Environment-friendly gasoline engine particle trap

A particle trap and environmental protection technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as inconvenient operation, regeneration delay or increase of regeneration temperature, and lower installation efficiency, so as to achieve convenient positioning and connection , reasonable structure, and the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Describe the present invention in further detail below in conjunction with accompanying drawing:

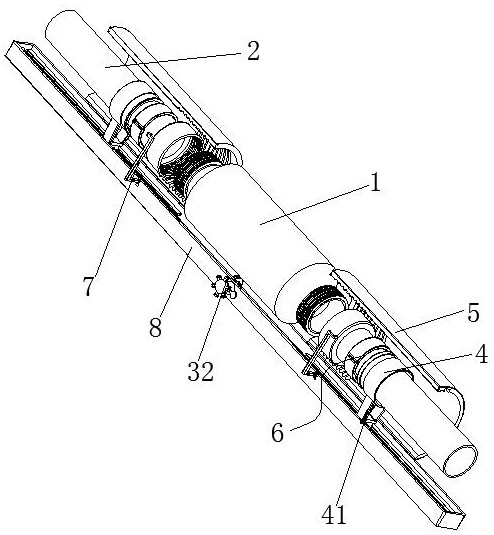

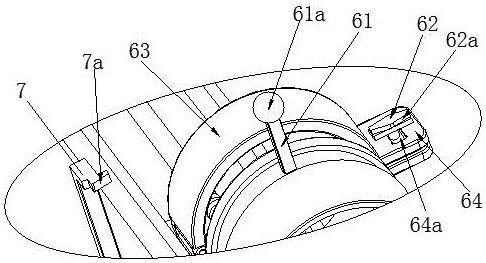

[0027] Such as Figure 1 to Figure 5 As shown, an environmental protection type gasoline engine particulate trap includes a trap 1 and an exhaust pipe 2 connected to both ends of the trap 1, and the exhaust pipe 2 is respectively fixed on a limit movement mechanism, The limit movement mechanism is driven by a two-way drive mechanism to move synchronously. The two-way drive mechanism includes a screw rod 31 and a driving member that drives the screw rod to rotate. 31a, the position-limiting movement mechanism includes a rotationally fitted clamping mechanism 6 and a position-limiting member 4, the exhaust pipe 2 is placed on the corresponding clamping mechanism 6, and the position-limiting member 4 is provided with The slider 41 matched with the corresponding threaded segment 31a; the limit movement mechanism is placed in the corresponding conduit 5, and the guide groove 5 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap