Removing device and removing method for particulate pollutants generated by combustion of biomass fuel

A biomass fuel and pollutant technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve complex problems such as water inflow and outflow, and achieve the effects of reducing exhaust gas temperature and reducing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings:

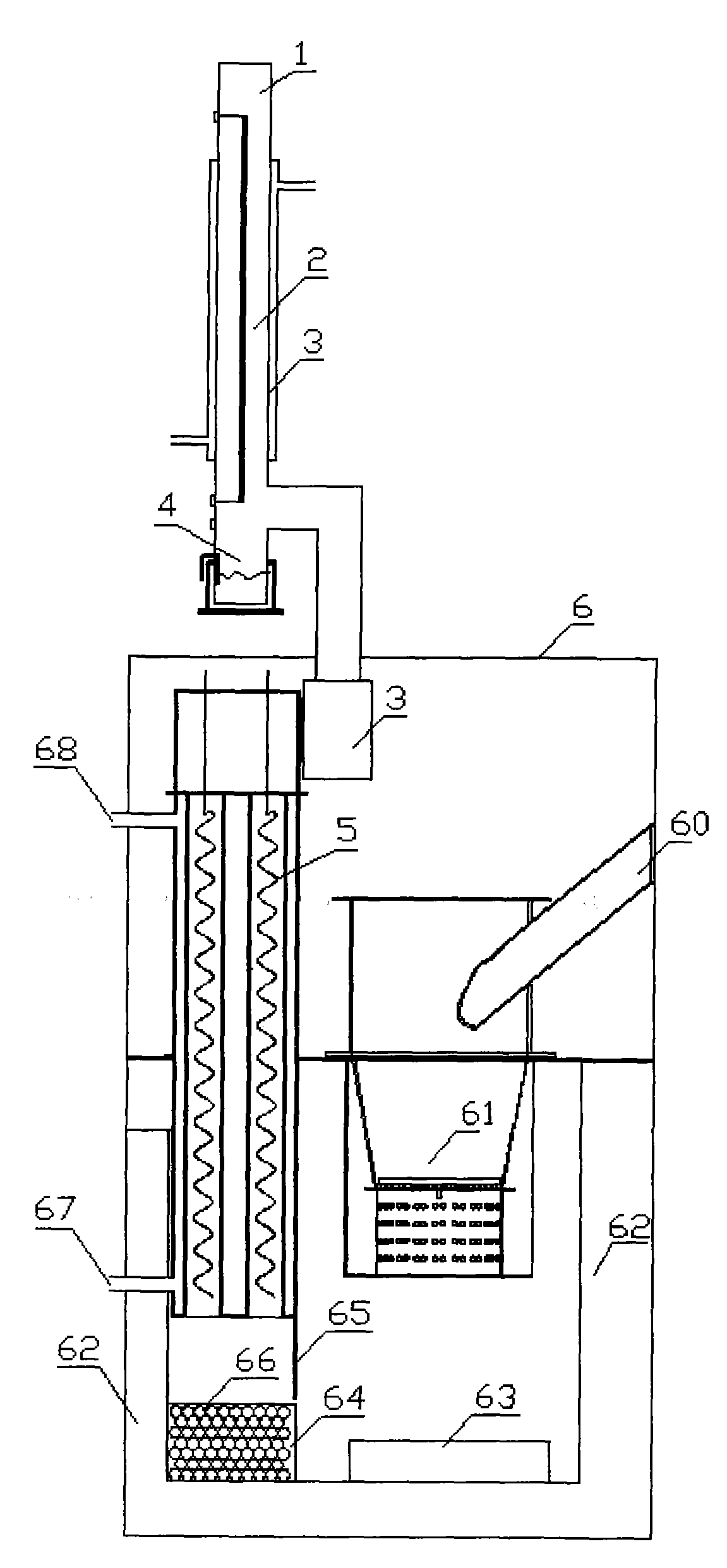

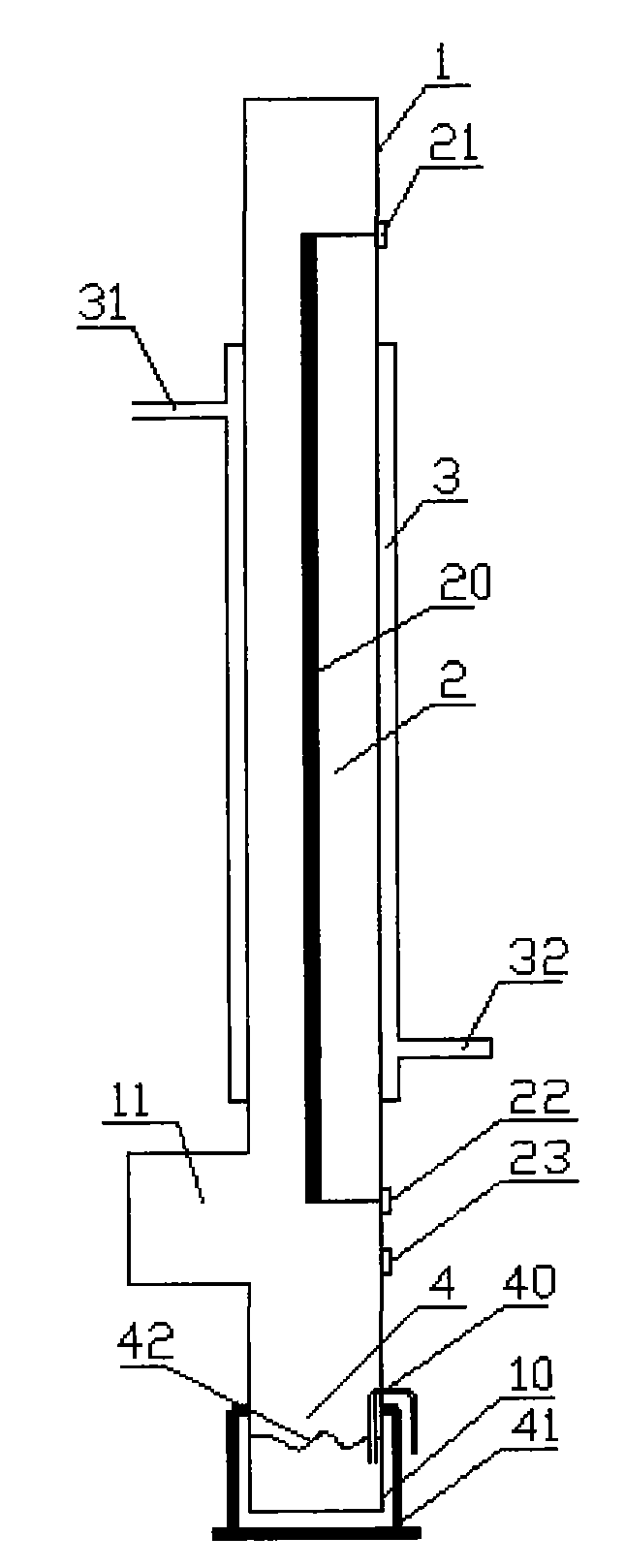

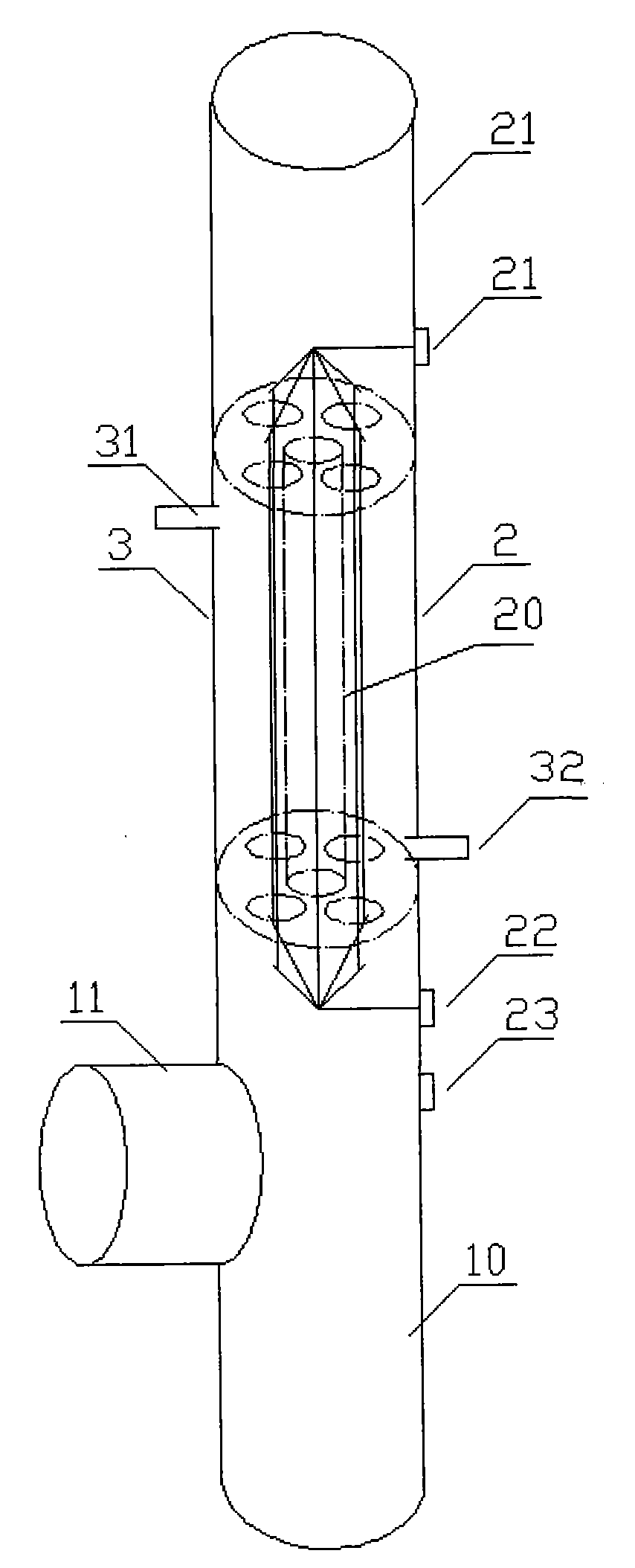

[0032] like Figure 1 to Figure 4 Shown: a biomass fuel combustion particle pollutant removal device according to the present invention includes a chimney 1, a wet electrostatic precipitator 2, a flue gas condenser 3, a wet ash cleaning device 4, a spiral ash cleaning device 5, a combustion The chamber 61 and the heating furnace shell 6 are arranged in the chimney 1, the flue gas condenser 3 is sleeved outside the chimney 1, the wet ash cleaning device 4 is arranged at the lower end of the chimney 1, the flue gas condenser 3 and the spiral ash cleaning device 5 are connected. The upper ends are connected, the combustion chamber 61 and the spiral ash cleaning device 5 are both arranged in the heating furnace shell 6 , and the combustion chamber 61 is provided with a feeding port 60 which communicates with the inside and outside of the heating furnace shell 6 .

[0033] li

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap