Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Chimney" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chimney is an architectural ventilation structure made of masonry, clay or metal that isolates hot toxic exhaust gases or smoke produced by a boiler, stove, furnace, incinerator or fireplace from human living areas. Chimneys are typically vertical, or as near as possible to vertical, to ensure that the gases flow smoothly, drawing air into the combustion in what is known as the stack, or chimney effect. The space inside a chimney is called the flue. Chimneys are adjacent to large industrial refineries, fossil fuel combustion facilities or part of buildings, steam locomotives and ships.

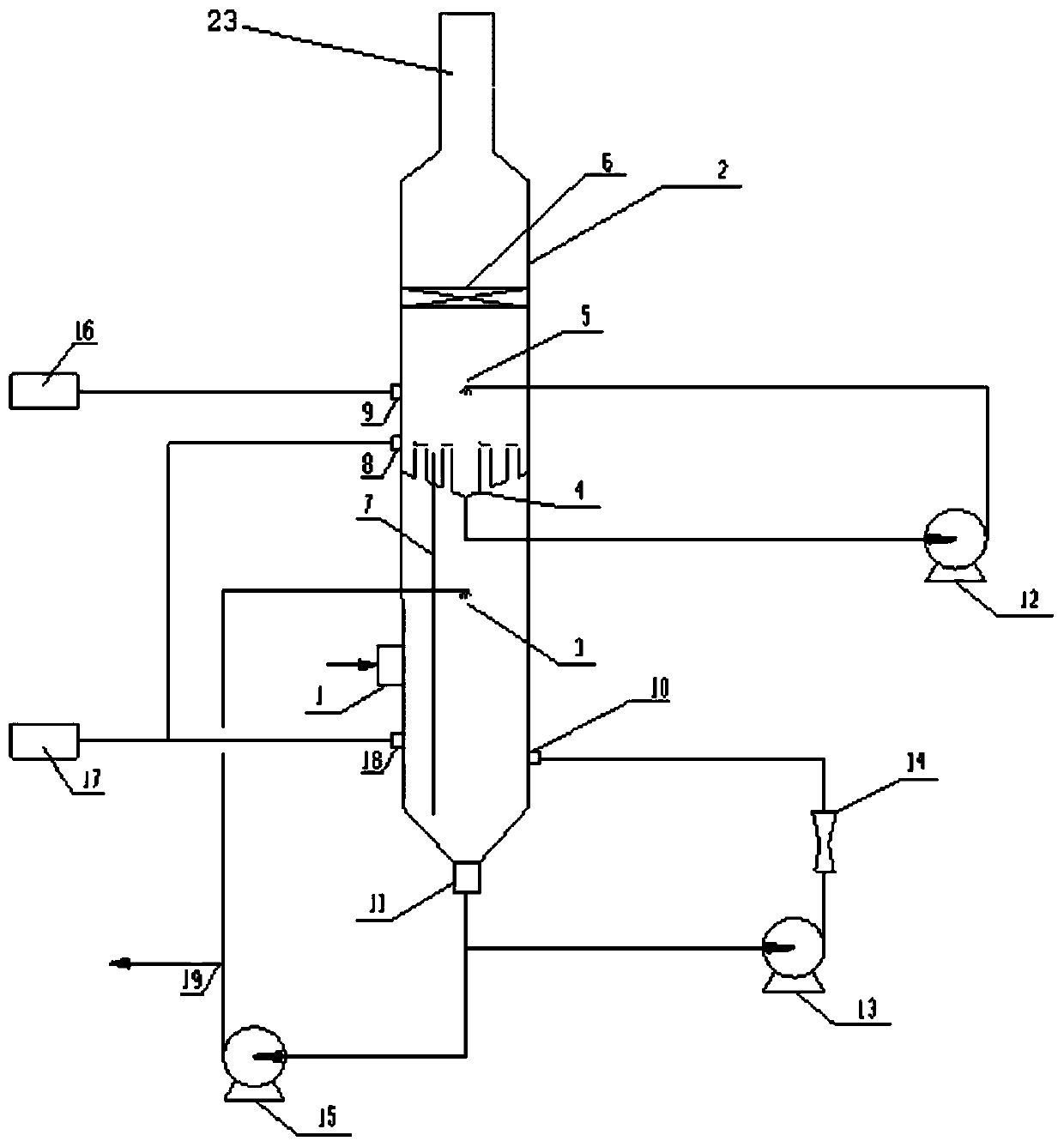

Device and technology for flue gas desulfurization through soda ash method

PendingCN110433637ANo noiseAchieve securityCombination devicesGas treatmentSulfite saltSodium sulfite

Owner:大连汉诺工程技术有限公司

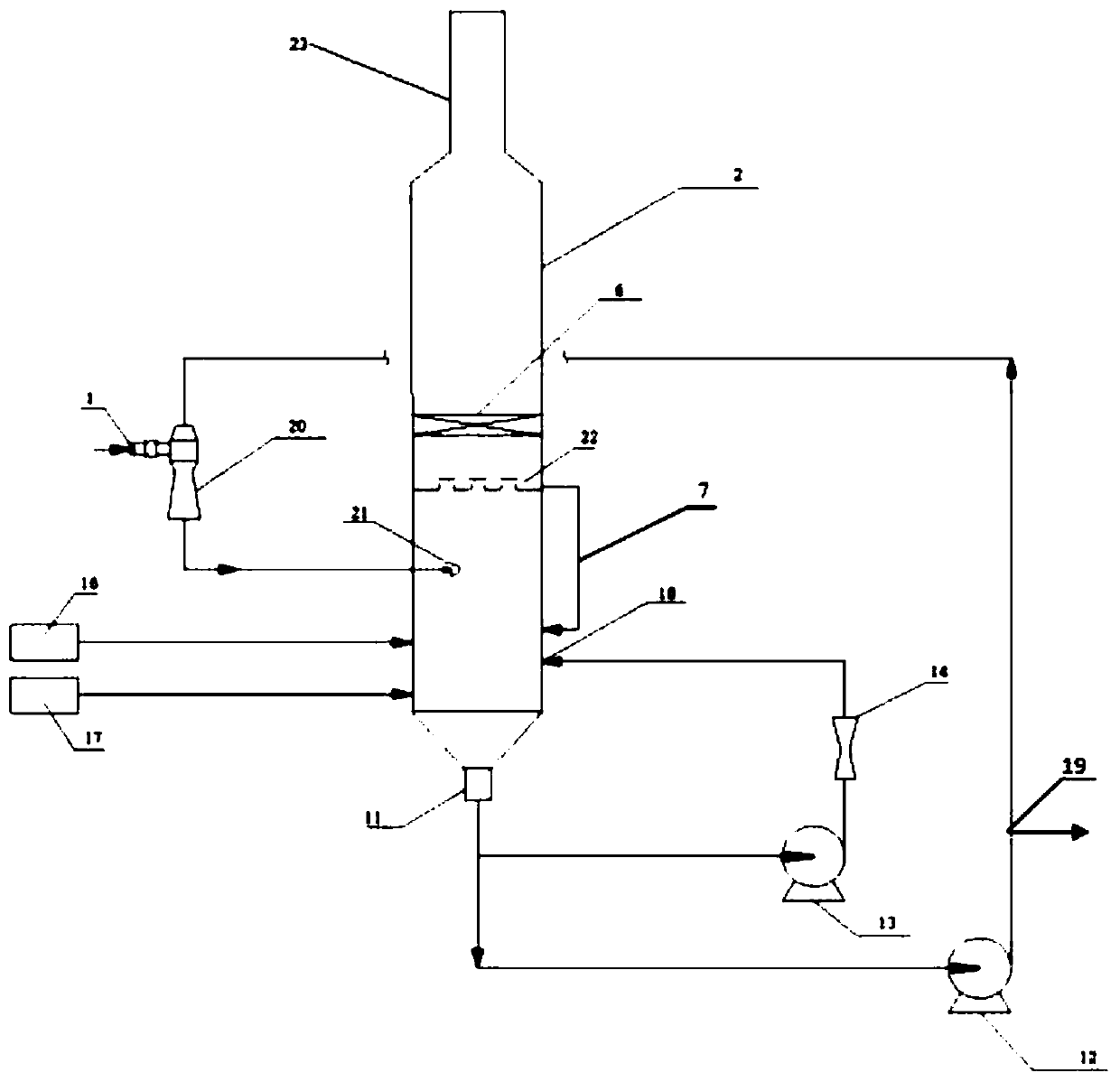

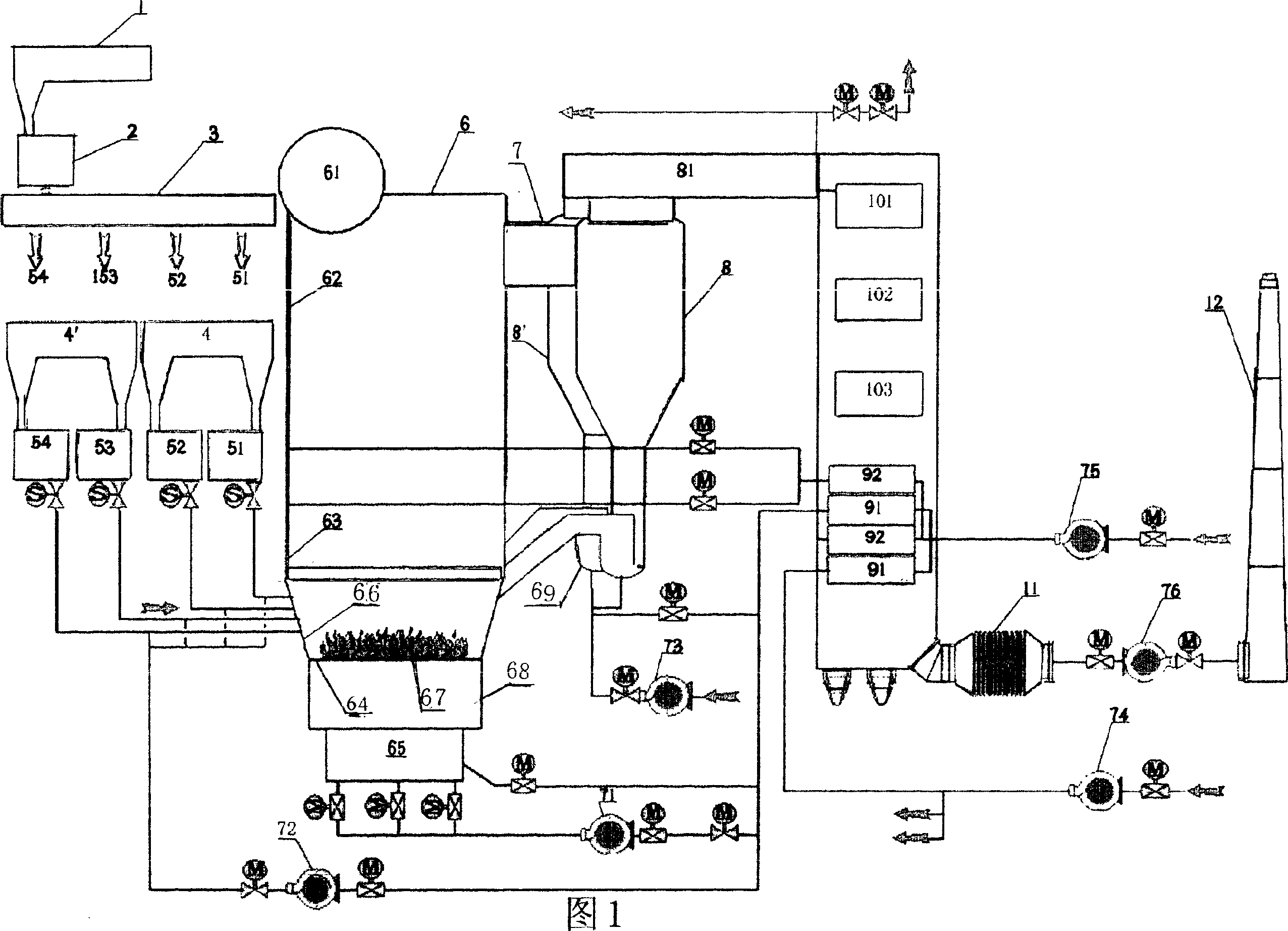

Flue gas desulfurization and denitration system and method

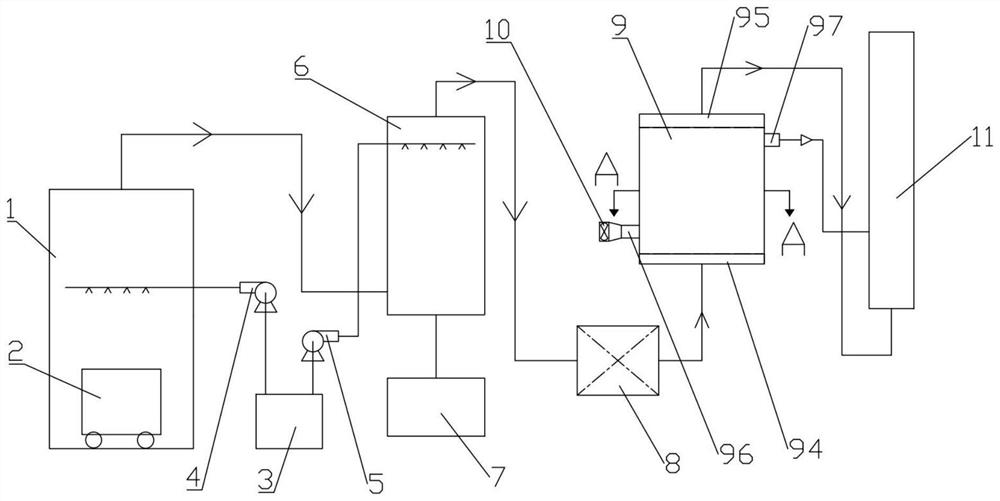

The invention discloses a flue gas desulfurization and denitration system and method, and belongs to the technical field of flue gas processing. The system comprises a pre-deduster, a rotating spray desulfurization and denitration system, an induced draft fan and a chimney, a circulating fluidized bed desulfurization system is arranged between the rotating spray desulfurization and denitration system and the induced draft fan, and a flue gas mixing axial adjustment damper is arranged between the rotating spray desulfurization and denitration system and the circulating fluidized bed desulfurization system; the system further comprises a booster conveying fan, a material conveying pump I and a material conveying pump II. Accordingly, the rotating spray desulfurization and denitration systemand the circulating fluidized bed desulfurization system are combined, step-by-step desulfurization and denitration on flue gas are achieved, and the desulfurization and denitration efficiency is high; due to step-by-step desulfurization and denitration, the system and method can be applied to desulfurization and denitration processing of the flue gas high in sulfur content and nitrate content, and the application range is high.

Owner:NANJING SHIBO ENVIRONMENTAL PROTECTION TECH CO LTD

Flue gas white smoke removal equipment for intelligent production factory of rubber plant

Owner:山东保蓝环保有限公司

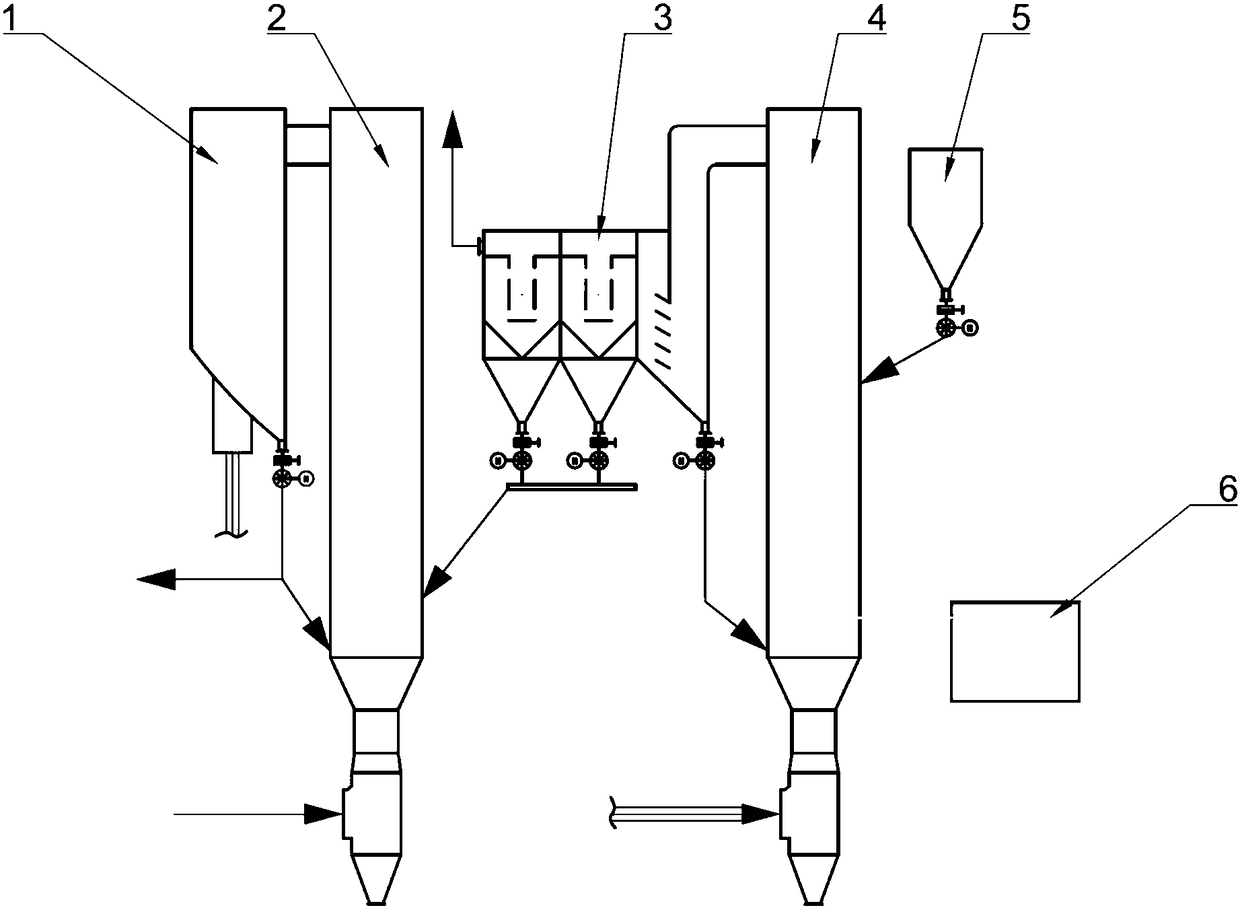

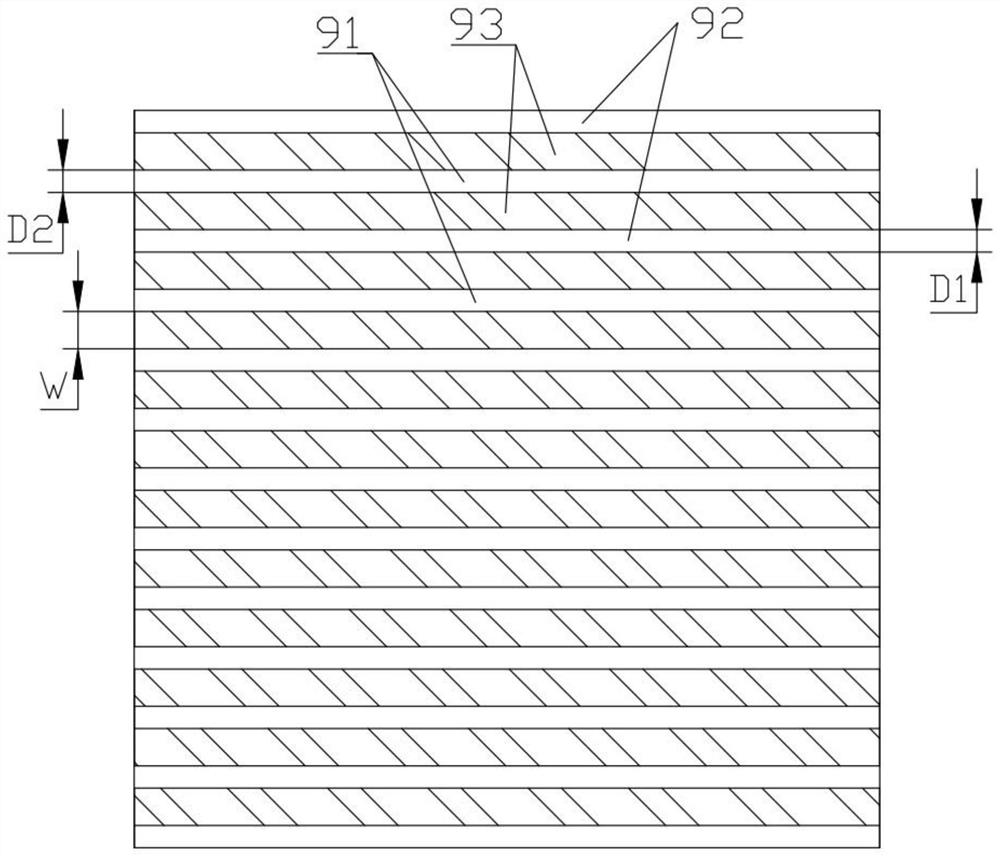

Powdery active coke combined desulfurization and denitration system and method

PendingCN108144443AImprove effective utilizationImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationGas solidBaghouse

Owner:SHANDONG UNIV

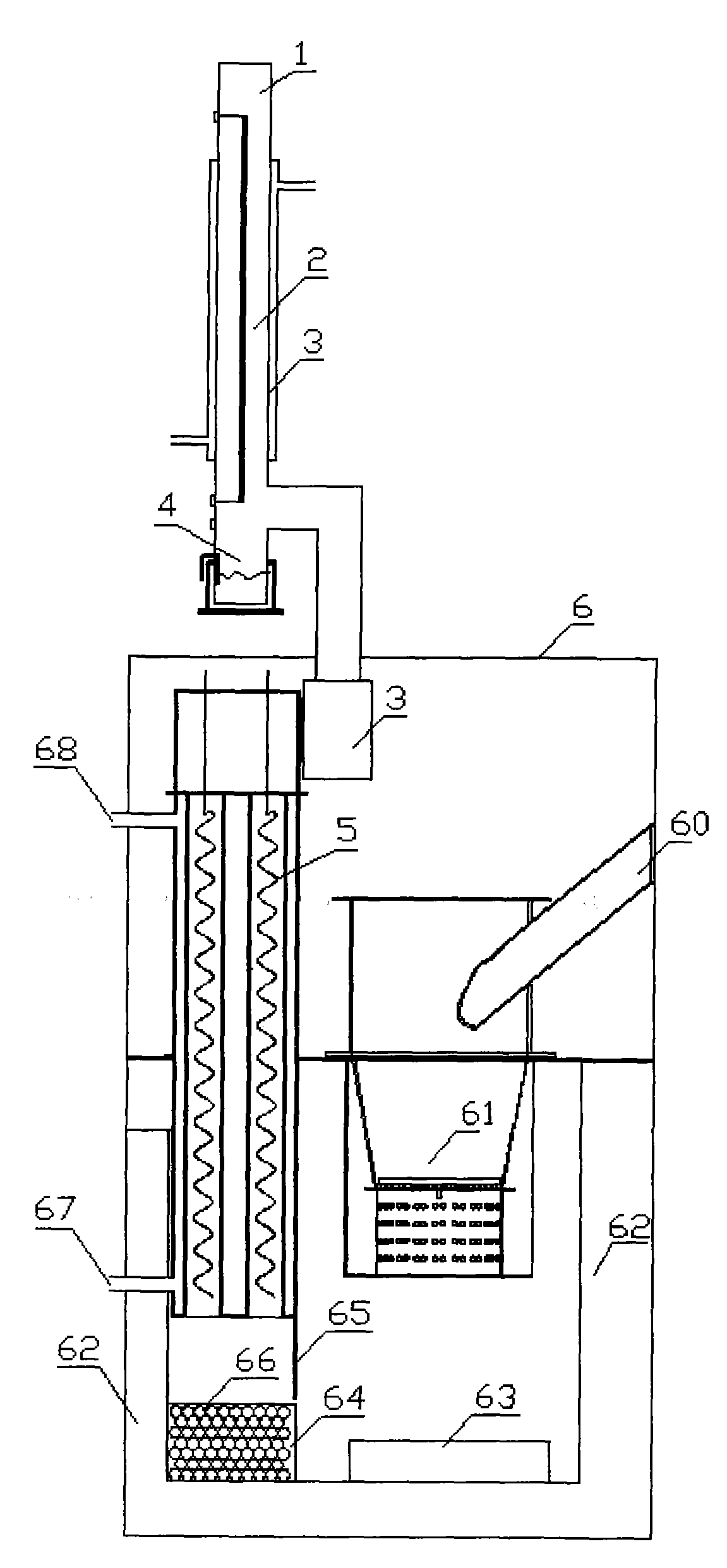

Device and process for purifying and treating tar tail gas and asphalt fume

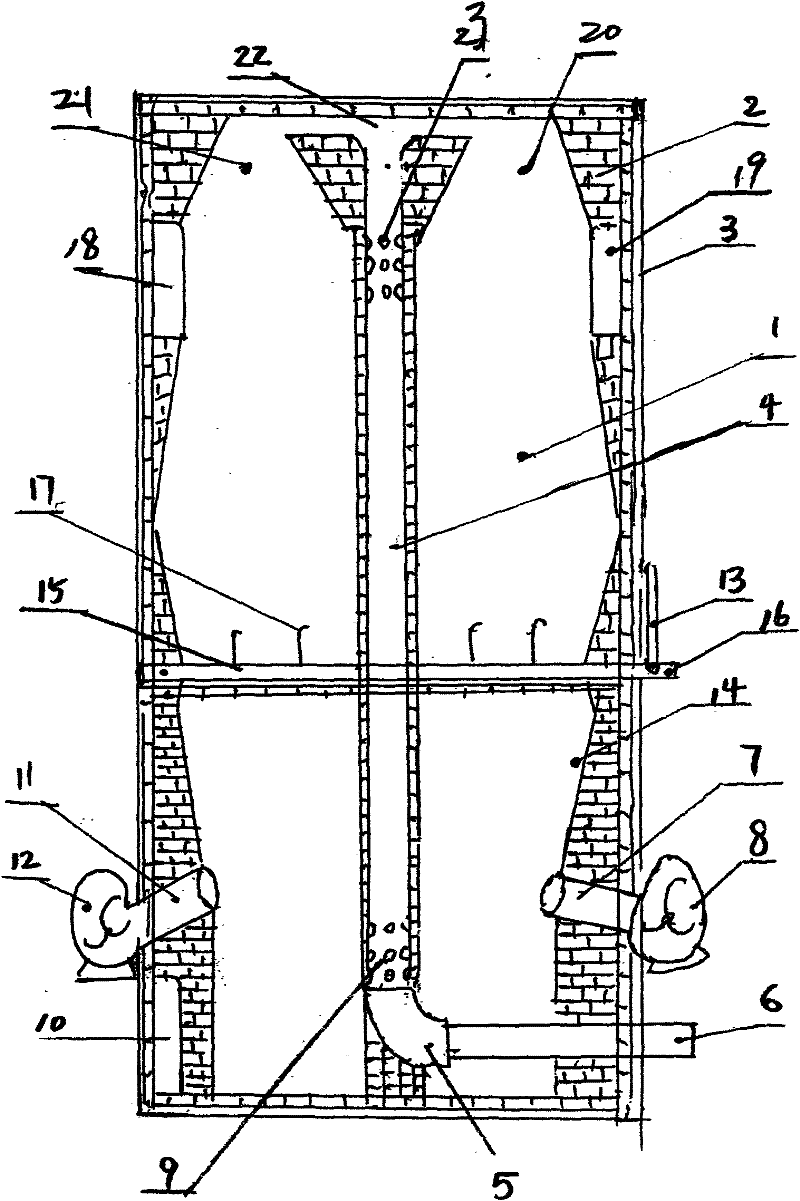

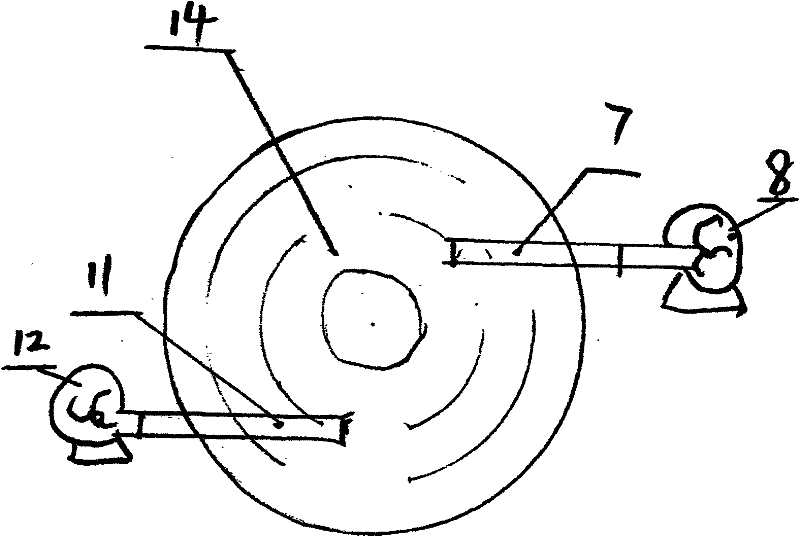

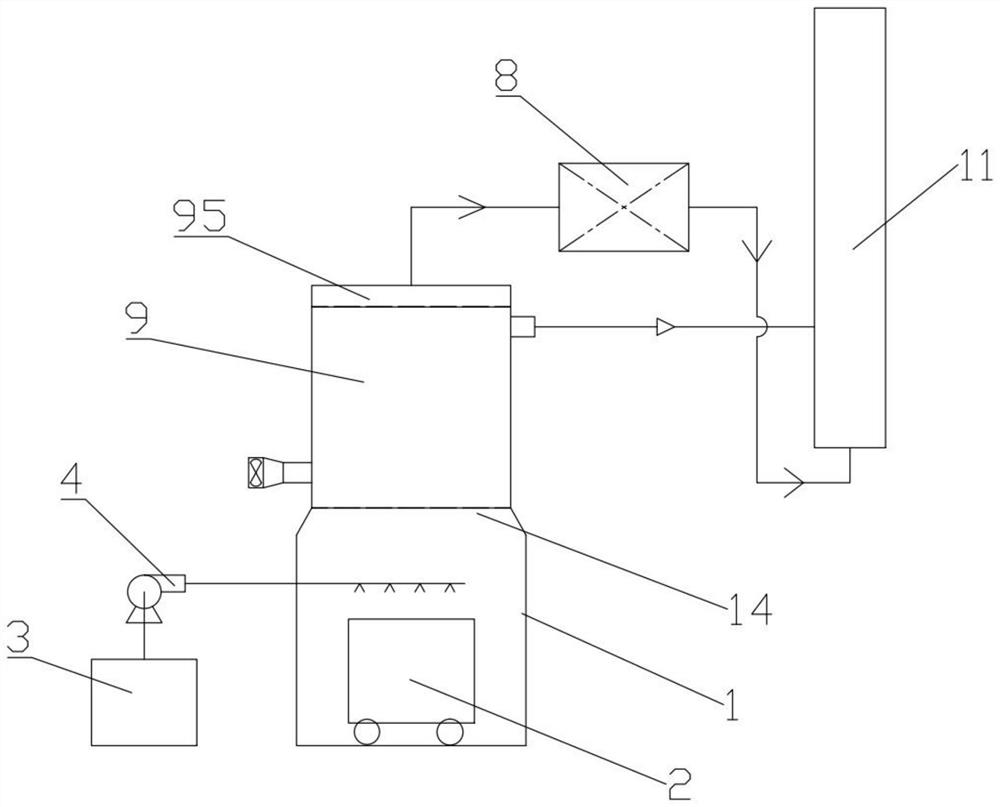

ActiveCN110425550ASolve the problem that it is difficult to purify asphalt fumeImprove thermal efficiencyIncinerator apparatusChimneysCombustion chamberEnvironmental geology

The invention relates to a device and process for purifying and treating tar tail gas and asphalt fume. The device comprises an incinerator and a chimney, wherein the incinerator is composed of a first combustion chamber, a second combustion chamber, a first heat storage chamber and a second heat storage chamber, the first combustion chamber is arranged below the second combustion chamber, and thefirst combustion chamber and the second combustion chamber communicates with each other; the two ends of the first combustion chamber communicates with the top of the first heat storage chamber and the top of the second heat storage chamber respectively, a first combustor is arranged inside the first combustion chamber, a second combustor is arranged inside the second combustion chamber, and a heat accumulator is arranged inside the first heat storage chamber and the second heat storage chamber. By adopting a process combining a heat storage type incinerator and a direct combustion type incinerator, the tar tail gas and the asphalt fume can be purified at the same time, the problem that the heat storage type incinerator is difficult to purify the asphalt fume and the direct combustion type incinerator is low in heat efficiency is solved, meanwhile, waste gas waste heat is recycled, the operation cost of the incinerator is reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

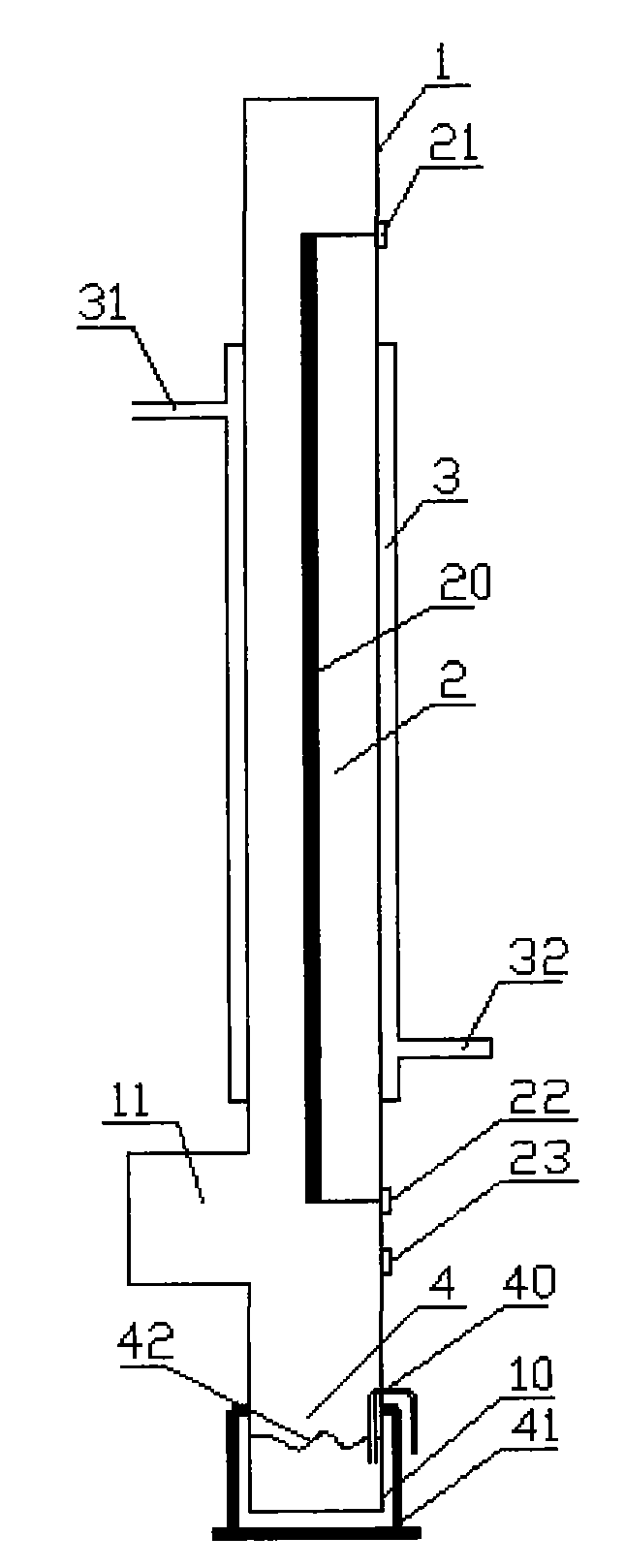

Waste gas neutralization treatment device for thermal power plant

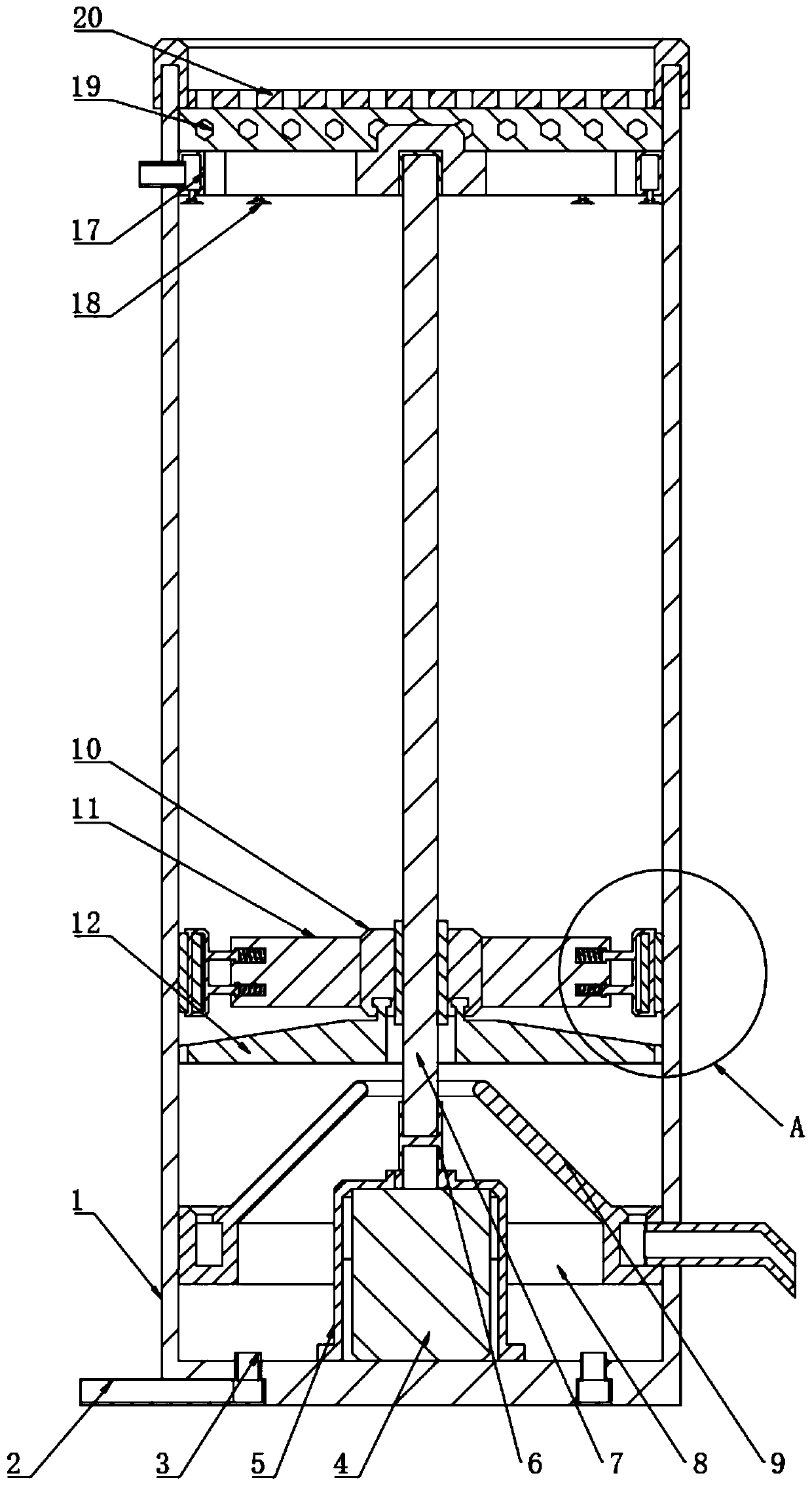

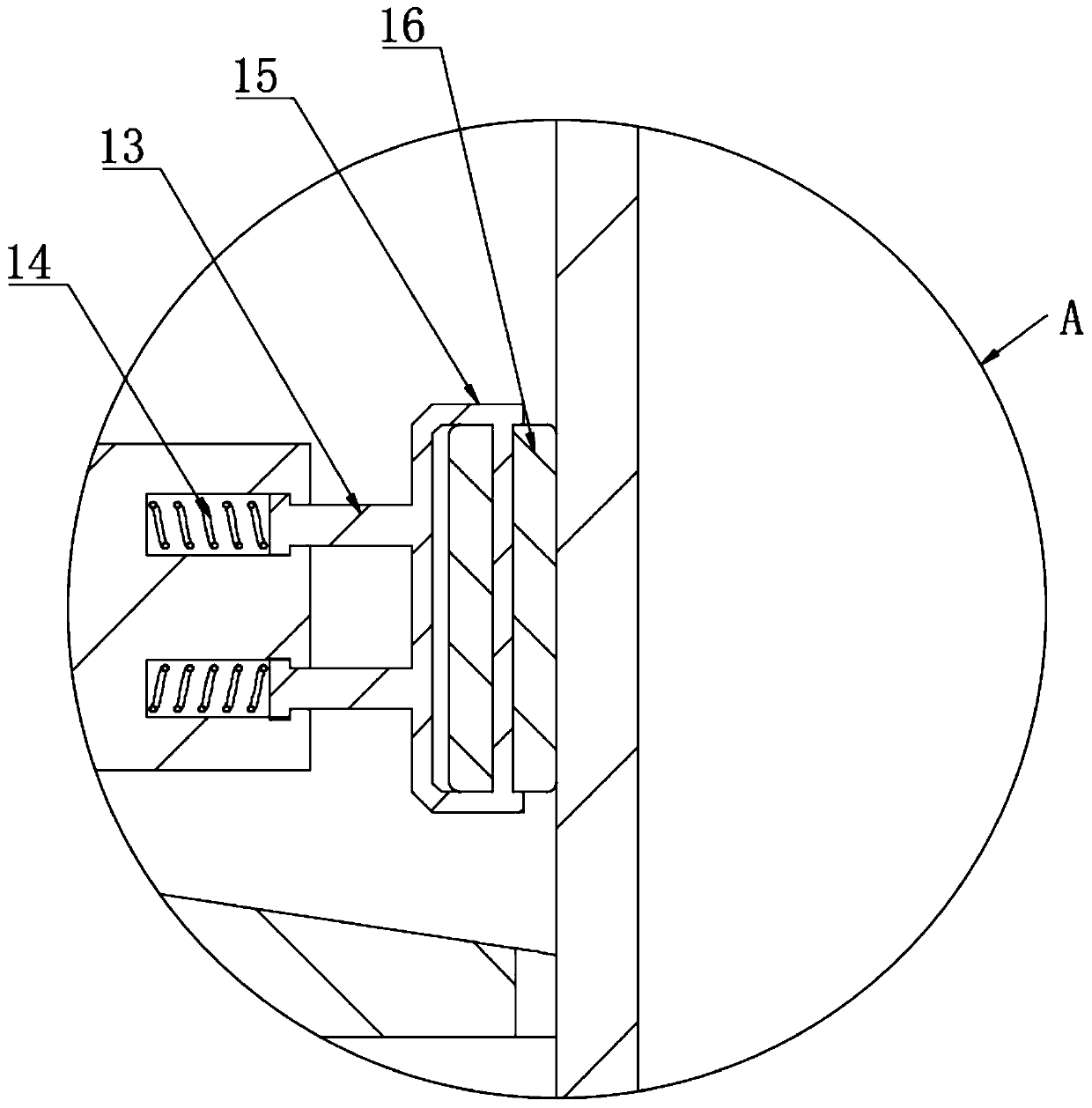

InactiveCN114307598AReduce manufacturing costSave the hassle of steering switchingLighting and heating apparatusHollow article cleaningPower stationEnvironmental engineering

The invention discloses a waste gas neutralization treatment device for a thermal power plant, relates to the technical field of waste gas treatment equipment, and solves the problems that most of existing waste gas treatment equipment needs to be additionally matched with a cleaning assembly for a smoke exhaust mechanism such as a chimney, an original spraying assembly cannot be used for internal cleaning, and the manufacturing cost of the equipment cannot be reduced. The waste gas neutralization treatment device for the thermal power plant comprises a chimney, the chimney is of a circular structure, a settlement cover is welded to the bottom of the chimney, a discharge pipe is welded and communicated to the bottom of the settlement cover, four vertical supporting shafts are symmetrically welded to the bottom of the chimney, and an annular base is welded and fixed to the bottoms of the four vertical supporting shafts; and two electric push rods are symmetrically mounted on the top end sections of the two vertical supporting fulcrum shafts which are in bilateral symmetry in a hanging and supporting mode, and a baffle is locked and fixed to the bottoms of the two electric push rods. The trouble that six vertical water spraying pipes are subjected to steering switching through manual driving operation can be omitted, and use is convenient, labor-saving and rapid.

Owner:杜苏月

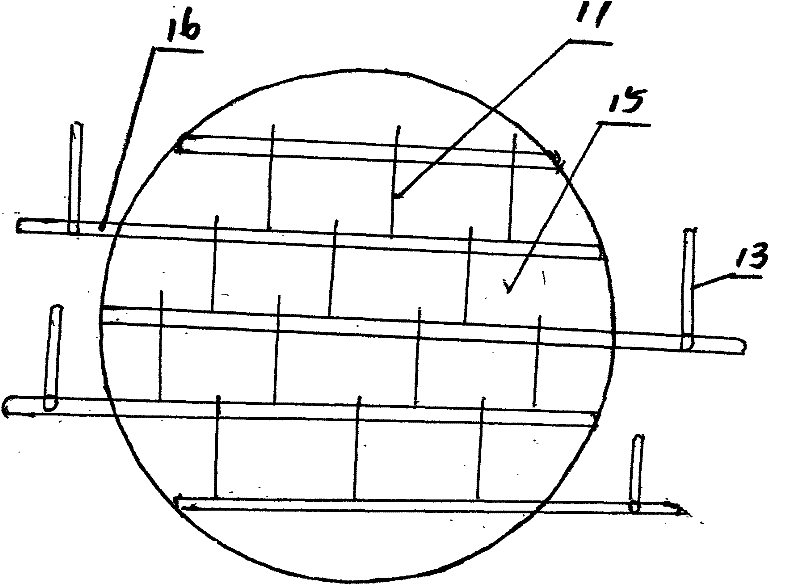

Burning device and process for oil shale fluidized bed

InactiveCN1587803AUniform air distributionStable bed pressureFluidized bed combustionCement productionAir volumeOil shale gas

Owner:广东亨达利水泥厂有限公司

High-power LED mining lamp

InactiveCN105180118AImprove cooling effectImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

The invention provides a high-power LED mining lamp. The high-power LED mining lamp comprises an LED light source, a uniform temperature board and a heat sink, wherein the LED light source is attached to the bottom face of the uniform temperature board; the heat sink is attached to the top face of the uniform temperature board; a chimney is arranged on the heat sink. The high-power LED mining lamp has the beneficial effect that the heat dissipation capacity of the heat sink and the heat dissipation efficiency can be greatly improved through the chimney.

Owner:SHENZHEN BANQ TECHNOLOGY CO LTD

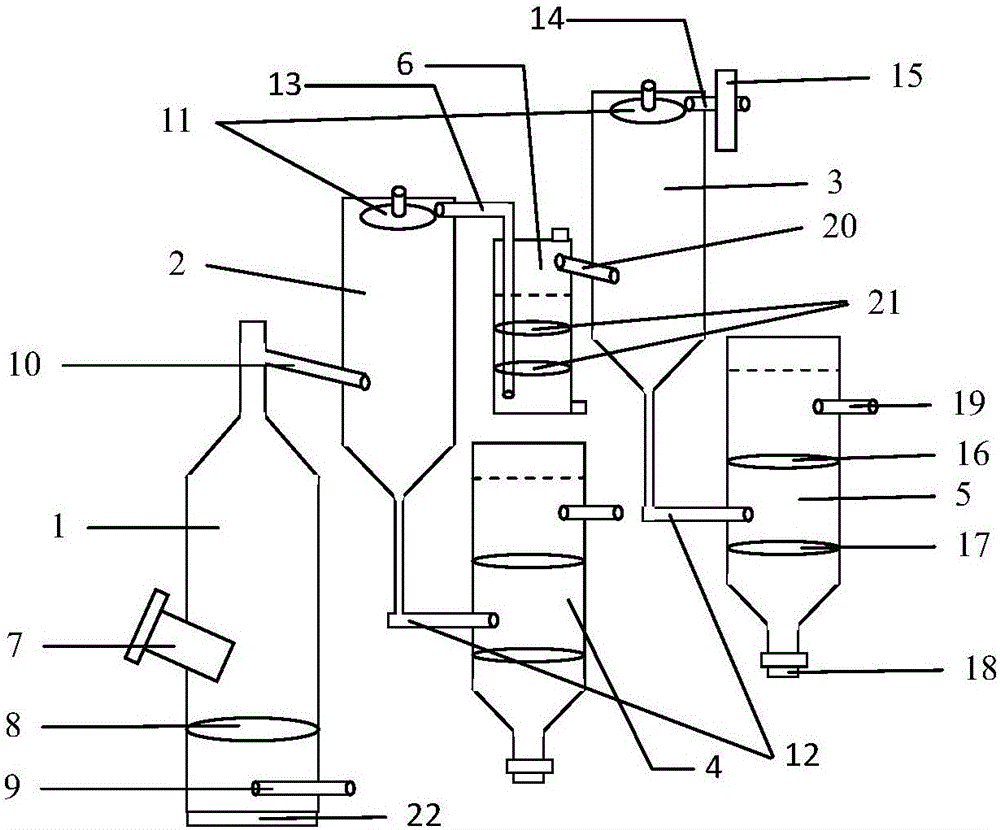

Device and method for carrying out low-concentration SO2 smoke desulfurization through alkaline waste liquid

The invention discloses a device and method for carrying out low-concentration SO2 smoke desulfurization through alkaline waste liquid. The device mainly comprises a SO2 smoke absorption tower, an electric mist precipitator, an active ore pulp buffer tank, an active ore pulp absorption-liquid buffer tank, a waste electrolyte buffer tank, a waste electrolyte circulating trough and a tail smoke discharging chimney. Acid gas SO2 in the smelting smoke is absorbed two times through alkaline ingredients in active ore pulp, and then the acid gas SO2 in the smelting smoke is further absorbed through alkaline ingredients in waste electrolytes; meanwhile, ore dust in the smelting smoke is removed, the two kinds of waste alkali liquid including the active ore pulp and the waste electrolytes are greatly used, the technological process is simple, running is reliable, the desulfurization effect is remarkable, investment is low, the floor area is small, operation is easy, desulfurization of the huge amount of low-concentration SO2 smoke can be completed only through low cost, the raw material cost of the desulfurization process is reduced, new waste can not be generated, and the aims that through treatment, environment-friendly collected SO2 meets the standard and economy reaches the standard are achieved in the mode that waste is controlled through waste.

Owner:金川集团镍钴有限公司

Combustion furnace

InactiveCN106765254AThe production of purificationEliminate hazardsCombination devicesLighting and heating apparatusSludgeSmoke Emission

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Removing device and removing method for particulate pollutants generated by combustion of biomass fuel

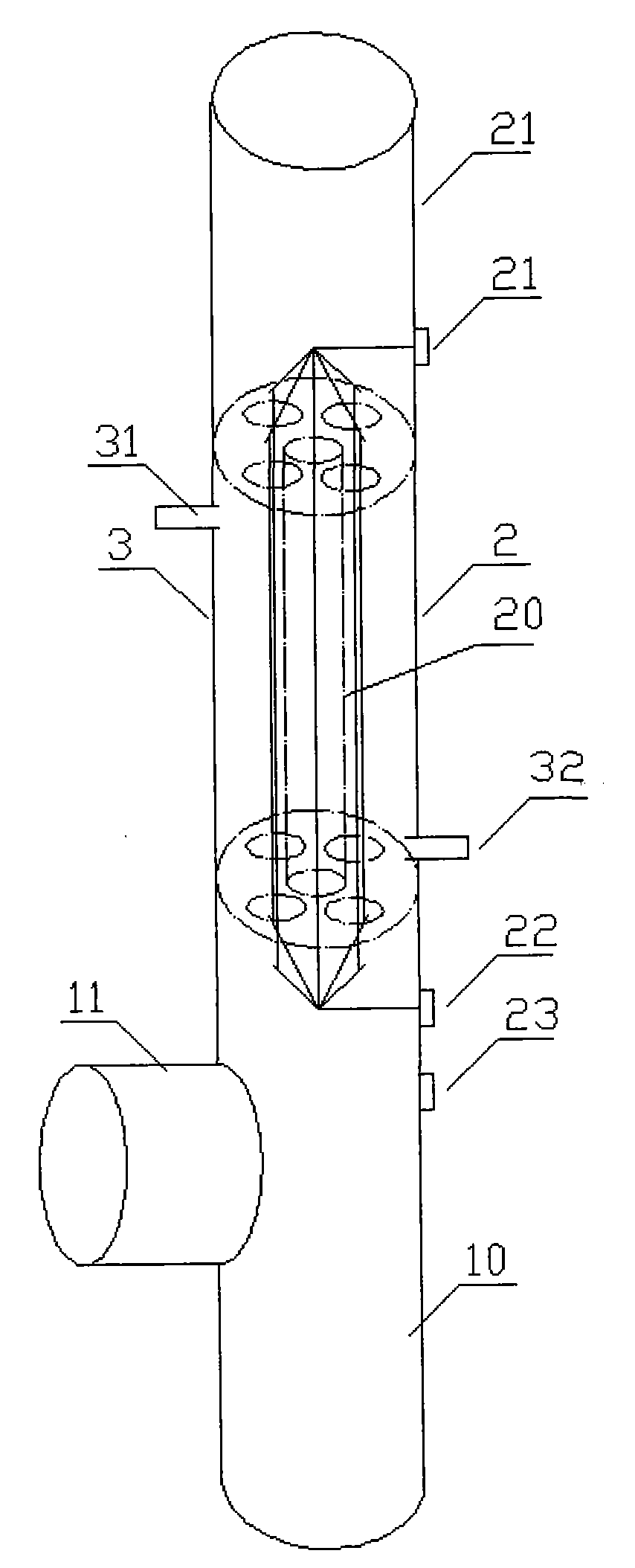

ActiveCN103912889ALighting and heating apparatusDispersed particle separationParticulatesCombustion chamber

Owner:SHANDONG JIANZHU UNIV

Coke quenching tower flue gas treatment system and treatment method

PendingCN112552936AReduce heatReduce humidityCoke quenchingHeat storage plantsPlate heat exchangerFlue gas

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap