Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Urea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication has 2 types of ingredients (emollient, keratolytic) that work together to treat or prevent dry, rough, scaly, itchy skin (e.g., eczema, keratosis, xerosis). Dry skin is caused by a loss of water in the upper layer of the skin. Emollients are substances that soften and moisturize the skin and decrease itching and flaking.

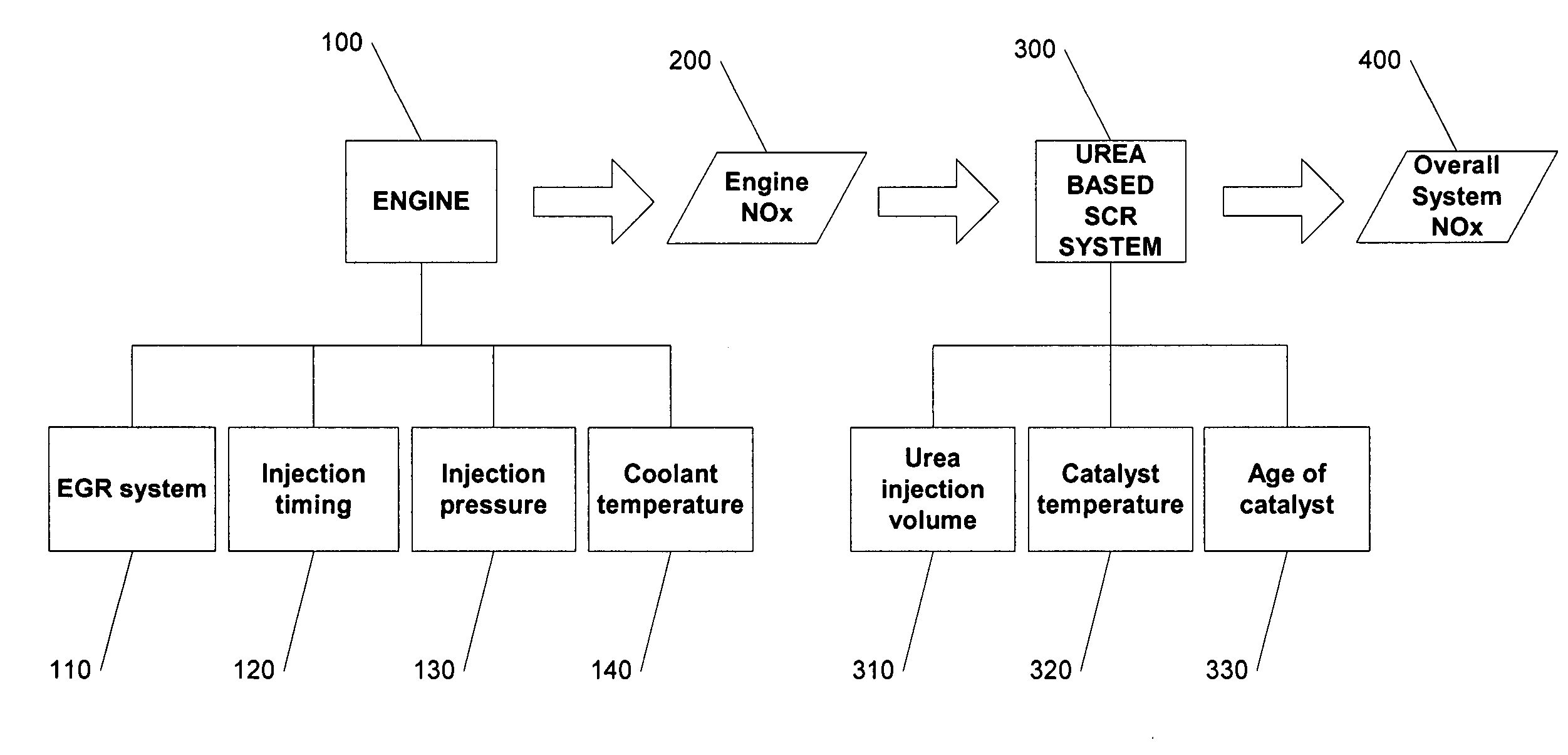

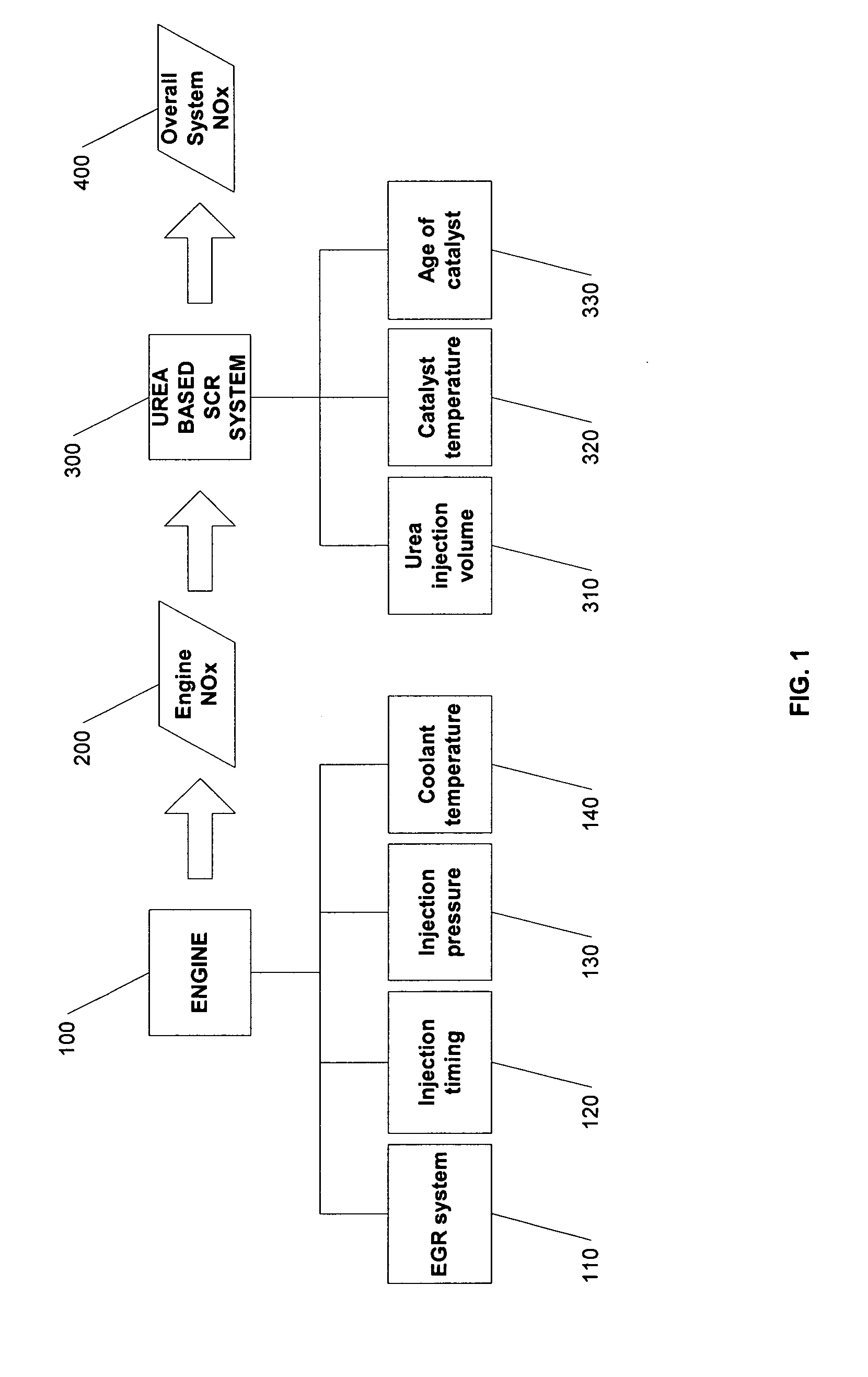

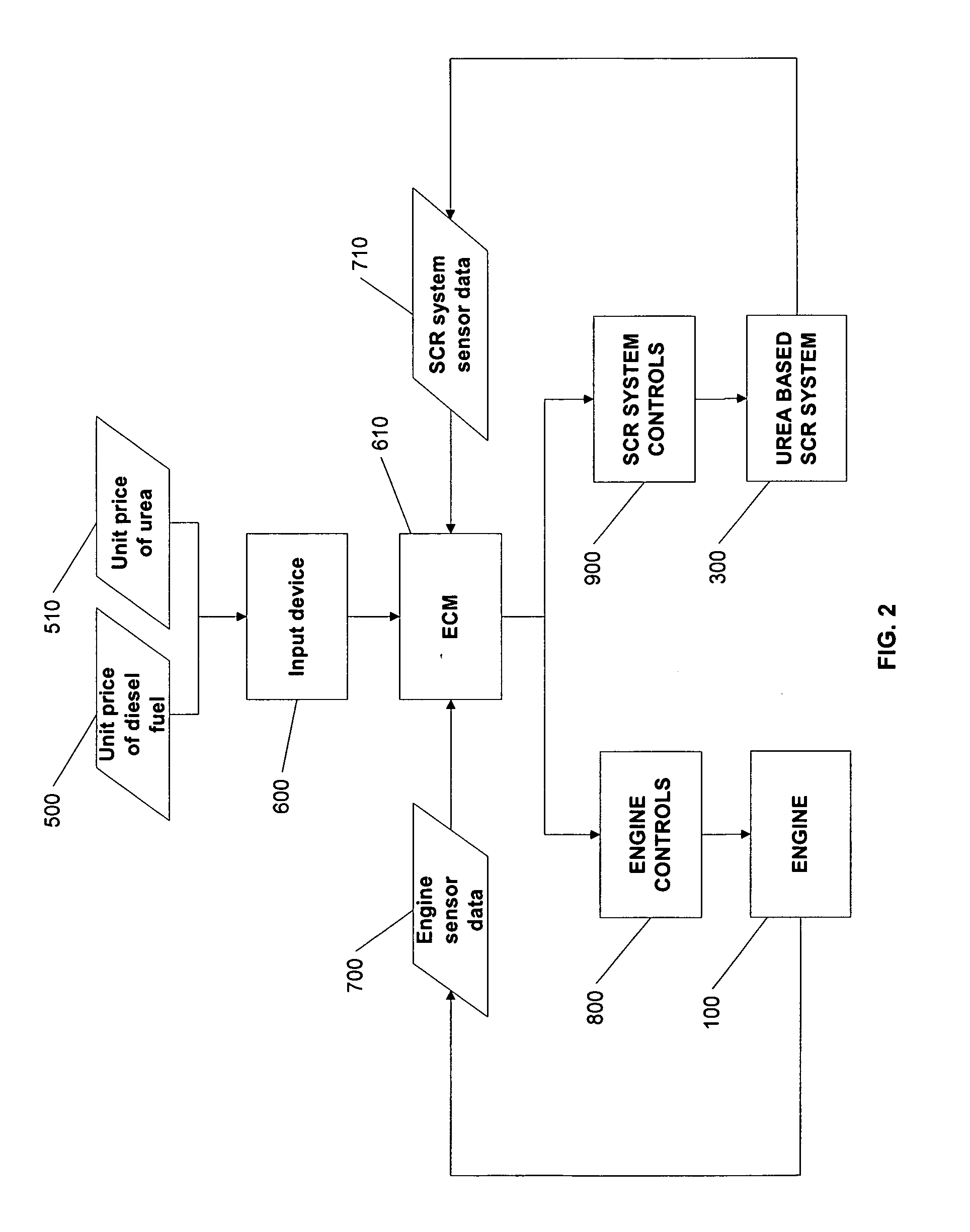

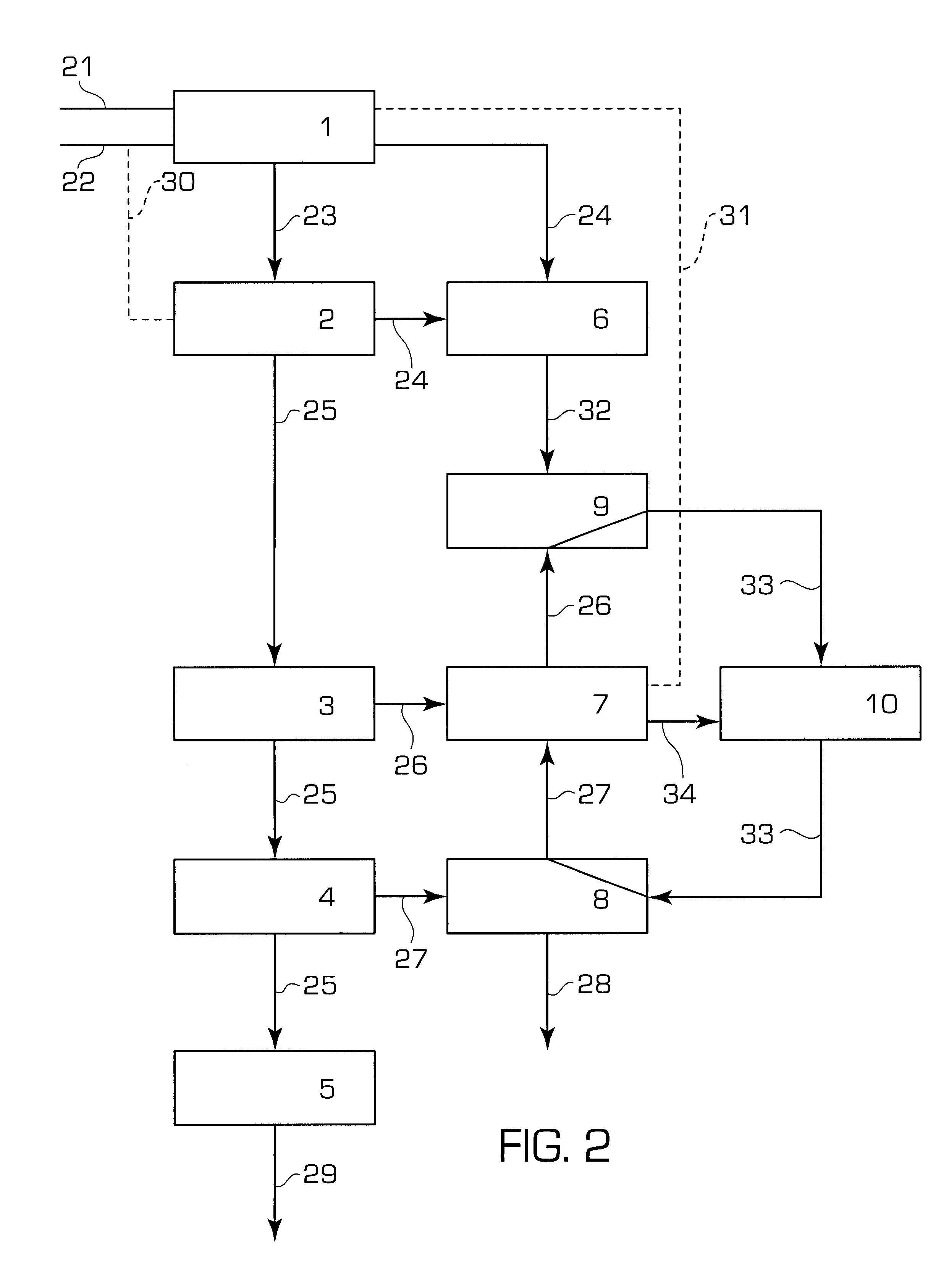

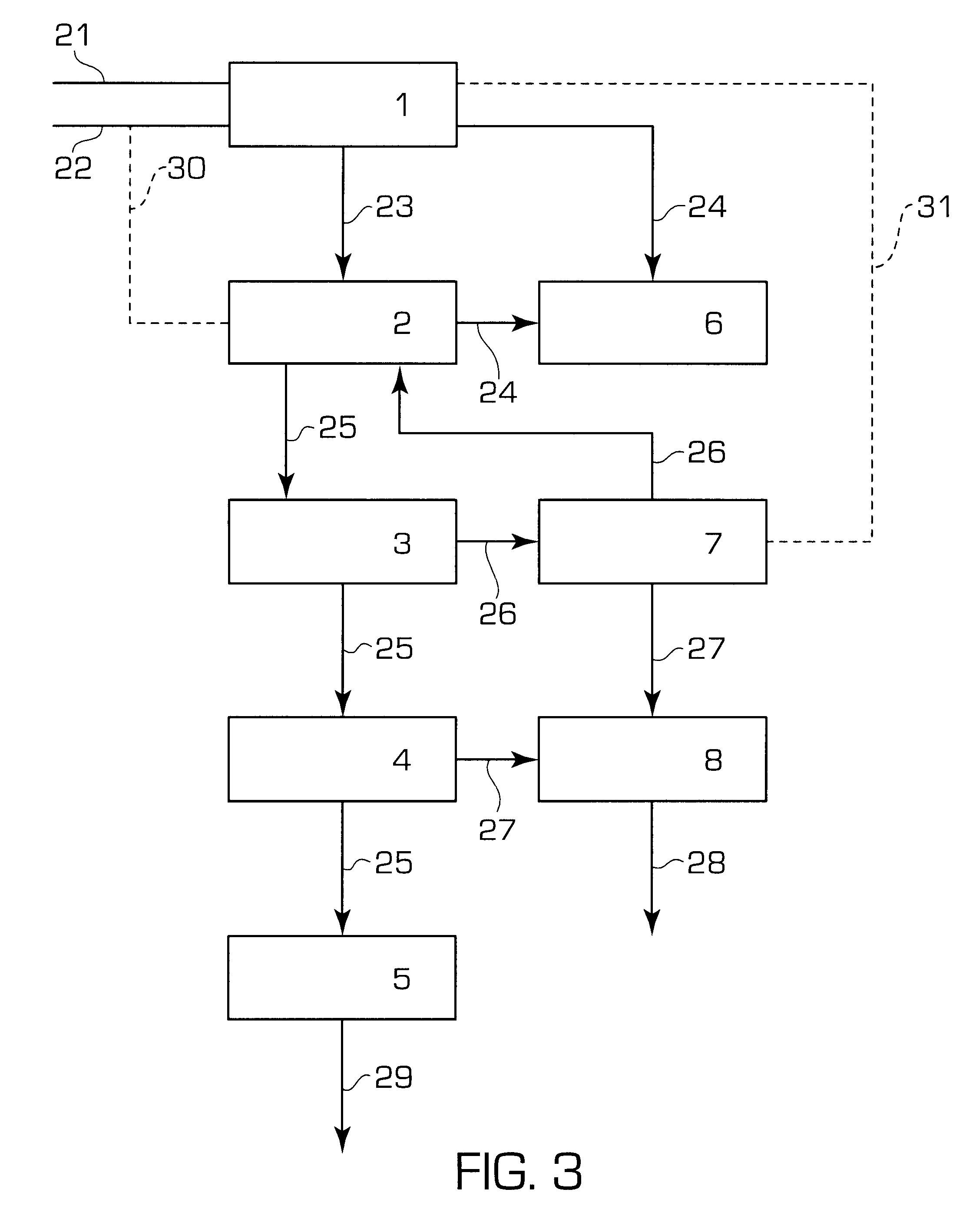

System and method for NOx reduction optimization

ActiveUS20070163244A1Reduced fuel efficiencyReduce nitrogen oxide contentAnalogue computers for vehiclesElectrical controlExhaust gas recirculationDiesel engine

Owner:CUMMINS INC

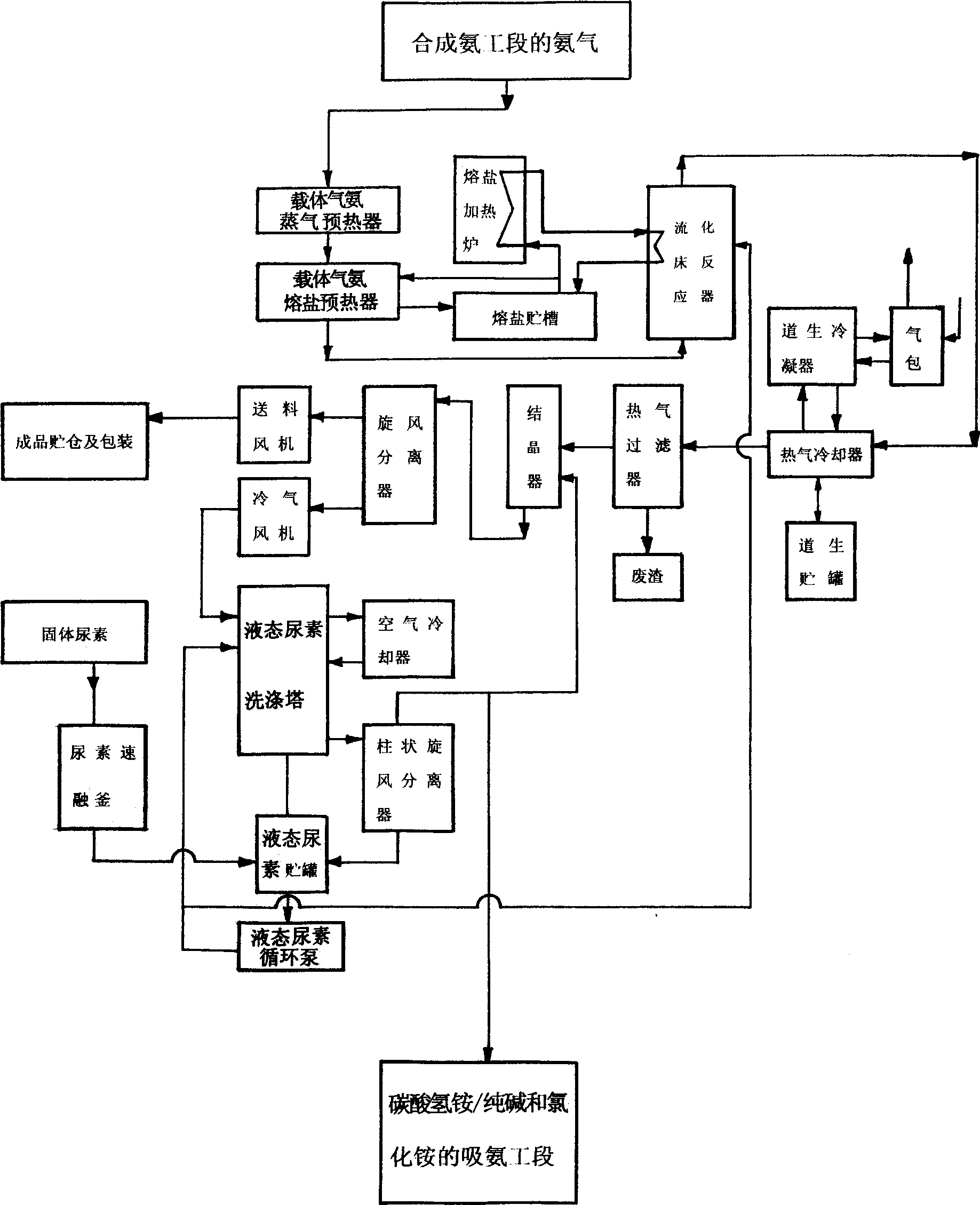

Trimeric cyanamide joint production method using one step method

InactiveCN1493565AImprove product qualityReduce labor intensityOrganic chemistryChemistryAmmonium chloride mixture

Owner:河南金山化工有限责任公司

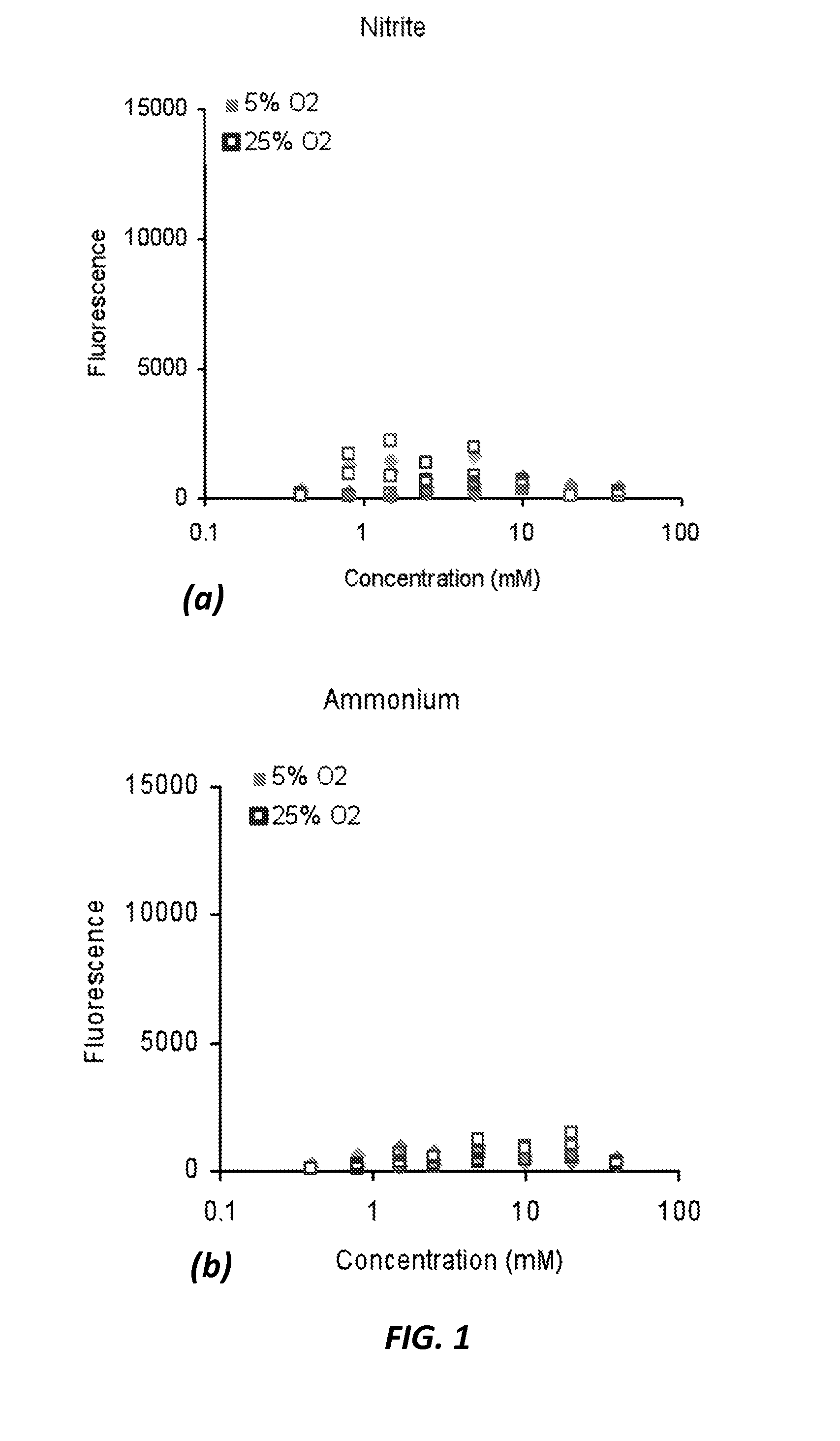

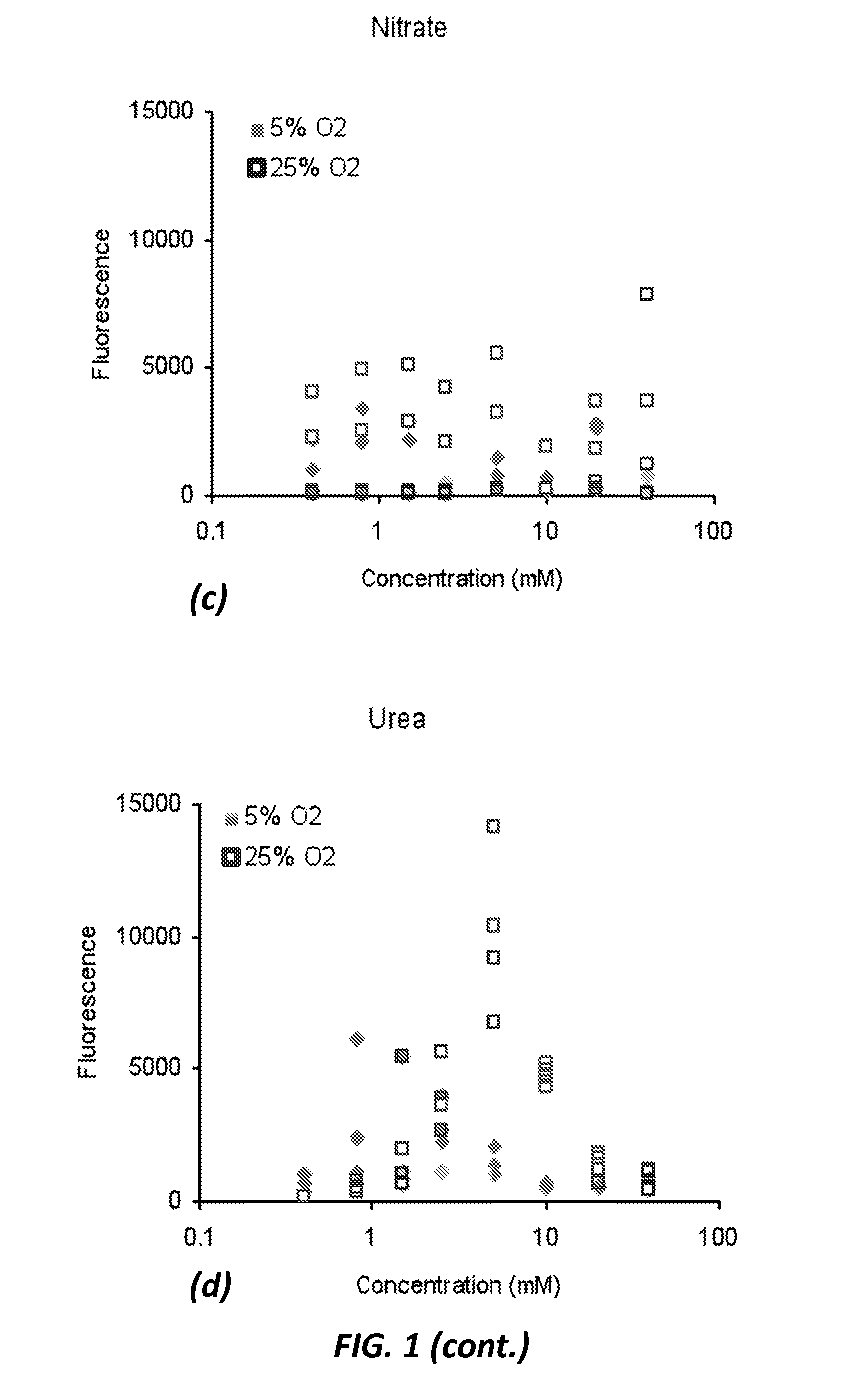

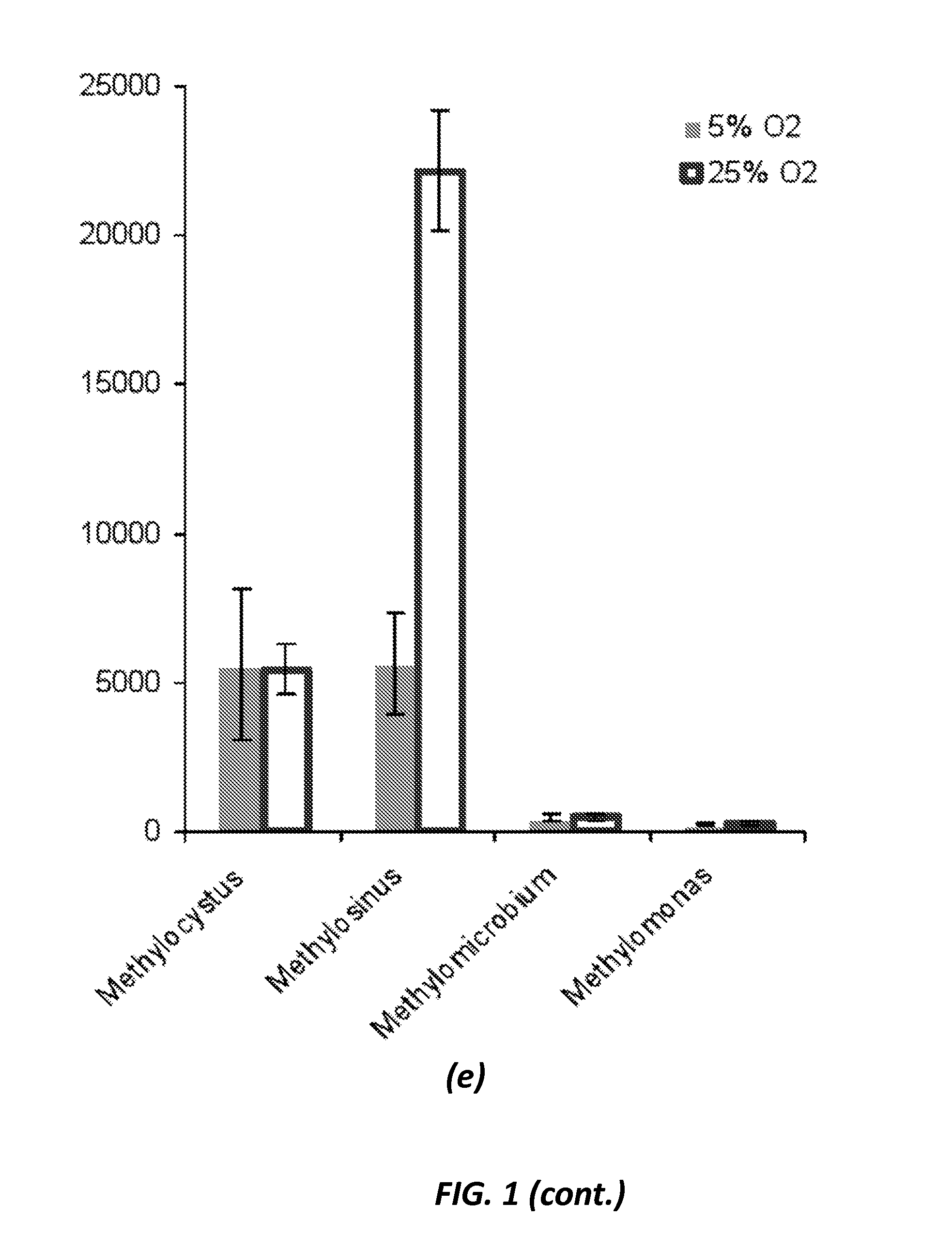

Process for the selection of PHB-producing methanotrophic cultures

ActiveUS20130052681A1Improve scalabilityIncrease typeMicrobiological testing/measurementMicroorganismNitrate

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Glutamic acid synergist urea and preparation method thereof

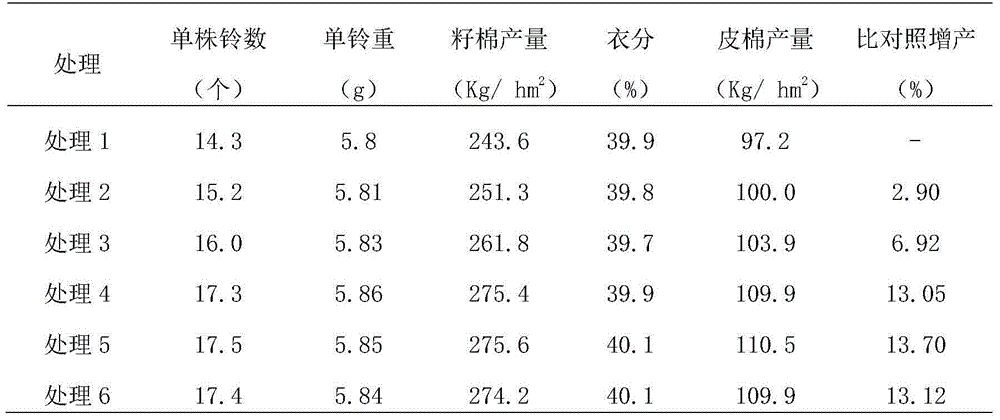

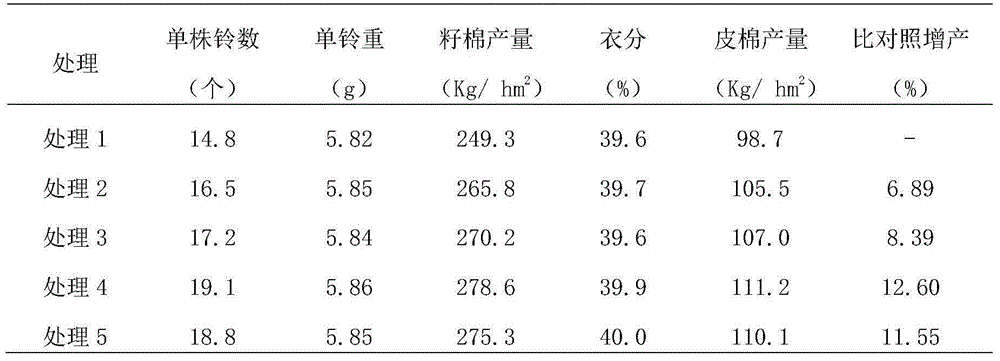

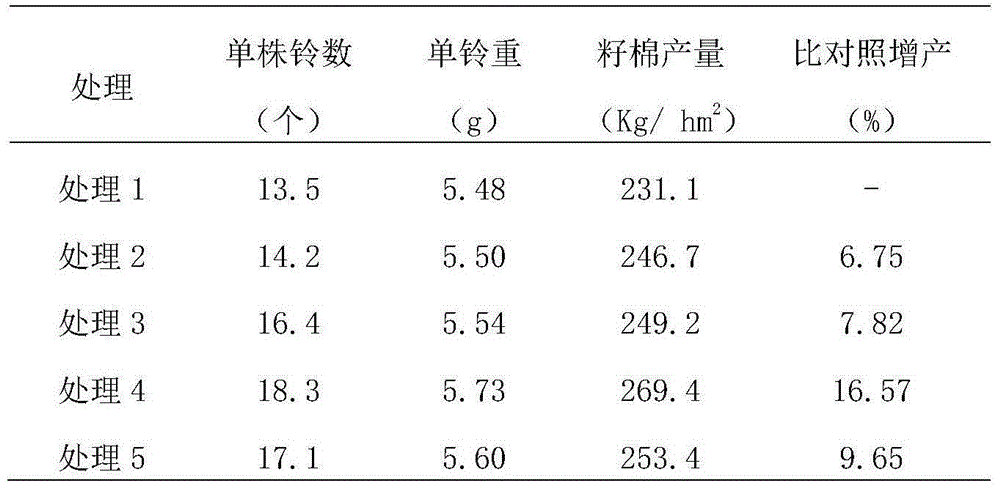

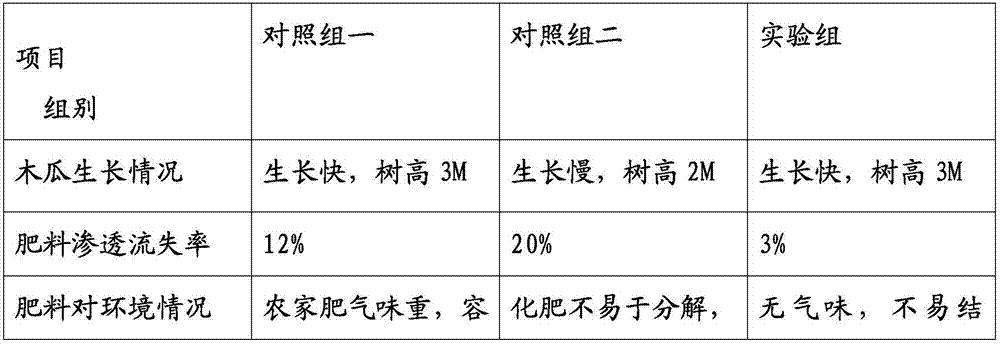

The invention relates to a glutamic acid synergist urea and a preparation method of glutamic acid synergist urea. The glutamic acid synergist urea provided by the invention consists of a glutamic acid synergist and urea. The production method of the glutamic acid synergist urea comprises the steps of preparation of the glutamic acid synergist, preparation of glutamic acid synergist urea, high tower cooling granulation and the like. By the fertilizer growth promotion effect of active ingredients in the glutamic acid synergist of the fertilizer on crops, the storage state of nitrogen elements in the plants can be improved, the ability of the crops to absorb nutrients is strengthened, the crop yield and the crop quality are improved, the utilization ratio of the fertilizer is increased (by 5%-10%), the loss of soil nutrients is reduced, and secondary pollution is avoided. The fertilizer product prepared by the invention is wide in source of raw materials, and has excellent application prospect.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

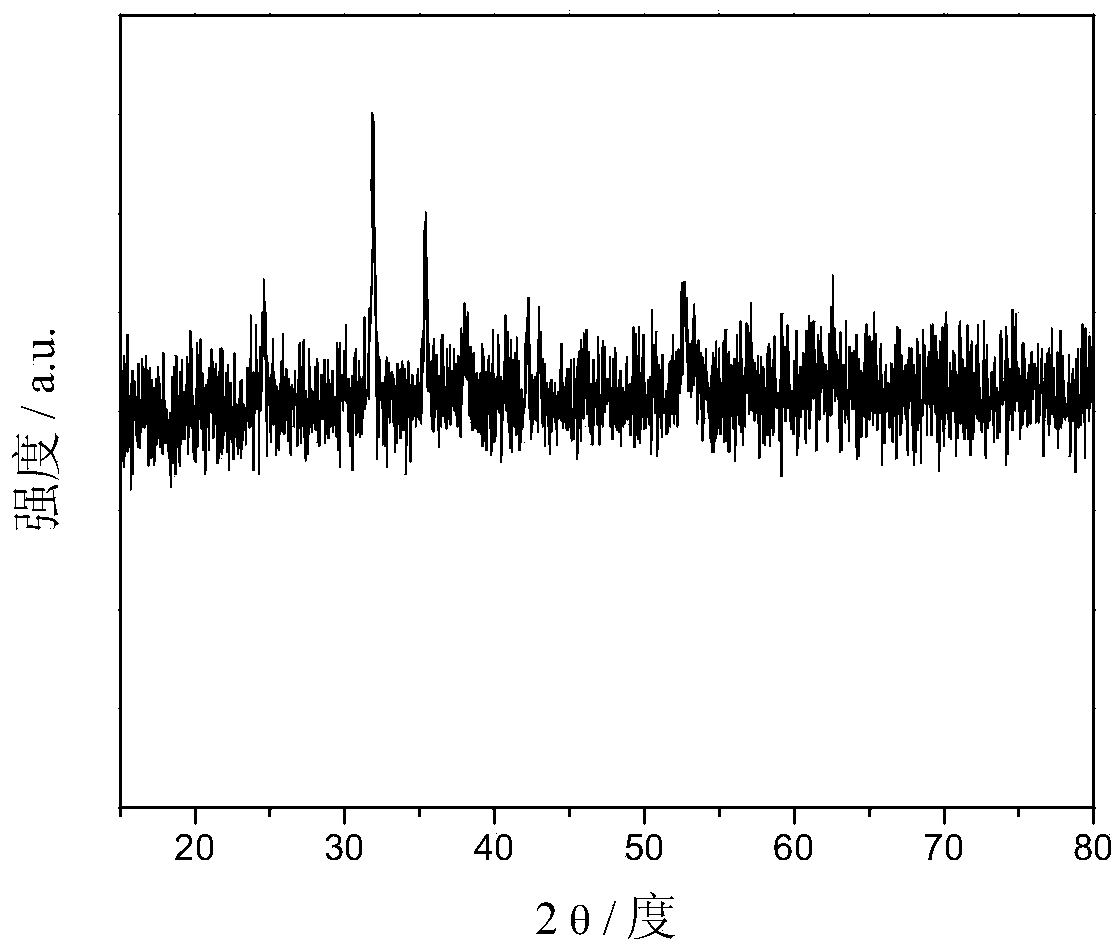

Metal aerogel with high specific surface area and preparation method thereof

InactiveCN105970193ALow densityHas metallic propertiesLiquid/solution decomposition chemical coatingAerogel preparationCelluloseChemical plating

The invention discloses metal aerogel with a high specific surface area and a preparation method thereof. The method comprises the steps that (1) cellulose aerogel is placed in a sensitizing solution to be soaked and then is washed with water; (2) the treated cellulose aerogel is soaked in a metal chemical plating solution for chemical plating, and metal / cellulose composite aerogel is obtained; (3) the metal / cellulose composite aerogel is placed in a LiOH / urea solution, the process of removing a cellulose aerogel template is conducted at a low temperature, and a nanometer porous metal solution is obtained; and (4) the prepared nanometer porous metal solution is washed with water, then is subjected to solvent exchange with acetone and is dried, and the metal aerogel with the high specific surface area is obtained. The method adopting the cellulose aerogel as the template for preparing the metal aerogel with the high specific surface area is provided for the first time. The cellulose aerogel has a high specific surface area and is of a pore structure suitable for chemical plating. Meanwhile, the template is easy to remove after the chemical plating, and reference is provided for preparation of metal aerogel with other templates.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

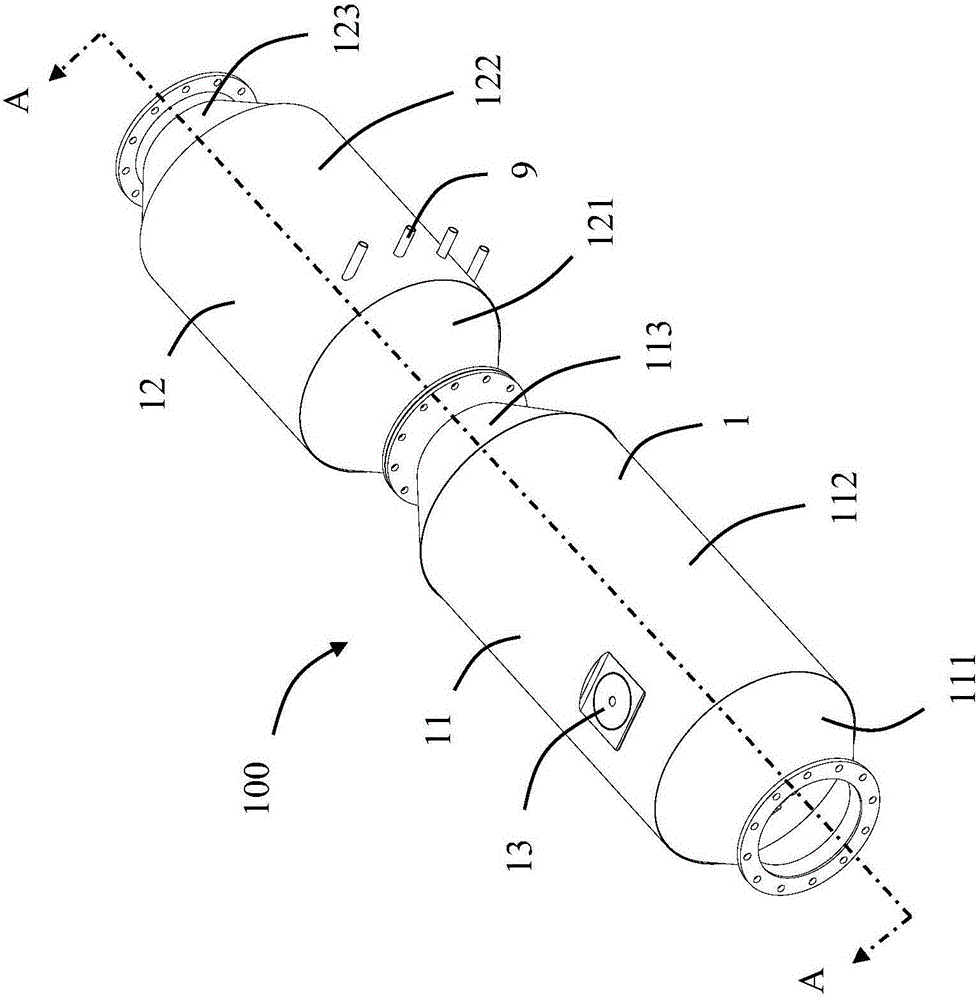

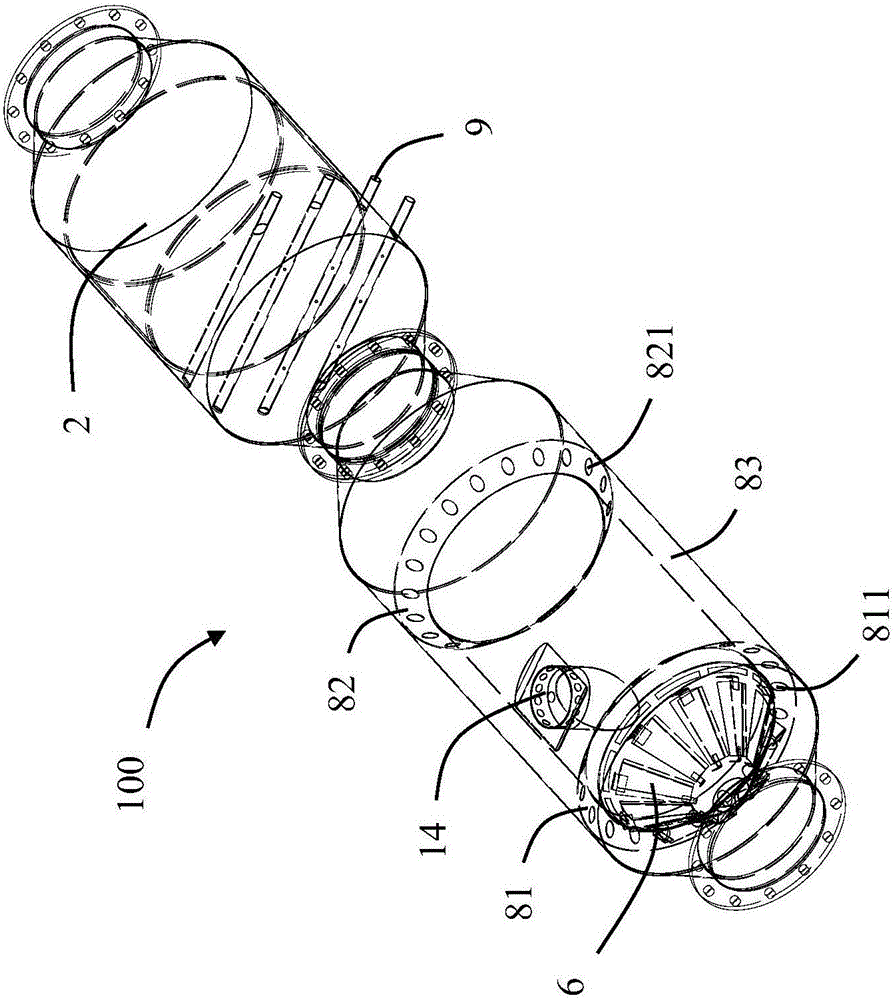

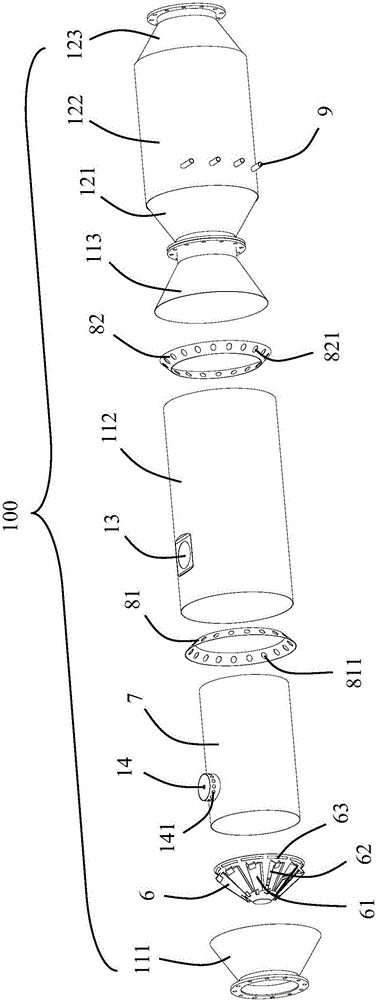

Exhaust gas treatment device

ActiveCN105804840AIncrease evaporation areaExtended stayExhaust apparatusSilencing apparatusEvaporationEngineering

Owner:TENNECO SUZHOU EMISSION SYST

Process and plant for the production of urea with high conversion yield and low energy consumption

Owner:UREA CASALE SA

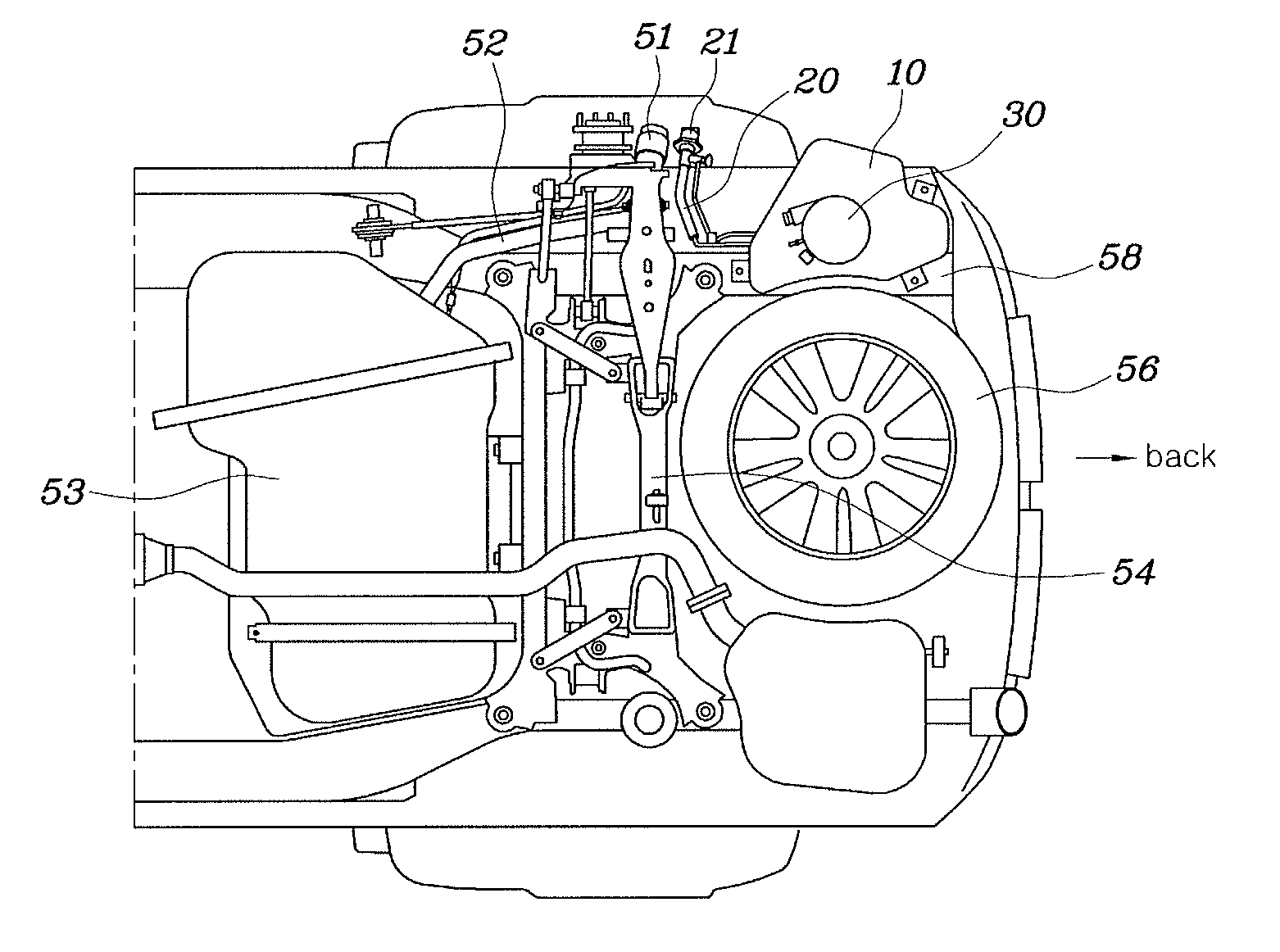

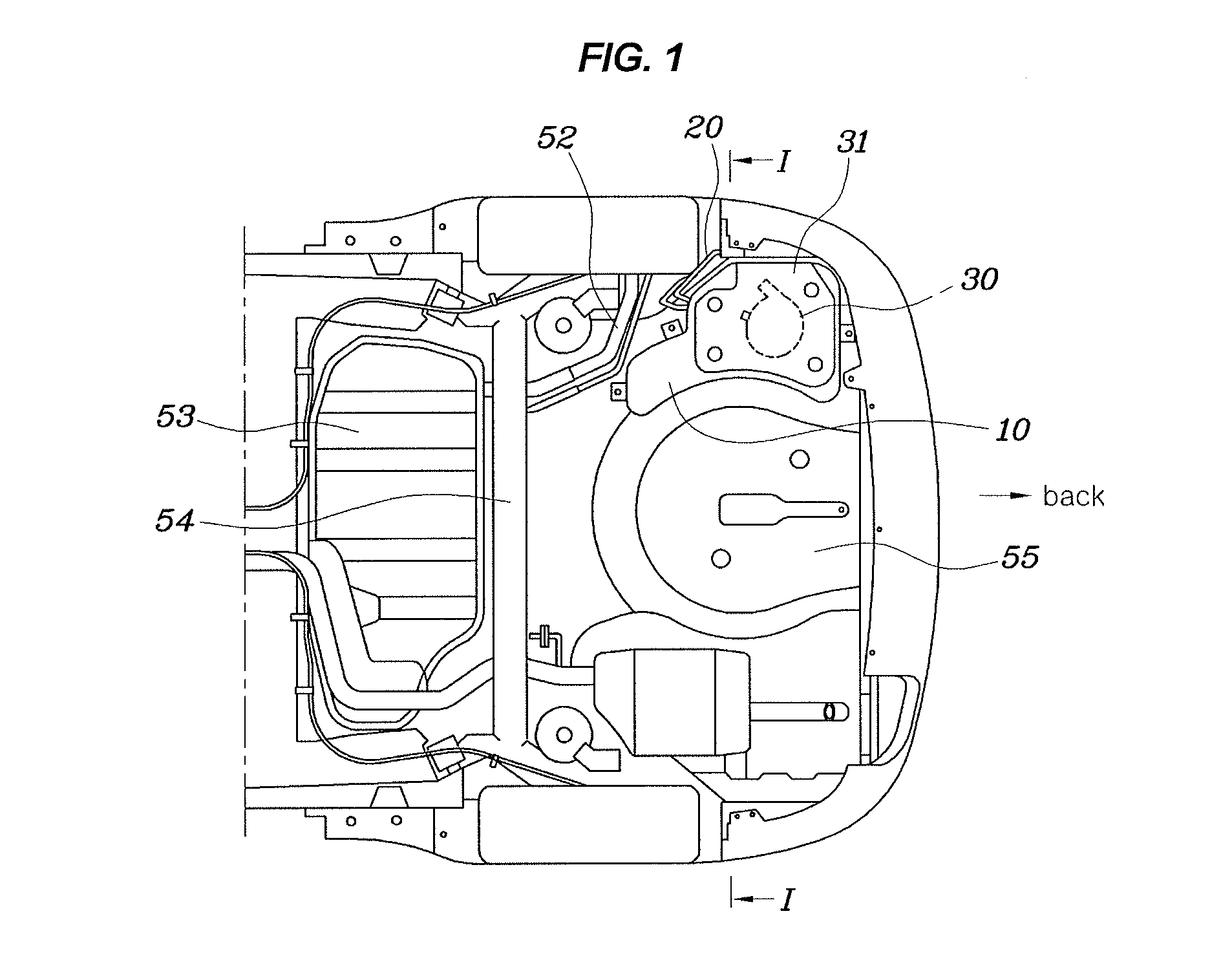

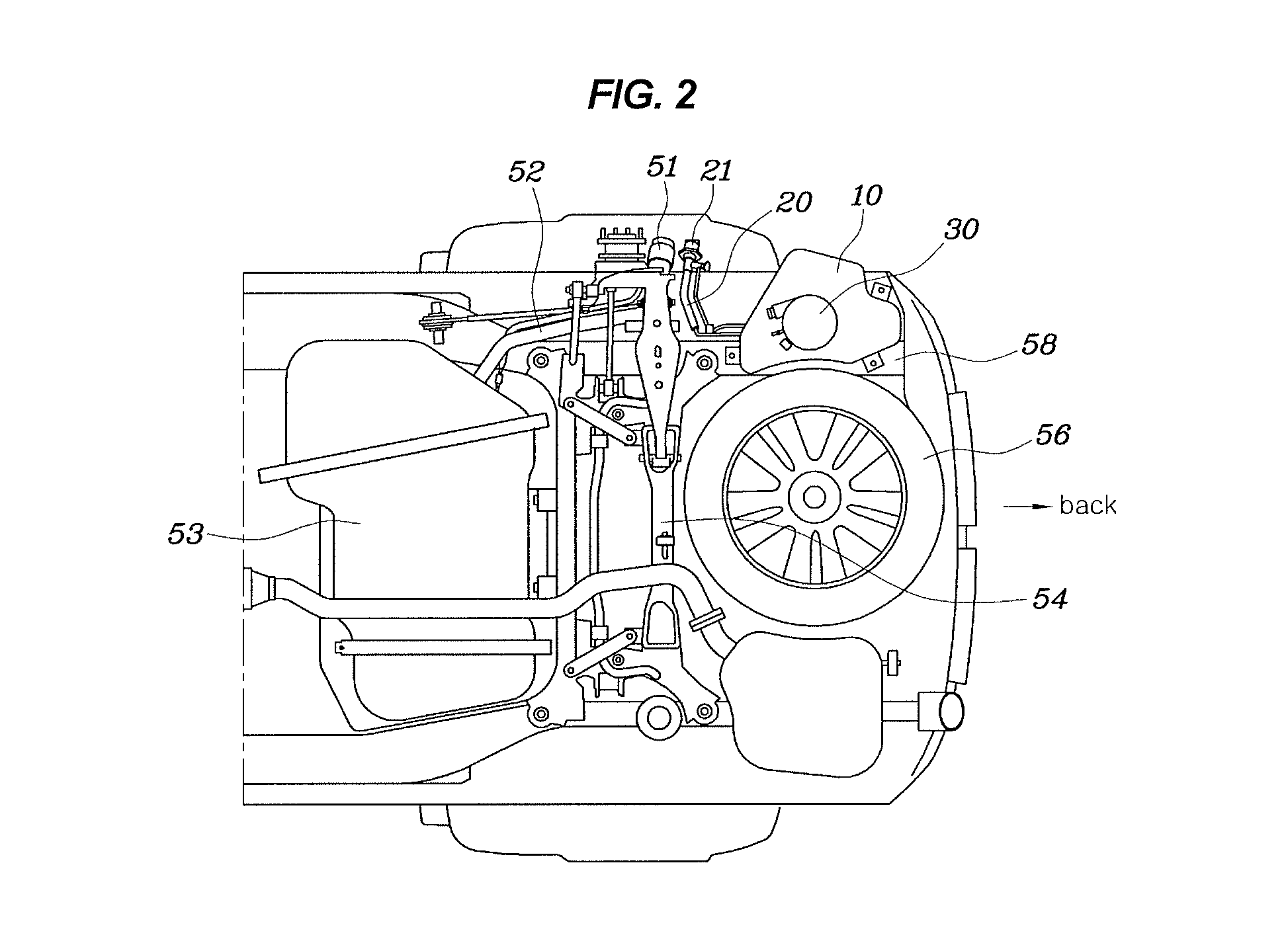

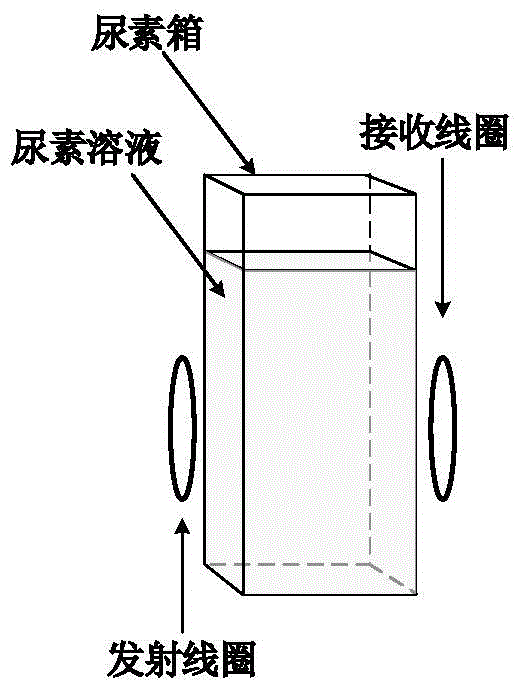

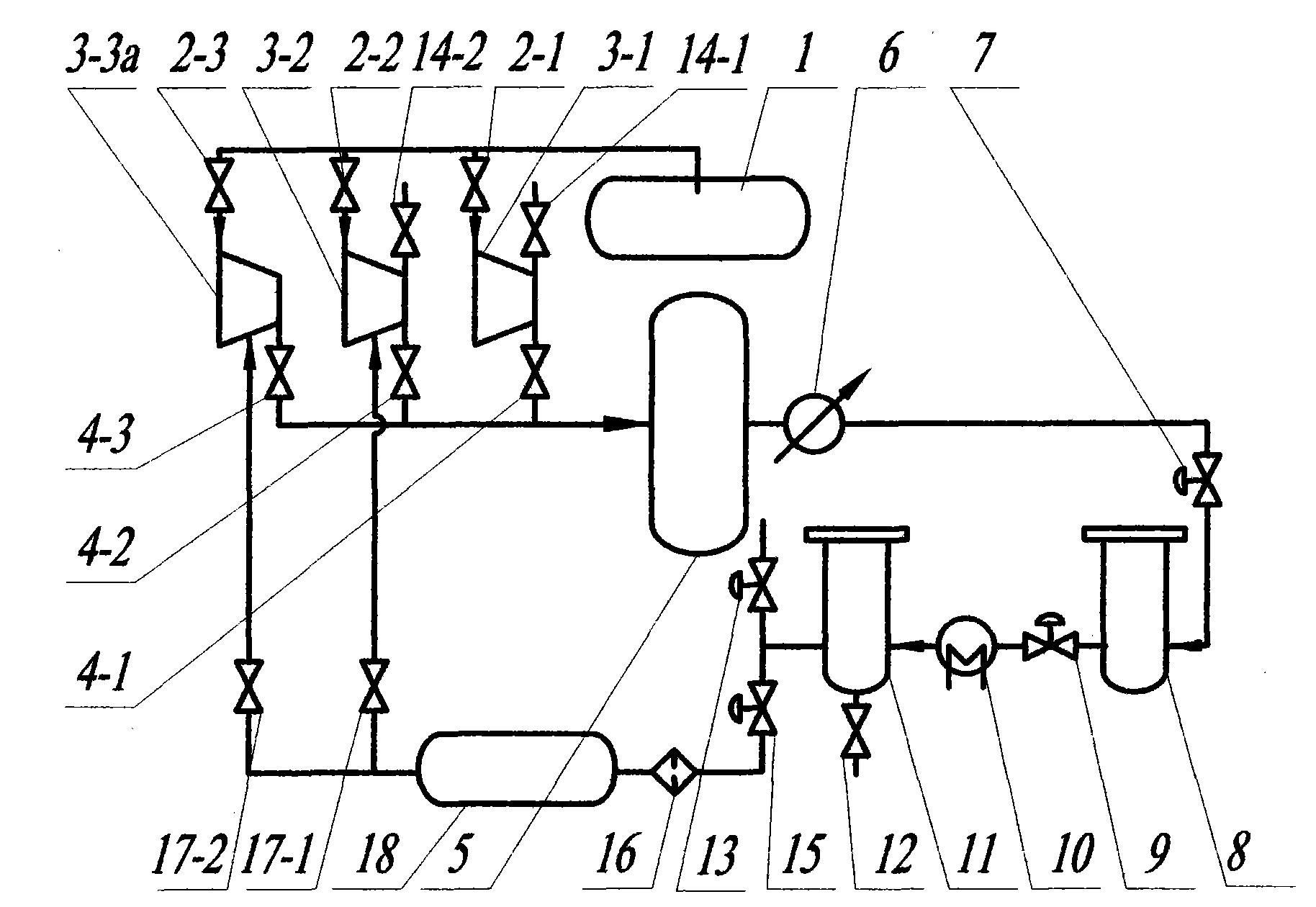

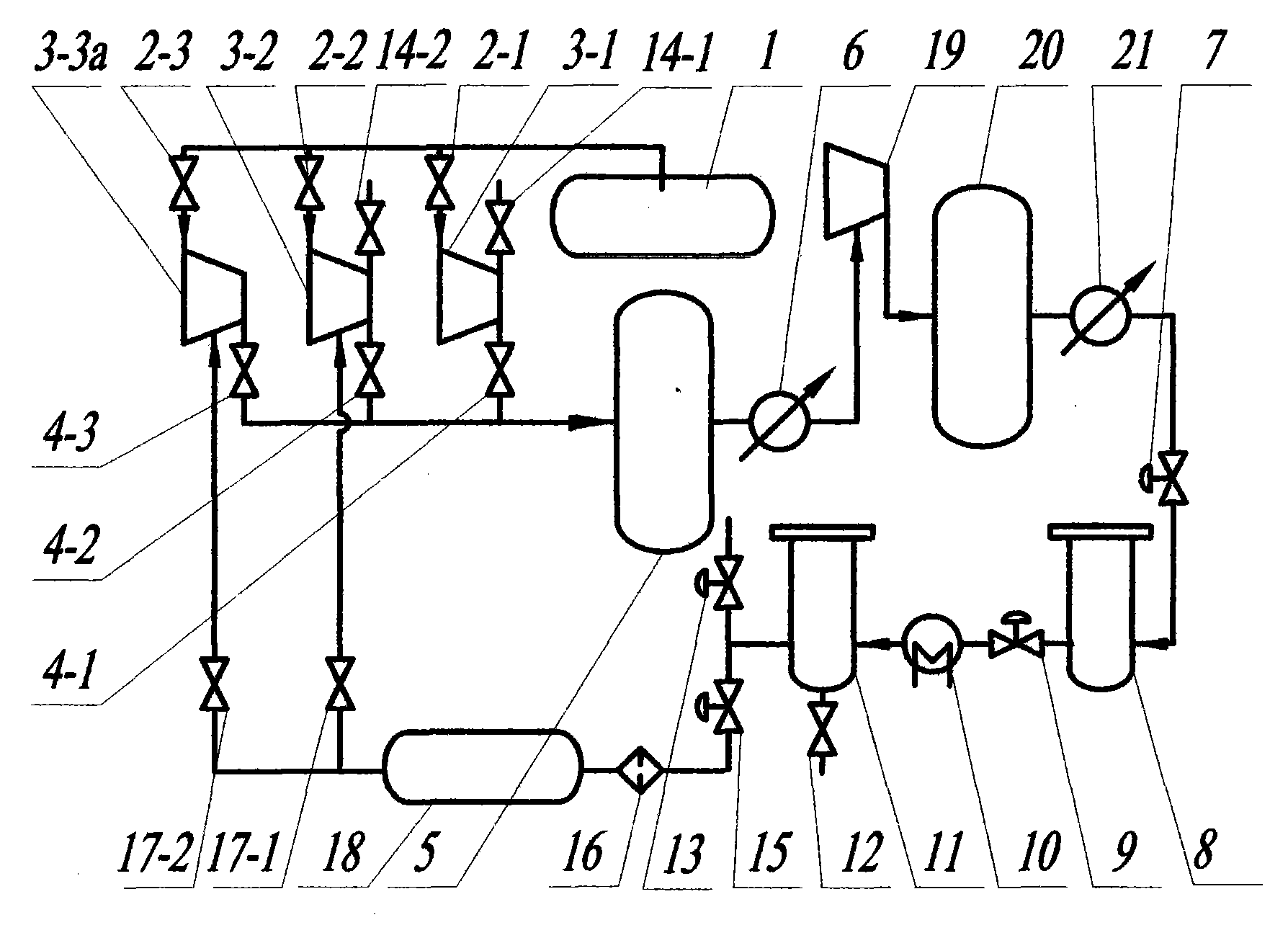

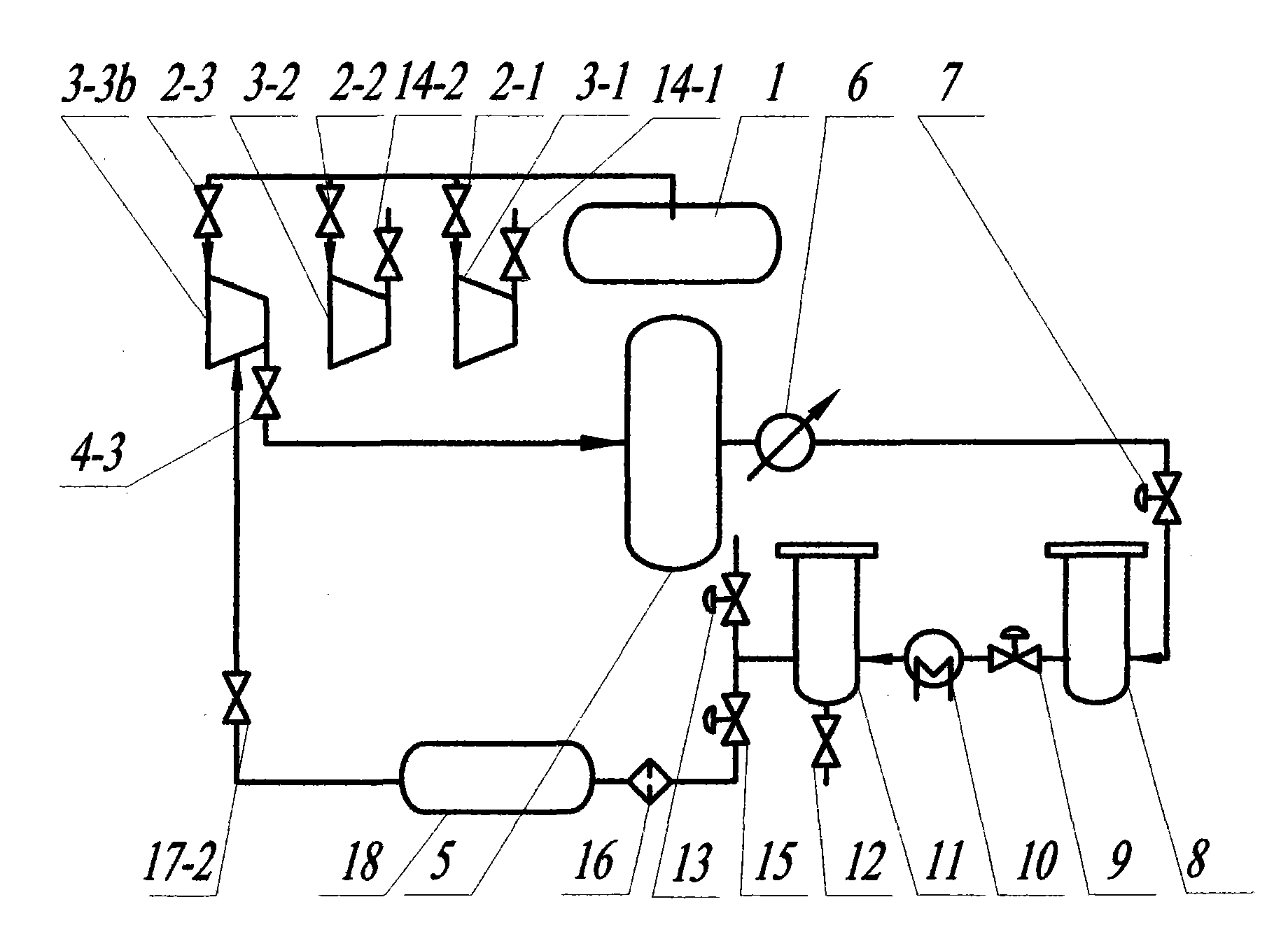

Urea solution apparatus for vehicles

InactiveUS20150114505A1Increasing usable partEasy to useInternal combustion piston enginesTank vehiclesEngineeringStorage tank

Owner:HYUNDAI MOTOR CO LTD

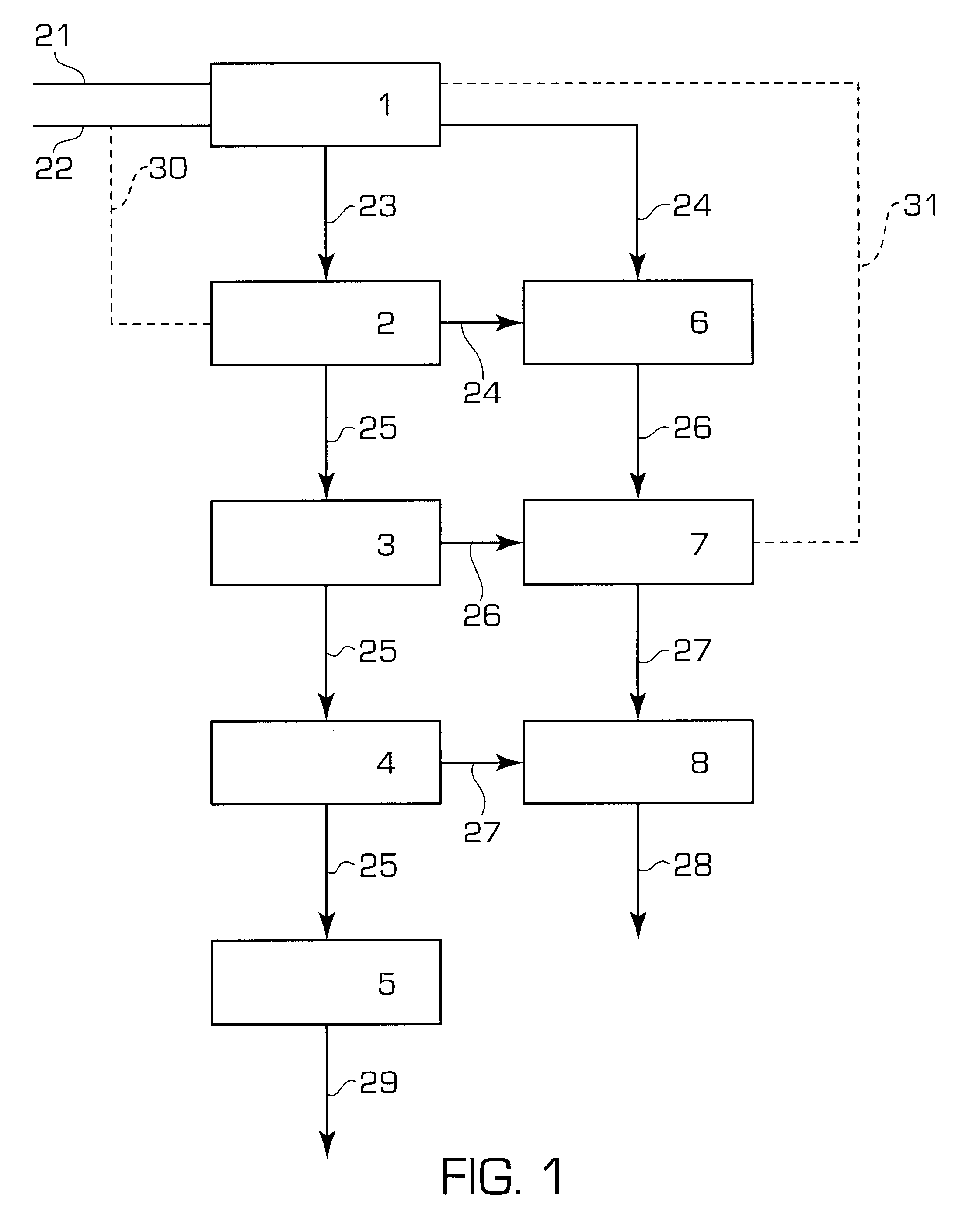

System and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy

The invention discloses a system and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy. The system comprises a renewable energy generation module, a power conditioning module, a urea-containing wastewater pretreatment module, an alkaline urea electrolytic hydrogen production module, a gas / liquid separation, drying and purifying module, an alkaline liquor circulating pump, a hydrogen storage tank and an anode product storage module, wherein an output end of the renewable energy generation module is connected with an input end of the power conditioning module, and an output end of the power conditioning module is connected with the alkaline urea electrolytic hydrogen production module. By means of the system, nearby in-time consumption of renewable energy power is facilitated, the hydrogen production cost is r educed, the tolerance of the hydrogen production system to the volatility and intermittence of a power supply is improved, a hydrogen production technology is combined with a water treatment technology, and while the hydrogen production energy consumption is reduced, environmental pollution is avoided; the applicability of the system is wide, the stability is high, the hydrogen produced by the system is high in purity, the process is simple, and industrial production is facilitated.

Owner:闫巍

Multifunctional organic/inorganic compound fertilizer and preparation method thereof

Owner:山东华粮生物工程集团股份有限公司

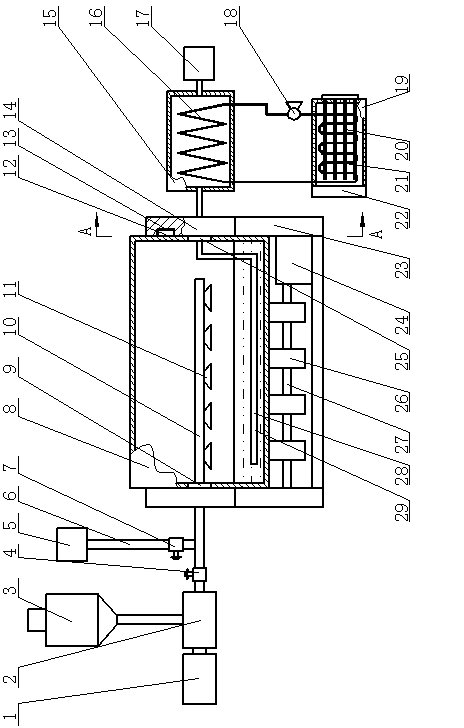

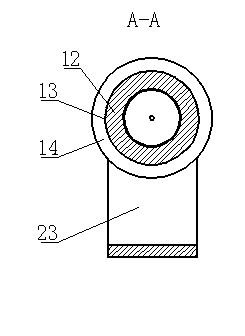

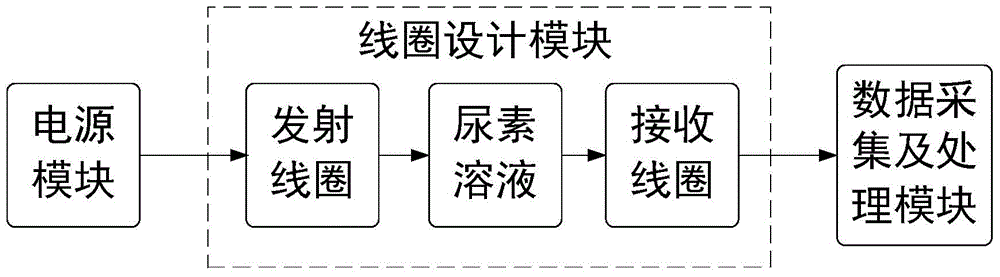

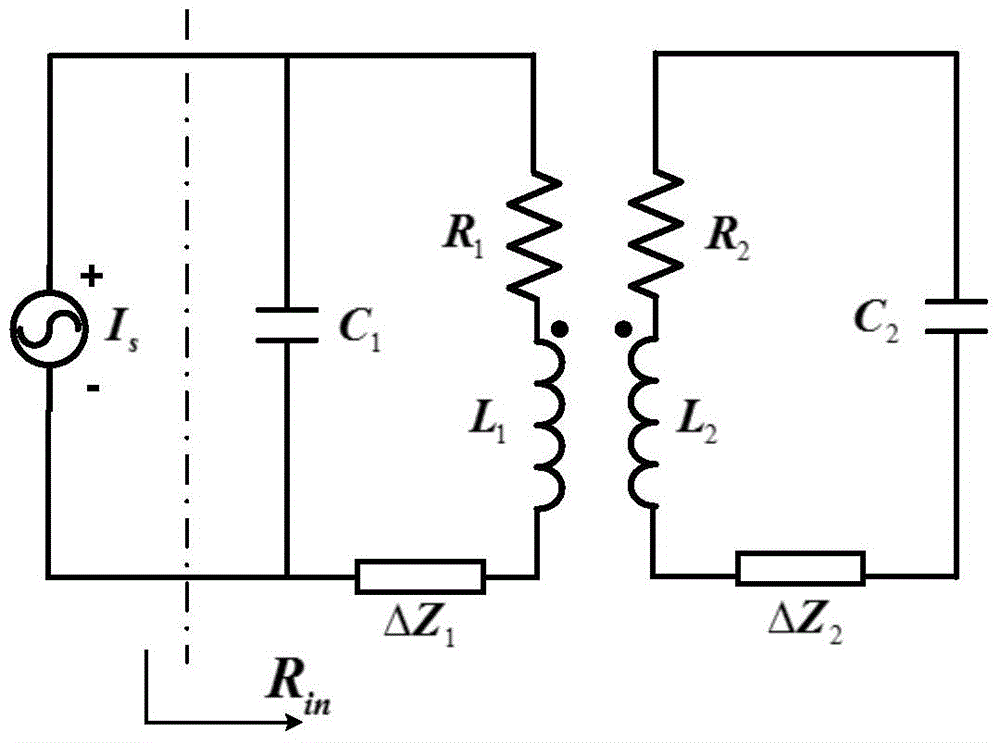

Online diesel exhaust fluid solution concentration monitoring system and monitoring method for automobile SCR system

InactiveCN104792828AAvoid contactIncreased sensitivityMaterial impedanceProcess moduleData acquisition

Owner:JILIN UNIV

Sodium bentonite processing agent for blue-green algae and preparation method thereof

InactiveCN104495960AFast gatheringQuick gather salvageBiocideDisinfectantsSodium BentoniteEutrophication

A sodium bentonite processing agent for blue-green algae is prepared from the following raw materials in parts by weight: 10-20 parts of serpentine, 40-45 parts of sodium-base bentonite, 2-3 parts of magnesium chloride, 8-13 parts of calcium chloride, 15-20 parts of potassium ferrate(VI), 12-16 parts of equisetum hyemale, 13-16 parts of pericarpium granati, 3-5 parts of polymaleic acid, 3-4 parts of sodium pyrophosphate, 2-3 parts of urea, 3-5 parts of anhydrous sodium sulfate, 3-5 parts of boric acid, 4-6 parts of polyvinyl alcohol, proper amount of water, and 3-4 parts of an adsorption auxiliary agent. By adding potassium ferrate(VI), the processing agent for blue-green algae has synergic effects of oxidation, adsorption, flocculating, precipitation, sterilization, disinfection, decoloring and deodoring, also does not generate any toxic and harmful substances, is capable of increasing water dissolved-oxygen content, has good removal effects on ammonia nitrogen, nitrites and algae in water, and is used to remove fulvic acid and suspensions in water and eutrophication phenomenon in fresh water. The processing agent for blue-green algae is good in dispersing suspending property and good in adsorption property, and can help to rapidly aggregate and salvage blue-green algae.

Owner:WUHU XIANGRONG FOOD

Thermoplastic starch-polyvinyl alcohol composite plastic film

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

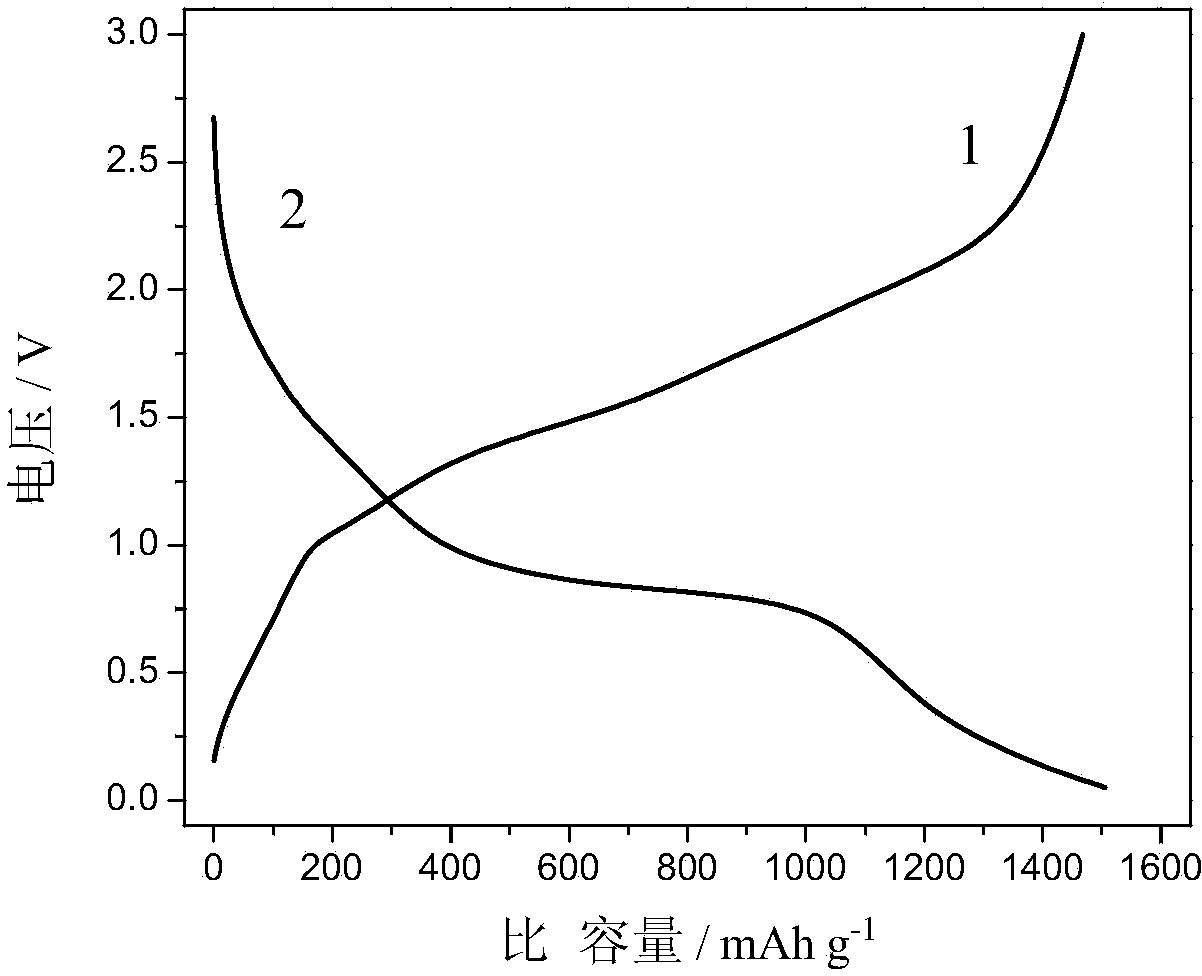

Ferrous carbonate/graphene composite material and preparation method and applications thereof

ActiveCN103840132AHigh specific capacityImprove cycle performanceNegative electrodesSecondary cellsMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

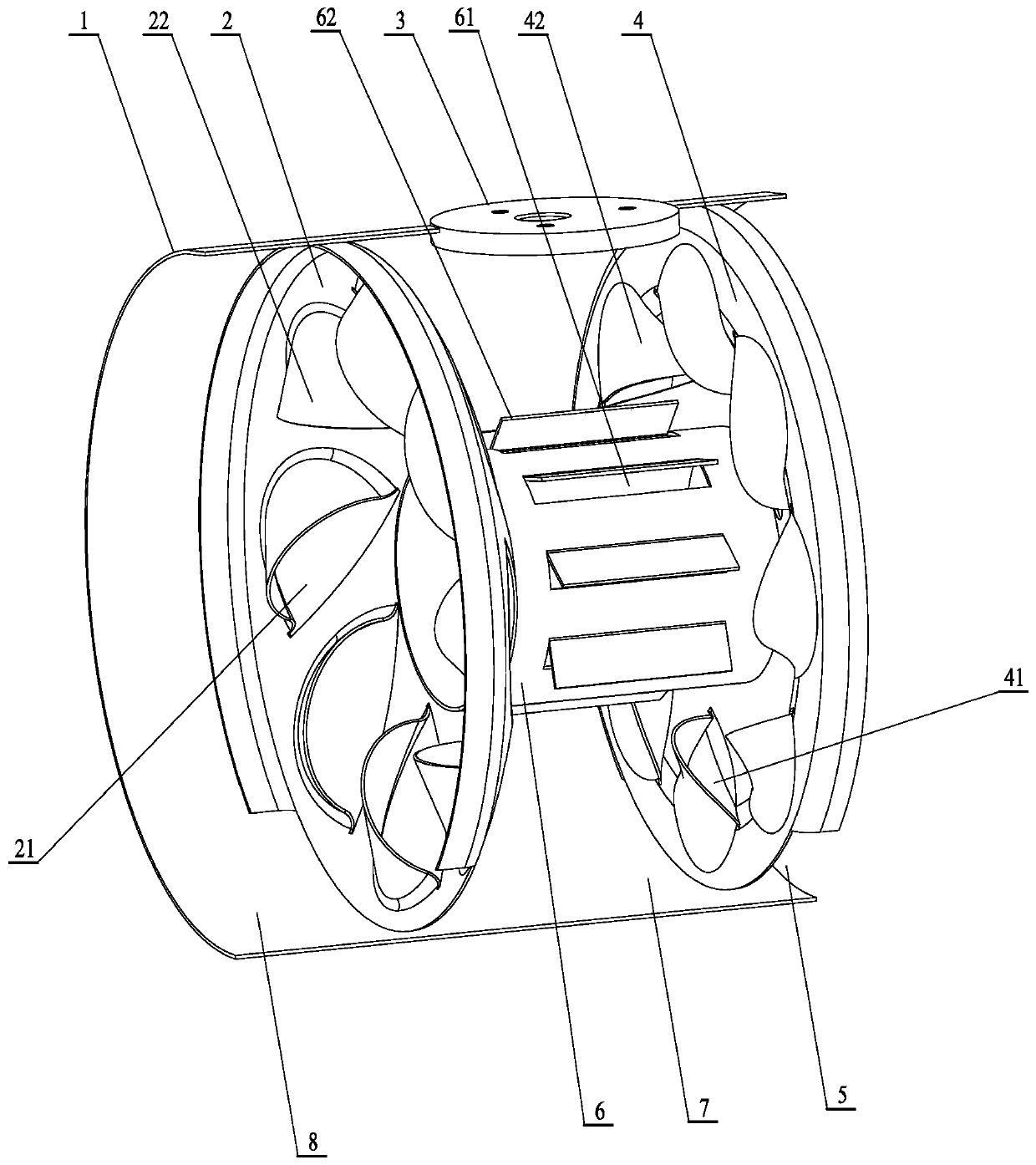

Complete equipment for denitration method in boiler

InactiveCN107626205AHigh yieldAvoid extra supplyLighting and heating apparatusDispersed particle separationBoiler furnaceFlue gas

The invention belongs to the field of environment-friendly equipment and particularly relates to complete equipment for a denitration method in a boiler. The complete equipment comprises an ammonia gas generating device, a gas mixing device and a catalyst cage. The yield of a target product ammonia gas is increased by using the ammonia gas generating device arranged in the boiler and high-temperature polymerized urea in the boiler, extra supply of energy is avoided and energy consumption is reduced; by arranging the gas mixing device, the ammonia gas overflows from a plurality of opening holesin the wall of an ammonia gas mixing pipe and is sufficiently mixed with NOx in high-temperature flue gas in a sleeve pipe; by arranging the catalyst cage, the ammonia gas and the NOx which are uniformly mixed repeatedly react under the action of high temperature and a catalyst, so that the denitration efficiency is greatly improved. The equipment disclosed by the invention has the advantages ofsimple structure, energy consumption conservation, greenness, environment friendliness and suitability for industrial denitration.

Owner:YANCHENG JISHENGDA ENVIRONMENTAL PROTECTION ENG CO LTD

External use medicine for treating dermatosis and its preparing method

InactiveCN1943581AEasy to useLow priceHydroxy compound active ingredientsAmide active ingredientsDiseaseMenthol

Owner:刘亚军

Tomato fertilizer containing rich nucleic acid and preparation method of tomato fertilizer

InactiveCN106007932AImprove water holding capacityImprove stabilityCalcareous fertilisersAlkali orthophosphate fertiliserHeavy metal chelationPolyvinyl alcohol

The invention discloses a tomato fertilizer containing rich nucleic acid. The tomato fertilizer is prepared from raw materials in parts by weight as follows: 200-210 parts of rice straw, 20-21 parts of kaoline, 10-11 parts of urea, 10-11 parts of furnace dust, 5-6 parts of hawthorn seeds, 7-8 parts of nucleic acid wastewater, 0.3-0.4 parts of ammonium polyphosphate, 0.1-0.2 parts of a urease inhibitor, 1-2 parts of gypsum powder, 1-2 parts of amino acid powder, 15-16 parts of polyvinyl alcohol, 1-1.1 parts of tea polyphenol, 1-1.1 parts of carbon nanotubes, 1.2-1.3 parts of beta-cyclodextrine and 800-810 parts of 28% ammonia water. Amino groups are introduced to biomass charcoal prepared from the rice straw and can be chelated with heavy metal, the heavy metal adsorption capability is improved, and the pollution influence of the heavy metal on soil and the environment is reduced. The carbon nanotubes are added to a film coating liquid, the mechanical strength of a film can be improved, and added tea polyphenol can improve the slow-release property of the film; besides, the tomato fertilizer contains rich nucleic acid, the activity of tomatoes can be enhanced, decaying of the tomatoes is delayed, and the yield is increased.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

Method for preparing bamboo mat used for external cable packaging

Owner:广德县泉村竹制品有限公司

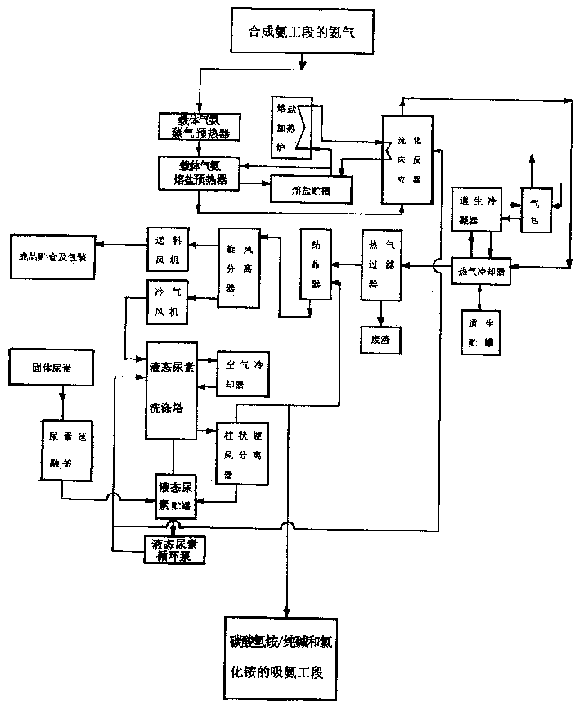

Supercritical carbon dioxide extraction process flow in combination with urea production system

InactiveCN101628186AIncrease productivityImprove resource utilizationSolid solvent extractionProcess conditionsAmount of substance

Owner:QINGDAO UNIV OF SCI & TECH

Double-cyclone urea mixing device

InactiveCN110374726AWell mixedGuaranteed treatment effectExhaust apparatusSilencing apparatusCycloneTreatment effect

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

Lime nitrogen multifunctional particle type soil amendment and preparation method thereof

Owner:SHANDONG ZOETICLAND BIOLOGICAL TECH

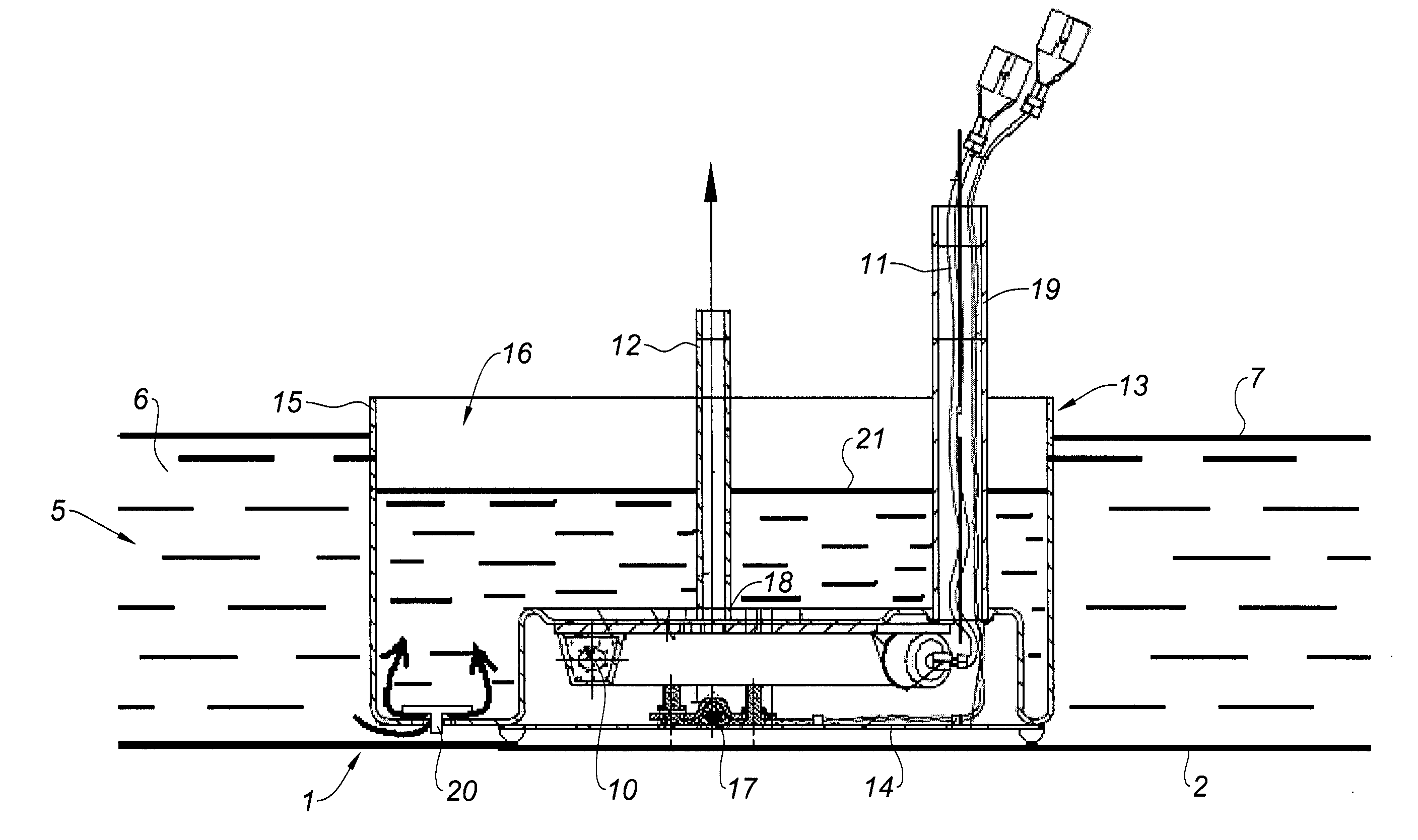

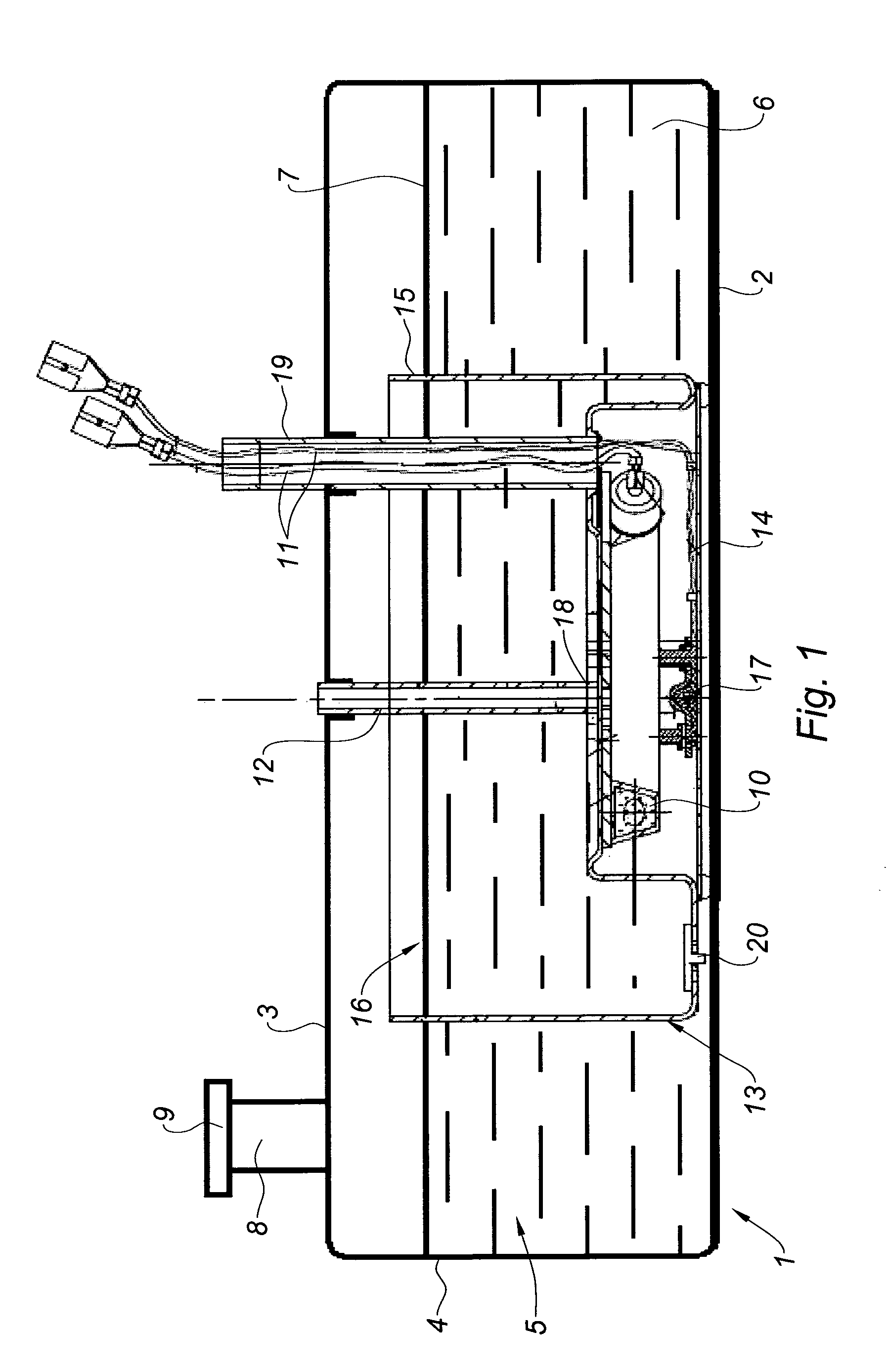

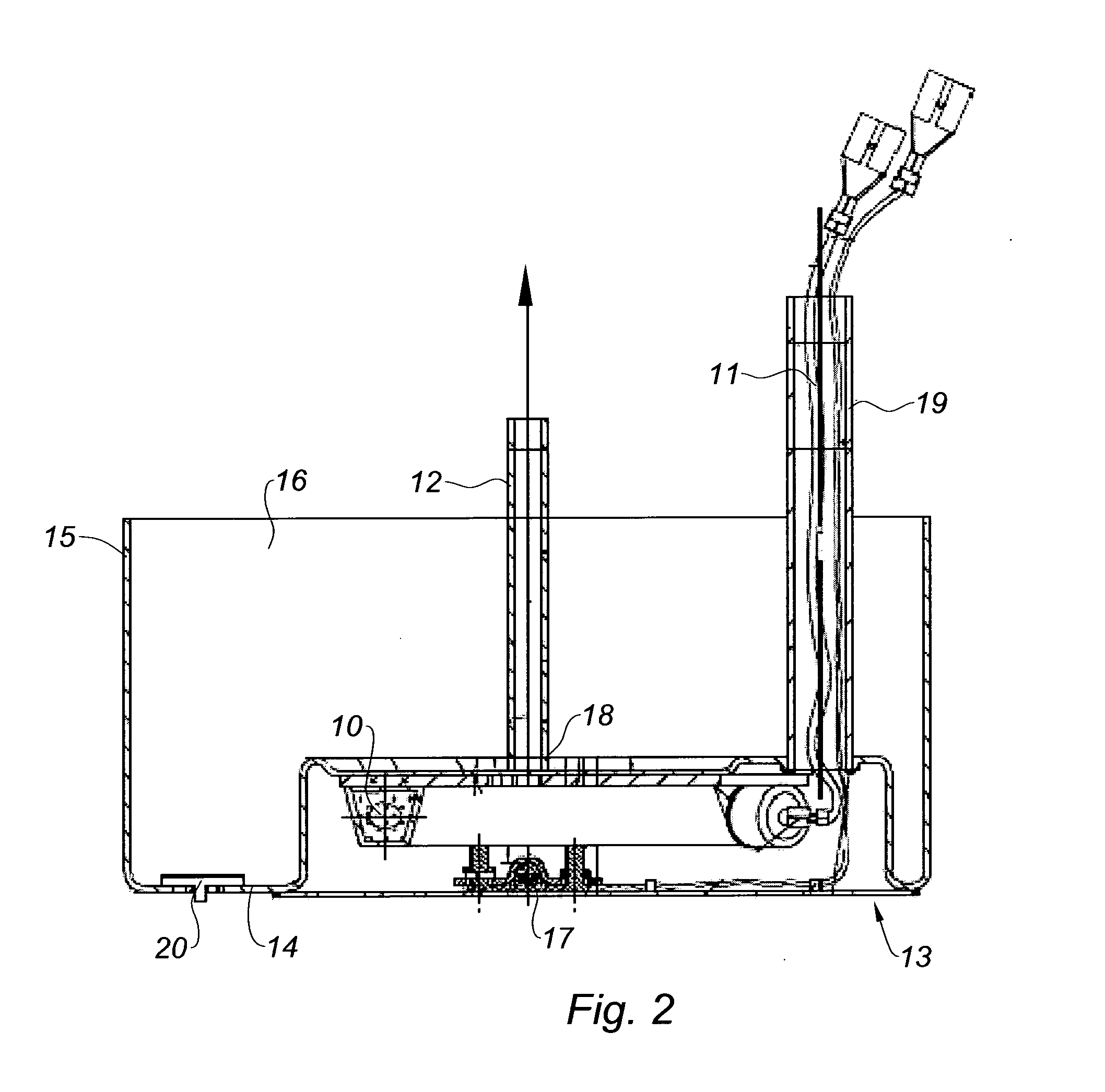

Fluid reservoir having a heating reserve bowl

InactiveUS20130129330A1Economical and fast and completely controllable operationEasy to solveInternal combustion piston enginesExhaust apparatusEngineeringPollution

Owner:MGI COUTIER SA

Liquid organic fertilizer prepared from silkworm excrement and production method of liquid organic fertilizer

Owner:陆良县大自在生物肥业有限公司

Diminazene aceturate production method

Owner:HENAN LINGXIAN SCI & TECHN PHARMA

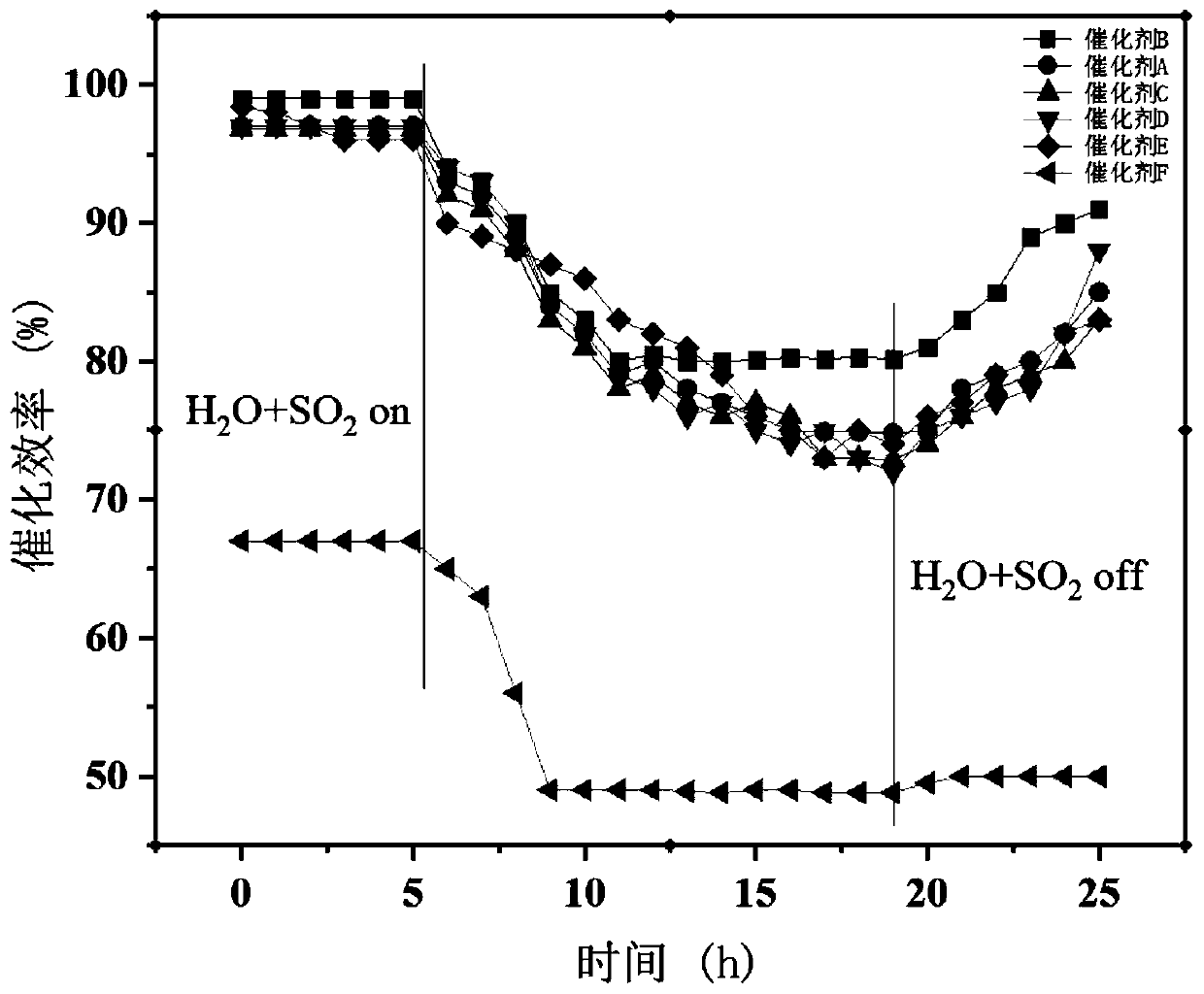

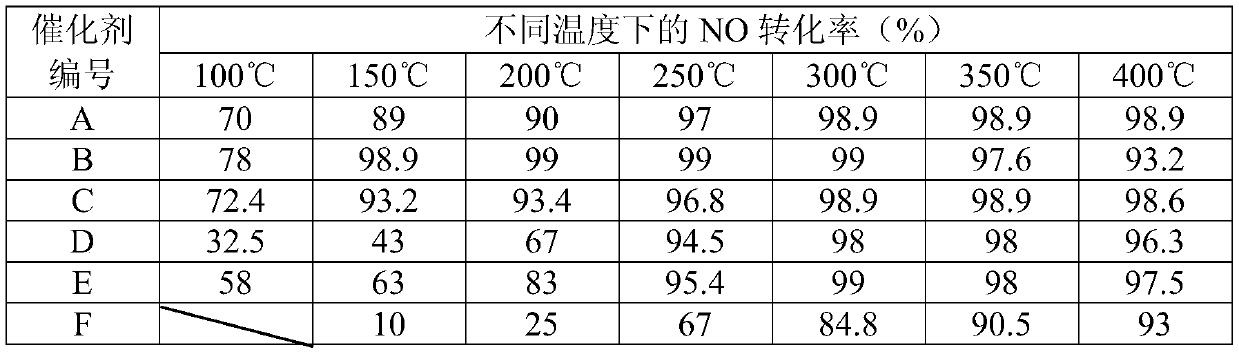

Low-temperature denitrification catalyst and preparation method thereof

Owner:上海毅帆环保科技有限公司

Method for preparing 4-amino-2,6-dihydroxypyrimidine by virtue of dry frying process

InactiveCN107721938AReduce manufacturing costReduce preparation energy consumptionOrganic chemistrySodium methoxideChemical synthesis

Owner:王微

Organic fertilizer for improving soil and preparation method thereof

InactiveCN107445703AThe transformation effect is goodPromote growthCalcareous fertilisersBioloigcal waste fertilisersSodium BentonitePeat

Owner:FOSHAN JIHE TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap