Method for manufacturing a semiconductor wafer

a manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, basic electric elements, electric devices, etc., can solve the problems of poor flatness of electrodes formed on difficult to remove ground particles by etching, and large number of ground particles that cannot be removed. , to achieve the effect of cleaning the back surface of semiconductor wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

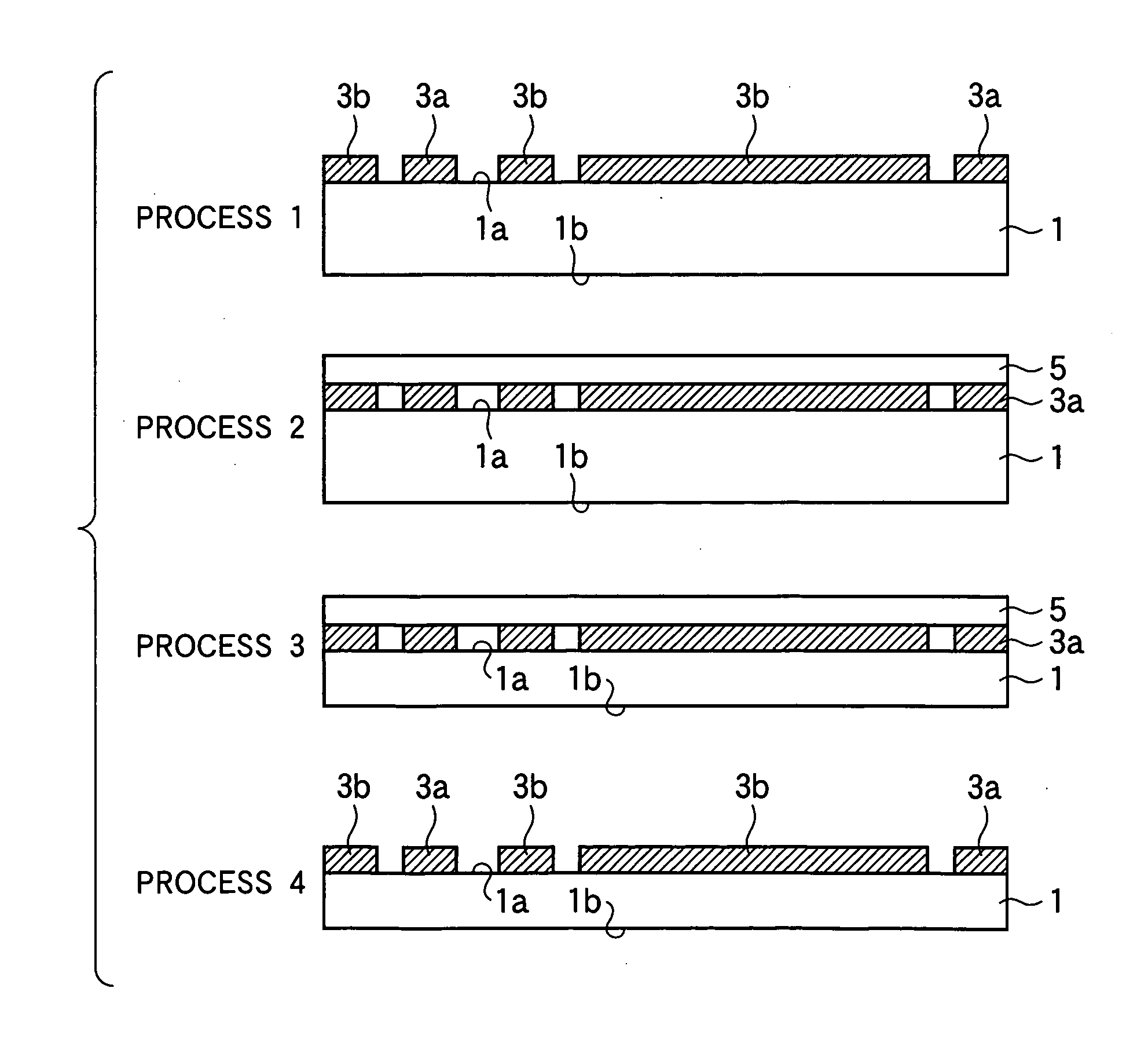

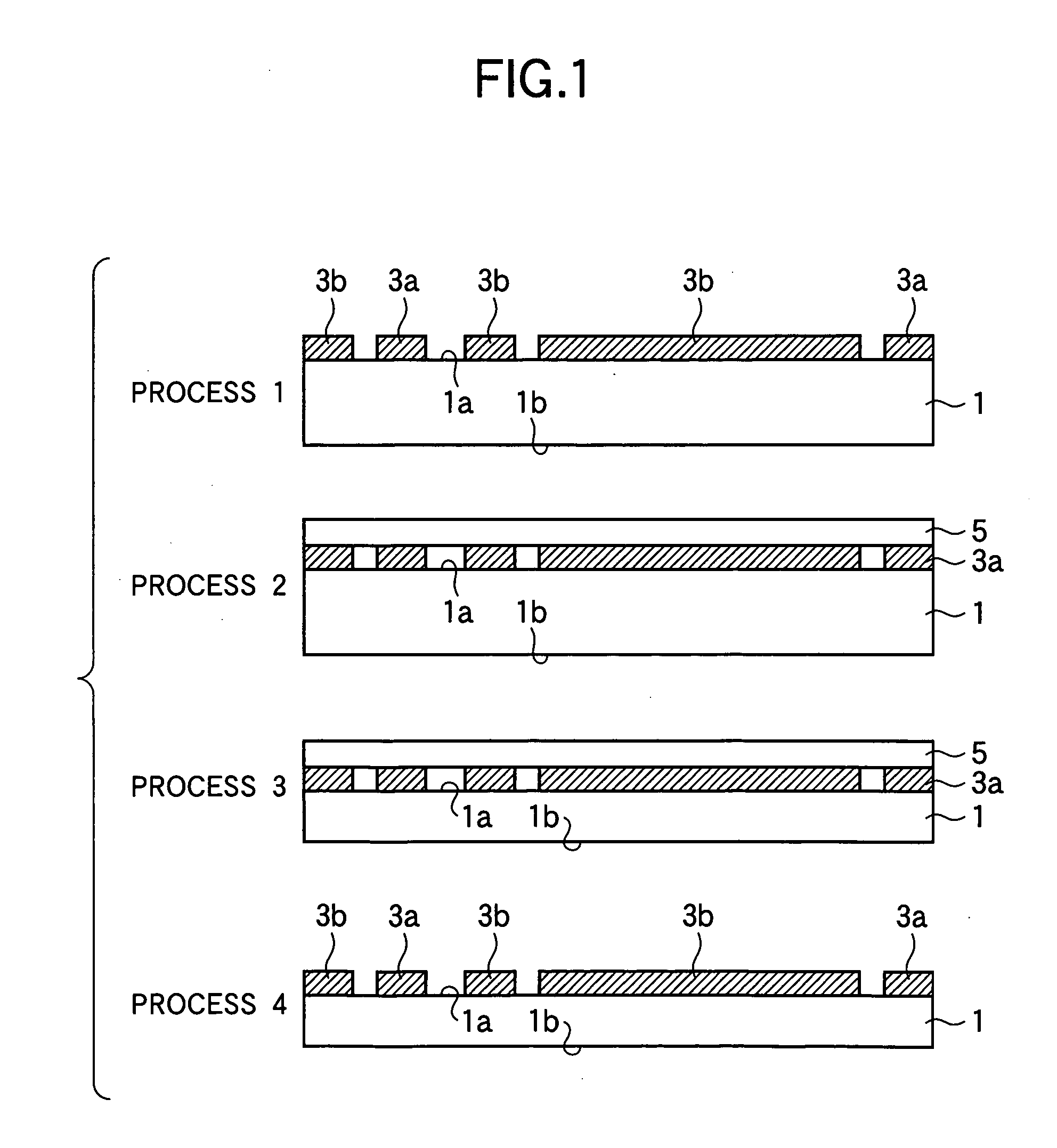

[0023]FIGS. 1 and 2 illustrate a method for manufacturing a semiconductor wafer according to the present invention. Referring to FIGS. 1 and 2, a semiconductor wafer 1 takes the form of a silicon substrate having a front surface la on which a plurality of semiconductor elements 3a (e.g., IGBTs) and surface electrodes 3b. The surface electrodes 3b serve as an anode electrode for the semiconductor elements. A protection tape 5 is a tape having an adhesive-coated side, and is used for use in a back grinding process. The protection tape 5 is attached to the semiconductor wafer 1 by placing the adhesive-coated side on the front surface 1a of the semiconductor wafer 1. The protection tape 5 protects the surface electrodes 3 formed on the front surface 1a of the semiconductor wafer 1 from damage, and prevents ground particles or debris from adhering to the surface electrode 3 during the back grinding process (later described “Process 3”).

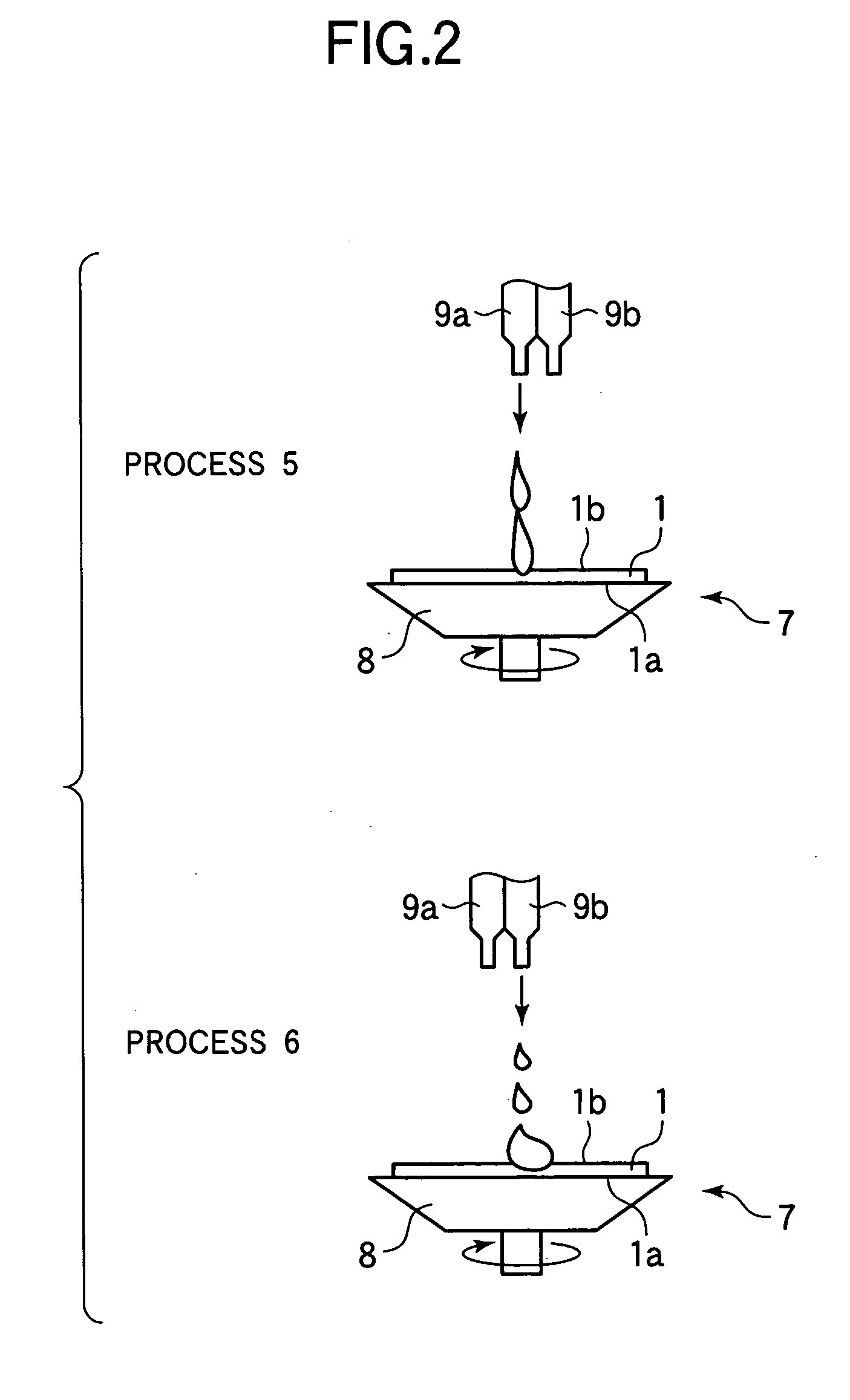

[0024] Referring to FIG. 2, a spin-etching apparatus 7

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap