System and method for oxidizing and thermally propelling by active metal wire

An active metal and metal technology, which is applied in the field of oxidative heat propulsion systems, can solve the problems of intractable, expensive, and complex solid fuel power systems, and achieve the effect of eliminating powder conveying devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

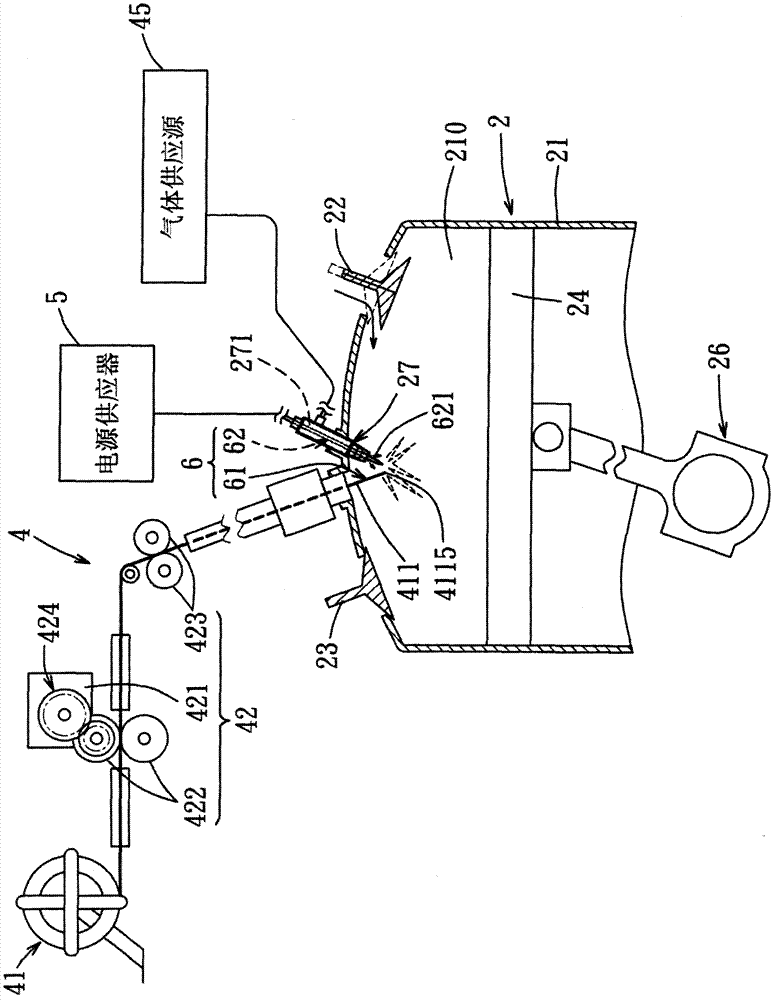

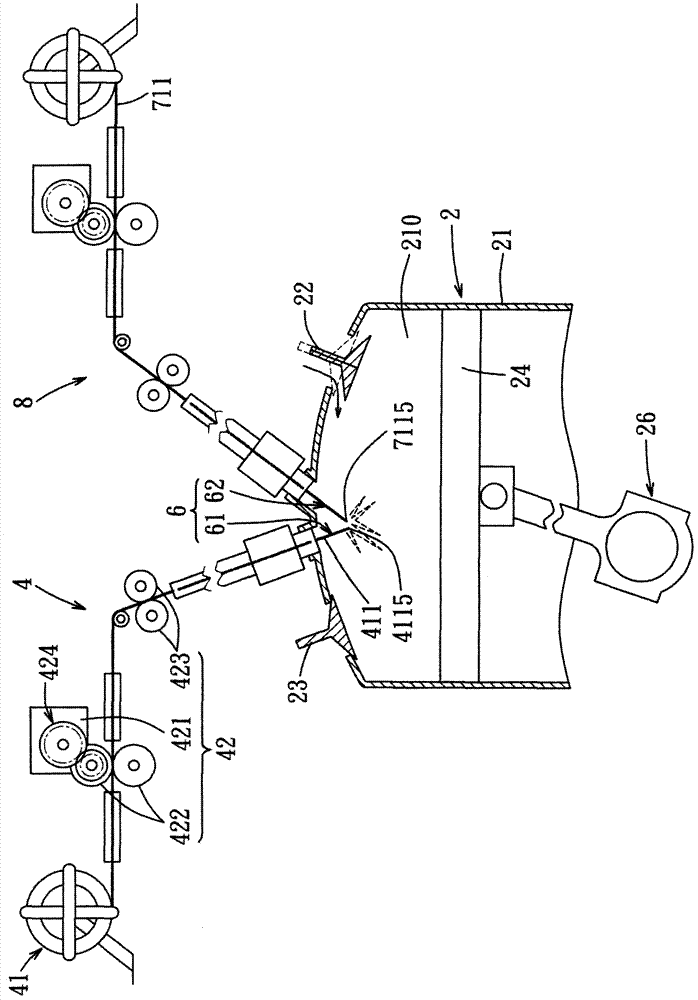

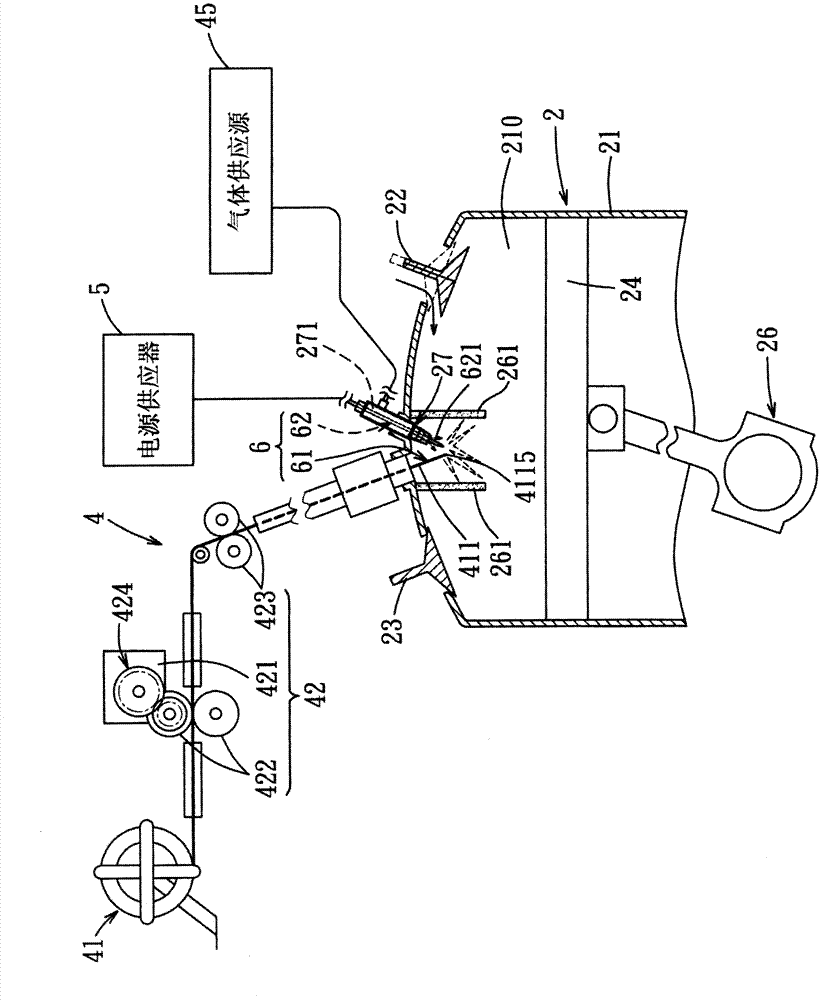

[0047] refer to figure 1 , a preferred embodiment of a system propelled by the oxidation heat of active metal wires of the present invention includes: a cylinder 2 with a cylinder body 21, an intake valve 22 located at the cylinder body 21, and an air intake valve located at the cylinder body 21. The exhaust valve 23 of the cylinder body 21 and an electrode connection seat 27 located on the cylinder body 21, the cylinder body 21 defines a combustion chamber 210, and the intake valve 22 is used for external Air is introduced into the combustion chamber 210, and the exhaust valve 23 is used to exhaust the exhaust gas from the combustion chamber 210 during the exhaust phase of the cylinder 2; a piston 24 is located in the cylinder body 21; A first electrode 61 and a second electrode 62 in the cylinder body 21, there is a small gap enough to generate an arc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap