Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about "Hollow article cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for treating a substrate with an ozone-solvent solution

InactiveUS6982006B1Improve user securityLighting and heating apparatusHollow article cleaningSolventAqueous solution

Owner:BOYERS DAVID G +1

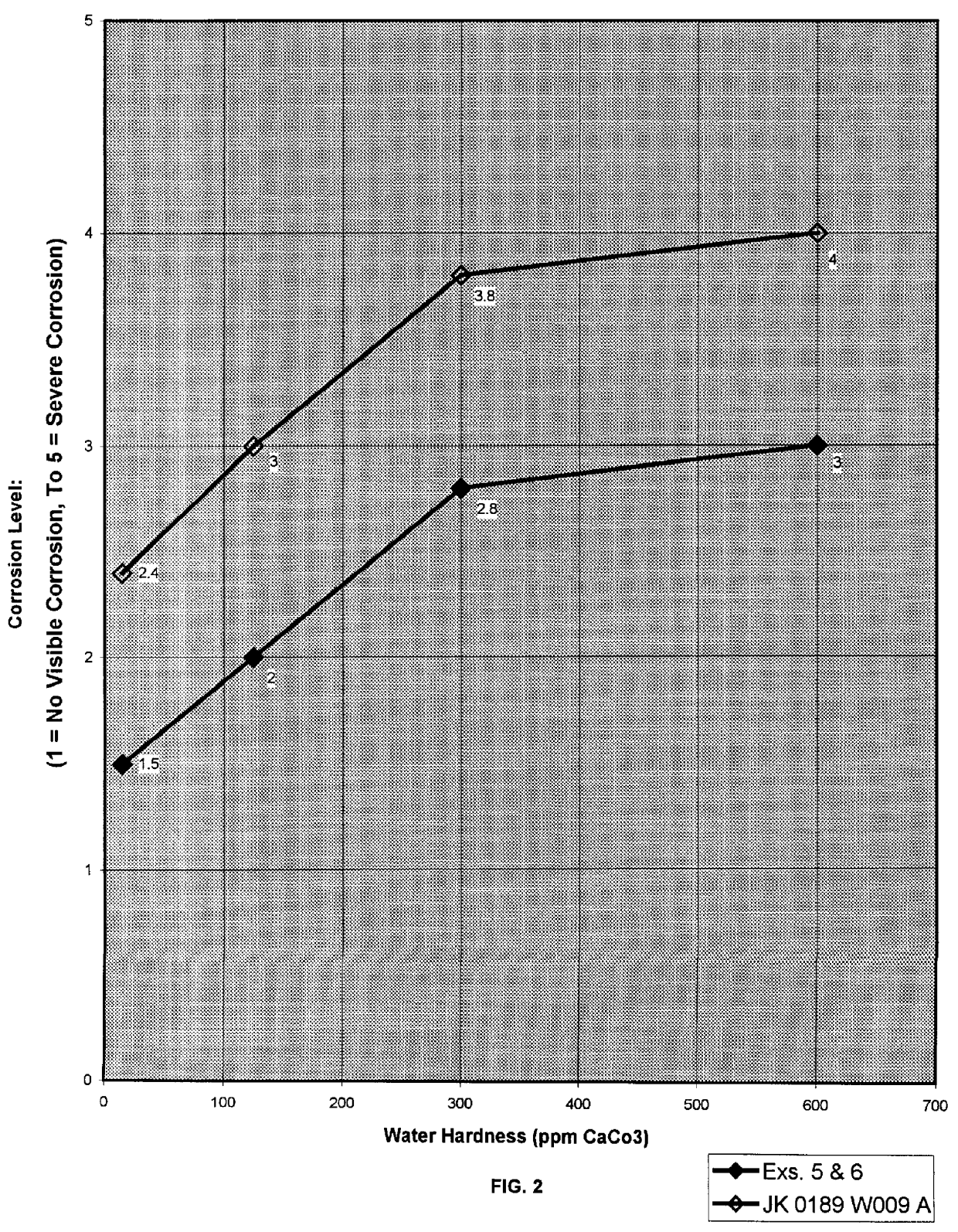

Liquid automatic dishwashing composition with glassware protection

InactiveUS6083894AImproved dishwashing compositionOrganic detergent compounding agentsAnionic surface-active compoundsHigh concentrationOrganozinc compound

Owner:JOHNSONDIVERSEY INC

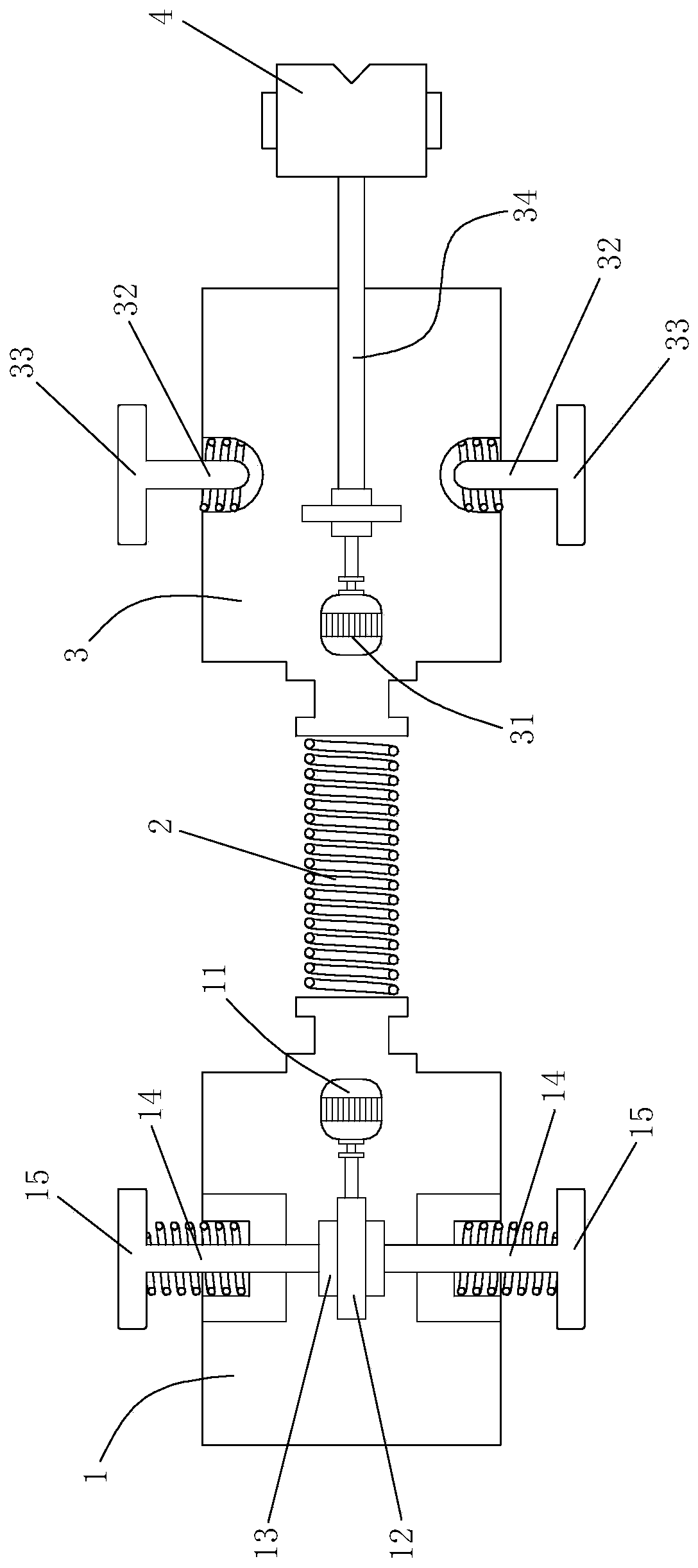

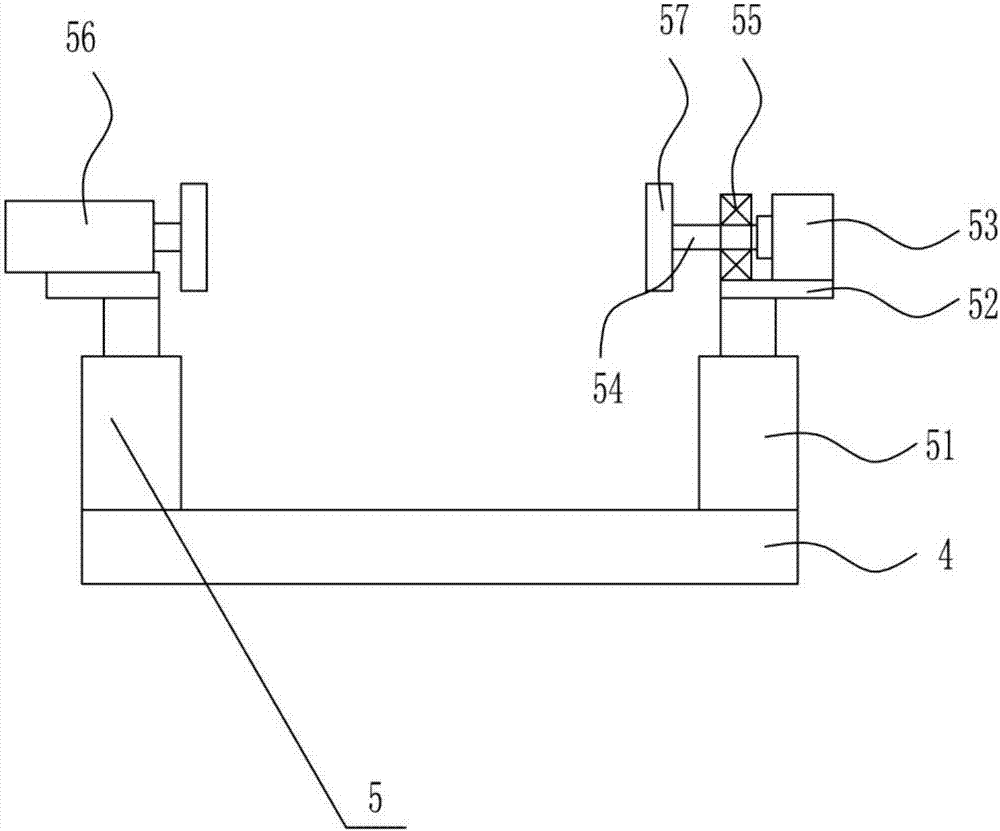

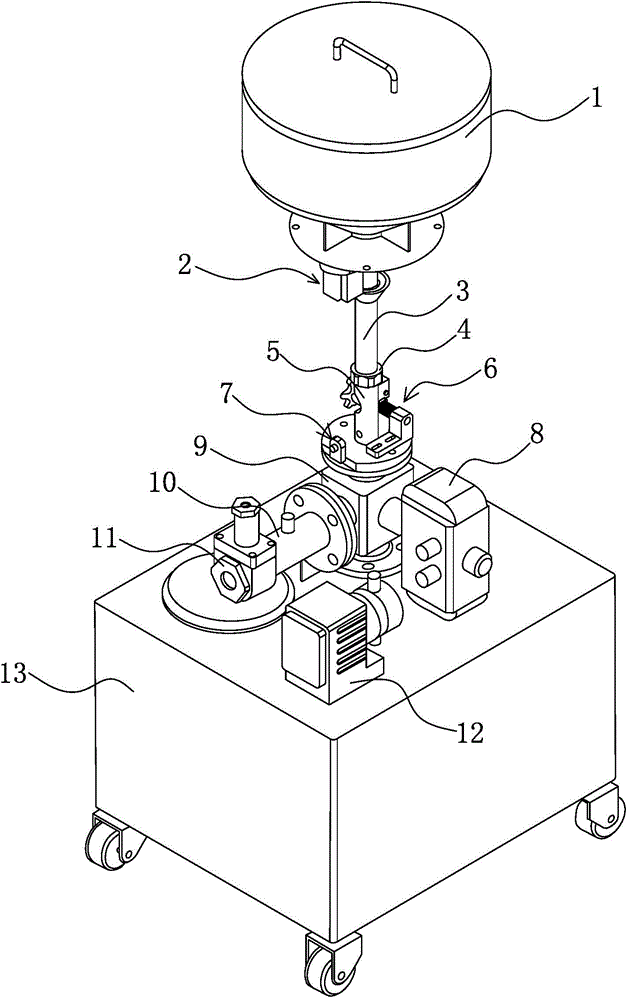

Efficient steel pipe cleaning device

Owner:上海申第实业有限公司

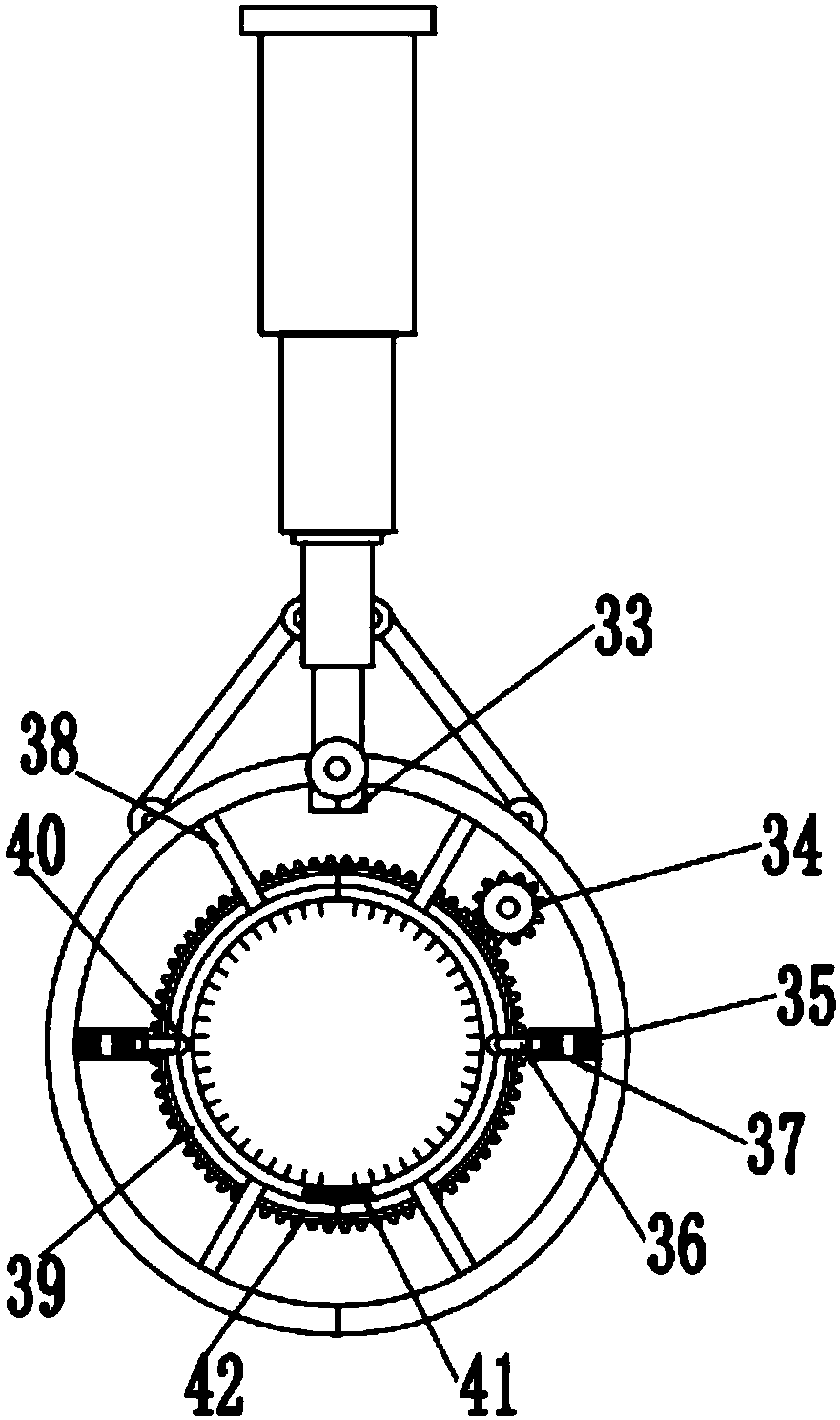

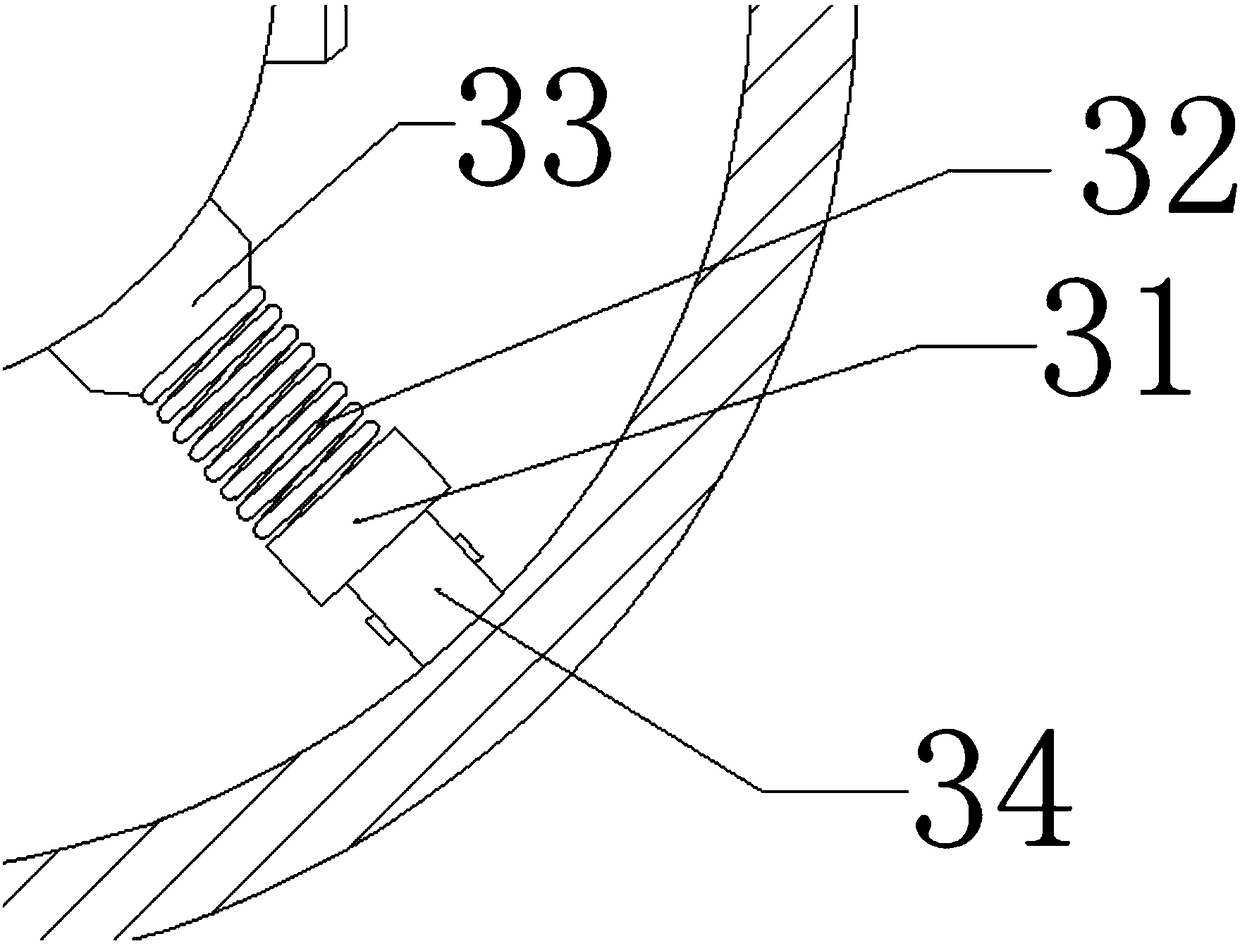

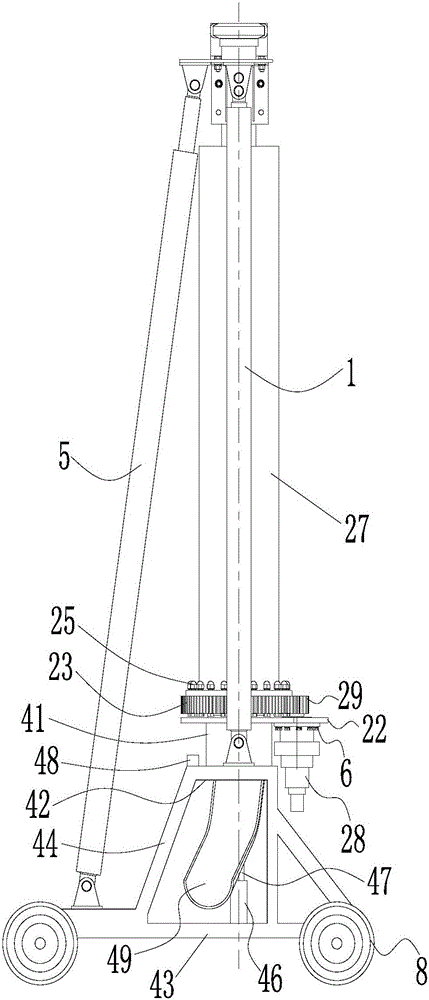

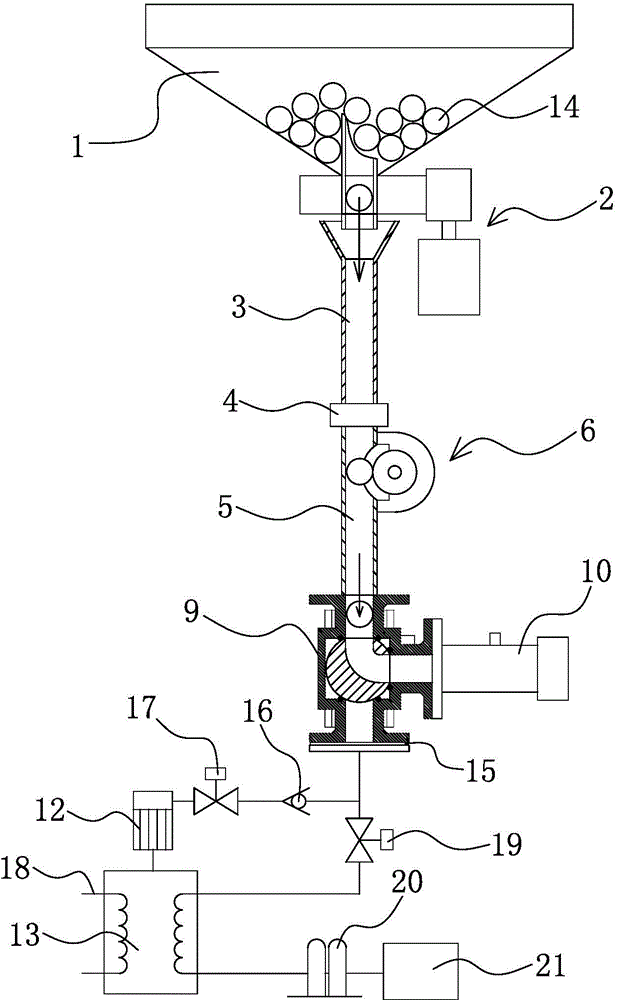

Flexible laser cleaning system applicable to bend pipeline

InactiveCN109821819AImprove motor coordinationControl switch stateHollow article cleaningFiberDrive wheel

Owner:SOUTH CHINA NORMAL UNIVERSITY

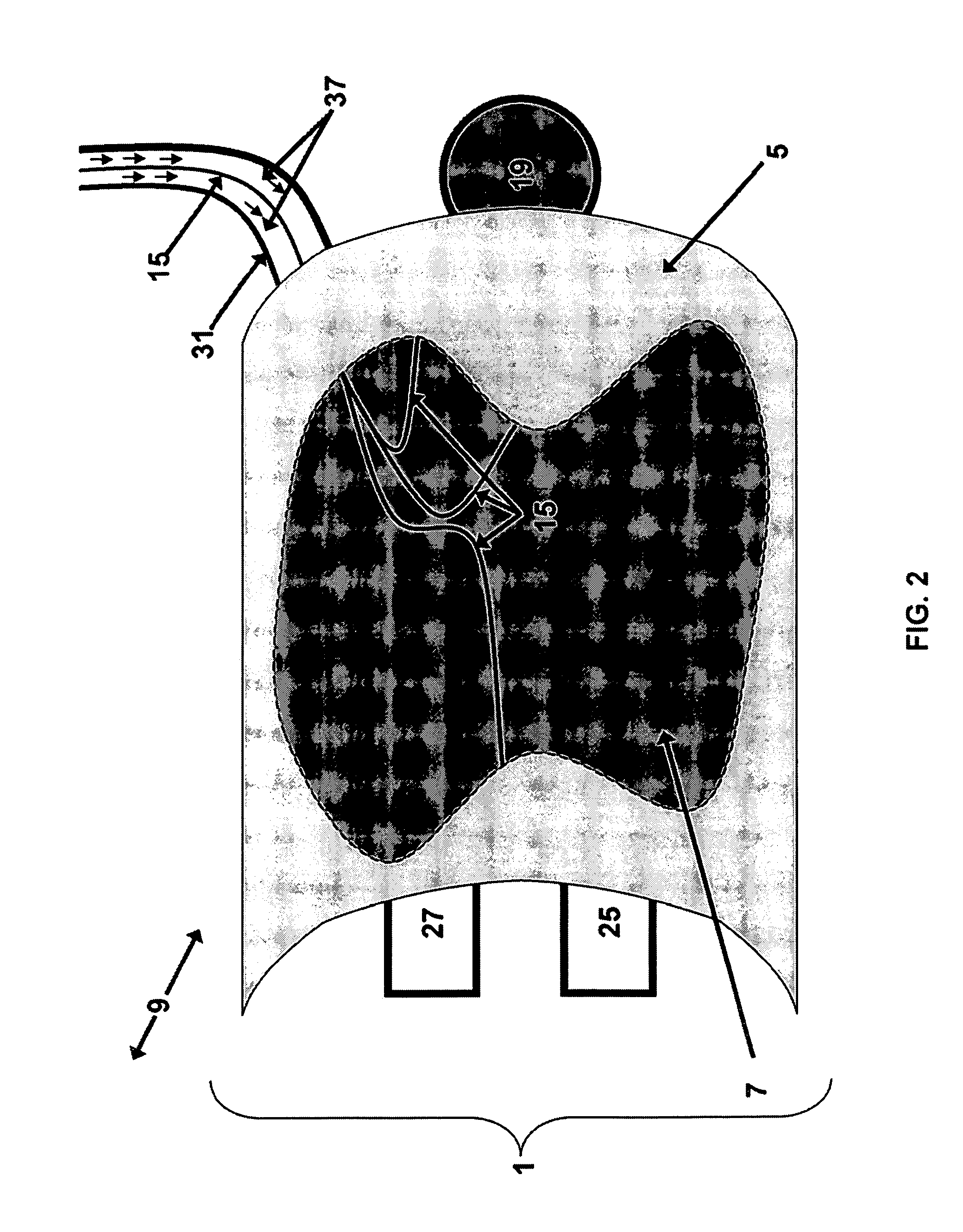

Explosion proof vehicle for tank inspection

ActiveUS8122780B1Impair integrityHollow article cleaningVessel partsInternal pressureElectrical conductor

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

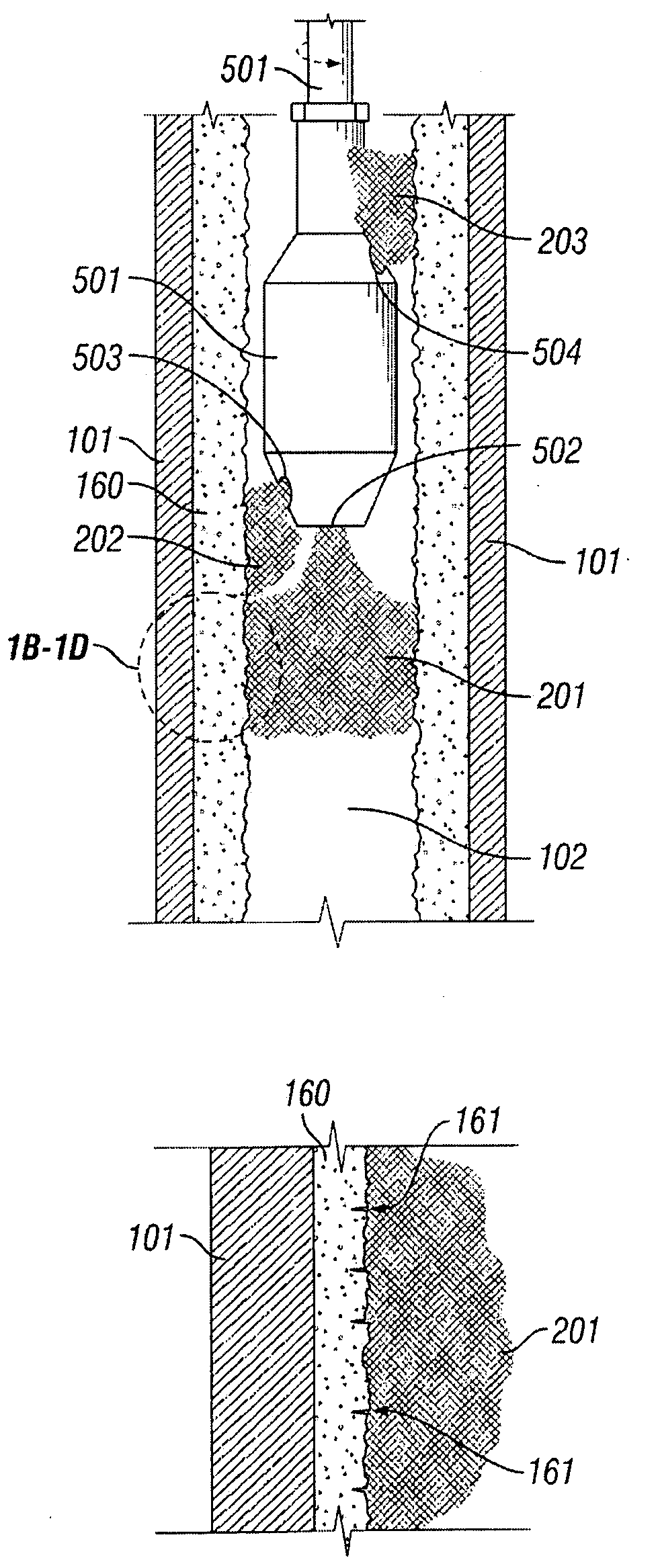

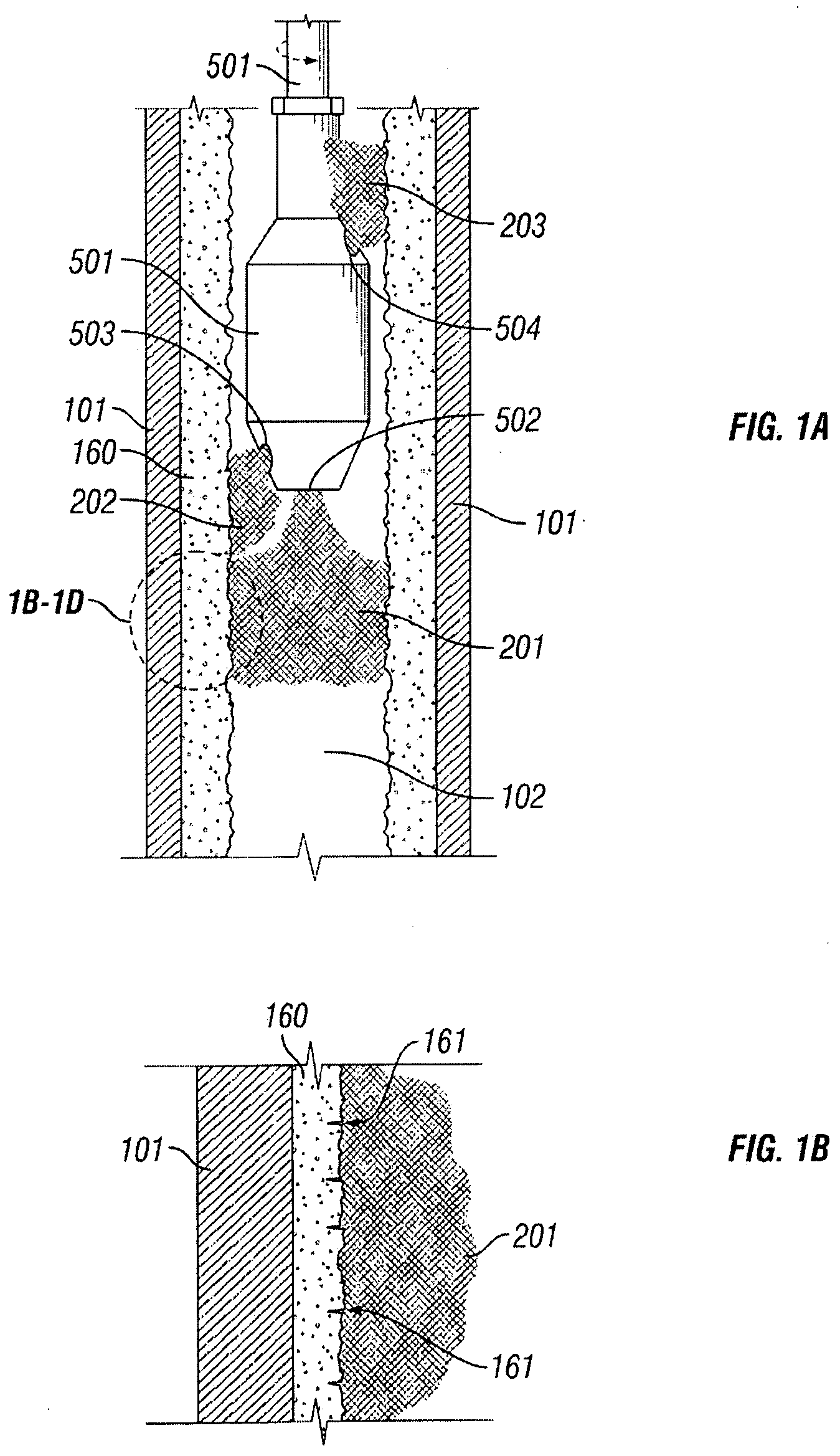

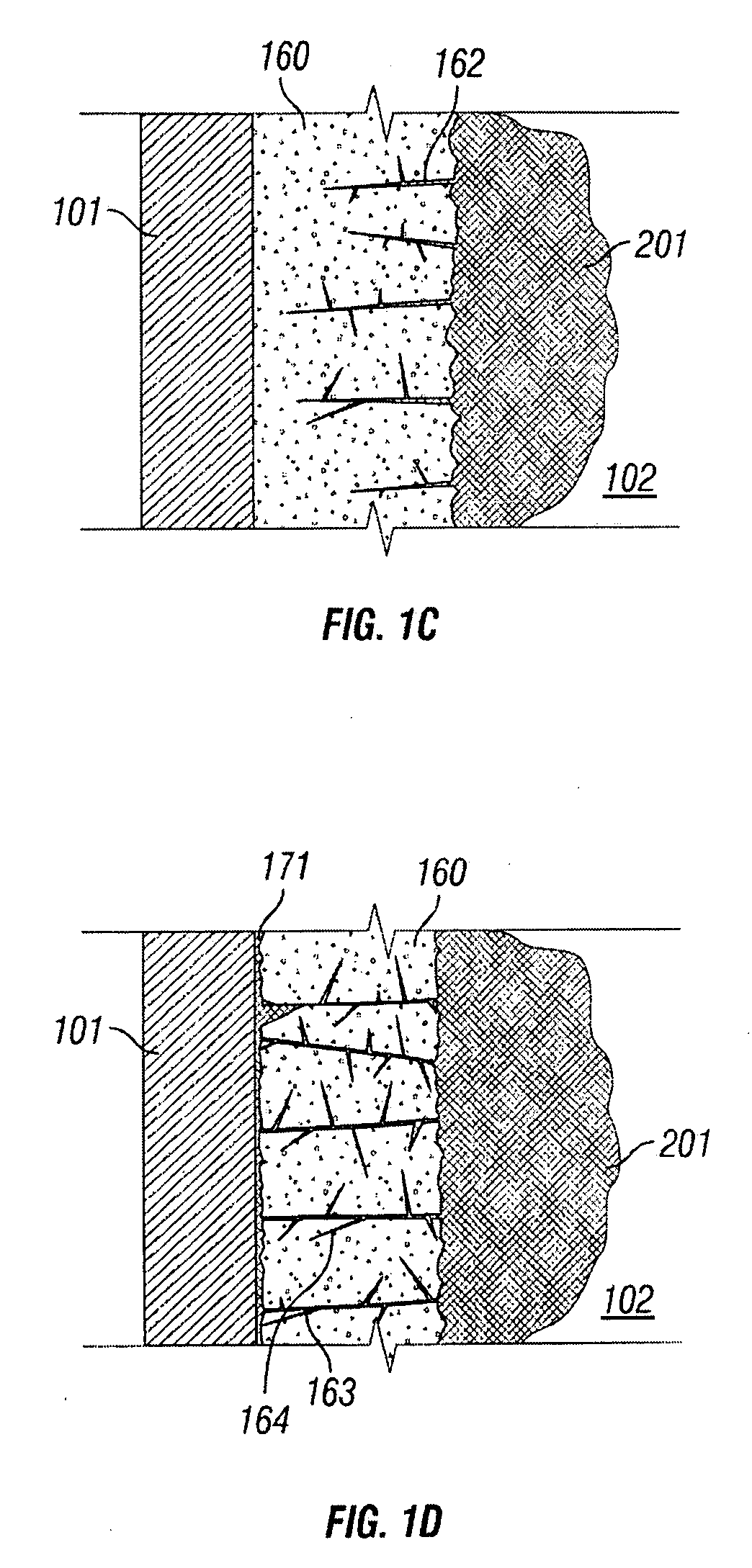

Thermal De-Scaling Surfaces With Cryogenic Liquids And Gases

InactiveUS20100132747A1Fast waySimple designCleaning heat-transfer devicesHollow article cleaningSolid phasesPollutant

Owner:APPLIED CRYOGENIC SOLUTIONS

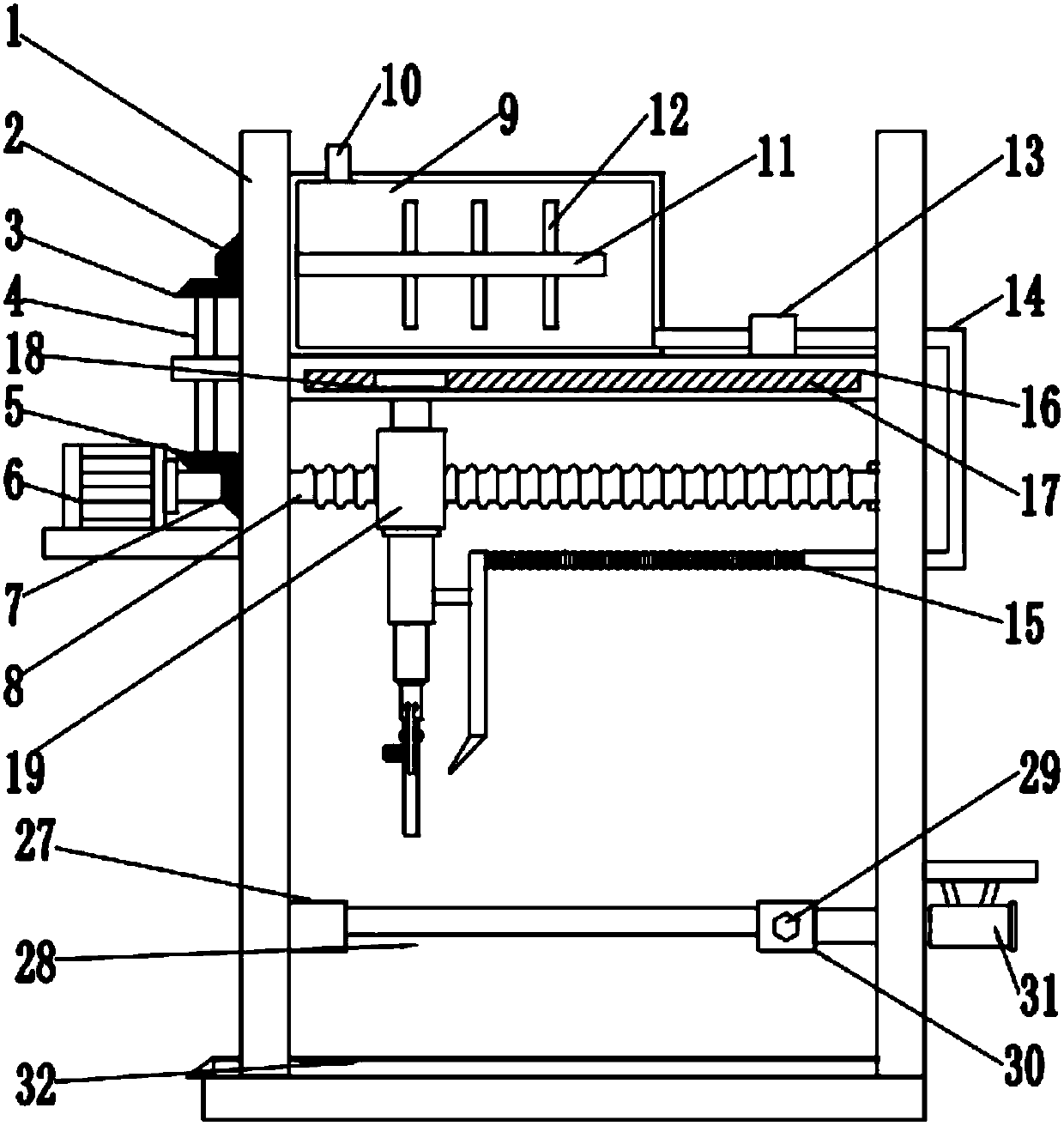

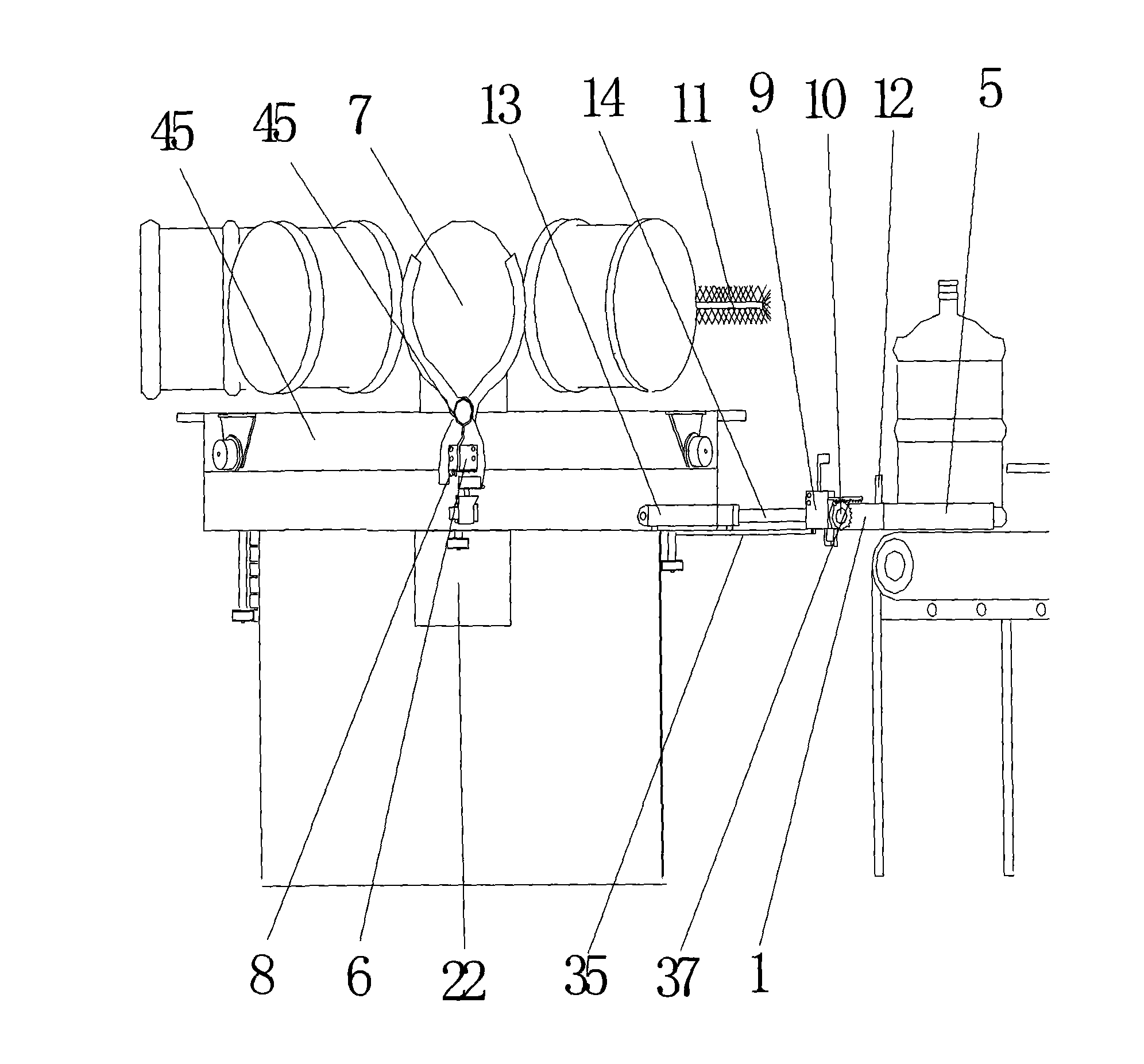

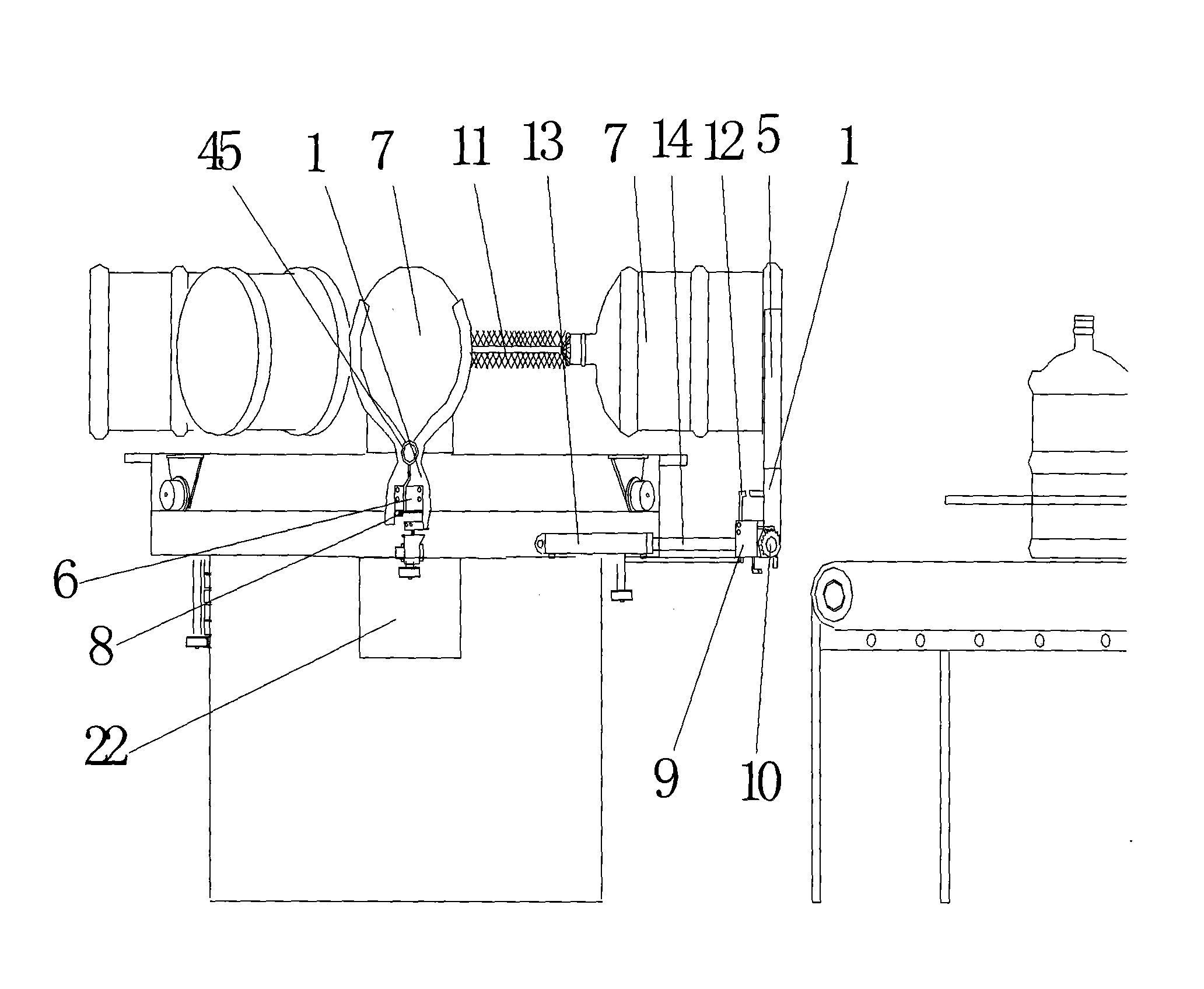

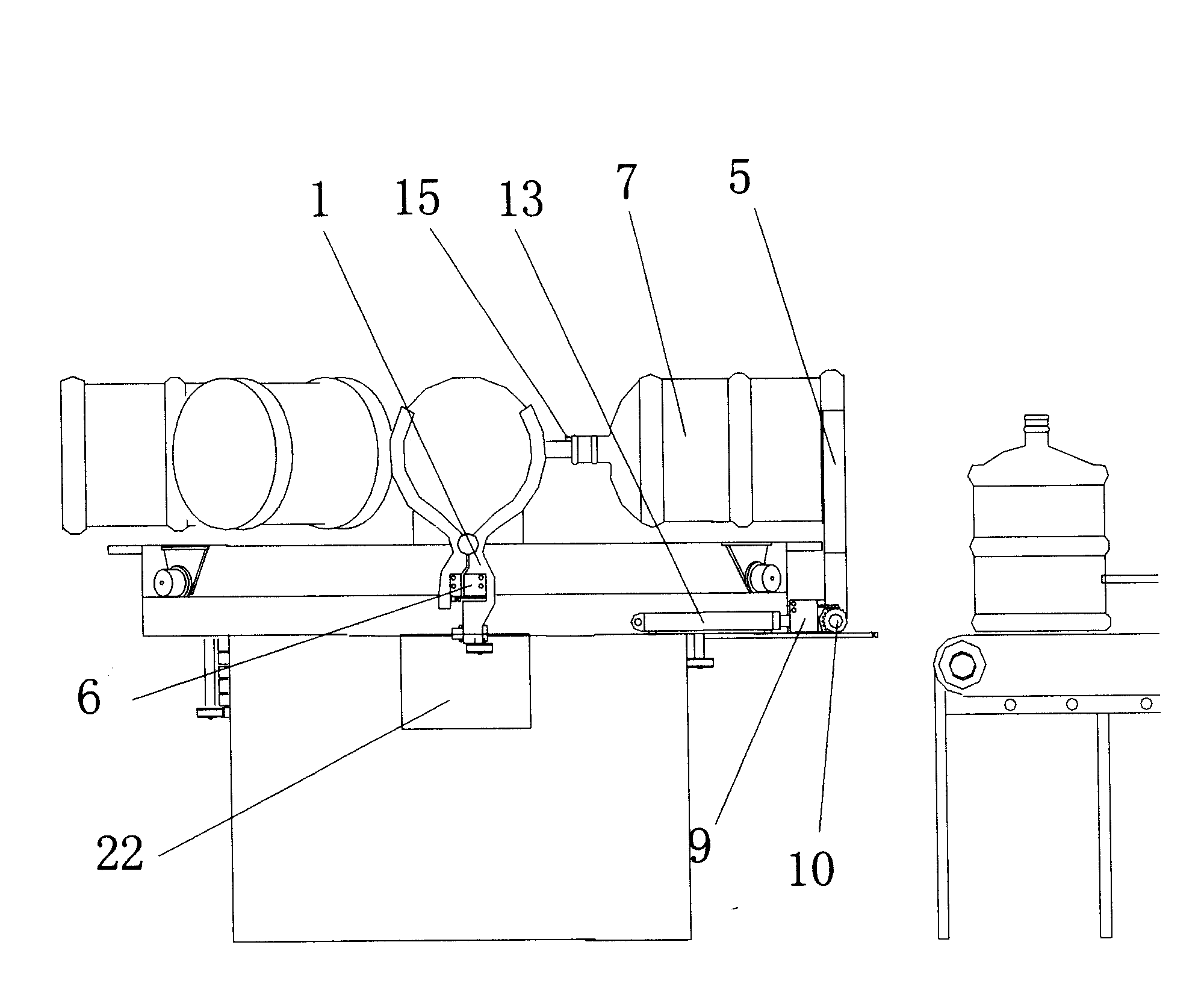

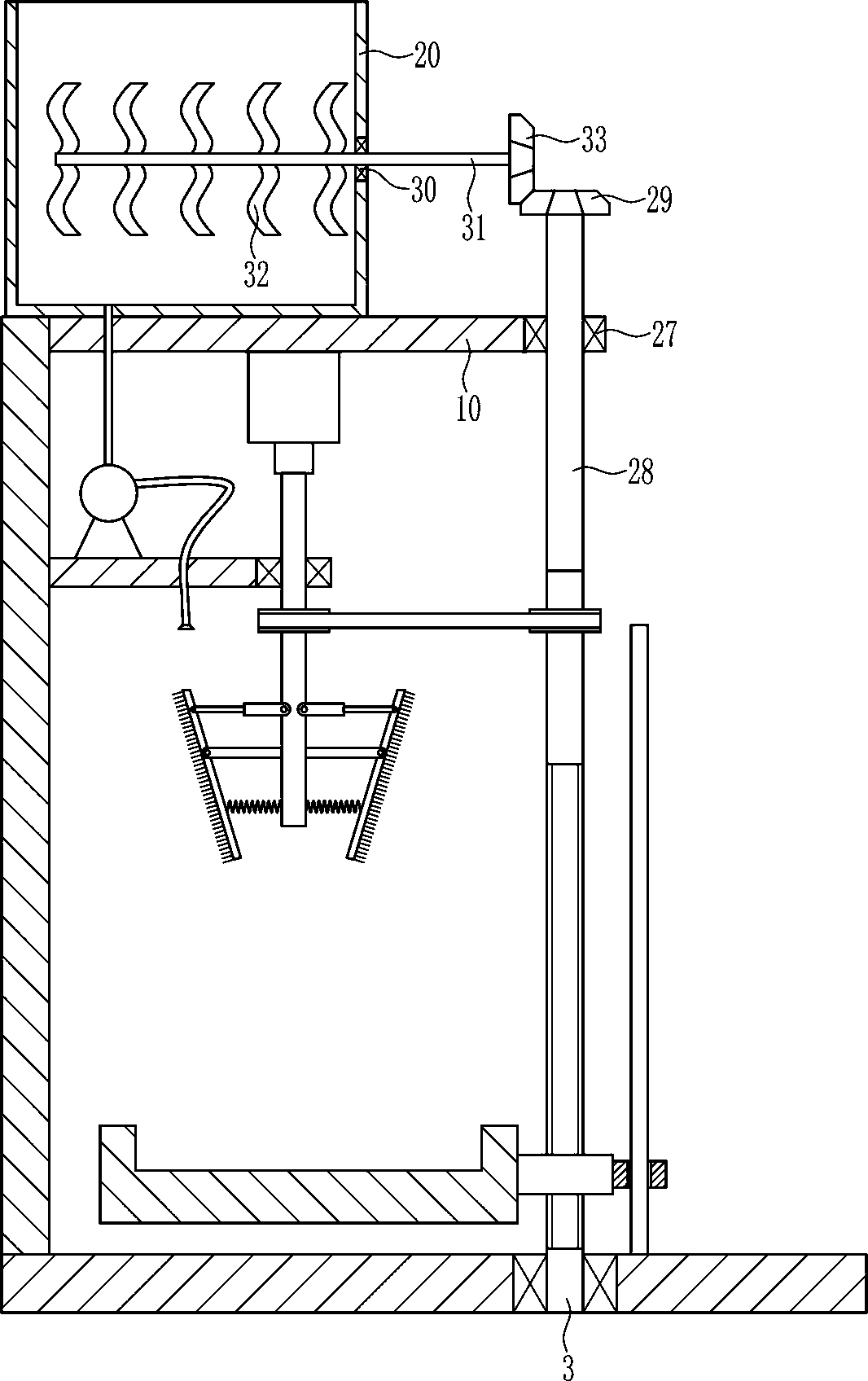

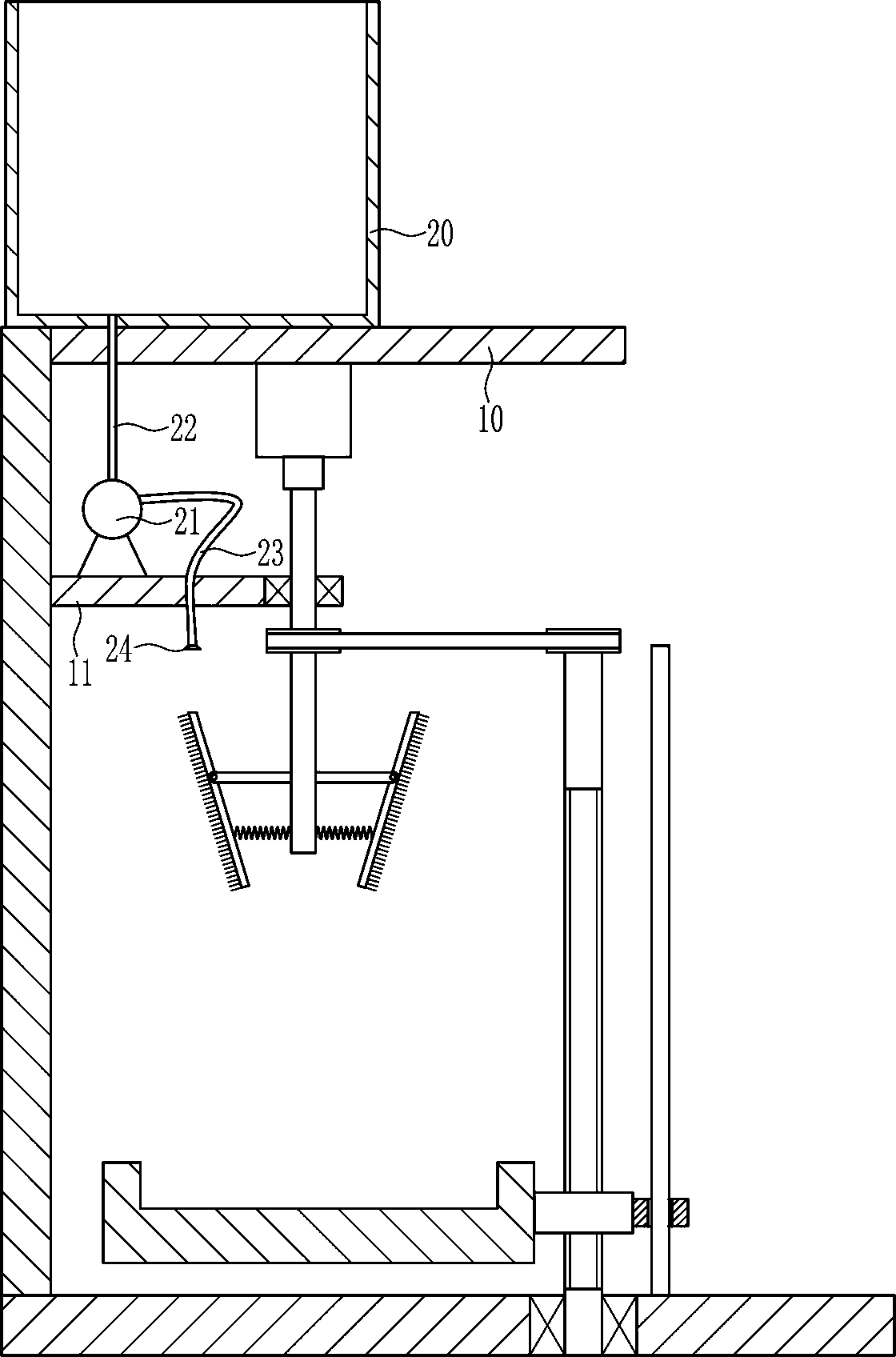

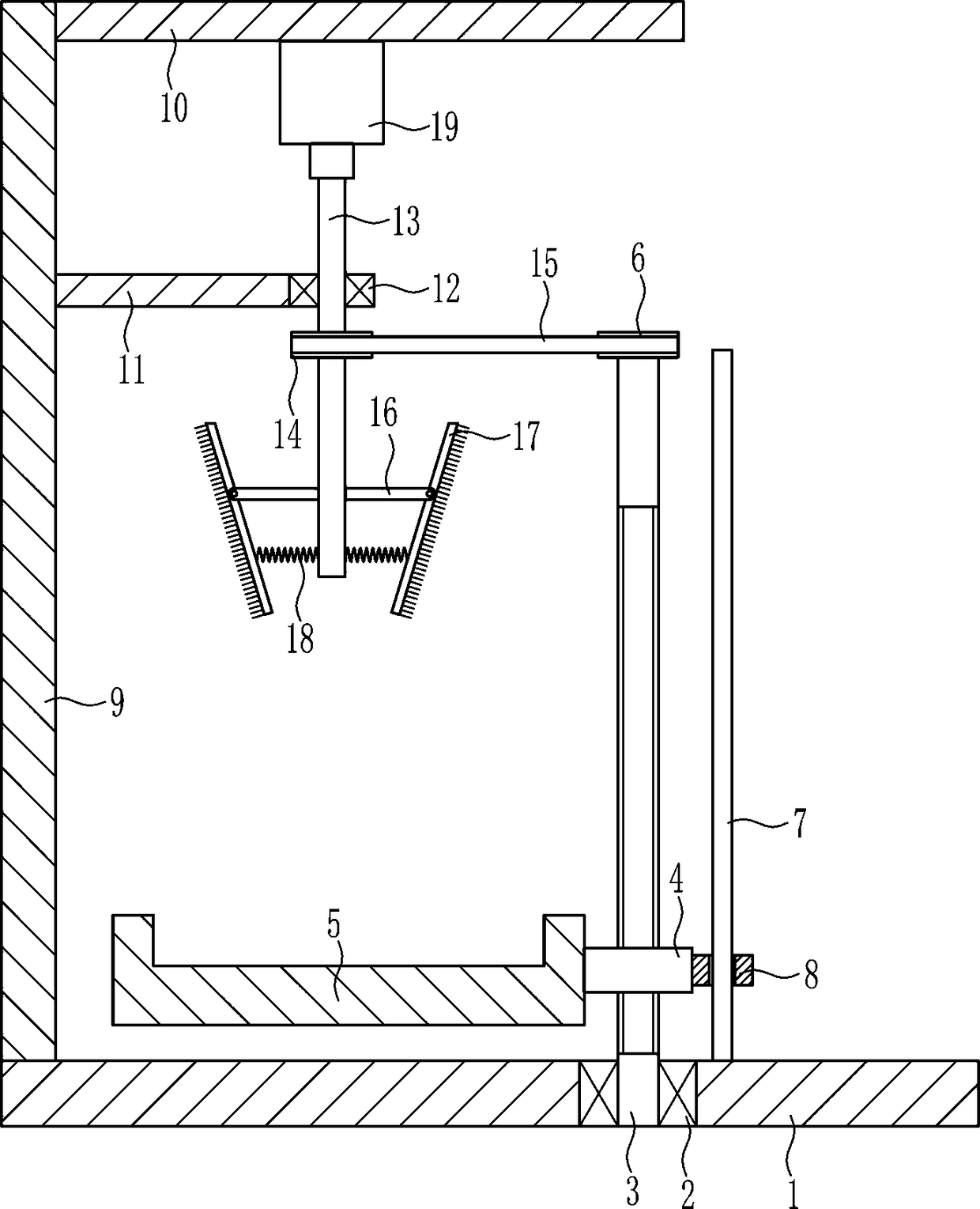

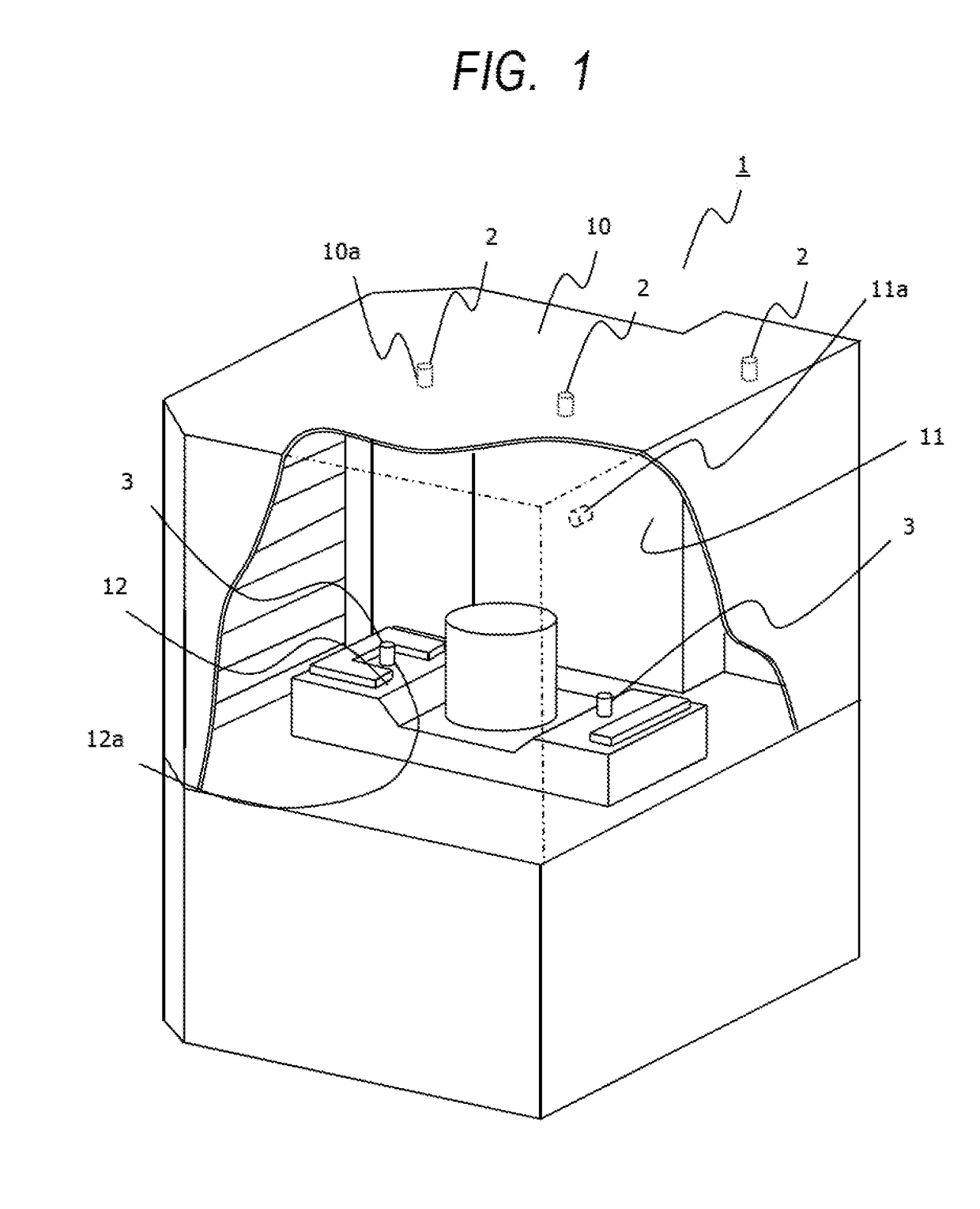

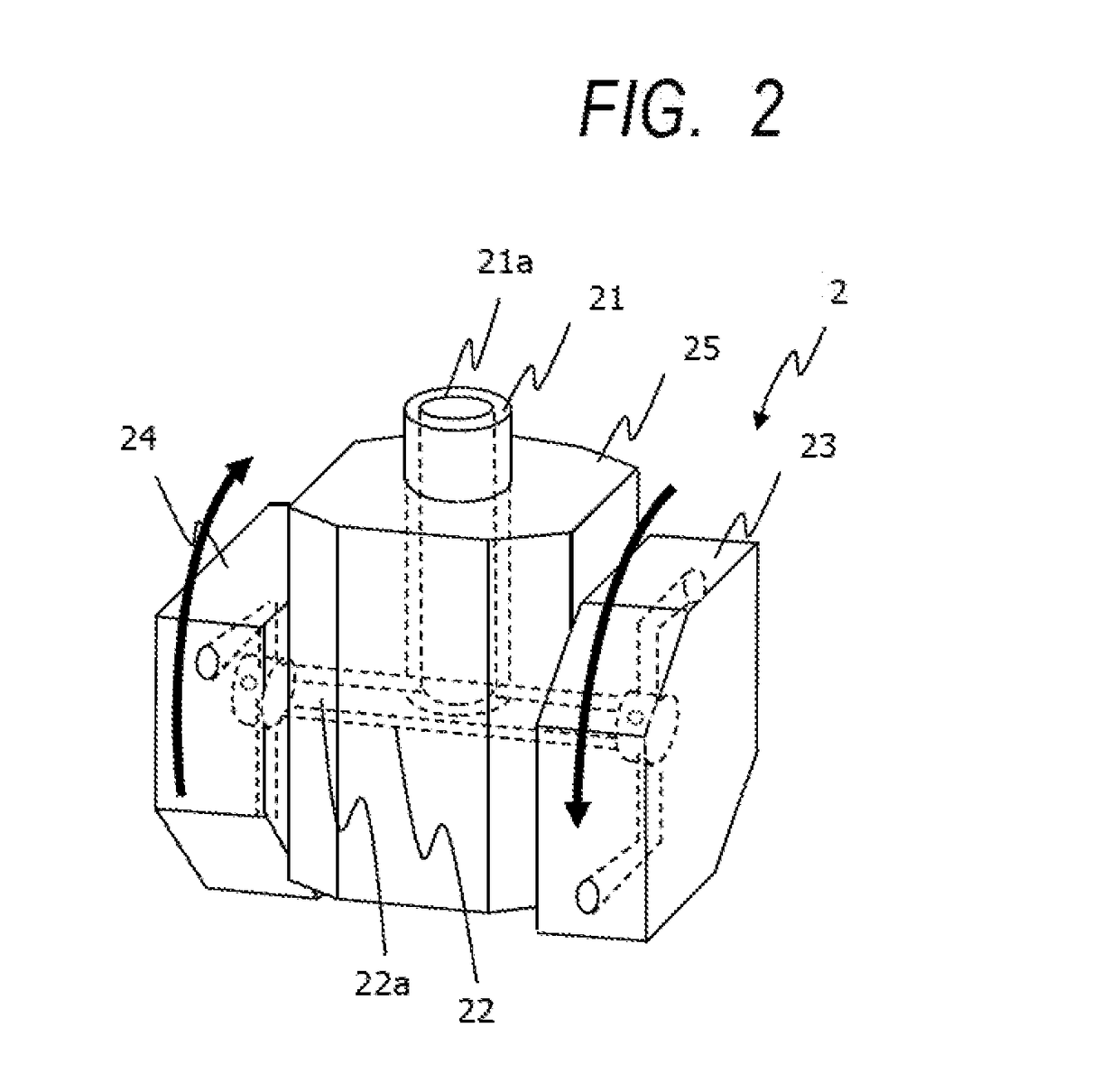

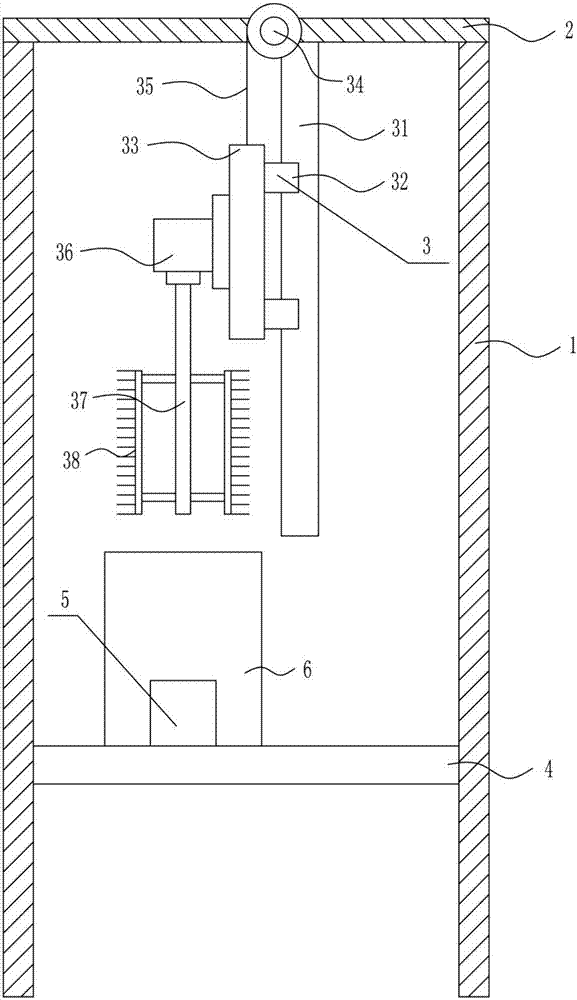

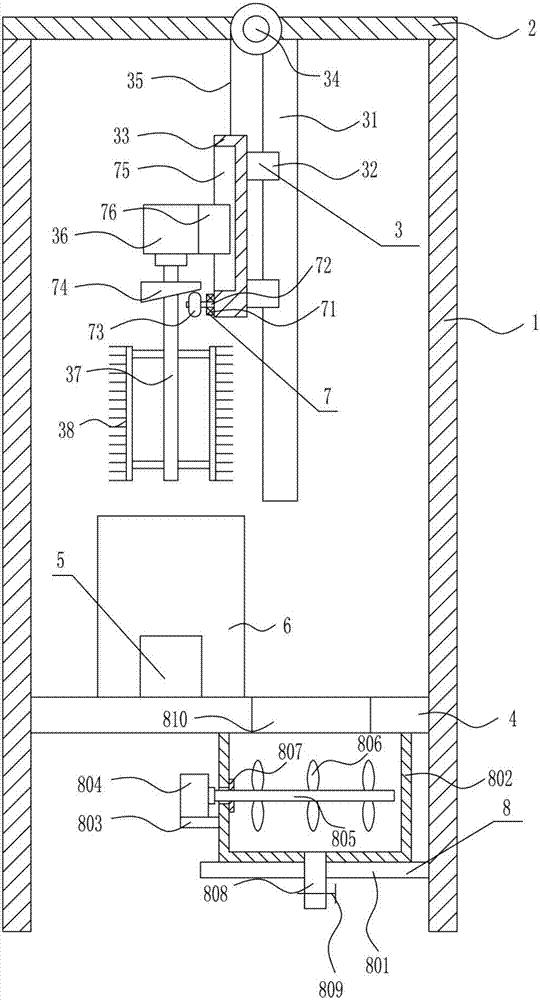

Fully automatic bucket-cleaning plant

The invention relates to a fully automatic bucket-cleaning plant mainly comprising a bucket-clamping device, a cleaning device, a power rotation part, a conveying part and the like, wherein the bucket-clamping device is provided with a pair of bucket-clamping pincers, and the bucket-clamping pincers firmly clamp a bucket under the suction of an electromagnetic valve. A rack in the electromagneticvalve drags a gear to enable the bucket-clamping pincers to rise to form an angle of 90 degrees with the electromagnetic valve. The mouth of the bucket is aligned to a cleaner, and a cylinder intake lever enables the cleaner to enter the bucket and to be opened in the bucket to carry out cleaning operation. The lever is wrenched to grip a gear ring and moves forward; a rotary table rotates once every 3 seconds, and the rotary table can rotate by 1 / 6 of the gear ring each time. Under the action of two worm wheels, the rotating speed per minute of the rotary table and the gear ring is reduced to200 rounds; when the rotary table rotates once, the bucket is rotated to the position of a conveyor, the lever rolls off the cylinder after the cleaning is completed to convey the bucket above a conveyer belt; the gear rotates outwards to put down the bucket-clamping pincers, a spring pushes a screw out to enable the screw to rotate 180 degrees, and the mouth of the bucket is downwards aligned tothe bucket pit of the conveyer belt, under the action of the spring, the bucket-clamping device puts down the bucket, and at the time, a switch bounces, enabling the electromagnetic valve to be powered on, and then the screw rotates 180 degrees so as to enable the bucket-clamping device to be restored to the original working state.

Owner:宋树建

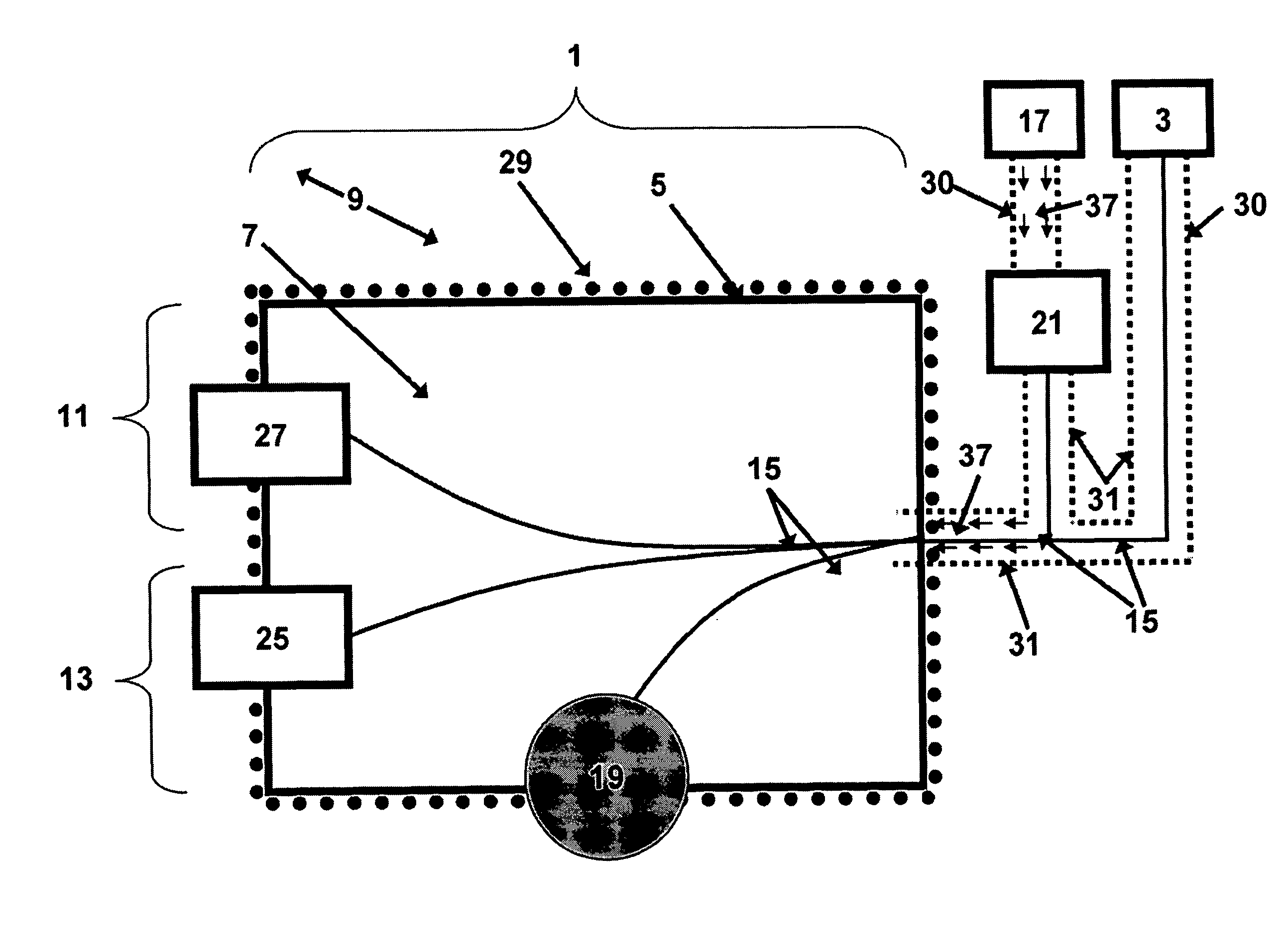

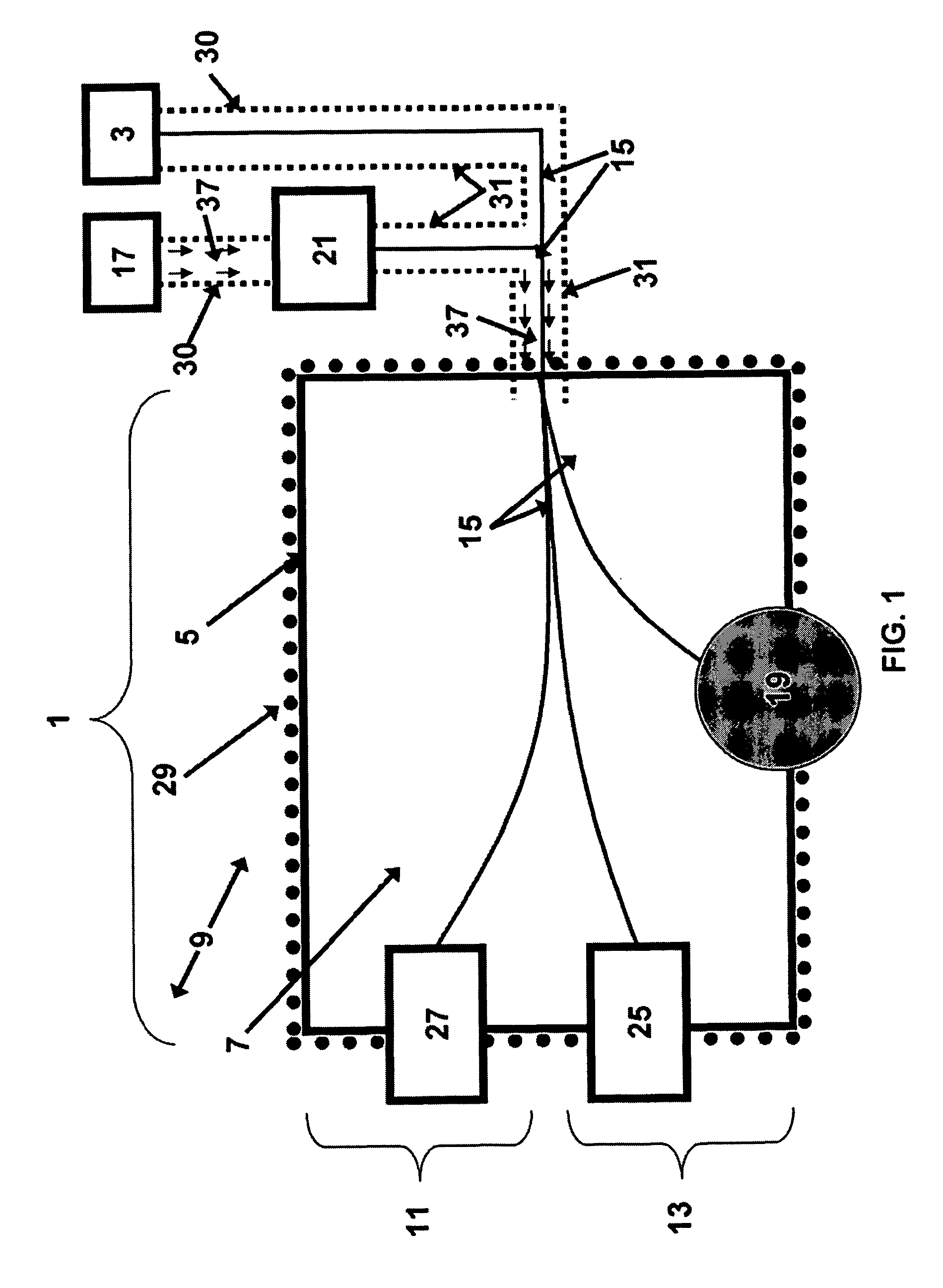

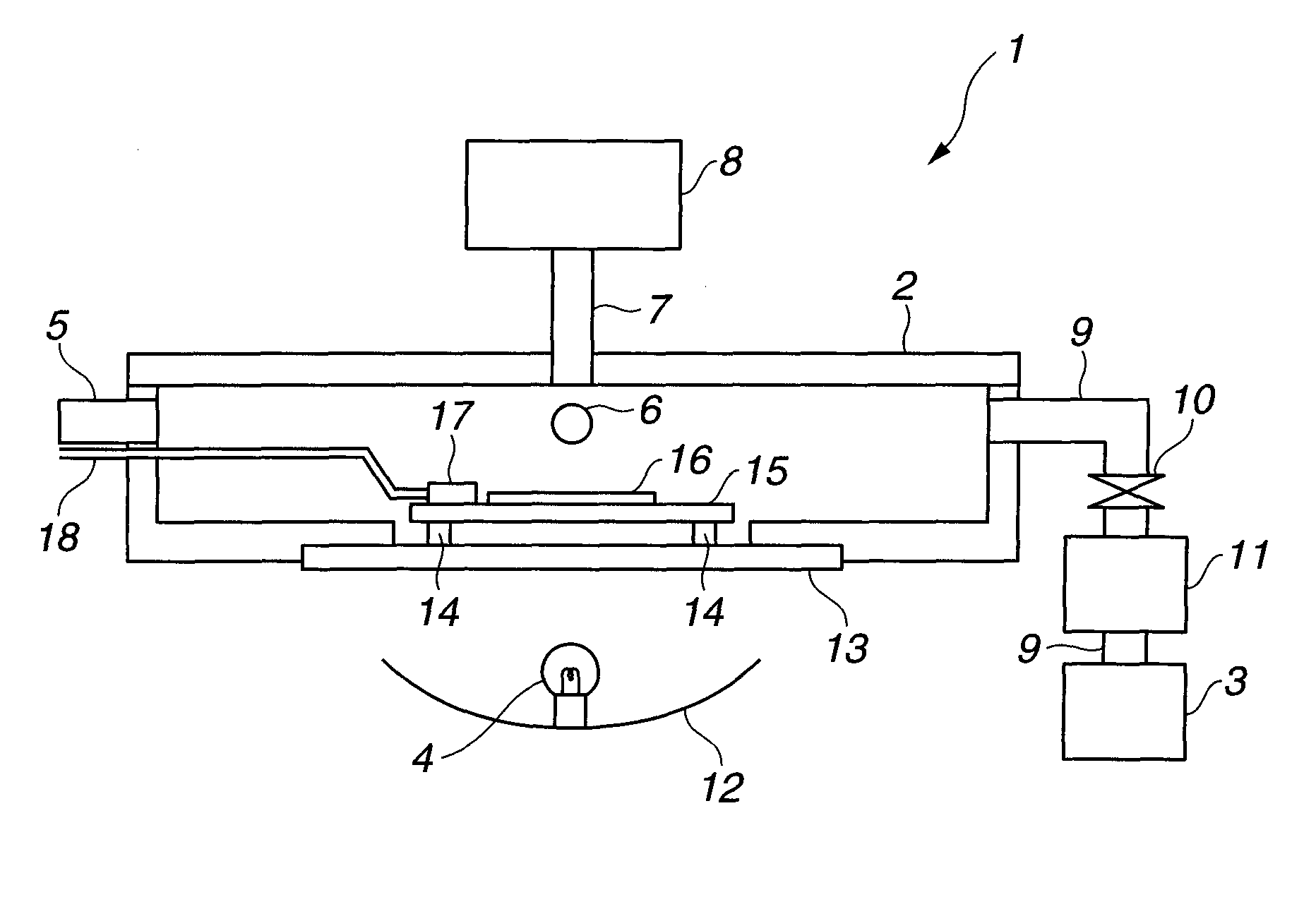

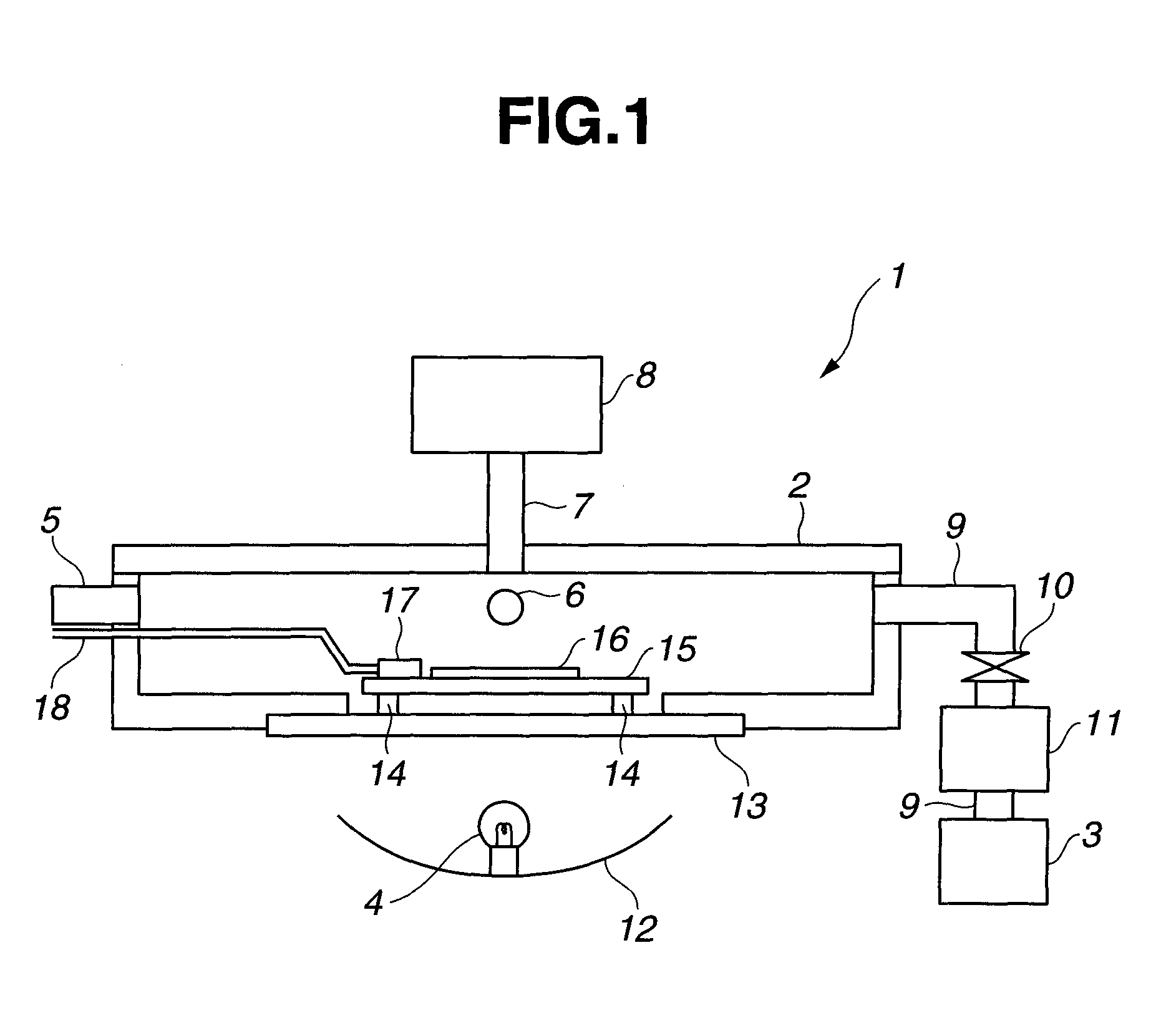

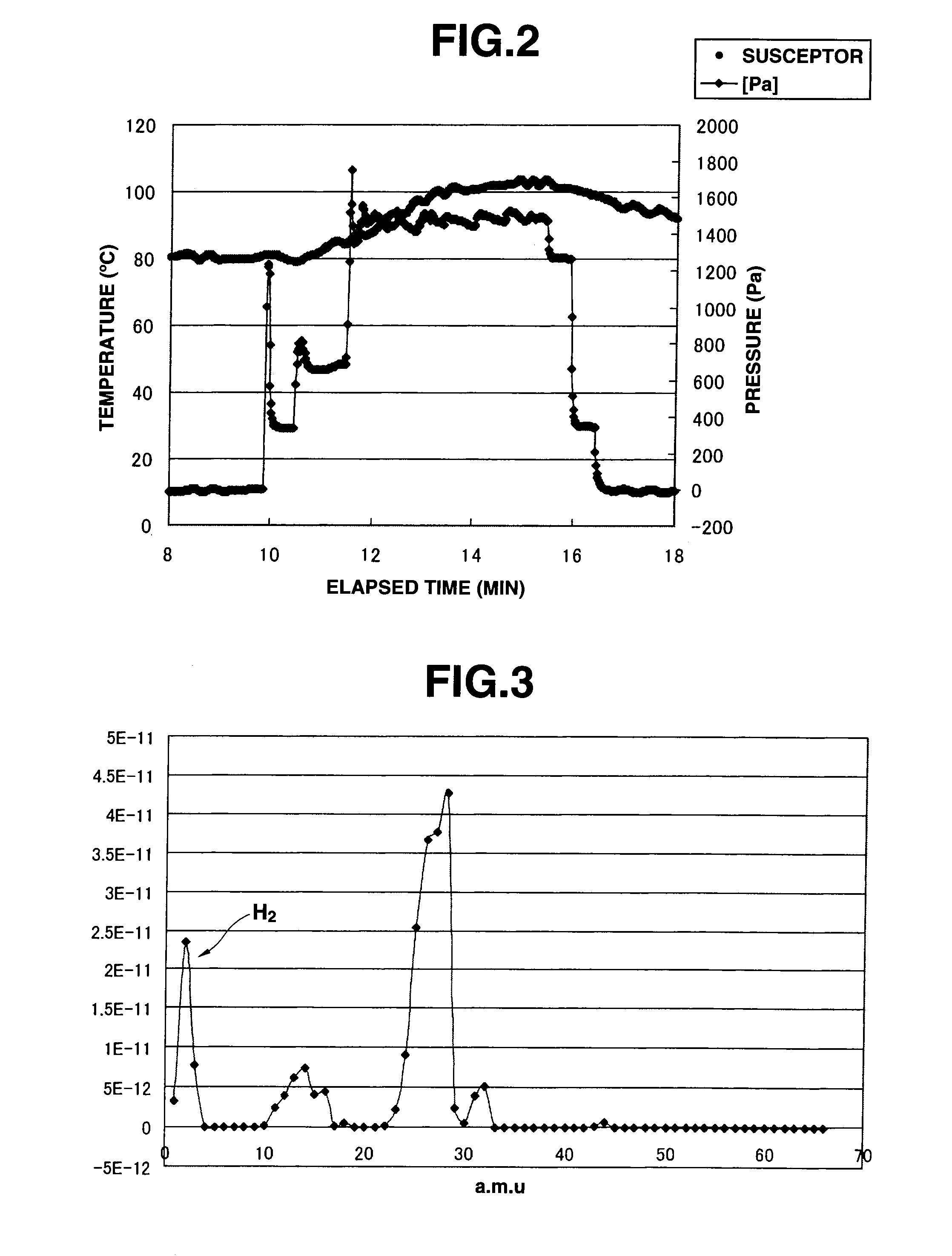

Method of removing resist and apparatus therefor

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

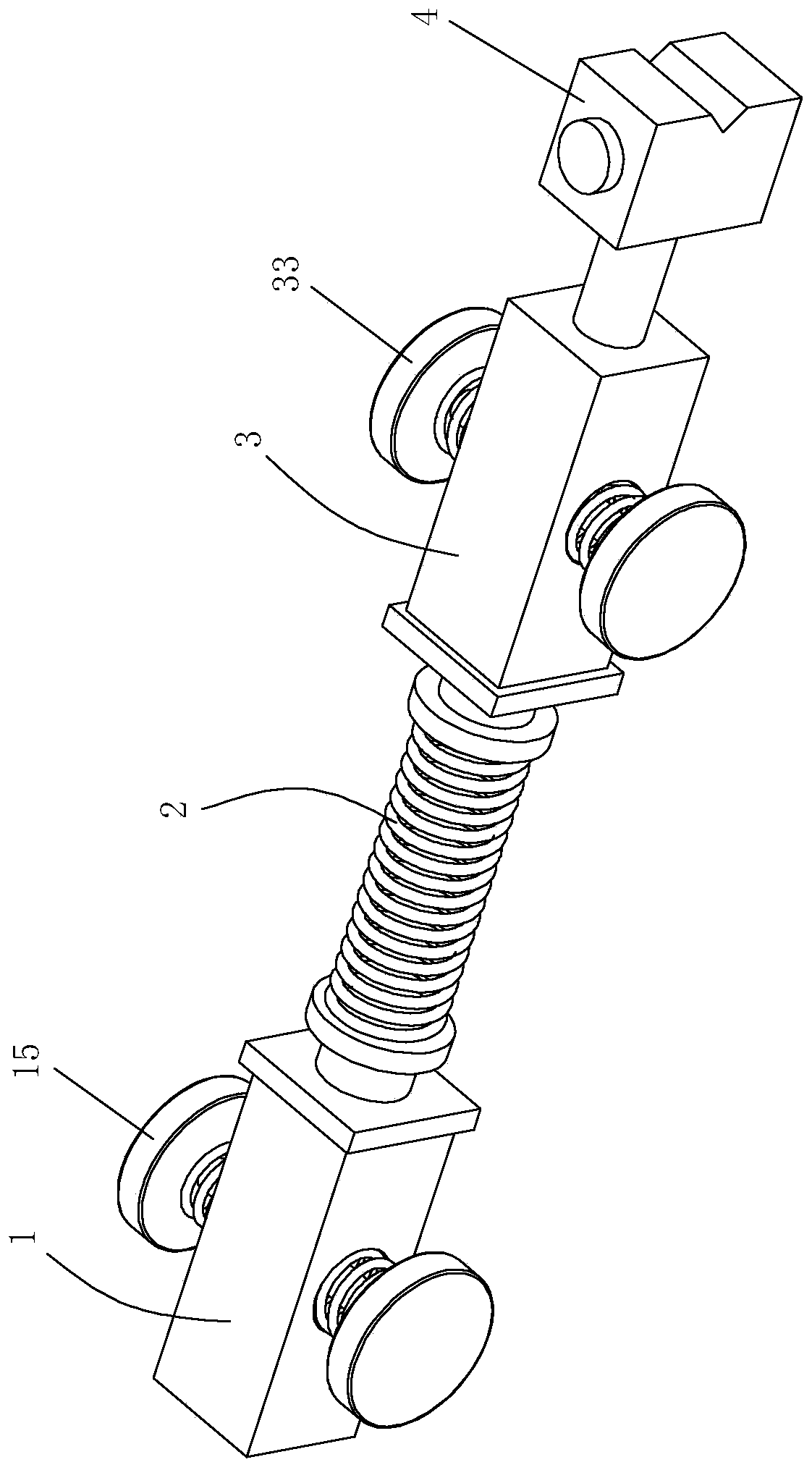

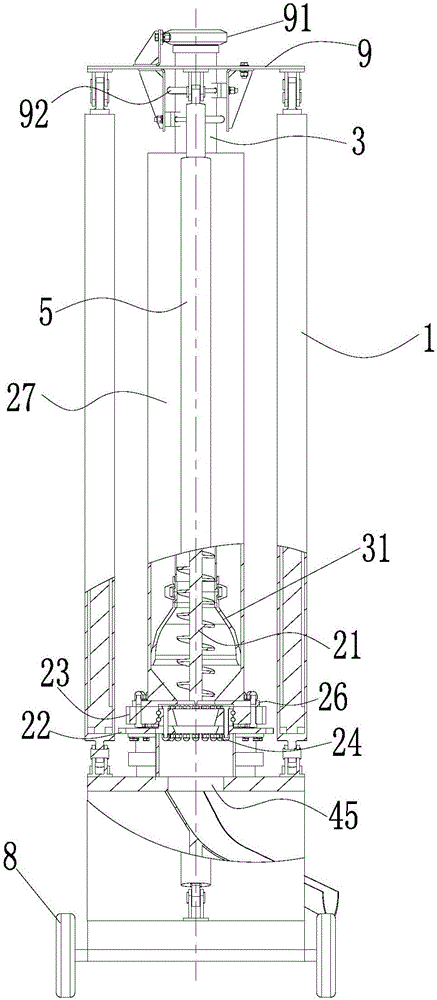

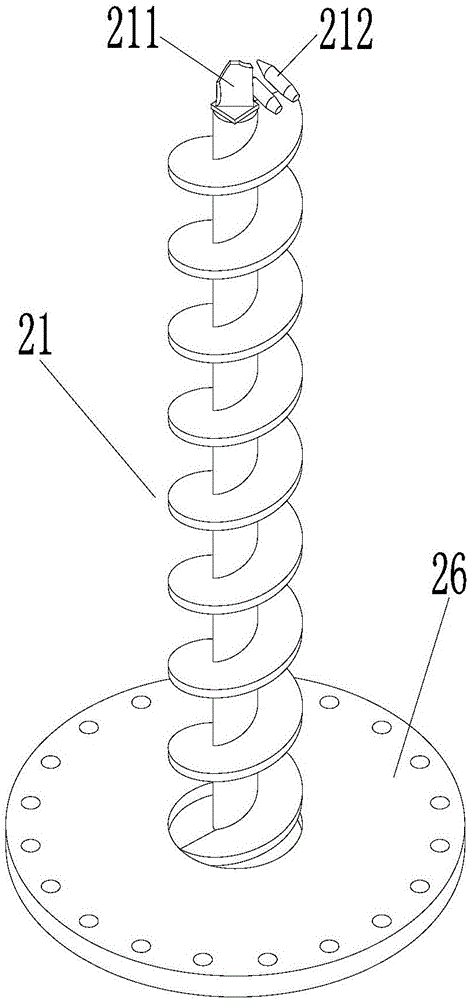

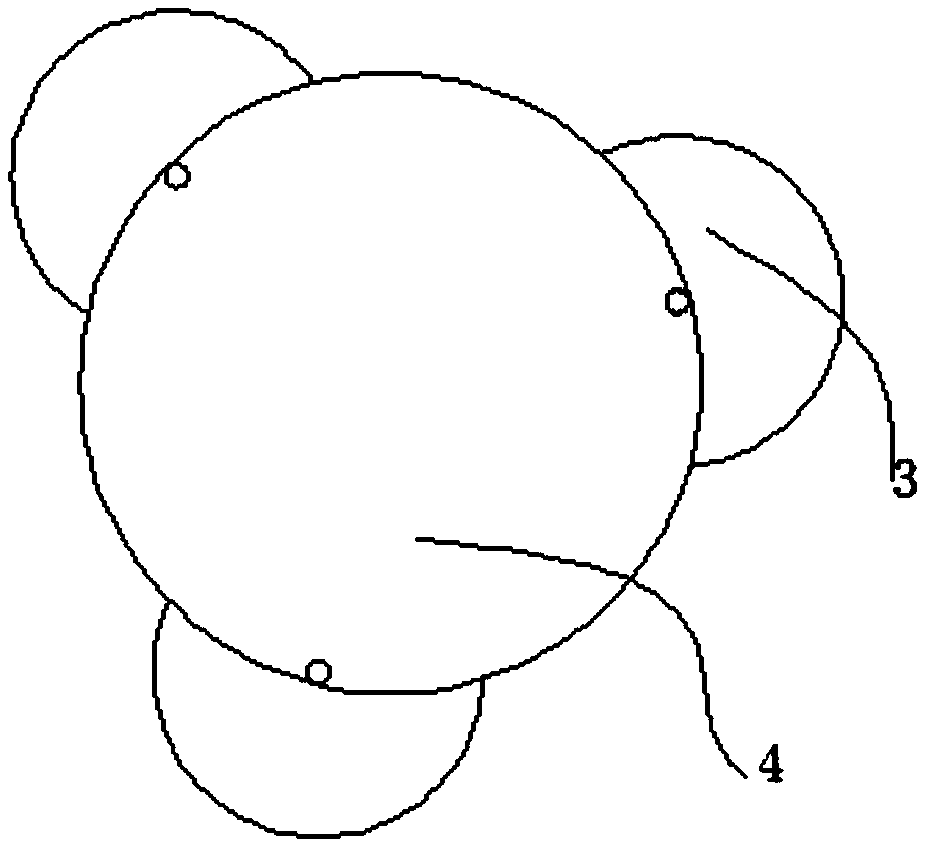

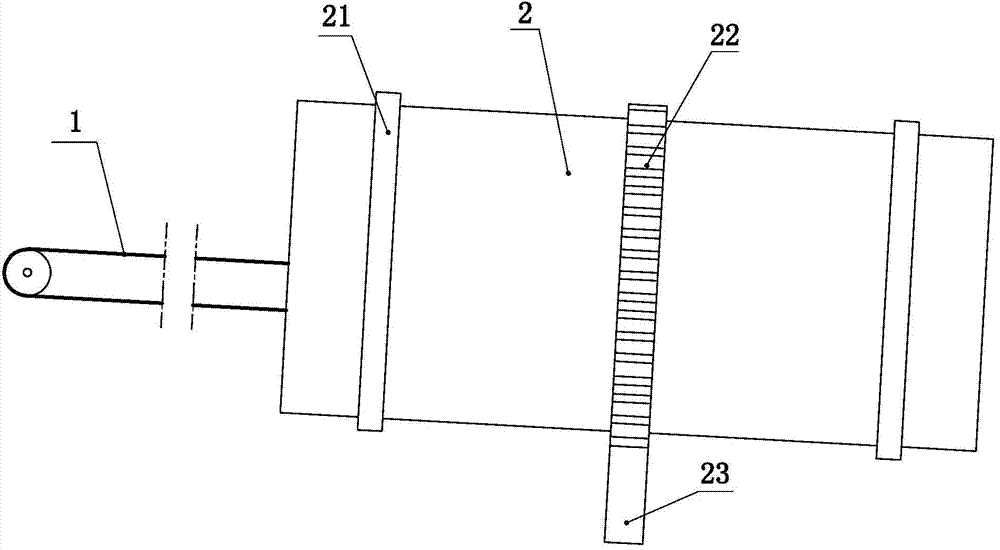

Descaling tool, descaling device and descaling method for pipe

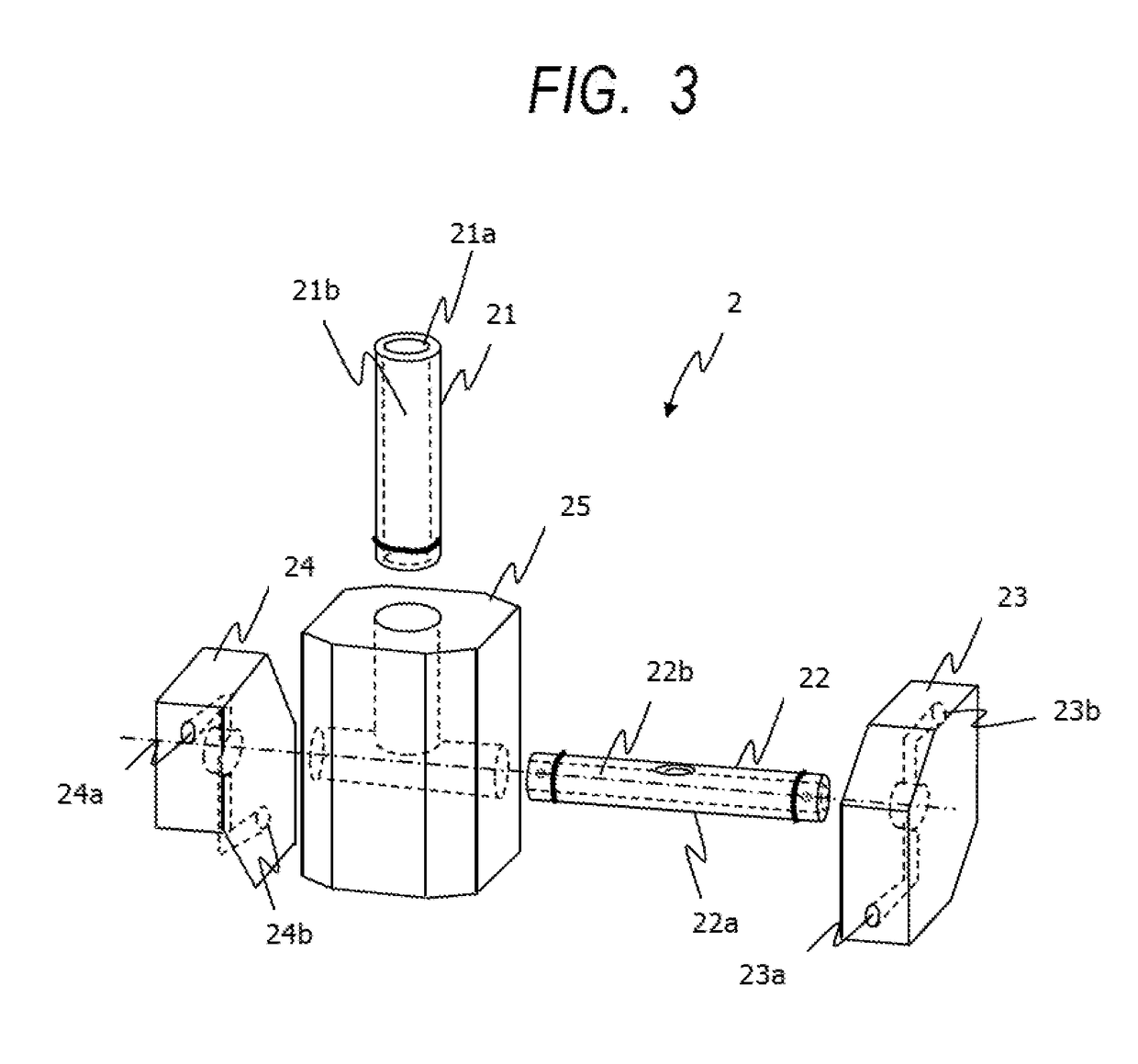

The invention provides a descaling tool for a pipe, which comprises a tool main body. The main body comprises a cylindrical cutting part and a connecting part which axially stretches from the cutting part, wherein the cutting part is provided with a plurality of spiral grooves which are uniformly distributed on the external circumferential surface of the cutting part around a central axis of the cutting part. The invention further provides a descaling device for the pipe, which comprises a driver and the descaling tool, wherein the driver is provided with a drive shaft, the descaling tool is the descaling tool provided by the invention, and the descaling tool is connected with the drive shaft. A descaling method for the pipe comprises the following steps: a) placing the descaling tool into the pipe; and b) driving the descaling tool to rotate and move linearly in the pipe. The descaling tool, the descaling device and the descaling method provided by the invention can fully avoid the problem of corrosion on the pipe and achieve higher descaling efficiency.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Trash can cleaning device special for bioexperiment

InactiveCN108405527AEasy to cleanReduce labor intensityHollow article cleaningEngineeringCleansing Agents

Owner:汤琴

Rapeseed oil squeezing device capable of collecting rapeseed oil conveniently

Owner:安徽茗峰机械制造股份有限公司

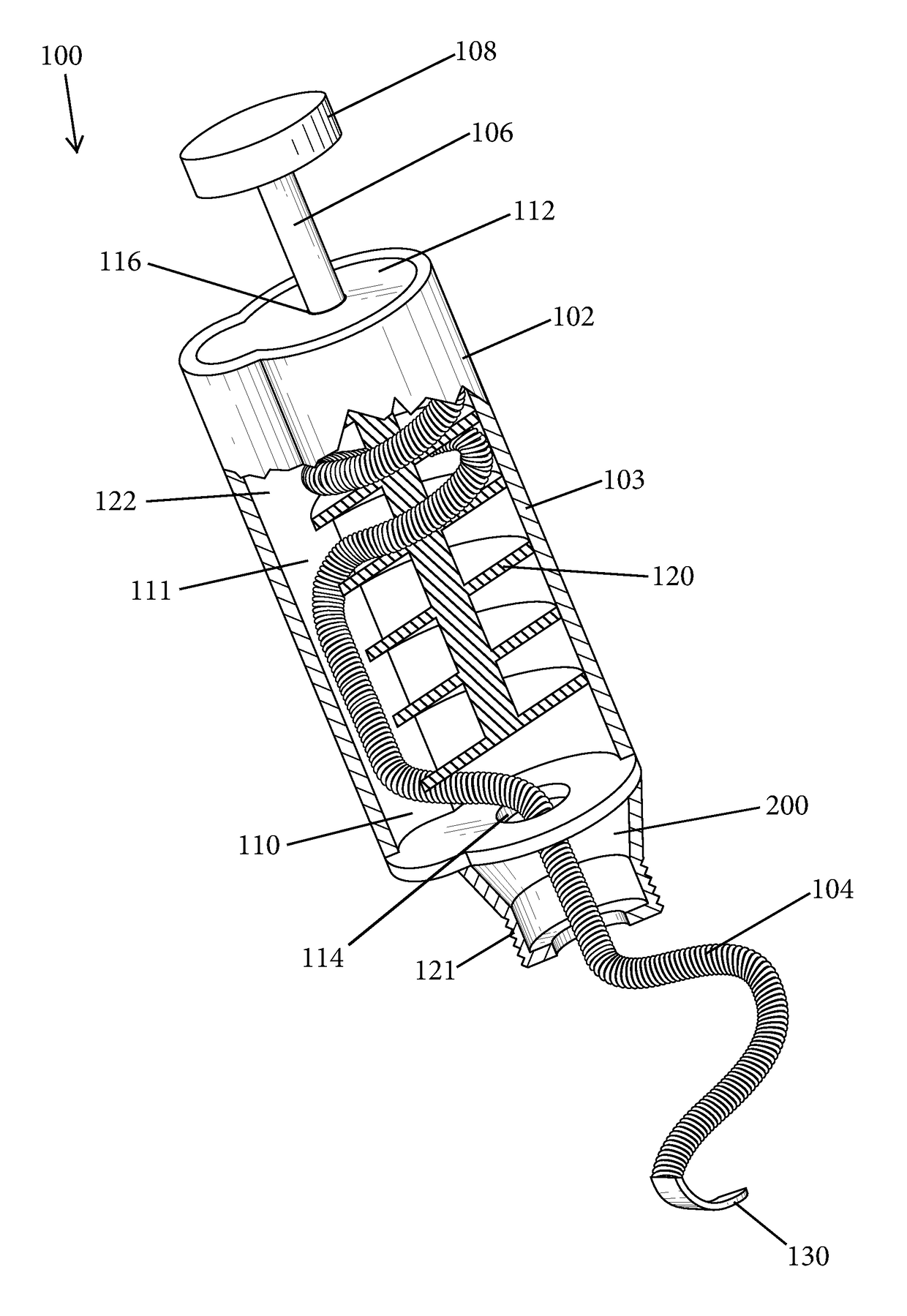

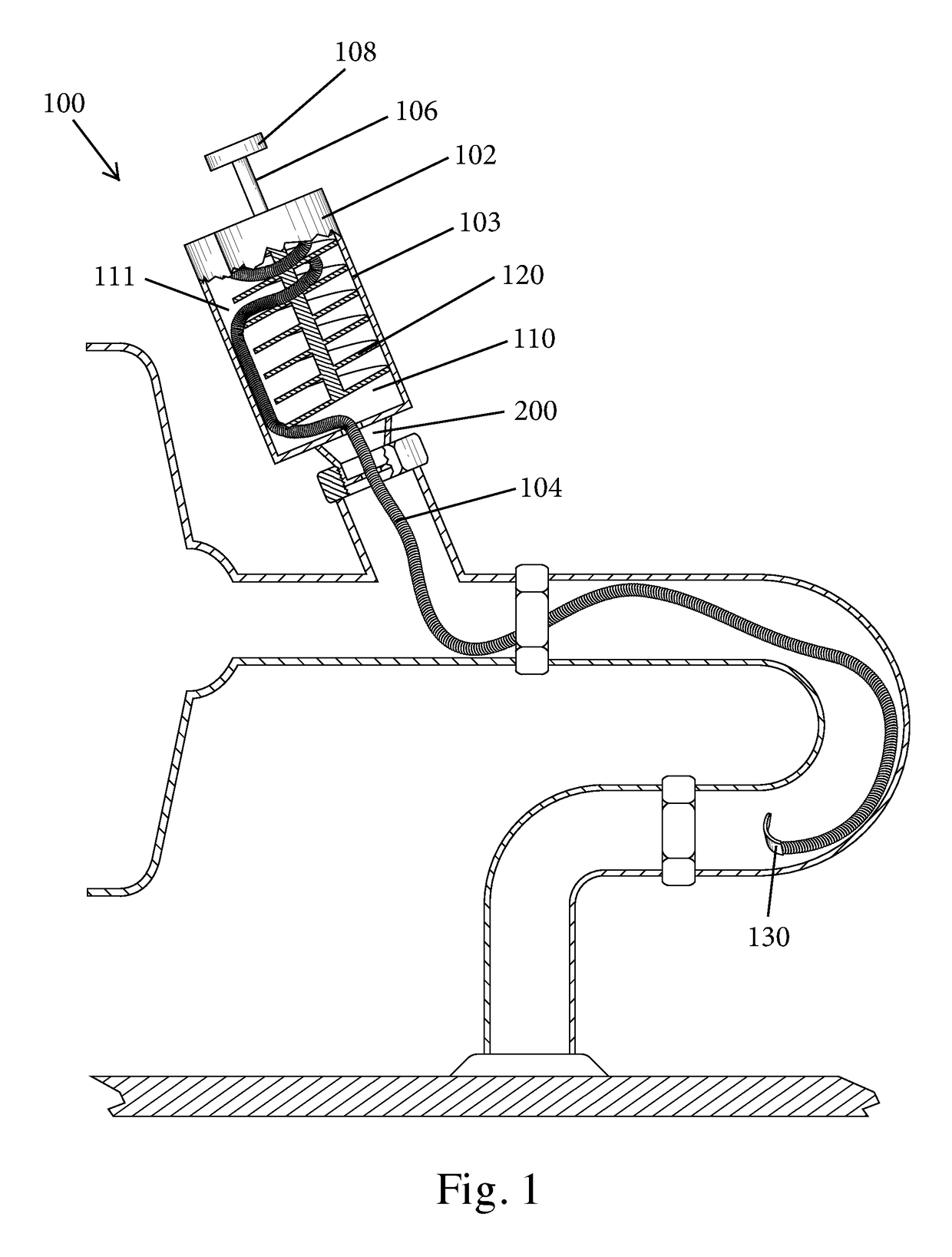

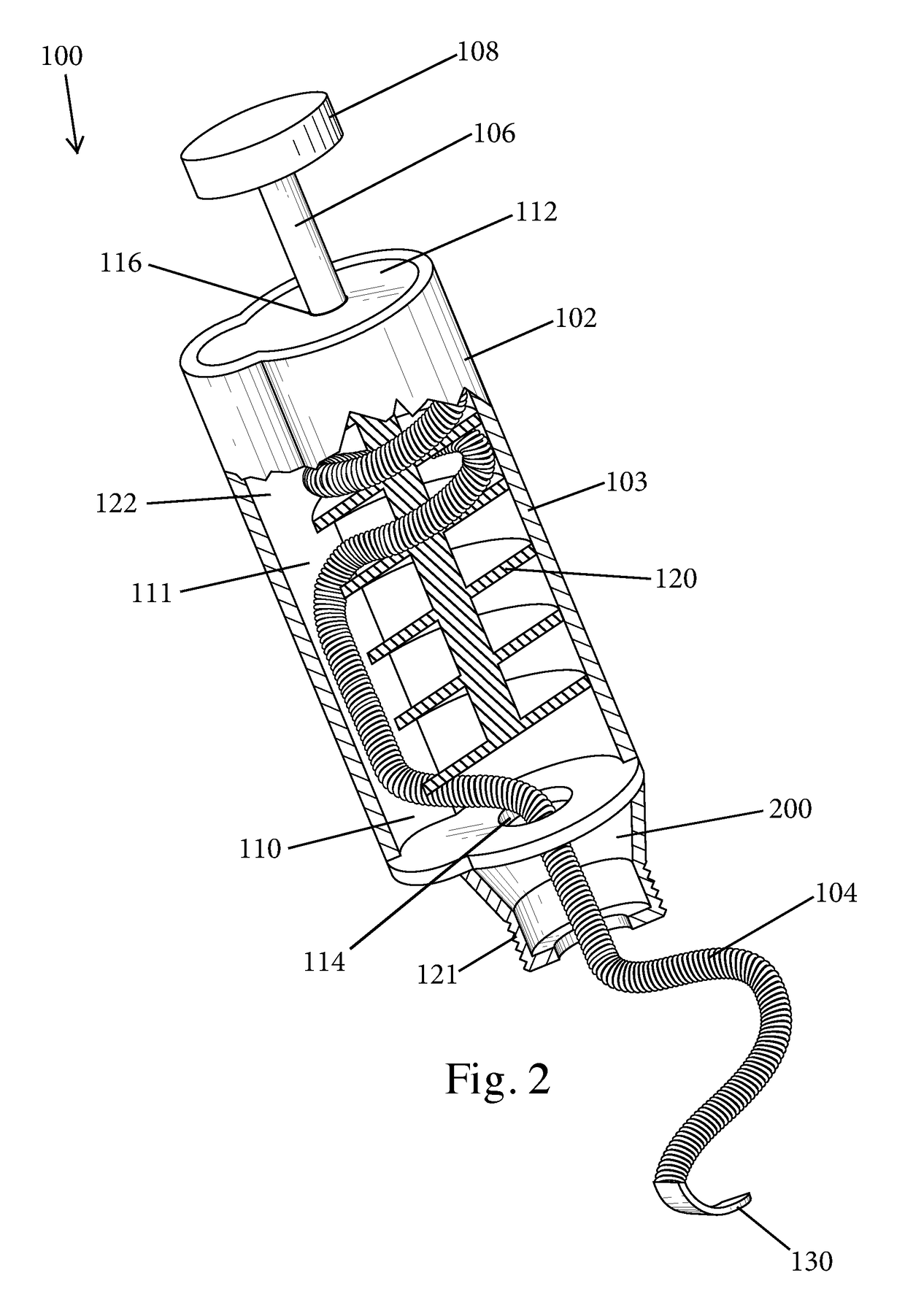

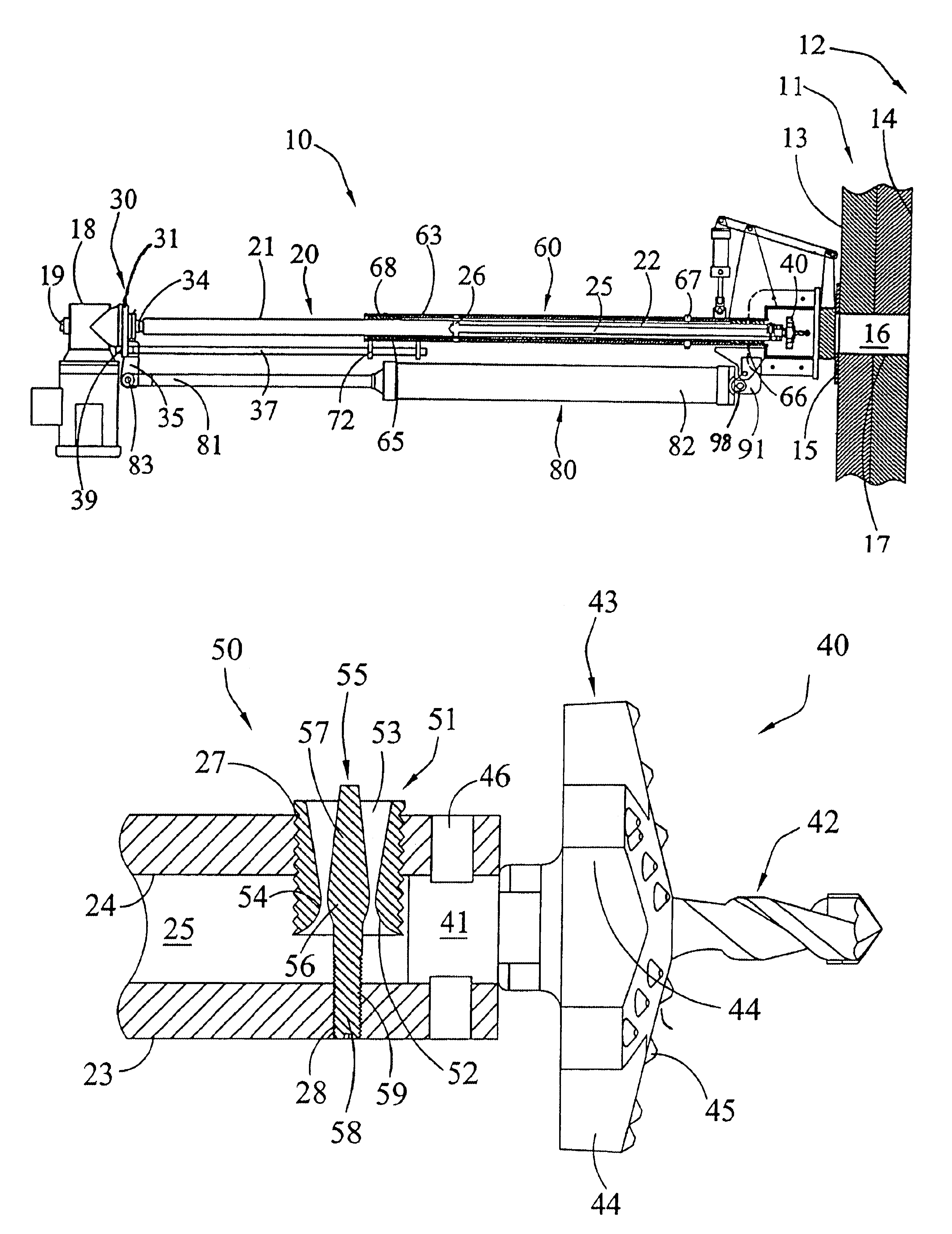

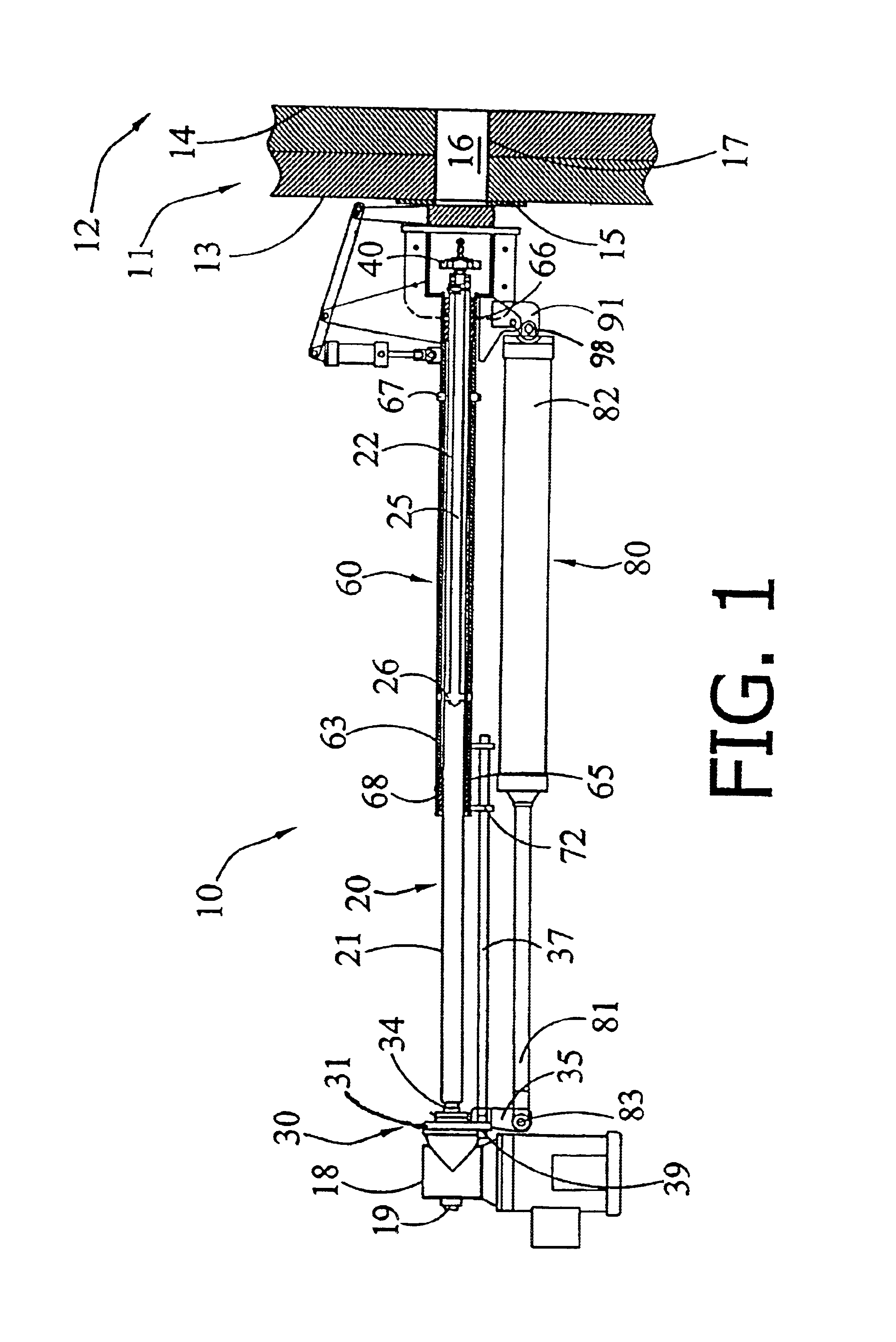

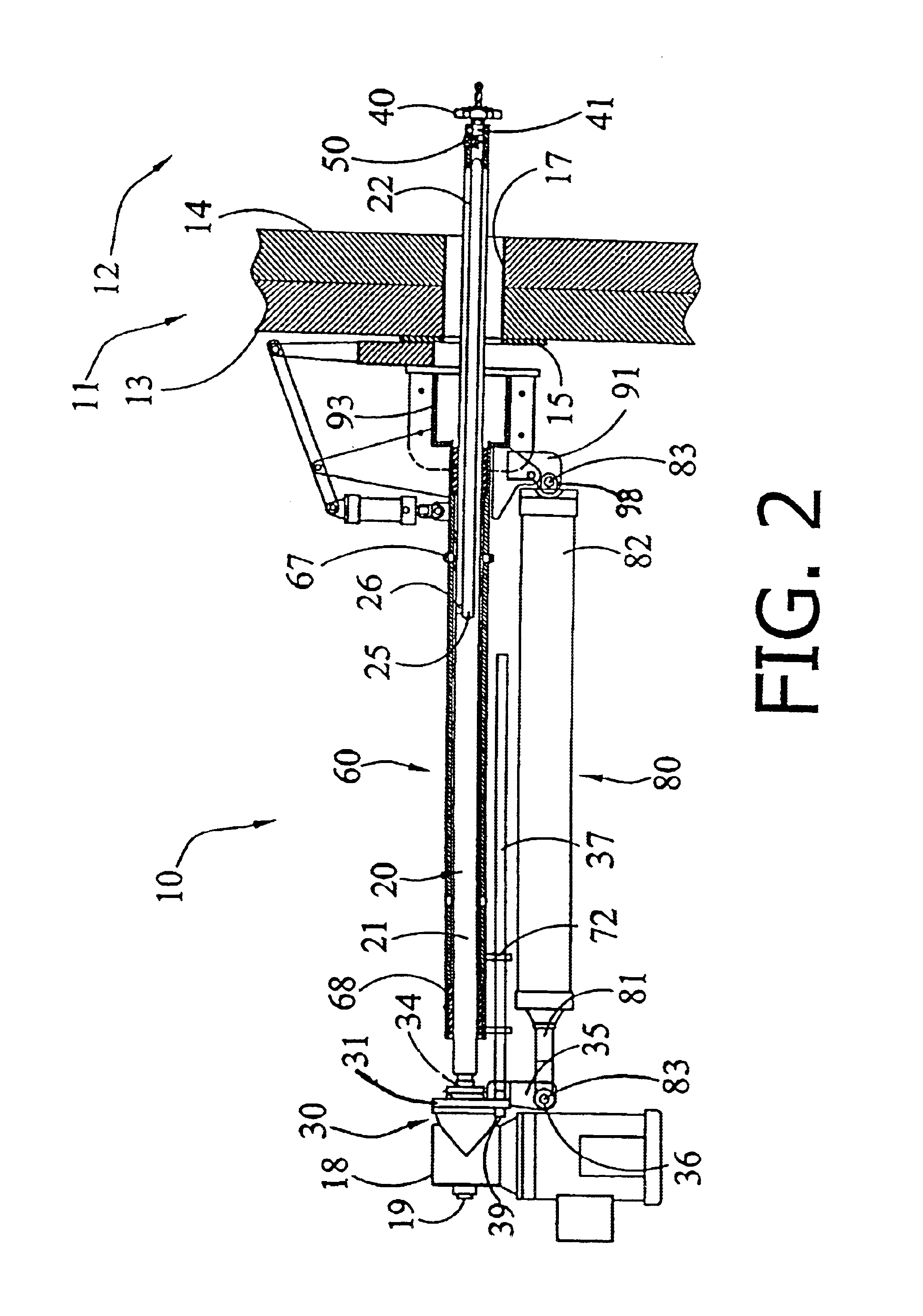

Auger arrangement for unclogging pipes

Owner:SELIUS LESLIE SAU

Pipeline oil stain cleaning device

Owner:四川天人能源科技有限公司

Flue gas white smoke removal equipment for intelligent production factory of rubber plant

Owner:山东保蓝环保有限公司

Washing device for test tube

Owner:CHONGQING THRIVE CHEM

Kiln cleaning apparatus

Owner:MARTIN ENG

Conveying pipe cleaning device

Owner:河北雷萨重型工程机械有限责任公司

Washing nozzle for machine tool and machine tool therein

ActiveUS20180369838A1Reduce in quantityReduce size of pumpHollow article cleaningMovable spraying apparatusMachine toolNozzle

Owner:KIWA MACHINERY

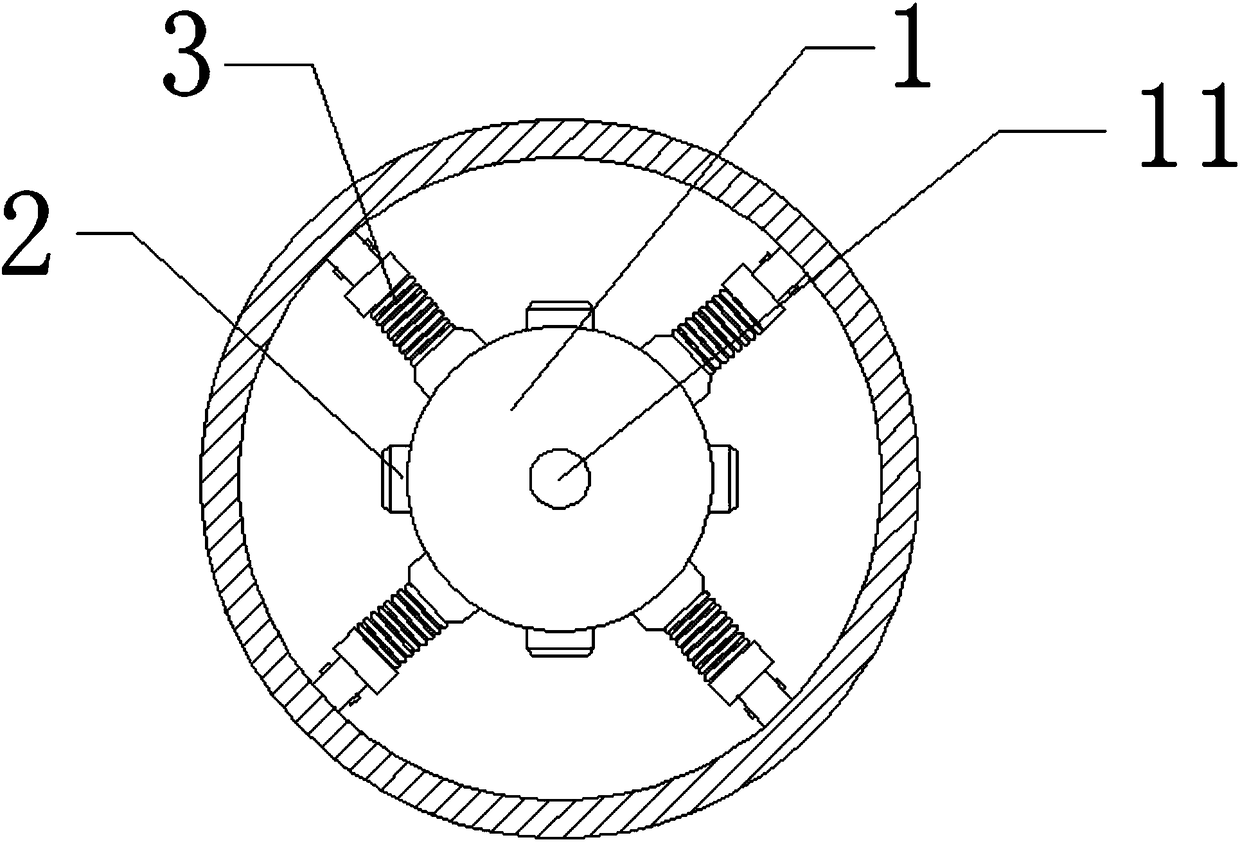

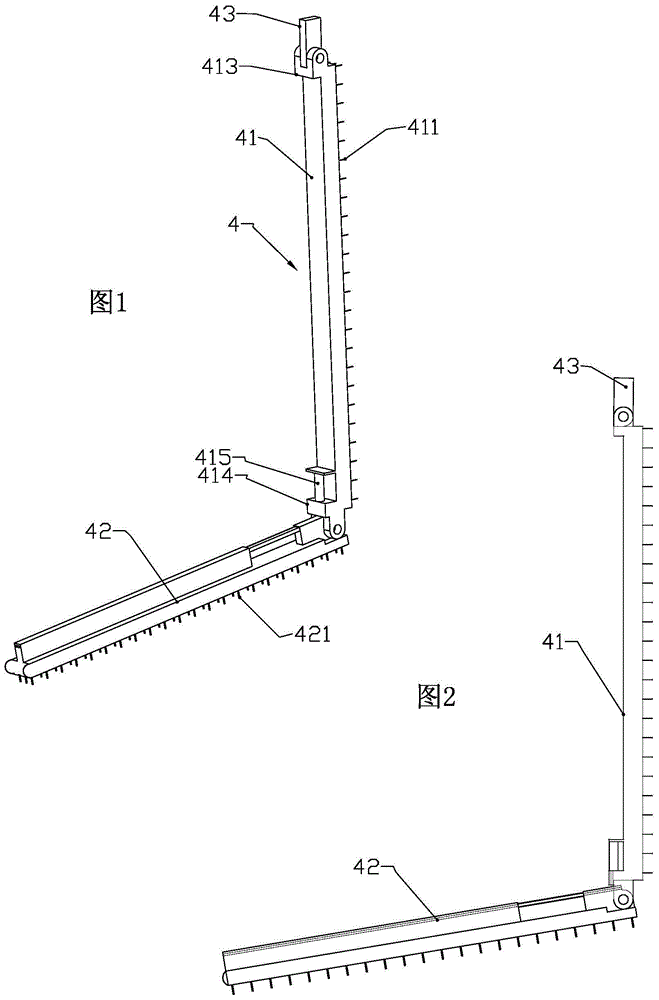

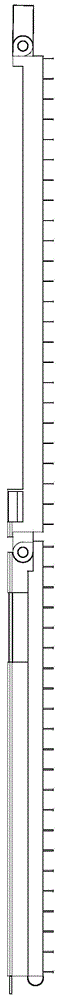

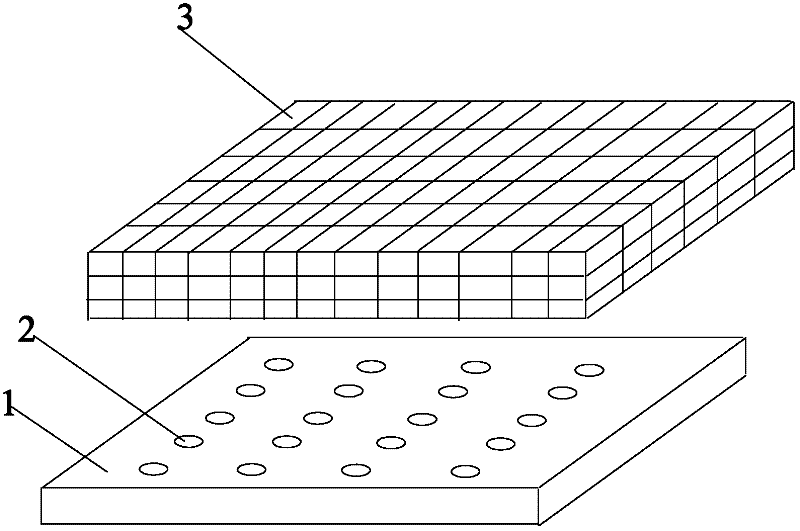

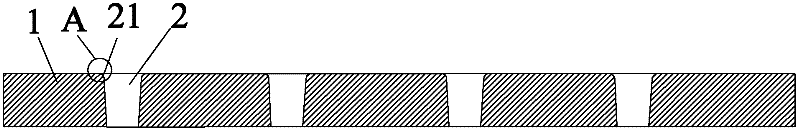

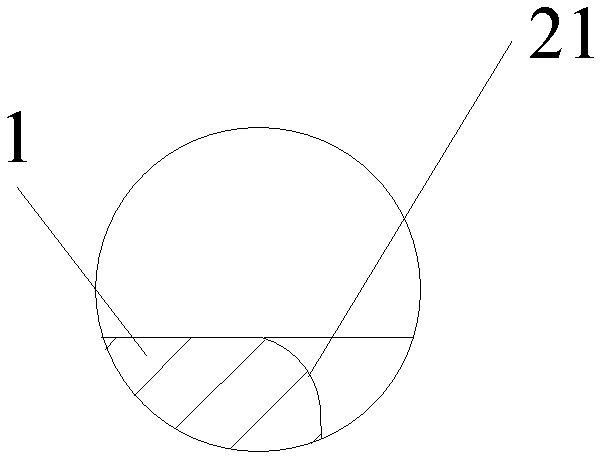

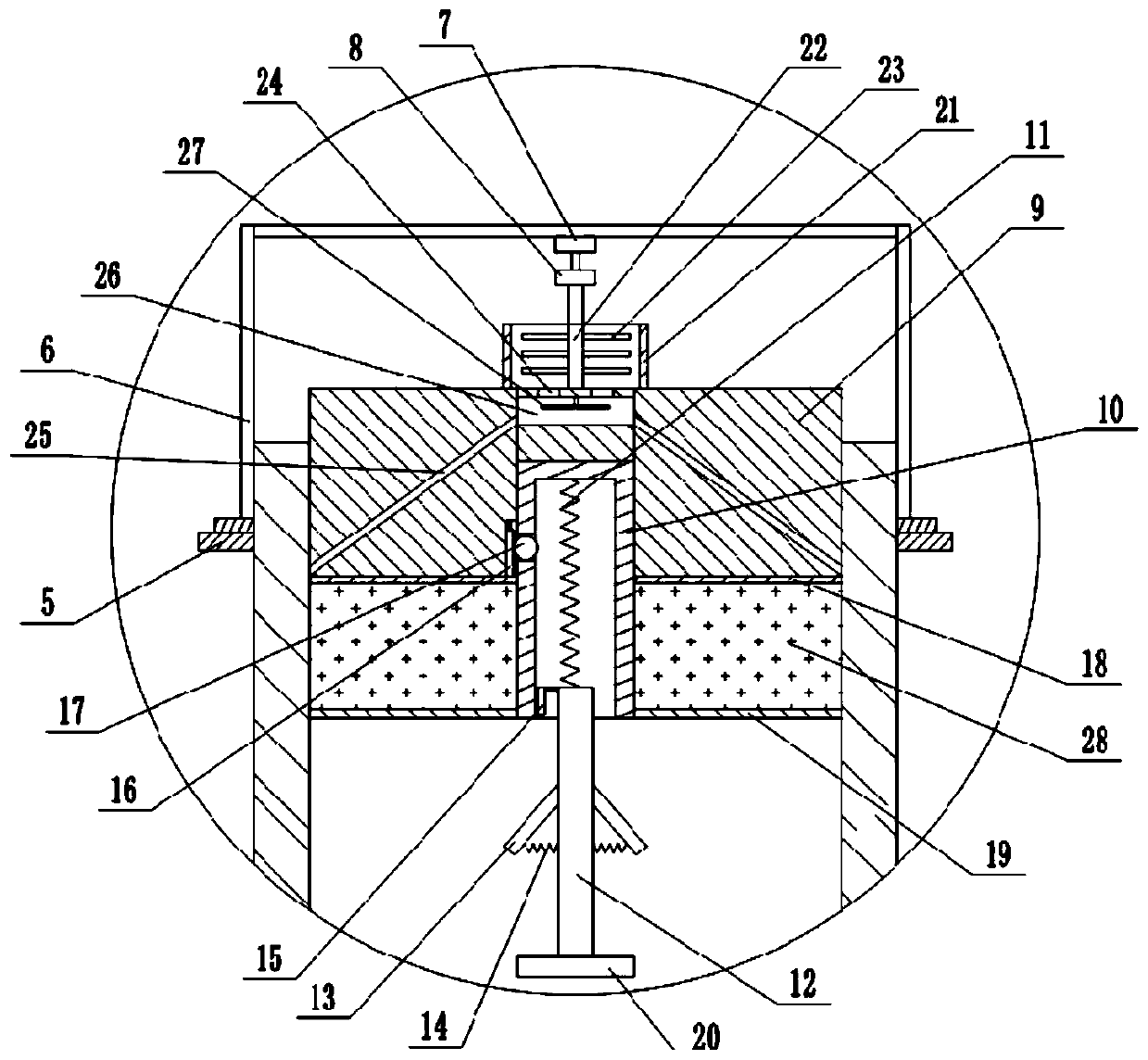

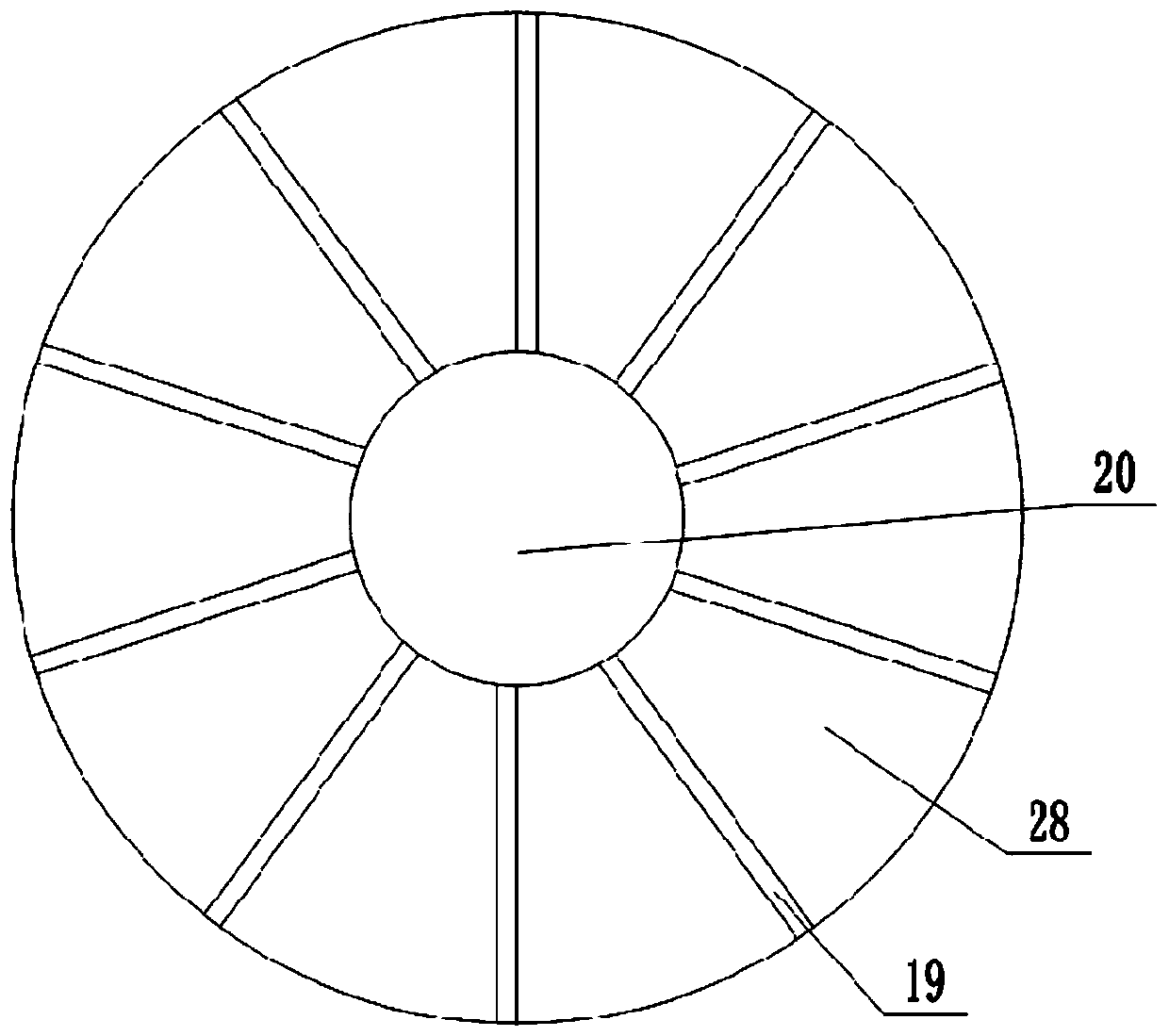

Device and method for mechanically cleaning inner wall of barrel-shaped container

InactiveCN104646375AAchieve mechanical cleaningEliminate distractionsHollow article cleaningLocking mechanismBarrel Shaped

Owner:俞少平

Chromatographic bottle cleaning device

ActiveCN102366752AImprove cleaning efficiencyImprove cleanlinessHollow article cleaningBiochemical engineeringBottle

Owner:CHINA TOBACCO GUANGDONG IND

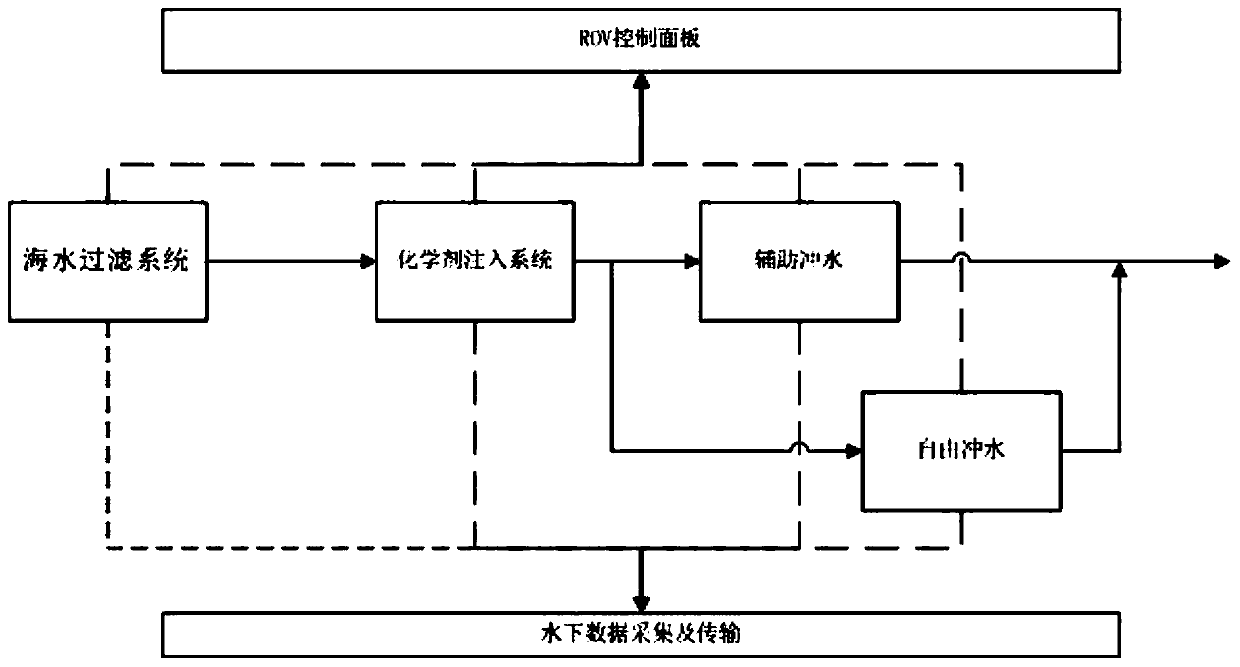

Device applicable to pipe washing work of deep sea oil and gas pipeline

InactiveCN110252750AOvercome stressOvercoming resistance along the wayHollow article cleaningPiggingPore water pressure

Owner:OFFSHORE OIL ENG +1

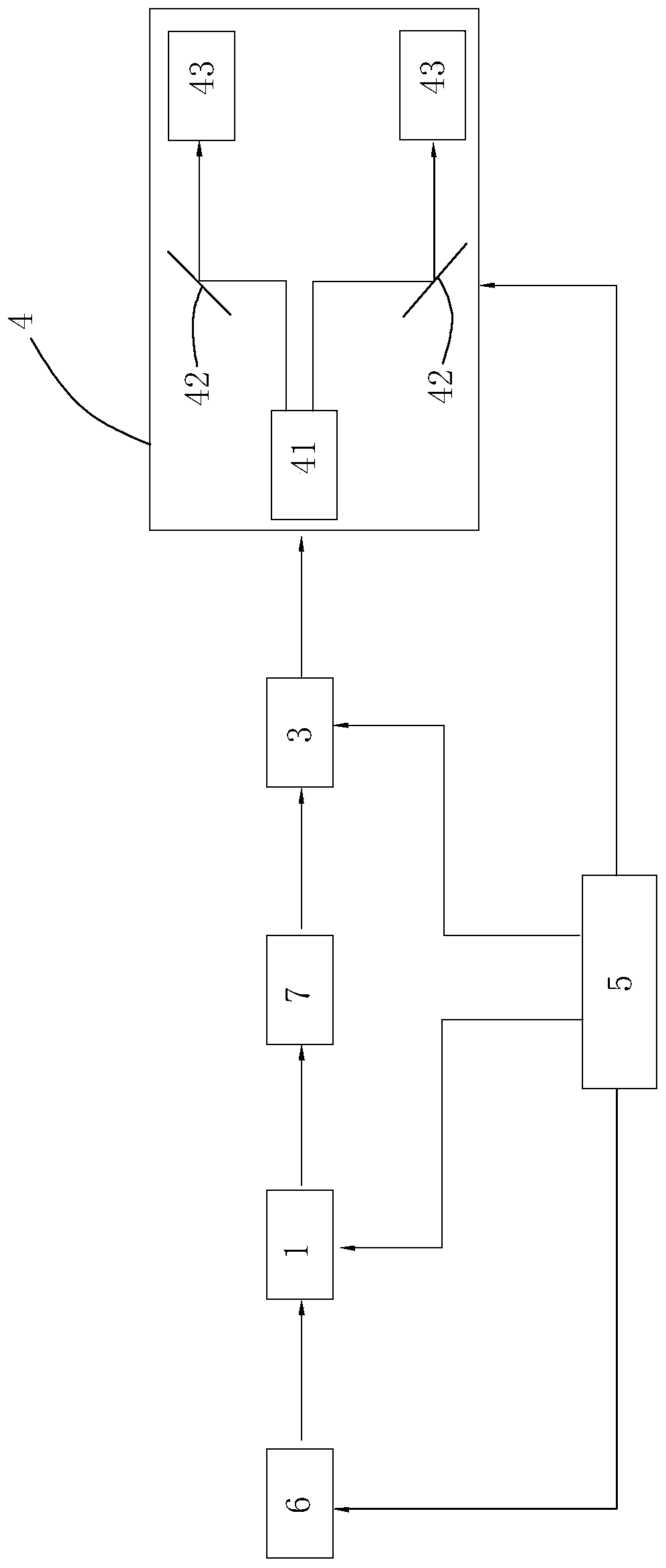

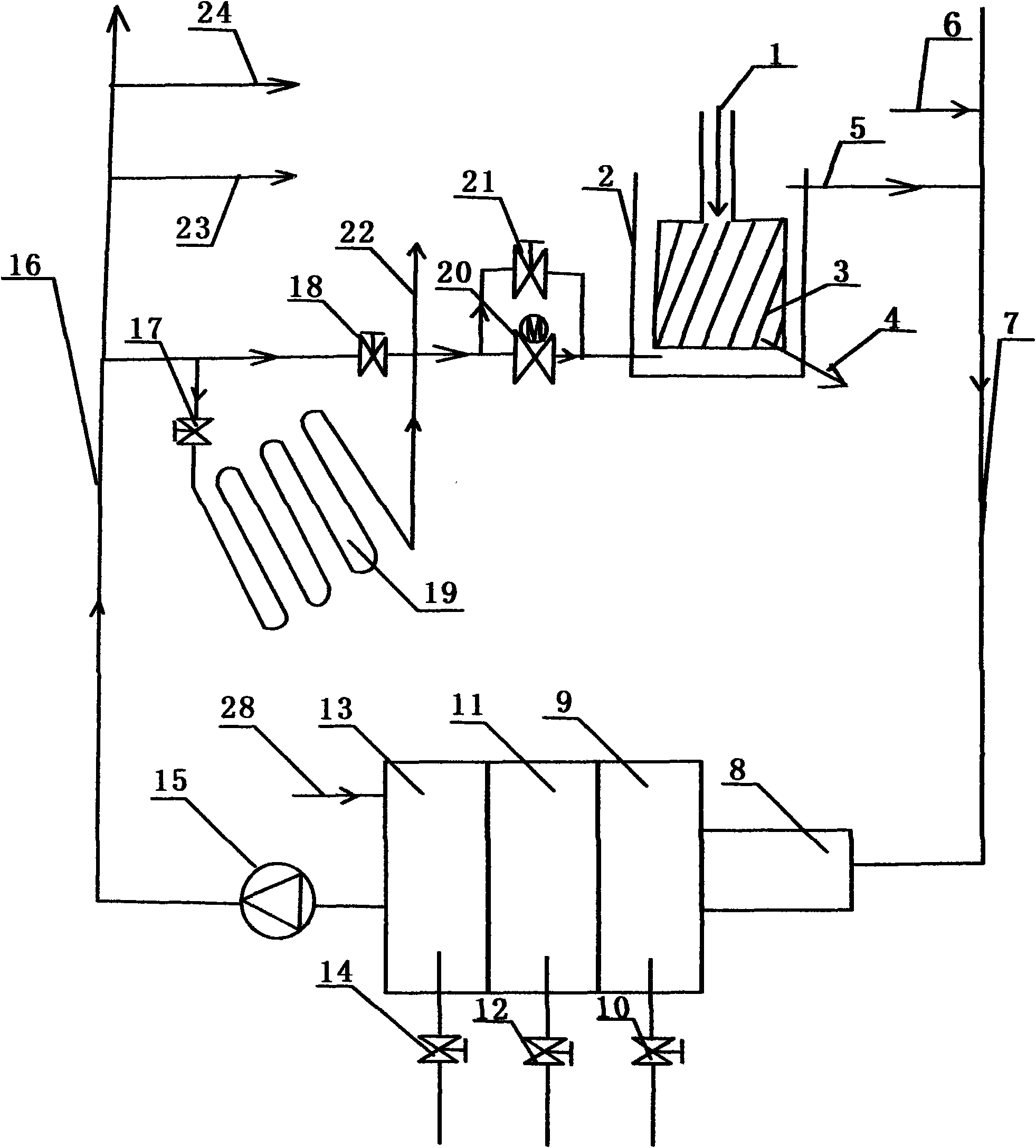

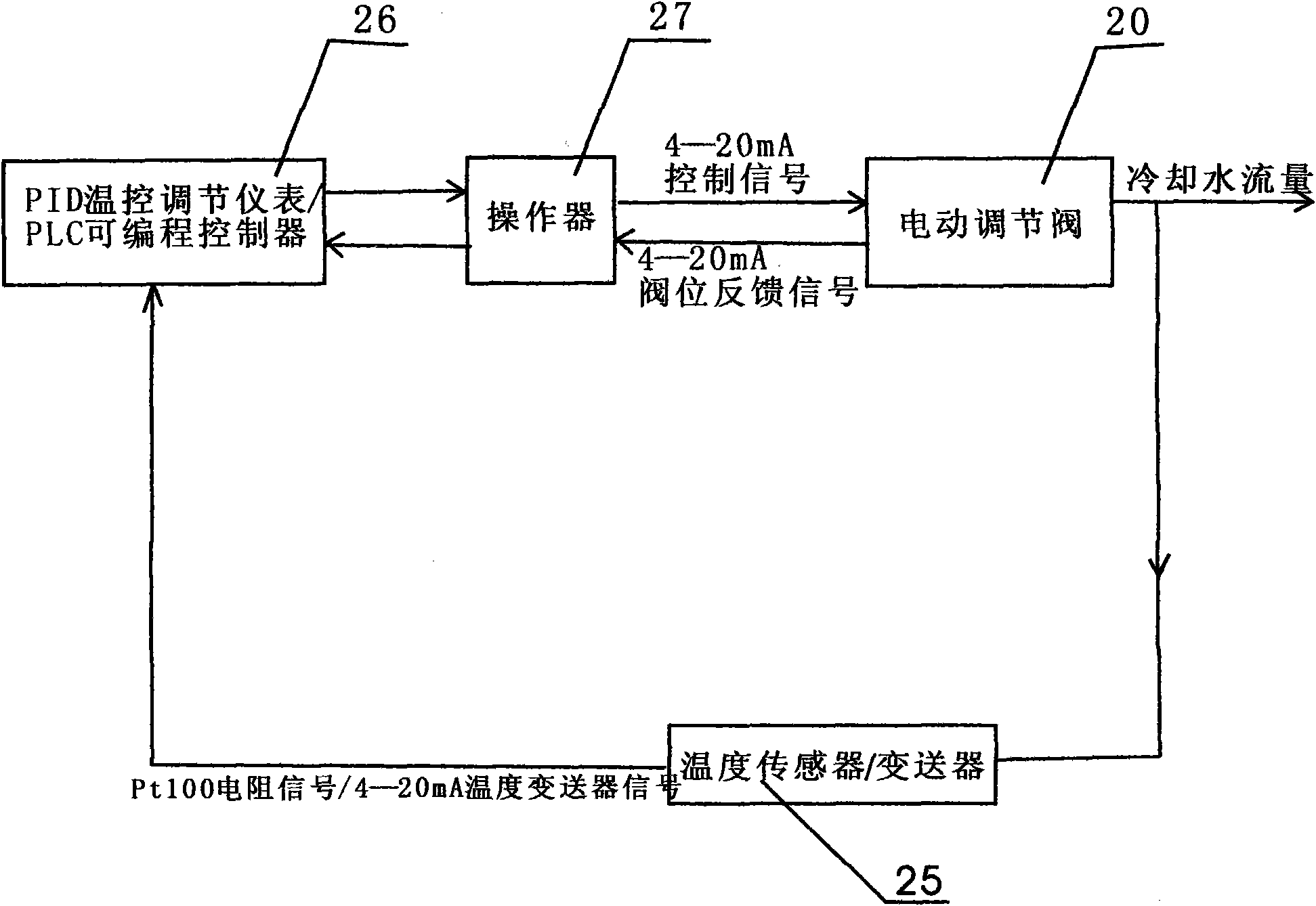

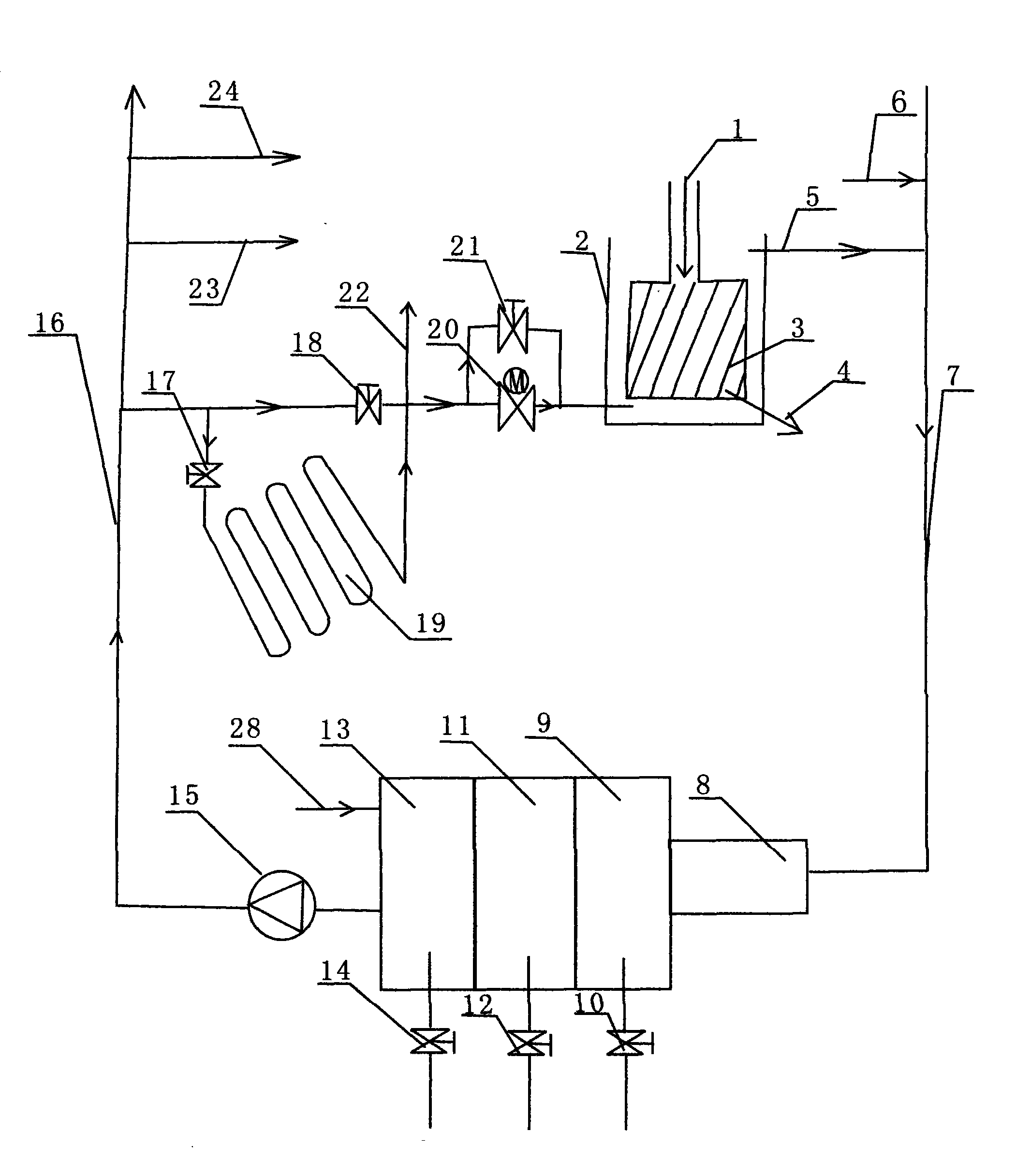

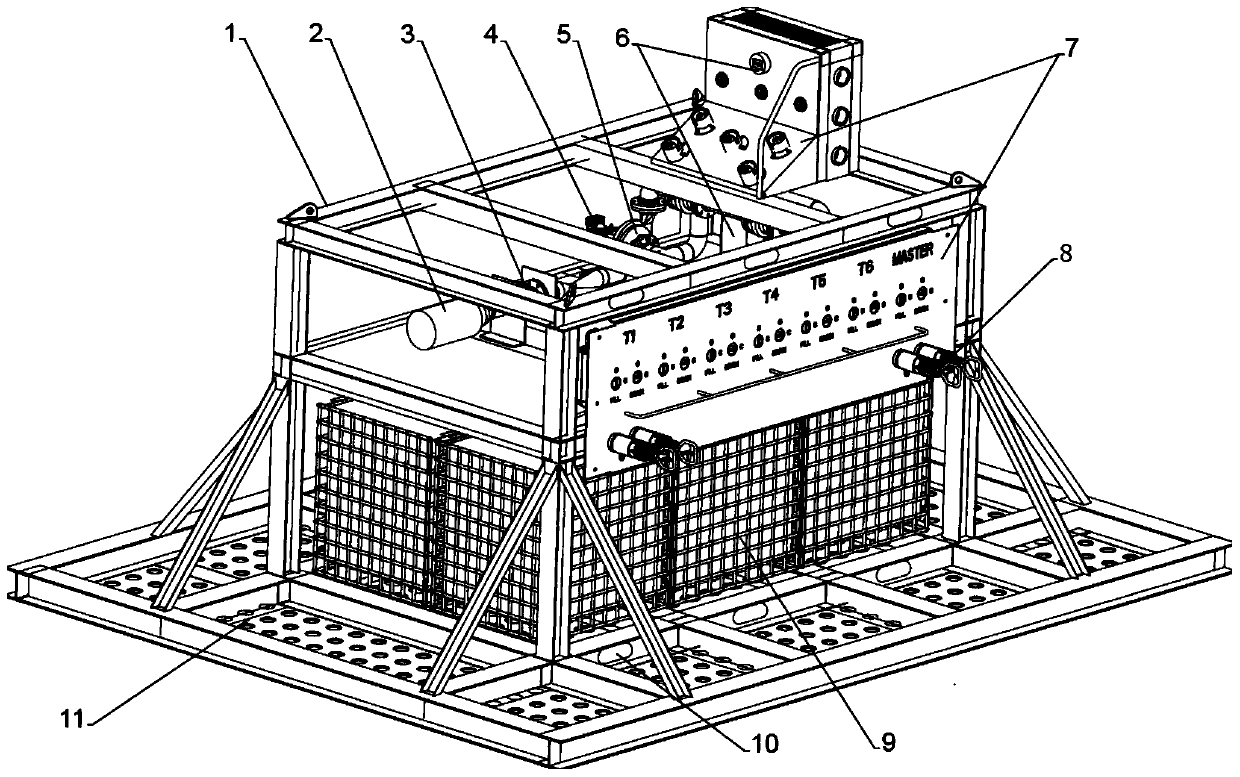

Flushing system for improving cleanliness of hydraulic pipeline

InactiveCN111672836ARealize self-circulation cleaningTimely cleaning effectHollow article cleaningWater/sewage treatment by magnetic/electric fieldsControl engineeringLiquid storage tank

The invention relates to a flushing system for improving the cleanliness of a hydraulic pipeline. The flushing system comprises a liquid storage tank, a liquid supply device, a reversing valve, a first pipeline, a second pipeline, a filtering device and a closed-loop pipeline. The liquid storage tank, the liquid supply device, the reversing valve and the filtering device are sequentially connectedto the closed-loop pipeline in series. One end of the first pipeline and one end of the second pipeline are communicated with the reversing valve, and the other end of the first pipeline and the other end of the second pipeline are used for being communicated with the pipeline to be flushed. A first valve is arranged on the first pipeline, a second valve is arranged on the second pipeline, and athird pipeline is communicated between the first pipeline and the second pipeline. A third valve is arranged on the third pipeline. The third pipeline is used for performing short circuit on the pipeline to be flushed. A first detection point is arranged on the filtering device. A second detection point is arranged on the liquid storage tank. By the adoption of the flushing system, the situation of singular cleaning mode is avoided, the self-circulation cleaning of the flushing system is achieved, the cleaning effect can be mastered in time by operators, and the situation that cleanliness is not standard is avoided.

Owner:GUANGZHOU GARNOR IND TECH CO LTD

Waste gas neutralization treatment device for thermal power plant

InactiveCN114307598AReduce manufacturing costSave the hassle of steering switchingLighting and heating apparatusHollow article cleaningPower stationEnvironmental engineering

The invention discloses a waste gas neutralization treatment device for a thermal power plant, relates to the technical field of waste gas treatment equipment, and solves the problems that most of existing waste gas treatment equipment needs to be additionally matched with a cleaning assembly for a smoke exhaust mechanism such as a chimney, an original spraying assembly cannot be used for internal cleaning, and the manufacturing cost of the equipment cannot be reduced. The waste gas neutralization treatment device for the thermal power plant comprises a chimney, the chimney is of a circular structure, a settlement cover is welded to the bottom of the chimney, a discharge pipe is welded and communicated to the bottom of the settlement cover, four vertical supporting shafts are symmetrically welded to the bottom of the chimney, and an annular base is welded and fixed to the bottoms of the four vertical supporting shafts; and two electric push rods are symmetrically mounted on the top end sections of the two vertical supporting fulcrum shafts which are in bilateral symmetry in a hanging and supporting mode, and a baffle is locked and fixed to the bottoms of the two electric push rods. The trouble that six vertical water spraying pipes are subjected to steering switching through manual driving operation can be omitted, and use is convenient, labor-saving and rapid.

Owner:杜苏月

Fluid pressure detection device

InactiveCN111426422AKeep dryPlay a drying roleHollow article cleaningDrying gas arrangementsElectric machineryEngineering

Owner:CHONGQING UNIV OF ARTS & SCI

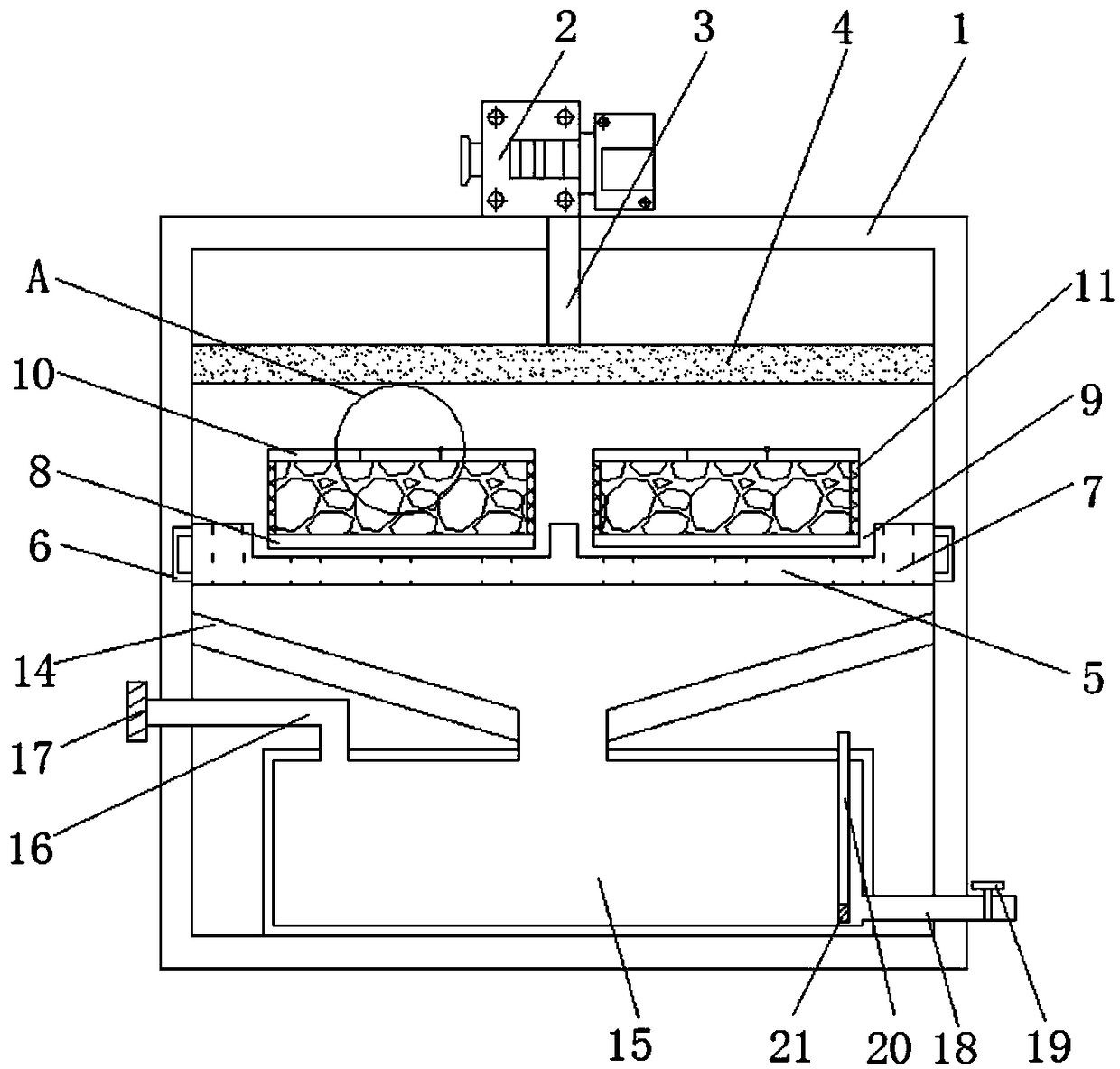

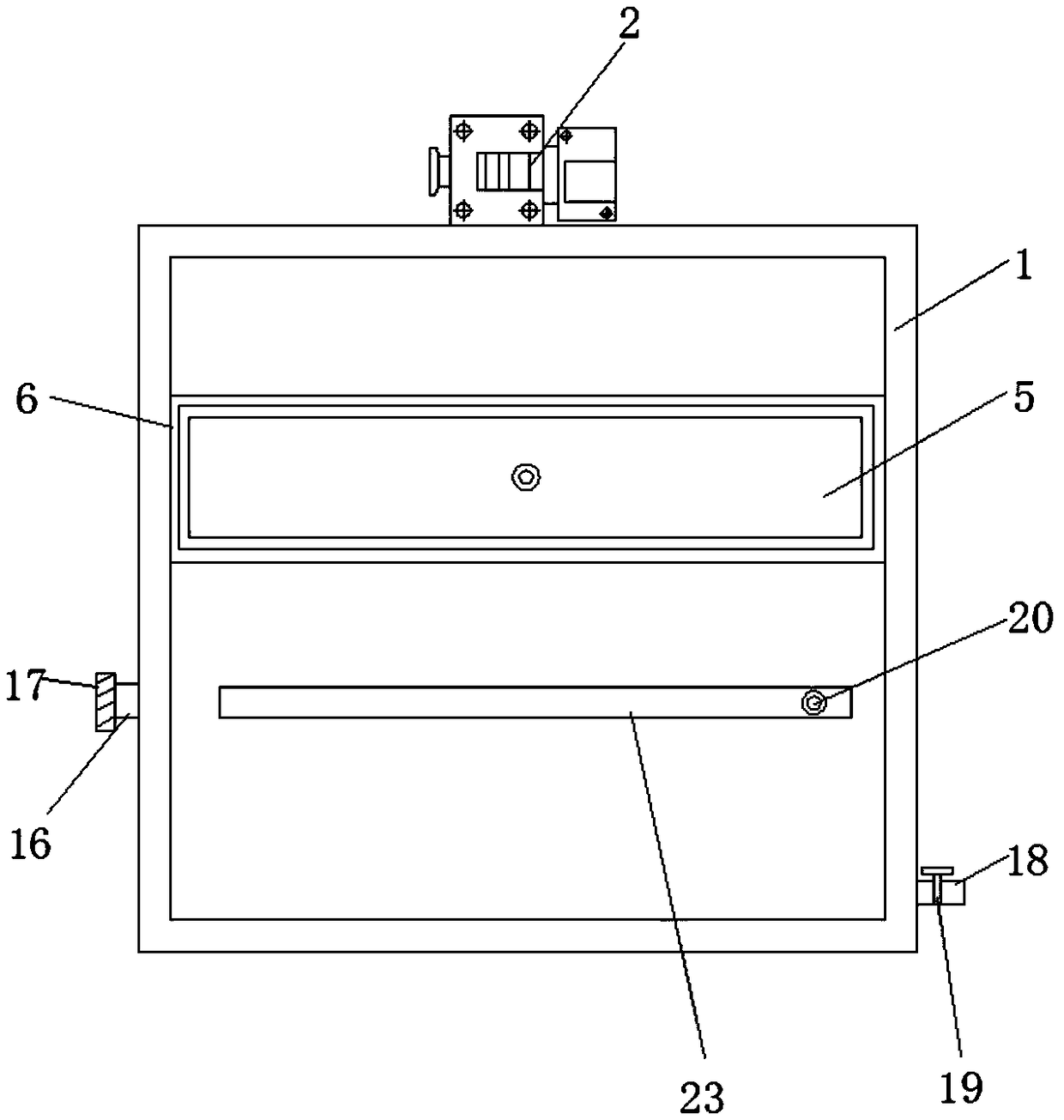

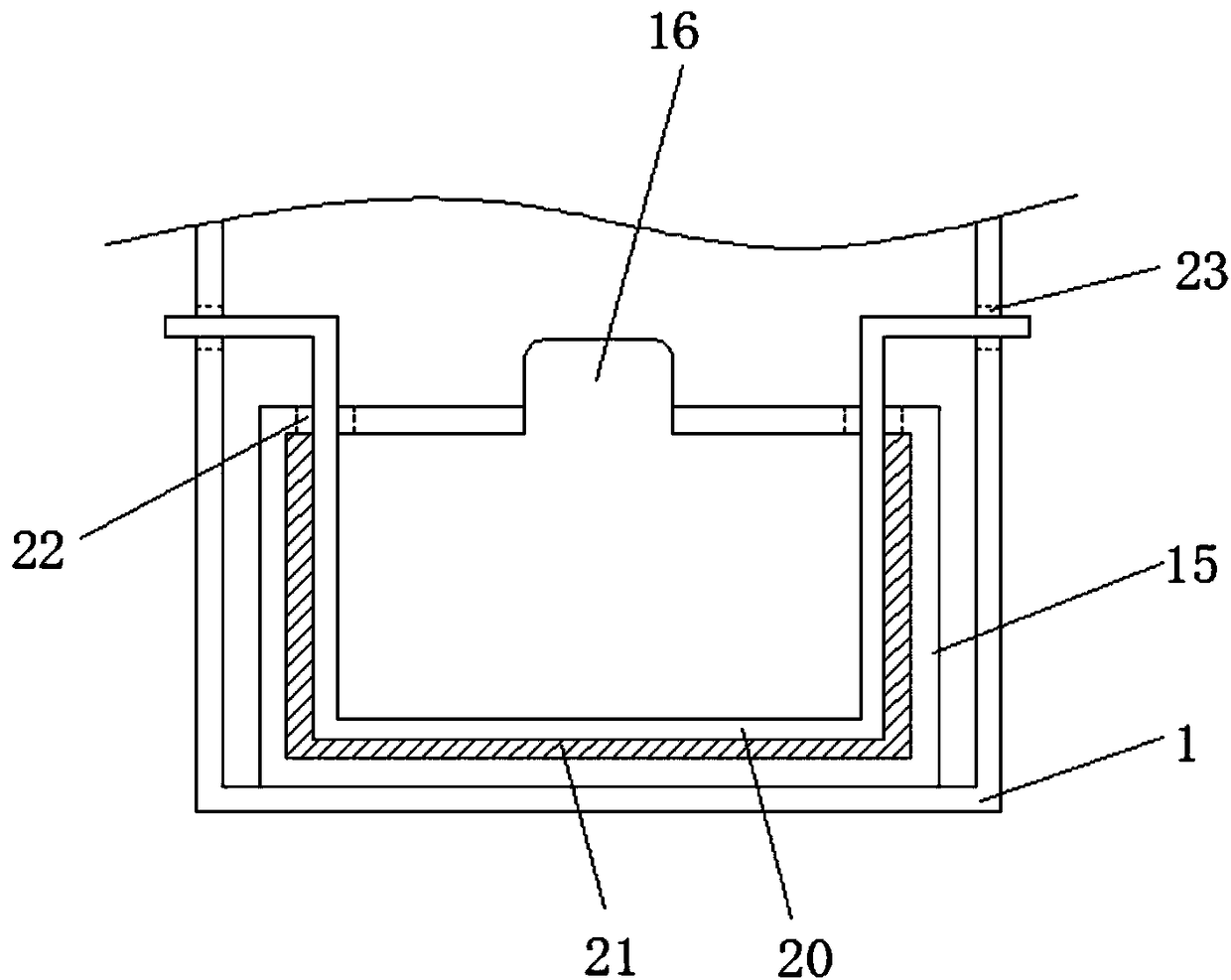

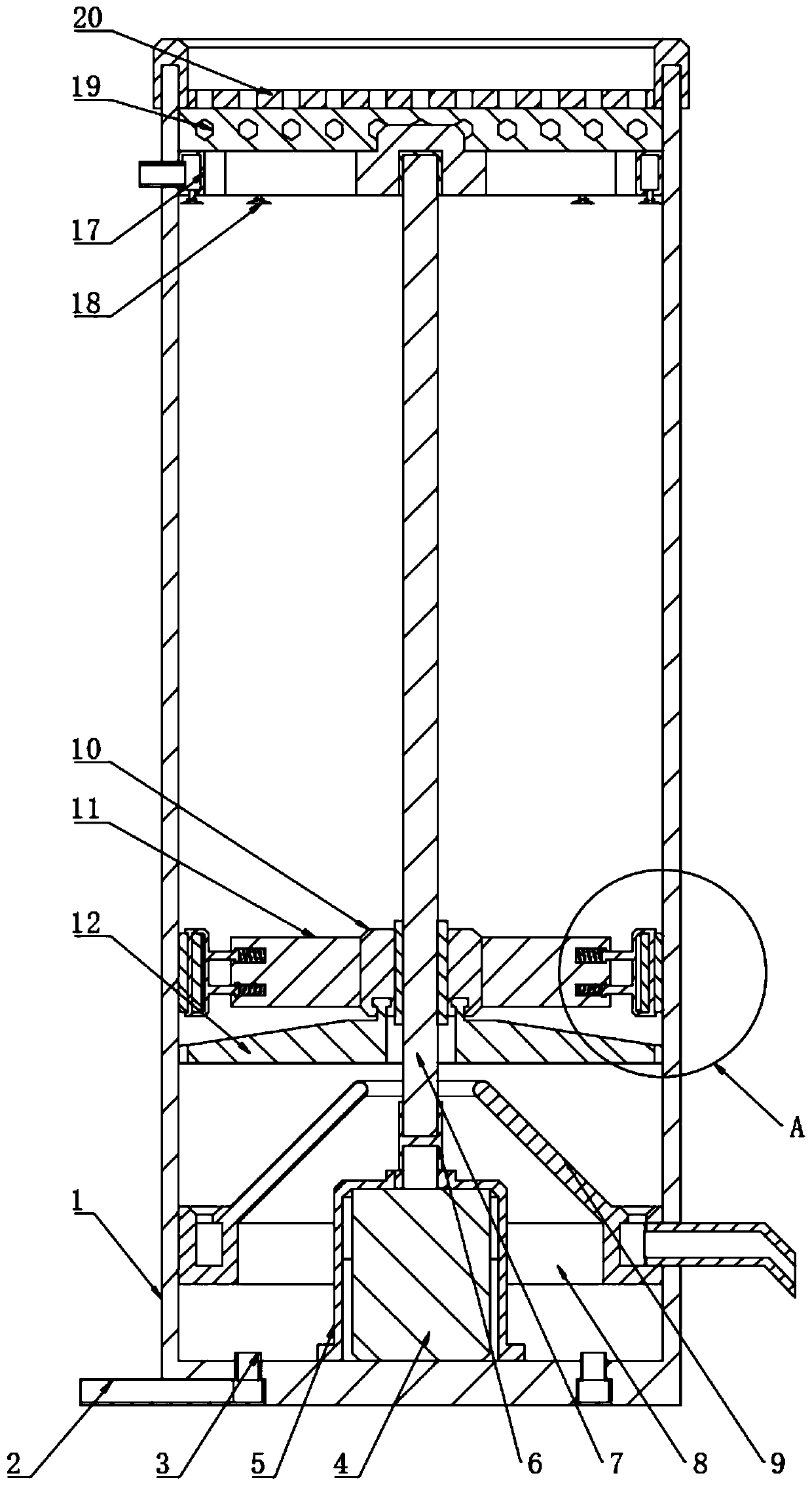

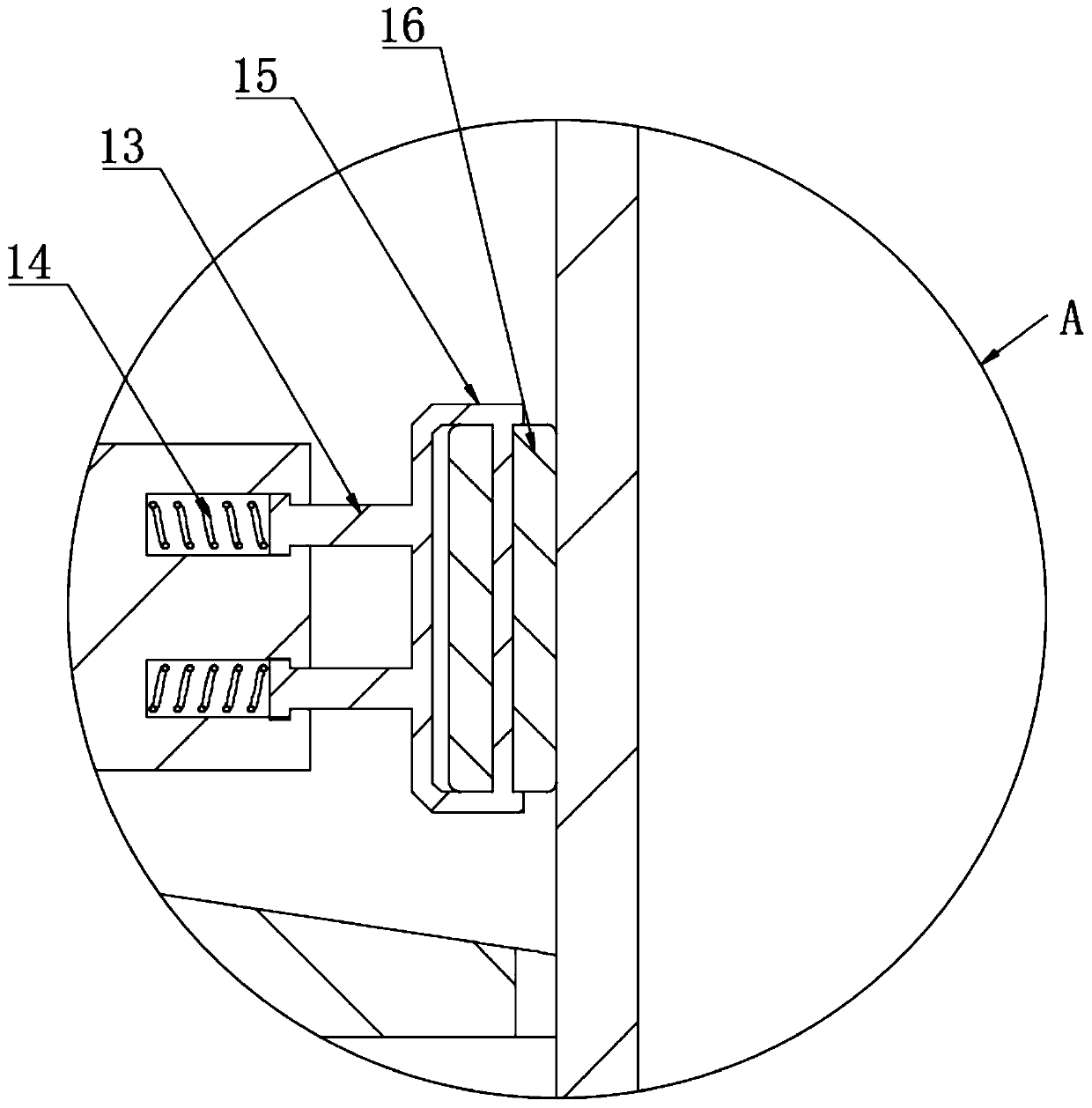

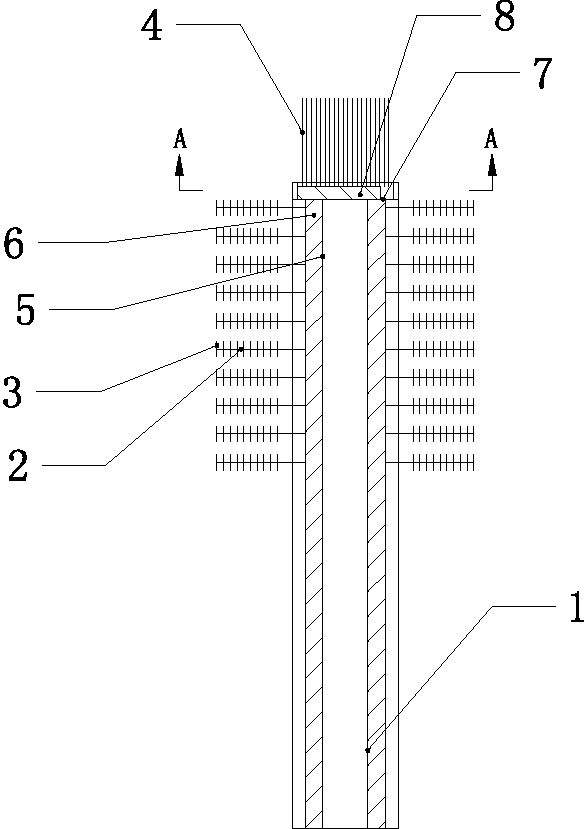

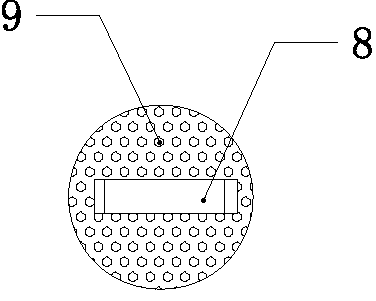

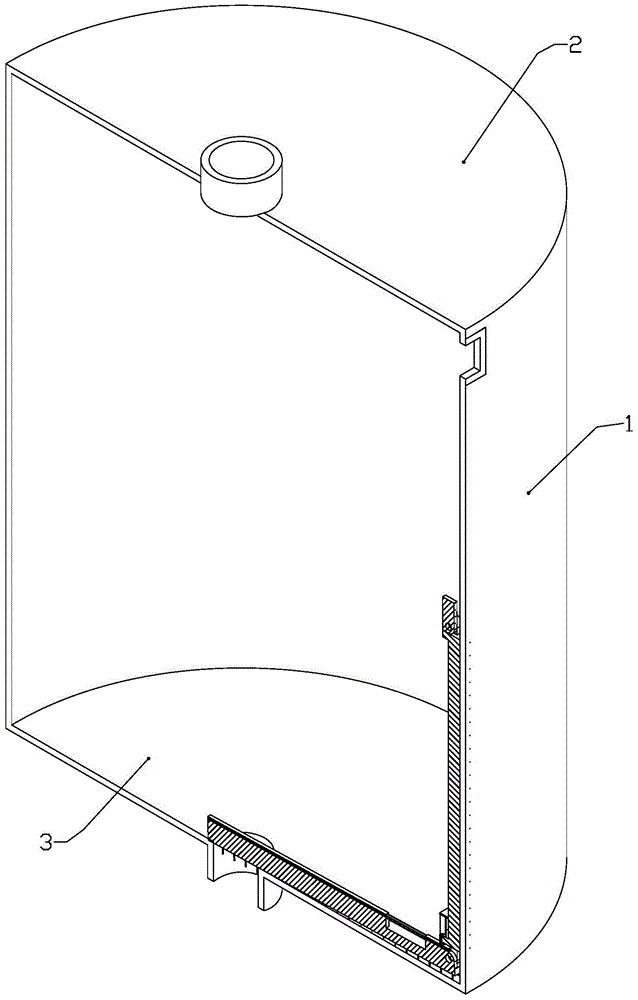

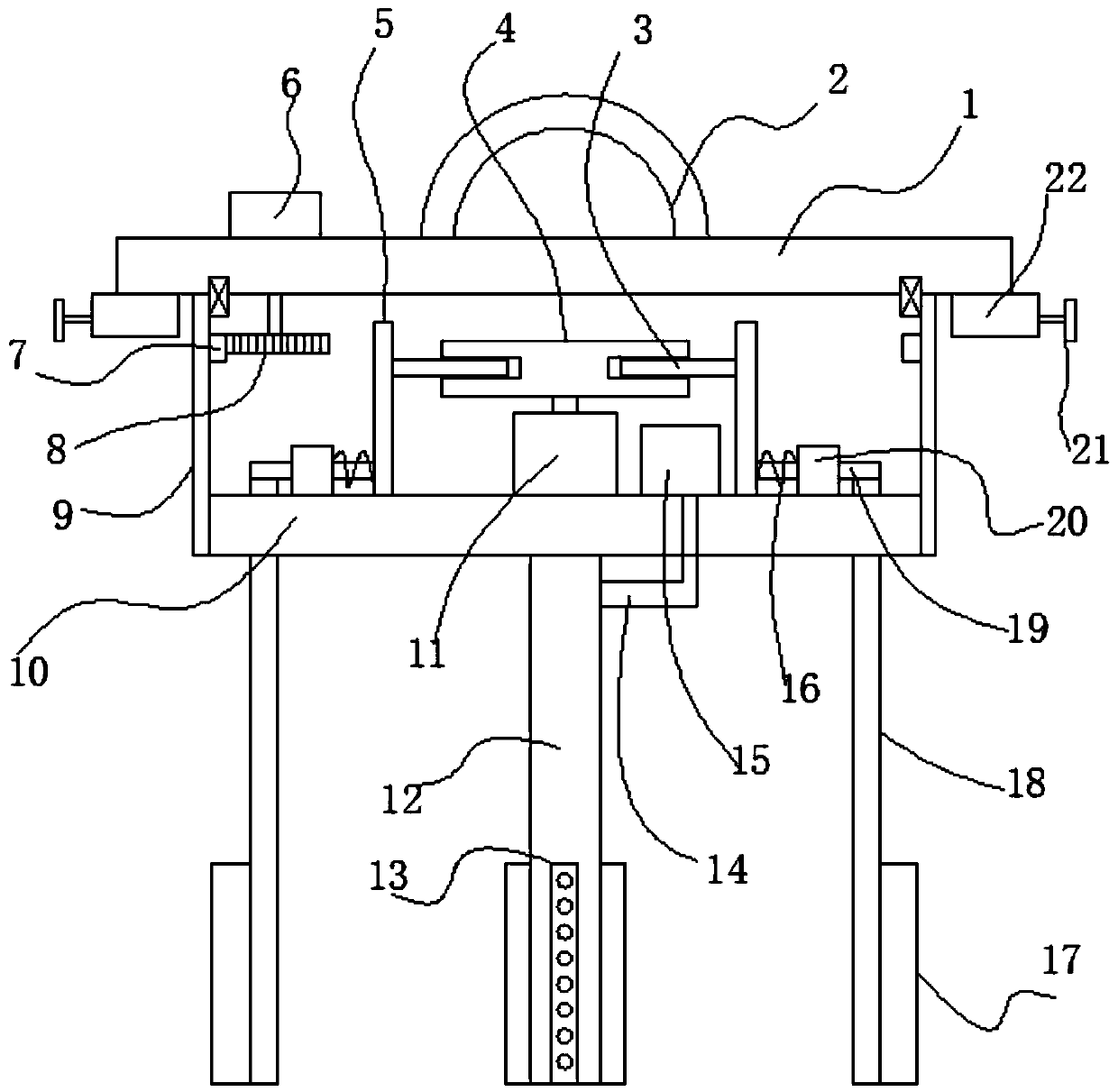

Inert chemical product charging bucket cleaning device

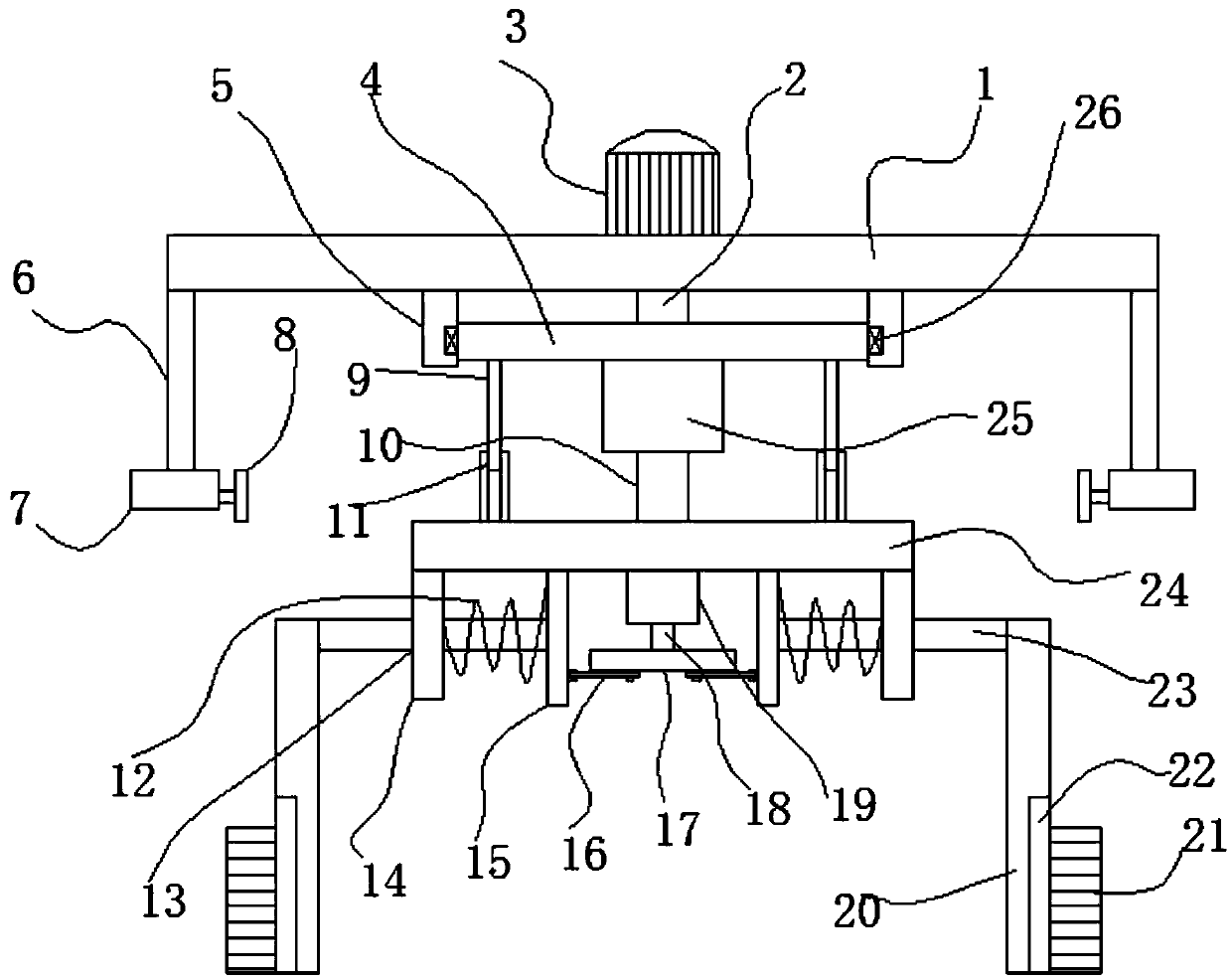

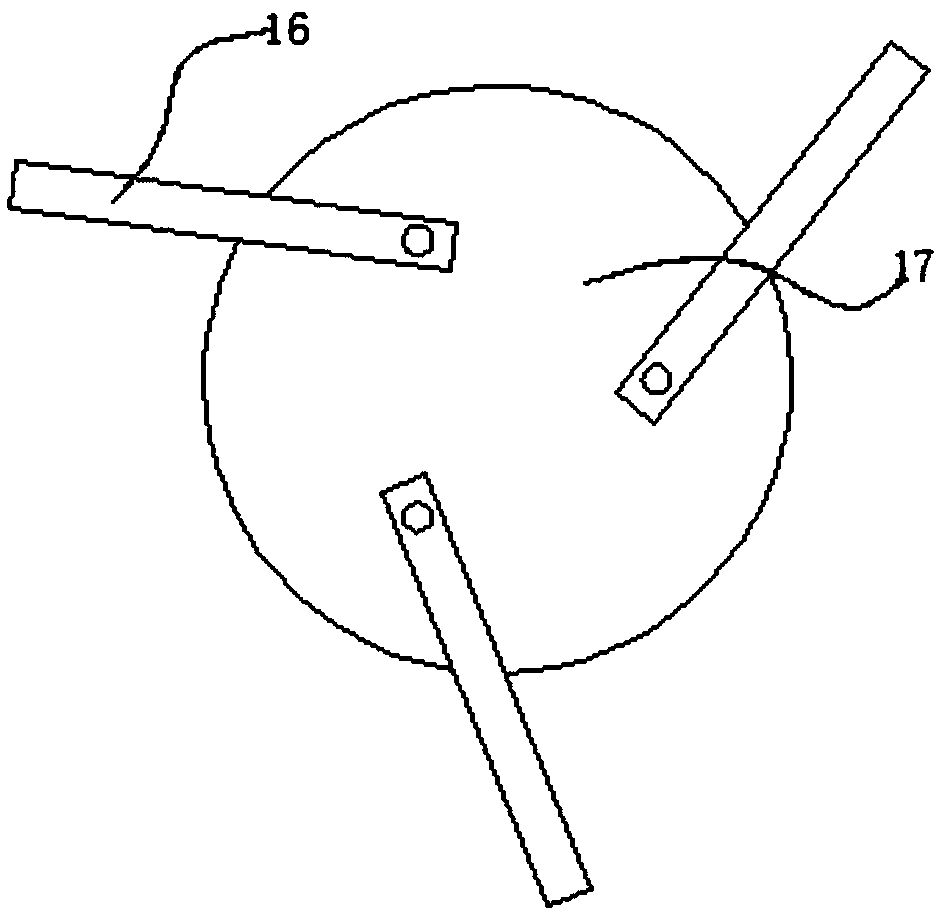

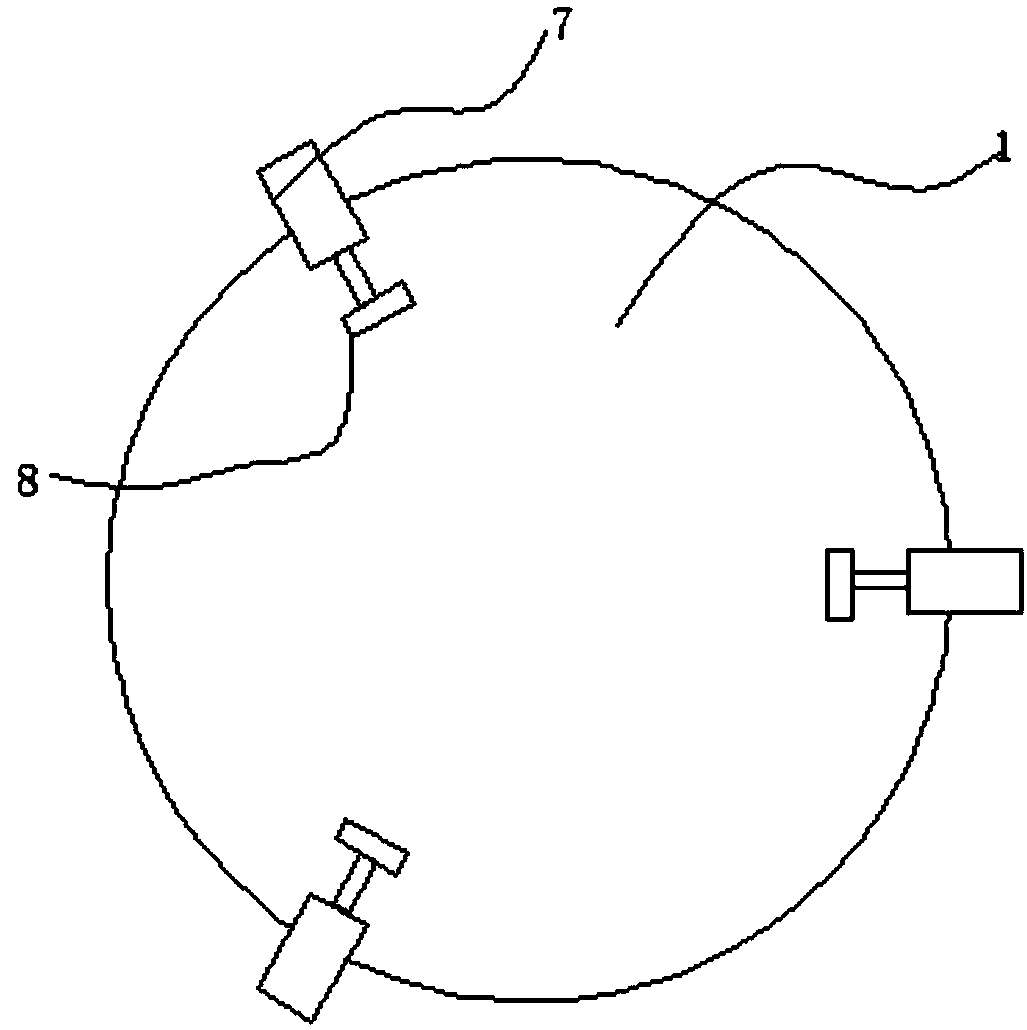

The invention relates to a cleaning device for chemical products, in particular to an inert chemical product charging bucket cleaning device. According to the technical purposes of the inert chemicalproduct charging bucket cleaning device, the cleaning effect is good, operation is easy and convenient, and injuries to human bodies are small. In order to achieve the technical purposes, the inert chemical product charging bucket cleaning device is provided and comprises supporting legs and the like; a first supporting plate is horizontally placed on the tops of the left and right side supportinglegs; a cleaning mechanism is installed in the middle of the bottom of the first supporting plate; and a second supporting plate is connected to the position, close to the upper portion, of the bottom between the left and right side supporting legs, and is provided with an overturning and tipping mechanism. According to the inert chemical product charging bucket cleaning device, due to mutual cooperation of the cleaning mechanism and the overturning and tipping mechanism, recycled charging barrels are cleaned, and meanwhile, by means of optimization of an auxiliary mechanism and a secondary treatment mechanism, the effects that the cleaning effect is good, operation is easy and convenient, and injuries to human bodies are small are achieved.

Owner:饶胜智

Automatic cleaning device for pipe inner wall

Owner:盐城漫澜信息科技服务有限公司

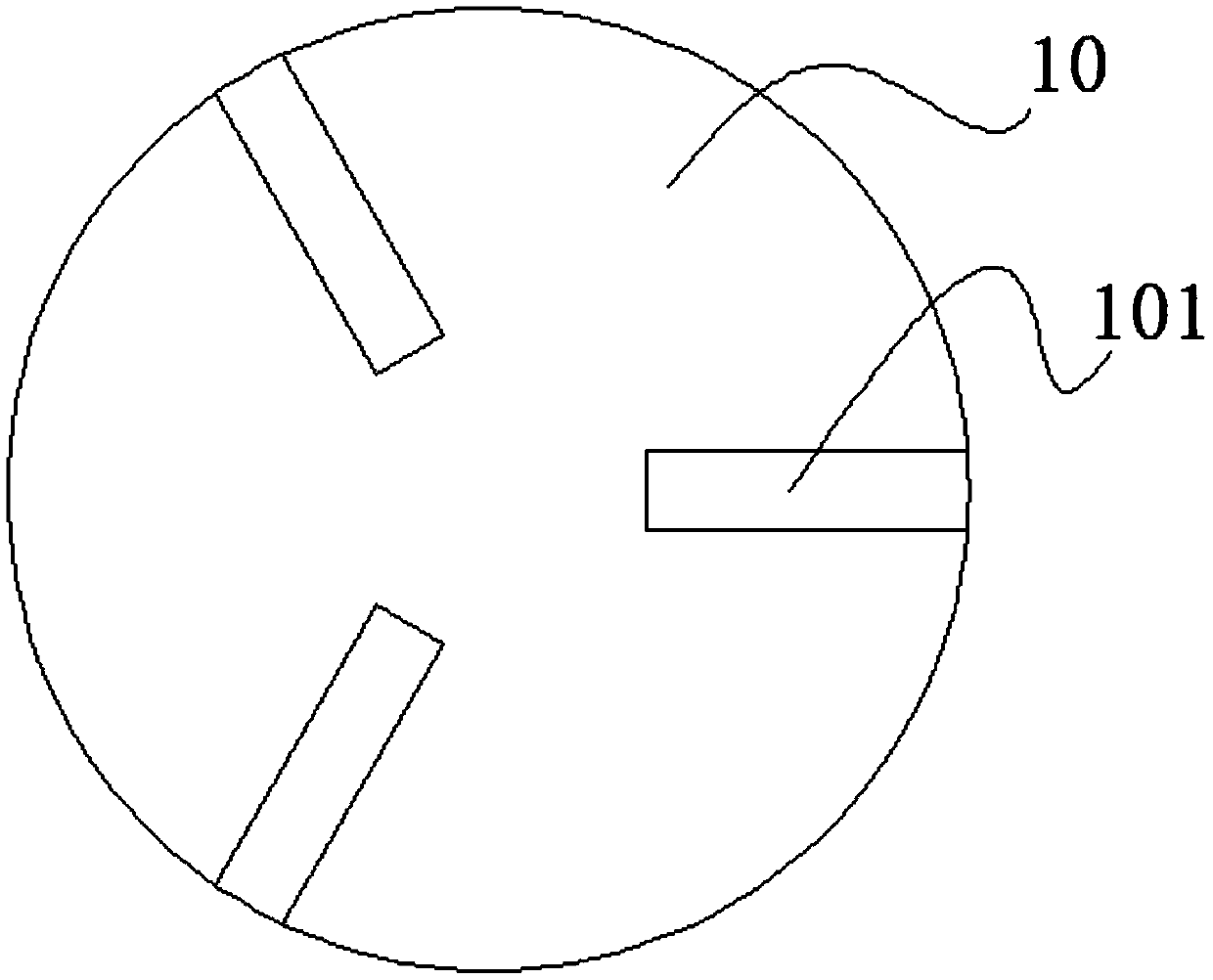

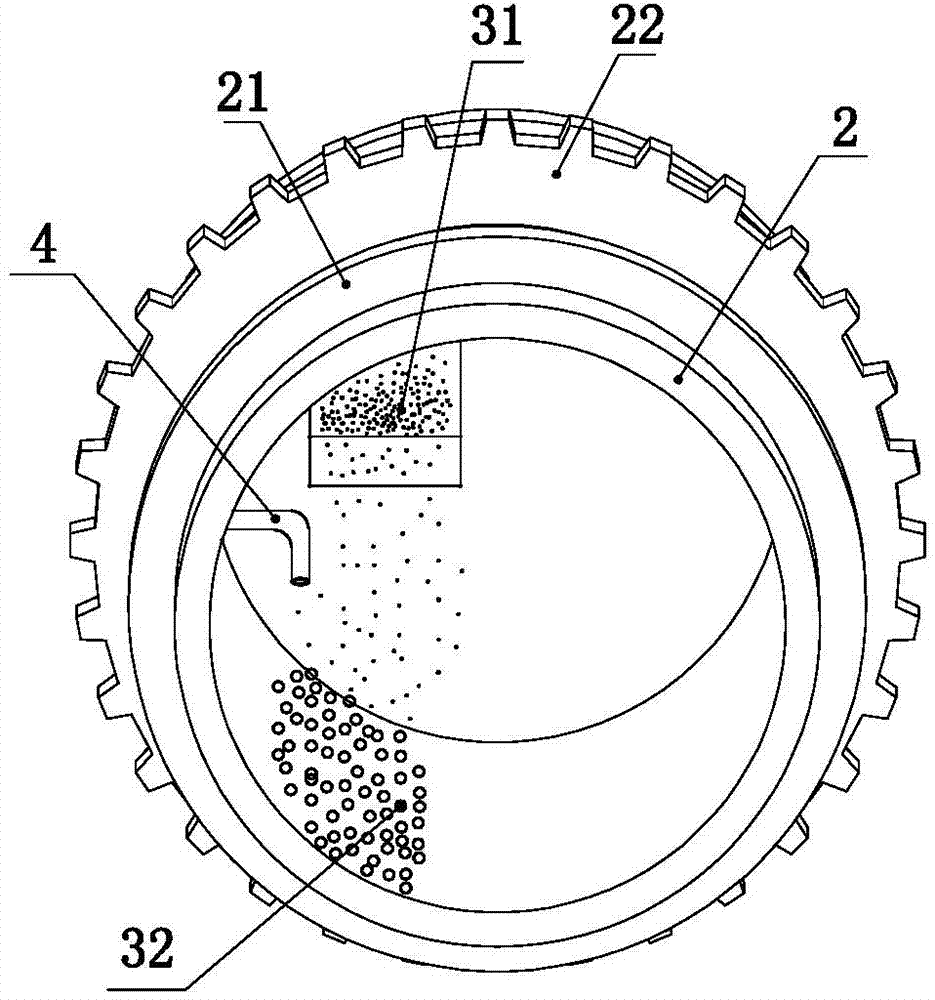

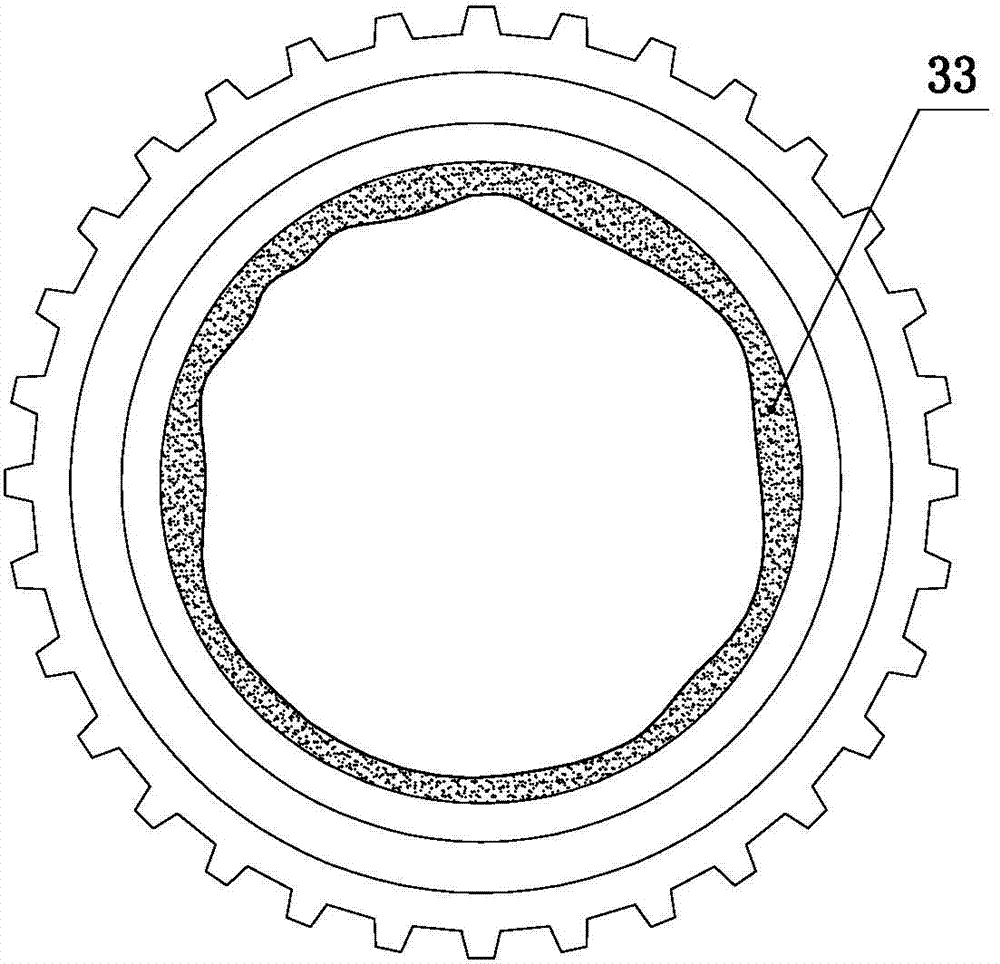

Device for removing blocking on inner wall of drum-type granulating machine

Owner:JINAN BADUN FERTILIZER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap