Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "NOx" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In atmospheric chemistry, NO x is a generic term for the nitrogen oxides that are most relevant for air pollution, namely nitric oxide (NO) and nitrogen dioxide (NO 2 ). These gases contribute to the formation of smog and acid rain, as well as affecting tropospheric ozone.

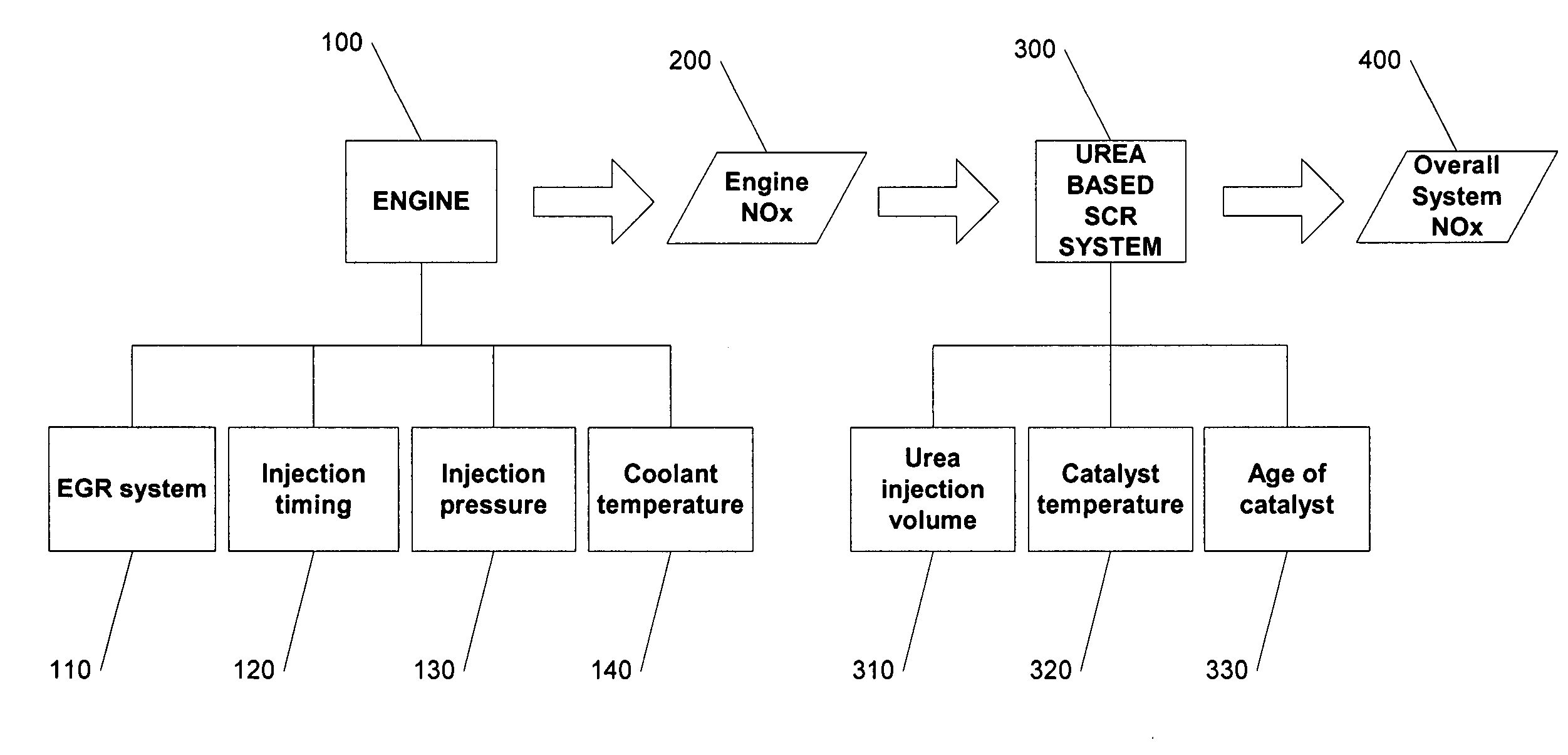

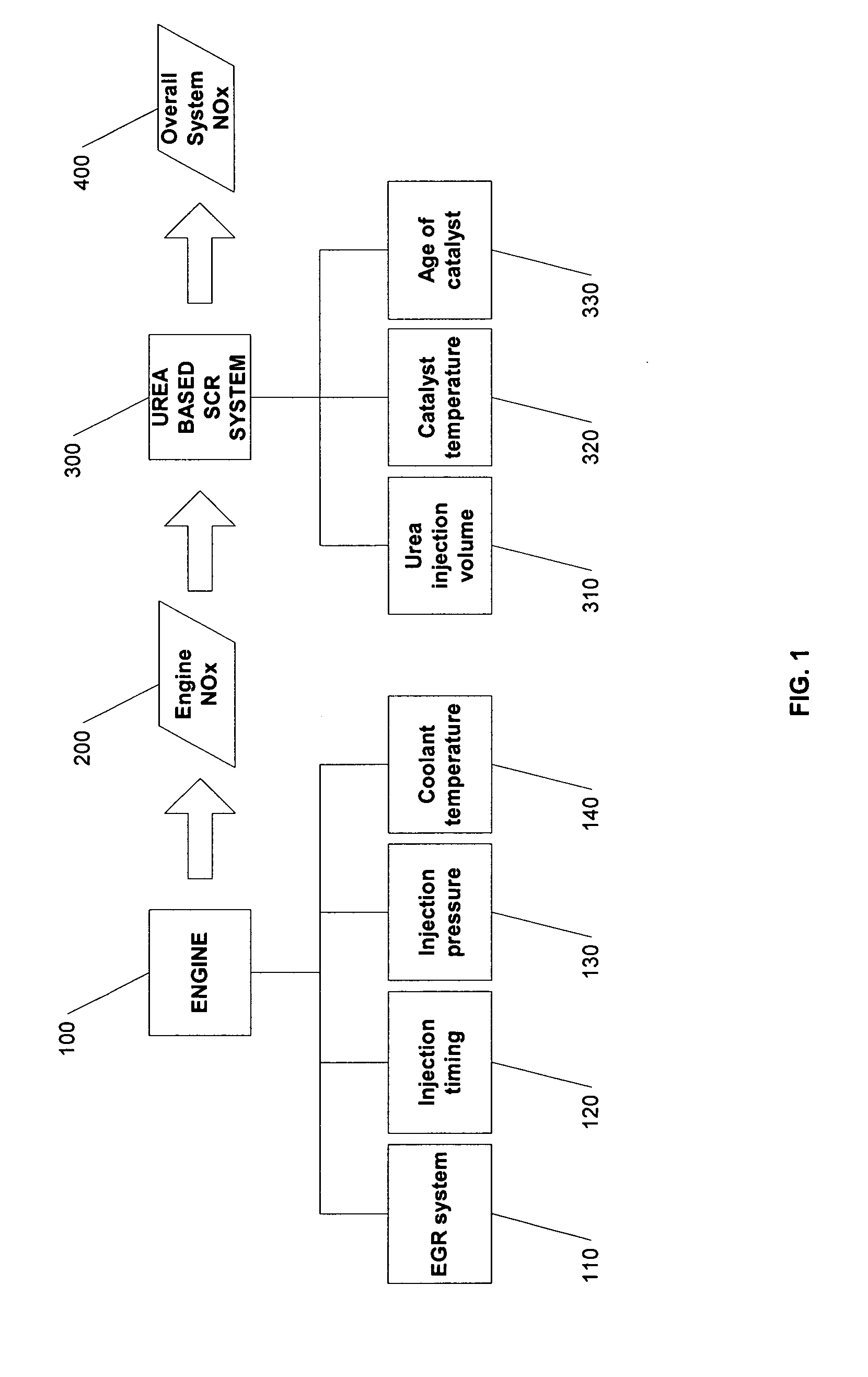

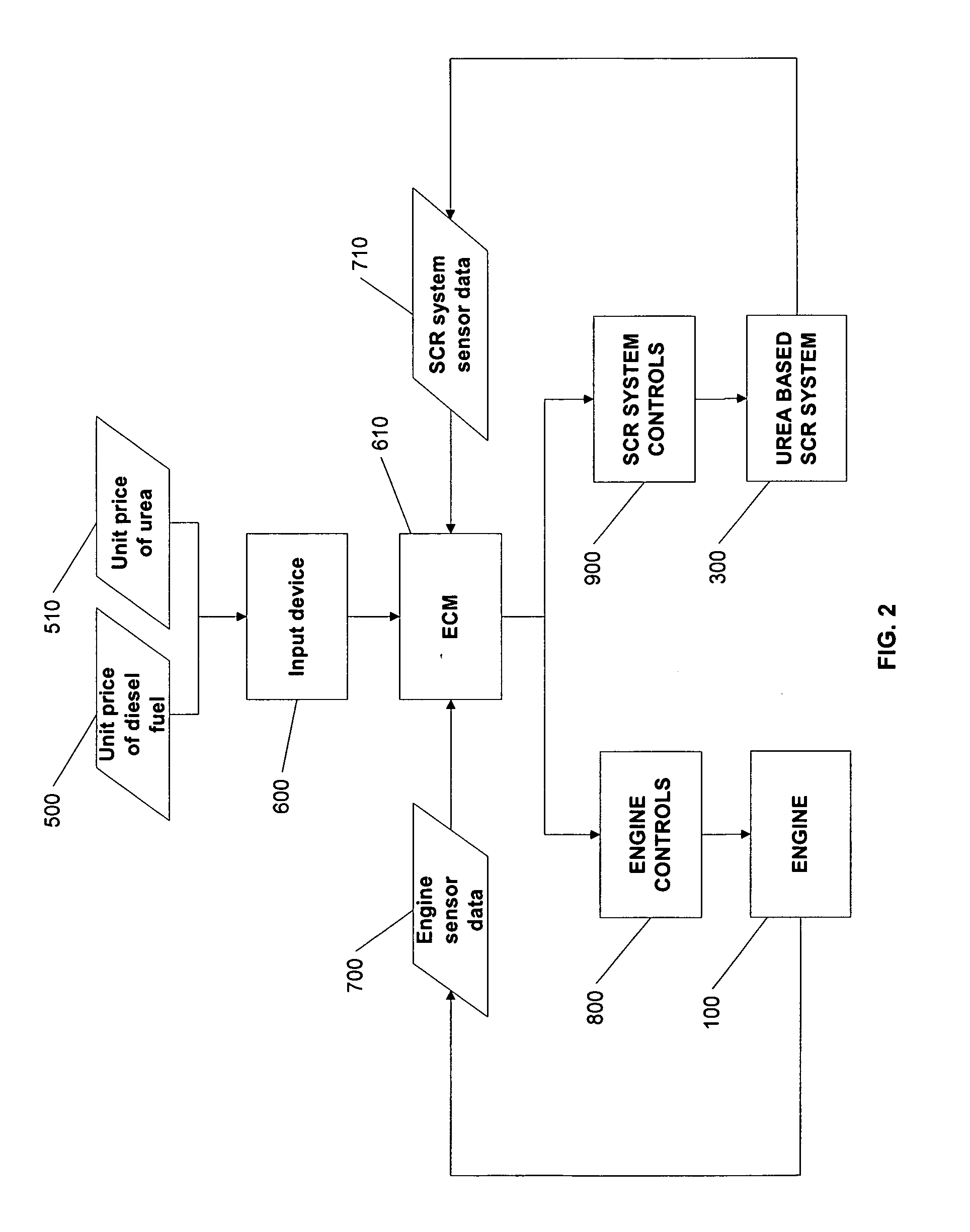

System and method for NOx reduction optimization

ActiveUS20070163244A1Reduced fuel efficiencyReduce nitrogen oxide contentAnalogue computers for vehiclesElectrical controlExhaust gas recirculationDiesel engine

Owner:CUMMINS INC

Low NOx combustion

InactiveUS7225746B2Reduce the amount requiredCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelOxygenHydrocarbon

Combustion of hydrocarbon liquids and solids is achieved with less formation of NOx by feeding a small amount of oxygen into the fuel stream.

Owner:PRAXAIR TECH INC

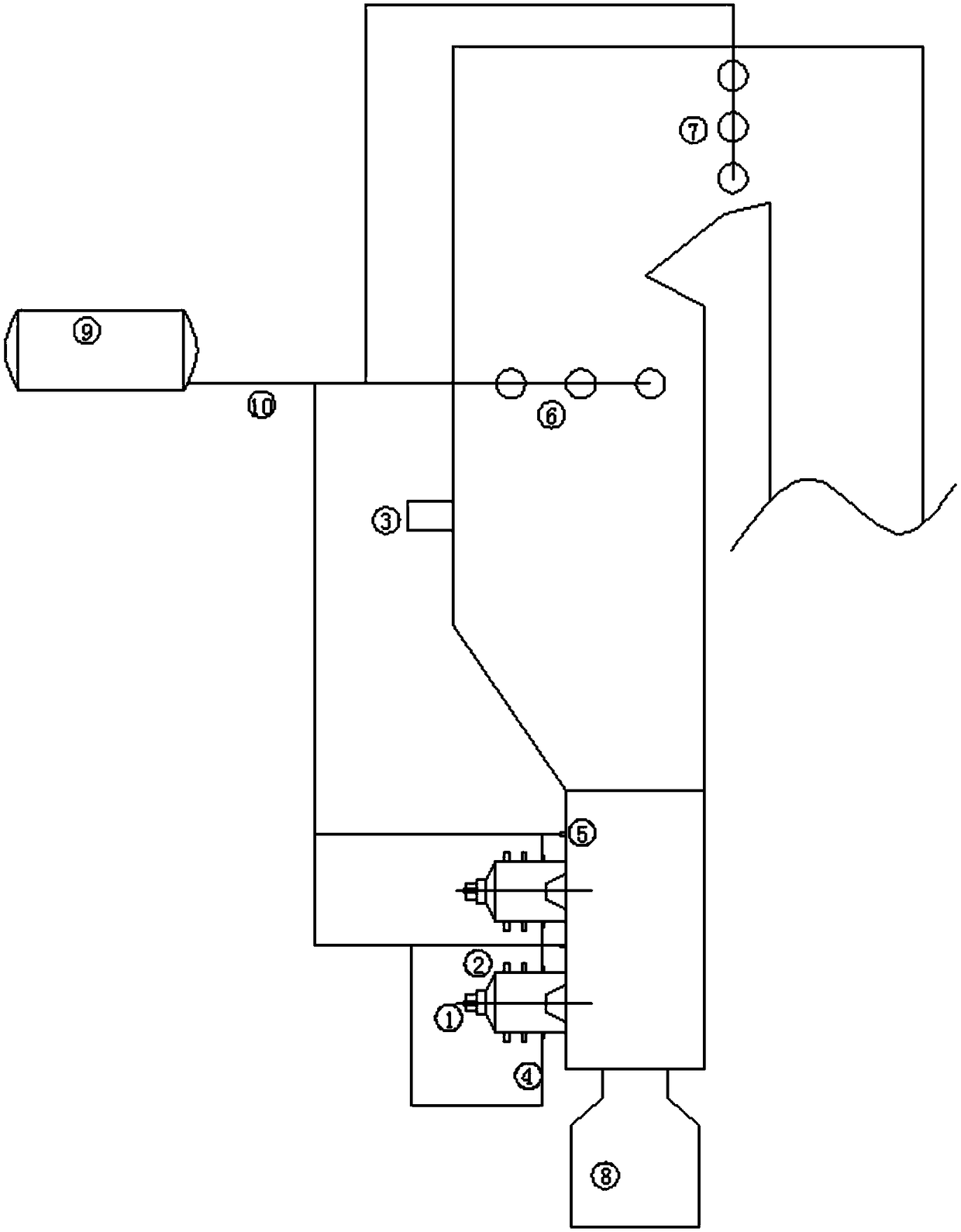

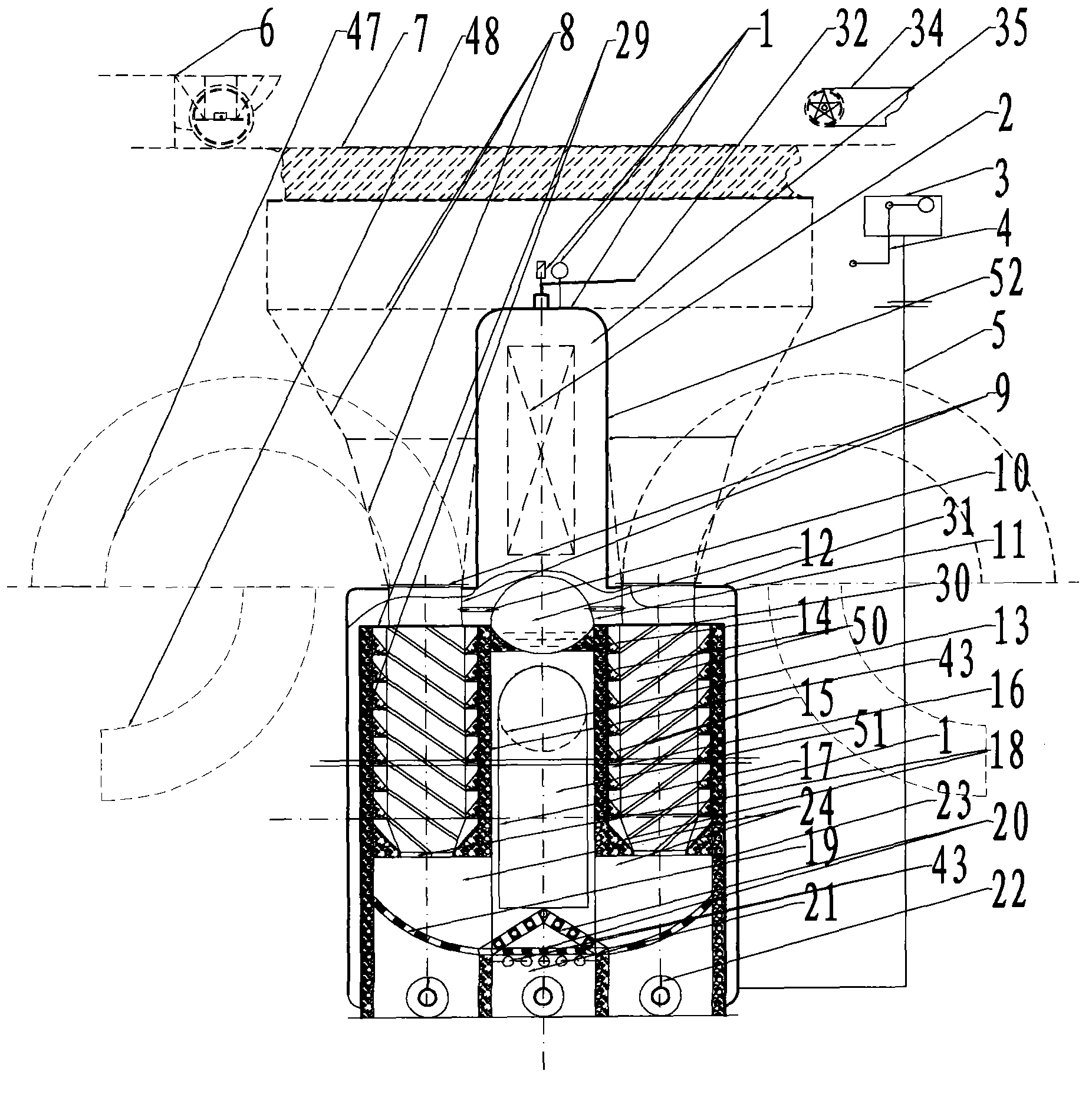

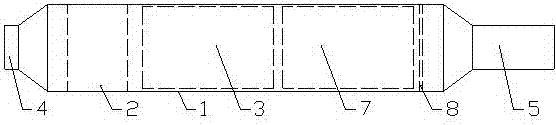

Complete equipment for denitration method in boiler

InactiveCN107626205AHigh yieldAvoid extra supplyLighting and heating apparatusDispersed particle separationBoiler furnaceFlue gas

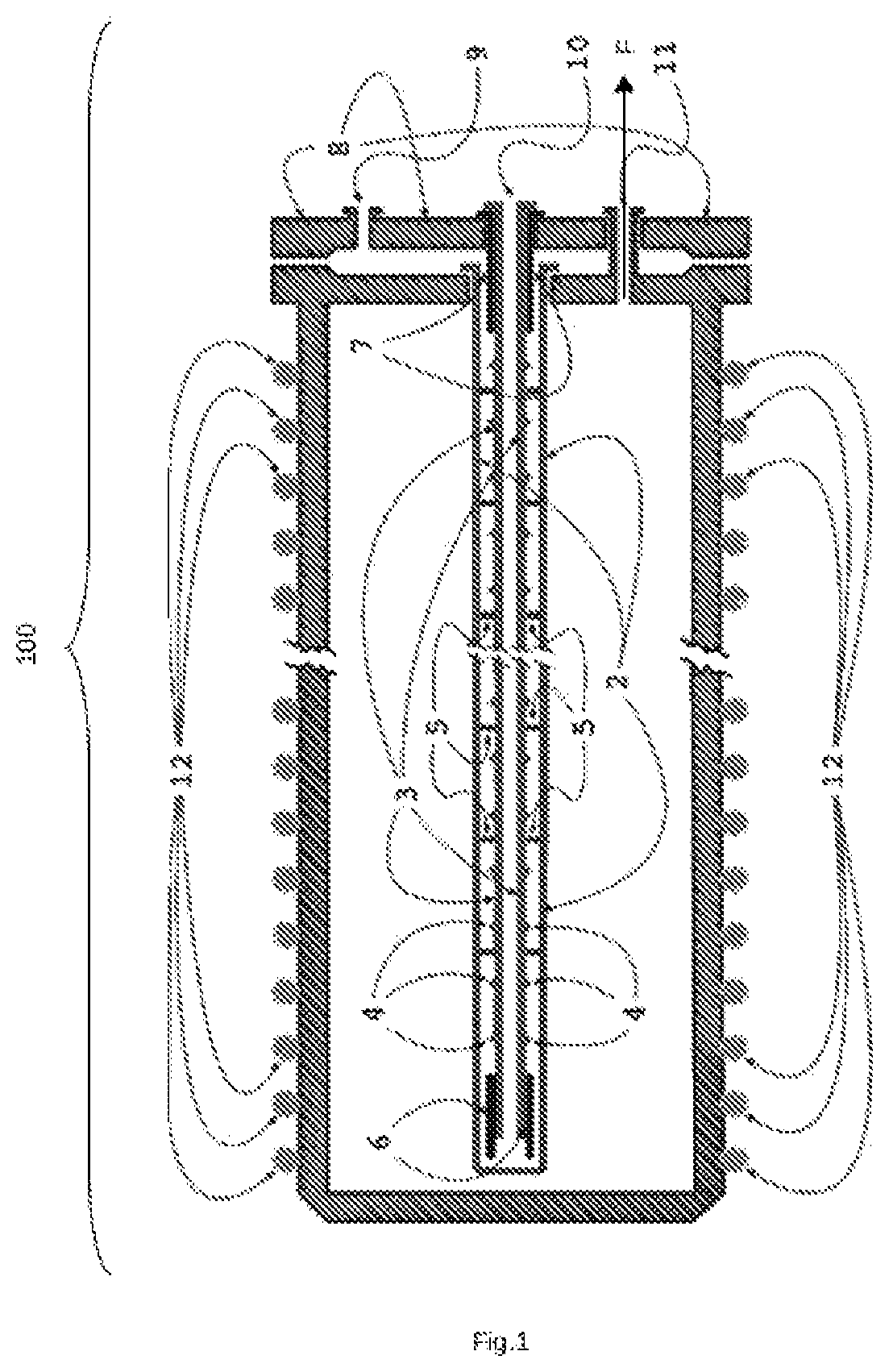

The invention belongs to the field of environment-friendly equipment and particularly relates to complete equipment for a denitration method in a boiler. The complete equipment comprises an ammonia gas generating device, a gas mixing device and a catalyst cage. The yield of a target product ammonia gas is increased by using the ammonia gas generating device arranged in the boiler and high-temperature polymerized urea in the boiler, extra supply of energy is avoided and energy consumption is reduced; by arranging the gas mixing device, the ammonia gas overflows from a plurality of opening holesin the wall of an ammonia gas mixing pipe and is sufficiently mixed with NOx in high-temperature flue gas in a sleeve pipe; by arranging the catalyst cage, the ammonia gas and the NOx which are uniformly mixed repeatedly react under the action of high temperature and a catalyst, so that the denitration efficiency is greatly improved. The equipment disclosed by the invention has the advantages ofsimple structure, energy consumption conservation, greenness, environment friendliness and suitability for industrial denitration.

Owner:YANCHENG JISHENGDA ENVIRONMENTAL PROTECTION ENG CO LTD

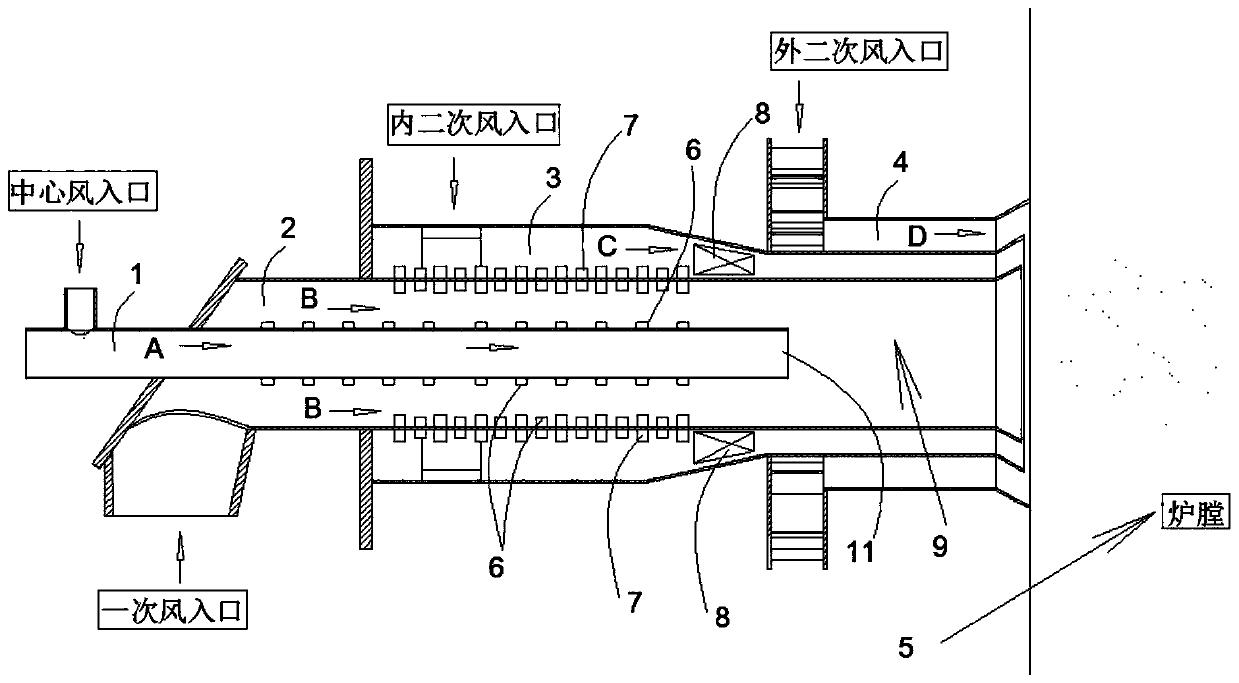

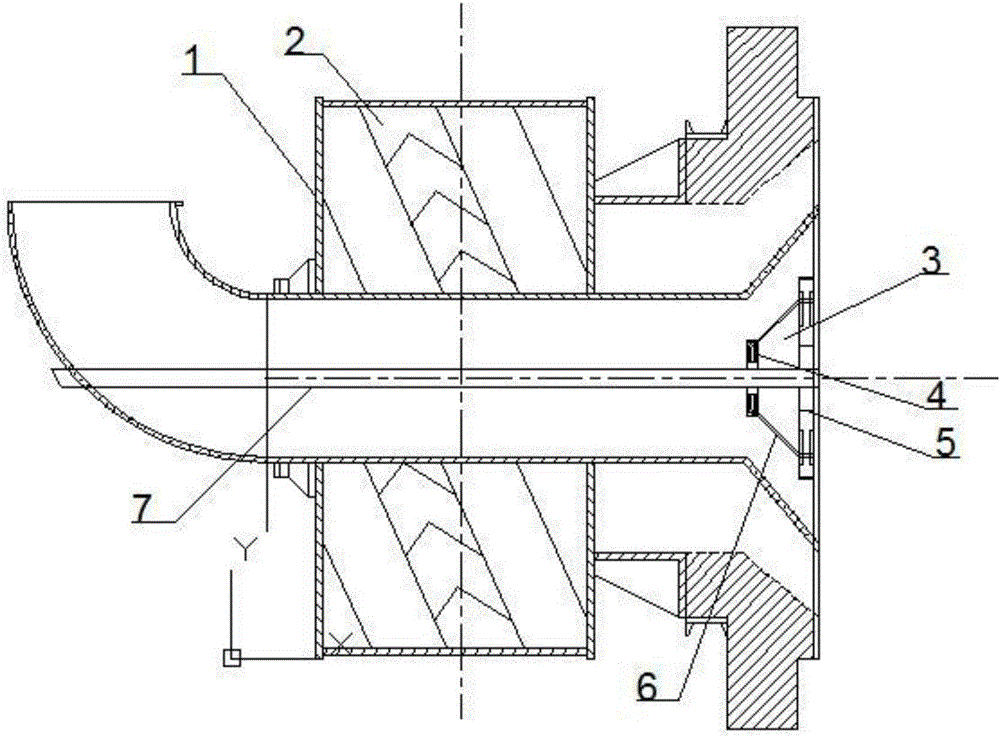

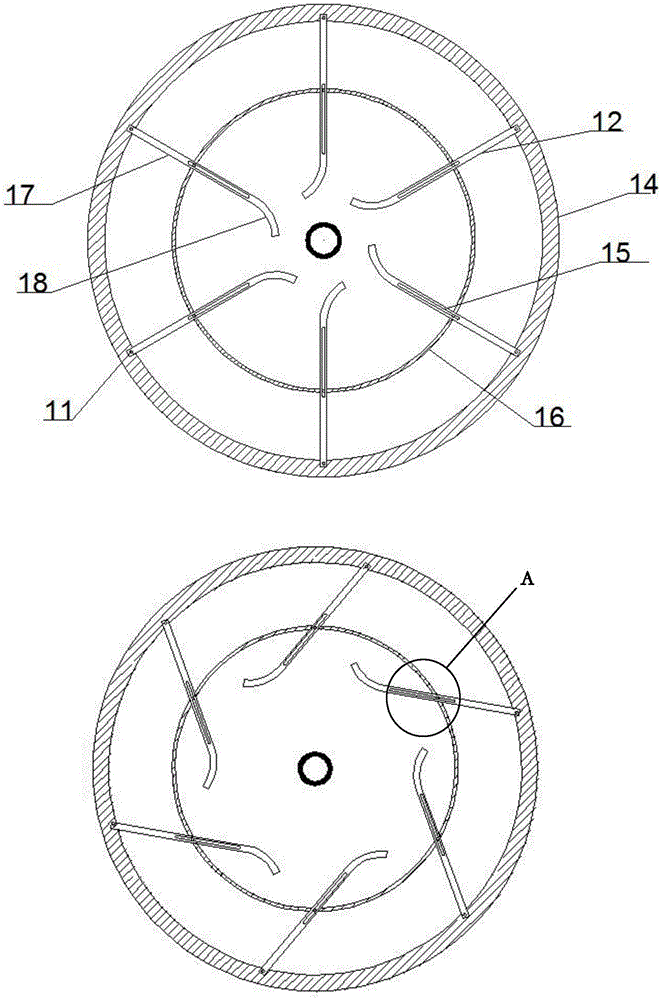

Cyclone furnace denitration system and method

PendingCN109058979AEmission reductionImprove economyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

Owner:CHINA HUANENG GRP CO LTD +1

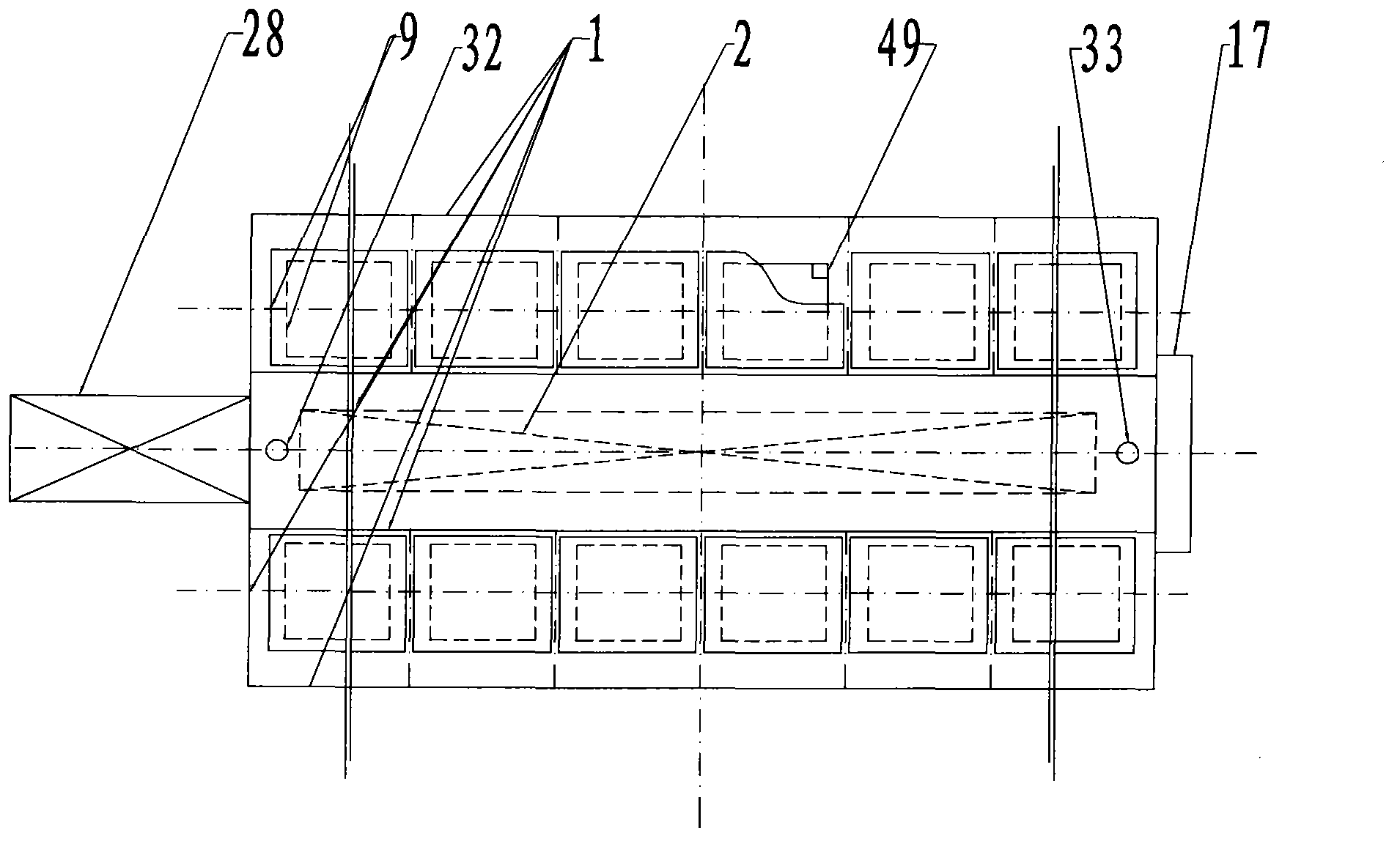

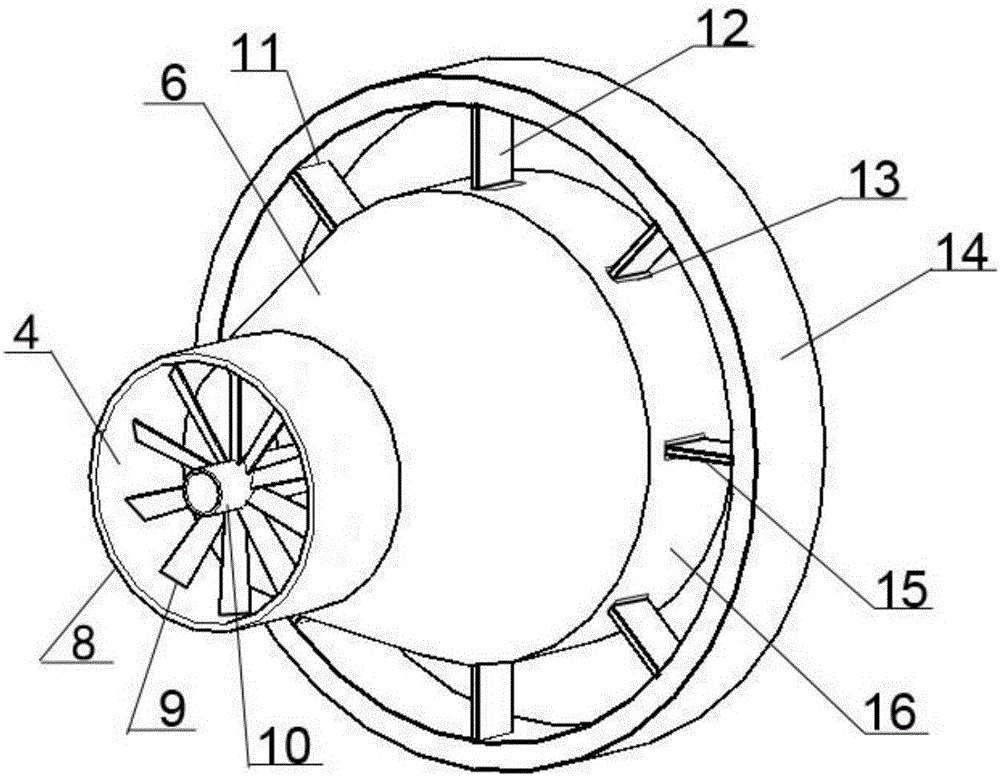

Swirl pulverized coal burner based on in-advance pyrolysis

PendingCN110186037AReduce incomplete combustion lossesIncrease temperaturePulverulent fuel combustion burnersNon-combustible gases/liquids supplyEngineeringCoal fired

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH

Water-based combustion-supporting straw particle boiler-kiln universal burner with fuel such as coal, gas and oil

InactiveCN104235832AKeep aliveResponse is continuous and stableCombustion using multiple fuelsCombustion using catalytic materialWater basedBrick

Owner:管理

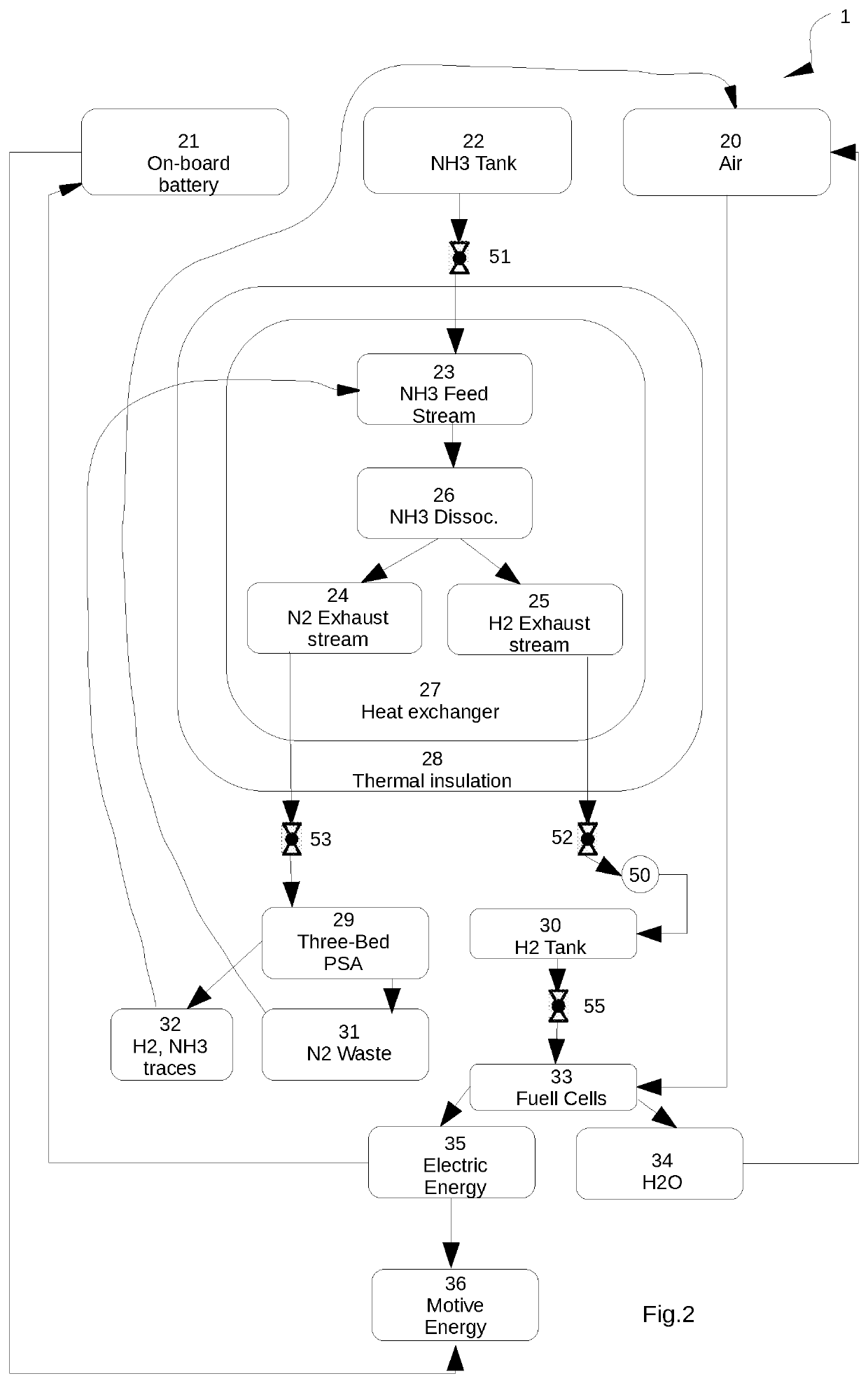

Separation system

ActiveUS20200388869A1Low costReduce thicknessReactant parameters controlHydrogen productionNitrogen oxidesNitrogen dioxide

Owner:GALBIATI CRISTIANO

Turbulent burner

Owner:SOUTHEAST UNIV

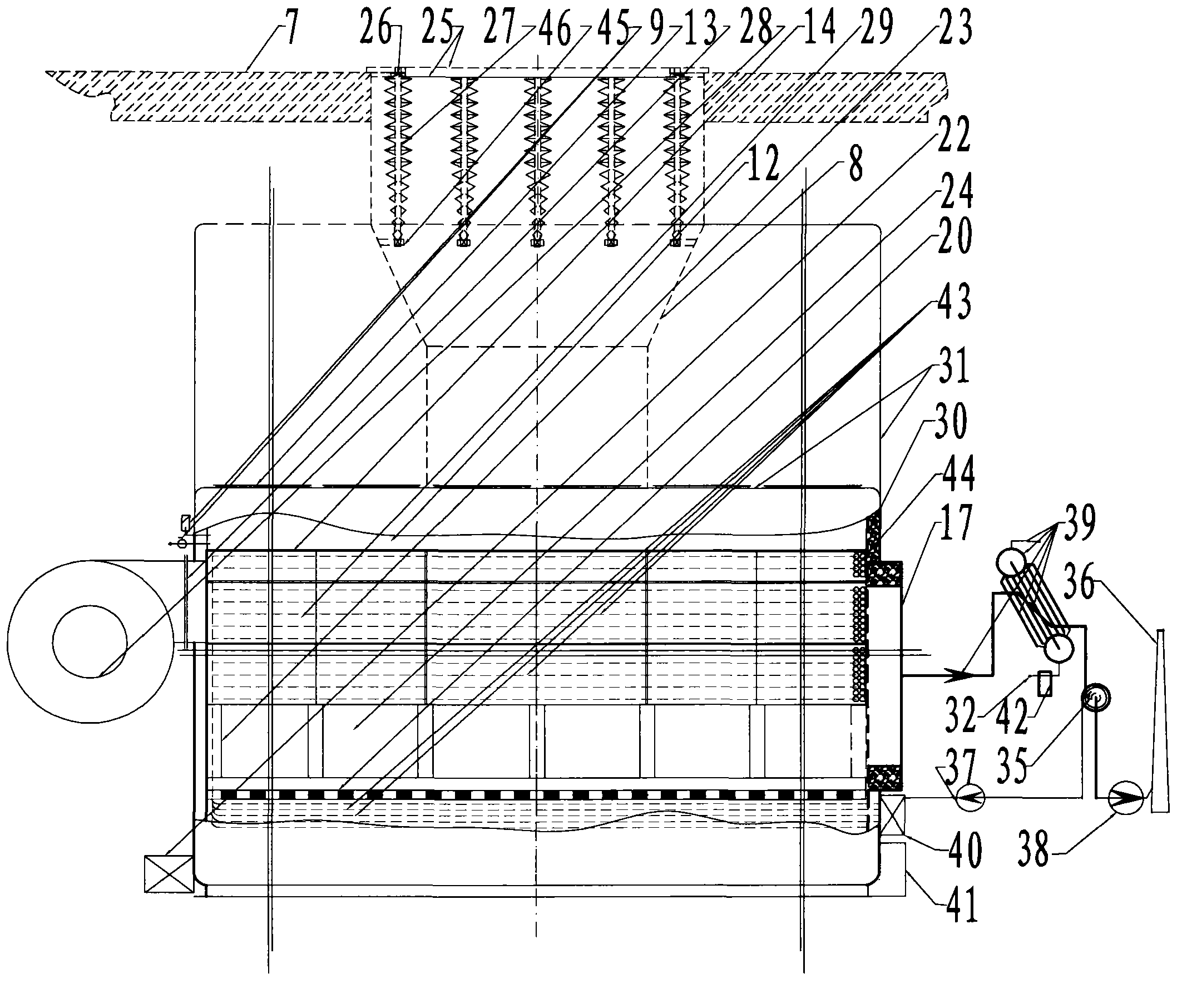

Straight-flow pulverized coal burner

ActiveCN109708106AEmission reductionImprove combustion stabilityAir supply regulationPulverulent fuel combustion burnersCoalNOx

The invention discloses a straight-flow pulverized coal burner. The straight-flow pulverized coal burner comprises a shell, a pulverized coal concentrator, a rich pulverized coal primary air pipe connected with a rich pulverized coal outlet of the pulverized coal concentrator, a lean pulverized coal primary air pipe arranged around part of the circumference of the concentrated pulverized coal primary air pipe and a secondary air pipe. The secondary air pipe and the thin pulverized coal primary air pipe are arranged oppositely at the periphery and arranged around the rest part of the circumference of the rich pulverized coal primary air pipe. The secondary air pipe is located on the backfire side of the rich pulverized coal primary air pipe. The nozzle end of the rich pulverized coal primary air pipe and the nozzle end of the lean pulverized coal primary air pipe are arranged in a spaced mode in the radial direction. The nozzle end of the rich pulverized coal primary air pipe and the nozzle end of the lean pulverized coal primary air pipe are both located behind the nozzle end of the secondary air pipe in the axial direction. The straight-flow pulverized coal burner can substantially improve the stable combustion capacity, the combustion efficiency and the anti-coking capacity, resolve the conflict between ignition stable combustion and flame underscouring capacity, can also reduce emissions of NOx, has the advantage of the wide coal quality application range and meets the requirements of boilers for deep peak regulation and fault coal combustion.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

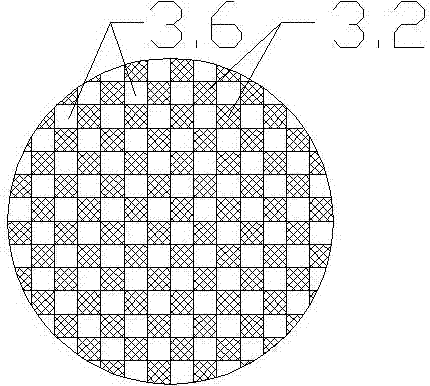

Tail gas filter with good black smoke filter effect

InactiveCN107542531AImprove purification effectEffective filteringExhaust apparatusSilencing apparatusEngineeringFilter effect

Owner:JIANGYIN HUAYIN CERAMIC ELECTROMECHANICAL TECH

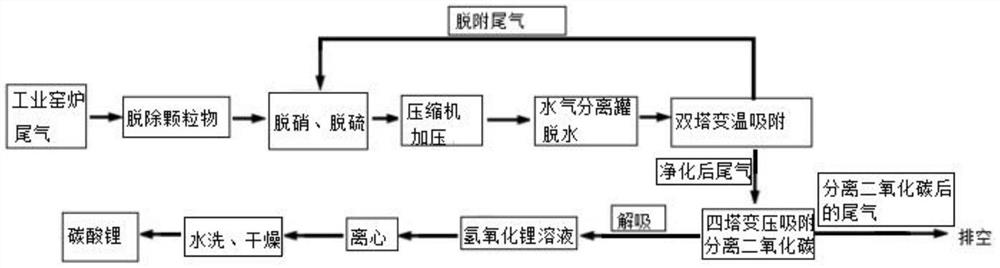

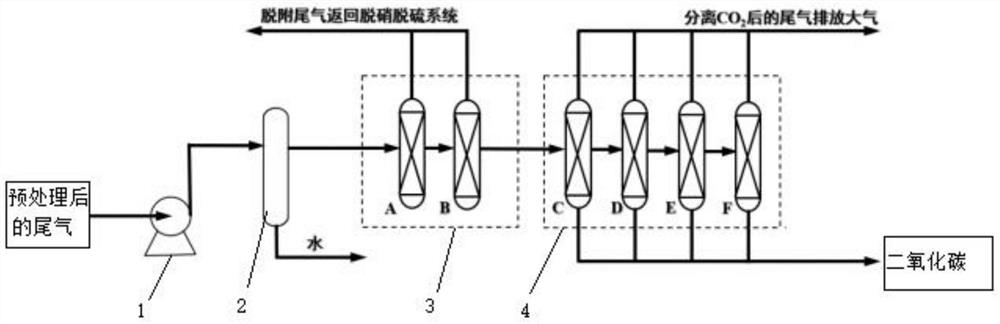

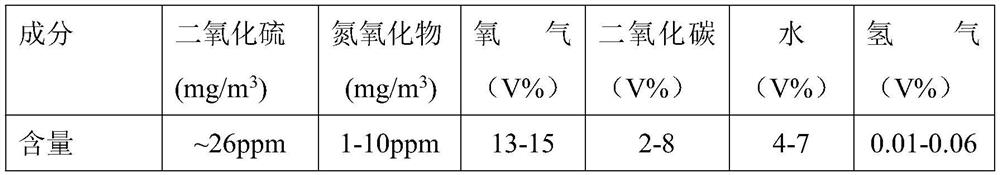

Method for recovering carbon dioxide from tail gas of industrial kiln and producing lithium carbonate

ActiveCN114835142AHigh gas purityHigh recovery rateProductsCarbon compoundsParticulatesLithium hydroxide

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap