Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Surface cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based airplane surface cleaning agent and preparation method thereof

ActiveCN101955854AThe formula is scientific and reasonableSimple production processInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedSurface cleaning

The invention relates to a water-based airplane surface cleaning agent, which is prepared by uniformly mixing the following components in percentage by weight: 21 to 30 percent of degradable surfactant, 5 to 7 percent of metal corrosion inhibitor, 0.3 to 2 percent of pH regulating agent, 1.7 to 5 percent of stabilizer, and the balance of deionized water. A preparation method comprises the following steps: (1) weighing the pH regulating agent, the degradable surfactant, the metal corrosion inhibitor, the stabilizer and the deionized water according to the ratio of weight percent; (2) adding the pH regulating agent, the metal corrosion inhibitor, the degradable surfactant and the stabilizer into the deionized water at the room temperature of between 23 and 25 DEG C; and (3) stirring the liquid at constant speed of 60 to 80r / min for 20 to 40 minutes to ensure that no bubble is generated in the liquid to prepare the cleaning agent after uniform mixing. The invention has scientific and reasonable formula and simple process without special equipment, and the cleaning agent has the advantages of strong cleaning capability, short cleaning time, low cost, high efficiency and is safe and reliable for use.

Owner:BEIJING KAILAN AVIATION TECH CO LTD

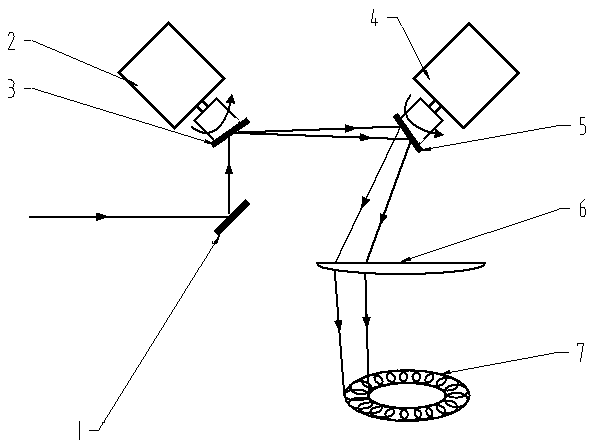

Two unidirectional rotating mirrors based method and device for realizing uniform laser cleaning

InactiveCN110262037AScan evenlyAvoid damageCleaning processes and apparatusOptical elementsSurface cleaningLight beam

Owner:WEIFANG UNIVERSITY

Liquid acidic hard surface cleaning compositions having improved viscosity

ActiveUS20190352579A1Organic detergent compounding agentsSurface-active detergent compositionsHydrotropeSurface cleaning

The need for an acidic hard surface cleaning composition which provides further improvements in the maintenance of surface shine, especially on inclined hard surfaces, while also using less thickener is met by formulating the acidic hard surface cleaning composition using a combination of a surface modification polymer and sulfonate hydrotrope.

Owner:PROCTER & GAMBLE CO

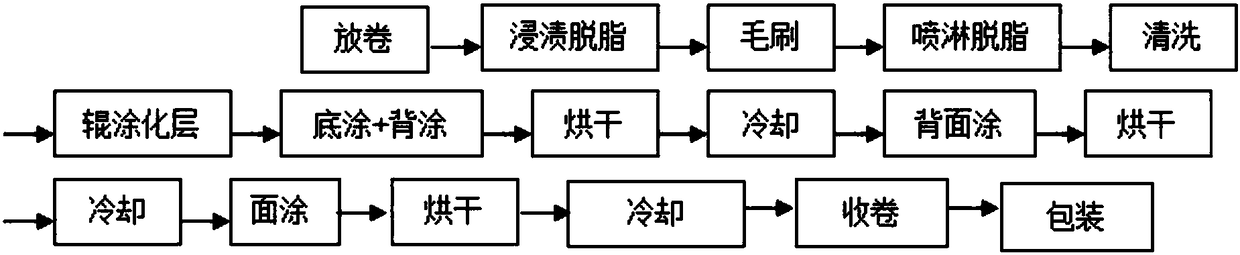

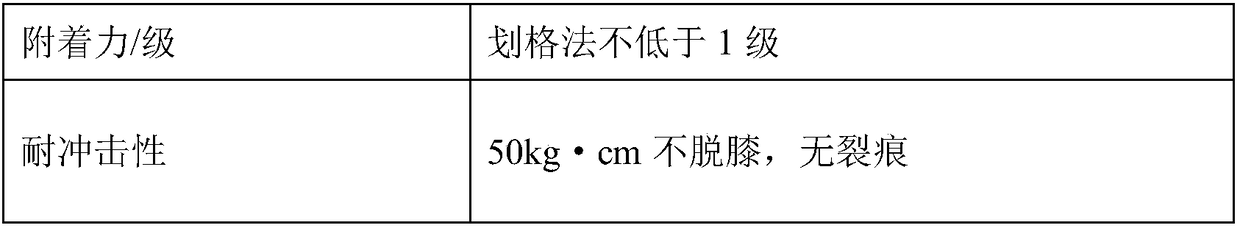

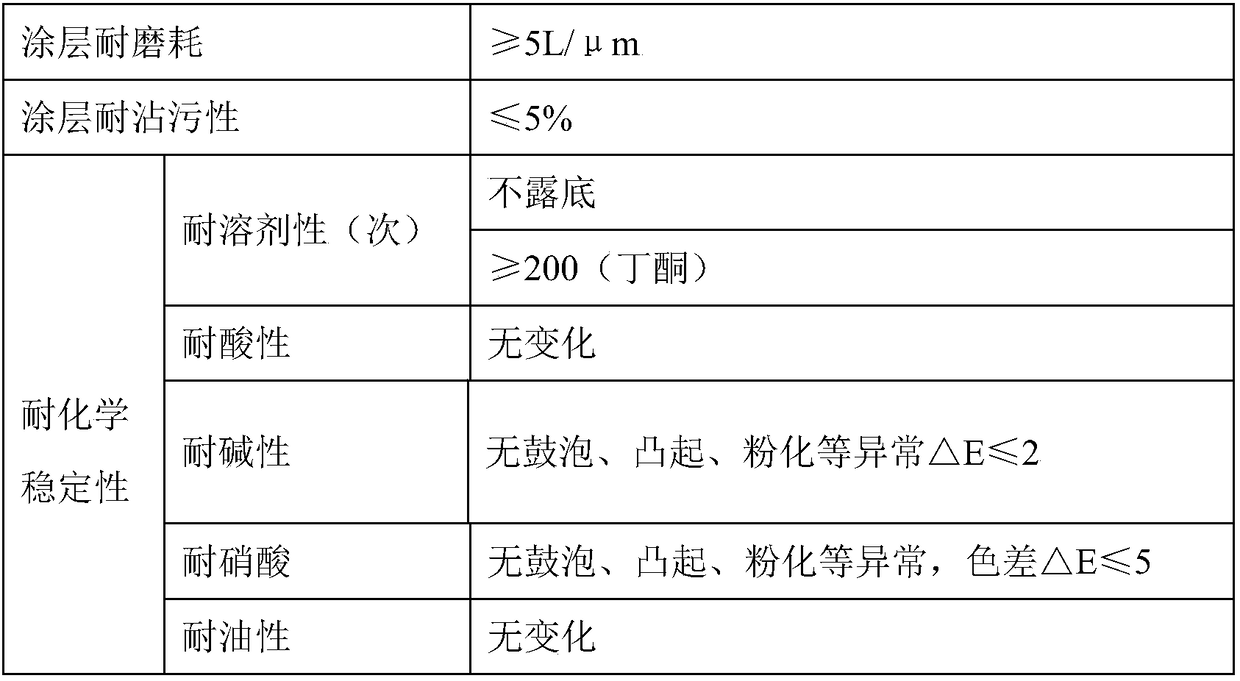

Double-face roller coating color aluminum plate preparing technology

InactiveCN108515010AGood effectImprove adhesionPretreated surfacesCoatingsSurface cleaningAssembly line

Owner:安徽墙煌彩铝科技有限公司

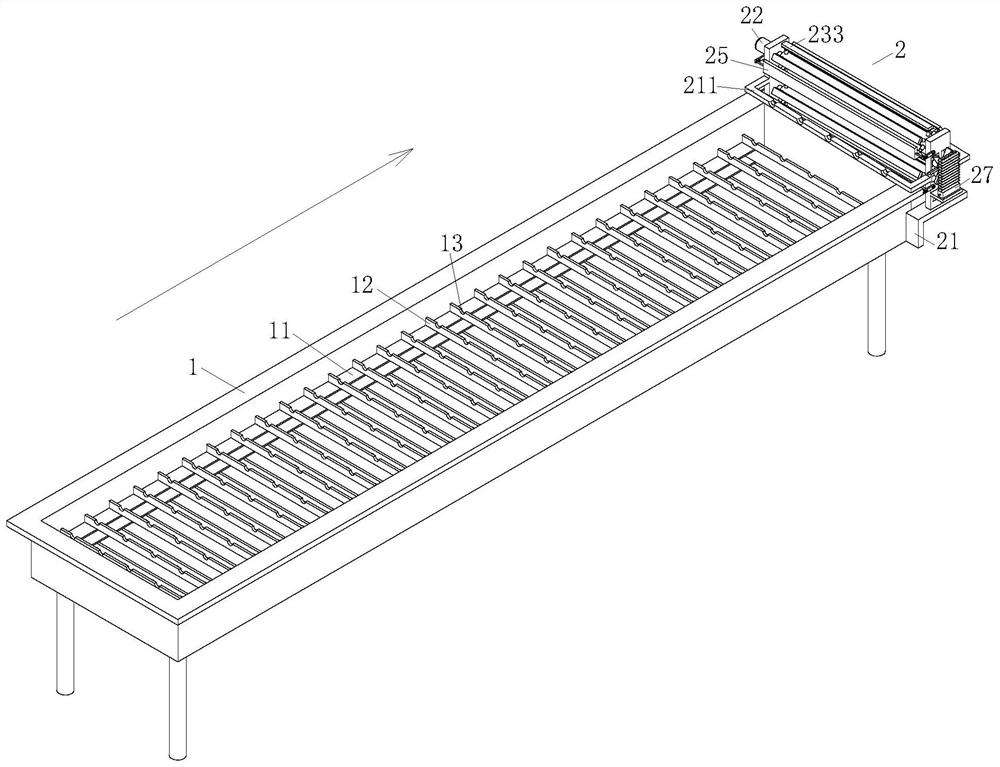

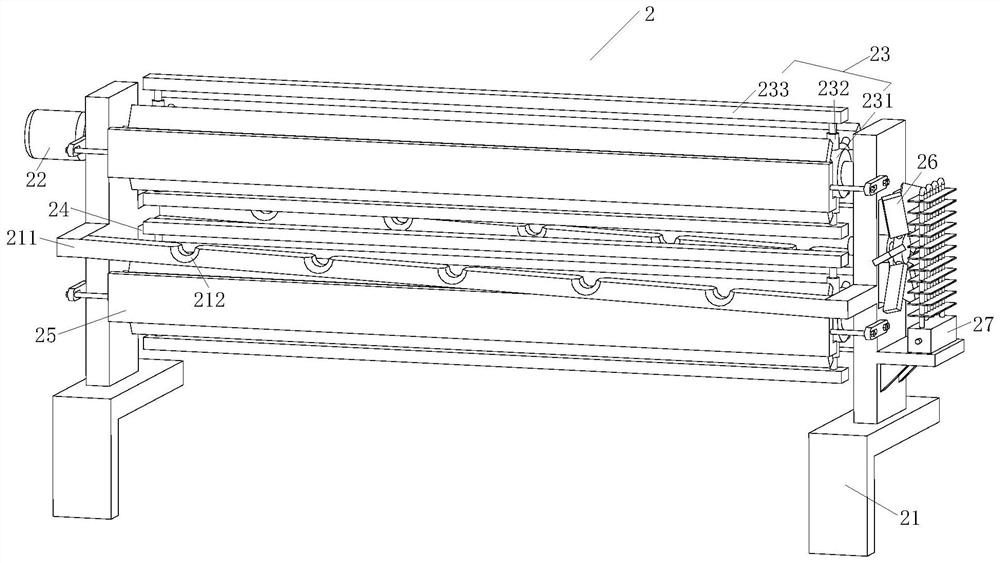

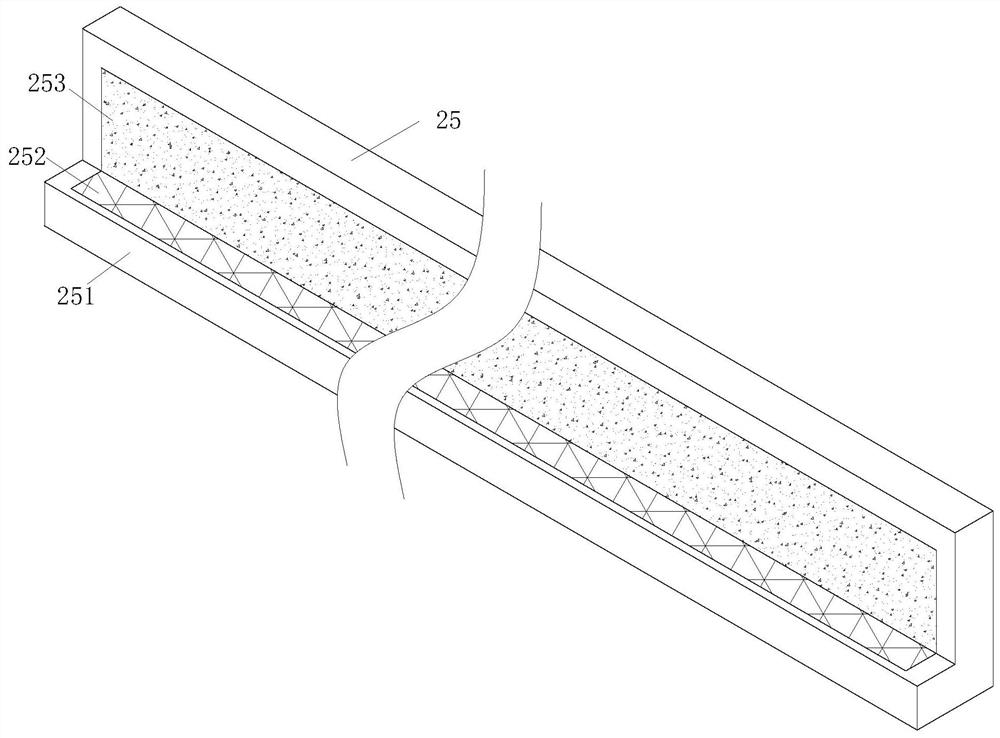

Preparation system of biodegradable composite material

PendingCN113478674ADry fastFully contactedDrying gas arrangementsDrying machines with progressive movementsSurface cleaningWater resources

Owner:李文干

Metal surface cleaning agent based on firmiana simplex bark extract and preparation method thereof

InactiveCN105543881ASulfadiazineSurface cleaning

Owner:铜陵铜官府文化创意股份公司

Method for improving endurance of battery electric vehicle based on connection of aluminum skin and steel vehicle body

InactiveCN111976845AGuaranteed flatnessGuaranteed bonding strengthSuperstructure connectionsSurface cleaningAdhesive glue

The invention discloses a method for improving the endurance of a battery electric vehicle based on connection of an aluminum skin and a steel vehicle body. The method comprises the following steps that the aluminum skin is treated, firstly, the inner surface of the aluminum skin is dried for 15 minutes after being cleaned, then prime coating operation is carried out, and drying is also carried out for 15 minutes after prime coating operation; a steel vehicle body framework is polished and then subjected to prime coating operation; limiting adhesive tape is pasted on the steel vehicle body framework; an area defined by the limiting adhesive tape on the steel vehicle body framework is glued; the aluminum skin is pasted on the steel vehicle body framework, and the aluminum skin is positionedthrough a clamp so as to adjust the height; the front end flange of the aluminum skin is nailed to achieve temporary fixation; the aluminum skin is tensioned; flame treatment is carried out to relieve stress so as to tightly attach the aluminum skin to the steel vehicle body framework; the front end flange of the aluminum skin is nailed and cut off; and the aluminum skin and the steel vehicle body are fixedly connected. According to the method for improving the endurance of the battery electric vehicle based on connection of the aluminum skin and the steel vehicle body, the aluminum skin andthe steel vehicle body are connected by adopting a glue bonding scheme, so that the flatness of the aluminum skin is ensured while the bonding strength is ensured.

Owner:NANJING GOLDEN DRAGON BUS

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap