Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag is the glass-like by-product left over after a desired metal has been separated (i.e., smelted) from its raw ore. Slag is usually a mixture of metal oxides and silicon dioxide. However, slags can contain metal sulfides and elemental metals. While slags are generally used to remove waste in metal smelting, they can also serve other purposes, such as assisting in the temperature control of the smelting, and minimizing any re-oxidation of the final liquid metal product before the molten metal is removed from the furnace and used to make solid metal. In some smelting processes, such as ilmenite smelting to produce titanium dioxide, the slag is the valuable product instead of the metal.

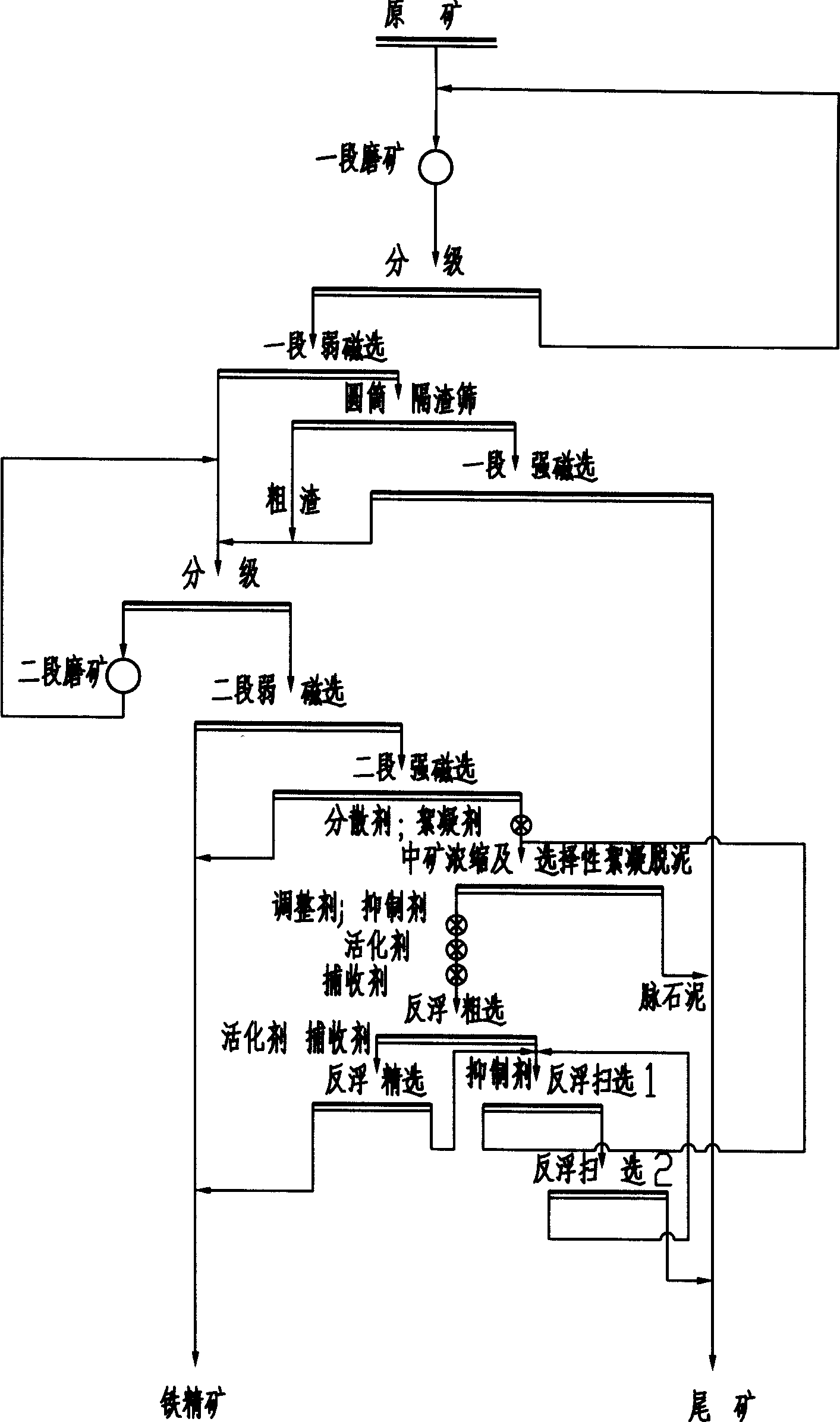

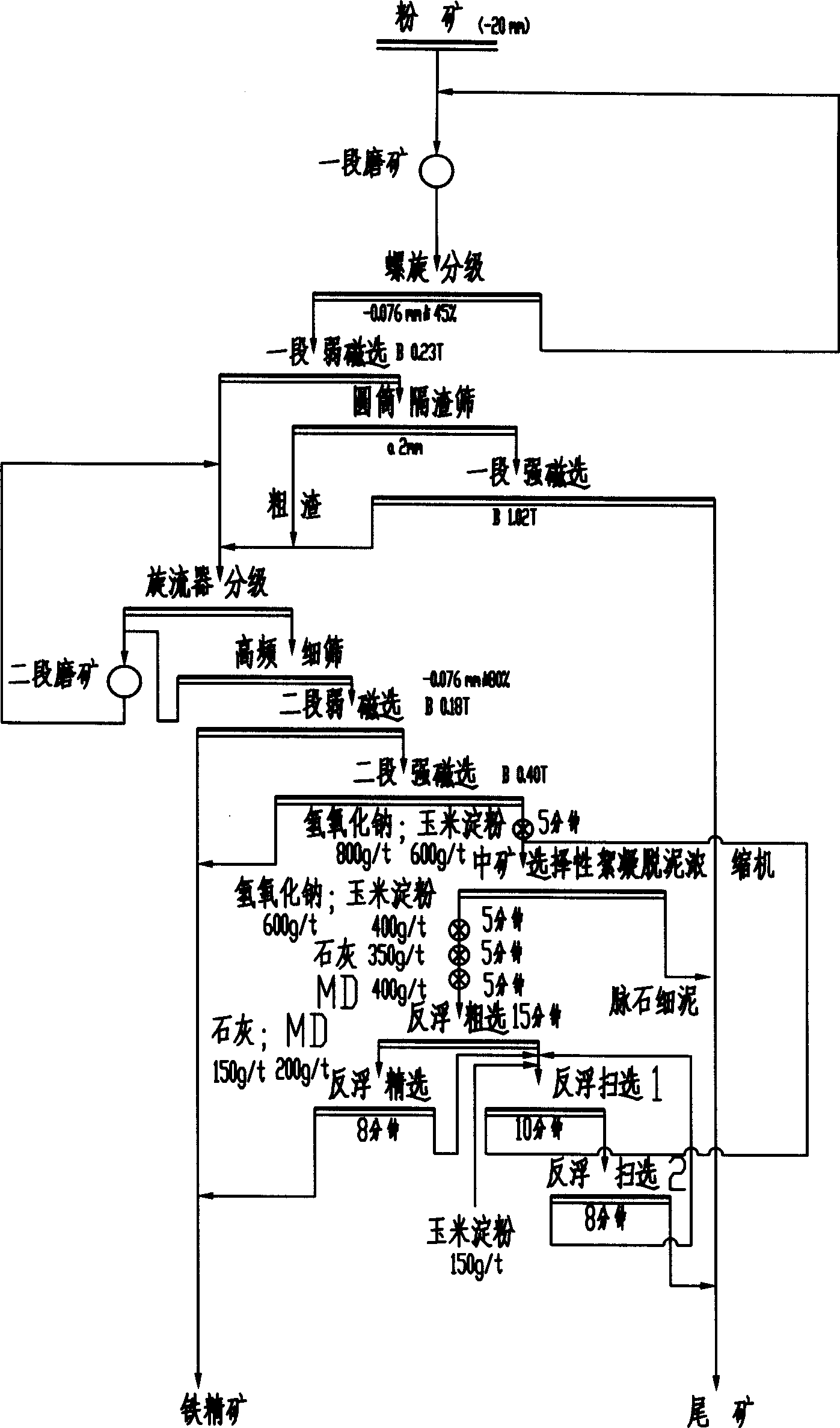

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

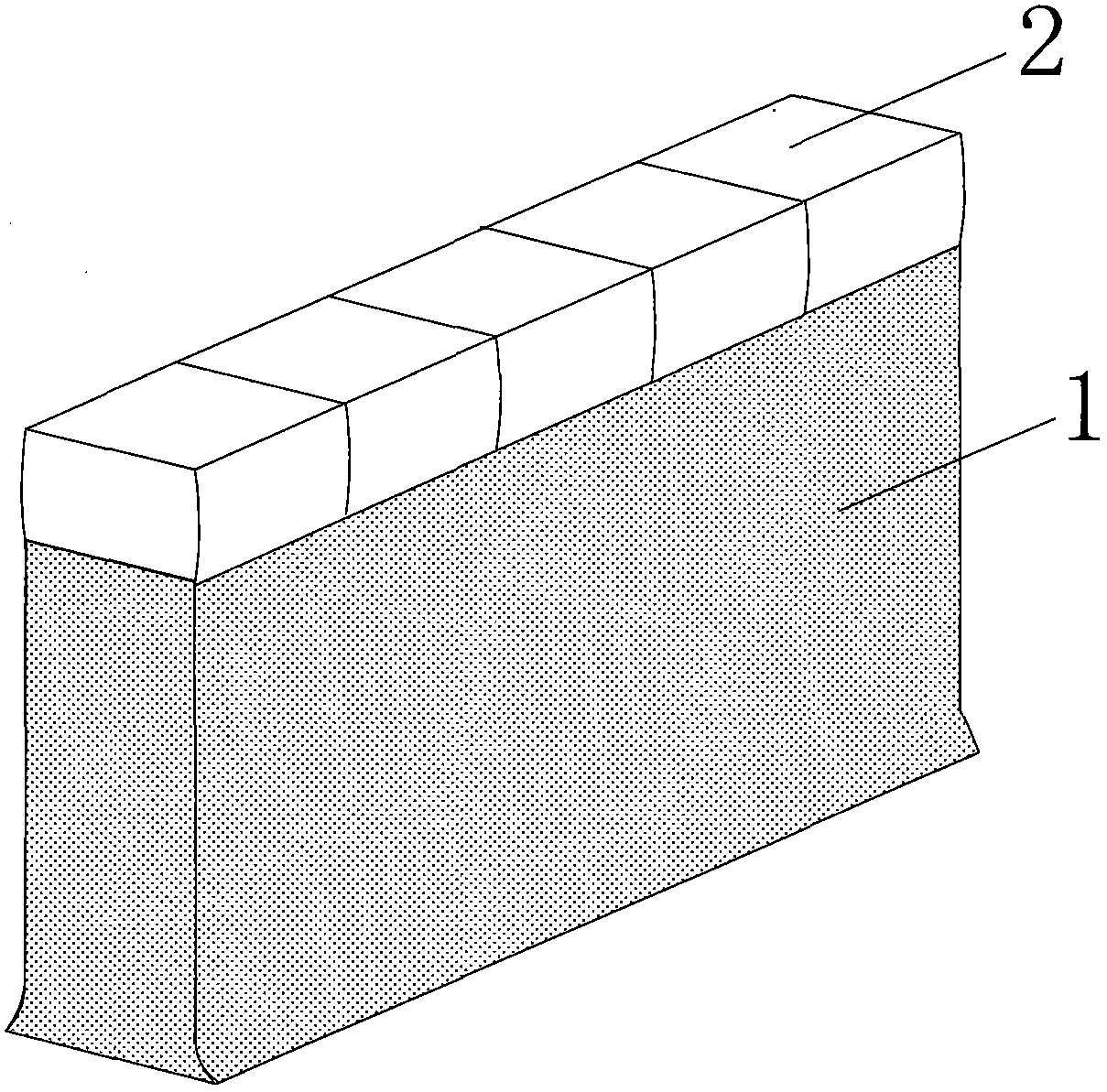

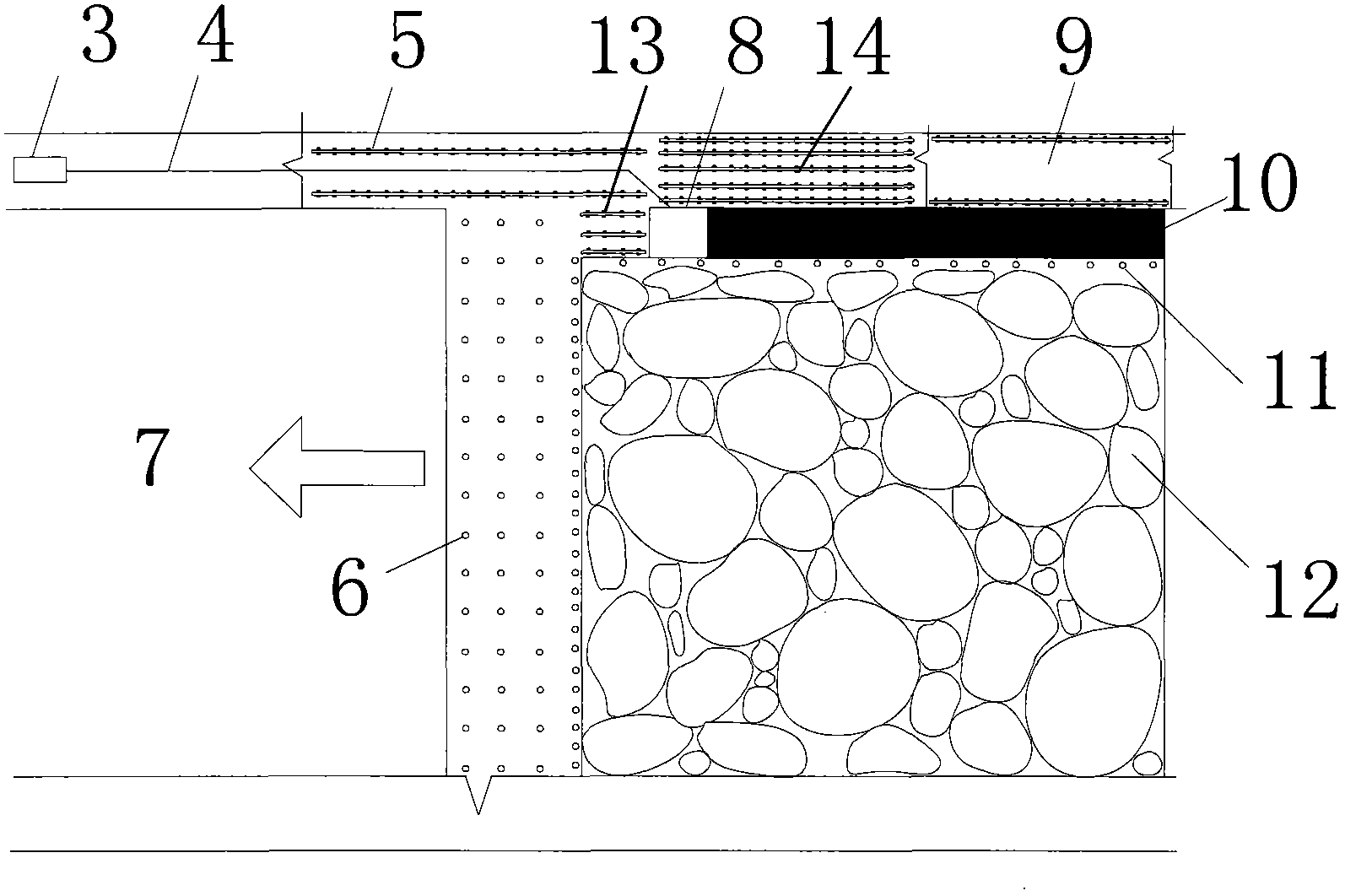

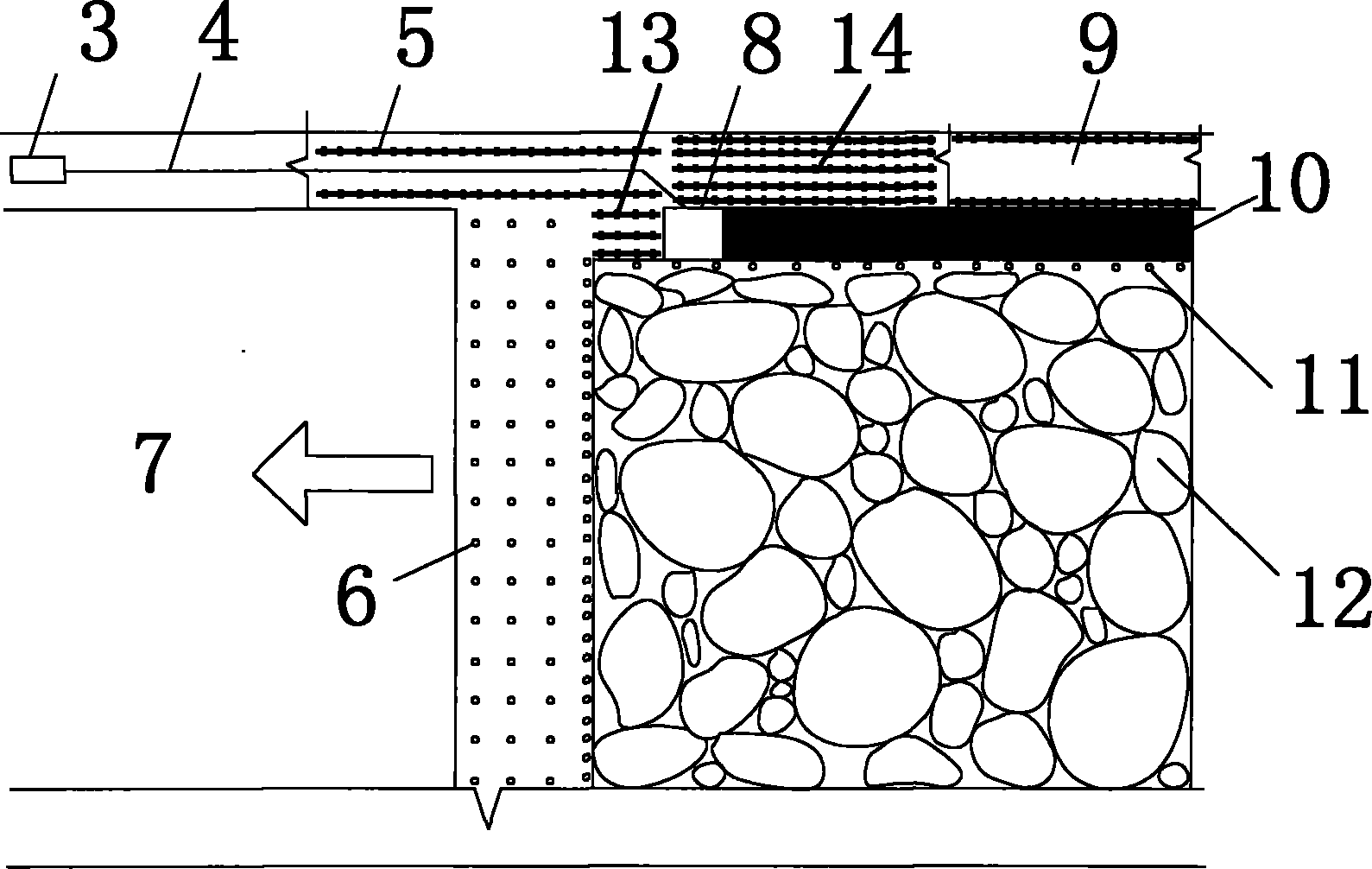

Roadside proper yielding unequal combined filling structure of gob-side entry retaining and construction method

Owner:SHANDONG UNIV OF SCI & TECH

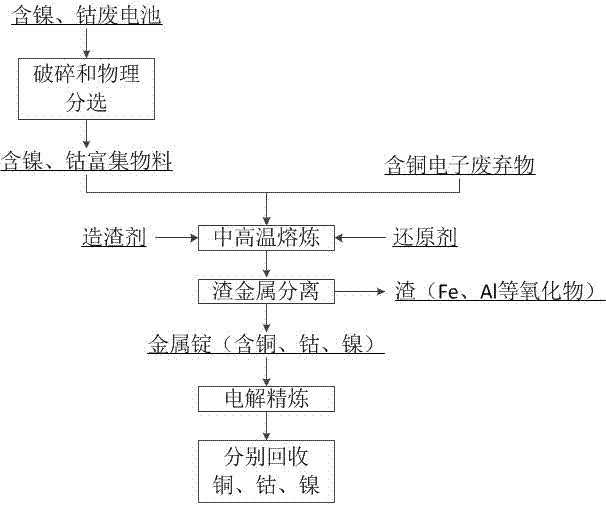

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals

The invention relates to a mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals, and belongs to the fields of mineral process engineering and comprehensive recycling of resources. The mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals comprises the following steps: carrying out low intensity magnetic separation and high intensity magnetic separation pre-concentration by taking bayan obo tailings as raw materials, then carrying out fluid bed roasting on obtained pre-concentrated concentrates, and carrying out low intensity magnetic separation operation on roasted minerals obtained by roasting so as to obtain weak-magnetism concentrates and rare-earth-containing weak-magnetism tailings; and carrying out rare earth flotation operation on the weak-magnetism tailings to obtain rare earth flotation concentrates and rare earth flotation tailings finally, then carrying out acid leaching process on the rare earth flotation tailings to obtain niobium-enriched slag and acid pickling tailings, and meanwhile, carrying out fluorite flotation operation on pre-concentrated strong-magnetism tailings to obtain fluorite flotation concentrates and fluorite flotation tailings. By the method, fluorite concentrates, iron core concentrates, rare earth concentrates and the niobium-enriched slag are obtained finally, and thus, the bayan obo tailings are utilized comprehensively.

Owner:NORTHEASTERN UNIV LIAONING

Dephosphorizing agent and application thereof

The invention relates to a dephosphorizing agent and application thereof, belonging to the technical field of ferrous metallurgy. The dephosphorizing agent solves the problems of low dephosphorizing efficiency, high residue consumption, environment pollution and difficulty in resource comprehensive utilization in the existing calcium-oxide-based molten iron pretreatment dephosphorizing agent. The dephosphorizing agent comprises the following components in percentage by mass: 25-50% of FeOt, 20-45% of CaO, 15-30% of SiO2, 2-10% of Na2O and 3-12% of Al2O3. After being molten, the molten iron dephosphorizing can form a solid-phase / liquid-phase coexistent multiphase residue system at 1300-1400 DEG C, wherein the solid phase is a 2CaO.SiO2 phase capable of providing a place for enriching oxidized phosphorus in molten iron, so that the dephosphorizing agent has the characteristics of favorable dephosphorizing effect, low slag consumption, no fluorine and small environmental pollution and is beneficial to comprehensive utilization of dephosphorizing slag.

Owner:CENT SOUTH UNIV

Nickel slag processing method for efficiently recovering iron resource

InactiveCN104988302APromote resource reuseSafe and easy to recycleProcess efficiency improvementSlagMagnetic separation

The invention provides a nickel slag processing method for efficiently recovering an iron resource. The method includes the steps that nickel slag is fused, the temperature is kept, a modification agent is added, heat preservation is carried out, and modified nickel slag with the alkalinity ranging from 1.0 to 1.4 is obtained after complete reacting is made; air or oxygen is blown from the bottom or from the top below the liquid face, weak oxidation treatment is carried out on the modified nickel slag, and oxidized nickel slag is obtained; after the temperature of the oxidized nickel slag falls to 1200 DEG C with the temperature fall rate smaller than or equal to 5 DEG C / min, water quenching cooling is carried out, and solidified nickel slag is obtained after complete solidification; the solidified nickel slag is crushed and ground until the particle size is smaller than 200 meshes; and magnetic separation is carried out on slag obtained after cracker grinding, magnetic materials are recovered, and nickel slag processing is completed. By means of the processing method, the iron resource can be recovered from the nickel slag, harmful elements in the nickel slag cannot be brought into iron-rich phases, and an iron ore concentrate can be completed replaced in use. Low-energy-consumption, low-cost and safe and easy processing recovery of the iron resource is achieved, and the method is of great significance in promoting nickel slag resource recycling, enterprise energy saving and emission reduction and environmental protection.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Artificial soil conditioner for slope

InactiveCN1766035AImprove physical and chemical propertiesPromote repairBuilding constructionsOrganic fertilisersSlagHumic acid

The invention provides a preparation method for artificial soil conditioner on slope, which comprises: alga slag, earthworm cast, valonia extract, humic acid and plant ash. This product is convenient to apply with small quantity, low cost, and strong pertinency, and has notable effect to improve earth properties.

Owner:SICHUAN UNIV

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Dry-mixed pre-mixed mortar prepared by alkali activated slag cement, and preparation method thereof

Owner:JIANGSU NIGAO SCI & TECH +1

Cold burden laying method and casting starting technology of sizing nozzle open type continuous casting billets

Owner:玉溪新兴钢铁有限公司

Roasting-leaching method of fine vanadium slags

Owner:CHINA ENFI ENGINEERING CORPORATION

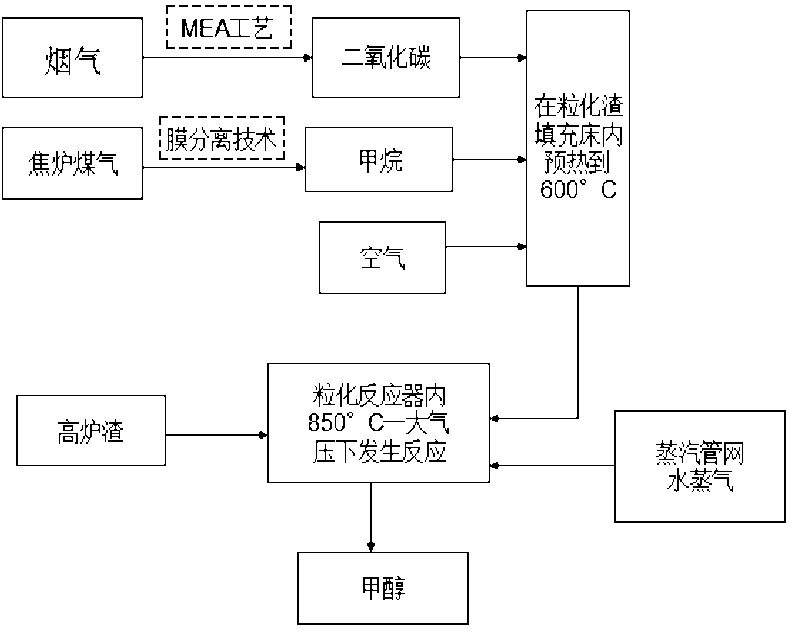

Method for preparing methanol by sensible heat of blast furnace slag

InactiveCN103304372AAlleviate or even eliminate the problem of carbon depositionEmission reductionPreparation by oxidation reactionsChemical industrySlagEnergy recovery

Owner:NORTHEASTERN UNIV

Full-position high-toughness self-protection flux-cored welding wire

Owner:HEBEI YICHEN INDAL GROUP

Degradable filter material biogas slurry filter and filtering method thereof

Owner:成都中农能源环境工程设计所有限责任公司

Preparation method of oryzenin antioxidant peptide

InactiveCN101748182AOptimize composition ratioHigh in proteinFermentationAlkaline proteaseProteinase activity

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Basic metal nitrate, process for producing the same and gas generating agent composition

InactiveUS20070119530A1Enhanced interactionDecrease in decomposition temperatureNitrogen-metal/silicon/boron binary compoundsExplosivesGuanidine derivativesSlag

Owner:ZHOU XINGXI +5

Silicon-calcium-barium-magnesium desoxidant for steelmaking and/or electroslag

The invention relates to a silicon-calcium-barium-magnesium desoxidant for steelmaking and / or electroslag. The desoxidant is composed of the following chemical components in mass percent: 20-50% of Si, 10-40% of Ca, 5-20% of Ba, 2-10% of Mg, 0-10% of RE, not larger than 0.030% of P, not larger than 0.040% of S, 0-2% of C and the balance of Fe. The preparation method comprises the following steps: firstly smelting iron and silicon in a melting furnace to an intermediate alloy, adding barium, calcium, magnesium and / or rare earth, melting and casting to an alloy block, and controlling the specific gravity of the silicon-calcium-barium-magnesium desoxidant to 3-5 g / cm<3>. When in use, the silicon-calcium-barium-magnesium desoxidant is directly thrown into a steel furnace and / or an electroslag remelting crystallizer slag bath, the specific gravity of the desoxidant is increased, the vapor pressure is reduced, the desoxidant is deposited at a slag-steel interface to generate a CaO-BaO-SiO2 type impurity, and the CaO-BaO-SiO2 type impurity is larger in granule, lower in melting point, easy to be captured by the slag and easy to float to be removed, so that the cleanness of molten steel is improved.

Owner:ZHONGYUAN SPECIAL STEEL

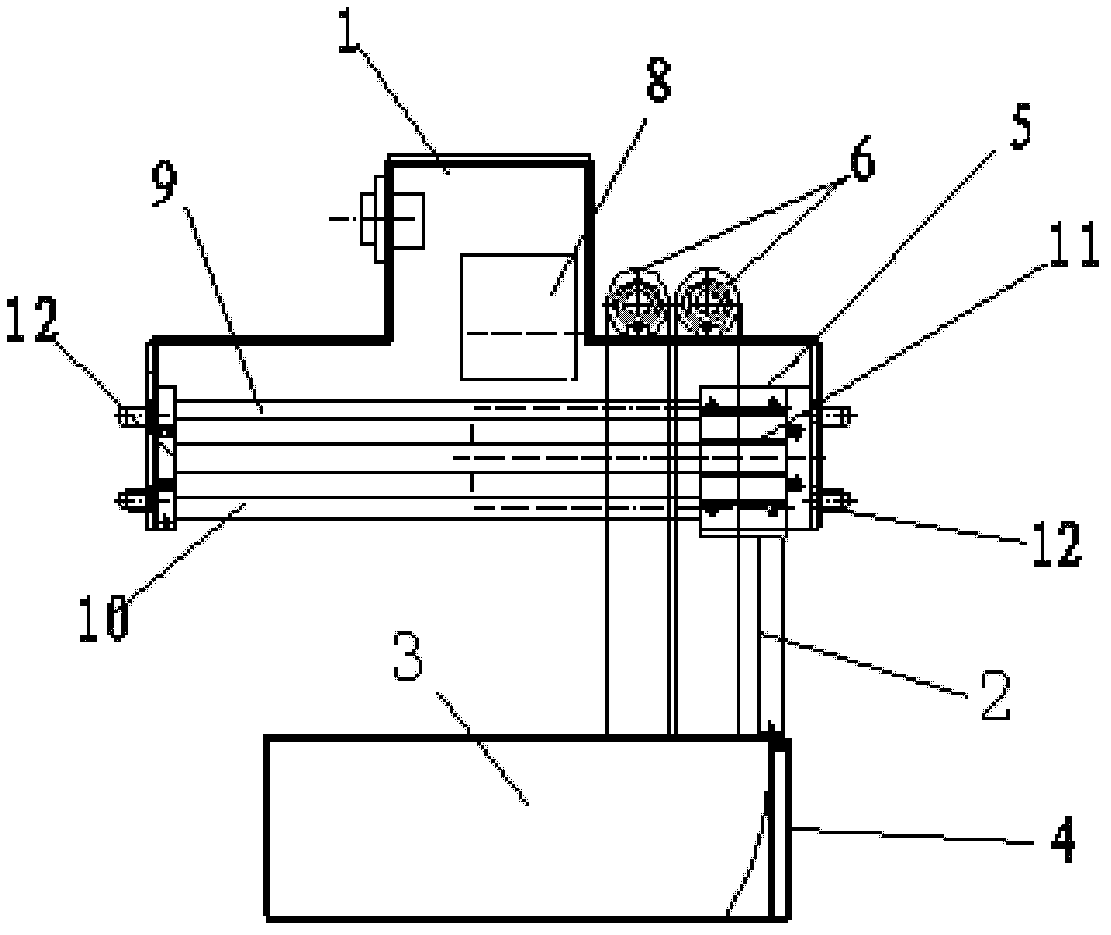

Transmission of manipulator for dredging slag from liquid zinc of zinc pot

InactiveCN102528012AExpand the scope of slag removalContinuous slag unloadingHot-dipping/immersion processesCharge manipulationSlagEngineering

Owner:WUHAN IRON & STEEL (GROUP) CORP

Production method of welding rod steel H08A

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

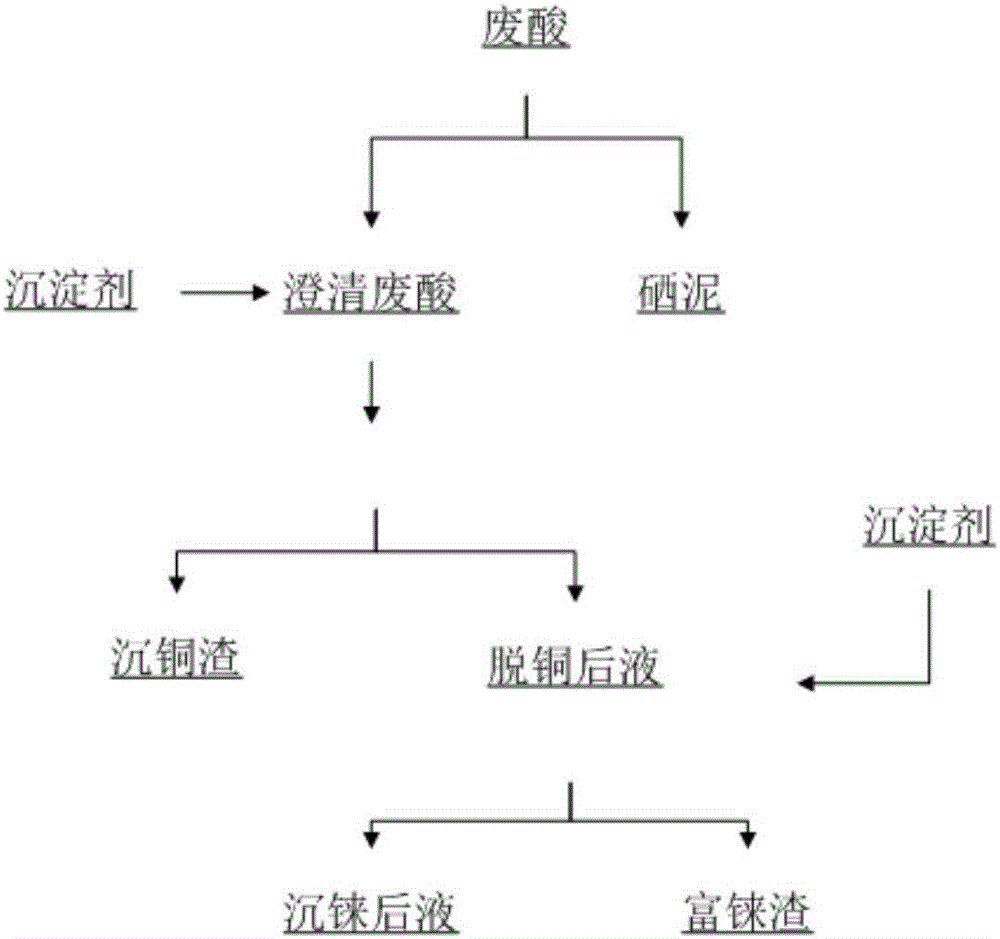

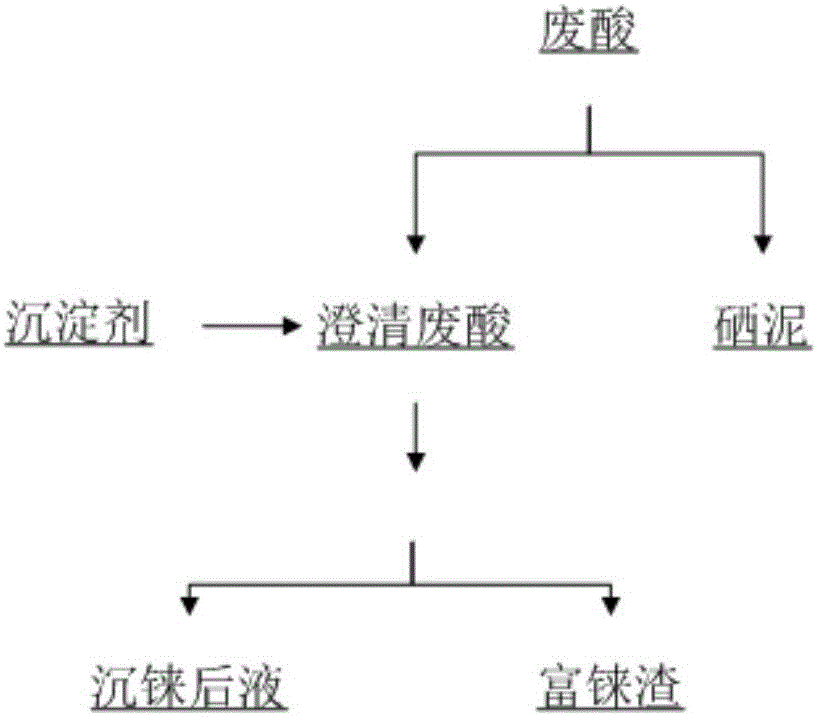

Method for recycling rhenium from copper smelting smoke washing waste acid

Owner:YANGGU XIANGGUANG COPPER

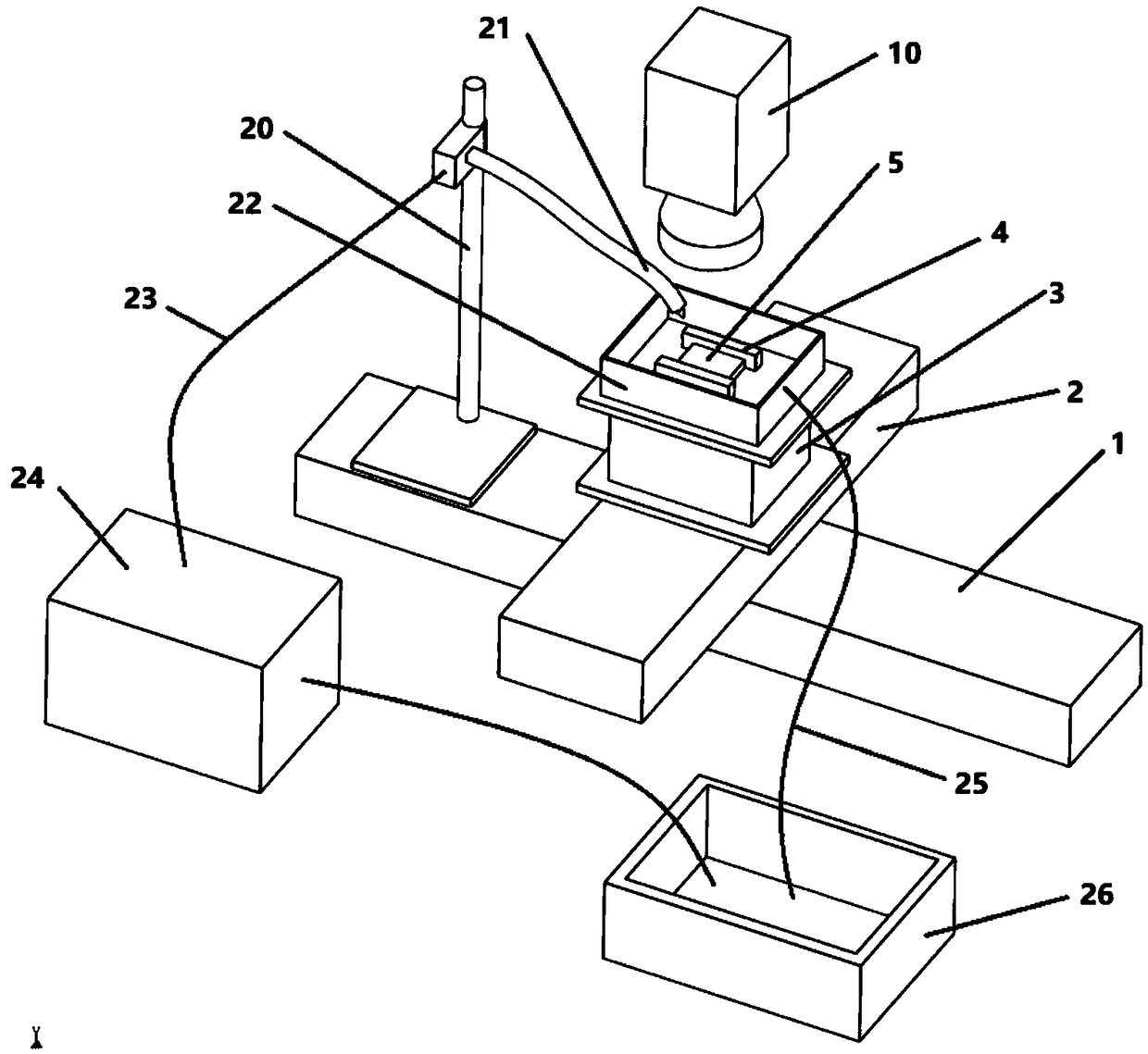

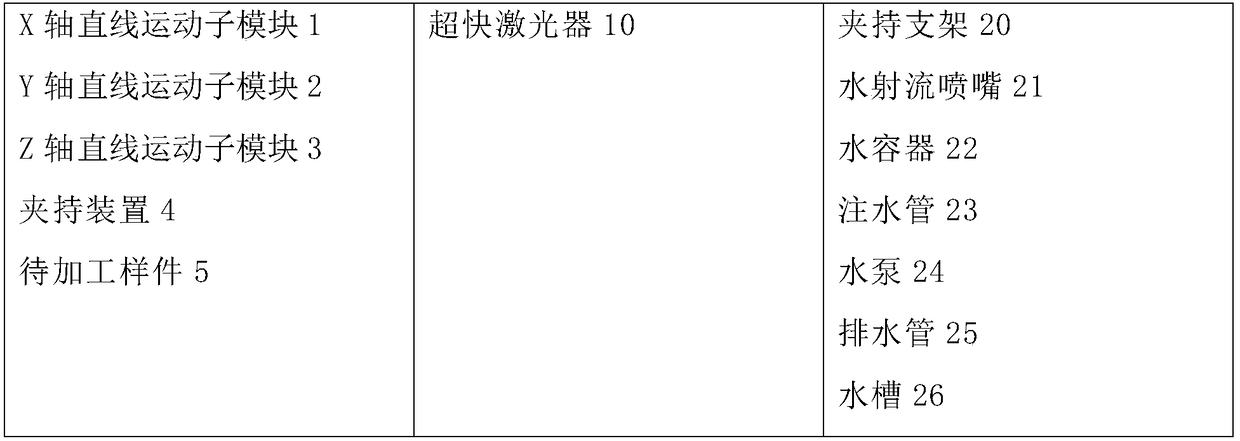

Device and method for conducting superfast laser machining of air film hole in water jet environment

Owner:SHANGHAI JIAO TONG UNIV

Microwave enhancement of the segregation roast

Owner:CATO RES CORP

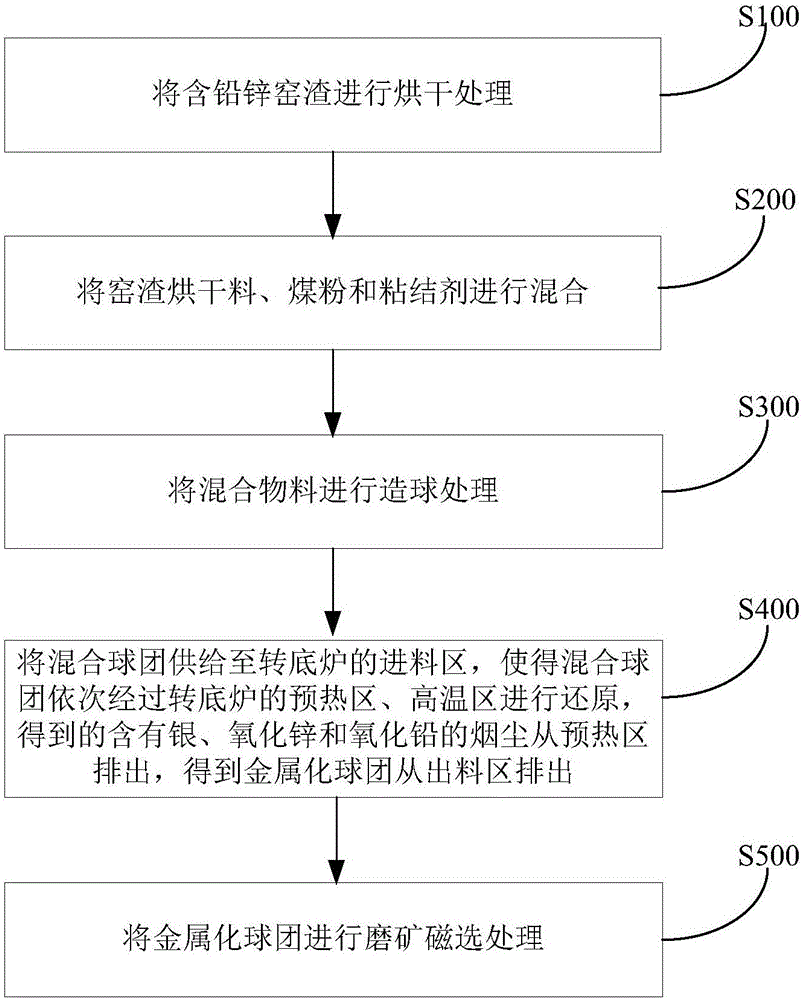

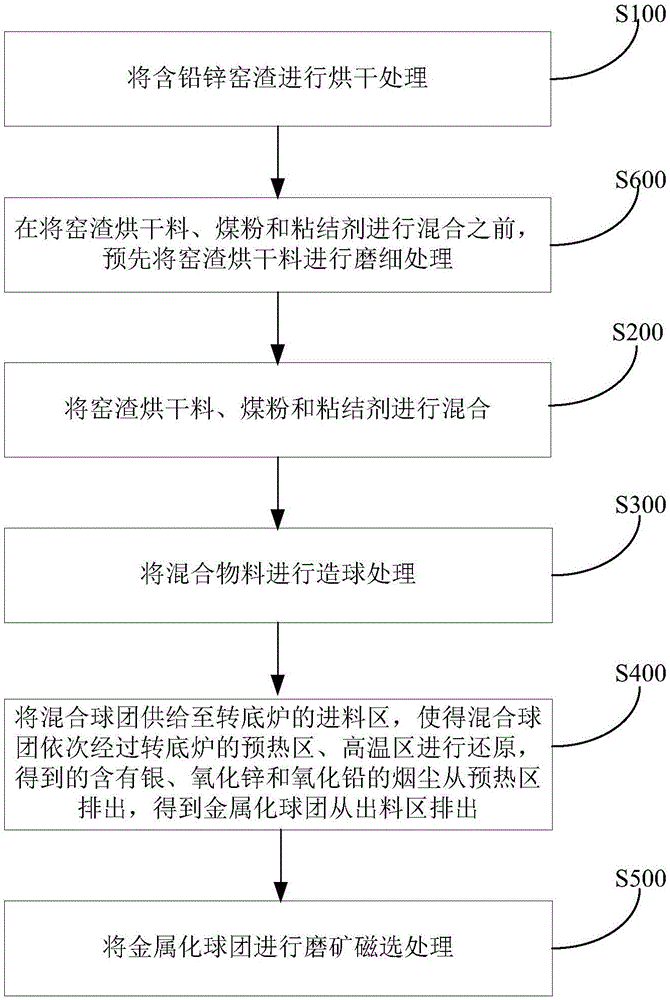

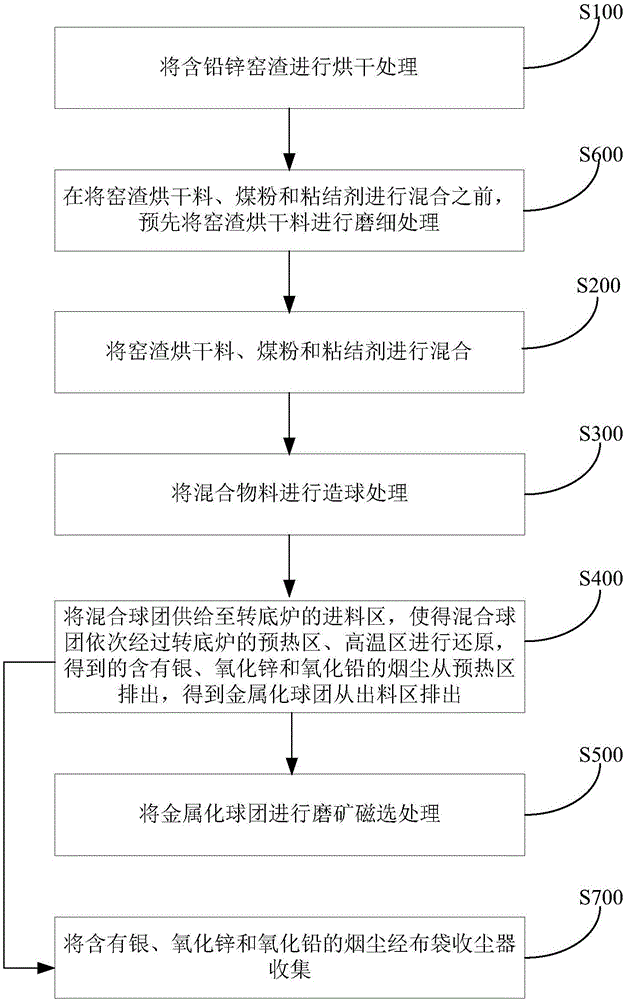

Method and system for treatment of kiln slag including lead and zinc

InactiveCN106148715AAchieve recyclingRealize resource utilizationProcess efficiency improvementIron powderSlag

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Preparation method of low-carbon aluminum-carbon refractory material for use in continuous casting

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for extracting valuable metal elements from coal gangue

ActiveCN113061728ALow chemical stabilityAchieve primary separationSilicaCarbon compoundsFerric hydroxideCalcium silicate

The invention provides a method for extracting valuable metal elements from coal gangue. The method comprises the following steps of: crushing and grinding coal gangue ore, performing supercritical / subcritical water activation, classifying the coal gangue ore into an organic liquid phase and a slag phase by a hydrocyclone, and synthesizing carbon dioxide and water from the organic liquid phase through a supercritical reaction, wherein the carbon dioxide is used for a subsequent sodium aluminate reaction to obtain aluminum hydroxide, the water is used for supplementing water to a shaking table, and the slag phase passes through the shaking table to obtain enriched ore of carbon and silicon dioxide, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements. Carbon and silicon dioxide are separated and collected through electric separation, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements are added into sodium carbonate and calcium carbonate to be roasted and dissolved after roasting, slag of calcium silicate and calcium titanate is obtained and can be used as a coating, a dissolving solution contains sodium aluminate, sodium ferrite and other substances, sodium hydroxide is added into the dissolving solution to generate ferric hydroxide and sodium aluminate, the ferric hydroxide can be used as a coating, and carbon dioxide is introduced into the sodium aluminate to generate aluminum hydroxide which is used as an inorganic flame-retardant additive.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

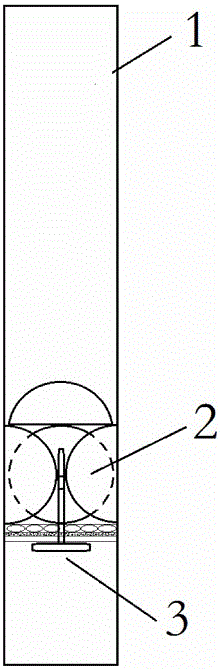

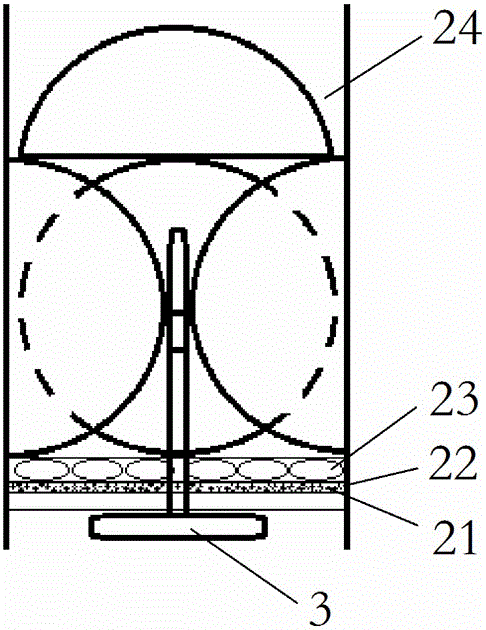

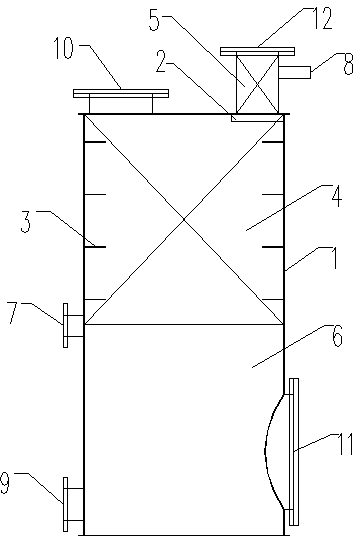

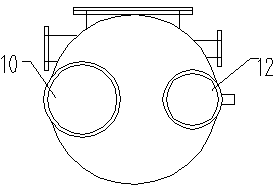

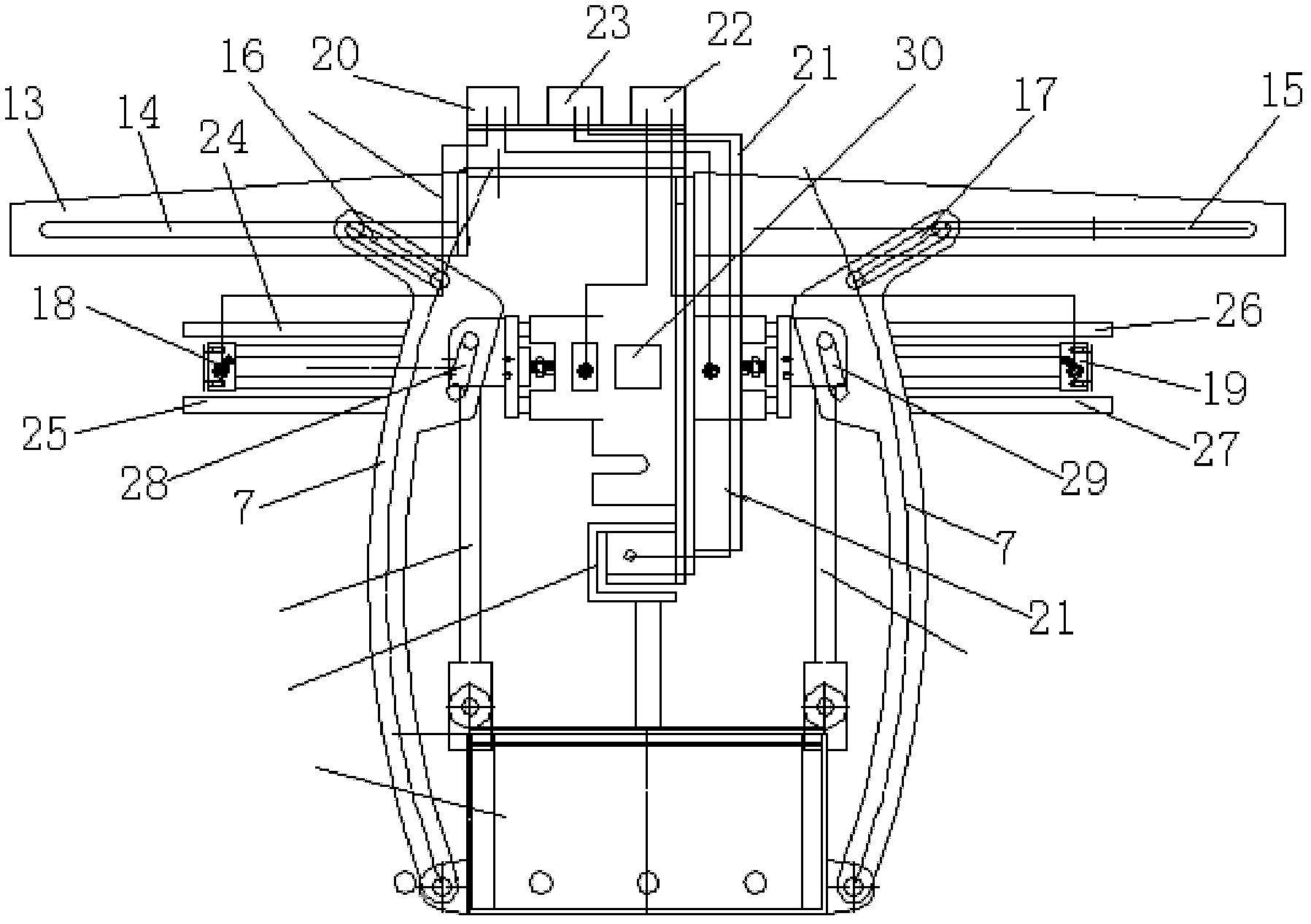

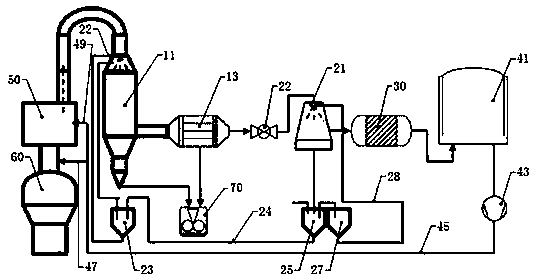

Slag removal machine of waste pyrolysis gasifier

The invention discloses a slag removal machine of a waste pyrolysis gasifier. The slag removal machine structurally comprises a furnace body, a material conveying pipe, a pushing machine, a feeding hopper, a fuel gas outlet, a hot air inlet and a slag removing mechanism, wherein the material conveying pipe is arranged at the top end of the left side of the furnace body, the pushing machine is arranged at the left end of the conveying pipe, the upper surface of the conveying pipe is connected with the feeding hopper, the fuel gas outlet is formed in the right side of the upper portion of the furnace body, and the hot air inlet is formed in the right side of the lower portion of the furnace body. The gasifier has the beneficial effects that a wiper and a scraper are arranged on the two sides of a rotating column, a motor drives the rotating column to rotate, a cutter is installed on the scraper so as to to scrape slag on the inner wall, the slag can fall into a material receiving disc, the inner wall is wiped through a cleaning brush on the wiper after the slag is scrapped, a ball pushing device and a stirring device are arranged inside the rotating column, a stirring rod can control balls in a rolling way, and the scraper and the wiper can be controlled to be stretched by changing the movement of the balls so as to adapt to furnace bodies with different sizes.

Owner:QUANZHOU TONGTONG ELECTRONIC EQUIP CO LTD

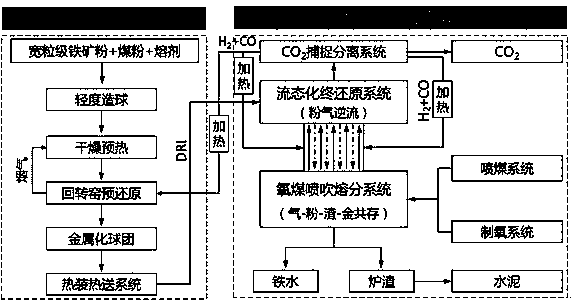

High density total oxygen short process high-efficiency cleaning iron-making process

InactiveCN108754056ASave the coking processSave grinding costRotary drum furnacesGas emission reductionCo2 removalSlag

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Concrete expansive agent

Owner:王嘉文

Extraction method and application of passion fruit anthocyanin and passion fruit juice drink

InactiveCN106578825ASignificant free radical scavenging effectAvoid destructionFood ingredient as colourNatural extract food ingredientsSlagHigh pressure

The invention discloses an extraction method of passion fruit anthocyanin. The extraction method comprises the steps of 1, choosing passion fruit and peel, and drying; 2, screening; 3, smashing; 4, conducting high-pressure extraction on the mixture of the smashed passion fruit and the peel; 5, filtrating; 6, conducting vacuum concentration and drying to obtain passion fruit anthocyanin. According to the extraction method of passion fruit anthocyanin, electric power is used, heat sources of a boiler and the like are not needed, and no waste matter and waste gases of dust, slag and the like are discharged; the solvent is recyclable in the extraction process, and no waste liquor is discharged. The extracted waste residues can also be used as a bioorganic fertilizer, and the extraction method is a fully green manufacturing technology. When passion fruit anthocyanin extracted from the method is applied in passion fruit juice drink, the passion fruit juice drink can be more natural in color, nutritional components can be more fully preserved, and the health care function of the product can be improved; moreover, the passion fruit juice drink has better antioxidation, and shelf life can be prolonged.

Owner:HEYUAN NONGSHE FOOD CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap