Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Reducing agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reducing agent (also called a reductant or reducer) is an element (such as calcium) or compound that loses (or "donates") an electron to another chemical species in a redox chemical reaction. Since the reducing agent is losing electrons, it is said to have been oxidized.

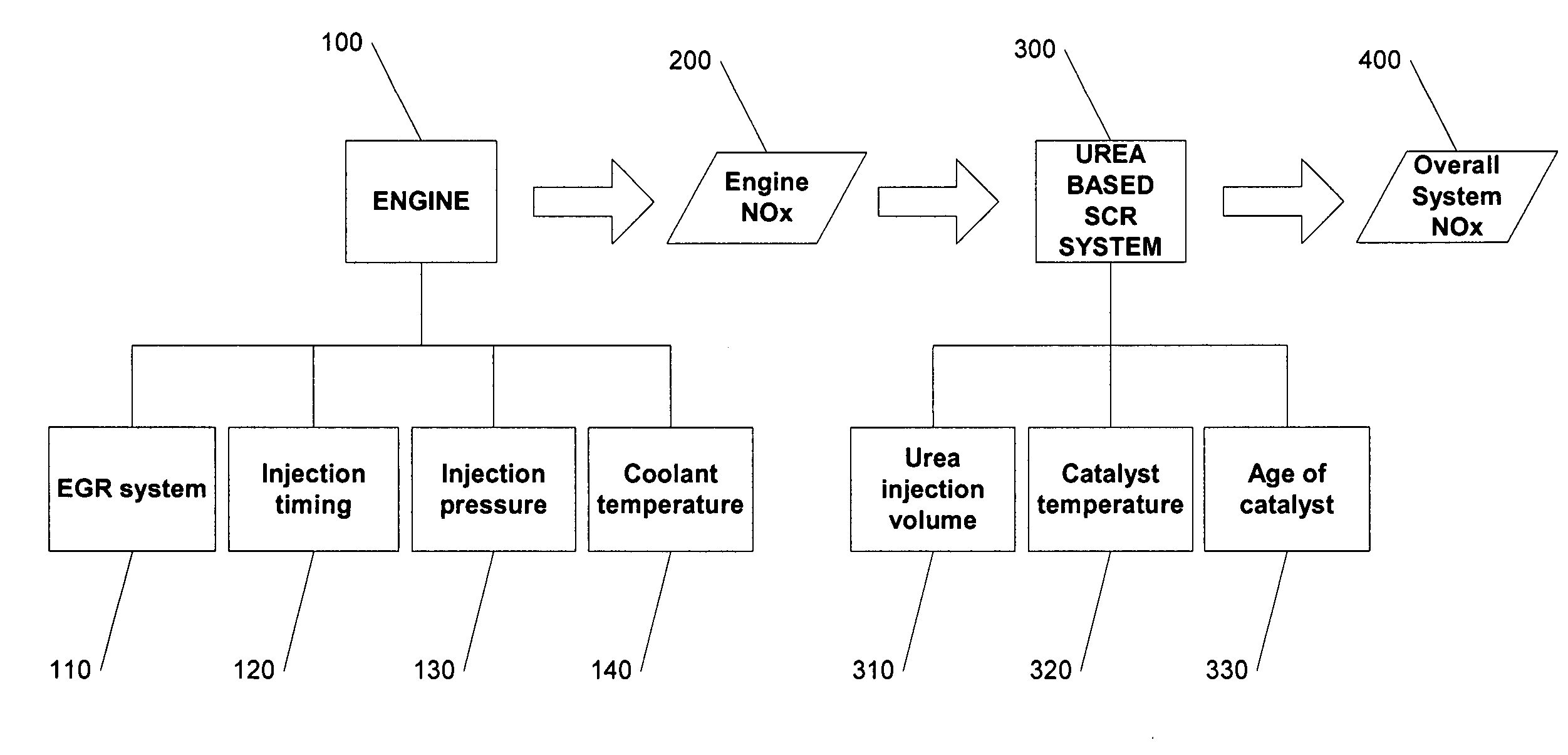

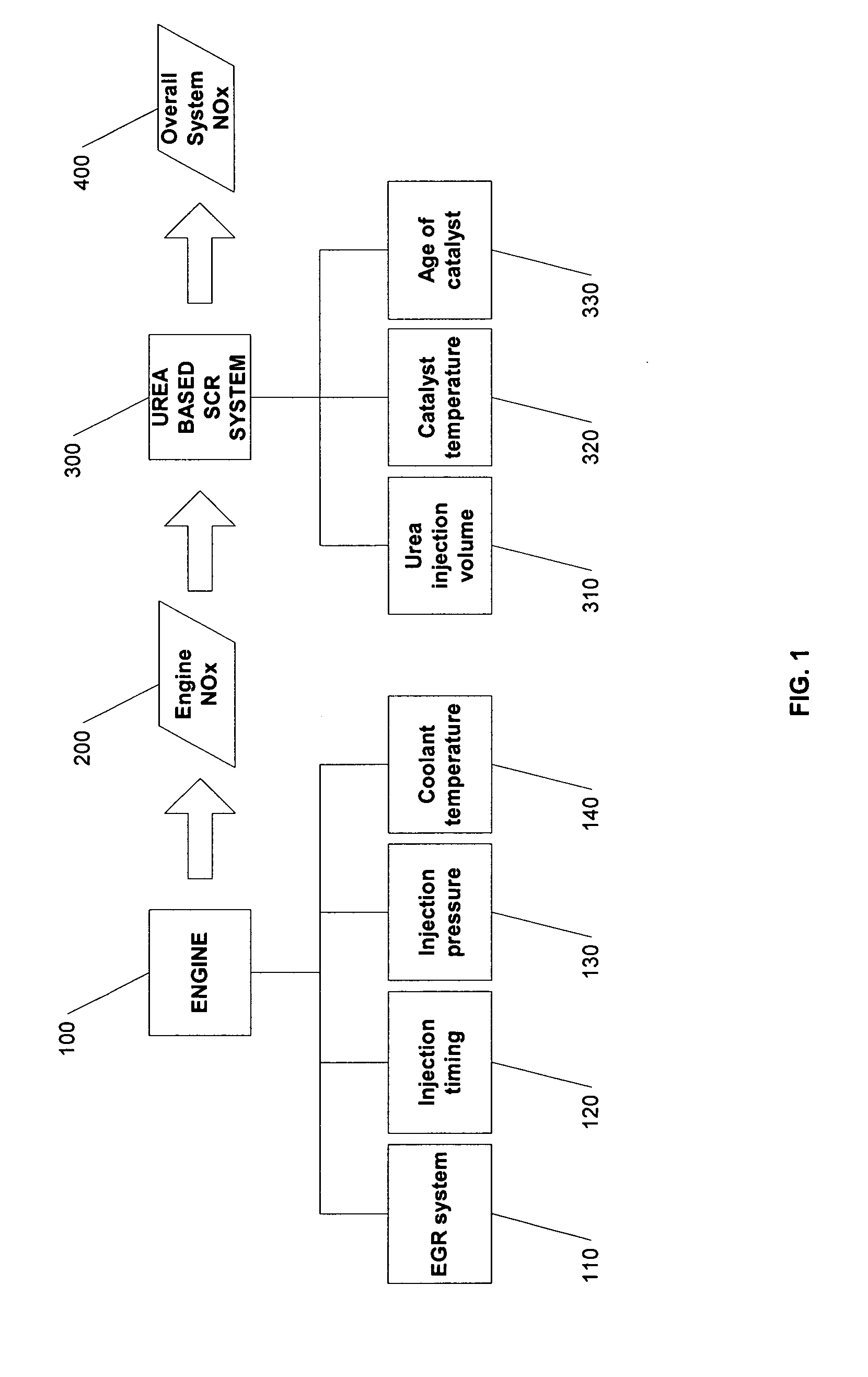

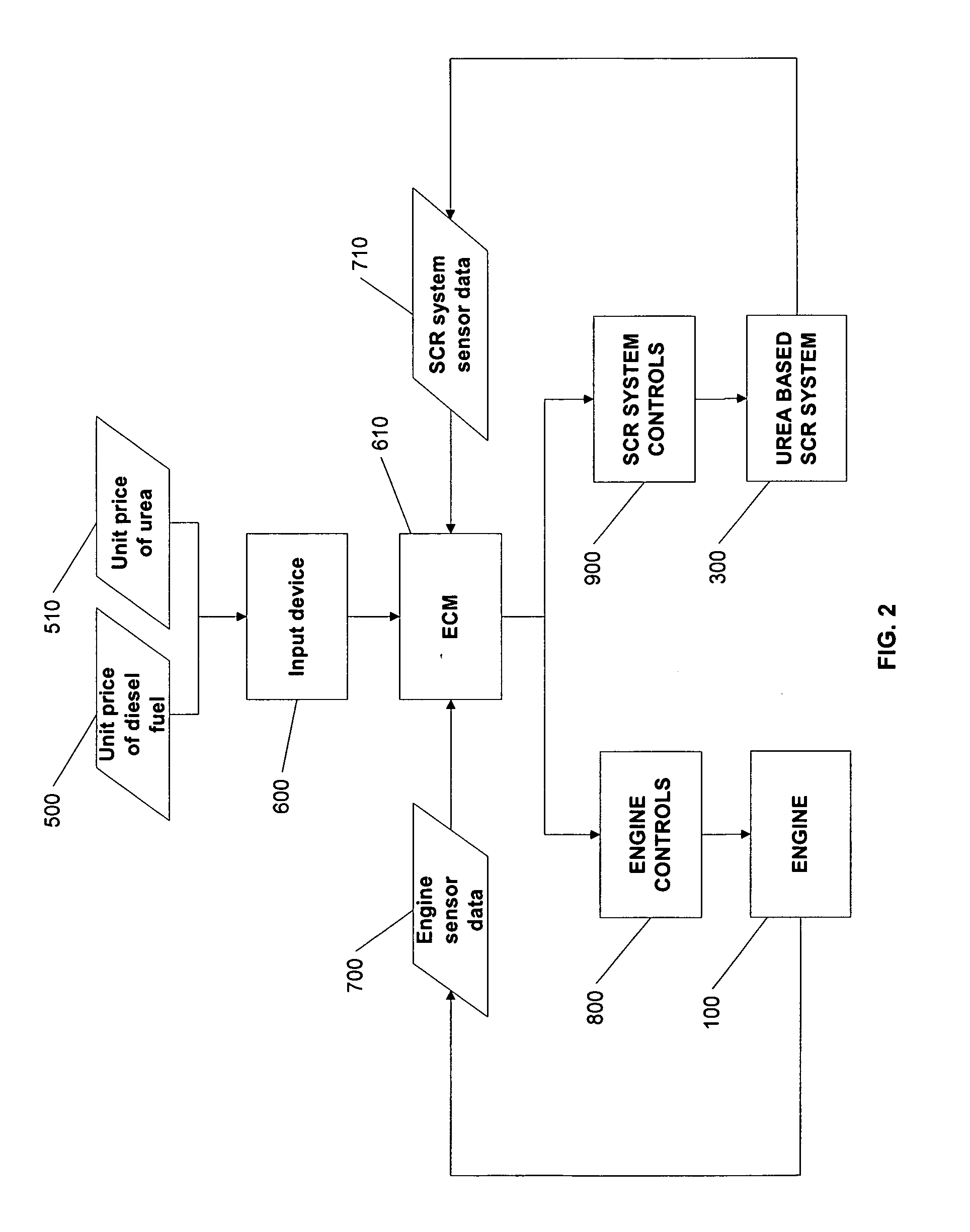

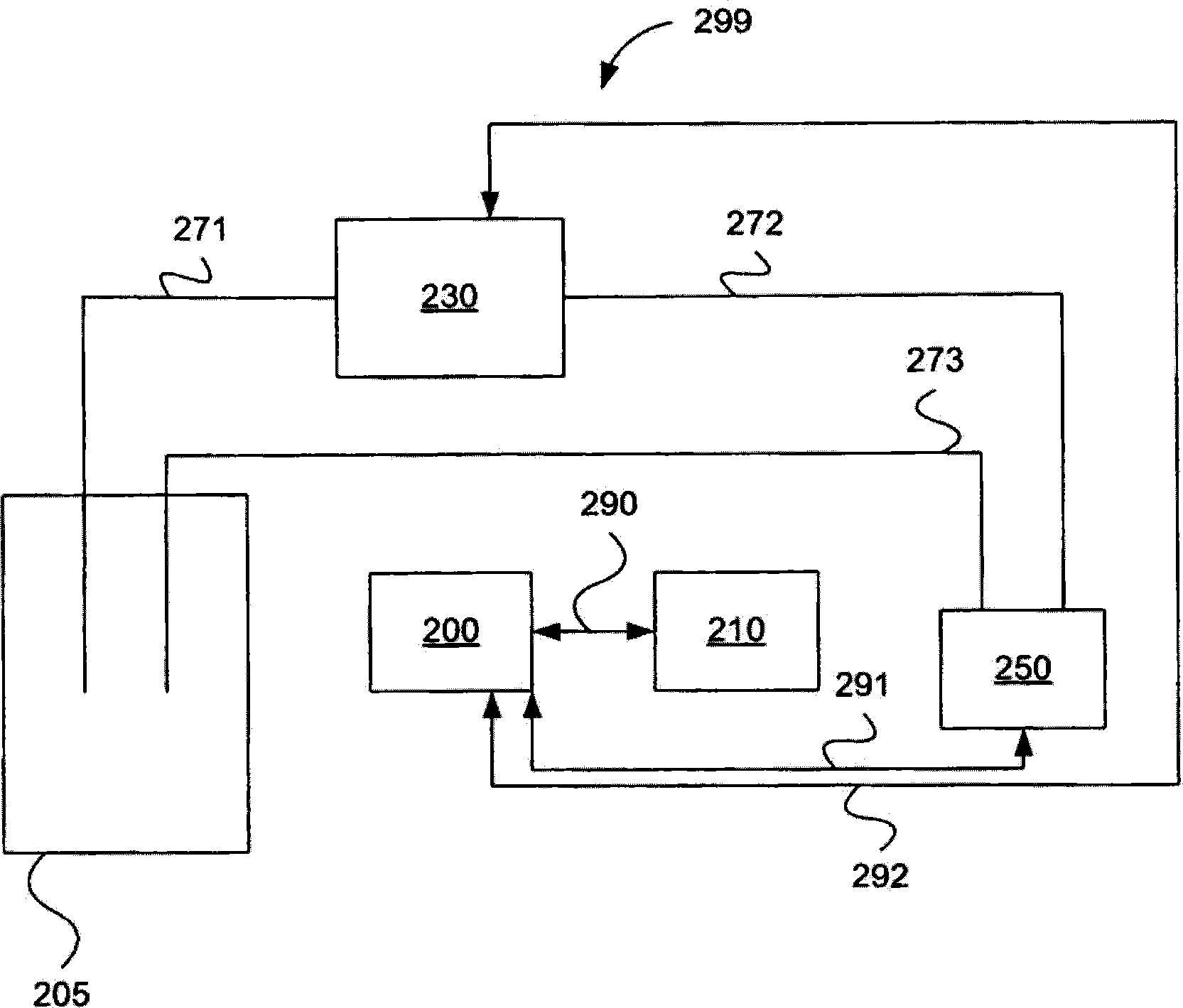

System and method for NOx reduction optimization

ActiveUS20070163244A1Reduced fuel efficiencyReduce nitrogen oxide contentAnalogue computers for vehiclesElectrical controlExhaust gas recirculationDiesel engine

Owner:CUMMINS INC

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareImprove performanceLiquid carbonaceous fuelsFuel additivesNew energyOil additive

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:YONGZHOU JINZHEN NEW ENERGY DEV CO LTD

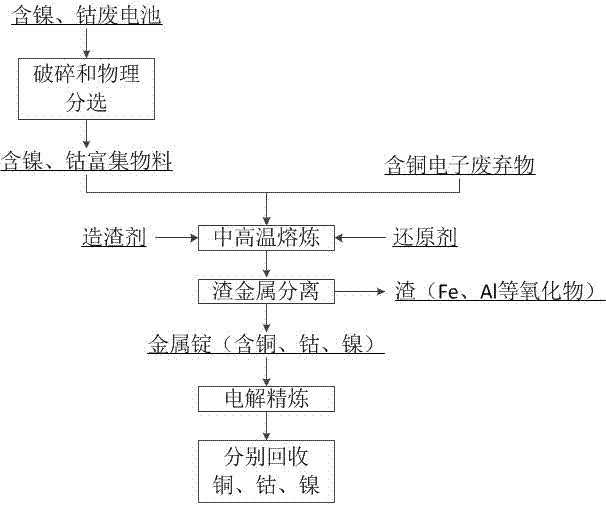

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

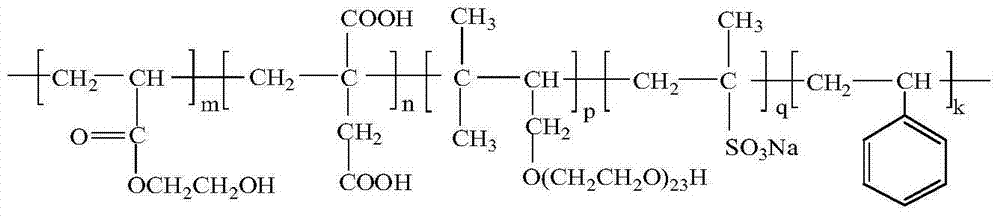

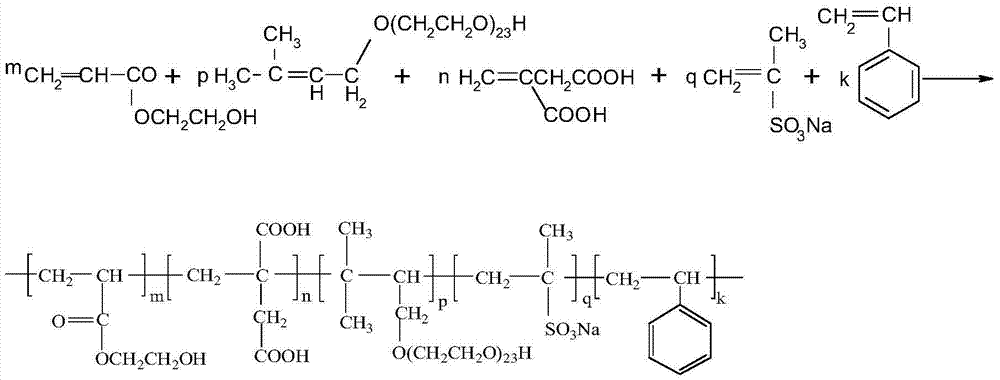

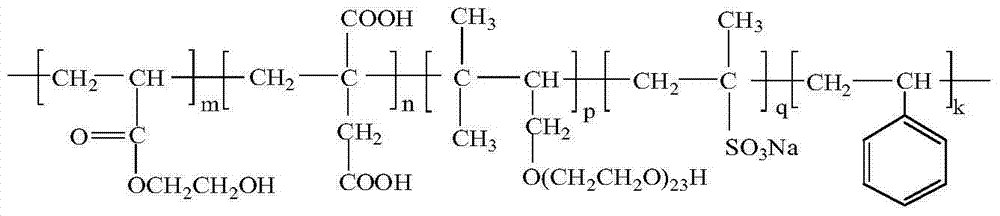

Water-reducing polycarboxylic concrete slump retaining agent and preparation method thereof

Owner:WUHAN UNIV OF TECH

Colored continuous-phase silicone-acrylic emulsion reactable with protective glue and preparation method thereof

Owner:中山市巴德富化工科技有限公司

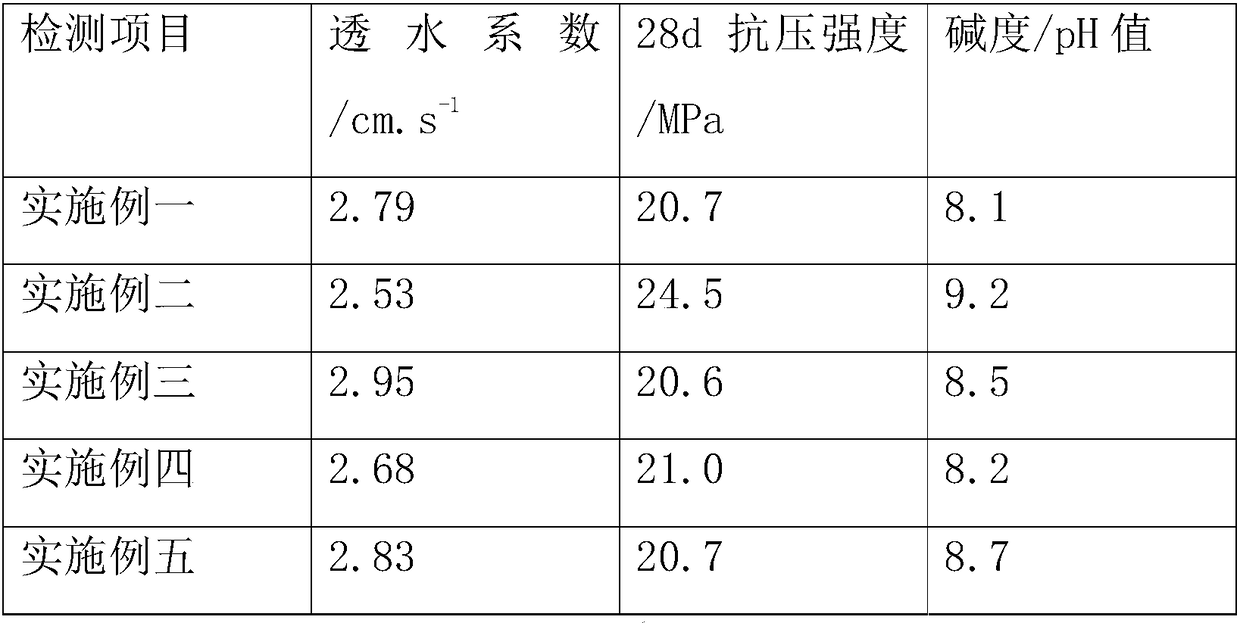

Plant growth type porous concrete suitable for plant growth

ActiveCN108101452AHigh compressive strengthHigh strengthExcrement fertilisersBioloigcal waste fertilisersFiberCompost

Owner:CHONGQING JIAOTONG UNIVERSITY

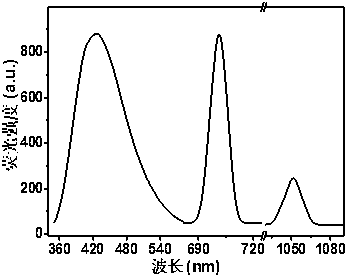

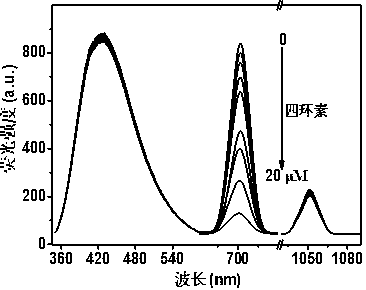

Preparation of fluorogold nano-clusters and application of fluorogold nano-clusters to tetracycline and copper fluorescent probes

PendingCN108760700AFluorescence intensity does not affectReduce distractionsMaterial nanotechnologyTransportation and packagingUltravioletQuenching

Owner:云南健牛环境监测有限公司

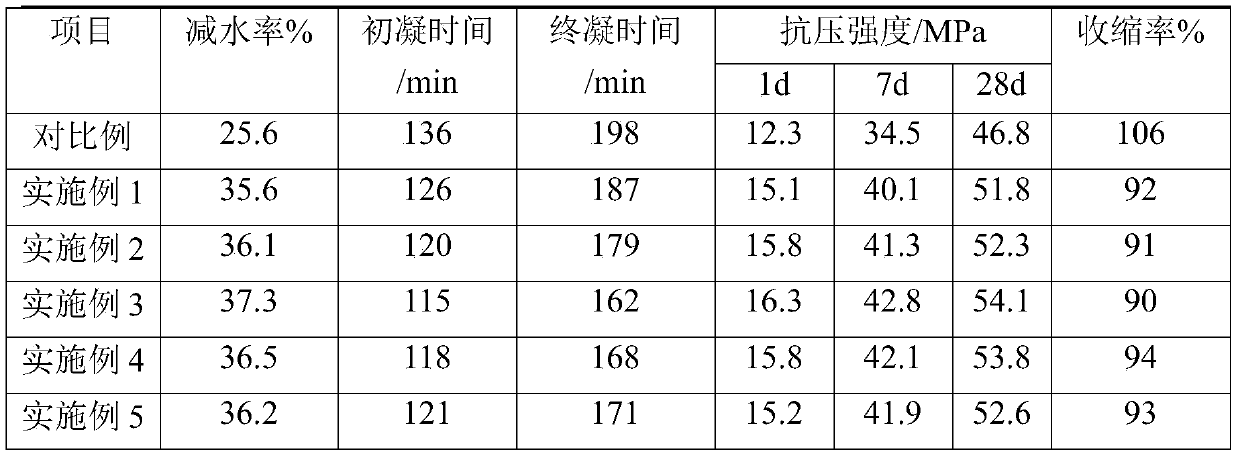

Powdery polycarboxylic acid water reducing agent, preparation method therefor and application of powdery polycarboxylic acid water reducing agent

The invention discloses a powdery polycarboxylic acid water reducing agent and a preparation method therefor. The water reducing agent contains the following ingredients: 100 parts of macromonomer A, 10-20 parts of monomer B, 0.6-2 parts of initiator and 0.6-2 parts of chain transfer agent, wherein the macromonomer A is R1-O-[CH2-CH2O]m-[CH2-CH(CH3)O]n-R2; and the monomer B is liquid-state unsaturated carboxylic acid. The method comprises the steps: mixing the macromonomer A with 5% to 20% of the monomer B, heating the mixture to 50 DEG C to 70 DEG C, and adding 60% to 80% of the initiator into the mixture; dropwise adding a mixed solution of the chain transfer agent and the rest of the monomer B, wherein the time for dropwise adding is 2 to 4 hours, 60% to 85% of the mixed solution is dropwise added uniformly in first 1 / 2 to 2 / 3 of the time, and the rest of the mixed solution is dropwise added uniformly in remaining time; and carrying out a heat-preservation reaction for 1 to 2 hours, and then, carrying out cooling and crushing. The powdery polycarboxylic acid water reducing agent disclosed by the invention is good in dispersity, high in water reducing rate, small in blended amount and good in slump loss resistant performance.

Owner:SHANGHAI DONGDA CHEM

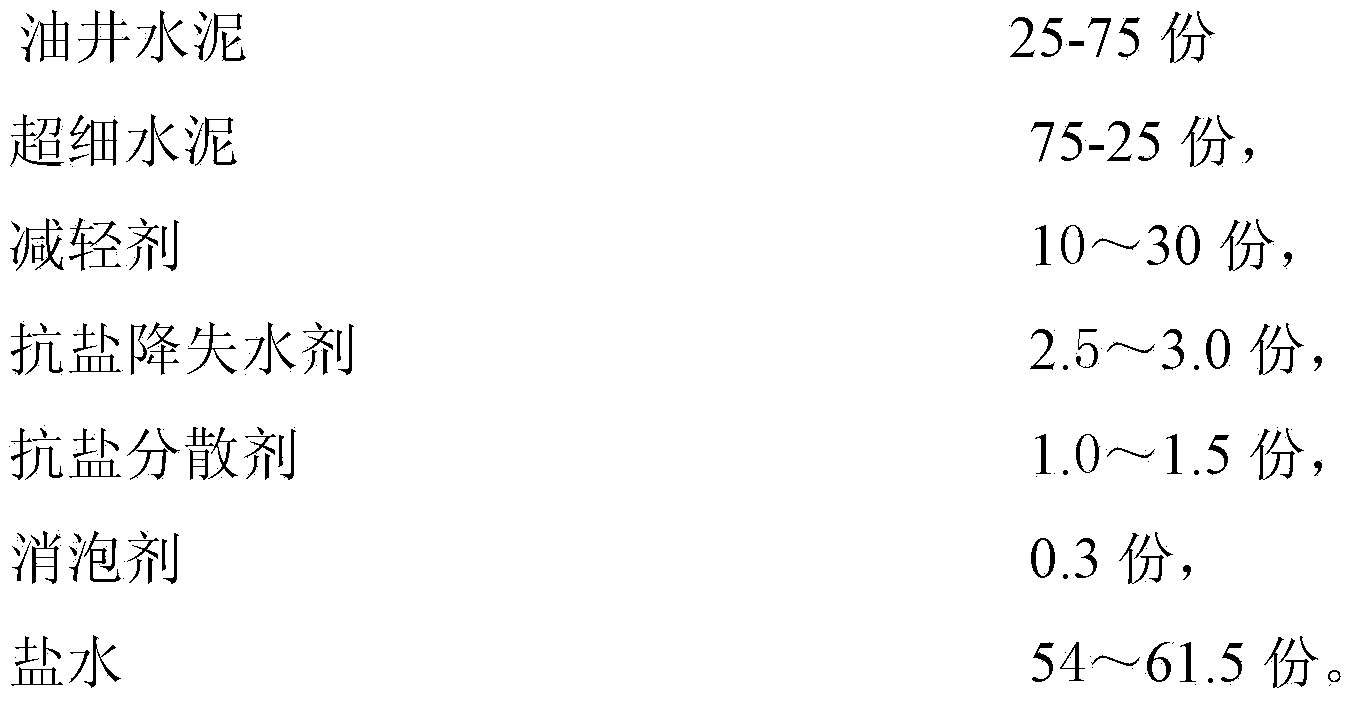

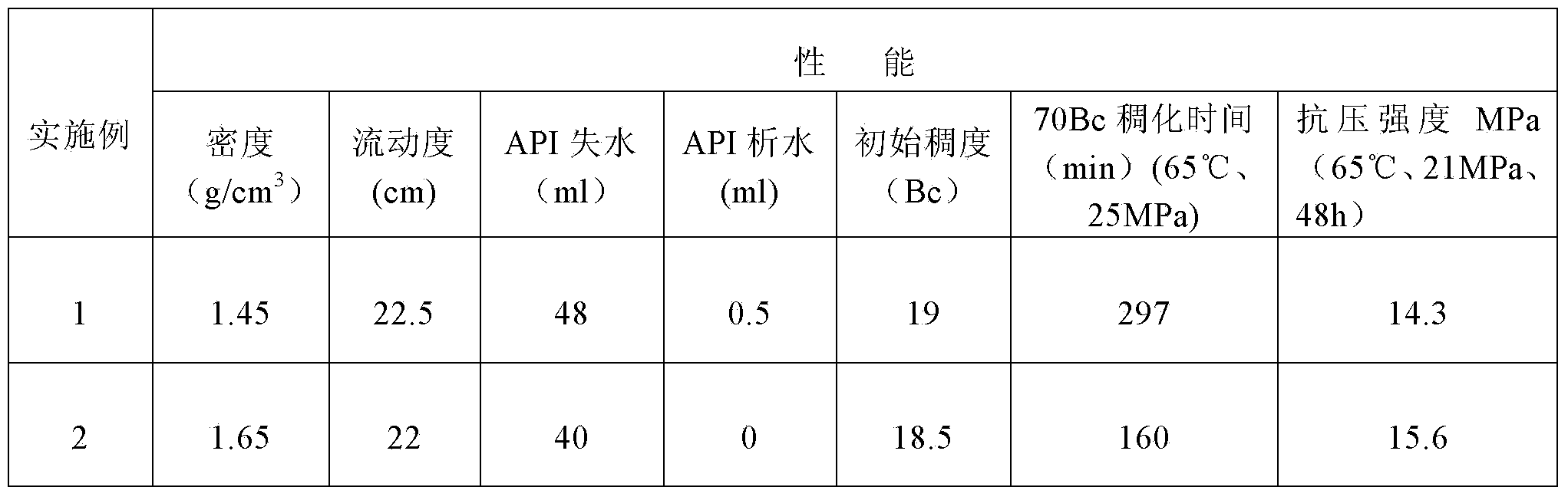

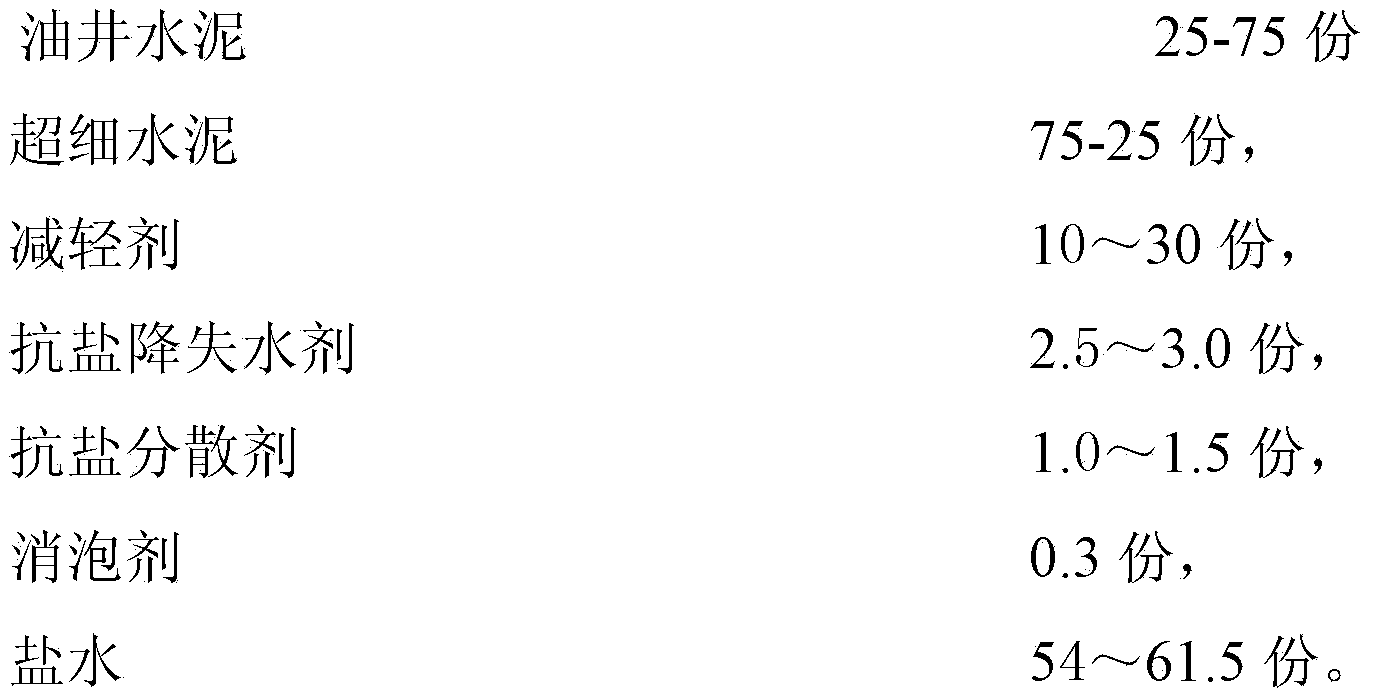

Low-density cement paste for salt-cavern gas storage well cementation

InactiveCN103865501ASolve quality problemsHigh bulk densityDrilling compositionMicrofine cementSalt deposit

Owner:CNPC BOHAI DRILLING ENG

Hexavalent chromium reducing agent and preparation method thereof

The invention provides a hexavalent chromium reducing agent and a preparation method thereof. The reducing agent contains the following components in parts by weight: 50-90 parts of an iron-based reducing agent, 0.57-3.6 parts of nanometer zero-valent iron and 0.9-7.1 parts of a dispersing agent. According to the hexavalent chromium reducing agent provided by the invention, an iron-based reducingagent is uniformly packaged by a dispersing agent solution containing nanometer zero-valent iron particles, and very high reaction activity is achieved by mixing nanometer zero-valent iron with the iron-based reducing agent, so that hexavalent chromium in the reducing agent solution can be rapidly reduced; dispersing agent molecules are capable of stabilizing nanometer zero-valent iron and packaging the iron-based reducing agent, so that the oxidation of the iron-based reducing agent by oxygen in the air is prevented, the hexavalent chromium reducing agent has a moisture preserving function, and the situations that because the partial water-entraining iron-based reducing agent is dehydrated under a high temperature condition, the solubleness is reduced, and the iron-based reducing agent isunlikely to participate in the reducing reaction of hexavalent chromium are prevented.

Owner:DONGYUAN HONGCHAO TECH

Method pertaining to an SCR system and an SCR system

InactiveCN103906903AReplacement Interval OptimizationTimely replacementInternal combustion piston enginesRegistering/indicating working of vehiclesEngineeringDosing units

Owner:SCANIA CV AB

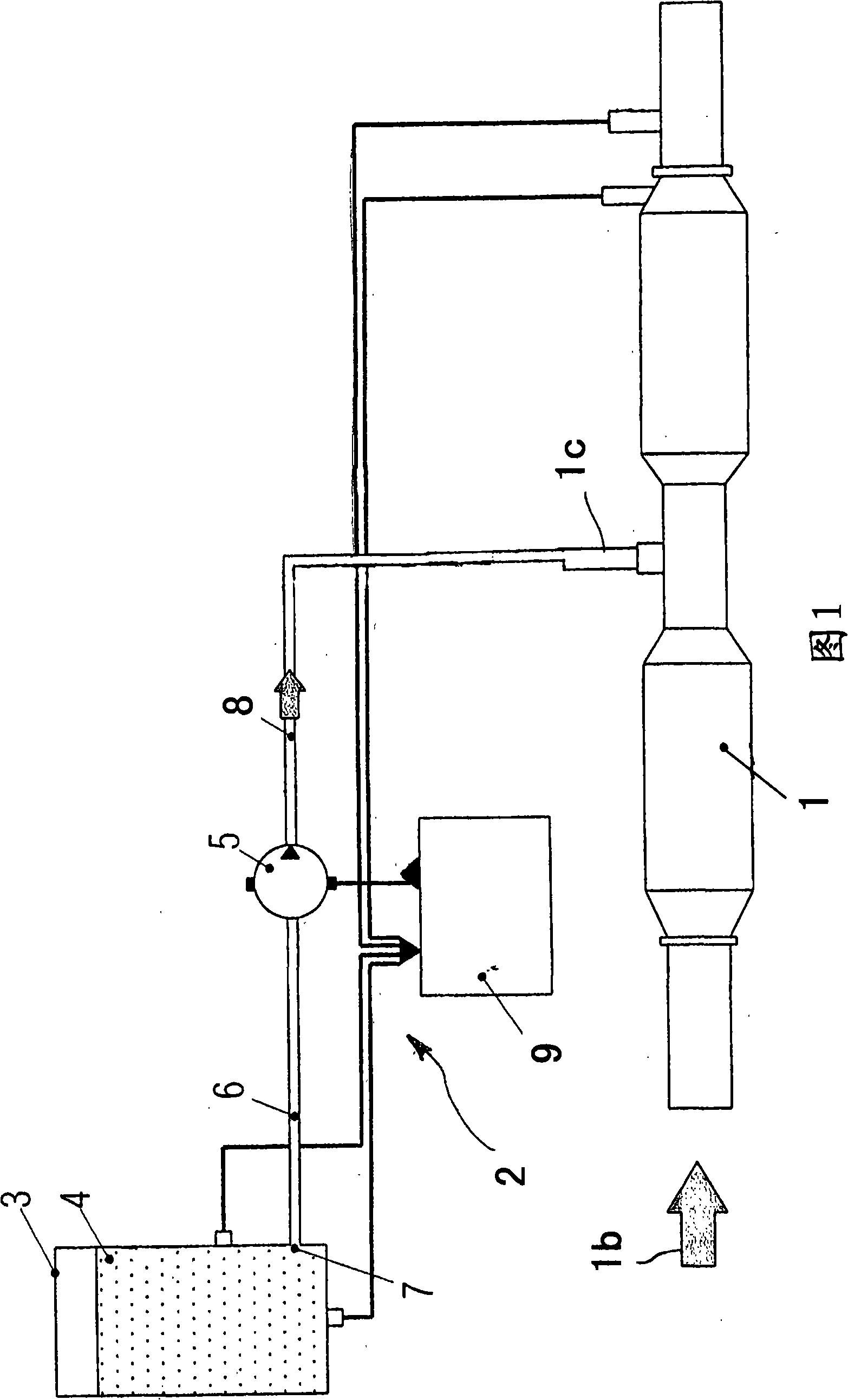

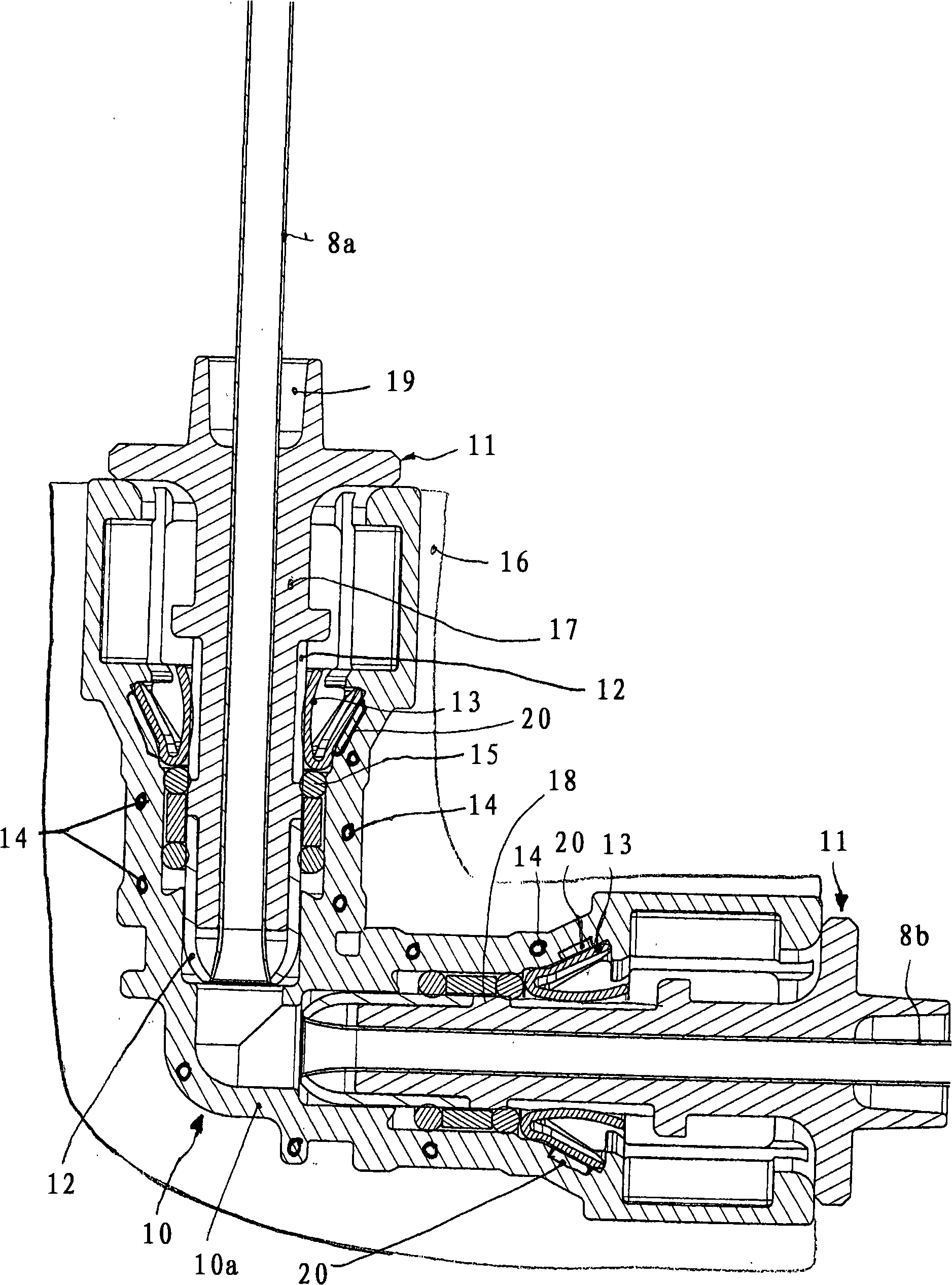

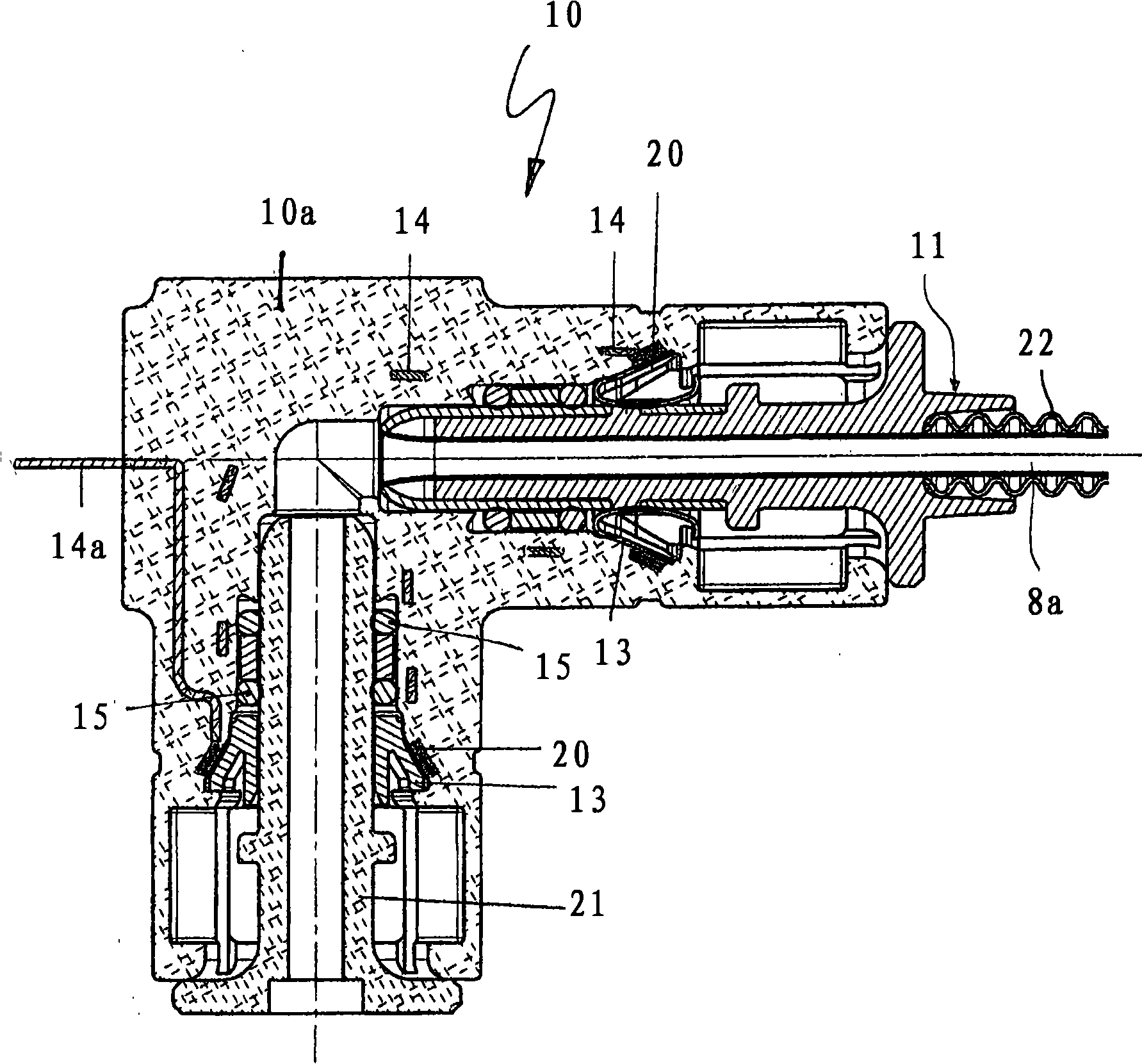

Reducing reagent supply system of internal-combustion engines and connecting component for connecting heating liquid conduit pipe thereof

InactiveCN101255812AEasy to installEasy to assembleExhaust apparatusDispersed particle separationElectricityCombustion

Owner:EICHENAUER HEIZELEMENTE

Weather-resistant impact-resistant waterproof plugging material with stable quality and its preparation method

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

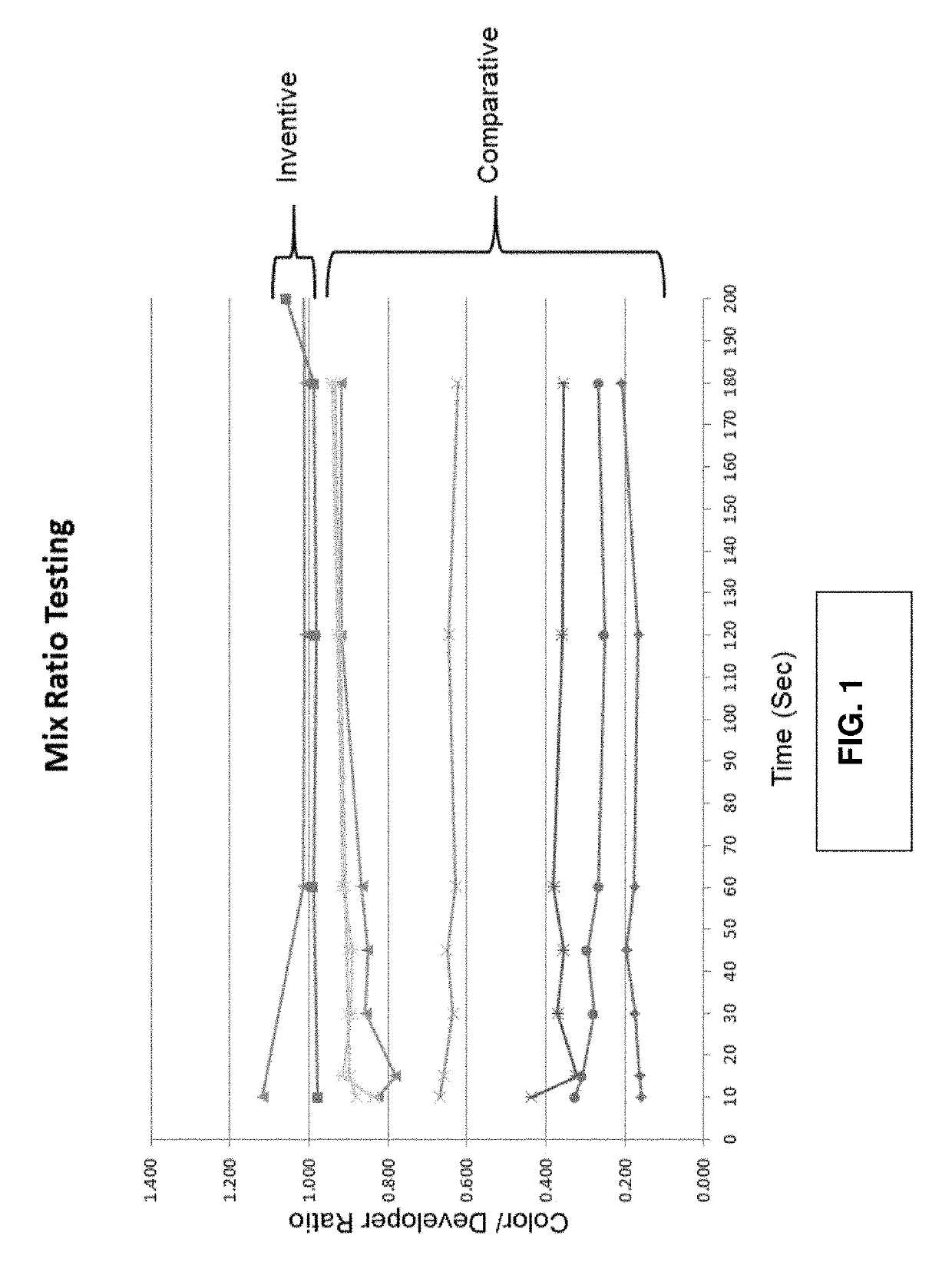

Hair color cartridge and compositions for use in the hair color cartridge

ActiveUS20190191844A1Combine accuratelyImprove consistencyCosmetic preparationsHair cosmeticsHair streamsWater soluble

Owner:LOREAL SA

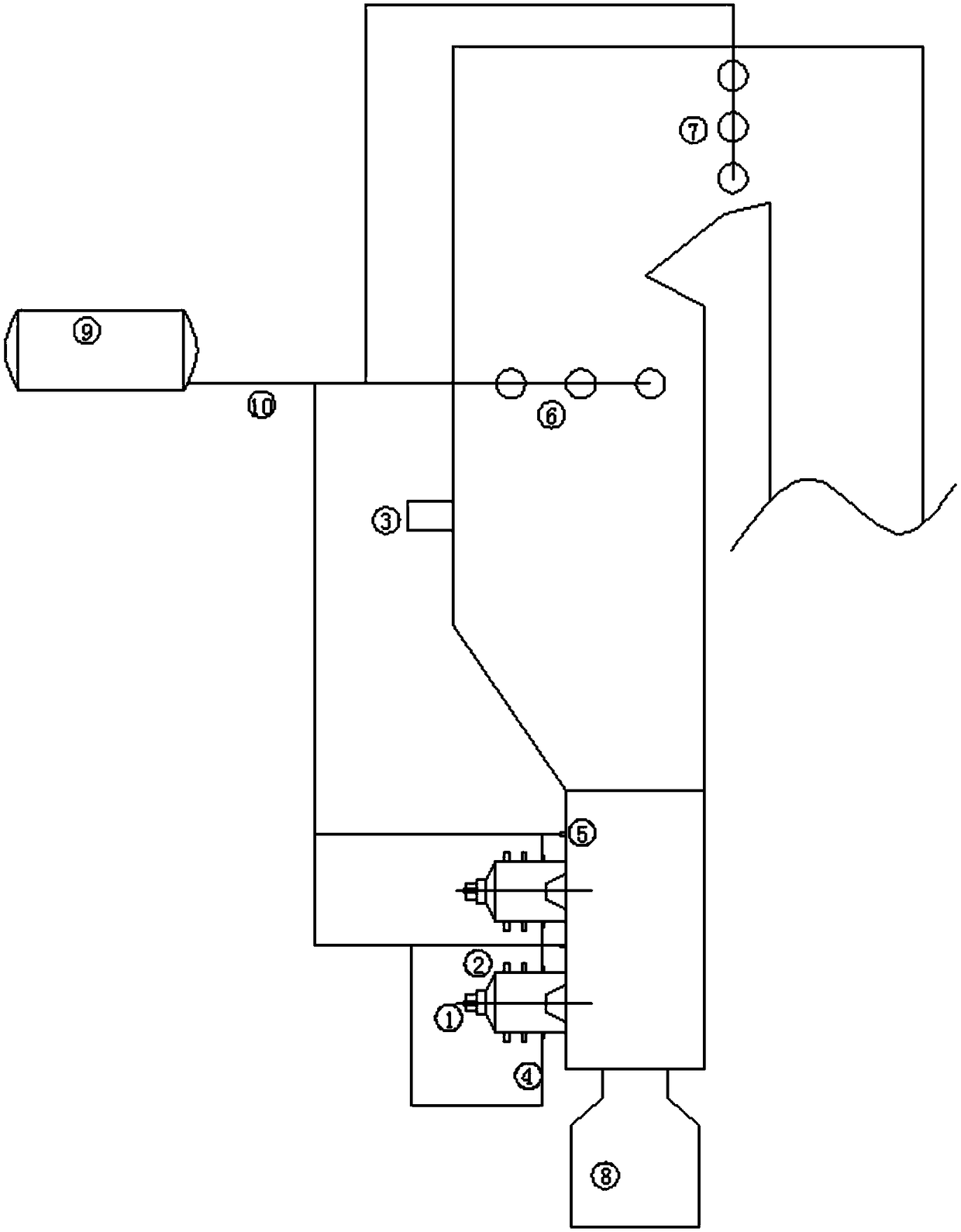

Cyclone furnace denitration system and method

PendingCN109058979AEmission reductionImprove economyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

Owner:CHINA HUANENG GRP CO LTD +1

Concrete high-efficiency water reducer and preparation method thereof

Owner:KUNMING ANXIA NEW MATERIAL SCI & TECH CO LTD

High-strength crack-resistant concrete and producing method thereof

Owner:南京加豪新型建筑材料有限公司

Method for preparing silver micron hollow frame structural material

Owner:合肥龙智机电科技有限公司

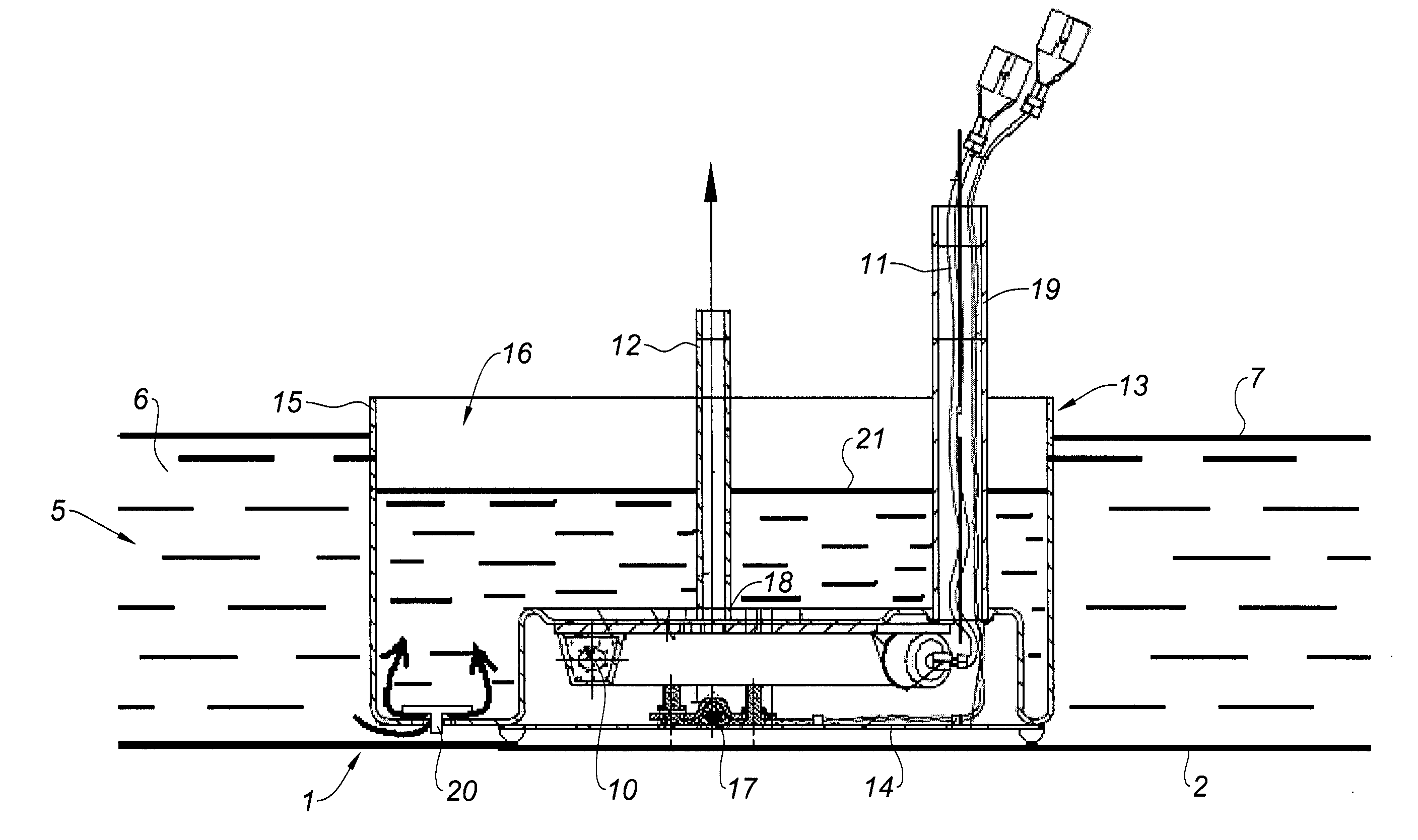

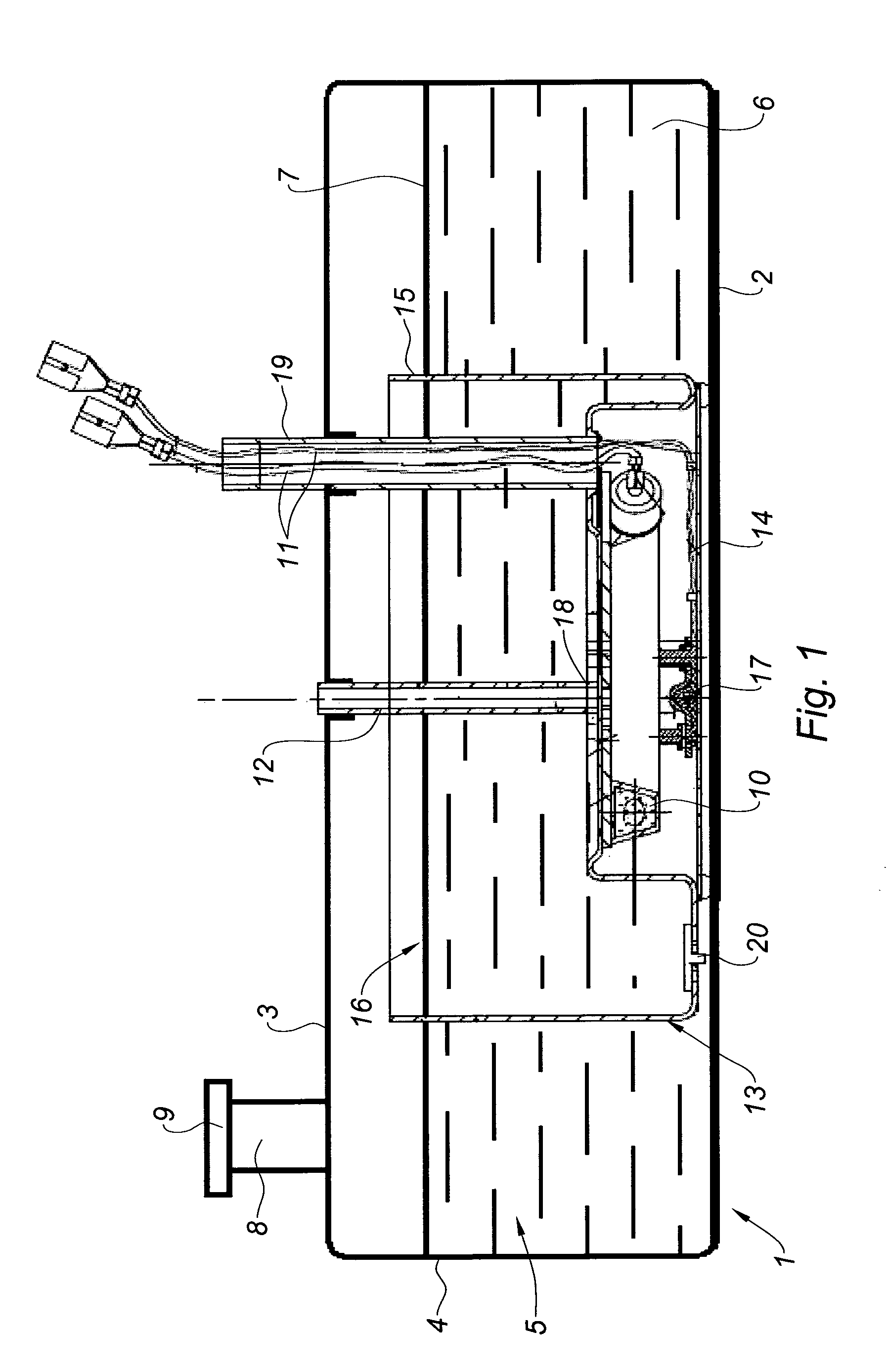

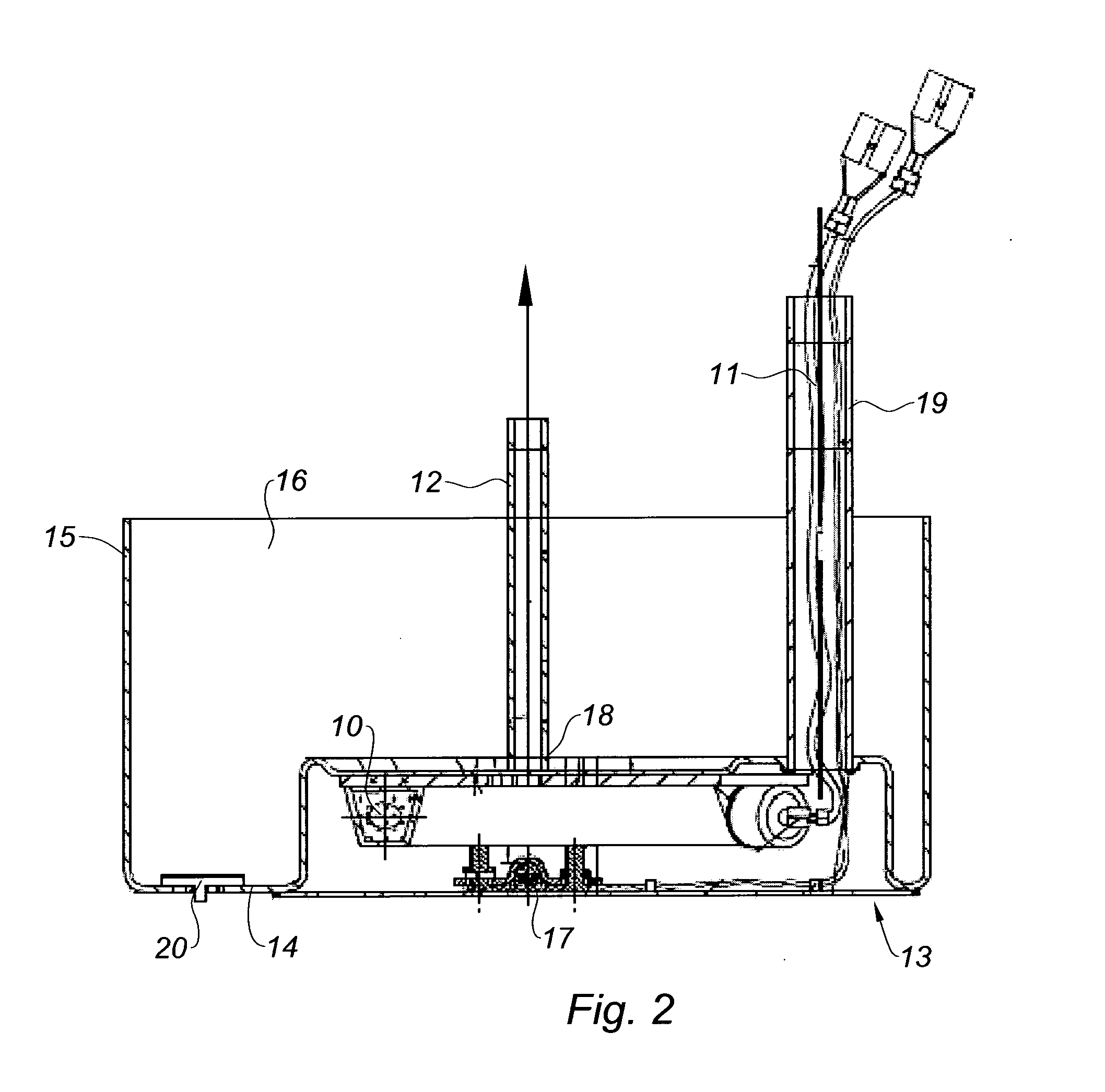

Fluid reservoir having a heating reserve bowl

InactiveUS20130129330A1Economical and fast and completely controllable operationEasy to solveInternal combustion piston enginesExhaust apparatusEngineeringPollution

Owner:MGI COUTIER SA

Novel ink

Owner:陈雁

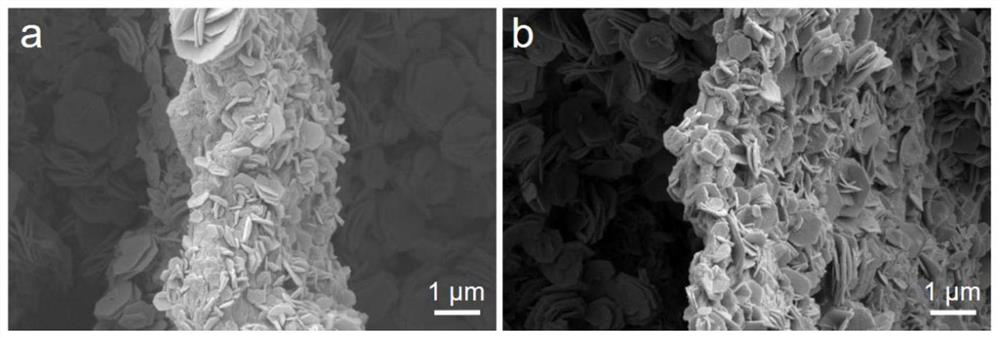

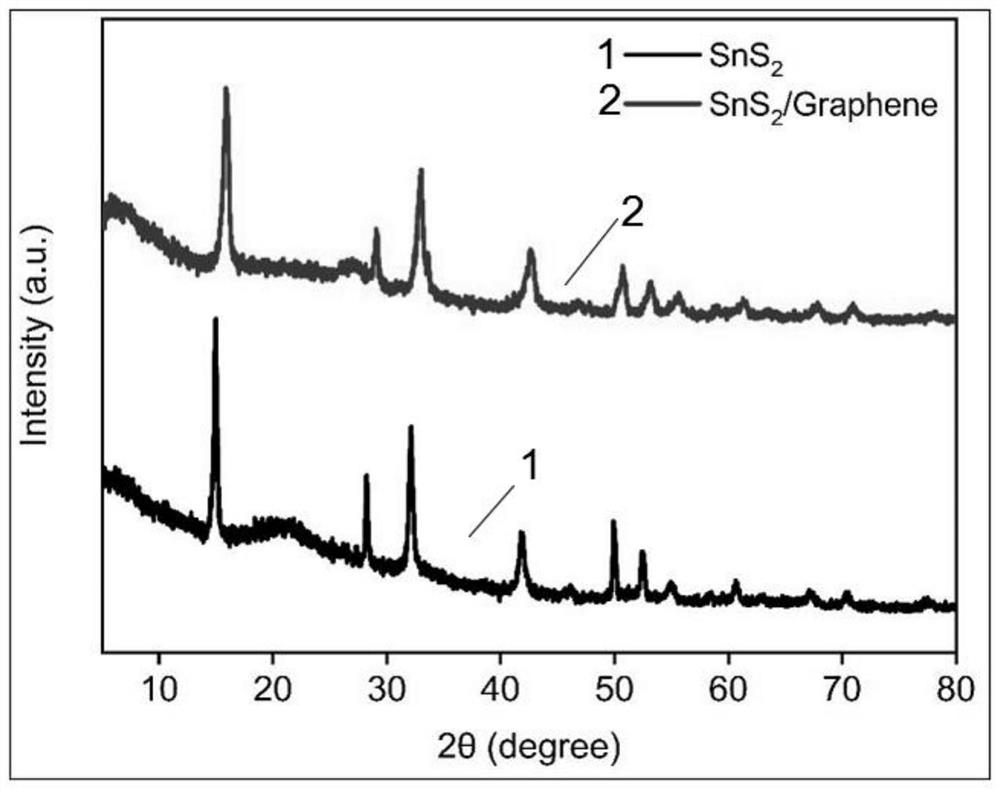

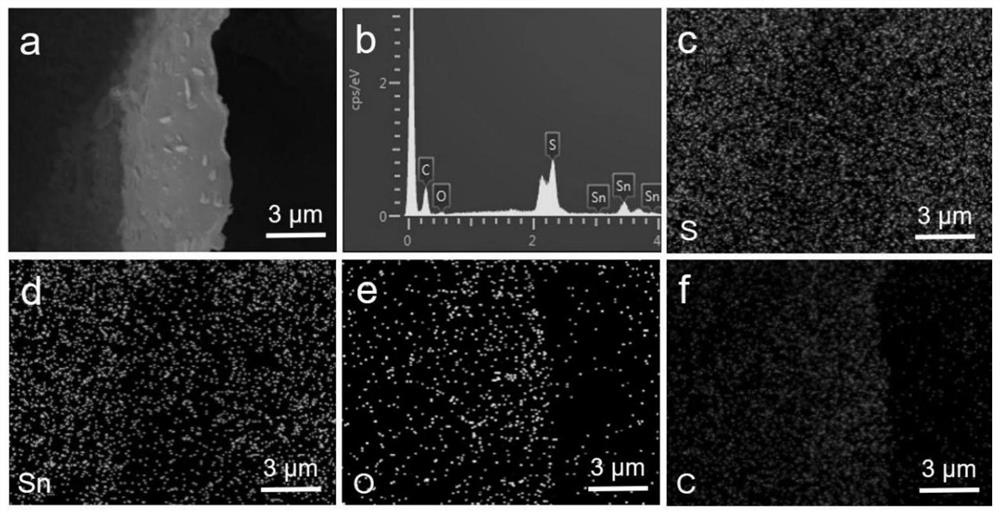

Preparation method of SnS2 nanosheet loaded graphene-based nanocomposite

Owner:安徽光特新材料科技有限公司

Method for comprehensively recycling sodium, aluminum and iron from red mud

ActiveCN108950212AAchieve deep dekalizationStrong magneticProcess efficiency improvementRed mudReducing agent

The invention discloses a method for comprehensively recycling sodium, aluminum and iron from red mud. The red mud is mixed with an additive to obtain a raw material, the mixed raw material is subjected to calcination to obtain clinker, the clinker is added to an alkaline adjustment liquid for leaching, slid-liquid separation is performed, and leachate containing aluminum and sodium and magnetic leaching residues are obtained; the additive is a mixed additive composed of a calcium-series additive, a magnesium-series additive and a sodium-series additive. According to the technical scheme, no reducing agent needs to be added, hematite or hematite is converted as magnesioferrite with high magnetism through the magnesium-series additive and enters the leaching residues, and then an iron ore concentrate product is obtained through magnetic separating. In the technical scheme, the atmosphere control process and generation of a great quantity of polluting atmosphere in the current iron recycling process are avoided. In the method, the aluminum recycling rate is 85%, the sodium recycling rate is 92% or above, the sodium content in final residues is lowered to 1% or below, the iron grade of the iron ore concentrate is 50-55%, and the recycling rate is about 70%.

Owner:CENT SOUTH UNIV

Highly water-retaining water-permeable brick prepared from building recycled material and preparation method thereof

Owner:广东怡兴食品有限公司

Nuclear power plant containment concrete

ActiveCN108059405AIncreased durabilityReduce porosityNuclear energy generationContainmentFiberCrack resistance

The invention relates to nuclear power plant containment concrete. The concrete consists of the following components in parts by mass: 130-200 parts of cement with strength of 52.5 or 42.5, 60-120 parts of slag, 50-100 parts of metakaolin, 50-150 parts of boron glass sand, 600-800 parts of nickel slag, 600-800 parts of barite, 200-400 parts of limonite, 100-300 parts of ceramsite, 20-50 parts of lead fibers, 130-160 parts of water, 4-6 parts of a water reducing agent and 4-6 parts of an early strength agent. After 28 days of curing of the concrete, the inner surface of the concrete is coated with a layer of anti-radiation coating. The nuclear power plant containment concrete provided by the invention has a good anti-radiation property, can well shield alpha, beta and gamma rays and neutronrays, and has good crack resistance, high-temperature resistance and durability, and simultaneously solid wastes such as nickel slag, glass powder and the like are utilized, so that the problems of resource waste and environmental pollution are solved to a certain extent.

Owner:SOUTHEAST UNIV

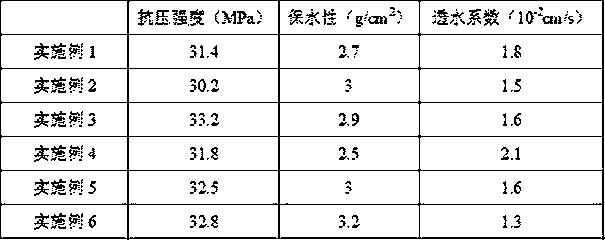

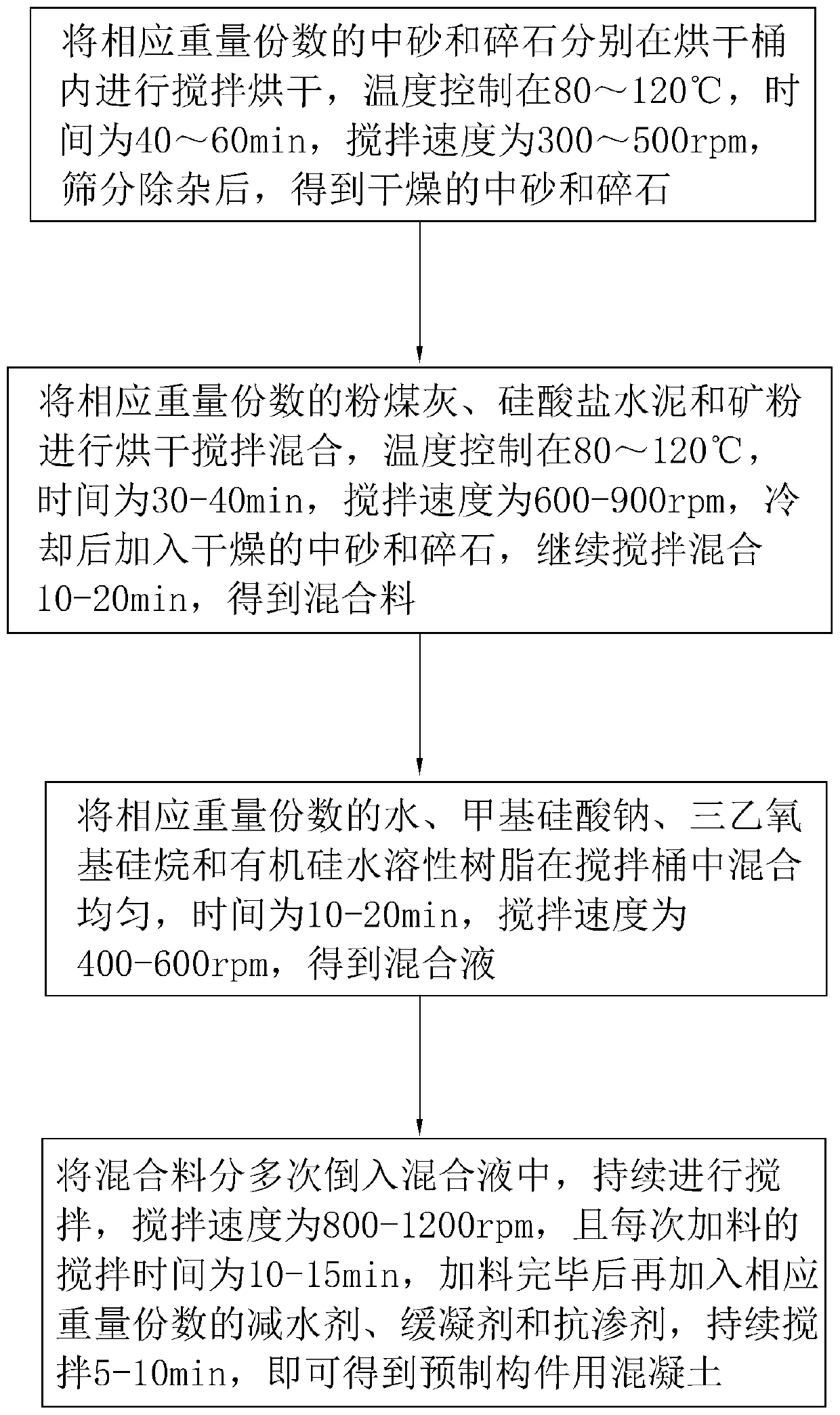

Concrete for prefabricated part and preparation method thereof

Owner:上海石化安东混凝土有限公司

Shield grouting material and preparation method thereof

Owner:北京华阳众信建材有限公司

Additive-free odorless super-stain-resistant acrylate emulsion and preparation method thereof

InactiveCN111205387AEasy to wrapIntertwined closelyAntifouling/underwater paintsPaints with biocidesPolymer scienceFunctional monomer

Owner:广东巴德富新材料有限公司

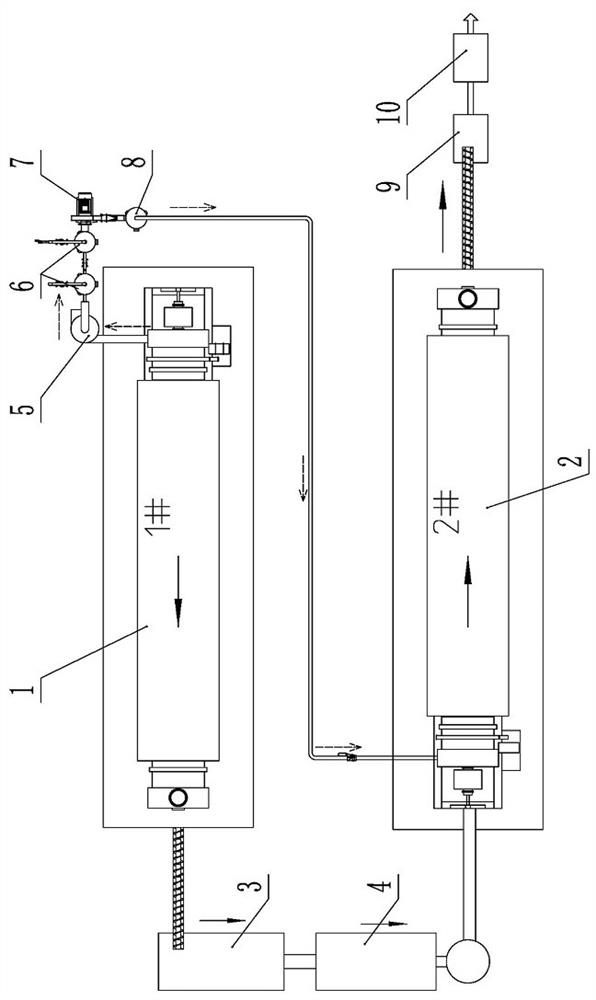

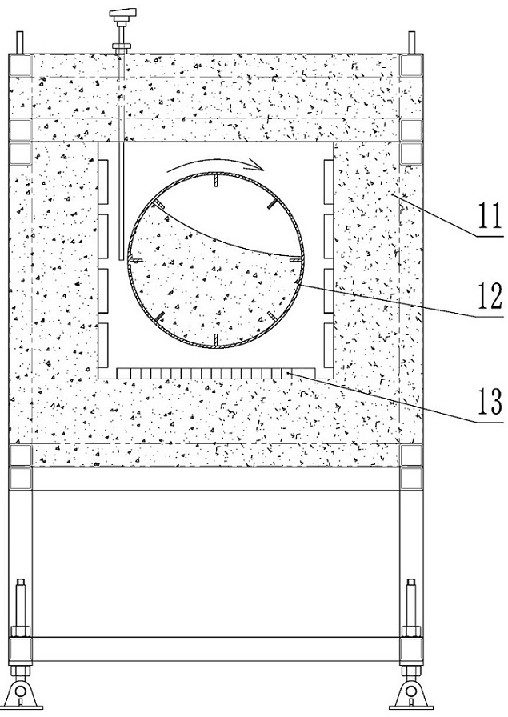

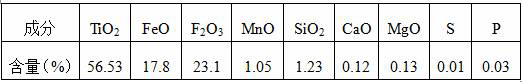

Preparation process and system for producing high-grade titanium-rich material by utilizing ilmenite

ActiveCN111733336AThere is no limit to the choice of materialsLow failure rateRotary drum furnacesMagnetic separationDust controlIlmenite

Owner:湖南碳谷装备制造有限公司

Dental Polymerizable Core Build-Up Material of Separately Packed Type

ActiveUS20070249752A1Easy to operateImprove mechanical propertiesImpression capsTeeth fillingMethacrylateMeth-

Owner:KURARAY NORITAKE DENTAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap