Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Vapor pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vapor pressure (or vapour pressure in British English; see spelling differences) or equilibrium vapor pressure is defined as the pressure exerted by a vapor in thermodynamic equilibrium with its condensed phases (solid or liquid) at a given temperature in a closed system. The equilibrium vapor pressure is an indication of a liquid's evaporation rate. It relates to the tendency of particles to escape from the liquid (or a solid). A substance with a high vapor pressure at normal temperatures is often referred to as volatile. The pressure exhibited by vapor present above a liquid surface is known as vapor pressure. As the temperature of a liquid increases, the kinetic energy of its molecules also increases. As the kinetic energy of the molecules increases, the number of molecules transitioning into a vapor also increases, thereby increasing the vapor pressure.

Ionic solvents used in ionic polymer transducers, sensors and actuators

InactiveUS20050103706A1Stable responseSolve the stability is not highMaterial nanotechnologySemi-permeable membranesIonomerTransducer

Ionic liquids are incorporated into transducers, actuators or sensors which employ the ionic polymer membranes. The ionic liquids have superior electrochemical stability, low viscosity and low vapor pressure. The transducers, actuators and sensors which utilize ionic polymer membranes solvated with ionic liquids have long term air stability. Superior results are achieved when a conductive powder and ionomer mixture is applied to the ionic polymer membrane to form the electrodes during or after the ionic liquid is imbibed into the ionic polymer membrane.

Owner:VIRGINIA TECH INTPROP INC +1

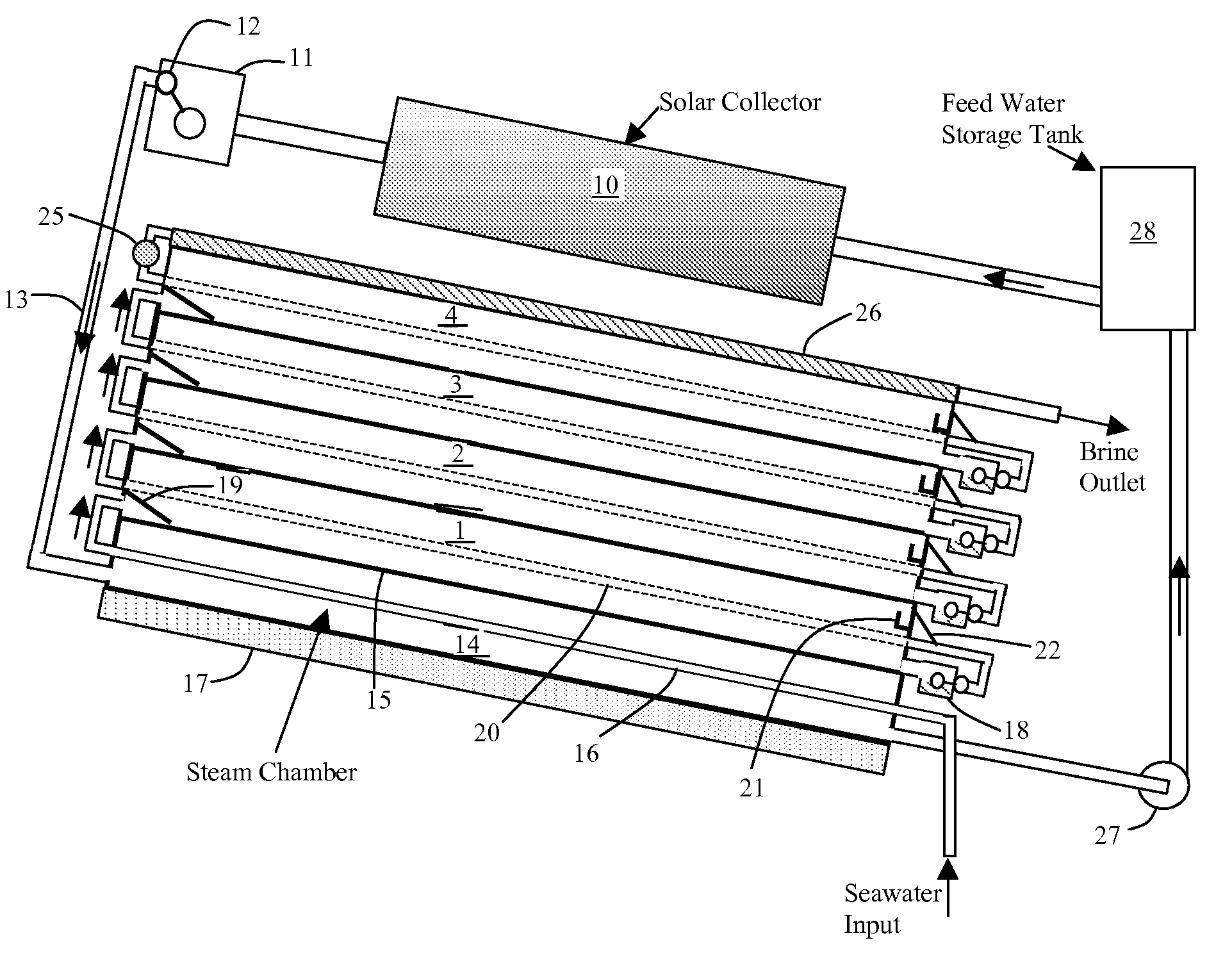

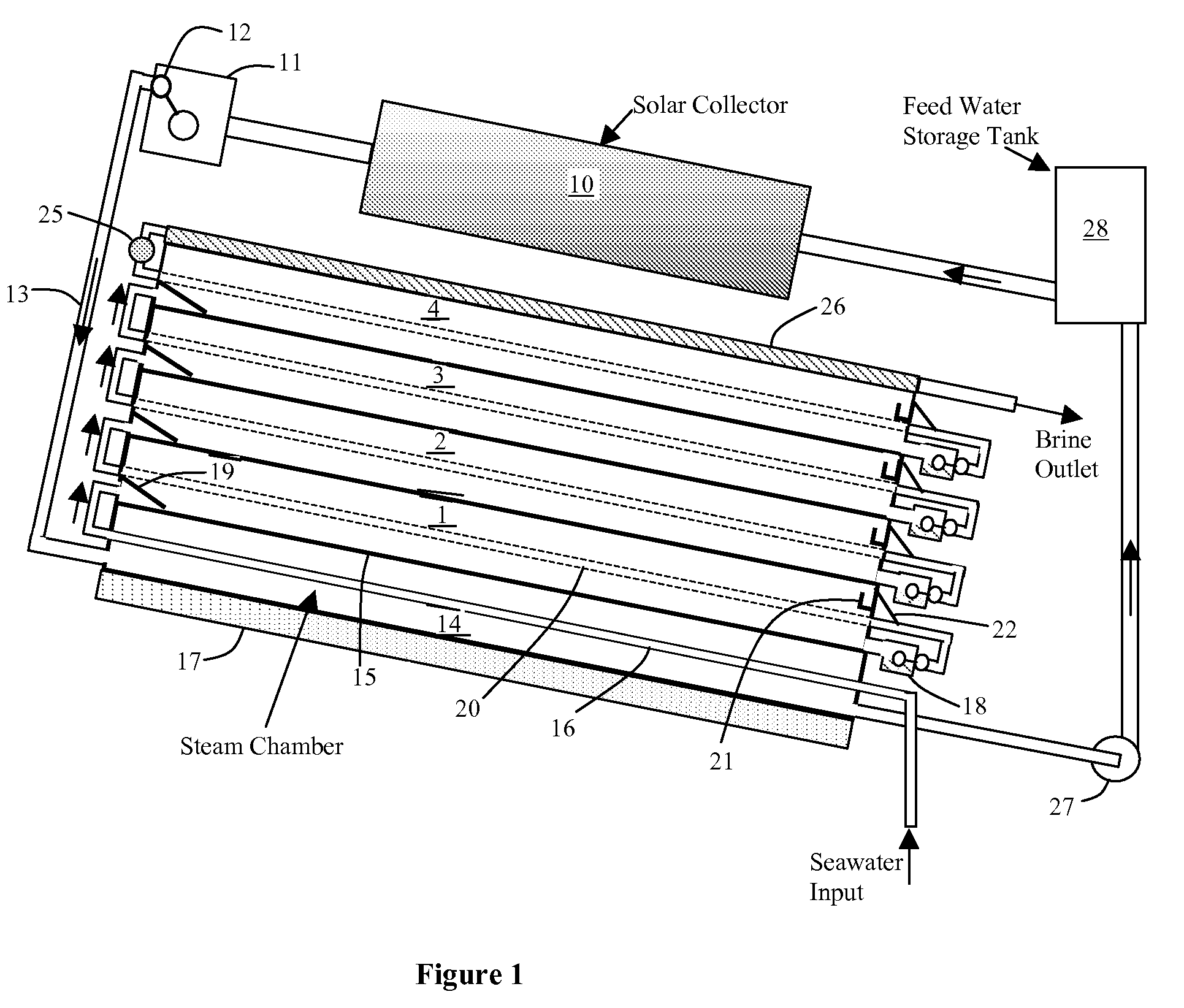

Solar-powered desalination system

InactiveUS20070193870A1Easy to useExcessive numberGeneral water supply conservationMultiple-effect/fractional condensationSaline waterParallel plate

Owner:PRUEITT MELVIN L

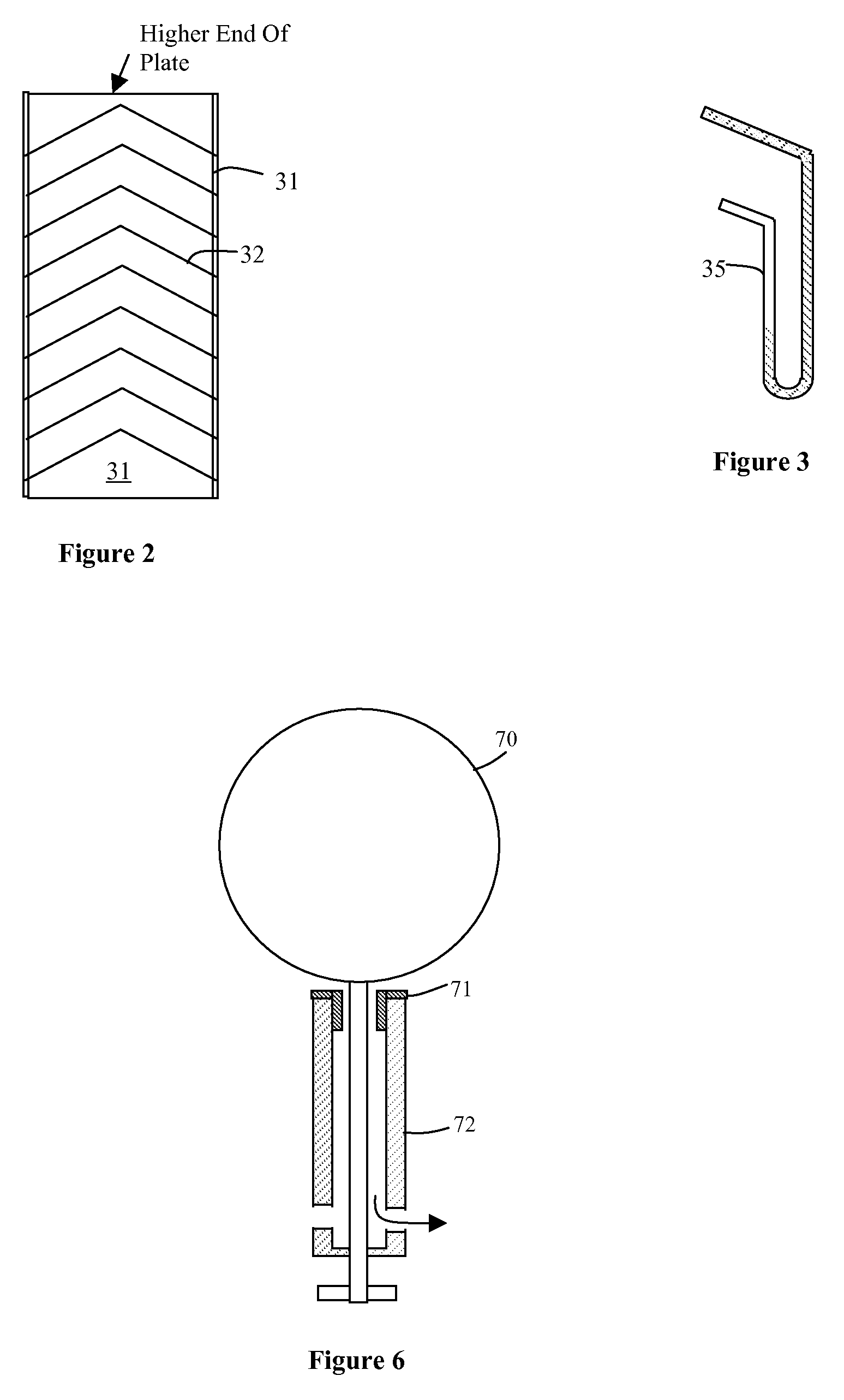

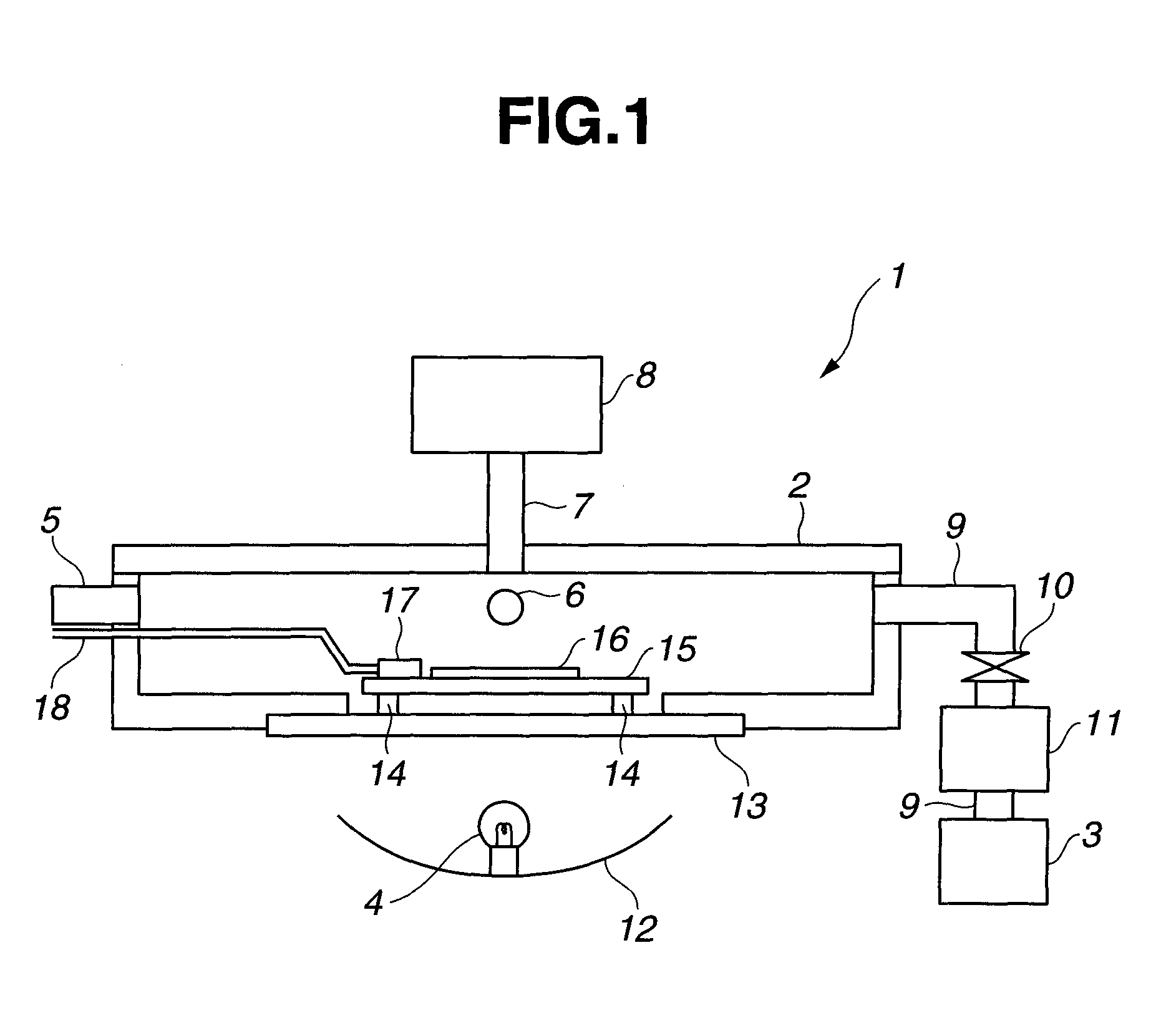

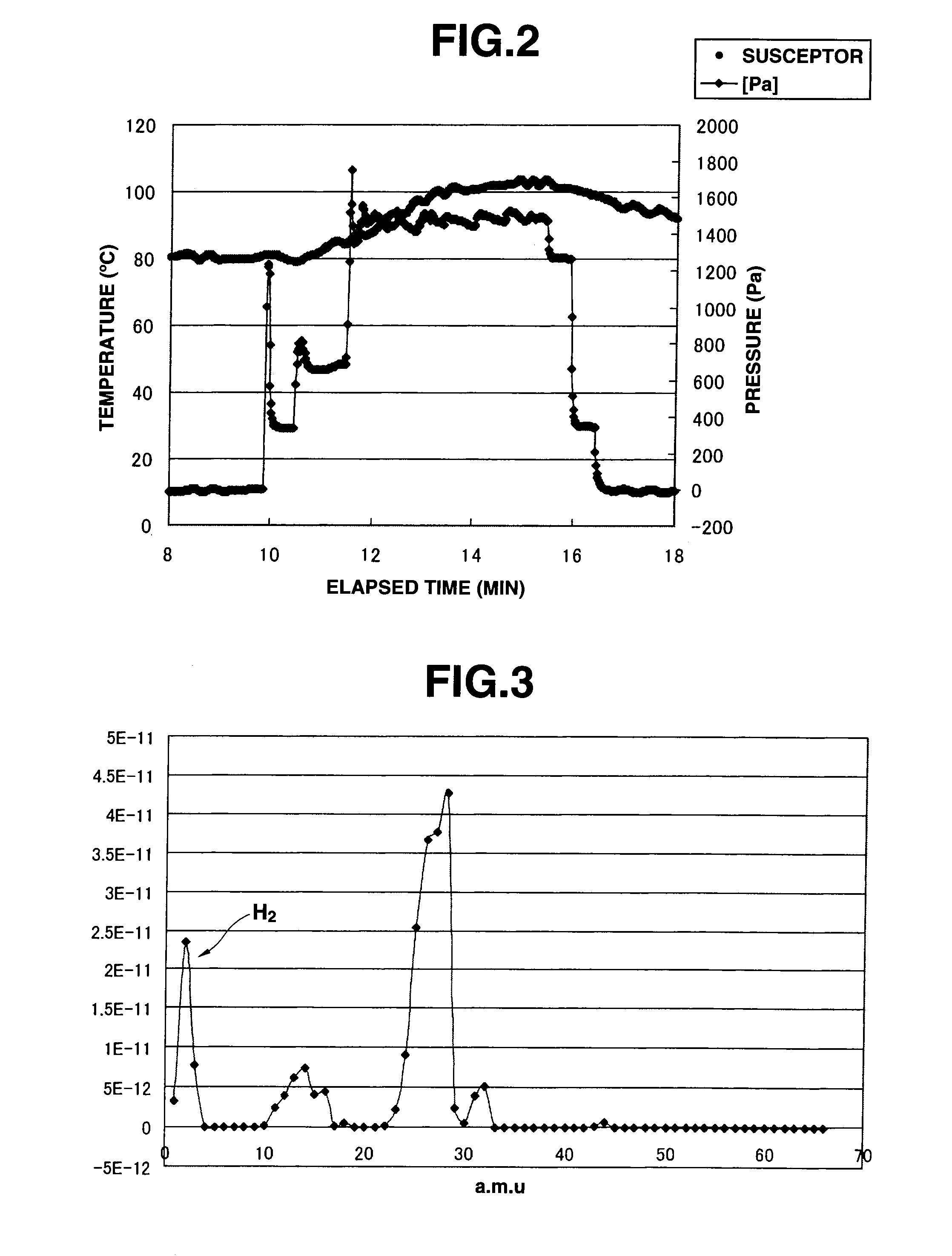

Method of removing resist and apparatus therefor

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Silicon-calcium-barium-magnesium desoxidant for steelmaking and/or electroslag

The invention relates to a silicon-calcium-barium-magnesium desoxidant for steelmaking and / or electroslag. The desoxidant is composed of the following chemical components in mass percent: 20-50% of Si, 10-40% of Ca, 5-20% of Ba, 2-10% of Mg, 0-10% of RE, not larger than 0.030% of P, not larger than 0.040% of S, 0-2% of C and the balance of Fe. The preparation method comprises the following steps: firstly smelting iron and silicon in a melting furnace to an intermediate alloy, adding barium, calcium, magnesium and / or rare earth, melting and casting to an alloy block, and controlling the specific gravity of the silicon-calcium-barium-magnesium desoxidant to 3-5 g / cm<3>. When in use, the silicon-calcium-barium-magnesium desoxidant is directly thrown into a steel furnace and / or an electroslag remelting crystallizer slag bath, the specific gravity of the desoxidant is increased, the vapor pressure is reduced, the desoxidant is deposited at a slag-steel interface to generate a CaO-BaO-SiO2 type impurity, and the CaO-BaO-SiO2 type impurity is larger in granule, lower in melting point, easy to be captured by the slag and easy to float to be removed, so that the cleanness of molten steel is improved.

Owner:ZHONGYUAN SPECIAL STEEL

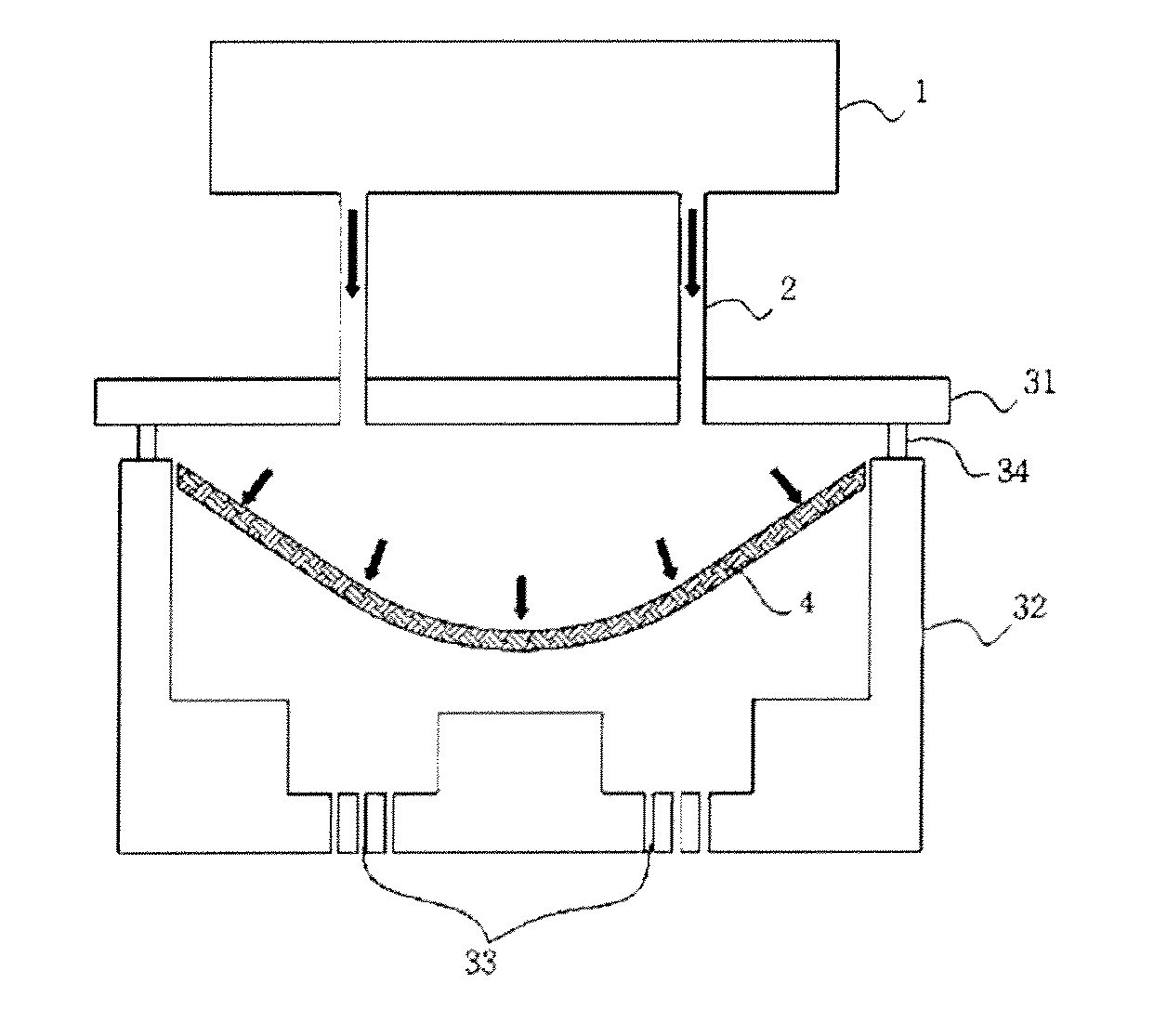

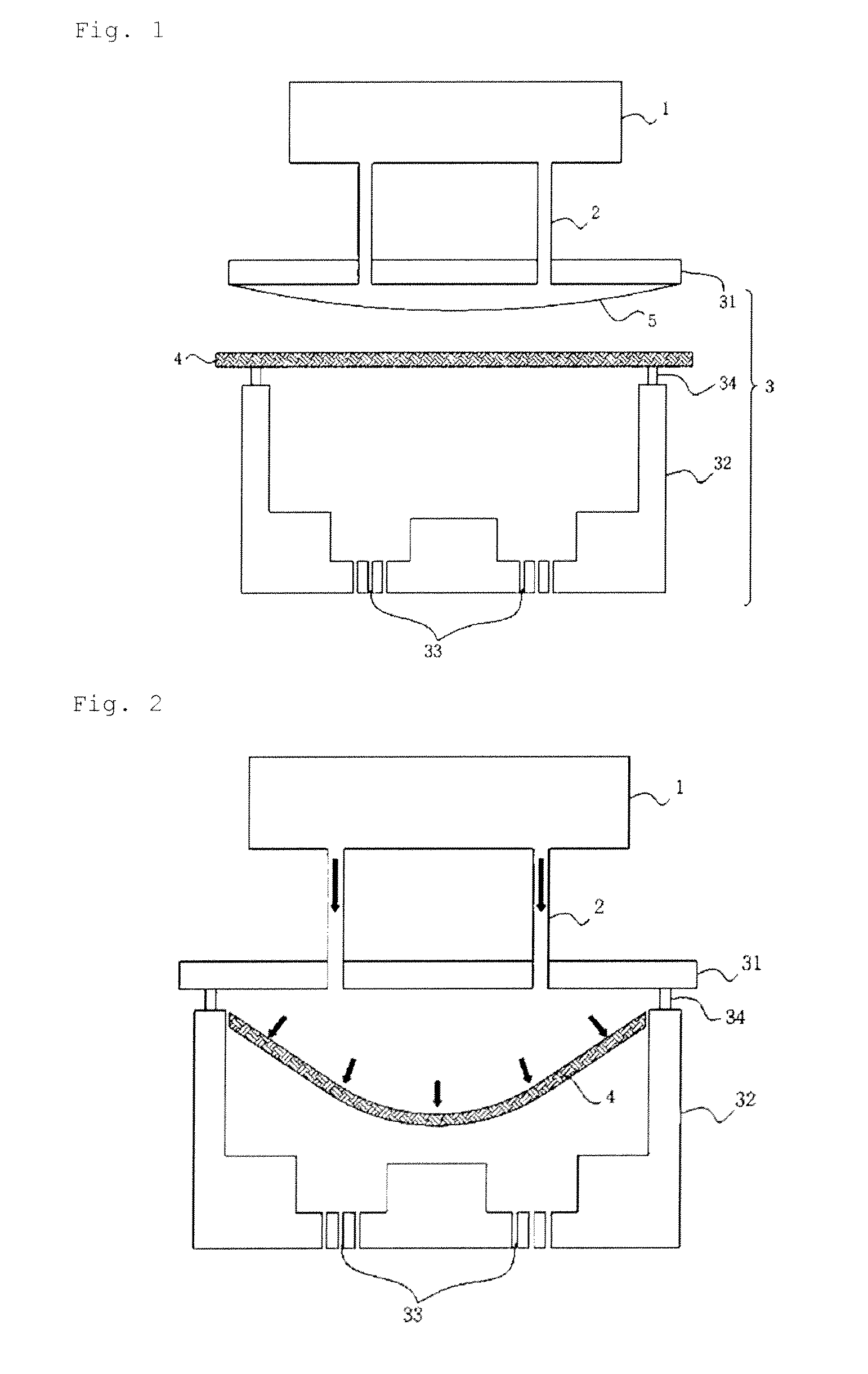

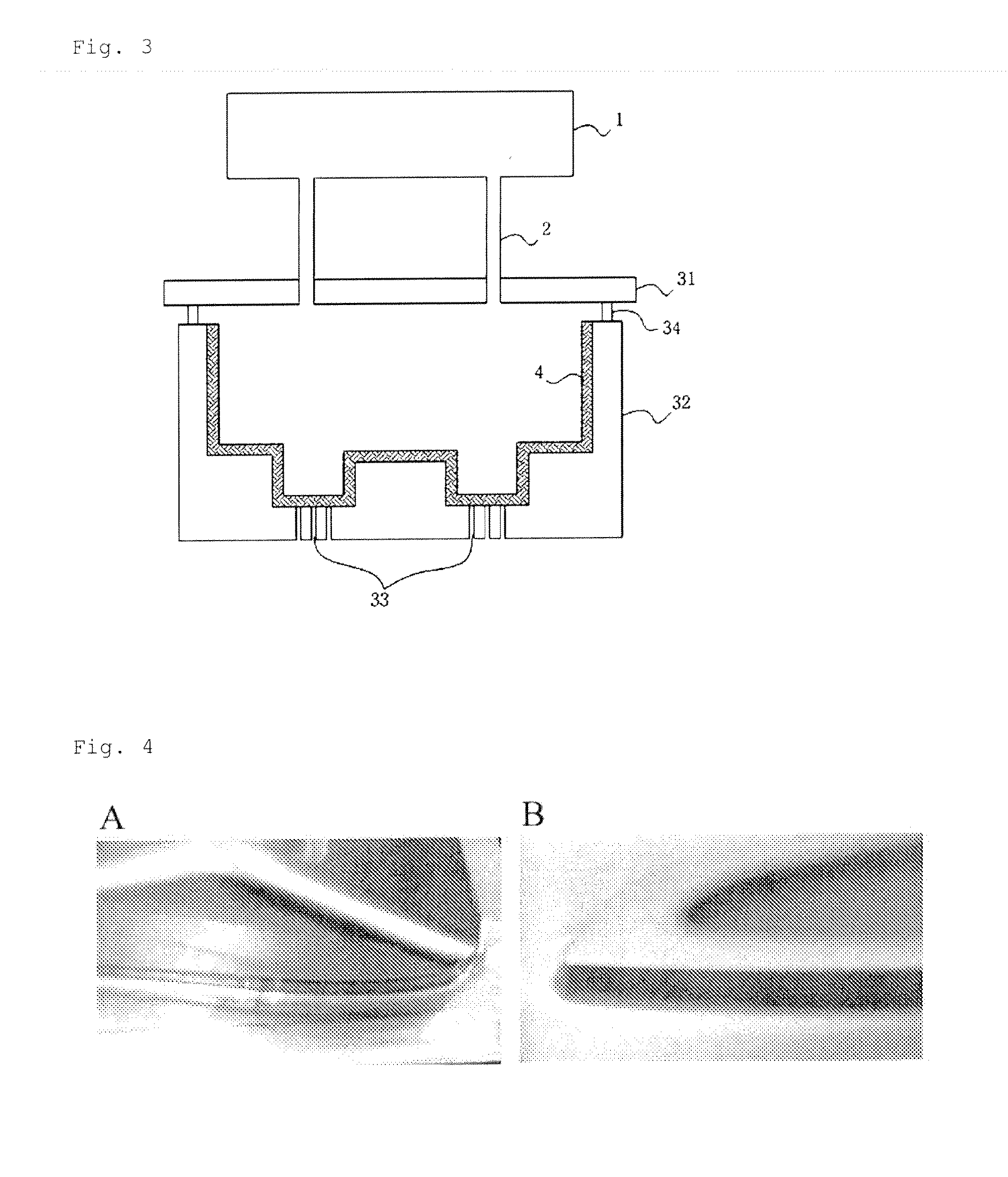

Forming apparatus and method using water pressure or vapor pressure

InactiveUS20110163485A1Improves pressure uniformityShort timeDomestic articlesPore water pressureWater pressure

Owner:LG HAUSYS LTD

Mixed molten salt type heat transfer and storage working medium and application thereof

InactiveCN105199678ALow cost of ingredientsSimple preparation processHeat-exchange elementsAdditive ingredientCoal

Owner:百吉瑞(天津)新能源有限公司

Method for preparing alkane through lignin derivative in ionic liquid system

ActiveCN109294614AOvercome the problem of high pressure in the reaction processReduce pressure requirementsLiquid hydrocarbon mixture productionBio-feedstockAlkaneIonic liquid

The invention discloses a method for preparing a high calorific value alkane by one-step hydrodeoxygenation of a lignin-derived aromatic compound in an ionic liquid system. The method adopts a transition metal supported catalyst and is characterized in that biomass alkane gasoline is prepared through lignin-derived compound high-efficiency hydrodeoxygenation in an intermittent reactor at 100-160 DEG C under hydrogen gas pressure of 1-5MPa for 2-10h. The catalytic system has mild reaction conditions and low energy consumption. The catalyst has good dispersibility in the ionic liquid. The ligninderivative conversion rate is 100%. The selectivity of the product cycloalkane is 95% or more. The method is free of protonic acid in the conventional catalytic system. The extremely low vapor pressure of the ionic liquid keeps the system low pressure during the reaction process, the requirements on the equipment are reduced, cycle performances of the catalytic system are good, and the method hasgood industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap