Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Molten steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

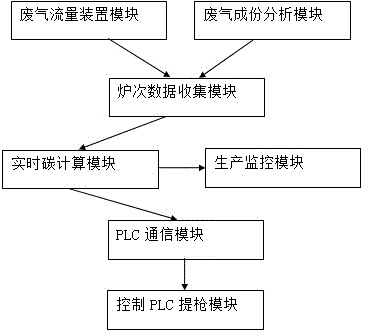

Mass spectrometer based RH dynamic decarbonization method and device

InactiveCN104131137ARealize automatic controlRealize stop blowingAutomatic controlRelevant information

Owner:NANJING MEISHAN METALLURGY DEV +2

Silicon-calcium-barium-magnesium desoxidant for steelmaking and/or electroslag

The invention relates to a silicon-calcium-barium-magnesium desoxidant for steelmaking and / or electroslag. The desoxidant is composed of the following chemical components in mass percent: 20-50% of Si, 10-40% of Ca, 5-20% of Ba, 2-10% of Mg, 0-10% of RE, not larger than 0.030% of P, not larger than 0.040% of S, 0-2% of C and the balance of Fe. The preparation method comprises the following steps: firstly smelting iron and silicon in a melting furnace to an intermediate alloy, adding barium, calcium, magnesium and / or rare earth, melting and casting to an alloy block, and controlling the specific gravity of the silicon-calcium-barium-magnesium desoxidant to 3-5 g / cm<3>. When in use, the silicon-calcium-barium-magnesium desoxidant is directly thrown into a steel furnace and / or an electroslag remelting crystallizer slag bath, the specific gravity of the desoxidant is increased, the vapor pressure is reduced, the desoxidant is deposited at a slag-steel interface to generate a CaO-BaO-SiO2 type impurity, and the CaO-BaO-SiO2 type impurity is larger in granule, lower in melting point, easy to be captured by the slag and easy to float to be removed, so that the cleanness of molten steel is improved.

Owner:ZHONGYUAN SPECIAL STEEL

NiCuSiFe alloy

Owner:WUFAN ALLOY ALUMINUM WUJIN

Production method of welding rod steel H08A

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Investment casting mould of high-temperature alloy bending pipe

Owner:江苏久保联实业有限公司

Composite desulfurizer of iron and steel and its preparing process

Owner:TAIYUAN UNIV OF TECH

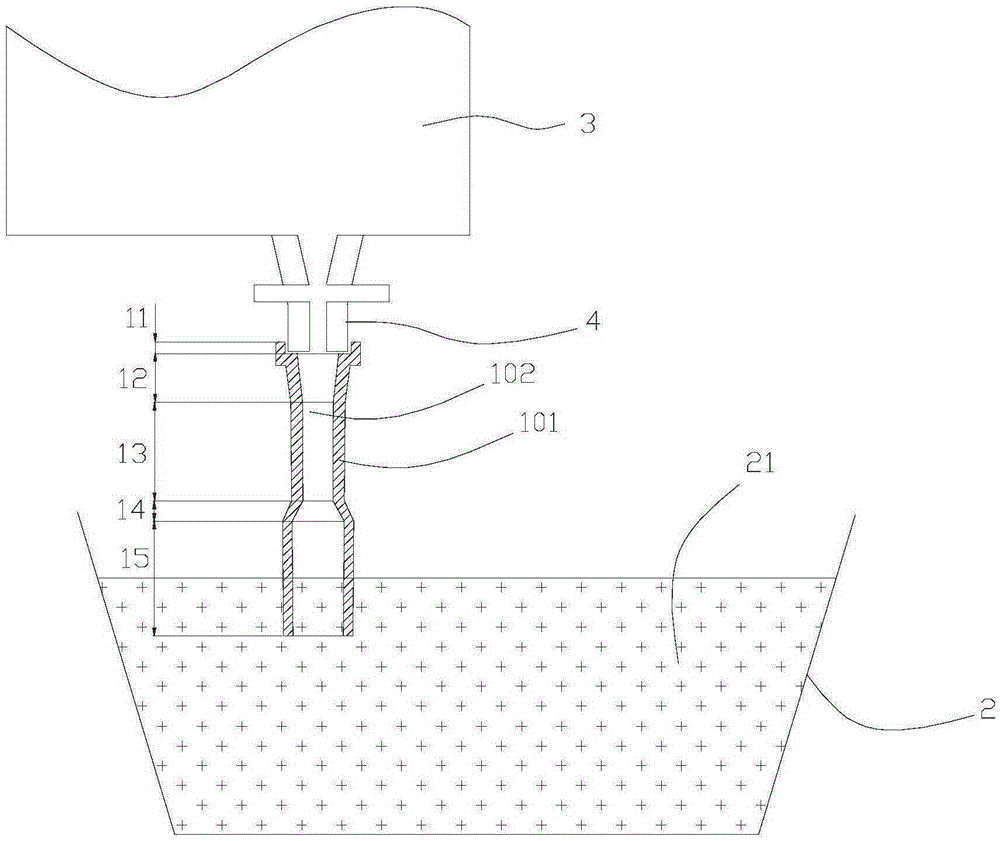

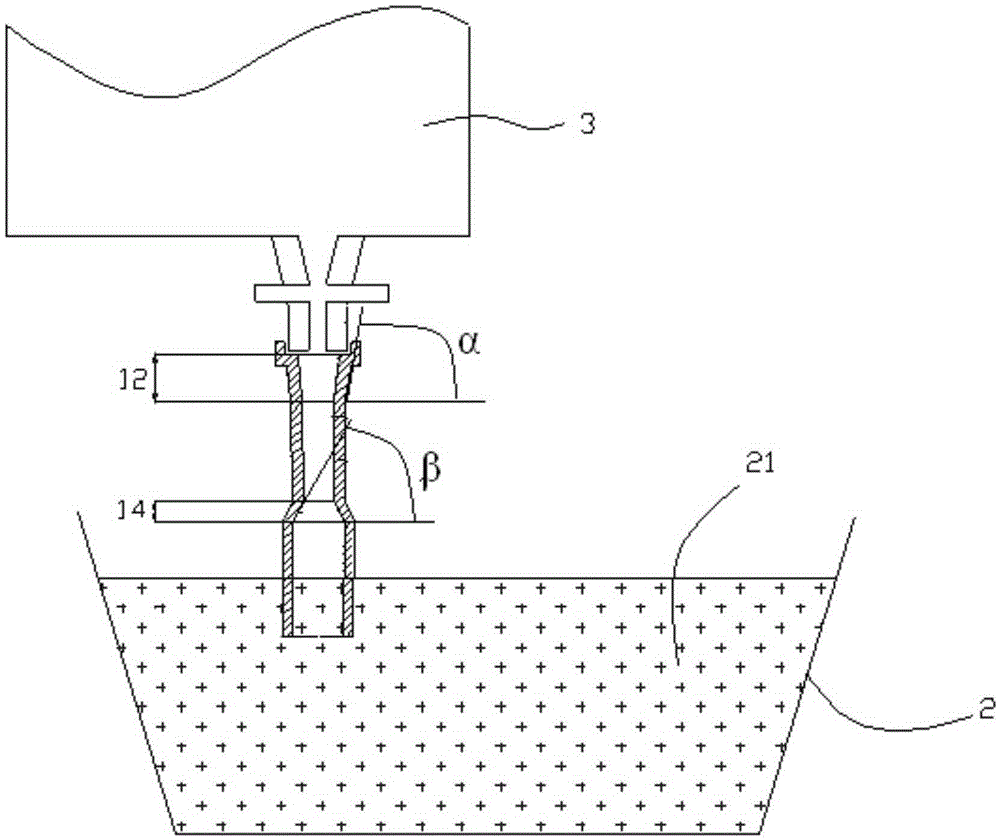

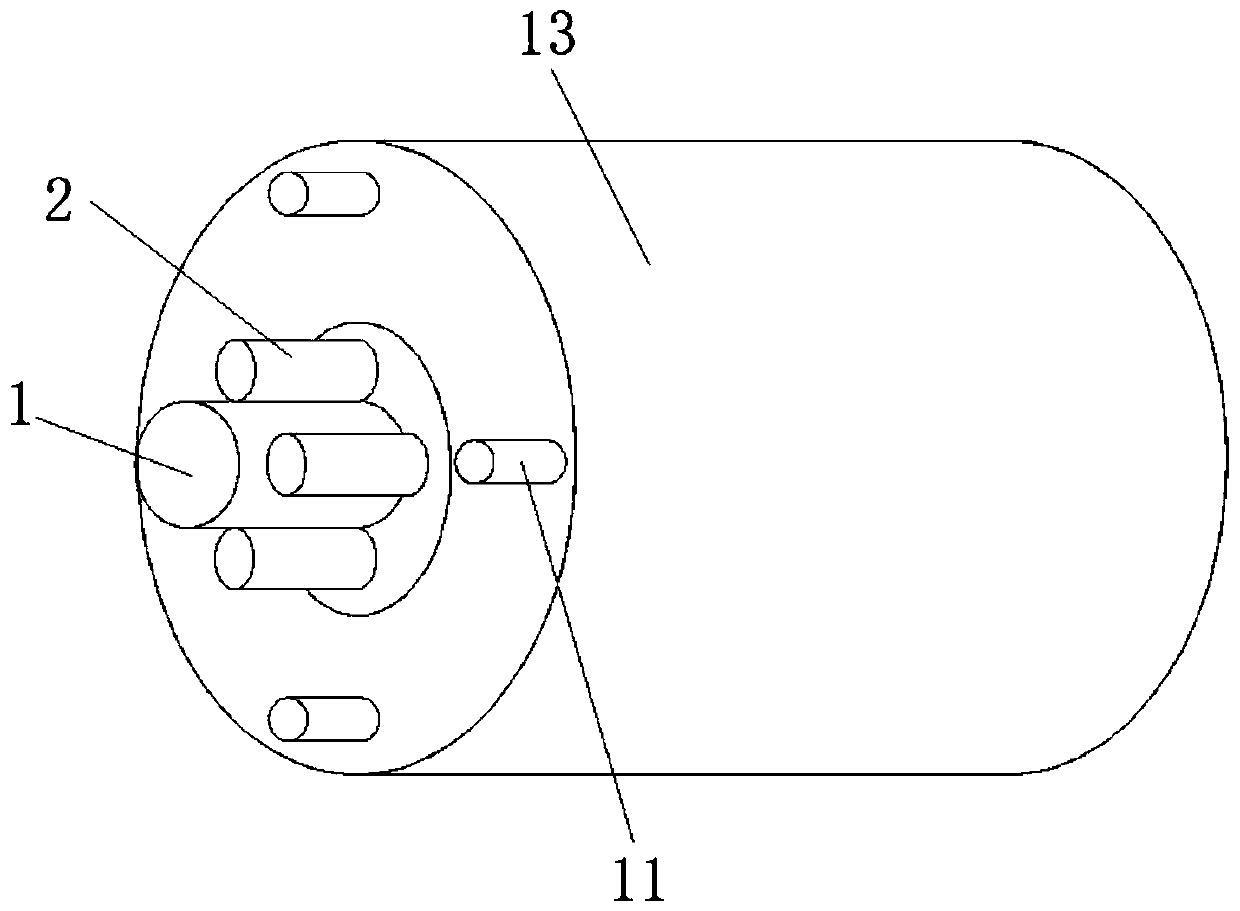

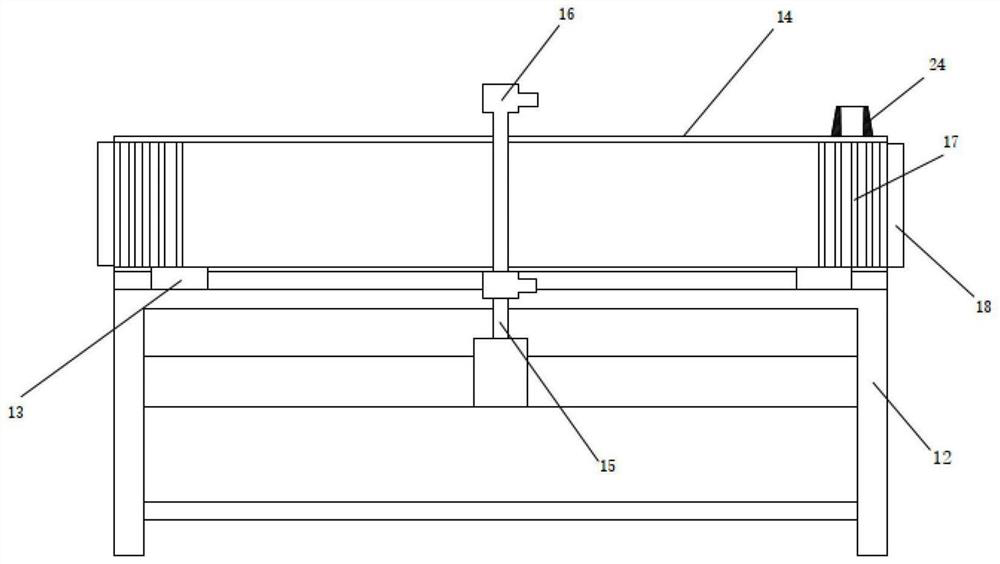

Pouring stream protecting device for pouring molten steel through large ladle in continuous casting

InactiveCN105397079ASolve the problem of pouring and overturning steel below the liquid level of molten steel inserted into the tundishEasy to installMelt-holding vesselsOperabilityMolten steel

Owner:SHANDONG IRON & STEEL CO LTD

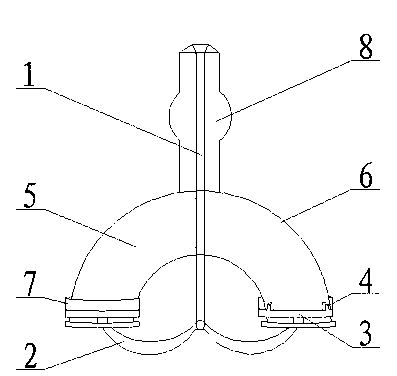

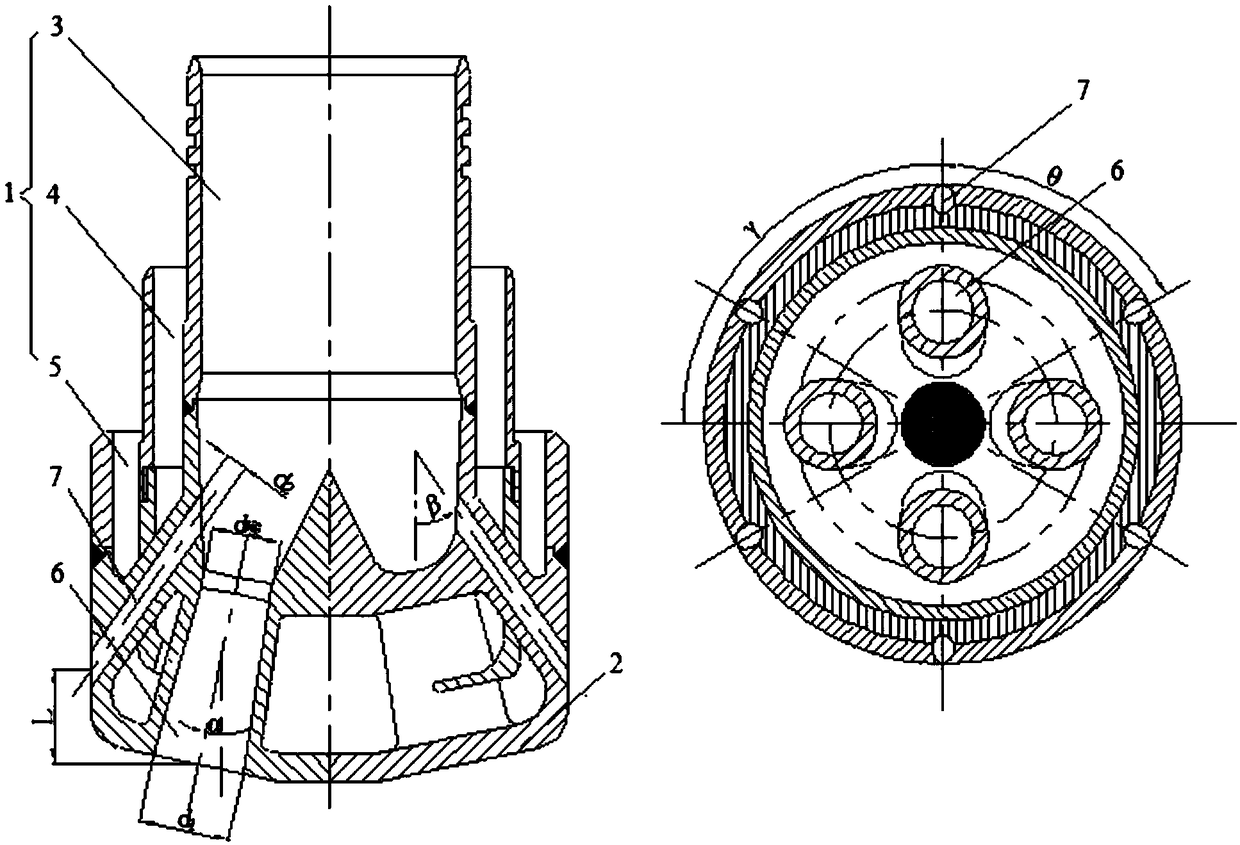

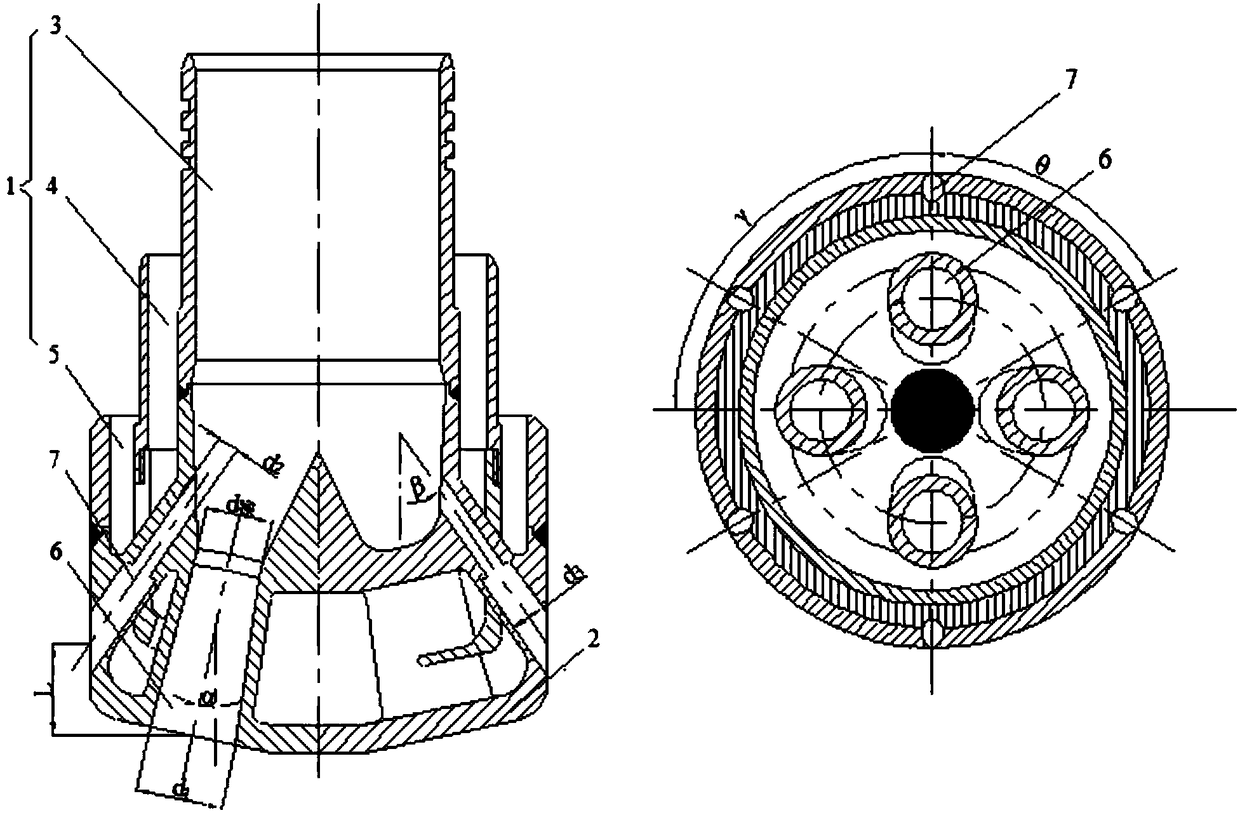

Single-flow-channel secondary combustion oxygen lance capable of improving scrap ratio of converter and application method of single-flow-channel secondary combustion oxygen lance

PendingCN108977620AHigh desulfurization rateIncrease the amount of steel scrap into the furnaceManufacturing convertersProcess efficiency improvementCombustionSpray nozzle

Owner:NORTHEASTERN UNIV

Baking-free long water gap for large-plate-blank continuous casing low-carbon and low-silicon steel and preparation process of baking-free long water gap

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Super high temperature resistant mobile cable for buggy ladle

InactiveCN110767352AImprove high temperature resistanceImprove tensile propertiesRubber insulatorsFlexible cablesElectric machineEngineering

Owner:安徽省飞翔特种电缆有限公司

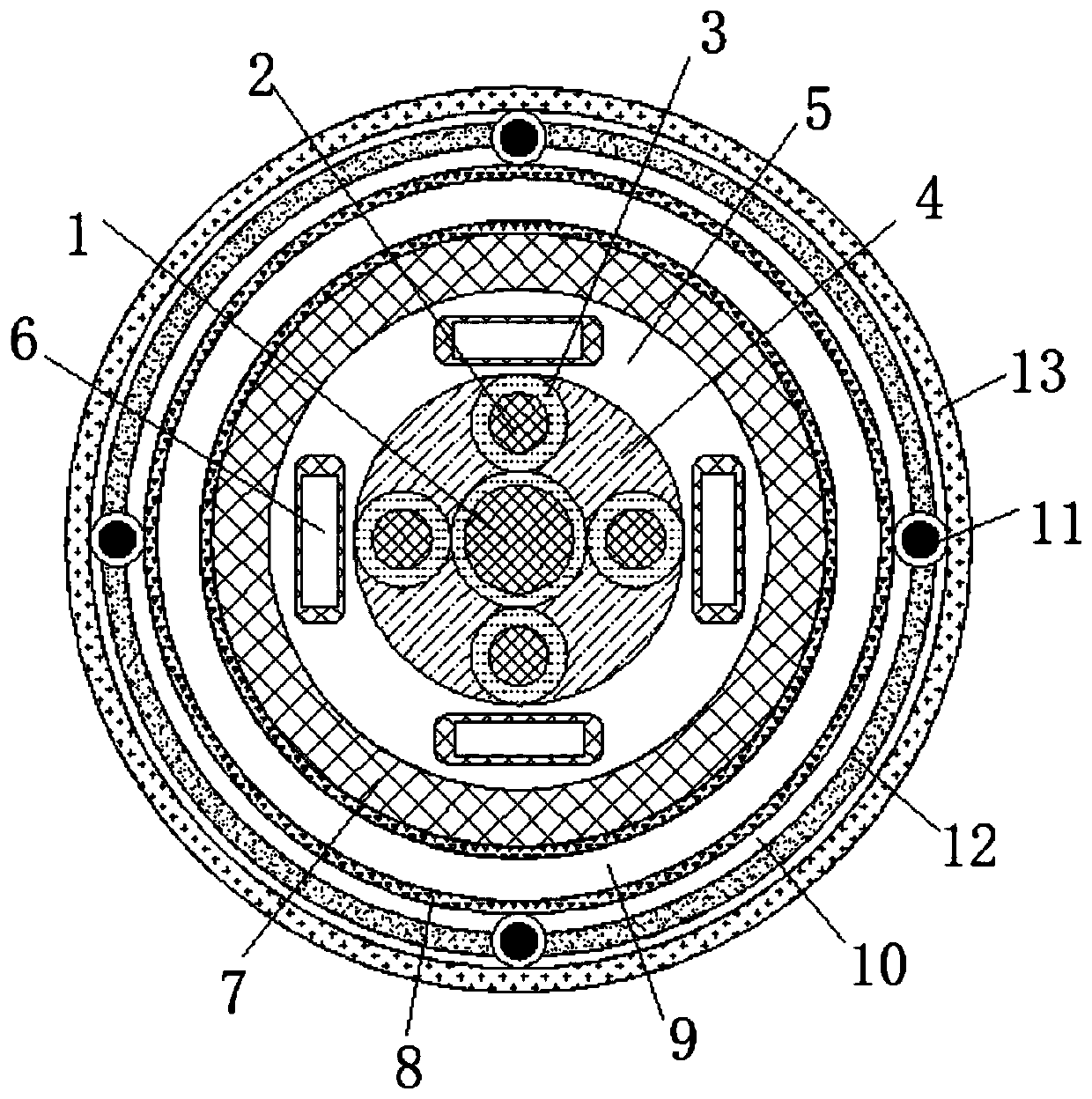

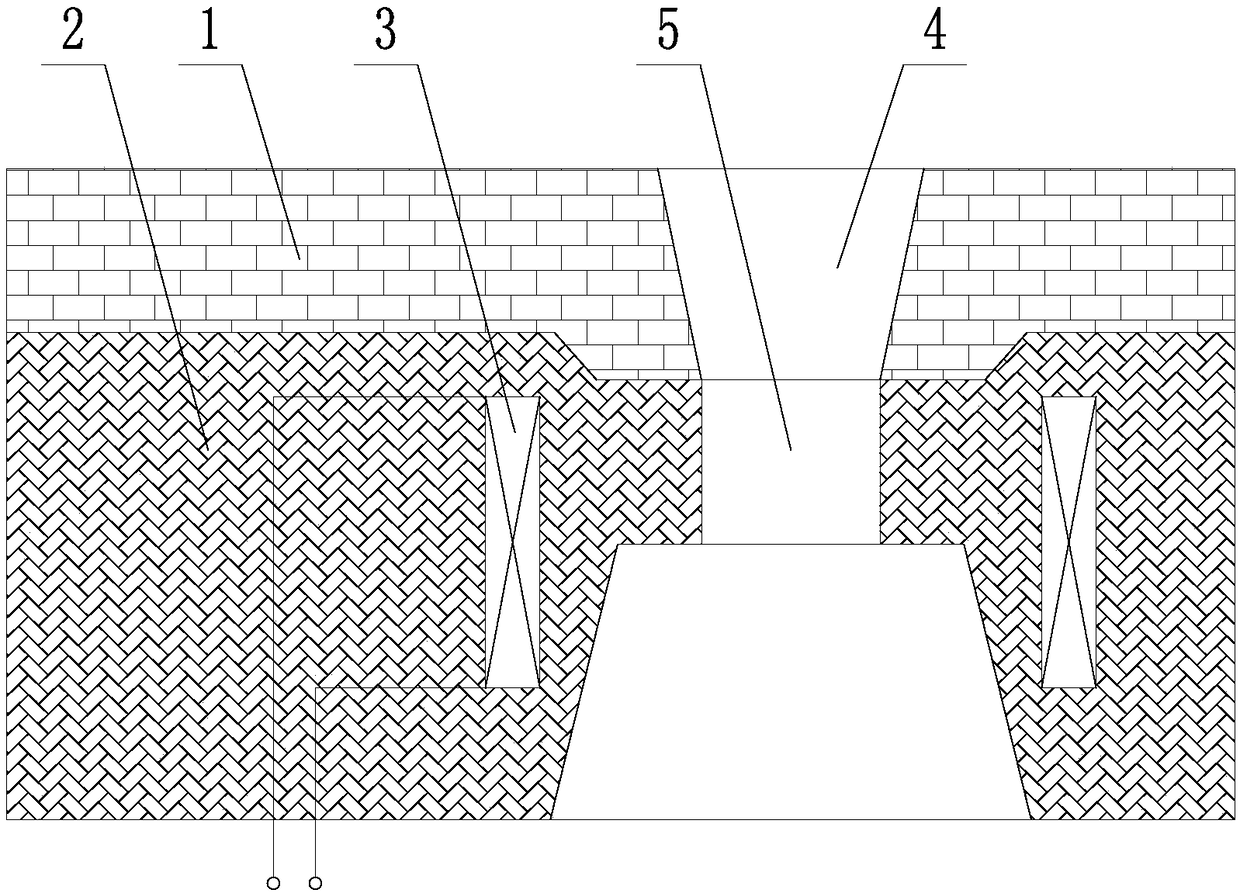

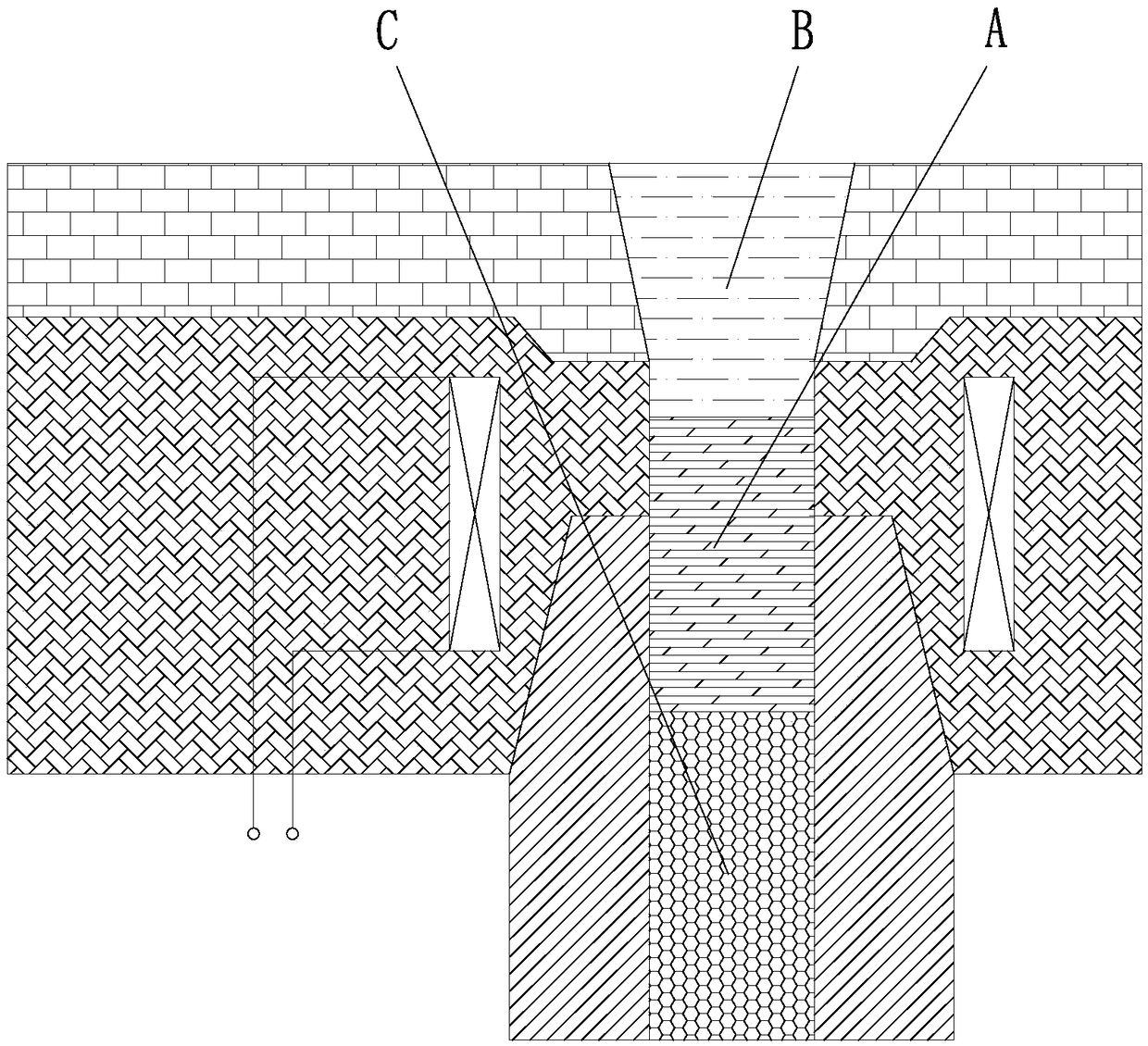

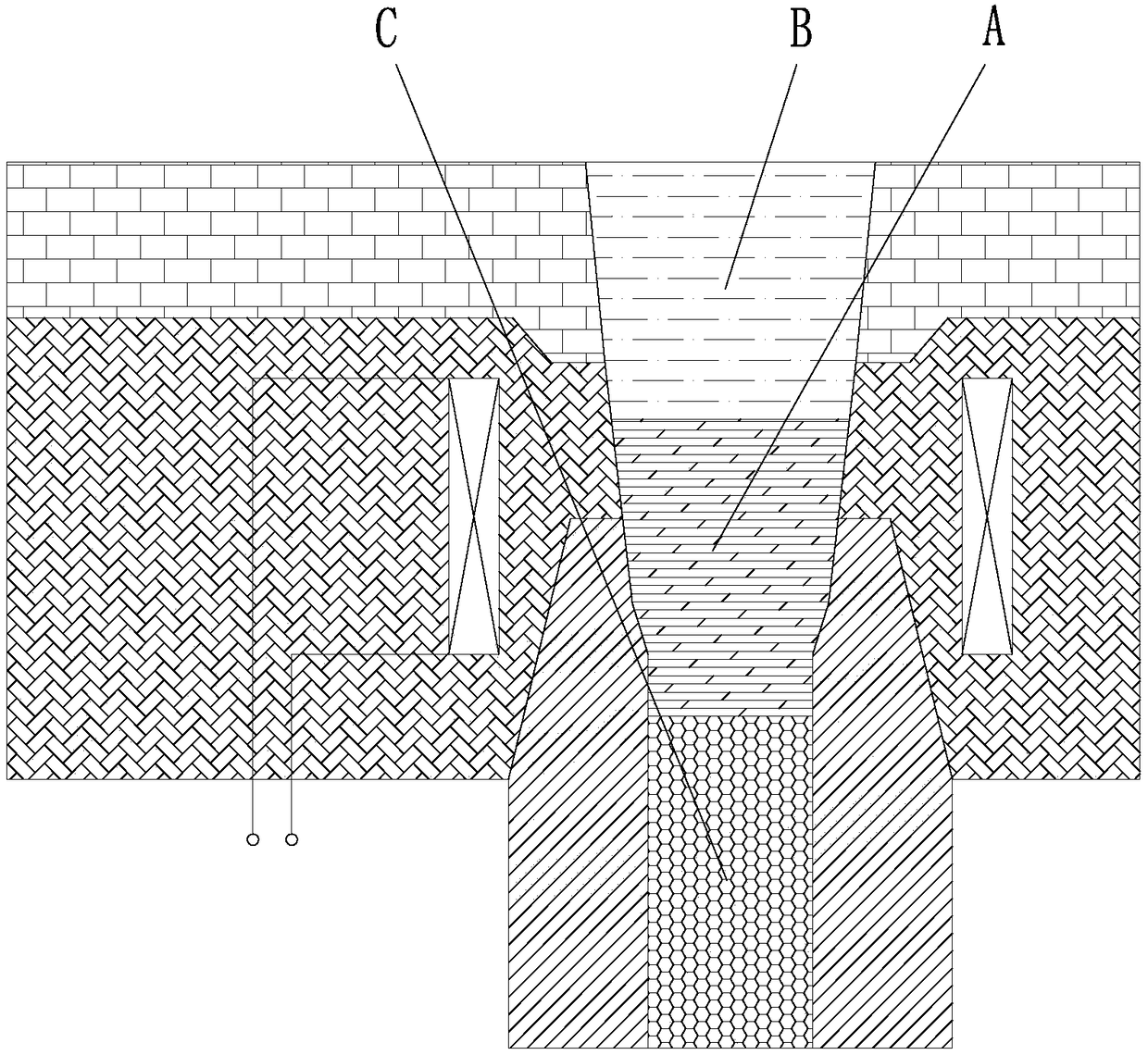

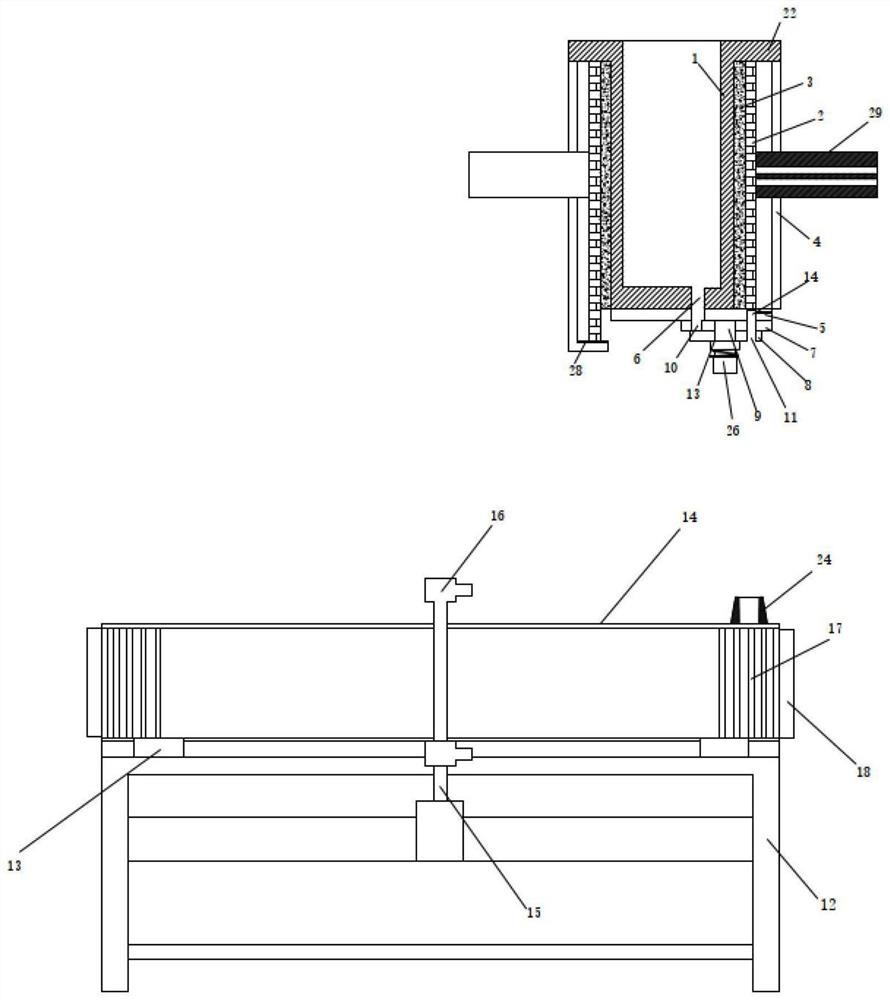

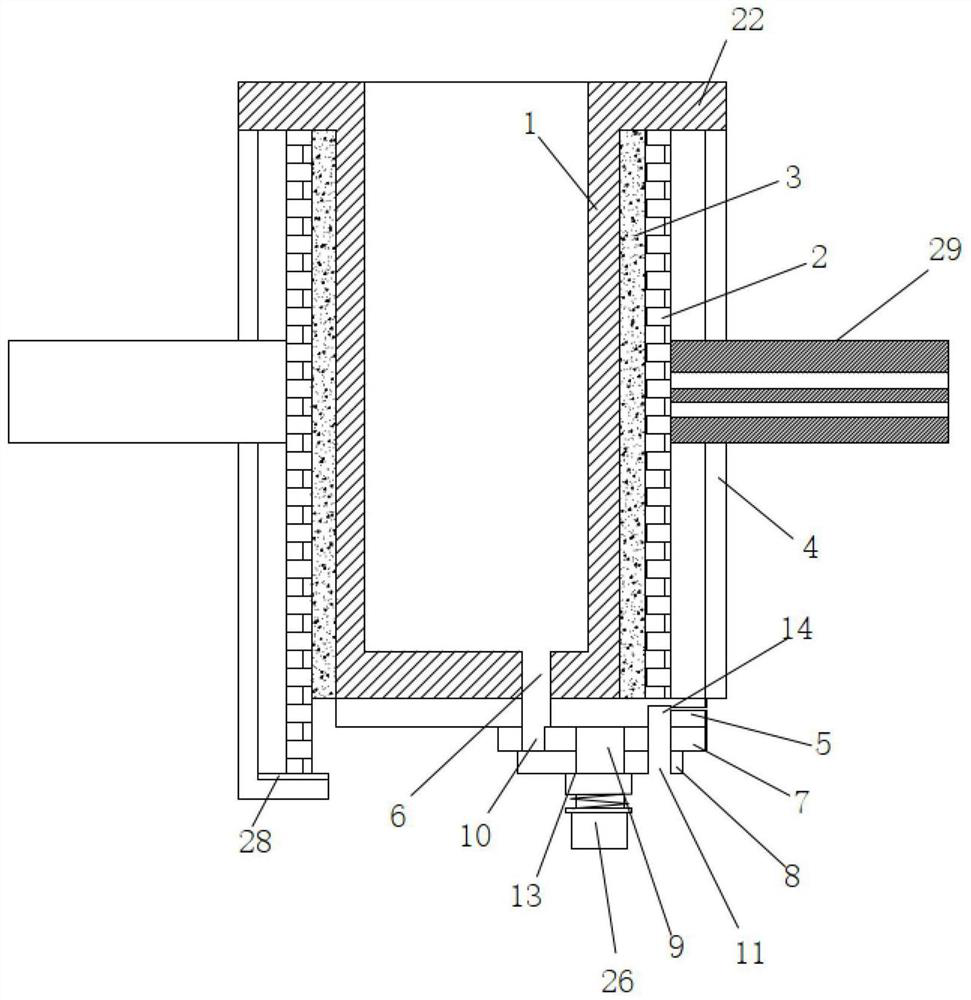

Combined type pocket block based on electromagnetic induction heating tapping technology

ActiveCN108356258ASolve the disadvantages of inability to recover induction coilsAchieve recyclingMelt-holding vesselsEngineeringMolten steel

Owner:NORTHEASTERN UNIV

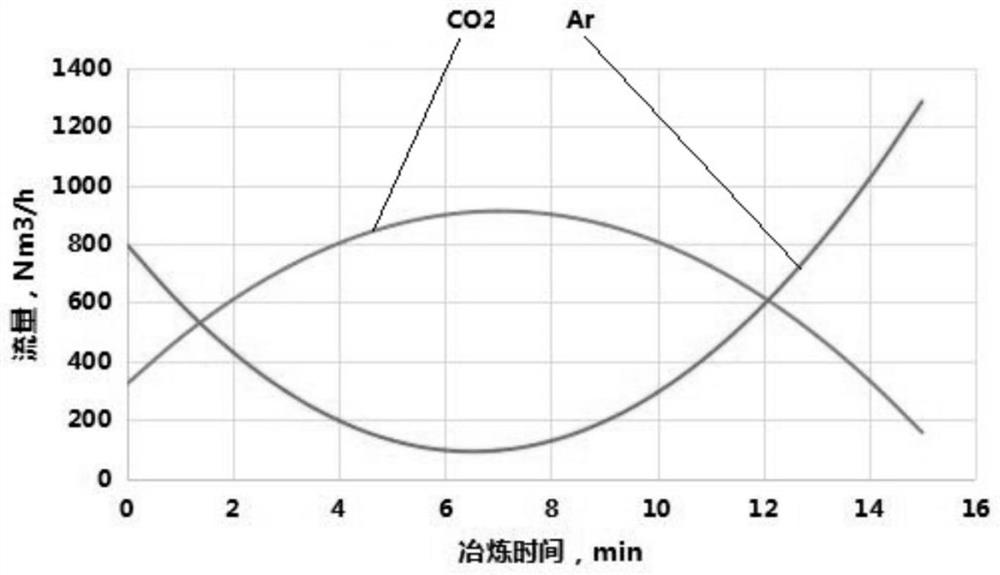

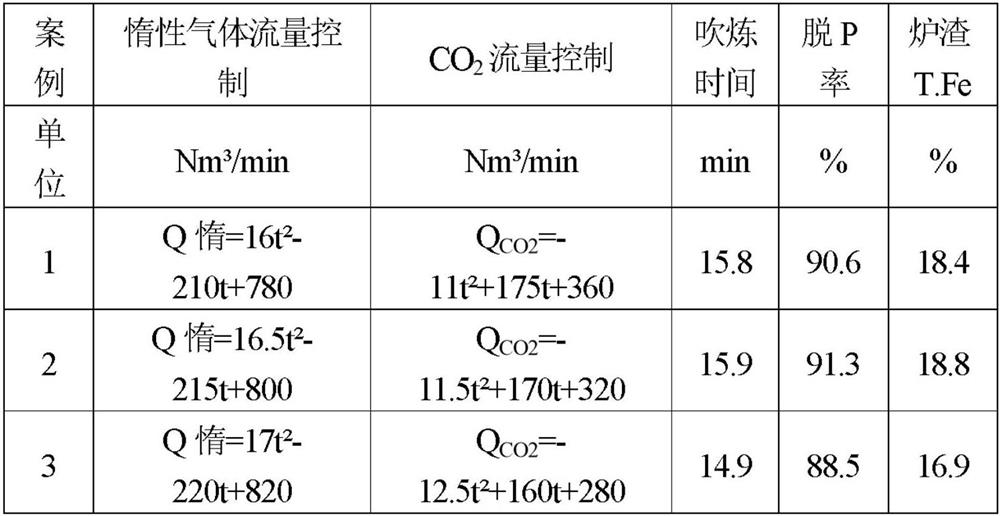

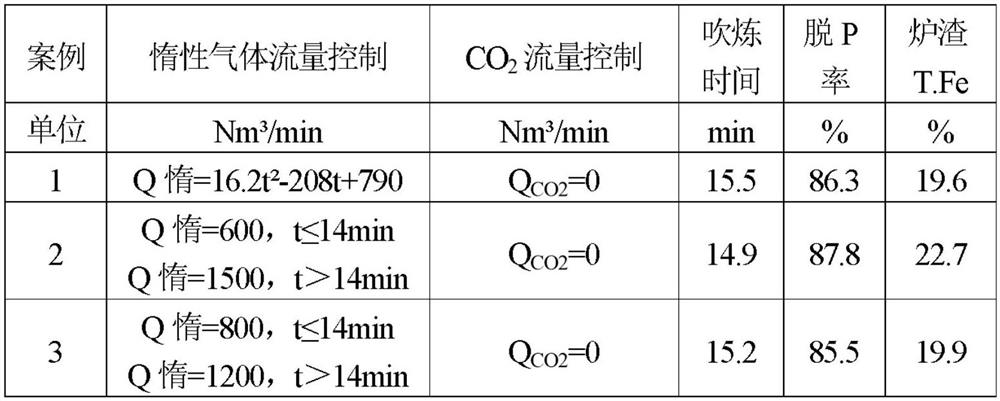

Converter smelting method

ActiveCN114369698AReduce oxidationReduce terminal oxidationSteel manufacturing process aspectsManufacturing convertersSteelmakingMolten steel

Owner:SHOUGANG CORPORATION

Method for treating various steel slags by tipping hot disintegration process

ActiveCN114774597AFully digestedReduce processing stepsRecycling and recovery technologiesSteelmakingMolten steel

Owner:中钢石家庄工程设计研究院有限公司

Dynamic deoxidization control system and method of converter

InactiveCN108866274APrecisely control the amount addedAccurate deoxygenationControl systemEngineering

The invention discloses a dynamic deoxidization control system and method of a converter. The dynamic deoxidization control system comprises an oxygen measurement probe, a controller and a measurementscale, wherein the oxygen measurement probe is used for measuring finishing-point oxygen content of molten steel before tapping; the controller is used for storing a corresponding relation between anadding amount of a deoxidization agent and the finishing-point oxygen content in advance; the controller is used for obtaining the adding amount of the deoxidization agent according to the finishing-point oxygen content measured by the oxygen measurement probe and the corresponding relation between the adding amount of the deoxidization agent and the finishing-point oxygen content; the measurement scale is used for weighing the deoxidization agent according to the adding amount of the deoxidization agent and adding the deoxidization agent. When the dynamic deoxidization control system of theconverter, disclosed by the invention, is used, the adding amount of the deoxidization agent can be accurately controlled through the controller; compared with the prior art, accurate deoxidization can be realized, so that the accuracy of deoxidization is improved.

Owner:SHANDONG IRON & STEEL CO LTD

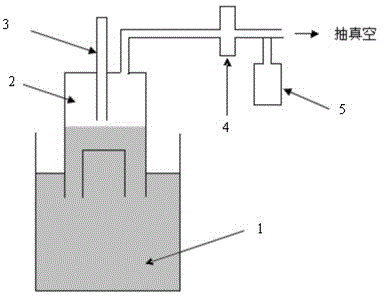

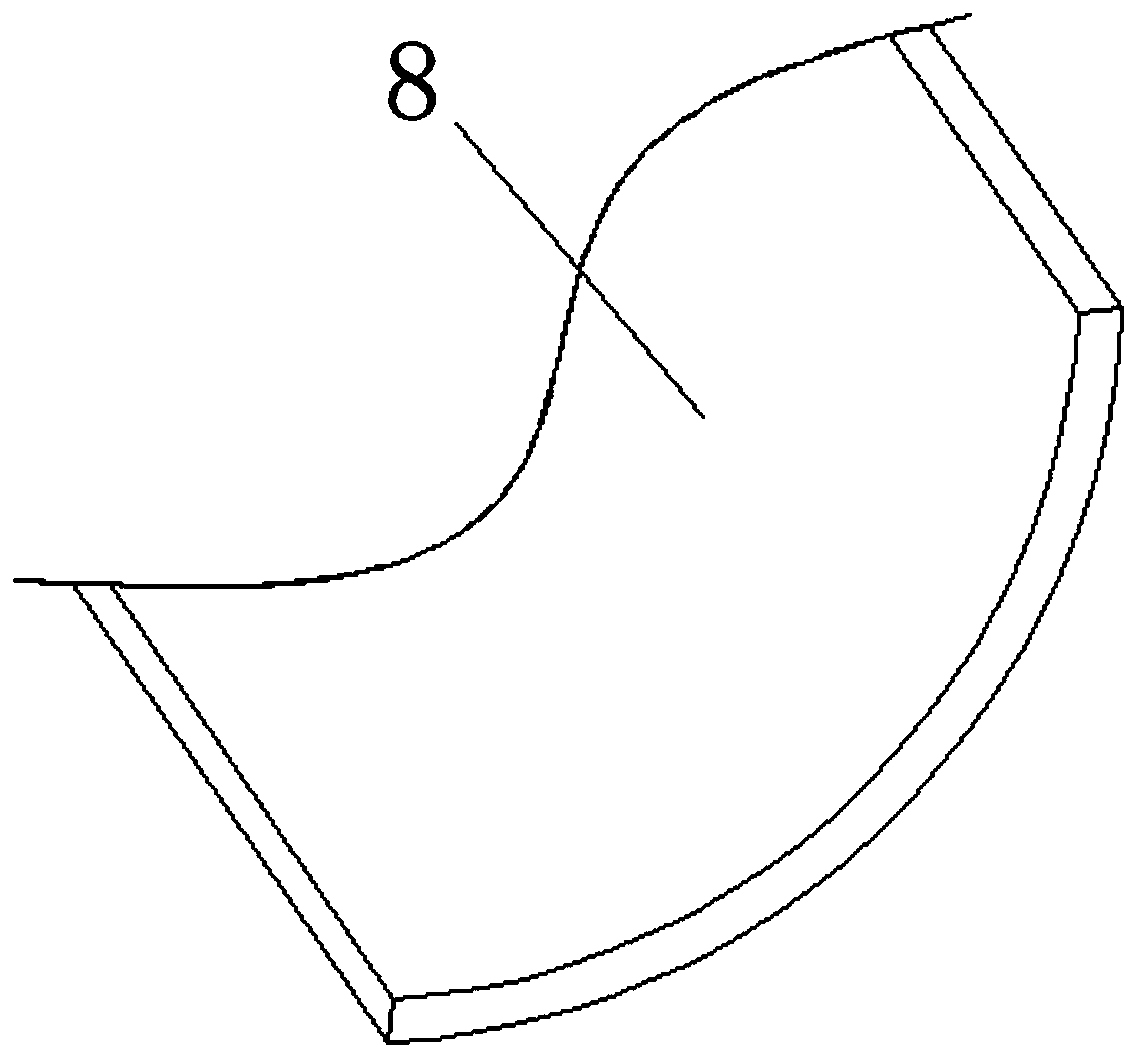

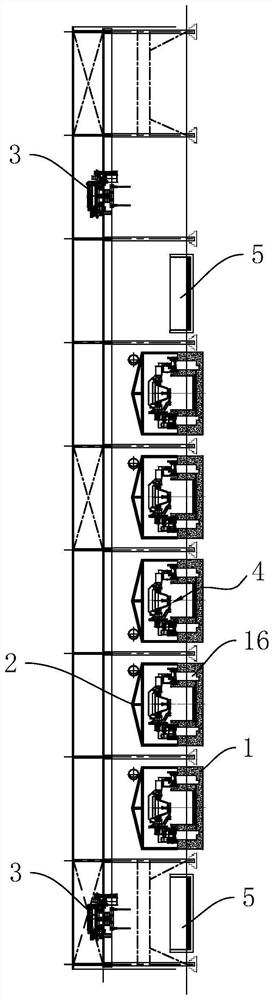

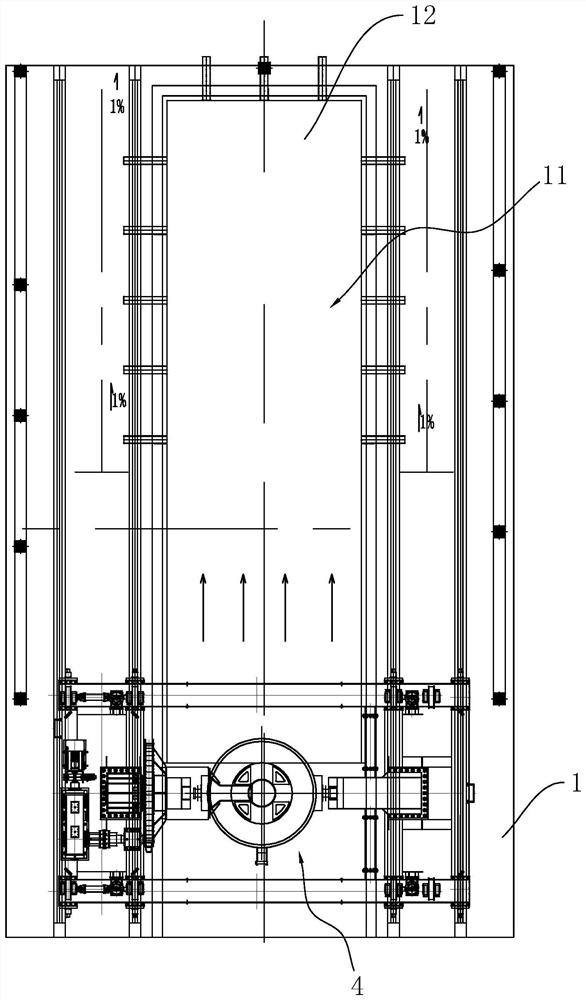

Automatic production system for directional crystallization

ActiveCN114309574ARapid directional cooling crystallizationCasting plantsMolten metal supplying equipmentsThermodynamicsCrucible

Owner:无锡刚正精密吸铸有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap