Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Combustor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A combustor is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustion chamber or flame holder. In a gas turbine engine, the combustor or combustion chamber is fed high pressure air by the compression system. The combustor then heats this air at constant pressure. After heating, air passes from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the air is directly fed to the nozzle.

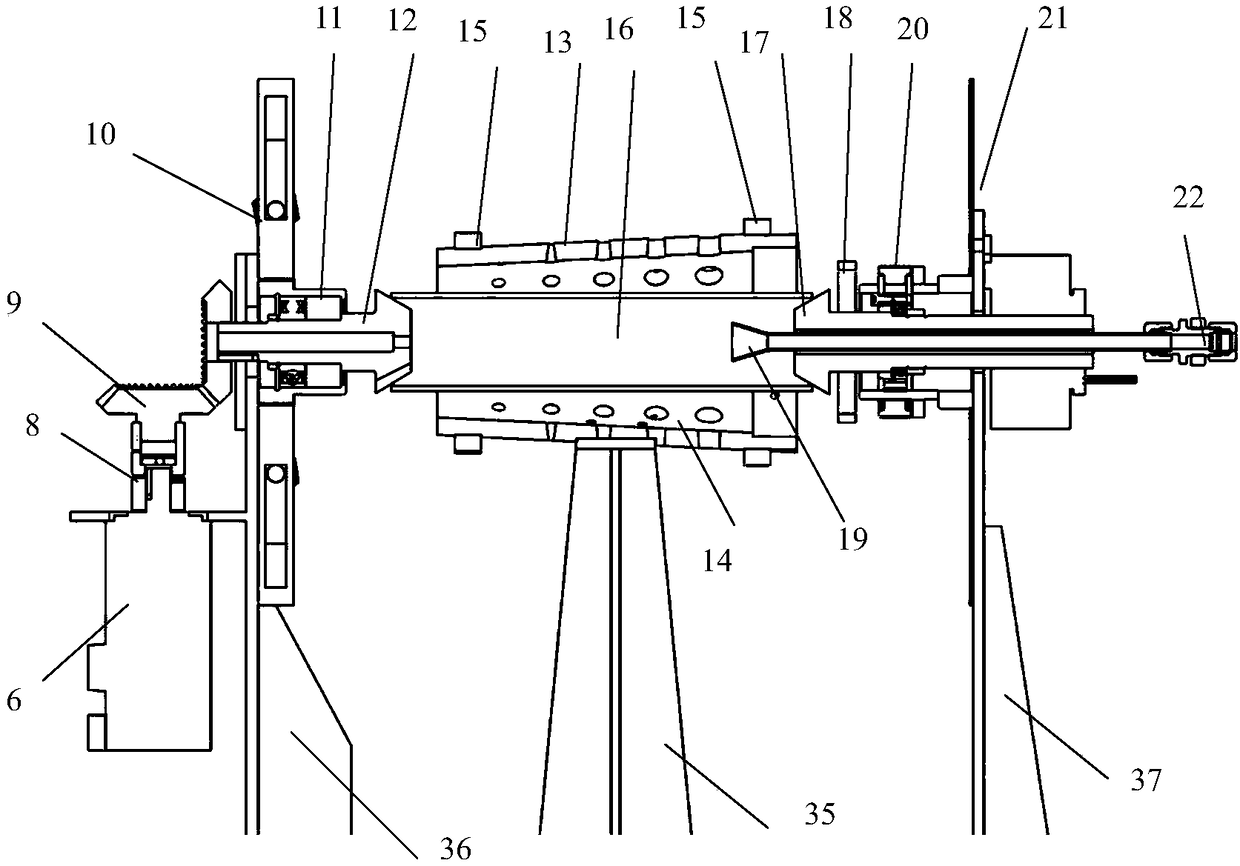

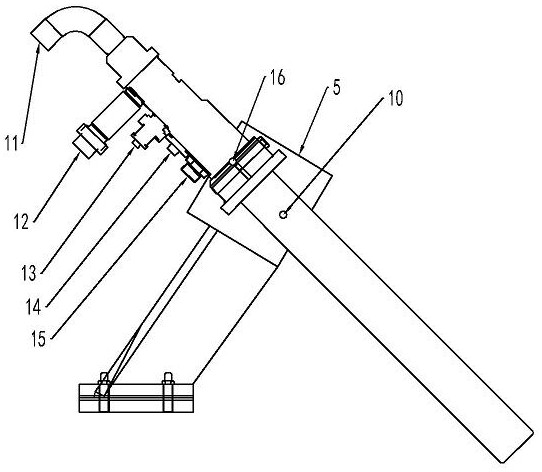

Asphalt mixture regenerating heating stirring roller

The invention discloses an asphalt mixture regenerative heating rod and mixing roller, and belongs to the concrete stirring technical field. The invention has a tilted roller supporting frame, a rolling ring, a roller and a roller driving device, wherein, the rolling ring is sleeved on the roller and supported by a rolling wheel arranged on the roller supporting frame, a burner is arranged at the lower end of the roller, a material outlet is arranged on the roller at the lower part of the burner, a material inlet is arranged at the other end of the roller, and a smoke outlet is arranged on the roller; wherein, an inner screening tube is sleeved inside the roller positioned at the material inlet end, and the inner screening tube is connected with the roller, the outer peripheral wall of the inner screening tube is composed of a screening mesh, a circular filtering mesh is sealed at the end part on the inner side of the inner screening tube, the material inlet is communicated with the inner screening tube, and an asphalt nozzle is arranged inside the roller positioned below the burner at the outlet end. The invention has compact and rational structure and high heat exchange efficiency, does not require secondary breakup of the waste asphalt mixture, can directly heat the block shape waste asphalt mixture for recycling; and the regenerated asphalt mixture can be directly utilized.

Owner:HENAN ROADY ROAD MACHINERY

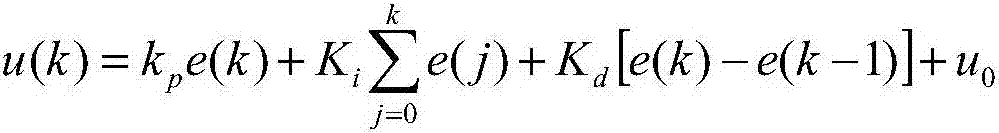

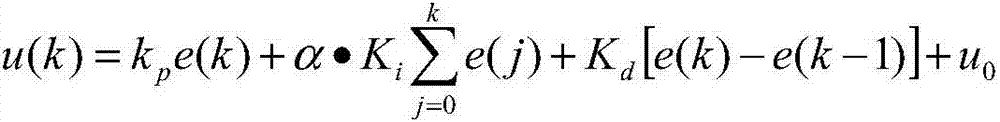

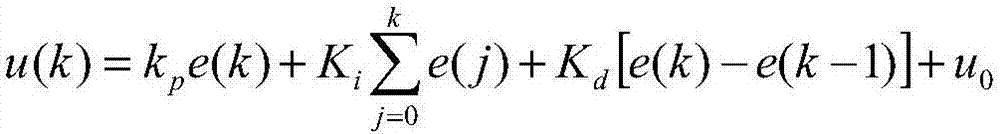

Non-road diesel engine combustor DPF regeneration temperature control method

InactiveCN107100703AReliable regeneration temperature managementClosed-loop control stabilityInternal combustion piston enginesExhaust apparatusTemperature controlCombustor

Owner:KAILONG HIGH TECH

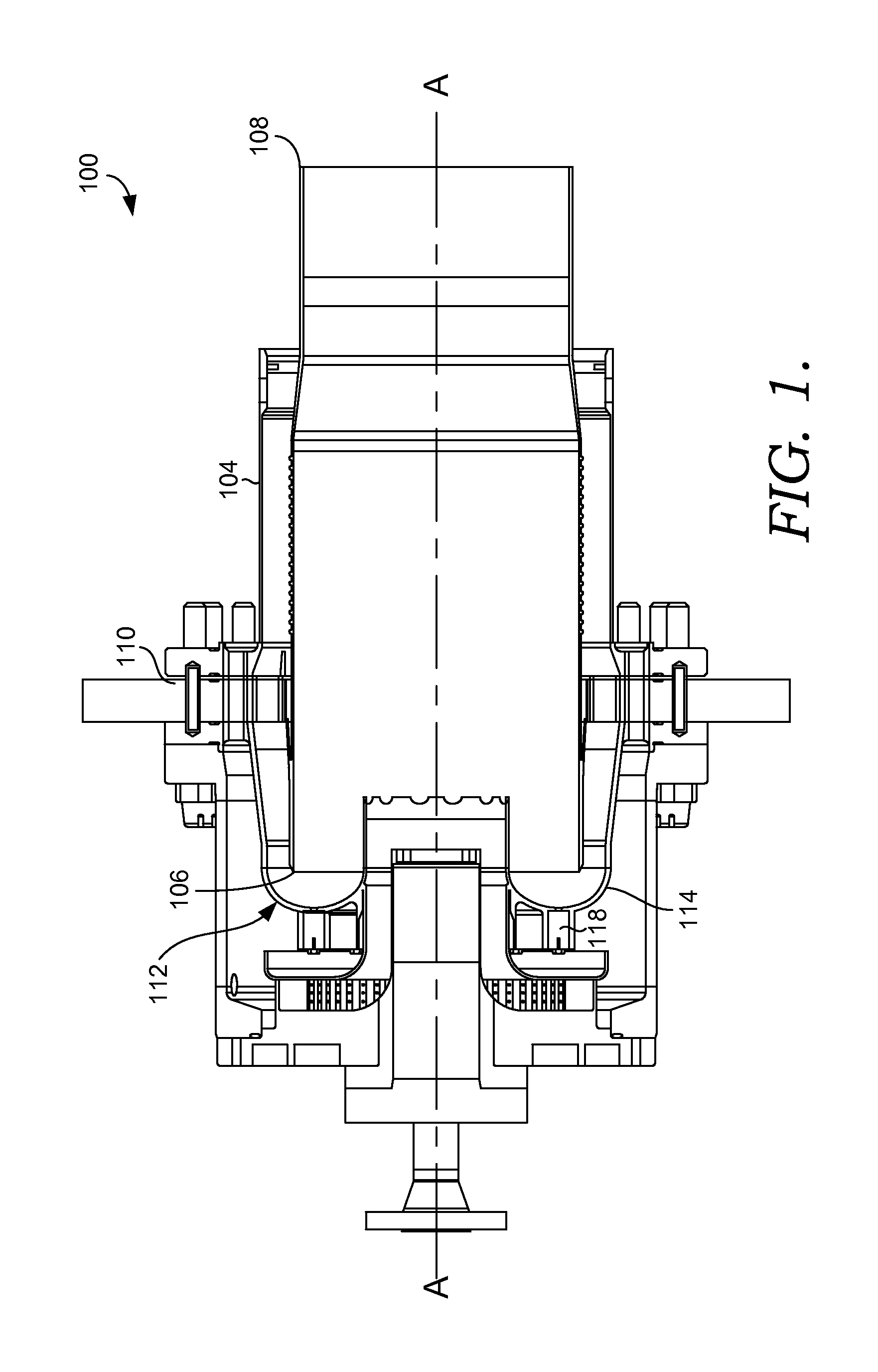

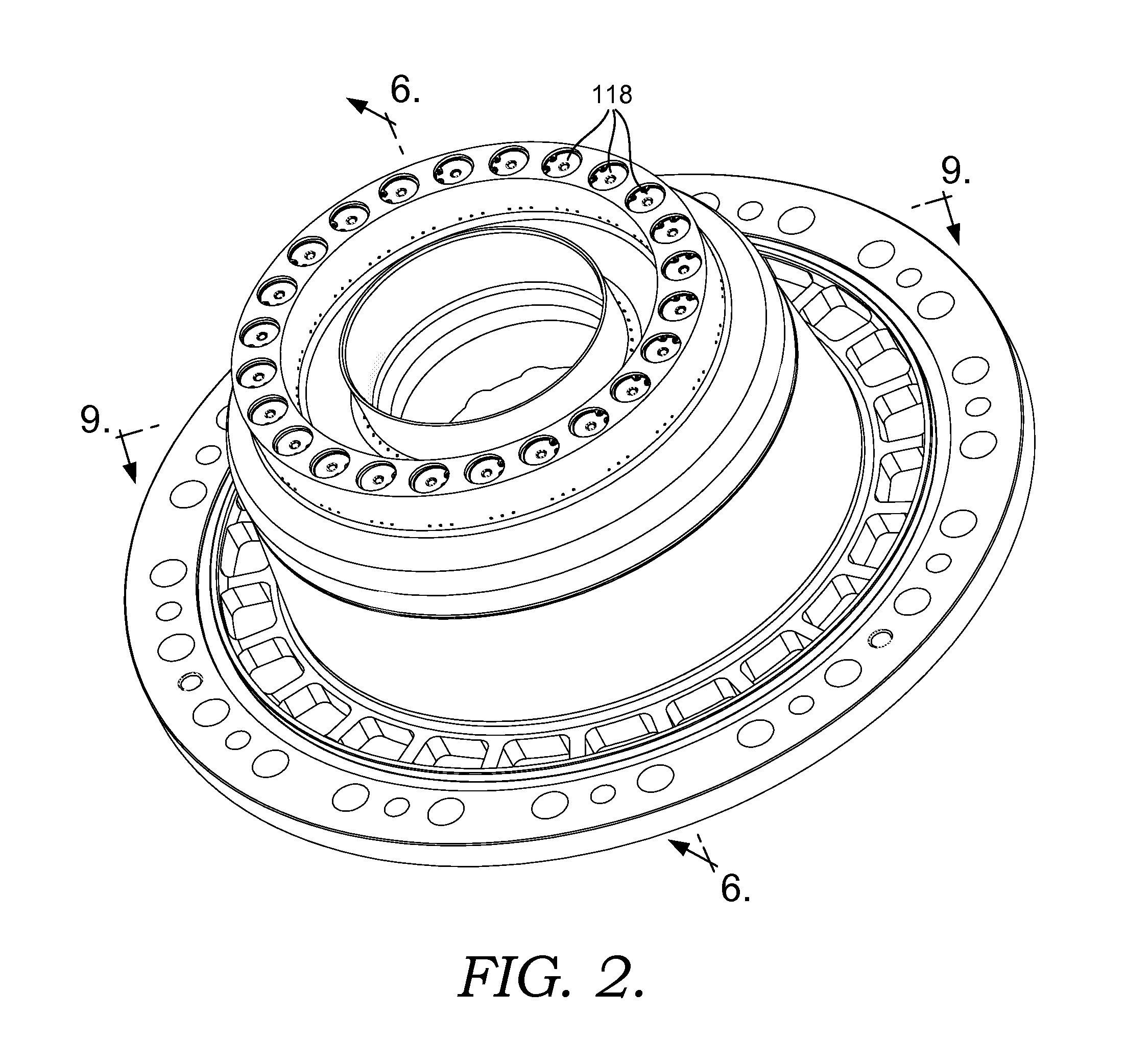

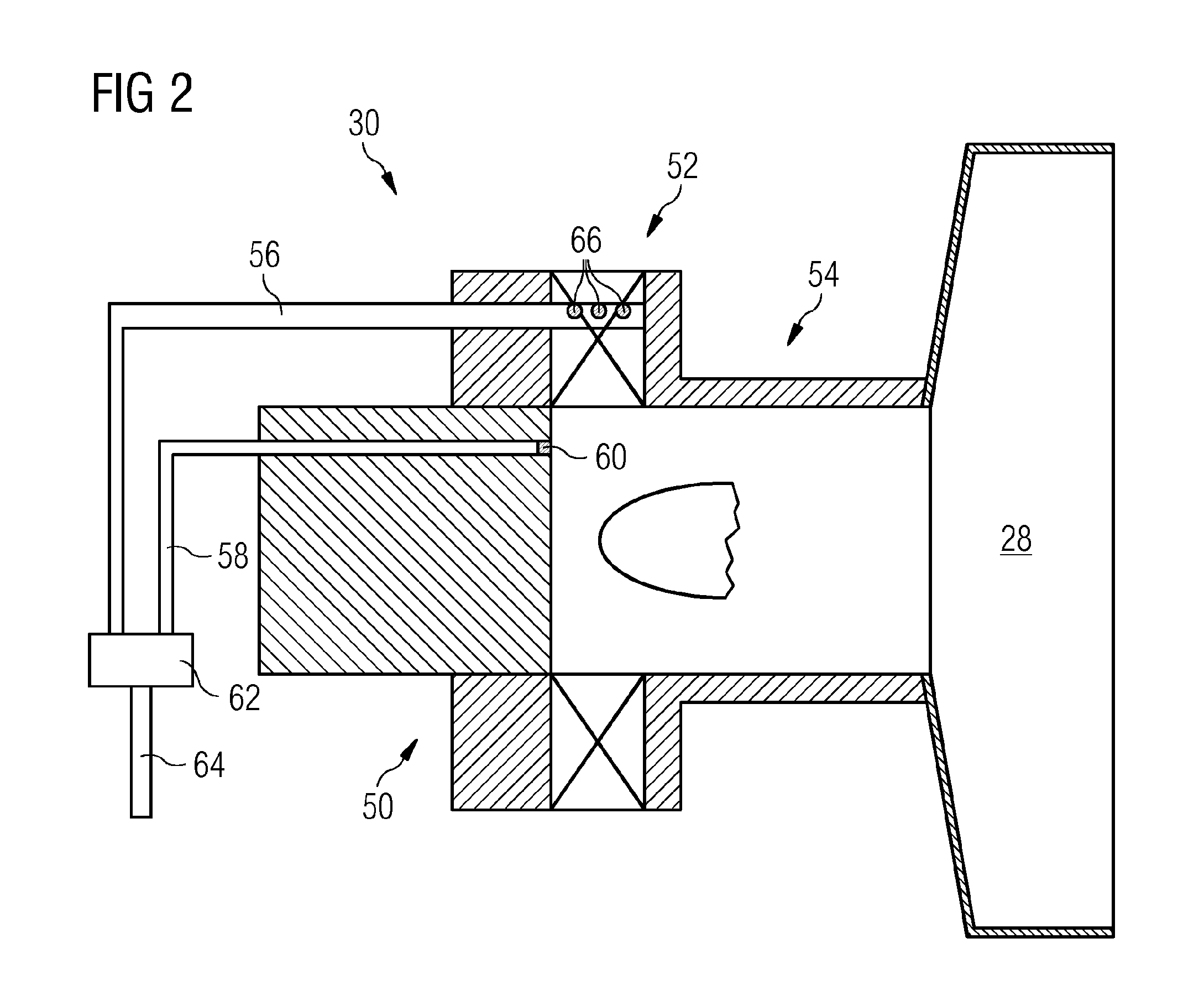

Combustor dome damper system

ActiveUS20160076772A1Adequately pressure fluctuationSmall sizeContinuous combustion chamberEngine fuctionsCombustion chamberCombustor

Owner:H2 IP UK LTD

Method of Operating a Furnace

Owner:AIR PROD & CHEM INC

Device for testing contamination characteristic of segmental temperature control coal burning boiler

InactiveCN102879415AImprove stabilityIncrease flexibilityMaterial thermal analysisTemperature controlCombustor

Owner:中国东方电气集团有限公司

Reverse flow combustor and double-wall elbow structure thereof

ActiveCN109974033AReduce peak wall temperatureHigh strengthContinuous combustion chamberCombustorCombustion chamber

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Industrial castoff fusing and solidifying device

InactiveCN101086334AFlammability ControlGood effectIndirect carbon-dioxide mitigationIncinerator apparatusCombustorPesticide residue

There is provided an industrial waste melting / solidifying apparatus comprising: melting furnace; an oxygen generating device for supplying oxygen-enriched air to the melting furnace; and a burner provided so as to face the inside of the melting furnace, wherein industrial wastes, such as asbestos, pesticide residues and incineration ashes, are thrown into the melting furnace, and combustible materials within the industrial wastes and fuel from the burner are combusted at high temperature by using the oxygen- enriched air, whereby a melting process is performed on the industrial wastes. An entrance slot formed on the melting furnace is provided with a water-cooling jacket via a throw-in gate. The water-cooling jacket is provided with a throw-in door for throwing the industrial wastes. The water-cooling jacket is further provided with a pusher for pushing the thrown industrial wastes out toward the entrance slot to control throwing speed and combustion speed.

Owner:高桥 贤三

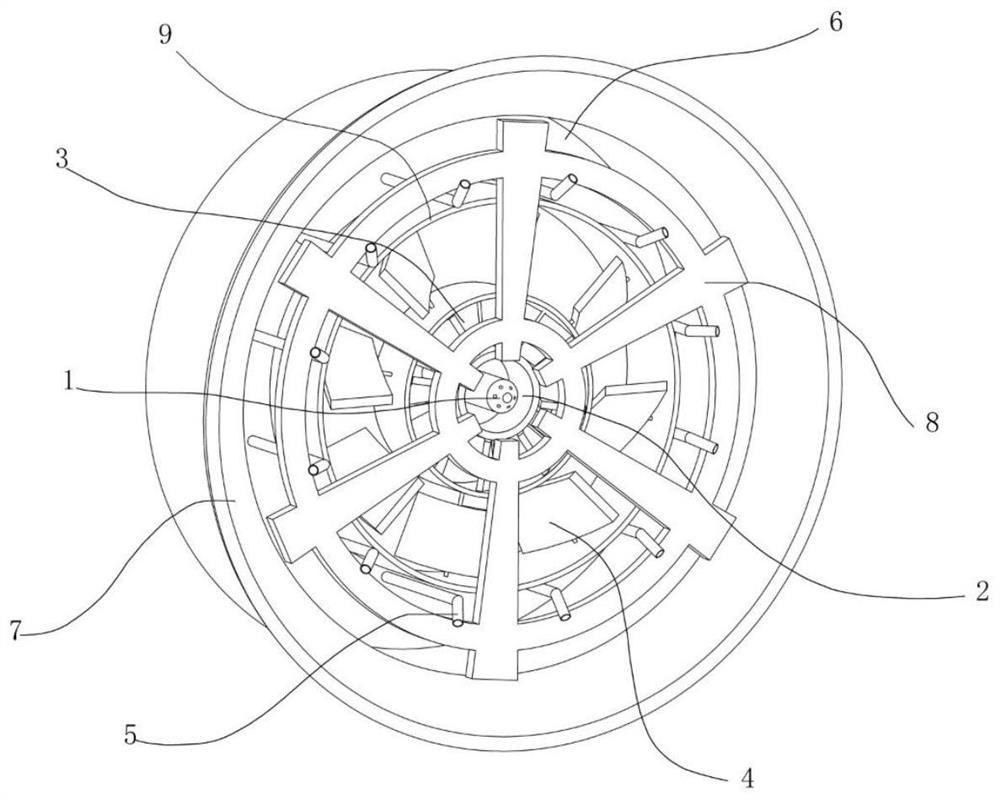

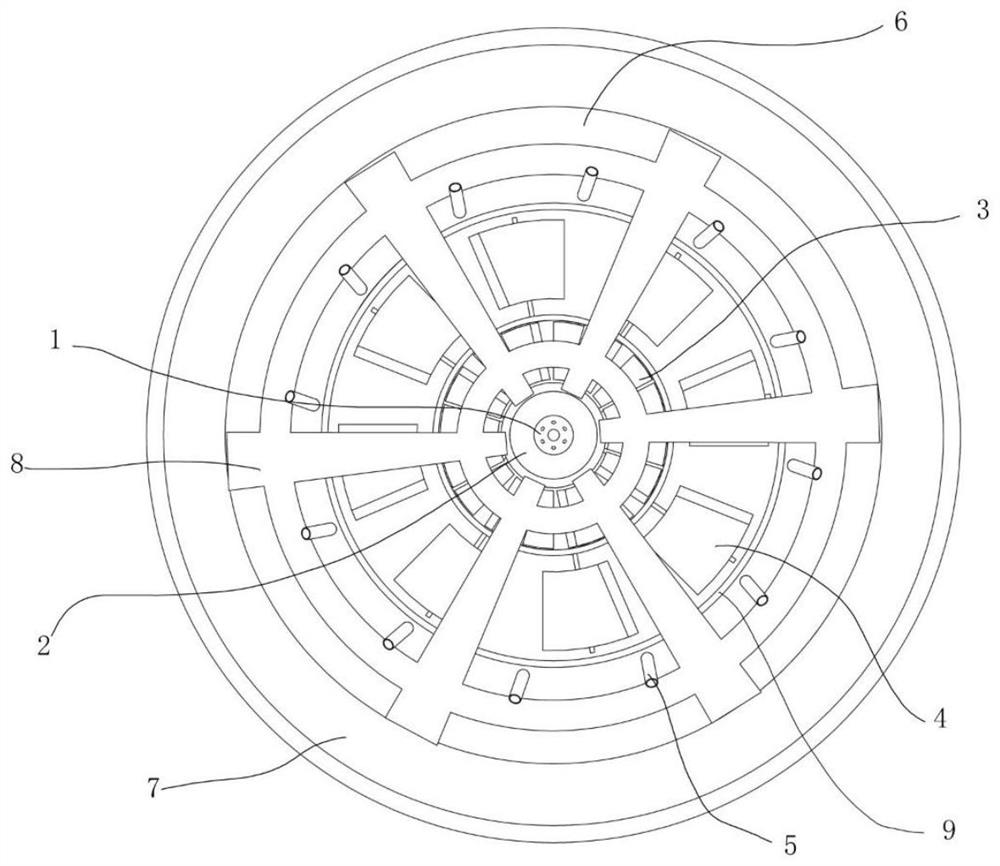

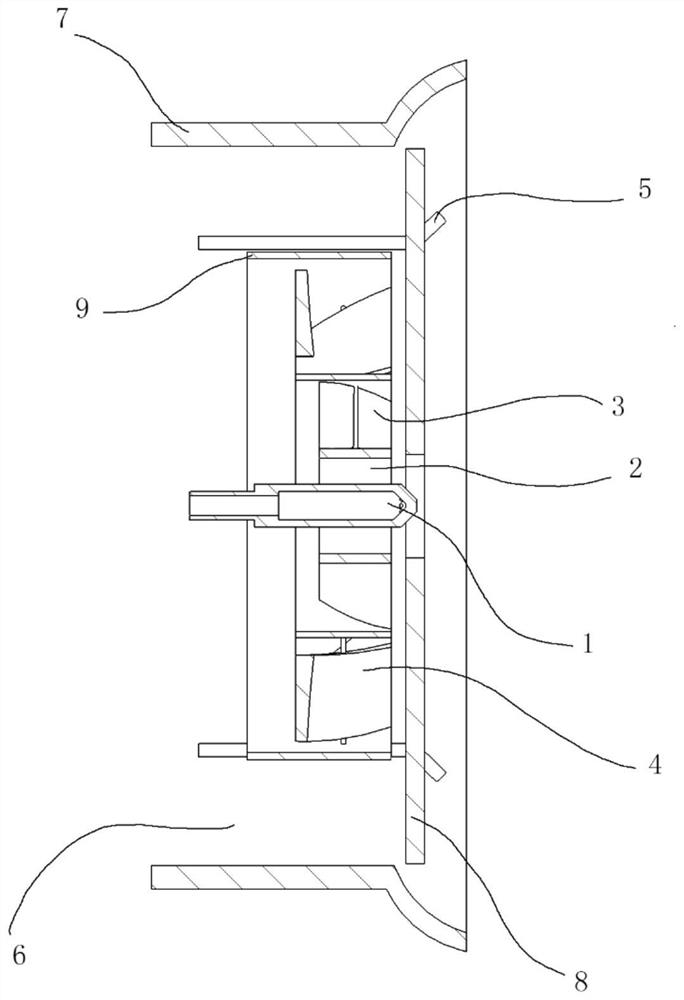

Low-NOx combustor suitable for various low-heat-value/low-pressure fuel gases

The invention belongs to the technical field of industrial combustors, and discloses a low-NOx combustor suitable for various low-heat-value / low-pressure fuel gases for solving the technical problem about how to further reduce the NOx emission of combustors. The low-NOx combustor is characterized in that a center air pipe, an inner pipe, an outer pipe, an outer sleeve and a throat are sequentially and coaxially arranged from inside to outside; a first combustion air channel is formed between the center air pipe and the inner pipe, and the upper end of the first combustion air channel is fixedly connected with a first swirler; a fuel gas channel is formed between the inner pipe and the outer pipe, and the upper end of the fuel gas channel is provided with a plurality of inward center fuel gas nozzles and a plurality of outward center fuel gas nozzles in a circular-ring uniform distribution manner; a second combustion air channel is formed between the outer pipe and the outer sleeve, and the end of the second combustion air channel is fixedly connected with a second swirler; and a third combustion air channel is formed between the outer sleeve and the throat. By the combination of a dense-dilute combustion method and a staged combustion manner, flames can be relatively stable, the intensity of dense combustion is improved, and an extremely strong reduction atmosphere is formed for restraining NOx generation. The low-NOx combustor is suitable for various low-heat-value / low-pressure fuel gases.

Owner:SHANGHAI WISEBOND TECH

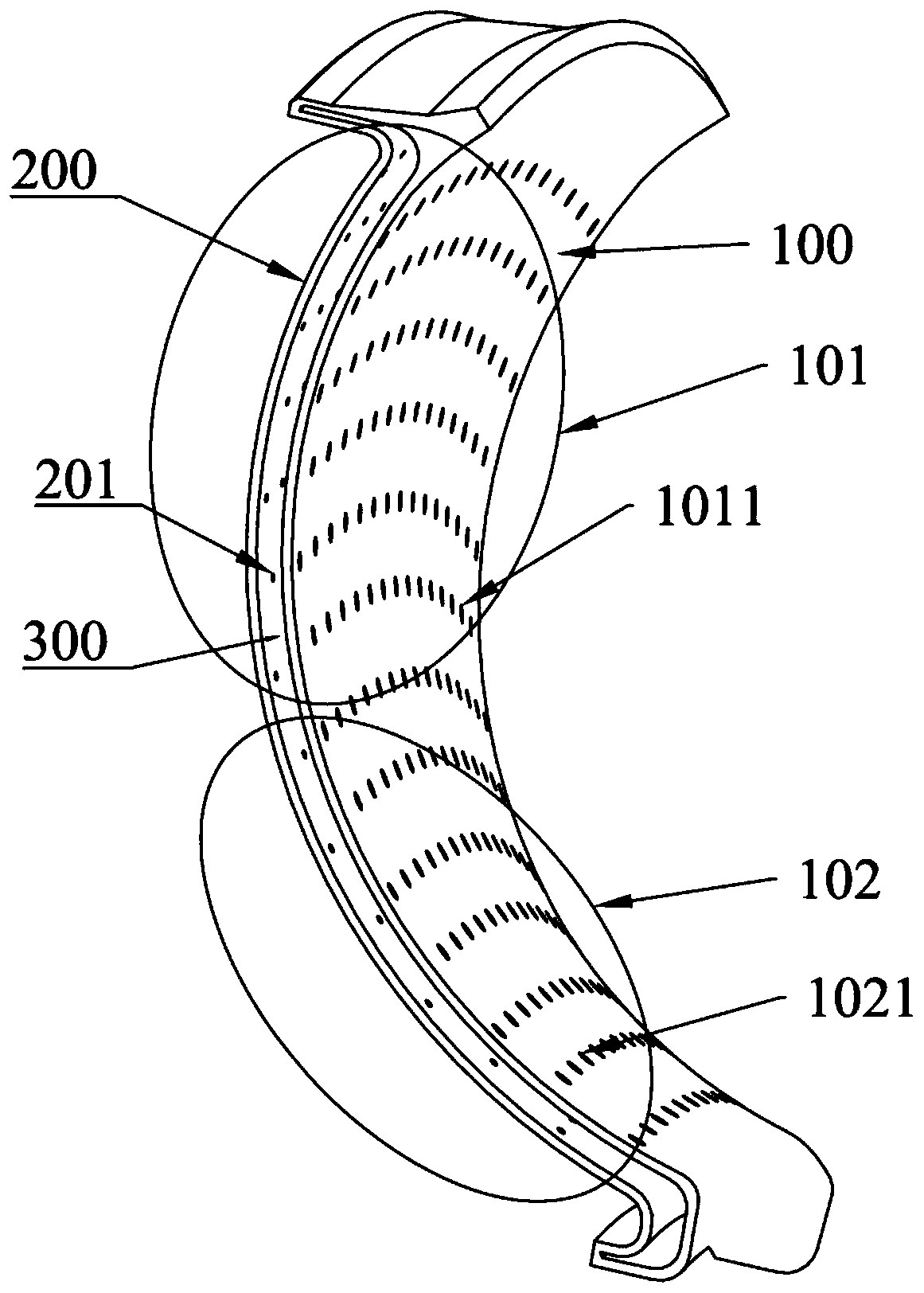

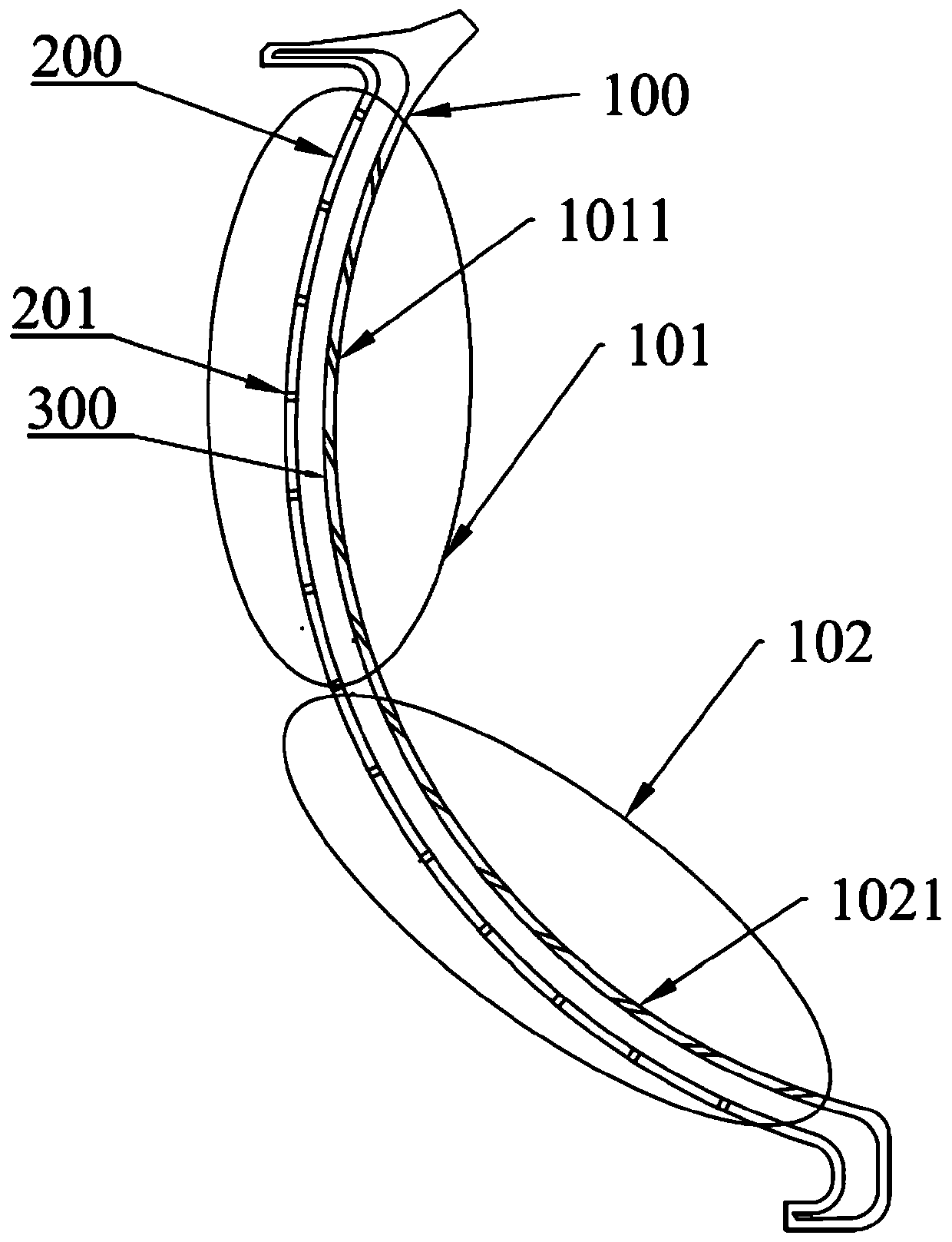

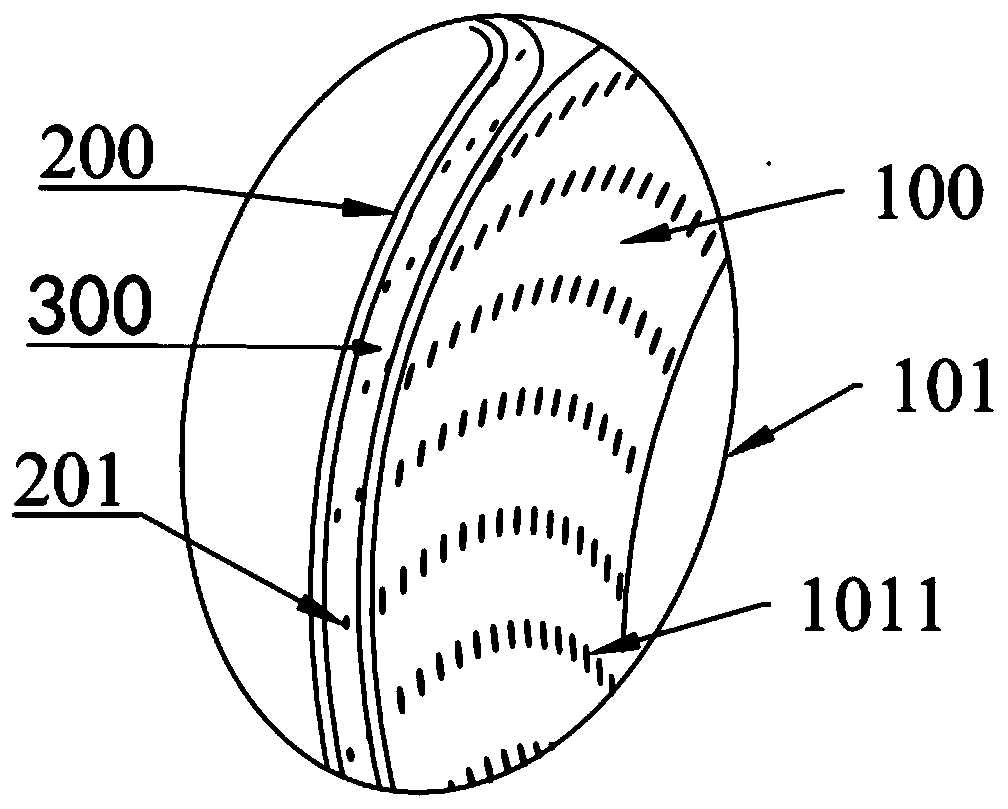

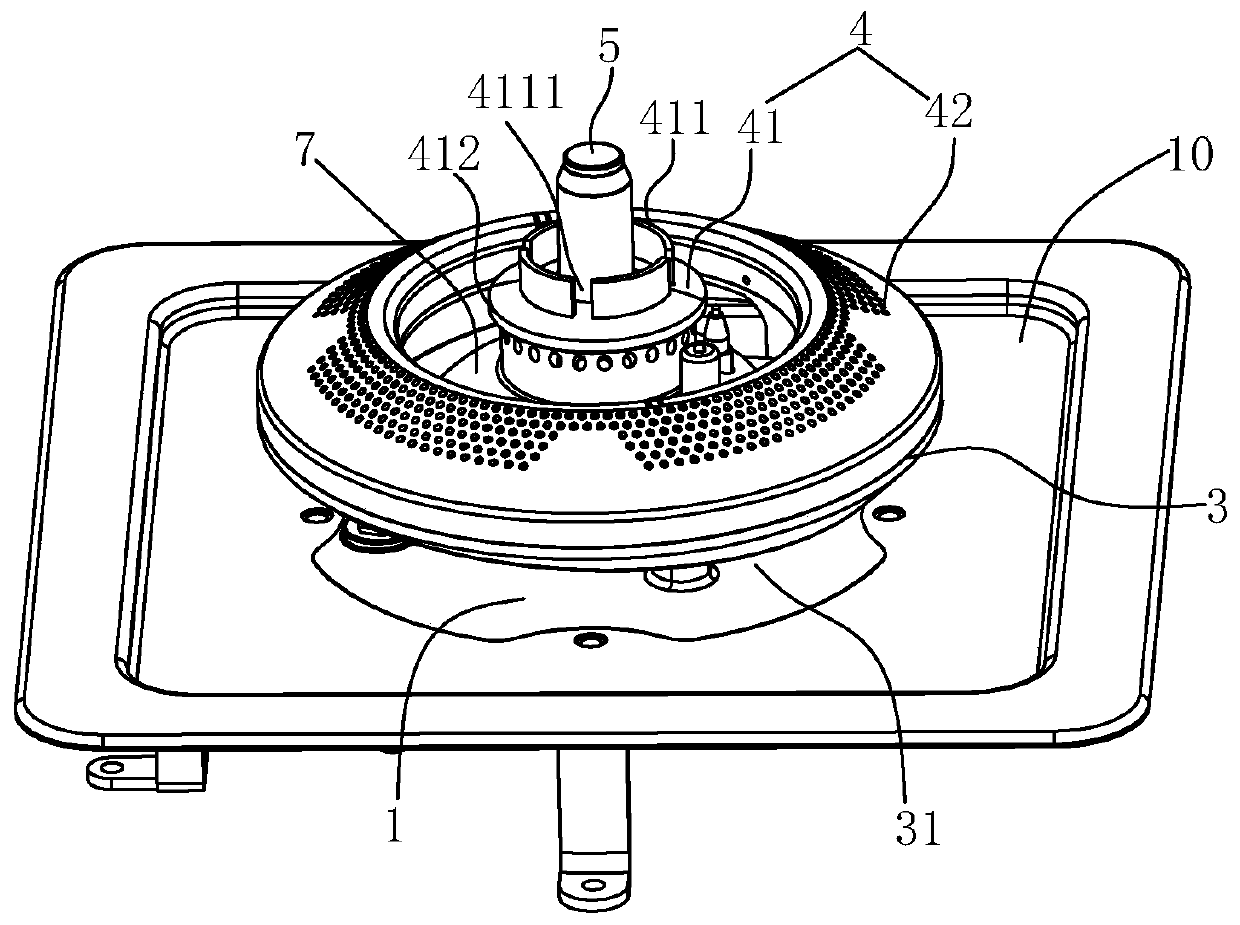

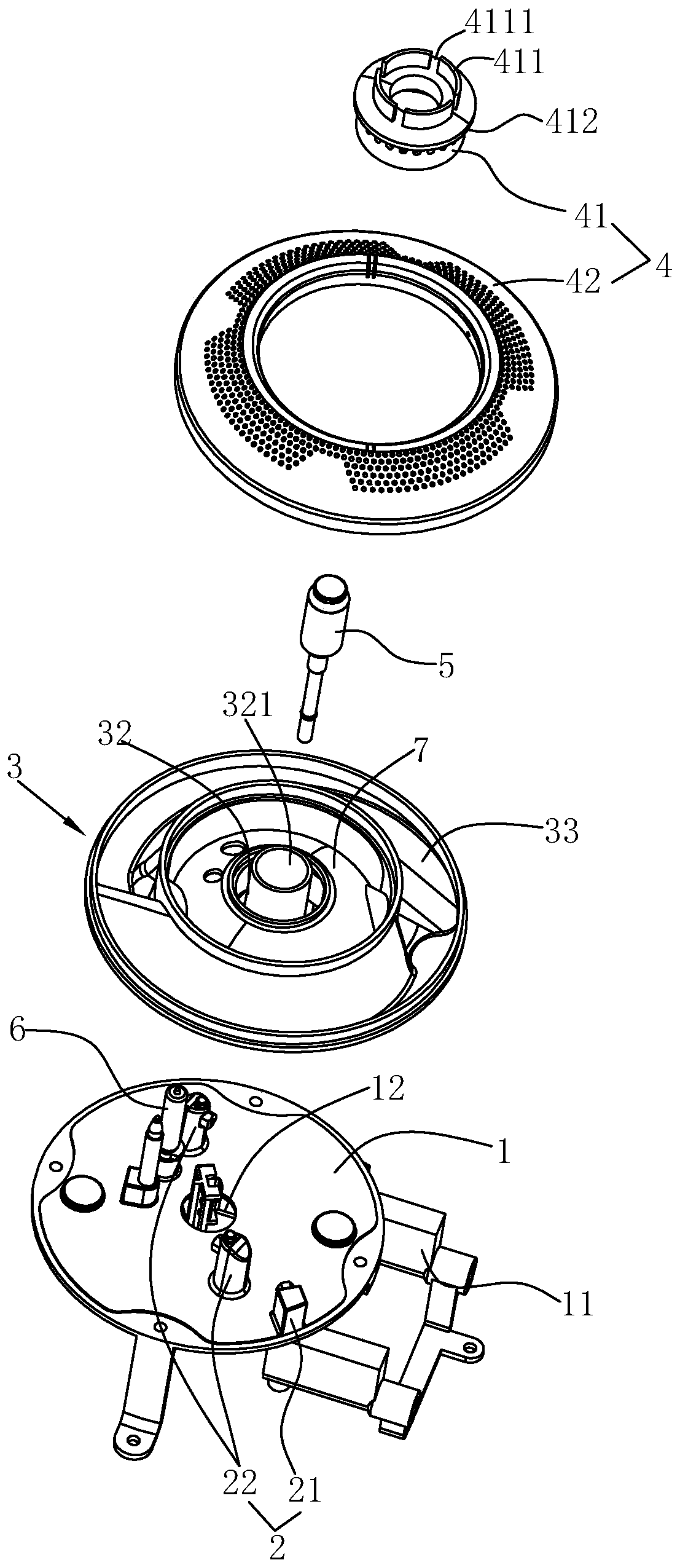

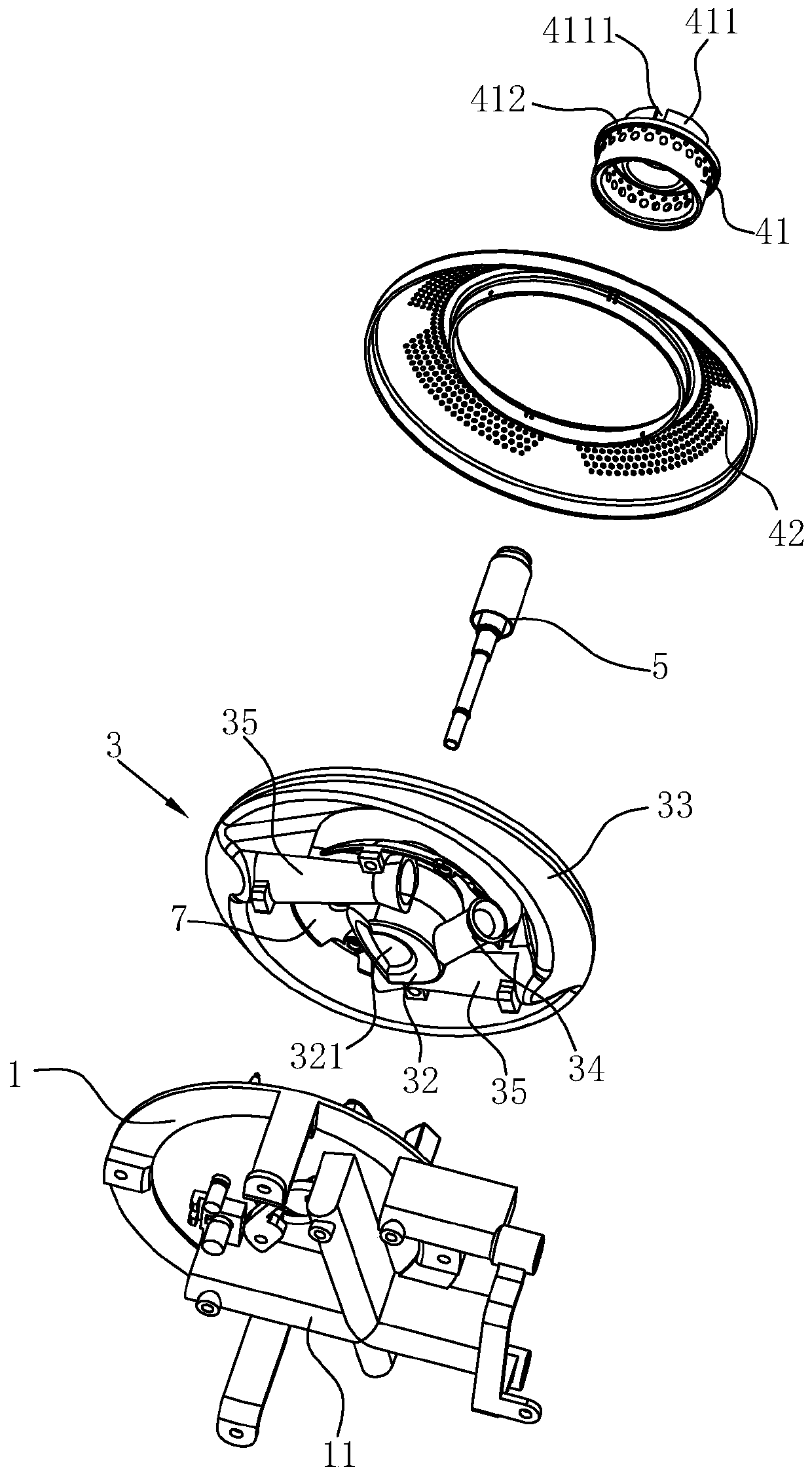

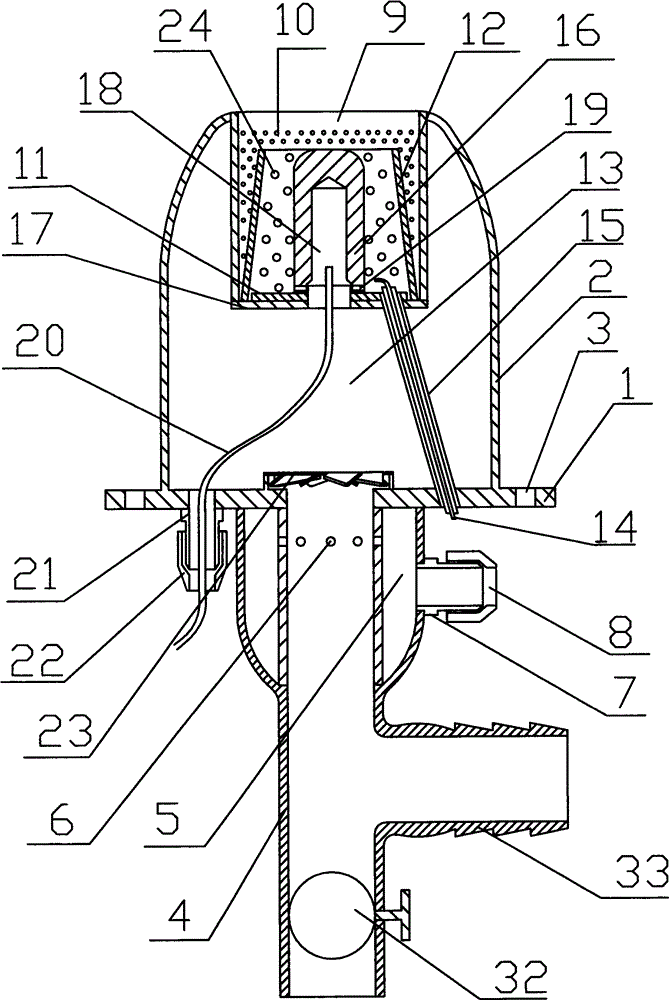

Upper-air-intake dual-ring combustor

PendingCN111486456AReduce the effect of temperature riseImprove temperature measurement accuracyDomestic stoves or rangesCooking fumes removalCombustorEngineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

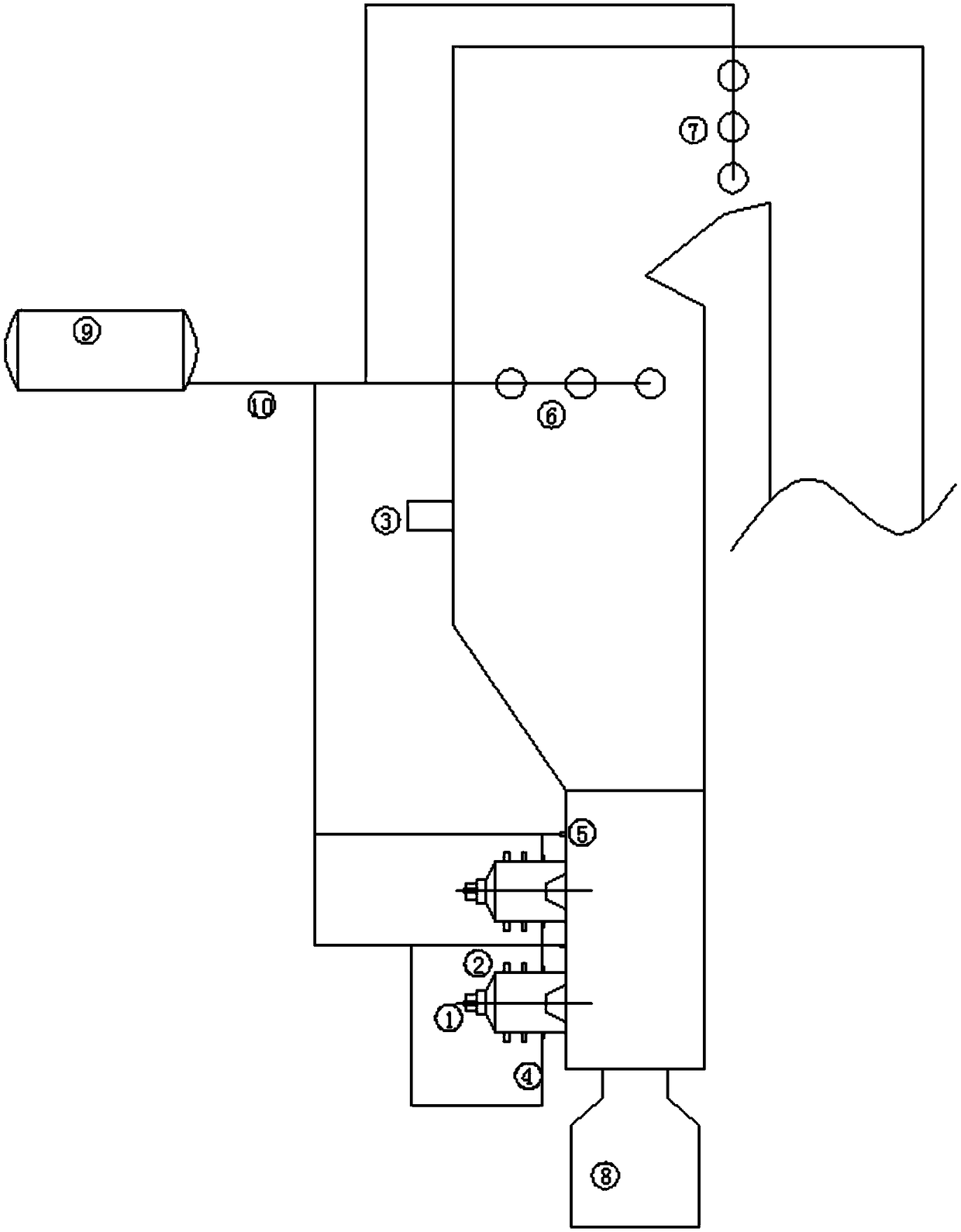

Cyclone furnace denitration system and method

PendingCN109058979AEmission reductionImprove economyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

Owner:CHINA HUANENG GRP CO LTD +1

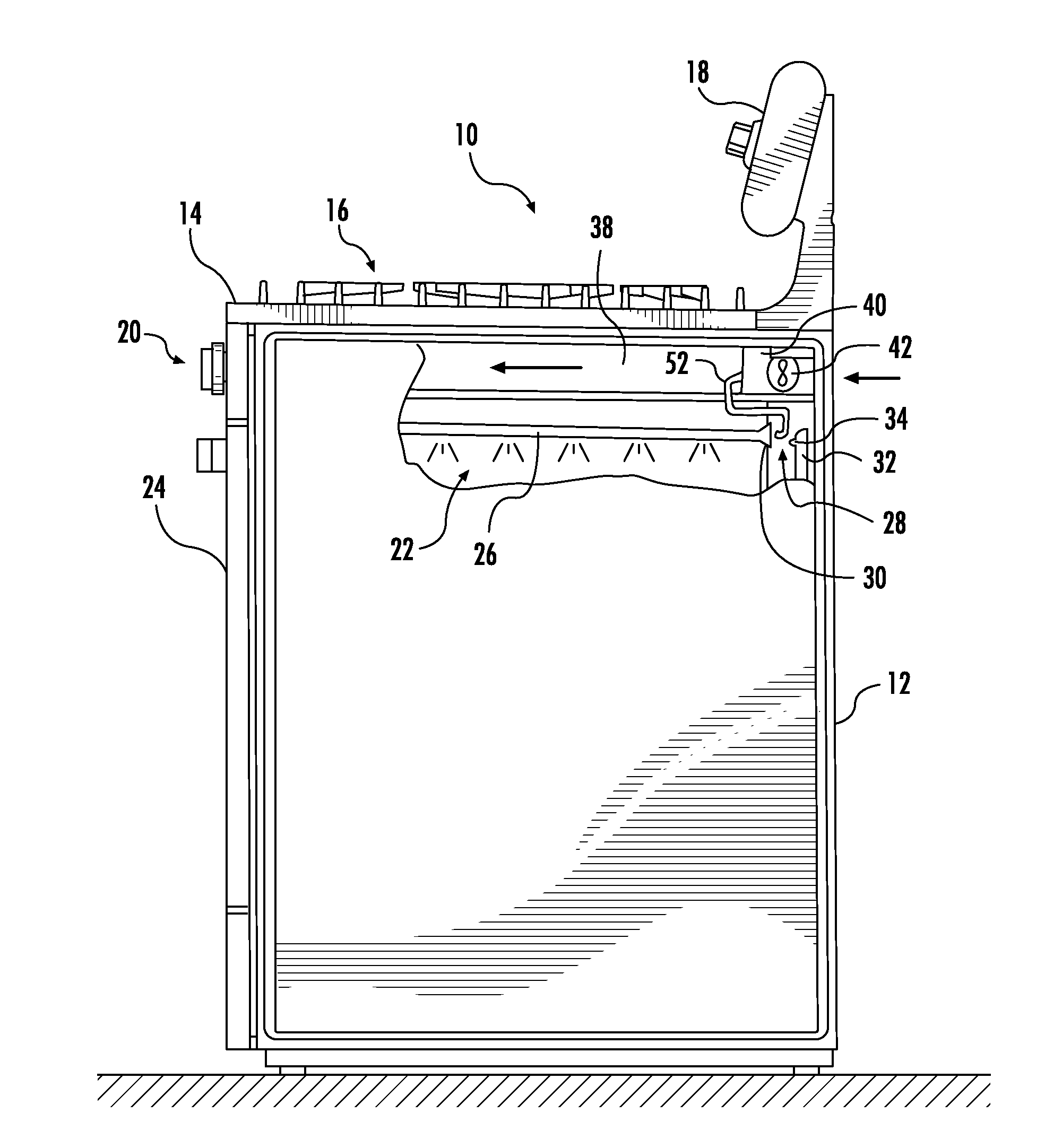

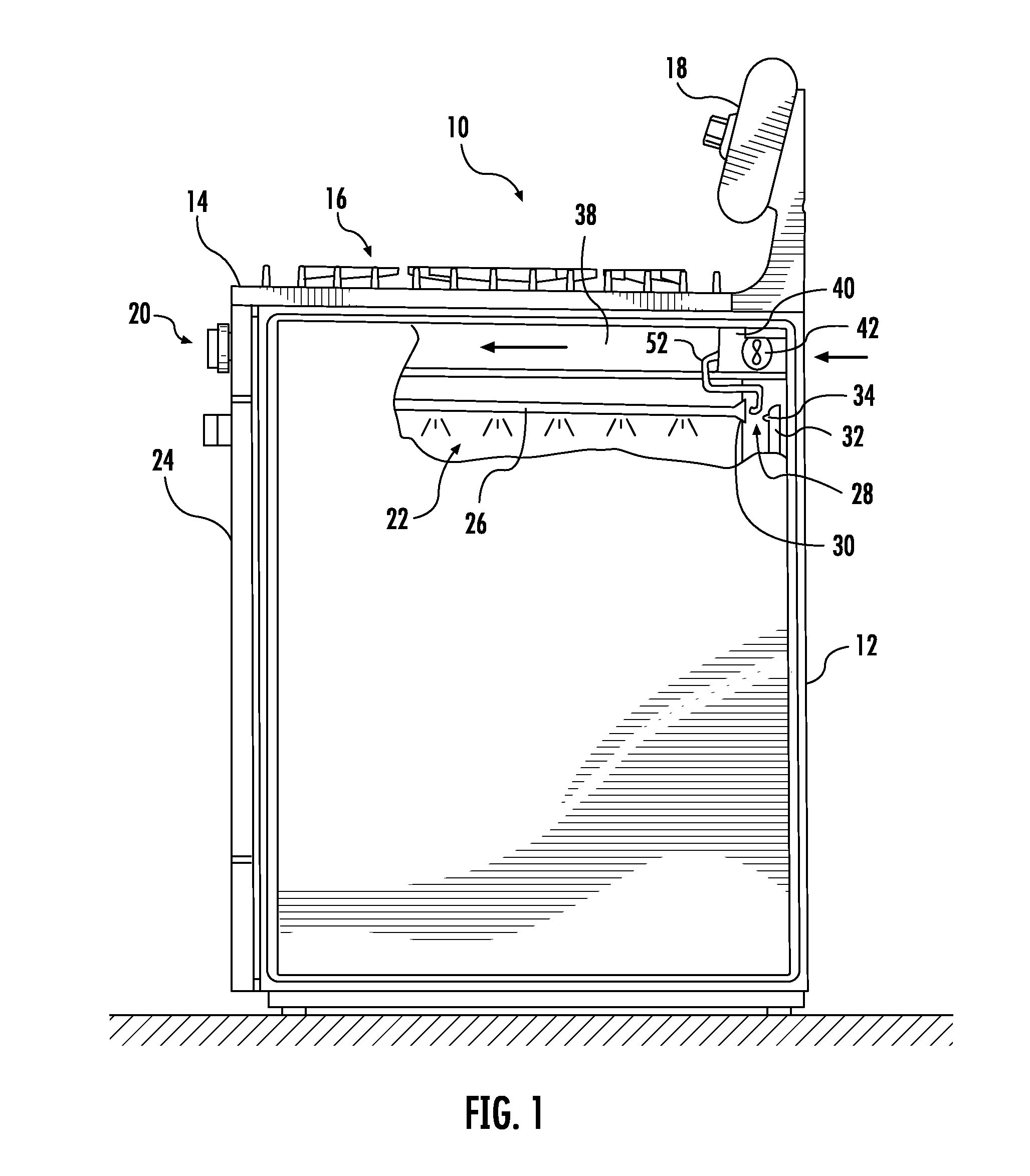

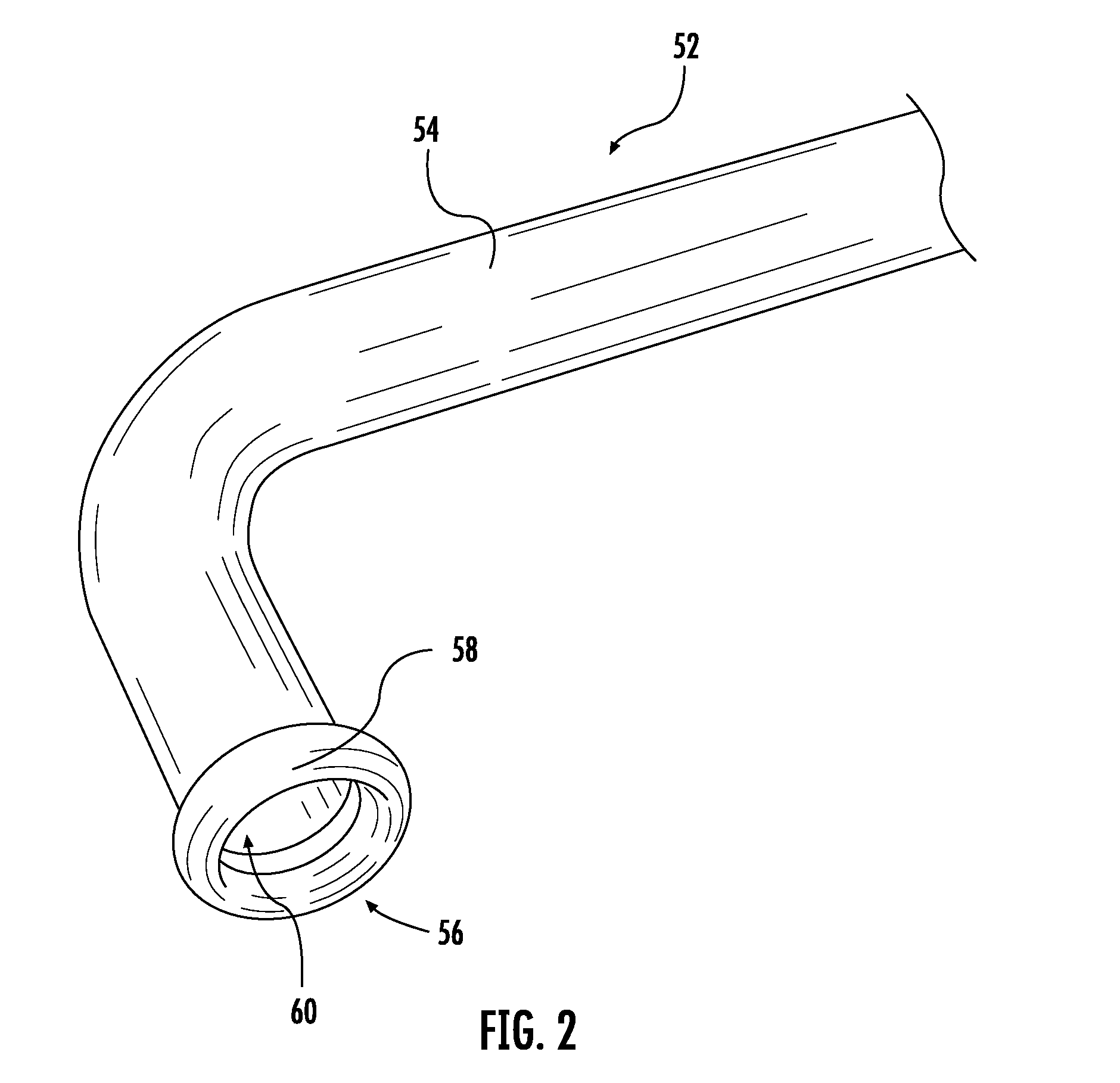

Home appliance with supplemental combustion air supply apparatus

ActiveUS20140305424A1Increasing burner efficiencyImprove efficiencyAir supply regulationDomestic stoves or rangesThermodynamicsCombustor

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

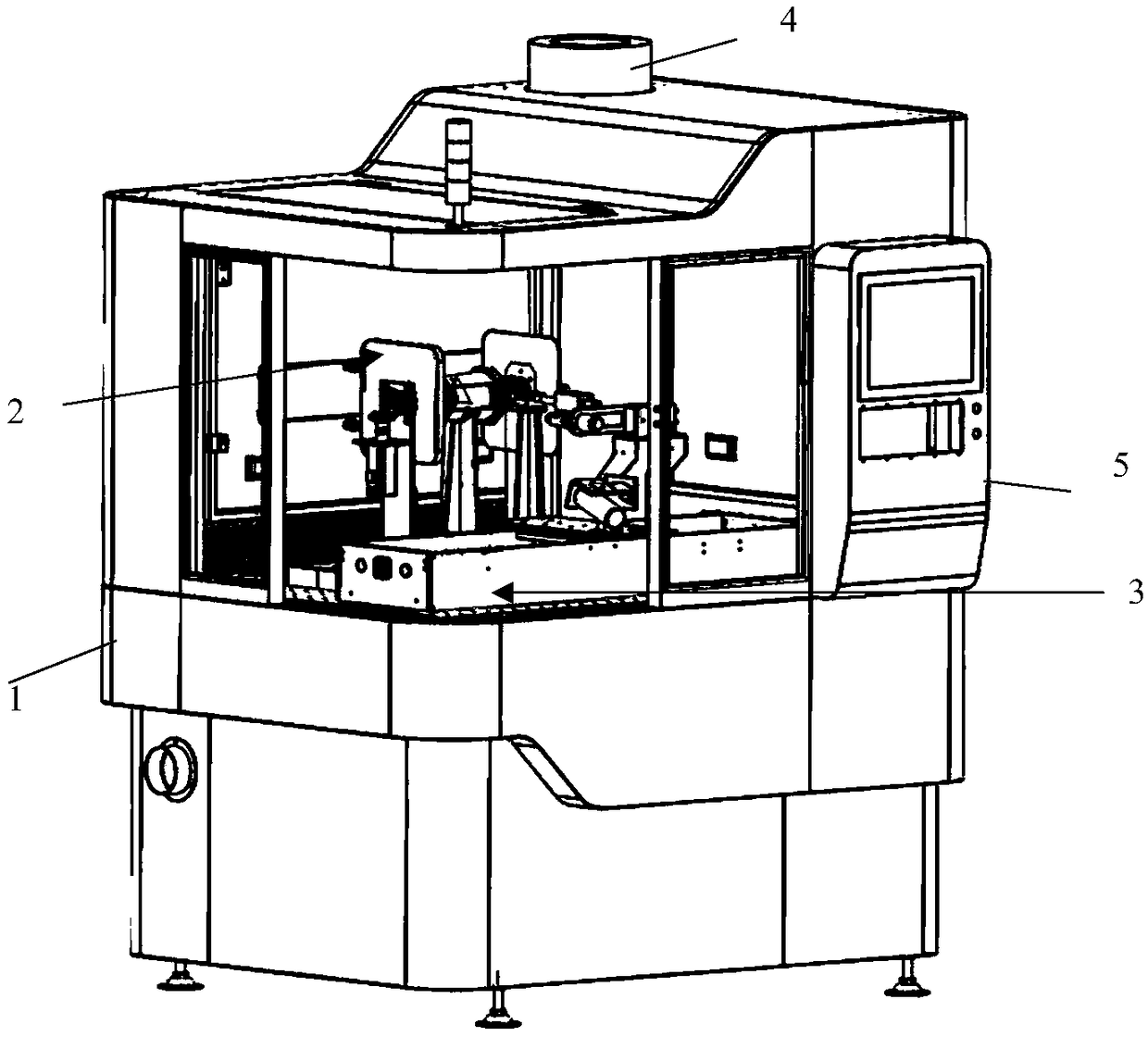

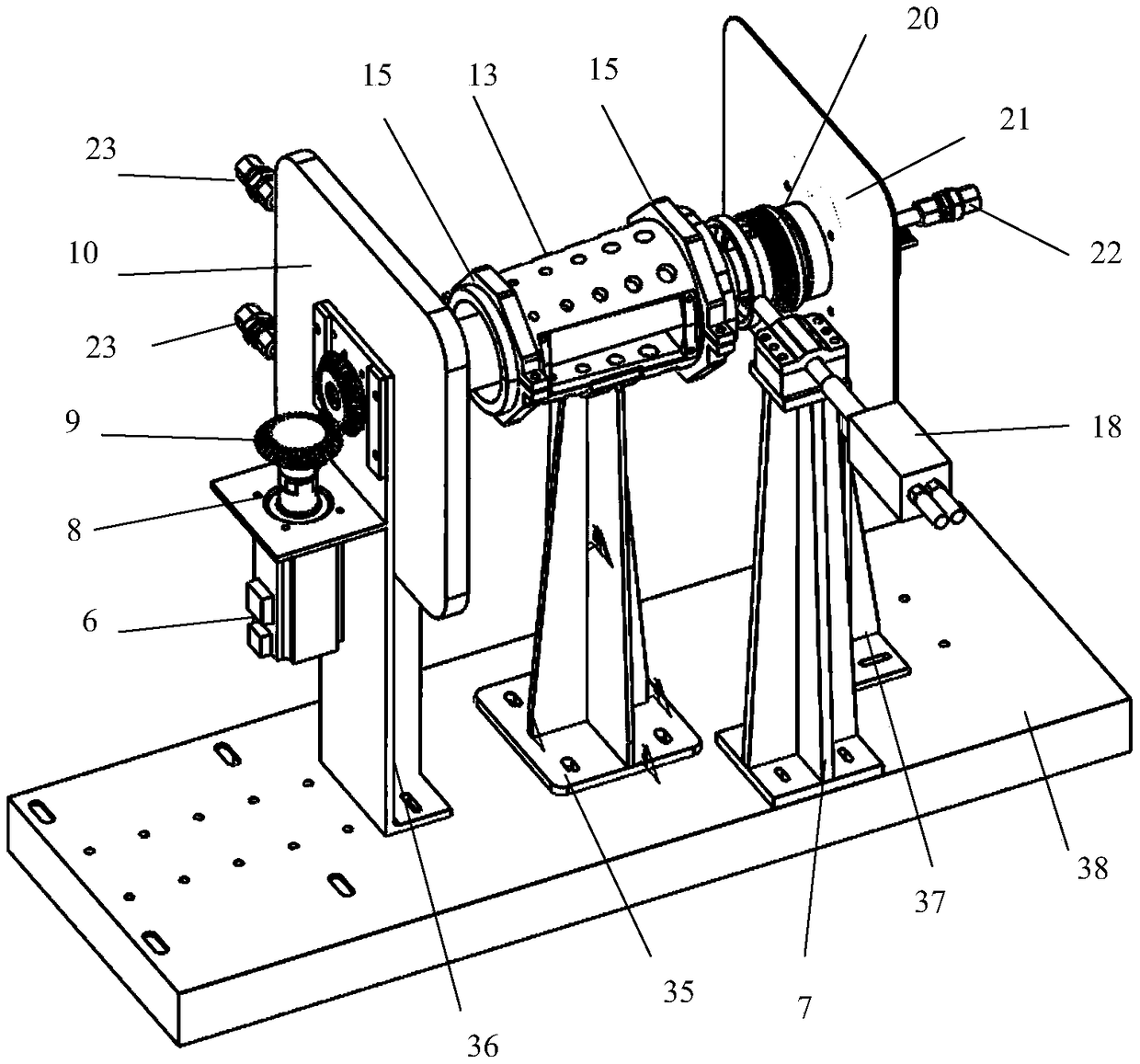

Steady-state-temperature-field-included simulation test bench of aero-engine combustor

InactiveCN109374308ALow costShort cycleGas-turbine engine testingJet-propulsion engine testingAviationSteady state temperature

Owner:CIVIL AVIATION UNIV OF CHINA

Combined burner and lance apparatus for electric arc furnaces

InactiveUS8333819B2Improve energy efficiencyEliminate cold spotFurnace componentsManufacturing convertersCombustorElectric arc furnace

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Ammonia low-nitrogen multi-stage rotational-flow burner

ActiveCN112963833AWell mixedUniform heat loadAir supply regulationGaseous fuel burnerCombustorThermal radiation

Owner:XI AN JIAOTONG UNIV

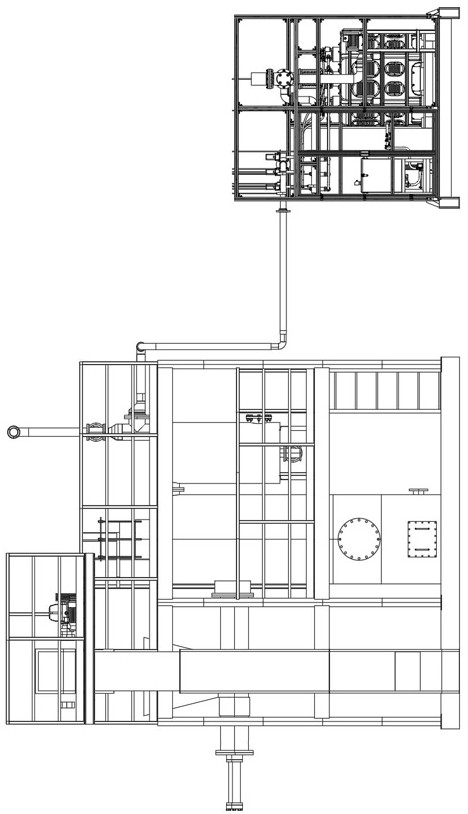

Device and process for purifying and treating tar tail gas and asphalt fume

ActiveCN110425550ASolve the problem that it is difficult to purify asphalt fumeImprove thermal efficiencyIncinerator apparatusChimneysCombustion chamberEnvironmental geology

The invention relates to a device and process for purifying and treating tar tail gas and asphalt fume. The device comprises an incinerator and a chimney, wherein the incinerator is composed of a first combustion chamber, a second combustion chamber, a first heat storage chamber and a second heat storage chamber, the first combustion chamber is arranged below the second combustion chamber, and thefirst combustion chamber and the second combustion chamber communicates with each other; the two ends of the first combustion chamber communicates with the top of the first heat storage chamber and the top of the second heat storage chamber respectively, a first combustor is arranged inside the first combustion chamber, a second combustor is arranged inside the second combustion chamber, and a heat accumulator is arranged inside the first heat storage chamber and the second heat storage chamber. By adopting a process combining a heat storage type incinerator and a direct combustion type incinerator, the tar tail gas and the asphalt fume can be purified at the same time, the problem that the heat storage type incinerator is difficult to purify the asphalt fume and the direct combustion type incinerator is low in heat efficiency is solved, meanwhile, waste gas waste heat is recycled, the operation cost of the incinerator is reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Water-based combustion-supporting straw particle boiler-kiln universal burner with fuel such as coal, gas and oil

InactiveCN104235832AKeep aliveResponse is continuous and stableCombustion using multiple fuelsCombustion using catalytic materialWater basedBrick

Owner:管理

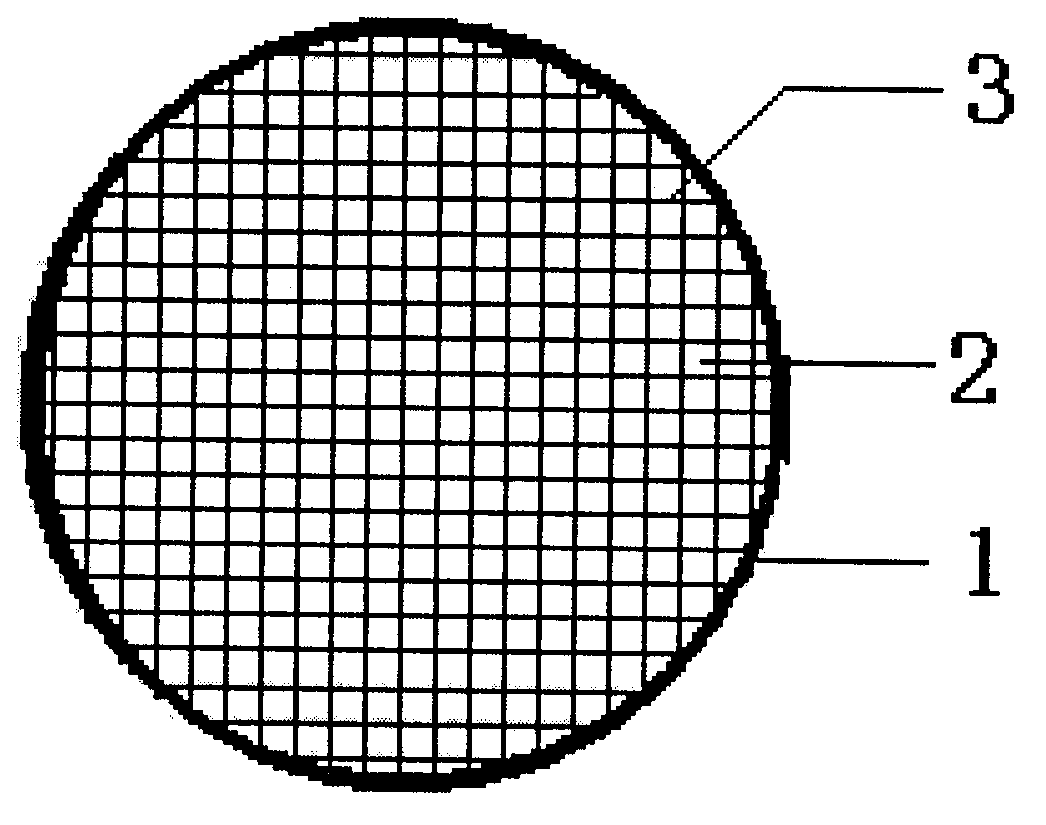

Non-metal honeycomb combustion plate for Chinese food kitchen range

InactiveCN103574608AReduce manufacturing costShorten the processing cycleGaseous fuel burnerEngineeringHearth

Owner:缪传云

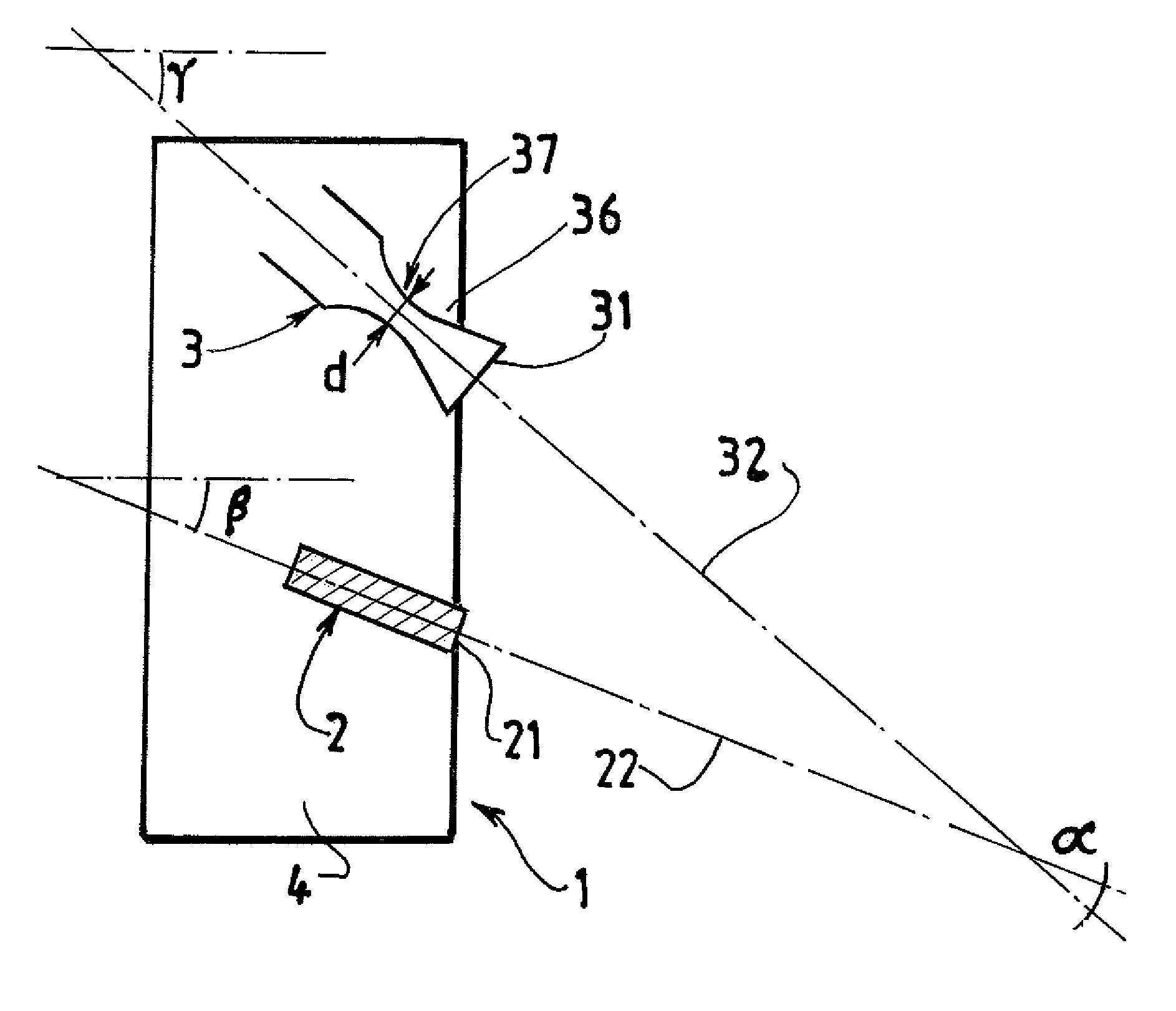

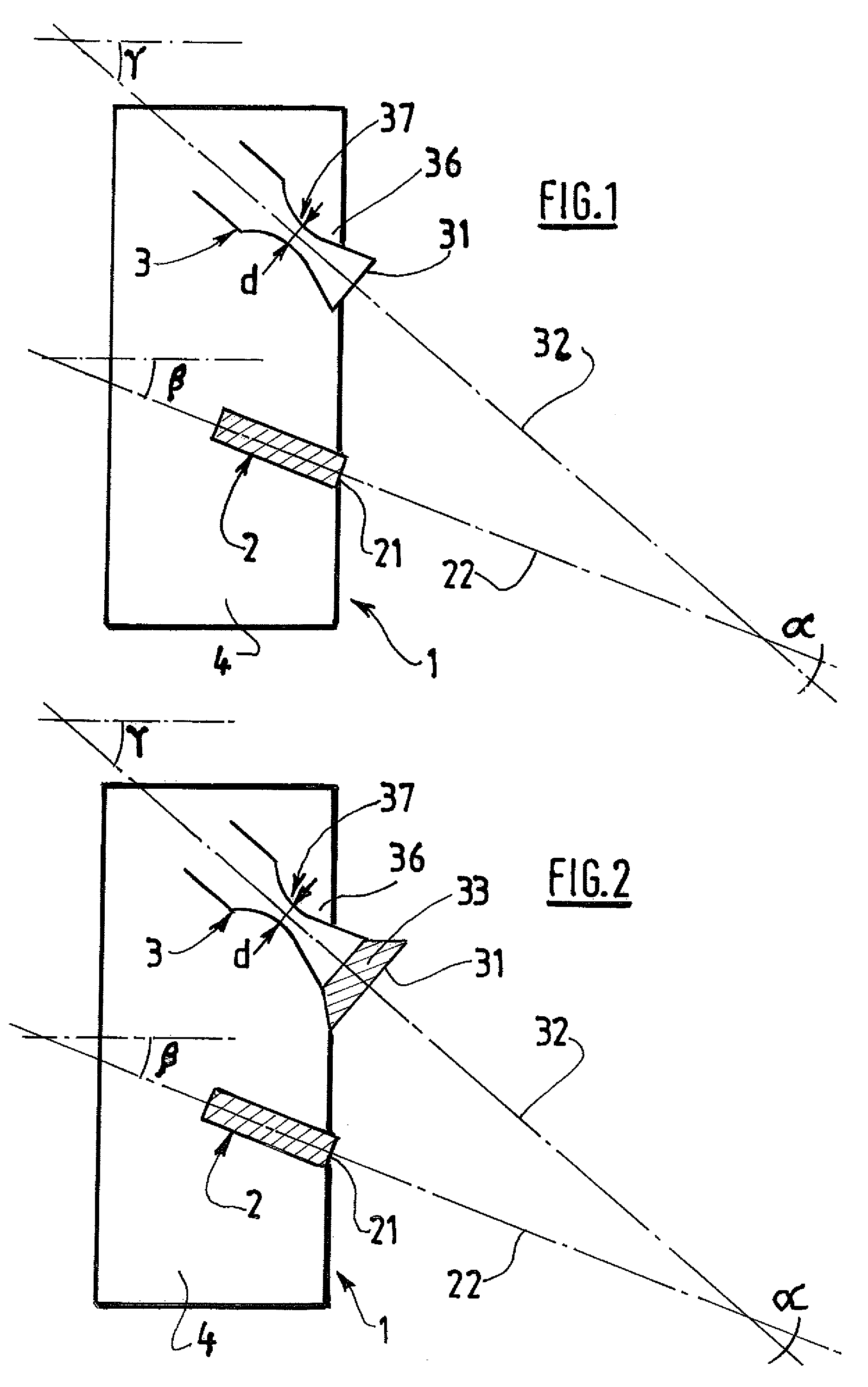

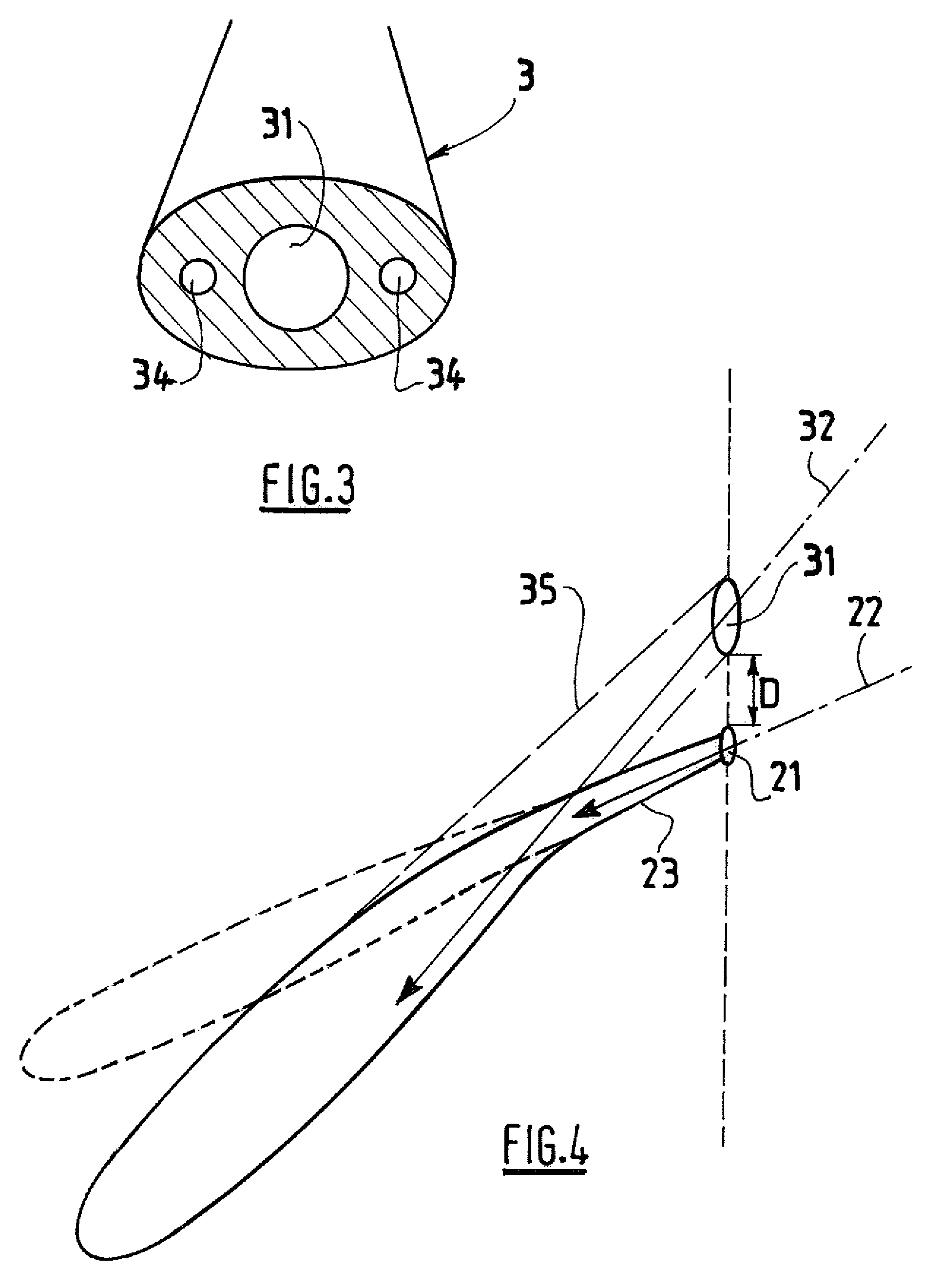

Burner

A burner operating with flameless combustion, comprising a system for sucking the recycling flue gases directly from the combustion chamber by means of an ejector (1) fed with the comburent, a heat exchange system positioned between the recycling flue gases and the comburent, a system for injecting the fuel directly into the recycling flue gases, the latter comprising or not comprising the comburent with formation of a mixture of fuel-recycling flue gases-comburent in the zone around the outlet of the comburent ejector and following introduction of the mixture into the combustion chamber.

Owner:SOFINTER

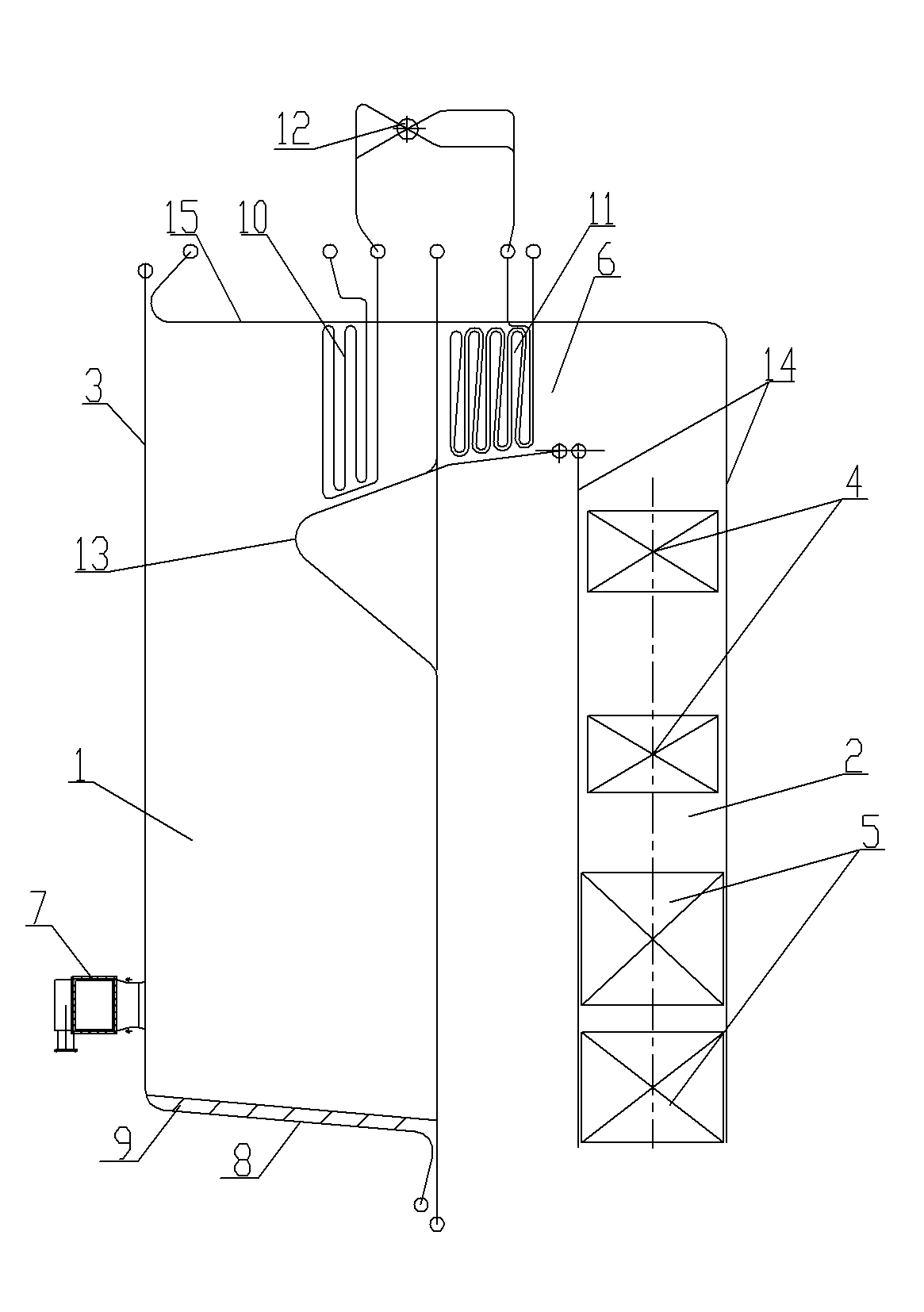

High heating value gas boiler

Owner:WUXI HUAGUANG BOILER

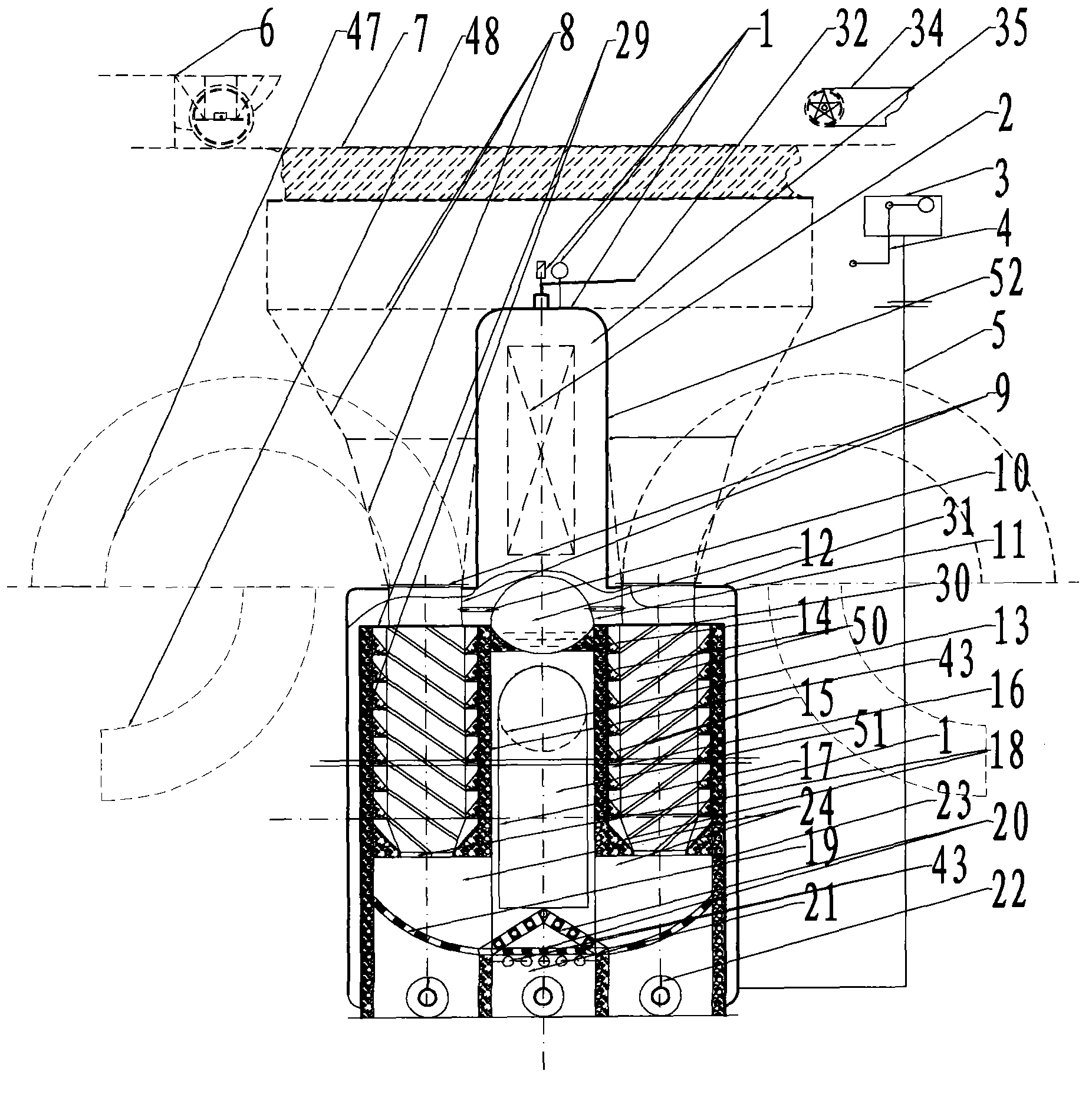

Spinning preheating furnace for aluminum alloy automobile hub

The invention discloses a spinning preheating furnace for an aluminum alloy automobile hub. The spinning preheating furnace comprises a furnace body, wherein a furnace cavity in the furnace body is partitioned into an upper layer and a lower layer; one end of the upper layer furnace cavity is provided with an upper furnace door; the same end of the lower layer furnace cavity is provided with a lower furnace door; the other end of the upper layer furnace cavity is communicated with the other end of the lower layer furnace cavity; the upper layer furnace cavity serves as a preheating area; the lower layer furnace cavity is partitioned into a forced heating area and a heat preserving area; combustion channels are formed outside the upper and the lower layers of furnace cavities; each combustion channel extends from one end of each furnace door along the length direction of the furnace body; the upper layer furnace cavity and the lower layer furnace cavity are provided with tracks respectively; the bottom of the furnace body is provided with an outer elevating frame; inner elevating frames are arranged in the upper layer furnace cavity and the lower layer furnace cavity; and the top of the combustion channel is provided with one or more high-temperature wind mills and a plurality of combustors. By adopting the spinning preheating furnace, a stable-temperature workpiece can be provided, heat energy can be utilized effectively, energy waste is reduced, and occupied space is reduced; and the spinning preheating furnace is convenient to operate, and is safe and environment-friendly for using.

Owner:ZHEJIANG YUELING

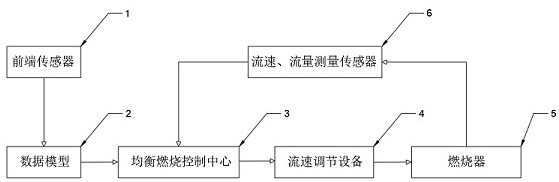

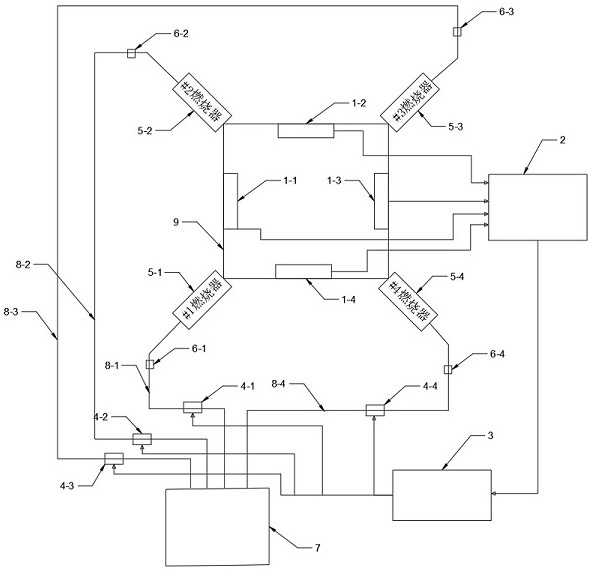

Power station boiler balanced combustion optimization method based on data driving

InactiveCN113760018ABurn evenlyBalanced Burn AdjustmentSimultaneous control of multiple variablesCombustorPower station

Owner:芜湖发电有限责任公司 +1

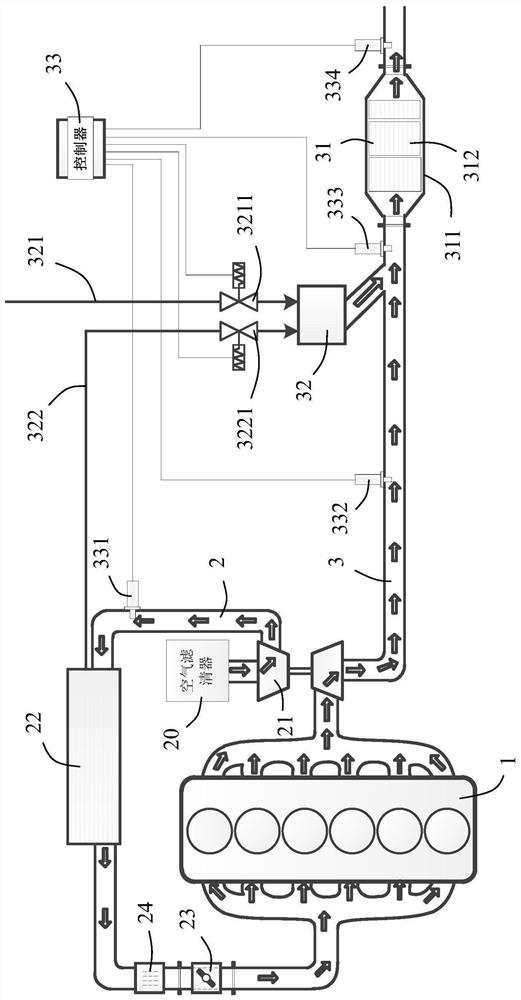

Tail gas after-treatment assembly and system for natural gas engine

PendingCN111852626AIncrease temperatureImprove conversion efficiencyInternal combustion piston enginesExhaust apparatusCombustorPtru catalyst

Owner:TENNECO SUZHOU EMISSION SYST

Gas-fired boiler flue gas recirculation low-nitrogen combustion device

InactiveCN107830514AReduce nitrogen oxide contentImprove combustion efficiencyStaged combustionFluegas recirculationCombustorCombustion chamber

The invention discloses a gas-fired boiler flue gas recirculation low-nitrogen combustion device which comprises a boiler main body. The bottom of the boiler main body is provided with a combustor which comprises a main combustion chamber. The other side of the main combustion chamber is connected with a circulation pipeline. A flow adjusting valve is arranged inside the circulation pipeline, a recombustion chamber is connected with the main combustion chamber through the circulation pipeline, the tops of the main combustion chamber and the recombustion chamber are provided with a complete combustion chamber, one side of the complete combustion chamber is connected with a third air blower, a partition plate is arranged between the complete combustion chamber and the main combustion chamber, a partition plate is arranged between the complete combustion chamber and the recombustion chamber, circulation holes are formed in the partition plates, the top of the complete combustion chamber is provided with a flue gas purifying device, and the glue gas purifying device is connected with a flue gas exhaust device through an induced draft fan. A large amount of reducing gas is generated inthe main combustion chamber and introduced into the recombustion chamber through the circulation pipeline, nitrogen oxide is reduced to nitrogen, emission standards are met, and the purpose of low-nitrogen combustion is achieved.

Owner:GUANGDONG TUOFENG IND CO LTD

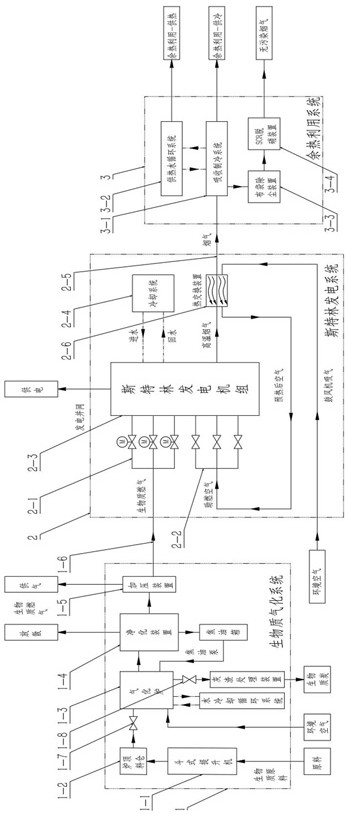

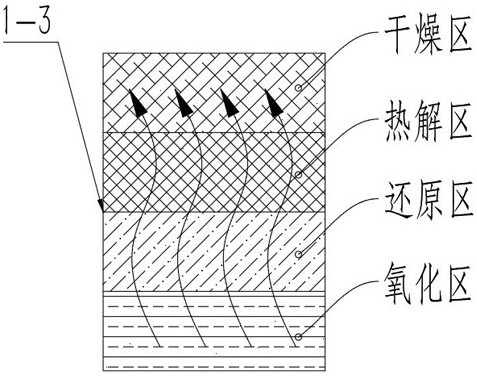

Biomass gasification Stirling power generation system

PendingCN112358896AIncrease profitEfficient use ofClimate change adaptationEnergy efficient heating/coolingDust controlElectric generator

Owner:青岛启迪能源与动力技术研究院

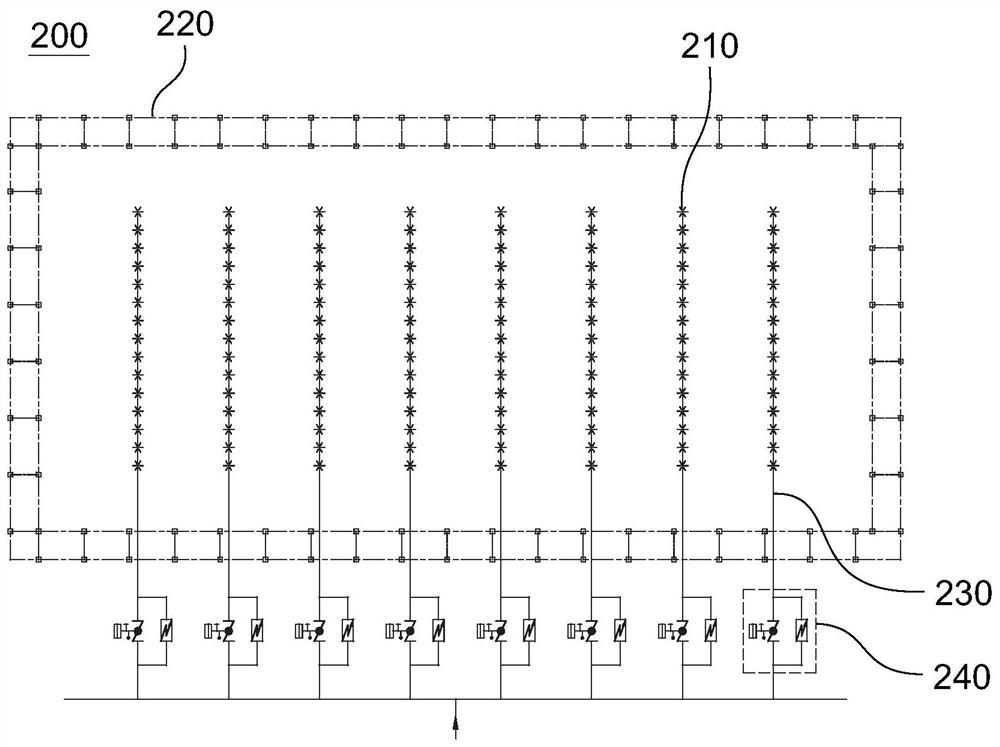

Ground torch system

PendingCN111928279AReasonable locationAvoid insufficient combustionIncinerator apparatusCombustorCombustible gas

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD +1

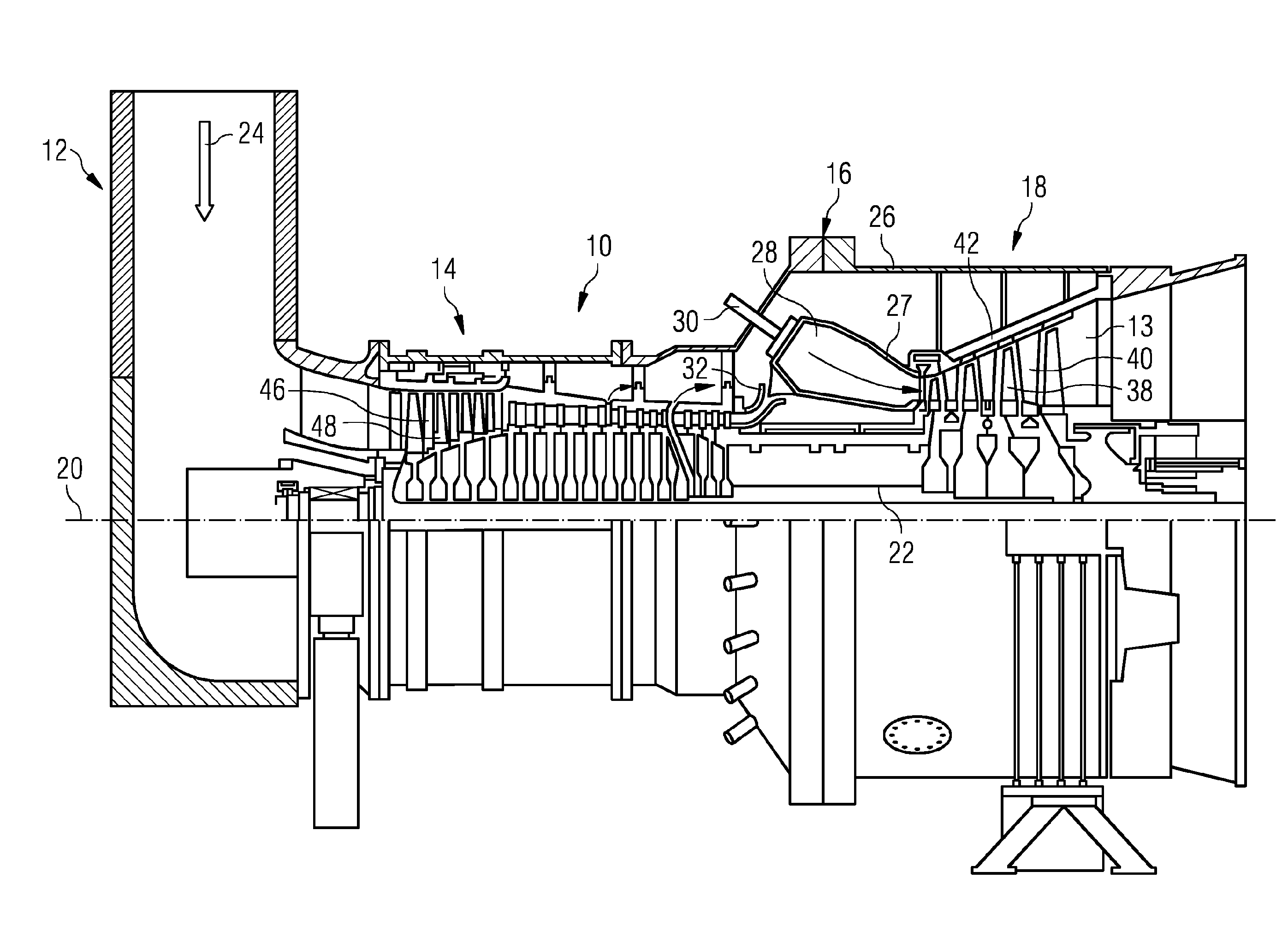

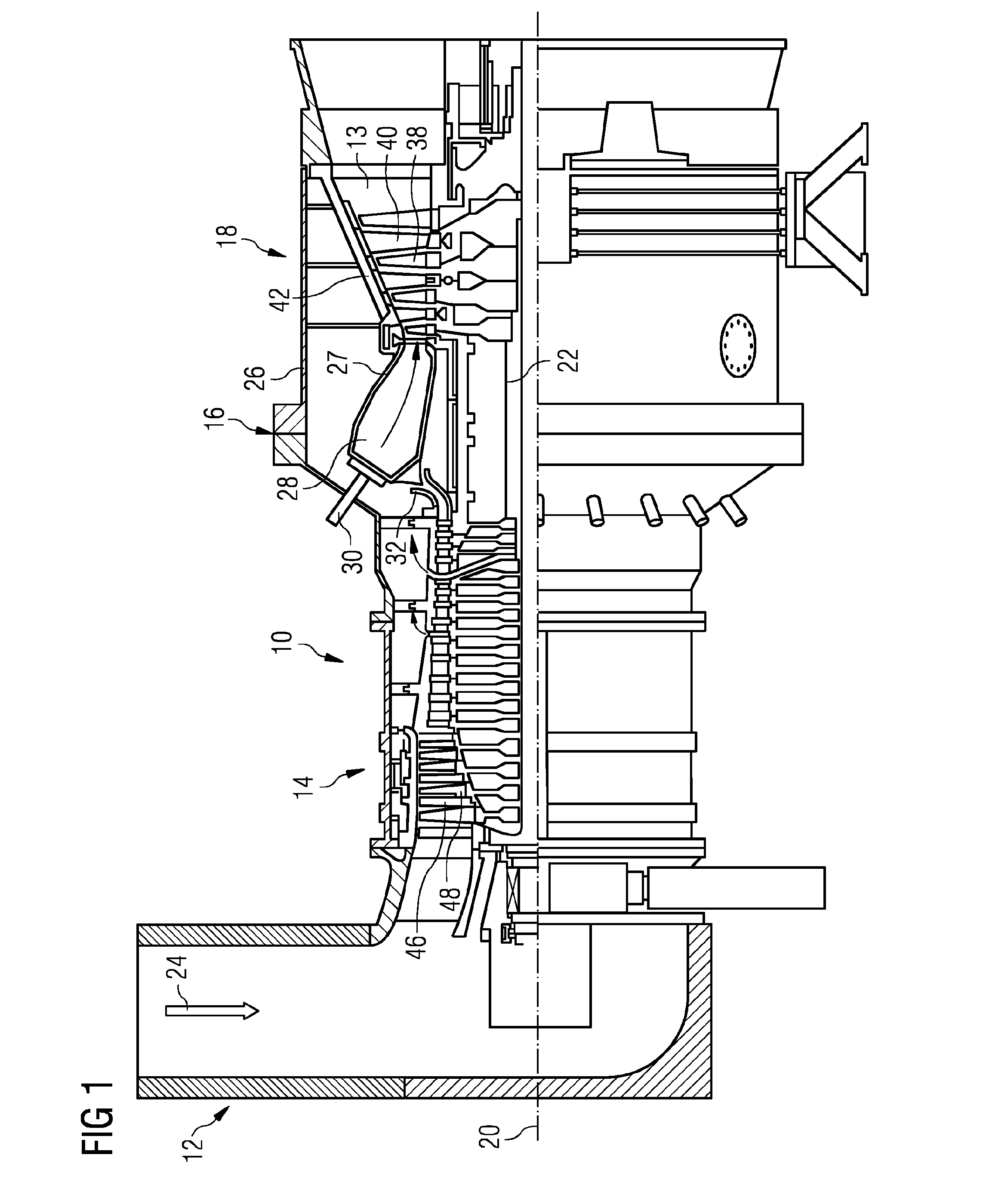

Method for monitoring a combustor

InactiveUS20170009598A1BurnersAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringCombustor

Owner:SIEMENS AG

Chemical waste incinerator

InactiveCN111928250ABurn fullyReduce the likelihood of an explosionIncinerator apparatusCombined combustion mitigationCombustorExhaust fumes

The invention discloses a chemical waste incinerator. The chemical waste incinerator comprises a furnace body, wherein a feed hopper is arranged on one side of the furnace body, a feed inlet is formedin the upper end of the feed hopper, a baffle plate is arranged in the position, corresponding to the feed hopper, of the interior of the furnace body, a rotating roller is arranged in the feed hopper, a guide blade is arranged on the rotating roller, a burner is arranged in the furnace body, an ash discharge hopper is arranged below the furnace body, an air supplement opening is arranged on oneside of the furnace body, a waste heat recovery device is arranged at the upper end of the furnace body, an air outlet is arranged at the top end of the furnace body, a water tank is arranged on one side of the furnace body, an air outlet pipe is arranged at the air outlet, an air exhaust opening is arranged on the water tank, and a spraying device is arranged in the furnace body. A user directlydumps chemical engineering garbage into the feed hopper, materials are conveyed through the inner guide blade, the baffle plate is pushed away under the action of gravity, the materials enter the furnace body for combustion, oxygenation work is regularly carried out through an air supplement opening, the interior of the furnace body is fully combusted, and then generated hot waste gas is subjectedto heat exchange work through the waste heat recovery device at the top.

Owner:HUNAN DELI SAFETY & ENVIRONMENTAL PROTECTION TECH CO LTD

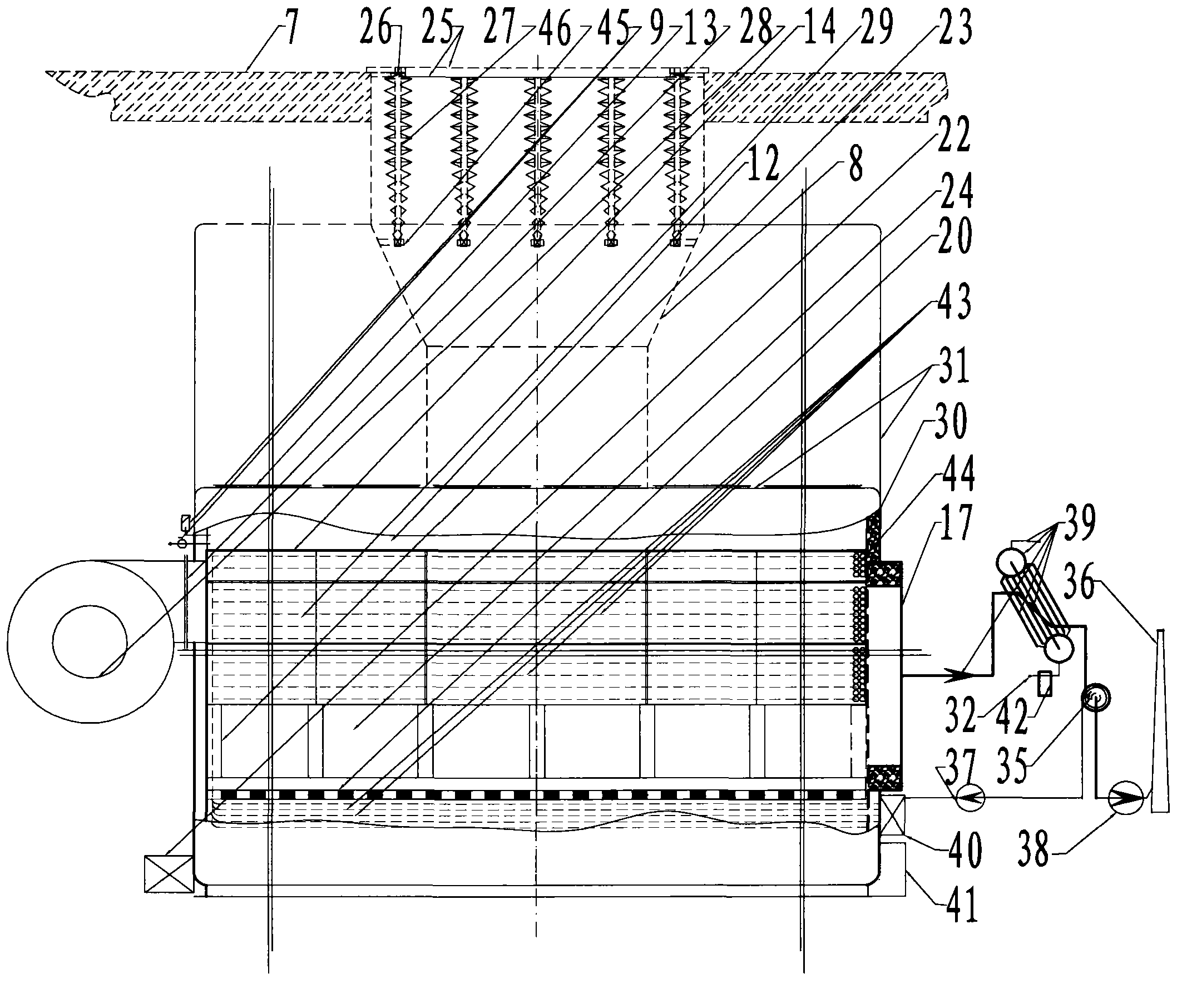

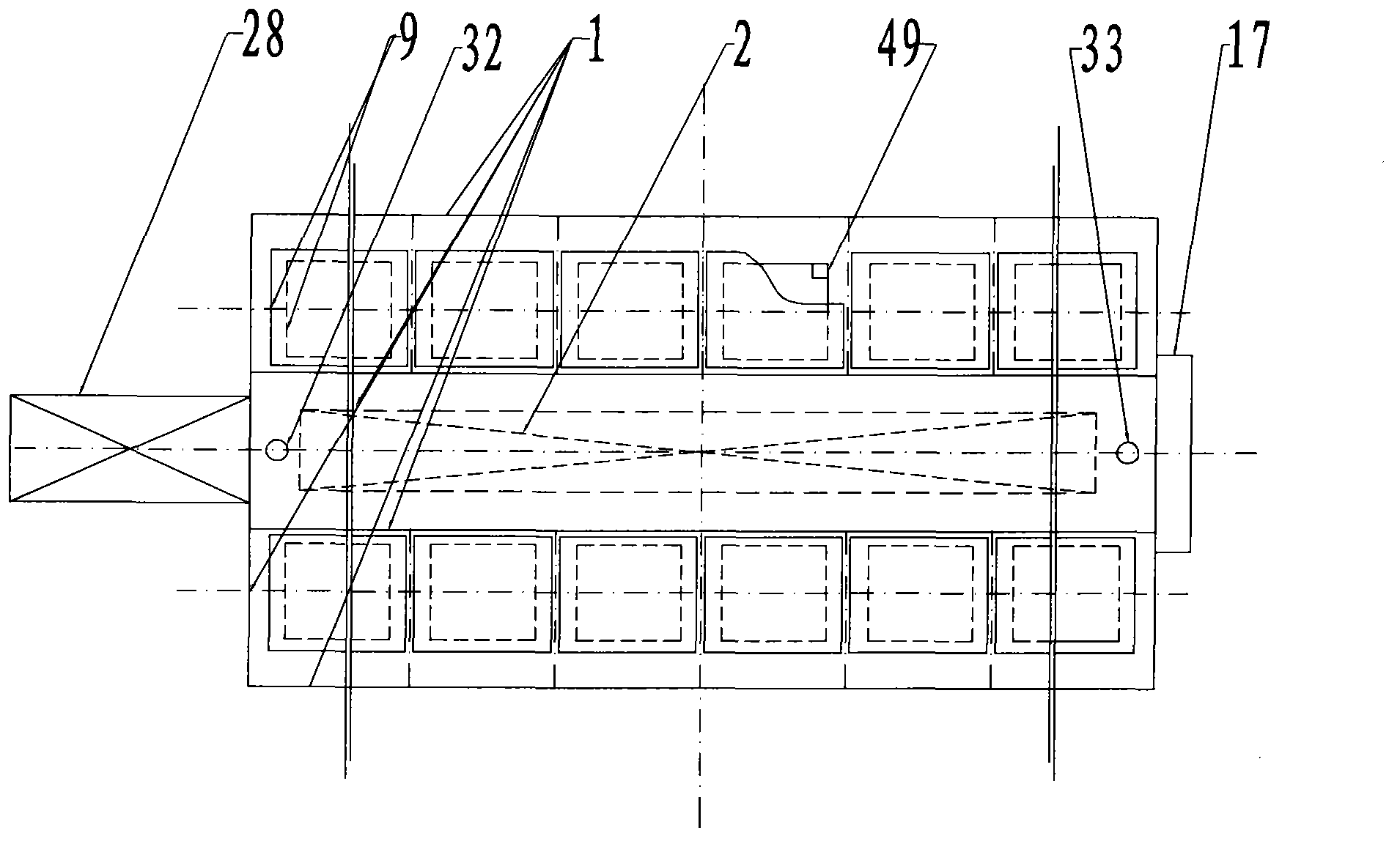

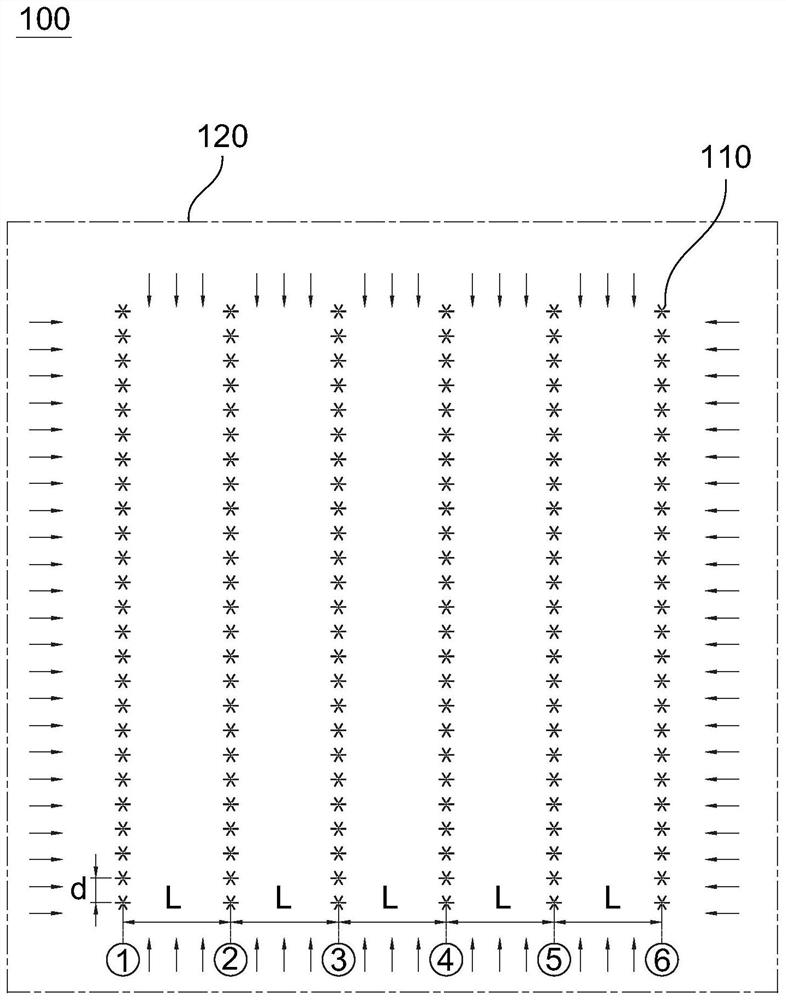

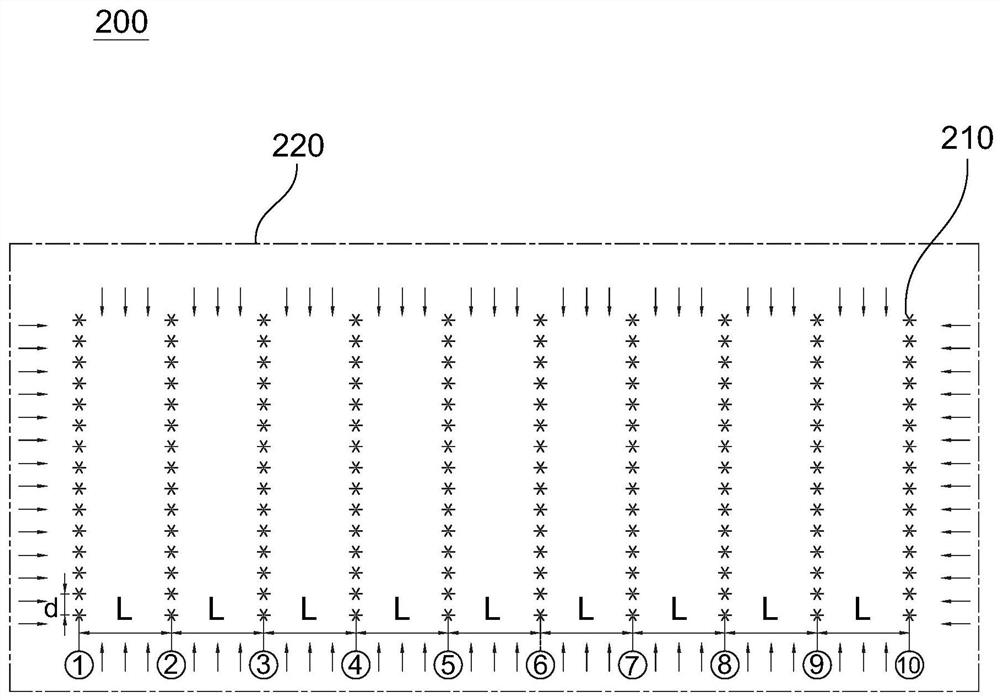

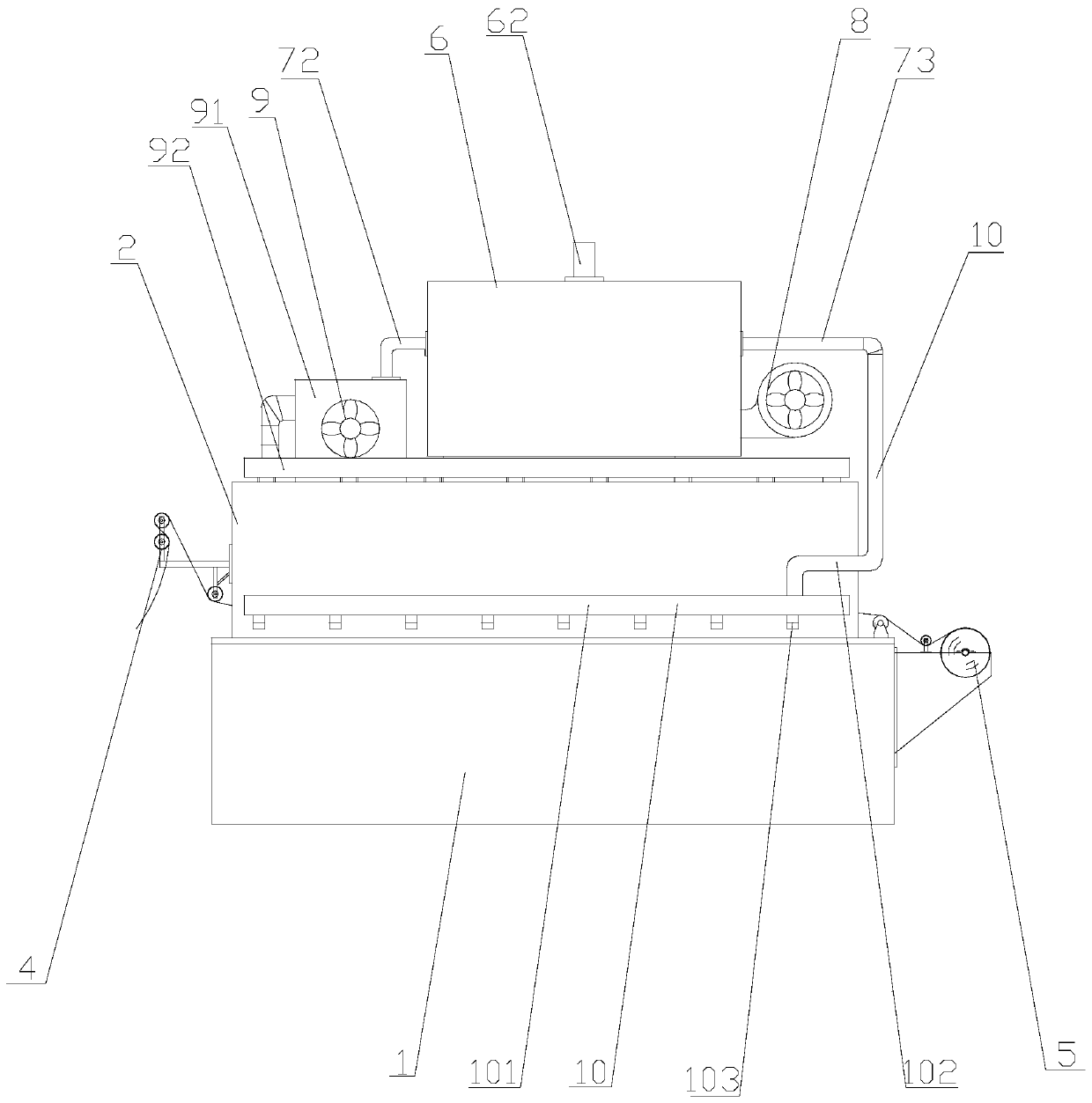

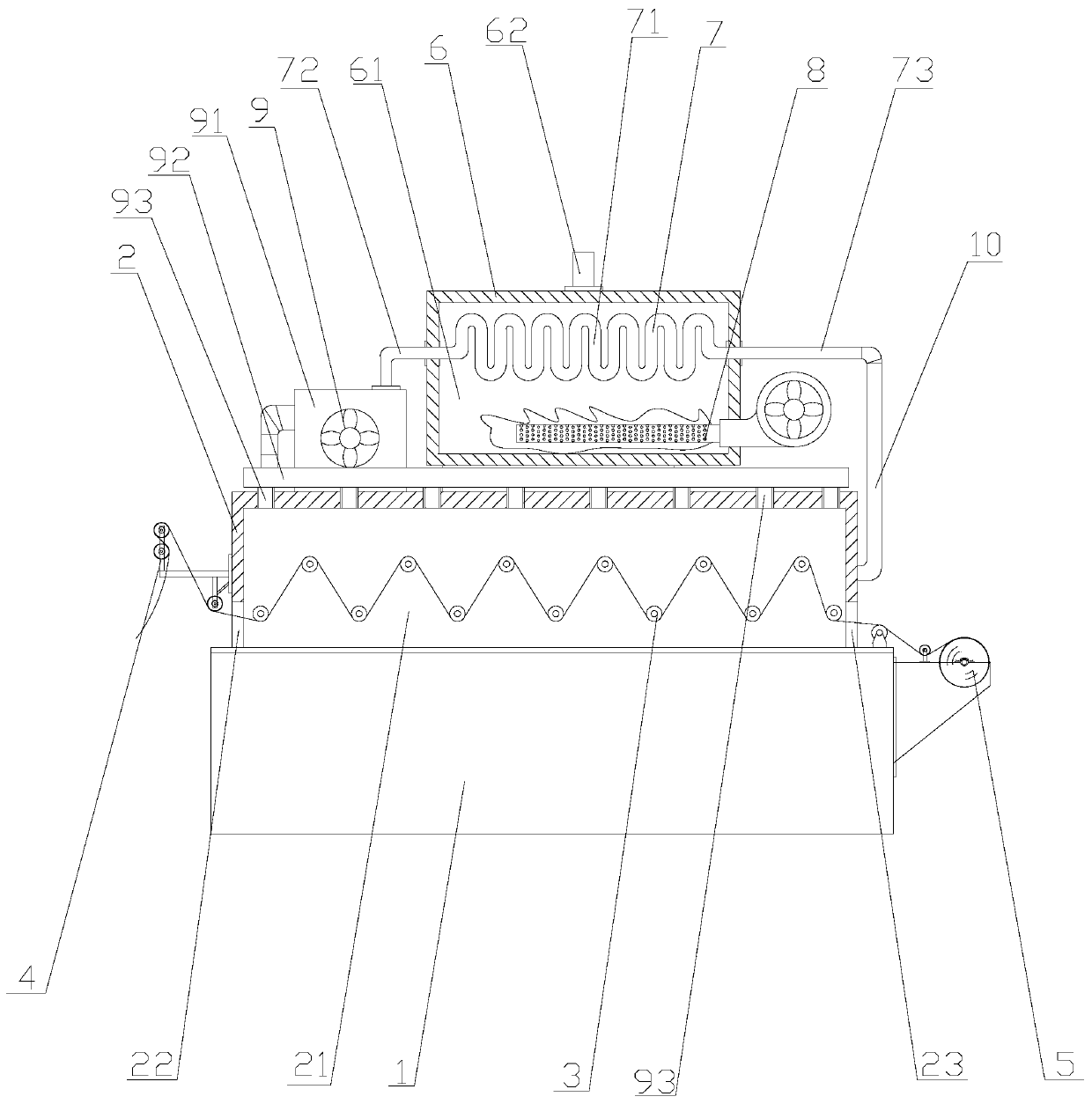

Direct combustion type hot air penetration internal circulation drying device for non-woven fabric production

PendingCN110500865AAchieve cycleEasy drying processDrying gas arrangementsDrying machines with progressive movementsFiberCombustor

Owner:ZHEJIANG WANGJIN NONWOVENS CO LTD

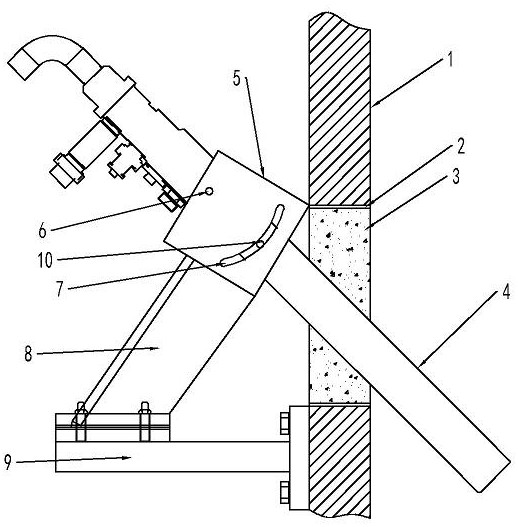

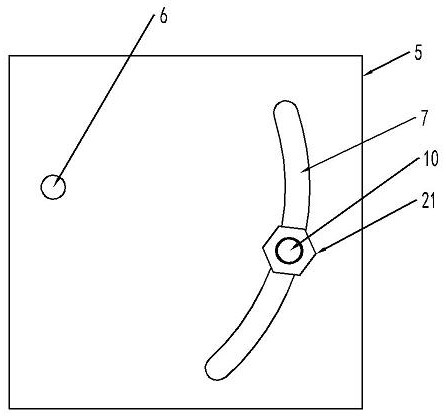

Submerged arc furnace capable of adjusting angle of combustor

PendingCN112033177ACombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelMechanical engineeringCombustor

Owner:山东金智炼技术服务有限公司 +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap