Fluid reservoir having a heating reserve bowl

a technology of flue gas and reservoir, which is applied in the field of flue gas reservoir, can solve the problems of not necessarily guaranteeing operation, complex solutions, and high cost, and achieve the effects of convenient and fast operation, convenient operation and complete controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

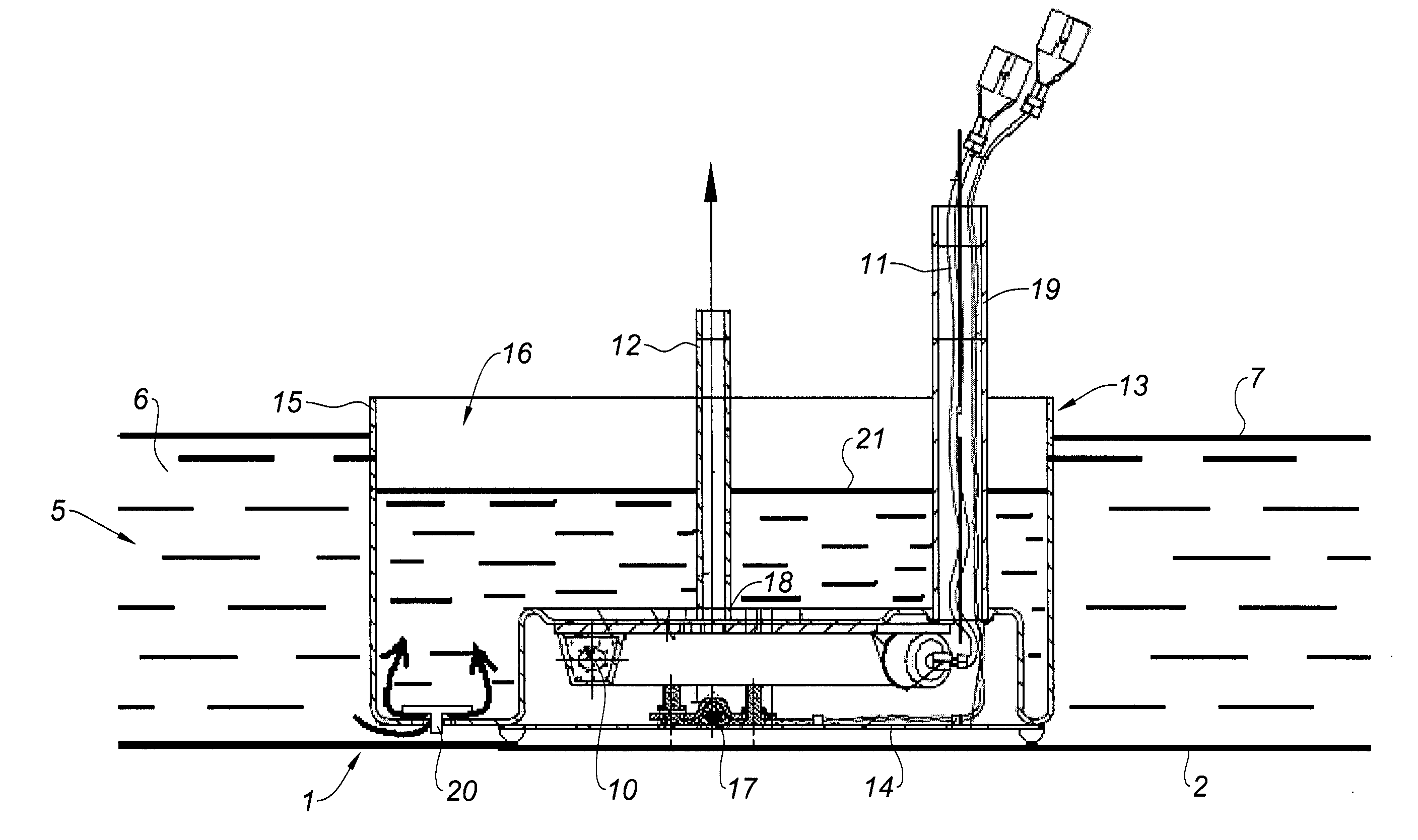

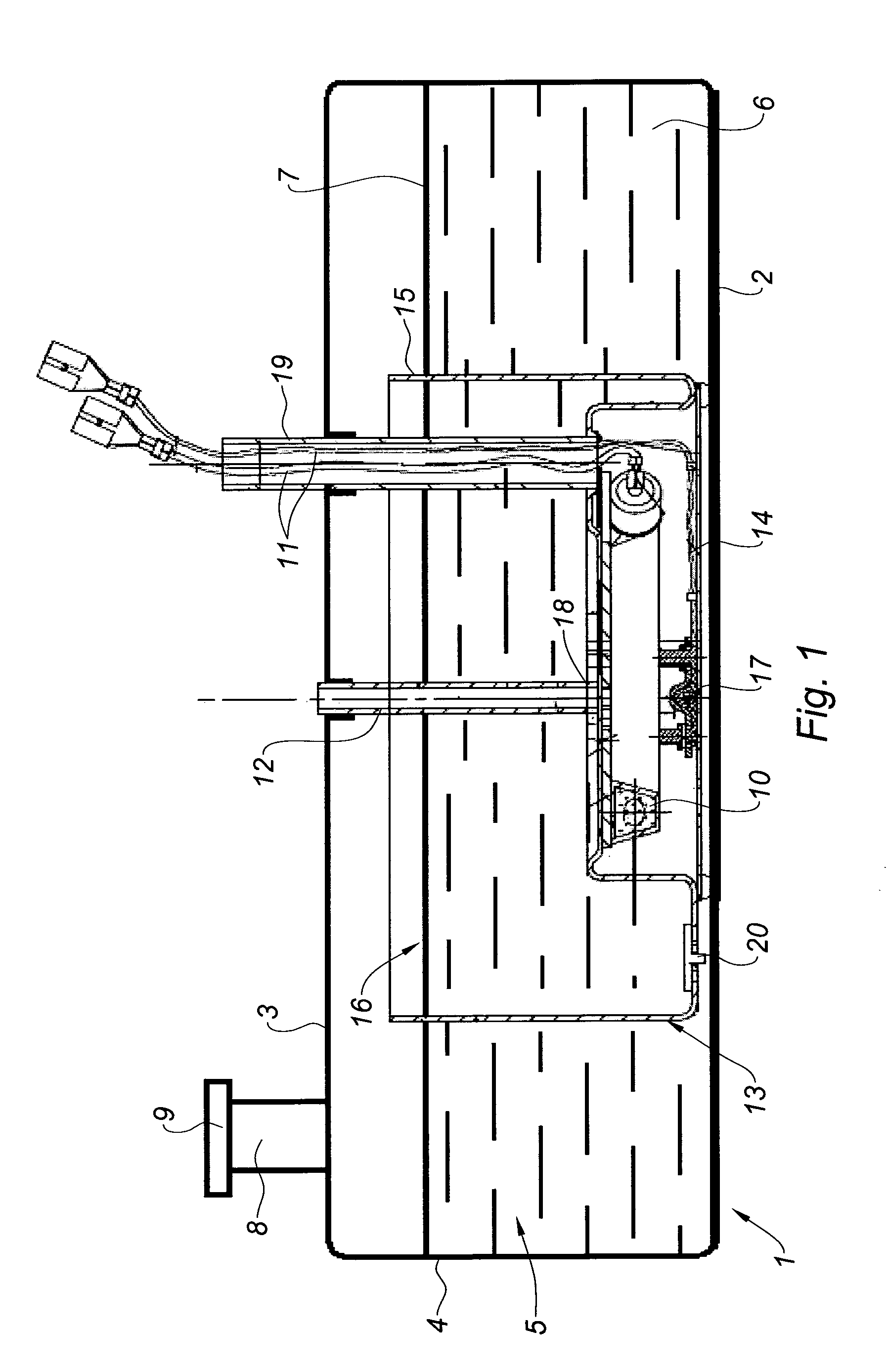

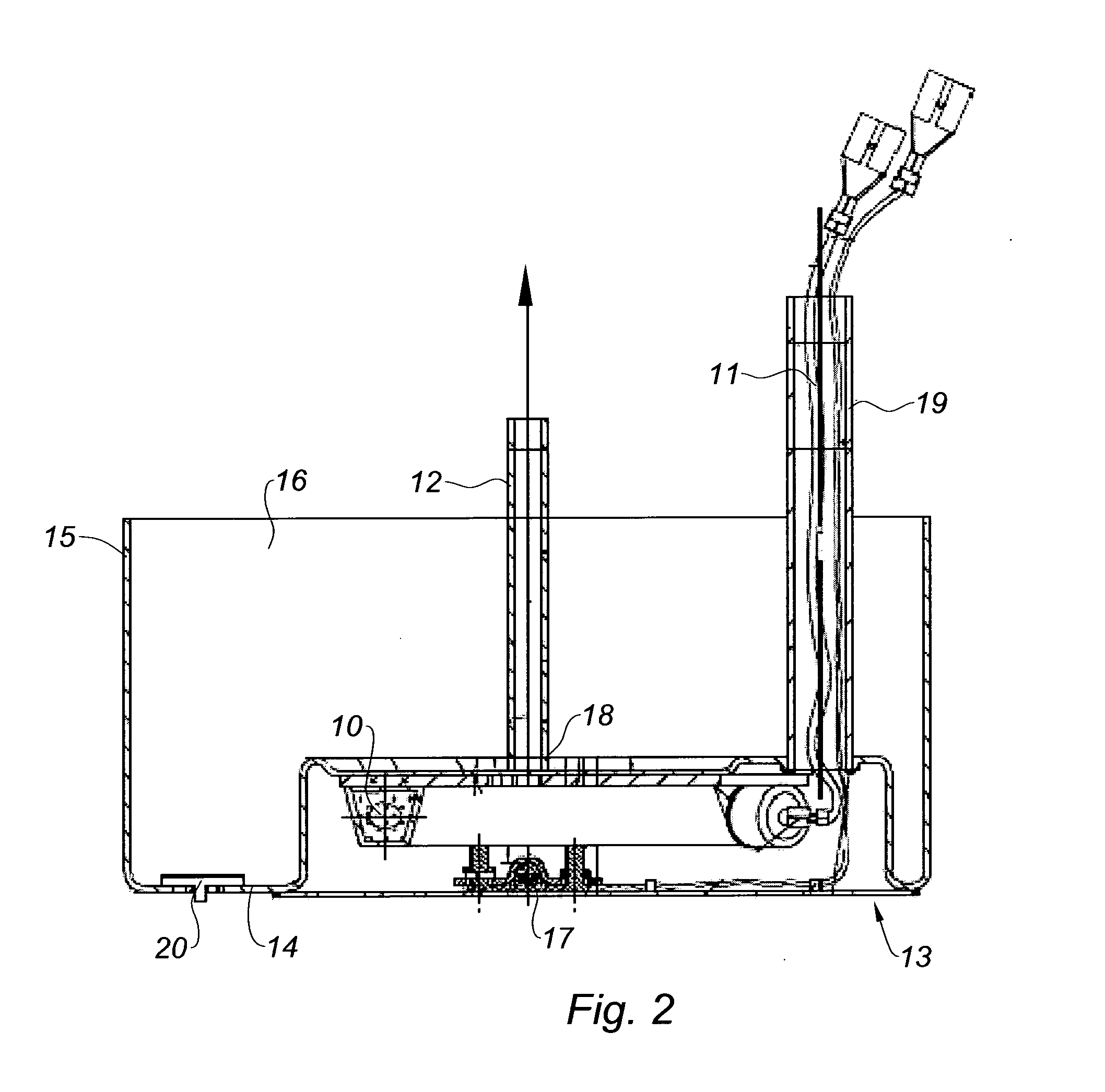

[0024]In the drawing, reference 1 designates, in its entirety, a reducing agent reservoir, which comprises a lower wall 2, an upper wall 3 and a side wall 4, which delimit an interior volume 5 of said reservoir 1.

[0025]The reservoir 1 contains, during use, a certain quantity of reducing agent 6, the level of which is indicated in 7. A filling orifice 8, placed on the upper wall 3 and normally covered by a plug 9, makes it possible to introduce the reducing agent 6 into the reservoir 1.

[0026]In its lower portion, the reservoir 1 is equipped with a heating element 10 of the electric type, powered by electrical conductors 11. The heating element 10 is provided to at least partially thaw the reducing agent 6 in order to allow it to be withdrawn by a suction pipe 12, even at low temperatures. The suction pipe 12 is oriented towards a pump (not shown) using which the reducing agent 6 is withdrawn from the reservoir 1 and sent towards an injector, which distributes the reducing agent in the e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap