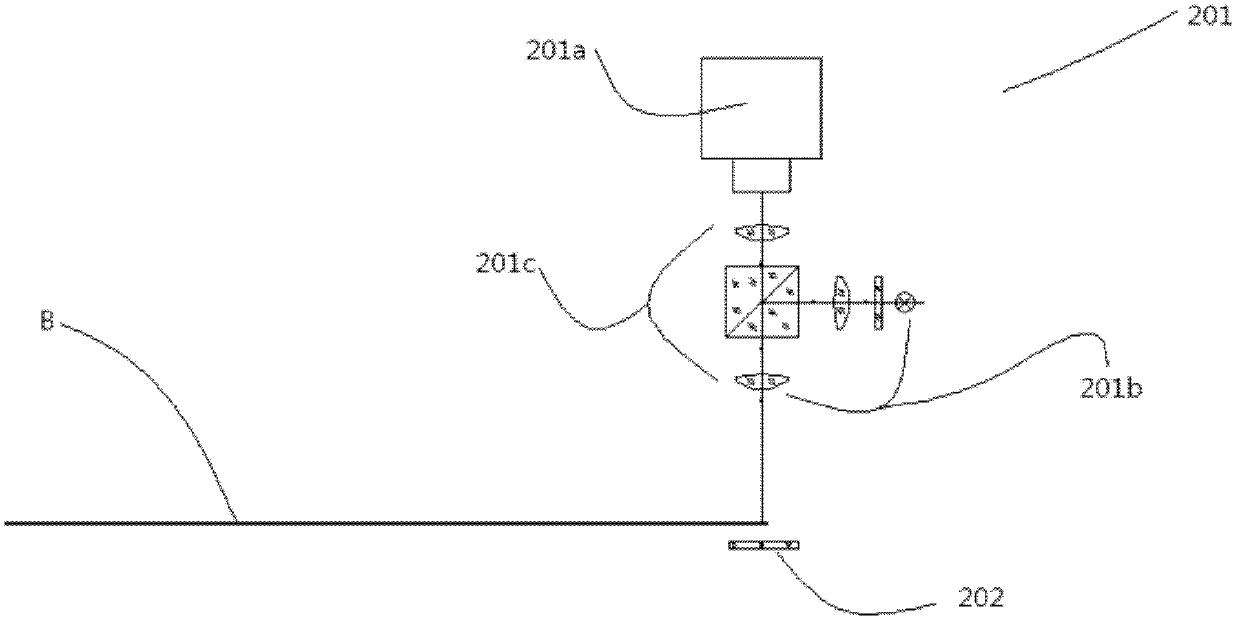

Laser Machining Apparatus with Adaptive Mirror

ActiveUS20140346155A1Stabilised betterSimple adaptationLaser beam welding apparatusOptoelectronicsInternal pressure

A laser machining apparatus comprises a laser radiation source that generates laser radiation. A first and a second adaptive mirror are provided each having a pressure chamber connected to a pressure source and a mirror substrate that bounds the pressure chamber. An internal pressure in the pressure chamber can be changed with the aid of the pressure source in such a way that the mirror substrate deforms if the internal pressure in the pressure chamber changes. The mirror substrate of the first adaptive mirror has a thickness which varies at least within a region of the mirror substrate that bounds the pressure chamber. The mirror substrate of the second adaptive mirror has a thickness which is constant over the entire region over which the mirror substrate is deformable.

Owner:LT ULTRA PRECISION TECH

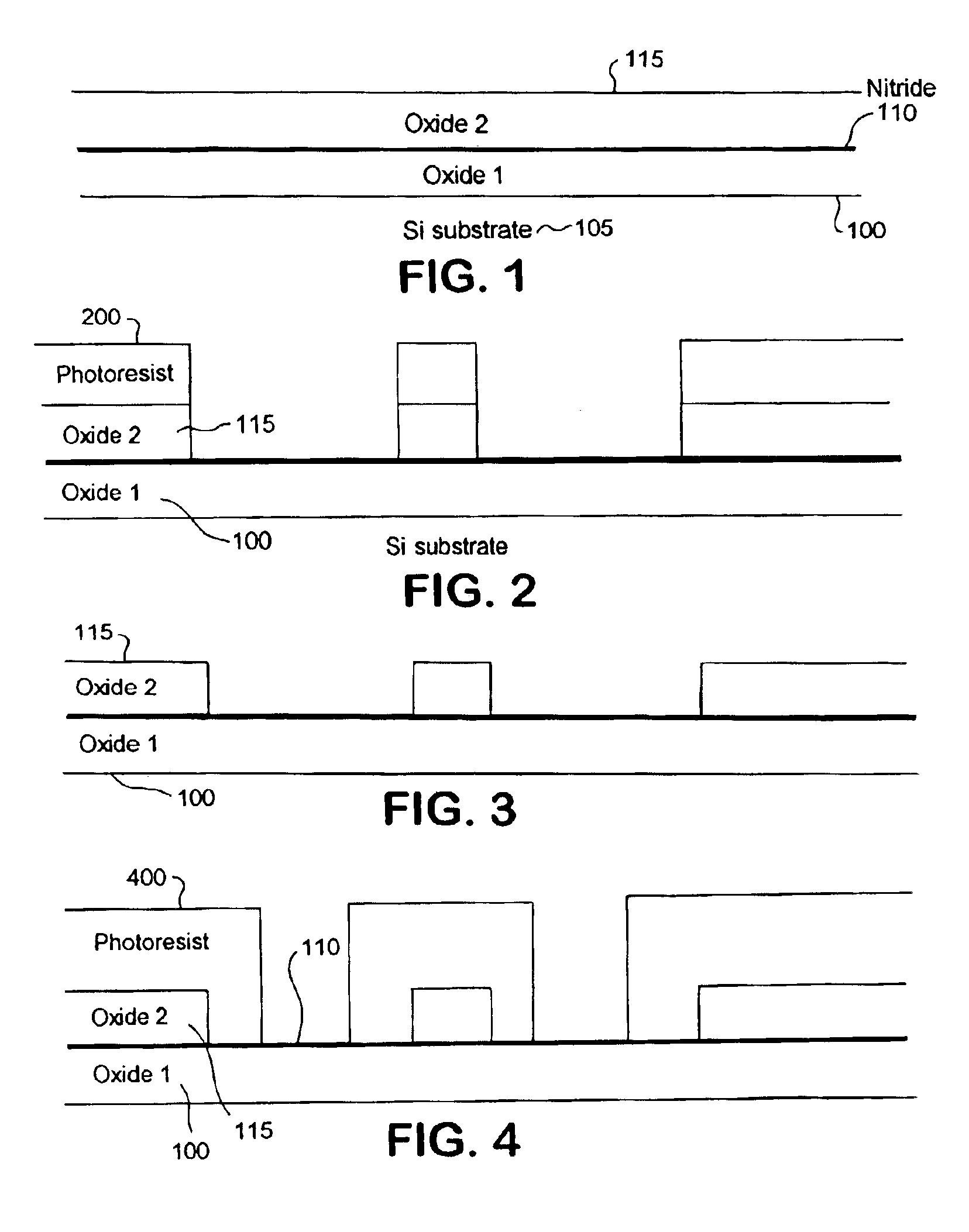

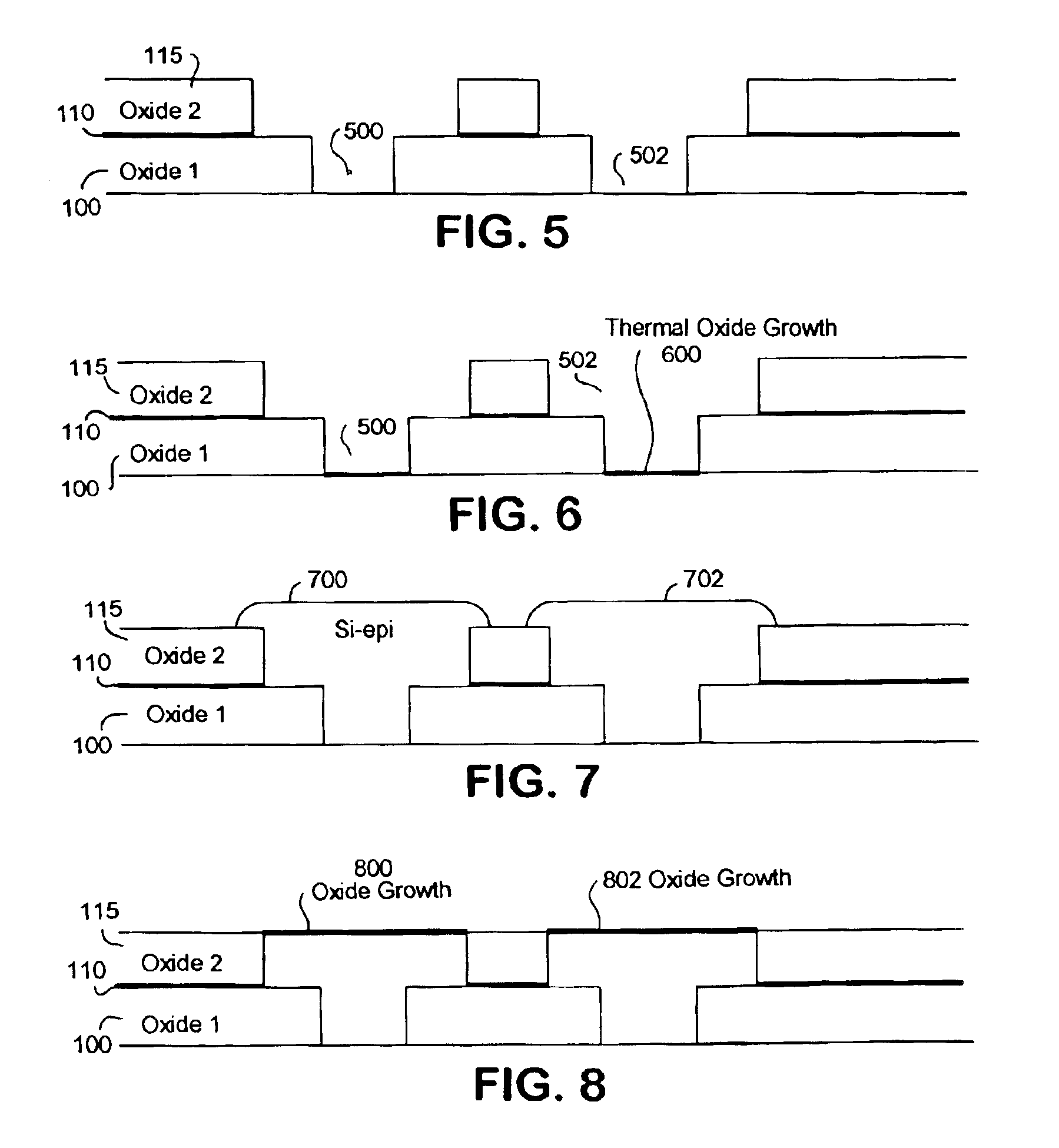

Active SOI structure with a body contact through an insulator

Owner:POLARIS INNOVATIONS

Semiconductor device manufacturing method, semiconductor device, and wiring board

InactiveUS20080174012A1Reduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device manufacturing method includes (a) bonding a first surface of a metal plate to a substrate, (b) forming a plurality of metal posts that are arranged in vertical and lateral directions in a plan view and include a first metal post and a second metal post, by partially etching the metal plate bonded to the substrate from a second surface of the metal plate, (c) fixing an integrated circuit (IC) element to the second surface of the first metal post, (d) coupling the second metal post and a pad terminal of the integrated circuit element via a conductive material, (e) resin-sealing the integrated circuit element, the metal posts, and the conductive material by providing a resin onto the substrate, and (f) removing the substrate from the resin and the first surfaces of the metal posts sealed using the resin.

Owner:SEIKO EPSON CORP

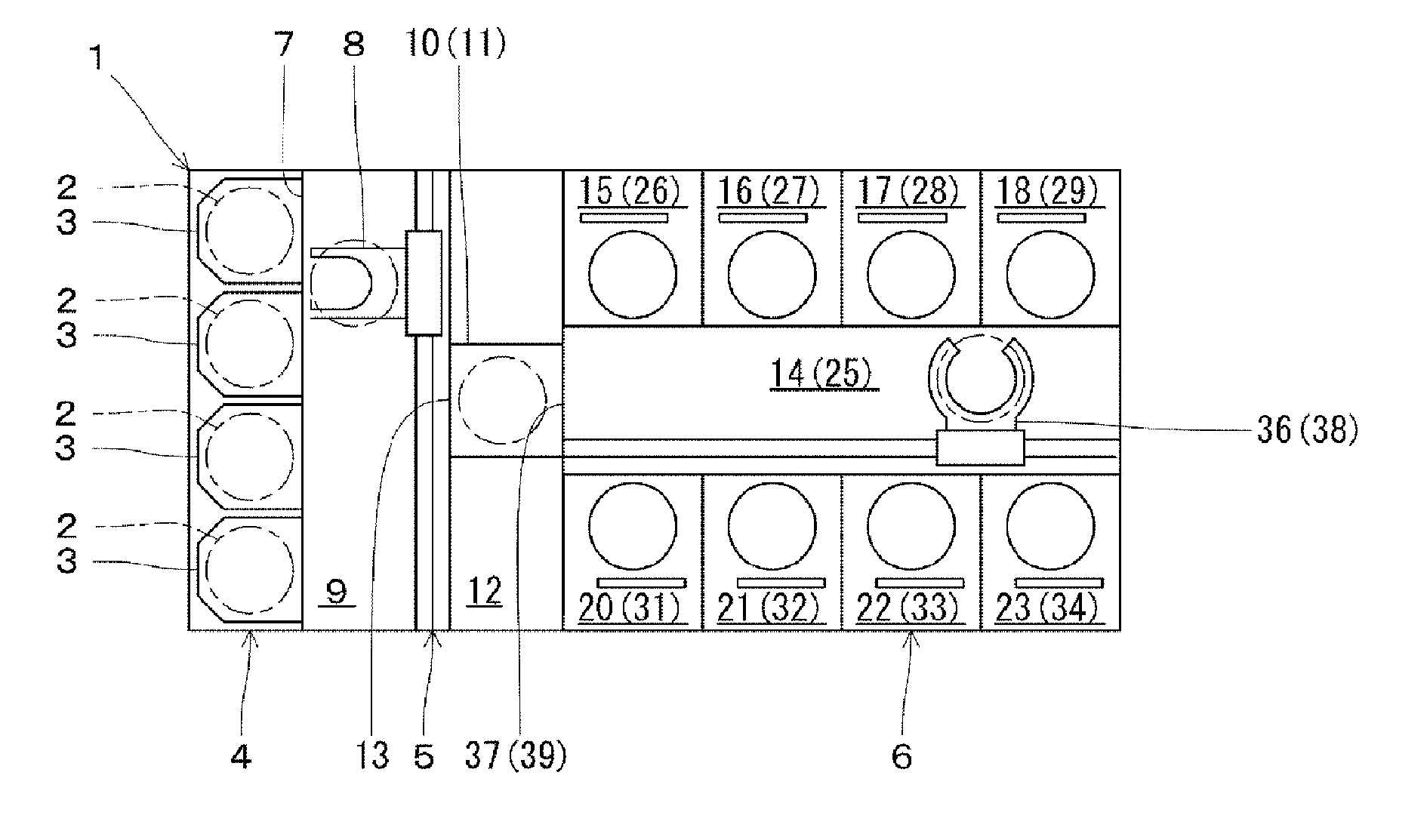

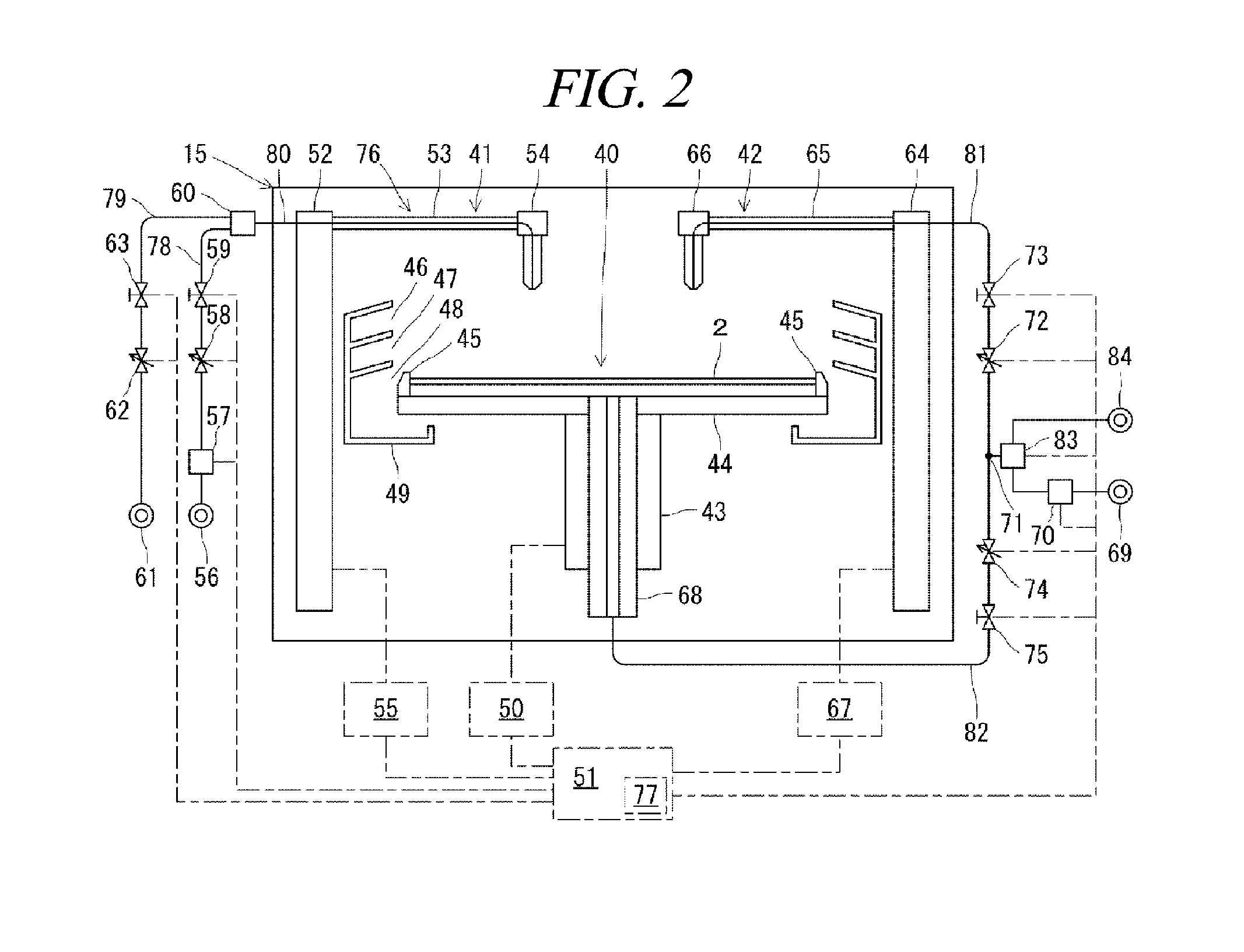

Liquid processing apparatus, liquid processing method and computer-readable storage medium storing liquid processing program

ActiveUS20110277793A1Semiconductor/solid-state device manufacturingCleaning using liquidsSi substrateAnalytical chemistry

Owner:TOKYO ELECTRON LTD

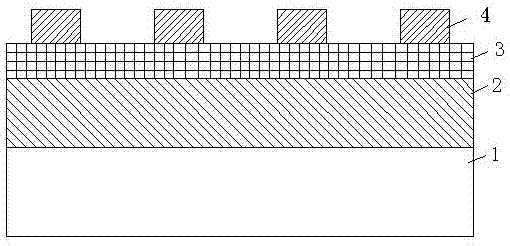

High-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit and preparation method of high-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit

ActiveCN108336062AHigh bulk densityShortened diffusion channelSemiconductor/solid-state device detailsSolid-state devicesHigh entropy alloysHeat stability

The invention relates to the technical field of semiconductor integrated circuits, in particular to a high-entropy alloy diffusion barrier layer for a Cu interconnect integrated circuit and a preparation method of the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit. The high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit sequentially comprises a Si substrate layer, a high-entropy alloy intermediate coating and a Cu film from bottom to top, wherein the high-entropy alloy intermediate coating sequentially comprises a third coating, a second coating and a first coating from bottom to top; the first coating is an AlCrTaTiZrMo high-entropy alloy coating; the second coating is a pure Ti coating; and the third coating is an AlCrTaTiZrMoNx high-entropy alloy coating. According to the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit, improvement of the atomic bulk density is facilitated,generation of defects, such as vacancies is reduced, a diffusion channel for atoms is reduced, and the diffusion barrier performance and the heat stability of the high-entropy alloy coatings are improved.

Owner:SHANGHAI DIANJI UNIV

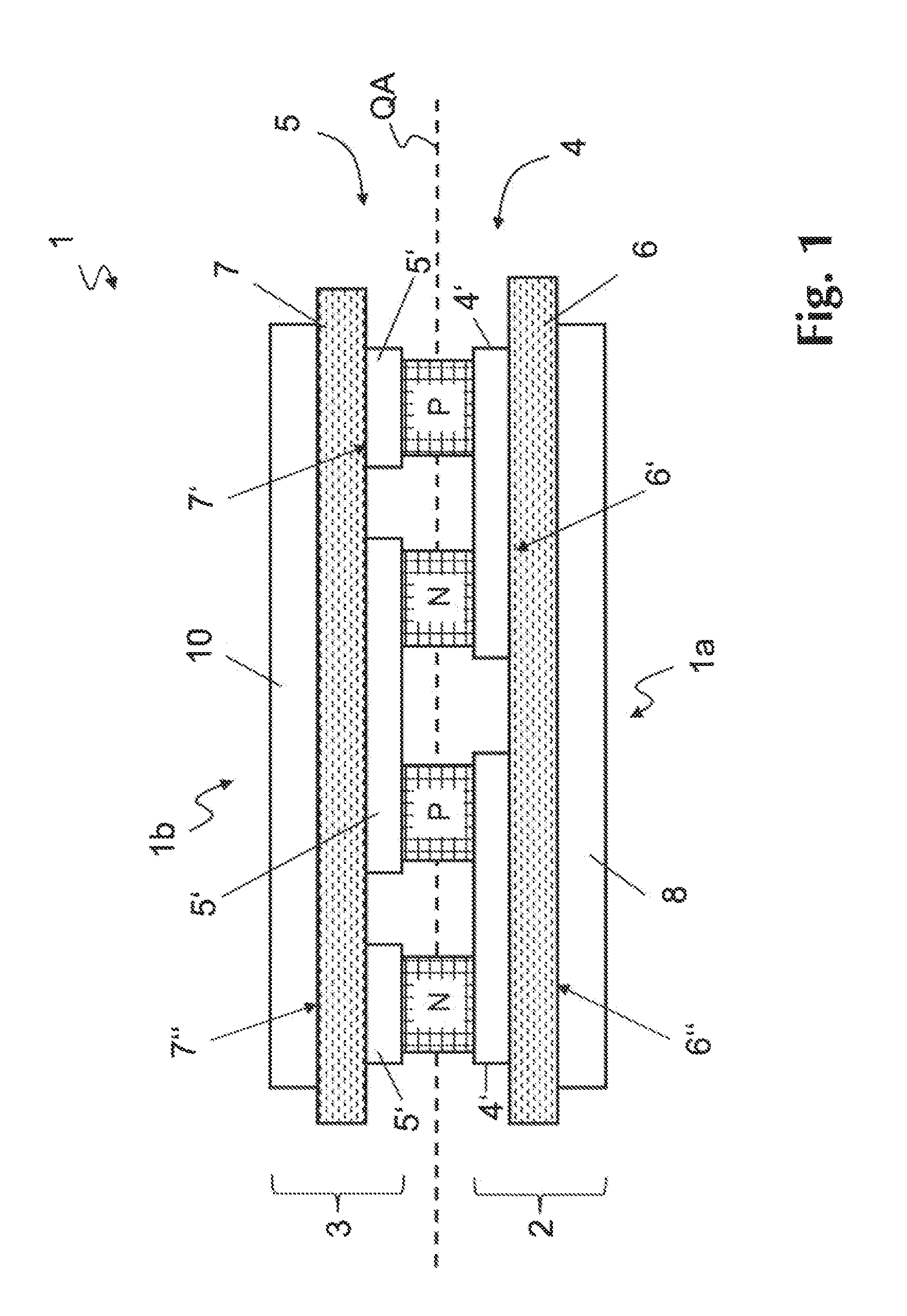

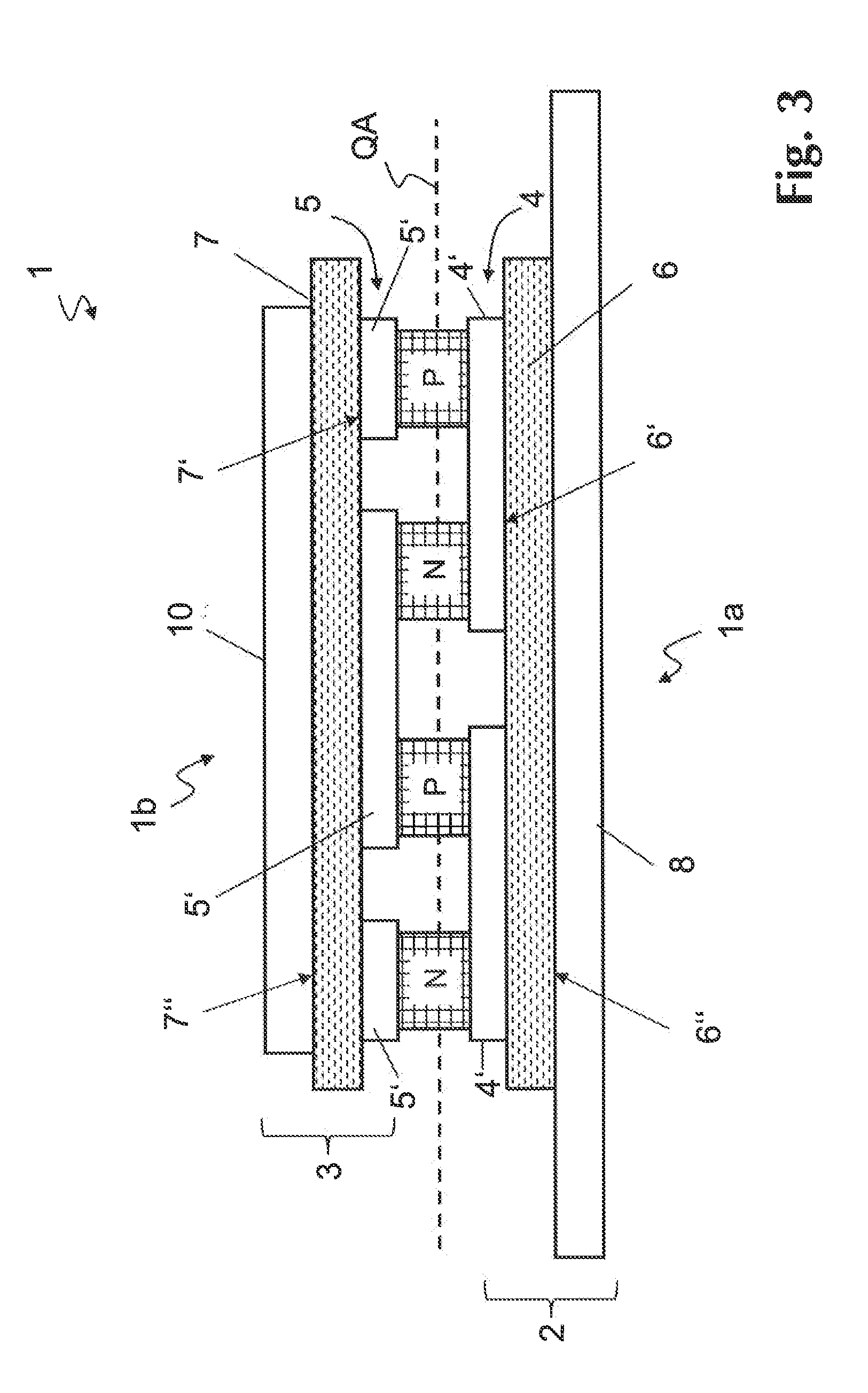

Thermoelectric generator module, metal-ceramic substrate and method of producing such a metal-ceramic substrate

InactiveUS20140345664A1Simple and reliable attachmentCircuit thermal detailsThermoelectric device with peltier/seeback effectHot zoneCeramic substrate

Owner:ROGERS GERMANY

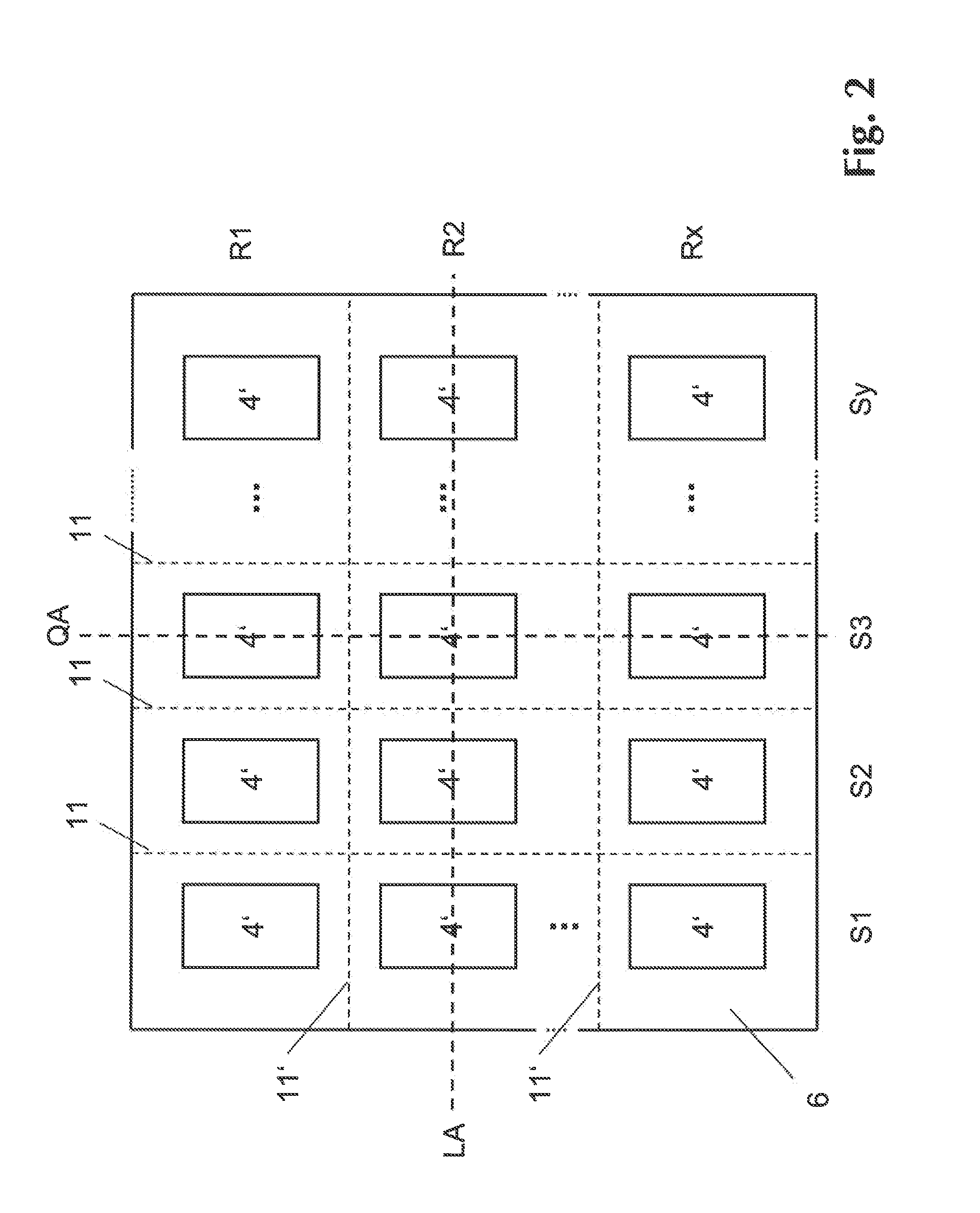

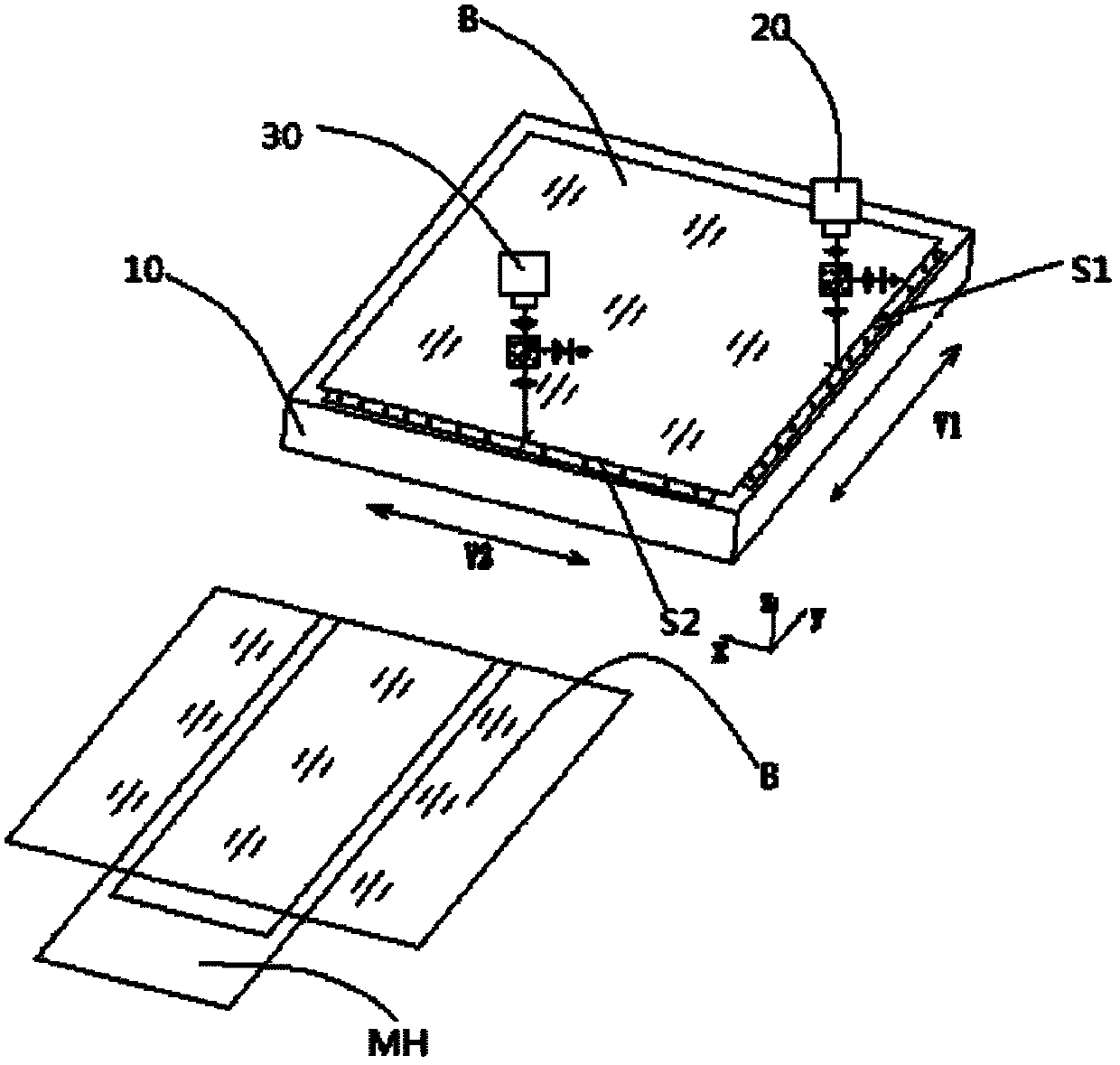

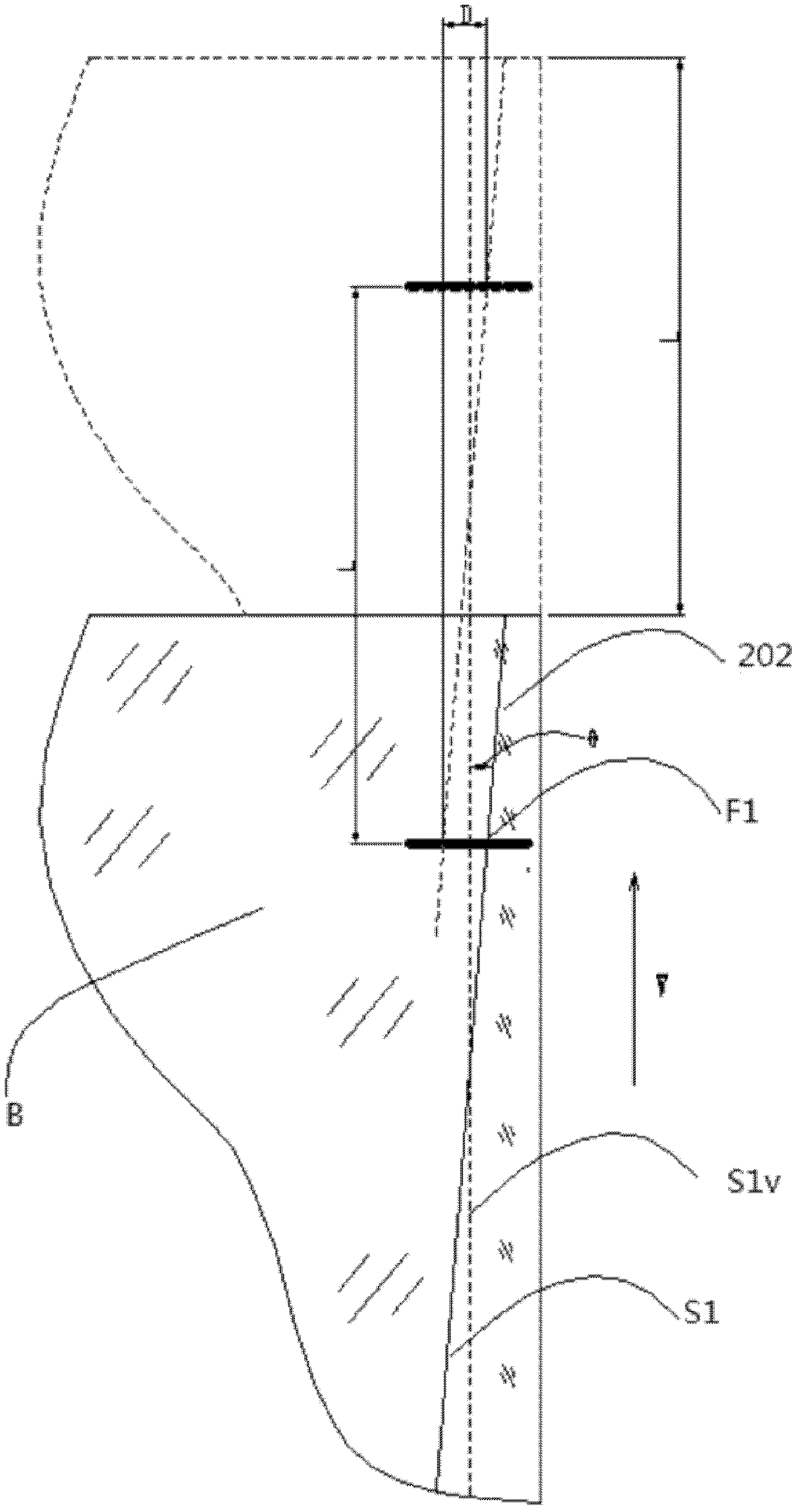

Pre-alignment device and method of square substrates

ActiveCN103293867AWon't breakImprove alignment accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRobot handEngineering

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Black matrix structure, manufacturing method thereof, color filter and display panel

The invention relates to the field of display, and discloses a black matrix structure, a manufacturing method thereof, a color filter and a display panel. The black matrix structure comprises a substrate and one or more black matrixes formed on the substrate, wherein the surface, making contact with the substrate, of each black matrix in the black matrixes is an uneven surface, so that light irradiating the display panel comprising the black matrix structure from the front face is subjected to diffuse reflection in the region of the black matrixes; in this way, the contrast ratio of display pictures is increased for the display panel.

Owner:TUNGHSU KUNSHAN DISPLAY MATERIAL CO LTD +2

Method for preparing semiconductor material through ion injection and fixed-point adsorption technologies

ActiveCN102737963AReduce defect densityHigh relaxivitySemiconductor/solid-state device manufacturingSemiconductor materialsSmart Cut

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

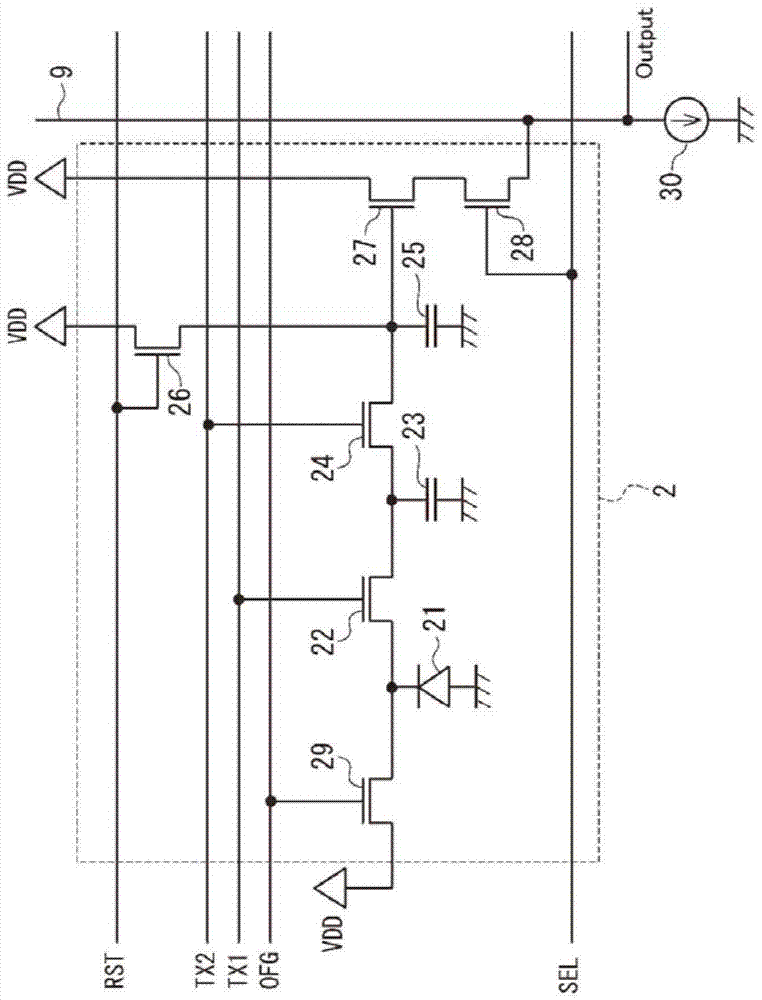

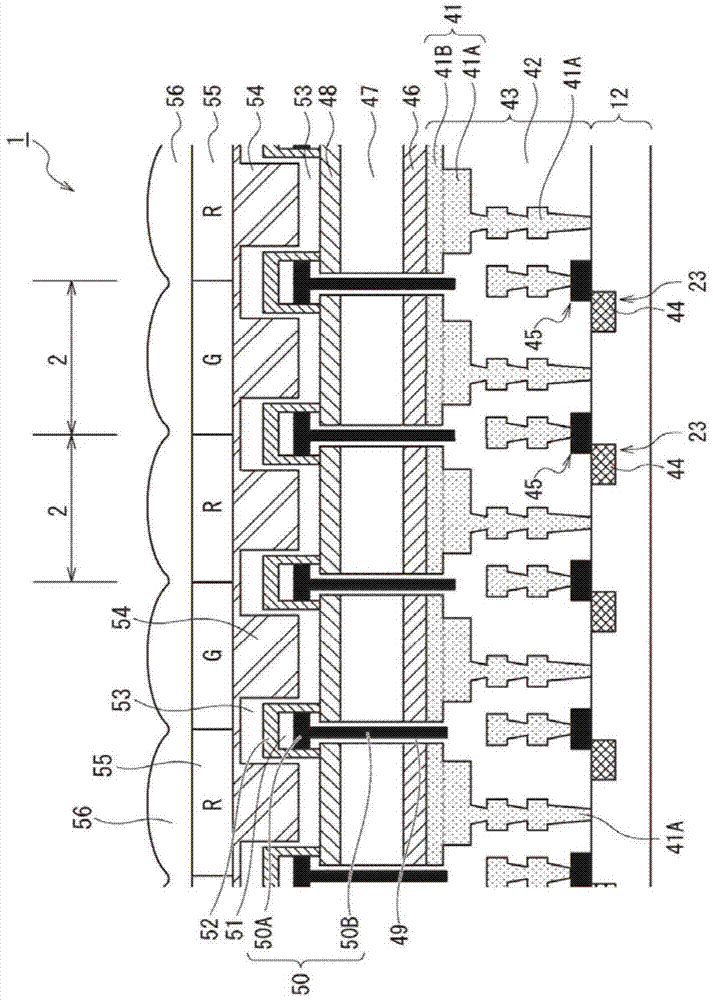

Solid-state image sensor, method of producing the same, and electronic apparatus

Owner:SONY SEMICON SOLUTIONS CORP

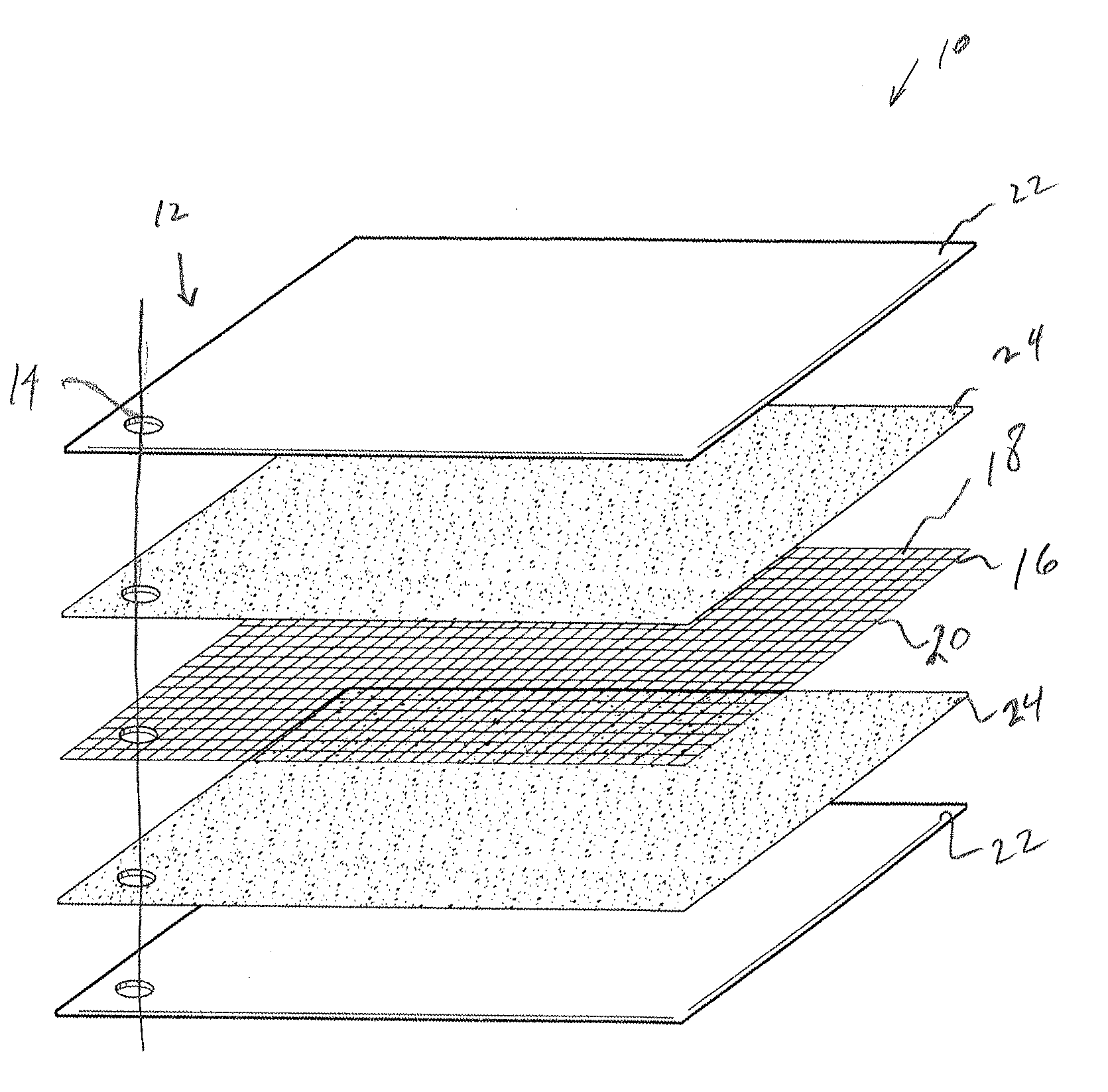

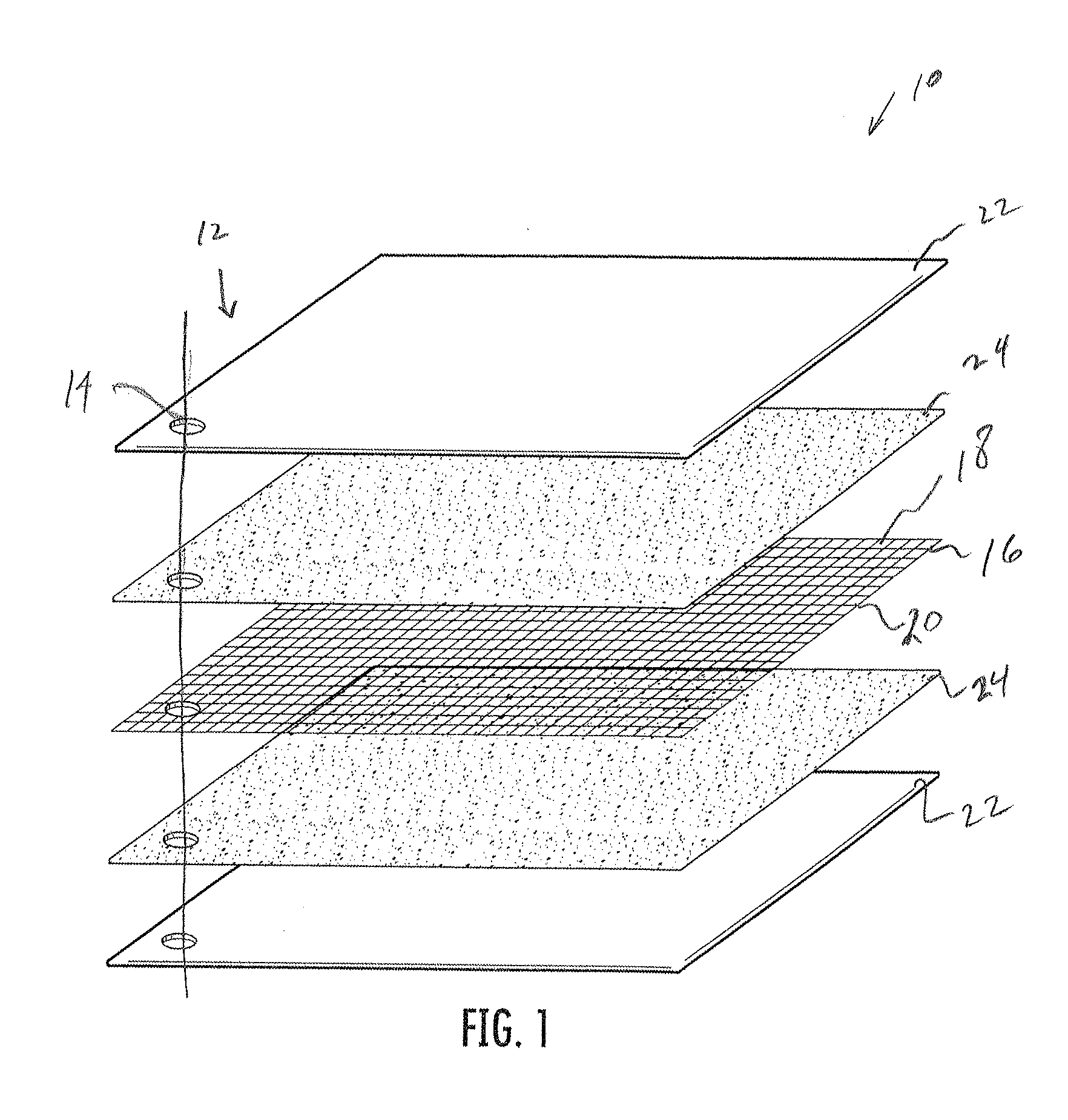

Systems and methods for enhancing mobility of atomic or molecular species on a substrate at reduced bulk temperature using acoustic waves, and structures formed using same

ActiveUS20140199550A1Improve mobilityReduce the temperatureRadiation applicationsVacuum evaporation coatingChemical physicsAcoustic wave

Under one aspect of the present invention, a method for enhancing mobility of an atomic or molecular species on a substrate may include exposing a first region of a substrate to an atomic or molecular species that forms a molecular bond with the substrate in the first region; directing a laser pulse to a second region of the substrate so as to generate an acoustic wave in the second region, the acoustic wave having spatial and temporal characteristics selected to alter the molecular bond; and transmitting the acoustic wave from the second region to the first region, the acoustic wave altering the molecular bond between the substrate and the atomic or molecular species to enhance mobility of the atomic or molecular species on the substrate in the first region.

Owner:THE AEROSPACE CORPORATION

Planar Optical Waveguide Based on Two-Dimensional Optical Gratings

ActiveUS20200264367A1Maximum flexibilityEnhanced visible areaOptical light guidesGratingParallel plate

A planar optical waveguide based on two-dimensional grating includes an optical waveguide substrate which is a transparent plane-parallel plate, and a functional grating element which includes a two-dimensional grating having two grating directions with an angle of 60° in between. The two-dimensional grating is either protruded or recessed into the top surface of the optical waveguide substrate. The output image from a micro-projector can enter the optical waveguide and then gets projected to cover the entire area of the functional grating element, enabling a human eye to view the output image across a large eye-box.

Owner:SHANGHAI NORTH OCEAN TECH CO LTD

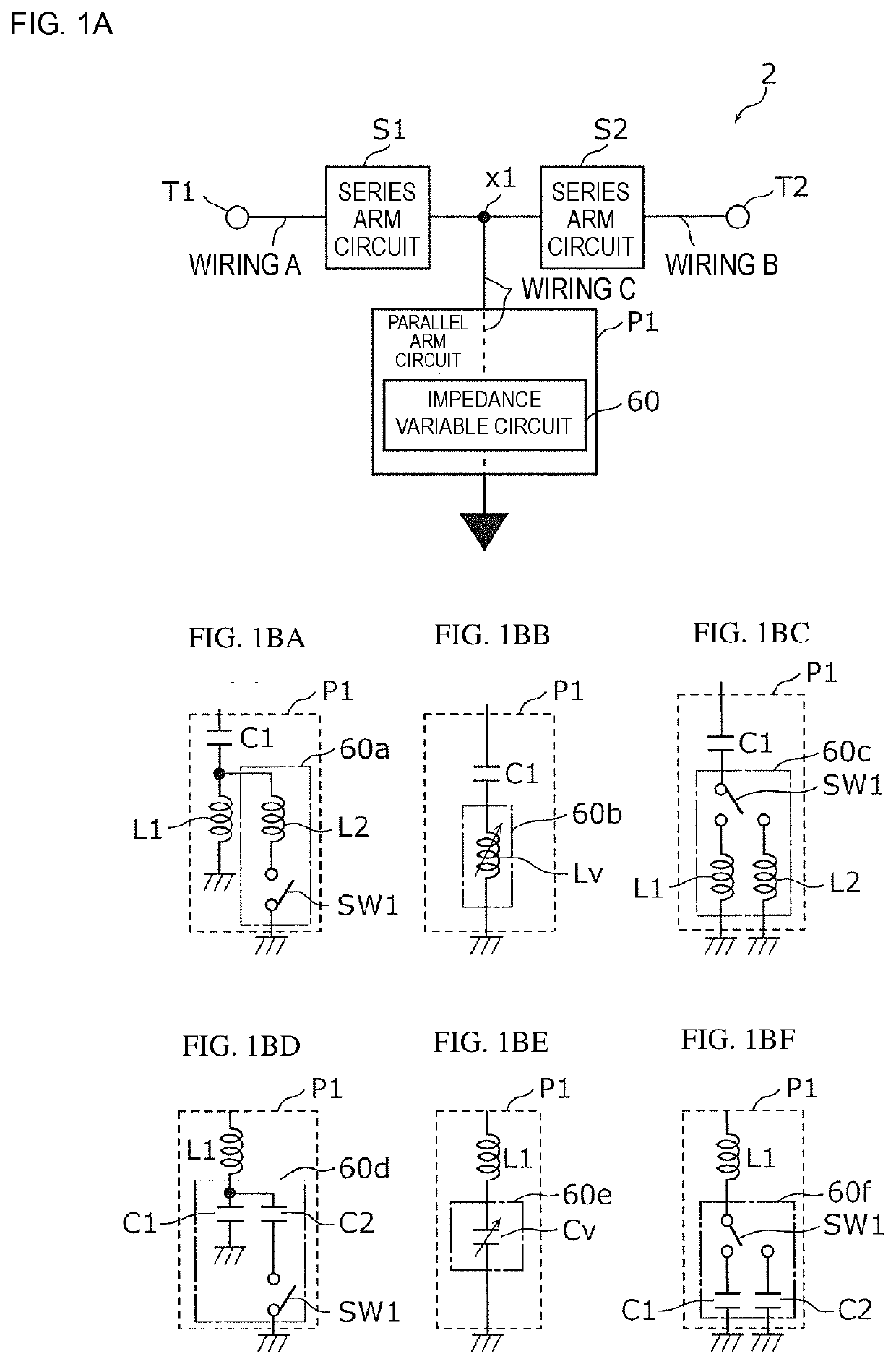

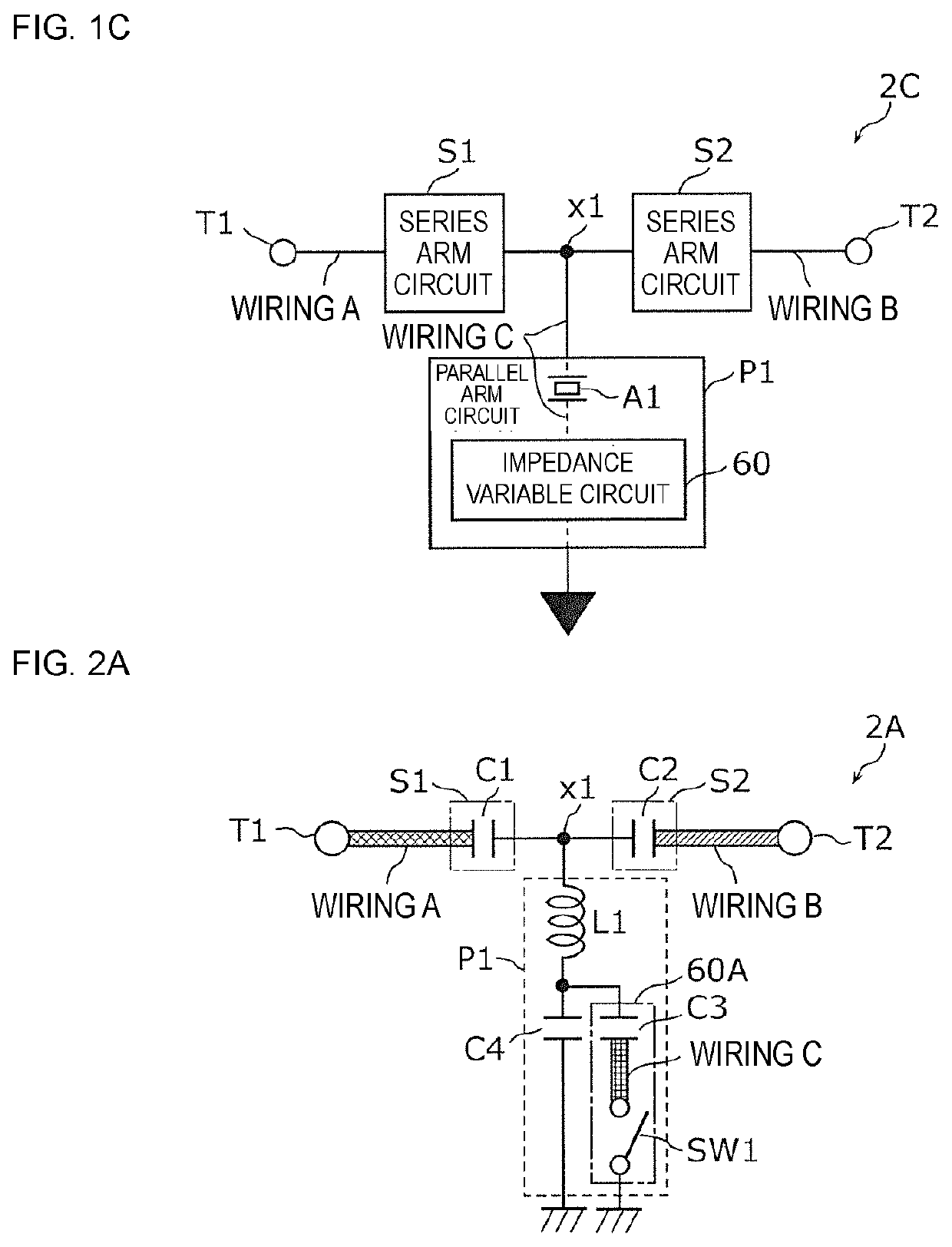

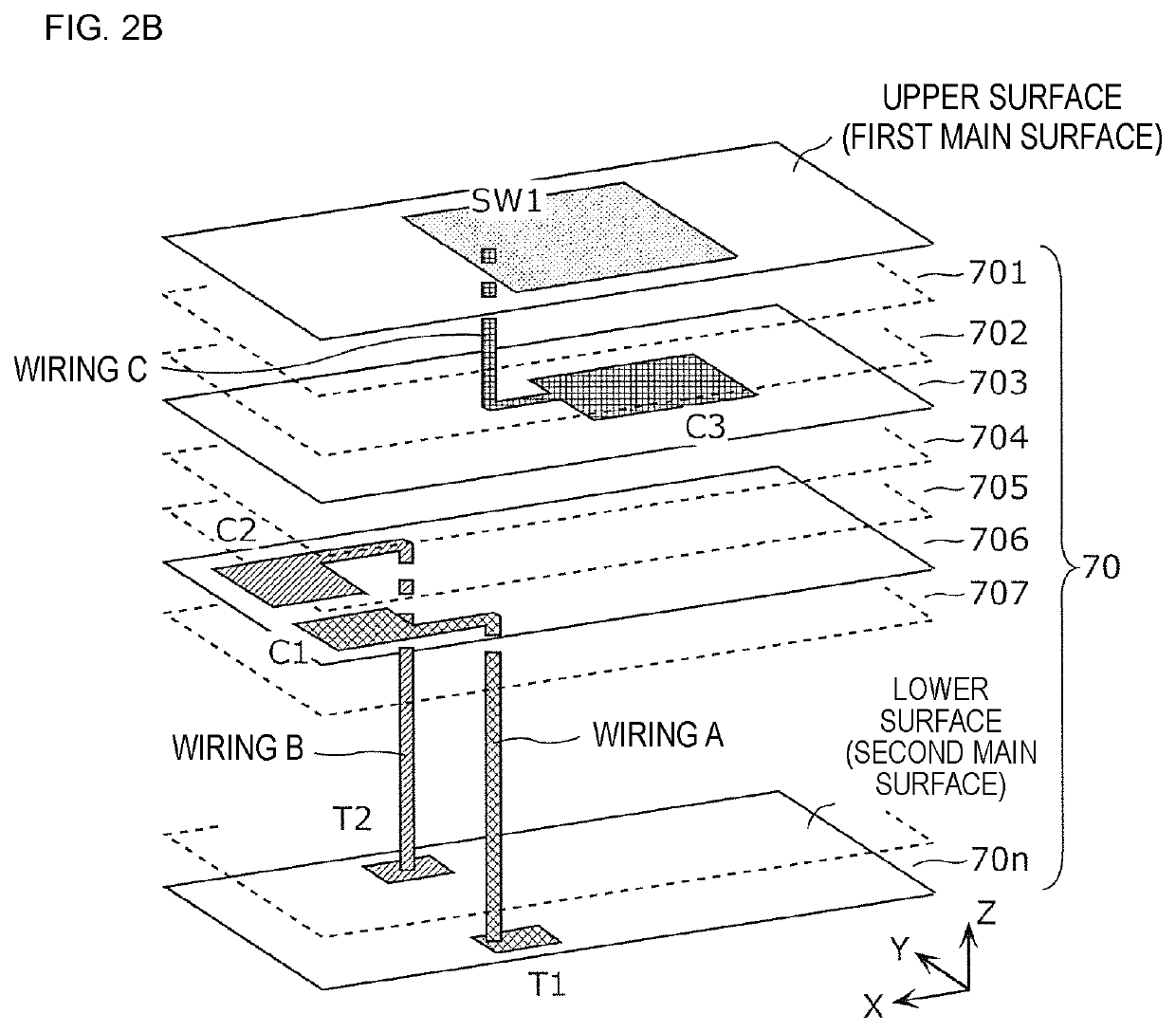

Radio frequency circuit, multiplexer, radio frequency front end circuit and communication apparatus

ActiveUS20200252042A1Reduce lossSpeed up the descentMultiple-port networksFrequency-division multiplex detailsMultiplexingMultiplexer

Owner:MURATA MFG CO LTD

Substrate forming mold, and plate thickness adjusting method of formed substrate in substrate forming mold

A substrate forming mold for forming a substrate by filling a cavity formed between a pair of matching molds 1, 2 with resin, that is, this substrate forming mold has shims 9, 12 disposed at least between a mirror finished surface plate 6 for composing one mold 1 and a stable mold base 8, and in a region inside of a fixed abutting ring 13, depending on fluctuations of plate thickness of formed substrate. As a result, the plate thickness of formed substrate can be adjusted finely, and fluctuations occurring in the radial direction or peripheral direction of the formed substrate can be decreased.

Owner:PANASONIC CORP

Process for produicng stamper for direct mastering, and stamper produced by such process and optical disc

InactiveUS20060290018A1Increased durabilityWeaken energyOptical articlesRecord information storageEngineeringInjection molding machine

In producing a stamper for molding an optical disc, a master disc which can be obtained from the steps of forming a thermosensitive material layer capable of acting as a negative type by a laser beam on a substrate, irradiating a laser beam to predetermined areas of the thermosensitive material layer so as to partially perform exposure and wet-etching the partially exposed thermosensitive material layer so as to form a fine pits-and-bumps pattern is used as a stamper for injection molding machine. Therefore, minute pits each having a size smaller than the spot of the laser beam of optical limit are formed, thereby providing a stamper with the small number of deficiencies.

Owner:PANASONIC CORP

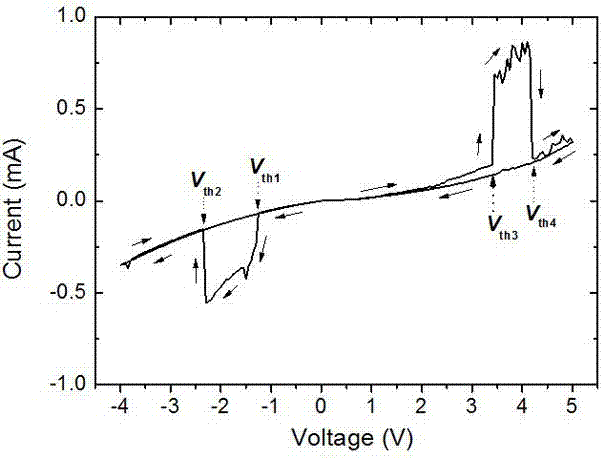

Complementary type resistive random access memory and preparation method thereof

InactiveCN107240642AAvoid crosstalkSimple chemical structureElectrical apparatusSputteringMedia layer

Owner:HENAN INST OF ENG

Method for improving distribution uniformity of LED (Light Emitting Diode) encapsulated fluorescent powder

InactiveCN103151434AEliminate "external electric fieldImprove light and color yieldSemiconductor devicesPotential differenceSilica gel

The invention belongs to the field of semiconductor illumination and particularly relates to a method for improving LED (Light Emitting Diode) encapsulation. The method for improving the LED encapsulation comprises the following steps that LED chips are fixedly arranged on a substrate containing a printed circuit layer; cathodes of the chips are connected with the cathode of the printed circuit layer of the substrate; anodes of the chips are connected with the anode of the printed circuit layer of the substrate; the anode of the printed circuit layer of the substrate is connected with the cathode of the printed circuit layer; the anode and the cathode of the printed circuit layer are connected in a short-circuit way; a mixture of well-proportioned fluorescent powder and silica gel is stirred and then coated onto the chips; and a light source semi-finished product is put in a roaster for roasting. With the adoption of the method for improving LED light source encapsulation provided by the invention, through the short-circuit connection between the anode and the cathode of the substrate, the anodes and the cathodes of the chips are located on the same potential difference, so that an external electric field resulting from LED intrinsic absorption is eliminated; and therefore, the purpose of evenly distributing the fluorescent powder is realized, and the light color yield of a light source product is further improved.

Owner:SHANGSHUN ELECTRONIC TECH (CHINA) CO LTD

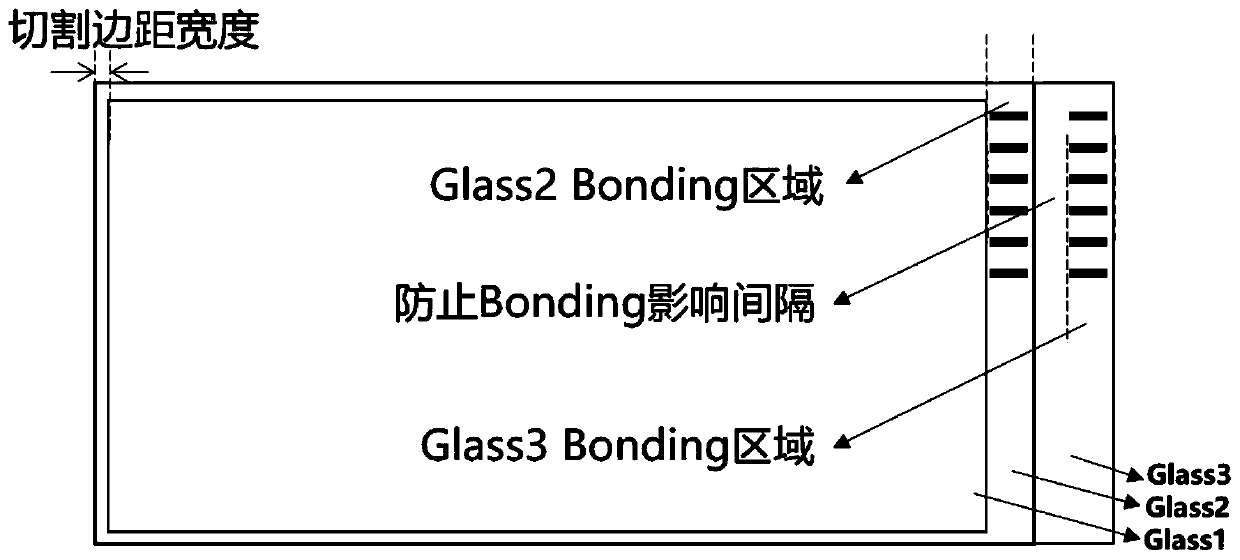

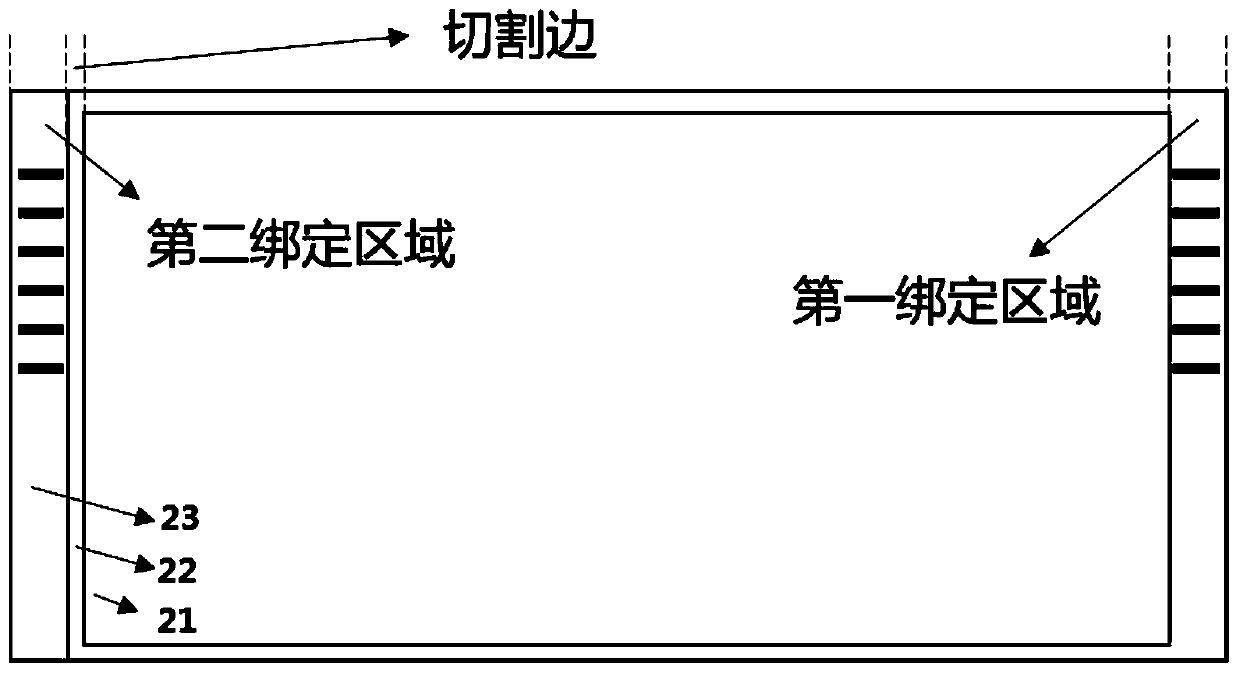

Fabrication method of display panel, display panel and display device

Owner:BOE TECH GRP CO LTD

Reversible electrochemical mirror

Provided is a reversible electrochemical mirror including a first substrate, a second substrate on the first substrate and spaced apart from the first substrate, a first transparent electrode on the first substrate, a second transparent electrode under the second substrate, a semi-transmissive film between the second substrate and the second transparent electrode, a barrier rib having a chamber between the first and second transparent electrode and an electrolyte solution filled in the chamber.

Owner:ELECTRONICS & TELECOMM RES INST

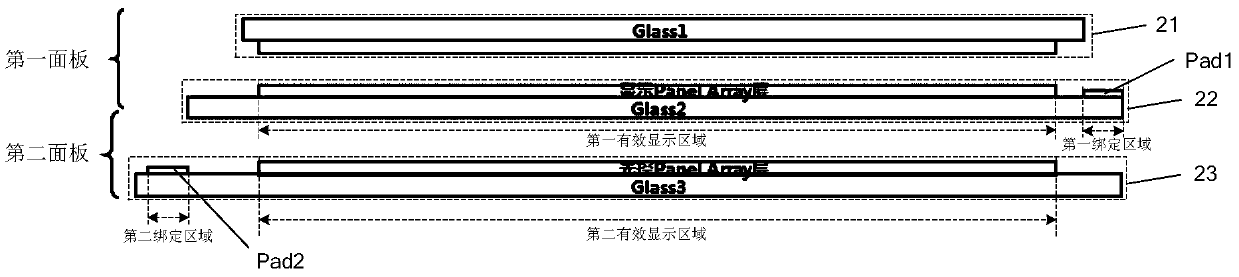

Process method for preparing lithium battery diaphragm by using 3D printing technology

Owner:ZHEJIANG KEATON NEW MATERIAL TECH CO LTD

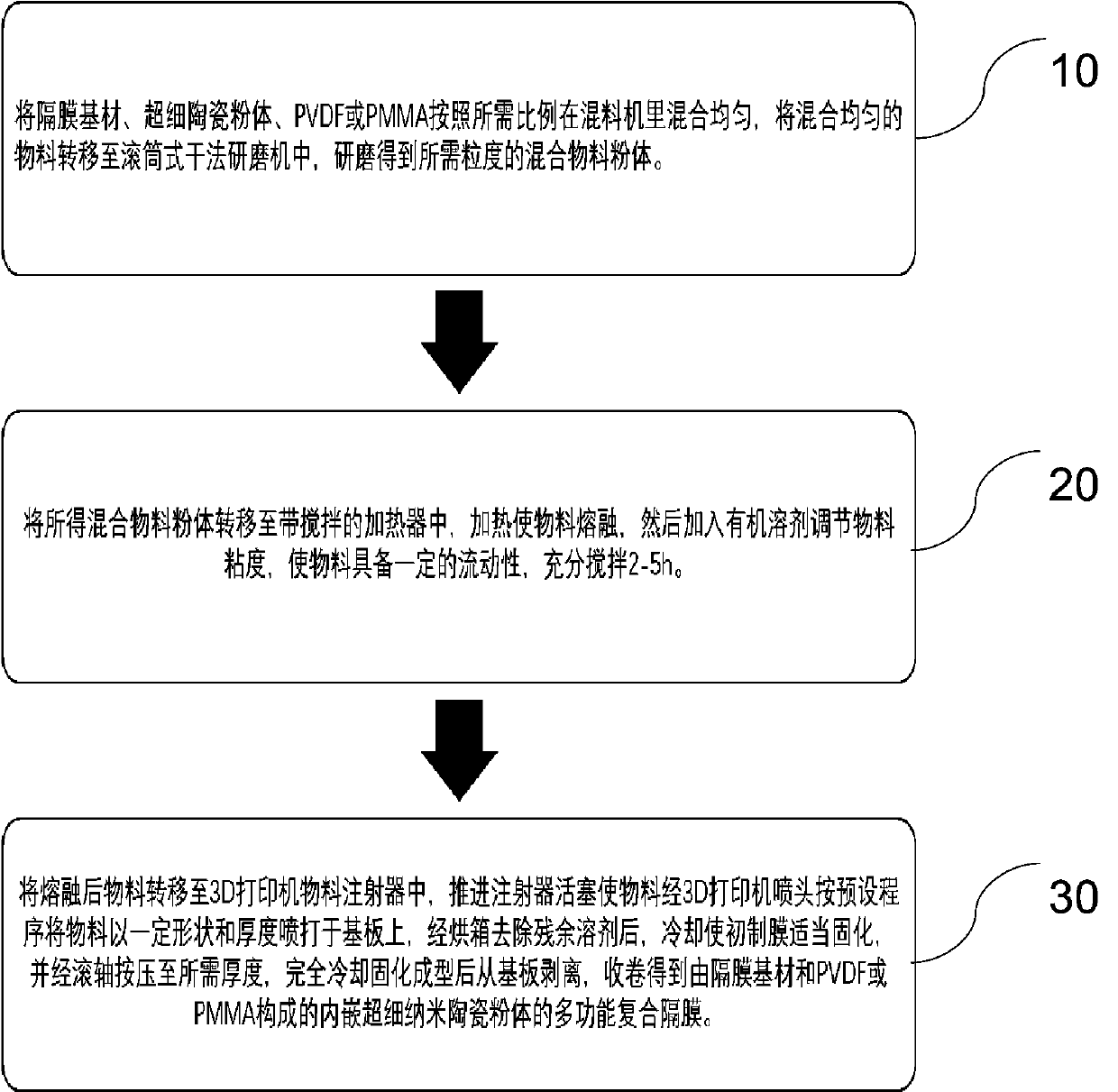

Array substrate, preparation method thereof and display panel

PendingCN112987416AEasy inflowAvoid the problem of abnormal liquid crystal deflectionNon-linear opticsEngineeringMaterials science

The invention provides an array substrate, a preparation method thereof and a display panel, and relates to the technical field of display. The array substrate comprises sub-pixels arranged in an array, each sub-pixel comprises a connecting electrode, an insulating layer and a pixel electrode, the pixel electrode comprises a first sub-electrode, a plurality of second sub-electrodes and a third sub-electrode, and the insulating layer is provided with a first via hole; the first sub-electrode is connected with the connecting electrodes through the first via holes, and a slit is formed between every two adjacent second sub-electrodes; each slit is provided with a first end facing the first sub-electrode, the first end of the first slit and the area of the first sub-electrode extending along the first direction have an overlapping area, and the first end of the second slit and the extending area do not have an overlapping area; the distance from the first end of at least one first slit to the plane where the side, away from the second sub-electrode, of the first sub-electrode is located is smaller than the distance from the first end of the second slit to the plane where the side, away from the second sub-electrode, of the first sub-electrode is located. The array substrate provided by the invention can improve the pocking mark undesirable phenomenon.

Owner:BOE TECH GRP CO LTD +1

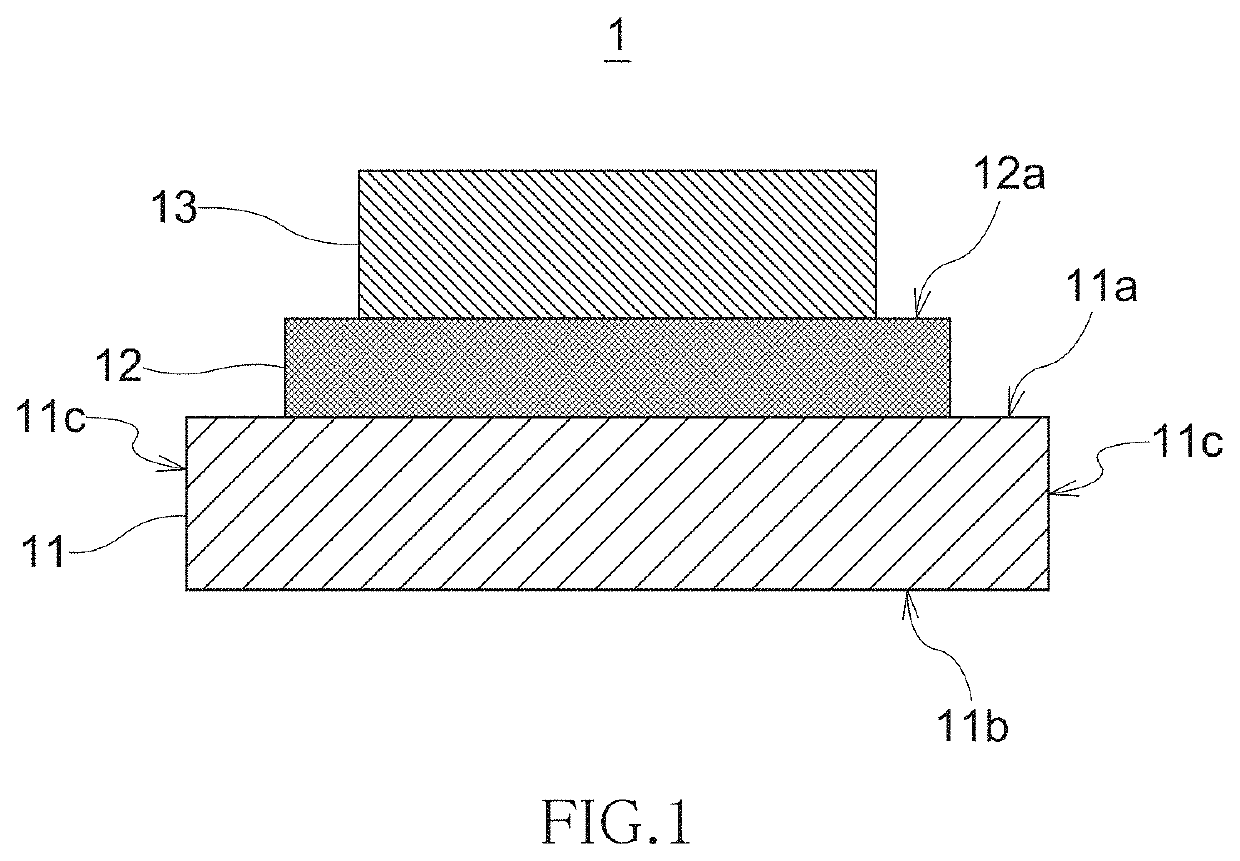

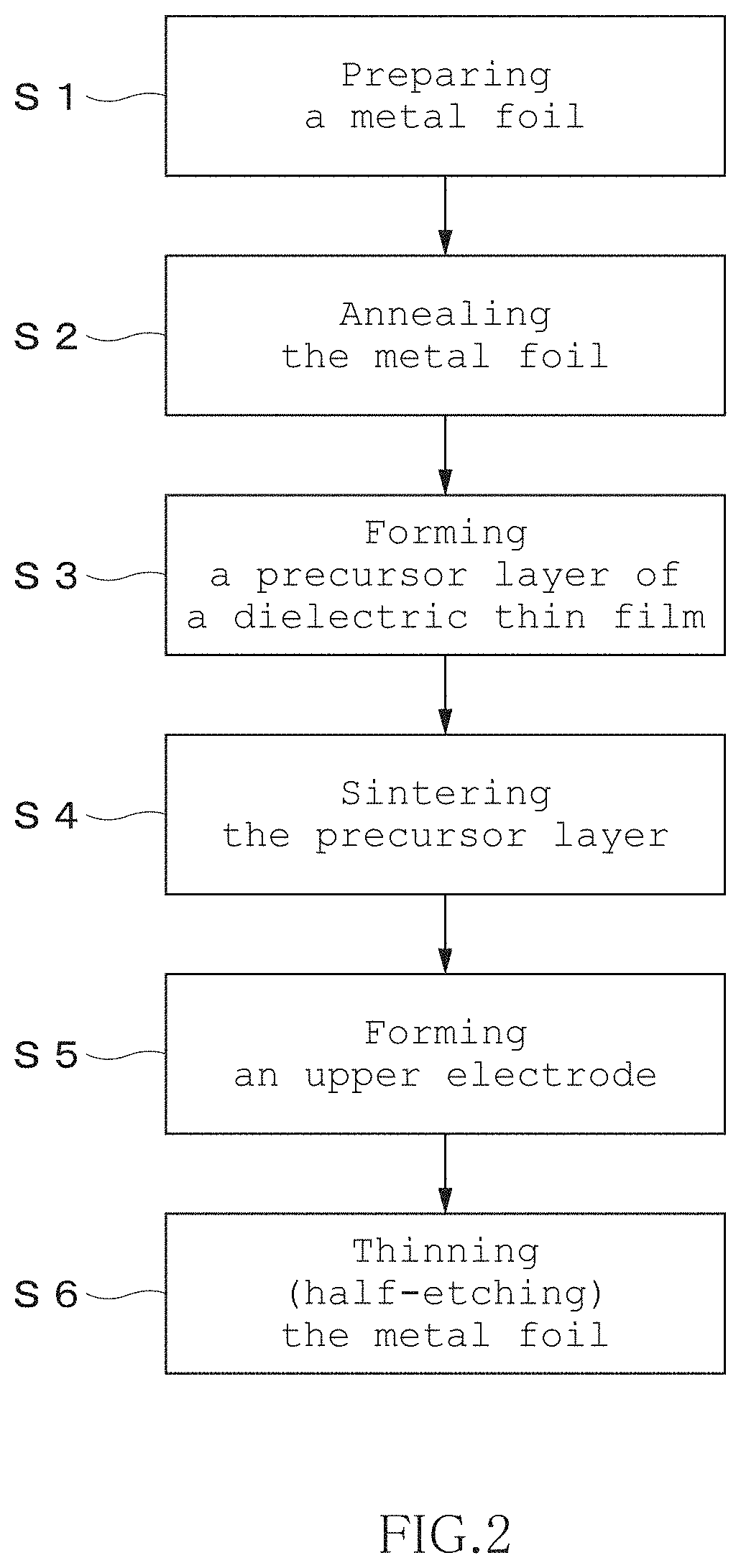

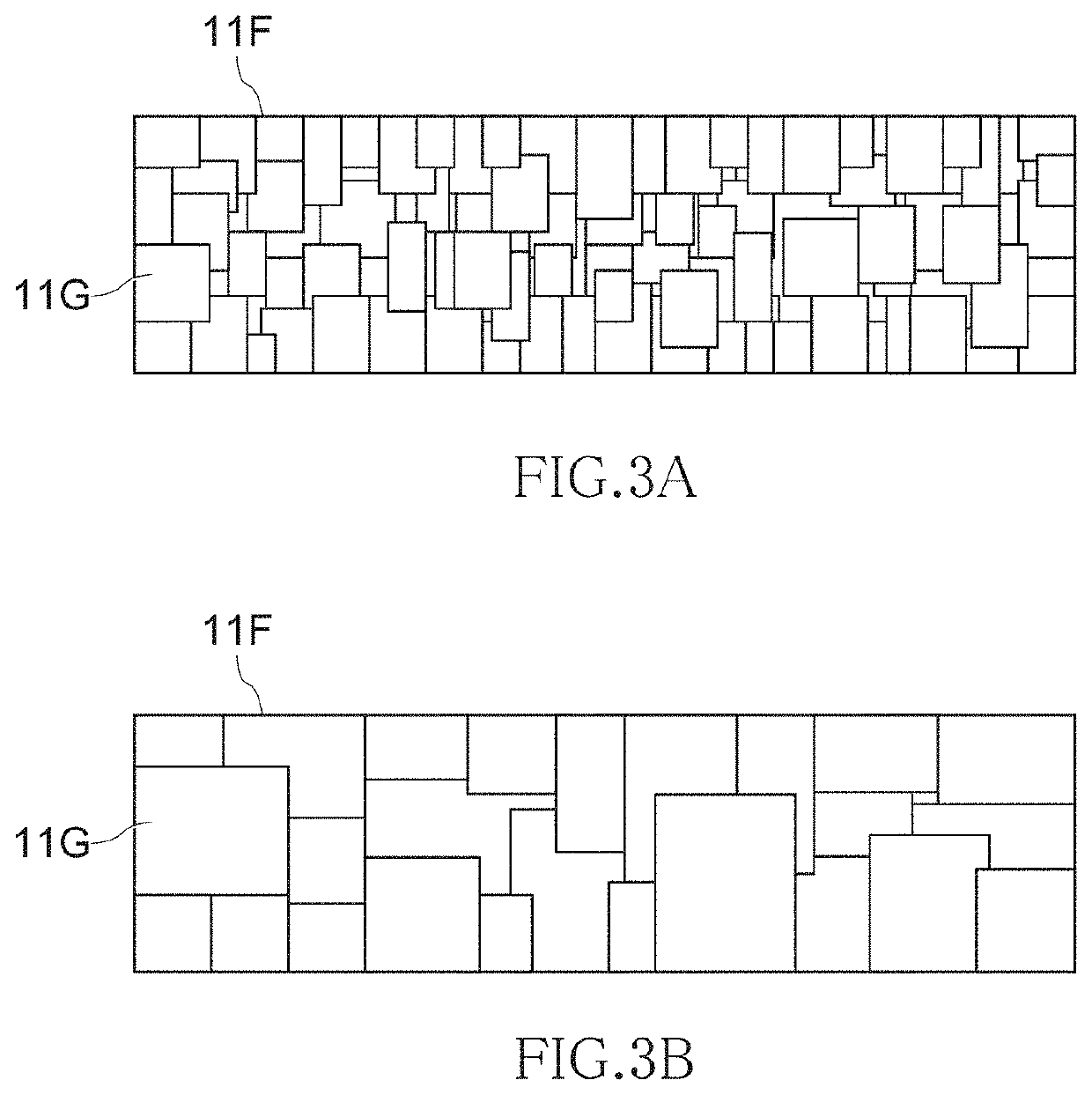

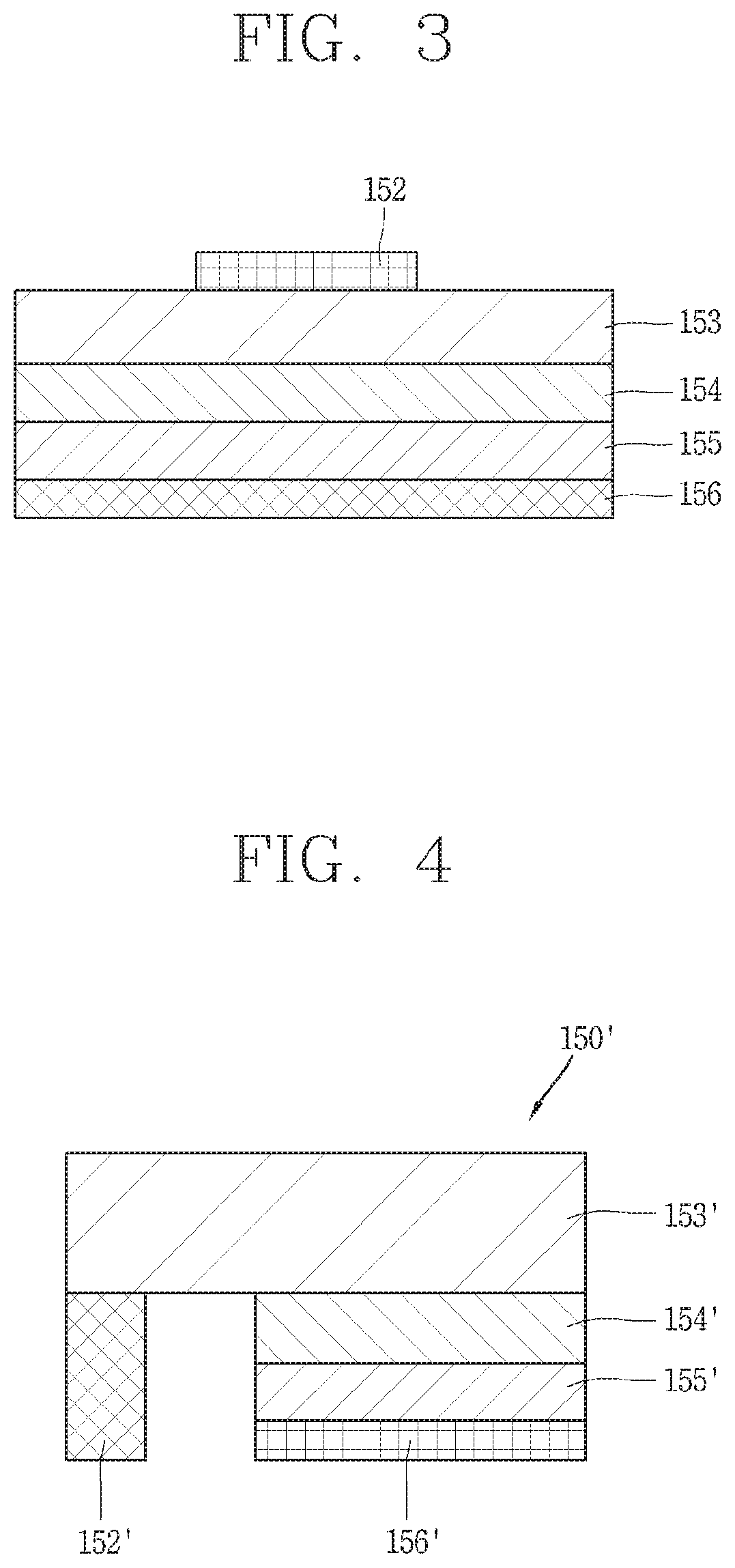

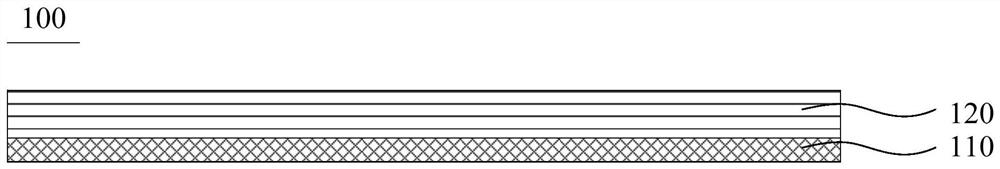

Thin film capacitor, manufacturing method therefor, and substrate with built-in electronic component

ActiveUS20200135406A1Reduce thicknessImprove cooling effectFixed capacitor electrodesThin/thick film capacitorMetal foilThin membrane

Owner:TDK CORPARATION

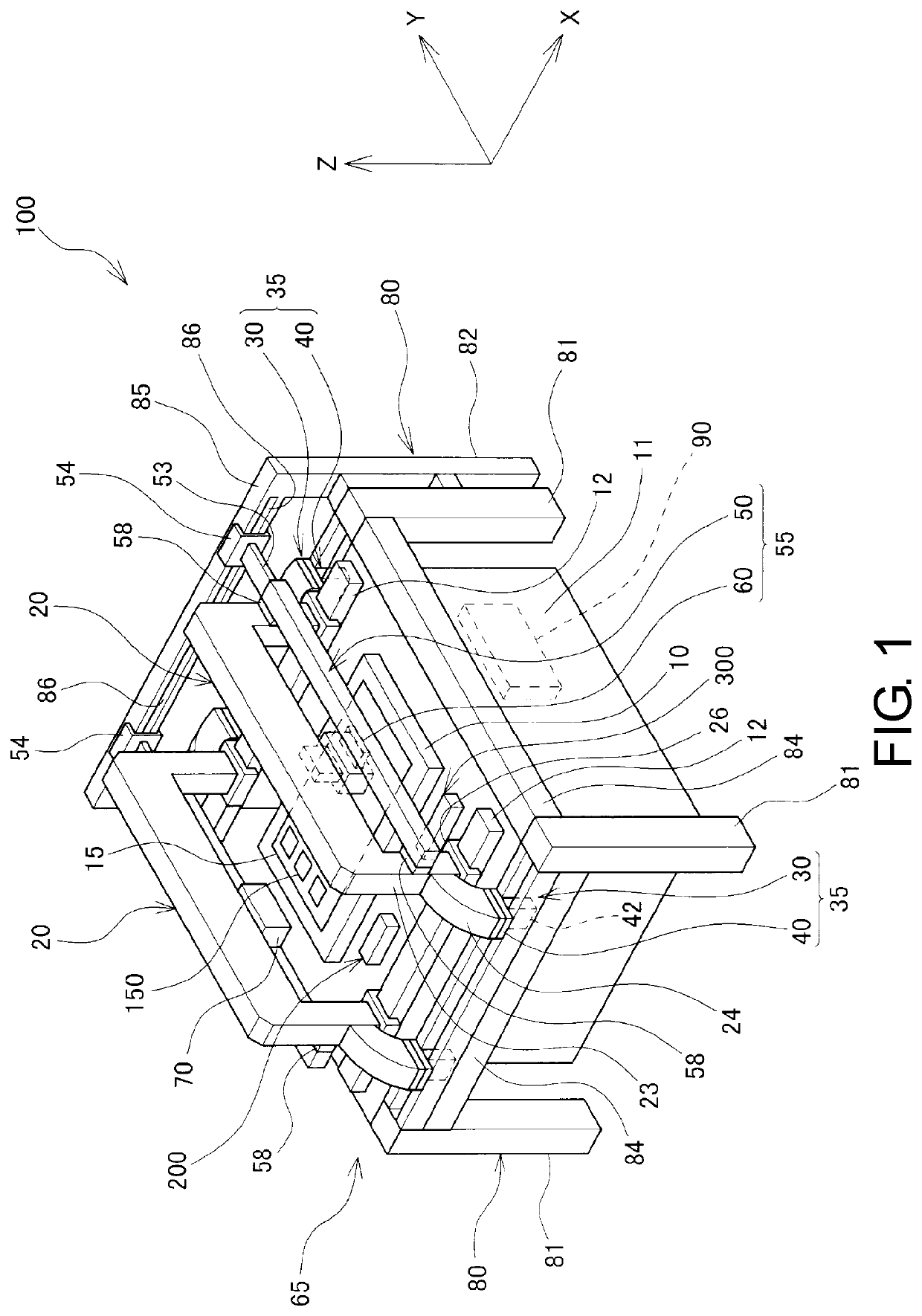

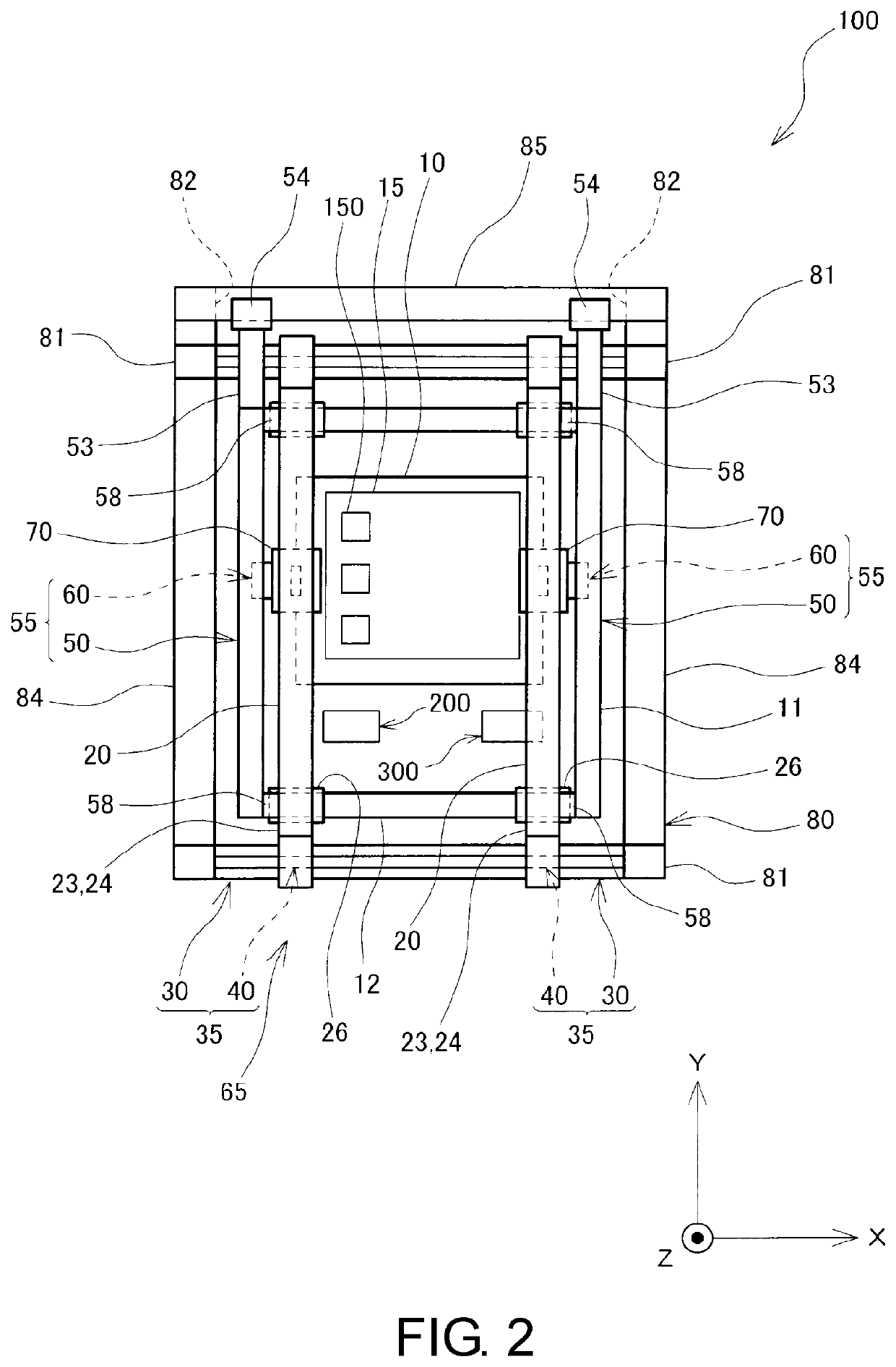

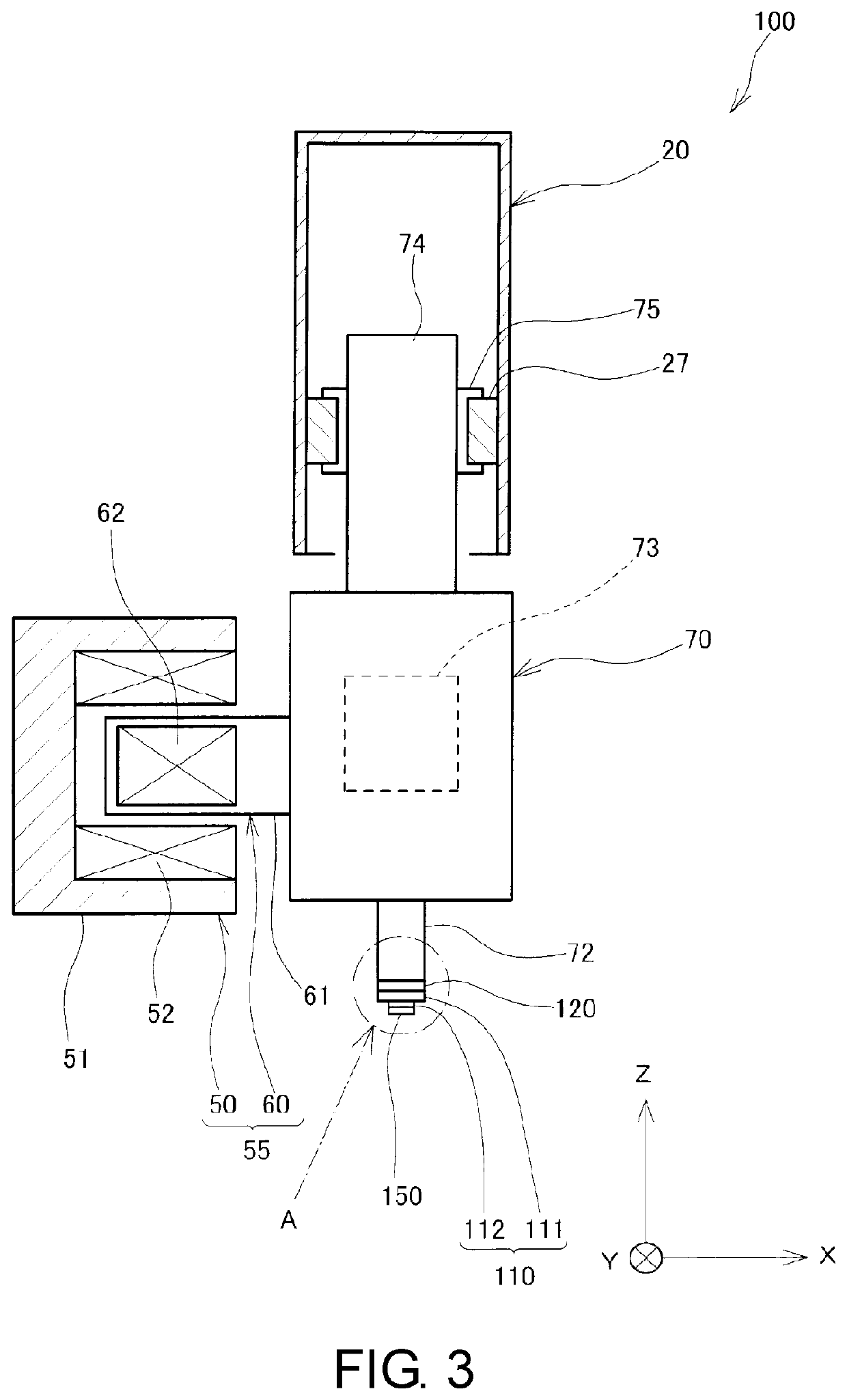

Alignment systems employing actuators providing relative displacement between lid assemblies of process chambers and substrates, and related methods

InactiveUS20160068951A1Improve process uniformityImprove uniformityPressure vessel componentsWing arrangementsRelative displacementEngineering

Alignment systems employing actuators provide relative displacement between lid assemblies of process chambers and substrates, and related methods are disclosed. A process chamber includes chamber walls defining a process volume in which a substrate may be placed and the walls support a lid assembly of the process chamber. The lid assembly contains at least one of an energy source and a process gas dispenser. Moreover, an alignment system may include at least one each of a bracket, an interface member, and an actuator. By attaching the bracket to the chamber wall and securing the interface member to the lid assembly, the actuator may communicate with the bracket and the interface member to provide relative displacement between the chamber wall and the lid assembly. In this manner, the lid assembly may be positioned relative to the substrate to improve process uniformity across the substrate within the process chamber.

Owner:APPLIED MATERIALS INC

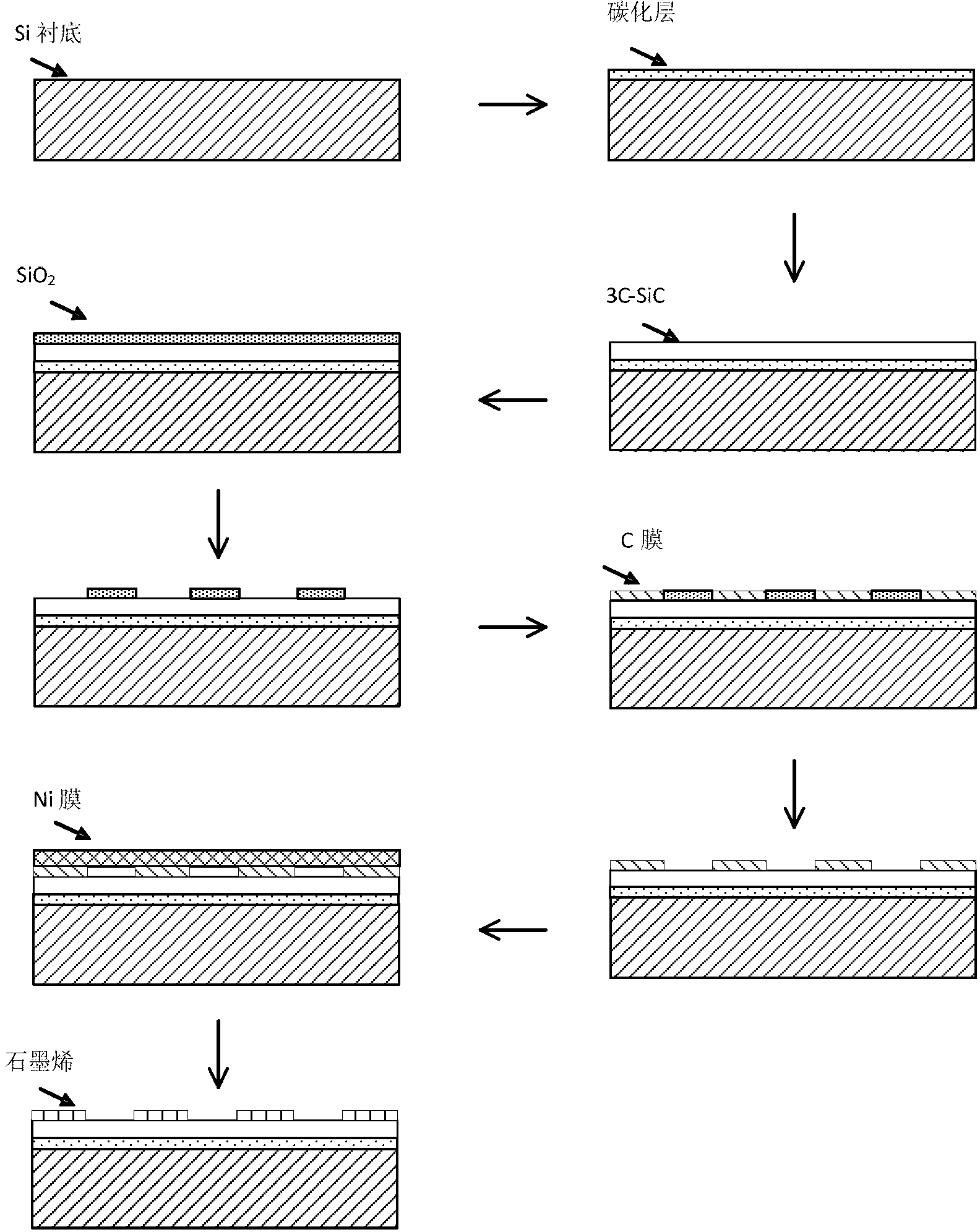

Ni film annealing patterned graphene preparation method based on 3C-SiC/chlorine gas reaction

InactiveCN102936011AEasy to refactorImprove continuityGrapheneCarbon filmState of art

Owner:XIDIAN UNIV

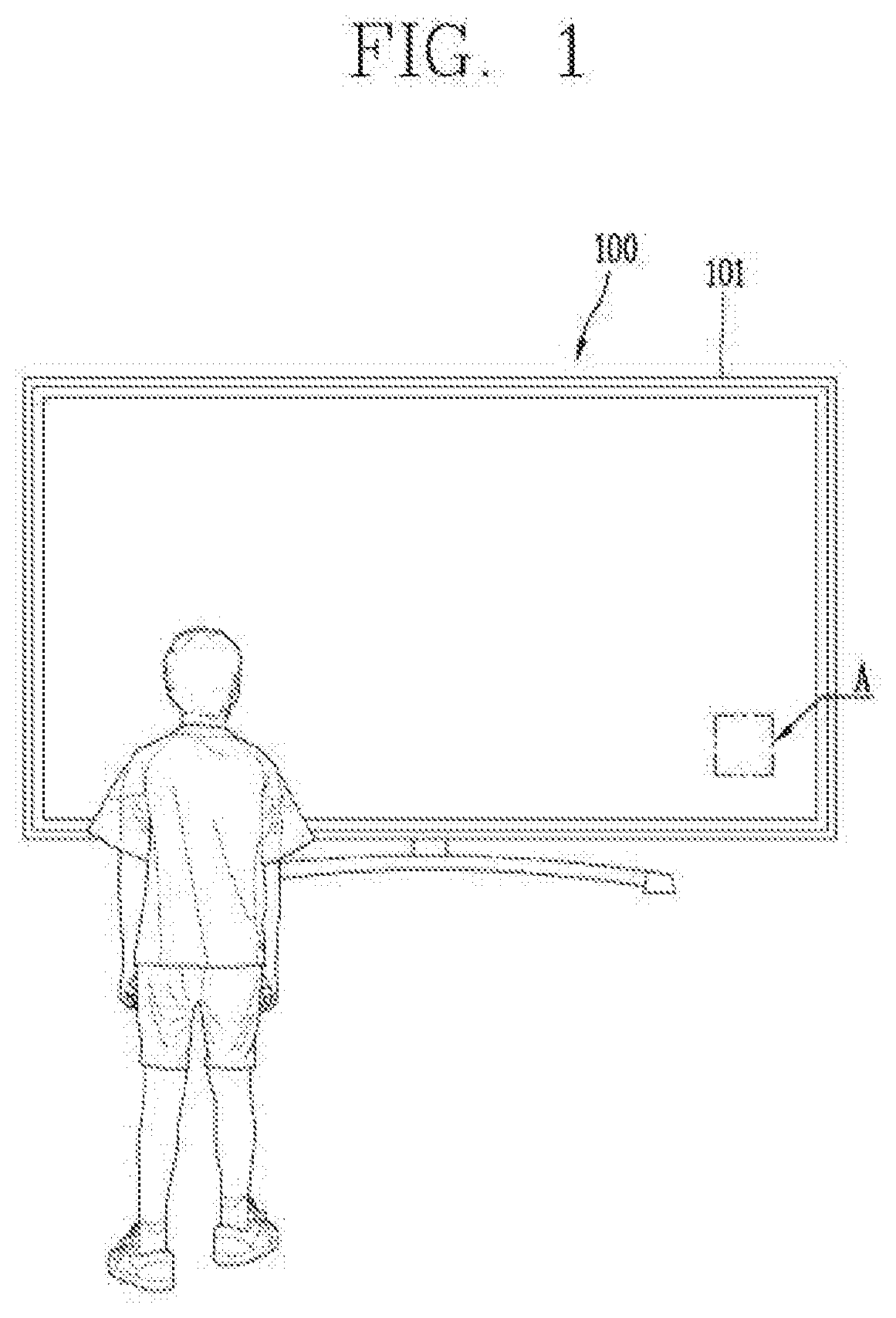

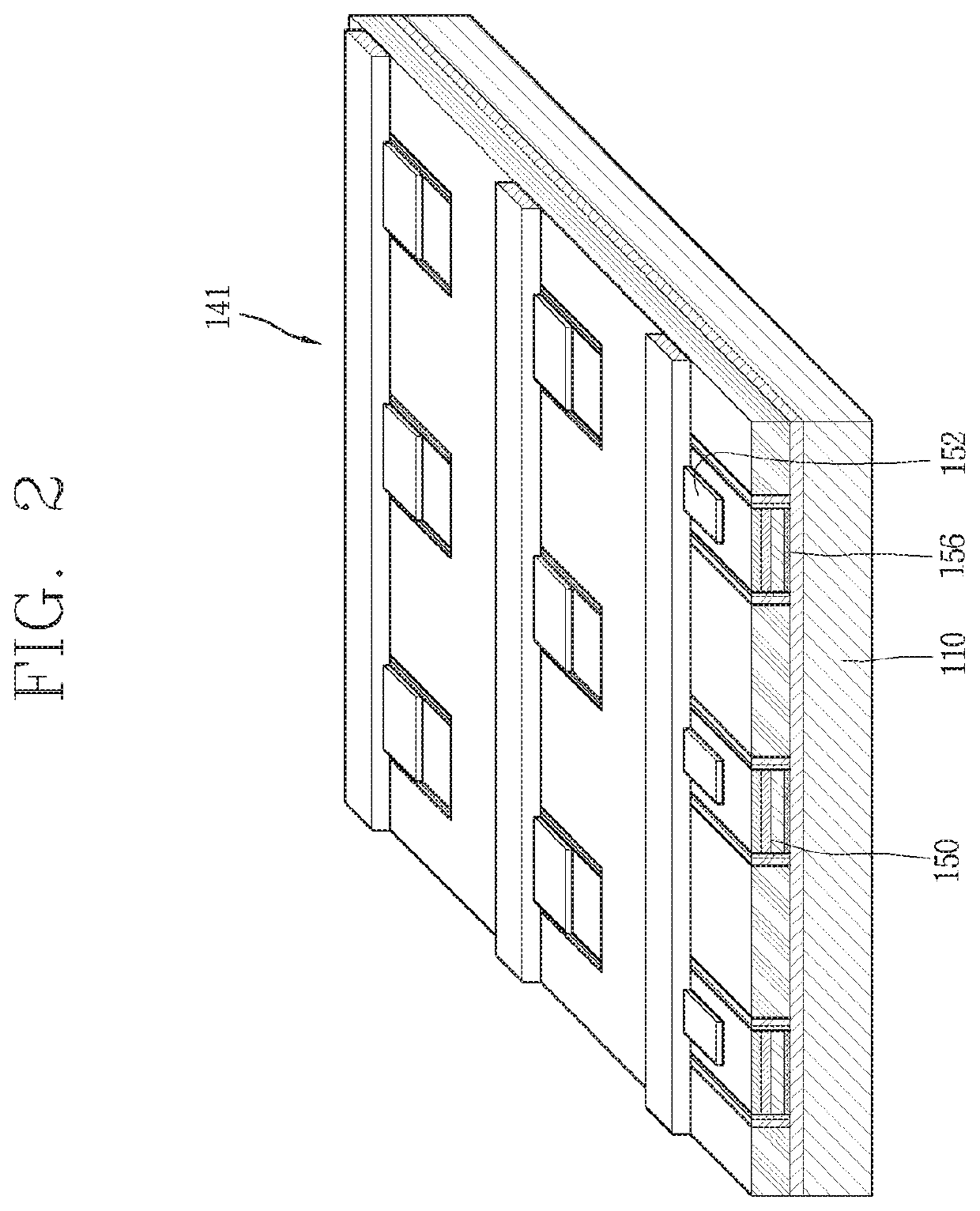

Device for self-assembling semiconductor light-emitting diodes

ActiveUS20210090916A1Improve assembly yieldEnsure reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Owner:LG ELECTRONICS INC

Cover plate, preparation method thereof and display device

PendingCN113054138AProtect luminous qualityExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMaterials science

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Electronic component mounting device

ActiveUS11373975B2Avoid stickingSimple methodSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectronic component

Owner:SHINKAWA CO LTD

Display panel, display substrate and preparation method thereof

PendingCN113299867AIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention provides a display panel, a display substrate and a preparation method of the display substrate. The display substrate comprises a substrate; a pixel defining layer which is arranged on the substrate and comprises a plurality of first pixel defining strips extending in the first direction and a plurality of second pixel defining strips extending in the second direction, wherein the first direction intersects with the second direction; the surface, back to the substrate, of the first pixel defining strip is located on the side, away from the substrate, of the surface, back to the substrate, of the second pixel defining strip; the first pixel defining strips are arranged in the first direction, the second pixel defining strips are arranged between every two adjacent first pixel defining strips, at least one second pixel defining strip in the second direction comprises a first pixel defining part and a second pixel defining part, and the thickness of the first pixel defining part is greater than that of the second pixel defining part. The ink utilization rate can be improved.

Owner:BOE TECH GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap