Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Combustion chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A combustion chamber is that part of an internal combustion engine (ICE) or a reaction engine in which the fuel/air mix is burned.

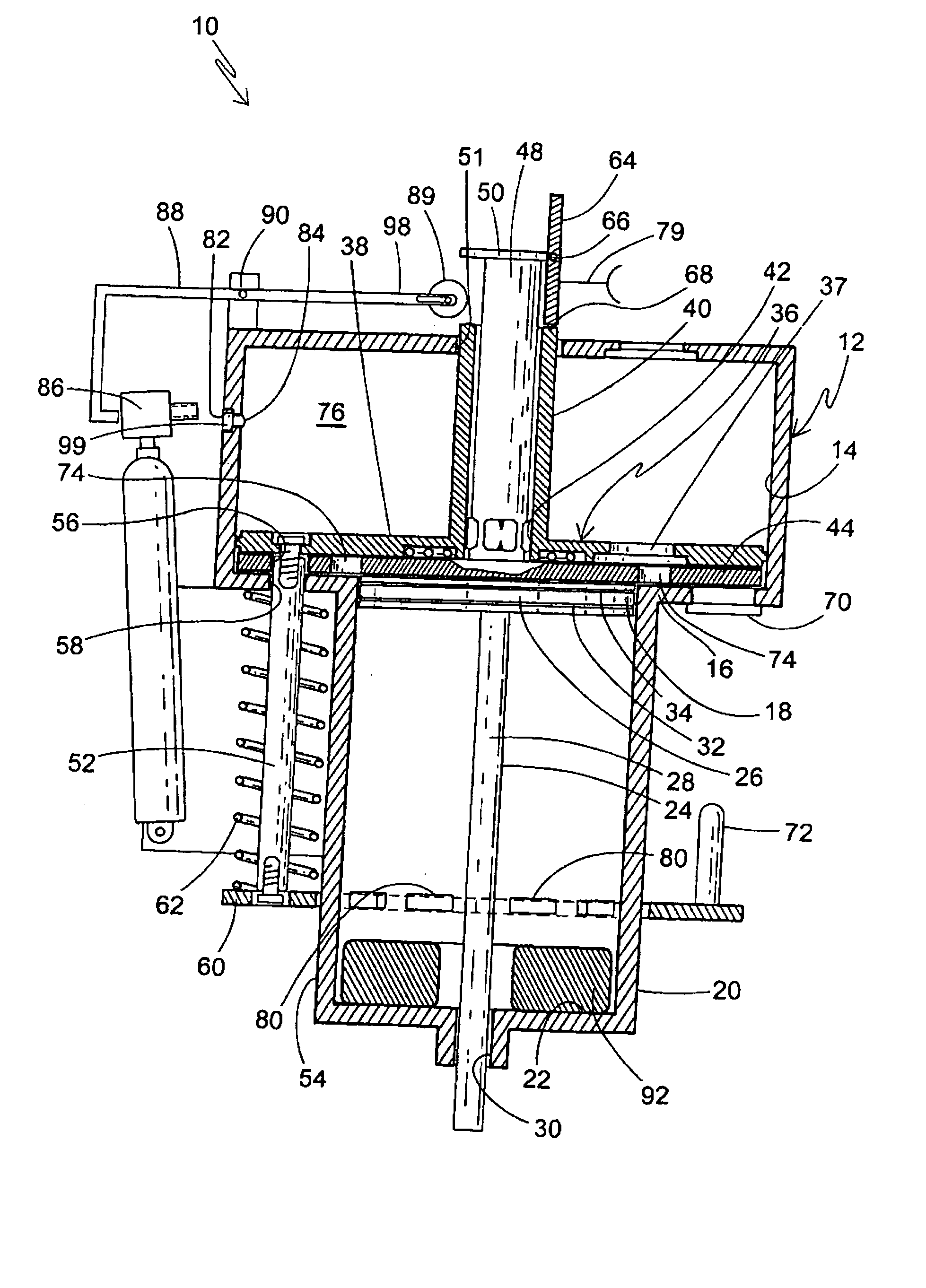

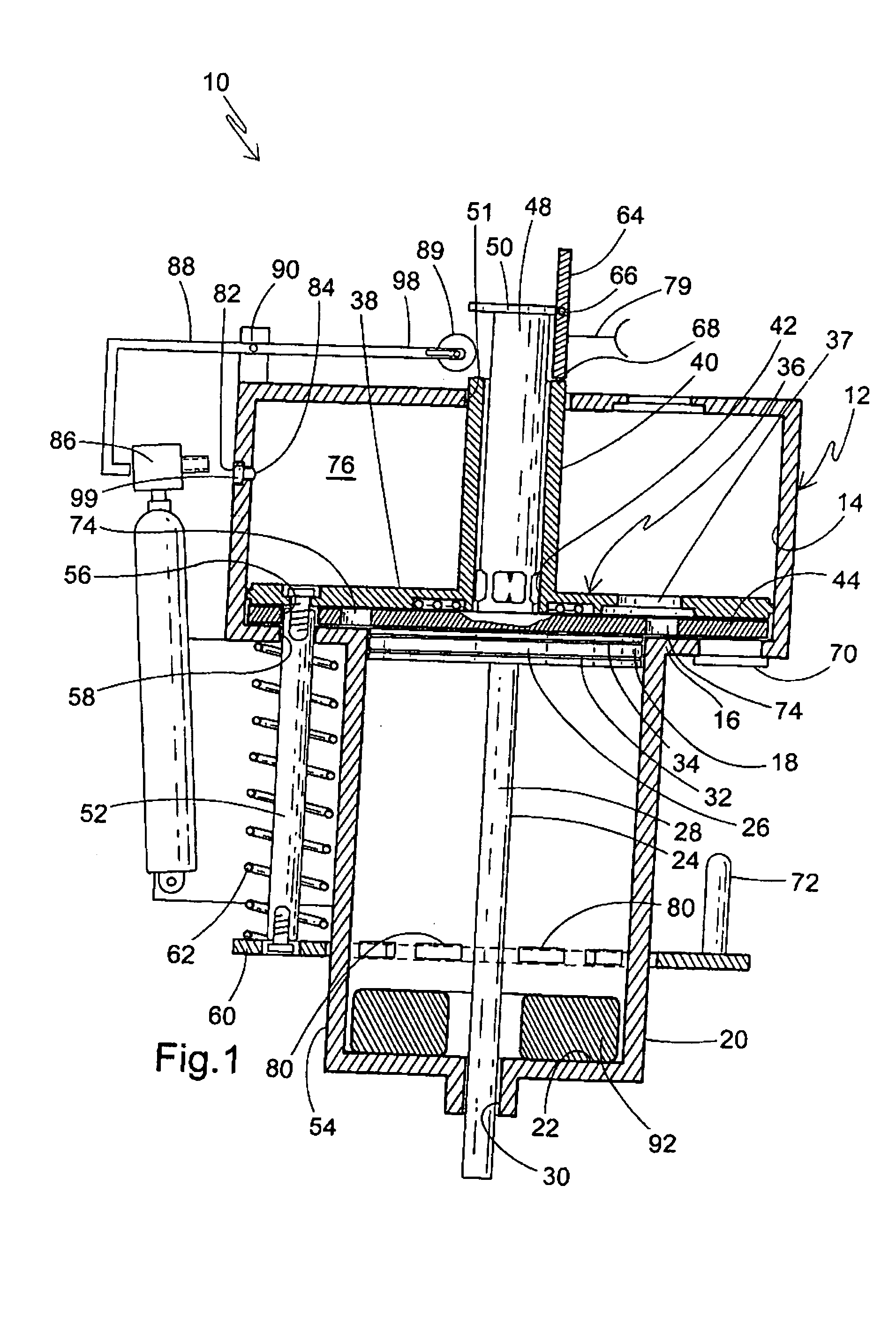

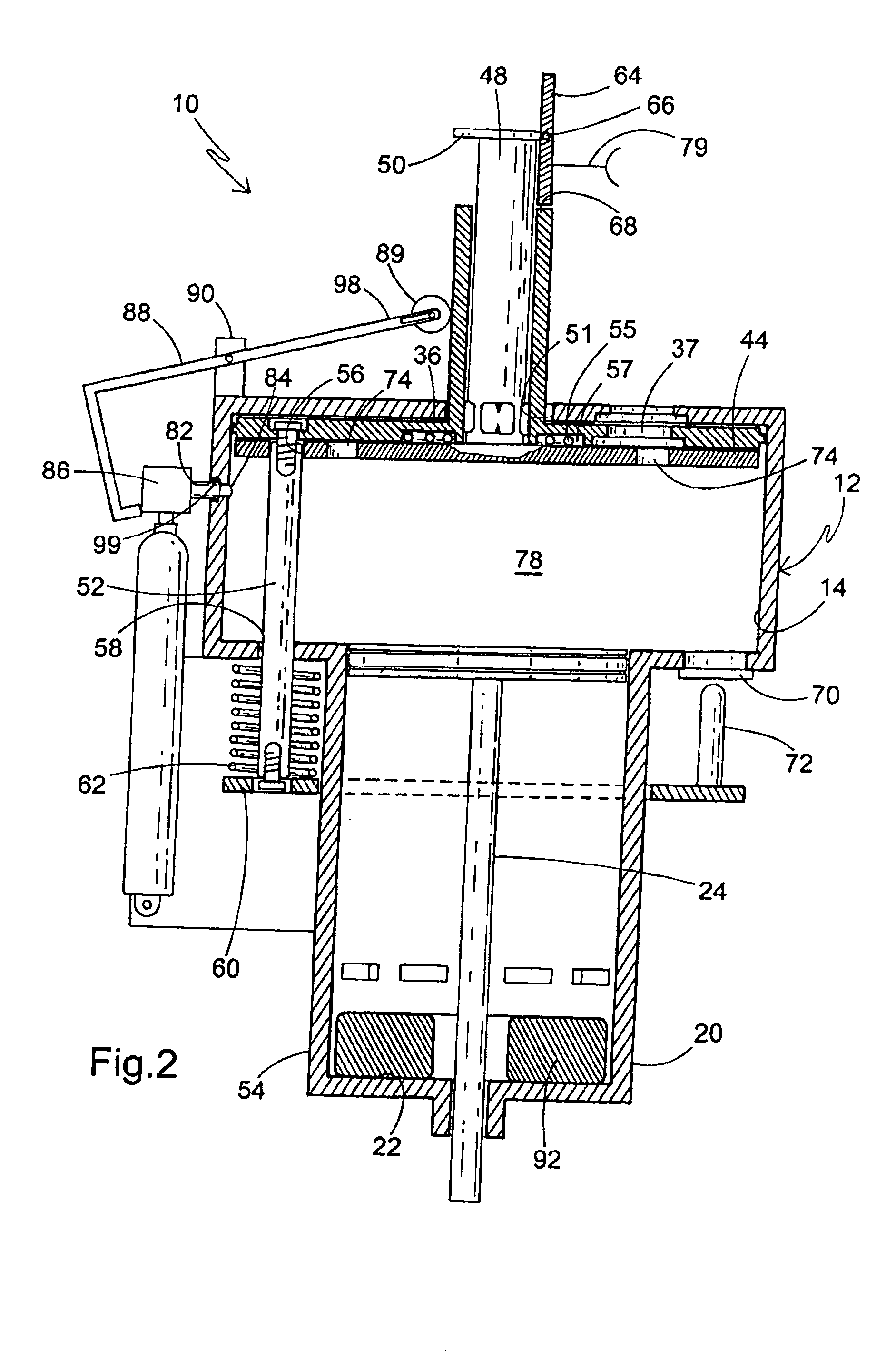

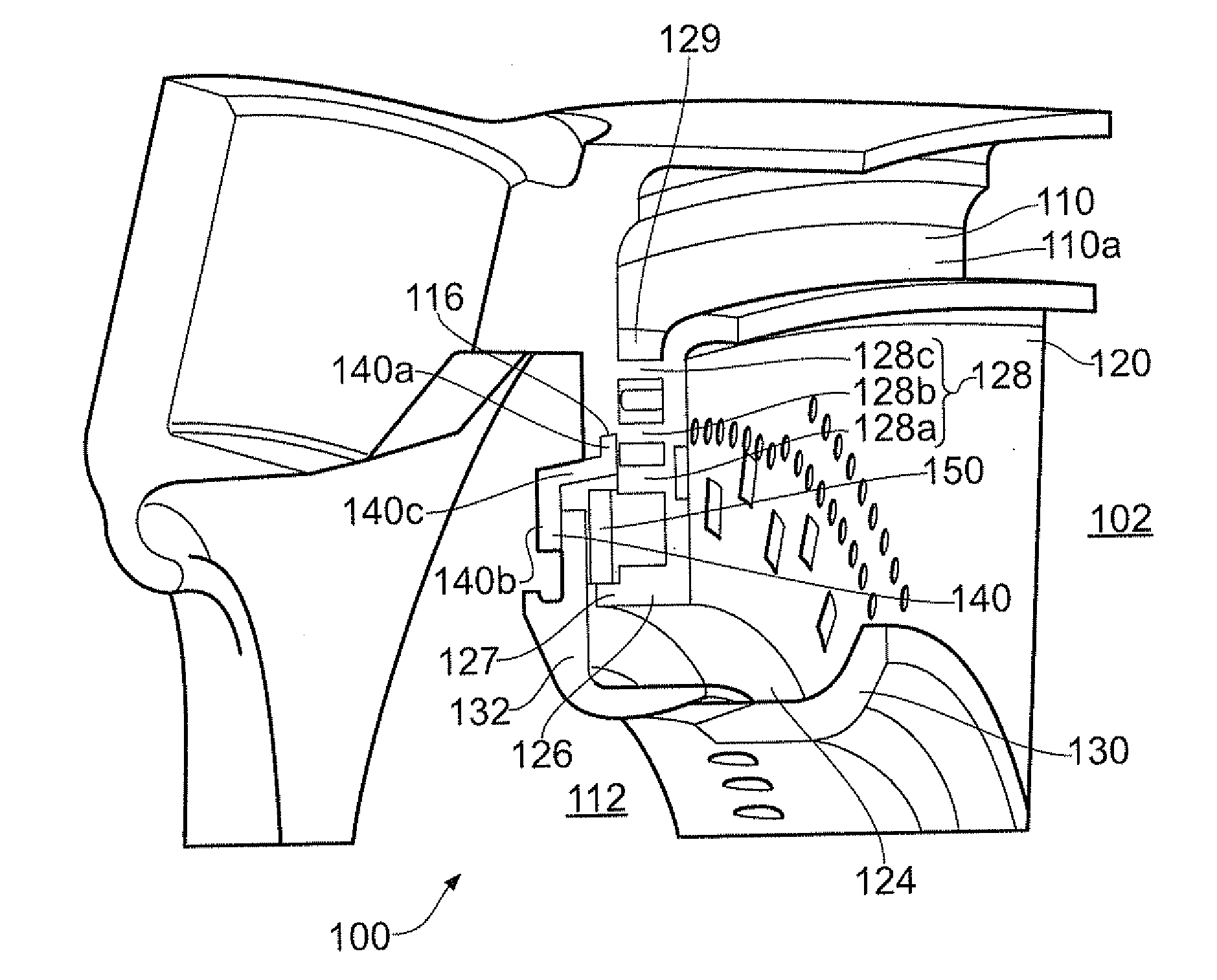

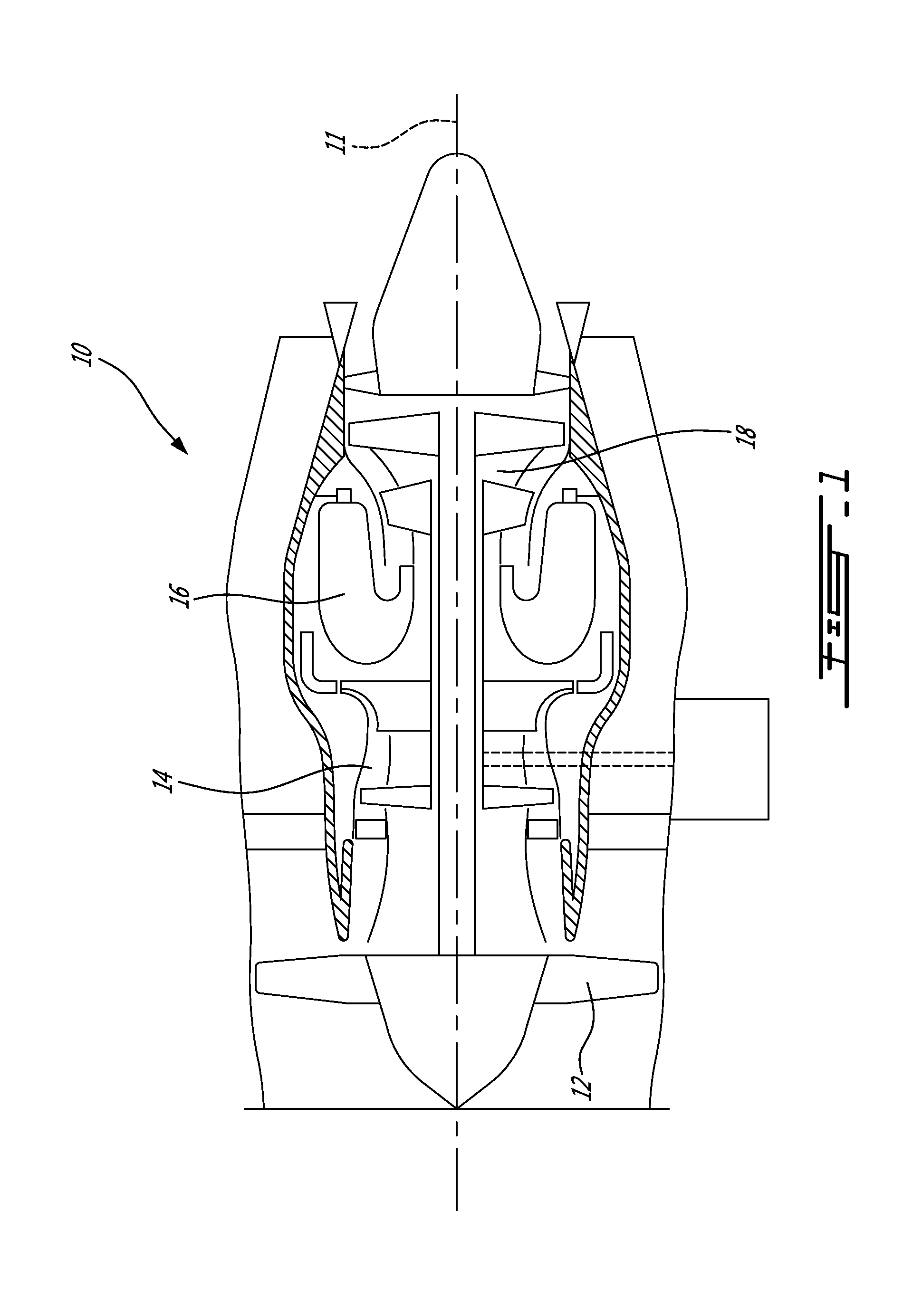

System and method for power production using a hybrid helical detonation device

InactiveUS20090102203A1Shorten the lengthFast fillEngine manufactureTurbine/propulsion fuel valvesCombustion chamberDeflagration to detonation transition

The system and method described herein uses a hybrid pulsed detonation engine (PDE) system to drive a turbine that powers an electric generator. The combustion chamber of the PDE is shaped in a helical form, so that the external length of the section is reduced, while maintaining the distance for acceleration to detonation. This allows the achievement of deflagration to detonation transition without the help of turbulence enhancing obstacles, while keeping the overall size of the detonation tube small. The PDE output can be scaled by: increasing the cross sectional area of the detonation chamber; increasing the number of detonation tubes; and increasing the frequency of operation of the PDE. The replacement of conventional deflagrative internal combustion engines, including gas turbines and reciprocating engines, with pulsed detonation engines for electric power generation, may provide fuel savings and have a lower environmental impact.

Owner:LU FR K +4

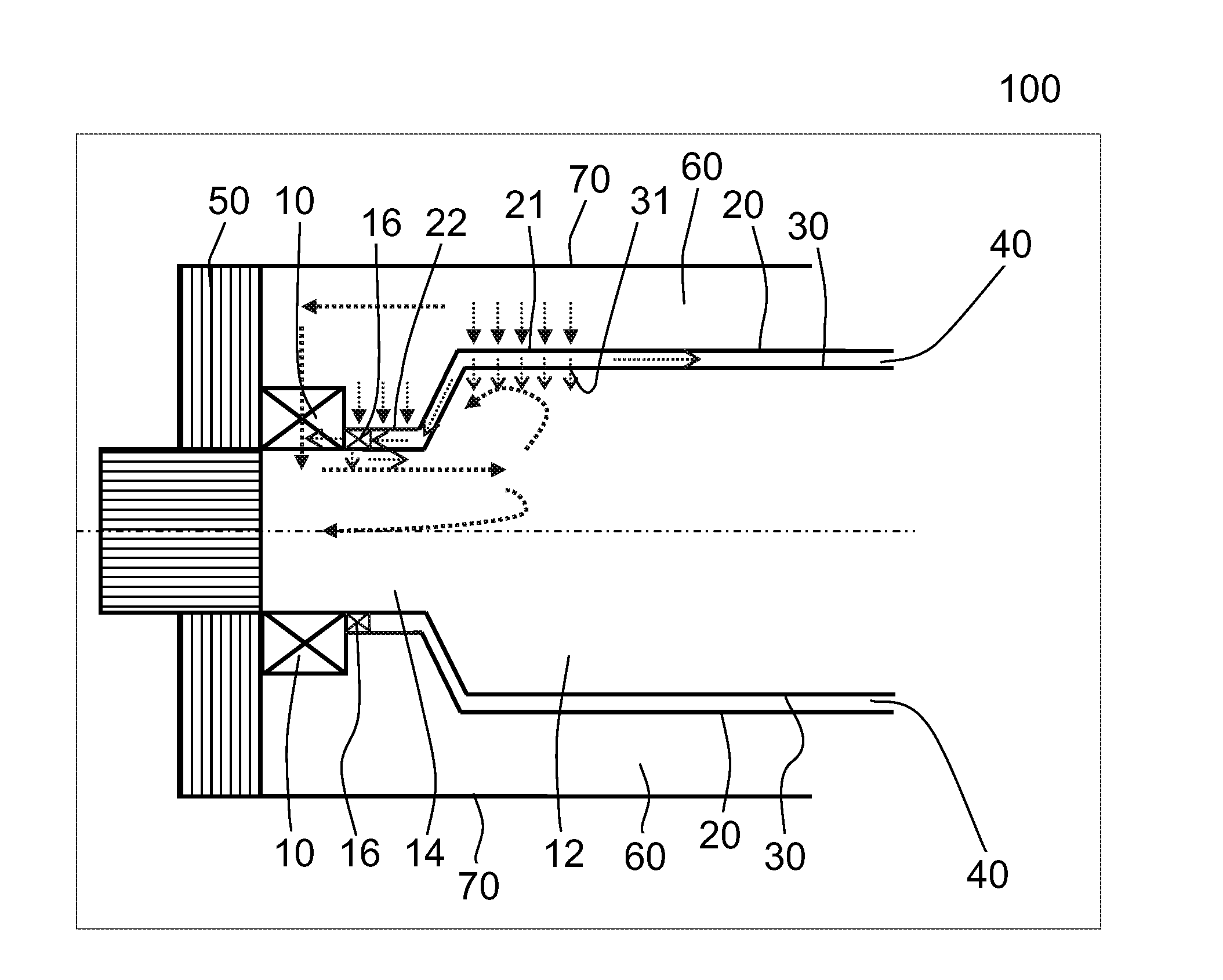

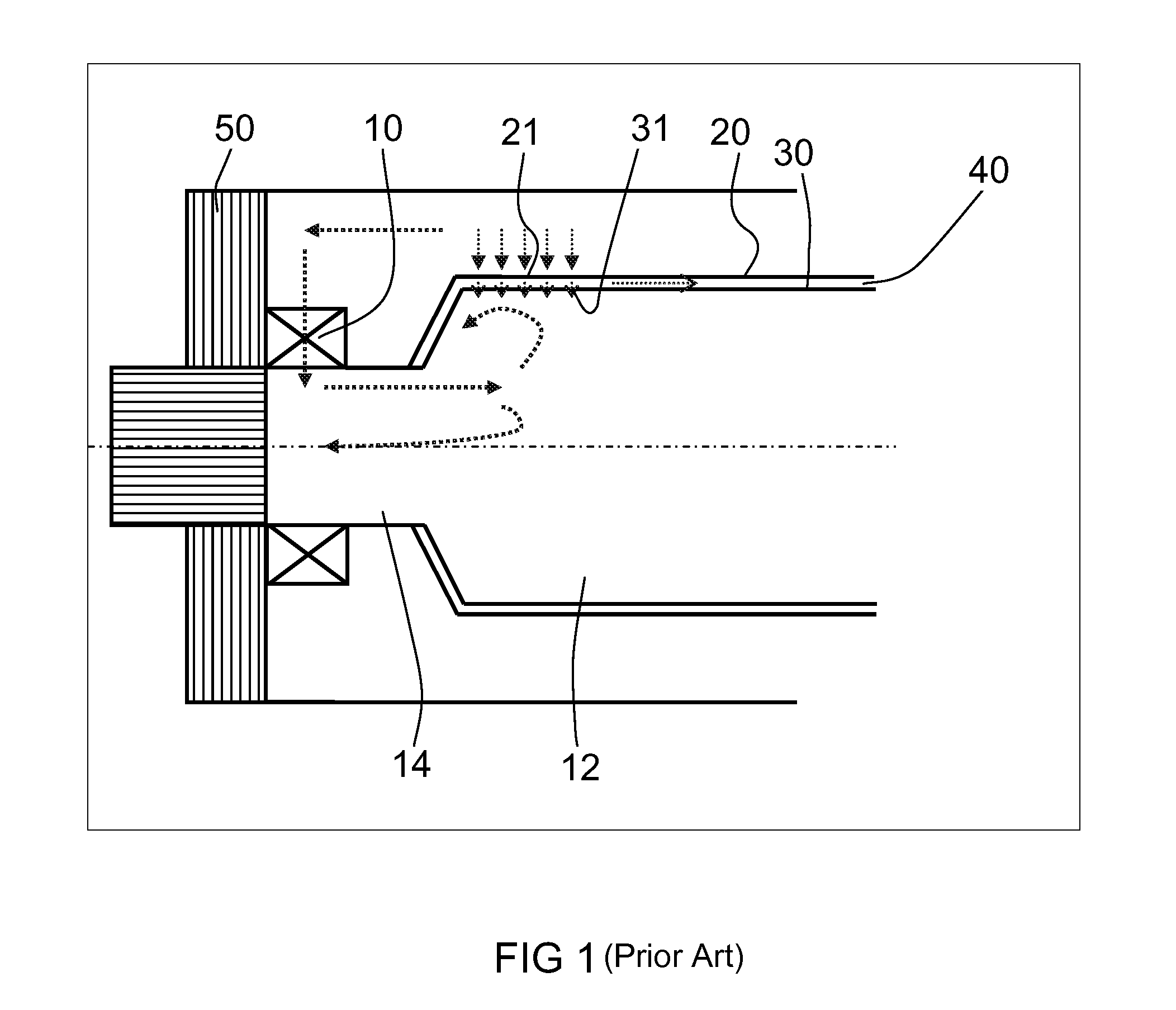

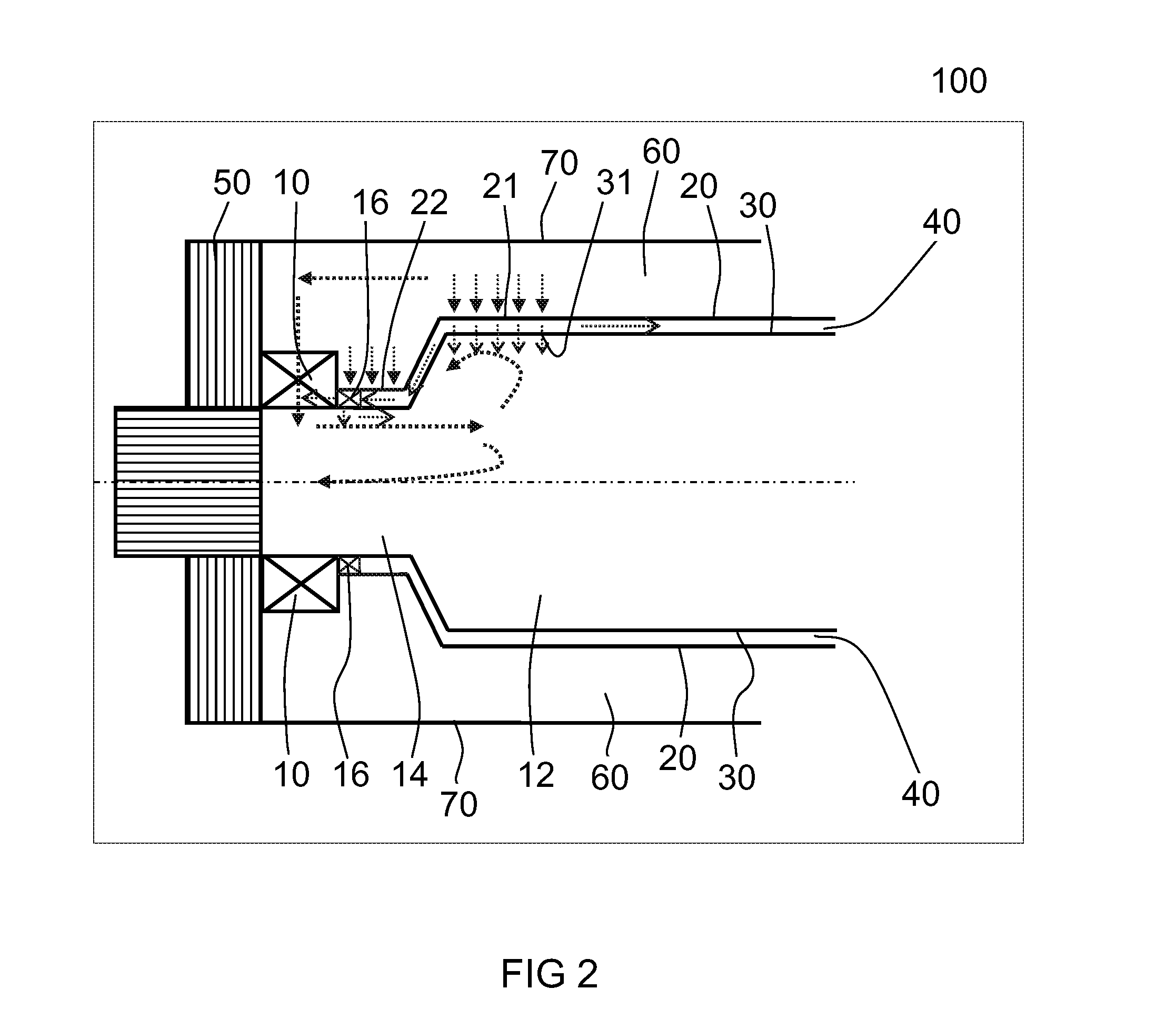

Counter-flow flame combustion chamber

Owner:BEIHANG UNIV

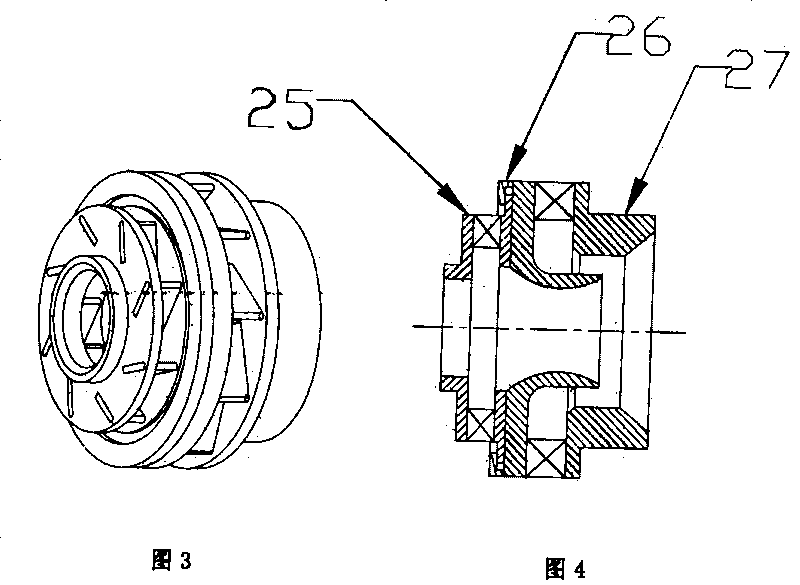

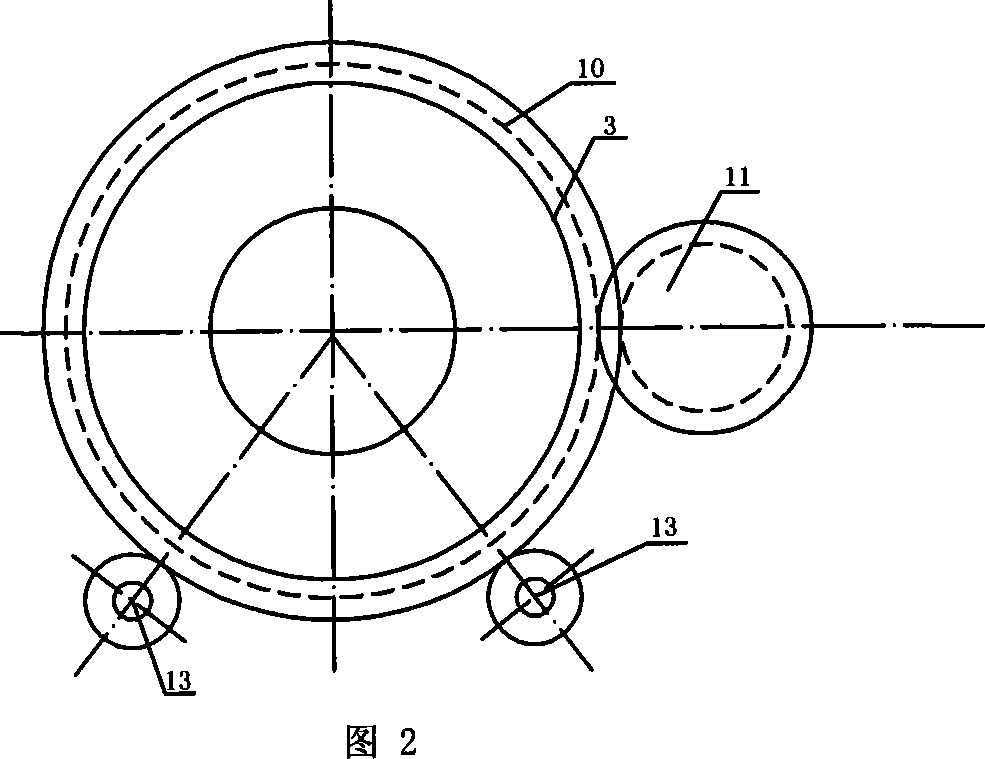

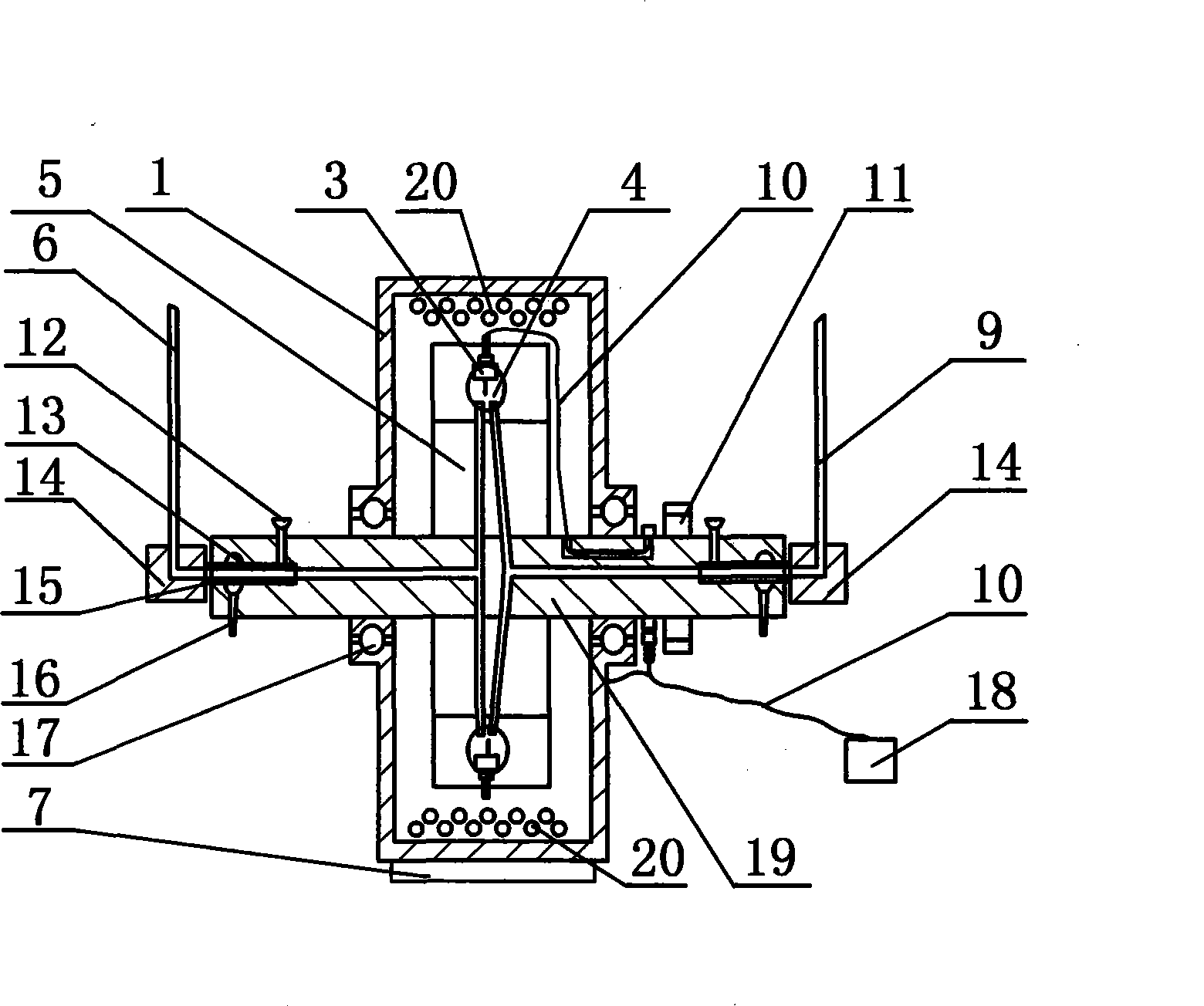

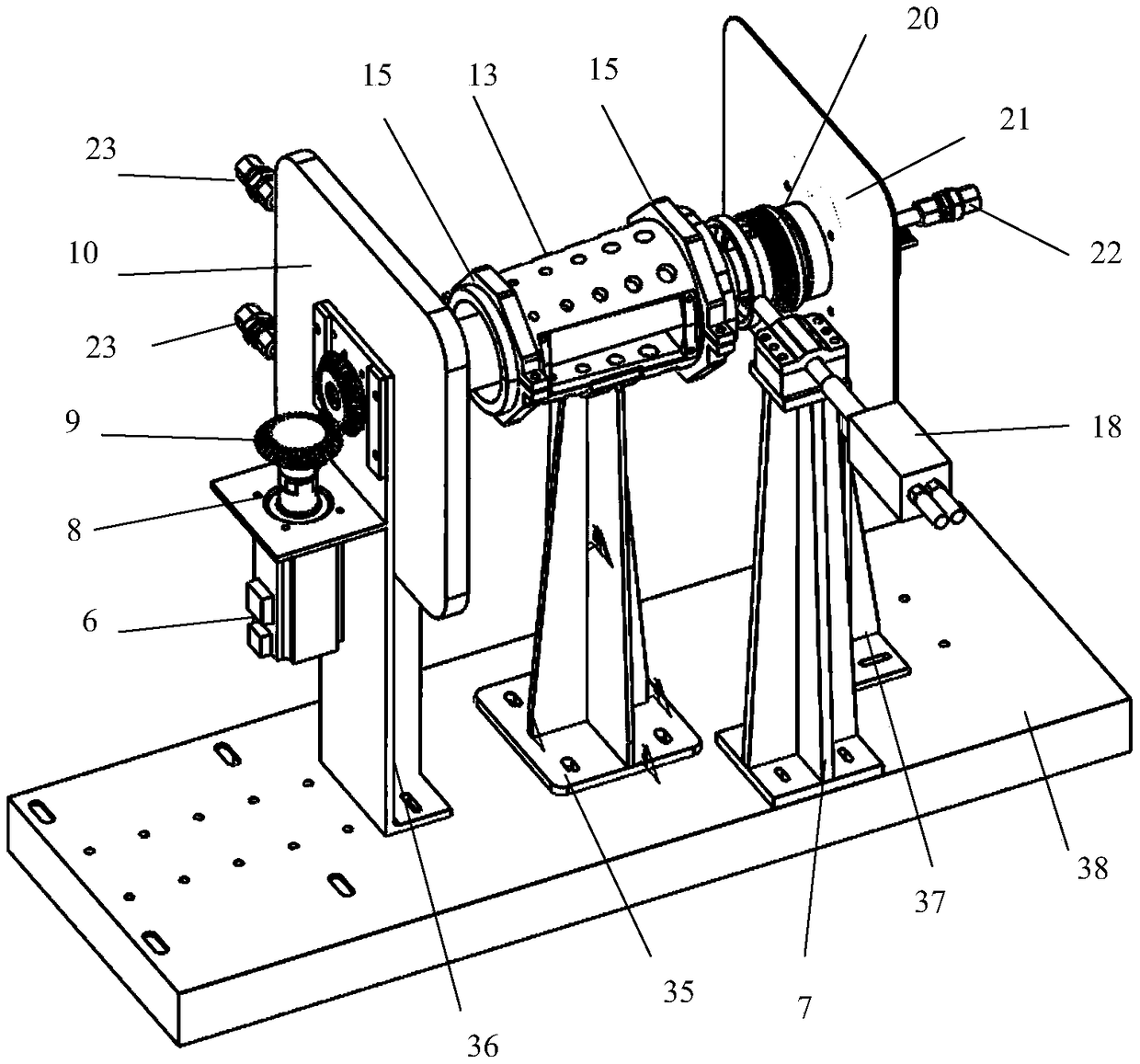

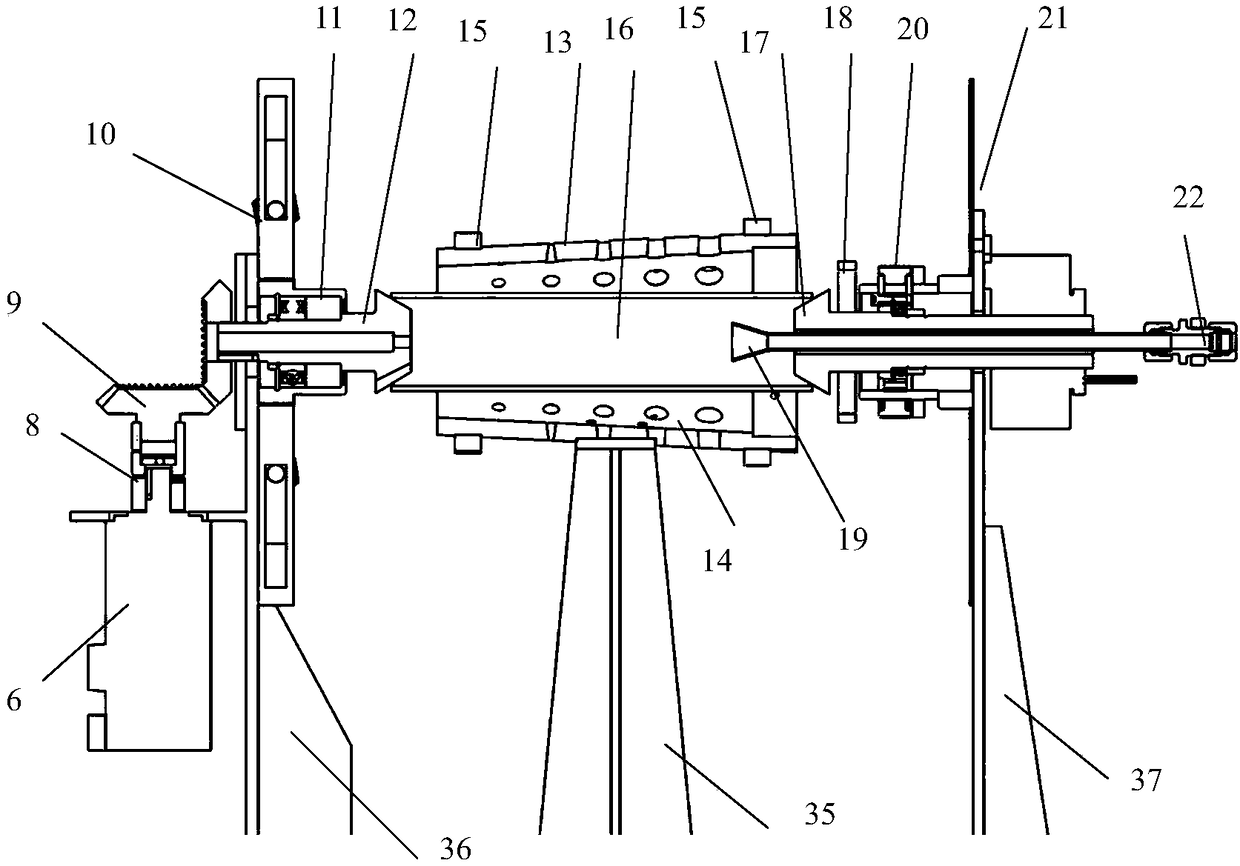

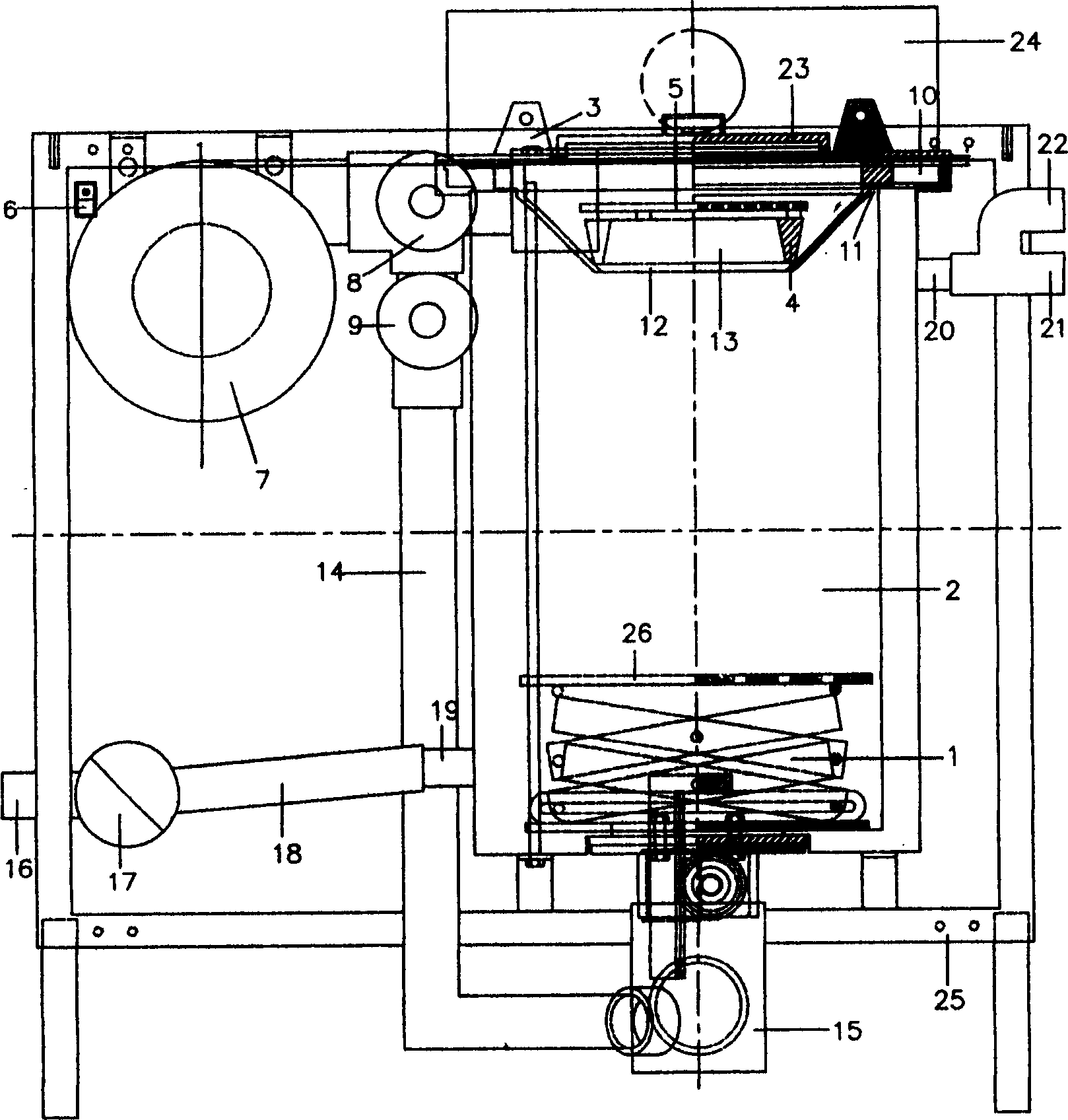

Sliding-disc-valve solid rocket ramjet engine flow-adjustable gas generator

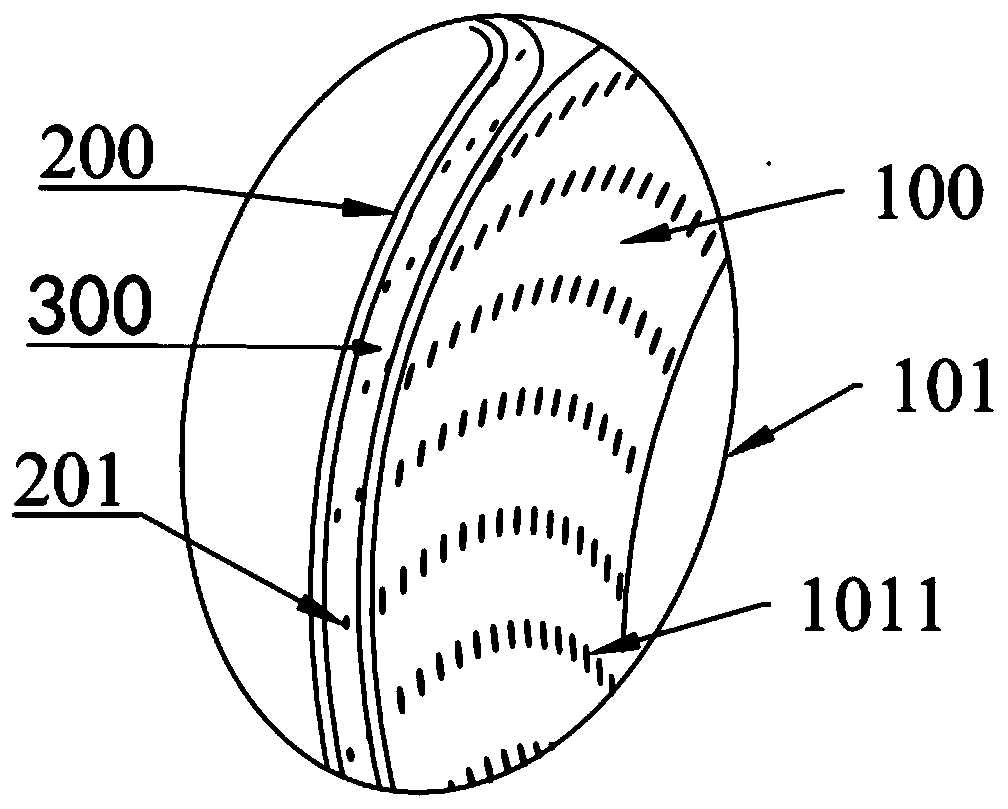

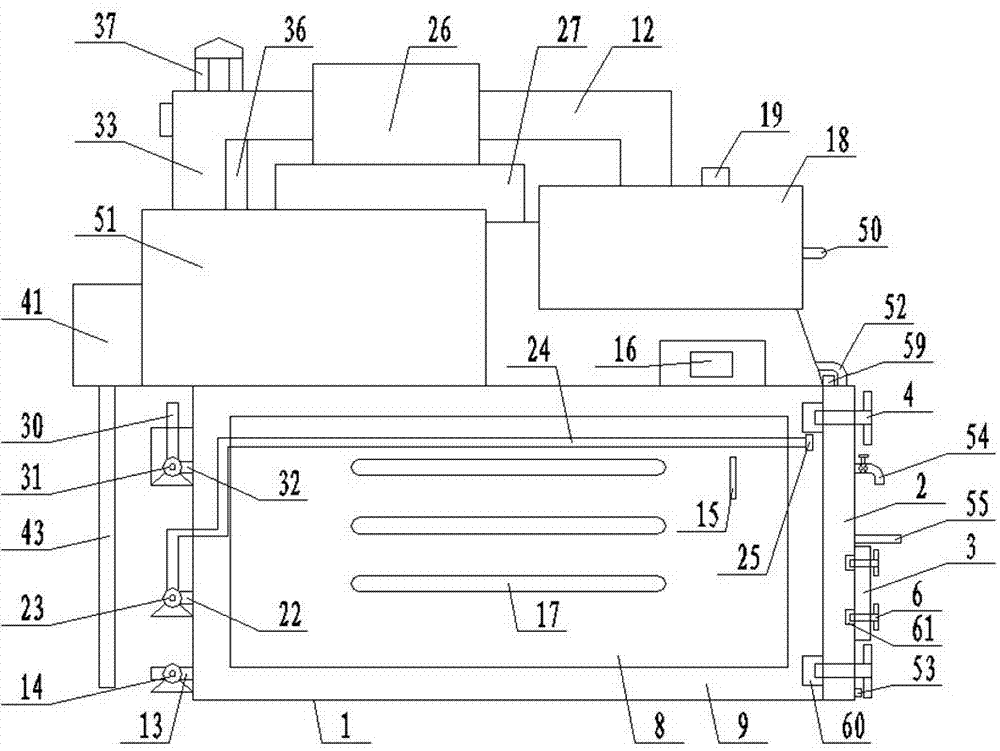

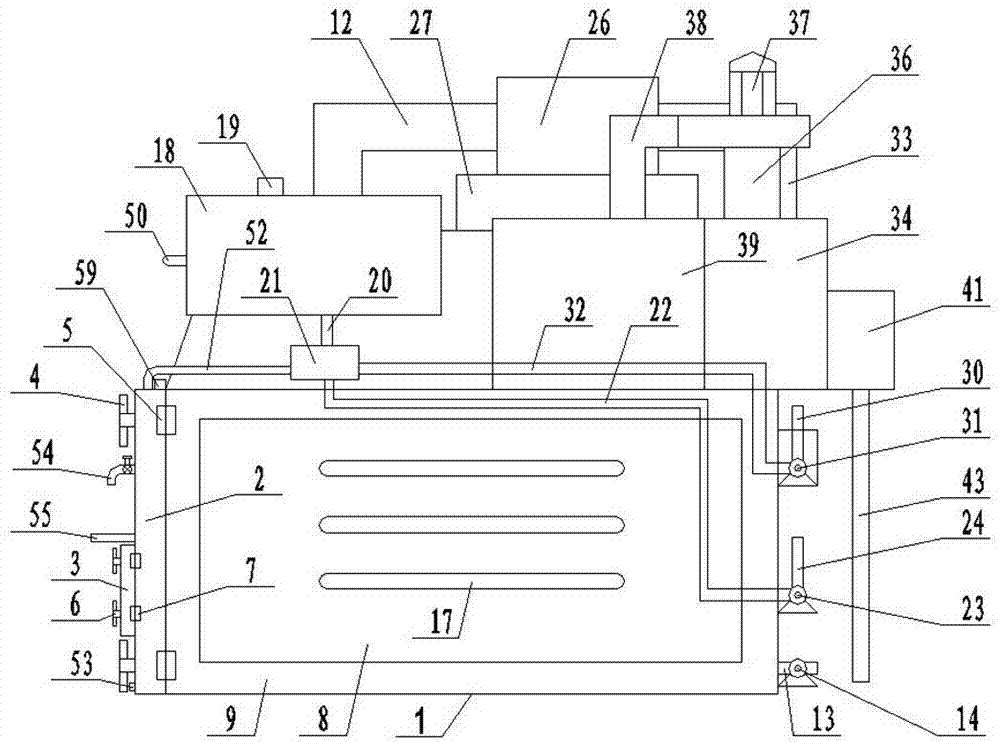

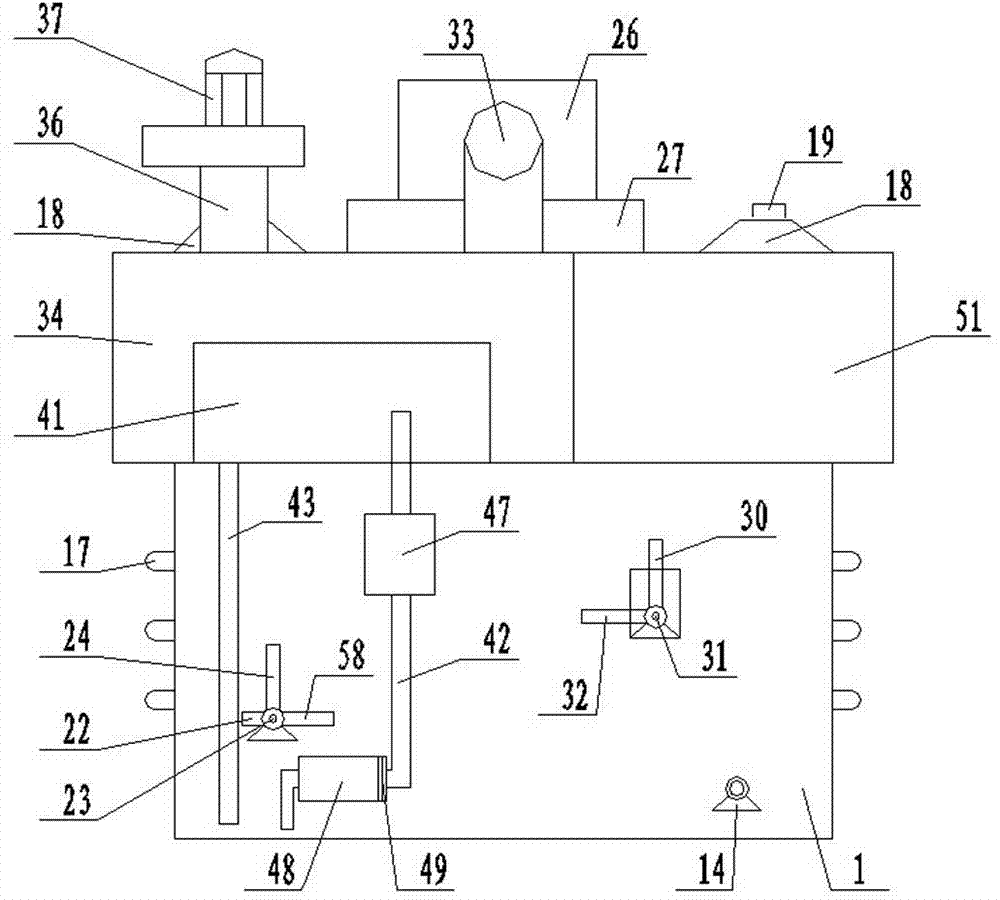

ActiveCN110552814AExpand charge spaceCircumvent thermal protectionRocket engine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a sliding-disc-valve solid rocket ramjet engine flow-adjustable gas generator which comprises a combustion chamber, a combustion chamber end cover, a motor fixing frame, a rotating servo motor, a control panel, a fan-shaped gear, a sliding disc valve sleeve, a spray pipe, a planetary gear speed reducer, an arc-shaped gear rack and a sliding disc valve, wherein the combustion end cover is fixedly connected with the spray pipe and fixed with the combustion chamber; one end of the sliding disc valve sleeve is arranged on the excircle of the spray pipe in a sleeving manner;the sliding disc valve sleeve and the spray pipe are sealed with each other and capable of rotating relative to each other; the other end of the sliding disc valve sleeve is fixedly connected with the sliding disc valve; the rotating servo motor is fixed on the combustion chamber end cover and connected with the fan-shaped gear through the planetary gear speed reducer; the arc-shaped gear rack isarranged on the excircle of the sliding disc valve sleeve; the fan-shaped gear is meshed with the arc-shaped gear rack; a group of vent holes are formed in an end cover of the spray pipe; a group ofadjusting holes are formed in the sliding disc valve; the positions of the adjusting holes directly face those of the vent holes; and the control panel is used for controlling the rotating angle of the rotating servo motor. By the adoption of the sliding-disc-valve solid rocket ramjet engine flow-adjustable gas generator disclosed by the invention, the accurate control of gas flow can be achieved.

Owner:NANJING UNIV OF SCI & TECH

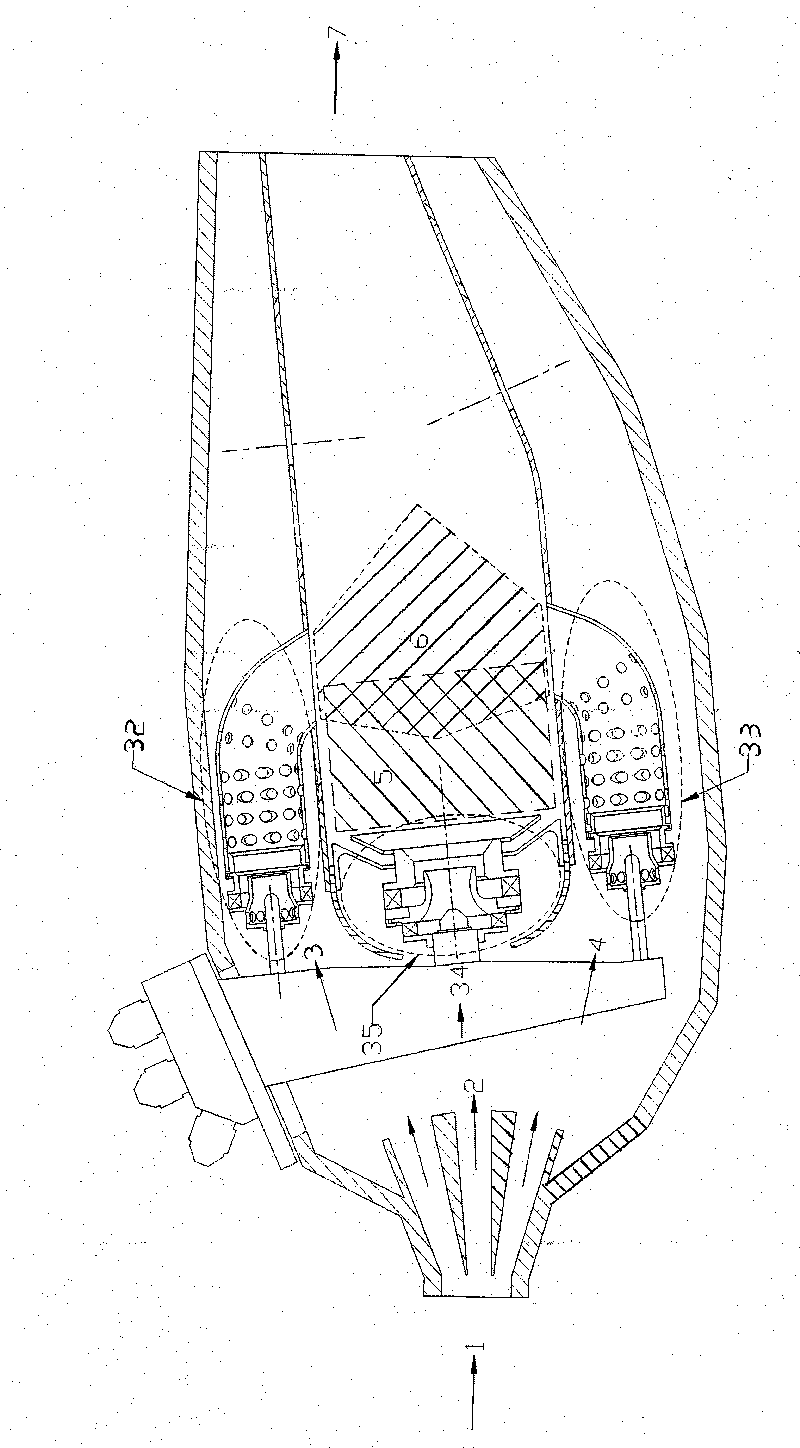

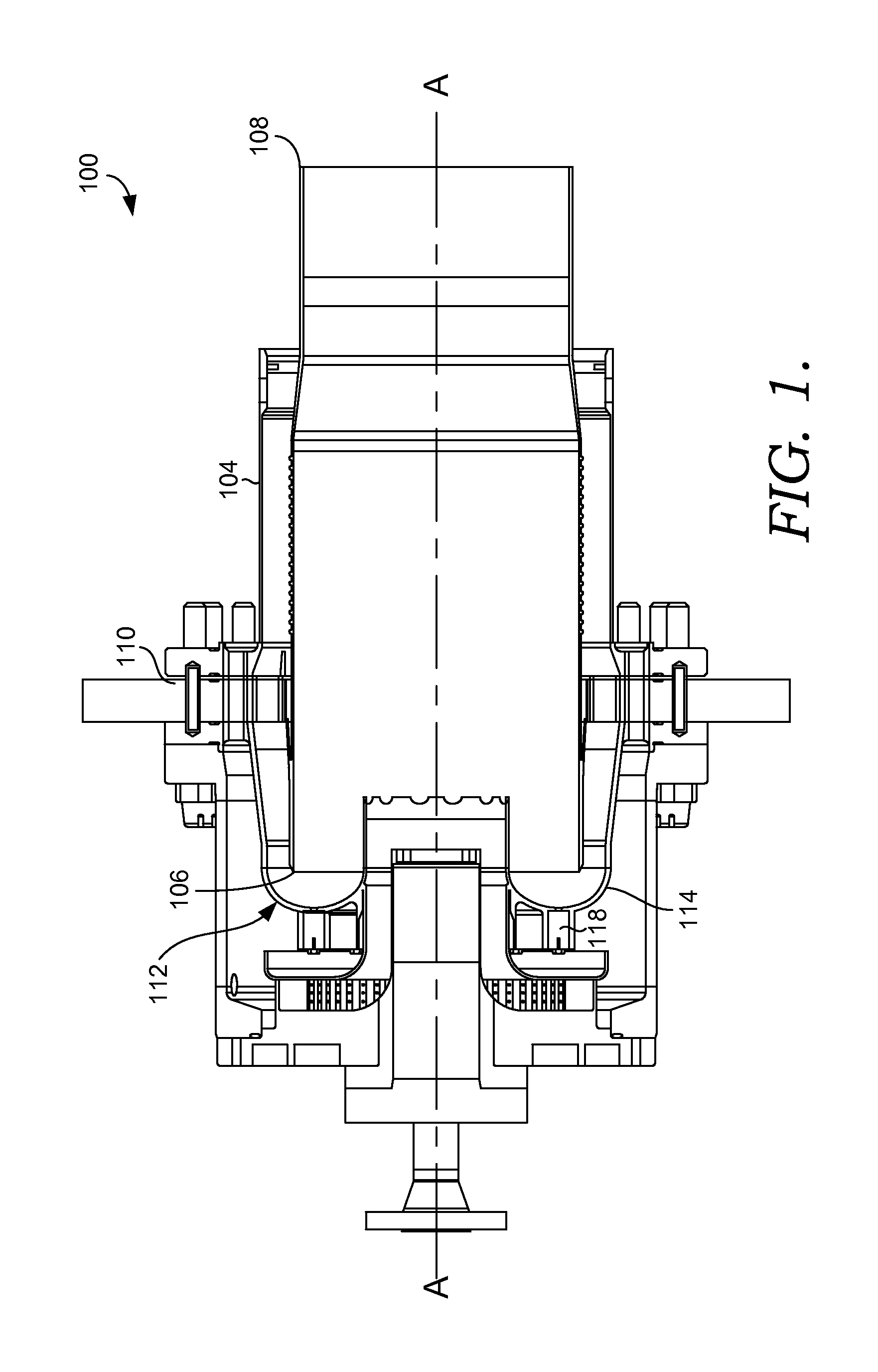

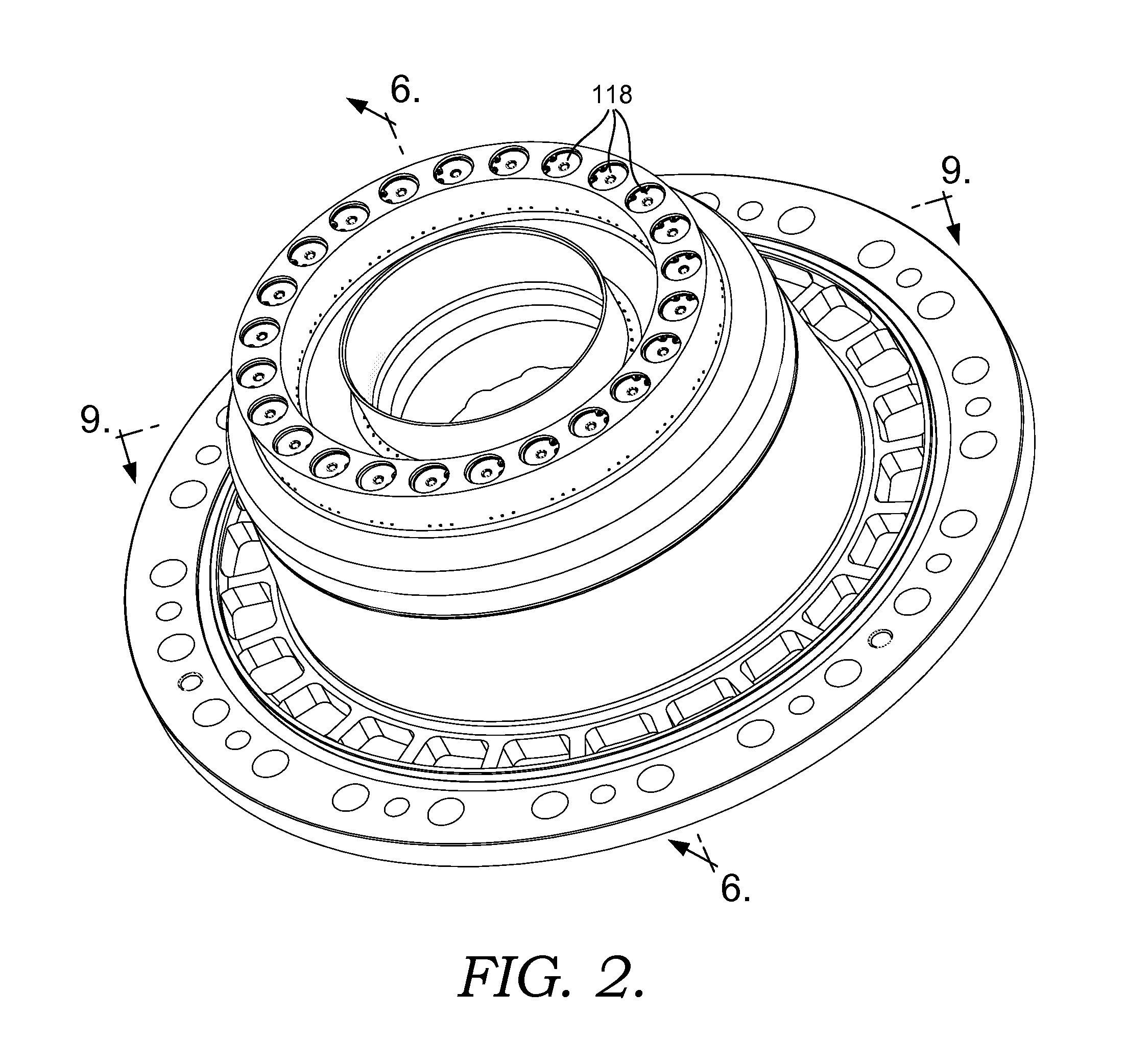

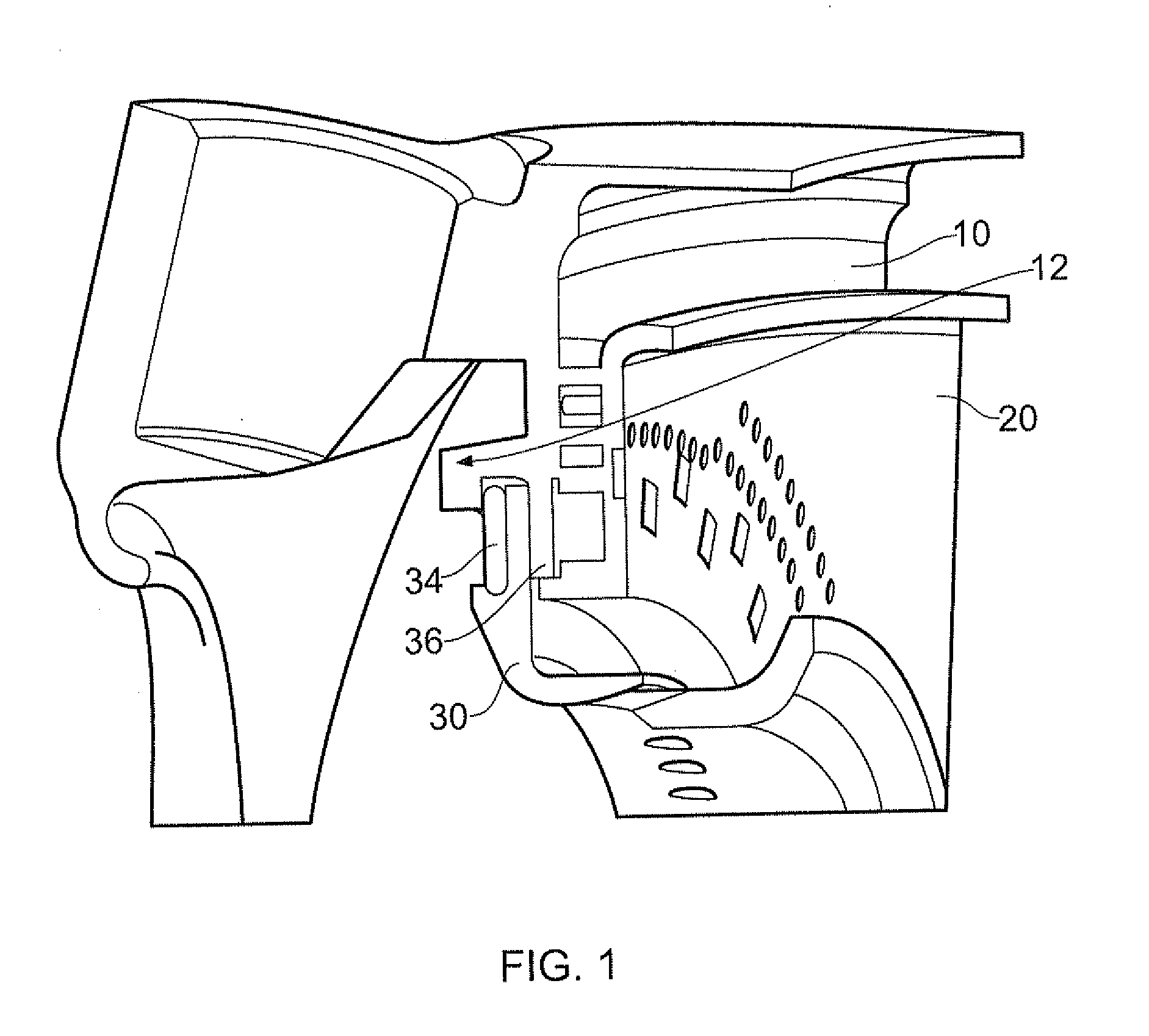

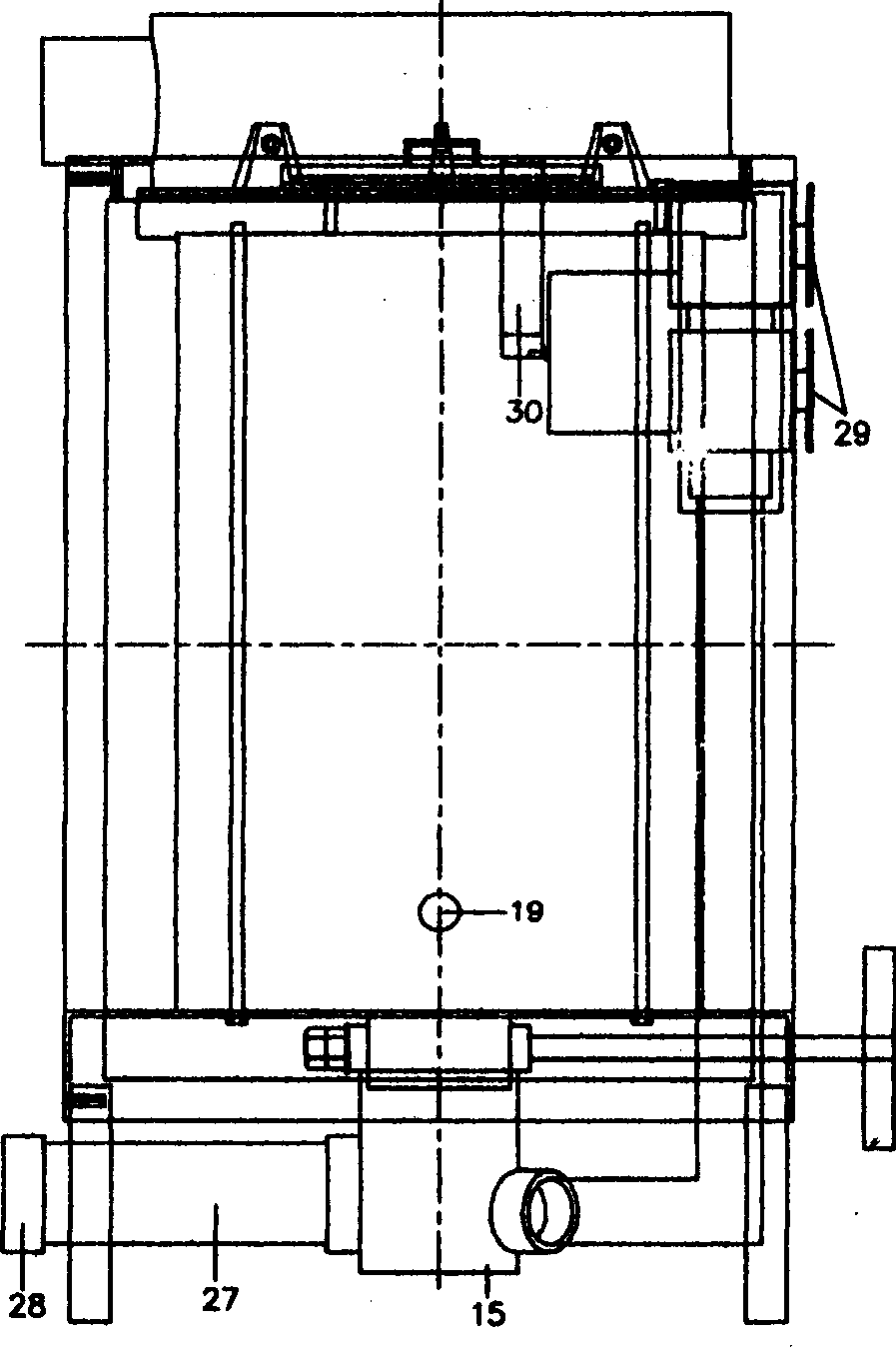

Turbine, particularly useful for small aircraft

InactiveUS20060107647A1Reducing weight and quantityImprove efficiencyRotary bearingsTurbine/propulsion fuel supply systemsCombustion chamberLow speed

A turbine includes a combustion chamber with deflectors generating vortices in a secondary gas flow into the combustion chamber, thereby confining the flame front from penetrating into the cold region of the chamber under variable operating conditions, simplifying cooling of the chamber walls. The turbine further includes devices for decoupling vibrations between the high- and low-speed shafts, including a loosely mounted spline coupling the high-speed shaft to the step-down system and disk dampening means coupling the step-down system to the low-speed output shaft.

Owner:FLORESTAN TECH PTY LTD

Latching mechanism for combustion chamber plate of a fastener driving tool

InactiveUS20050091962A1Less-expensive to manufactureLess-expensive to repairCombustion enginesGas turbine plantsCombustion chamberReciprocating motion

Owner:ILLINOIS TOOL WORKS INC

Combustor dome damper system

ActiveUS20160076772A1Adequately pressure fluctuationSmall sizeContinuous combustion chamberEngine fuctionsCombustion chamberCombustor

Owner:H2 IP UK LTD

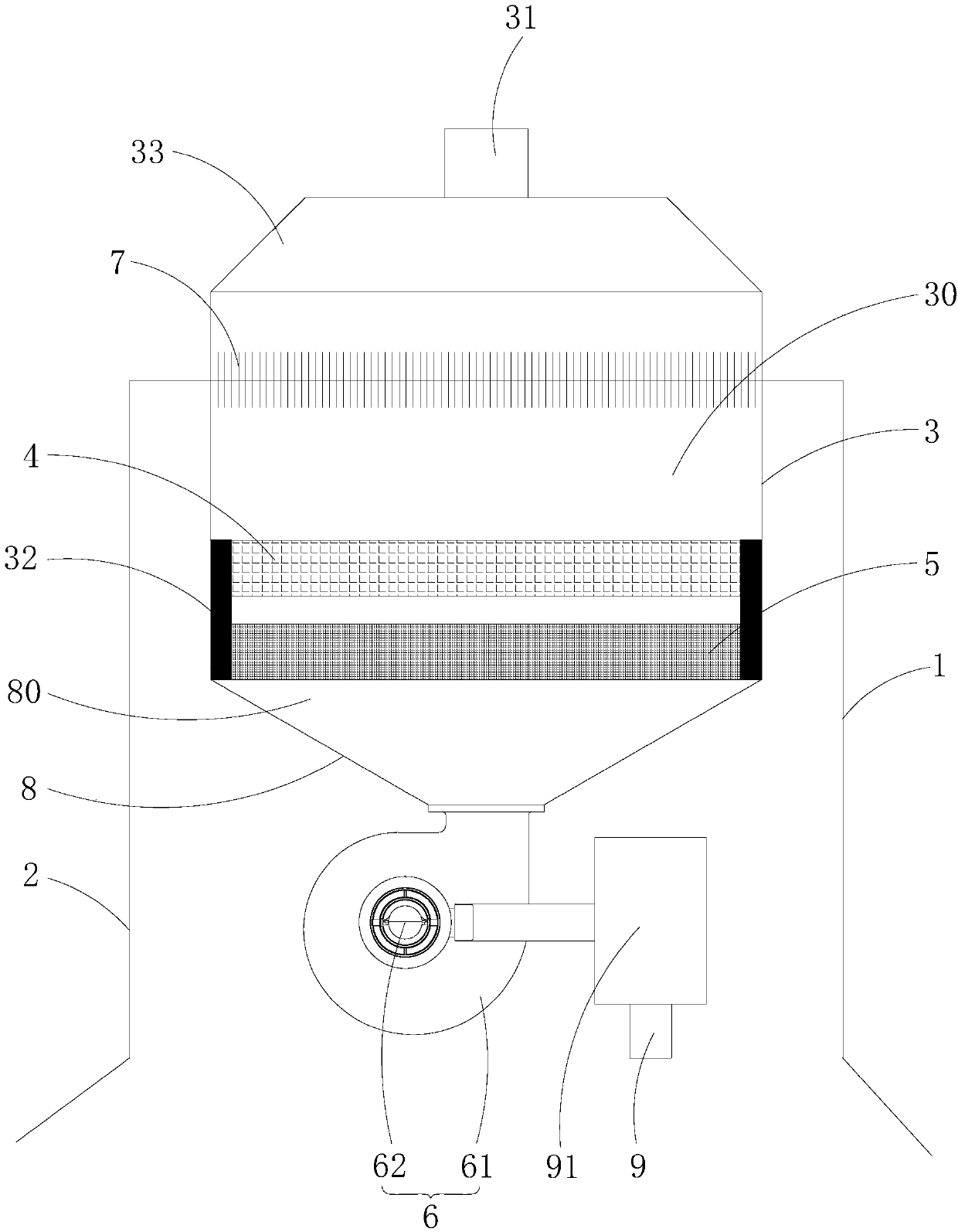

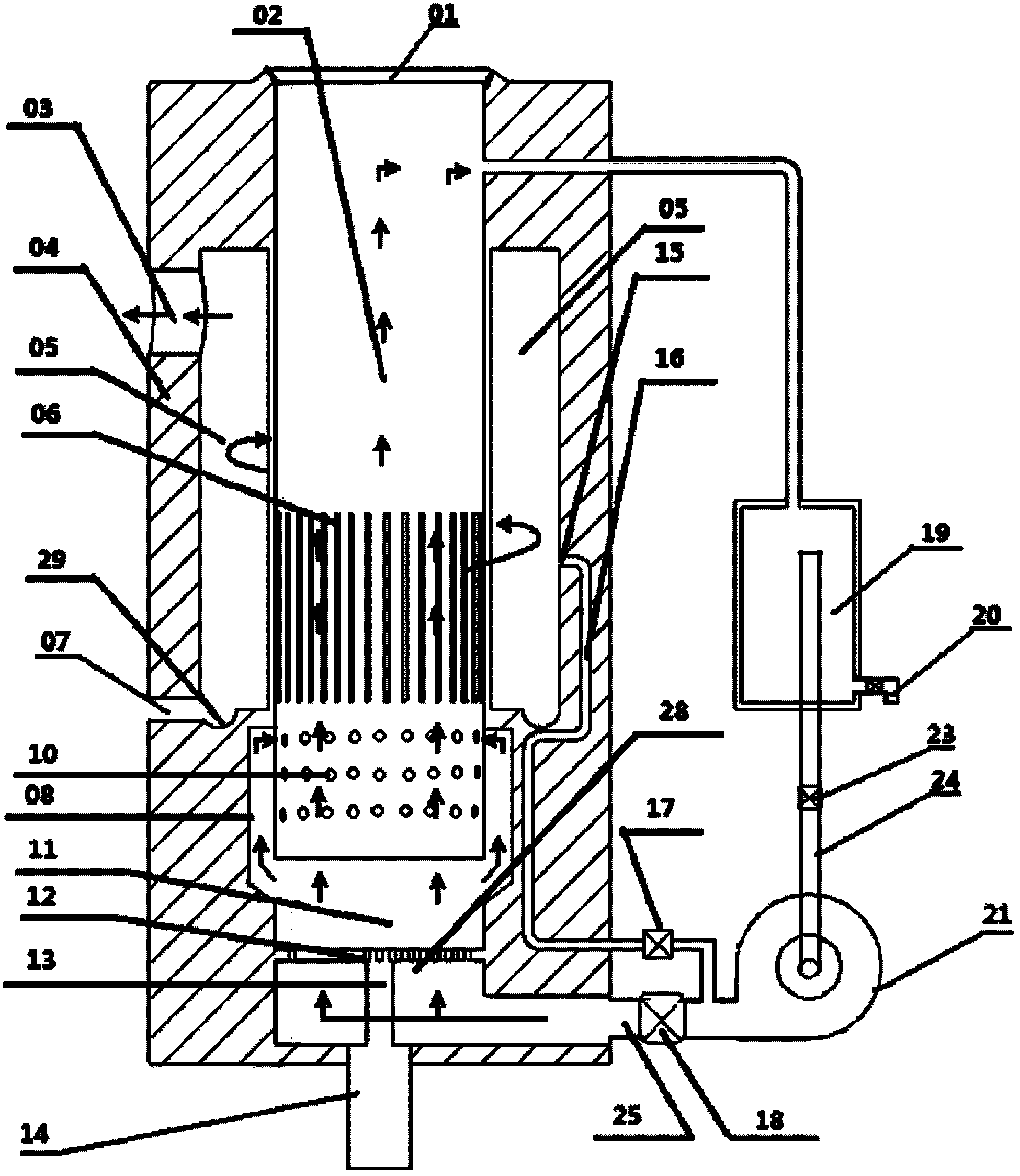

Gas water heater

PendingCN109708299ASimple structureCompact structureWater heatersGaseous fuel burnerPlate heat exchangerCombustion chamber

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

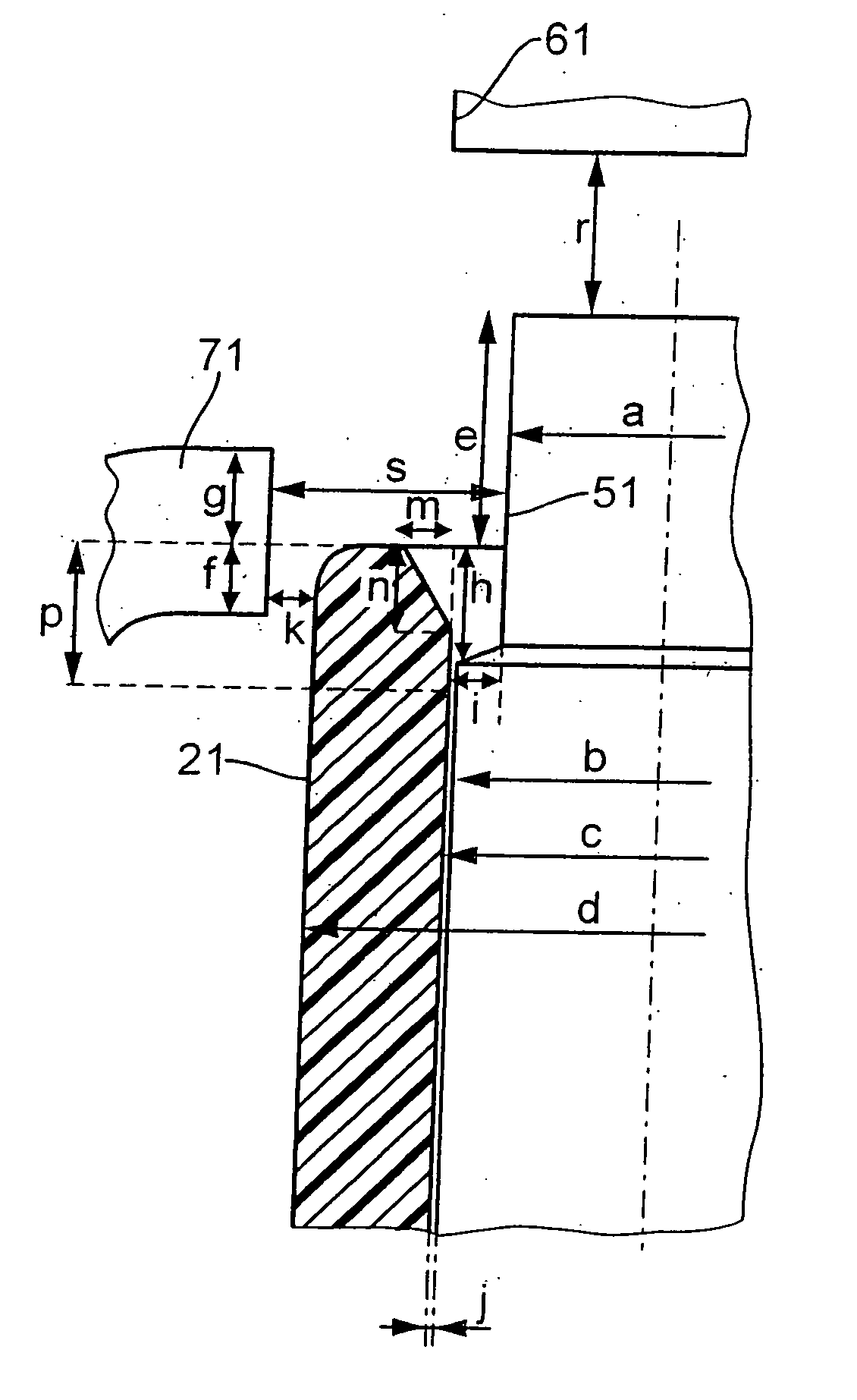

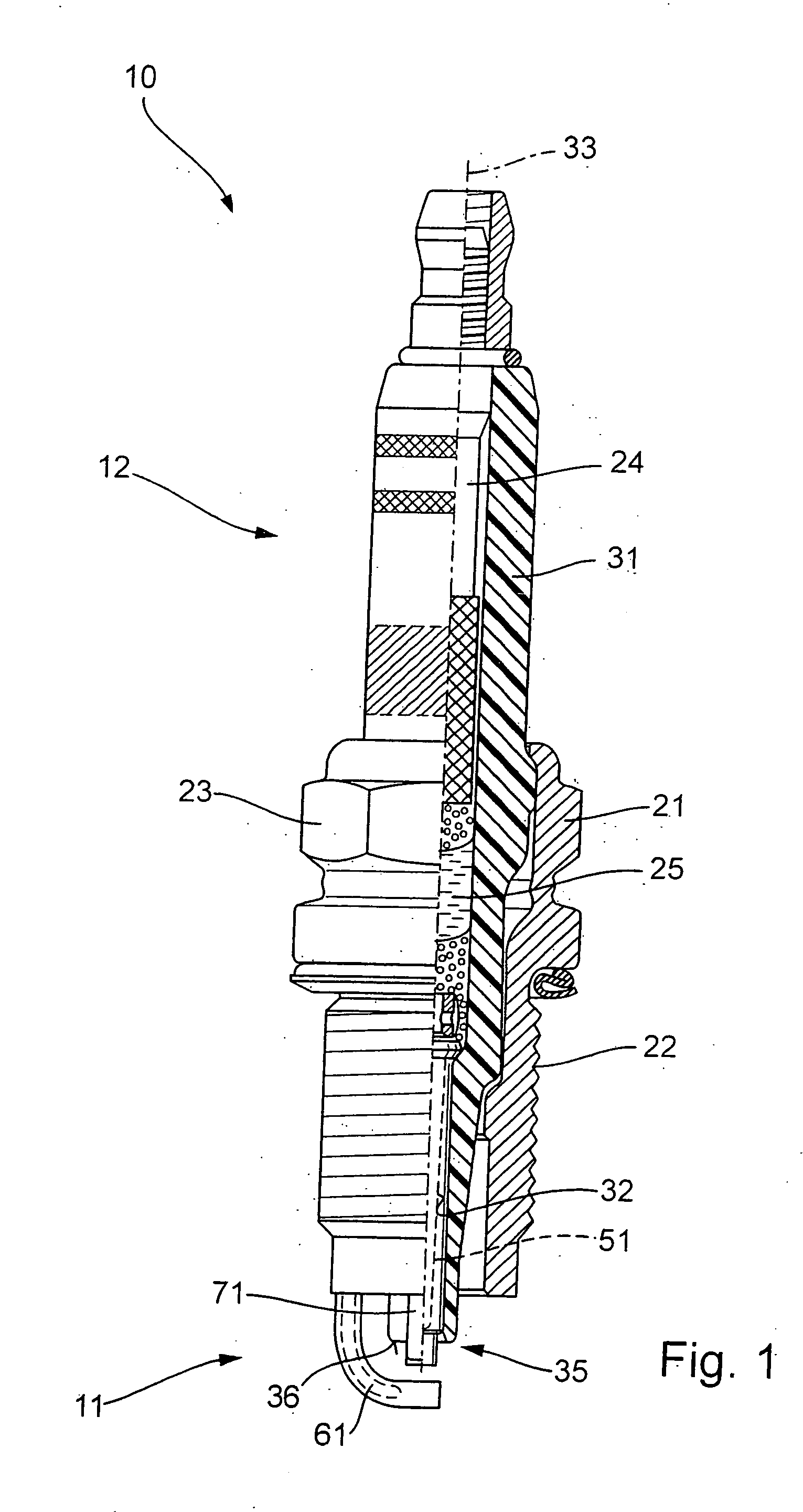

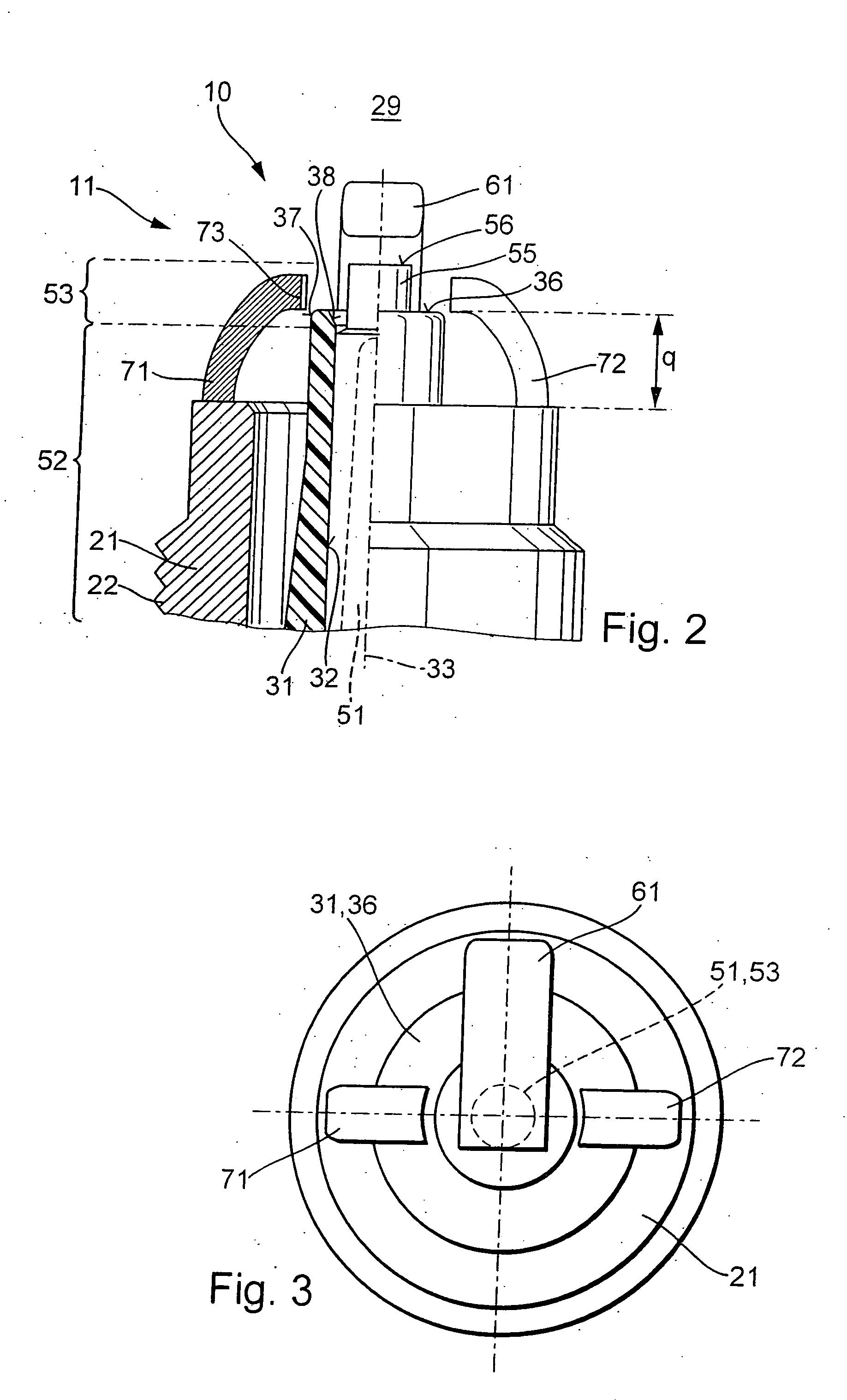

Spark plug

InactiveUS20050052107A1Formation of sootInhibition formationSparking plugsCombustion chamberEngineering

Owner:ROBERT BOSCH GMBH

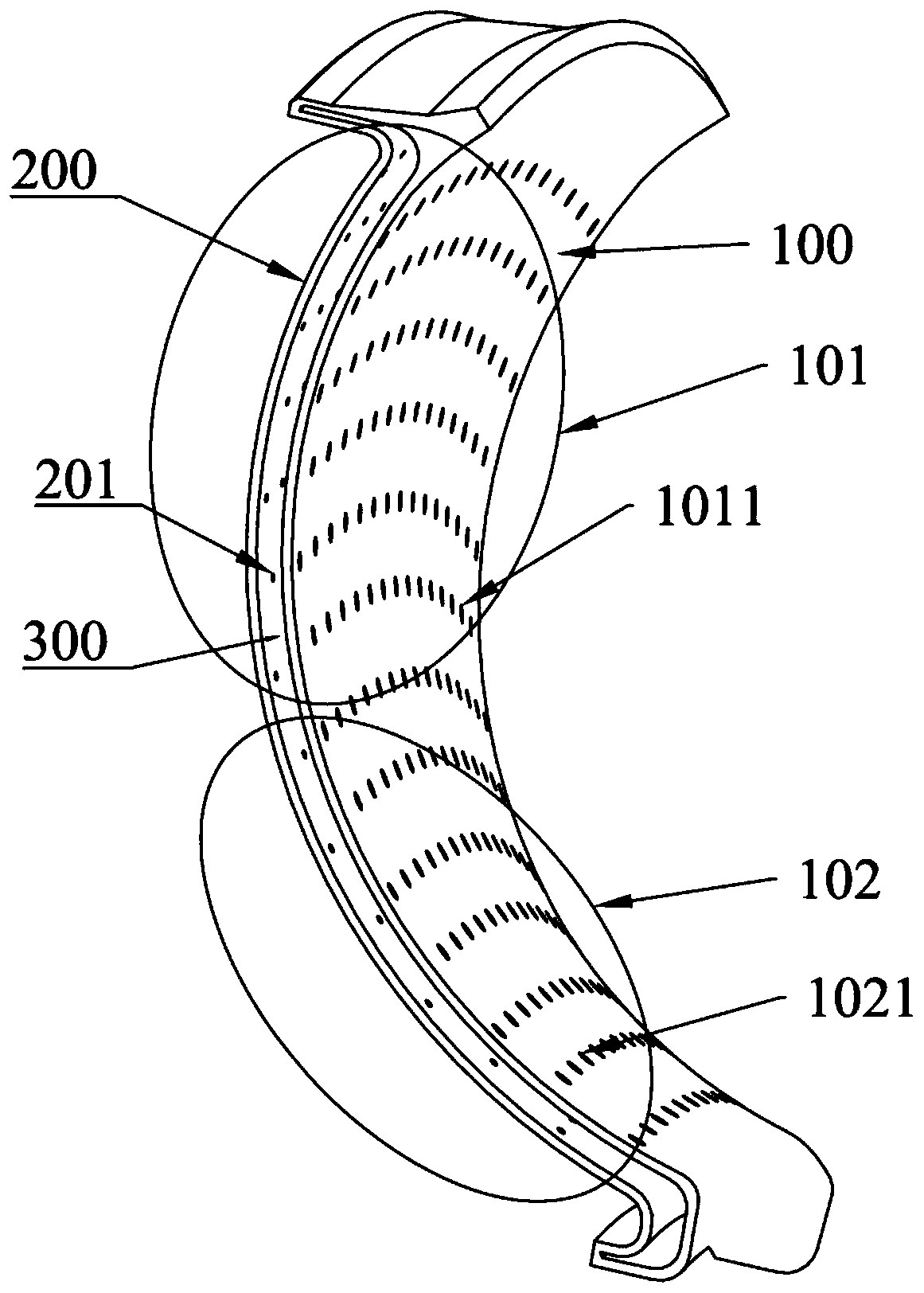

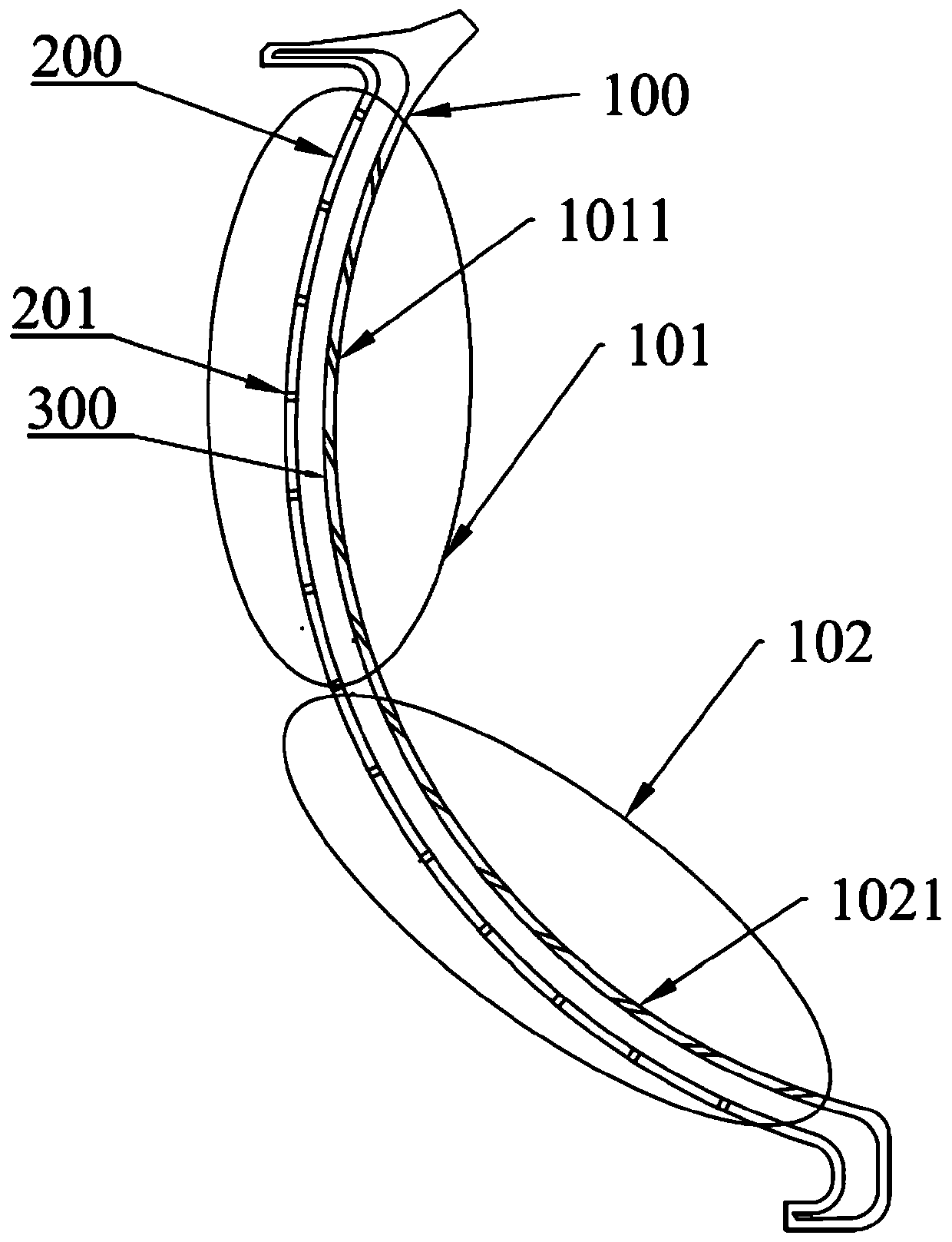

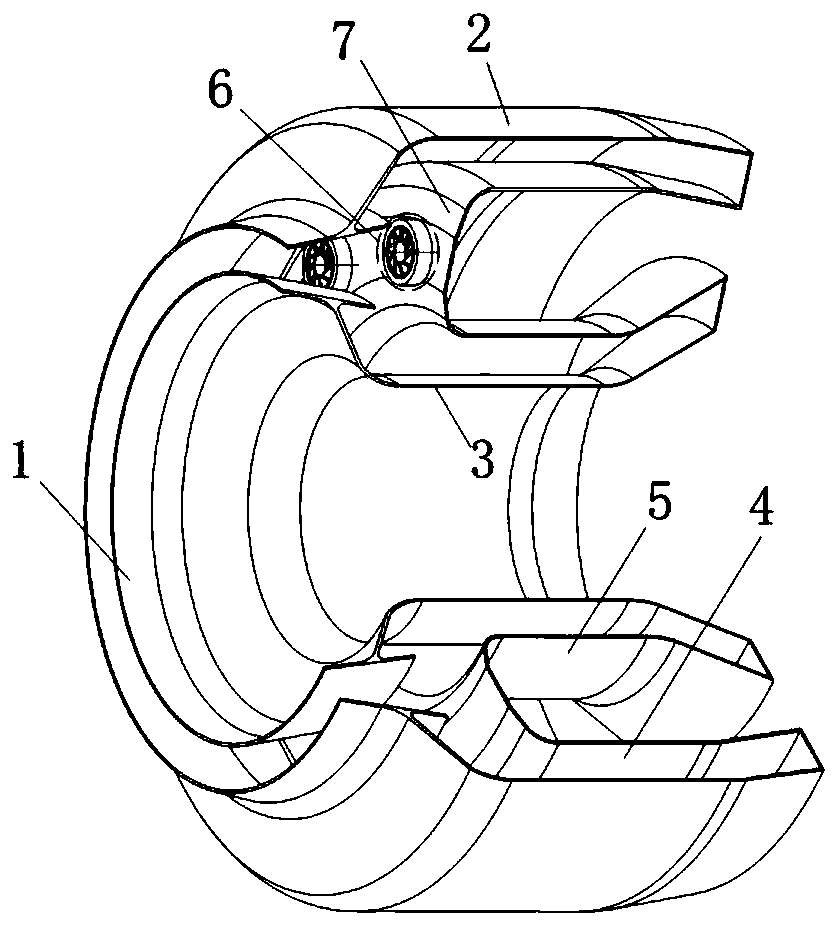

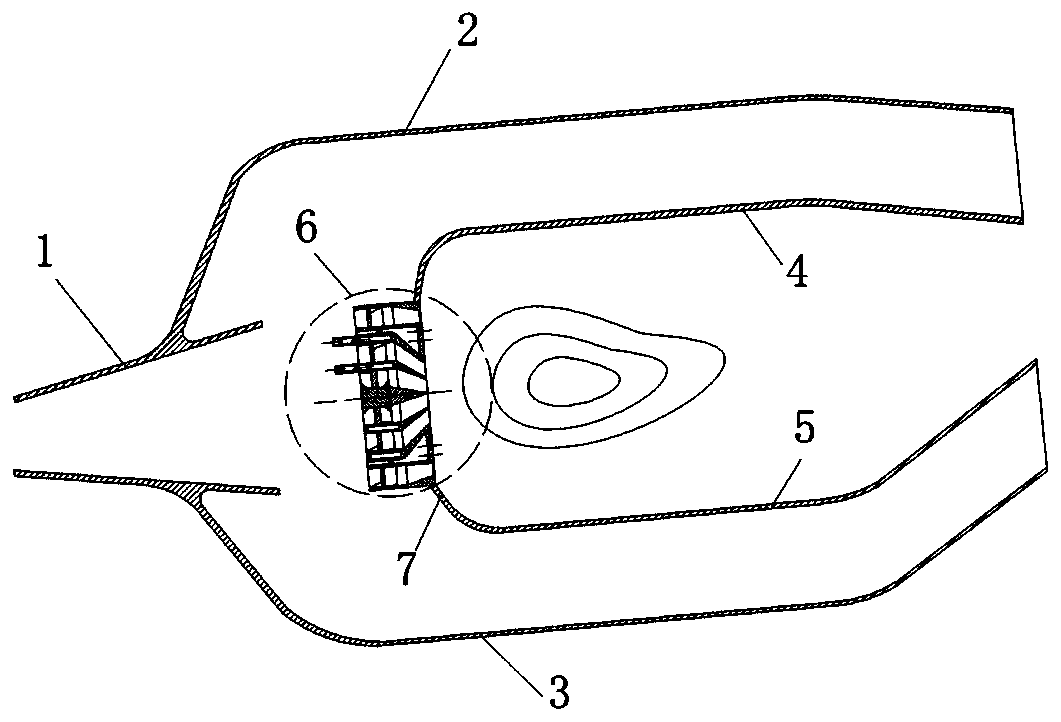

Head part of an annular combustion chamber

ActiveUS20120272661A1Reduce weightContinuous combustion chamberEfficient propulsion technologiesCombustion chamberGas turbines

Owner:ROLLS ROYCE PLC

Reverse flow combustor and double-wall elbow structure thereof

ActiveCN109974033AReduce peak wall temperatureHigh strengthContinuous combustion chamberCombustorCombustion chamber

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

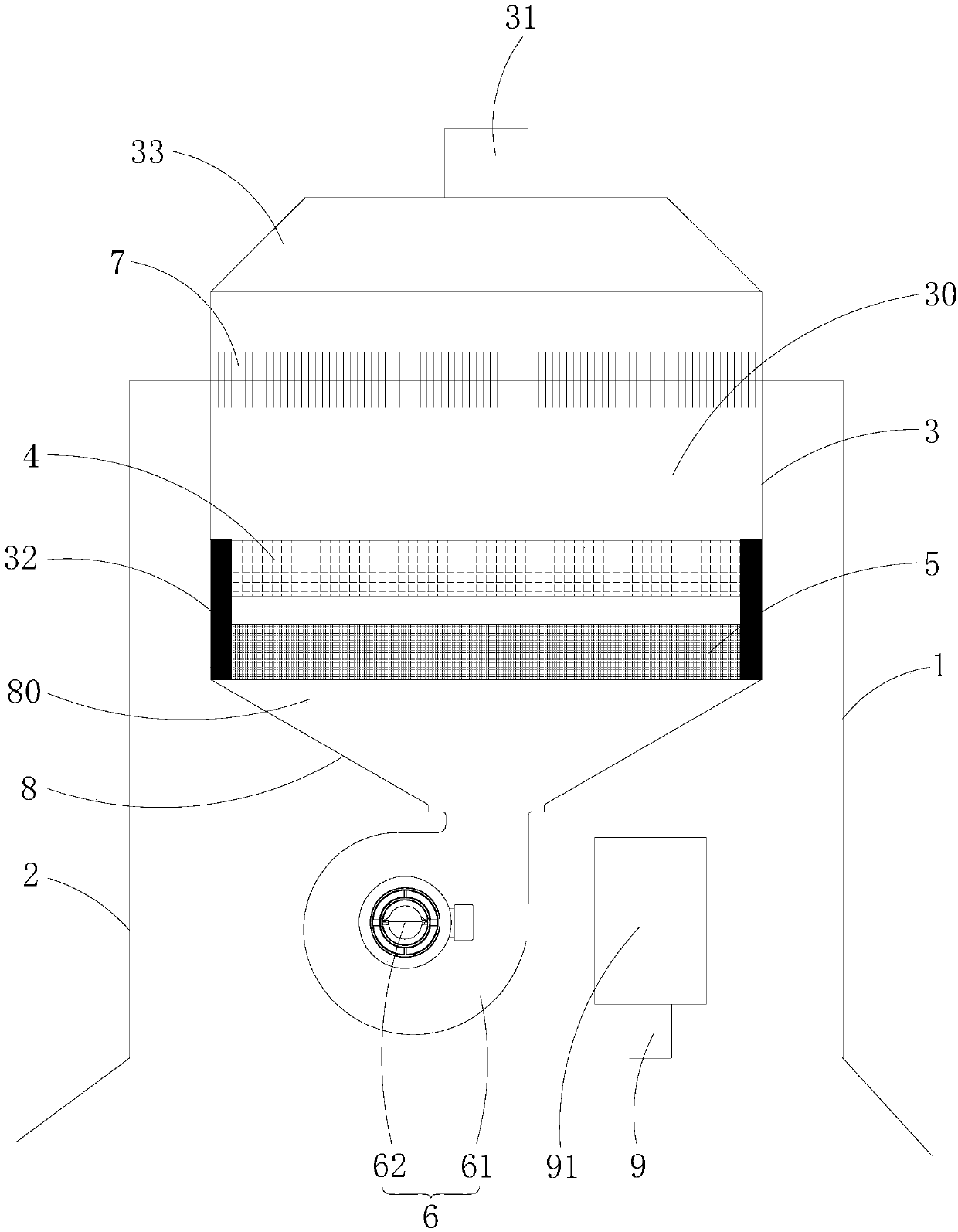

Straw carbonization furnace

InactiveCN103497773AAchieve recyclingHigh heat conversion efficiencyBiofuelsEnergy inputCombustion chamberCarbonization

Owner:YANCHENG CHENGXIN MACHINERY MFG

Central grading lean oil premixed low-pollution combustion chamber

ActiveCN111174233ABroaden the boundaries of workPromote atomizationContinuous combustion chamberSpontaneous combustionCombustion chamber

Owner:NORTHWESTERN POLYTECHNICAL UNIV

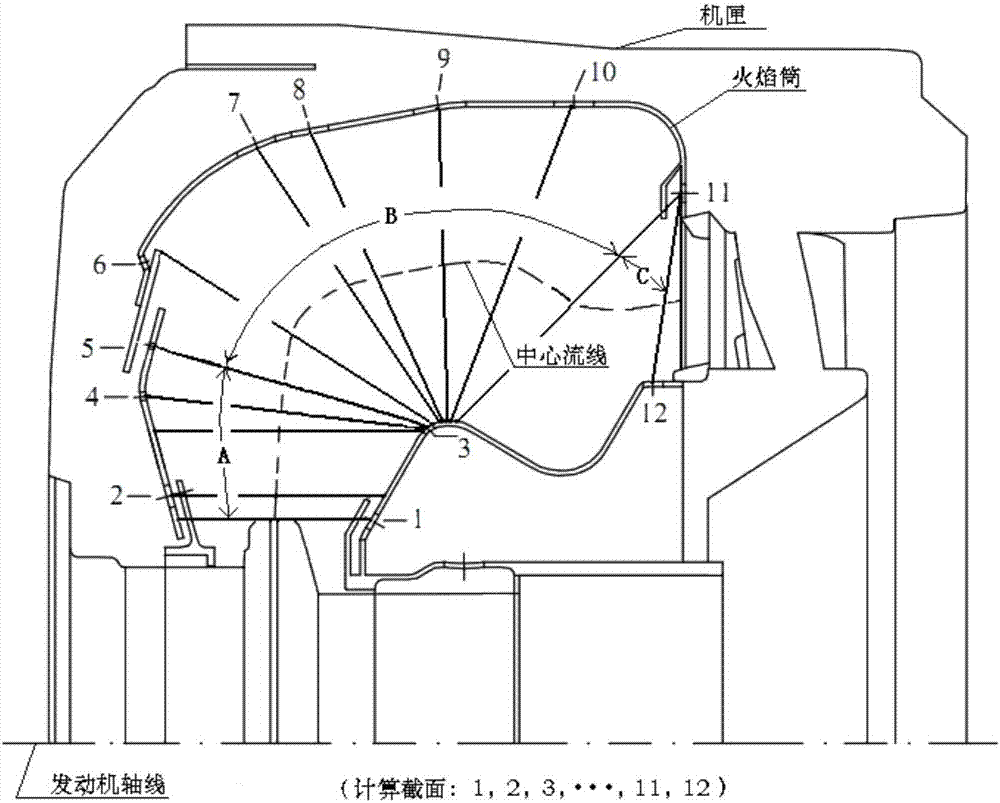

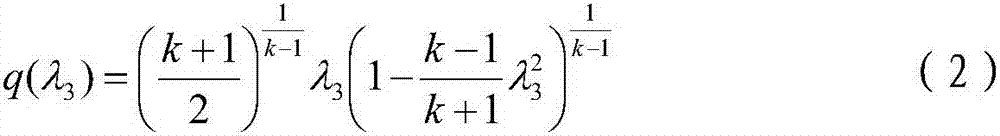

Fast virtual numerical value test method for aerodynamic performance of baffled combustor

InactiveCN107992655ADesign optimisation/simulationSpecial data processing applicationsAutomotive engineeringCombustion chamber

Owner:BEIJING POWER MACHINERY INST

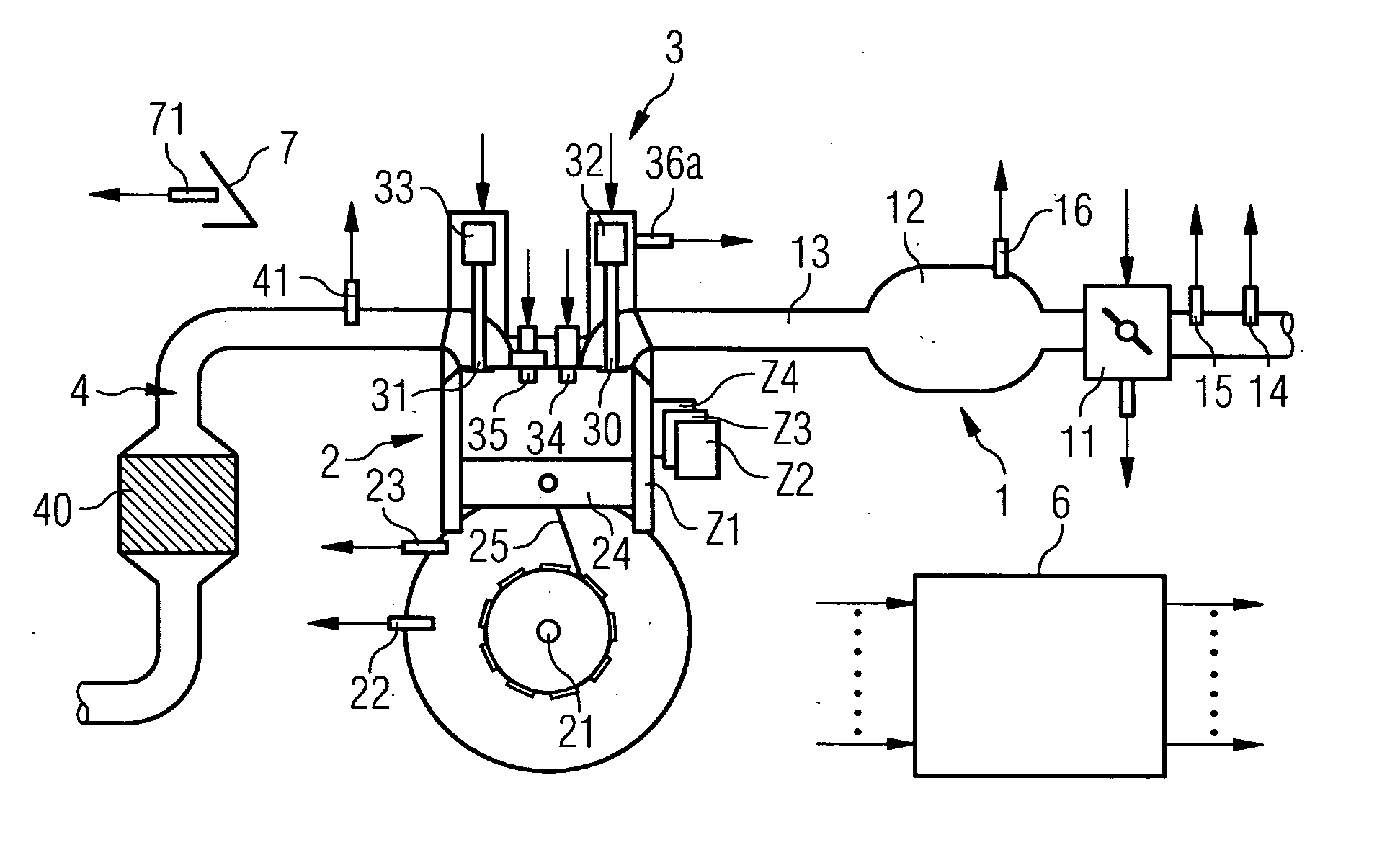

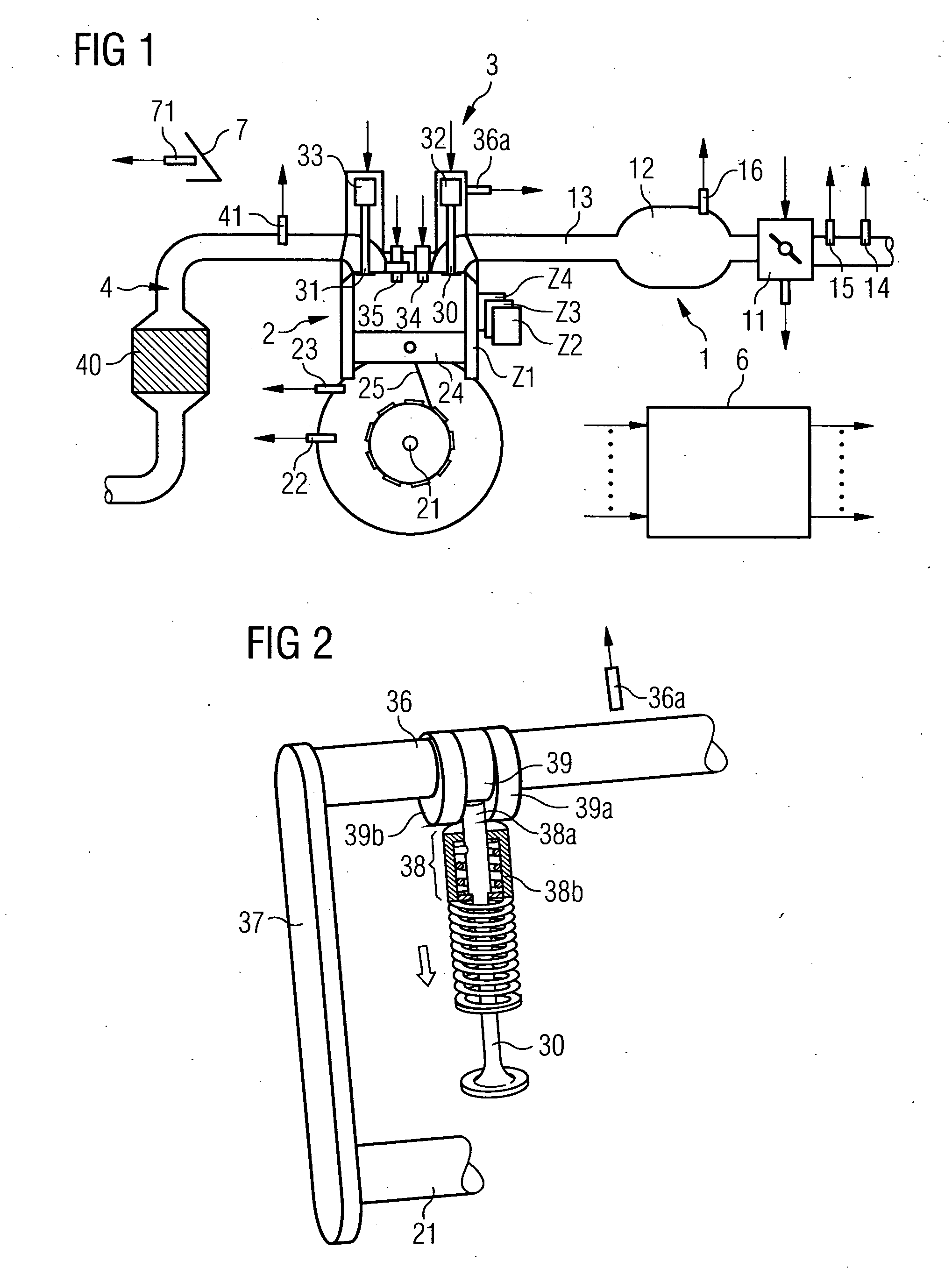

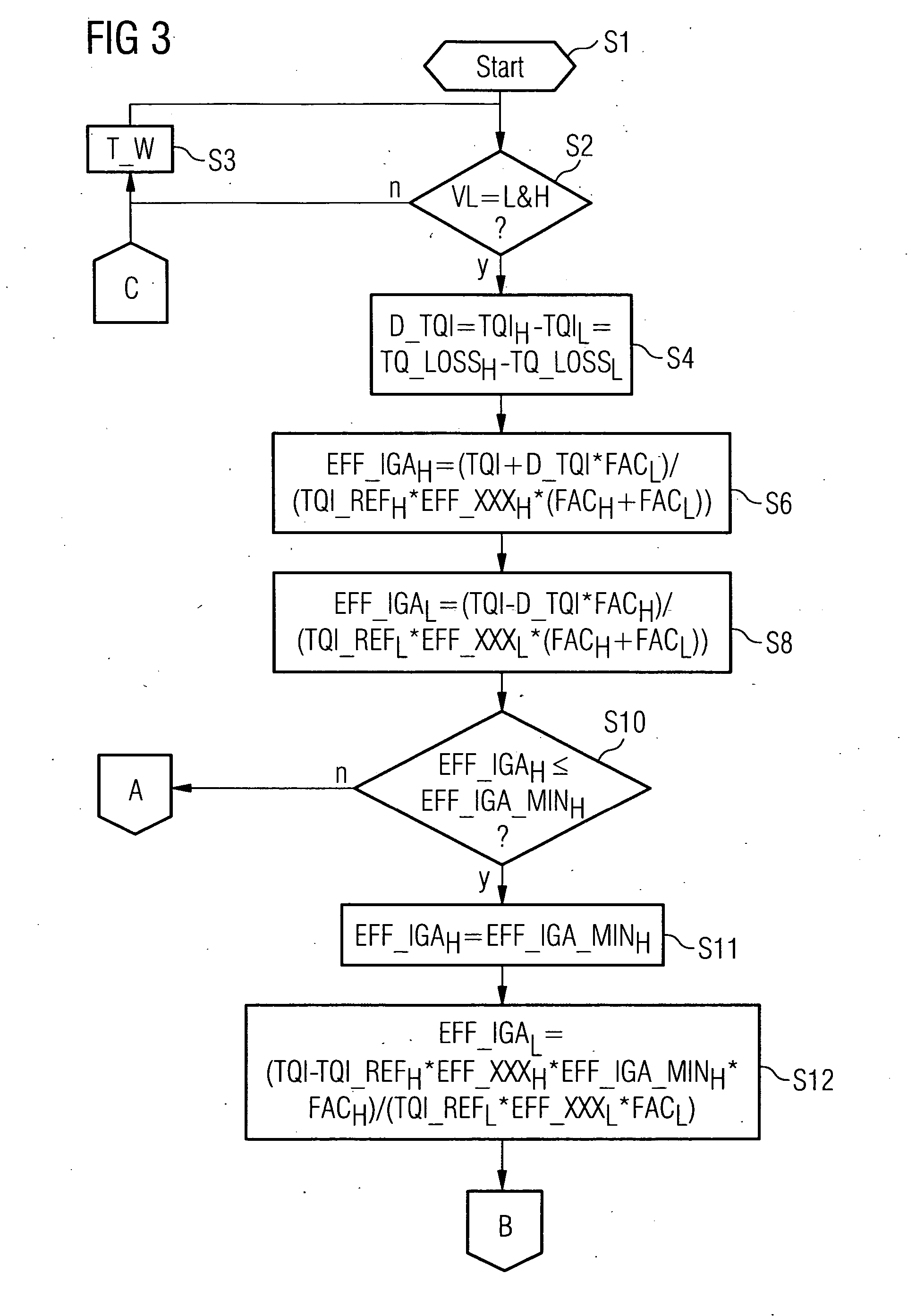

Method and Device for Controlling an Internal Combustion Engine

ActiveUS20070250252A1Evenly goodKnocking can reliablyAnalogue computers for vehiclesElectrical controlCombustion chamberAir mass

Owner:VITESCO TECH GMBH

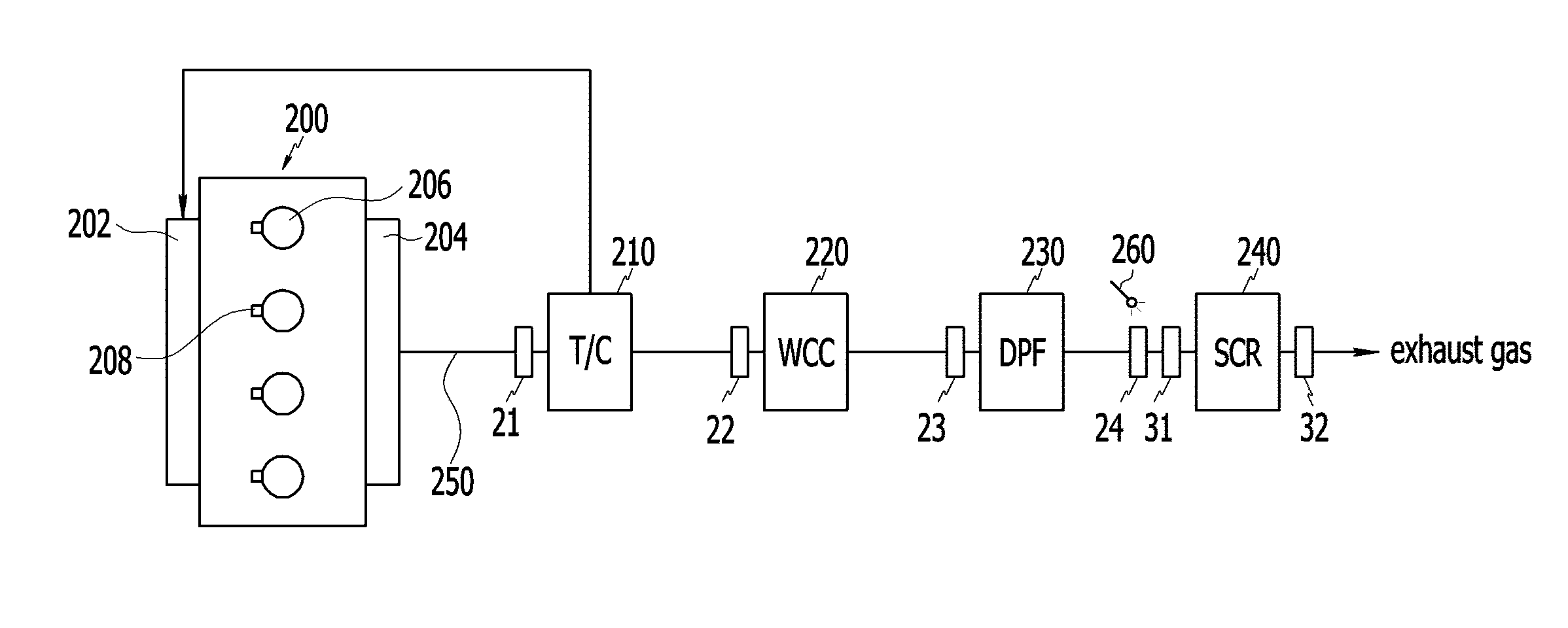

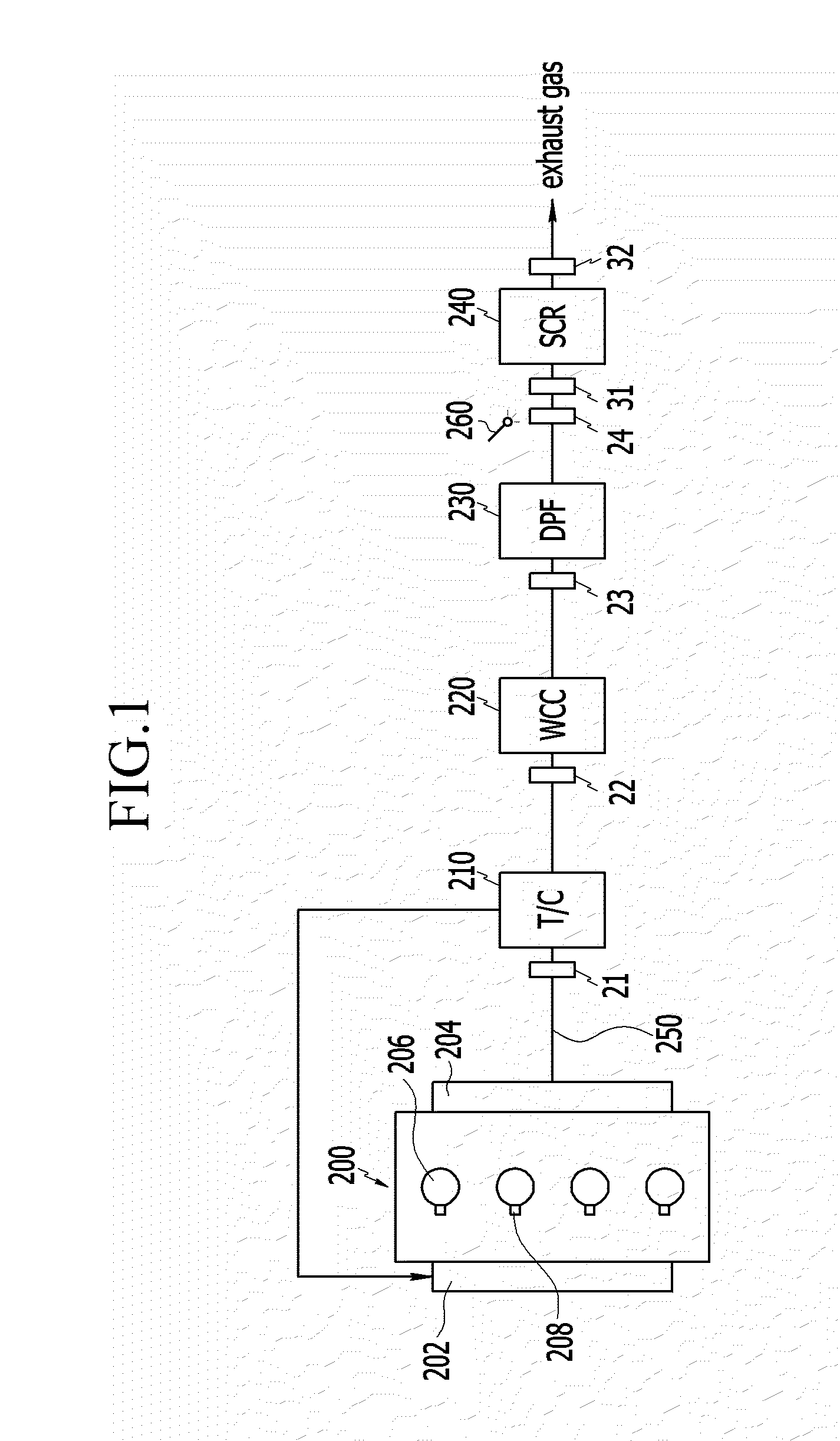

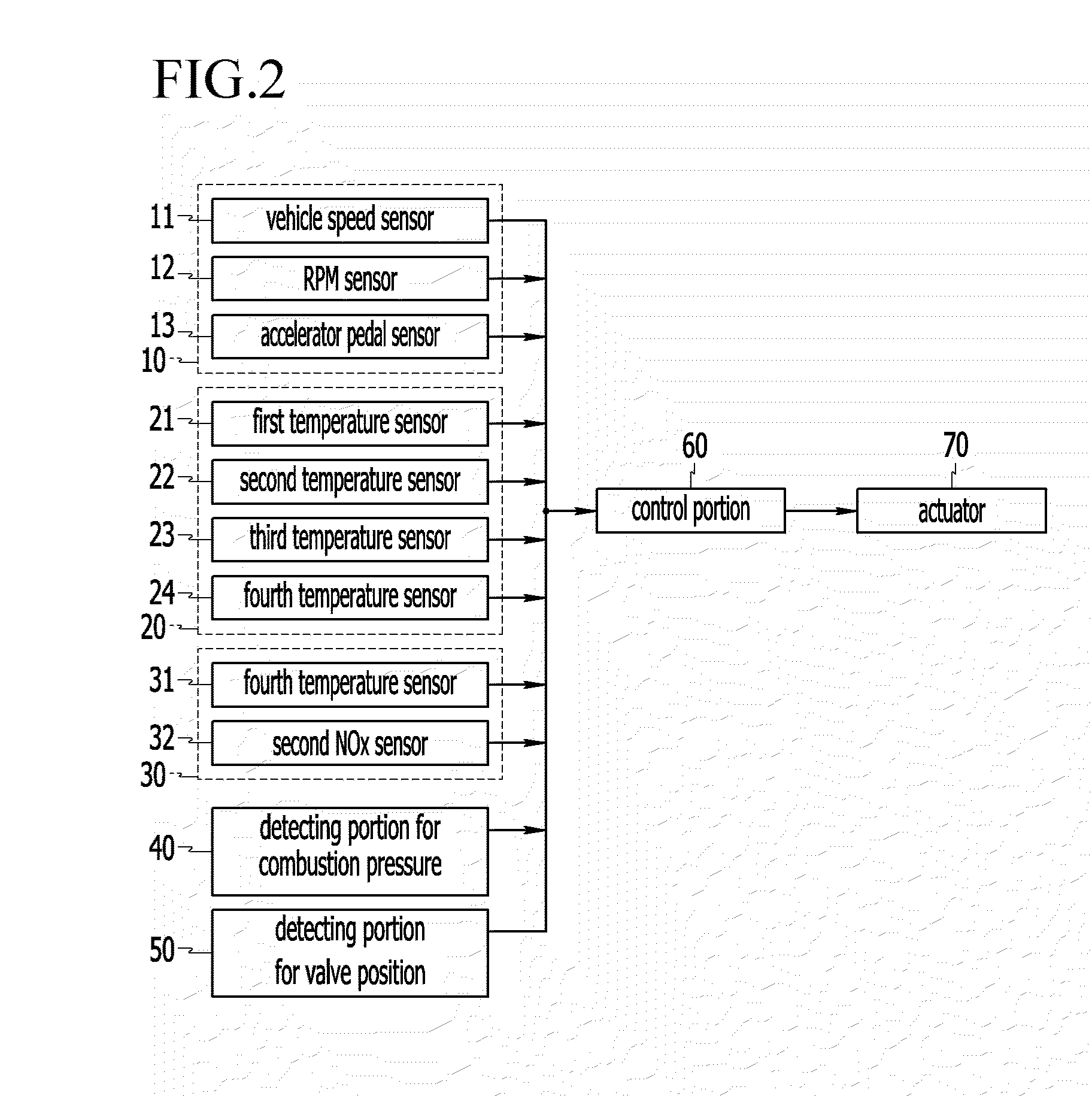

System for controlling continuous variable valve lift actuator of diesel engine, and method thereof

Owner:HYUNDAI MOTOR CO LTD +1

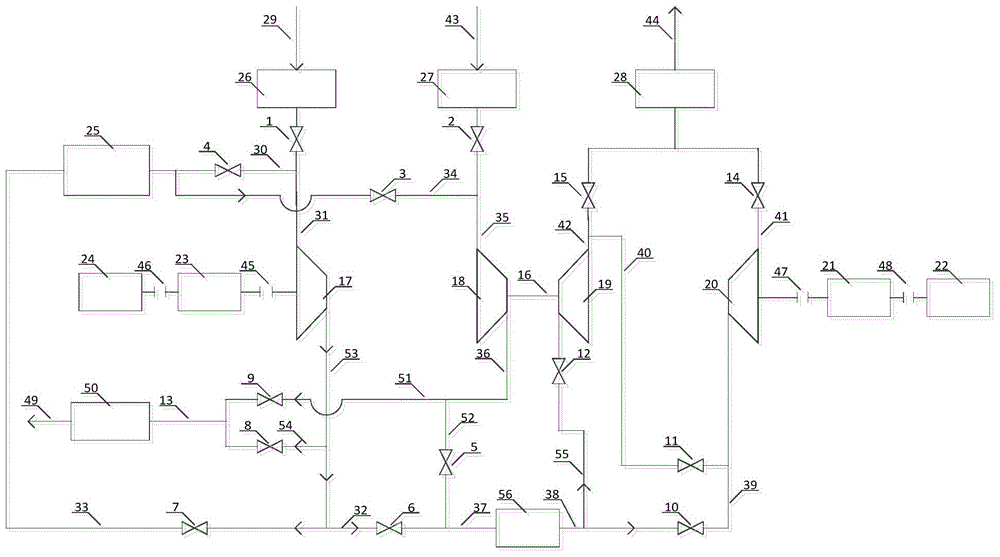

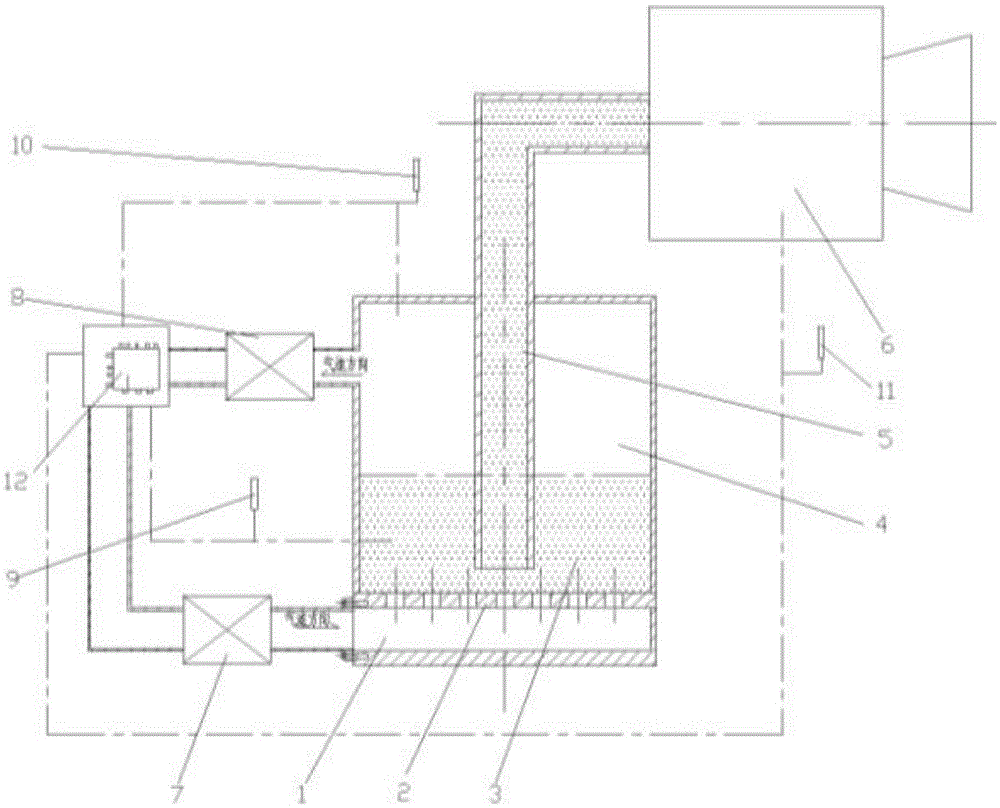

Multifunctional compound supercharging test system

ActiveCN104155114AInternal-combustion engine testingMatching testSingle stage

Owner:HARBIN ENG UNIV

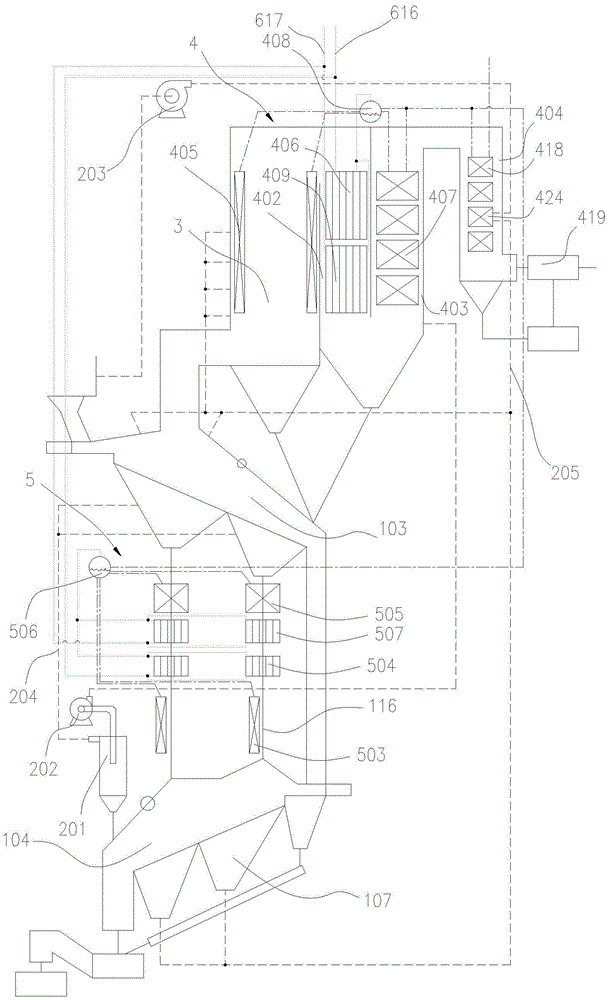

Dual-layer mechanical grate type garbage gasifying incinerator and dual-boiler power generation system thereof

ActiveCN105465793AImprove insulation effectPrevent leakageMachines/enginesIncinerator apparatusCycloneCombustion chamber

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

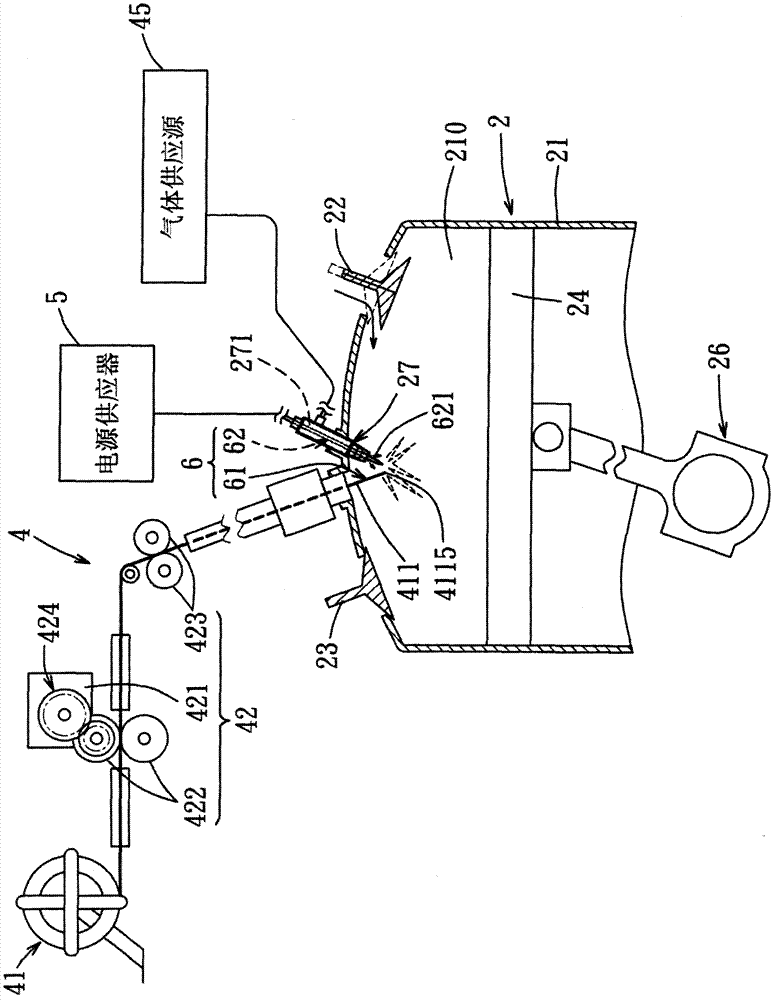

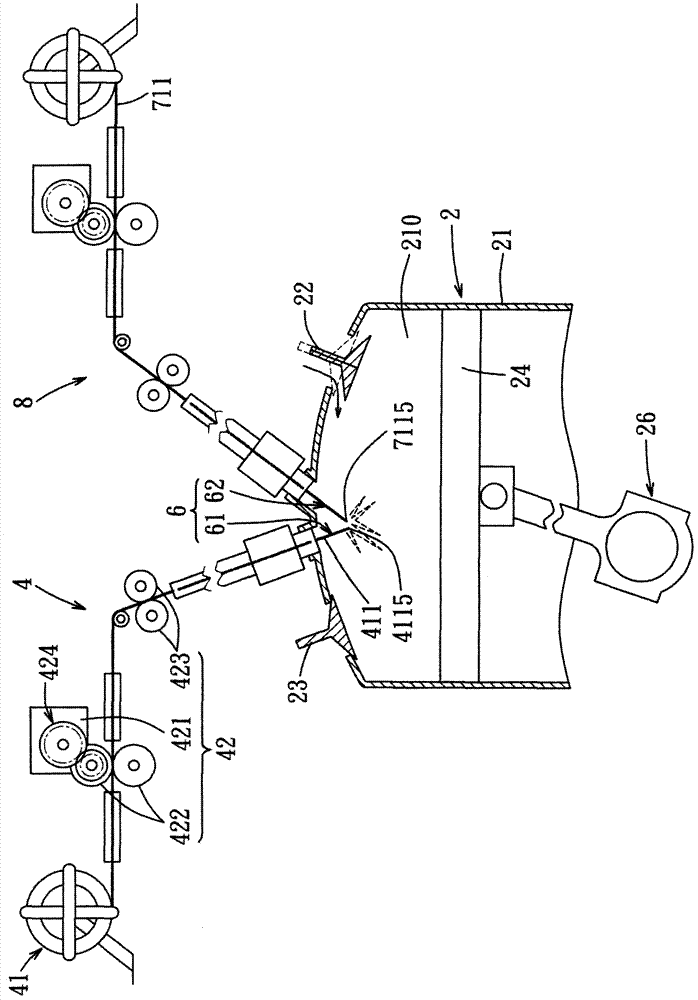

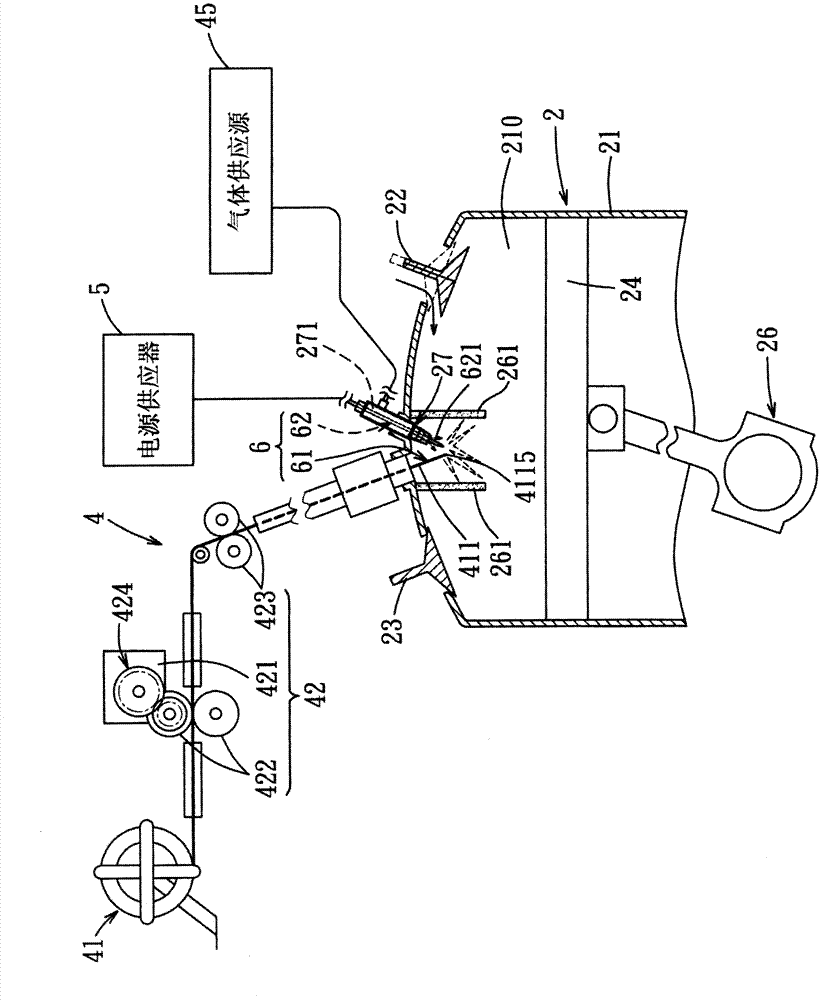

System and method for oxidizing and thermally propelling by active metal wire

InactiveCN102788430AExothermal chemical reaction heat productionInternal combustion piston enginesPistonCombustion chamber

Owner:叶均蔚

High-pressure metal powder supply system based on pressure difference control

ActiveCN105484901AInternal combustion piston enginesFuel supply apparatusCombustion chamberHigh pressure

Owner:HARBIN ENG UNIV

Air cylinder cover of miniature type engine precast with cooling water jacket

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

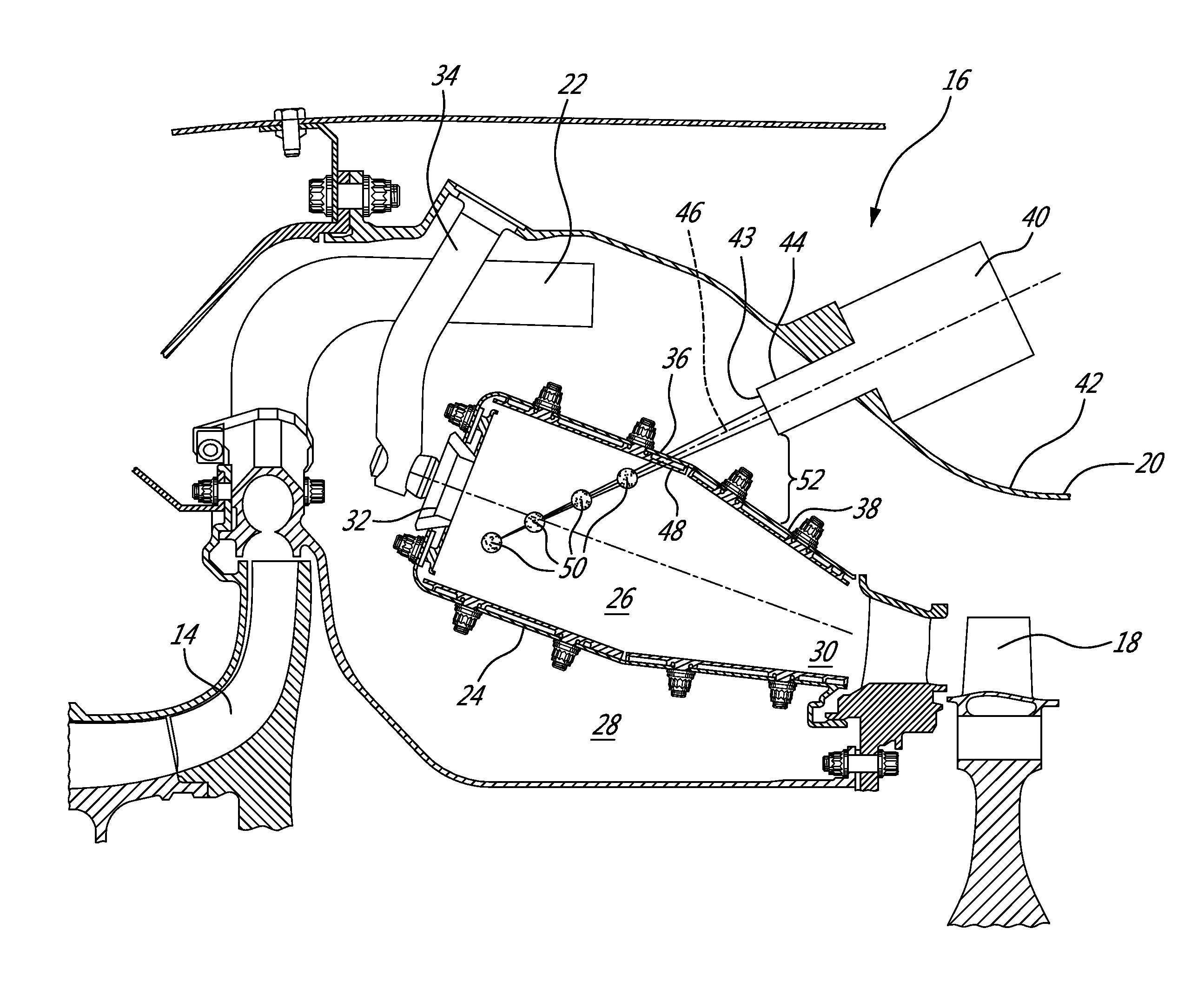

Combustion apparatus and gas turbine engine

InactiveUS20140144143A1Increase supplyEliminate cavitiesContinuous combustion chamberGas turbine plantsCombustion chamberEngineering

Owner:SIEMENS AG

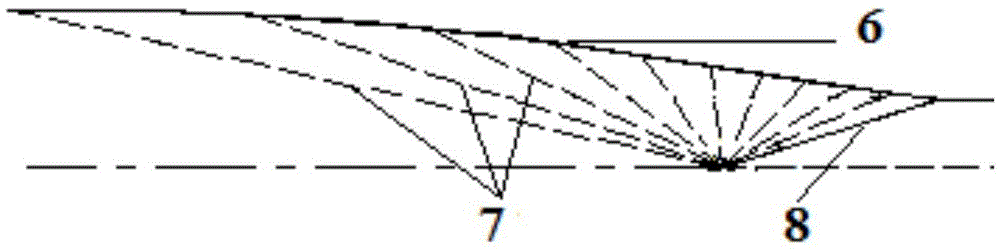

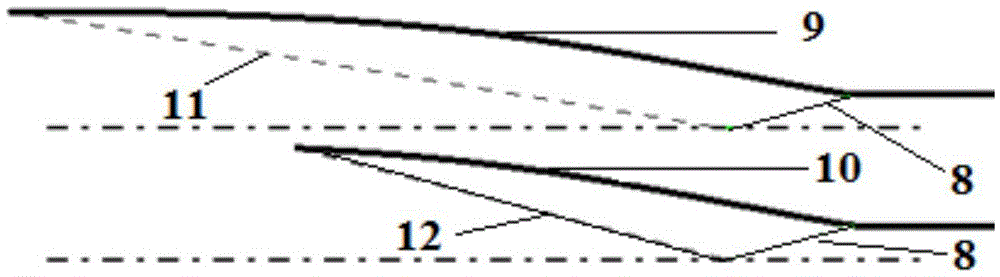

Integrated aerodynamic layout method for hypersonic aircraft forebody, air inlet duct and supporting plate

ActiveCN105539863AGround installationsPower plant air intake arrangementsCombustion chamberSpeed of sound

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Whole set smelting device for ferrotitanium series product

ActiveCN101054648AControl the intake air volumeHeating up fastFurnace componentsCrucible furnacesCombustion chamberHeating time

Owner:攀枝花市银江金勇工贸有限责任公司

Jet engine

Owner:朴德春

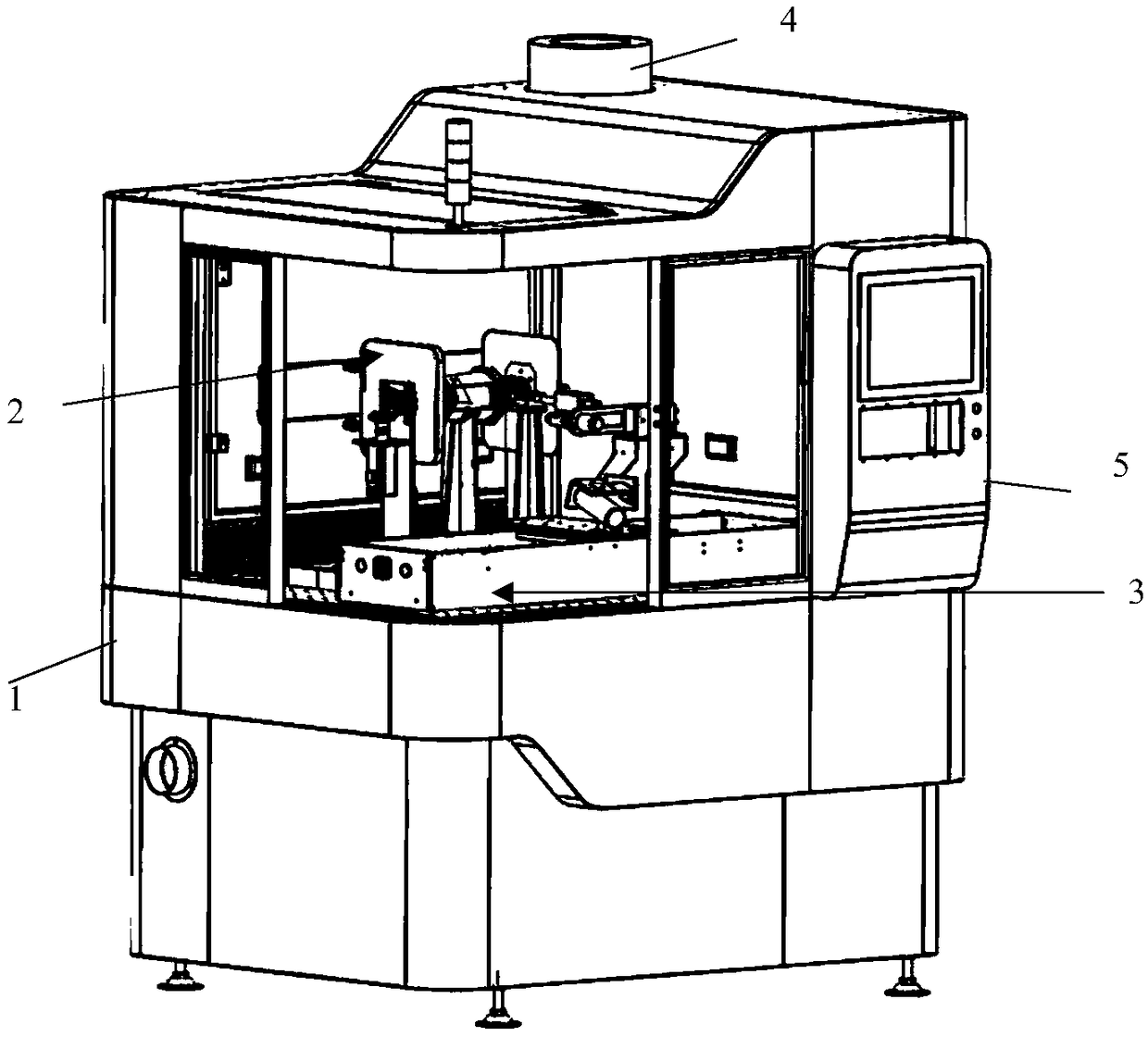

Steady-state-temperature-field-included simulation test bench of aero-engine combustor

InactiveCN109374308ALow costShort cycleGas-turbine engine testingJet-propulsion engine testingAviationSteady state temperature

Owner:CIVIL AVIATION UNIV OF CHINA

Laser-ignition combustor for gas turbine engine

Owner:PRATT & WHITNEY CANADA CORP

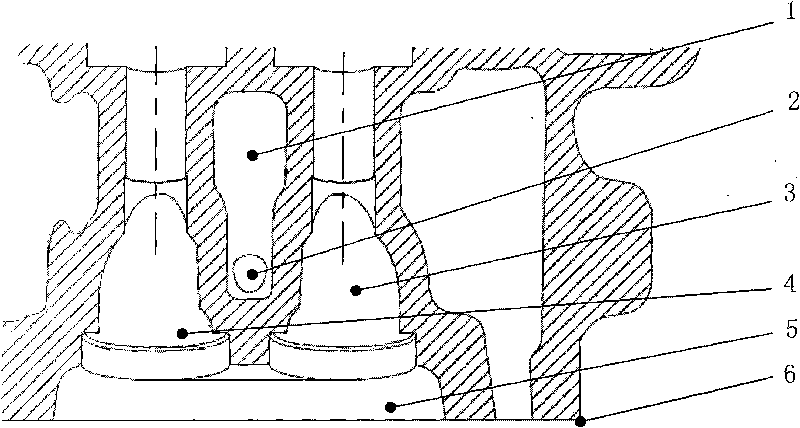

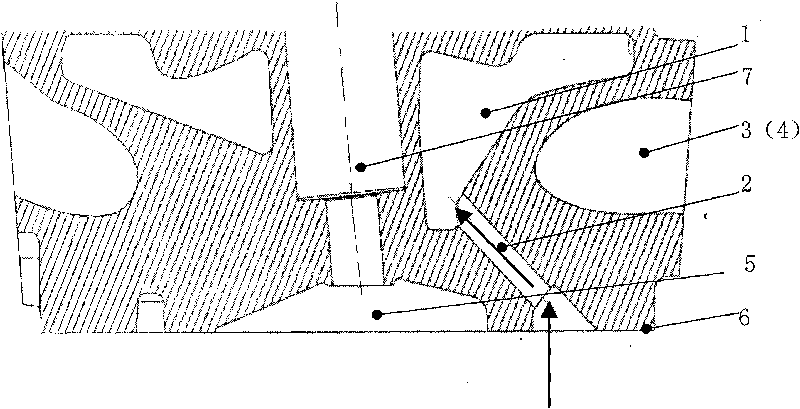

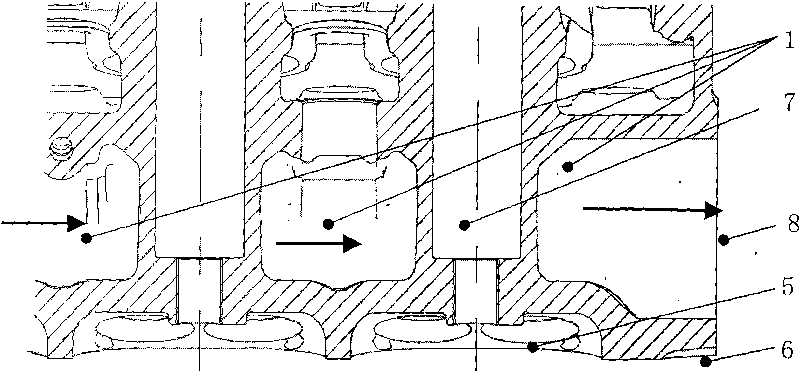

Auxiliary actuating apparatus of diesel engine

InactiveCN101117935AReduce external forceIncrease temperatureMachines/enginesEngine startersCombustion chamberCylinder head

The present invention relates to the technical field of the single-cylinder diesel engine in the gas engine, in particular to a diesel engine start-up device; the cylinder head is provided with an ignition needle, a switch that provides ignition power is arranged somewhere near the start-up shaft on the gear case cover, the front end of the handle is provided with a collision block, each rotation of the handle bumps into the switch to make the ignition needle produce electric sparkle and ignite the spray fuel, and for better start-up, an inlet air pipe is provided with a combustible gas inlet hole to deliver combustible gas into the combustion chamber when starting up; due to the above technical measures, each oil injection can be burned when the diesel engine starts up to increase the temperature in the combustion chamber and decrease the outside force required by the diesel engine when starting up, thus making the start-up more easily.

Owner:孙爱平

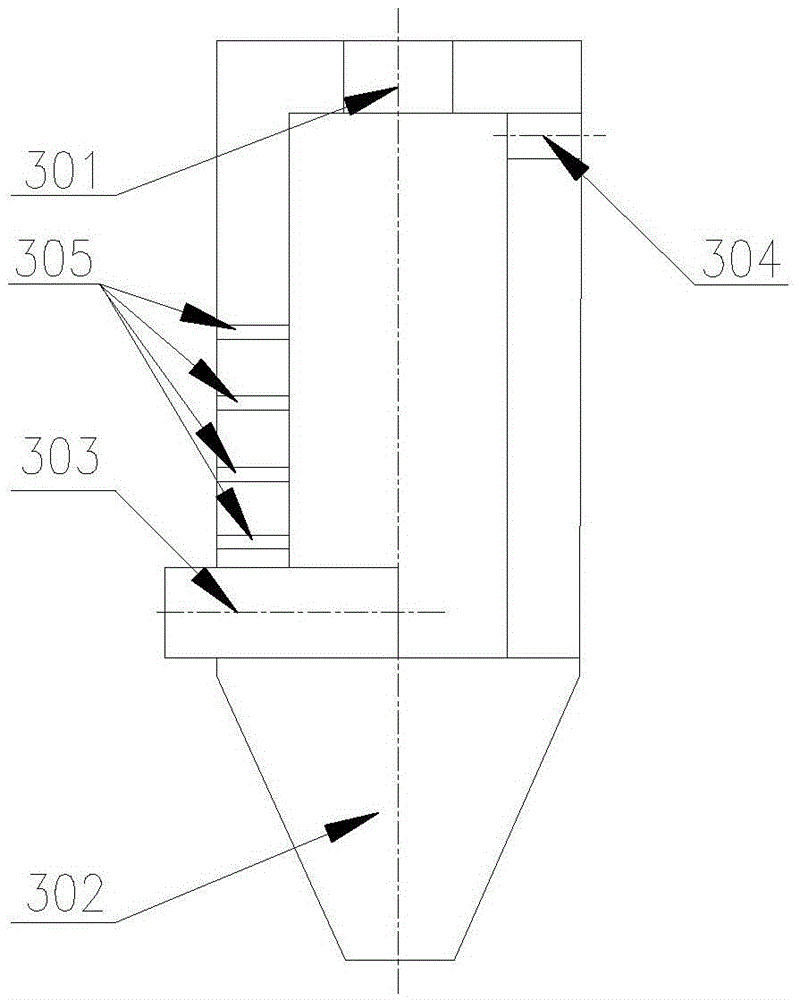

Oxygen-deficiency pyrolyzing circular sludge incinerator

Owner:TIANJIN BIAO DASI TECH

Device and process for purifying and treating tar tail gas and asphalt fume

ActiveCN110425550ASolve the problem that it is difficult to purify asphalt fumeImprove thermal efficiencyIncinerator apparatusChimneysCombustion chamberEnvironmental geology

The invention relates to a device and process for purifying and treating tar tail gas and asphalt fume. The device comprises an incinerator and a chimney, wherein the incinerator is composed of a first combustion chamber, a second combustion chamber, a first heat storage chamber and a second heat storage chamber, the first combustion chamber is arranged below the second combustion chamber, and thefirst combustion chamber and the second combustion chamber communicates with each other; the two ends of the first combustion chamber communicates with the top of the first heat storage chamber and the top of the second heat storage chamber respectively, a first combustor is arranged inside the first combustion chamber, a second combustor is arranged inside the second combustion chamber, and a heat accumulator is arranged inside the first heat storage chamber and the second heat storage chamber. By adopting a process combining a heat storage type incinerator and a direct combustion type incinerator, the tar tail gas and the asphalt fume can be purified at the same time, the problem that the heat storage type incinerator is difficult to purify the asphalt fume and the direct combustion type incinerator is low in heat efficiency is solved, meanwhile, waste gas waste heat is recycled, the operation cost of the incinerator is reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap