Combined type pocket block based on electromagnetic induction heating tapping technology

A technology of electromagnetic induction heating and nozzle seat bricks, which is applied in metal processing equipment, casting melt containers, casting equipment, etc., can solve the problem that the nozzle seat bricks cannot be recovered by induction coils, etc., to ensure the automatic pouring rate and reduce labor intensity. , the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

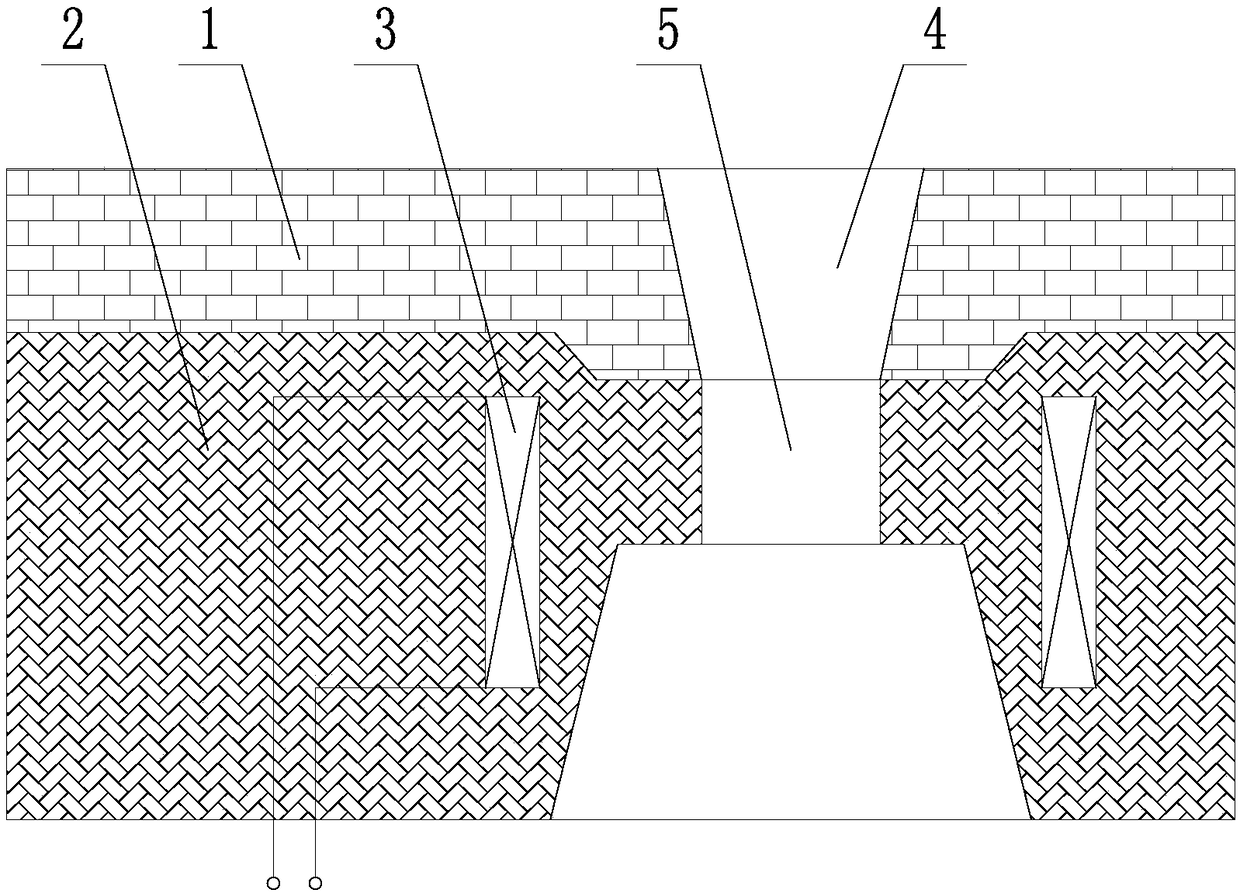

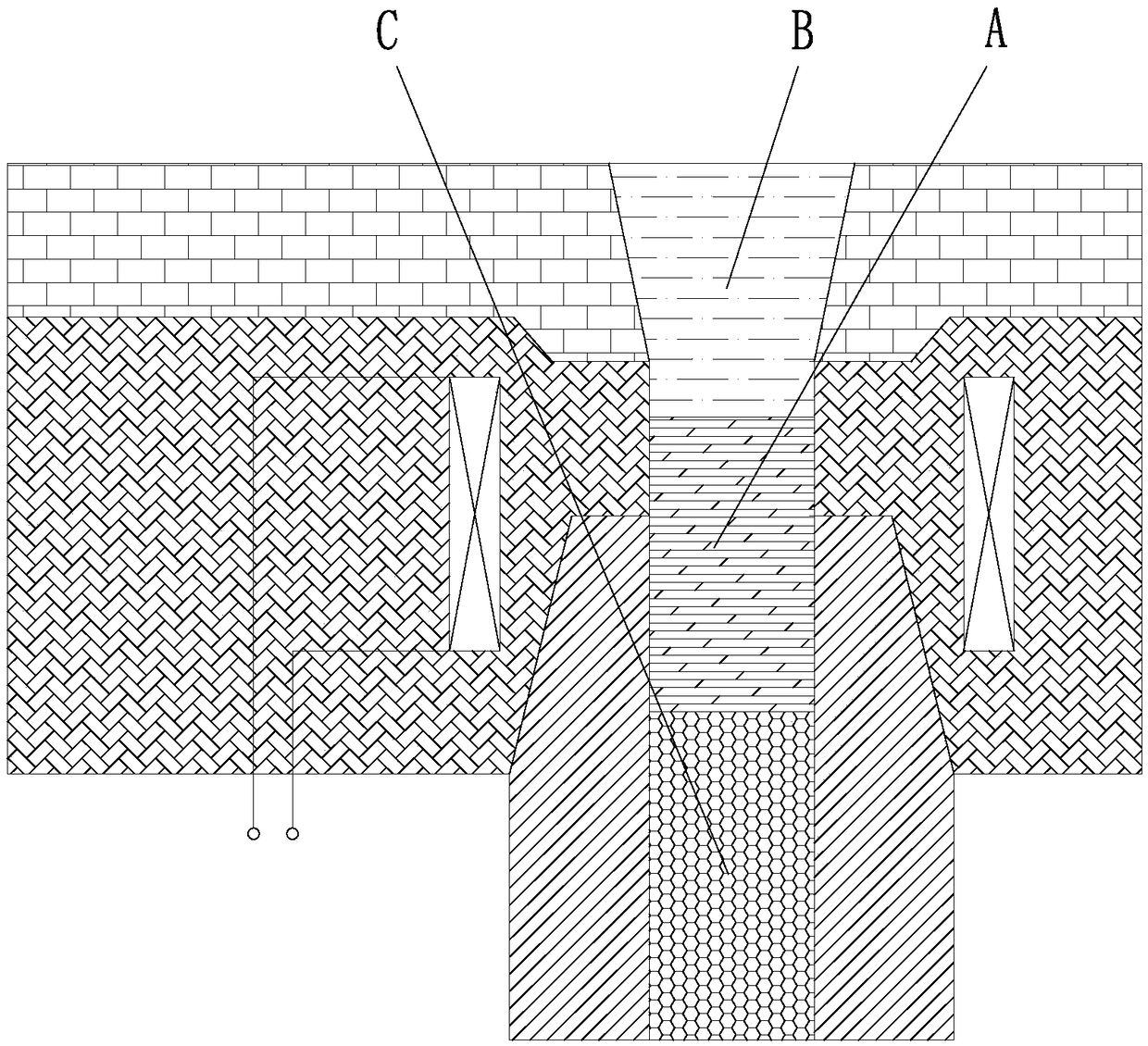

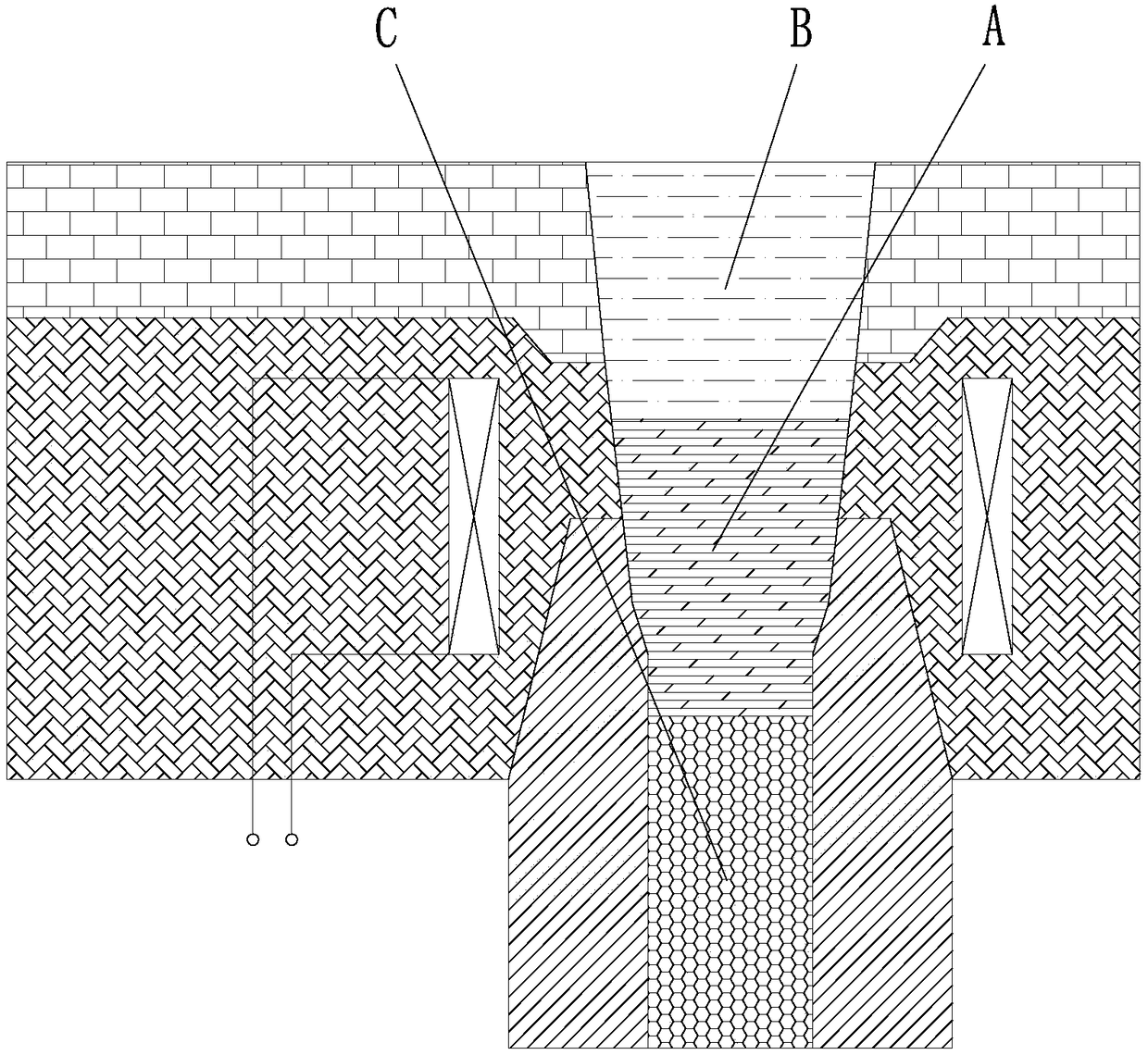

[0020] Such as figure 1 As shown, a combined nozzle seat brick based on electromagnetic induction heating tapping technology includes an upper brick body 1 and a lower brick body 2, and an induction coil 3 is poured and encapsulated inside the lower brick body 2, and the induction coil 3 The lead wires of the upper brick body 2 are drawn out from the bottom of the lower brick body 2, and are connected to the induction heating power supply through the bottom shell of the ladle; the upper brick body 1 is stacked on the top of the lower brick body 2, and the upper brick body 1 and the lower brick body 2 are positioned and connected through the protrusion and groove structure on the contact surface.

[0021] An upper molten steel channel 4 is arranged in the upper block body 1, and the upper molten steel channel 4 adopts a truncated conica

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap