Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about "Maintainance and safety accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

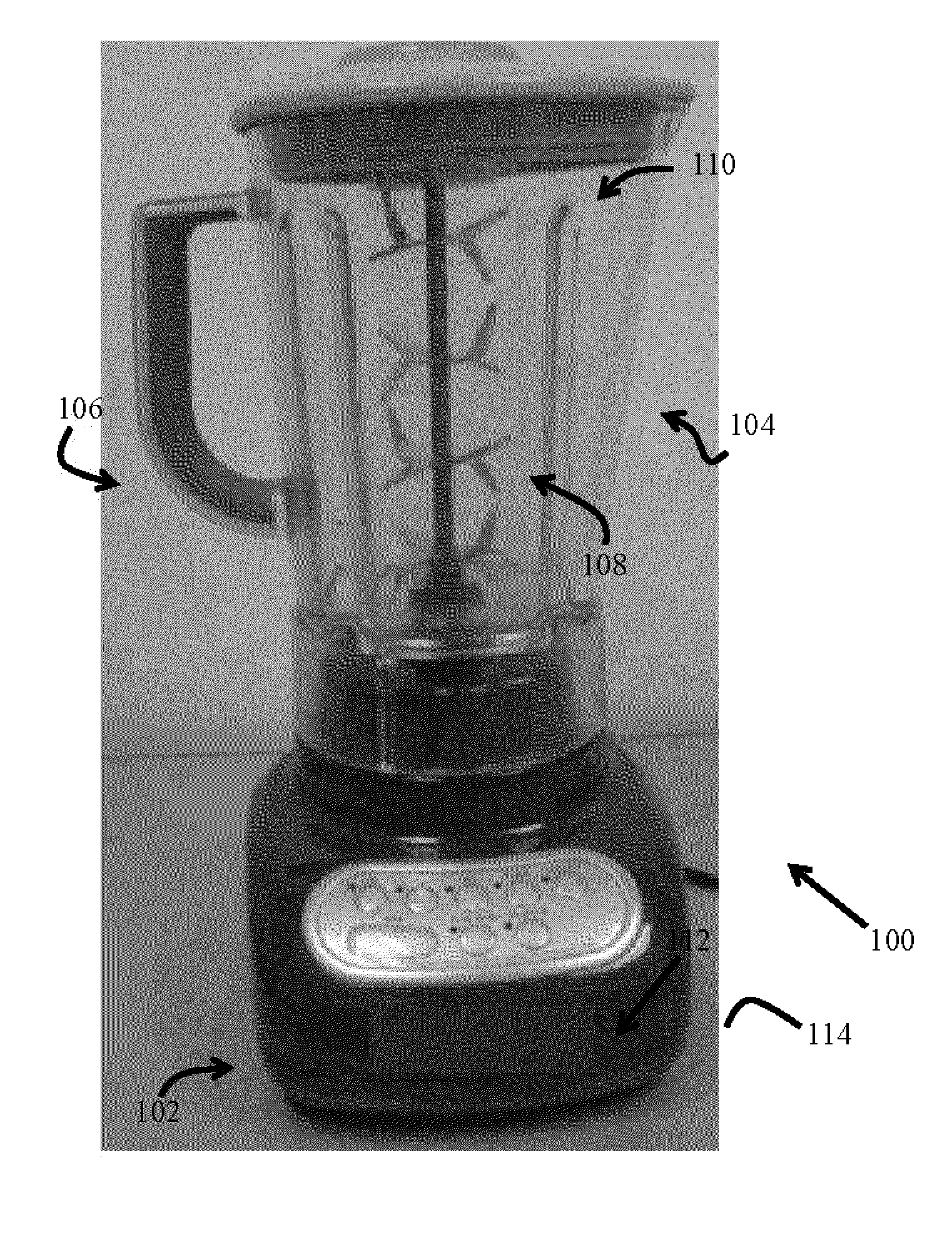

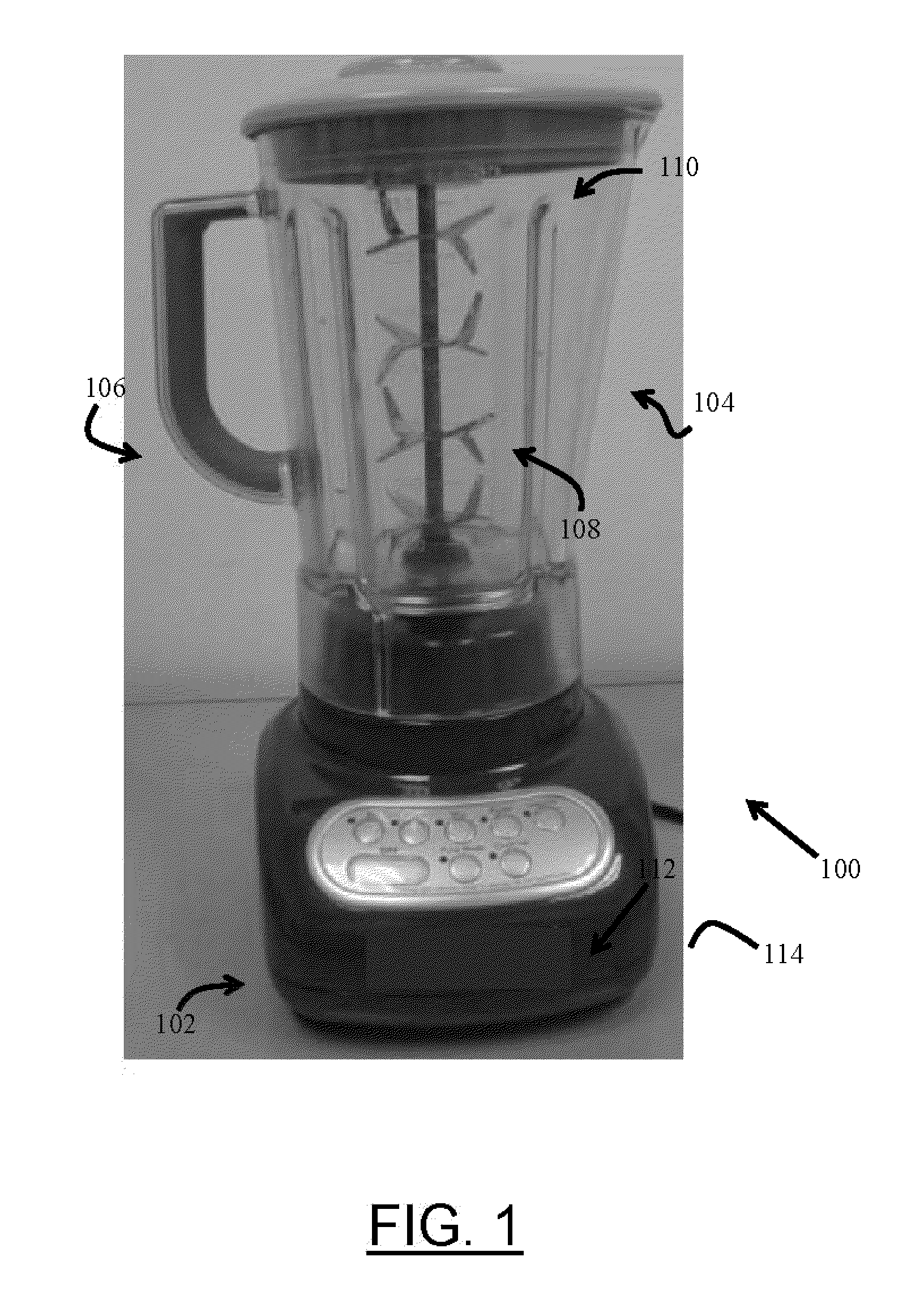

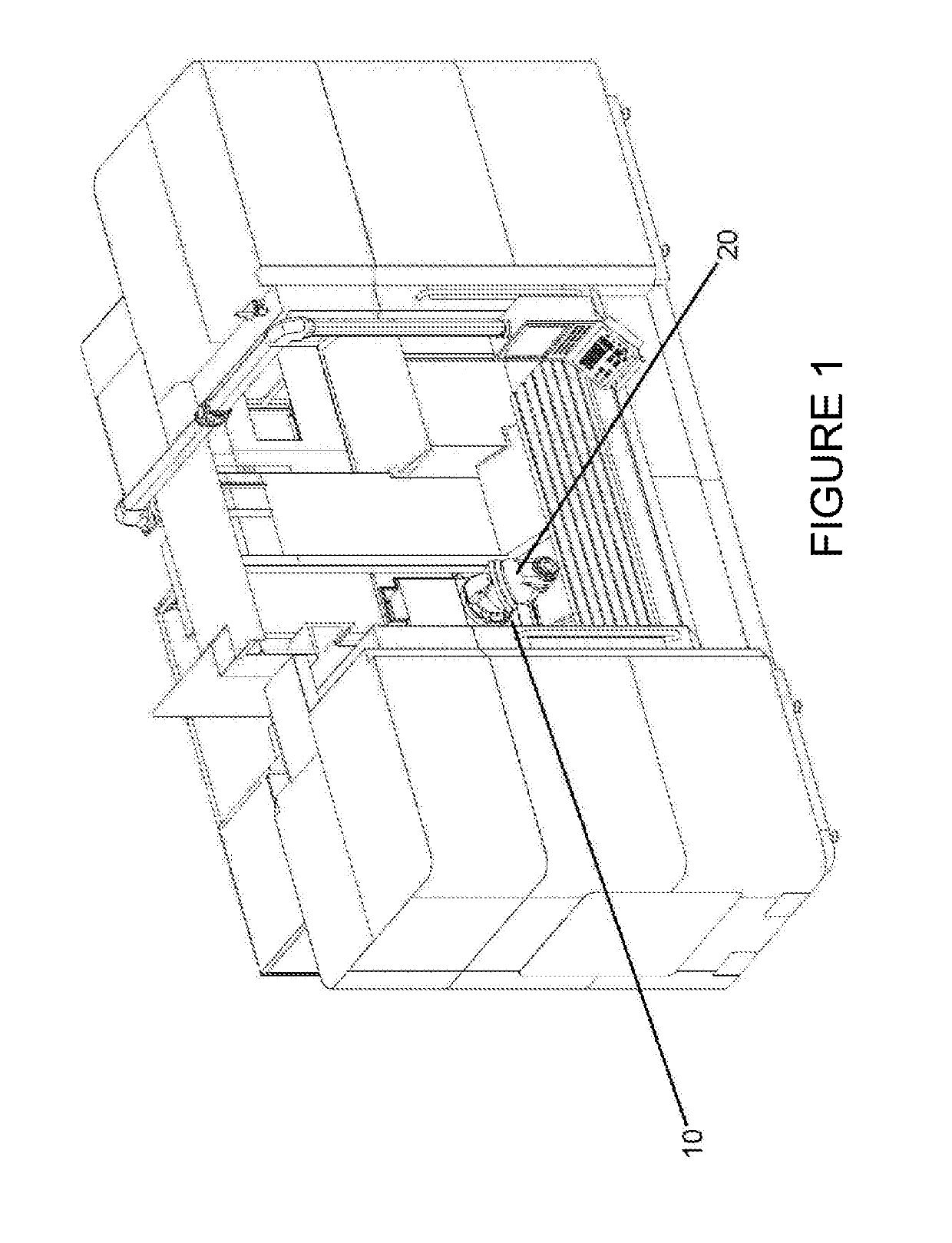

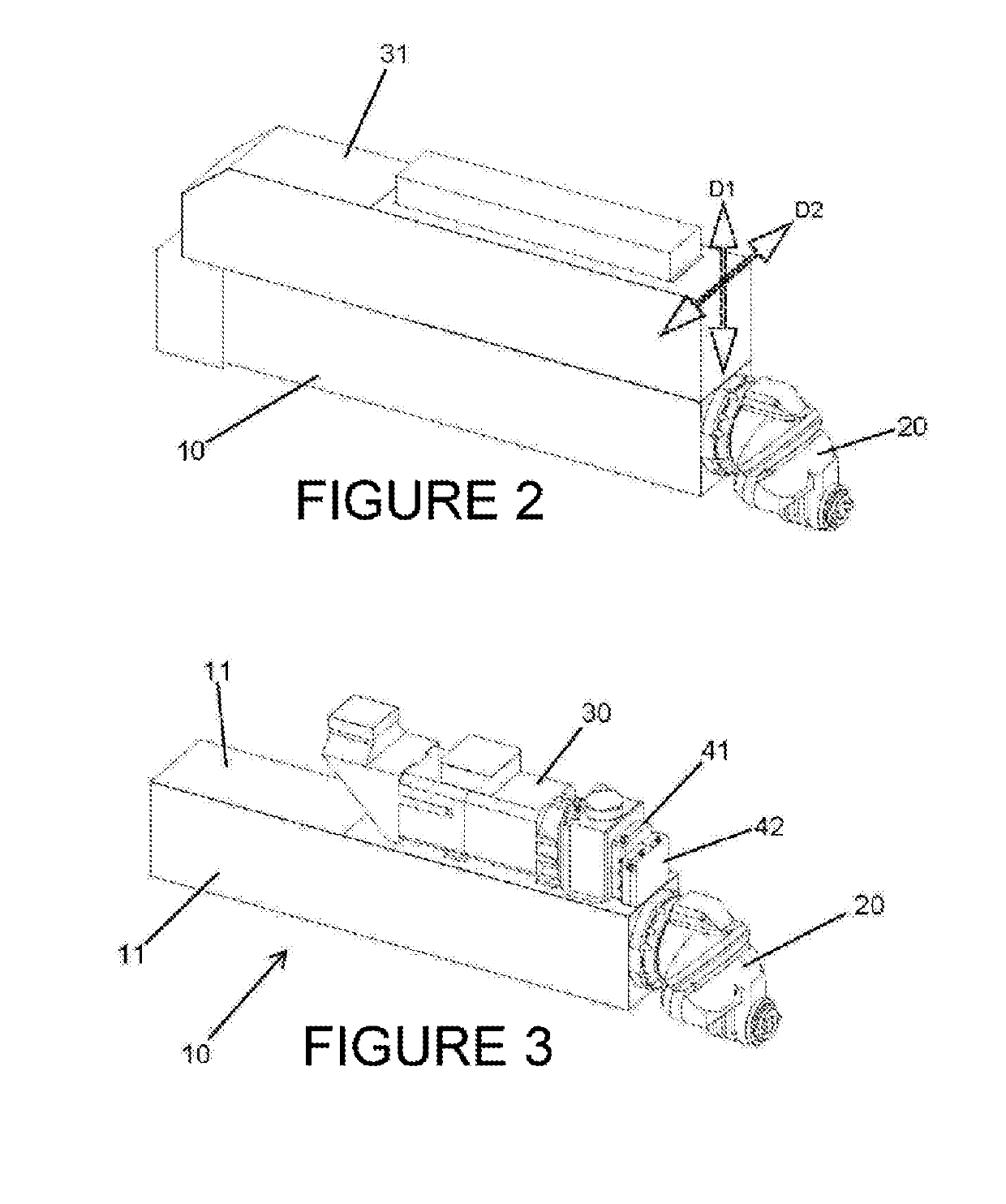

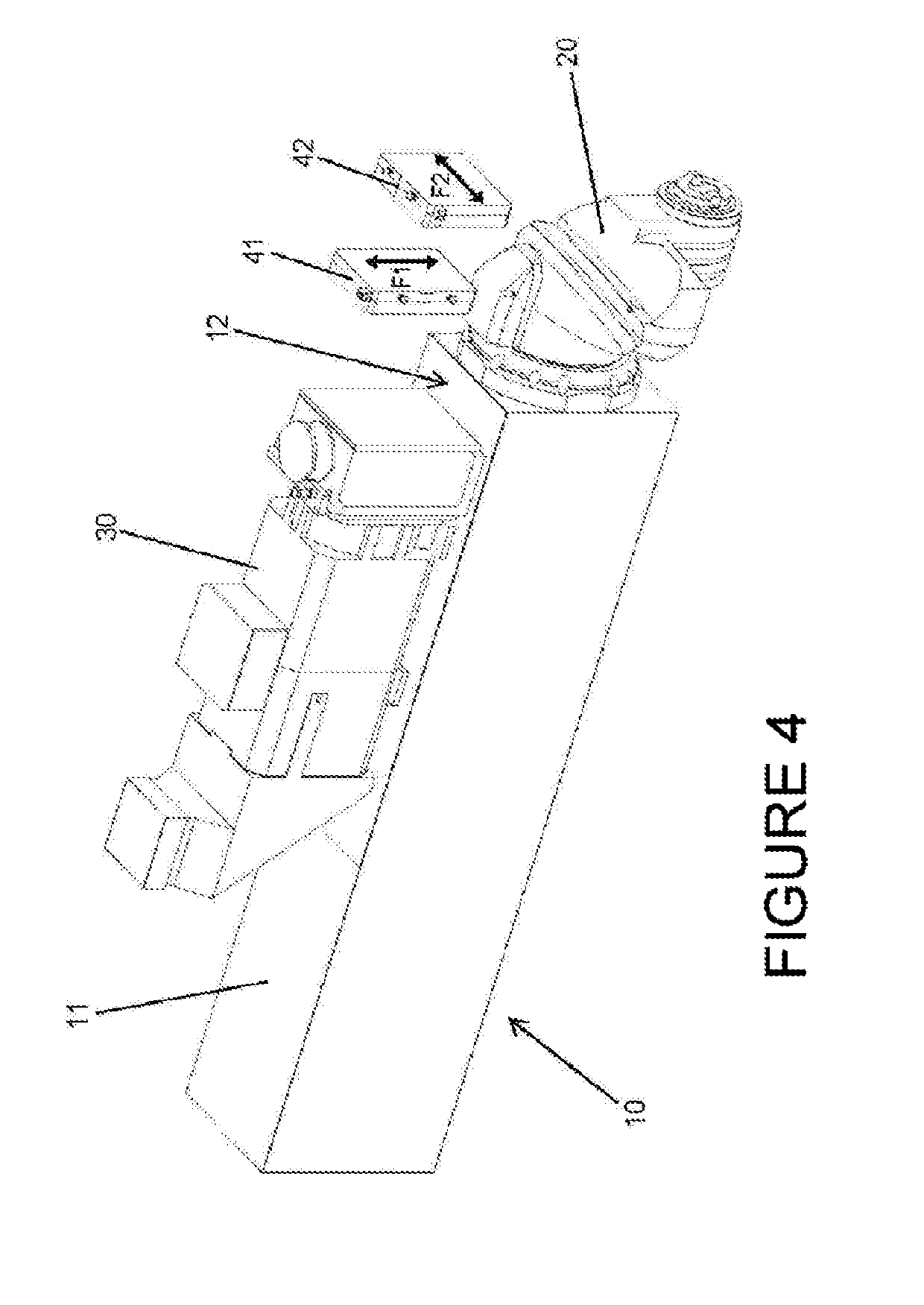

Blender and food processor device

Owner:CARRIERE MARK C

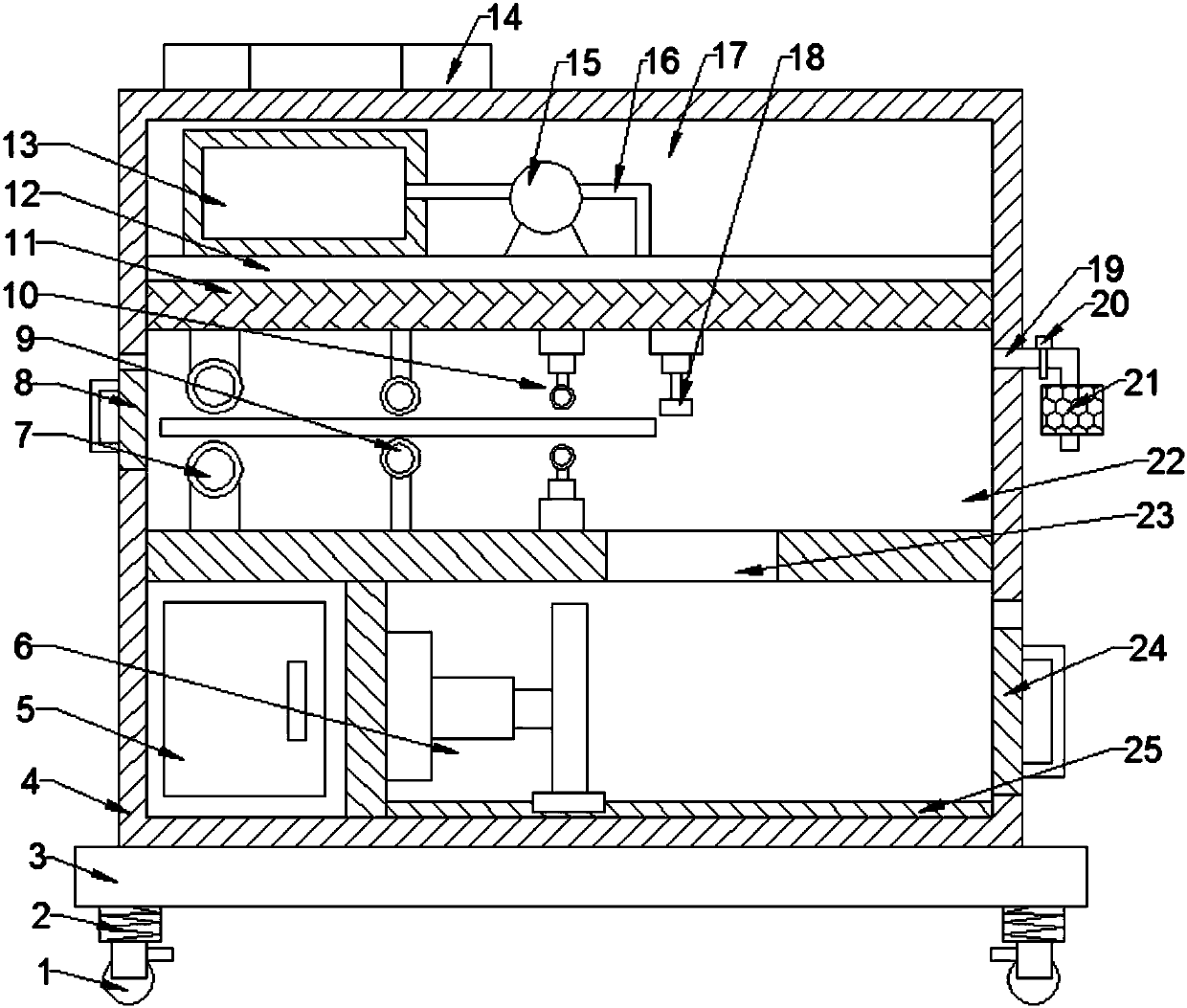

Dust-free type building material cutting and polishing device

InactiveCN107649882AOther manufacturing equipments/toolsMaintainance and safety accessoriesBuilding materialEngineering

Owner:QUANZHOU HUIAN MINTOU TRADING CO LTD

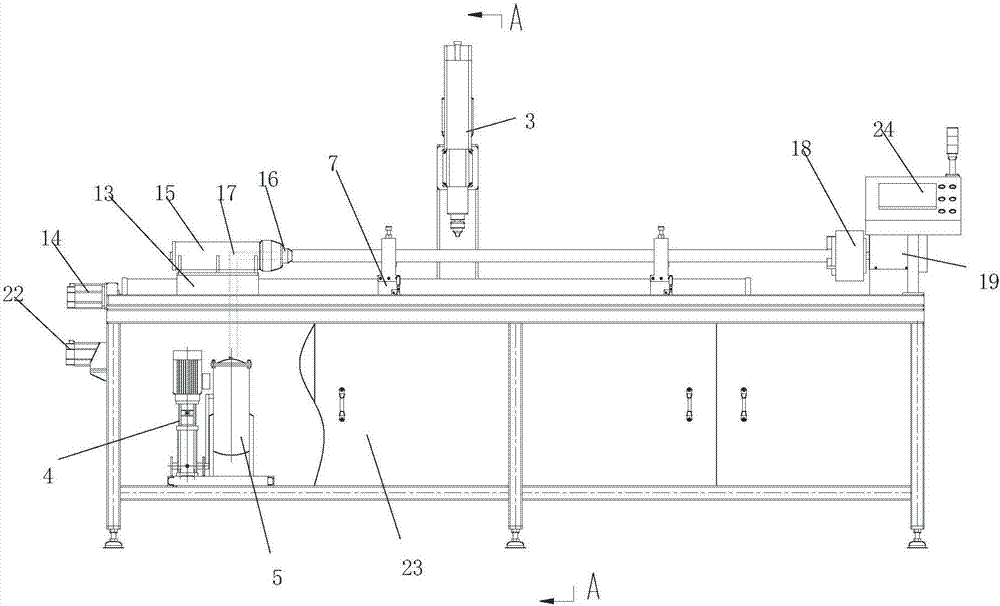

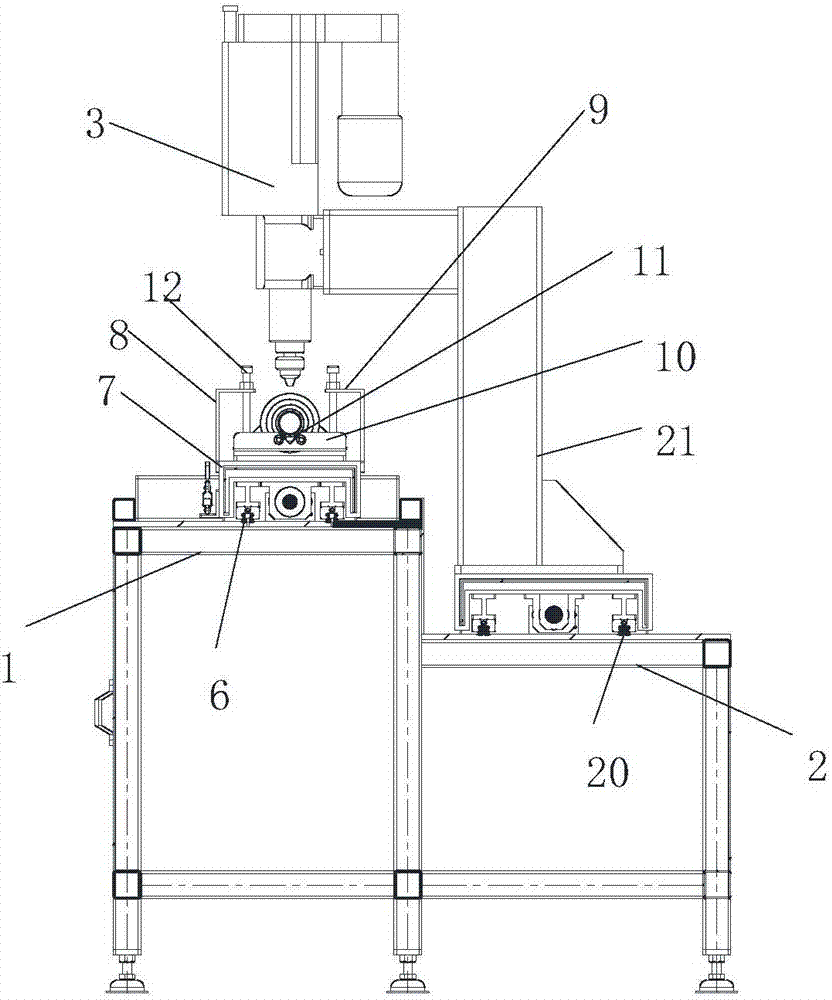

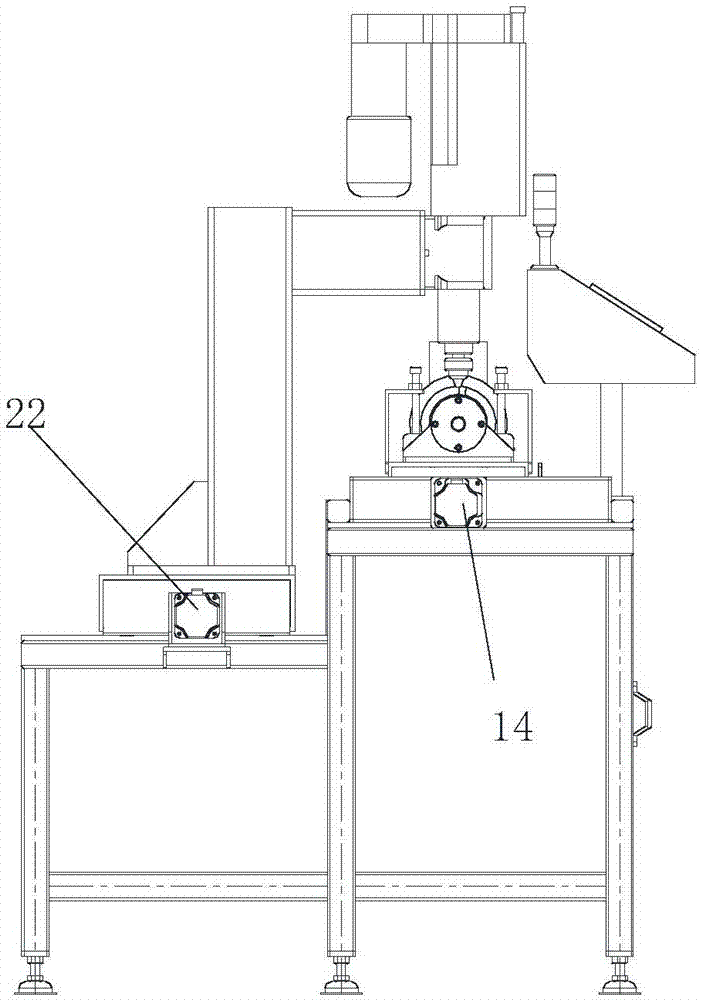

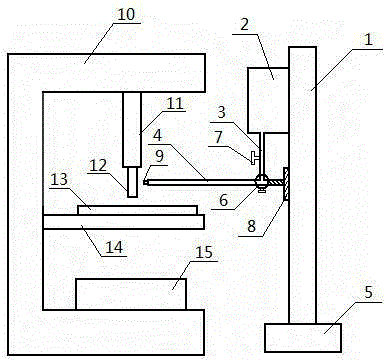

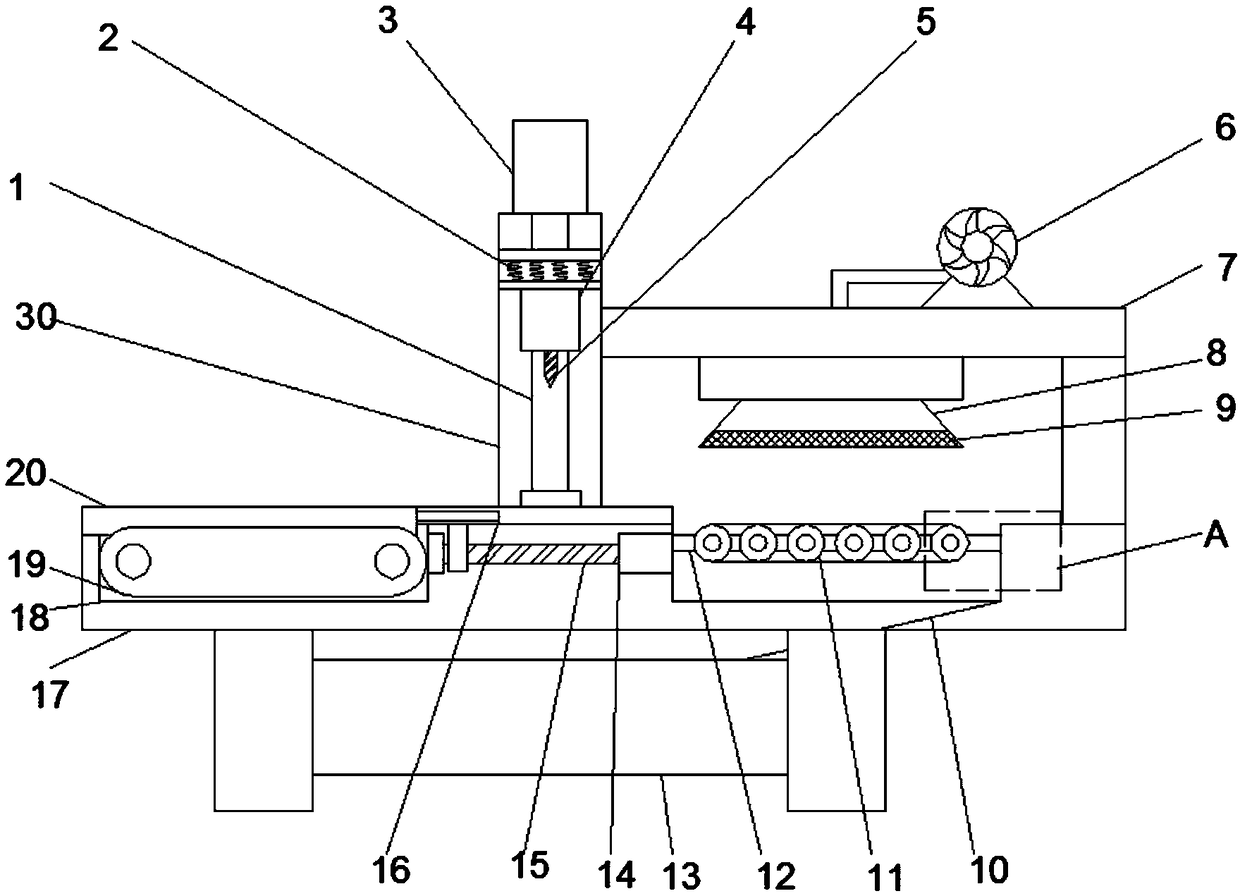

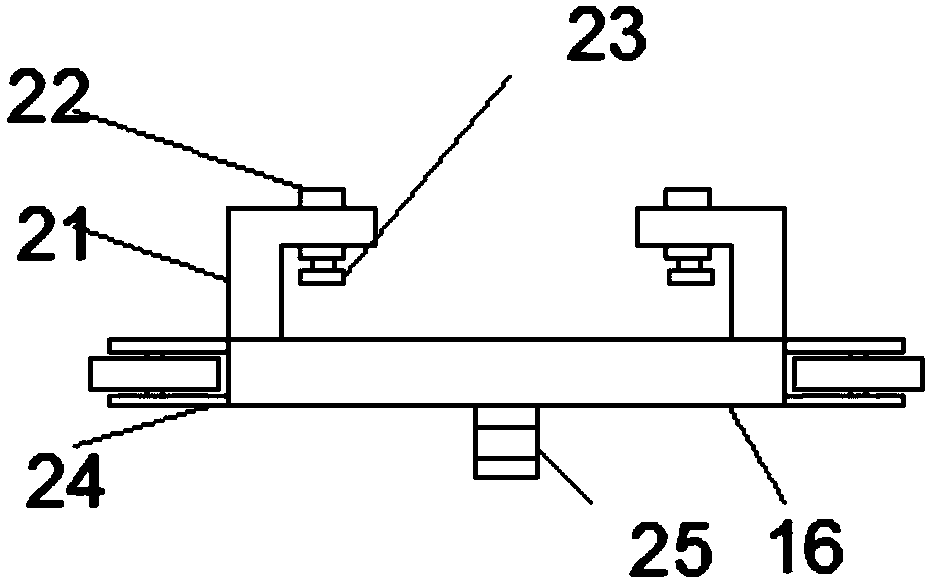

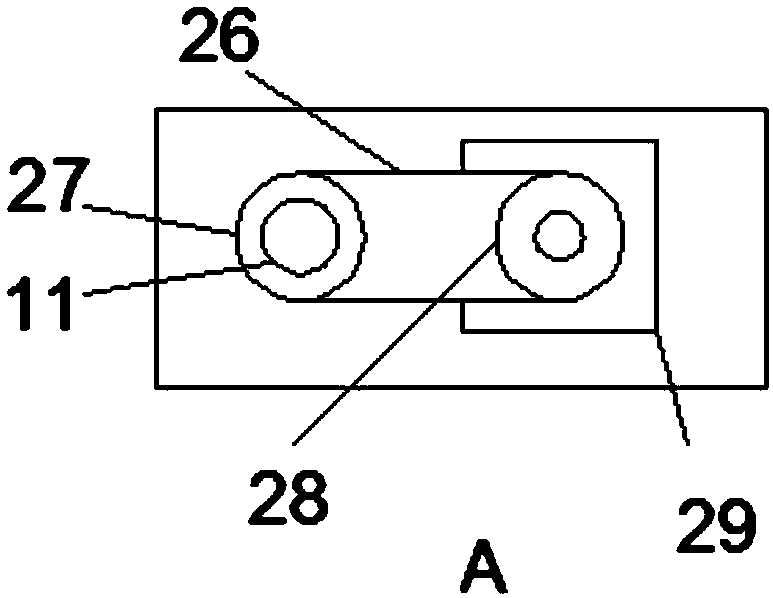

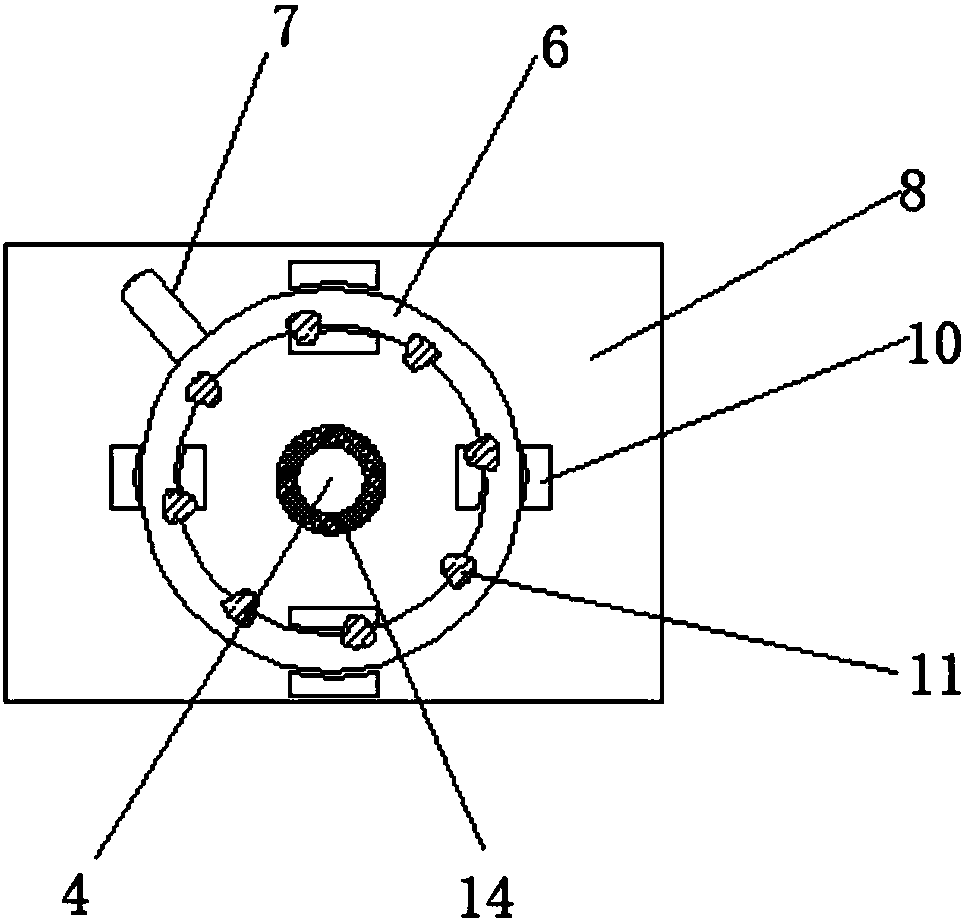

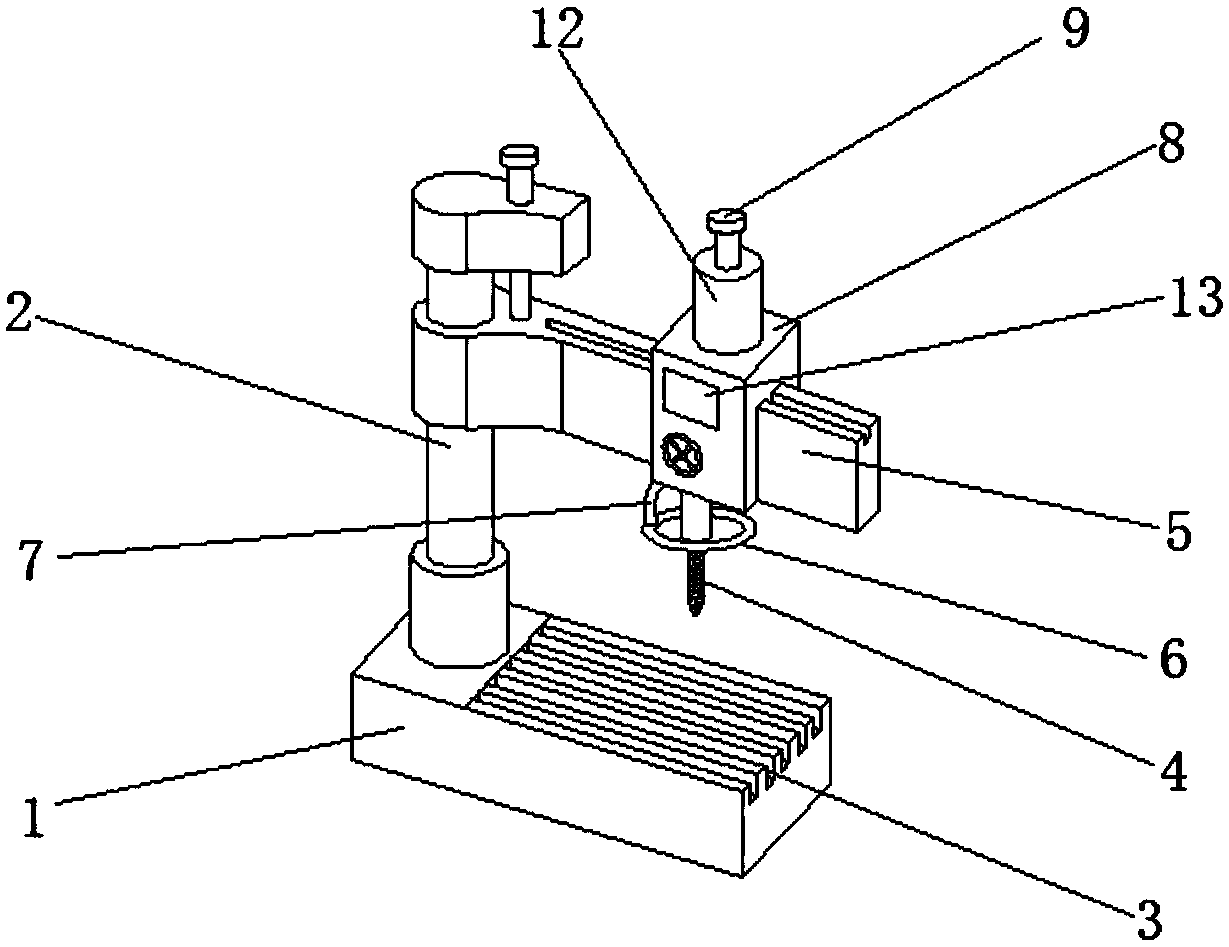

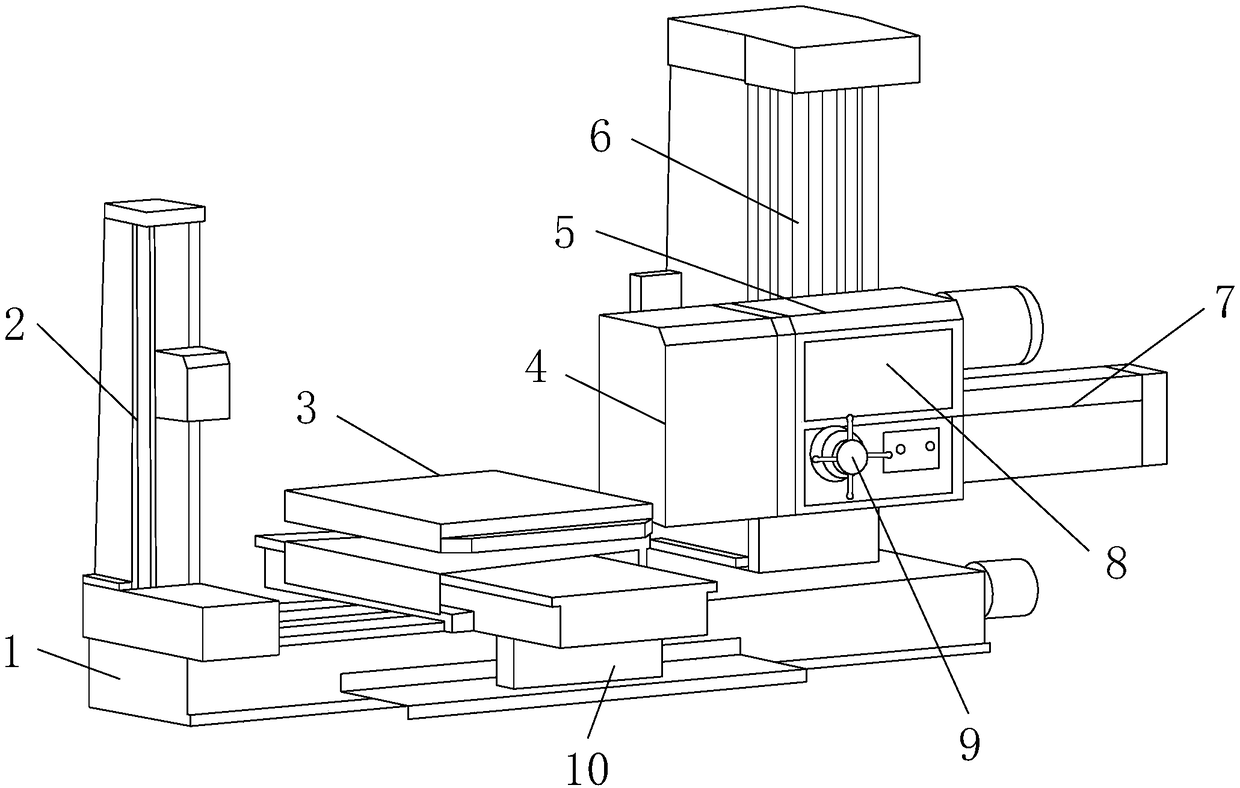

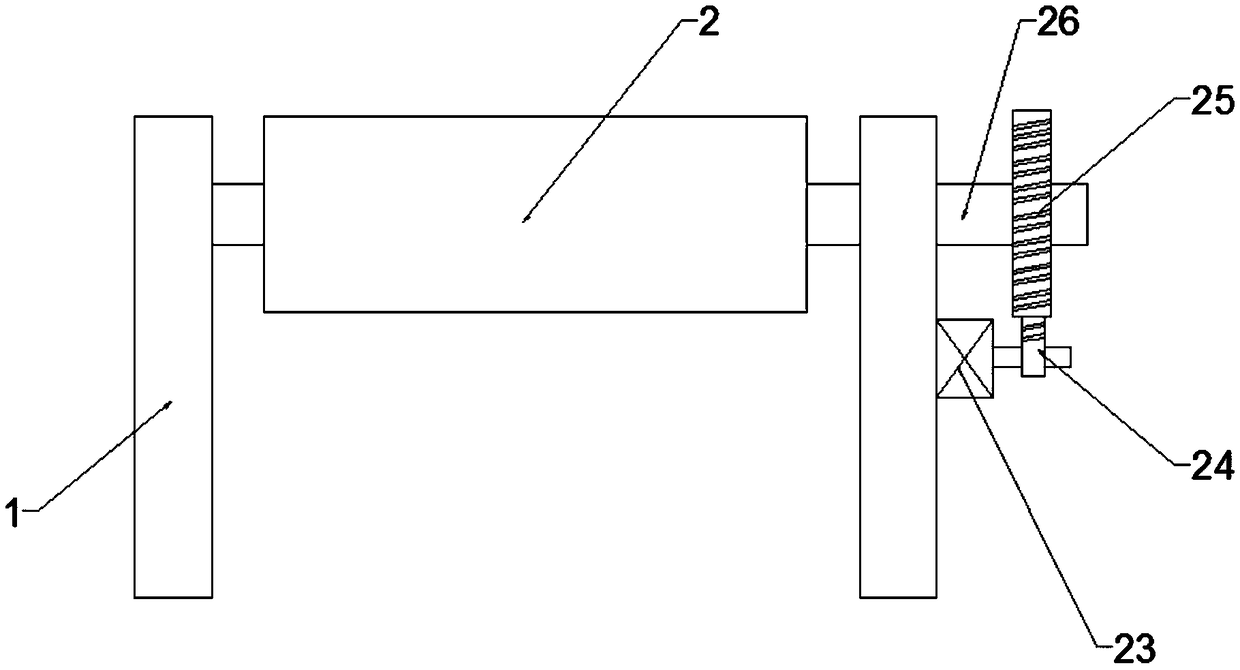

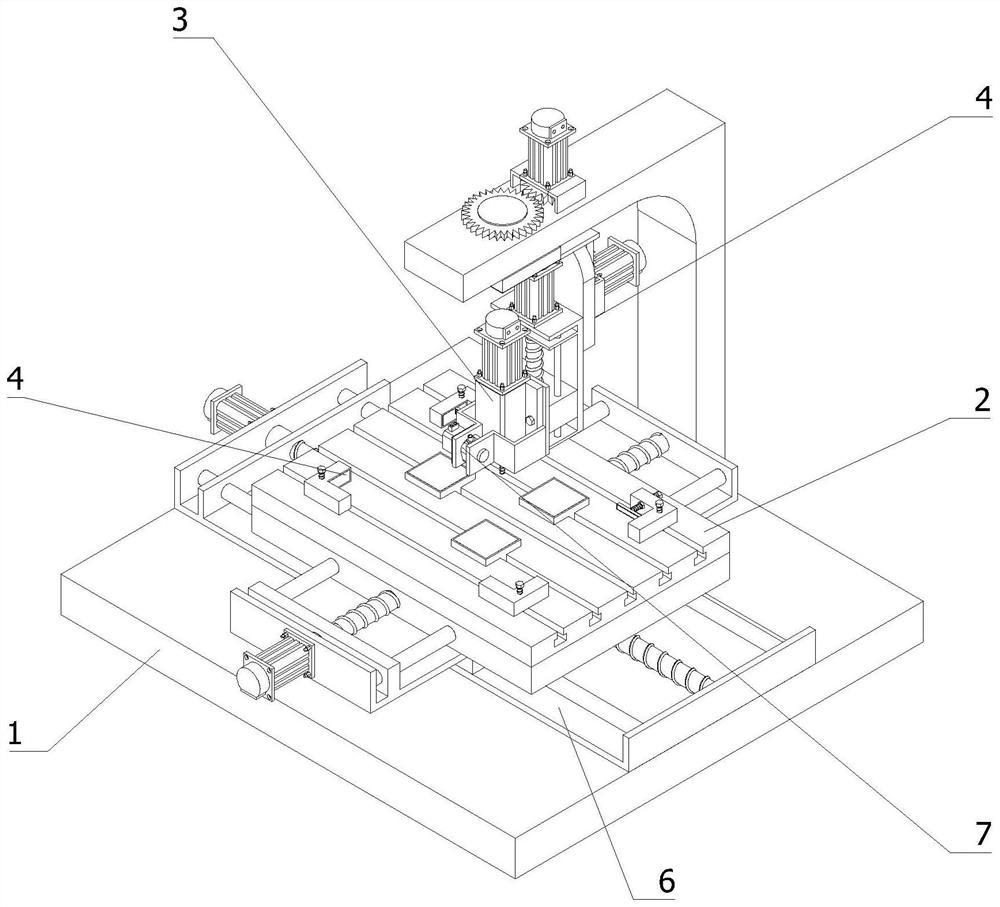

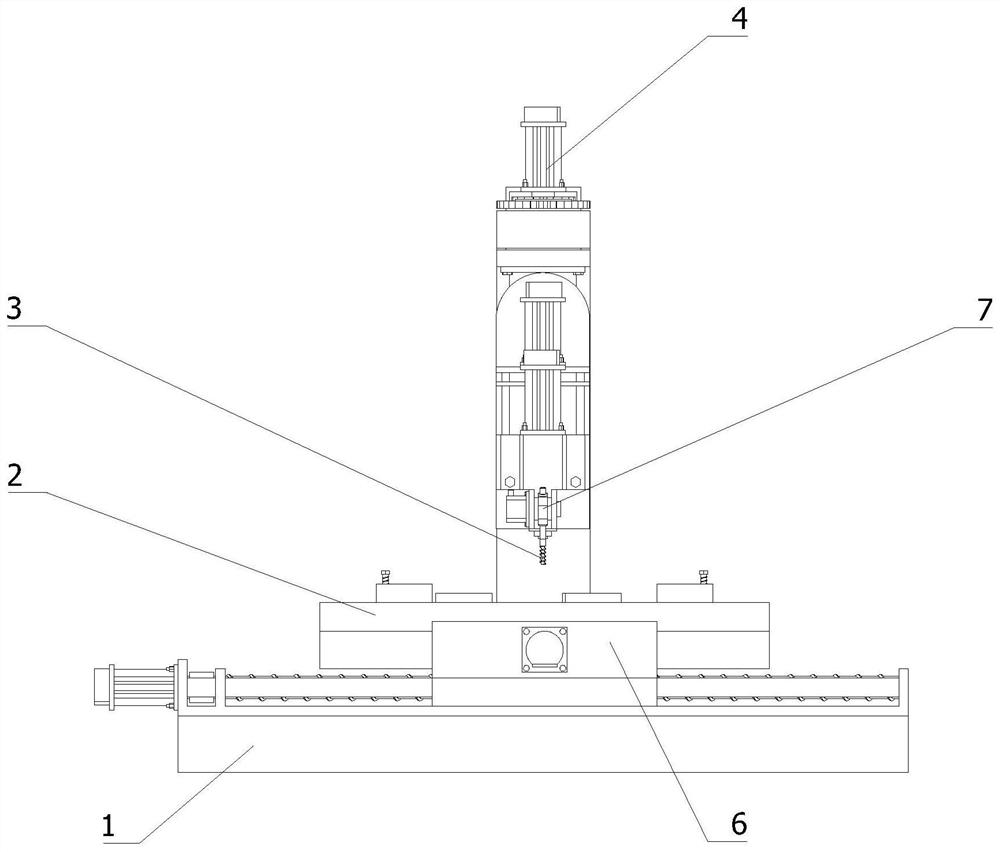

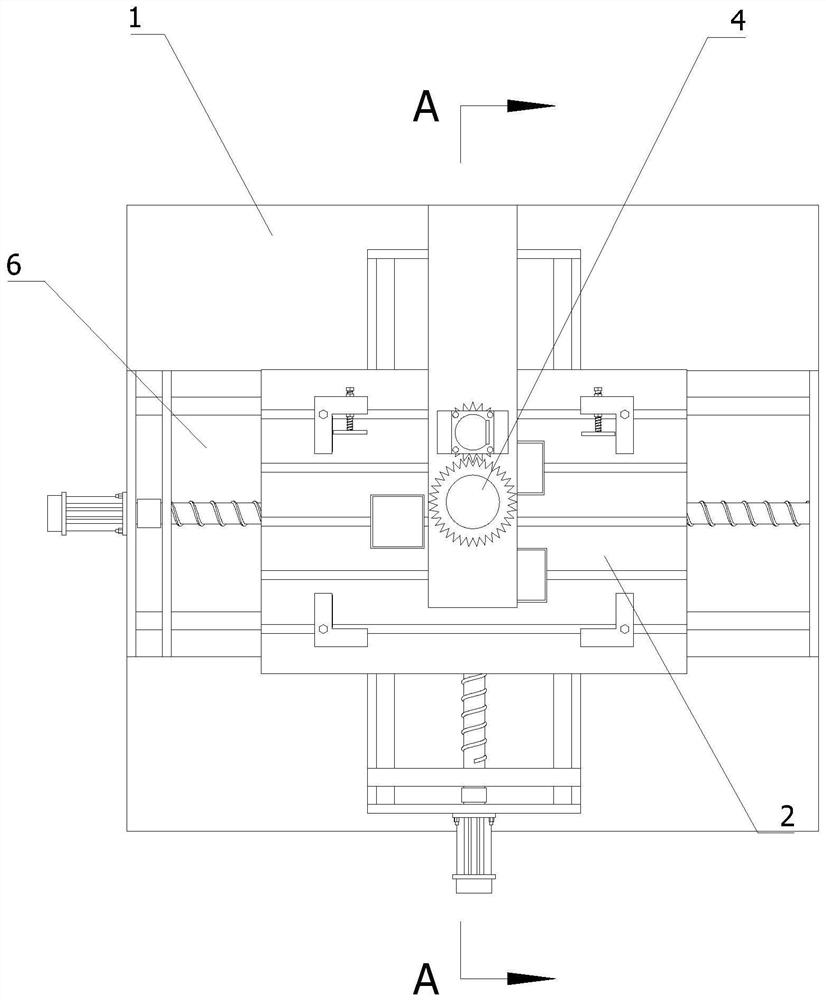

Intelligent steel pipe drilling device

The invention relates to the technical field of drilling devices, in particular to an intelligent steel pipe drilling device. The intelligent steel pipe drilling device comprises a steel pipe fixing workbench, a drilling machine moving workbench, an automatic feed drilling machine, a negative-pressure pump and a negative-pressure tank. A first guide rail is fixedly arranged on the steel pipe fixing workbench. Steel pipe support mechanisms are arranged on the first guide rail. The steel pipe support mechanisms are in sliding fit with the first guide rail. The drilling machine moving workbench is arranged on one side of the steel pipe fixing workbench. A second guide rail is arranged on the drilling machine moving workbench. The bottom of the automatic feed drilling machine is in sliding fit with the second guide rail through a drilling machine bracket. A third stepping motor is arranged on one side of the drilling machine moving workbench. According to the intelligent steel pipe drilling device, the negative-pressure pump and the negative-pressure tank are arranged and communicate with a jackscrew through a gas pipe, scrap iron in a steel pipe enters the negative-pressure tank from the jackscrew under the negative-pressure function, the purpose of collecting the scrap iron is achieved, and it is indicated by the actual use of the applicant that the effect of collecting the scrap iron is extremely good, and the steel pipe is internally cleaned extremely clearly.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

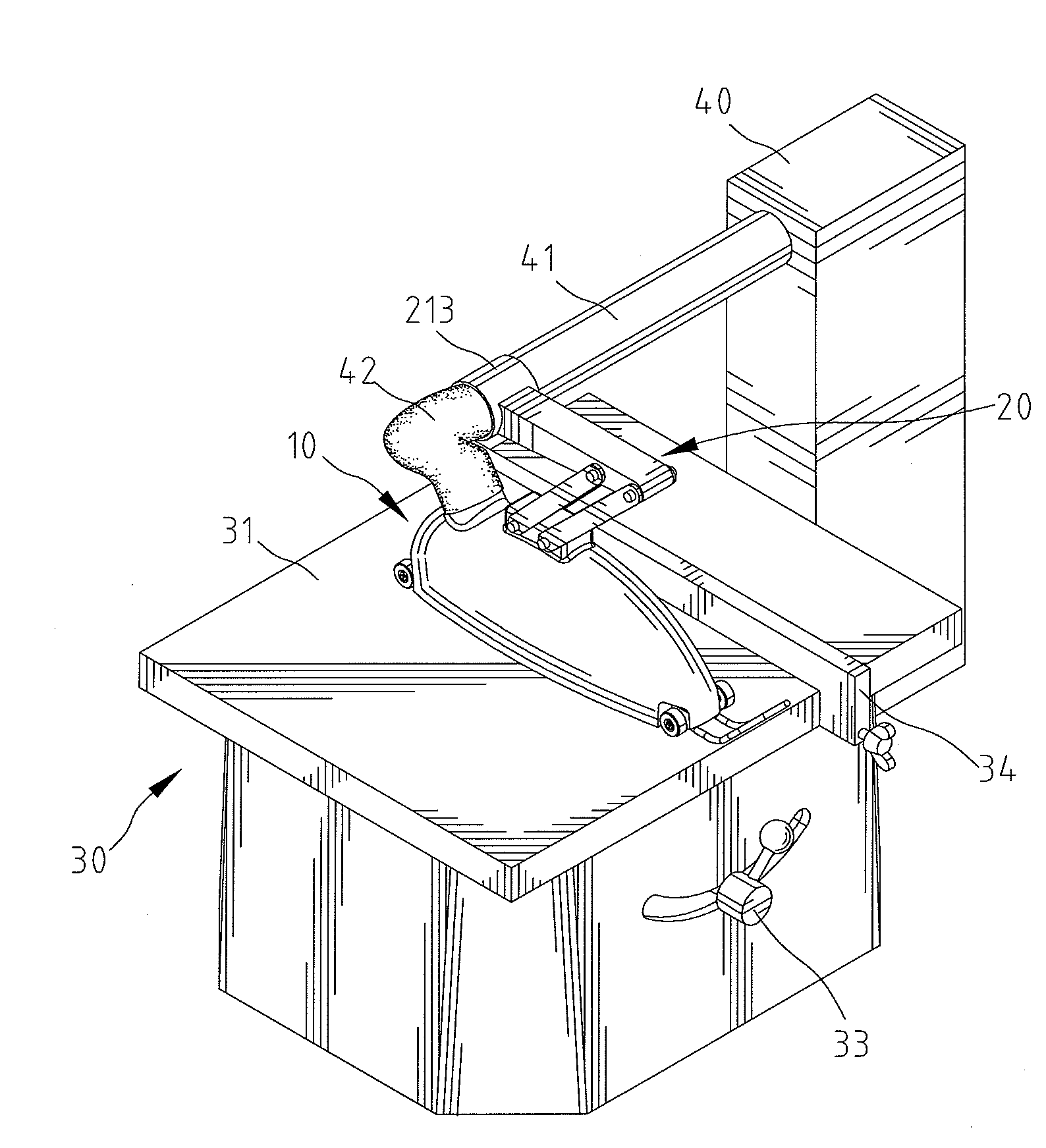

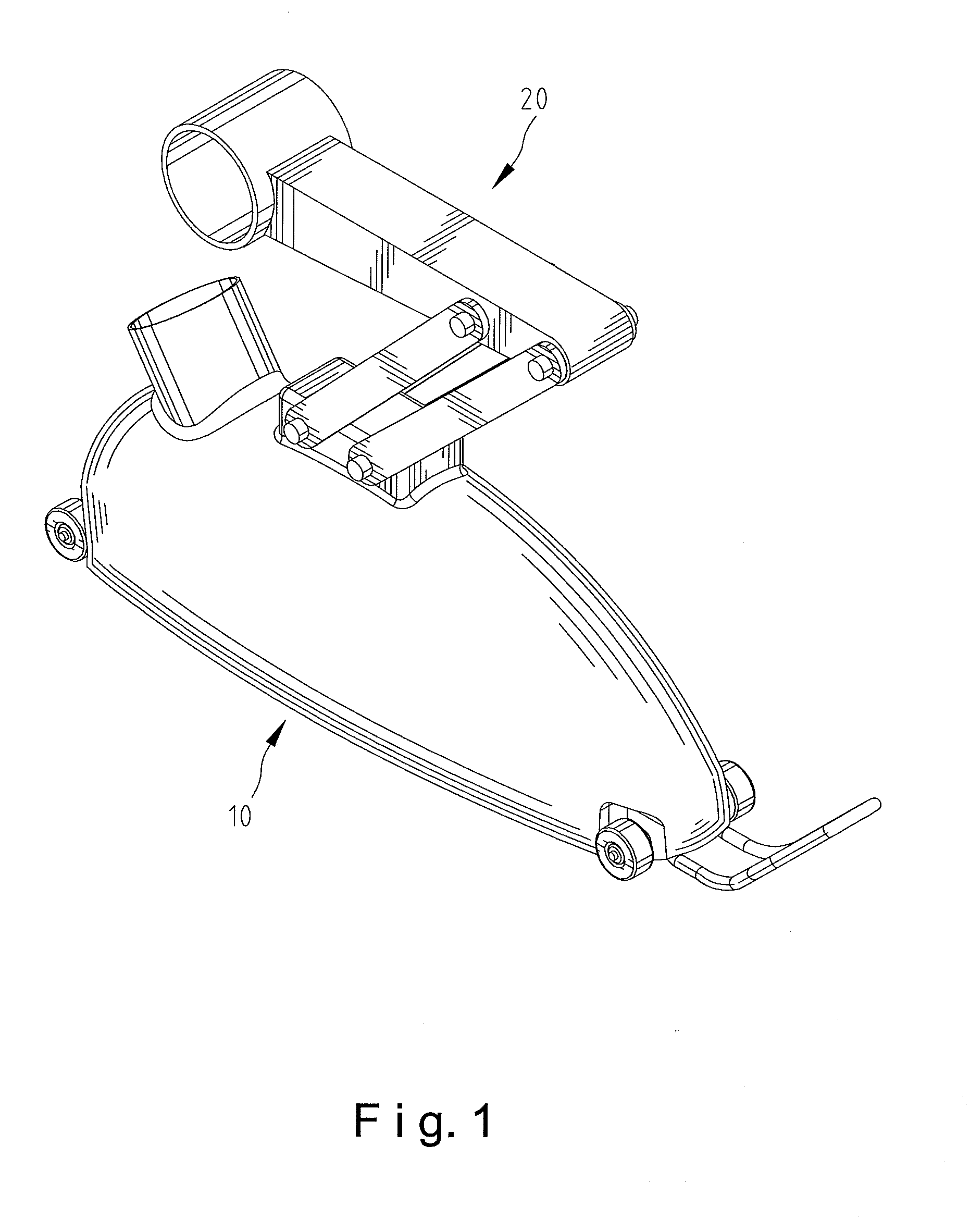

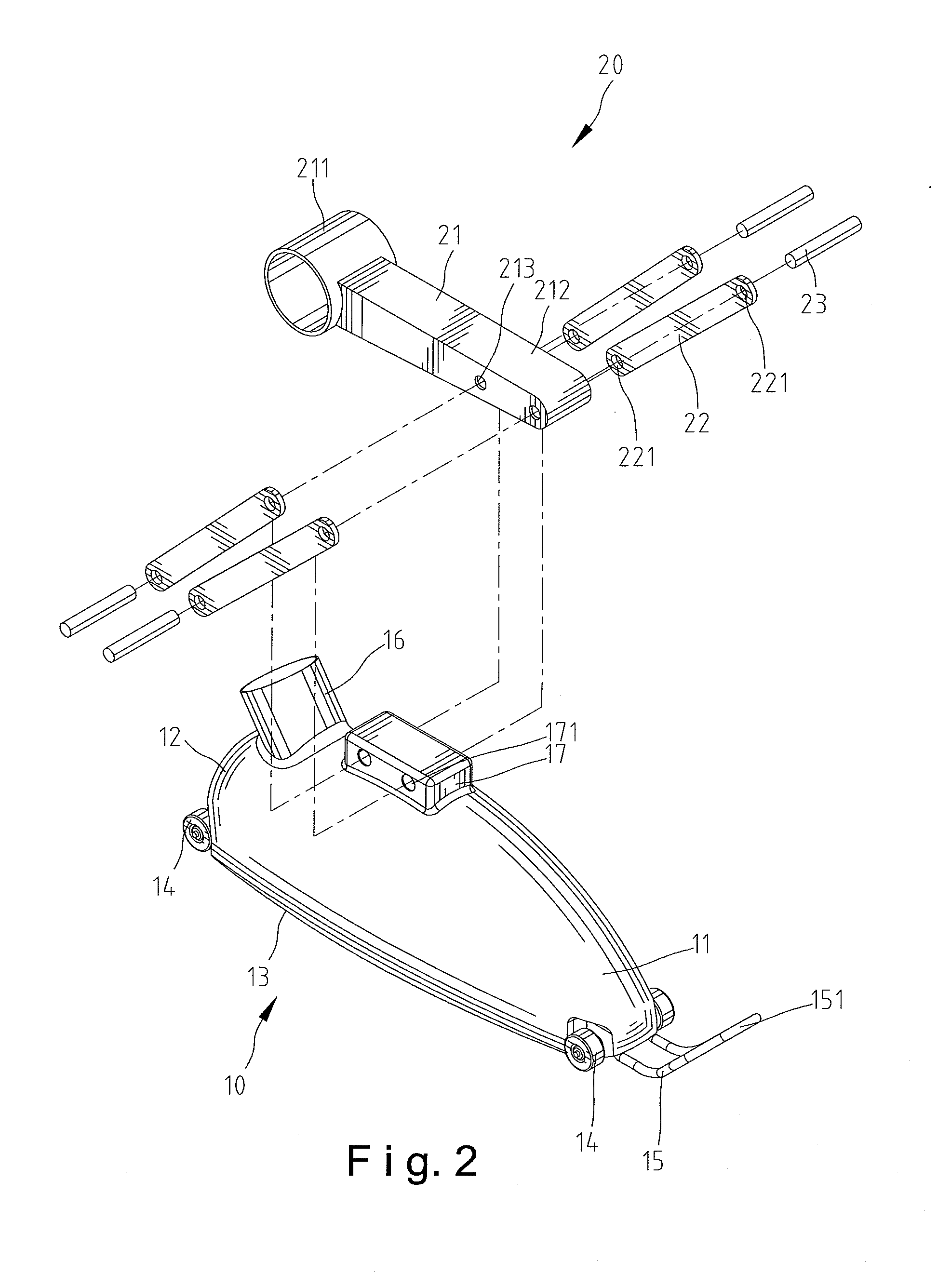

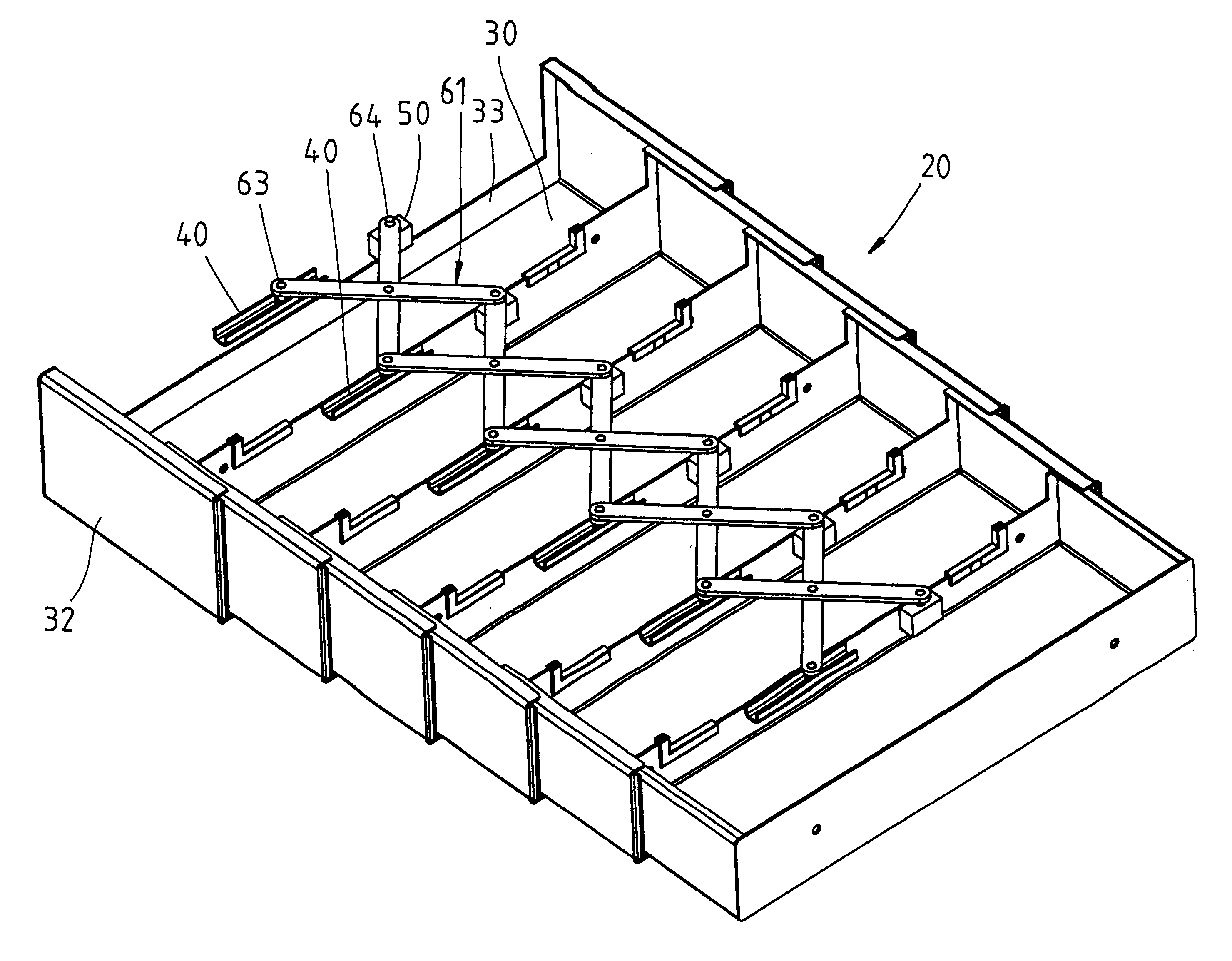

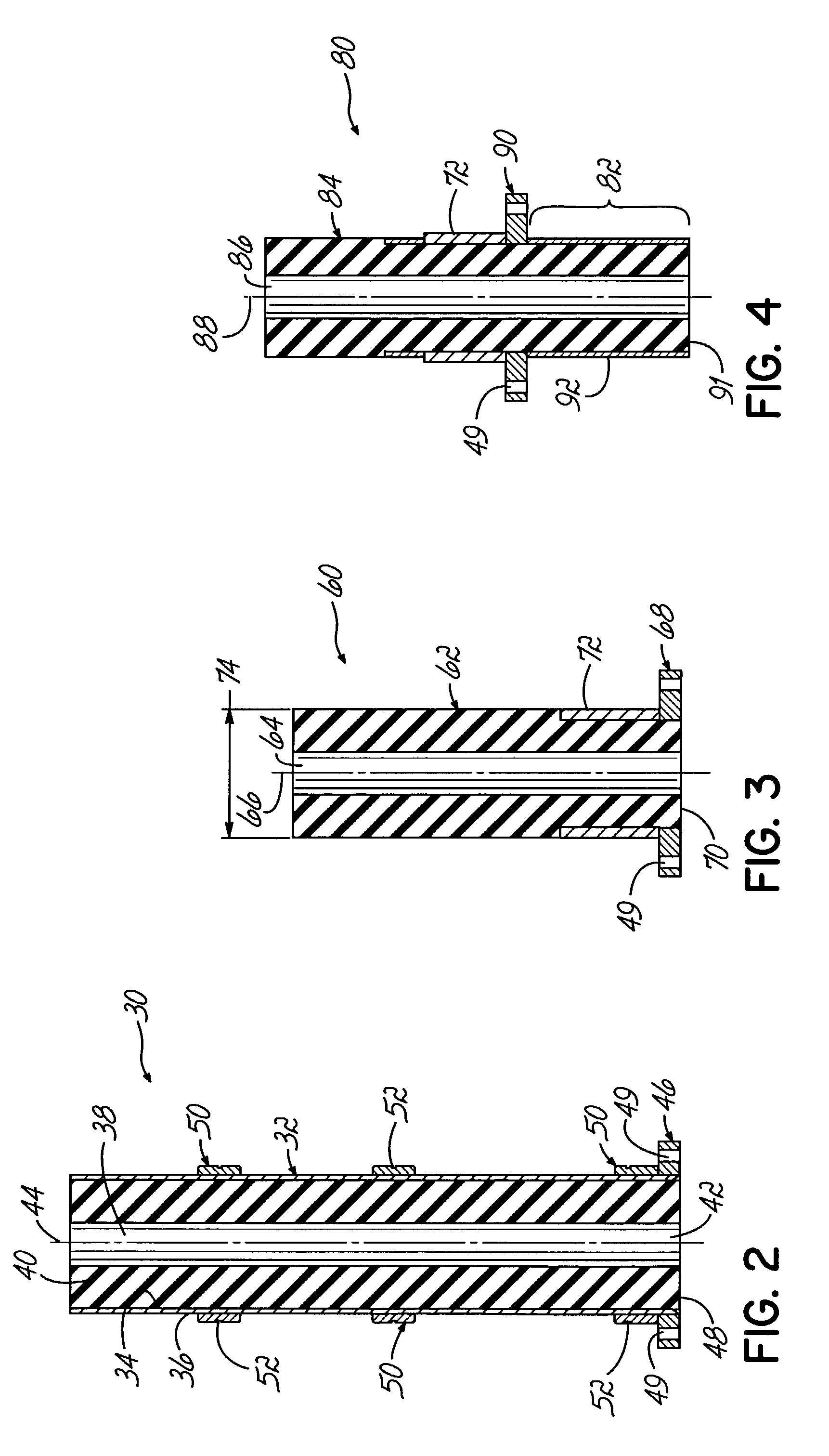

Dust Control Hood Assembly for a Cutting Machine

InactiveUS20100037740A1Easy to moveMetal sawing accessoriesShearing machinesDust controlHOOD assembly

Owner:META INT

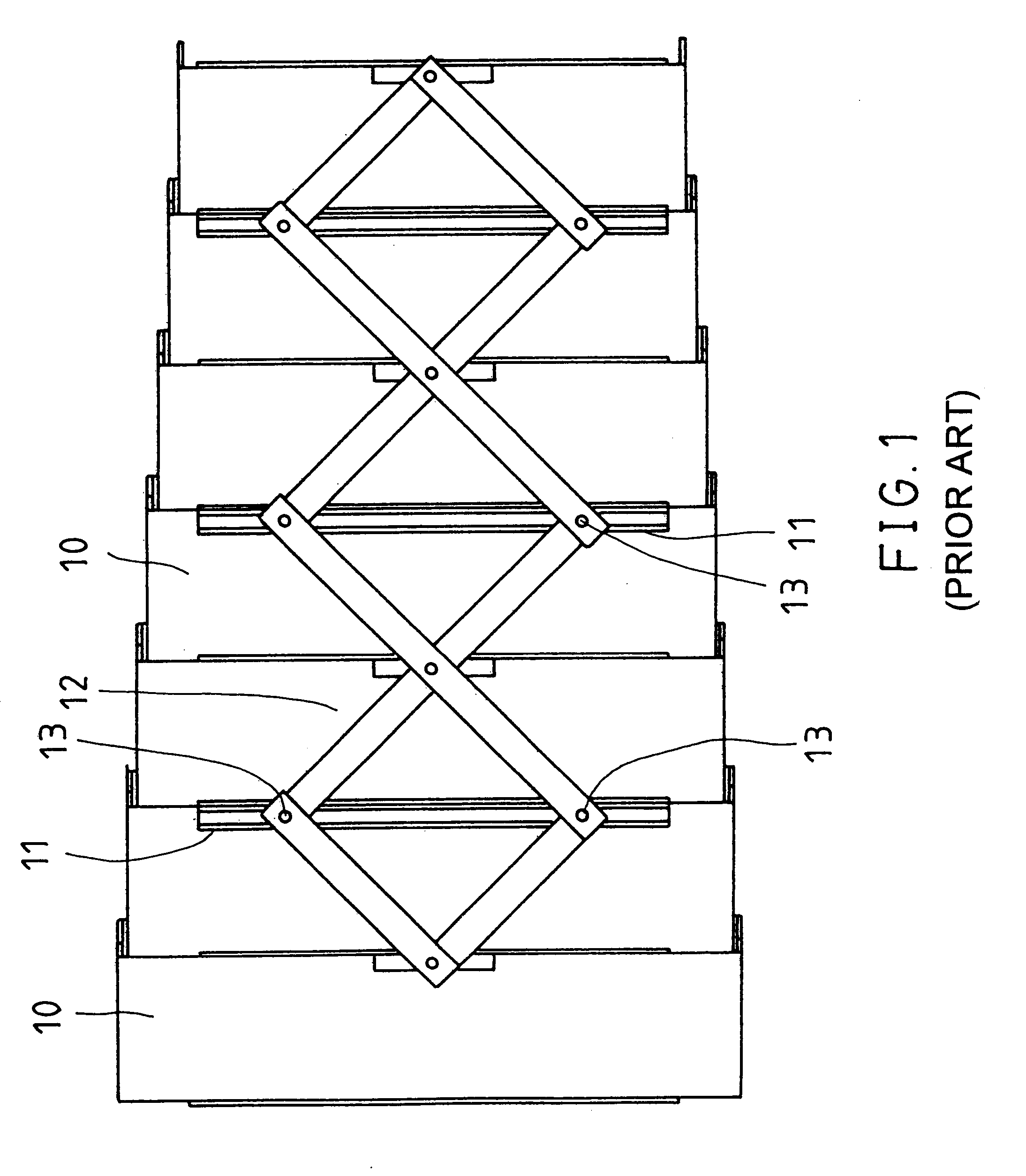

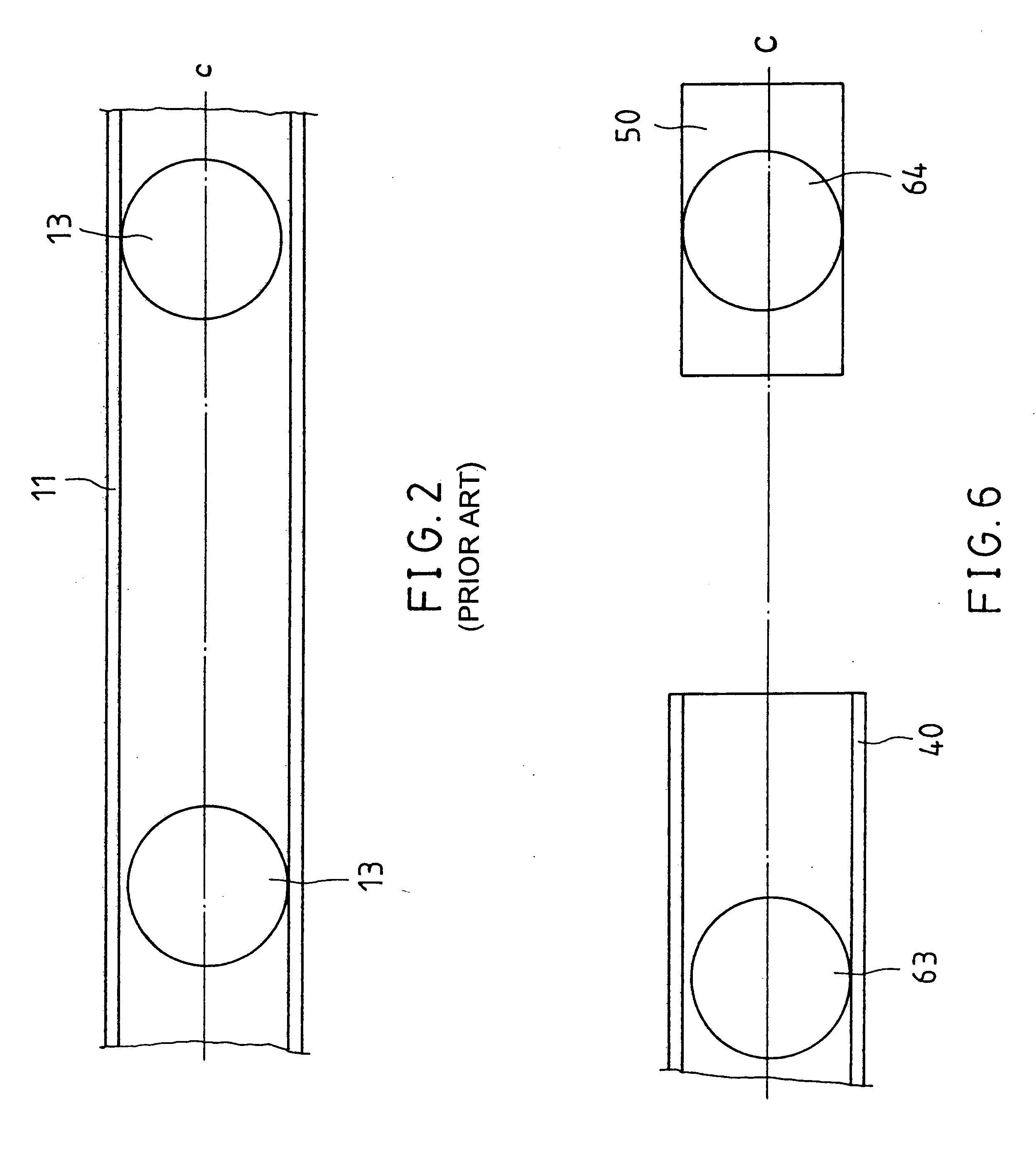

Dust-proof cover with connecting rods

Owner:WANG GREG

Machine tool spindle liners and methods for making same

Owner:J F BERNS

Special fixed perforating device for automobile aluminum alloy hubs

Owner:TAIZHOU WEIHUA COATING TECH CO LTD

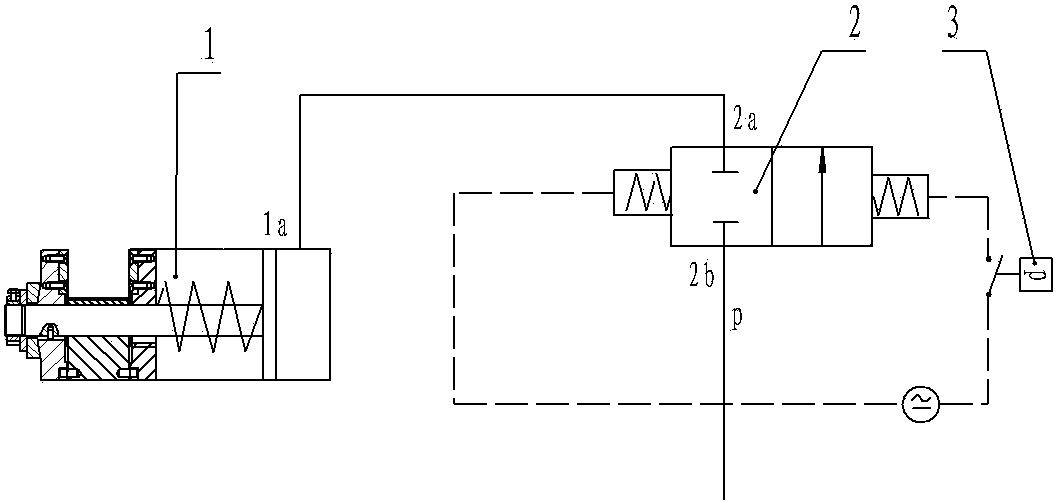

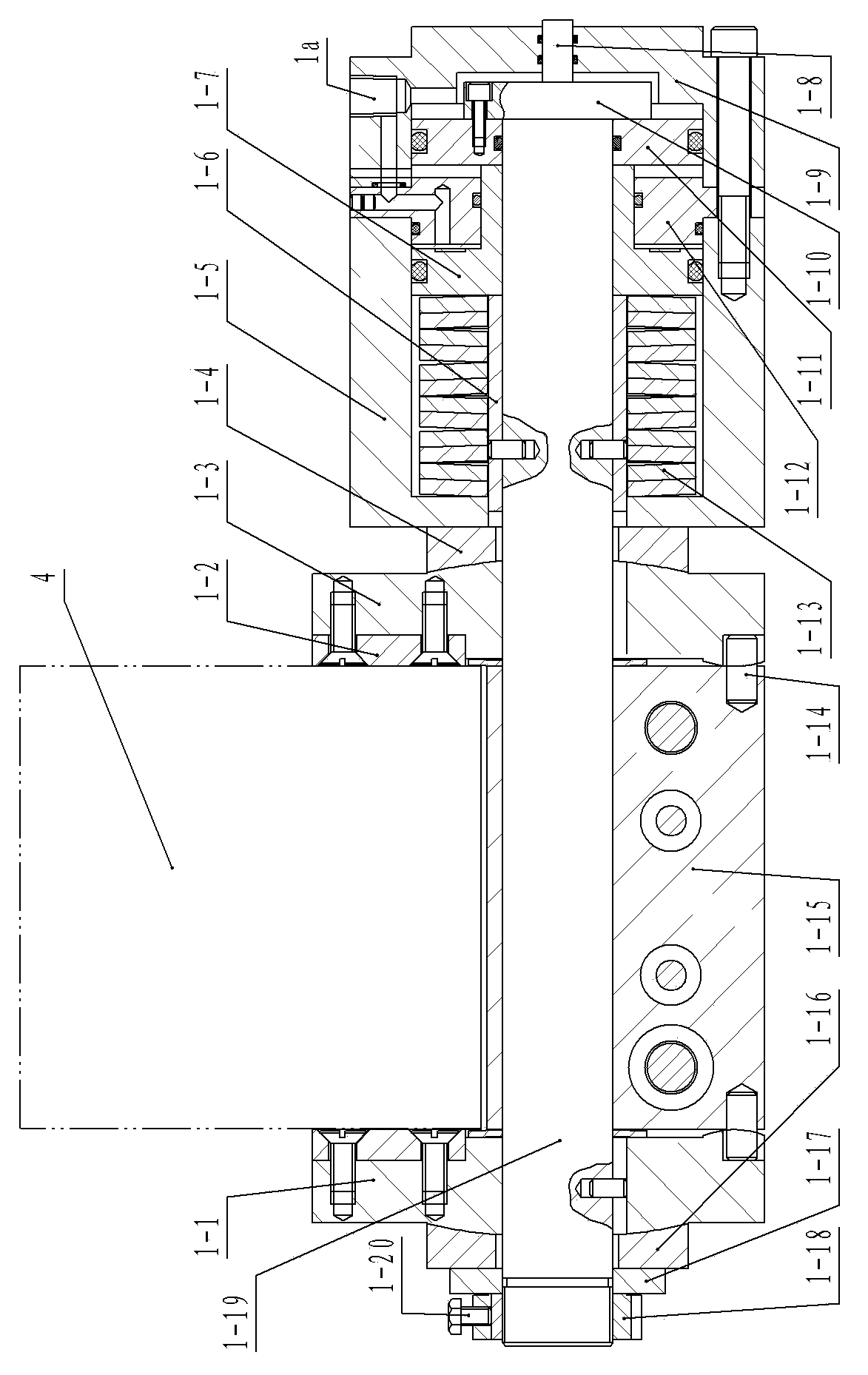

Oil mist recovery system

InactiveCN104511789ALow costReduce pollutionMaintainance and safety accessoriesPulp and paper industryPollution

The invention discloses an oil mist recovery system. The oil mist recovery system comprises a pipeline, a plurality of oil mist collection devices connected with the pipeline, and an exhaust fan and a filter box which are located at an outlet of the pipeline, wherein the filter box is connected with the exhaust fan, the lower end of the filter box is connected with an oil outlet pipe, and the upper end of the filter box is connected with an exhaust funnel. The oil mist recovery system is mainly used to perform uniform recovery processing and discharging on oil mist discharged by a plurality of machining centers, and not only can improve plant environments, but also can save cost of the pipeline, and furthermore can reduce pollution on the plant environments.

Owner:赵立平

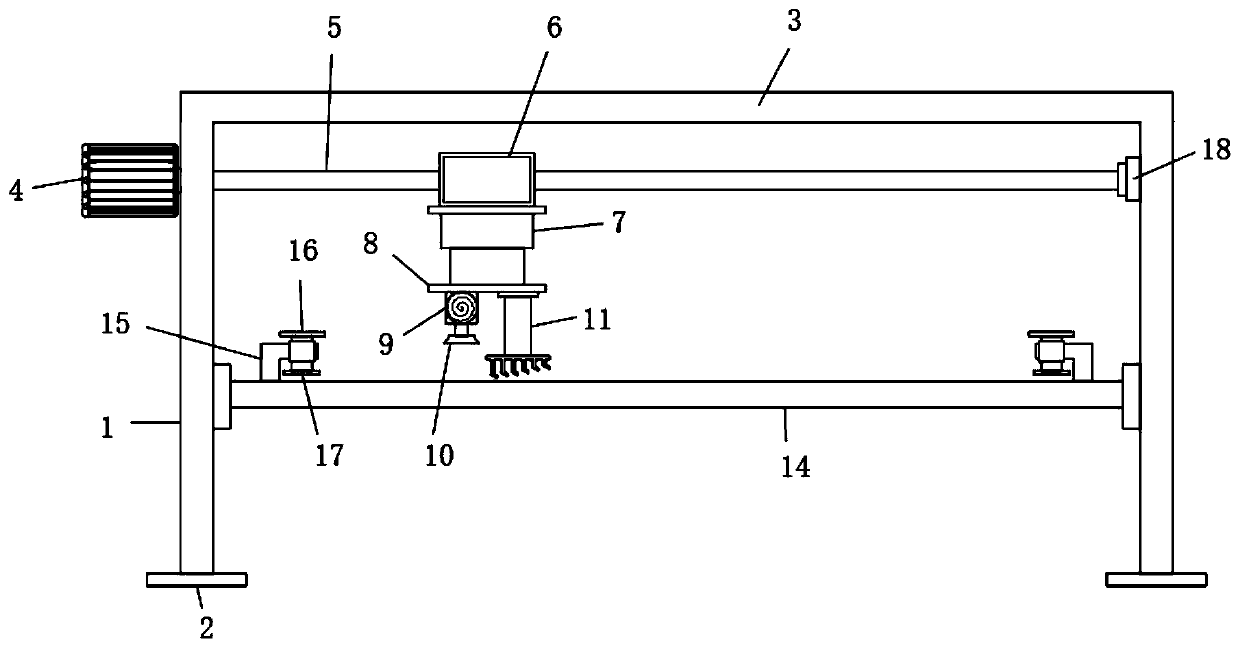

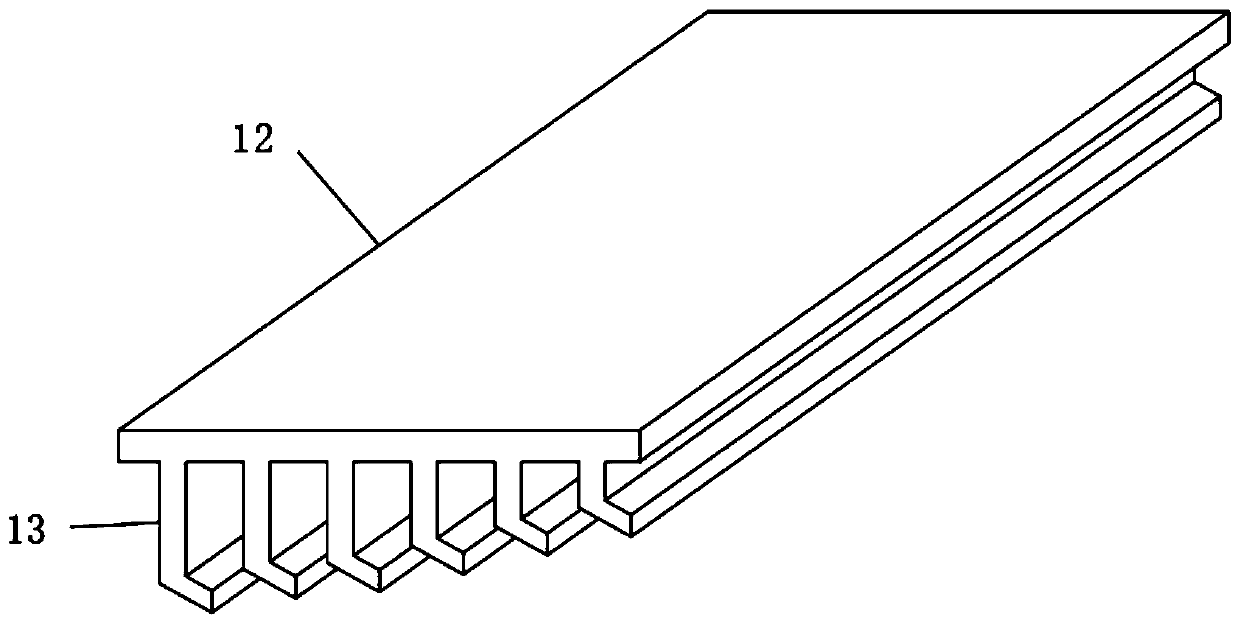

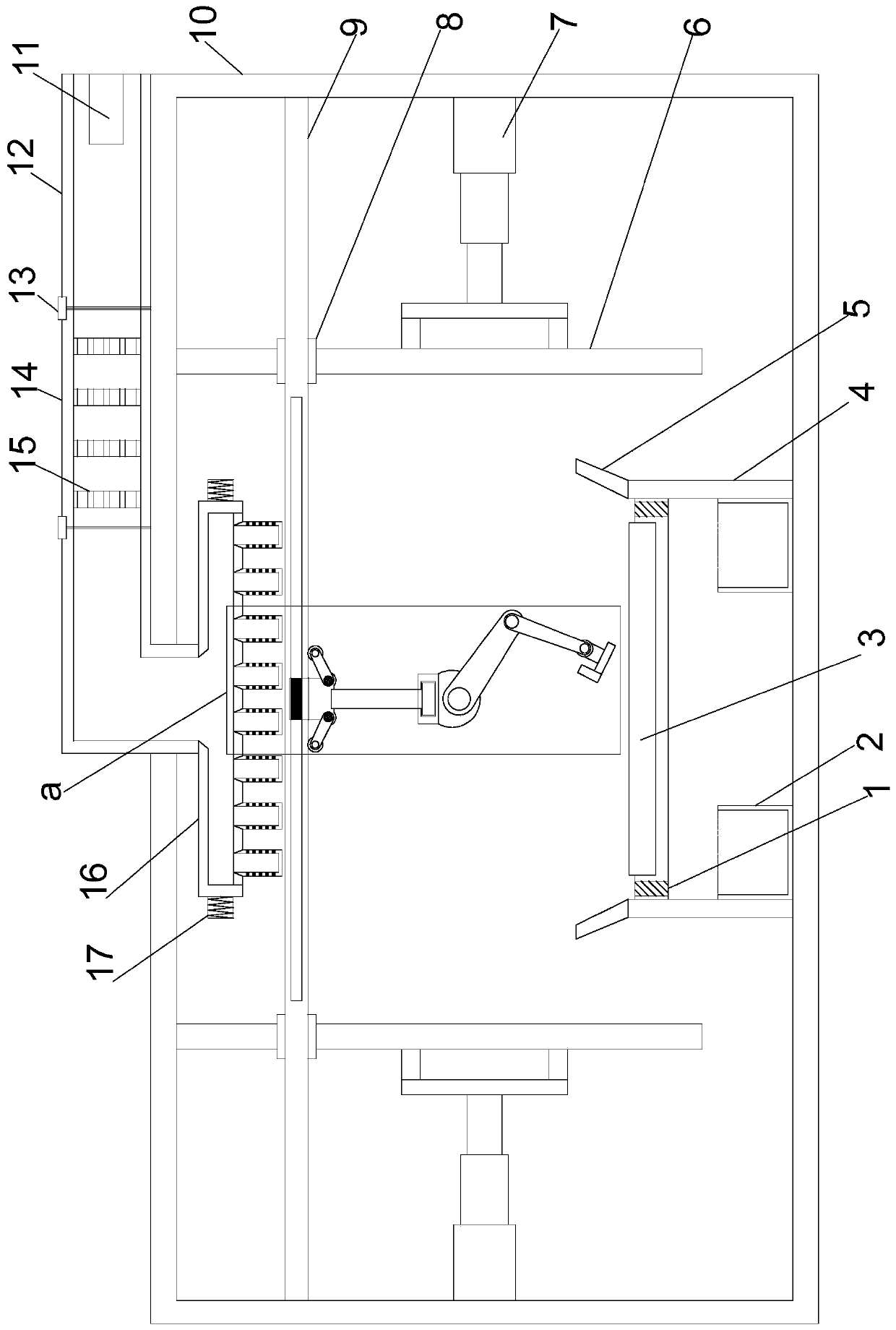

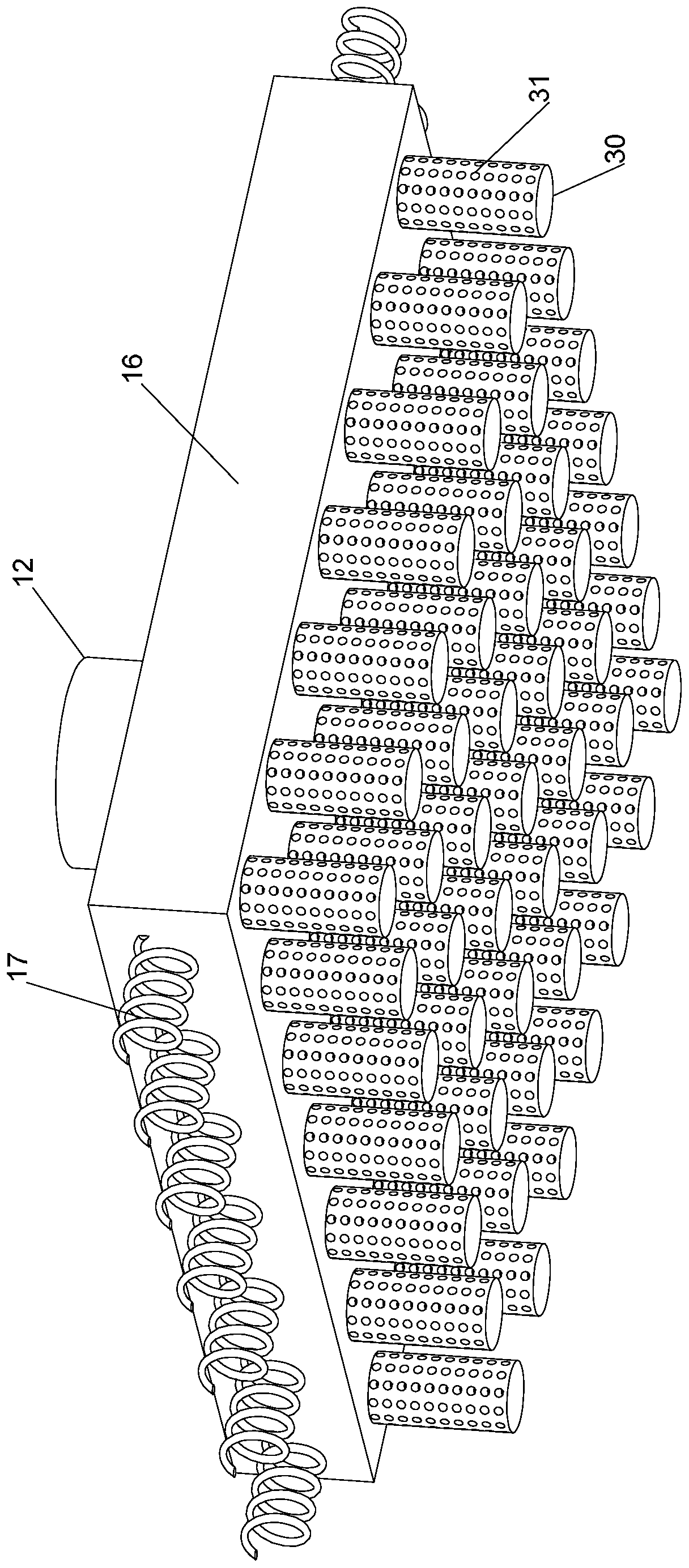

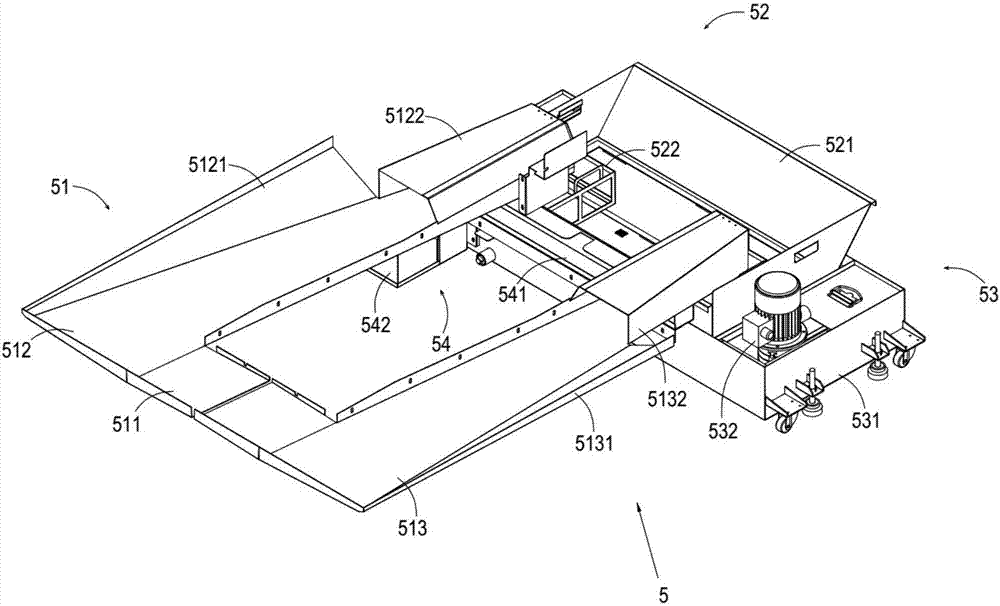

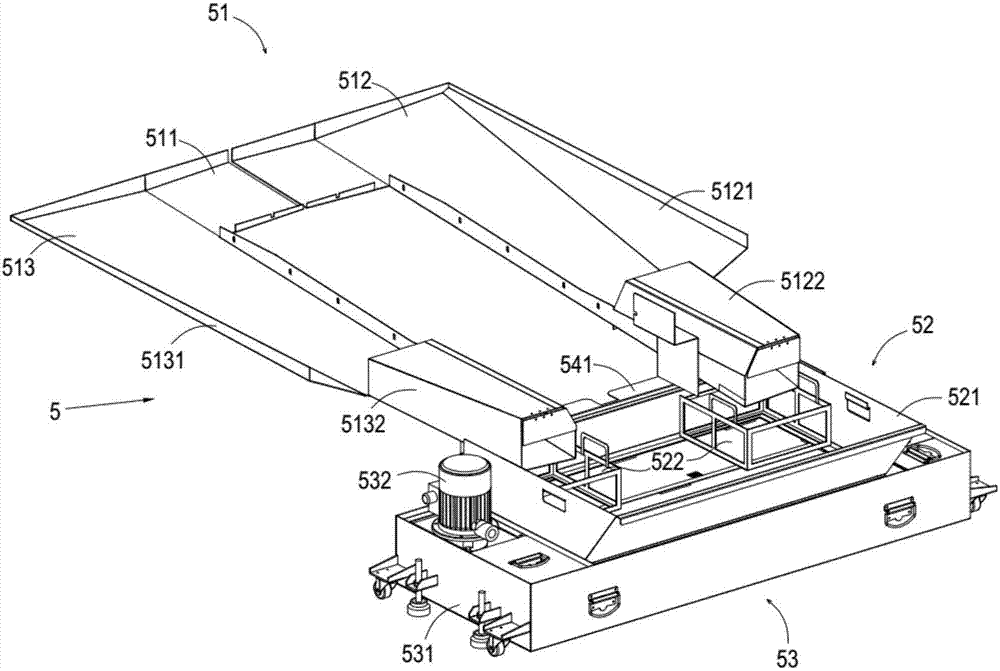

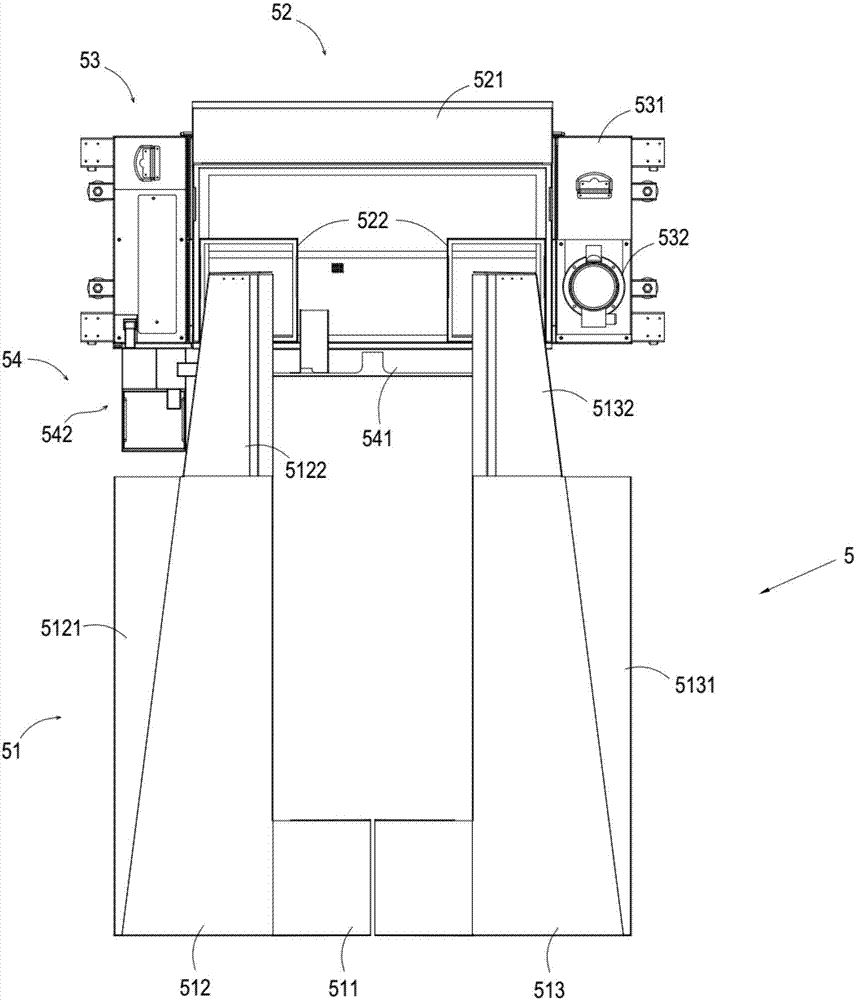

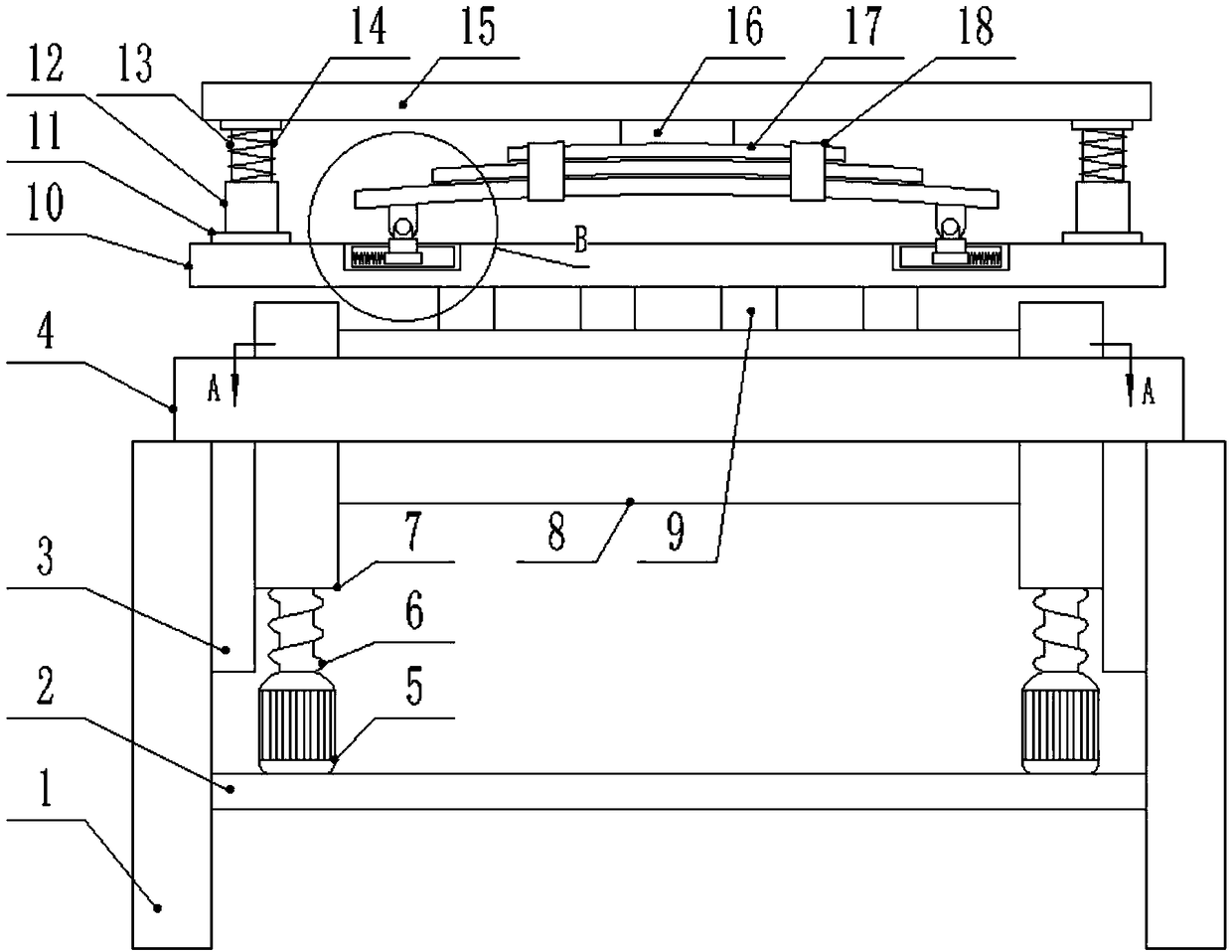

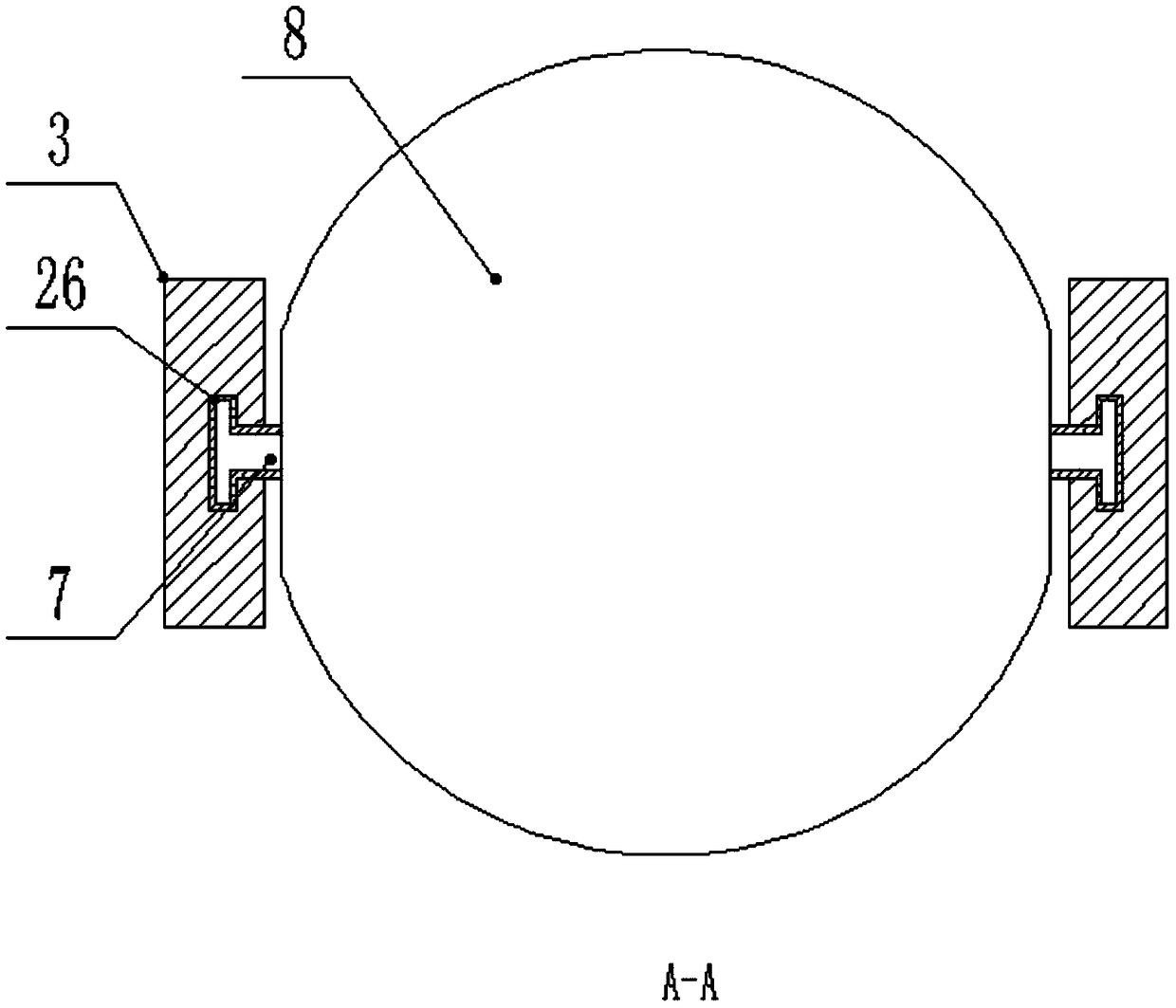

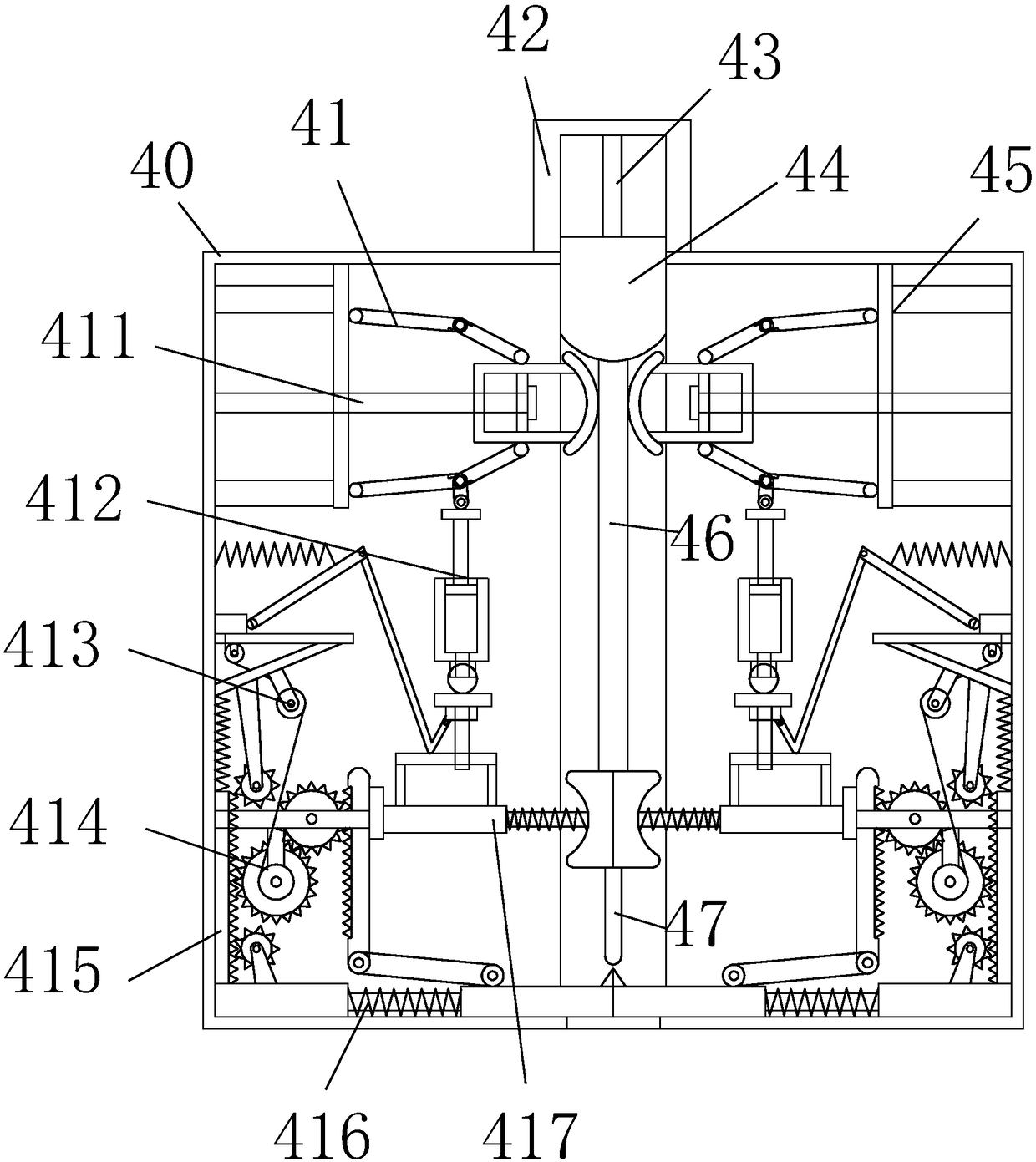

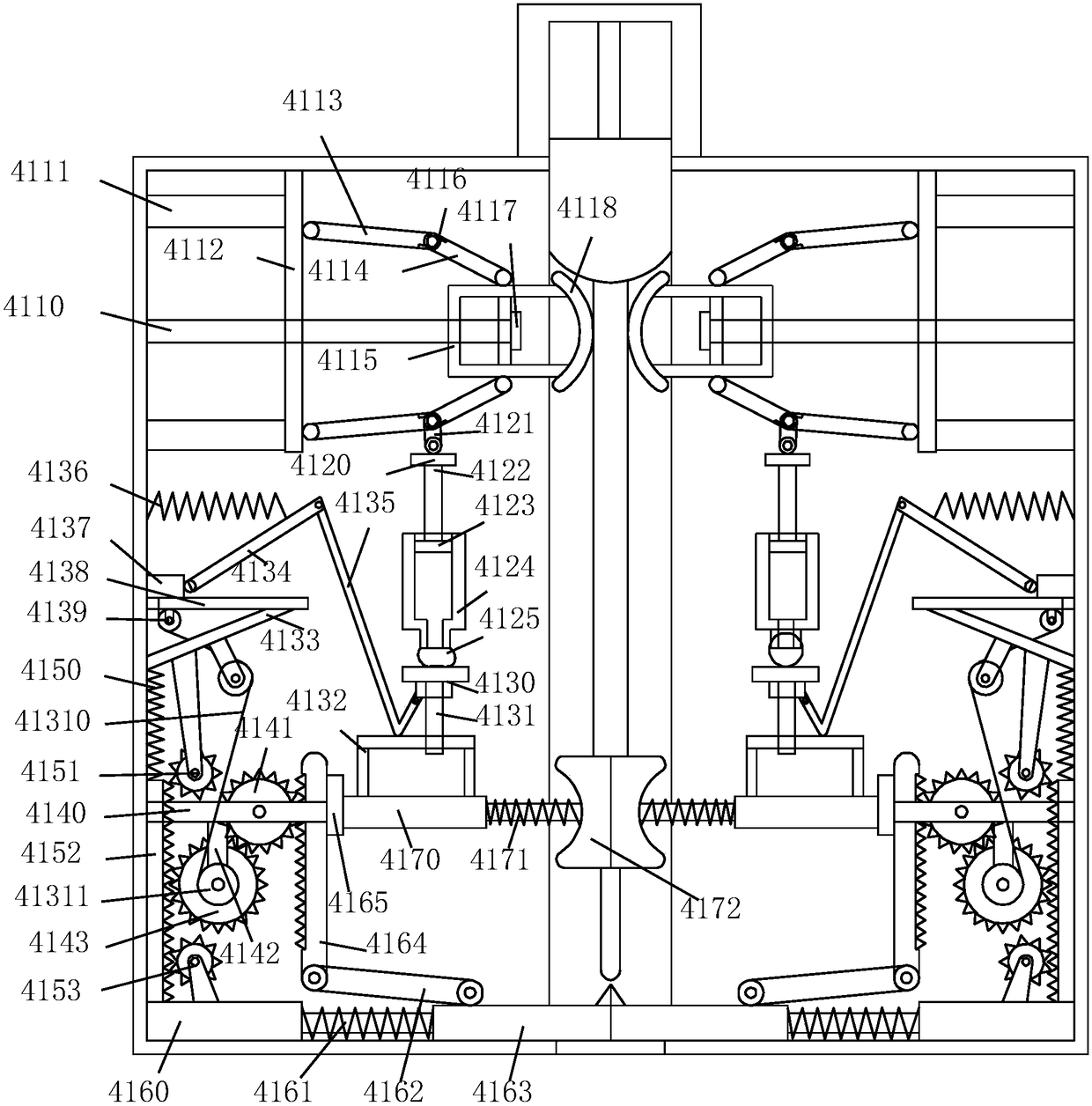

Supporting plate feeding system of numerical-control scraping rolling machine

InactiveCN112476011AAssisted movementReduce the impact of movementFeeding apparatusMaintainance and safety accessoriesGear wheelControl engineering

The invention relates to the technical field of oil cylinder machining, and discloses a supporting plate feeding system of a numerical-control scraping rolling machine. The supporting plate feeding system comprises a rack, wherein guide rails are fixedly mounted on the left side and the right side of the top end of the rack, fixed frames are movably mounted at the top ends of the guide rails, andracks are fixedly mounted at the ends, close to each other, of the two guide rails; and fixed seats are fixedly mounted on sides of the back surfaces of the fixed frames. According to the supporting plate feeding system of the numerical-control scraping rolling machine disclosed by the invention, the bottom ends of the output shafts of servo motors are fixedly sleeved with the gears, the racks arearranged on the side surfaces of the guide rails and connected to the gears in a meshed mode; and when the fixed frames need to be moved, the gears at the bottom ends of the servo motors can be driven to rotate at the moment by starting the servo motors; the gears can be driven by the racks to move relative to the guide rails and drive the fixed frames to move relative to the guide rails, so thatthe influence of sliding friction on movement of the fixed frames is reduced, and therefore, the advantage of assisting movement of the fixed frames is achieved.

Owner:LOUDI DINGLI HYDRAULIC TECH CO LTD

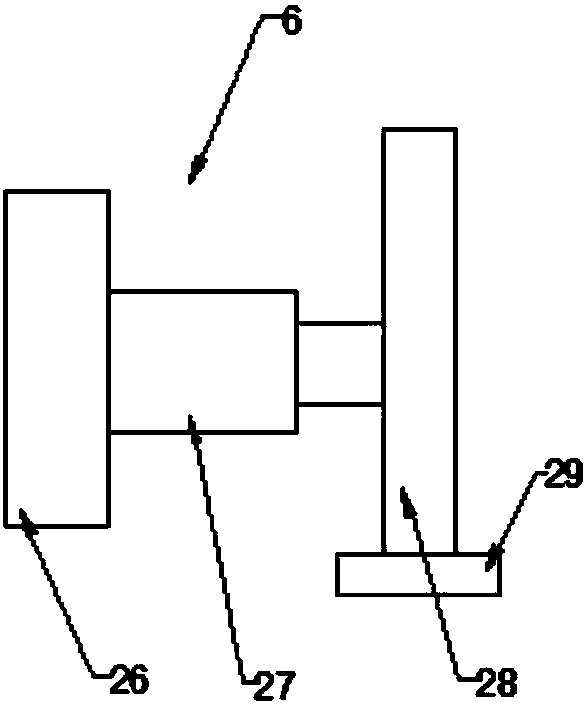

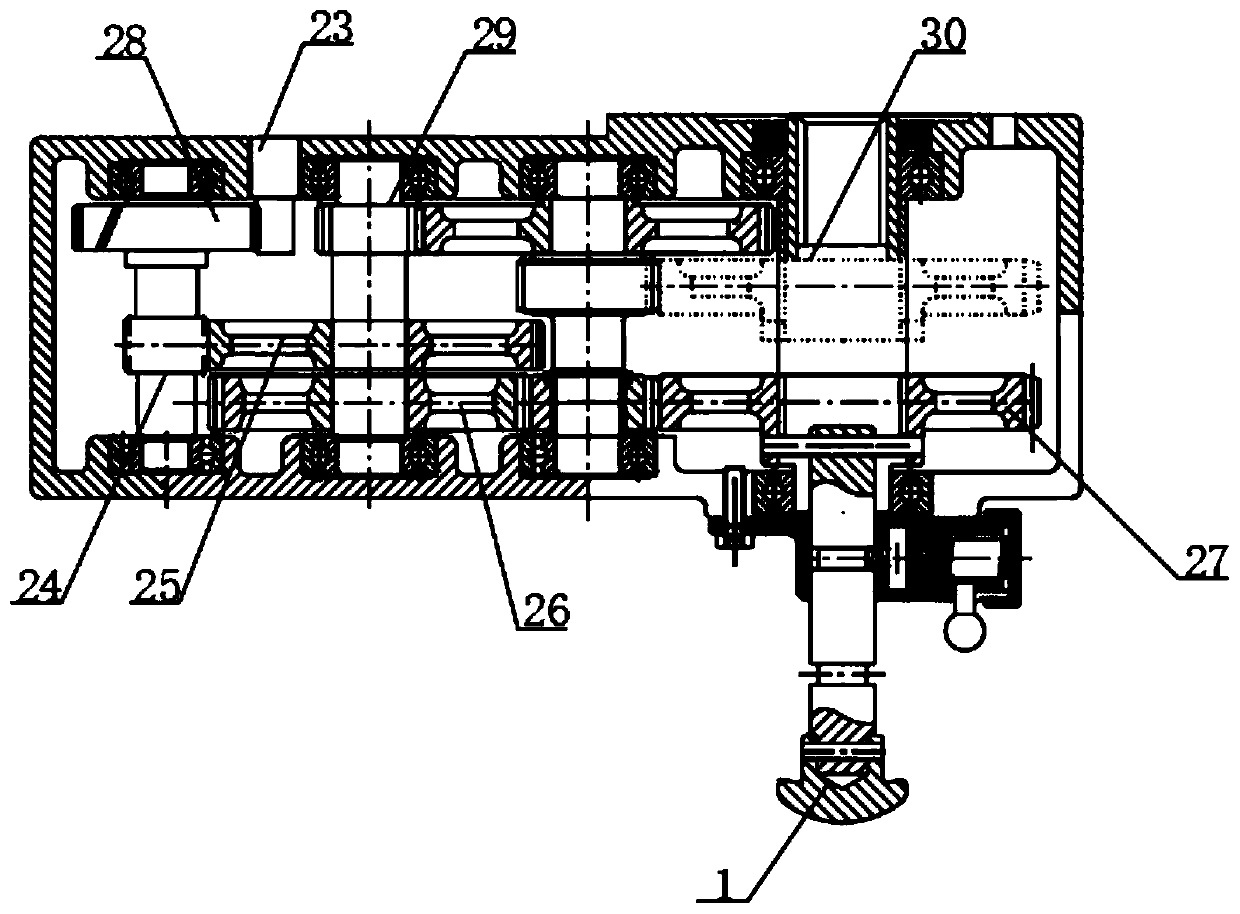

Gearbox device of speed regulating tapping machine

InactiveCN109926619APositioning apparatusMaintainance and safety accessoriesAgricultural engineeringUnderground tunnel

Owner:ANHUI TONGFA EQUIP CO LTD

Color steel deburring device

InactiveCN110116241APlay a role in cleaningImprove practicalityFeeding apparatusPositioning apparatusFixed frameArchitectural engineering

Owner:ZHONGXIANG DINGMAO TECH

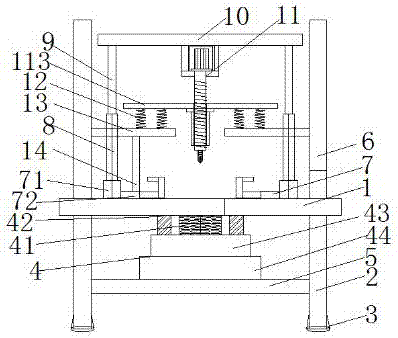

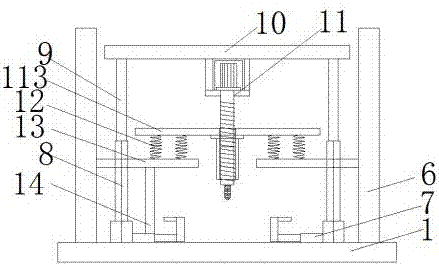

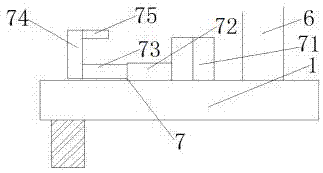

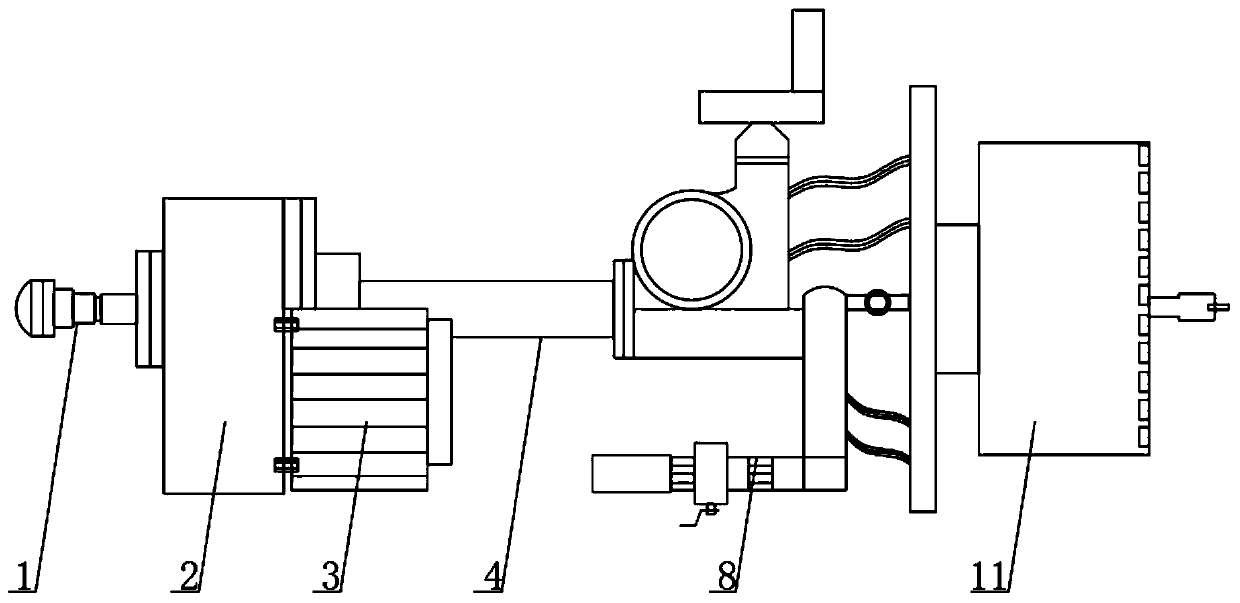

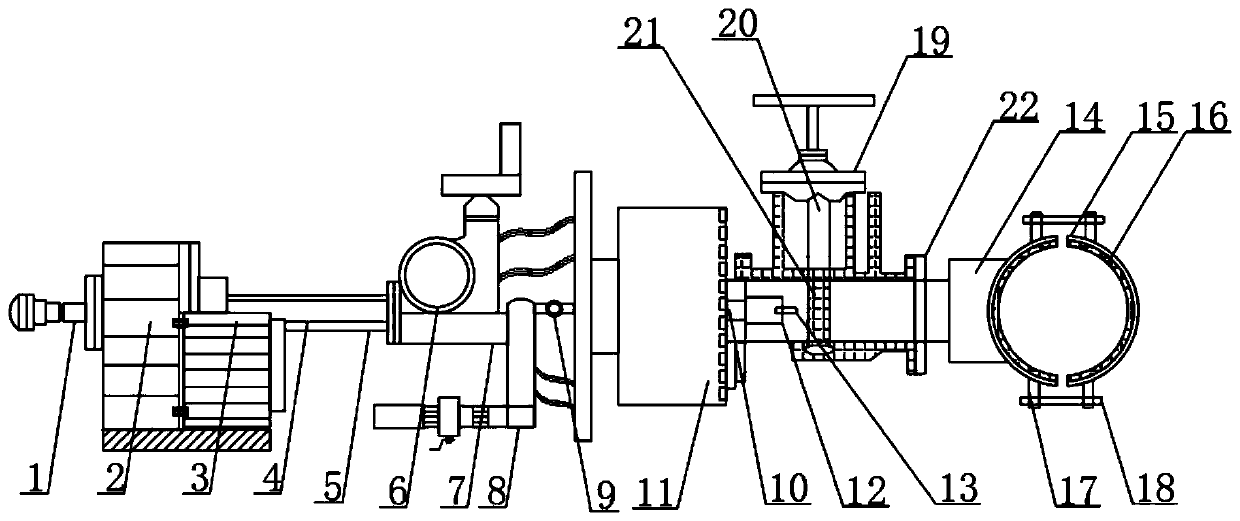

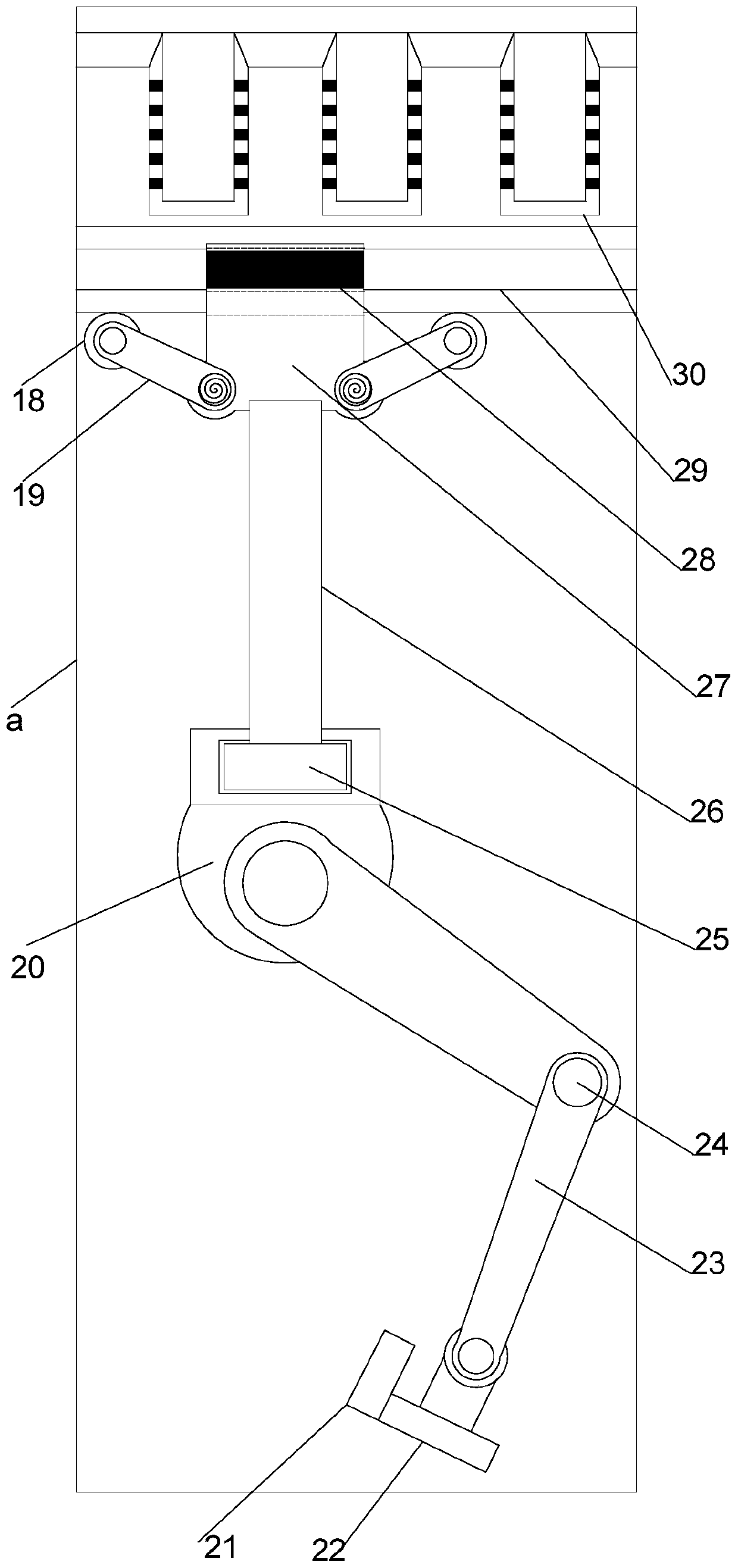

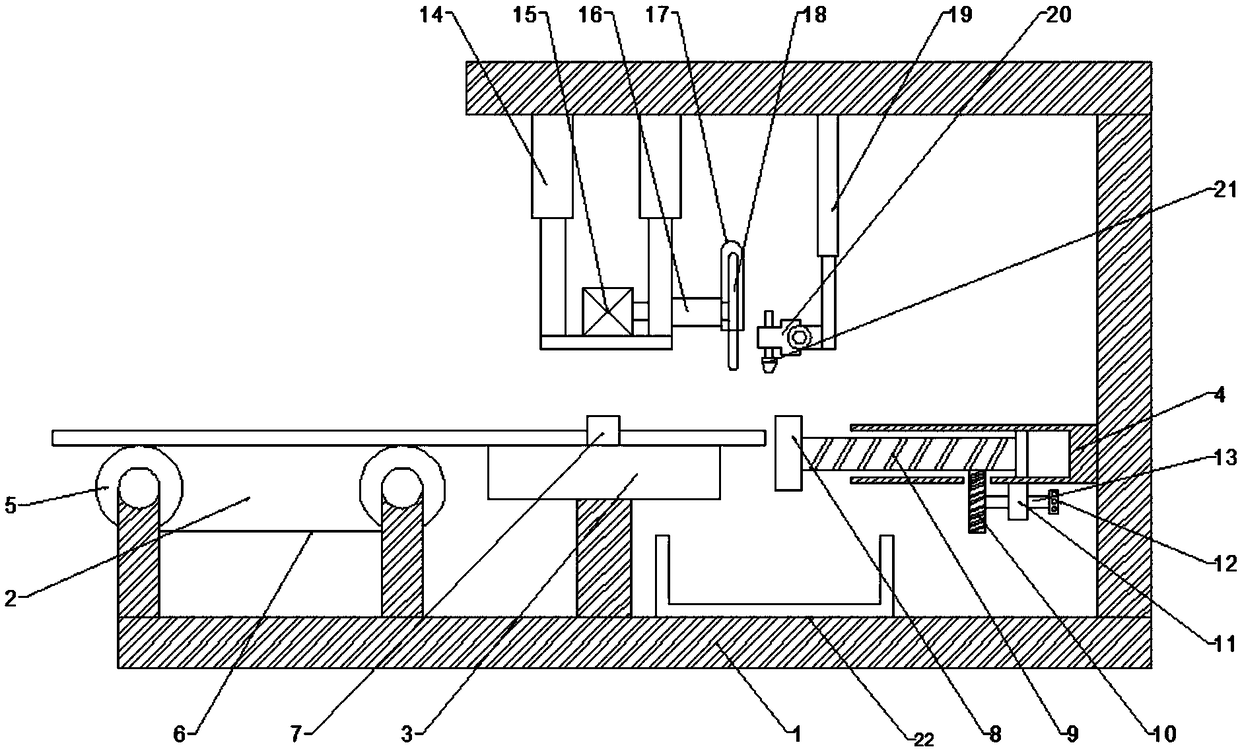

Gas cooker pipeline machining device

InactiveCN107971783AFast processingImprove processing efficiencyPositioning apparatusMaintainance and safety accessoriesEngineeringCooker

The invention relates to the technical field of gas cooker part machining, and discloses a gas cooker pipeline machining device which comprises a base and a supporting frame. The supporting frame is fixedly connected to the upper surface of the base, two electric push rods are fixedly connected to the top of the inner side of the supporting frame, and a bearing plate is fixedly connected to the tail ends of the two electric push rods. By means of mutual cooperation of the base, the supporting frame, the electric push rods, the bearing plate and a driving device, the problem that an existing gas cooker pipeline machining device is low in machining efficiency is solved. By means of mutual cooperation of an installation plate, the driving device and a clamp device, the problem that an existing gas cooker pipeline machining device cannot rapidly and effectively position gas pipelines is solved. By means of mutual cooperation of the installation plate, the driving device, the clamp device and a cleaning device, the problem that fragment stacking produced in the using process of an existing gas cooker pipeline machining device affects machining precision is solved.

Owner:XINCHANG CHANGCHENG AIR-CONDITIONER COMPONENTS INC

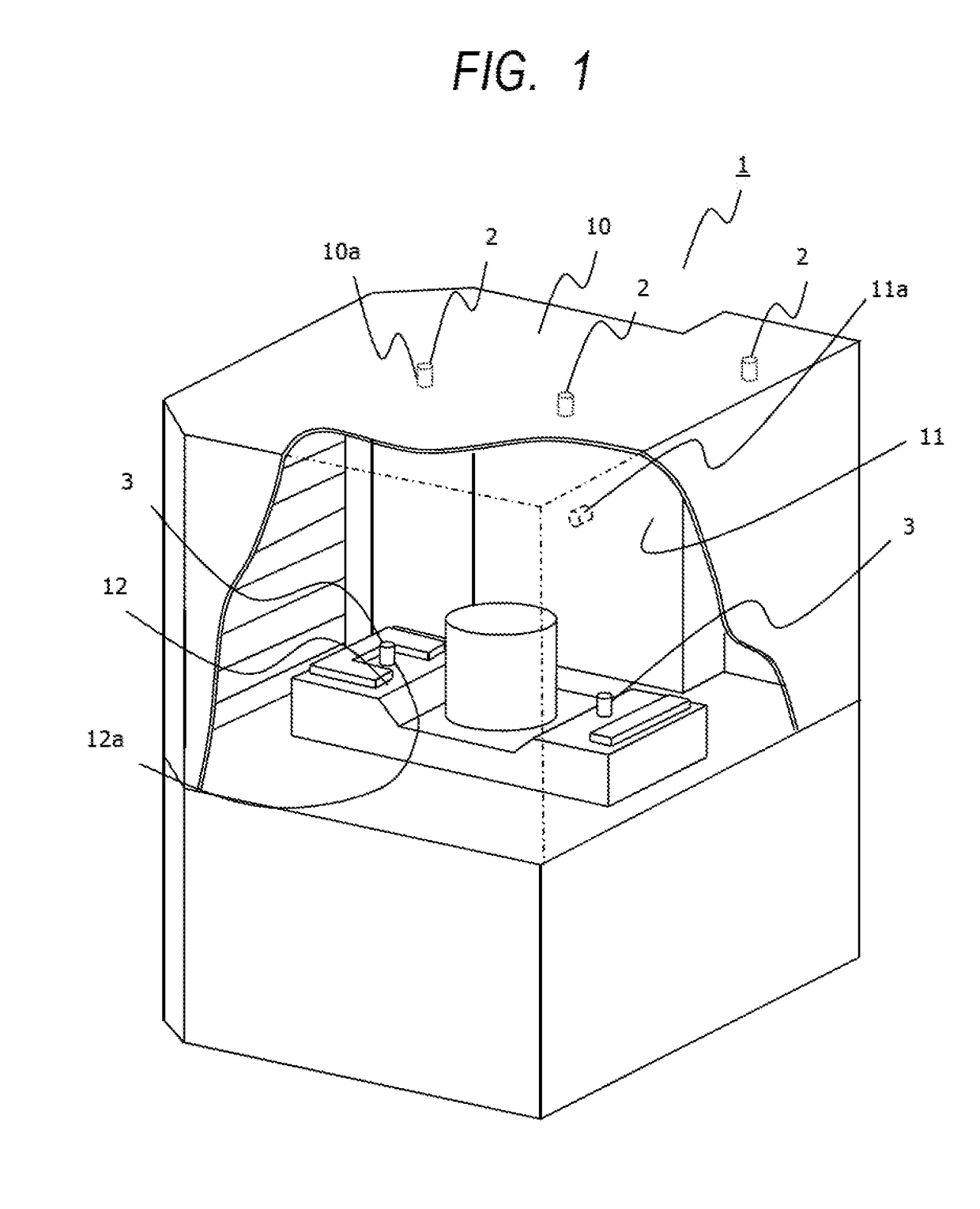

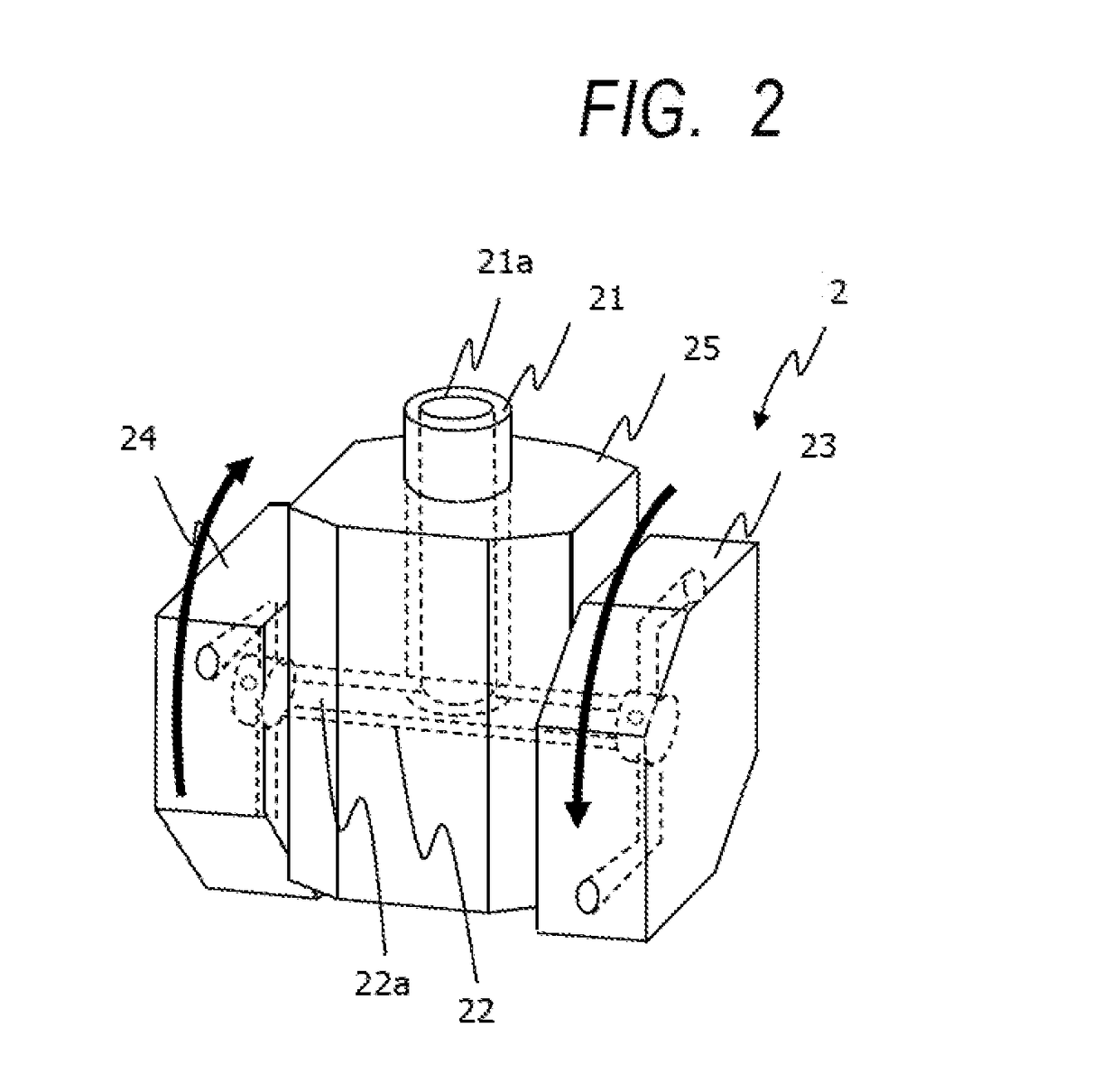

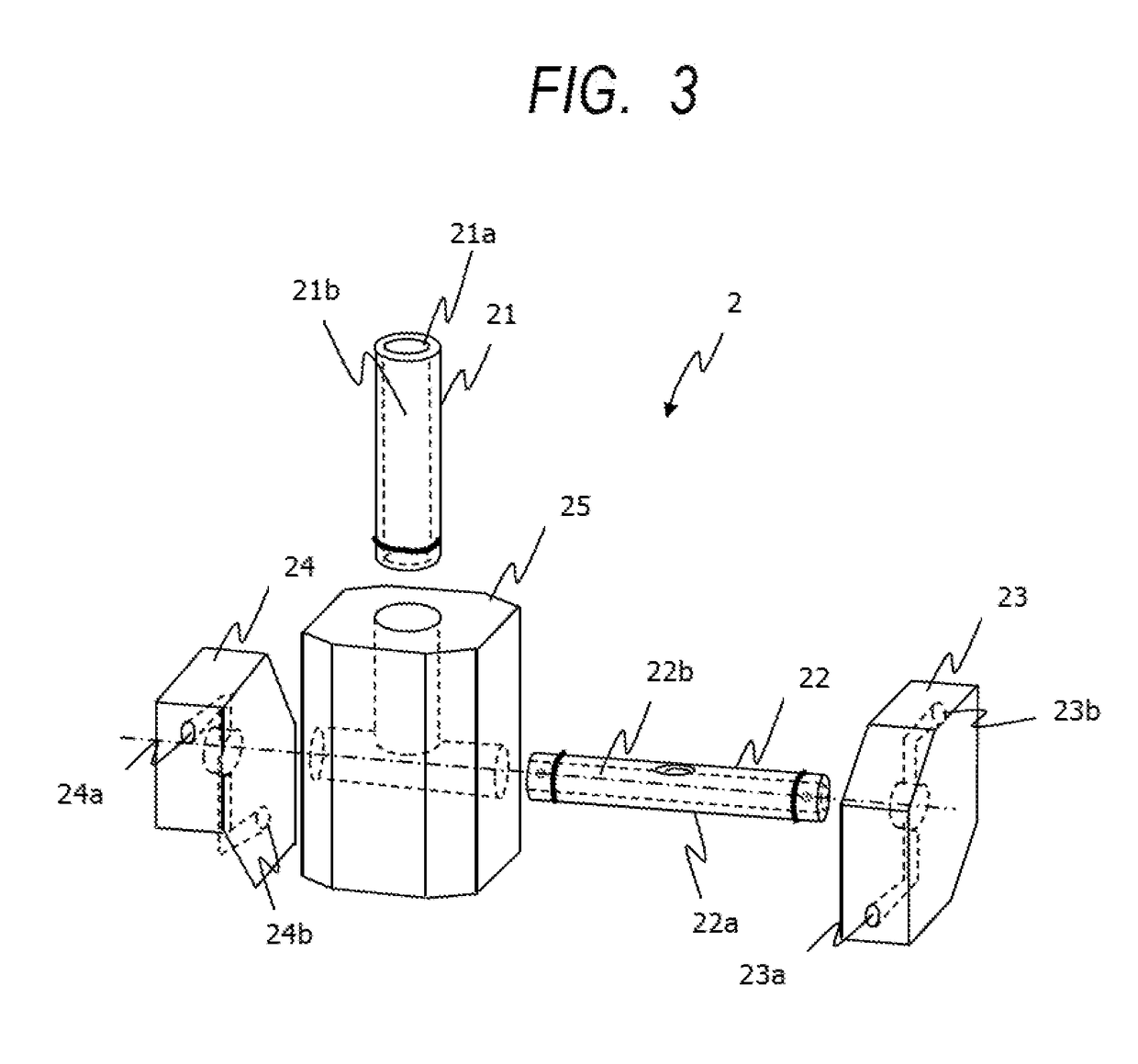

Washing nozzle for machine tool and machine tool therein

ActiveUS20180369838A1Reduce in quantityReduce size of pumpHollow article cleaningMovable spraying apparatusMachine toolNozzle

Owner:KIWA MACHINERY

Mechanical device for automatic pouring of cutting fluid

Owner:CHANGSHU MIAOQUAN COMPRESSOR ACCESSORIES

Numerical control machine tool equipment capable of improving equipment reliability by improving environmental friendliness

ActiveCN111546122ADispersed particle filtrationMaintainance and safety accessoriesProcessing accuracyEnvironmentally friendly

Owner:JILIN UNIV

Vehicle brake disc conveying drilling device

InactiveCN109128274AMaintainance and safety accessoriesBoring/drilling machinesEngineeringUser needs

Owner:广德亚太汽车智能制动系统有限公司

Cooling liquid recovery device for numerical control machine tool

PendingCN107470976AEfficient collectionImprove recycling rateMaintainance and safety accessoriesNumerical controlEconomic benefits

Owner:苏州富强加能精机有限公司

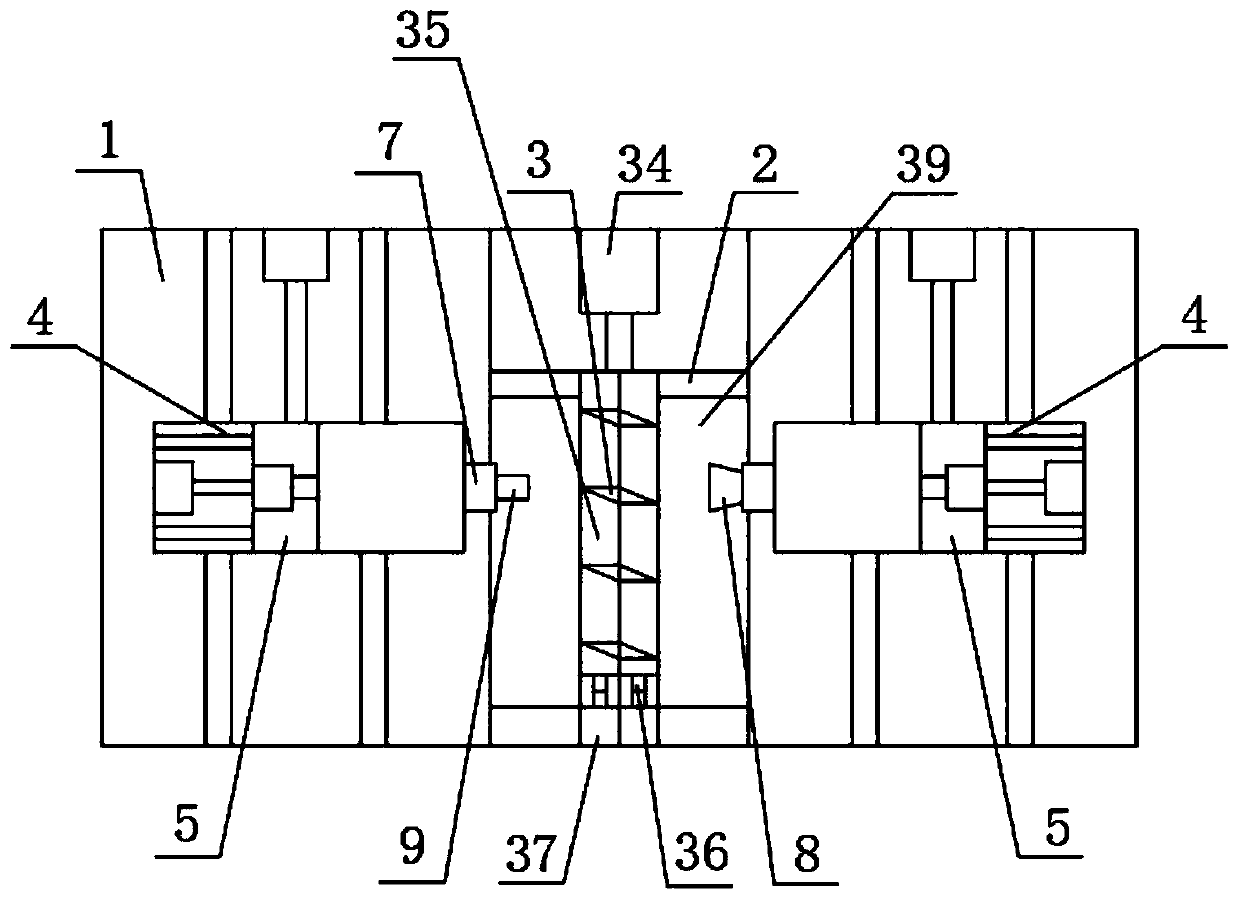

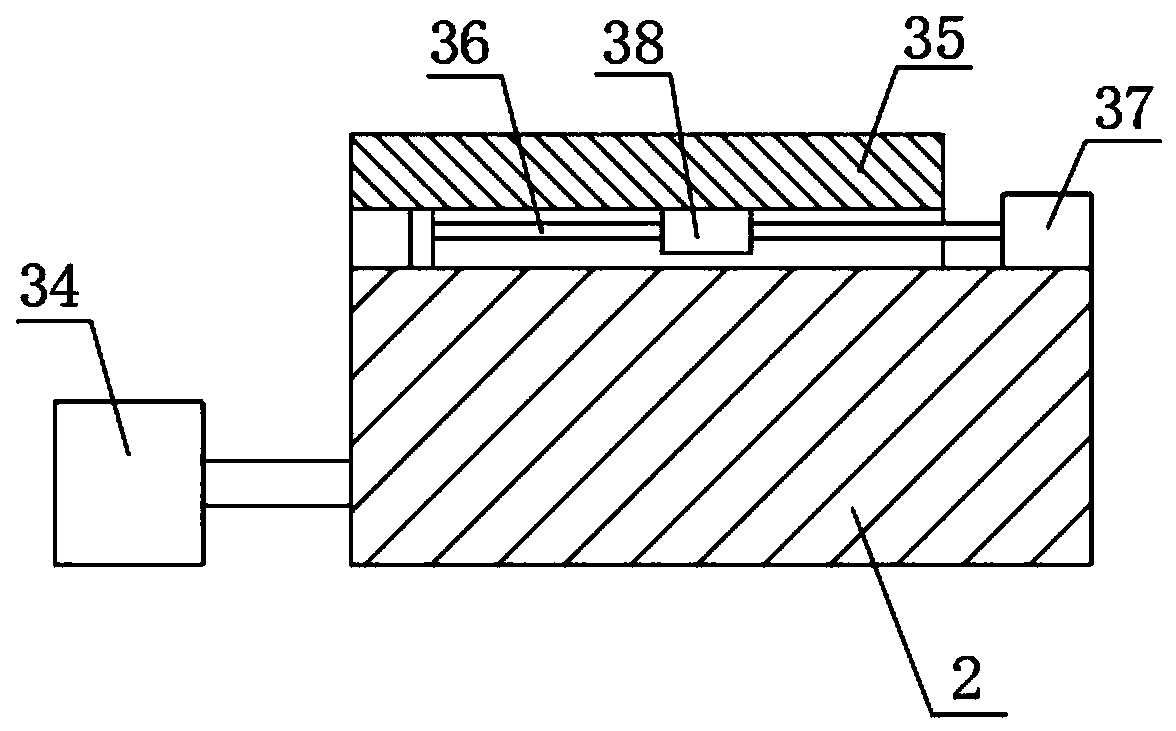

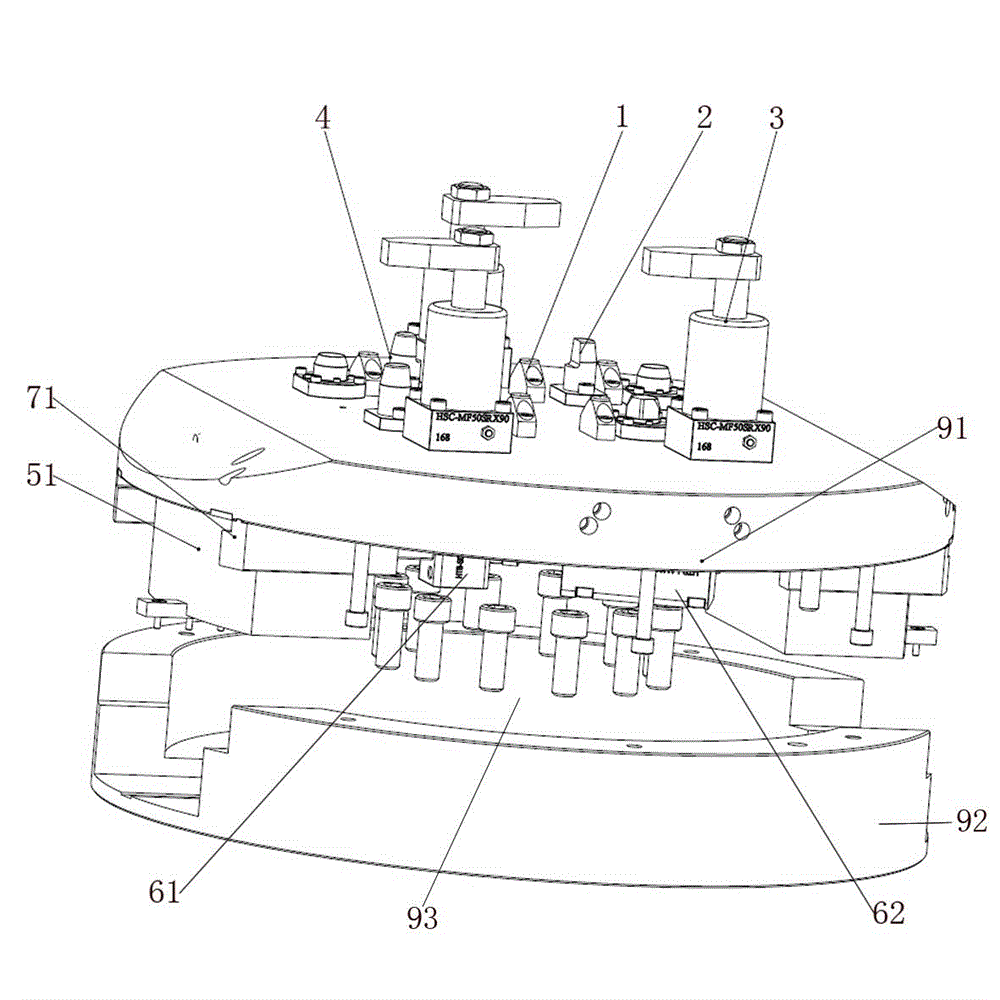

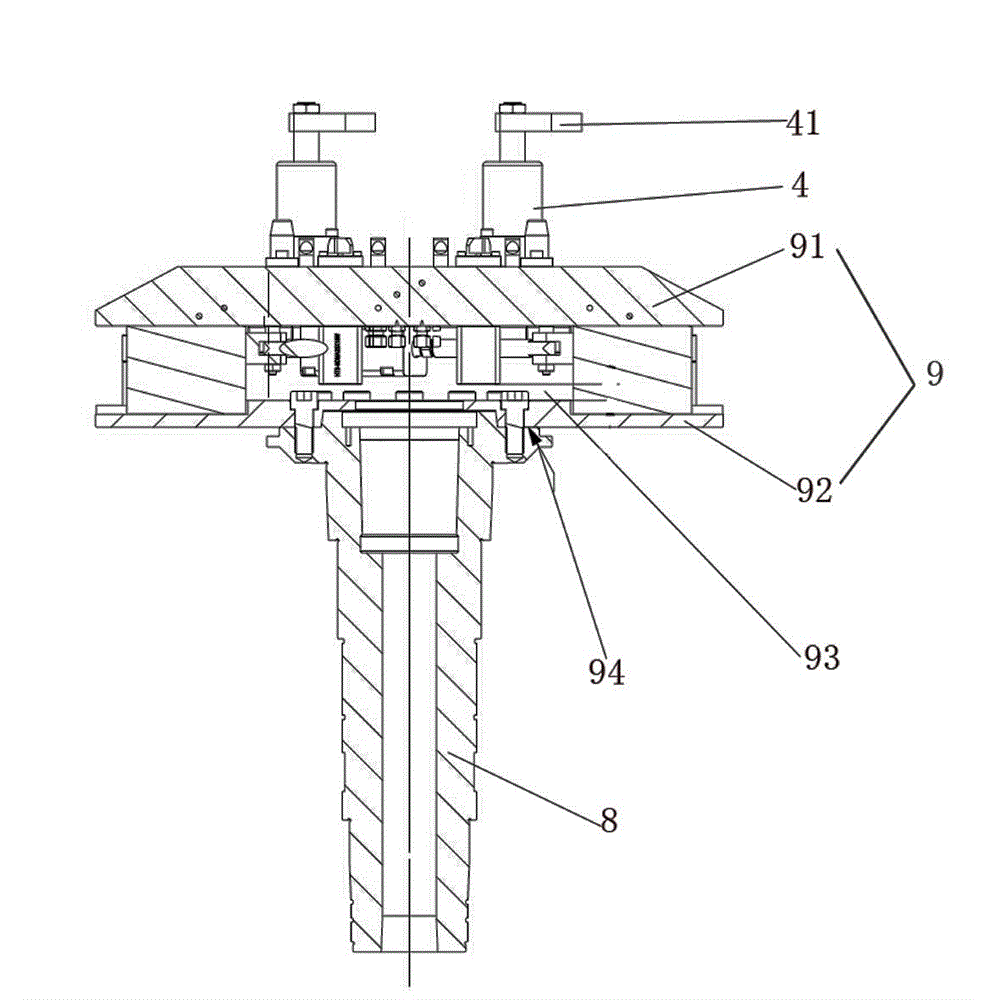

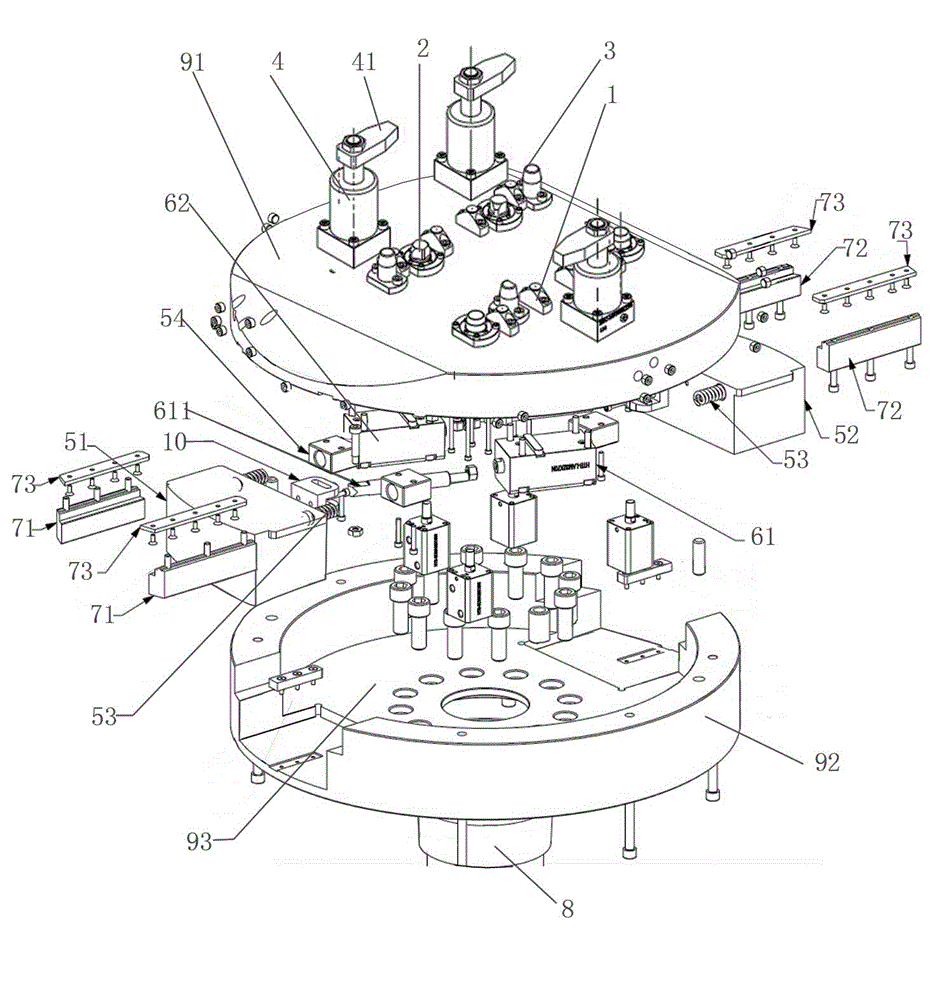

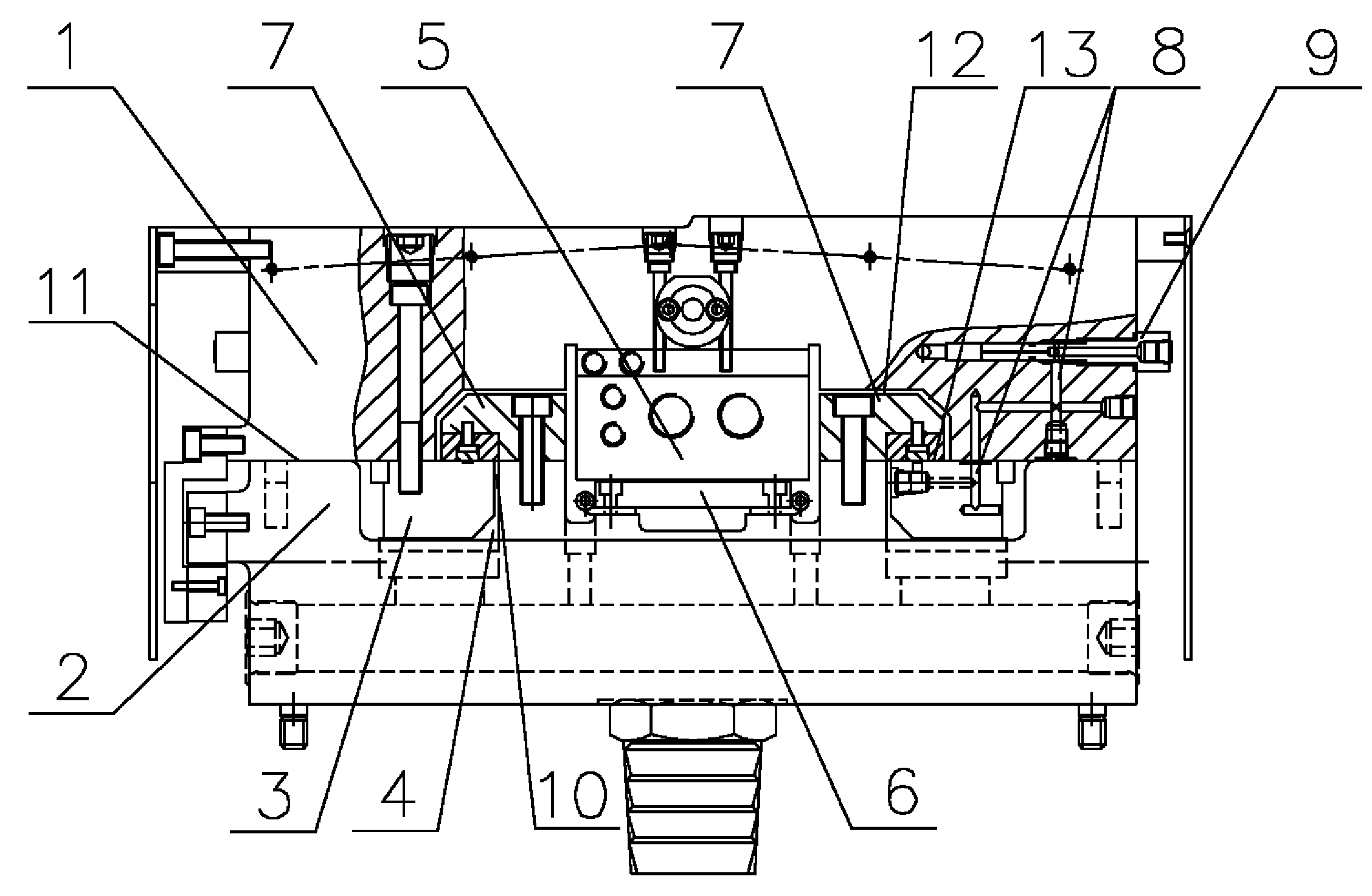

Clamping device of boring-milling machine

ActiveCN104325297AThe overall structure is simple and reliableImprove machining accuracyLarge fixed membersMaintainance and safety accessoriesFuel tankEngineering

Owner:靖江市普瑞新量具有限公司

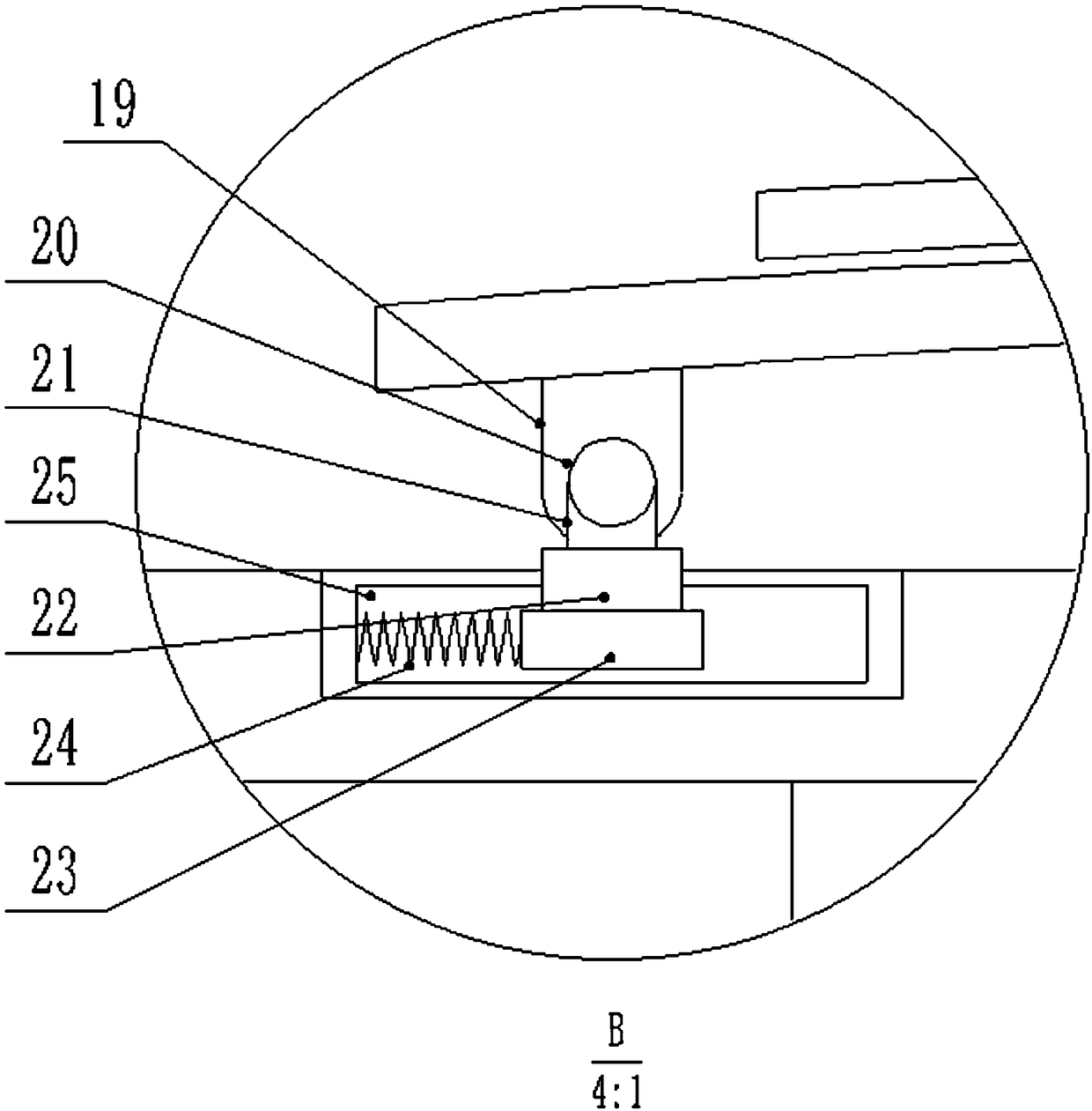

Elastic piece type damping device for machining

Owner:南宁众创空间科技有限公司

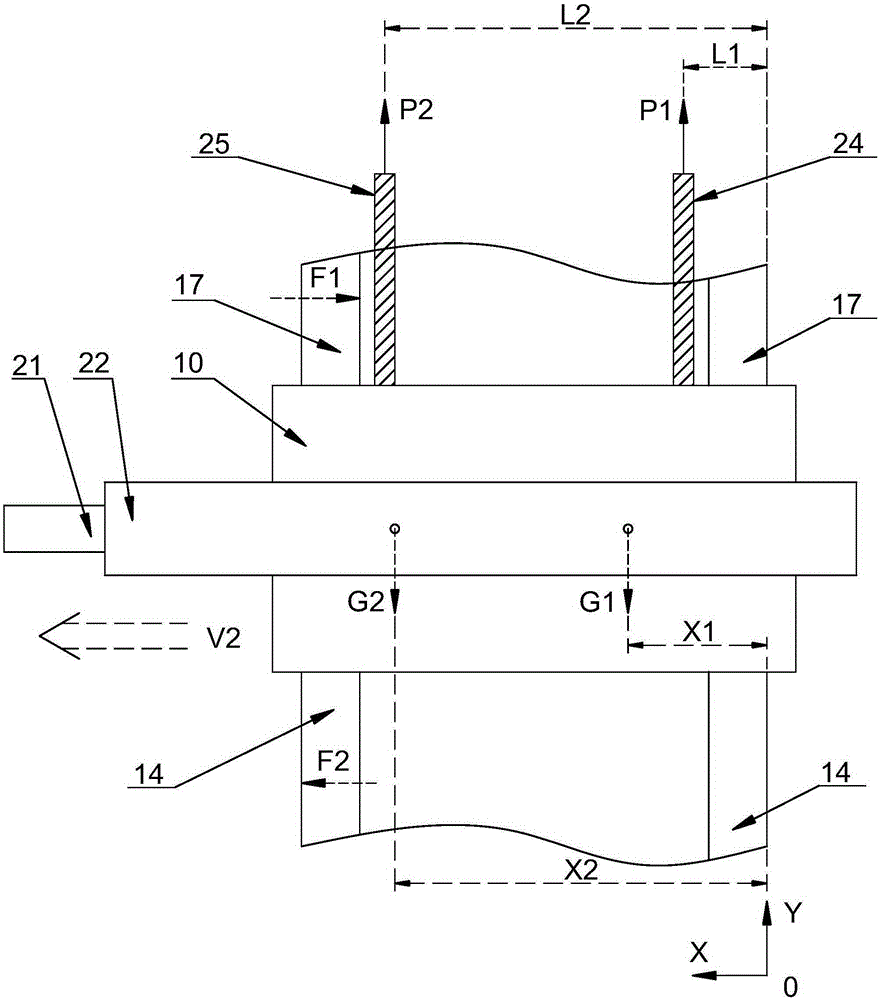

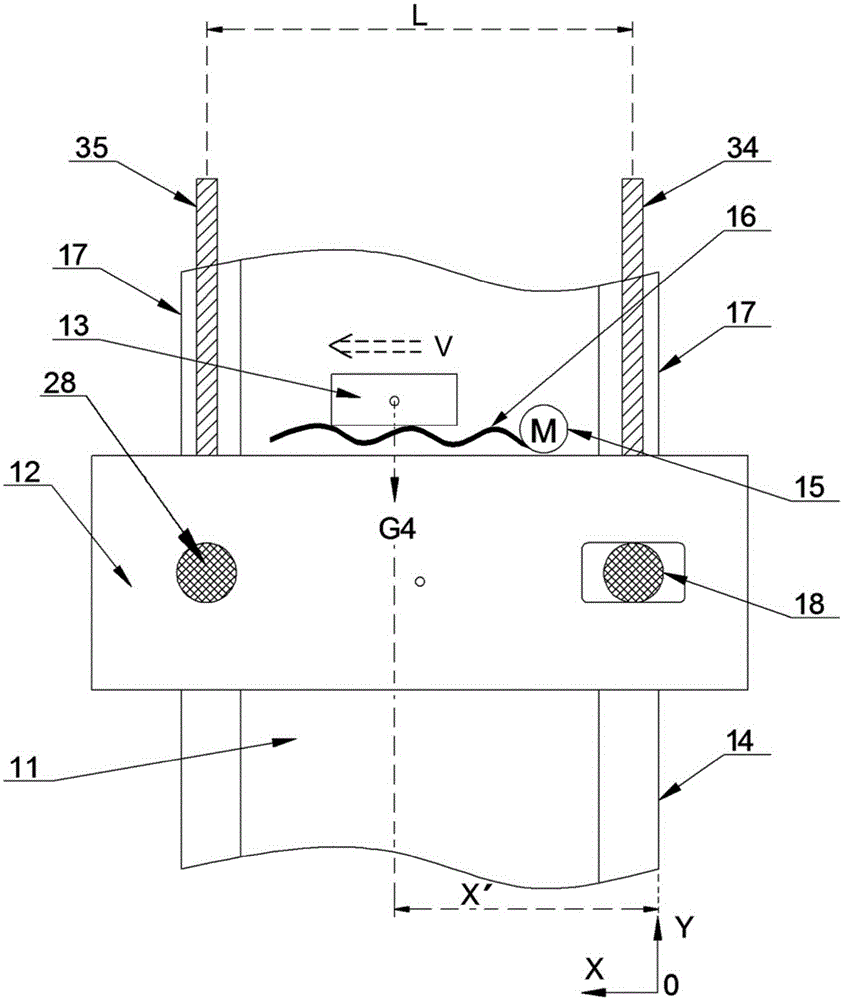

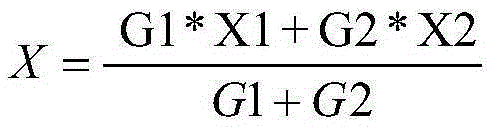

Self-adaptation gravity center compensation device and method for floor type boring-milling machine

Owner:东莞市埃弗米数控设备科技有限公司

Machine tool with active damping

ActiveUS20190299349A1Easy and efficient solutionMachine tool componentsMeasurement/indication equipmentsEngineeringMachine tool

Owner:SORALUCE S COOP

Butt joint type automatic double-spindle numerical control machine tool for polygon turning

ActiveCN110280787AAutomatic/semiautomatic turning machinesMaintainance and safety accessoriesTool holderEngineering

Owner:兰溪瑞鼎机床股份有限公司

Multi-freedom-degree machine tool for machining circuit boards

ActiveCN108145203AGuaranteed cleanlinessPrevent fallingMaintainance and safety accessoriesBoring/drilling machinesEngineeringMachine tool

Owner:佛山市鑫科源电子有限公司

Cutting equipment for machining metal connecting piece of cleaning gun head

InactiveCN109048454AEasy to cutImprove machining accuracyPositioning apparatusMetal working apparatusWater flowCooling effect

Owner:安徽京冠派克流体科技有限公司

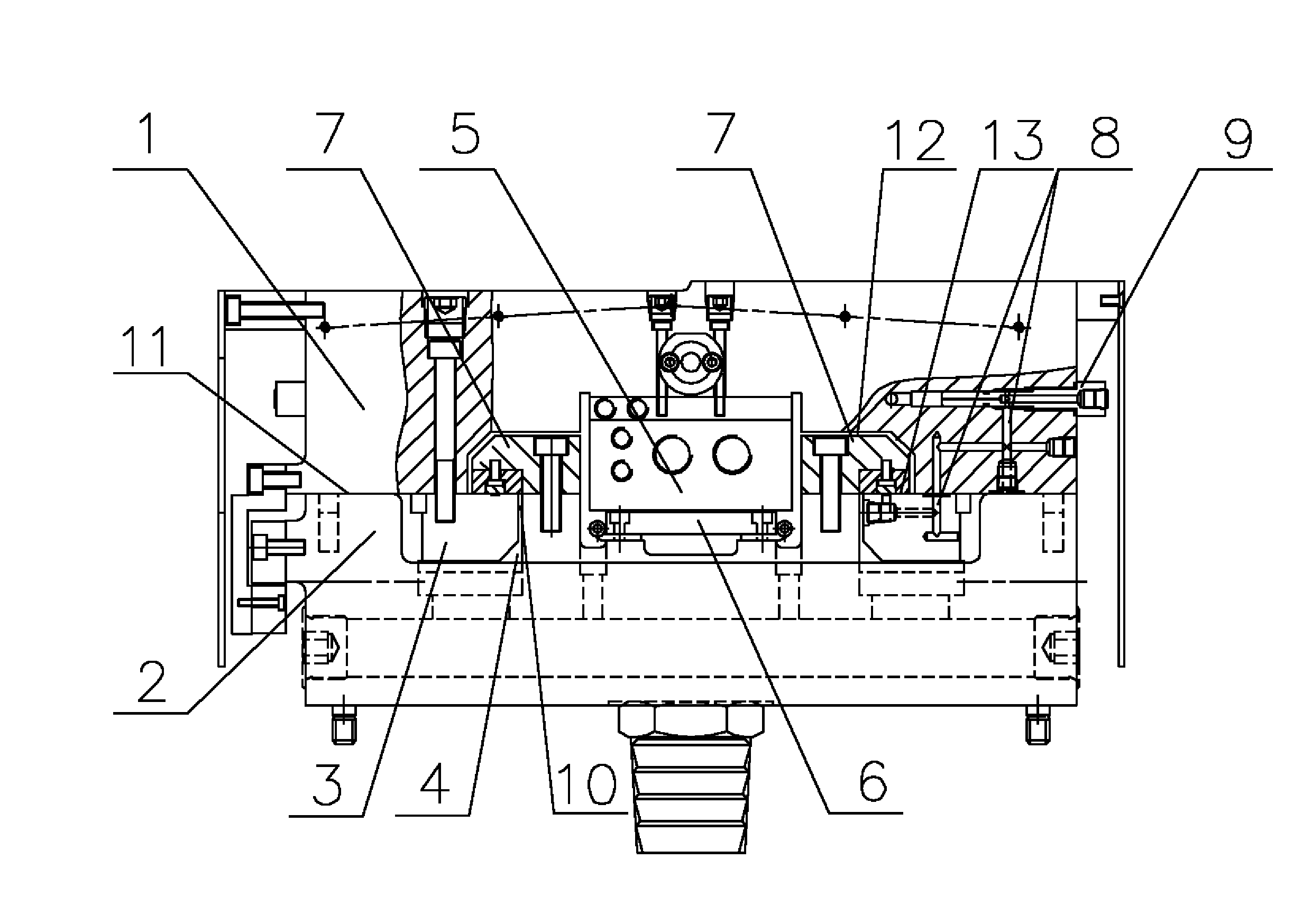

Self-balancing type lathe fixture

ActiveCN104476287APositioning apparatusMaintainance and safety accessoriesAutomatic processingEngineering

Owner:JIANGXI JUST NUMERICAL CONTROL TECH

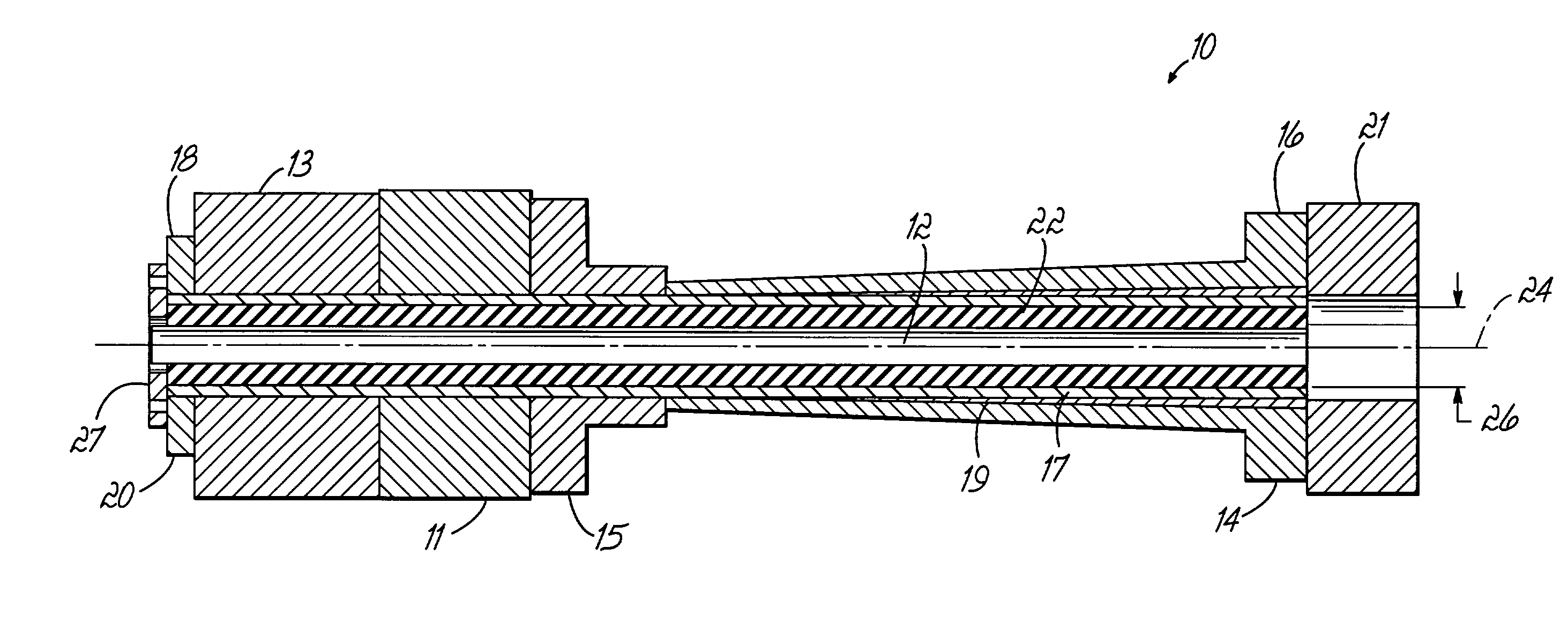

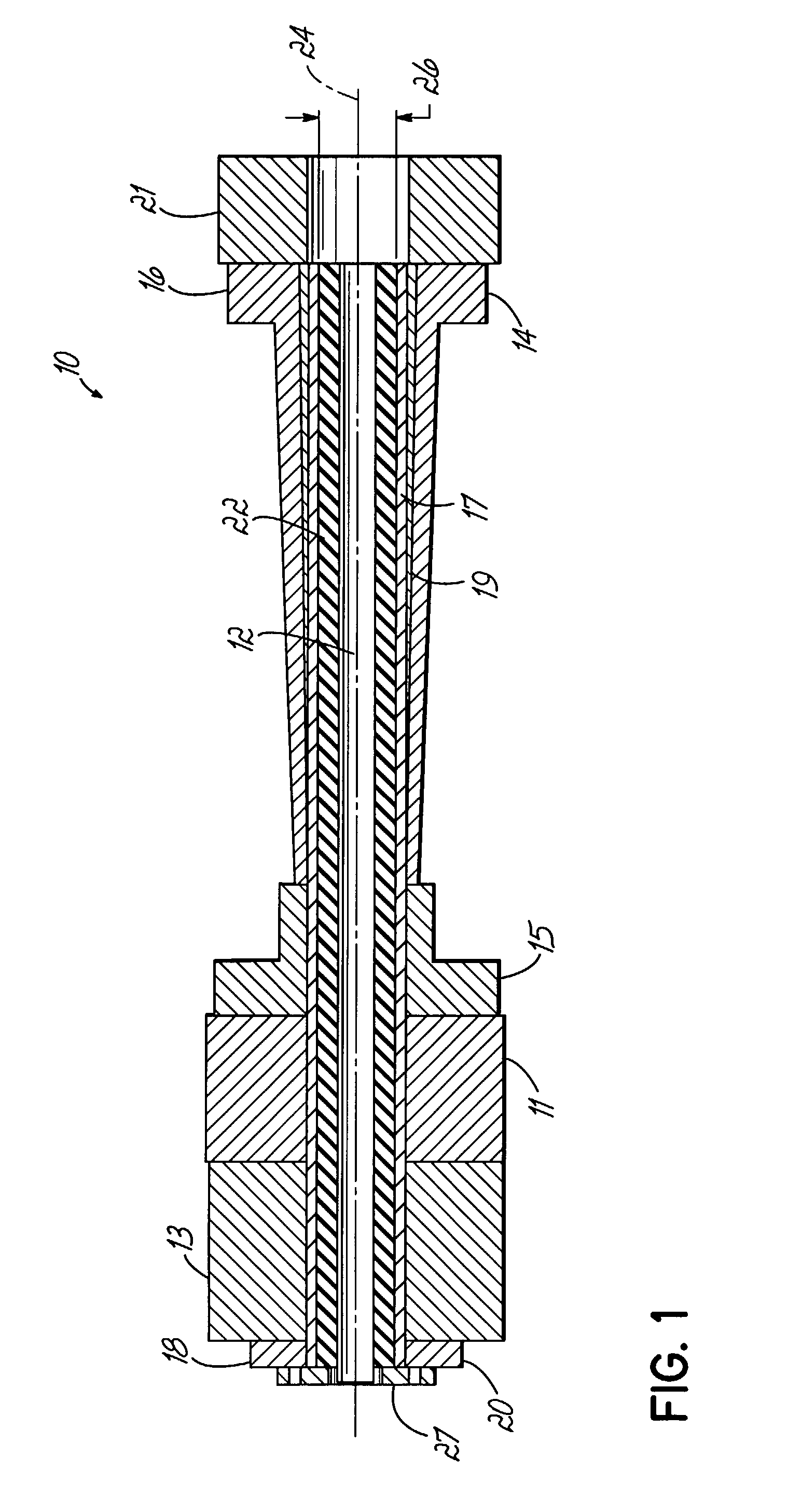

Linear feeding mechanism for machine tool

Owner:WUXI MACHINETOOL

Multi-angle hole opening device for porous steel plate

InactiveCN113579311AAchieve fixationAvoid damageAutomatic control devicesFeeding apparatusMachine toolMachining

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

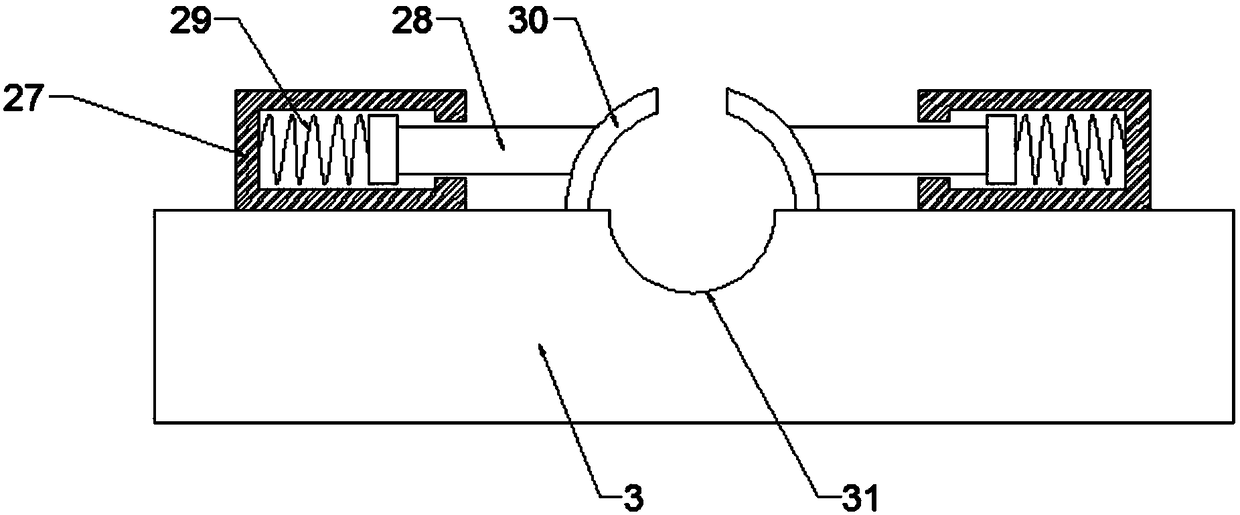

Machine tool for machining wheel hub

InactiveCN106078346AEffective protectionExtended service lifeMaintainance and safety accessoriesEngineeringSpray cooling

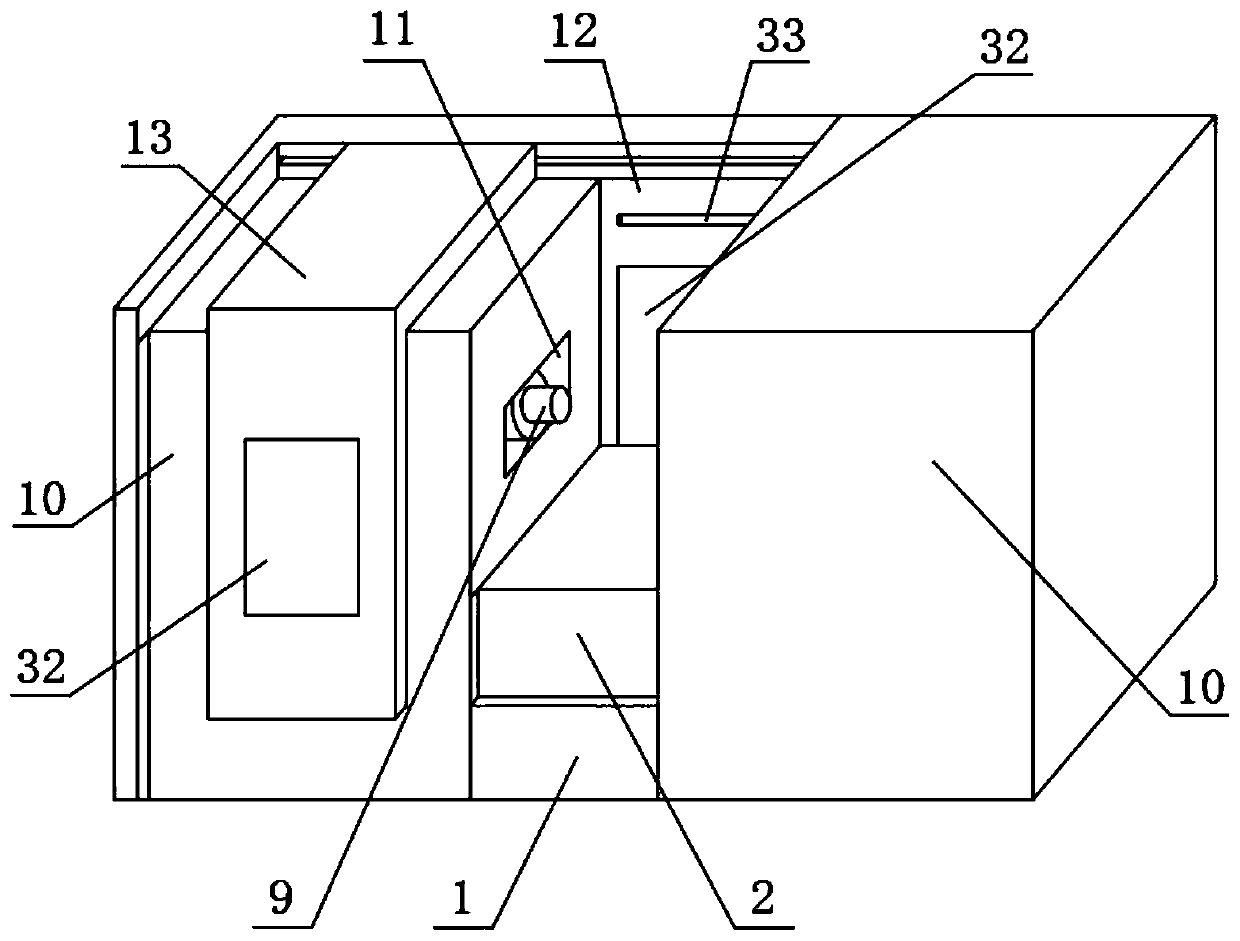

The invention discloses a machine tool for machining a wheel hub. The machine tool for machining the wheel hub comprises a machine shell; a wheel hub fixing die and a machining device are rotationally arranged in the machine shell; a hollow annular water spray cavity is further slidably formed in the machine shell; a plurality of water spray heads communicate with the inner side surface of the annular water spray cavity; an external water pipe further communicates with the annular water spray cavity; a lighting lamp tube is fixed to the inner wall of the machine shell; an opening is formed in the shell and slidably provided with a sliding door; a hollow cylindrical metal sleeve matched with the lighting lamp tube is fixed to the inner side surface of the sliding door; and when the sliding door is moved to close the opening, the cylindrical metal sleeve can cover the outside of the lighting lamp tube. The problems that a water spray device in a traditional machine tool for machining a wheel hub cannot effectively conduct spray cooling on all surfaces of the wheel hub, and meanwhile, a lighting lamp in the machine tool is prone to being affected by cooling water or scrap splashing and is damaged are solved.

Owner:WUHU HUANGYAN IND

Milling tool for retaining groove of automobile hub axle tube

InactiveCN110919416AEasy to collectReduce operational burdenPositioning apparatusMaintainance and safety accessoriesStructural engineeringMachine

The invention discloses a milling tool for a retaining groove of an automobile hub axle tube and belongs to the field of automobile hub axle tube machining. The tool comprises a collecting box, wherein the collecting box is of a cuboid structure with an opening formed at the top, a filter screen is fixed in the collecting box, a milling machine is fixed to a bottom wall of the collecting box through a supporting rod, a sliding groove is formed on an upper surface of the milling machine in the length direction, a sliding block is slidably connected into the sliding groove, an installation plateis fixed to a top end of the sliding block, positioning blocks are symmetrically welded to an upper surface of the installation plate, a check block is installed on one side of an upper surface of the installation plate through a fixing rod, an installation block is welded to the other side of the upper surface of the installation plate, a threaded hole is formed on the installation block, a screw is in threaded connection in the threaded hole, and a pressing block is fixed to one end of the screw. The tool is advantaged in that design is novel, a hub axle tube can be milled conveniently, themilling effect is good, waste chips and waste liquid generated by milling can be collected and recycled, resources are saved, and the tool is worthy of popularization.

Owner:SHIYAN HEYUE IND & TRADE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap