Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Etching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Etching is traditionally the process of using strong acid or mordant to cut into the unprotected parts of a metal surface to create a design in intaglio (incised) in the metal. In modern manufacturing, other chemicals may be used on other types of material. As a method of printmaking, it is, along with engraving, the most important technique for old master prints, and remains in wide use today. In a number of modern variants such as microfabrication etching and photochemical milling it is a crucial technique in much modern technology, including circuit boards.

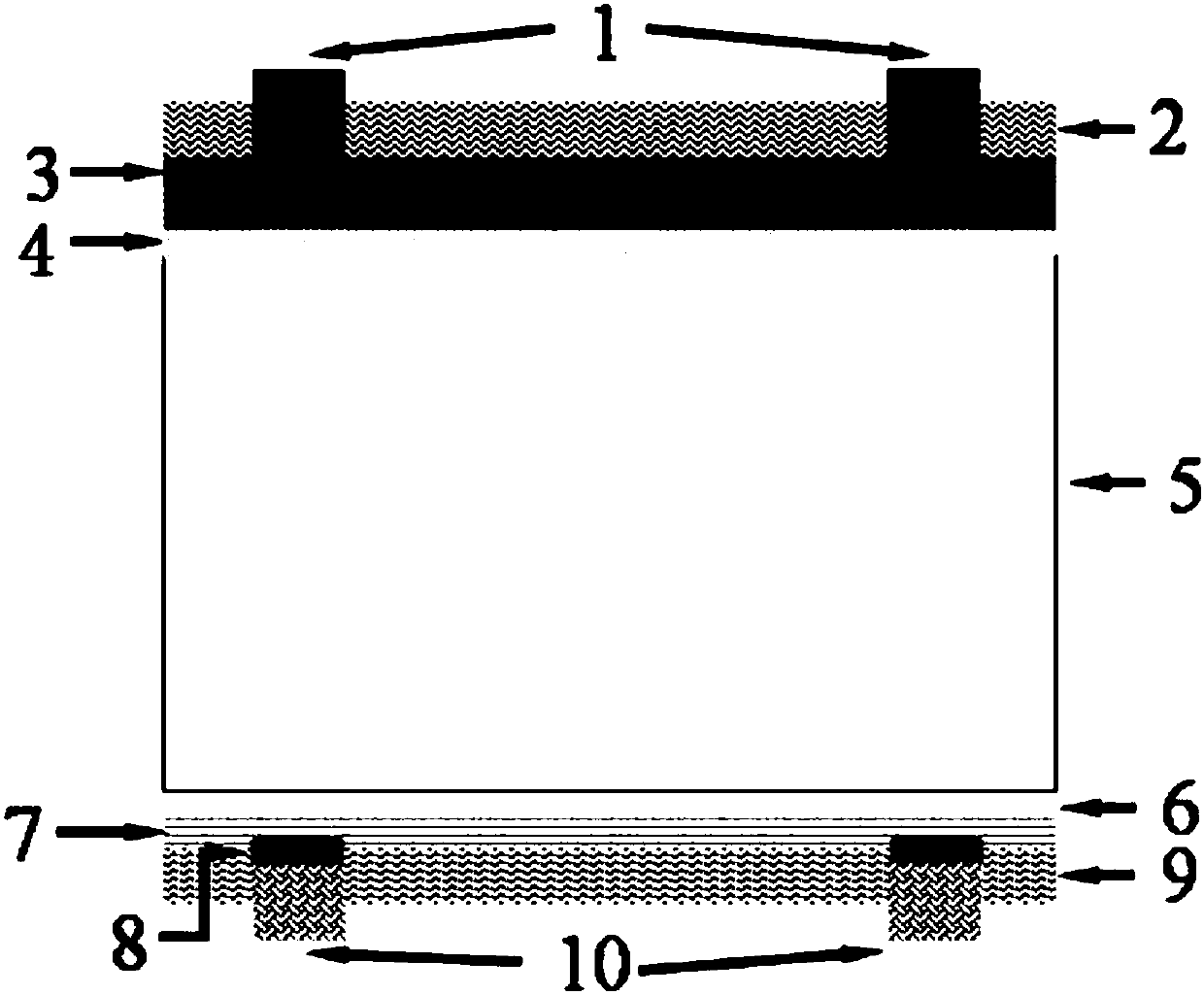

Preparation method of top gate metal oxide thin film transistor (TFT)

InactiveCN102157564ASolve the technical problem of insufficient chargingIncrease the on-state currentTransistorSemiconductor/solid-state device manufacturingEtchingElectrical conductor

Owner:SHANGHAI JIAO TONG UNIV

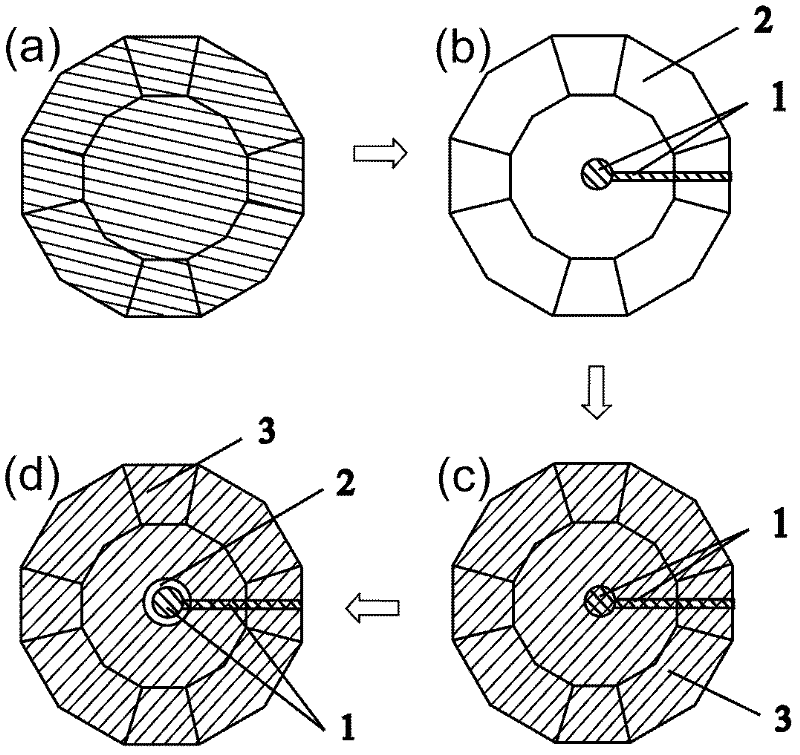

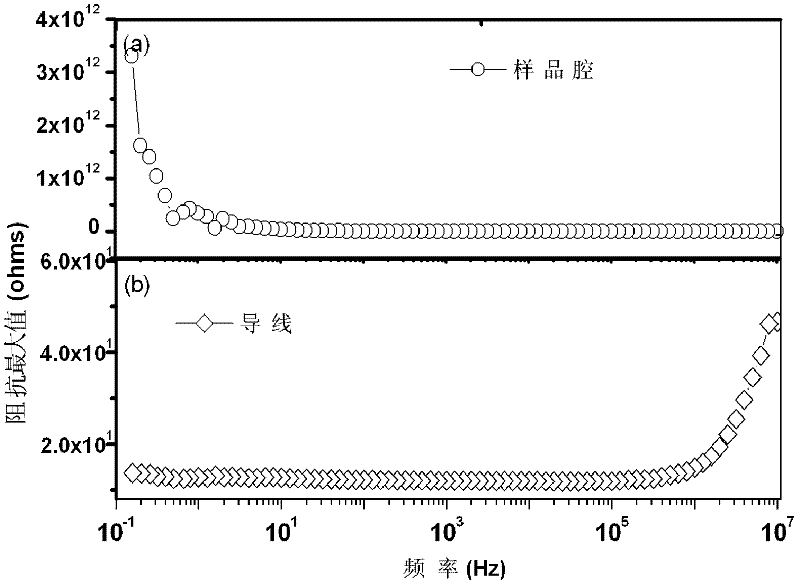

Electrode for high-voltage in-situ impedance spectroscopy measurement and its preparation method and application

InactiveCN102288824AFix fixitySolve insulation problemsResistance/reactance/impedenceEtchingInsulation Problem

Owner:JILIN UNIV

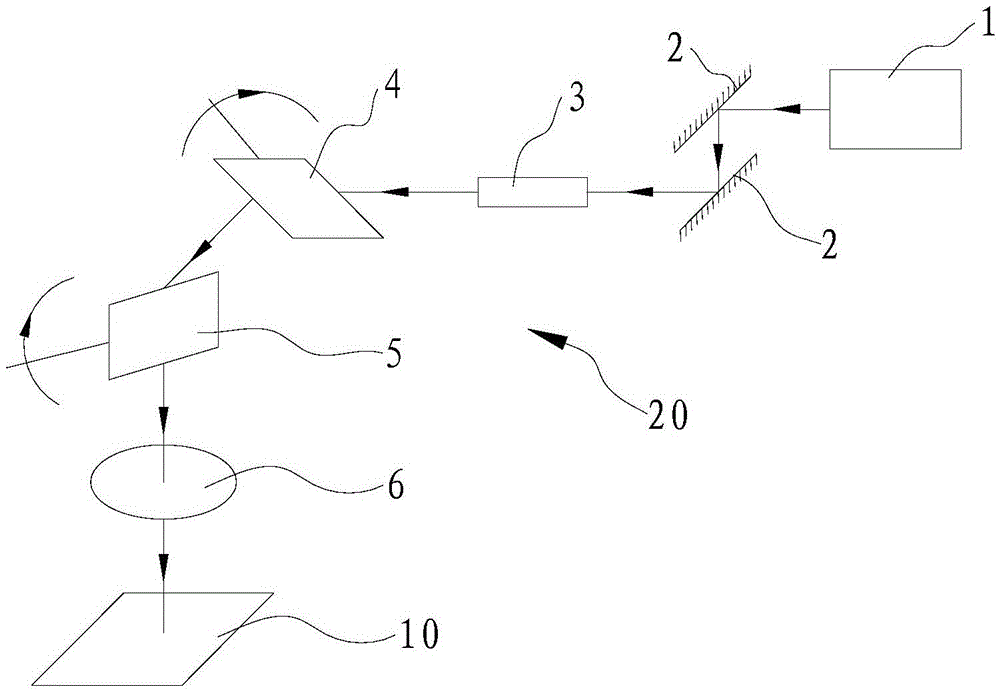

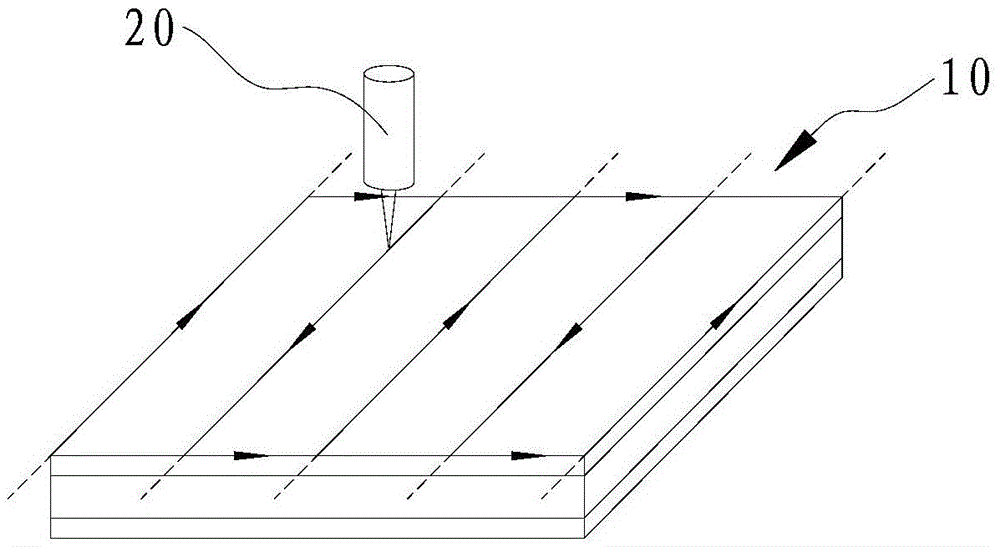

Multi-wavelength femtosecond laser scanning type etching method for printed circuit board

InactiveCN105562939AEasy to processImprove machining accuracyPrinted circuitsMetal working apparatusEtchingLine width

Owner:SUZHOU UNIV

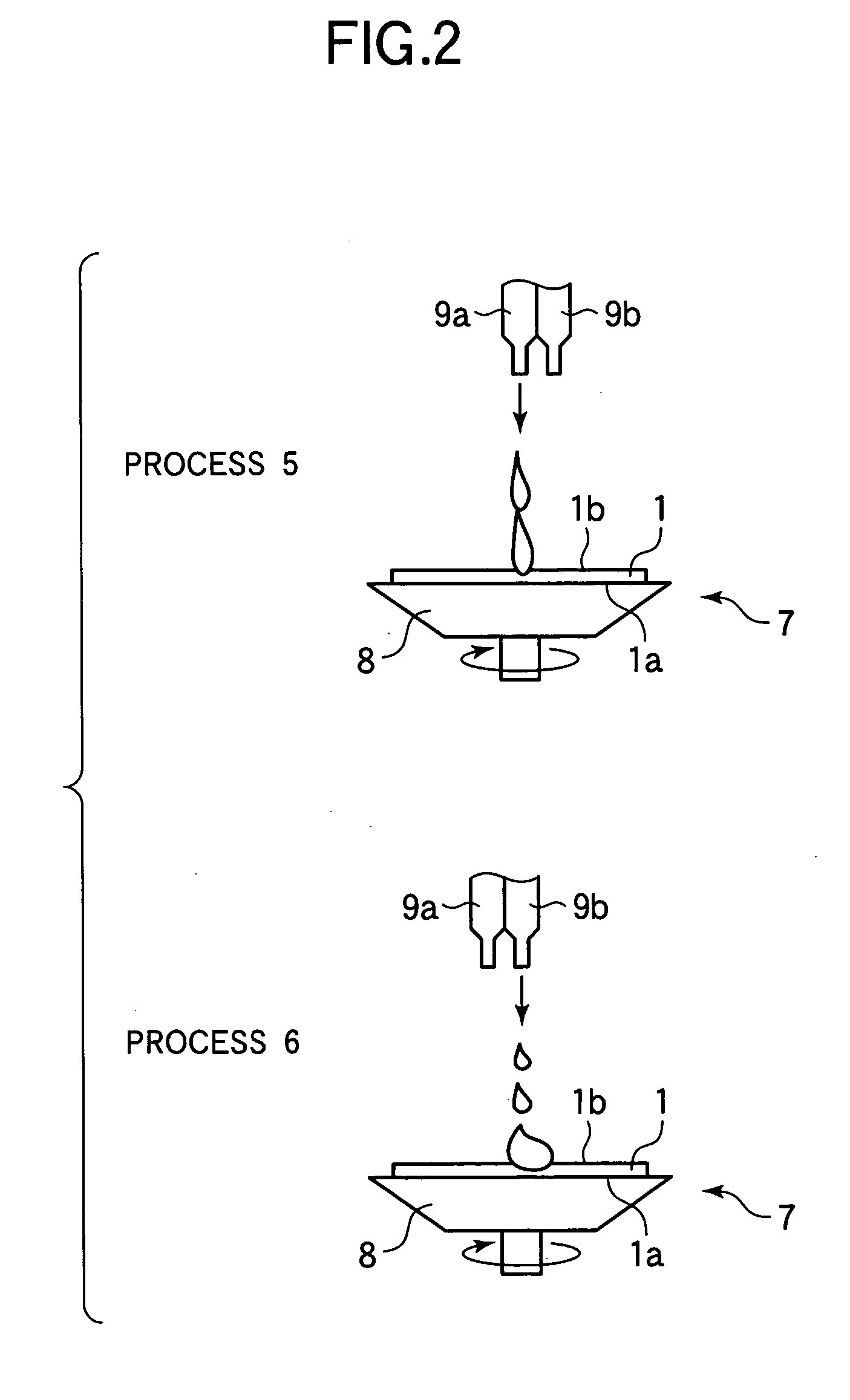

Method for manufacturing a semiconductor wafer

InactiveUS20070093065A1Clean back surfaceSemiconductor/solid-state device manufacturingHydrofluoric acidEtching

Owner:LAPIS SEMICON CO LTD

Preparation method of tunneling oxidation passivation PERC battery with selective contact with emitter junction

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

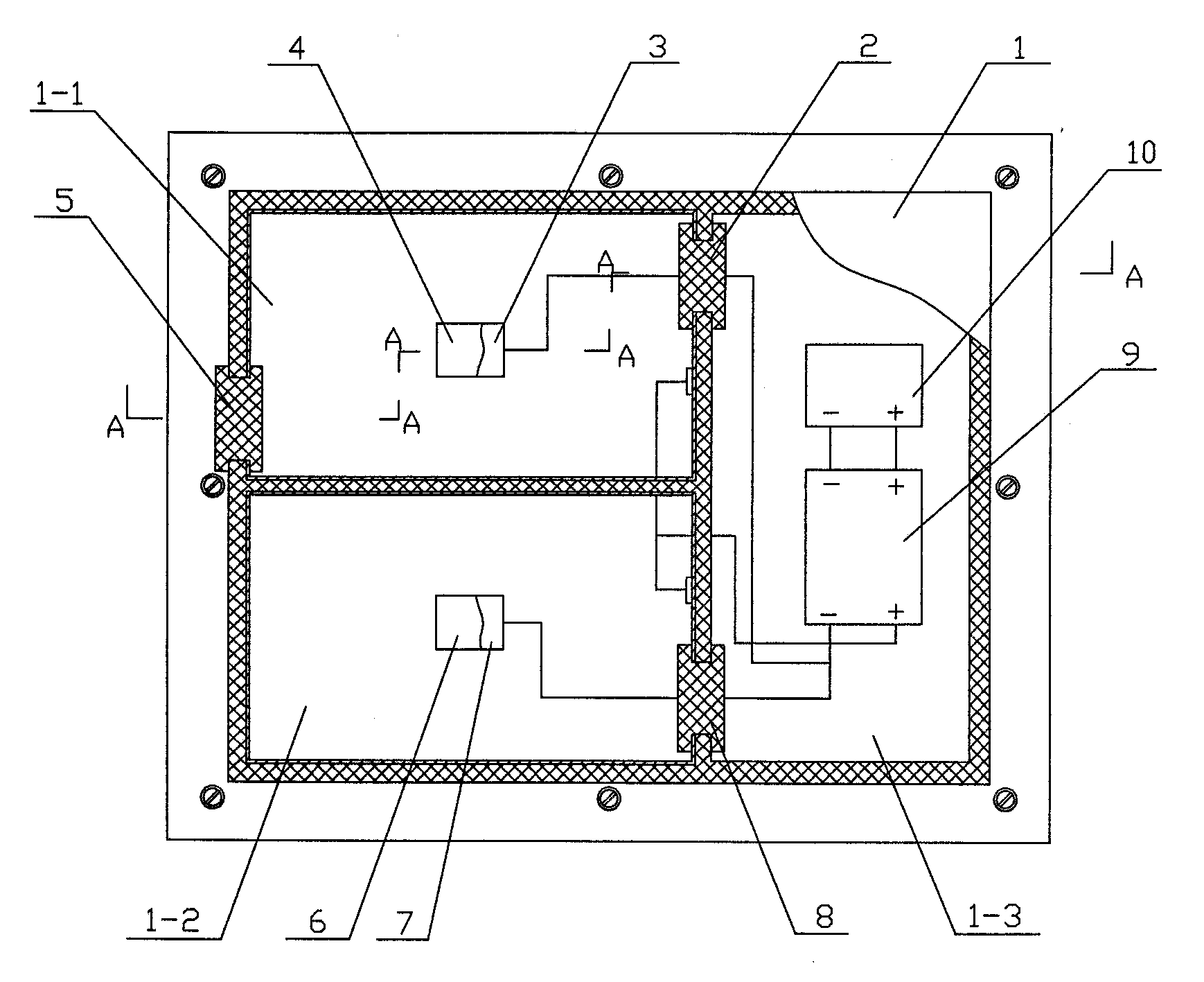

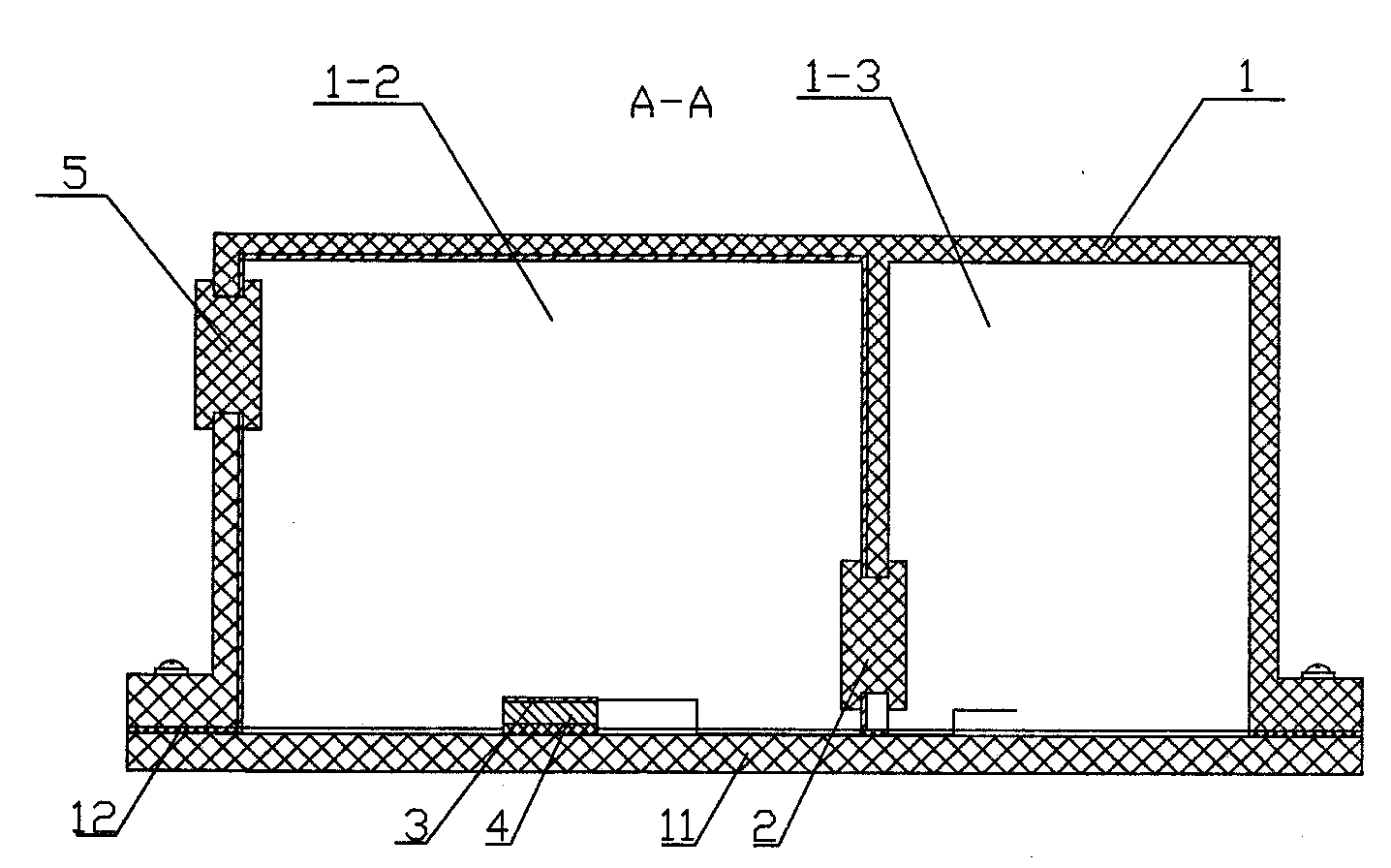

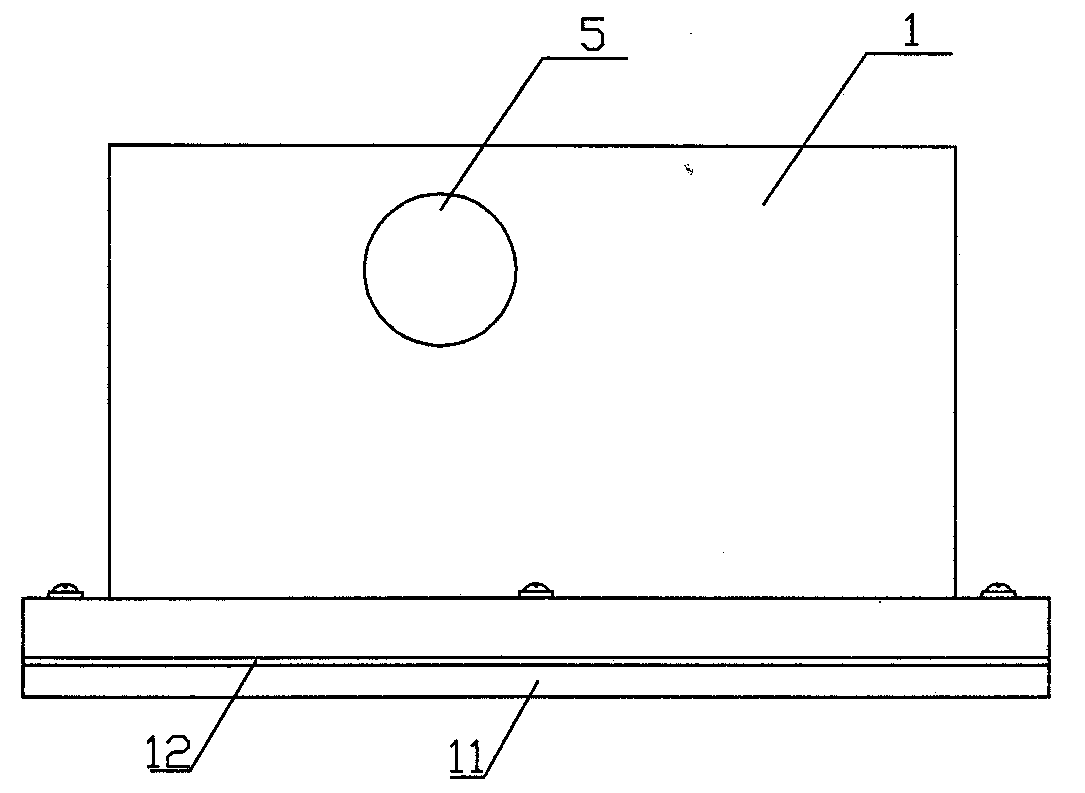

Device and method for measuring concentration of <222>Rn and <220>Rn synchronously by adopting electrostatic collection and solid nuclear track

ActiveCN103983999ASimple and reliable measurement processThe calculation method is simple and reliableRadiation intensity measurementMeasurement deviceEtching

Owner:HENGYANG NORMAL UNIV

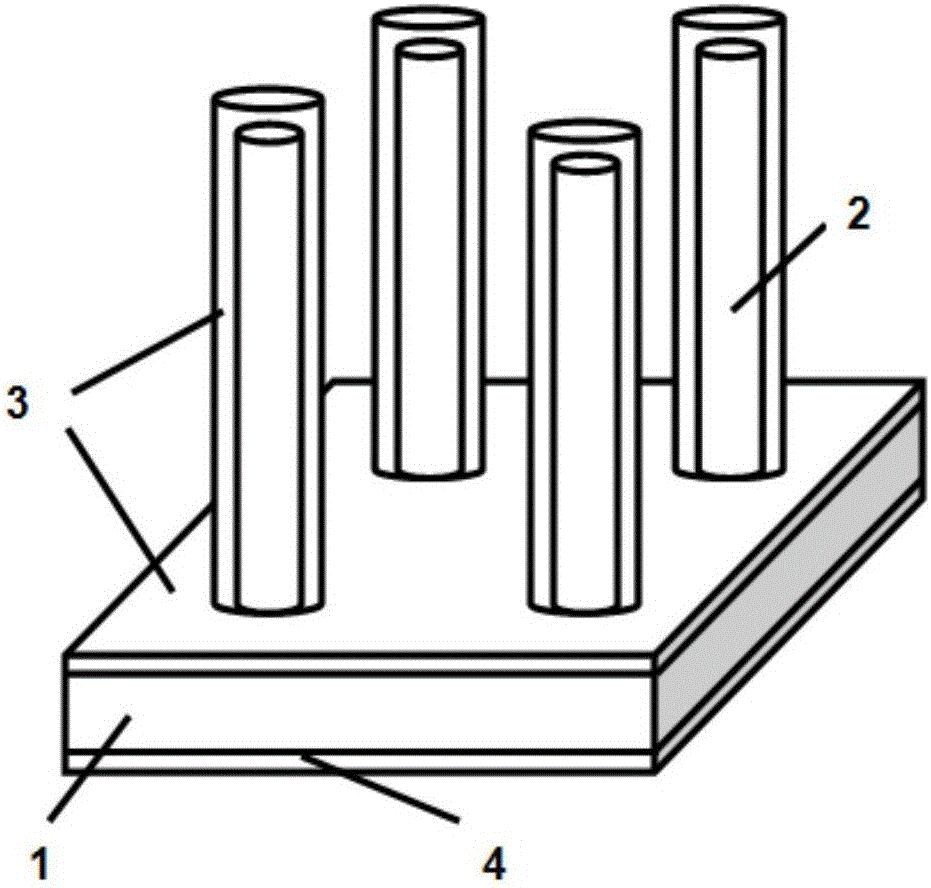

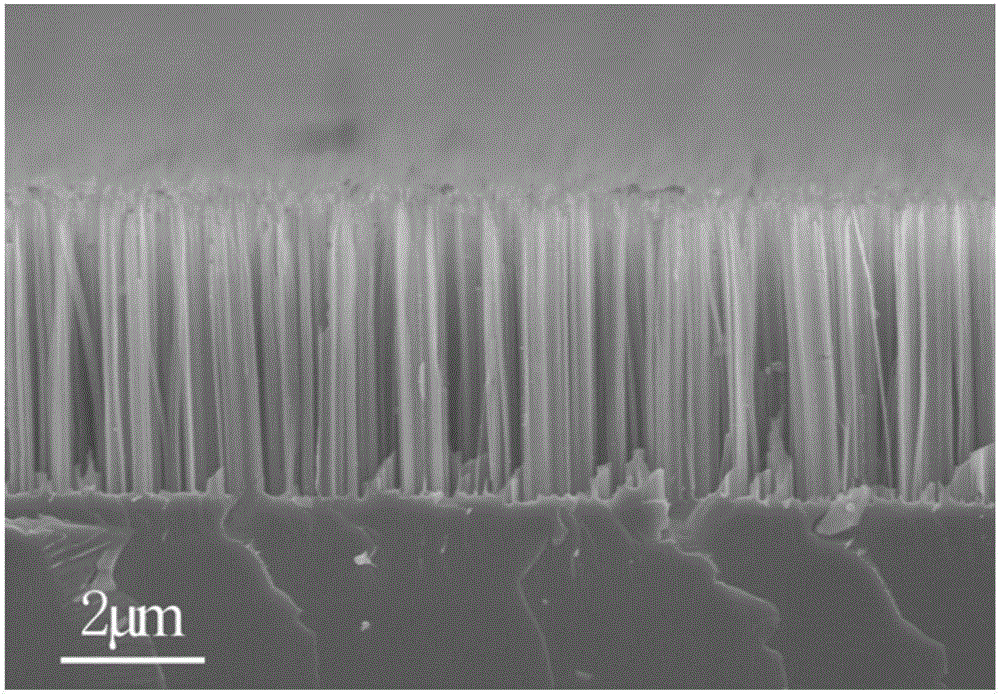

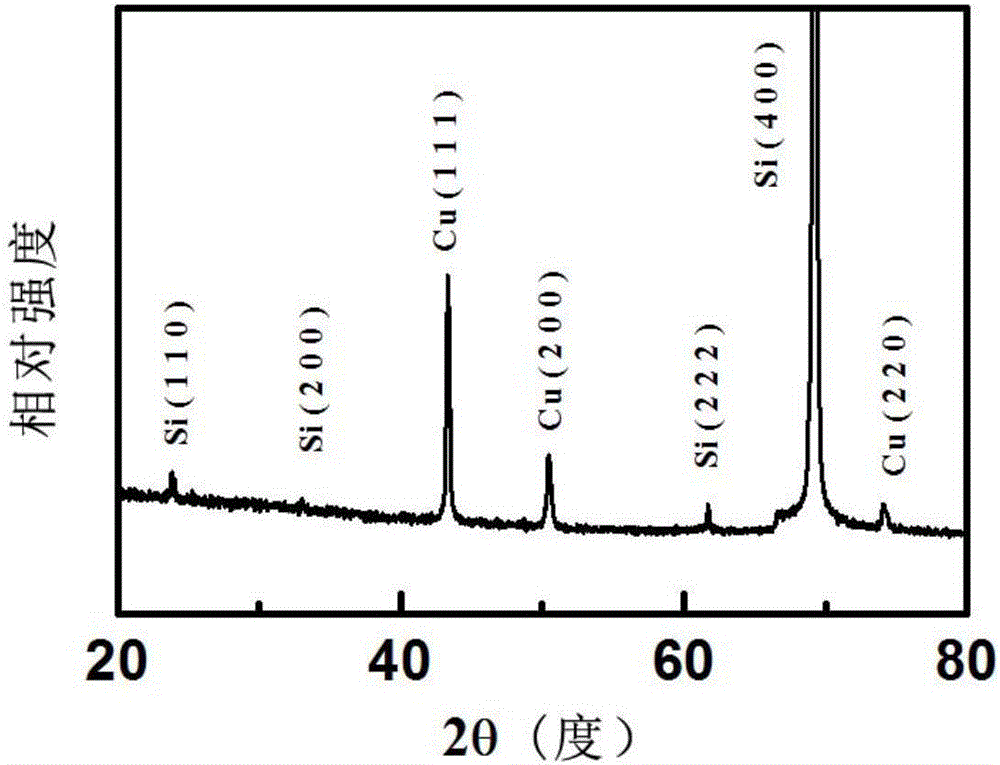

Self-driven Schottky junction near-infrared photoelectric detector based on silicone nanowire array and preparation method of photoelectric detector

InactiveCN105702774AGood process compatibilityRealize industrial productionFinal product manufactureSemiconductor devicesEtchingOhmic contact

Owner:HEFEI UNIV OF TECH

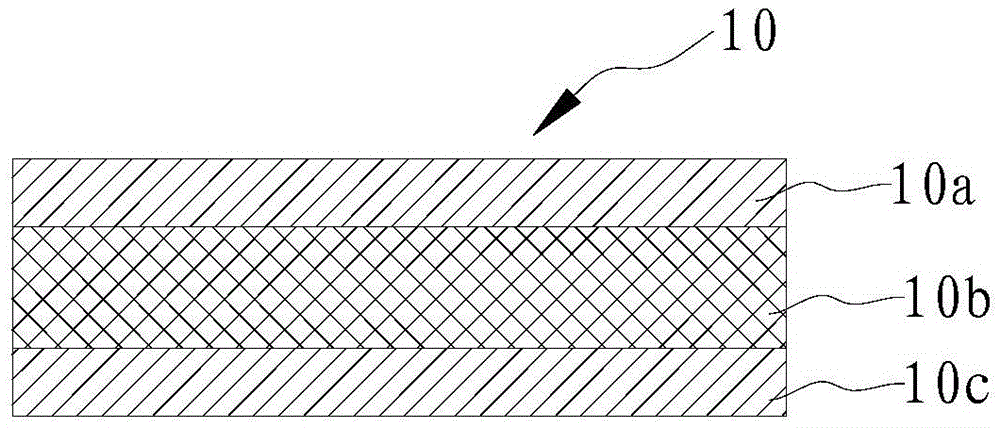

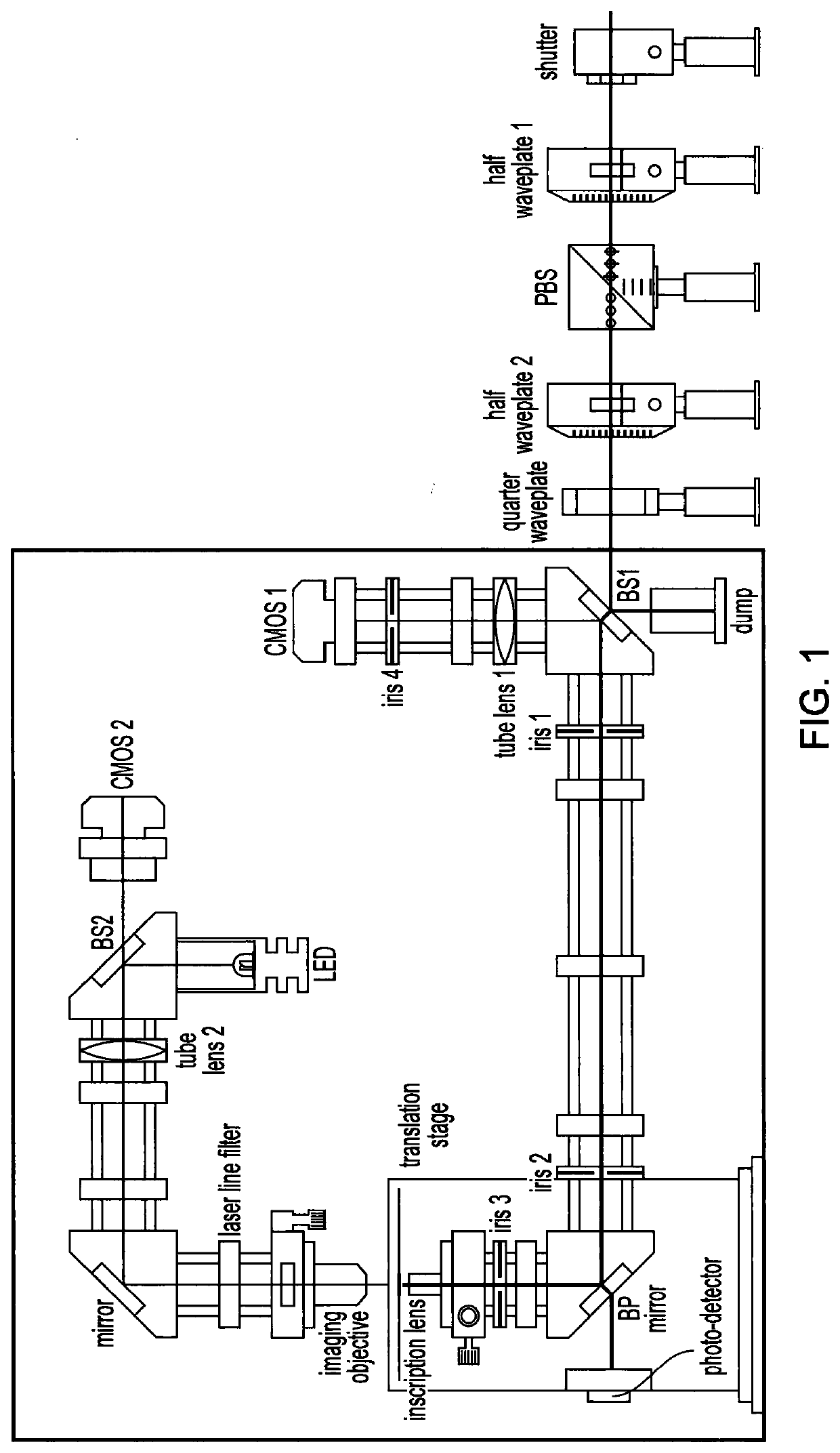

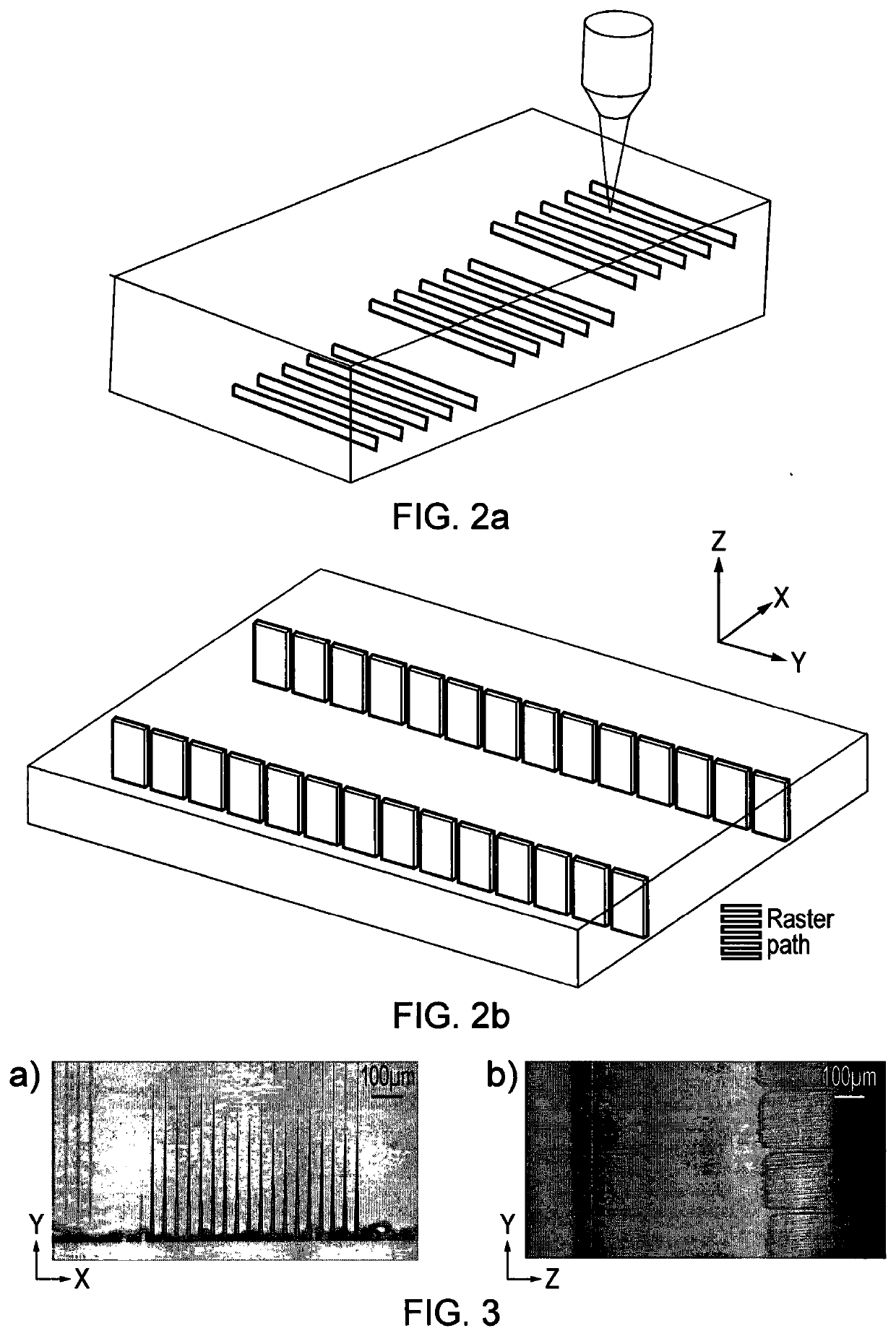

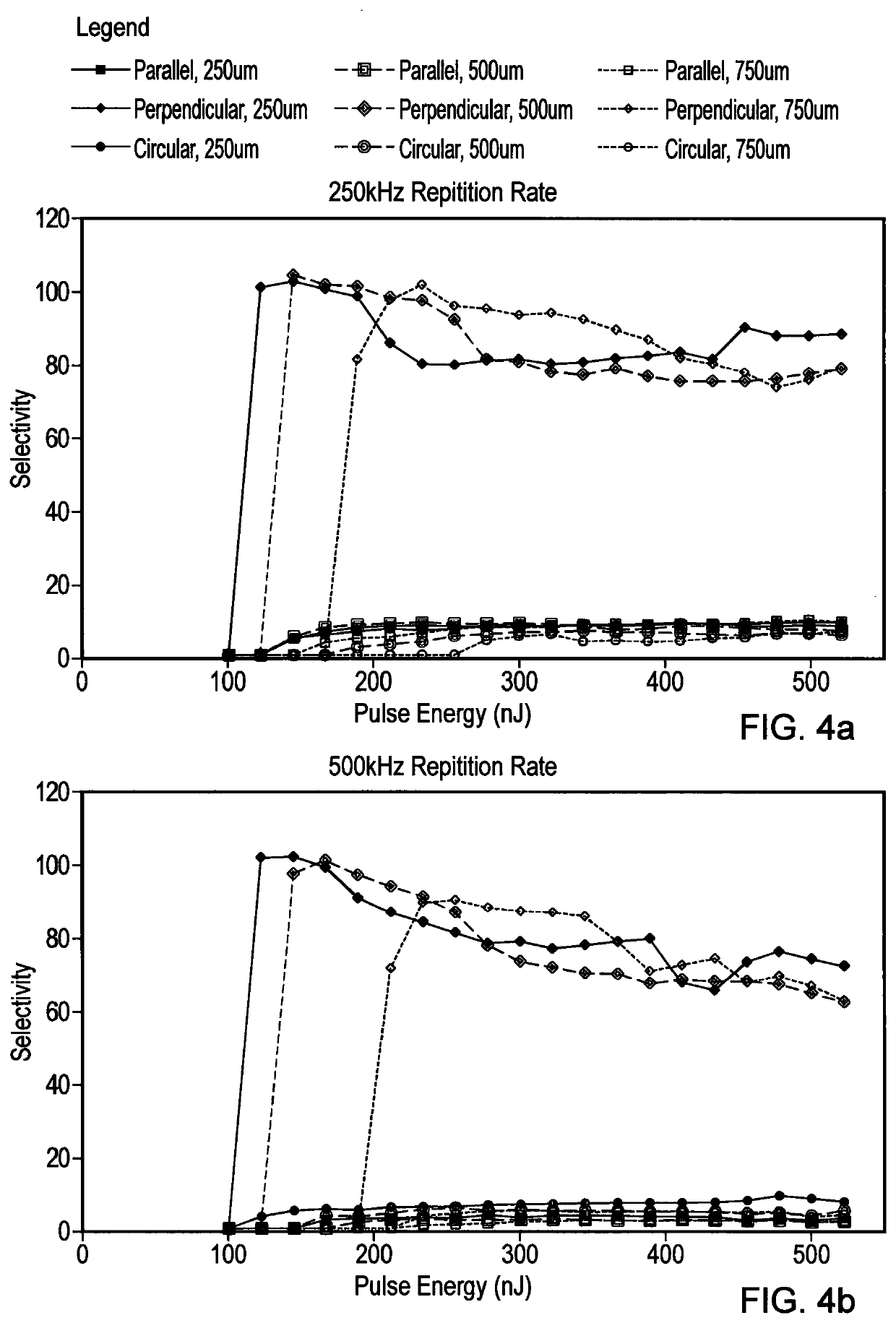

Direct laser writing and chemical etching and optical devices

ActiveUS20190361174A1Increase the area ratioSimplify polishingOptical articlesEndoscopesPhysicsEtching

Owner:HEROIT WATT UNIV

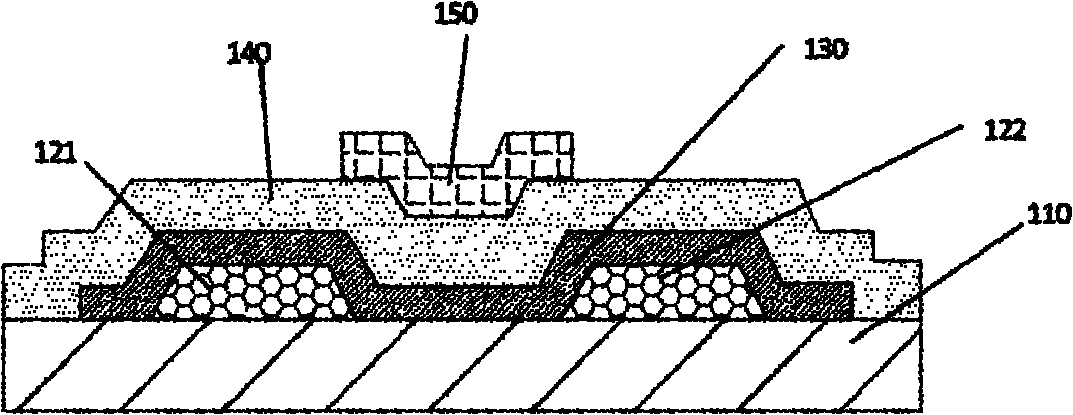

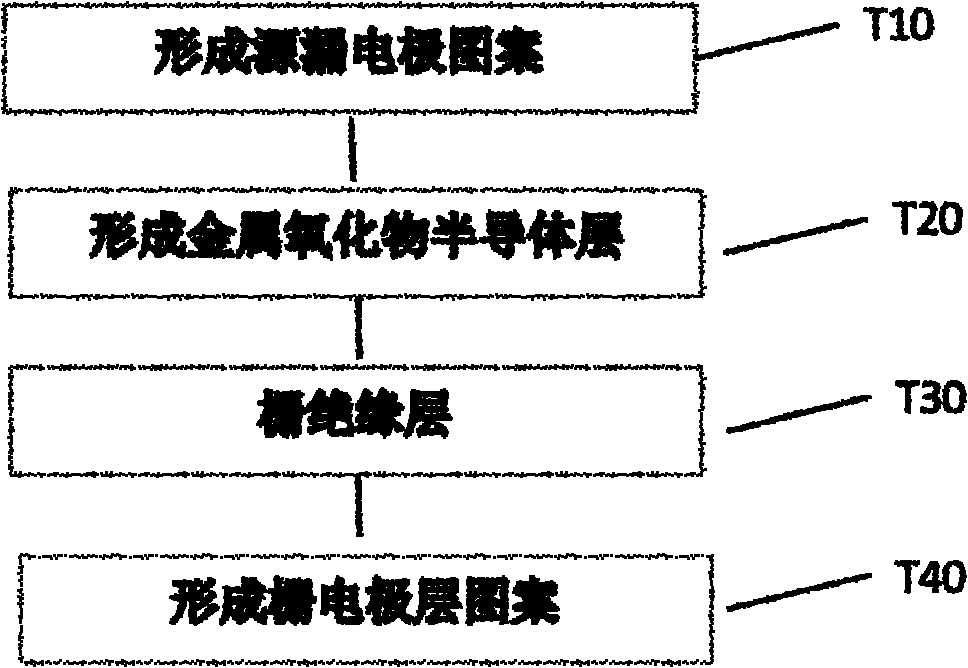

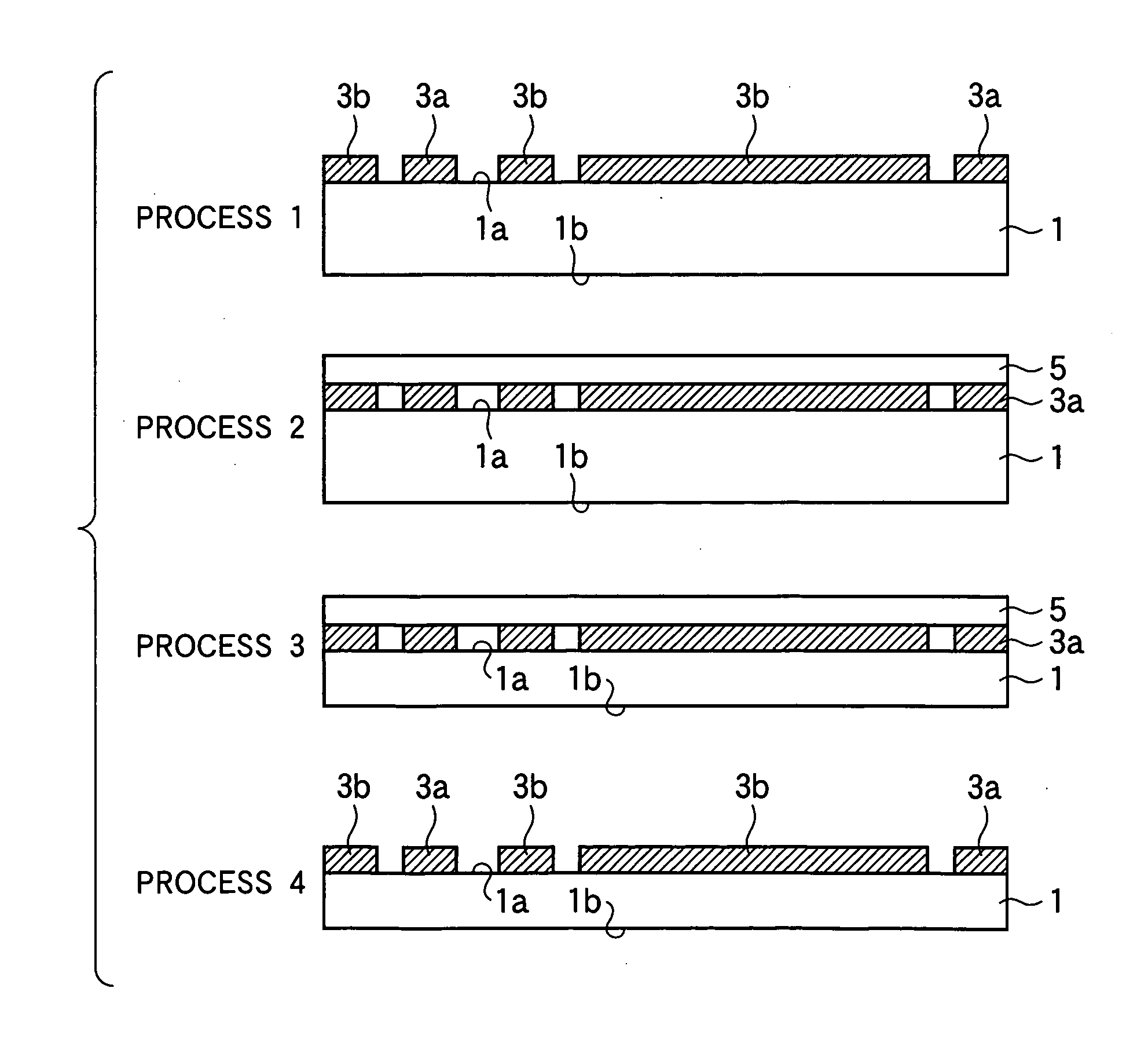

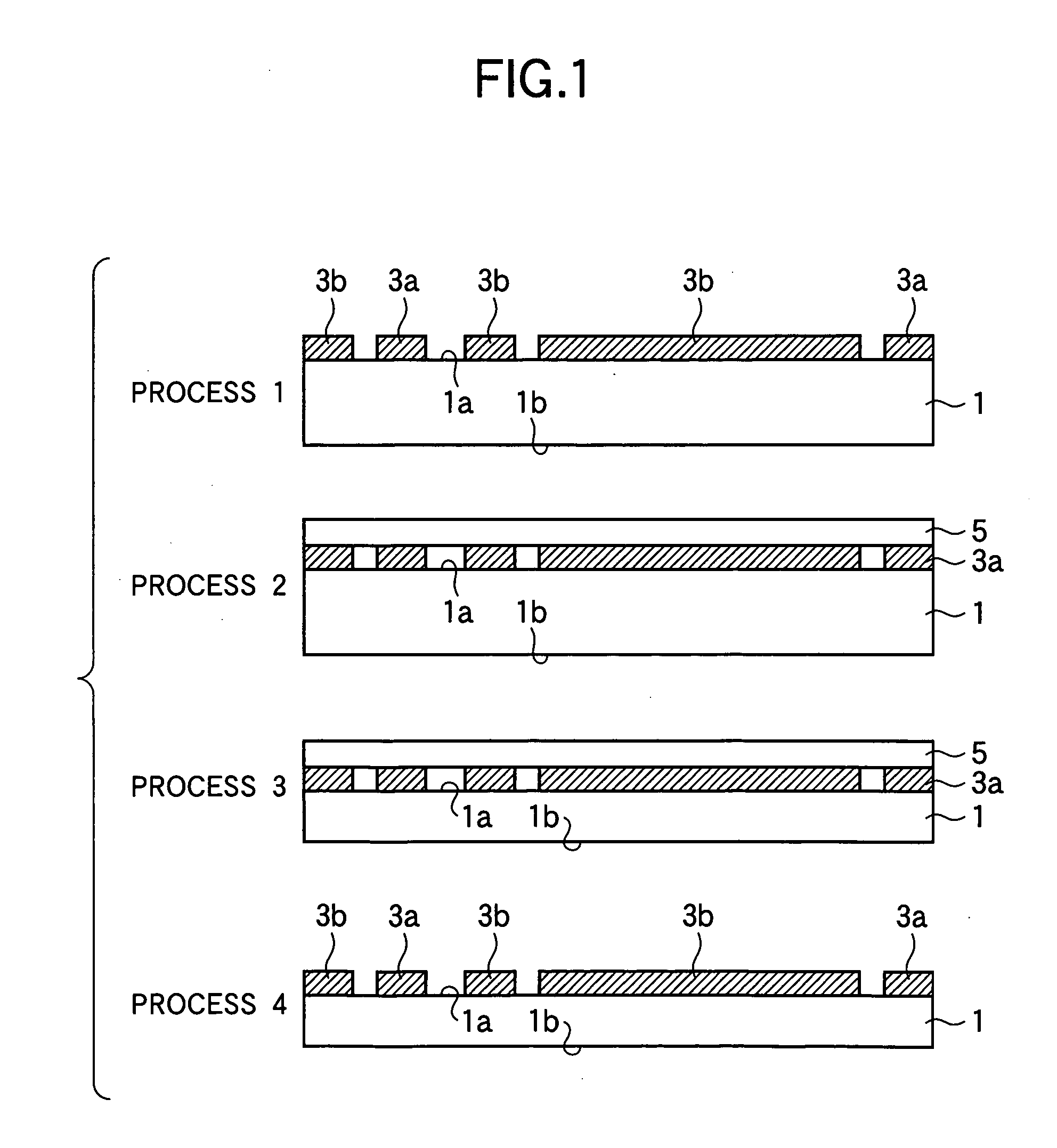

Photoelectric conversion element, method of manufacturing photoelectric conversion element, and electronic device

ActiveUS20140077321A1Avoid residueSuppress corrosion of the first conductive filmFinal product manufactureSolid-state devicesEtchingPhotoelectric conversion

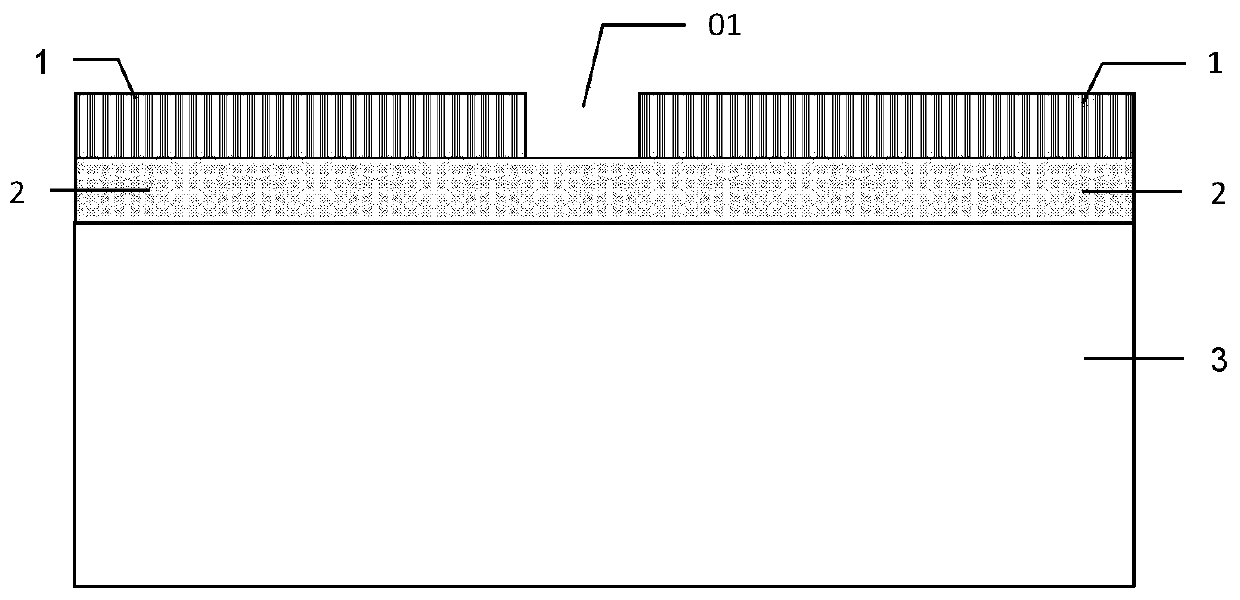

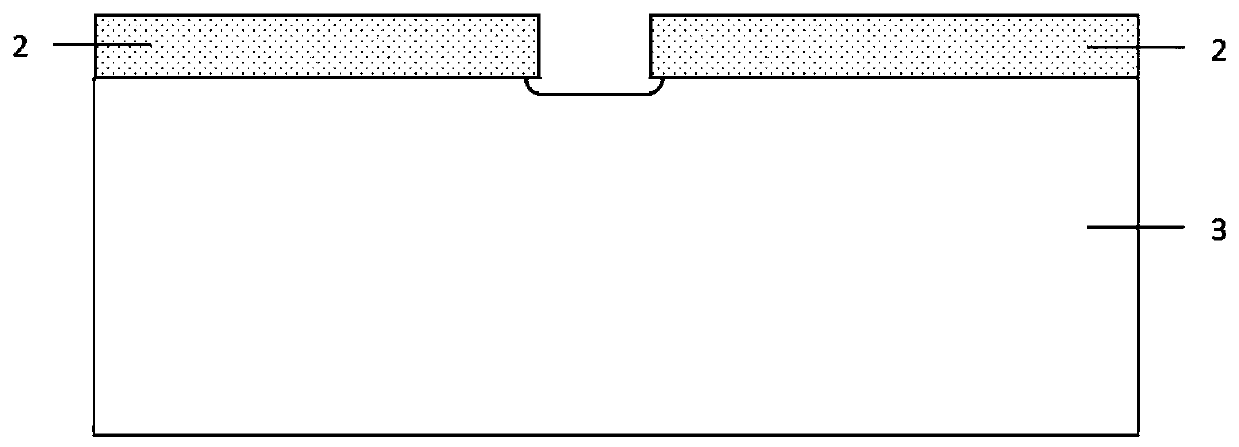

A method of manufacturing a photoelectric conversion element, which is provided with a substrate, a first electrode film having first and second conductive films provided on the substrate, a metal compound film covering the first electrode film, a semiconductor film connected with the metal compound film, a second electrode film connected with the semiconductor film, and an insulating film covering and surrounding the substrate, the first electrode film, the semiconductor film, and the metal compound film, the method including: forming the first conductive film to be connected with the substrate and the second conductive film to be connected with the first electrode film; forming the second conductive film in a predetermined shape using wet etching after the forming of the first and second conductive films, and forming the metal compound film which covers the first electrode film after the forming of the metal compound film.

Owner:SEIKO EPSON CORP

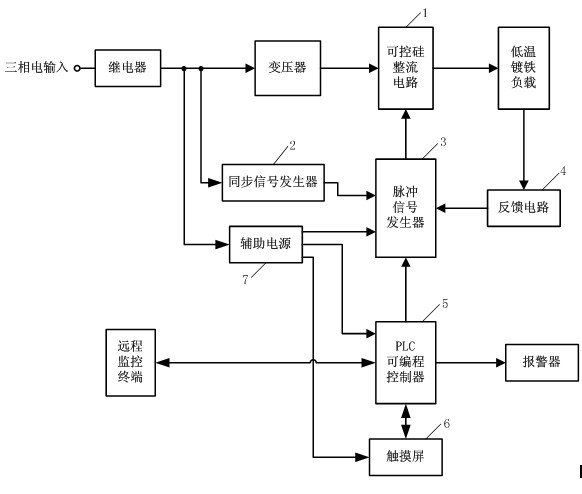

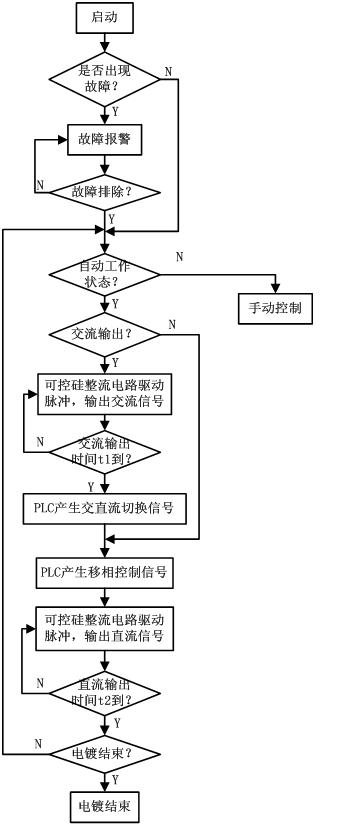

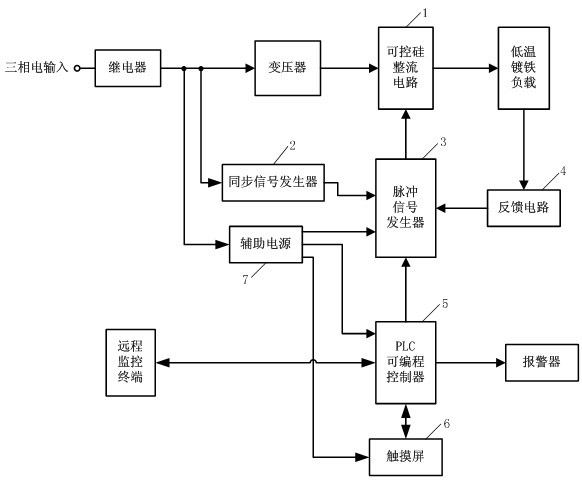

Intelligent power supply device for low-temperature etching-free iron plating process and power supply method thereof

InactiveCN102185498AAC and DC amplitude adjustmentStrong reliabilityAc-dc conversionSilicon-controlled rectifierEtching

Owner:HUANGSHAN JINYI POWER SUPPLY

Plasma treatment method

ActiveCN105720006ASolid-state devicesSemiconductor/solid-state device manufacturingEtchingSemiconductor structure

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

A kind of etching method of diffusion layer of crystalline silicon solar cell

InactiveCN102290491ASimple processLow equipment requirementsAfter-treatment detailsFinal product manufactureEtchingPhosphoric acid

Owner:WUXI SAIJING SOLAR

Phosphorus-doped amorphous diamond film electrode and preparation method of the same

InactiveCN1963484ASemiconductor/solid-state device manufacturingMaterial electrochemical variablesIonEtching

Owner:HARBIN INST OF TECH

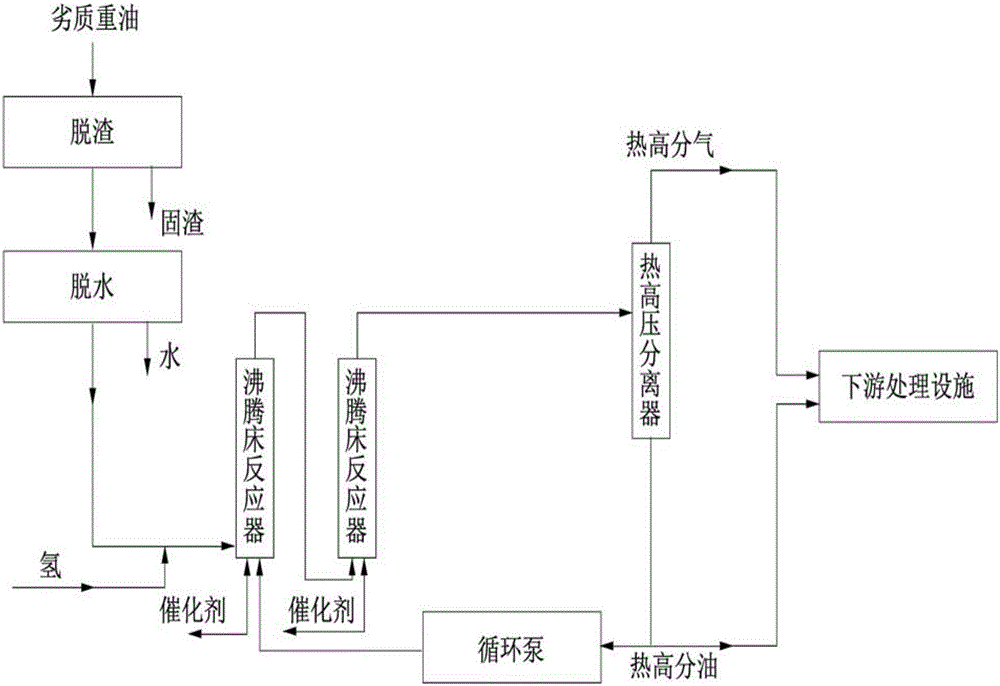

Method for arranging circulating pump in fluidized bed hydrogenation device

ActiveCN106701160AEfficient separationLess investmentHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenEtching

Owner:上海竣铭化工工程设计有限公司

Method for preventing abnormal chip etching caused by damage to parts

Owner:HEJIAN TECH SUZHOU

Atomic-scale precision lossless layer-by-layer etching method for two-dimensional layered material

ActiveCN113421826APrecise control of diffusion depthAtomic precision controlFinal product manufactureSemiconductor/solid-state device manufacturingEtchingChemical reaction

The invention provides an atomic-scale precision lossless layer-by-layer etching method for a two-dimensional layered material. The method comprises the following steps of: manufacturing lattice defects on the surface layer of a material to be etched by using a surface treatment technology; depositing a thermal diffusion sacrificial material on the surface layer of the material to be etched; performing thermal annealing on the material to be etched at a certain temperature, so that the diffusion sacrificial material is diffused into the surface layer of the material to be etched to form an alloy layer; and removing the diffusion sacrificial material and the alloy layer thereof by using a selective chemical reaction to finish local etching, wherein the two-dimensional layered material to be etched comprises one or a combination of metal sulfide, metal selenide, metal telluride, graphene and black phosphorus, and the diffusion sacrificial material comprises one or combination of low-atomic-radius metal, low-atomic-radius non-metal material and small-molecular organic matter. The sacrificial layer does not diffuse into an internal retention layer of the material to be etched, so that the etching process does not damage crystal lattices of the material retention layer, the intrinsic electrical property of the material is maintained, and the atomic-scale precision lossless layer-by-layer etching method is a lossless etching technology.

Owner:NANJING UNIV

Alignment method of photoetching process

ActiveCN112394623AAchieve alignmentReduce complexitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusConvex structureGraphics

Owner:ZHEJIANG HIKSTOR TECHOGY CO LTD

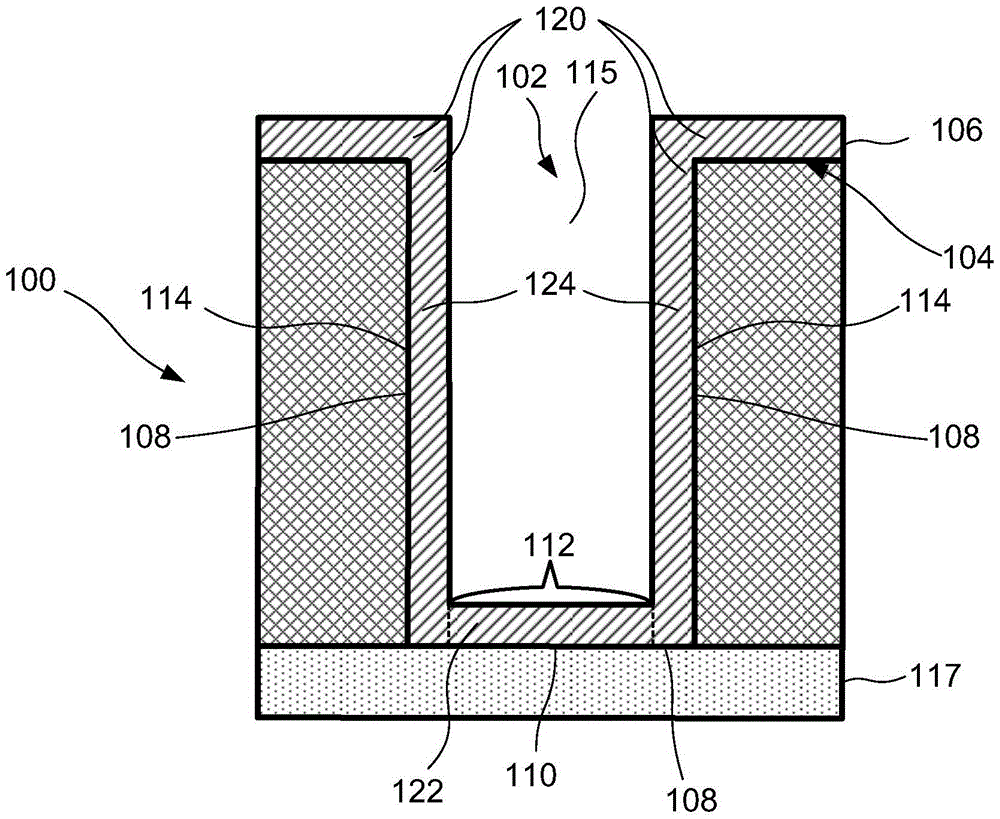

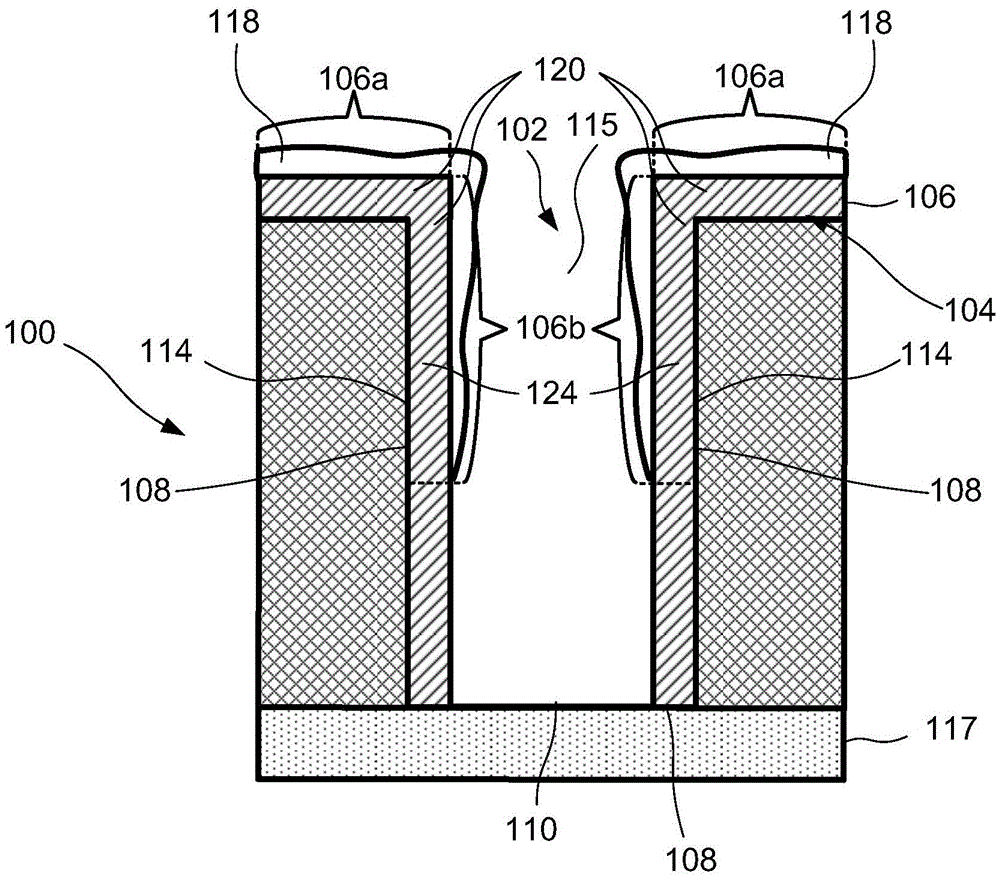

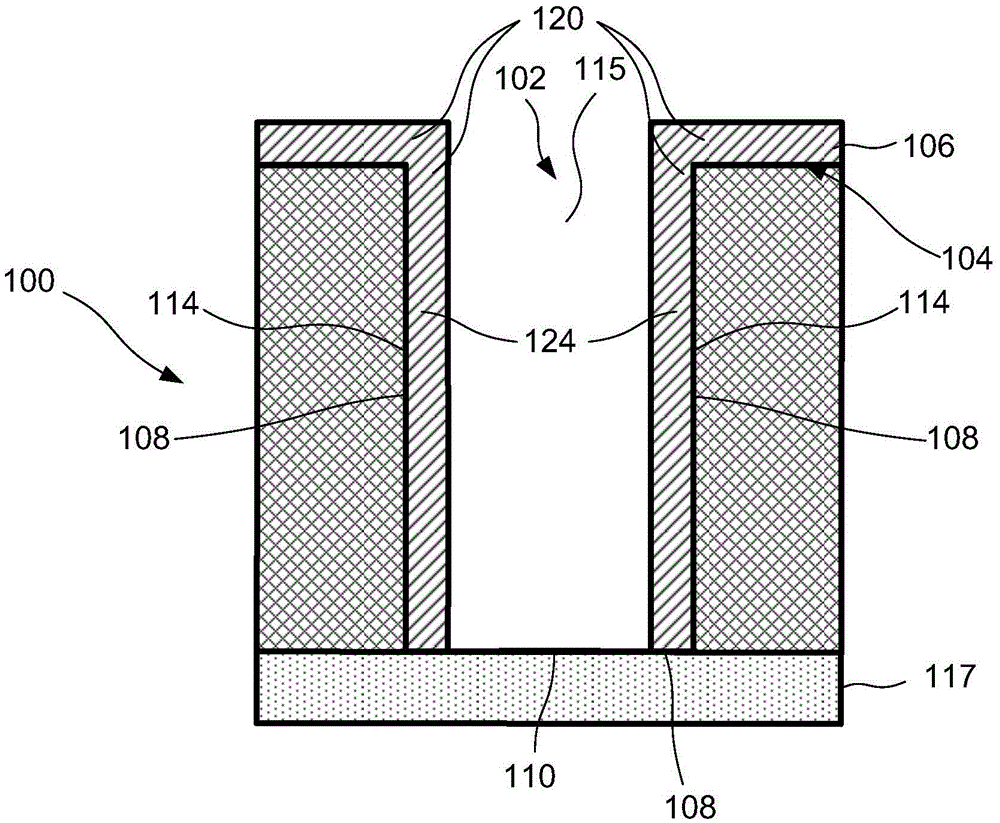

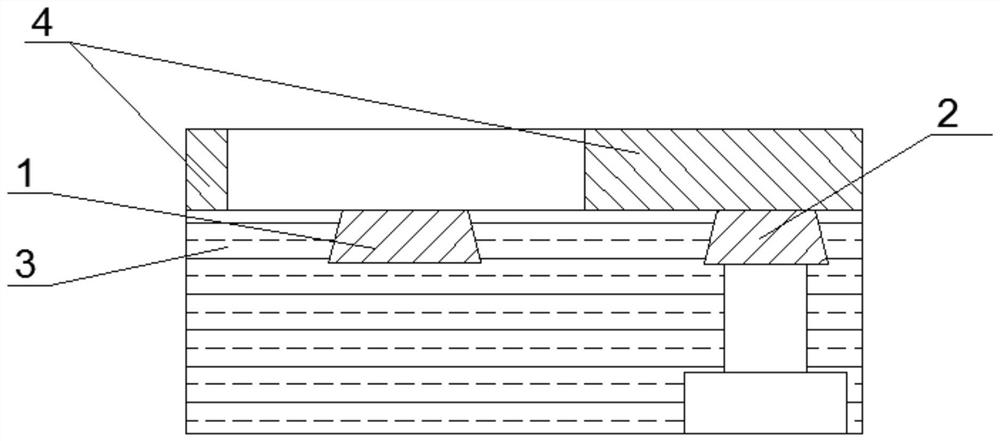

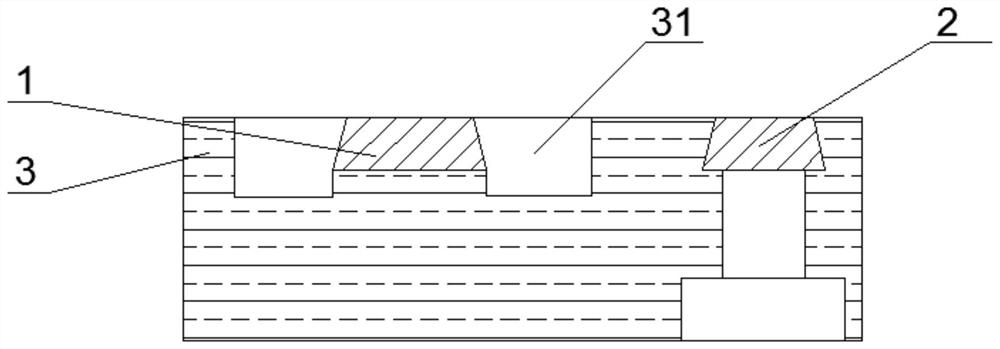

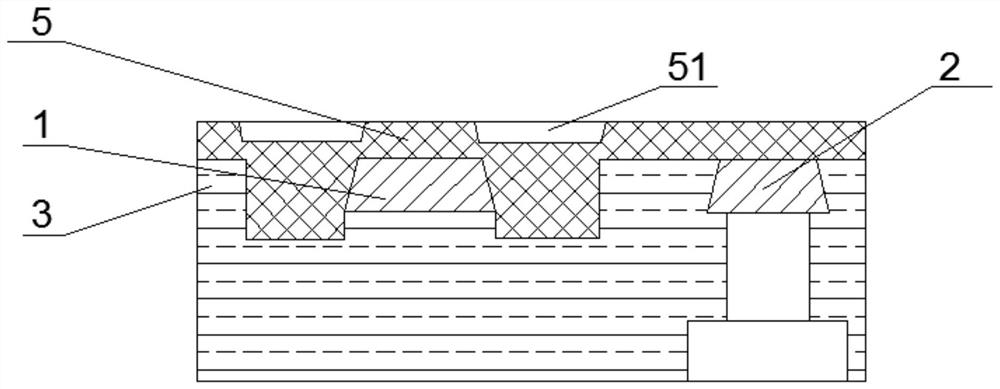

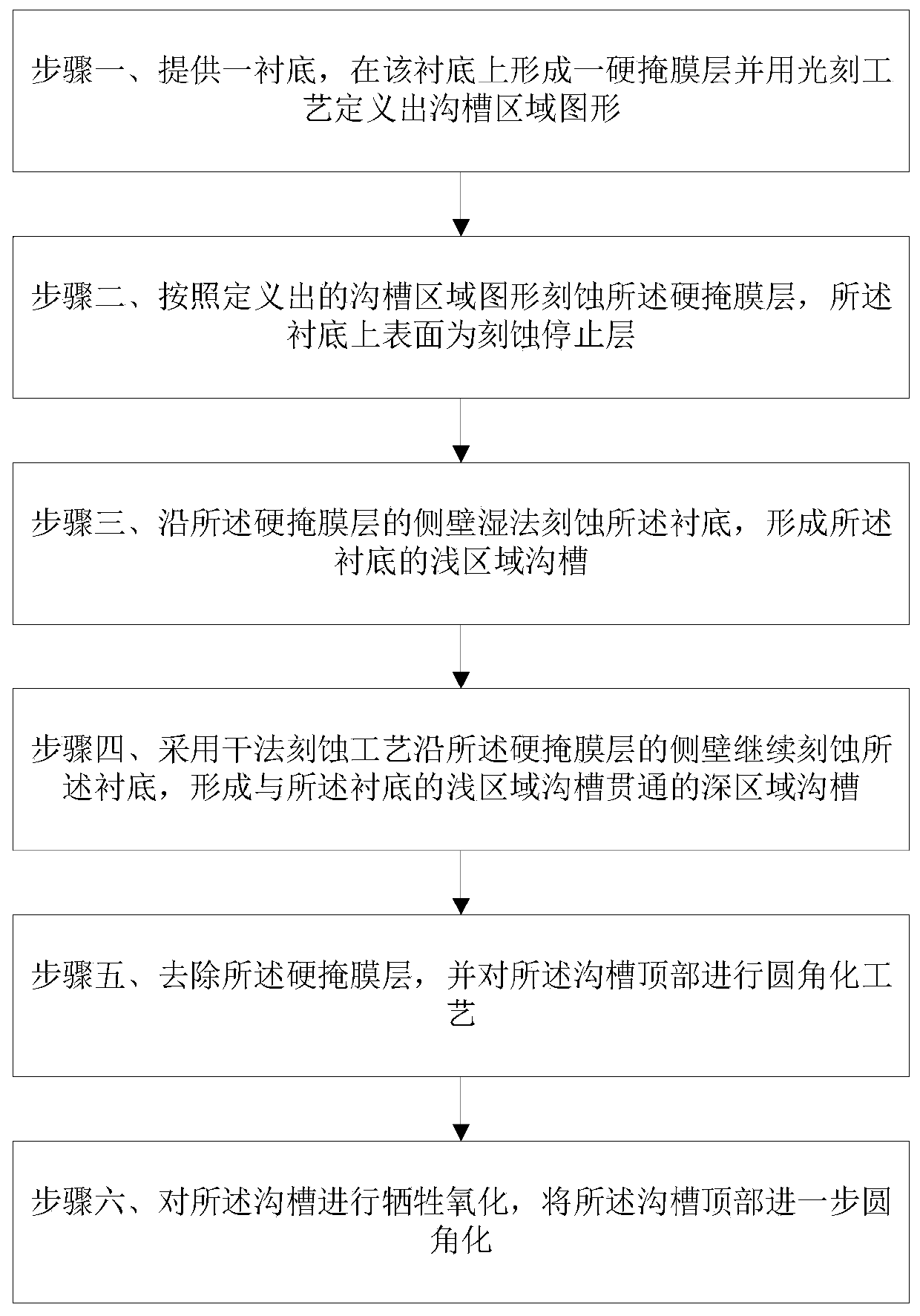

Method for rounding top of trench

InactiveCN110993497ASimple processReduce manufacturing costSemiconductor/solid-state device manufacturingEtchingLithography process

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

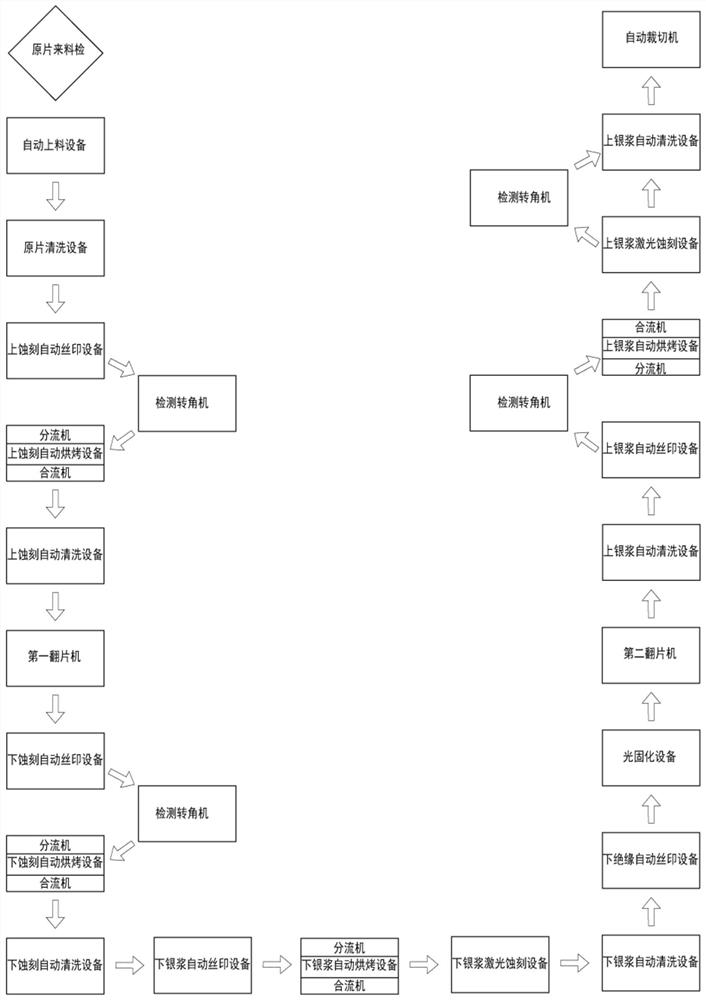

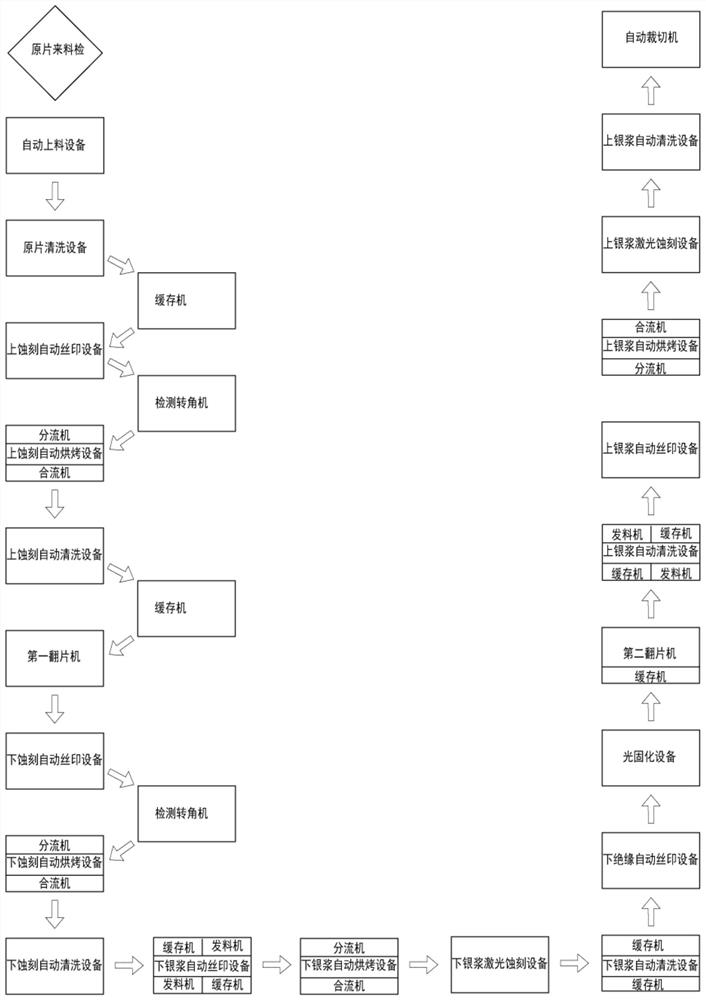

Automatic line body for front-section printing of touch screen

Owner:LIANCHENG ZHONGCHU ELECTRONICS CO LTD

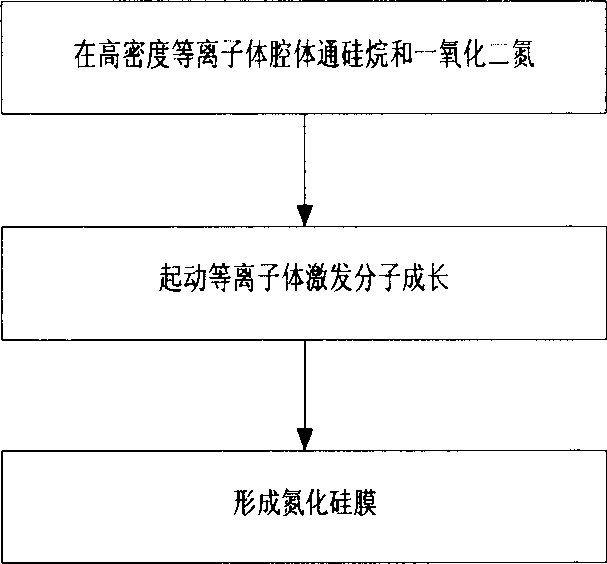

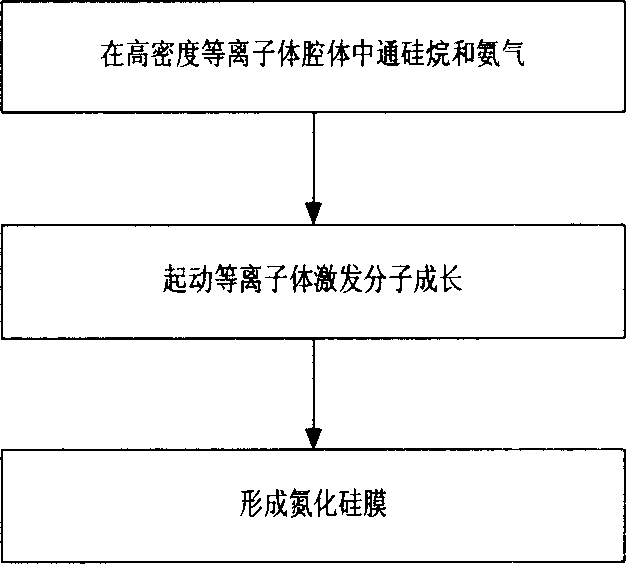

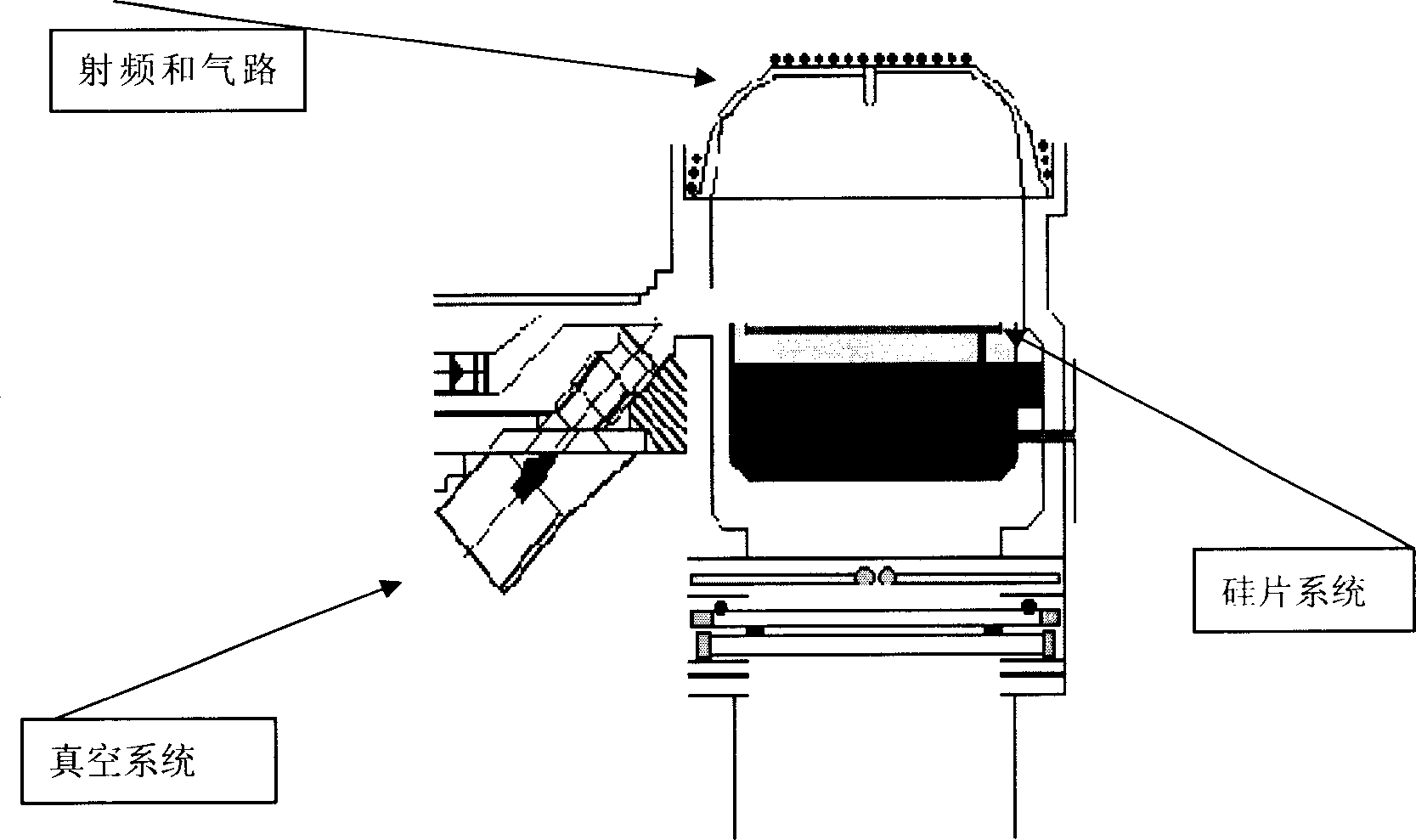

Growth of silicon-nitride film

ActiveCN1855386AGood filling effectSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh densityEtching

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

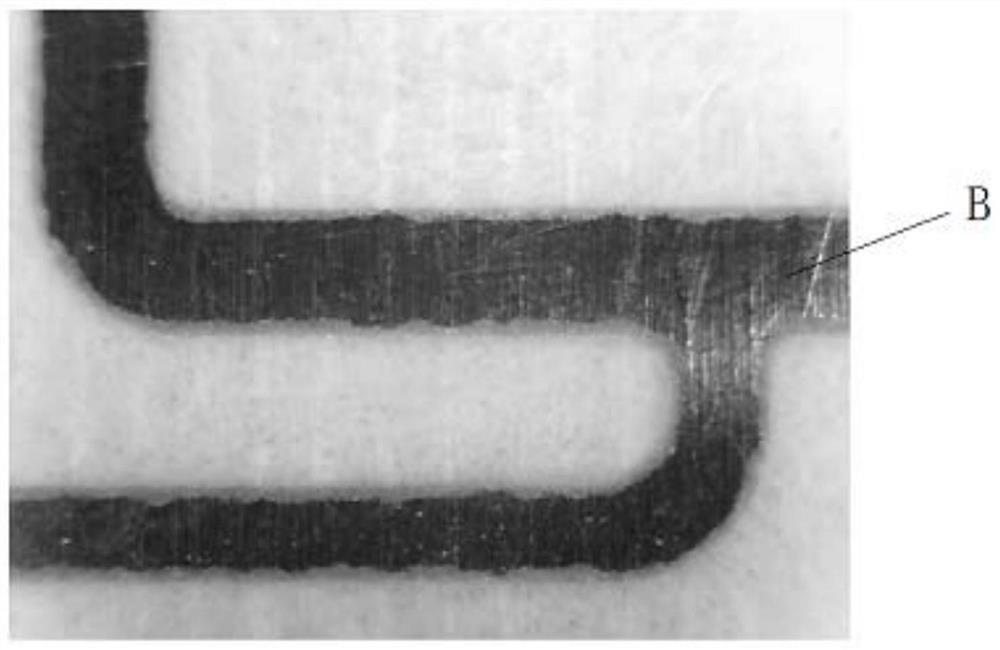

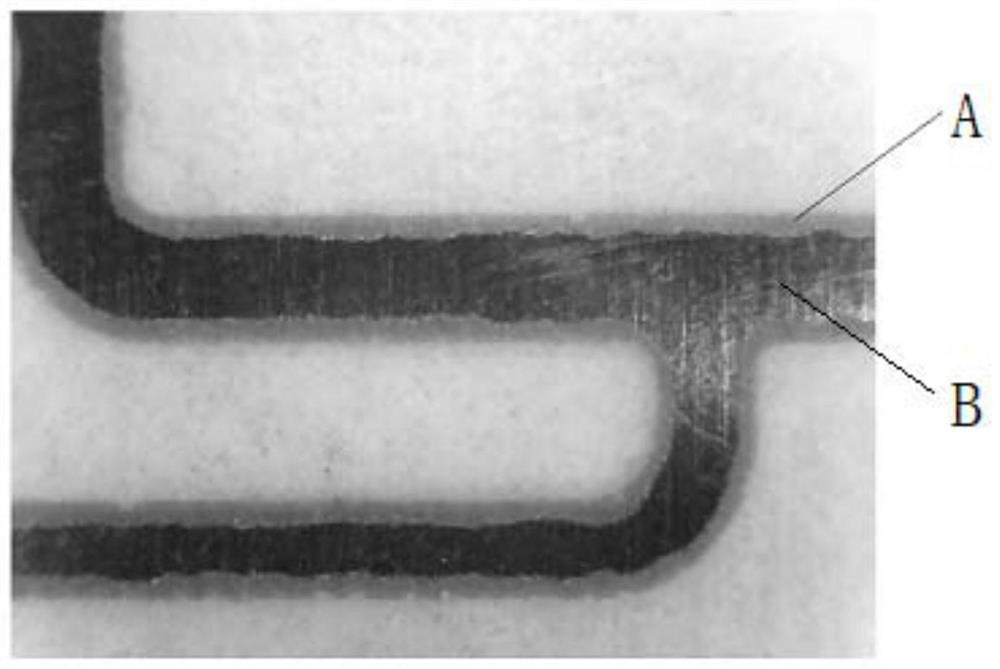

Corrosion inhibitor for reducing lateral etching of etched antennas and using method thereof

PendingCN112239869AImprove stabilityMeet environmental protection requirementsEtchingHexamethylenetetramine

Owner:HANGZHOU DIANZI UNIV

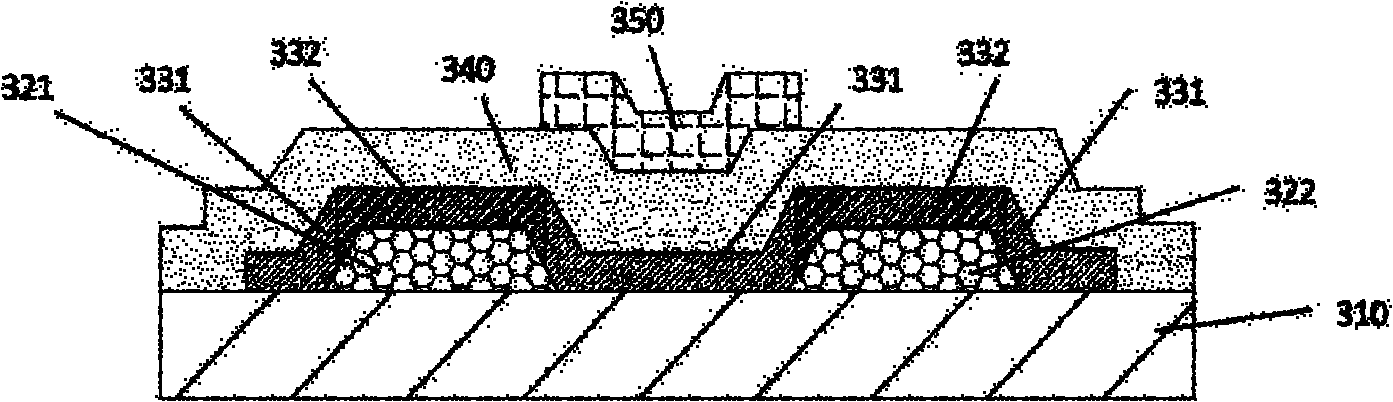

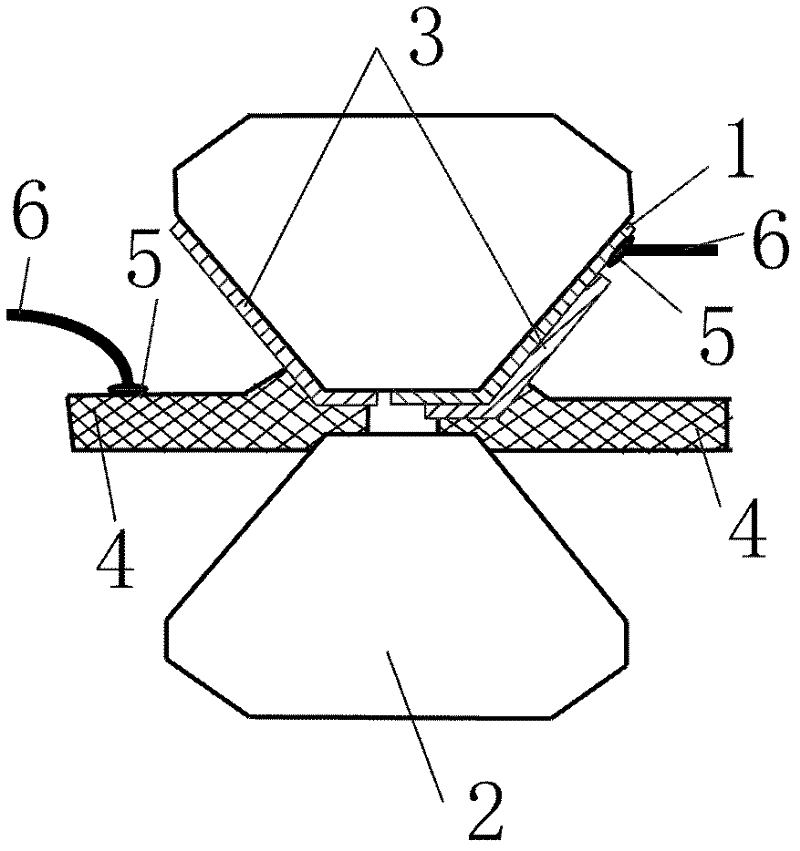

Micro-electromechanical switch fabricated by simultaneous formation of a resistor and bottom electrode

The present invention provides a method and product-by-method of integrating a bias resistor in circuit with a bottom electrode of a micro-electromechanical switch on a silicon substrate. The resistor and bottom electrode are formed simultaneously by first sequentially depositing a layer of a resistor material (320), a hard mask material (330) and a metal material (340) on a silicon substrate forming a stack. The bottom electrode and resistor lengths are subsequently patterned and etched (350) followed by a second etching (360) process to remove the hard mask and metal materials from the defined resistor length. Finally, in a preferred embodiment, the bottom electrode and resistor structure is encapsulated with a layer of dielectric which is patterned and etched (370) to correspond to the defined bottom electrode and resistor.

Owner:TEXAS INSTR INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap