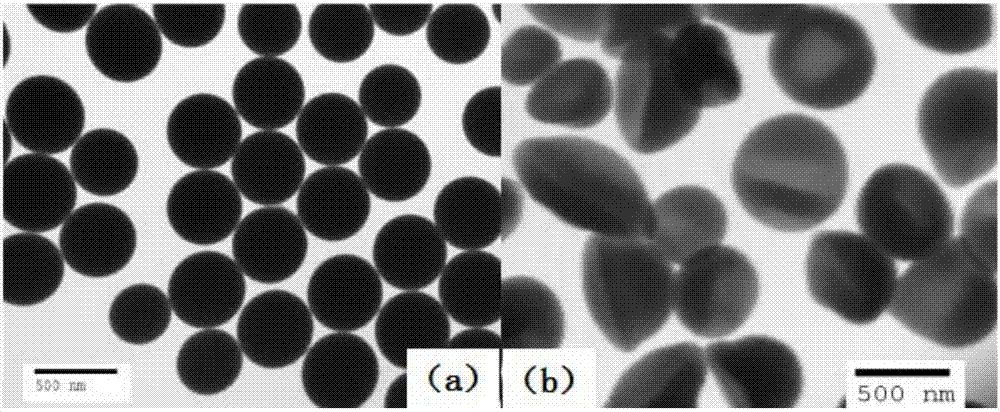

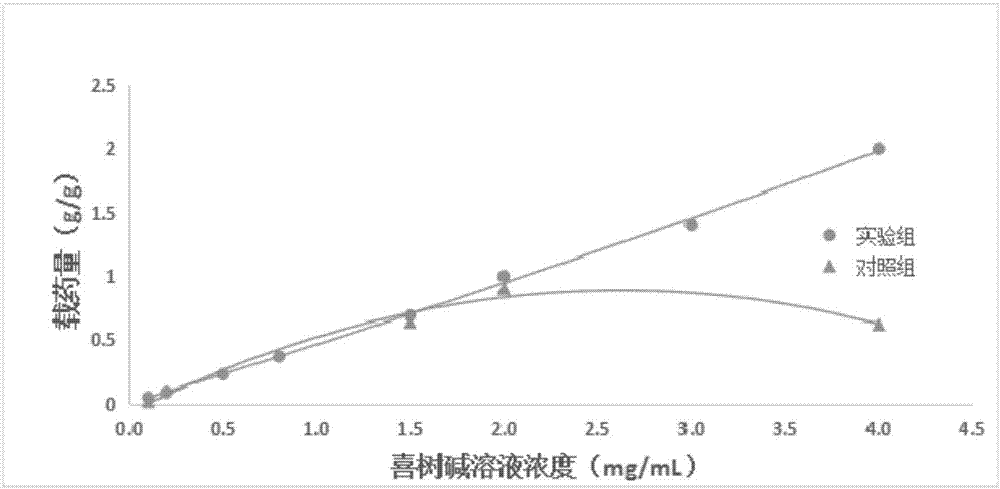

Hydrophilic hollow silicon sphere as well as preparation method and application thereof

A hollow silicon, hydrophilic technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, anti-tumor drugs, etc., can solve problems such as cytotoxicity, reduce toxic side effects, improve dispersibility, improve hydrophobicity and biological The effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of hydrophilic hollow silicon spheres, comprising the following steps:

[0028] (1) Preparation of nano-double-bonded silicon spheres by silane hydrolysis: Accurately measure 2.0 mL of vinyltriethoxysilane and add it to 30 mL of pure water, and mechanically stir at a speed of 300 r / min until vinyltriethoxysilane is completely dissolved , the solution becomes clear; then take 1mL of 5% (v / v) ammonia water and add it dropwise to the clear vinyltriethoxysilane solution while stirring. The dropwise addition is completed within 1.5h, and the stirring is continued for 1h after the dropwise addition , centrifuge, collect the precipitate, wash with absolute ethanol and water in sequence, and dry under reduced pressure at 40°C for 12 hours to obtain double-bonded silicon spheres;

[0029] (2) Preparation of glutathione-modified double-bond silicon spheres: Weigh 80 mg of the prepared double-bond silicon spheres and disperse them in 40 mL of acetonitrile to

Embodiment 2

[0032] A preparation method of hydrophilic hollow silicon spheres, comprising the following steps:

[0033] (1) Preparation of nano-double-bonded silicon spheres by silane hydrolysis: Accurately measure 3.0 mL of vinyltriethoxysilane into 50 mL of pure water, and mechanically stir at a speed of 350 r / min until vinyltriethoxysilane is completely dissolved , the solution becomes clear; then take 1mL of 5% (v / v) ammonia water and add it dropwise to the clear vinyltriethoxysilane solution while stirring. h, centrifuge, collect the precipitate, wash with absolute ethanol and water in sequence, and dry under reduced pressure at 40°C for 12 hours to obtain double-bonded silicon spheres;

[0034](2) Preparation of glutathione-modified double-bond silicon spheres: Weigh 100 mg of prepared double-bond silicon spheres and disperse them in 50 mL of acetonitrile; weigh 100 mg of glutathione and dissolve them in 13 mL of distilled water; combine the above two solutions , ultrasonically di

Embodiment 3

[0037] A preparation method of hydrophilic hollow silicon spheres, comprising the following steps:

[0038] (1) Preparation of nano-double-bonded silicon spheres by silane hydrolysis: Accurately measure 4.0 mL of vinyltriethoxysilane and add it to 70 mL of pure water, stir mechanically at a speed of 400 r / min until vinyltriethoxysilane is completely dissolved , the solution becomes clear; then take 1mL of 5% (v / v) ammonia water and add it dropwise to the clear vinyltriethoxysilane solution while stirring. The dropwise addition is completed within 1.5h, and the stirring is continued for 2h after the dropwise addition , centrifuge, collect the precipitate, wash with absolute ethanol and water in sequence, and dry under reduced pressure at 40°C for 12 hours to obtain double-bonded silicon spheres;

[0039] (2) Preparation of glutathione-modified double-bond silicon spheres: Weigh 120 mg of prepared double-bond silicon spheres and disperse them in 60 mL of acetonitrile; weigh 120

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap