Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Gasoline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gasoline (American English), or petrol (British English), is a colorless petroleum-derived flammable liquid that is used primarily as a fuel in spark-ignited internal combustion engines. It consists mostly of organic compounds obtained by the fractional distillation of petroleum, enhanced with a variety of additives. On average, a 42-U.S.-gallon (160-liter) barrel of crude oil yields about 19 U.S. gallons (72 liters) of gasoline (among other refined products) after processing in an oil refinery, though this varies based on the crude oil assay.

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareImprove performanceLiquid carbonaceous fuelsFuel additivesNew energyOil additive

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:YONGZHOU JINZHEN NEW ENERGY DEV CO LTD

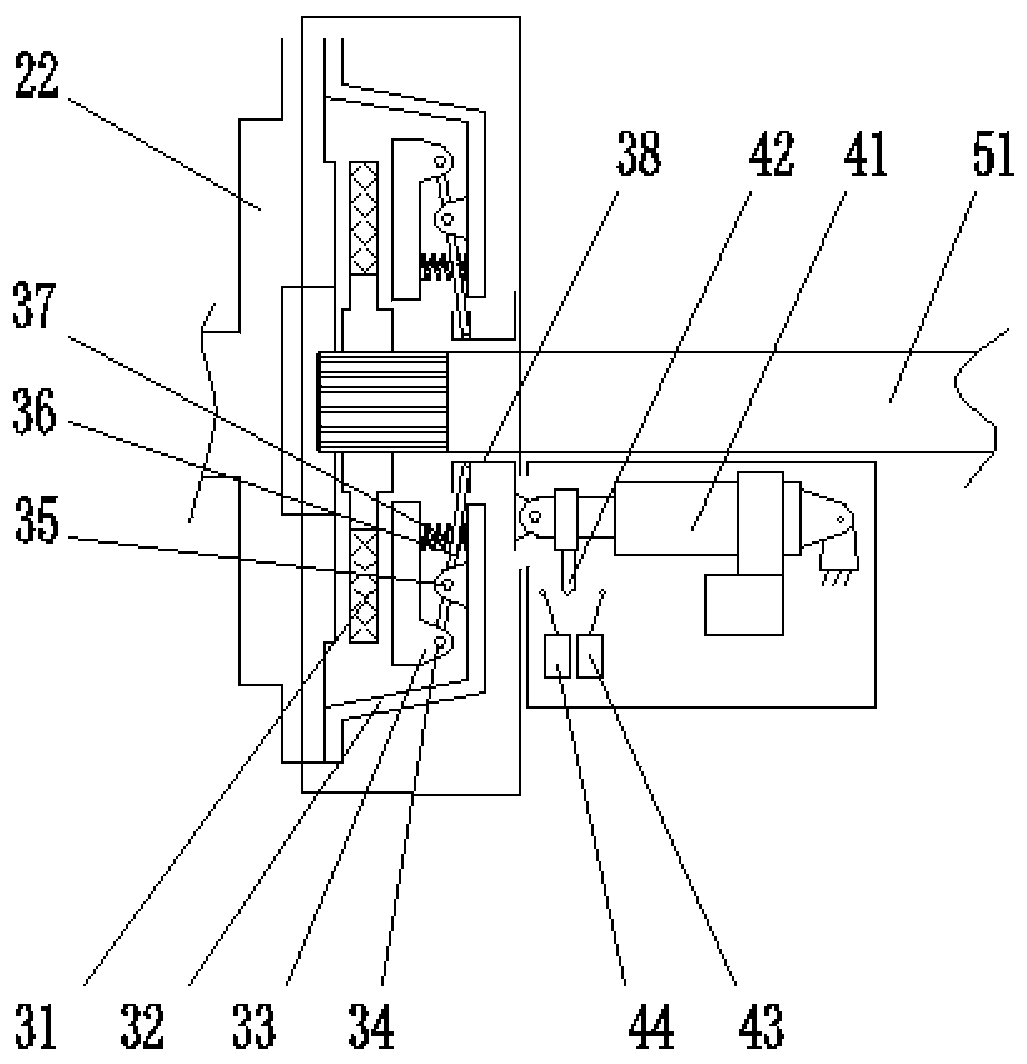

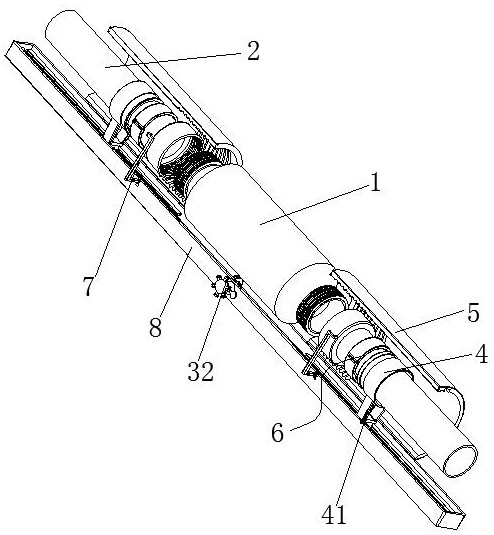

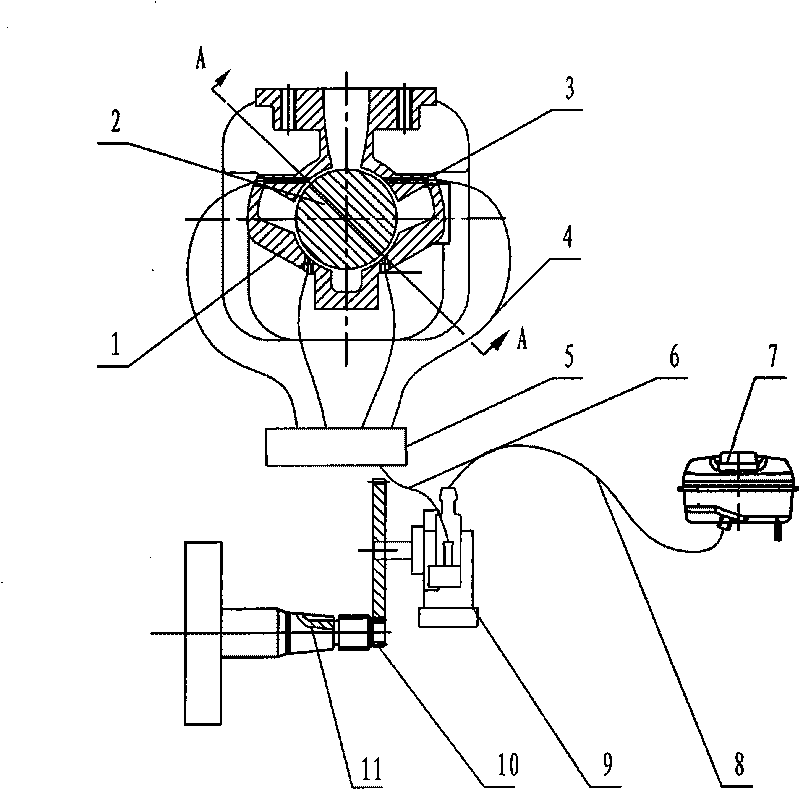

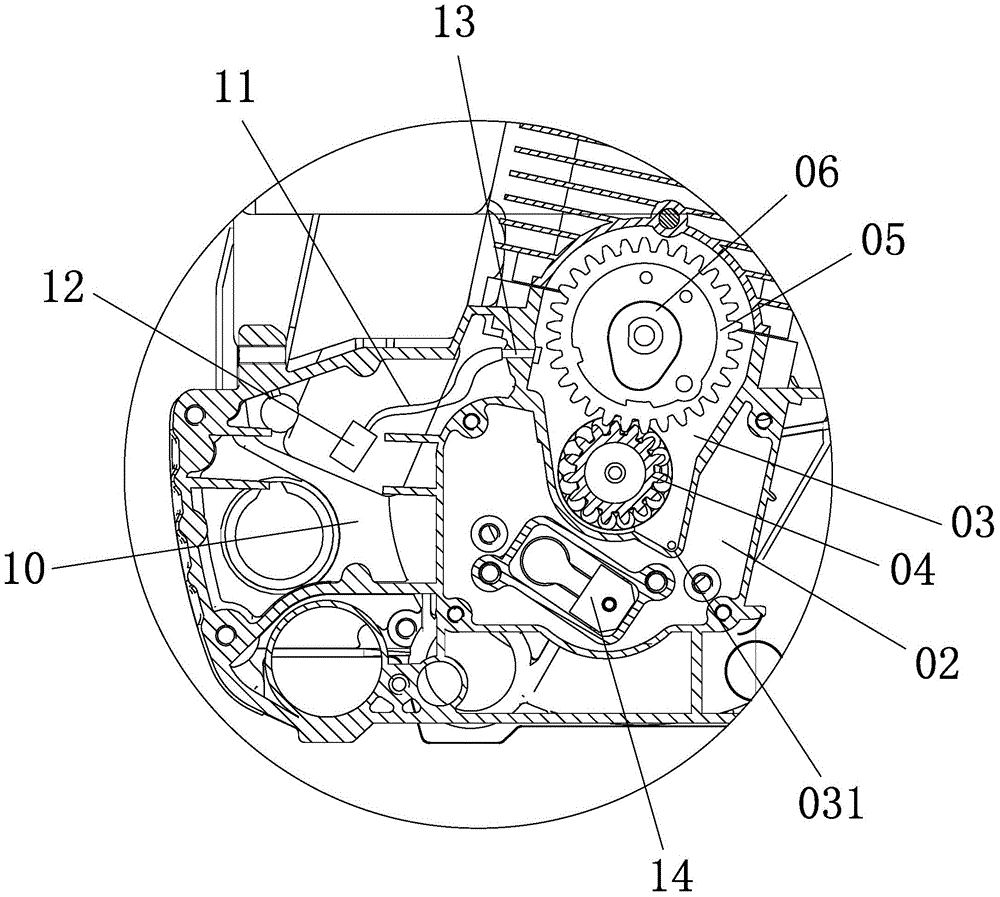

Engine exhaust gas recirculation (EGR) valve closed-loop control system

InactiveCN103089460AImprove combustion effectEngine controllersMachines/enginesProportion integration differentiationLoop control

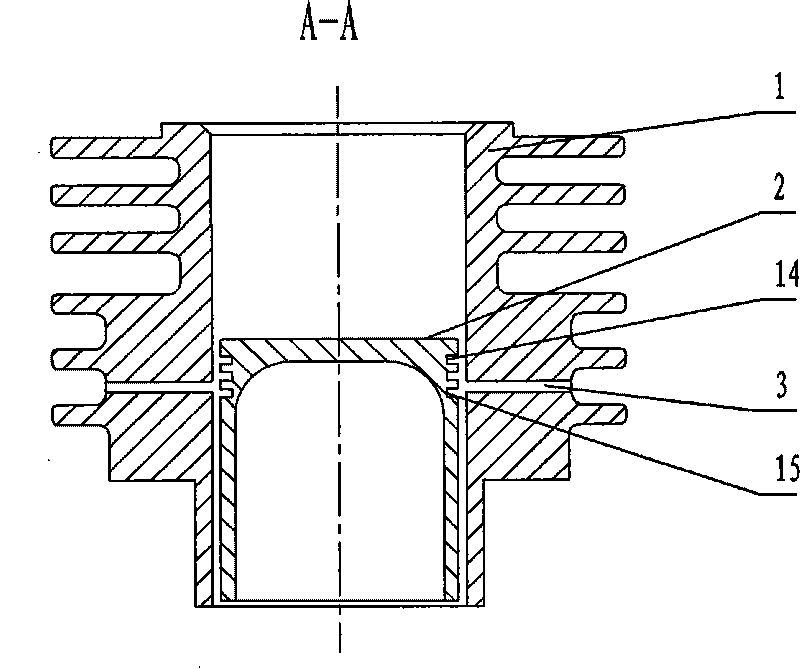

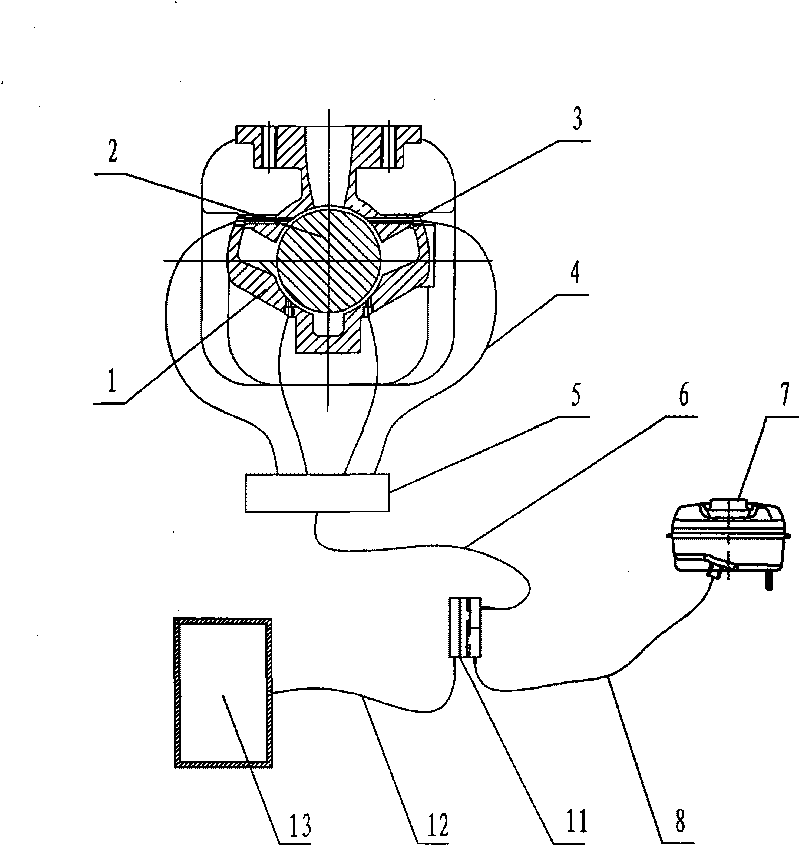

The invention relates to the field of engine exhaust gas recirculation rate control, in particular to an engine exhaust gas recirculation (EGR) valve closed-loop control system which comprises an EGR valve, a target EGR rate selection module, an actual EGR rate measurement module and a proportion integration differentiation (PID) controller. The target EGR rate selection module stores target EGR rates under different work conditions, the actual EGR rate measurement module can measure the actual EGR rate of an EGR valve under the current work condition, the actual EGR rate measurement module can send the actual EGR rate under the current work condition to the PID controller, and the target EGR rate selection module can send a target EGR rate corresponding to the current work condition to the PID controller. If the actual EGR rate and the target EGR rate are identical, the EGR valve remains valve core opening degree. If the actual EGR rate and the target EGR rate are different, the valve core opening degree of the EGR valve is adjusted so as to adjust the EGR rate. The system can monitor the EGR rate in real time, guarantees that the actual EGR rate and the target EGR rate are identical, enables an engine to be in the best condition and improves gasoline combustion performance.

Owner:CHERY AUTOMOBILE CO LTD

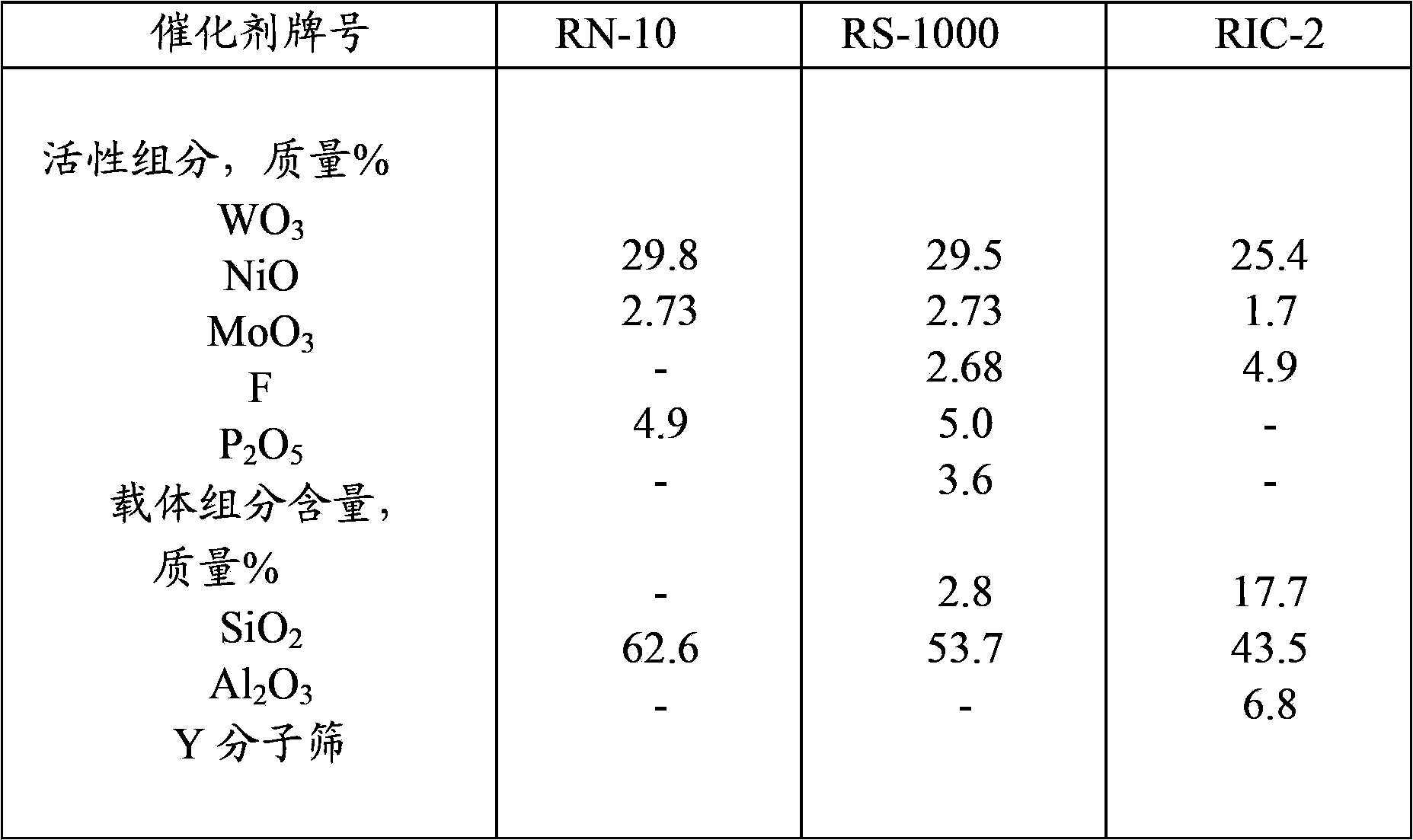

Hydrogenation catalyst and preparation method thereof

ActiveCN101062484AOrganic reductionCatalyst carriersPorous metalGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

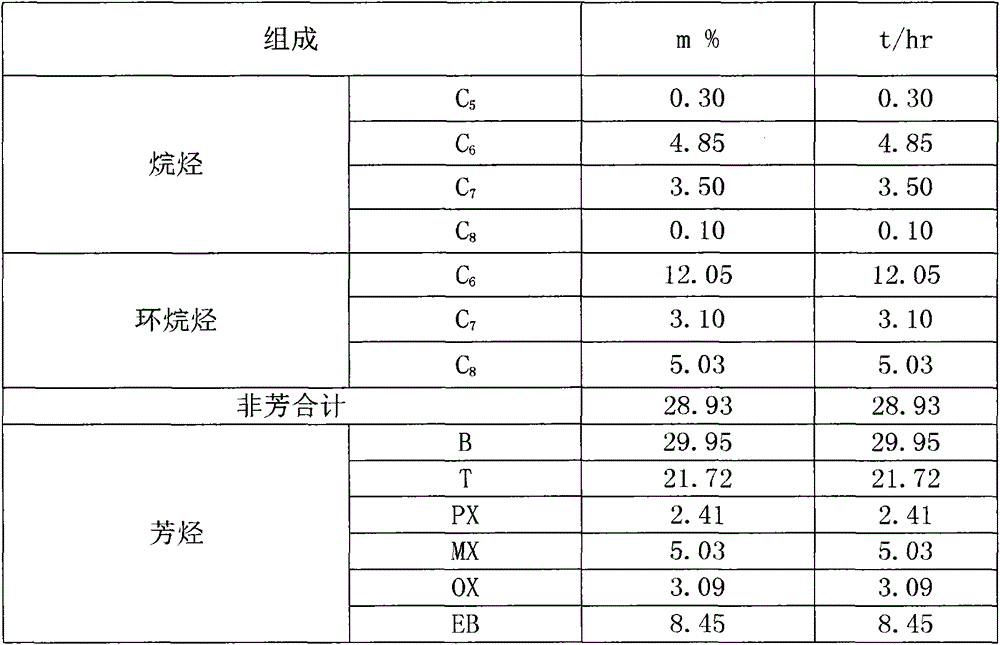

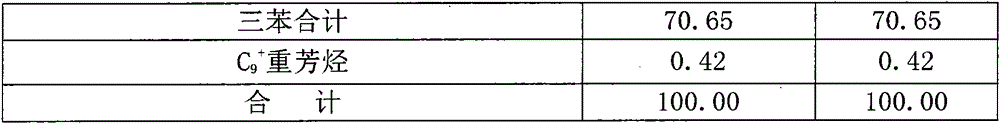

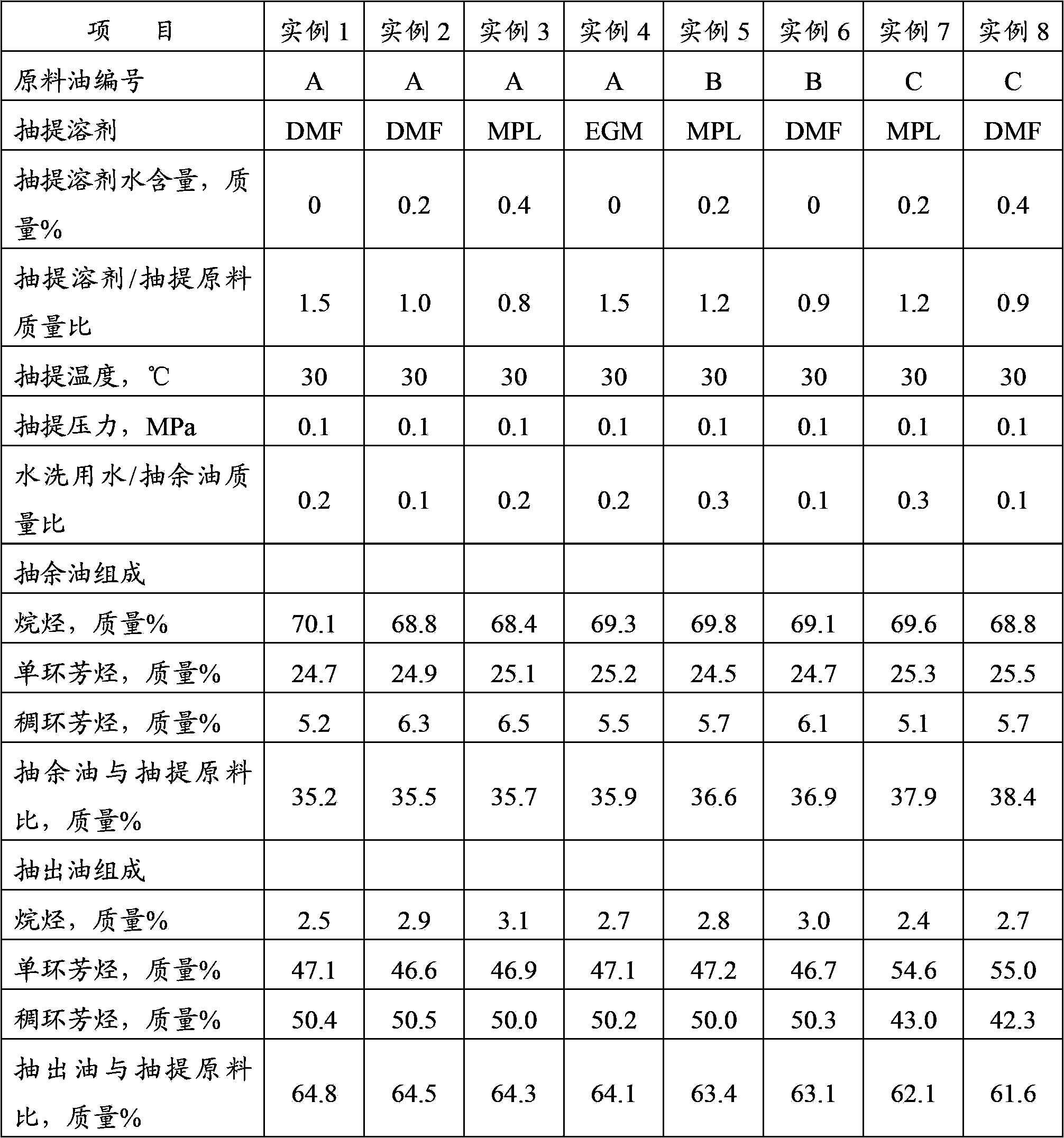

Aromatic hydrocarbon extraction method

InactiveCN104694158ATreatment with plural serial refining stagesExtraction purification/separationGasolineRaw material

Owner:杨志强

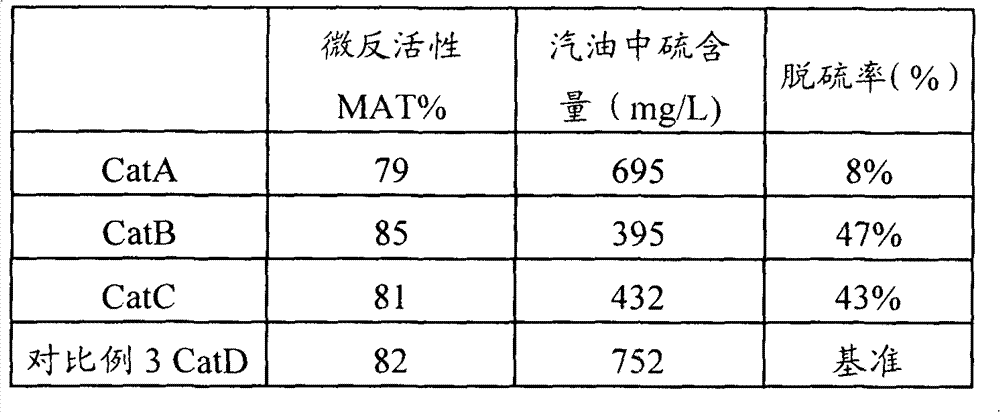

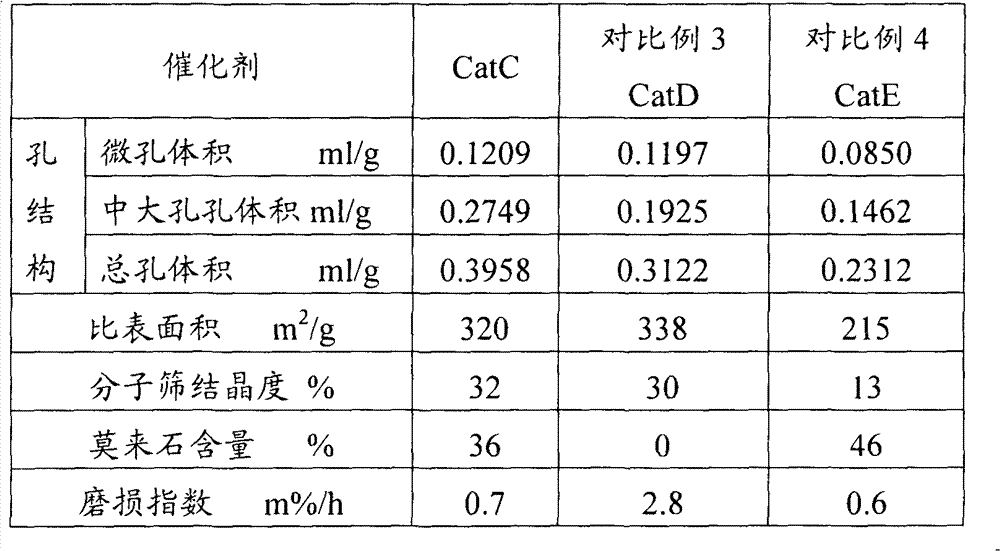

Wear-resistant heavy oil catalytic cracking catalyst capable of reducing sulfur content of gasoline and preparation method thereof

ActiveCN103028432AImprove wear resistanceHigh activityCatalytic crackingMolecular sieve catalystsMicrosphereWear resistant

Owner:EAST CHINA UNIV OF SCI & TECH +1

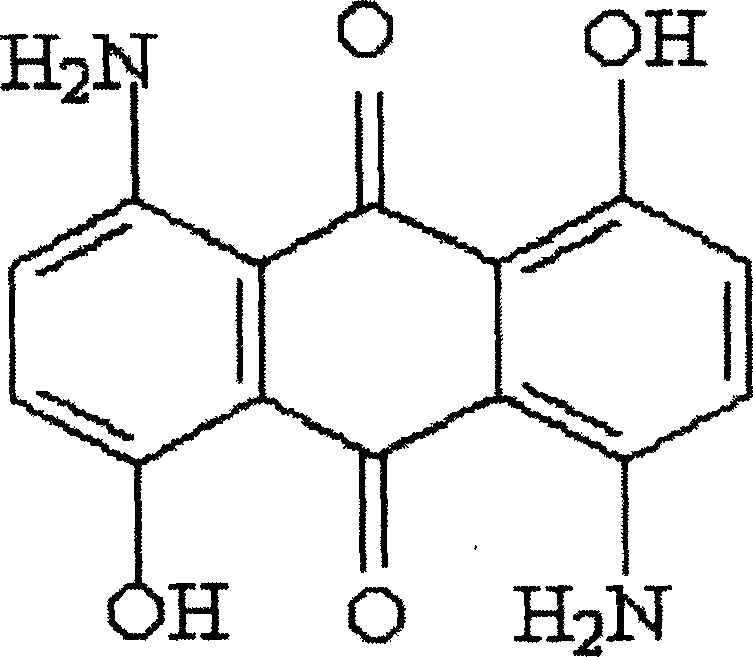

Preparation method of corrosion inhibitor of methanol gasoline

ActiveCN103725335AGood compatibilityAdd lessLiquid carbonaceous fuelsFuel additivesActive agentPolyethylene glycol

Owner:南通市通州区五接农业机电管理站有限公司

Gasoline engine knocking judging and occurrence time predicting method considering influence of external exhaust gas recirculation (EGR)

ActiveCN103758641AImprove fuel economyImprove powerMachines/enginesEngine componentsGasolineEngineering

The invention provides a gasoline engine knocking judging and occurrence time predicting method considering the influence of external exhaust gas recirculation (EGR). The in-cylinder pressure Pi of the cylinder pressure sensor test on the basis of the crankshaft angle and the in-cylinder pressure PIVC and the temperature TIVC of an air inlet vale at the closing moment and a variable index gamma are user as the input to obtain the temperature Ti of the unburned mixed fuel gas on the basis of the crankshaft angle in a engine cycle starting from the air inlet valve closing moment; the crankshaft angle theta KO is calculated when the provided knocking integral value is 1, the theta K0 is compared with the 95% accumulation heat release rate crankshaft angle theta 95% HR; if theta KO is larger than theta 95% HR, no knocking occurs under the working condition; otherwise, if the theta KO is not larger than the theta 95% HR, knocking occurs under the working condition, and the knocking occurs at theta KO. By the method, an effective approach for gasoline engine knocking prediction and performance development after EGR is used.

Owner:SHANGHAI JIAOTONG UNIV

Process for modifying FCC gasoline distillation and co-producing low-carbon olefine and catalyst thereof

InactiveCN1844323AGood transitivityGood reaction selectivityOrganic chemistryNaphtha reformingLiquid productMolecular sieve

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

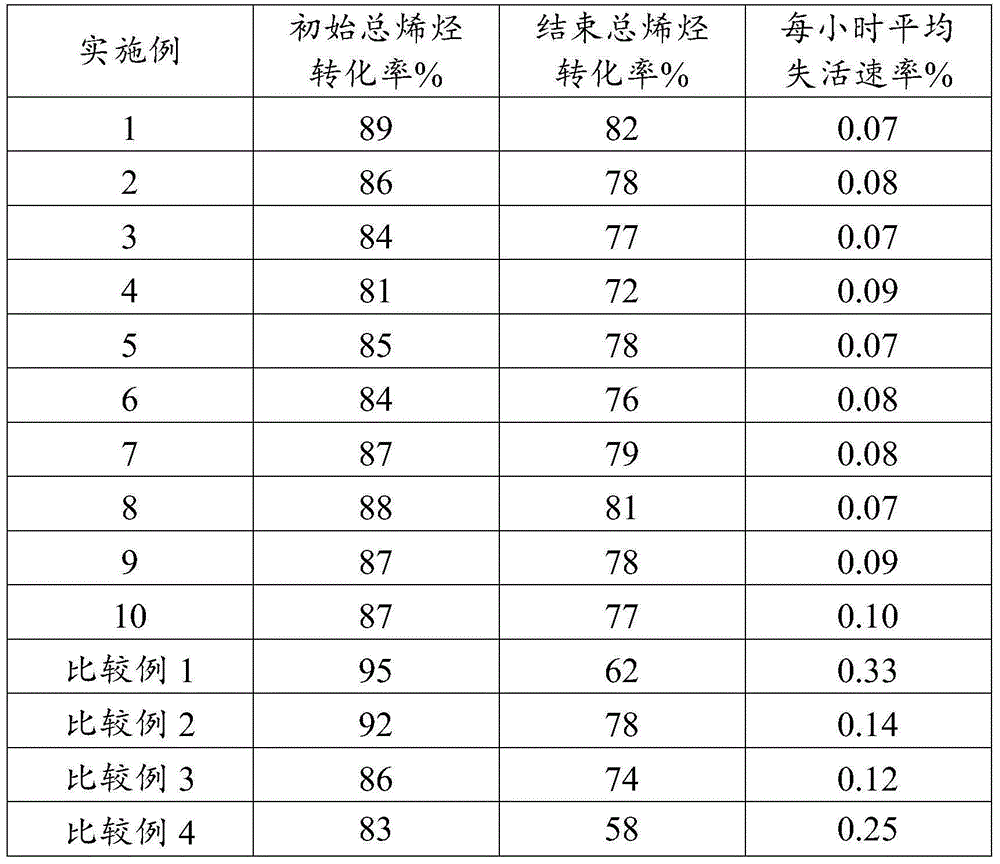

Method for preparing gasoline rich in isoparaffin from methanol and/or dimethyl ether

InactiveCN106867564AImprove qualityBroaden the application marketMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention relates to a method for preparing gasoline rich in isoparaffin from methanol and / or dimethyl ether. A catalyst used in the method is prepared from a molecular sieve-loaded active metal component. Since the catalyst used in the method has excellent selectivity on isoparaffin in a gasoline fraction (hydrocarbons with a carbon atom number of 5 to 11; and low selectivity on olefins and aromatic hydrocarbons, the composition of the gasoline produced by using the method can meet the national gasoline standard VI in China, or even meet requirements on the contents of aromatic hydrocarbons and olefins in world advanced standards for clean fuels (such as the European standard V and standards for motor gasoline in California of the US). The method provides a feasible technical route for direct acquisition of non-petroleum resources and has good market prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing clean diesel oil from inferior diesel oil

ActiveCN103773470ALow investment costLow operating costTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel Fe-Co-based wave absorbing micro powder and preparing method thereof

The invention provides novel Fe-Co-based wave absorbing micro powder and a preparing method thereof. According to the method, Fe, Co, Al and Er are used as raw materials and are proportioned according to the atomic ratio of Fe10Co7AlxEr2-x (0.5<=x<=1), then smelting is conducted in a vacuum arc furnace, smelted alloy is placed in a vacuum glass tube for homogenizing annealing, then quenching and preliminary smashing are conducted, and finally, ball milling is conducted with a planetary ball mill under the protection of gasoline so that the wave absorbing micro powder can be obtained after the milled product is taken out and dried in the air.

Owner:孙炜炜

Dialkene-containing gasoline fraction hydrotreating method

InactiveCN102559261AEasy to removeSolve cokingTreatment with hydrotreatment processesFluid phaseReaction temperature

The invention provides a dialkene-containing gasoline fraction hydrotreating method. The method comprises the following steps: (1) directly mixing a dialkene-containing gasoline fraction raw material with a hot hydrogen-donor solvent, and feeding the mixture into a hydropretreating reactor for dialkene-removing reaction when the temperature of the mixture reaches the dialkene-removing reaction temperature; (2) mixing reaction effluent of the hydropretreating reactor with hydrogen gas, feeding the mixture into a heating furnace, heating the mixed material until the temperature of the mixed material reaches the temperature required by the inlet of the hydrotreating reactor, feeding the mixed material into a separator, separating the mixed material into a gas phase and a liquid phase, wherein the liquid phase is mainly the hydrogen-donor solvent and is circulated to the step (1) for use, and the separated gas phase is fed into the hydrotreating reactor so as to be subjected to hydrogenation impurity-removal reaction; and (3) feeding the reaction effluent of the hydrotreating reactor into a separation system, separating out the hydrotreated gasoline fraction and a gas phase, wherein the gas phase is mainly the hydrogen gas and is recycled. Compared with the prior art, the method provided by the invention can be used for effectively solving the coking problem of a dialkene-containing gasoline fraction hydrotreater.

Owner:何裕松

Method for preparing alkane through lignin derivative in ionic liquid system

ActiveCN109294614AOvercome the problem of high pressure in the reaction processReduce pressure requirementsLiquid hydrocarbon mixture productionBio-feedstockAlkaneIonic liquid

The invention discloses a method for preparing a high calorific value alkane by one-step hydrodeoxygenation of a lignin-derived aromatic compound in an ionic liquid system. The method adopts a transition metal supported catalyst and is characterized in that biomass alkane gasoline is prepared through lignin-derived compound high-efficiency hydrodeoxygenation in an intermittent reactor at 100-160 DEG C under hydrogen gas pressure of 1-5MPa for 2-10h. The catalytic system has mild reaction conditions and low energy consumption. The catalyst has good dispersibility in the ionic liquid. The ligninderivative conversion rate is 100%. The selectivity of the product cycloalkane is 95% or more. The method is free of protonic acid in the conventional catalytic system. The extremely low vapor pressure of the ionic liquid keeps the system low pressure during the reaction process, the requirements on the equipment are reduced, cycle performances of the catalytic system are good, and the method hasgood industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

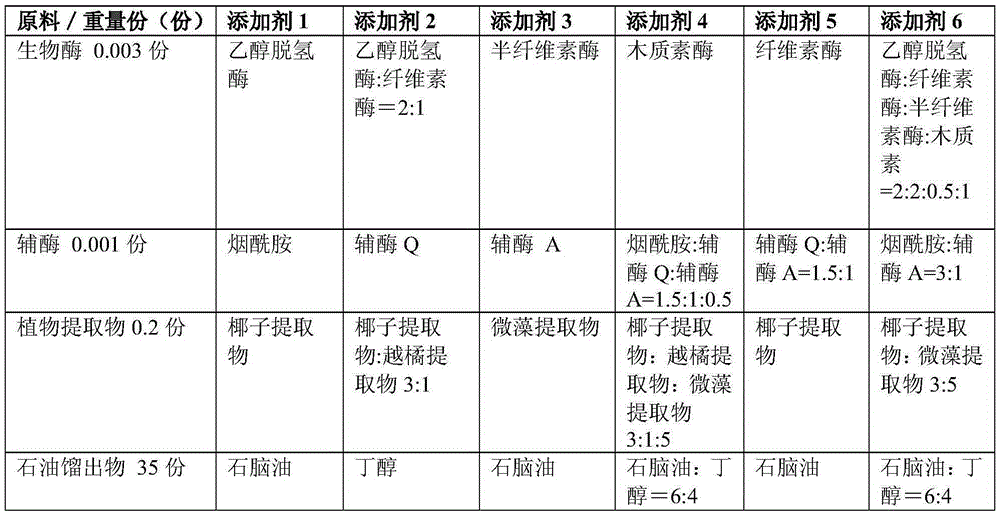

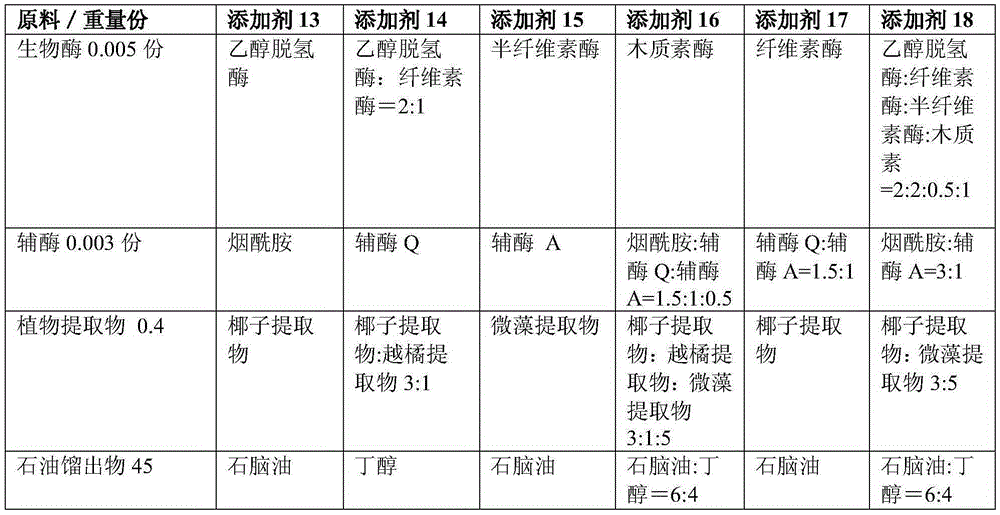

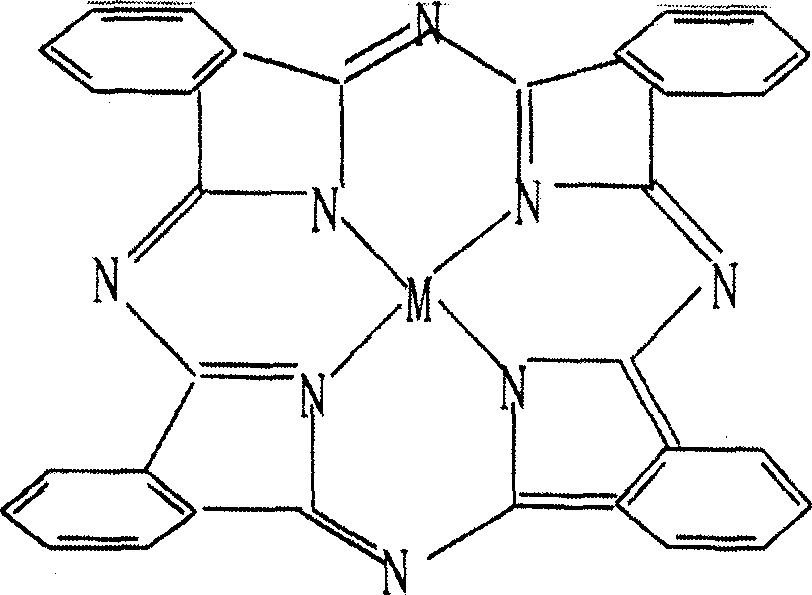

Gasoline environmental-protection and energy-saving additive and environmental-protection and energy-saving gasoline

InactiveCN106590775AReduce consumptionImprove synchronous combustionLiquid carbonaceous fuelsEngineeringPetroleum

Owner:国科蓝天清洁能源技术有限公司

Diesel-engine-driven self-priming pump and control protection method

PendingCN110219807ARealize automatic exhaustAvoid damageMagnetically actuated clutchesFriction clutchesElectricityWater source

Owner:哈尔滨庆功林泵业股份有限公司

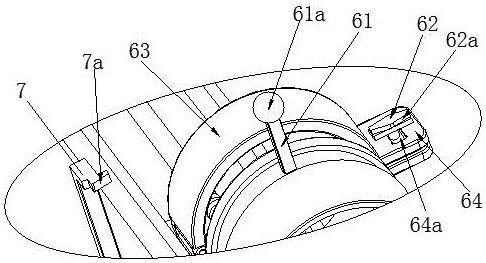

Environment-friendly gasoline engine particle trap

ActiveCN113431663AReasonable structureImprove installation efficiencyExhaust apparatusSilencing apparatusGasolineControl theory

Owner:宁波开特环保科技有限公司

Methanol fuel safety additive an dits adding method

Owner:山西佳新能源化工实业有限公司

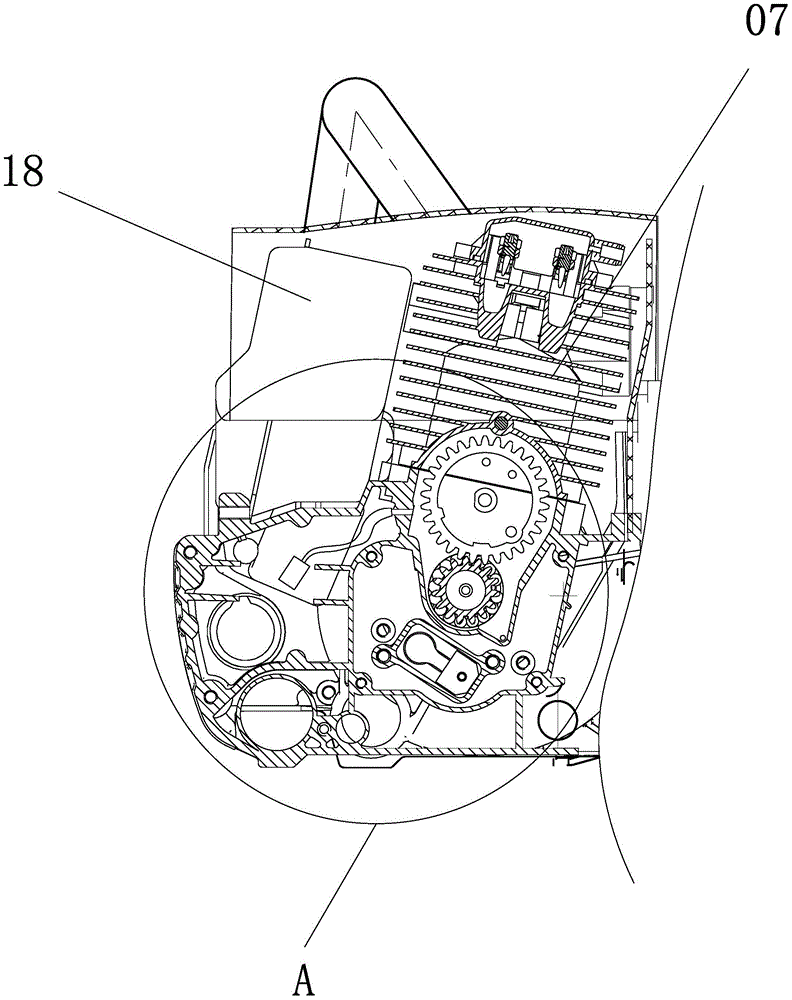

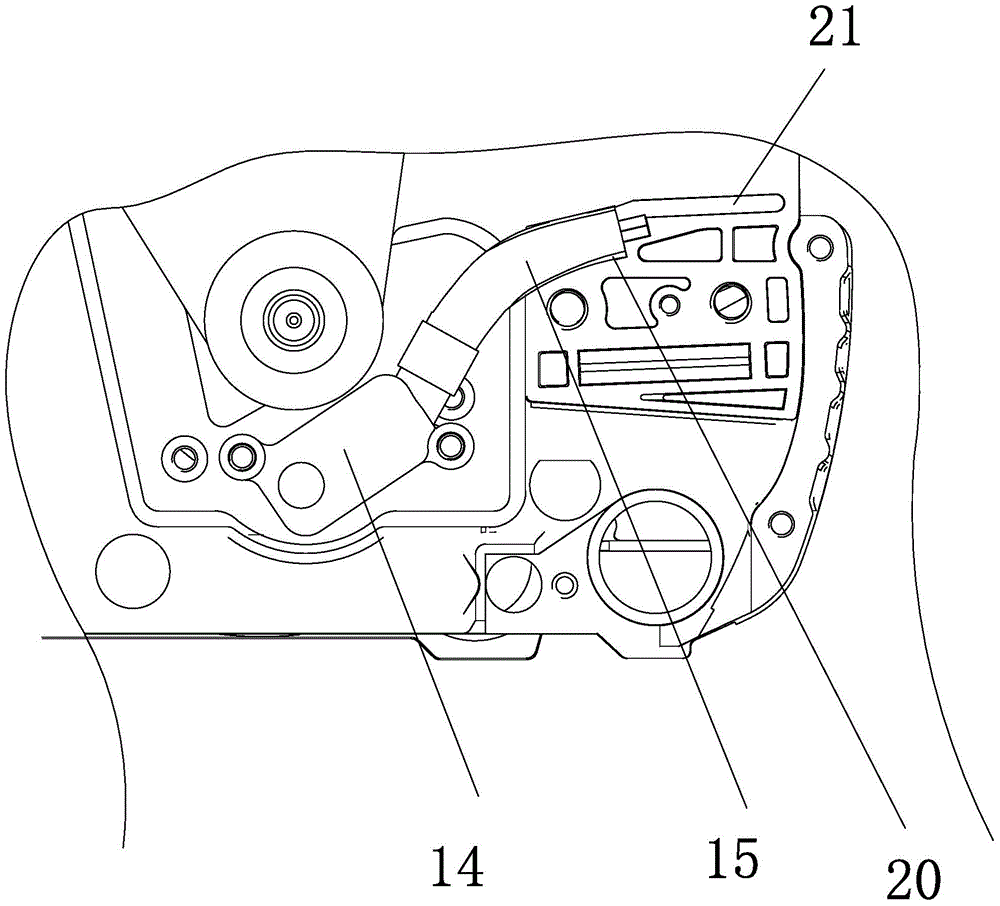

Lubricating system for double-stroke gasoline engine

InactiveCN101737115AGuaranteed emission standardsIncrease powerPressure lubrication with lubrication pumpDiaphragm pumpGasoline

Owner:JIANGSU NONGHUA WISDOM AGRICULTURAL SCIENCE AND TECHNOLOGY CO LTD

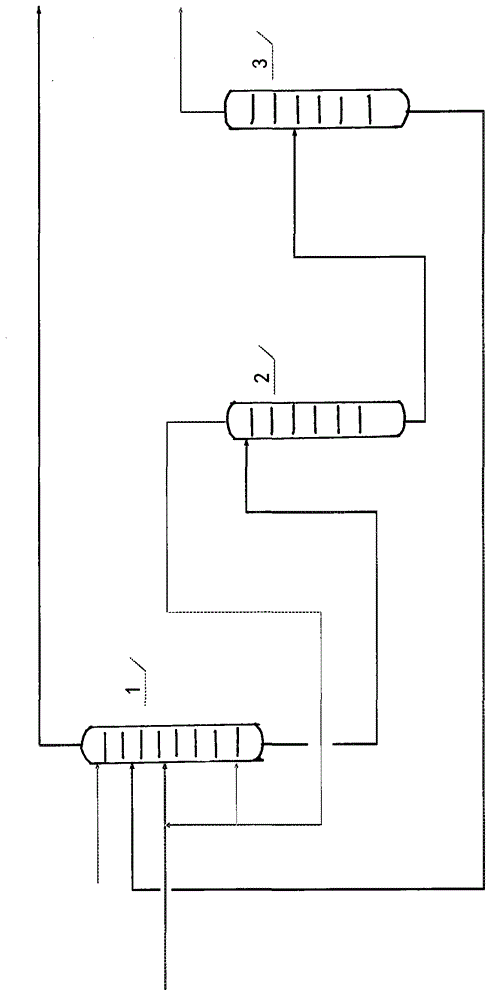

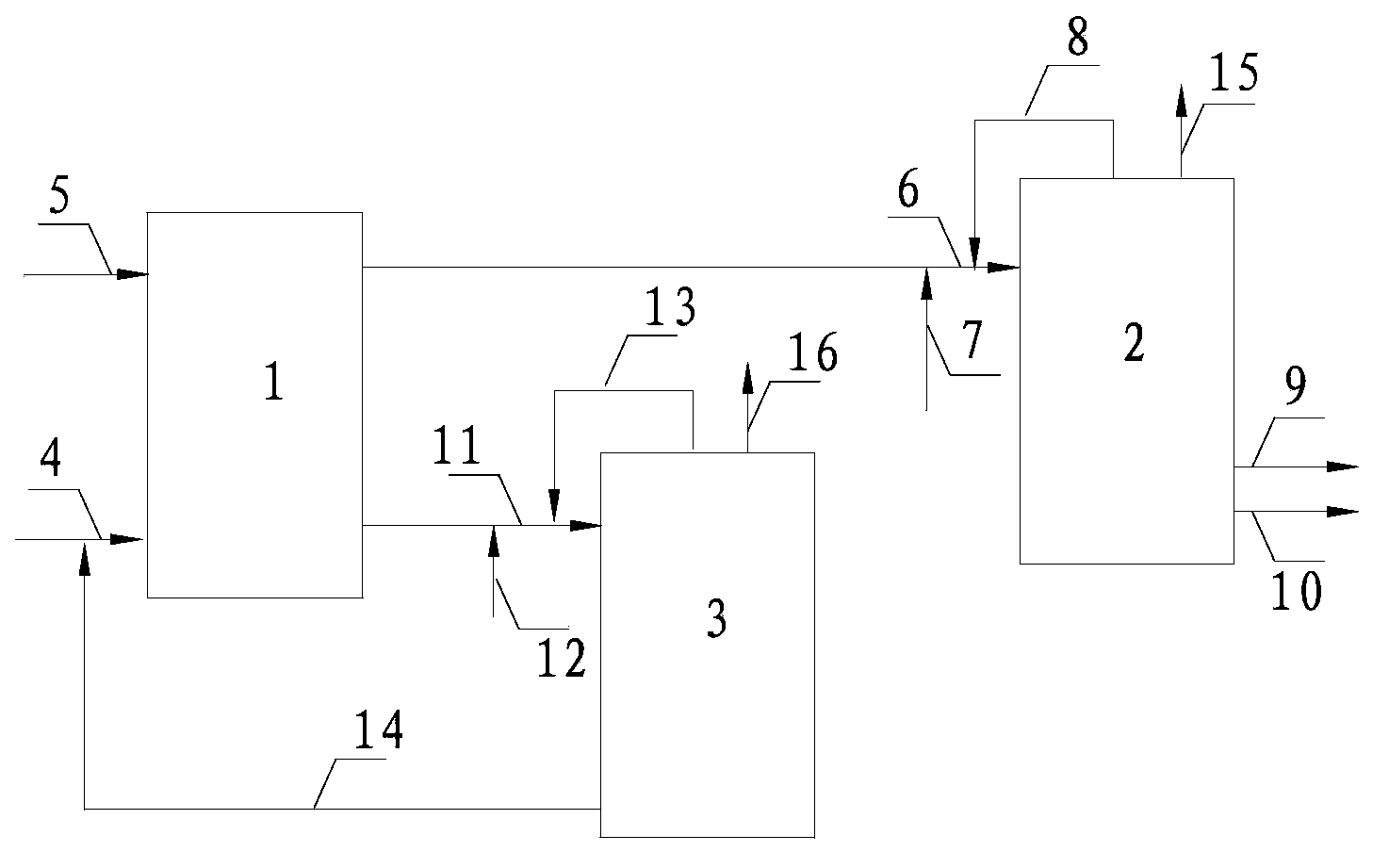

Full-range FCC gasoline combined desulfurization process and device

ActiveCN106590736AReduce operating loadGuaranteed octane ratingTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenHydrodesulfurization

The invention provides a full-range FCC gasoline combined desulfurization process which comprises the following steps: one, making full-range FCC gasoline and hydrogen gas contact with a dealkadiene catalyst, to remove alkadiene in the full-range FCC gasoline; two, fractionating to form a heavy component, an intermediate component and a light component; three, carrying out hydrodesulfurization on the heavy component, to obtain a low-sulfur heavy component; and carrying out hydrogen presence desulfurization adsorption desulfurization on the intermediate component, to obtain a low-sulfur intermediate component; four, mixing the low-sulfur heavy component, the low-sulfur intermediate component and the light component, to obtain super-low-sulfur gasoline with the sulfur content of less than 10 ppmw. The invention also provides a full-range FCC gasoline combined desulfurization device. Through selective hydrogenation dealkadiene and the hydrodesulfurization and hydrogen presence adsorption desulfurization combined ultra-deep desulphurization composite type treatment, sulfur in the full-range FCC gasoline sulfur is removed to 10 ppmw or less, the loss of octane number is less than 2 units, and the liquid yield is more than 99.8%.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Engine oil oil-way system of gasoline engine

Owner:YONGKANG LINGHANG MACHINE POWER

Method for producing gasoline blending component from dry gas

InactiveCN106244224AMolecular sieve catalystsLiquid hydrocarbon mixtures productionBenzeneWater vapor

Owner:CHINA PETROLEUM & CHEM CORP +1

Inner liner rubber for tubeless tire

The invention discloses inner liner rubber for a tubeless tire. Butadiene styrene rubber is added, has a good anti-ageing property and heat resistance and has more uniform texture than natural rubber; additionally, chloroprene rubber is added, rubber molecules contain chlorine atoms, and the chloroprene rubber has good anti-oxidant and ozone-resistant properties, is nonflammable, can be self-extinguished after being ignited and has good oil resistance, solvent resistance, acid-base resistance, ageing resistance and air tightness; acrylonitrile-butadiene rubber has great gasoline and aliphatic hydrocarbon oil resistance, good heat resistance, relatively good air tightness, wear resistance, water resistance and the like and high bonding force. Besides, other auxiliary ingredients are added, the prepared inner liner rubber for the tubeless tire is low in air transmittance, the tire has good air tightness, good oil resistance and heat resistance, and requirements of the inner liner rubber for the tubeless tire can be fully met.

Owner:SHANDONG YONGTAI CHEM GROUP

Method for producing high-quality gasoline by catalyzing diesel oil hydro-conversion

PendingCN111100690ATreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonPtru catalyst

The invention discloses a method for producing high-quality gasoline by catalyzing diesel oil hydro-conversion, comprising the following steps: (1) high aromatic hydrocarbon catalytic diesel oil and recycle hydrogen are mixed to enter a hydrofining reaction zone for reaction, the hydrofining reaction zone is provided with at least two catalyst beds, and the vulcanization degree of the catalyst inthe material flow direction is in a decreasing trend; (2) the generated oil obtained in the step (1) enters the hydrocracking reaction zone to be in contact with a hydrocracking catalyst to carry outa ring-opening conversion reaction of polycyclic aromatic hydrocarbon; and (3) the generated oil obtained in the step (2) passes through a separation system to obtain gas, gasoline and diesel fractions, part of the diesel fractions can be recycled back to the hydrofining reaction zone, and the rest of the diesel is discharged out of the device. By the method, the problems of long initial adjustment period and long octane number and long-term low octane number of the main target product gasoline fraction in the technical application process can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Velocit cracking method

InactiveCN1552807AImprove wear resistanceOvercome the disadvantages of poor anti-wear performanceCatalytic crackingMolecular sieveGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap