Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Improve cleaning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Six-axis high-speed motion controller based on PLC architecture

ActiveCN112996308AImprove cleaning efficiencyCasings/cabinets/drawers detailsCleaning using gasesDust controlElectrical and Electronics engineering

Owner:威海盛发机械设备有限公司

Oyster cleaning system

PendingCN114451443AImprove cleaning efficiencyImprove cleanlinessBivalves processingEnvironmental engineeringOyster

Owner:广东潮汇水产有限公司

Road and bridge spraying device

PendingCN113652943AEasy to operateImprove cleaning efficiencyRoad cleaningRoads maintainenceBevel gearBrush

Owner:丁道勇

Blade height measuring device and dicing saw

ActiveCN114345812AGood cleaning effectImprove cleaning efficiencyCleaning using gasesCleaning using liquidsEngineeringKnife blades

Owner:沈阳和研科技有限公司

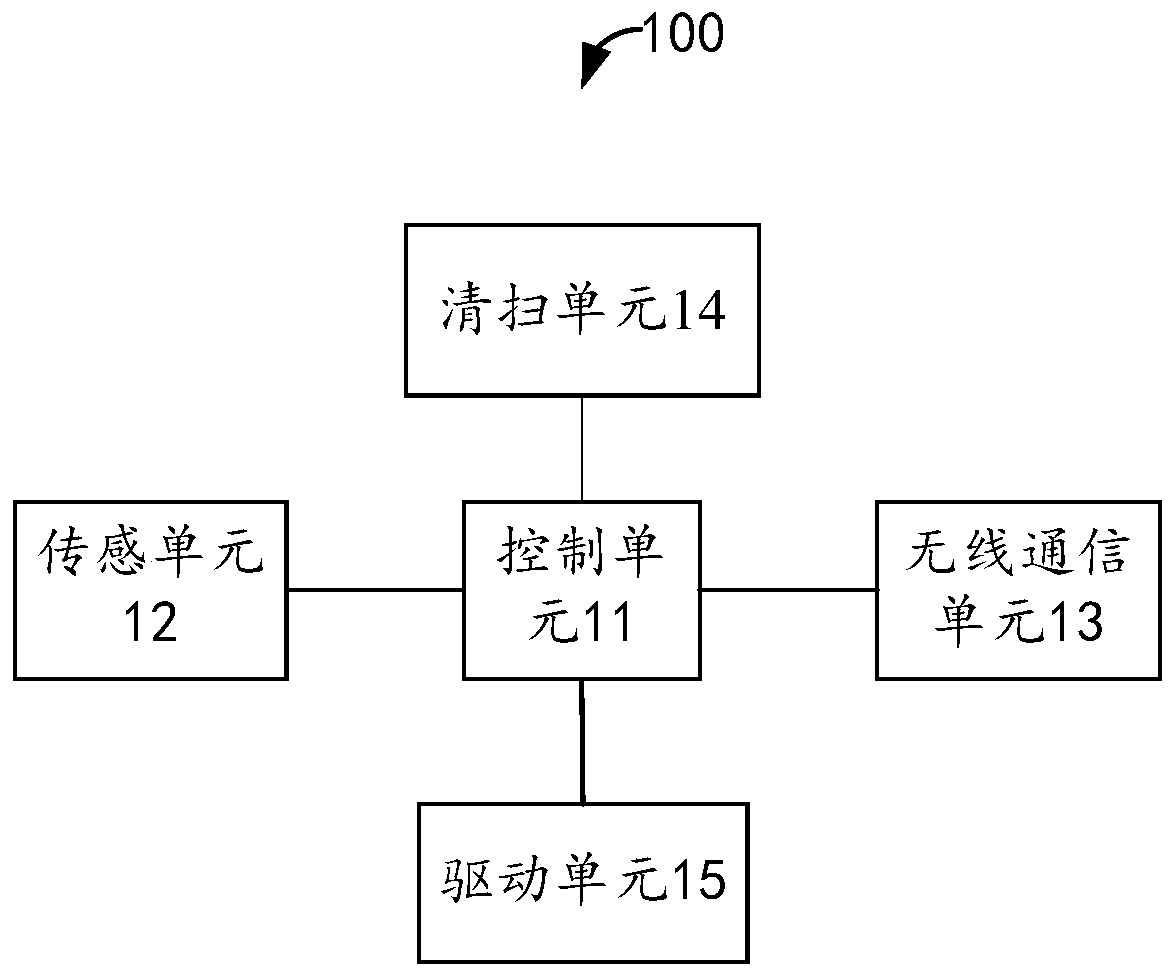

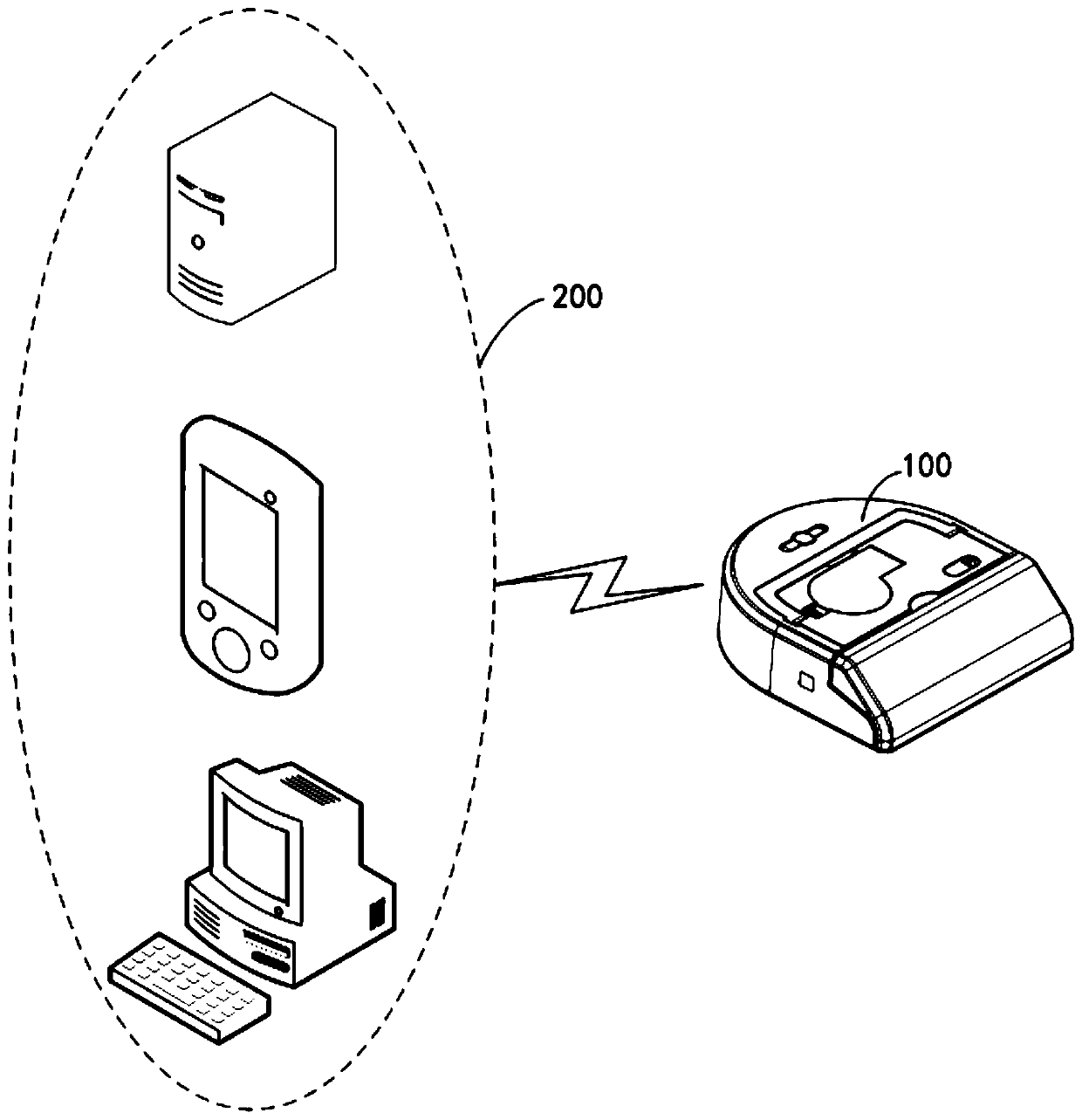

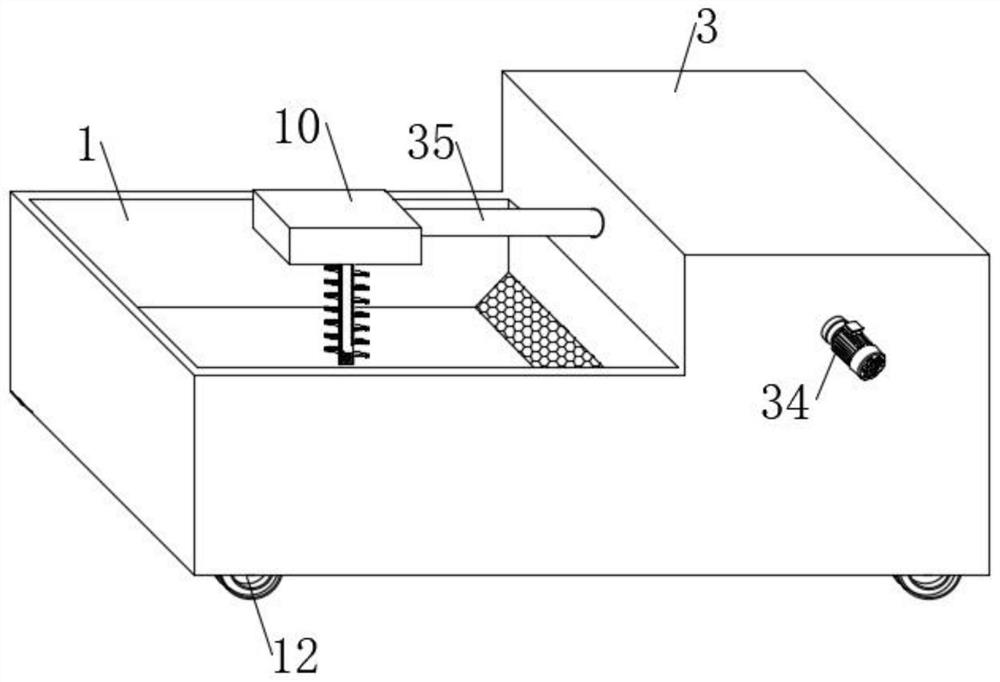

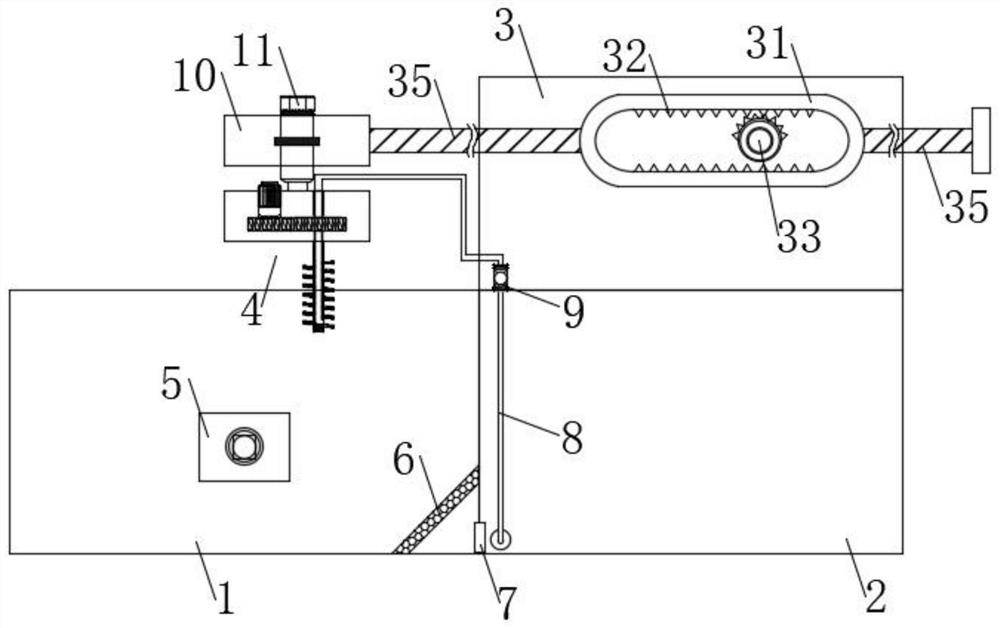

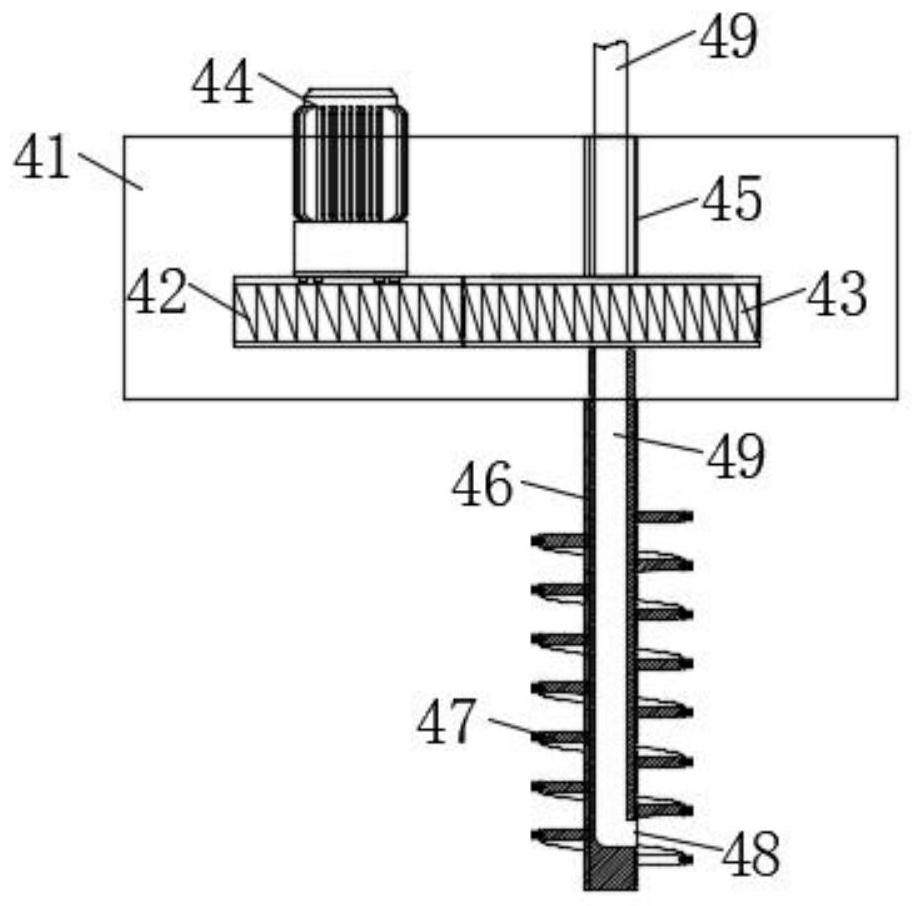

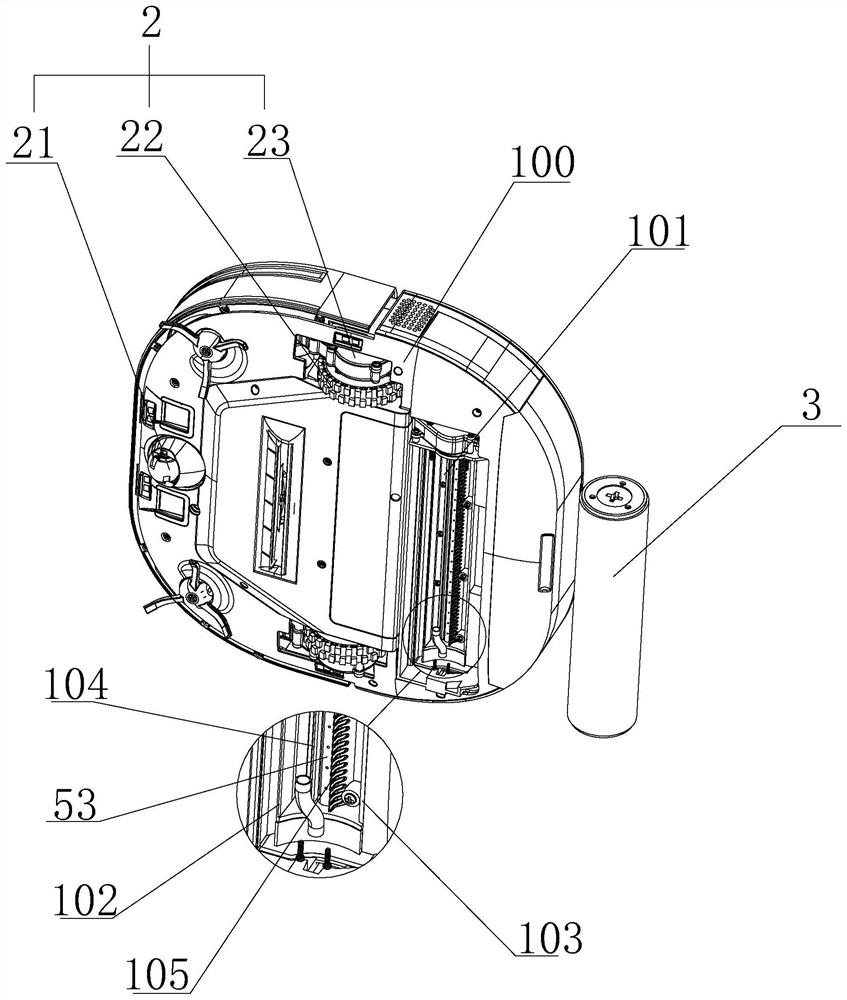

Cleaning robot

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

Intelligent control split-type vegetable, fruit, bowl and chopstick washing machine

InactiveCN109171506AImprove cleaning efficiencyKitchen equipmentTableware washing/rinsing machine detailsControl systemElectric machinery

Owner:李少群

Complete treatment equipment for cutting waste liquid

PendingCN111453879AImprove cleaning efficiencyFatty/oily/floating substances removal devicesMultistage water/sewage treatmentActivated carbon filtrationAir compressor

Owner:HUBEI PETROKH MACHINE MFG

Alkaline type washing method for block-shaped silicon raw materials

InactiveCN106623218AGuaranteed cleaning qualityImprove cleaning efficiencyCleaning using liquidsDrying gas arrangementsImpurityMaterials science

Owner:江苏迩高新能源科技有限公司

Industrial environment gas purification and dust removal device

InactiveCN112121582AAvoid troubleImprove cleaning efficiencyCombination devicesHuman health protectionDust controlEnvironmental engineering

Owner:松阳县景鸿设计工作室

Water-saving potato high-efficiency washing device

InactiveCN108378389AEasy to cleanSave waterClimate change adaptationFood treatmentWater savingWater resources

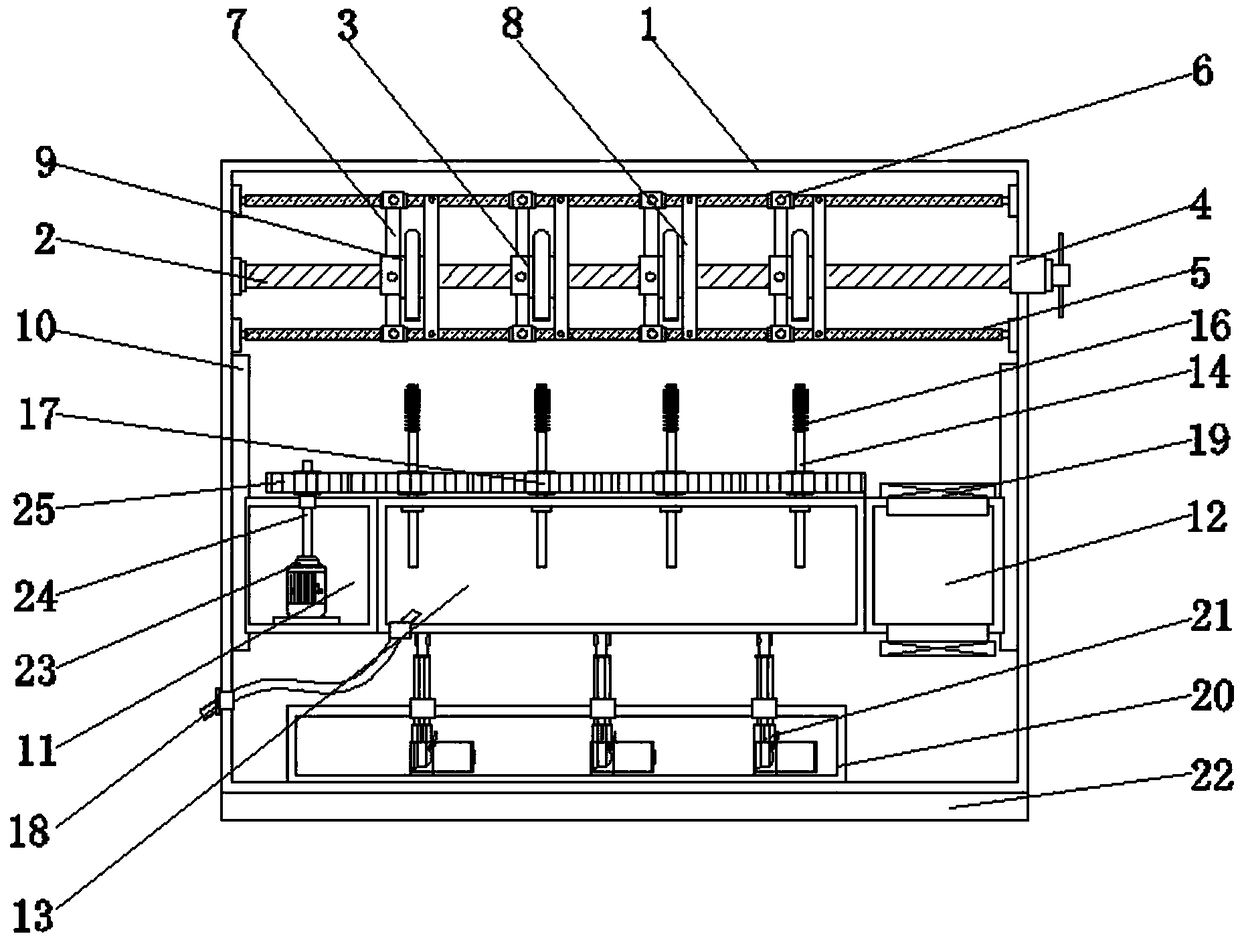

The invention discloses a water-saving potato high-efficiency washing device. The water-saving potato high-efficiency washing device comprises a bracket, a washing bucket, a rotating motor, a cylinderbody, a water tank and a washing roller, wherein the washing bucket is fixedly connected with the bracket; the washing roller is arranged in the washing bucket; a threaded sleeve penetrates through the upper end of the cylinder body and is rotatably connected with the cylinder body; the lower end of a threaded rod is fixedly connected with a piston; a pushing rod is fixedly mounted at the lower end of the piston; the lower end of the pushing rod is hinged to a sleeve; a propping and pressing rod penetrates through the bottom of the washing bucket and is rotatably connected with a disk; and moving rods are fixedly mounted on the disk, and penetrate through the lower end of the side wall of the washing roller to extend to a cavity of the side wall. According to the water-saving potato high-efficiency washing device disclosed by the invention, intermittent water supply is performed through pumping of clean water by the arranged cylinder body to wash potatoes, so that the washing effect is good, and water resources are saved; and the potatoes are washed through the rotating of the arranged washing roller, and brushes on the washing roller can also perform washing in an up-and-down brushing manner, so that the multi-direction washing is realized, and the water-saving potato high-efficiency washing device is high in washing efficiency, high in practicality and high in automation degree.

Owner:孙灵科

Cleaning system used for metal mask plate

PendingCN109382365AReduce volatilityEasy to fixDrying gas arrangementsDirt cleaningEngineeringMechanical engineering

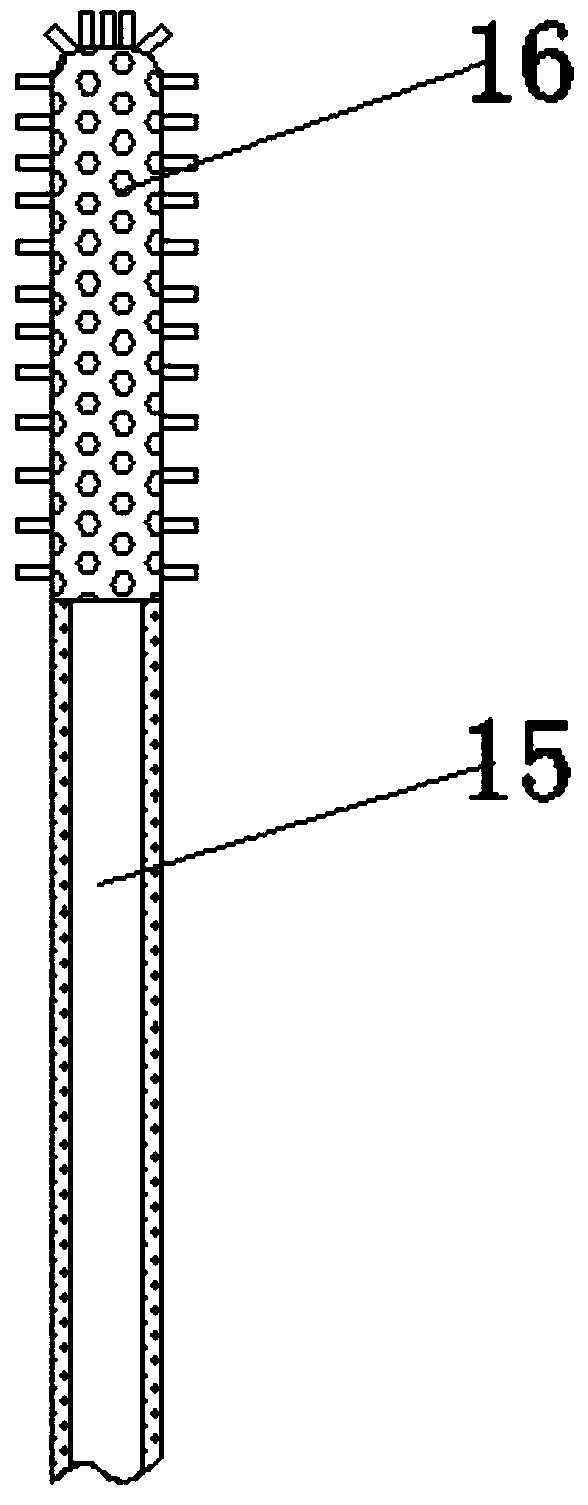

The invention relates to the technical field of metal mask plates, in particular to a cleaning system used for a metal mask plate. The system includes a closed workshop, a row of cleaning tanks are placed on the floor in a workshop, and dewatering tanks are installed at the back ends of the cleaning tanks. The system is characterized in that two longitudinal beams are installed above the cleaningtanks in the workshop, two longitudinal beams are provided with mechanical arms, the cleaning system further includes a lifting appliance used for loading the metal mask plate, and the mechanical armscan lift or horizontally move the lifting appliance. The cleaning tanks include bubble cleaning tanks and alcohol cleaning tanks. The cleaning efficiency is higher, the cleaning effect is better, theoperation cost is lower, and the system is suitable for improvement of an existing metal mask plate cleaning machine.

Owner:湖北浚山光电有限公司

Aluminum profile cleaning equipment

InactiveCN105234118AReasonable equipment designImprove cleaning efficiencyCleaning using toolsCleaning using liquidsWater pipeEngineering

Owner:CHENGDU BIAOJIAN ALUMINUM

Test tube cleaning device for food inspection

InactiveCN109290314AExtended service lifeImprove cleaning efficiencyHollow article cleaningEngineeringFood inspection

Owner:青岛聚思信息科技有限公司

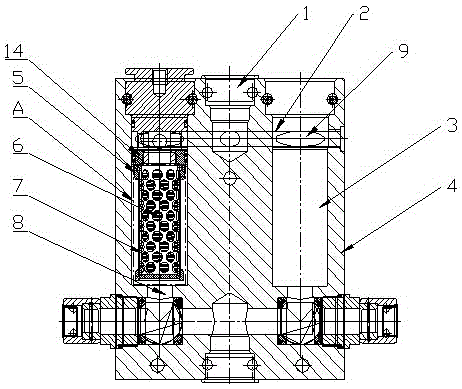

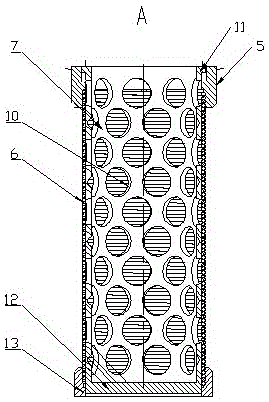

Filter element equipped with variably spaced reverse-washing filter

ActiveCN105107248AEasy to cleanImprove cleaning efficiencyStationary filtering element filtersFilter elementMechanical engineering

Owner:NANTONG LANGGAO PETROCHEM EQUIP +1

Railway ballast cleaning device used for tamping wagon and tamping wagon

ActiveCN104963248AEasy to storeRealize automatic ballast cleaning operationBallastwayEngineeringBallast

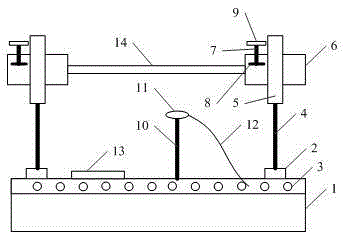

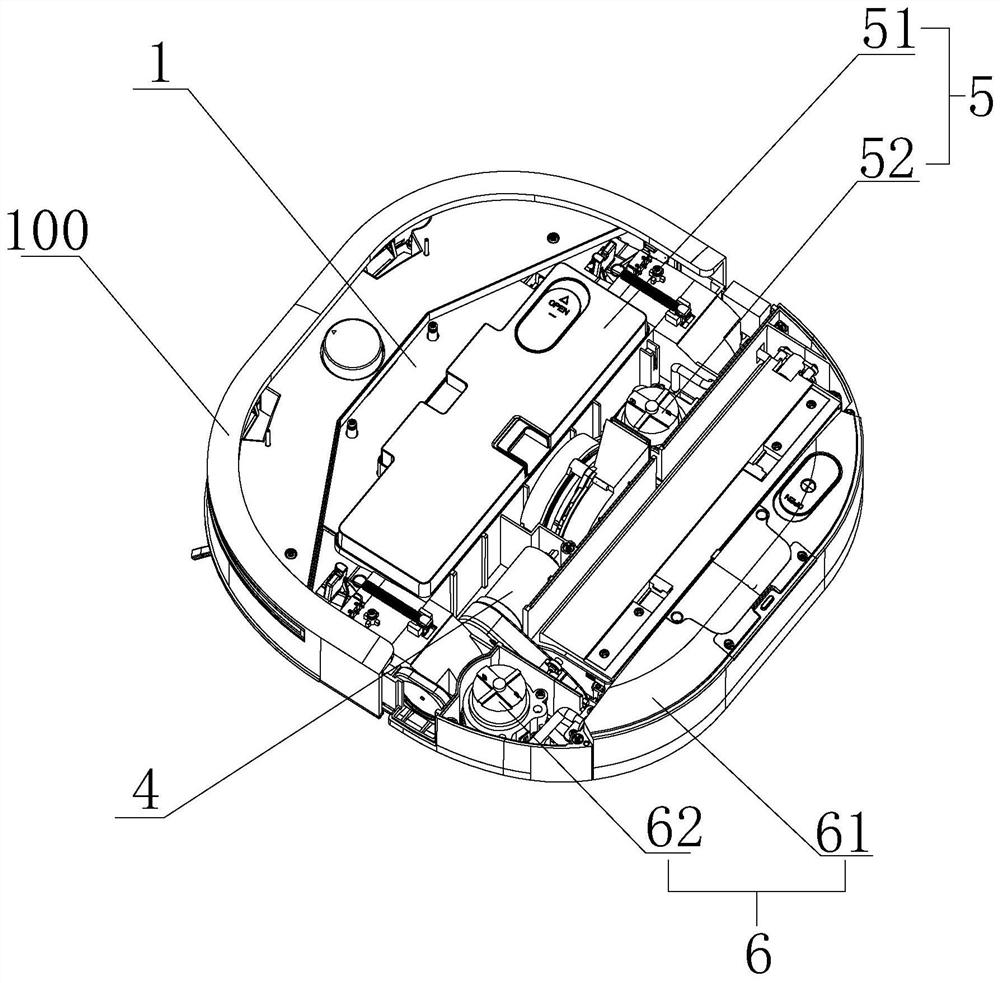

The invention relates to the field of railway maintenance machines and discloses a railway ballast cleaning device used for a tamping wagon and the tamping wagon. The railway ballast cleaning device is provided with an installing portion which can be installed at the lower portion of the tamping wagon (100) and further comprises a cleaning structure (1) and an elevating structure (2). The elevating structure (2) is used for driving the cleaning structure (1) to elevate such that the cleaning structure (1) can be in contact with a railway ballast and performing cleaning operation on the railway ballast. The cleaning structure (1) comprises cleaning parts arrayed along a transverse direction (A) of the railway ballast cleaning device. The railway ballast cleaning device is capable of automatically cleaning the railway ballast and is advantaged by being high in cleaning efficiency.

Owner:CHINA SHENHUA ENERGY CO LTD +1

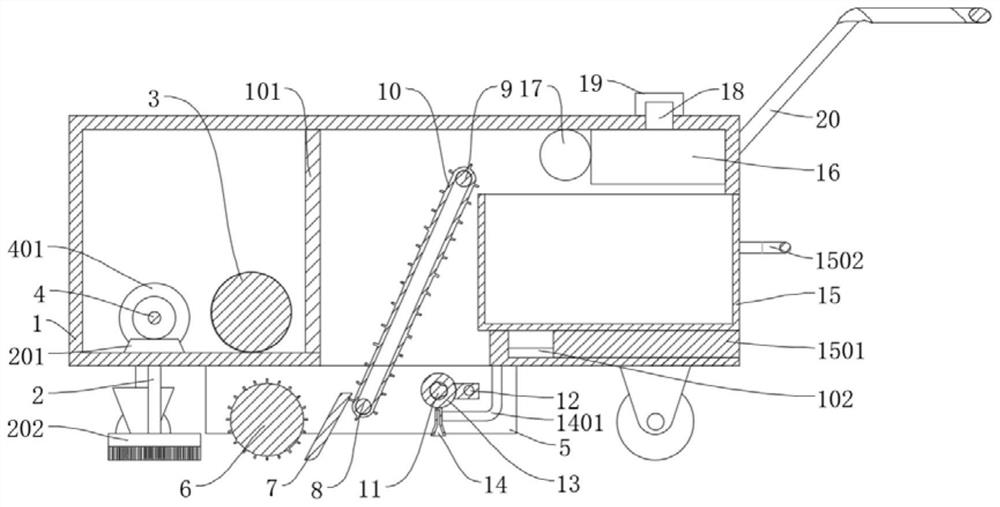

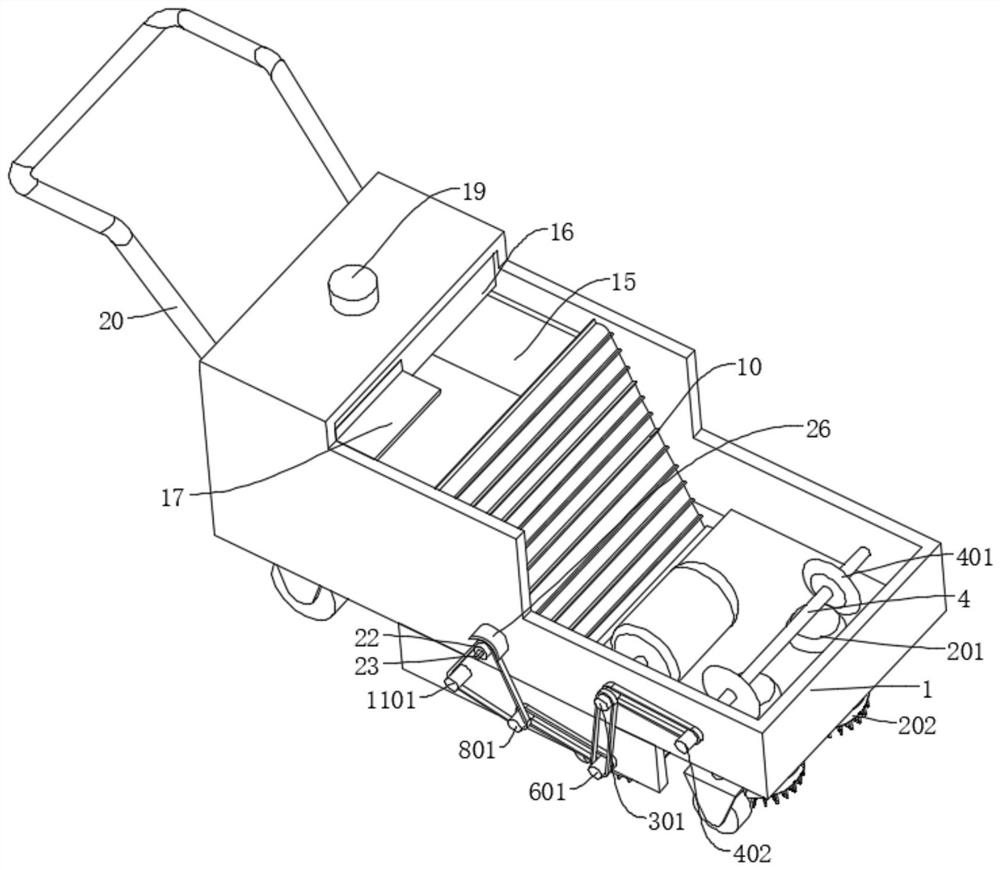

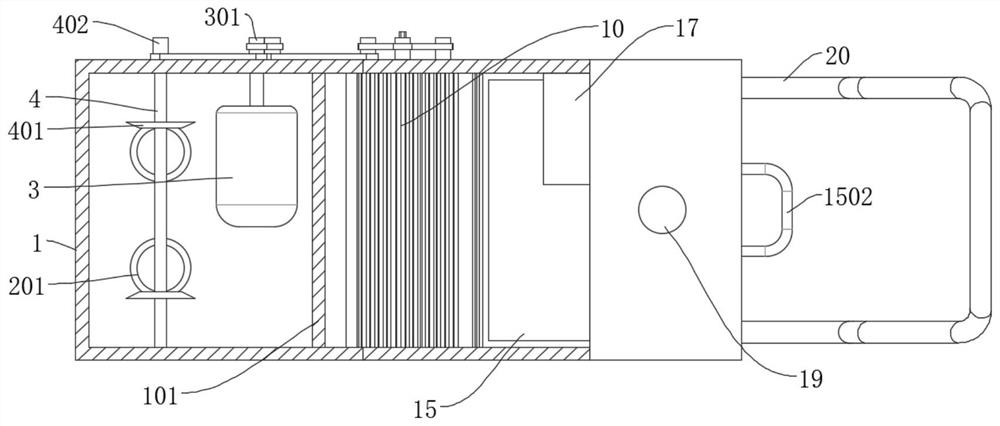

Raise-dust-free hand-push type road sweeper

Owner:重庆司科朗环卫服务有限公司

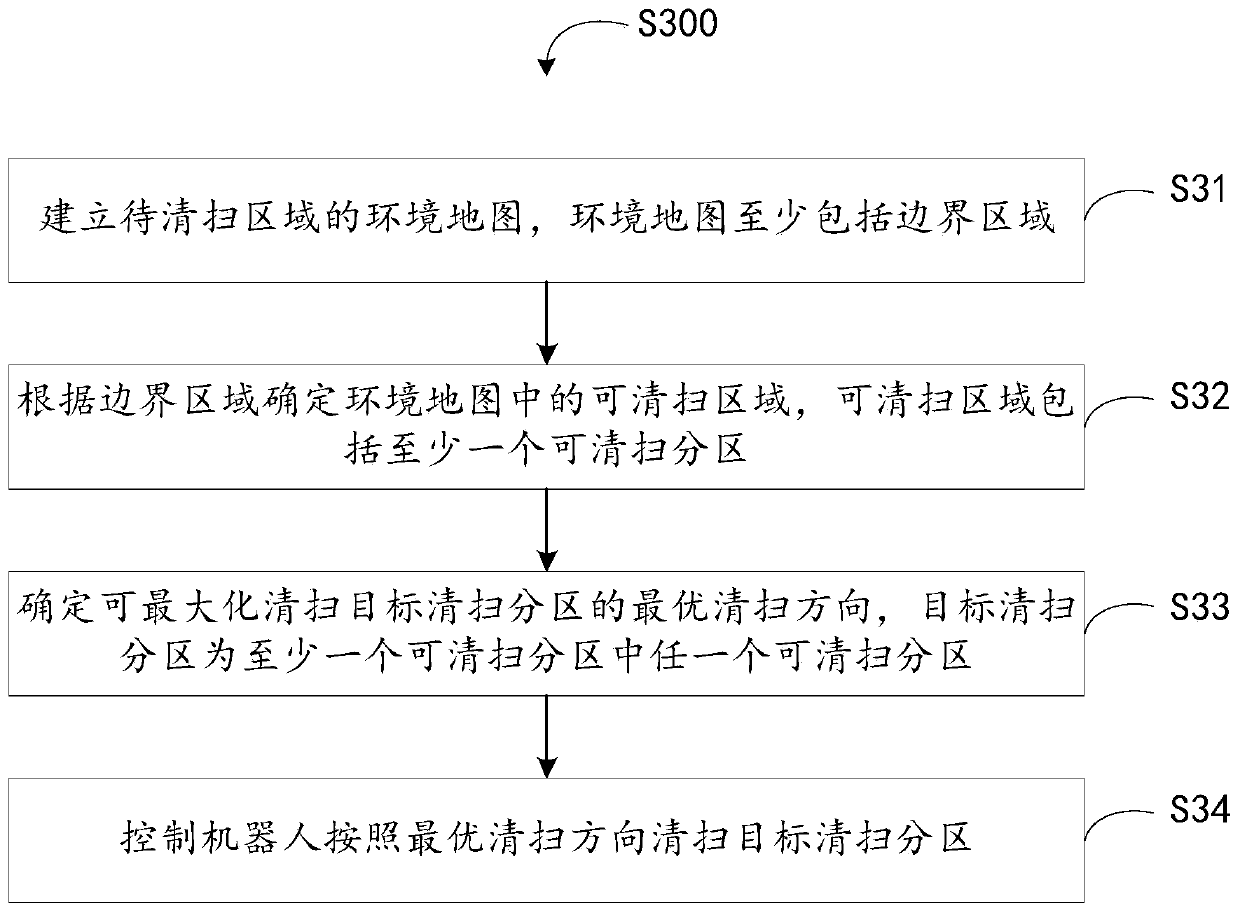

Robot cleaning method and robot

PendingCN111399524AAvoid missed scansImprove cleaning efficiencyPosition/course control in two dimensionsFuture of roboticsIndustrial engineering

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

Automatic cleaning equipment for clothes

InactiveCN106269633AEasy to operateEasy to adjustCleaning using liquidsWater storageAutomatic test equipment

The invention relates to the technical field of clothes processing, in particular to automatic cleaning equipment for clothes. The automatic cleaning equipment for the clothes comprises a chassis, and further comprises a water spraying part arranged on the chassis, a water pump arranged on the water spraying part, a support part inserted in the chassis and a motor rotationally arranged at the end part of the support part; and the water spraying part includes a conveying pipe, a shunting pipe, a guide pipe arranged at the end part of the shunting pipe, a water storage box, a main water spraying pipe arranged on the side wall of the water storage box, a fixed disc, a first screwing rod arranged on the side wall of the fixed disc, a sub spraying pipe arranged on the main water spraying pipe, and a nozzle arranged at the end part of the sun spraying pipe. The automatic cleaning equipment for the clothes is convenient for operation and adjustment and high in cleaning efficiency.

Owner:姚雅珍

Multifunctional sealing gland for hydraulic plunger pump

PendingCN107191595AImprove cleaning efficiencyImprove functionalityEngine sealsLiquid fuel engine componentsEngineeringMechanical engineering

Owner:江苏雨灵机械科技有限公司

Textile cleaning and drying integrated machine

InactiveCN108035102AReduce cost inputEasy to integrateMechanical cleaningPressure cleaningAgricultural engineeringProcessing cost

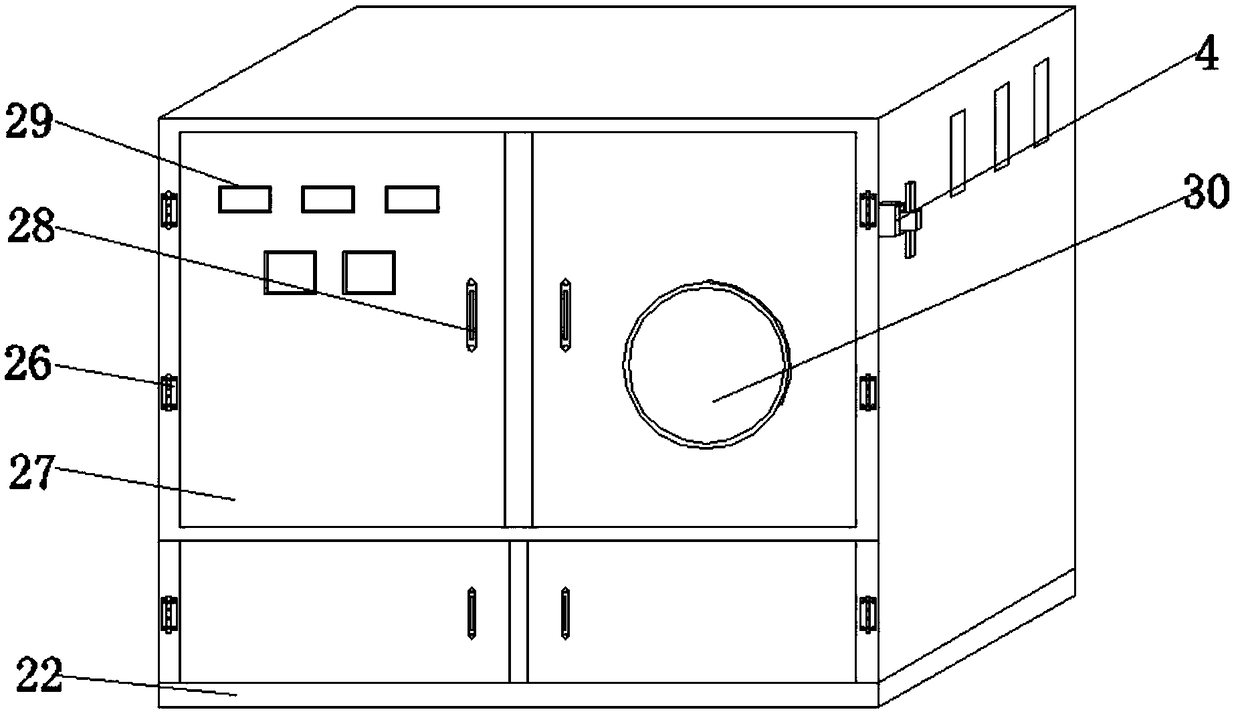

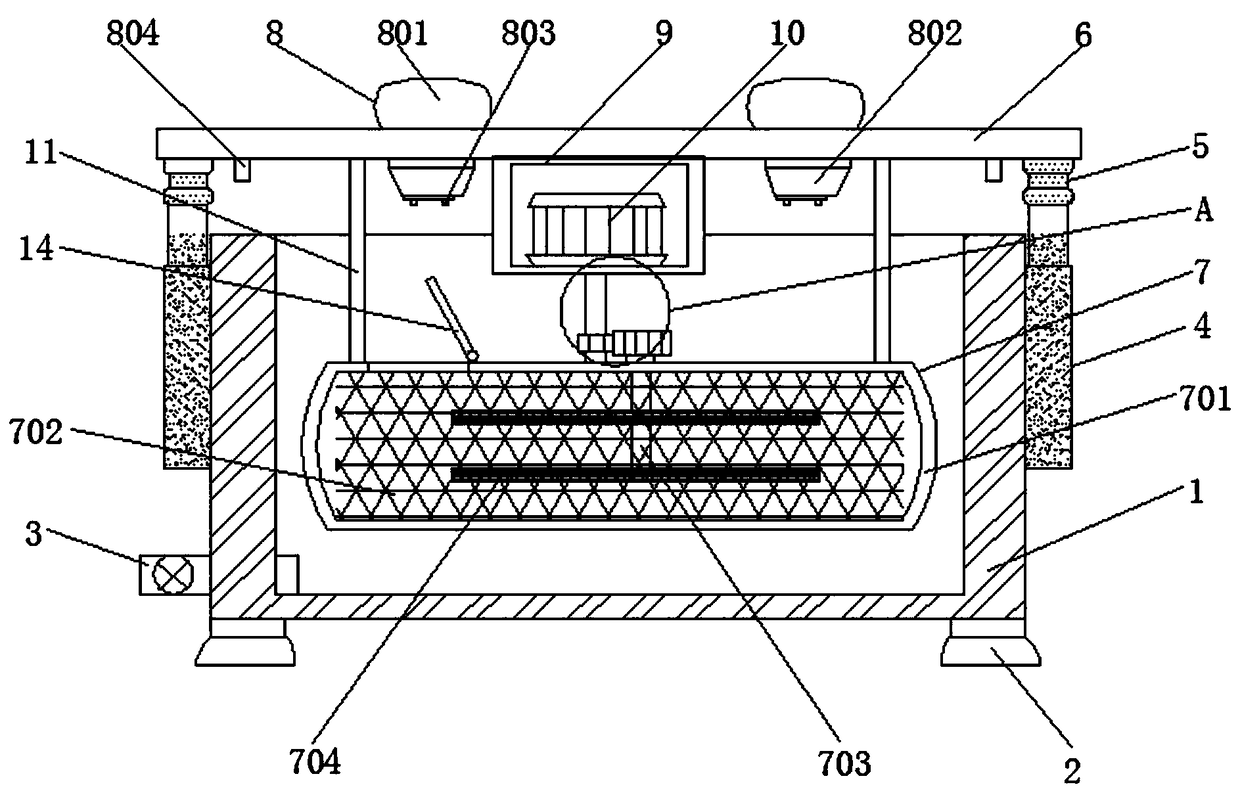

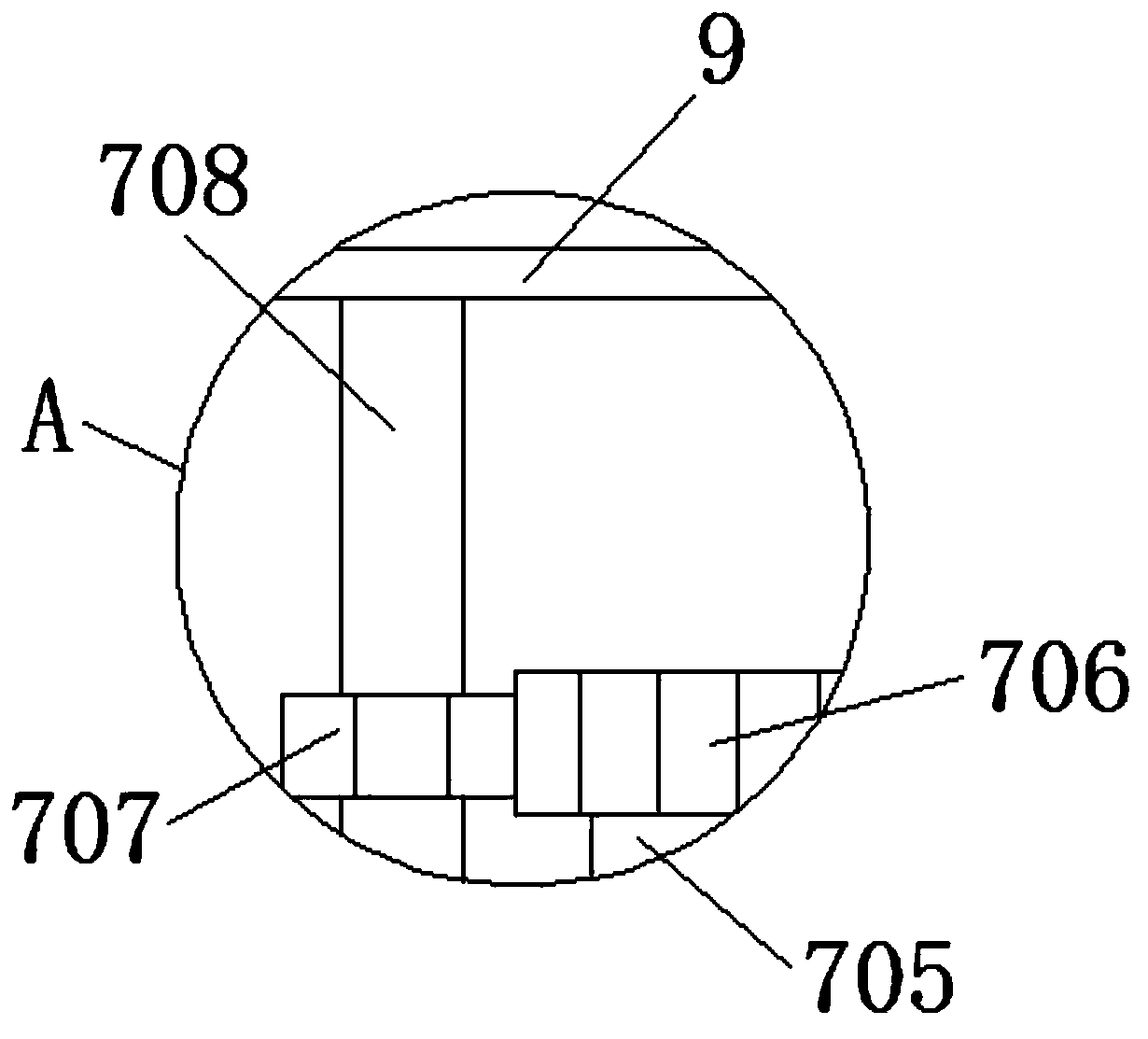

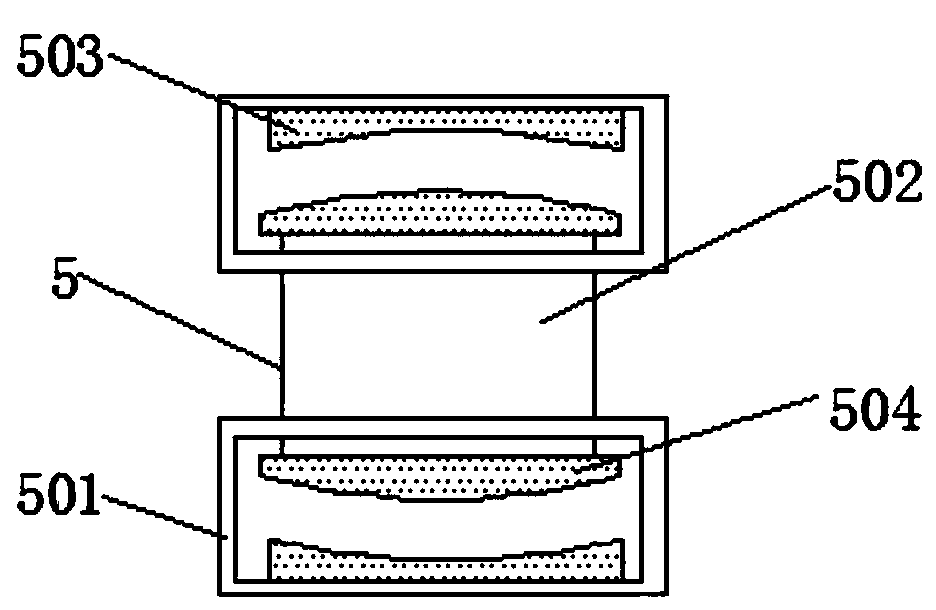

The invention discloses a textile cleaning and drying integrated machine and relates to the technical field of textile processing equipment. The textile cleaning and drying integrated machine includesa box body, a filtering mechanism, a lifting mechanism, a material guiding mechanism, a water inlet pipe, a water outlet pipe, a partition plate, a long hole, strip-shaped holes, mounting plates, bearings, rotating shafts, mounting holes, connecting rods, motors, bobbins, a hot air fan, a three-way pipe, air outlet pipes, air exhaust pipes, a box door and a water tank. The middle of the front face of the box body is movably connected to the box door through hinges, and the water tank is fixedly installed in the inner bottom wall of the box body. According to the textile cleaning and drying integrated machine, the box body can be divided into two spaces for cleaning and drying through the partition plate fixedly connected in the box body, the cleaning and drying operation in the same machine can be conducted, the integration degree is high, the processing cost of the machine can be effectively saved, and accordingly the cost input of manufacturers is reduced.

Owner:SHAOXING KEQIAO CHENGXIN PRECISION CASTING CO LTD

Auxiliary bag suitable for mold release agent to be cleaned

The invention discloses an auxiliary bag suitable for mold release agent to be cleaned, and belongs to the technical field of mold release agent cleaning. The auxiliary bag suitable for the mold release agent to be cleaned comprises a large-diameter multi-layer bag, the large-diameter multi-layer bag comprises a first waterproof layer, a second waterproof layer and a third waterproof layer, the second waterproof layer is located between the first waterproof layer and the third waterproof layer, and the end, away from the second waterproof layer, of the first waterproof layer is fixedly connected to an annular air bag. According to the auxiliary bag, an auxiliary device used for cleaning the mold release agent on the surface of a mold is provided, the cleaning agent flows between the mold and the interior of the device by the device, full contact and emulsification dissolution of the cleaning agent and the mold release agent are achieved, meanwhile, in combination with contact friction of the mold release agent cleaning device on the surface of the mold, removal of the mold release agent can be further promoted, and therefore the one-time circulating cleaning process of the mold release agent is achieved, multiple cleaning steps in the prior art are omitted, and the cleaning efficiency of the mold release agent is greatly improved.

Owner:黄婉霞

Efficient cleaning equipment for copper machining

InactiveCN109647751AAccelerateImprove cleaning efficiencyCleaning using liquidsCleaning using toolsAgricultural engineeringCopper

Owner:瑞安市汇金铜材有限公司

Garbage sorting and screening mechanism of automatic sorting processor for kitchen wastes

InactiveCN112808749AEasy to cleanImprove screening efficiencySievingScreeningElectric machineProcess engineering

The invention discloses a garbage sorting and screening mechanism of an automatic sorting processor for kitchen wastes, in particular to the technical field of sorting and screening of the kitchen wastes. The garbage sorting and screening mechanism comprises a box body and an oily water collection box, wherein a water drain plate is horizontally and fixedly connected to the interior of the box body; reserved holes are formed in the water drain plate; and the oily water collection box is arranged at the bottom end of the water drain plate and is positioned in the box body. According to the garbage sorting and screening mechanism disclosed by the invention, through arrangement of a driving motor, rotary shafts, a frame body, a screening box, clamping slots, a cover plate, a handle and fixed blocks, the cover plate is opened, garbage is poured into the screening box, and then the fixed blocks are embedded in the clamping slots; the driving motor is started, the rotary shafts are driven through a driving shaft to be rotated; and because round holes are formed in the screening box, oily water and small solid garbage can be screened to the bottom of the screening box in a rotation process of the screening box, so that large solid garbage can be remained in the screening box, and therefore, the screening effect is better, the screening efficiency is higher, and the oily water can be conveniently separated from the solid garbage.

Owner:FUJIAN ZHONGHUI ENVIRONMENTAL PROTECTION EQUIP CO LTD

Novel packaging barrel cleaning system

InactiveCN111760866AImprove cleaning efficiencyPracticalHollow article cleaningStationary filtering element filtersWater tanksWater supply

Owner:珠海光瑞新材料有限公司

Cleaning robot control system and cleaning route generation method

ActiveCN112256039AImprove cleaning efficiencyTotal factory controlPosition/course control in two dimensionsControl mannerControl engineering

The invention relates to the field of cleaning robots, in particular to a cleaning robot control system and a cleaning route generation method, and mainly aims to solve the problem that an existing cleaning robot control system does not support manual robot cleaning area designation and route planning. The cleaning robot control system can respond to the division operation of a user on a cleaningarea, divide the cleaning area into a plurality of cleaning areas, automatically generate a cleaning route of each cleaning area, and then guide the cleaning robot to advance according to the cleaningroute of a target cleaning area selected by the user. Through the control mode, the cleaning robot can clean the cleaning area specified by the user according to the planned cleaning route, and the cleaning efficiency is effectively improved.

Owner:SHENZHEN REEMAN INTELLIGENT EQUIP CO LTD

Environment-friendly water-based ink cleaning agent and preparation method thereof

Aiming at the disadvantages that the cleaning effect of water-based ink cleaning agents on the current market is not ideal, the surface of cleaned workpiece is corroded by added strong alkaline assistants, the environment is easily polluted and the like, the invention provides an environment-friendly water-based ink cleaning agent which has high cleaning efficiency, does not easily corrode the surface and is easily biodegrade, and a preparation method of the ink cleaning agent. The water-based ink cleaning agent comprises the following components in percentage by mass: 5-10% of an anionic-cationic surfactant compound, 6%-15% of a polar solvent, 2%-5% of a solubilizer, 5%-10% of other auxiliary agents and the balance of water.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Fodder cleaning and drying device for livestock breeding

InactiveCN108636916AEnhanced flushingImprove cleaning efficiencyCleaning using liquidsDrying gas arrangementsAgricultural machineryCentrifugal force

Owner:陶令

Raw material cleaning device for clinopodium polycephalum tablet production

PendingCN114226332AEasy to operateImprove cleaning efficiencyCleaning using liquidsClinopodium polycephalumManufacturing engineering

Owner:HUIYINBI GROUP ANHUI PHARMA

Railway ballast bed cleaning working method

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Surface cleaning equipment and self-cleaning mopping control method thereof

PendingCN113796792ASimple structureImprove cleaning efficiencyAutomatic obstacle detectionTravelling automatic controlProcess engineeringEnvironmental geology

The invention discloses surface cleaning equipment and a self-cleaning mopping control method thereof. The surface cleaning equipment comprises a main machine, a control system, a driving wheel assembly, a roller assembly, a roller driving mechanism, a clean water spraying system and a sewage recycling system. A containing cavity with a downward opening is formed in the main machine, the roller assembly is installed in the containing cavity, a cleaning cavity is formed between the upper portion of the containing cavity and the roller assembly in a matched mode, and the roller driving mechanism is used for driving the roller assembly to rotate. The driving wheel assembly is installed at the front end of the bottom of the host and used for receiving instructions of the control system to drive the host to move. The clear water spraying system is used for spraying clear water to the roller and the sewage recycling system is used for recycling sewage formed in the cleaning cavity. According to the invention, the ground is wiped through the roller, self-cleaning of the roller can be achieved in the wiping process, and the cleaning effect of the device is greatly improved; and meanwhile, the control method of the equipment can greatly reduce the working power consumption and water consumption, and the cruising ability is effectively improved.

Owner:NINGBO SAWADIKA ELECTRICAL APPLIANCE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap