Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Cooker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooker may refer to several types of cooking appliances and devices used for cooking foods.

Full-period electric pressure cooker production control method

InactiveCN107713732AIncrease profitStrong targetingPressure-cookersIndustrial engineeringTechnical Guide

The invention discloses a full-period electric pressure cooker production control method. The method includes the steps that demand order data input by a customer is received, and a material ratio meeting electric pressure cooker production is automatically calculated and determined; an electric pressure cooker is produced according to the material ratio, and raw materials are weighed. In the full-period electric pressure cooker production control method, the electric pressure cooker is produced according to customer demands, the customer only needs to provide various demands such as food types and the product usage area when buying an electric pressure cooker, and then the electric pressure cooker which is needed by the customer and is suitable for food cooking and the product usage areacan be produced, which is like that an electric pressure cooker expert provides special technical guidance of electric pressure cooker production for the customer, so that the method has high pertinence to food cooking and the product usage area and is beneficial to increasing the electric pressure cooker utilization rate.

Owner:GUANGDONG HUILIPU ROAD & BRIDGE INFORMATION ENG

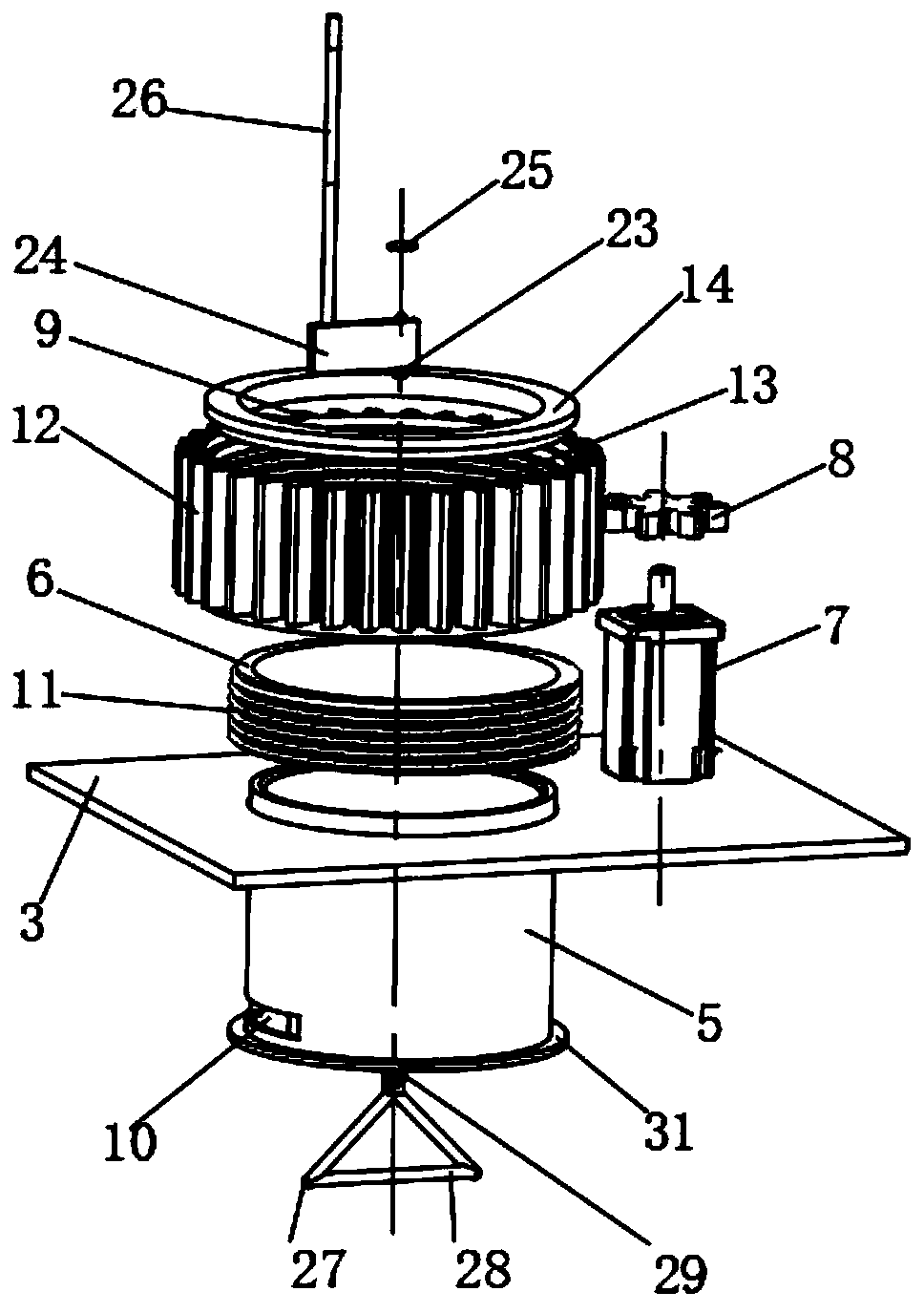

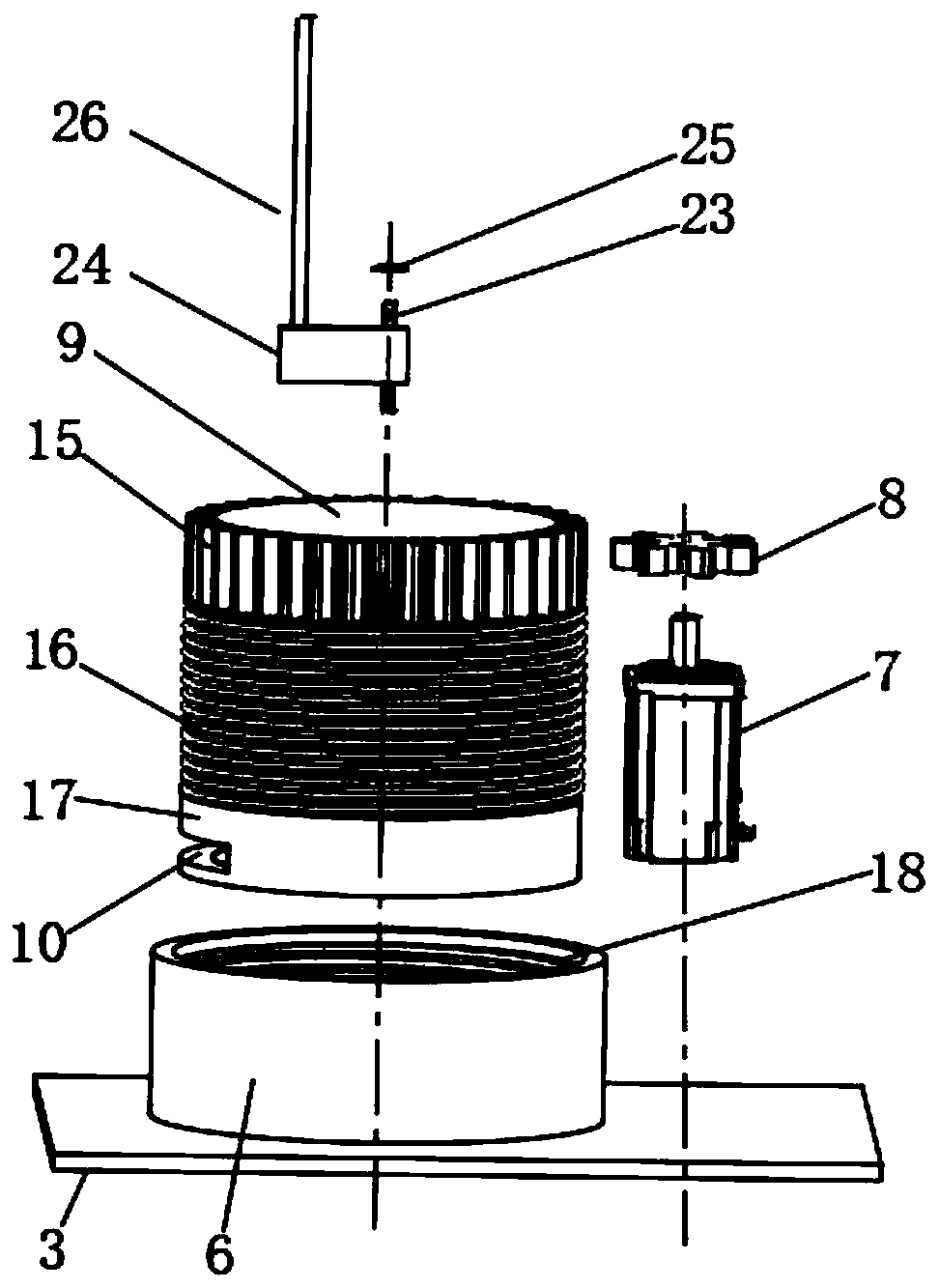

Full-automatic cooker

InactiveCN107647767AImprove automationReduce pollutionCombination devicesDomestic stoves or rangesElectricityMovement control

Owner:SHENZHEN ADVANCED TECH CO LTD

Intelligent cooker

ActiveCN105725735AAvoid mouthfeelAvoid wastingVessels with intergral heatingCooking vessel constructionsControl systemElectrical control

Owner:ZHONGSHAN JINGWEI ELECTRONICS TECH +1

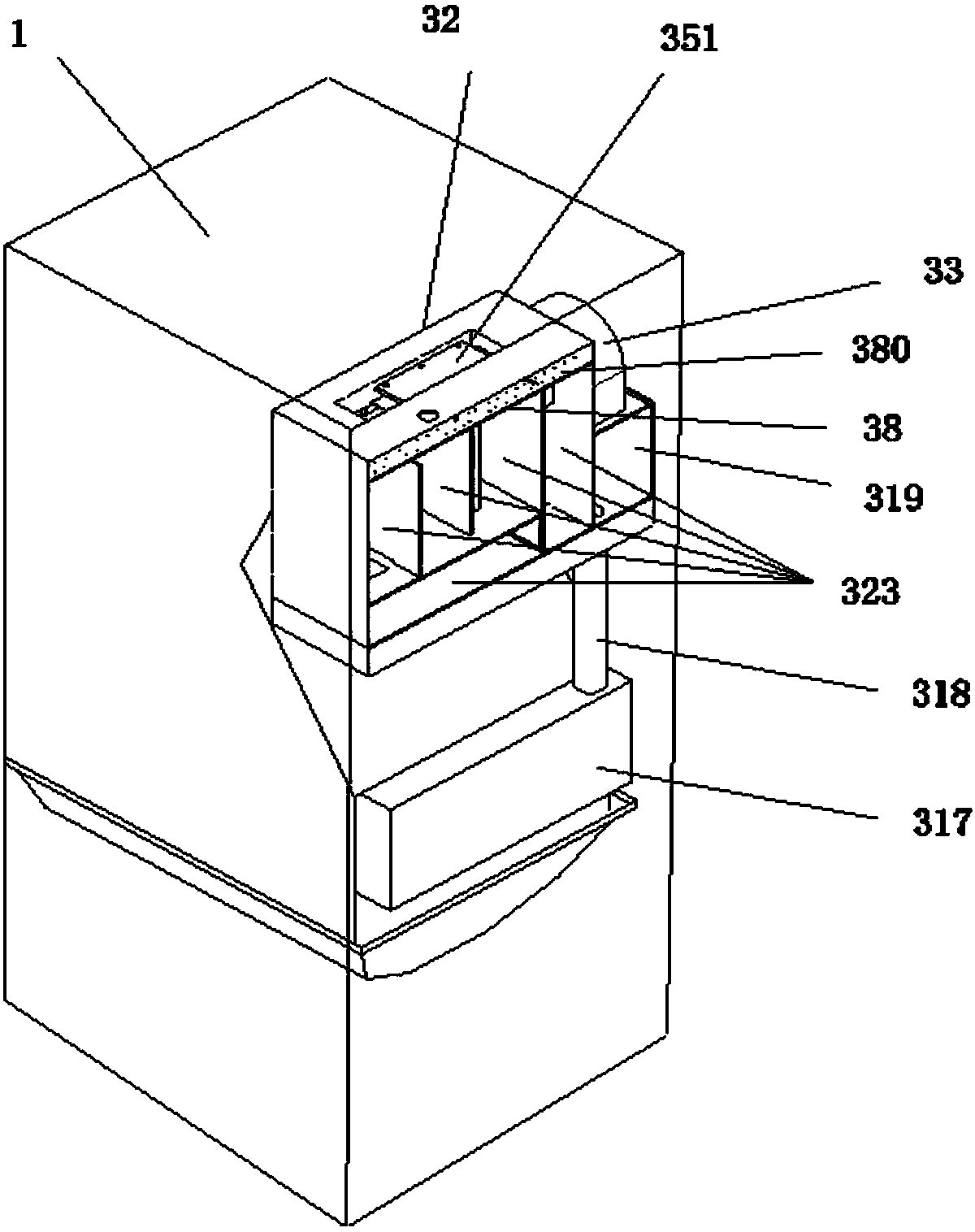

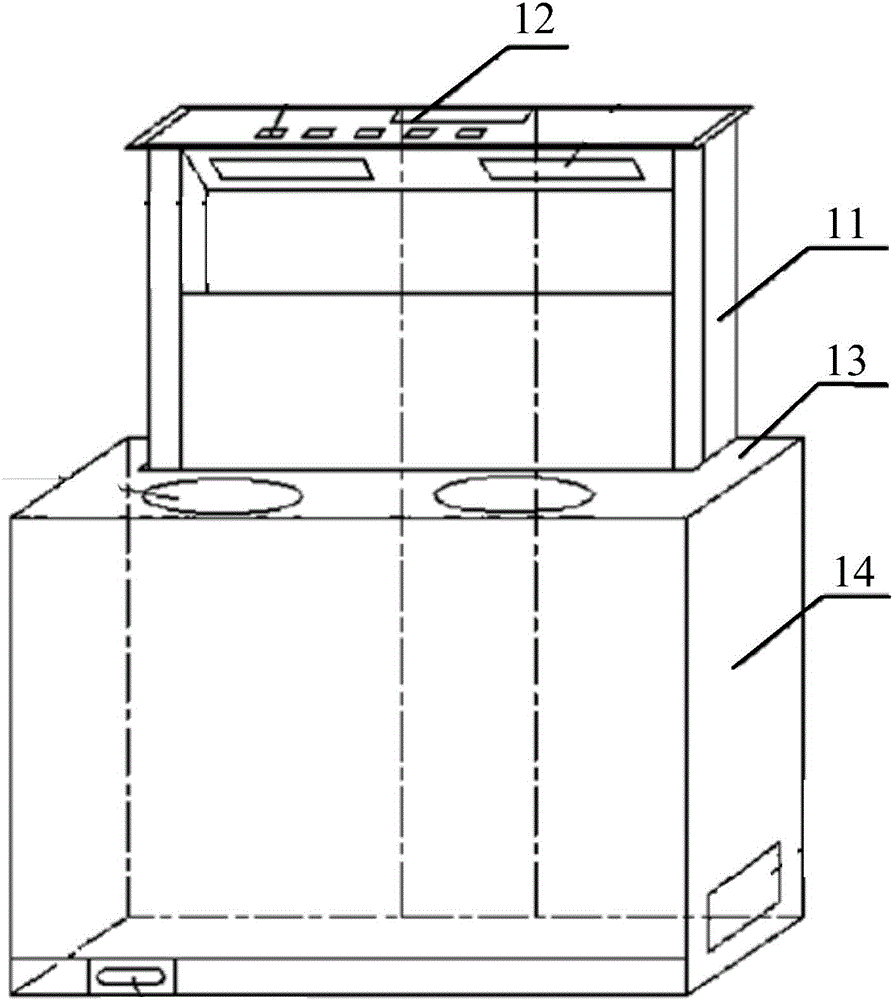

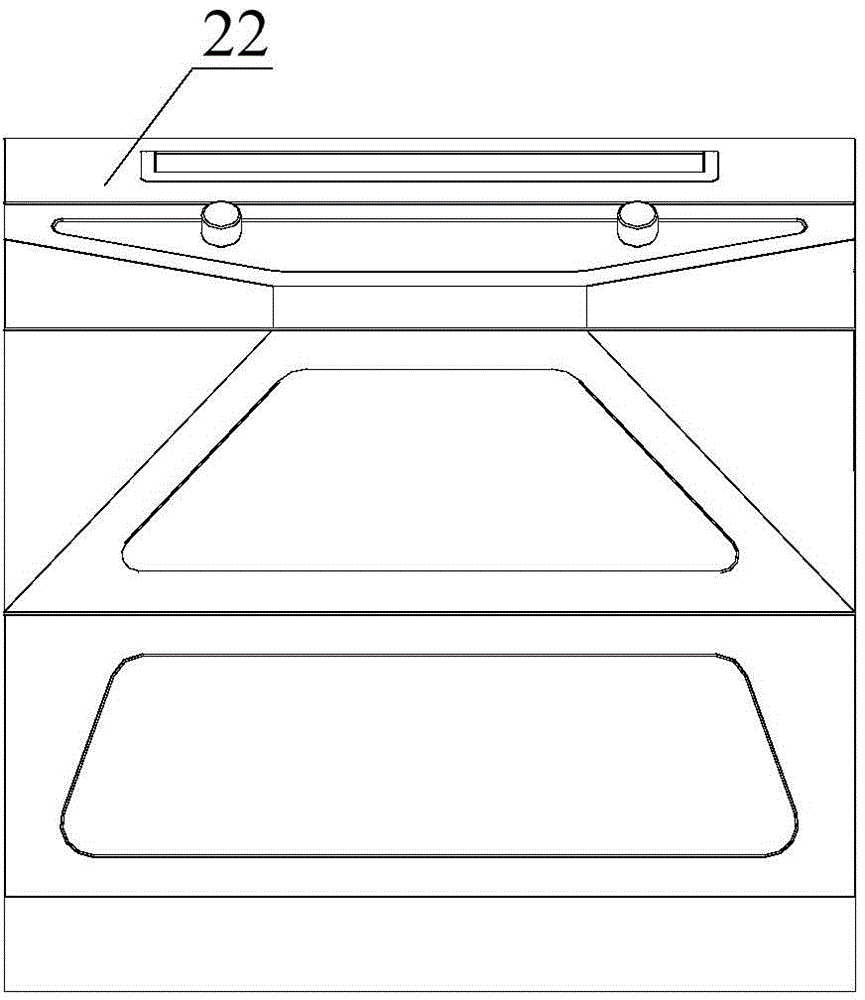

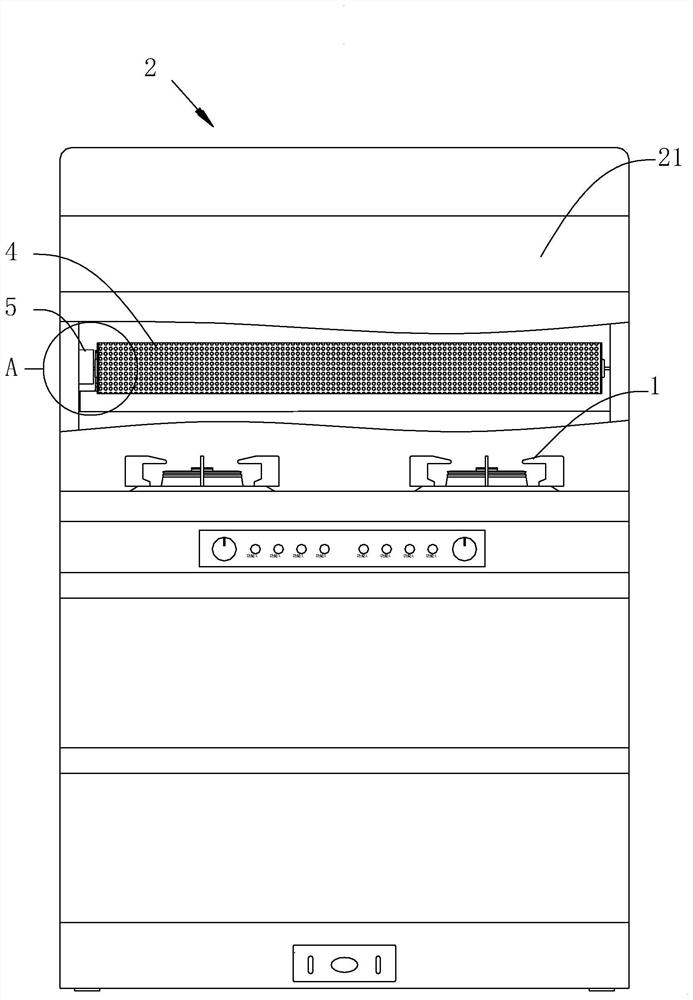

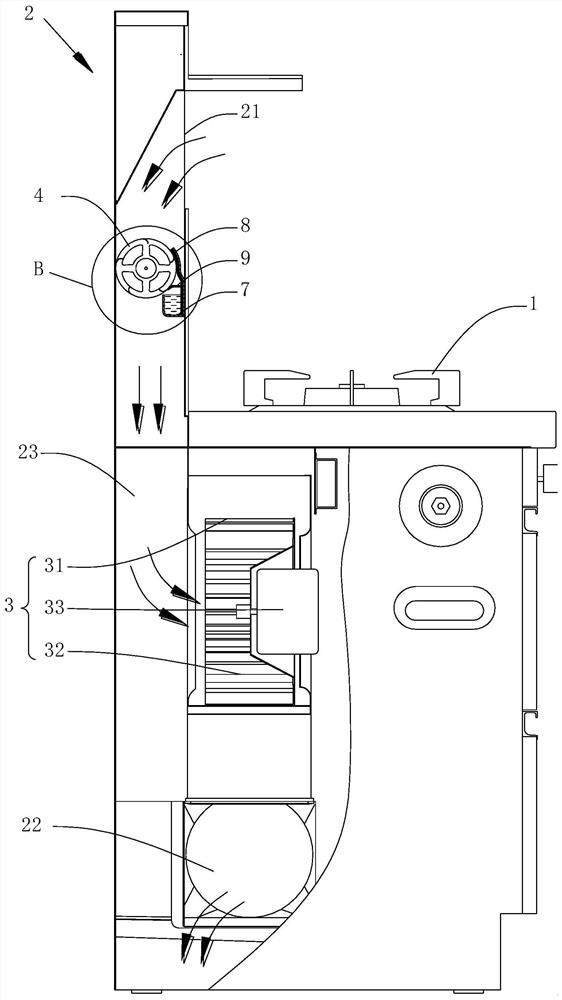

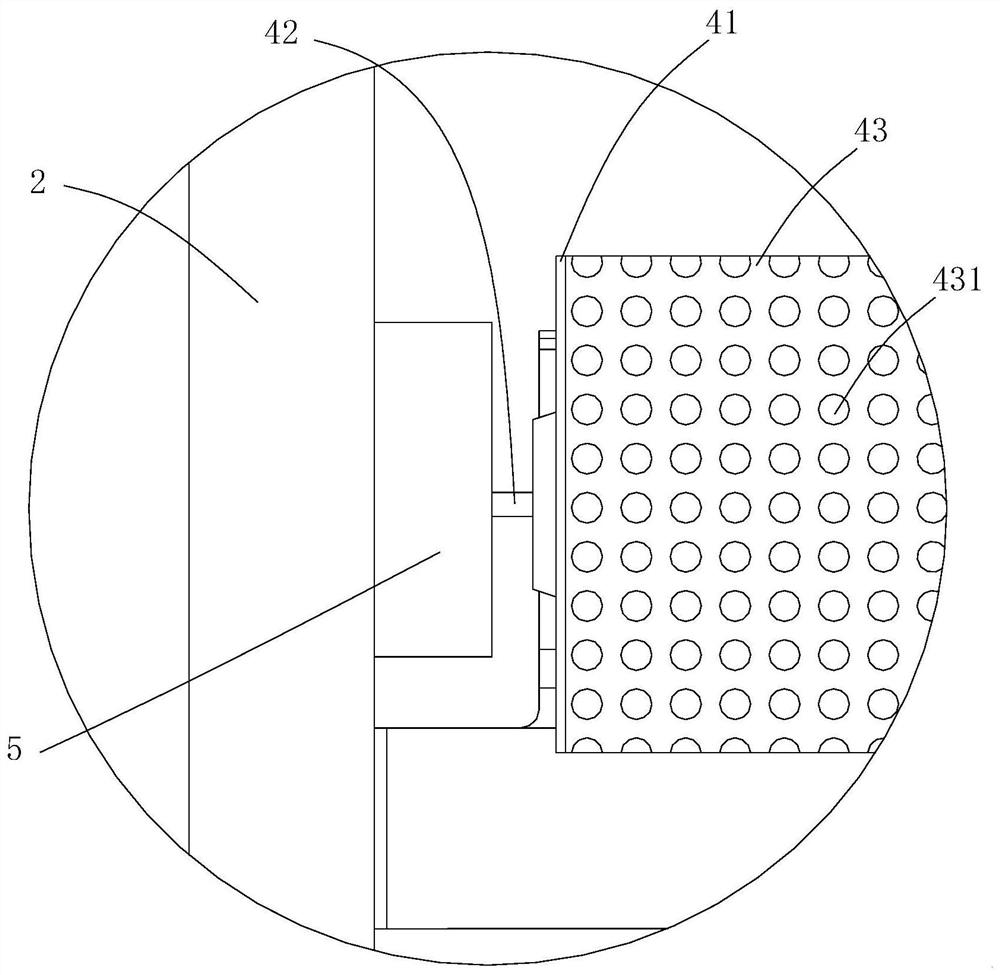

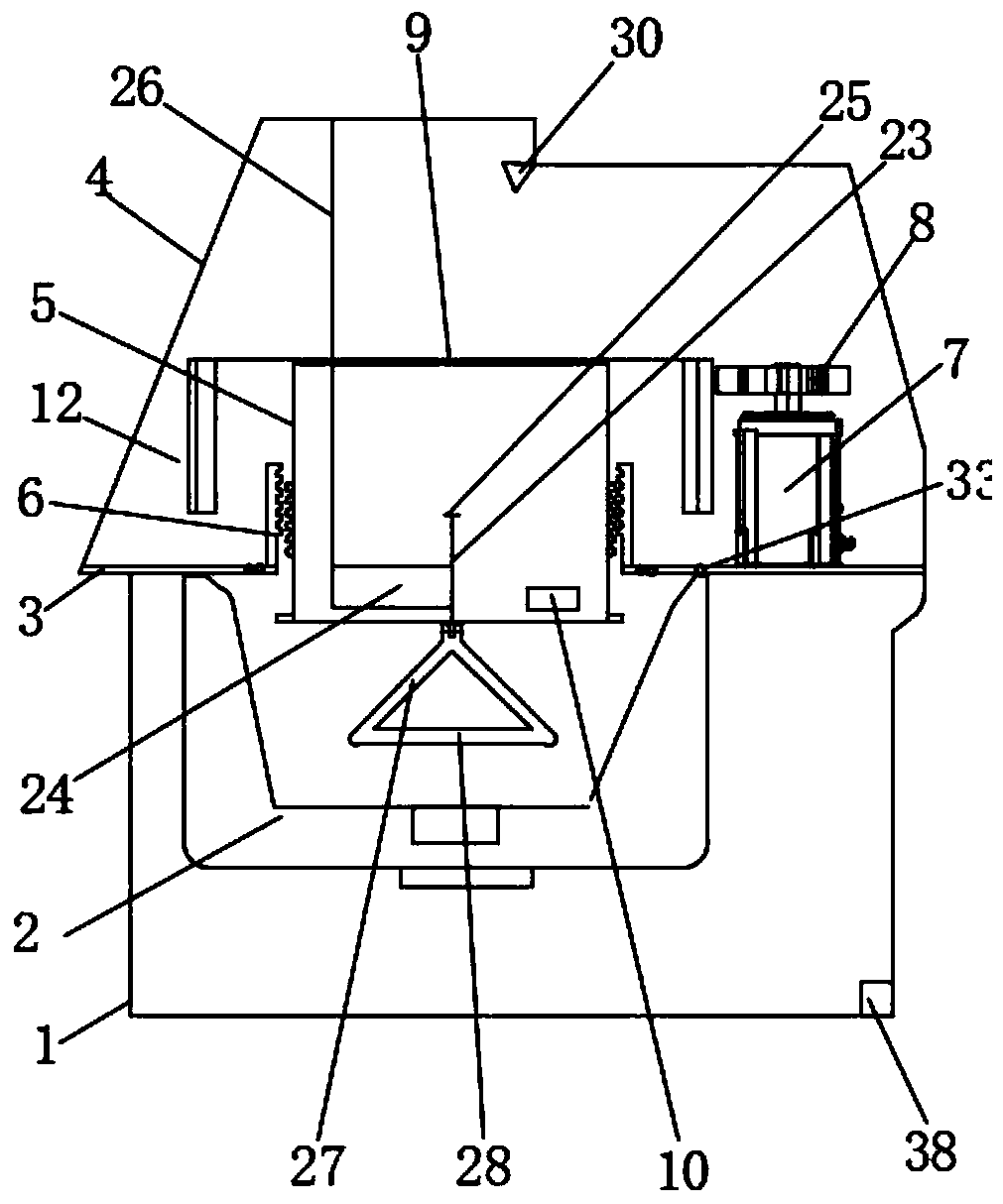

Flipping type integrated cooker

InactiveCN104456681AKeep clean and hygienicRealize the function of oil smokeDomestic stoves or rangesLighting and heating apparatusIndustrial engineeringCooker

Owner:ZHEJIANG AOTIN ELECTRIC APPLIANCE

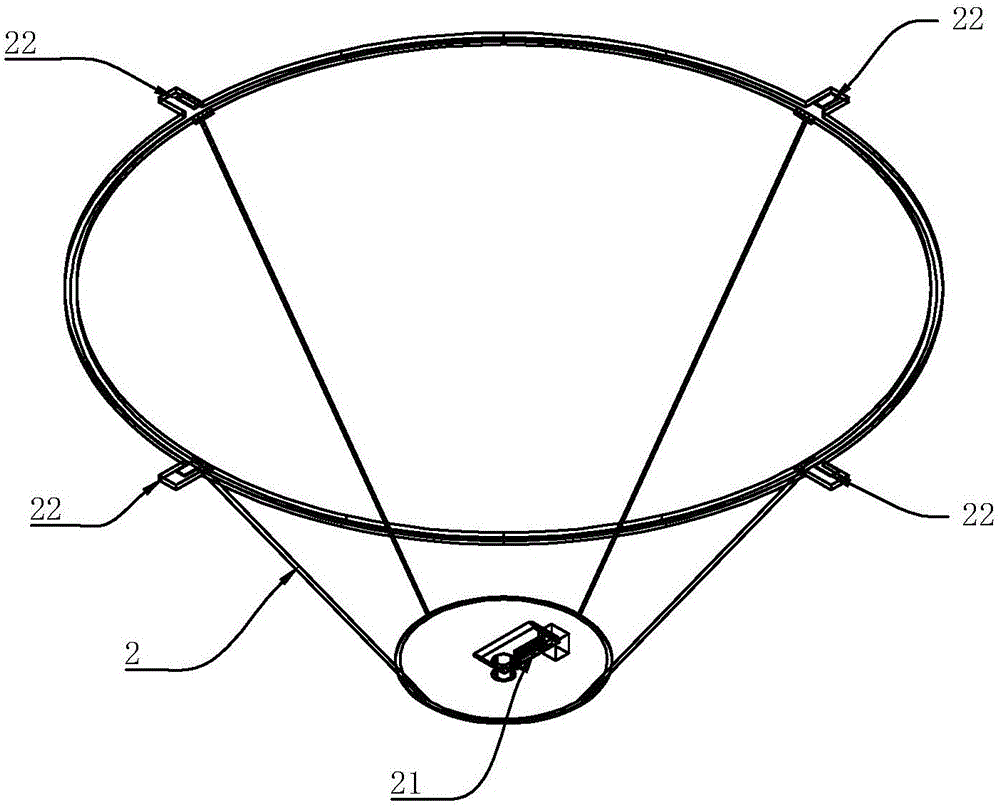

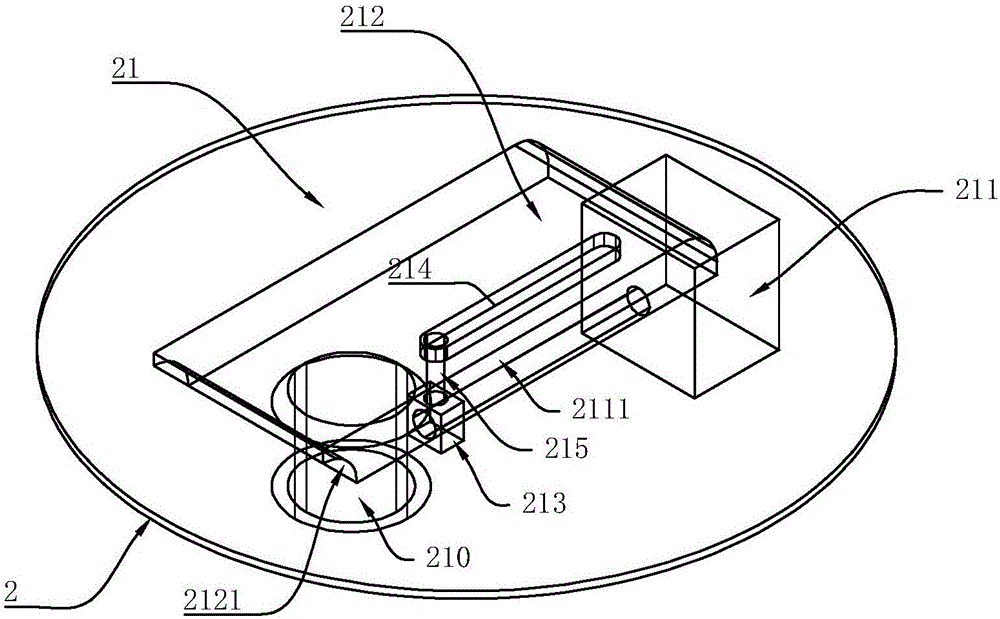

Full-automatic cooking device

InactiveCN104207624AImprove final performanceIncrease inner diameterCooking vesselsWater leakageEngineering

Owner:刘伟强

Superhard non-stick silicon cooker coating prepared by sol-gel hybridization technique

InactiveCN102002268ALower sintering temperatureIncreased durabilityCoatingsSilicic acidCeramic coating

The invention discloses a superhard non-stick silicon cooker coating prepared by a sol-gel hybridization technique. The coating comprises the following components: 30-50% of nanometer silica, 20-40% of silicic acid compound, 5-10% of magnesium-calcium compound, 3-5% of ammonium chloride, 0.5-2.0% of catalyst, 1-4% of accessory ingredient, 0.5-2.0% of silane coupling agent, 15-25% of multielement organosilicon material, 5-10% of absolute ethyl alcohol and 10-20% of distilled water. The preparation method of the coating comprises the following steps: using a sol-gel method to synthesize nano CaO-SiO2 power; replacing Ca by Mg to develop a (Ca, Mg)SiO3 nano power material; introducing low-temperature sintered assistant precursors into sol to reduce the sintering temperature of ceramics; and adding a defined amount of organosilicon material to adjust the hardening temperature of the ceramics to obtain the low-temperature sintering nano ceramic coating at the temperature below 250 DEG C. The superhard non-stick silicon cooker coating has strong adhesive force, high hardness, small possibility of scratch, and impact resistance, is non-toxic and environment-friendly, and can completely replace Teflon non-stick coatings.

Owner:DONGGUAN EONTEC CO LTD

Micro-pressure steam rice cooker

ActiveCN106724767AGood for steamingSuit one's needsSteam cooking vesselsPressure-cookersEngineeringCooker

Owner:蓝治成

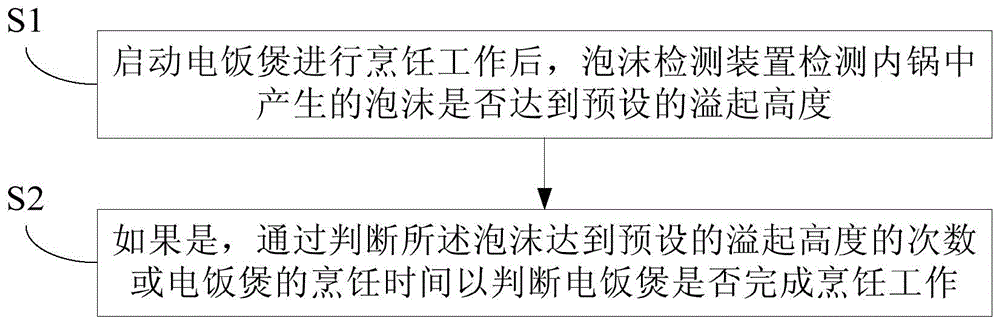

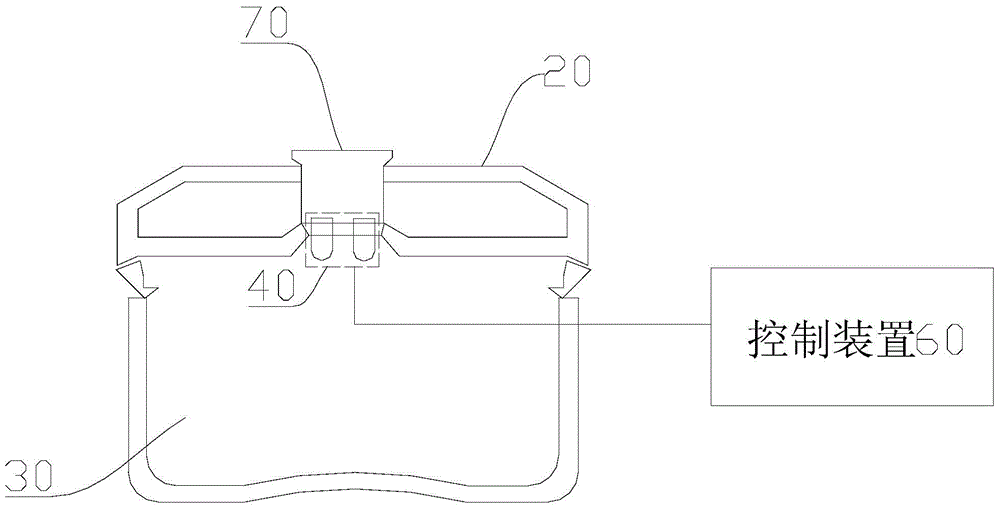

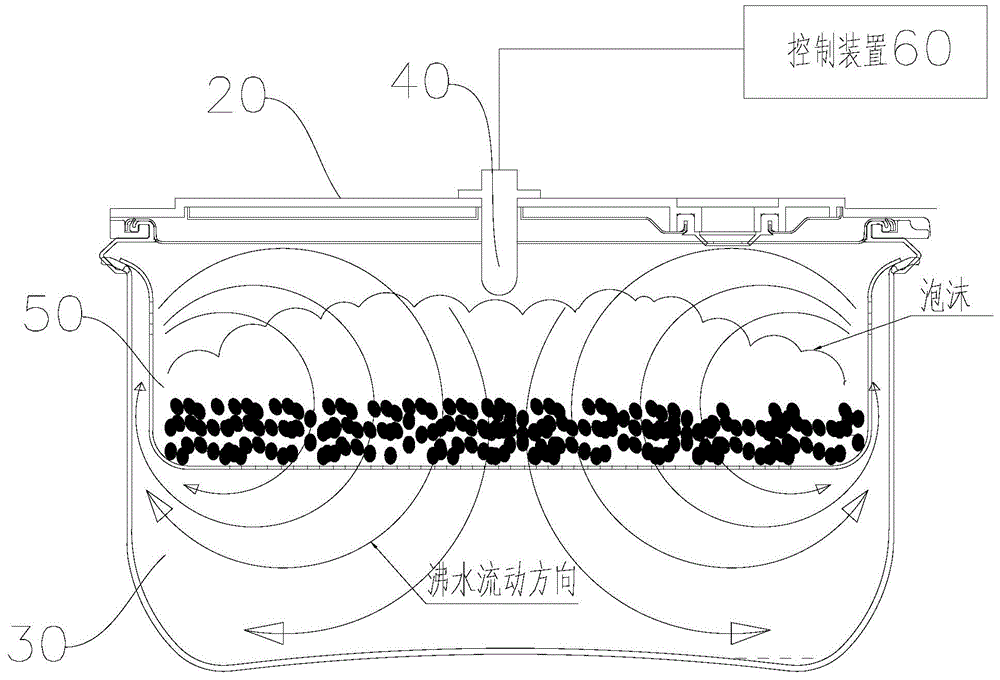

Electric rice cooker and control method thereof

Owner:MIDEA GRP CO LTD +1

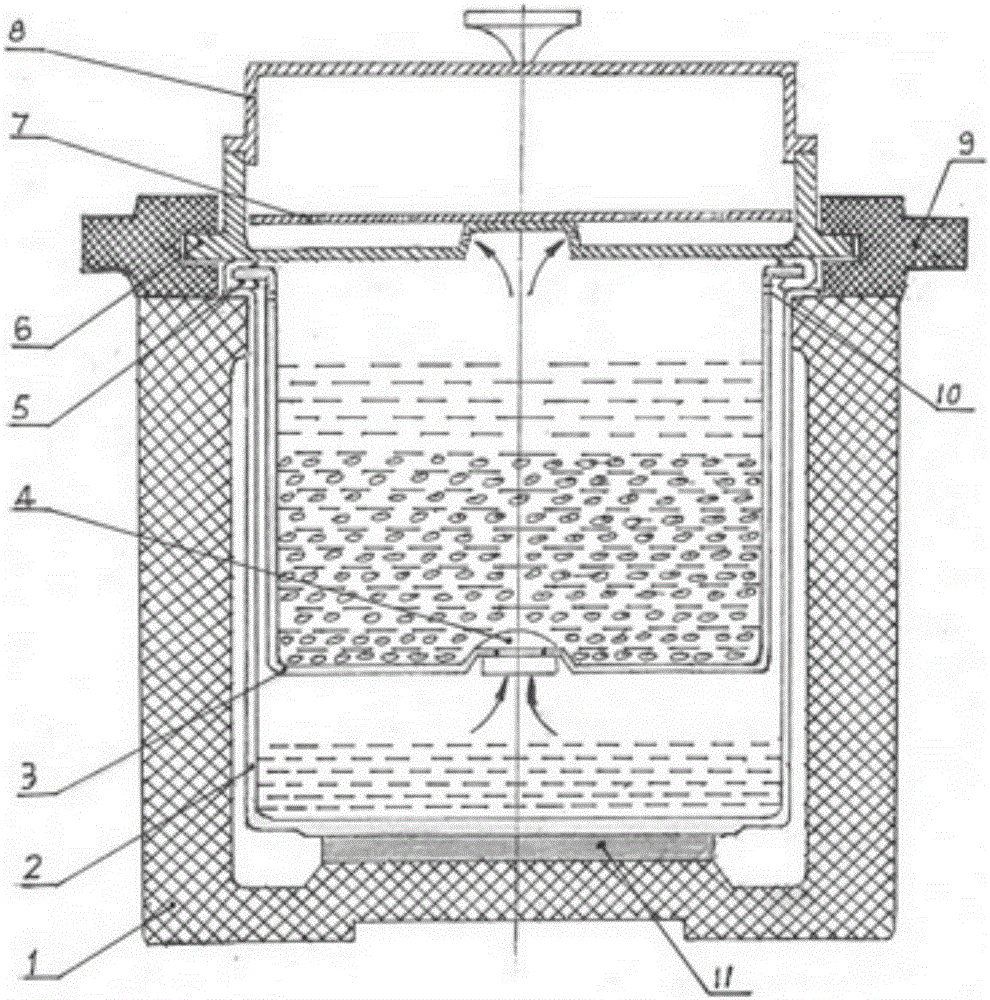

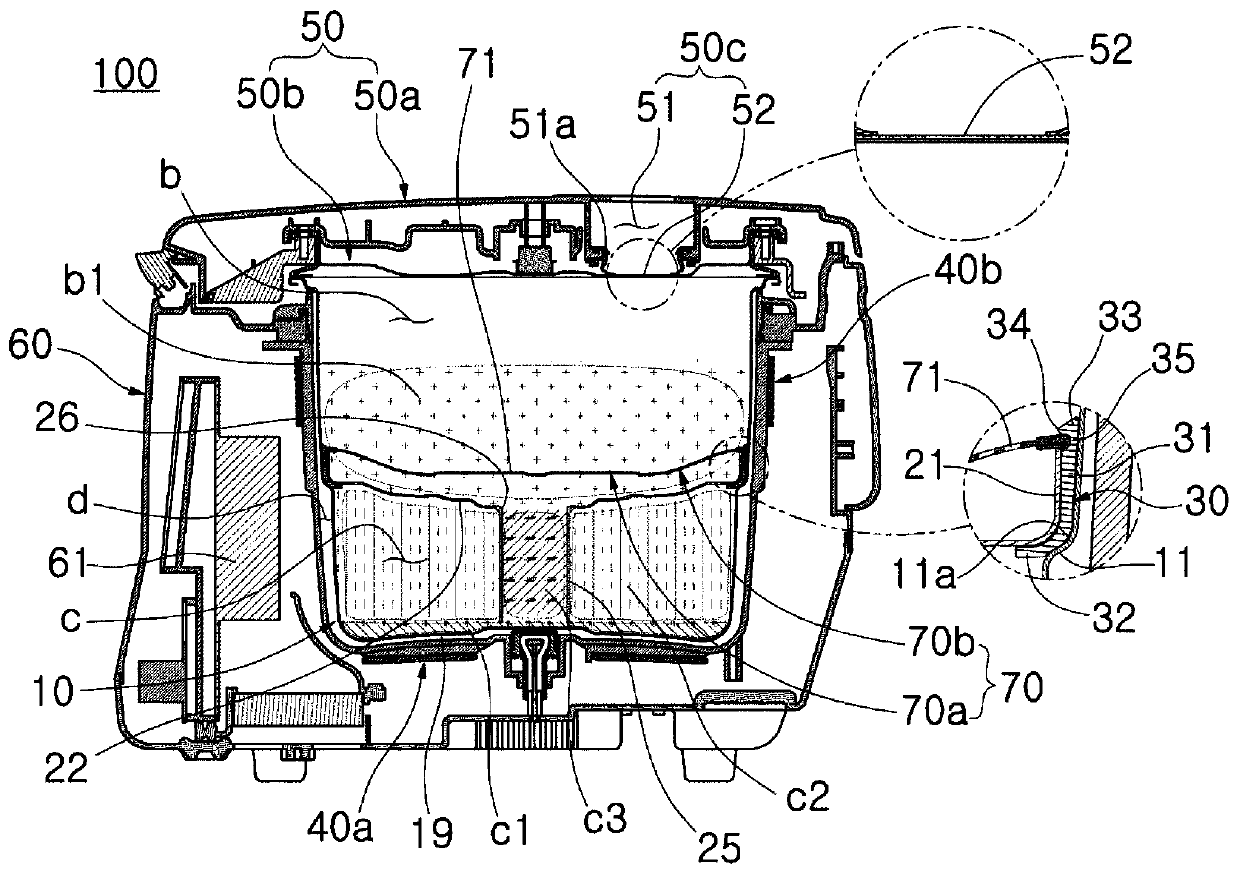

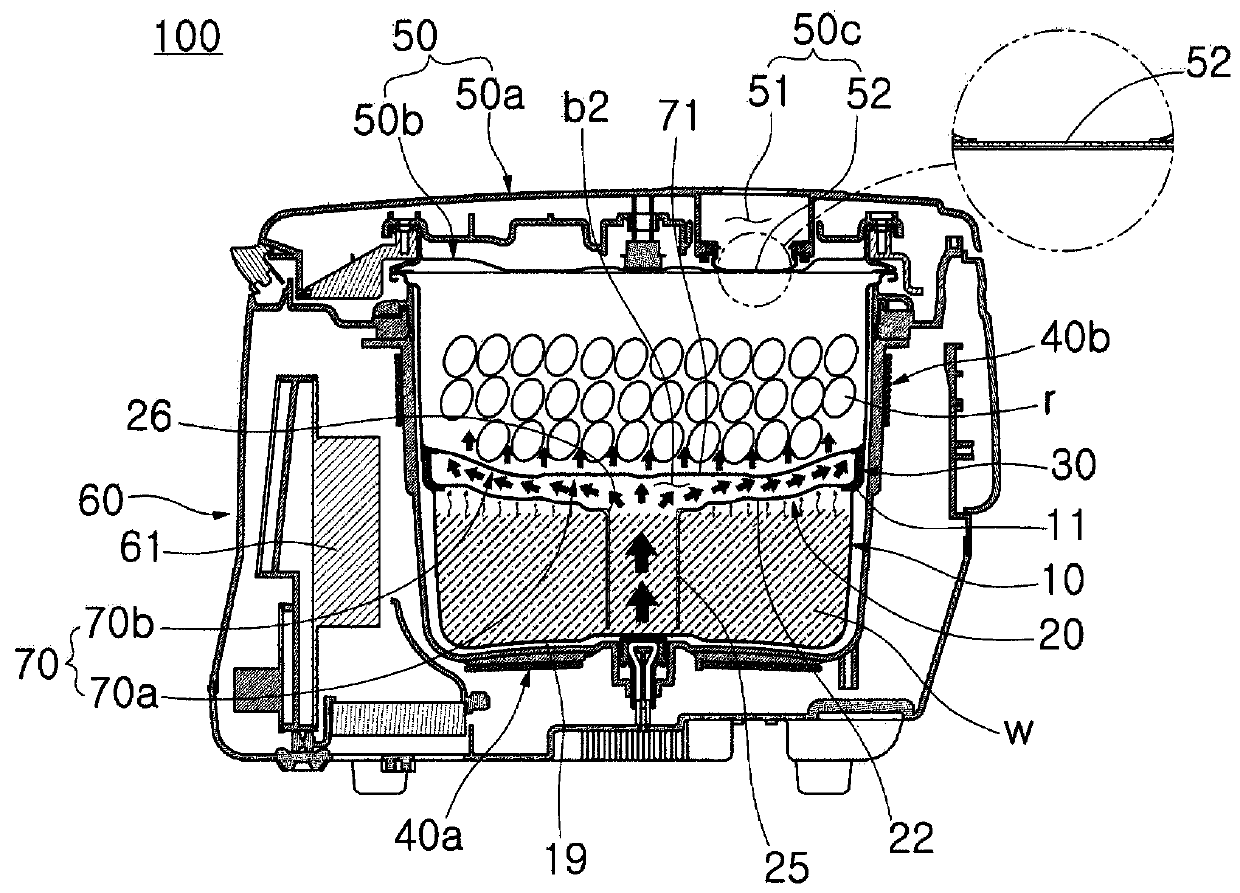

Electric cooker

The invention provides an electric cooker. The electric cooker comprises a cooker body and a pot body. An electric heating device is arranged on the cooker body, the pot body is rotatably arranged onthe cooker body, and the electric heating device is used for heating the pot body. The pot body comprises a first inner pot and a second inner pot which can accommodate foodstuffs. Openings of the first inner pot and the second inner pot are opposite to each other, and the first inner pot is detachably connected to the second inner pot. The pot body further comprises a steaming separation plate mounted between the first inner pot and the second inner pot. Mesh holes are formed in the steaming separation plate. By the electric cooker, rice and water can be automatically separated from each other during cooking, prepared conventional zengzi rice is dry and plump, and sweet and delicious rice water is also obtained. When the electric cooker is used for cooking rice, users do not need to consider the problem of insufficient rice hardness caused by excessive water, and can obtain the rice water at the same time, so that the electric cooker is convenient for the users to use.

Owner:GREE ELECTRIC APPLIANCE INC OF ZHUHAI

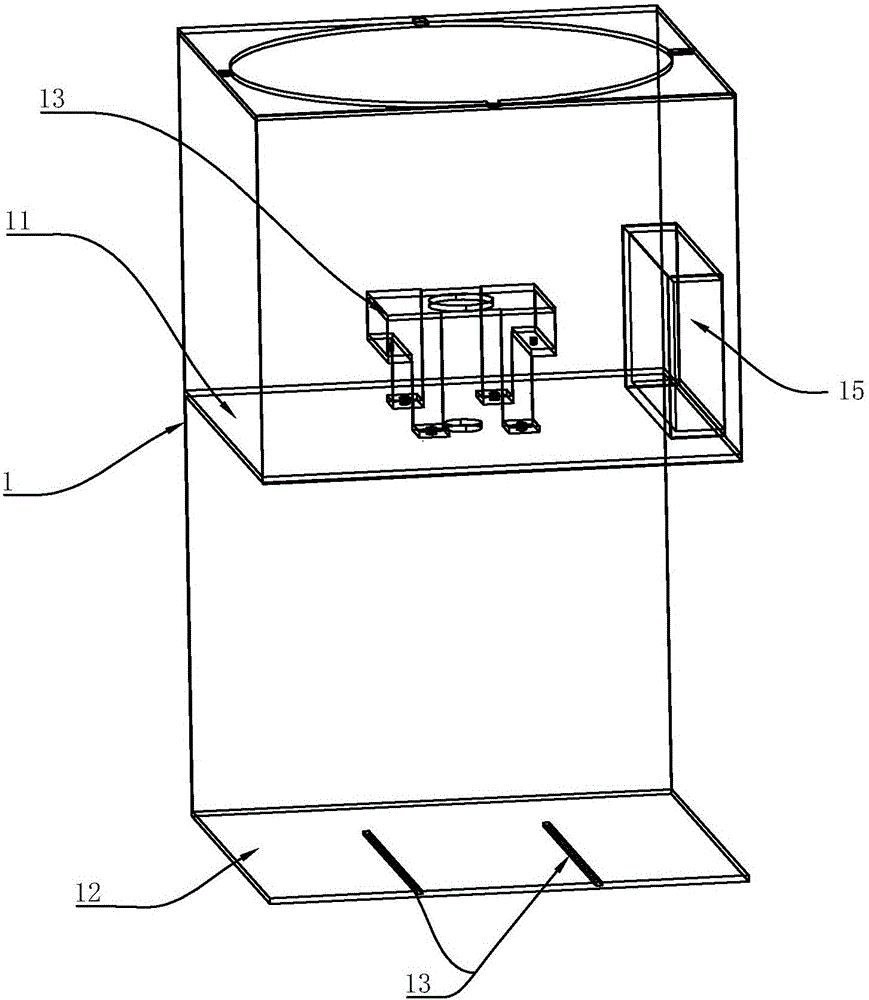

Gas cooker pipeline machining device

InactiveCN107971783AFast processingImprove processing efficiencyPositioning apparatusMaintainance and safety accessoriesEngineeringCooker

The invention relates to the technical field of gas cooker part machining, and discloses a gas cooker pipeline machining device which comprises a base and a supporting frame. The supporting frame is fixedly connected to the upper surface of the base, two electric push rods are fixedly connected to the top of the inner side of the supporting frame, and a bearing plate is fixedly connected to the tail ends of the two electric push rods. By means of mutual cooperation of the base, the supporting frame, the electric push rods, the bearing plate and a driving device, the problem that an existing gas cooker pipeline machining device is low in machining efficiency is solved. By means of mutual cooperation of an installation plate, the driving device and a clamp device, the problem that an existing gas cooker pipeline machining device cannot rapidly and effectively position gas pipelines is solved. By means of mutual cooperation of the installation plate, the driving device, the clamp device and a cleaning device, the problem that fragment stacking produced in the using process of an existing gas cooker pipeline machining device affects machining precision is solved.

Owner:XINCHANG CHANGCHENG AIR-CONDITIONER COMPONENTS INC

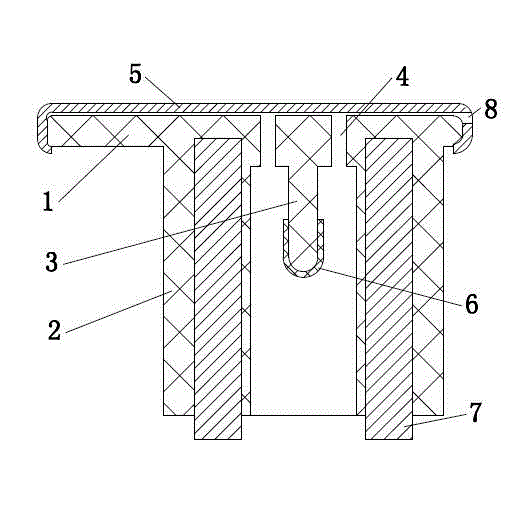

Electric cooker

ActiveCN110811294AImprove cooking qualityImprove separation efficiencyRefuse receptaclesPressure-cookersSiphonWater storage

Owner:CUCKOO ELECTRONICS CO LTD

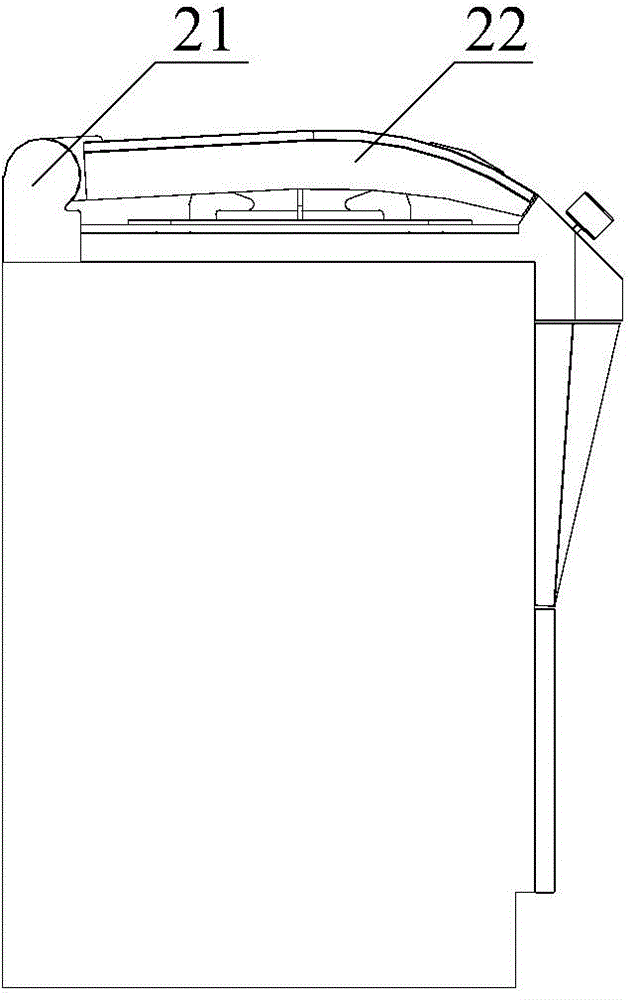

Side-exhaust exhaust valve bonnet

Owner:袁振华

Air Pressure Cooker

An air pressure cooker comprising an upper cover and a bottom cover, wherein an uncovering knob and a heat insulation cover are arranged on the upper cover; the uncovering knob is fixedly connected on the right side of the outer surface of the upper cover, and the heat insulation cover is fixedly connected inside the upper cover; a handle locking block is arranged underneath the uncovering knob, and a motor, a switch connecting rod, cold wind fan blades and a heating tube cover are arranged on the heat insulation cover; the motor is fixedly connected in the middle of the upper end of the heat insulation cover, and the switch connecting rod is fixedly connected on the right side of the heat insulation cover; the cold wind fan blades are movably connected inside the heat insulation cover.

Owner:ZHEJIANG TIANXI KITCHEN APPLIANCE CO LTD

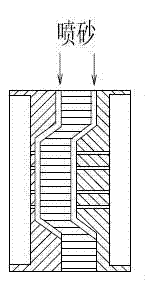

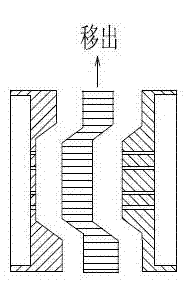

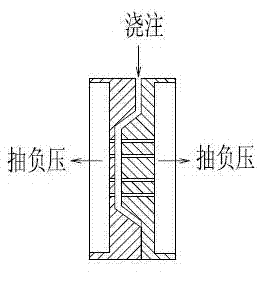

Production technology for casting thin-wall cookware through using precoated sand hot box method

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

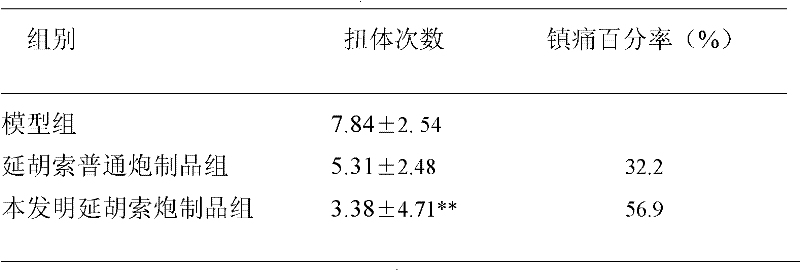

Processing method of rhizoma corydalis

InactiveCN102406710AGood analgesic effectIncrease production capacityNervous disorderAntipyreticEngineeringCorydalis boweri

Owner:卞毓平

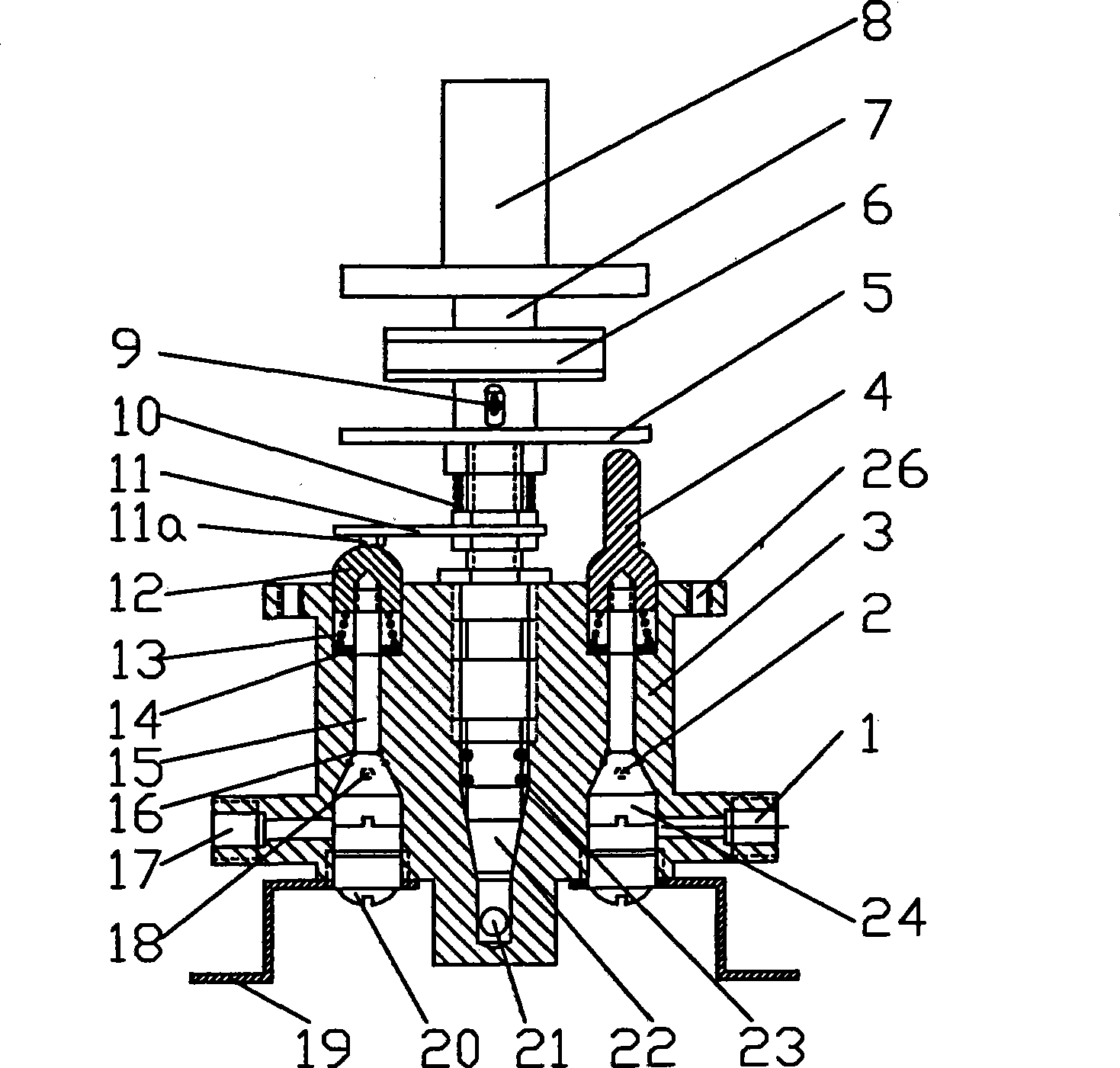

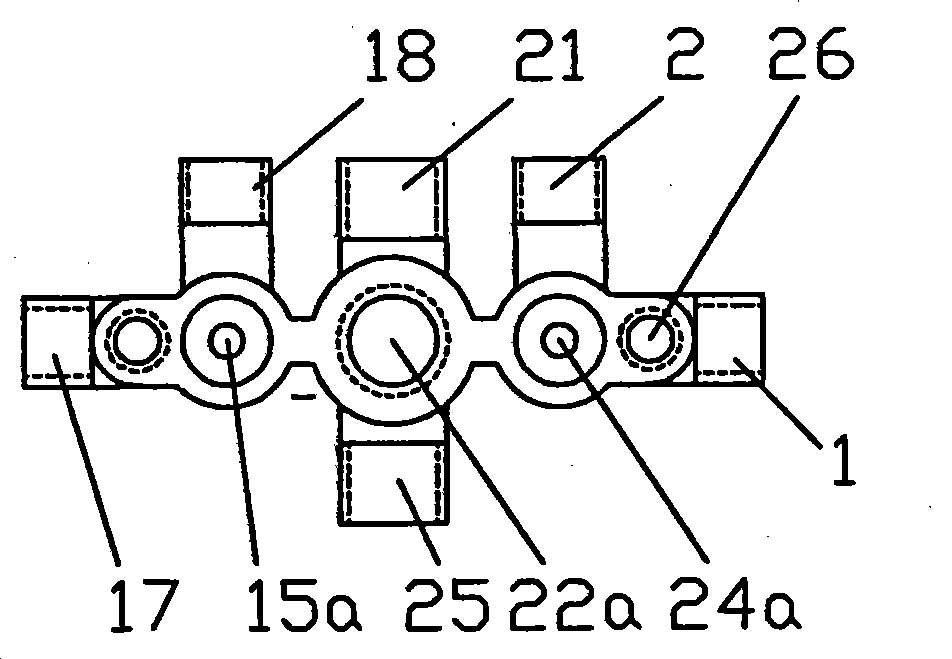

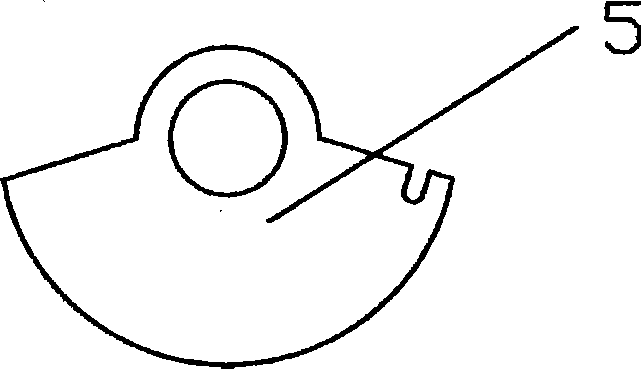

Switch assembly of synthetic liquid fuel range

InactiveCN101435597ACompact structureFlexible structureDomestic stoves or rangesLighting and heating apparatusEngineeringLiquid fuel

Owner:张世贵

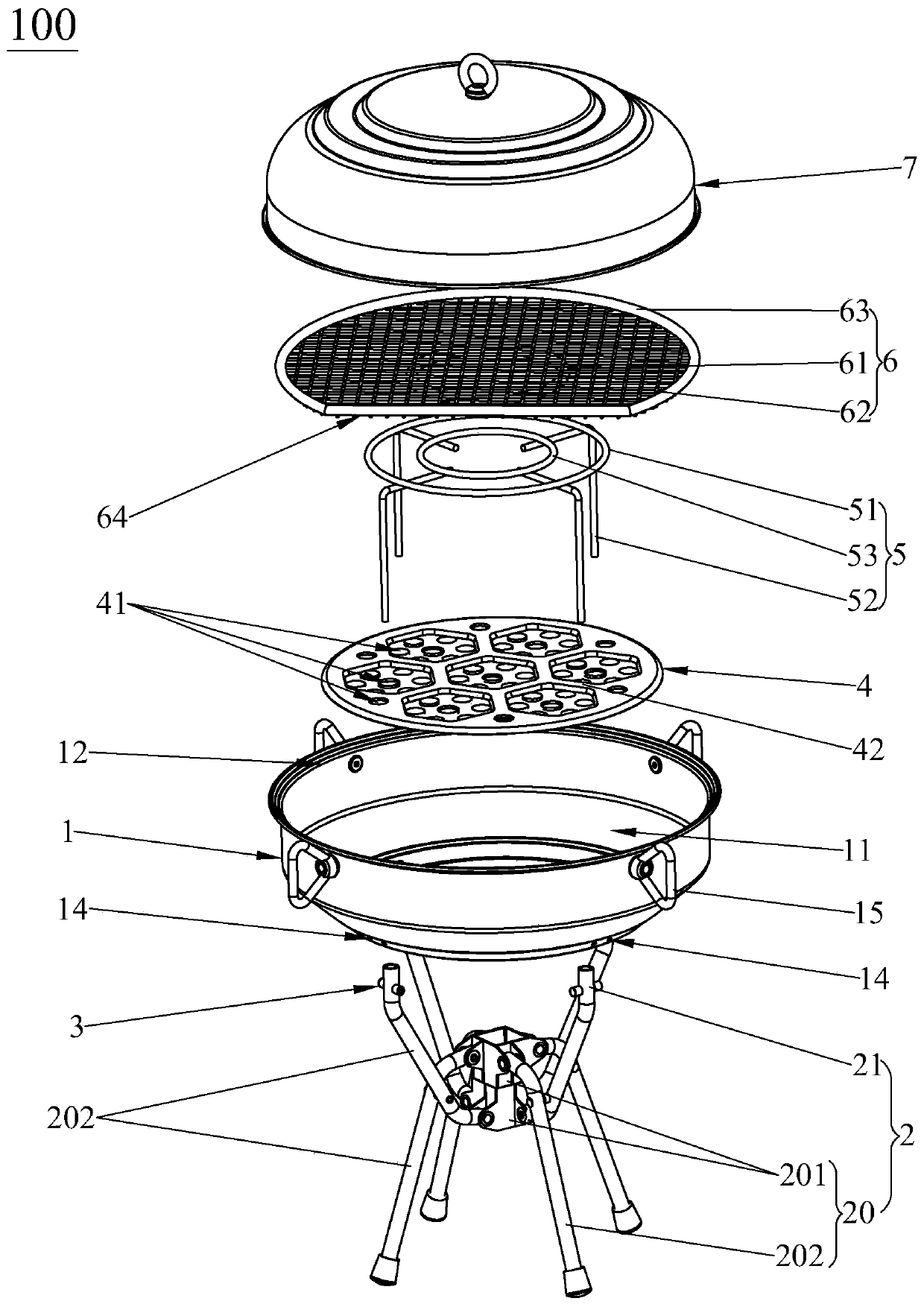

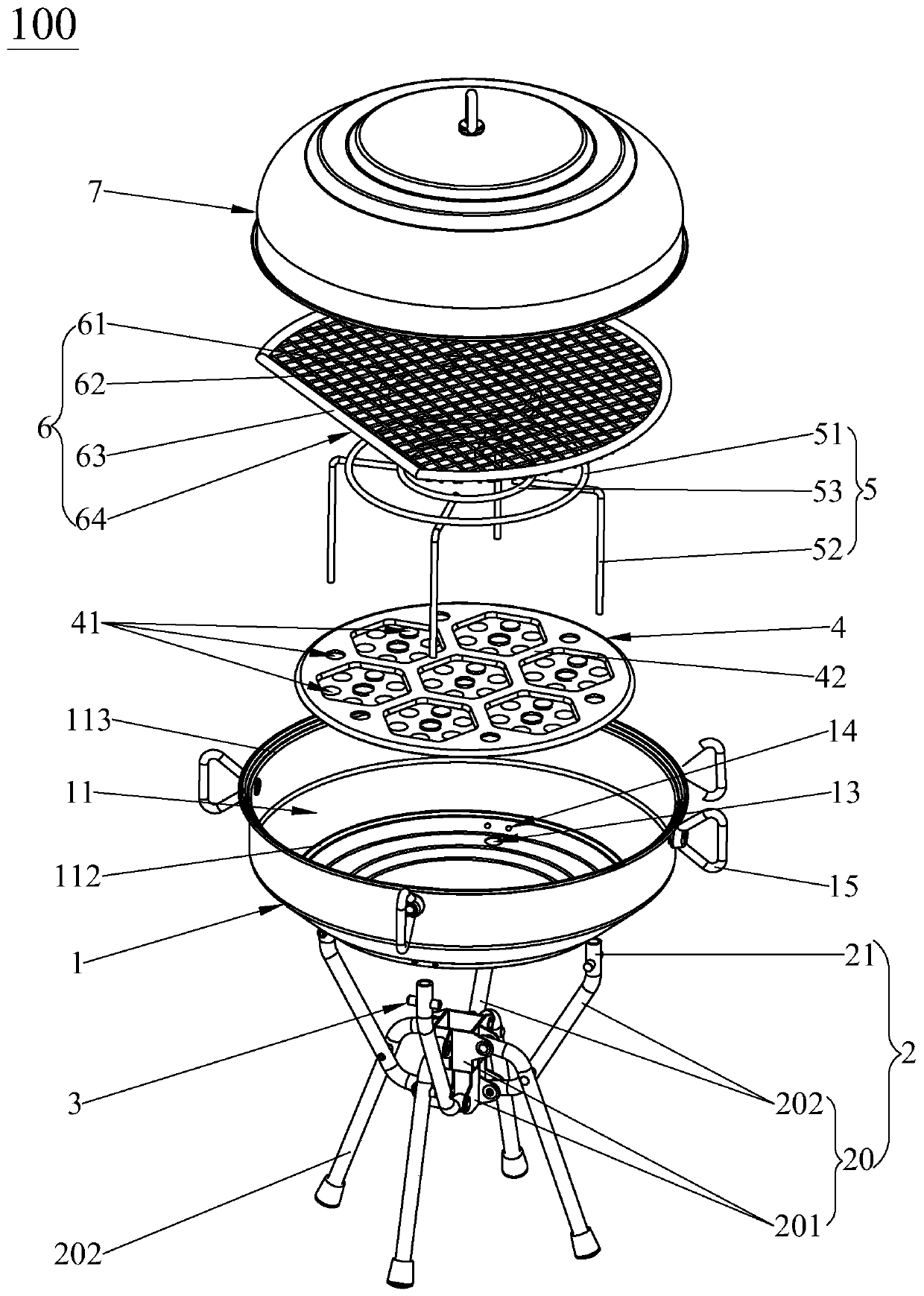

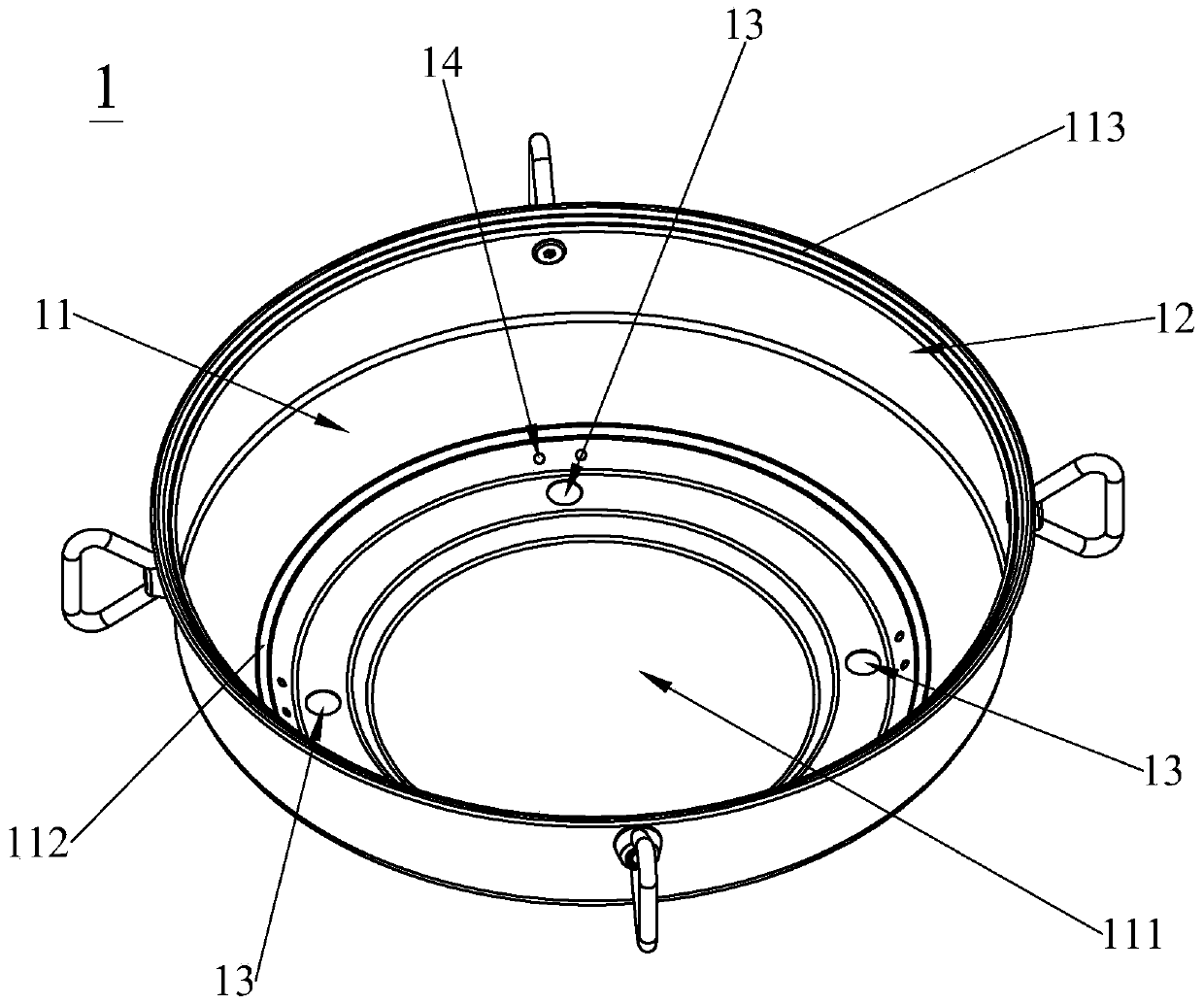

Outdoor cooking utensil

Owner:泉里志

Device for producing dried bean curd sticks through cooking soybean milk

Owner:广西武宣农家富食品有限公司

Electric fuel, gaseous fuel and solid biomass fuel integrated heat furnace and using method

ActiveCN109798541AImprove utilization efficiencyReduce early churnDomestic stoves or rangesLighting and heating apparatusElectricityHoneycomb

Owner:长阳清江农机制造有限公司

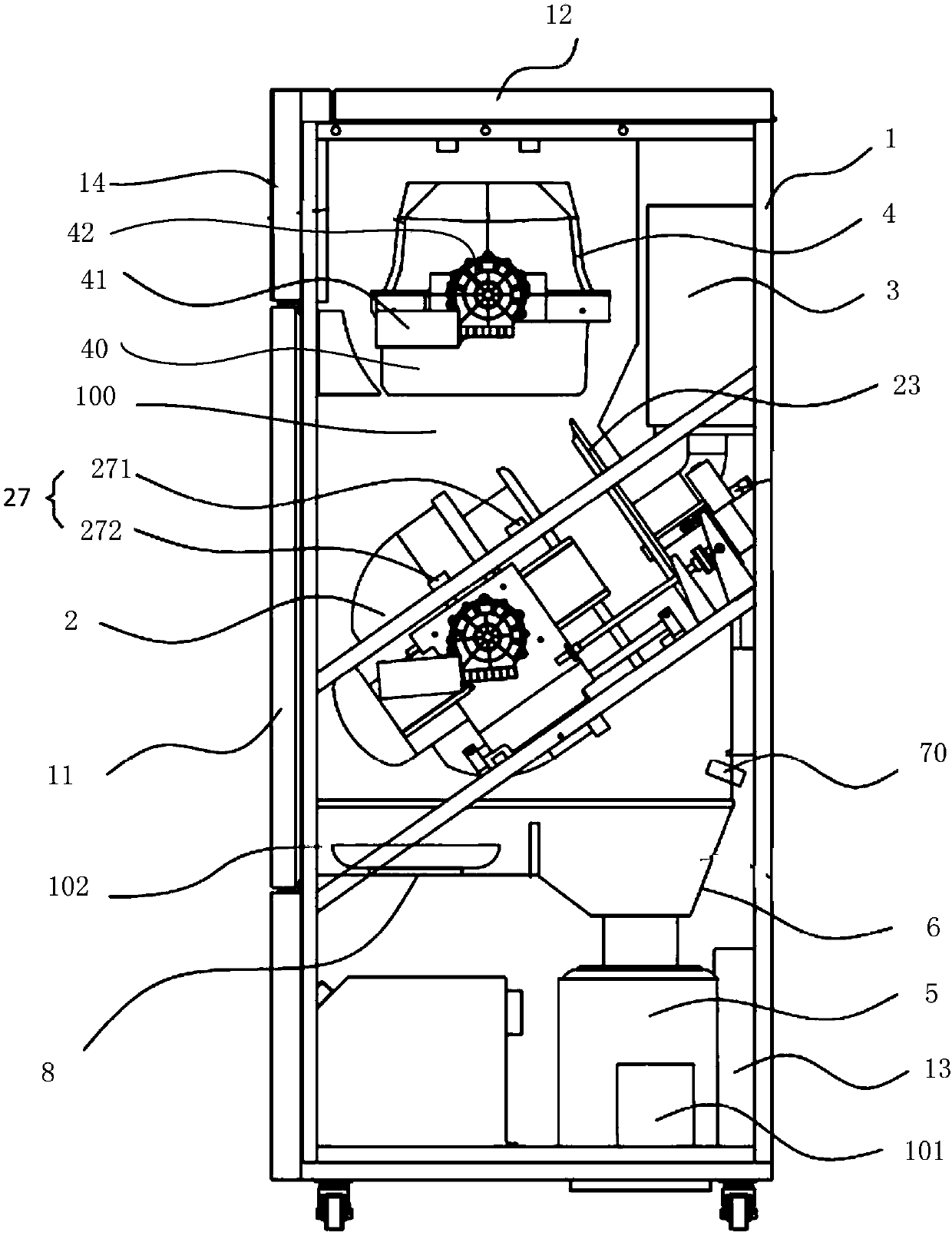

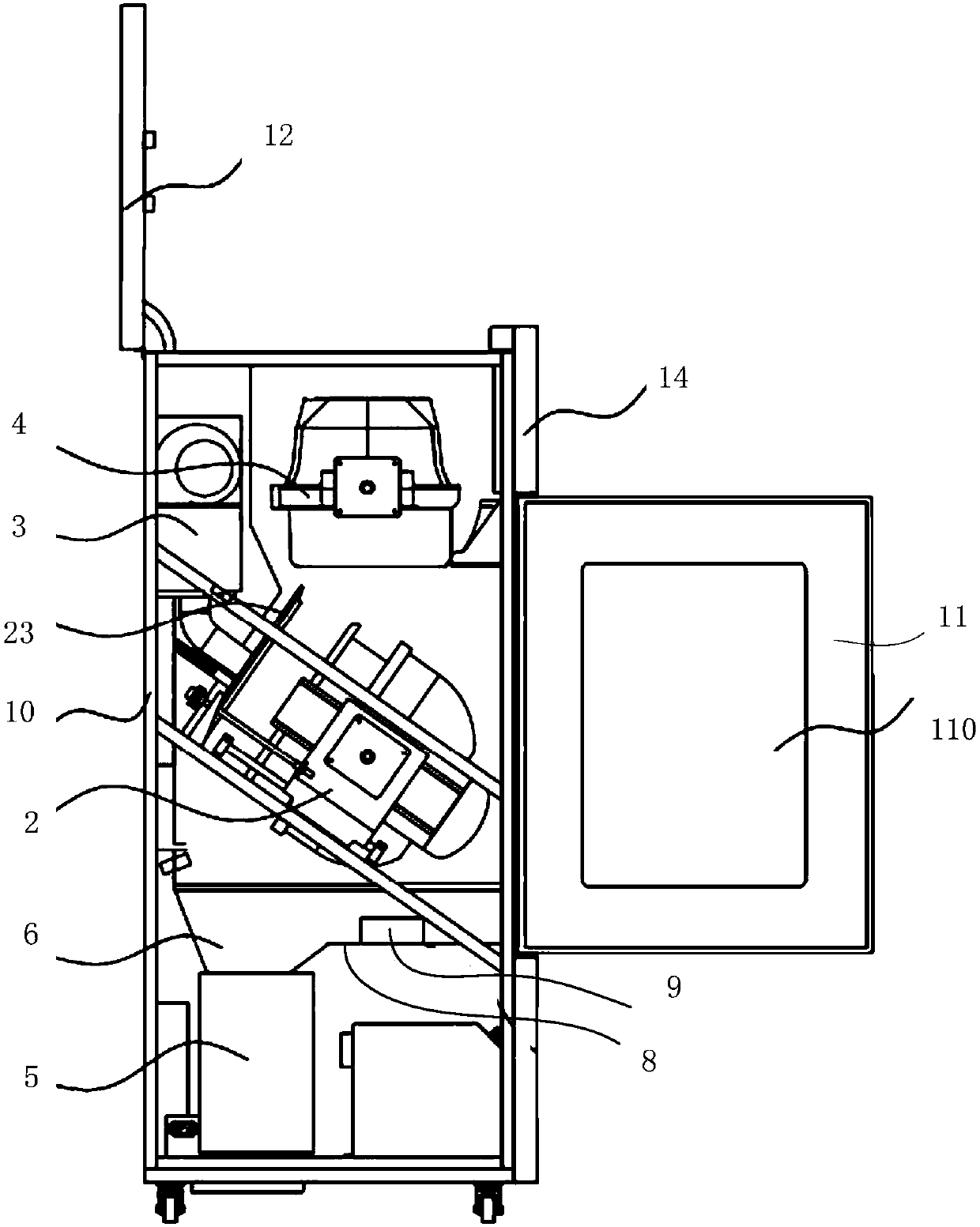

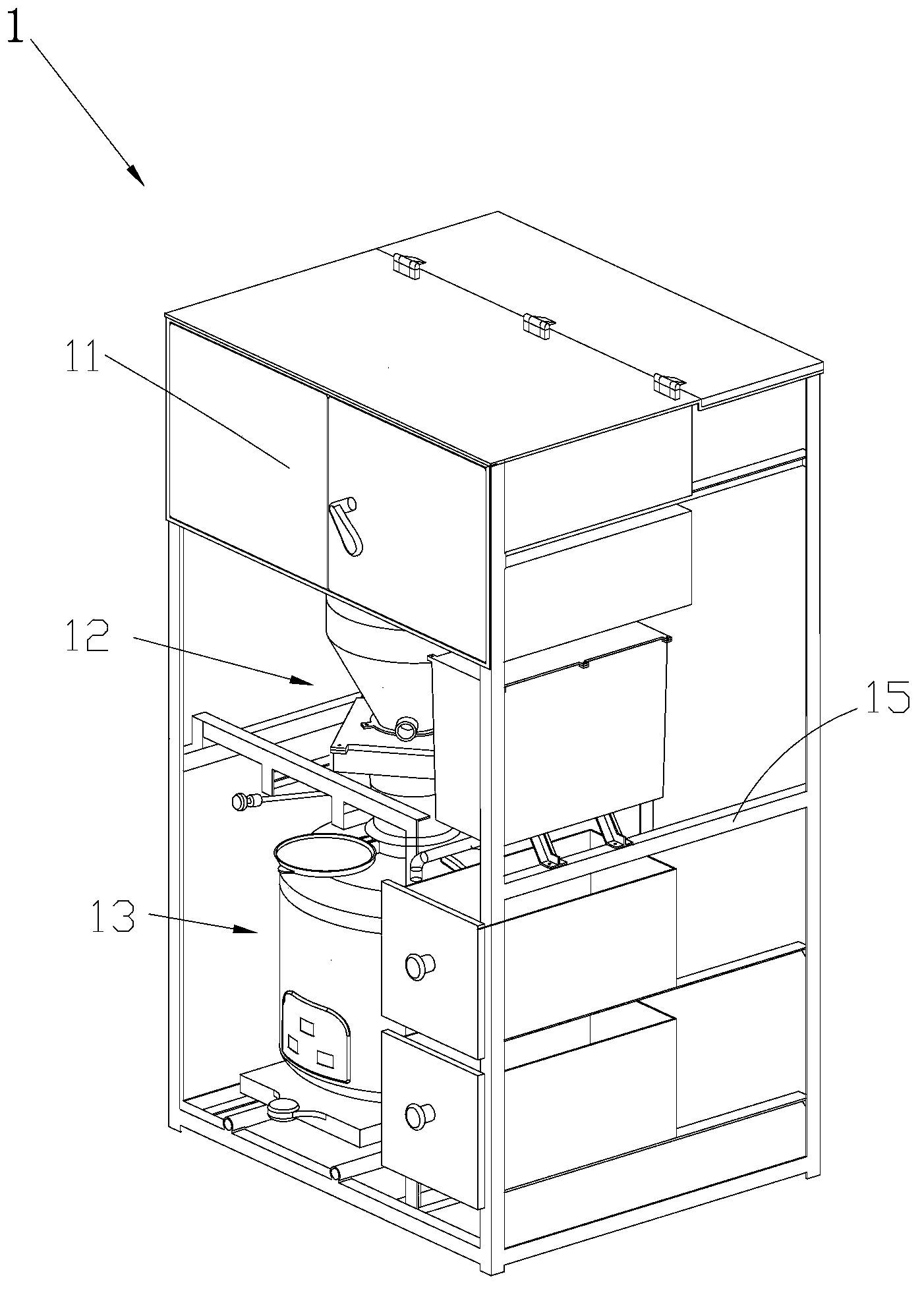

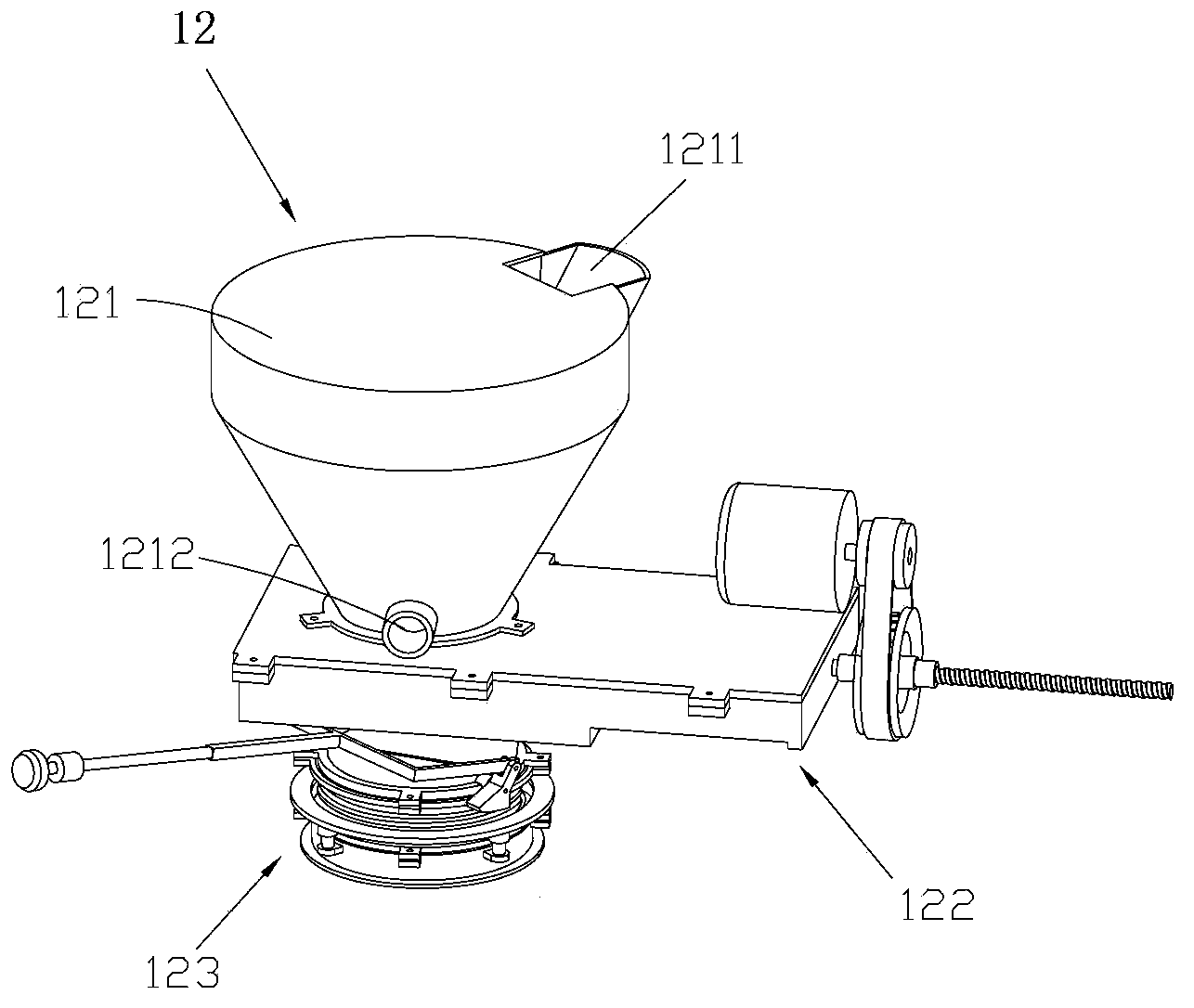

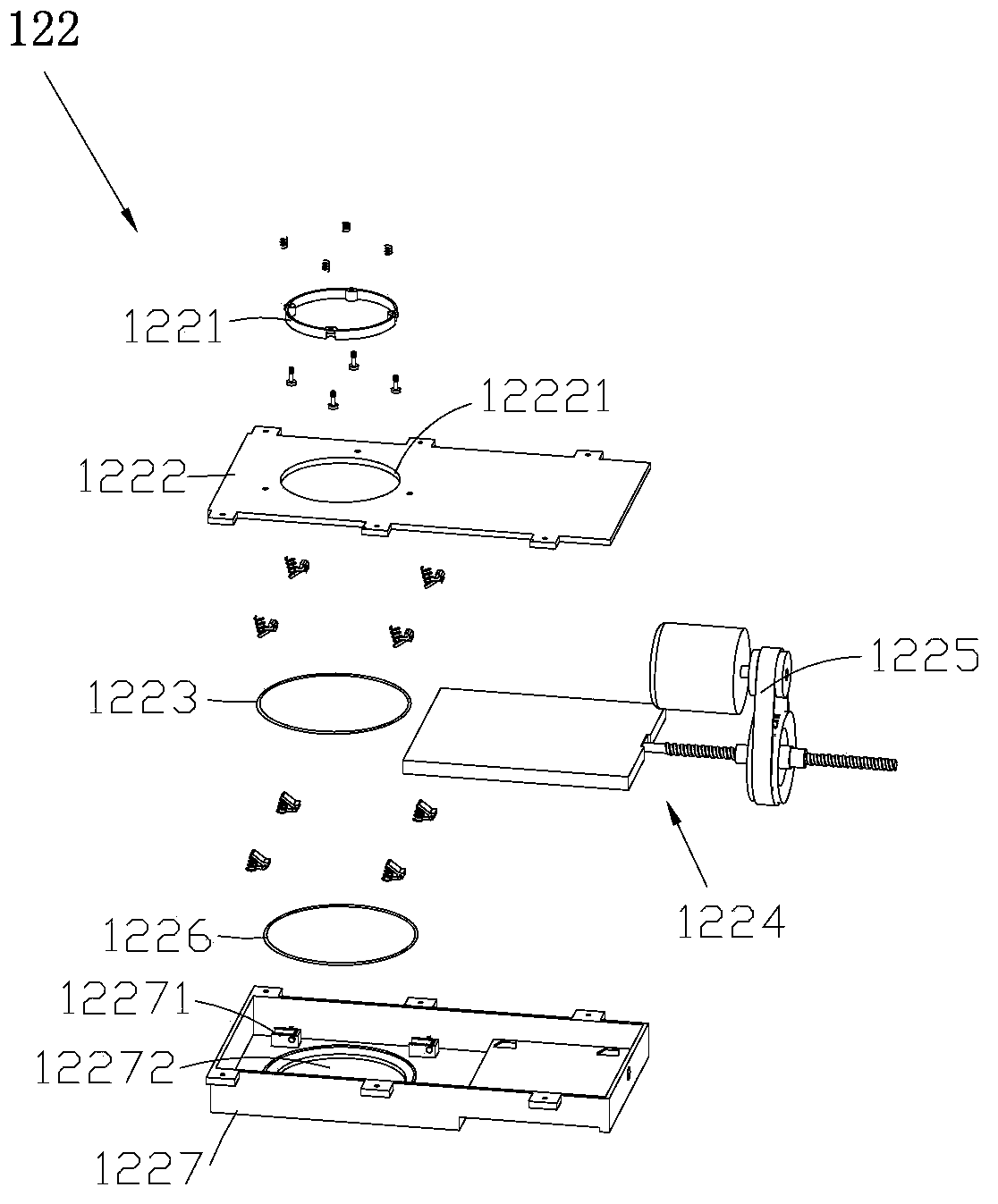

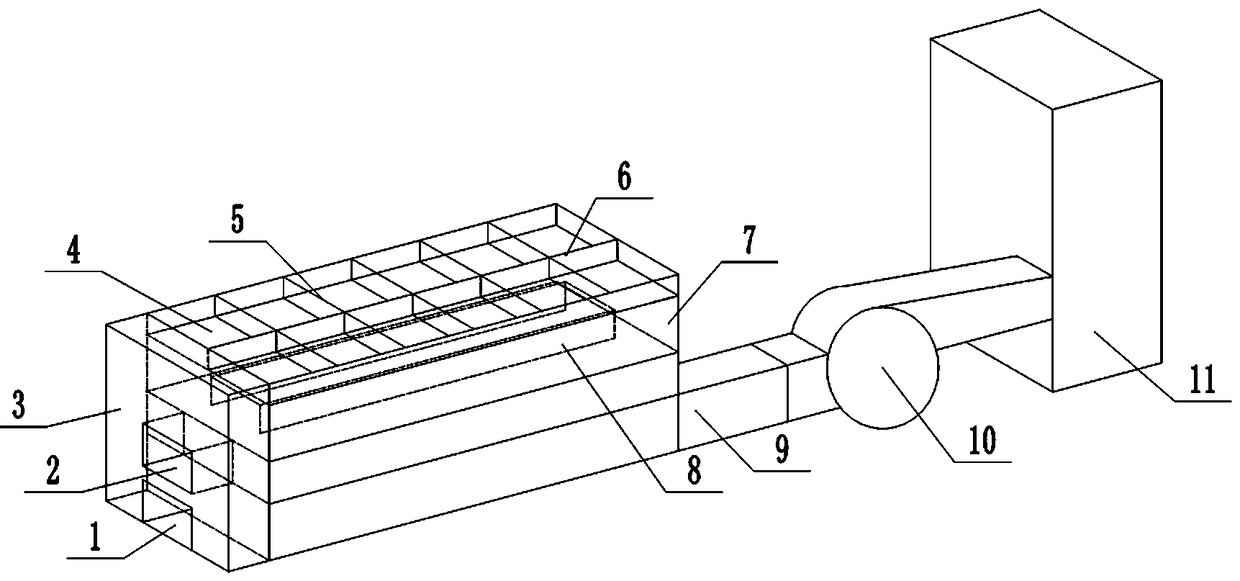

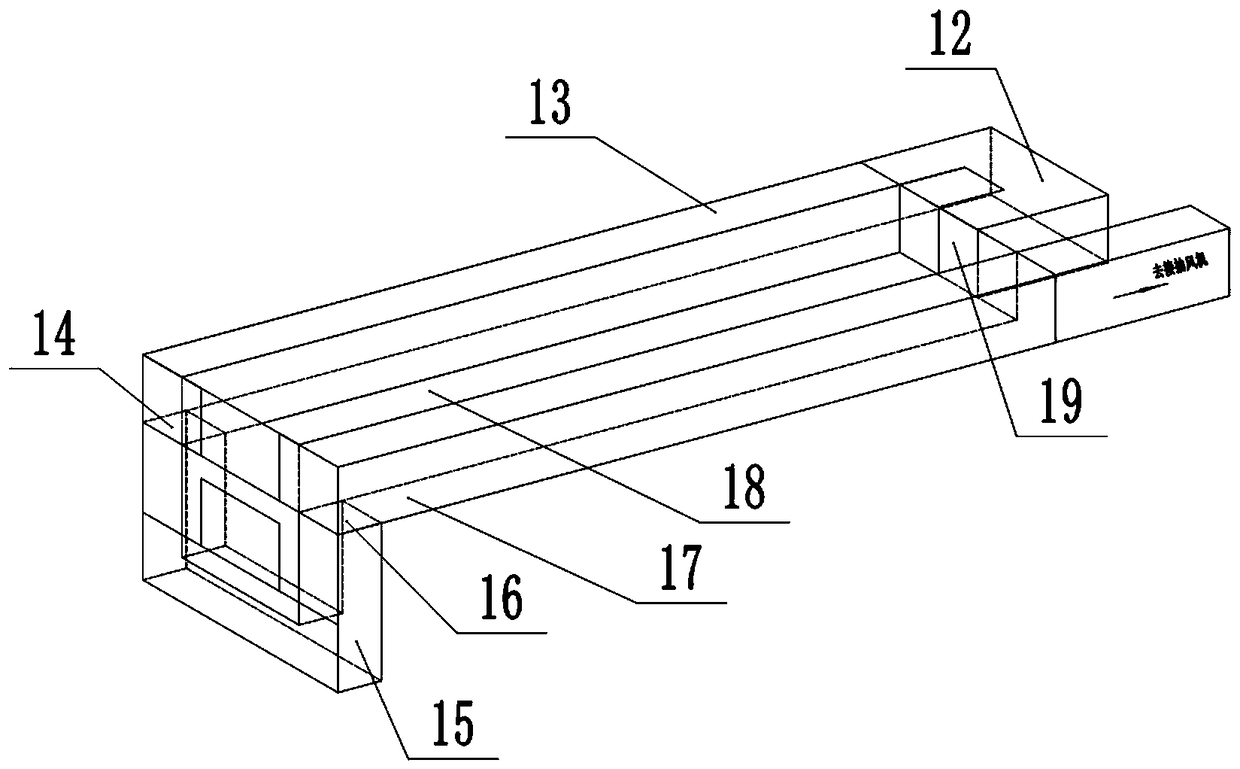

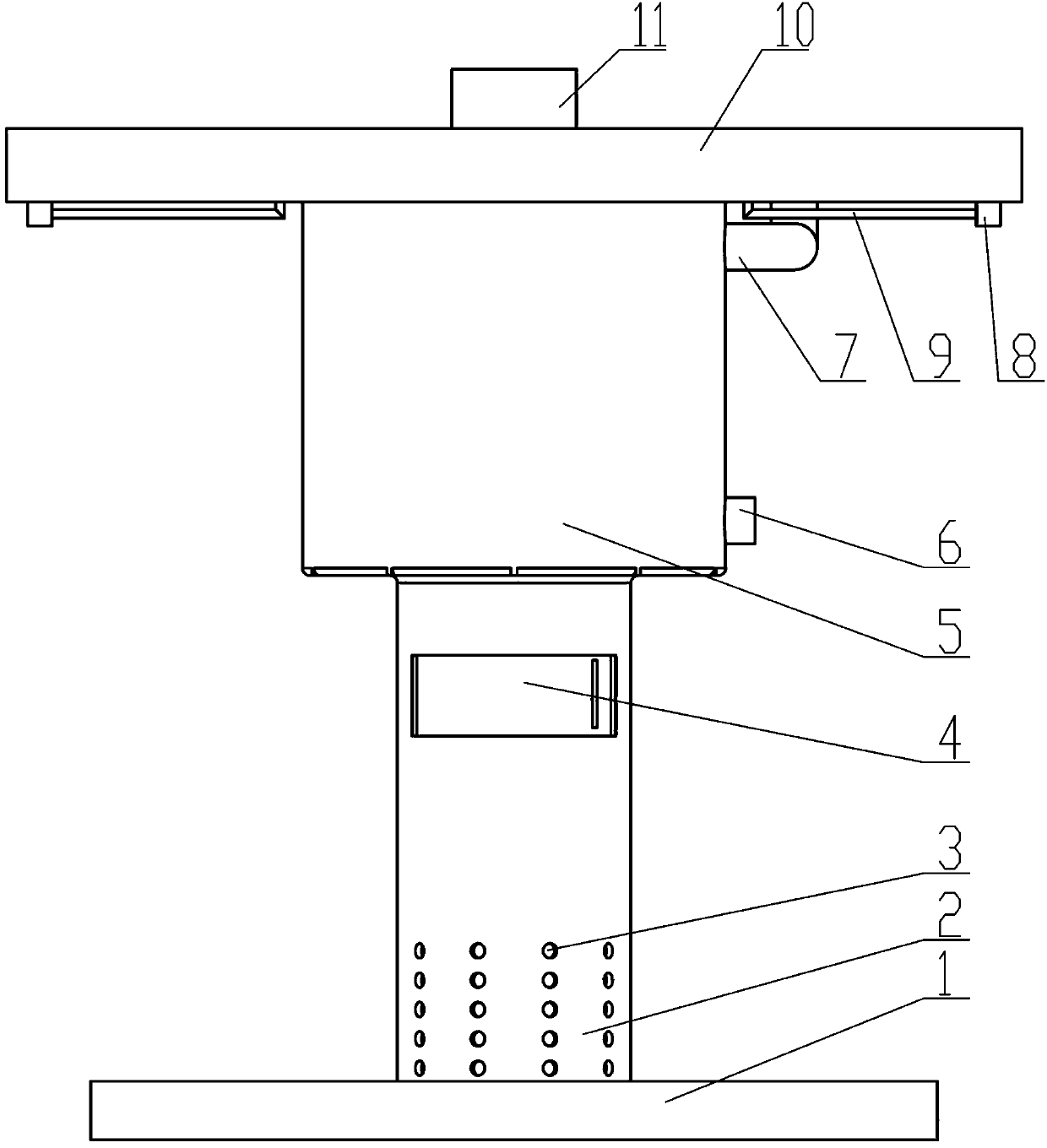

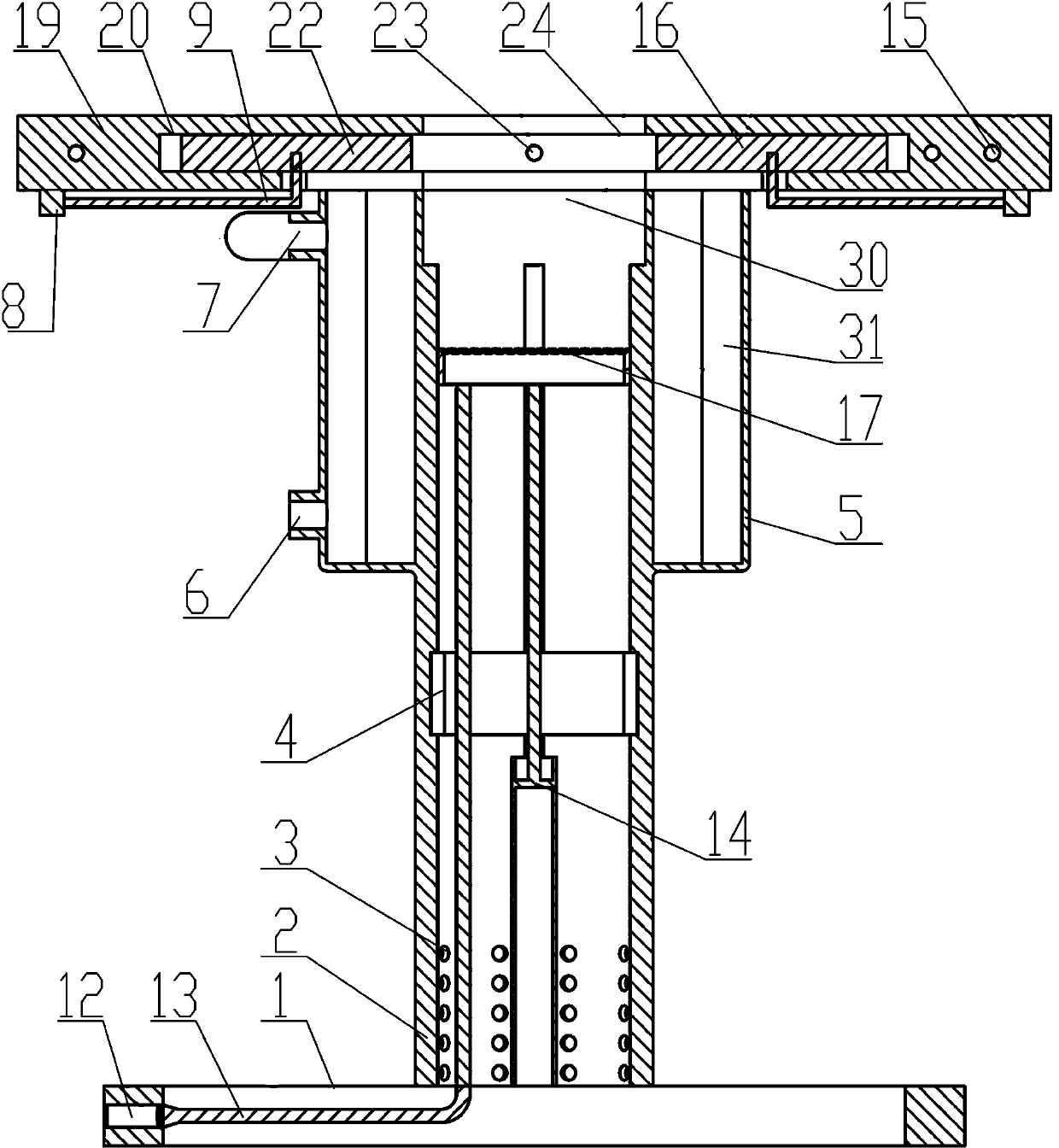

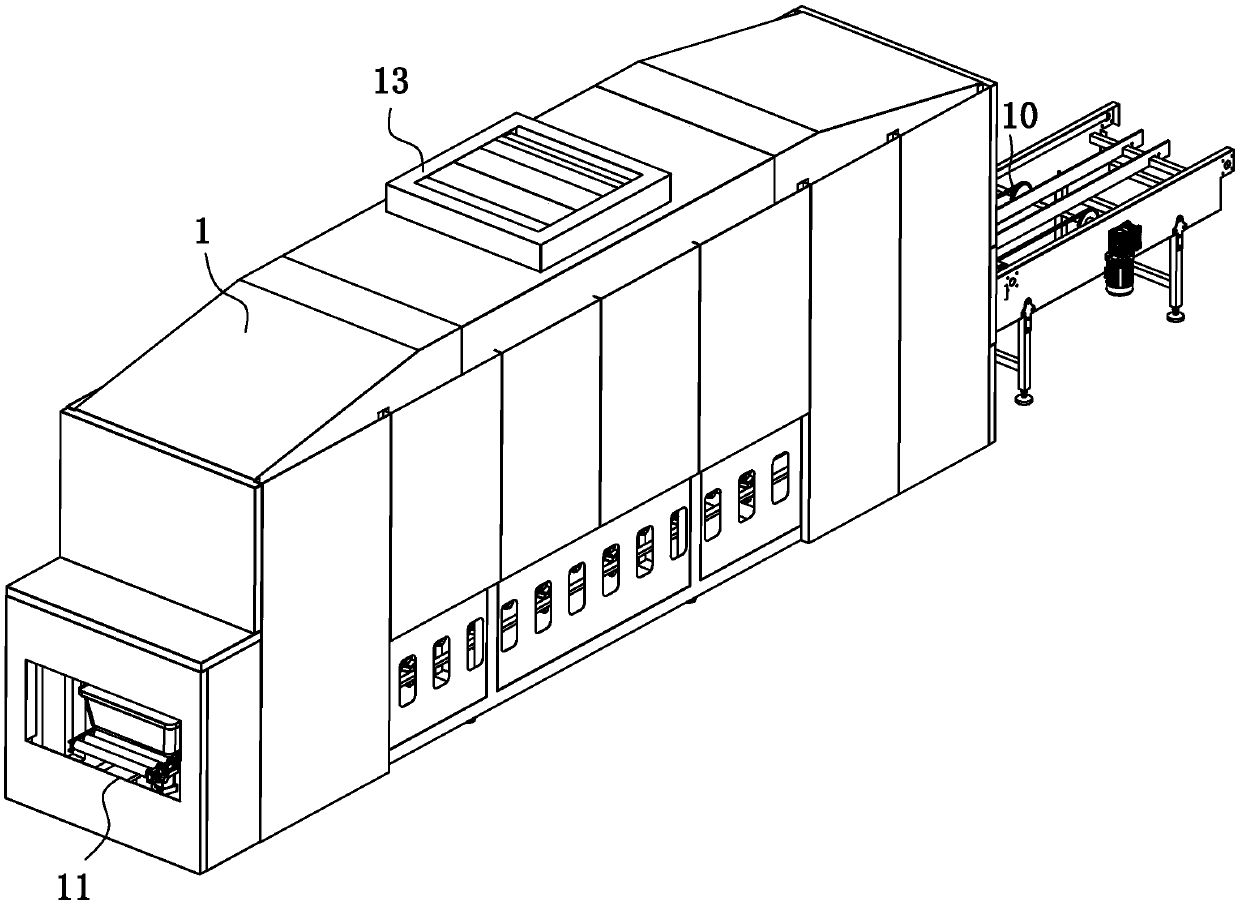

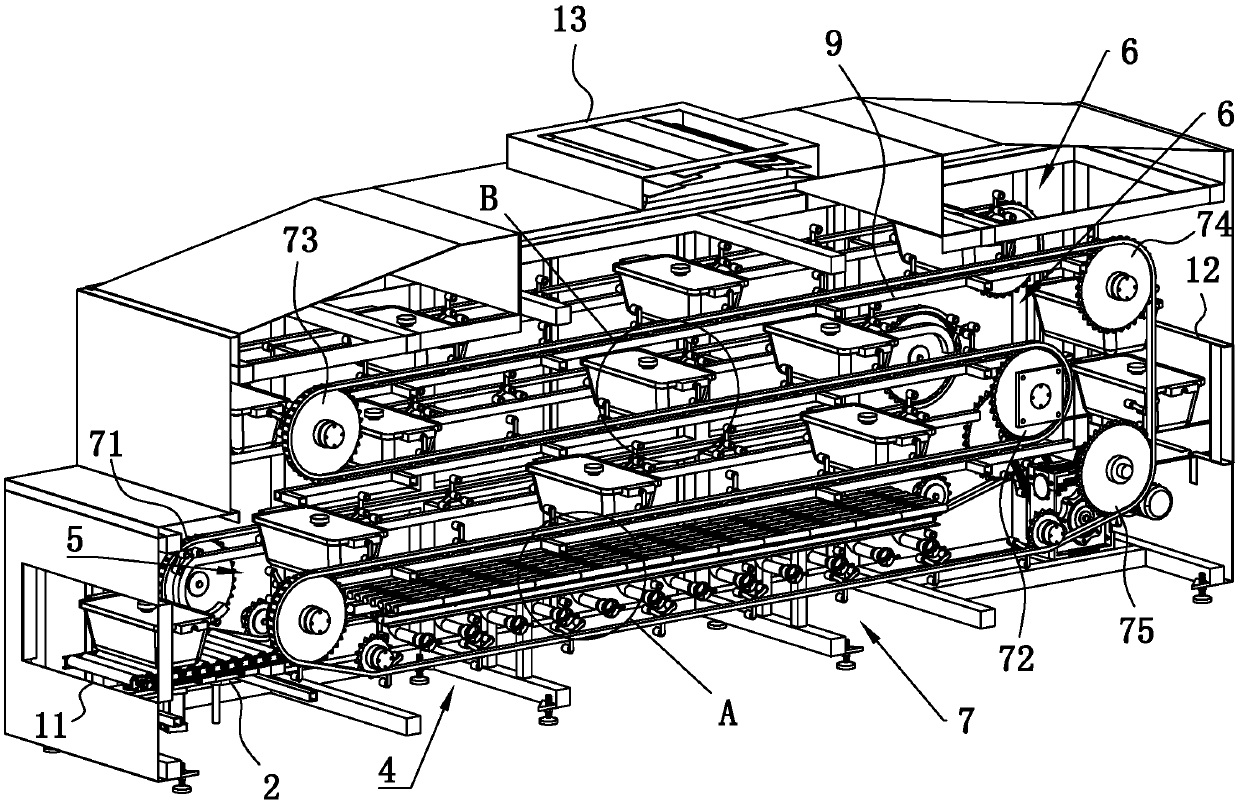

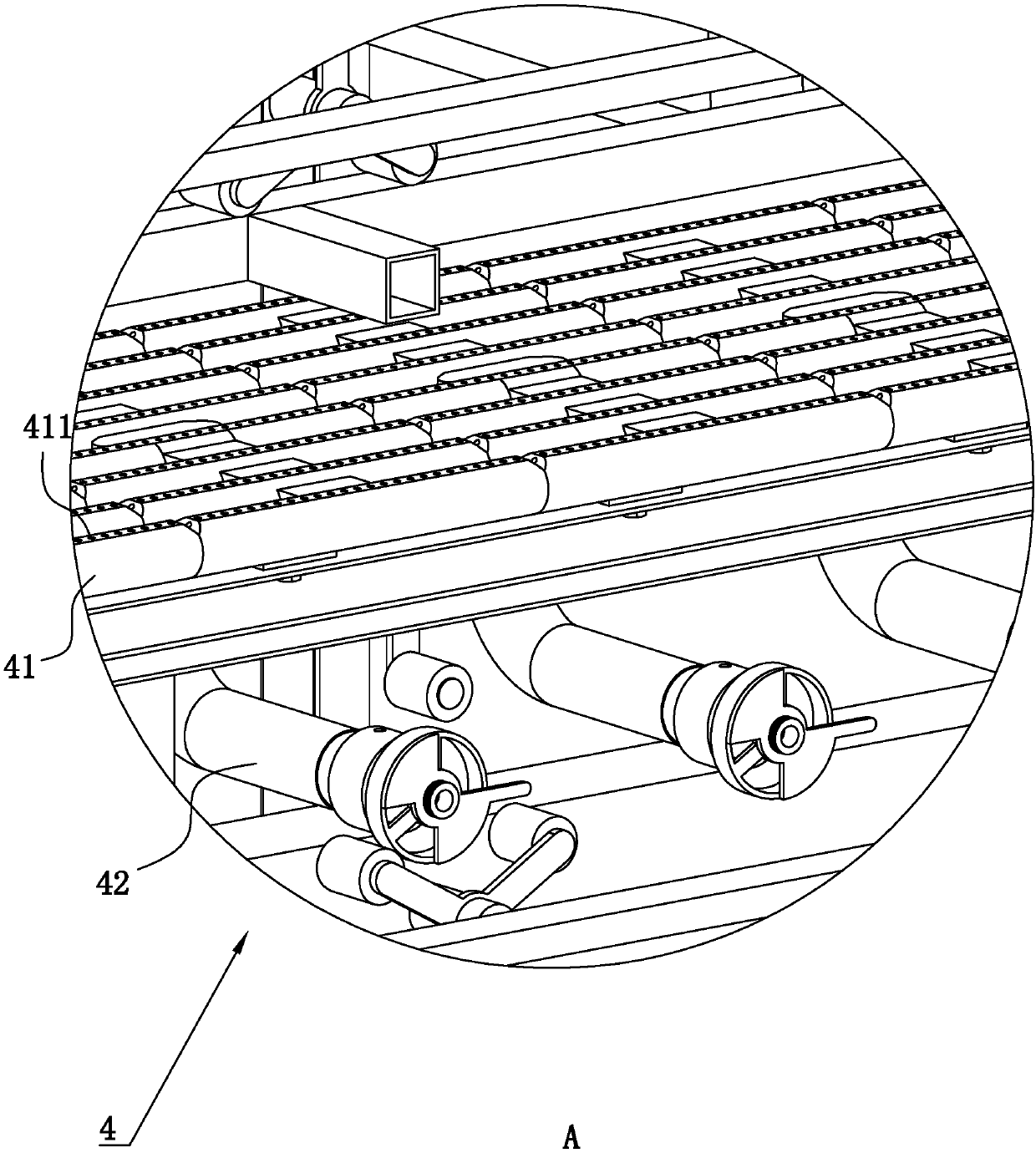

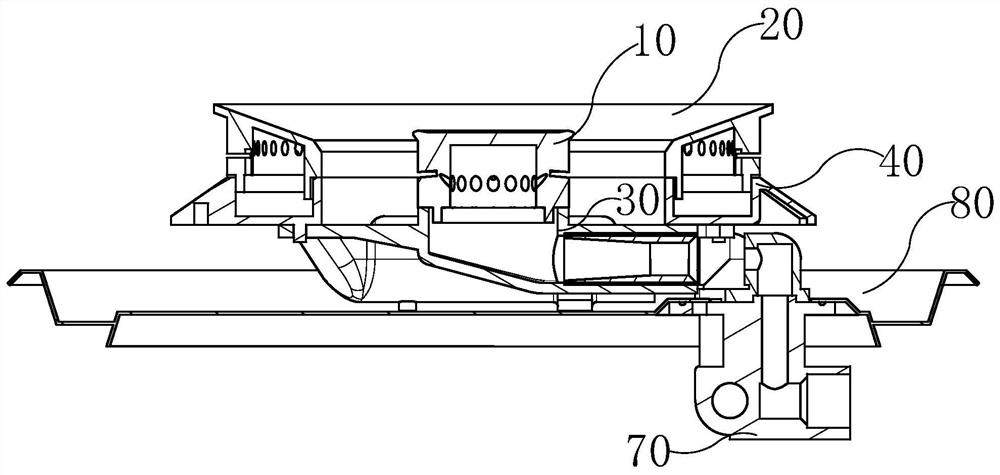

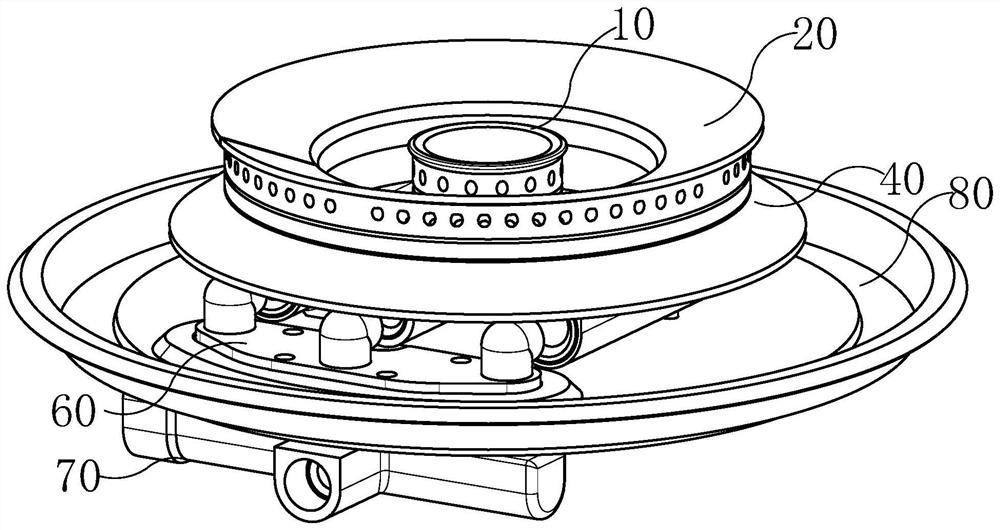

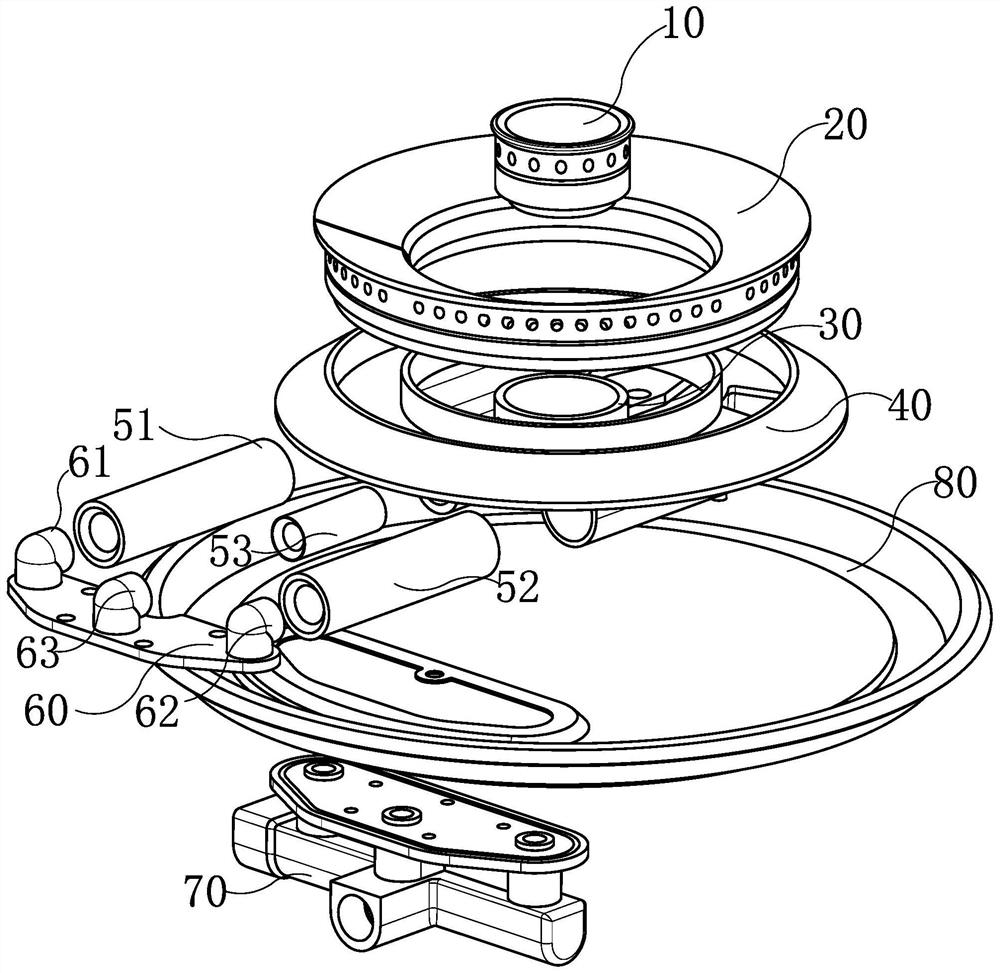

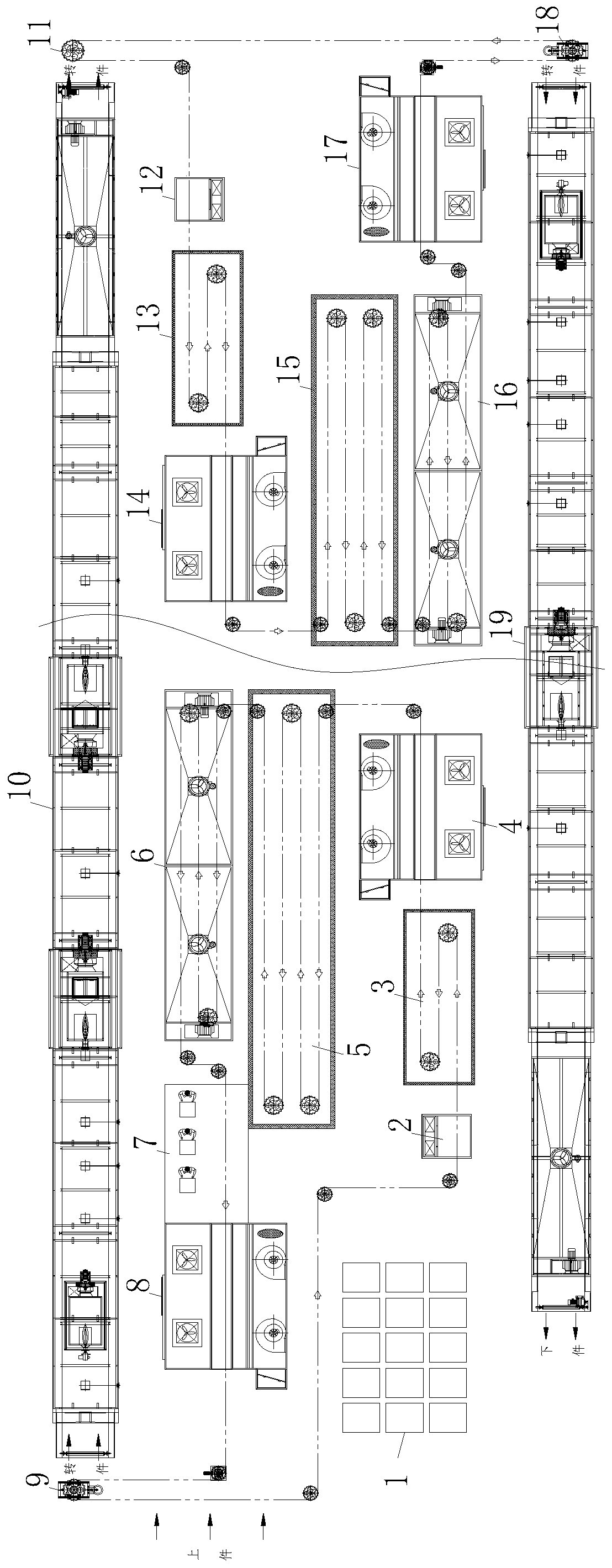

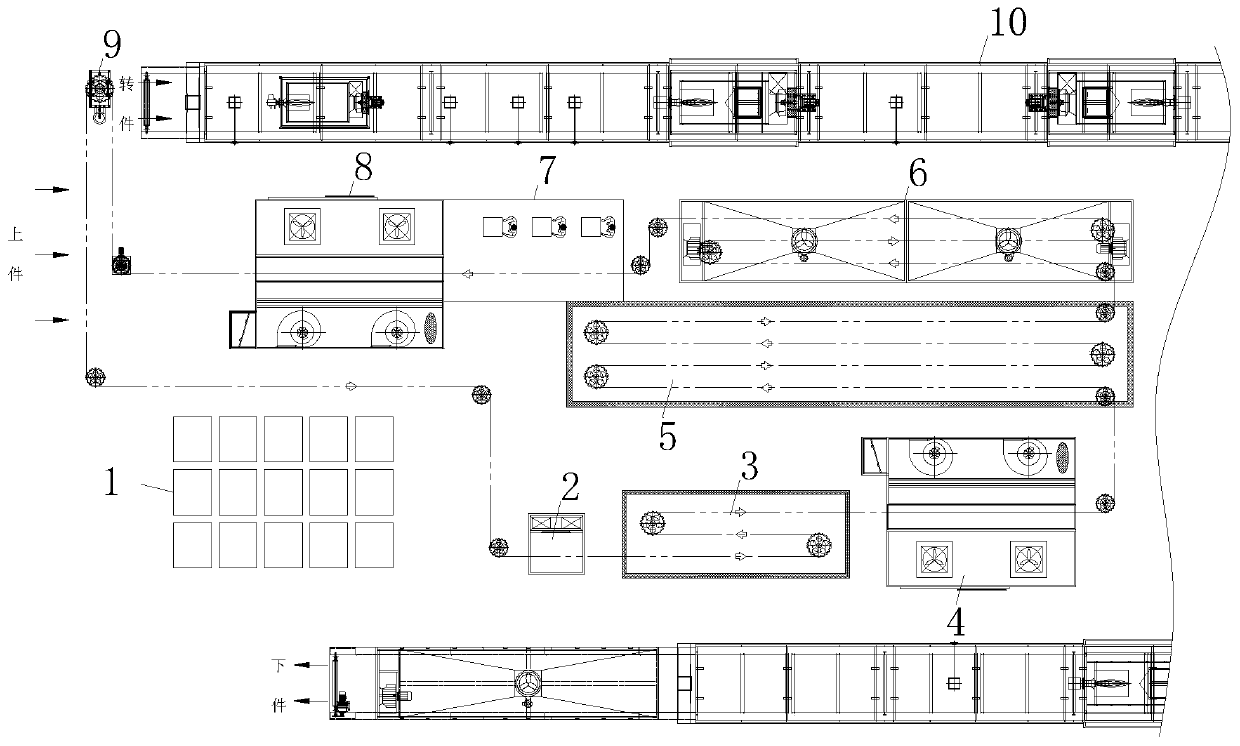

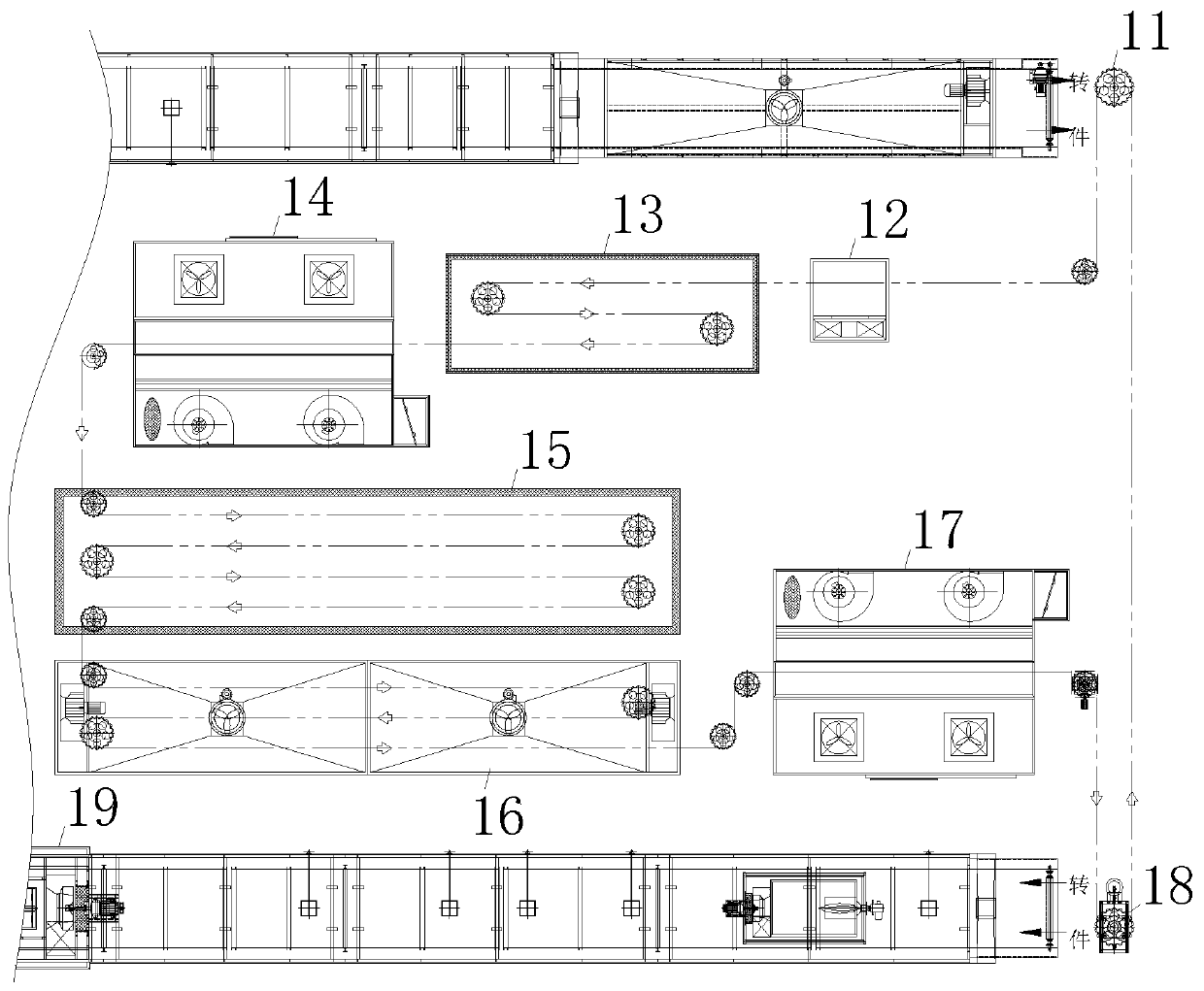

Continuous rice cooking and braising machine

ActiveCN108670018AGuaranteed uptimeSmooth transmissionSteam cooking vesselsProcess engineeringCooker

Owner:燕诚智能设备制造河北有限公司

Kitchen range burner and making method thereof

Owner:浙江博顿燃具科技有限公司

Additional anti-scalding device for cooking bench

InactiveCN104456684AImprove the smoke effectDomestic stoves or rangesLighting and heating apparatusSpray nozzleEngineering

Owner:KUNSHAN CITY YUSHAN TOWN SHILONG DESIGN STUDIO

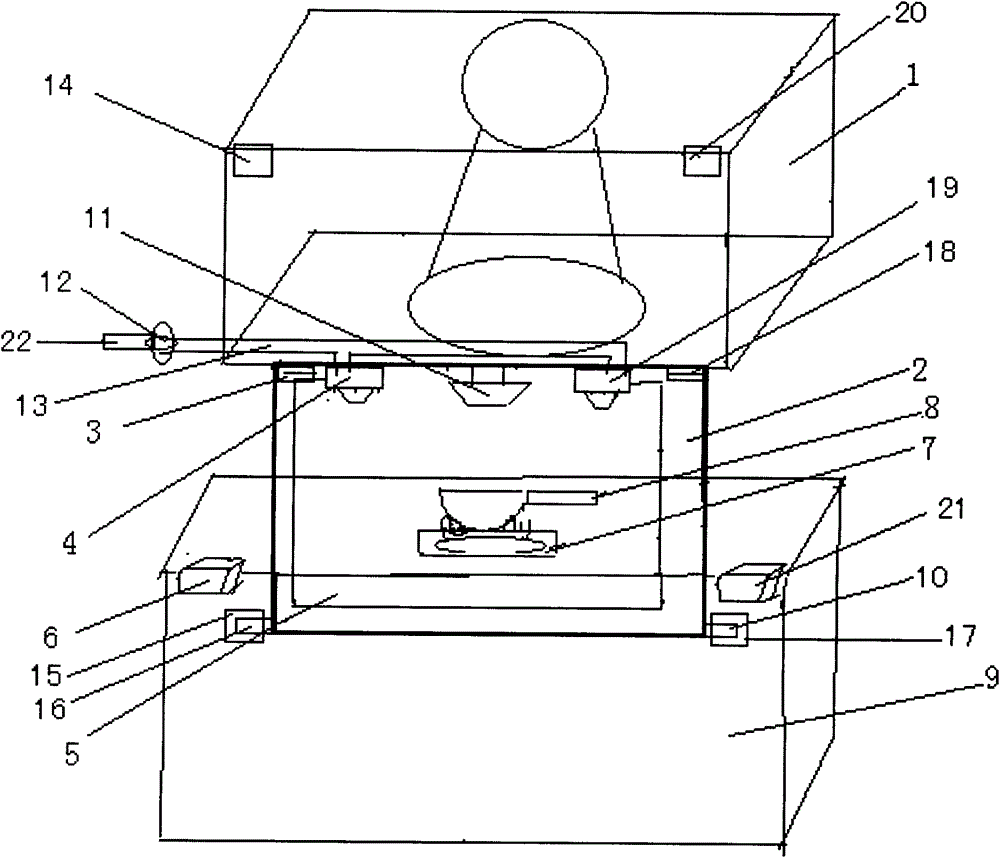

Integrated cooker and control method and control device thereof

PendingCN114688563ADomestic stoves or rangesLighting and heating apparatusOil and greaseControl engineering

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

Electric rice cooker inner and outer paint coating line

Owner:佛山市益泉机电设备科技有限公司

Stirring paddle and automatic cooker

PendingCN114027709AReduce the difficulty of cleaningEnsure consistencyCooking insertsEngineeringFood material

The invention relates to the technical field of household appliances, in particular to a stirring paddle and an automatic cooker. The stirring paddle comprises: a paddle blade; and a stirring paddle assembly seat which is fixedly connected with one end of the paddle blade. The stirring paddle assembly seat is mounted in an inner pot, and a gap is reserved between the paddle blade and the inner pot; the stirring paddle assembly seat is suitable for driving the paddle blade to rotate relative to the inner pot in the rotating direction of the paddle blade, the surface of the paddle blade in the width direction and the tangential direction of the surface of the inner pot at the corresponding position form an angle alpha, and the alpha is larger than 0 degree and smaller than 90 degrees. According to the stirring paddle provided by the invention, the paddle blade is designed to be in an inclined form, so that food materials can be turned over after being scratched by the paddle blade, the paddle blade is prevented from pushing a certain part of food materials to move around the bottom of the inner pot all the time, the stir-frying consistency of the food materials and the uniformity of salt and seasonings are ensured, non-uniform stir-frying is avoided, food sticking to the pan is reduced, and the difficulty of cleaning the inner pot by a user due to scorching is reduced.

Owner:GREE ELECTRIC APPLIANCE INC OF ZHUHAI

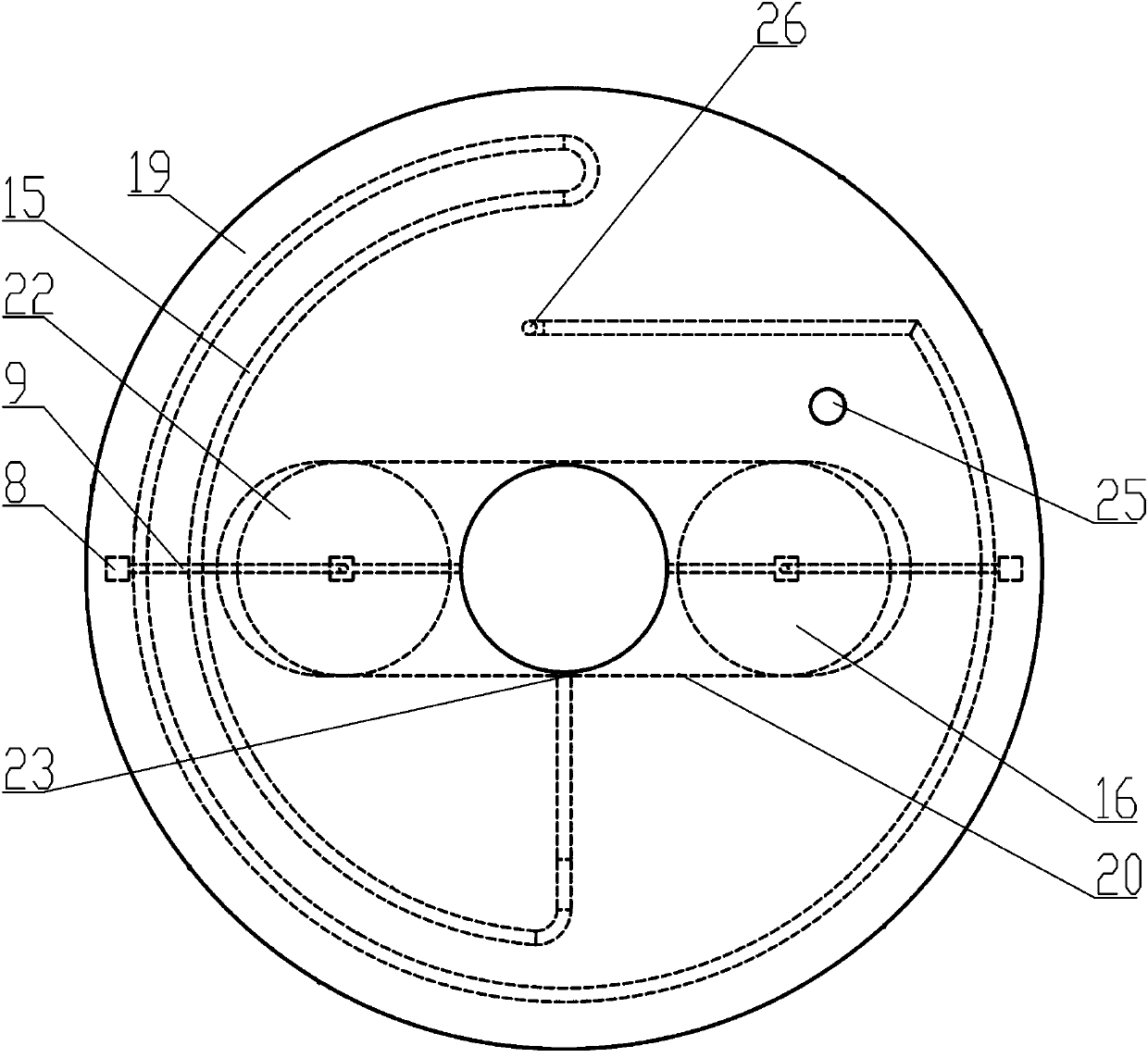

Gas distribution disc, combustor and gas stove

PendingCN114763902AImprove heating uniformityReduce complexityGaseous fuel burnerThermodynamicsGas cooking stove

The invention relates to the technical field of gas cookers, and discloses a gas distribution disc, which comprises a lower gas distribution disc, an upper gas distribution disc, an upper gas distribution disc and a lower gas distribution disc, and the upper gas distribution disc comprises gas distribution channels located in different loop lines from inside to outside, and the gas distribution channels of part of or all non-adjacent loop lines are communicated with the one or more first gas inlet subareas. According to the gas distribution disc disclosed by the embodiment of the invention, through the arrangement of the first gas inlet subarea on the lower gas distribution disc, fuel gas entering from one gas inlet channel on the lower gas distribution disc can be distributed to fire hole rings corresponding to the gas distribution channels on different loop lines on the upper gas distribution disc; the annular lines of the fire hole rings corresponding to the same gas inlet channel are located at different internal and external heating positions, so that synchronous adjustment of fire power at different internal and external heating positions can be simultaneously realized by adjusting the gas flow of the single gas inlet channel, and therefore, the heating uniformity is improved, and the operation complexity is reduced. The invention further discloses a combustor and a gas stove.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +2

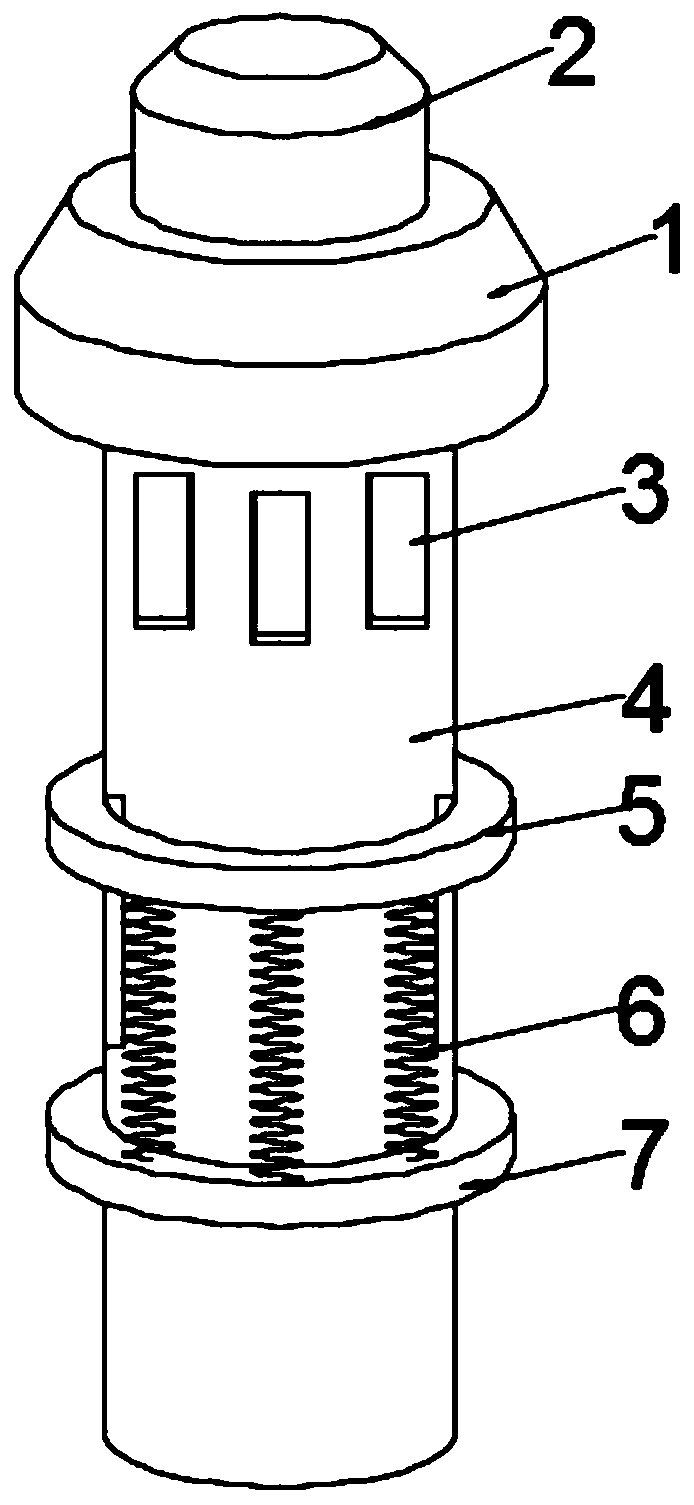

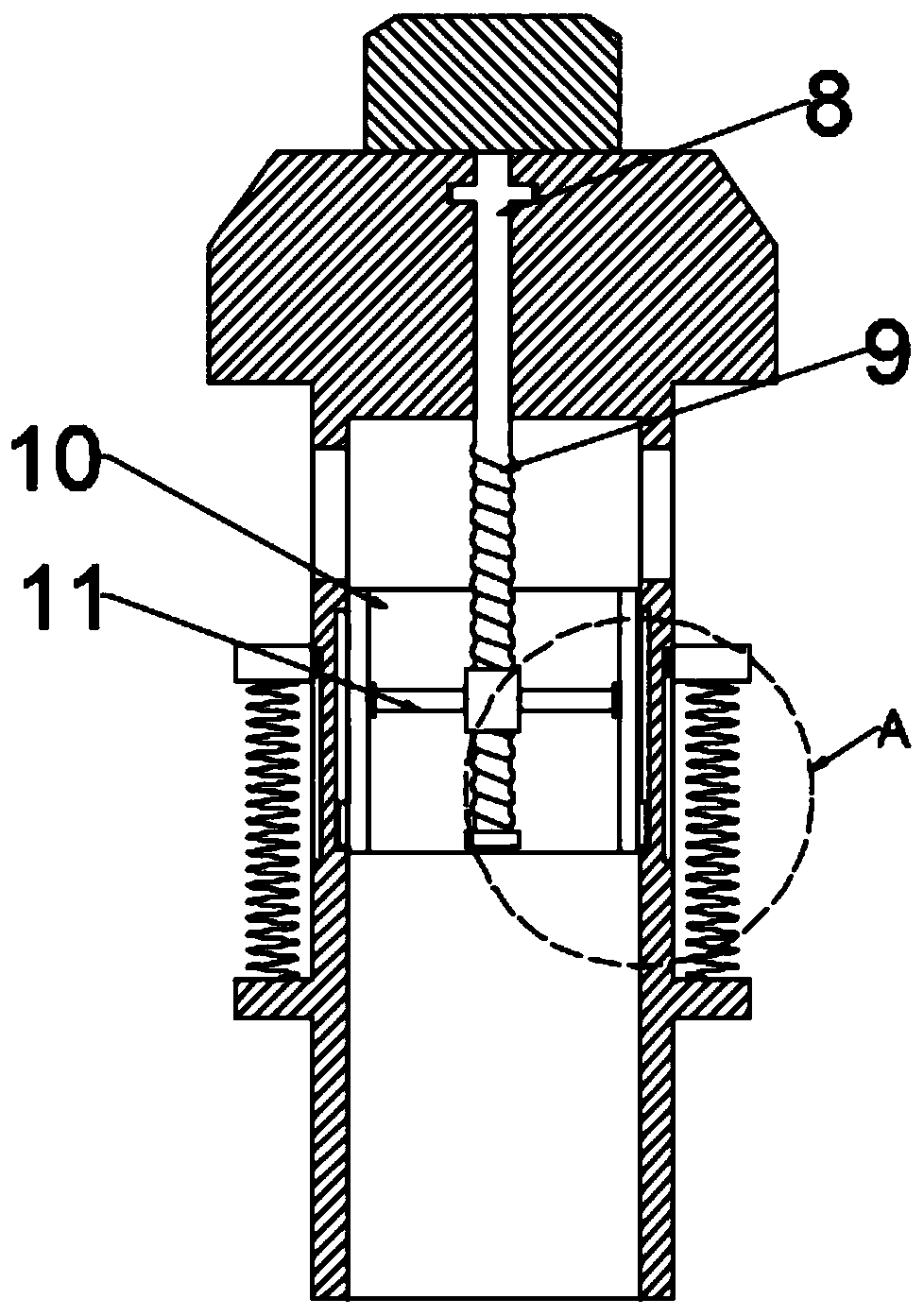

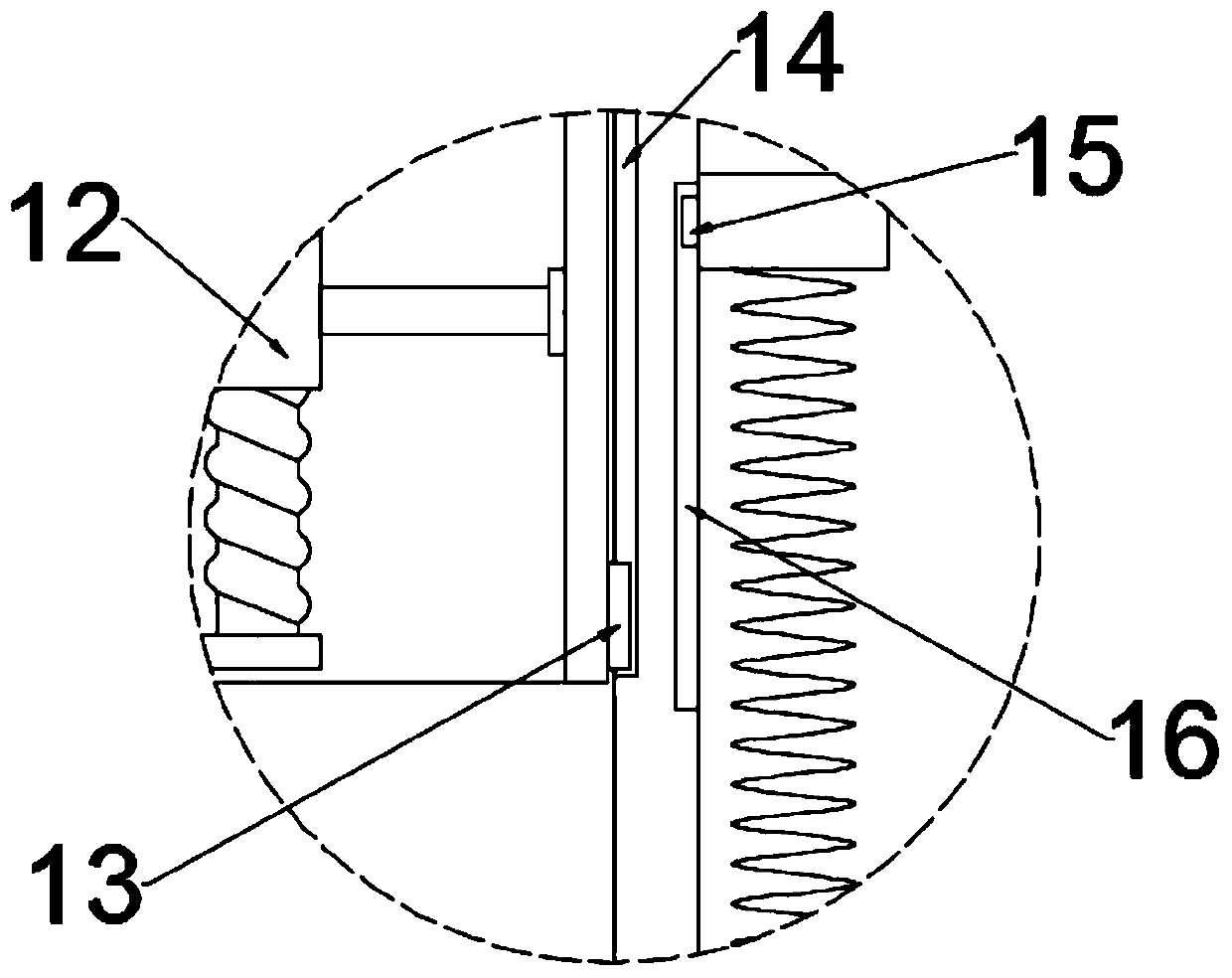

Pressure relief structure for pressure cooker, pressure cooker cover and pressure cooker

Owner:武义伟诺工贸有限公司

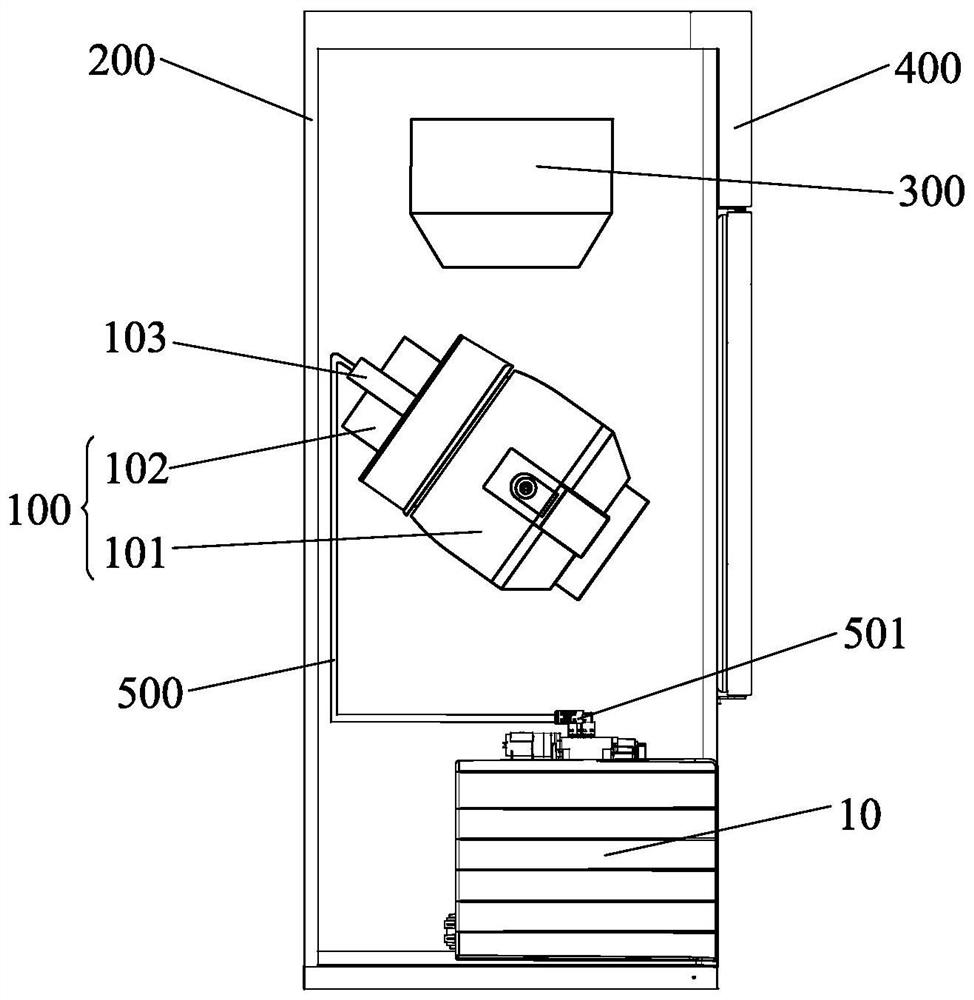

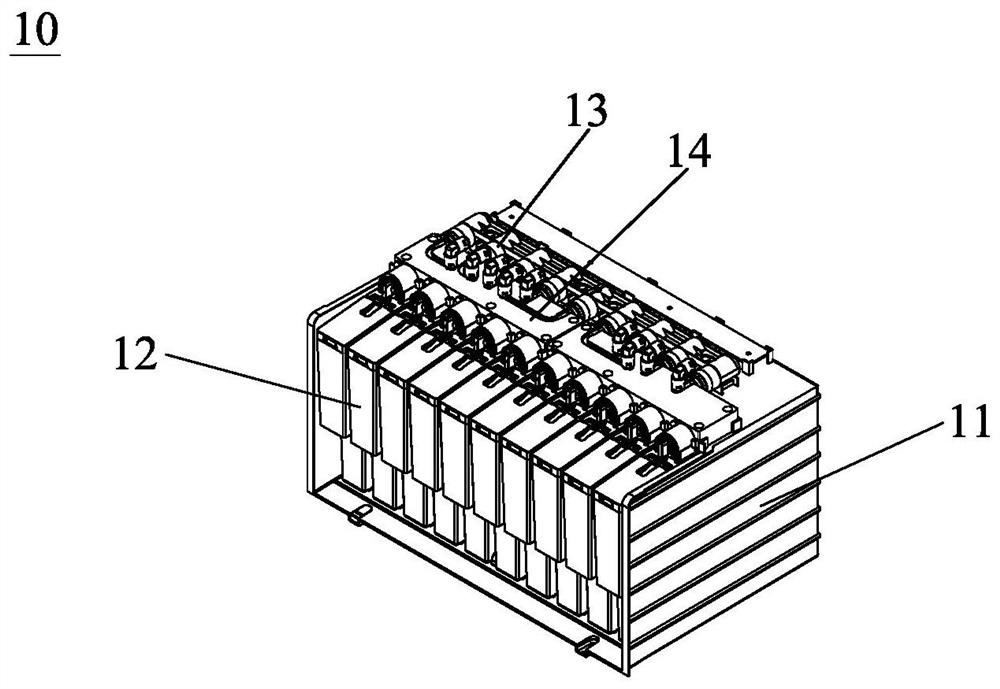

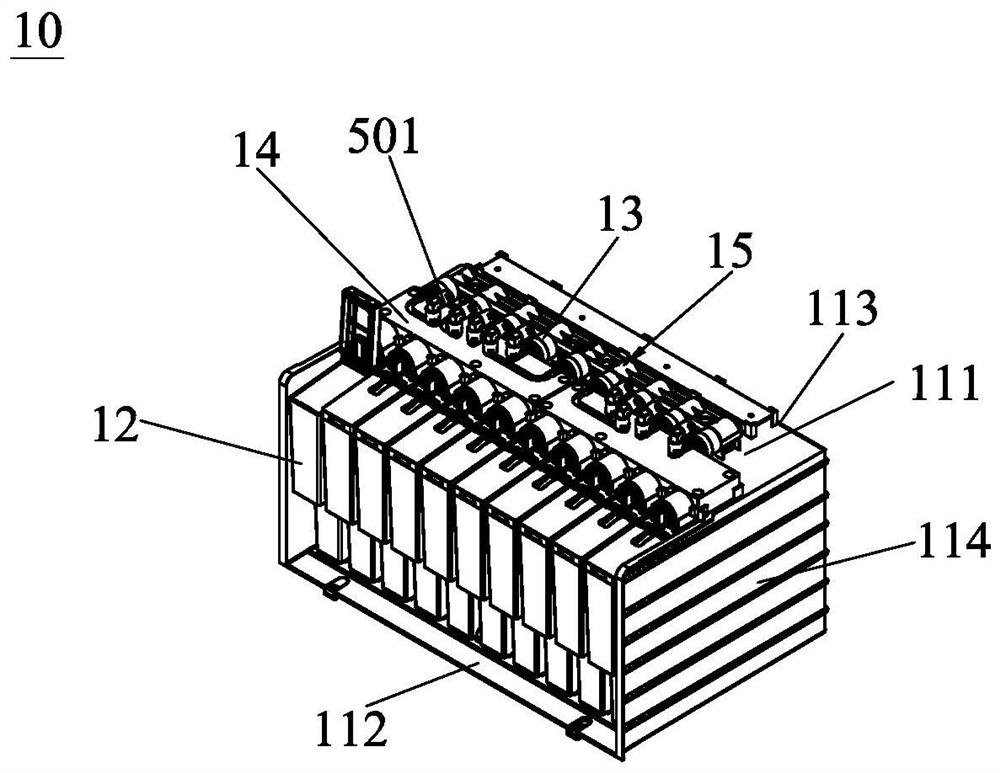

Liquid supply device, stir-frying pan device and cooker

PendingCN111631607AAvoid complex structuresQuick disconnect and quick connectCooking vessel constructionsProcess engineeringCooker

The invention relates to the technical field of intelligent manufacturing and intelligent service. The invention discloses a liquid supply device comprising a rack, a plurality of liquid containers, aplurality of liquid pumps and a liquid channel integration module, wherein the plurality of liquid containers, the plurality of liquid pumps and the liquid channel integration module are arranged onthe rack; the liquid channel integration module is connected between the plurality of liquid containers and the plurality of liquid pumps. The invention further discloses a stir-frying pan device anda cooker. The technical problems that an existing automatic seasoning adding device is complex in structure, leaks liquid and is inconvenient to install and replace are effectively solved. According to the liquid supply device, the multiple seasoning bottles and the multiple seasoning pumps as well as the multiple seasoning pumps and the multiple external pipelines can be rapidly disassembled andrapidly connected, so that the assembling efficiency is improved, and the connecting and sealing effects between the seasoning bottles and the seasoning pumps as well as between the seasoning pumps and the external pipelines are good.

Owner:SHANGHAI AICAN ROBOT GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap