Electric fuel, gaseous fuel and solid biomass fuel integrated heat furnace and using method

A technology of solid biomass and gas fuel, applied in heating methods, lighting and heating equipment, applications, etc., can solve the problems of single application of heat furnace energy, waste of resources, single function, etc., to reduce heat loss in advance and improve utilization efficiency , the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

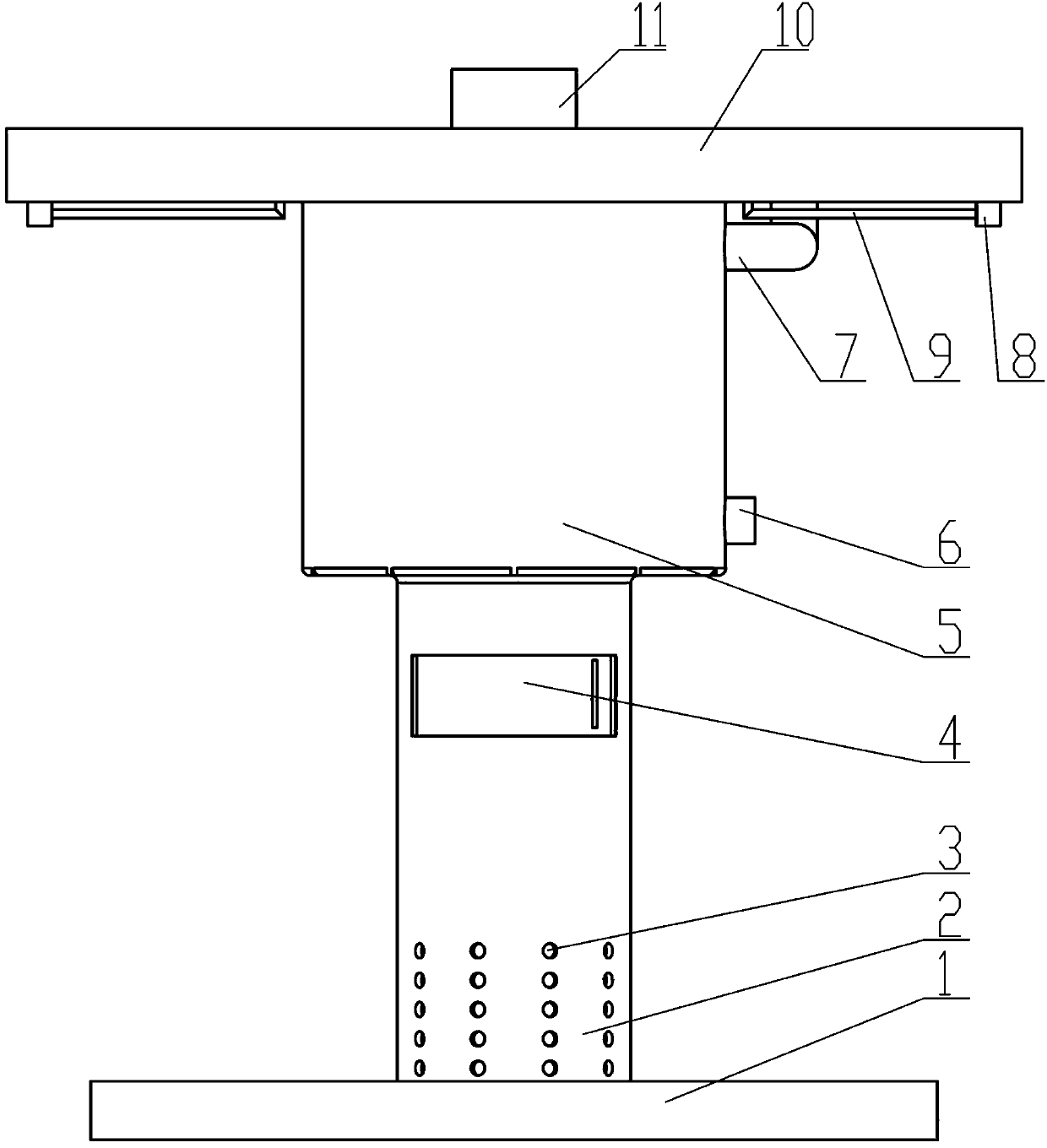

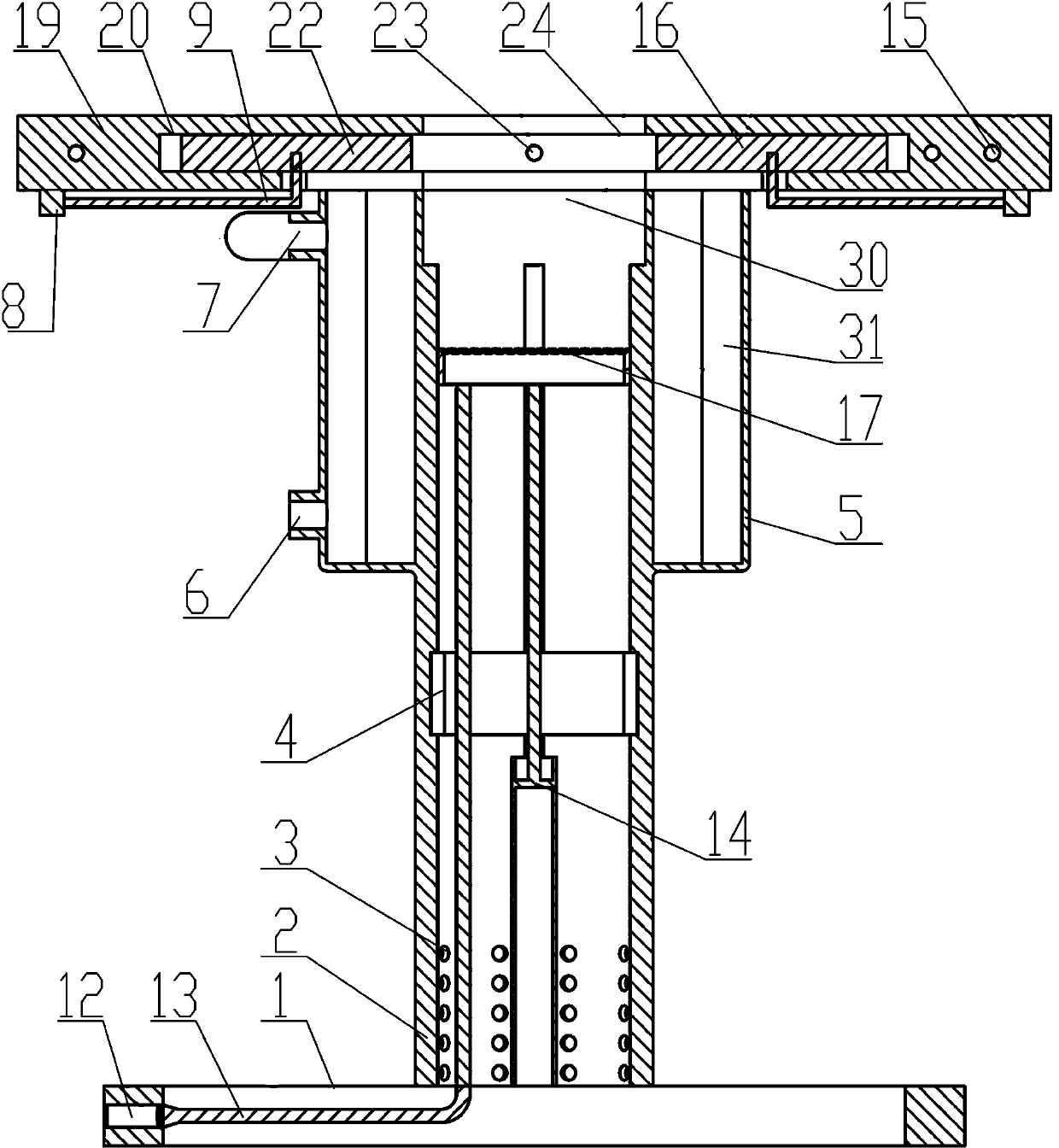

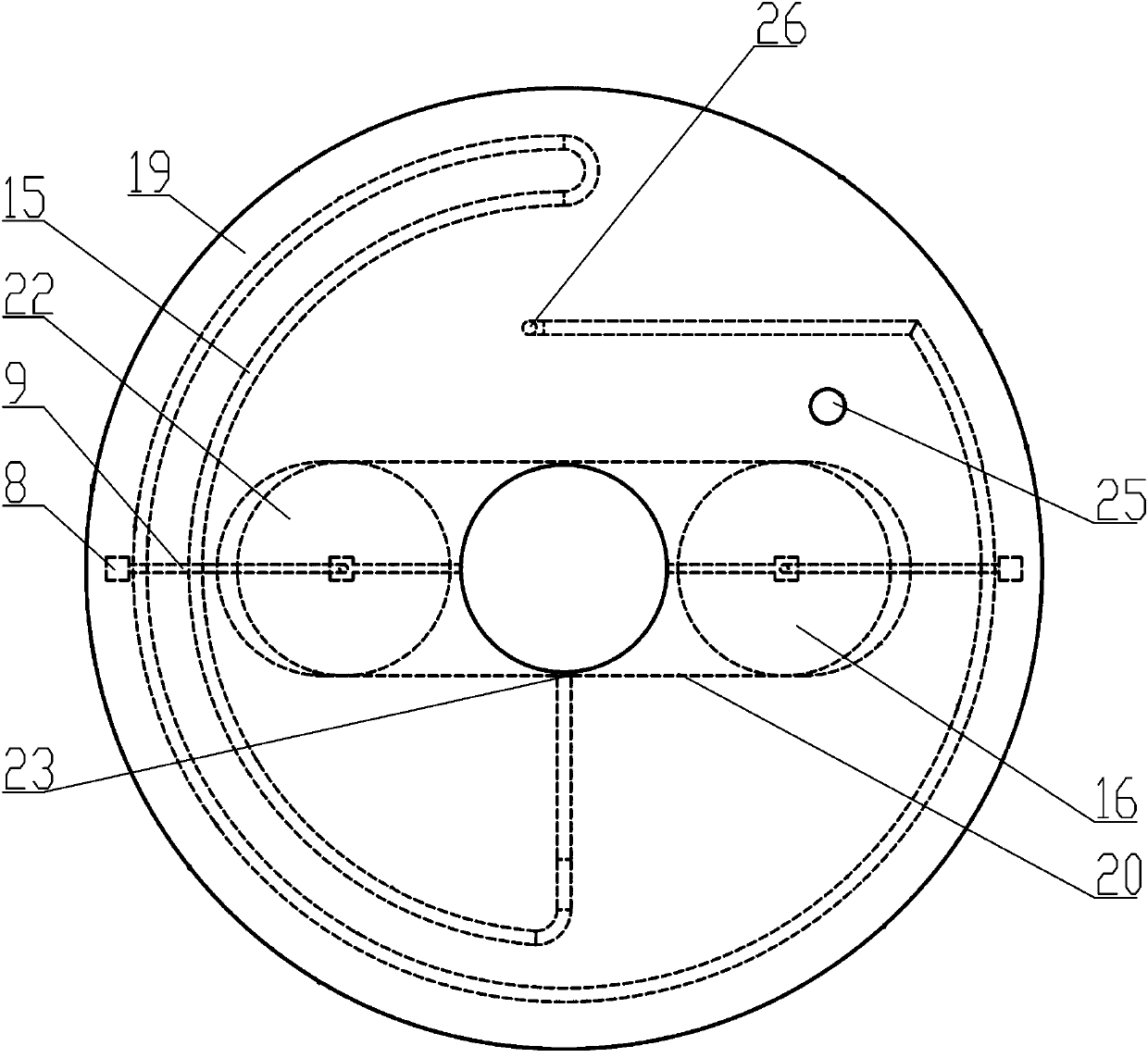

[0035] see Figure 1-8 , an integrated thermal furnace with electricity, gas fuel and solid biomass fuel, which includes a furnace base 1, a furnace body 2 is installed on the top of the furnace base 1, a furnace platform 10 is installed on the top of the furnace body 2, and the furnace body 2 is equipped with a lifting mechanism 14 at the bottom of the interior, the top of the lifting mechanism 14 is fixedly equipped with a furnace bridge 17, and the bottom of the furnace body 2 is provided with evenly distributed air intake honeycomb holes 3. A furnace door 4 is arranged on the outer wall; a combustion cavity 30 is formed between the top of the furnace bridge 17 and the furnace platform 10; the inside of the furnace platform 10 is fitted with an electromagnetic oven tray 22 for electric heating by sliding fit; the electromagnetic oven panel The opposite side of 22 is fitted with a support disc 16 by sliding fit; a gas heating structure is arranged inside the furnace body 2 . T

Embodiment 2

[0048] The use method of any one of the electric, gaseous fuel and solid biomass fuel integrated furnace:

[0049] When the pure electric system is working, the above-mentioned slider 8 is manually pushed, the push rod 9 is pushed by the slider 8, and the above-mentioned electromagnetic hob 22 is pushed by the push rod 9 to move along the hob slide rail 20 to the position where the center hole 24 of the hob is located. , and then start the electromagnetic oven tray 22, and heat the pot through the electromagnetic oven tray 22;

[0050] When the pure gas system is working, the induction hob 22 is manually put away, and the above-mentioned support disc 16 is pushed along the hob slide rail 20 to the position where the center hole 24 of the hob is located, and the pot is placed on the support disc 16 , forming a semi-closed combustion chamber, the exhaust gas can only enter the flue 28 and the circulation coil 15, so as to realize the discharge of the exhaust gas and the heating of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap