Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about "Drying machines with progressive movements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

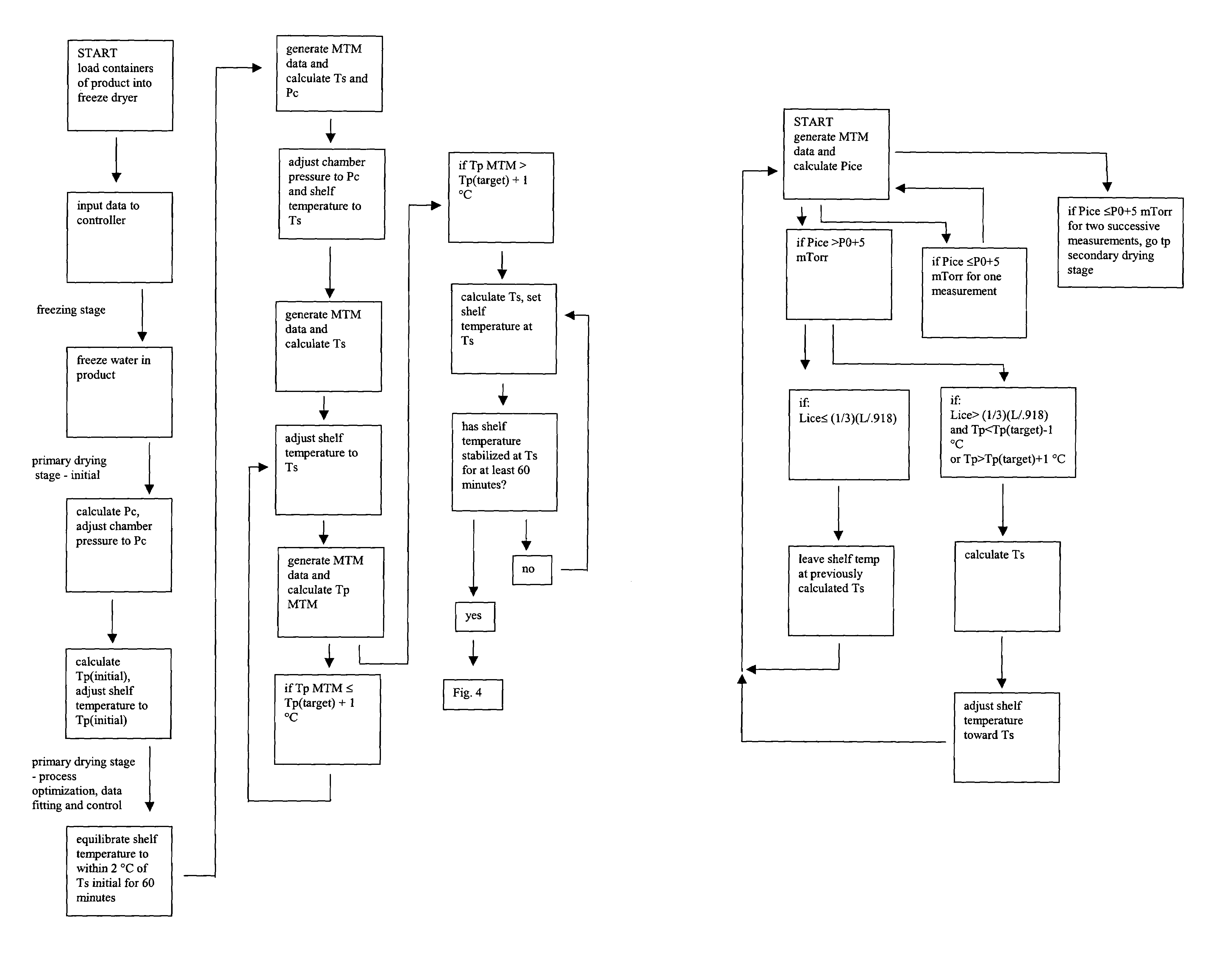

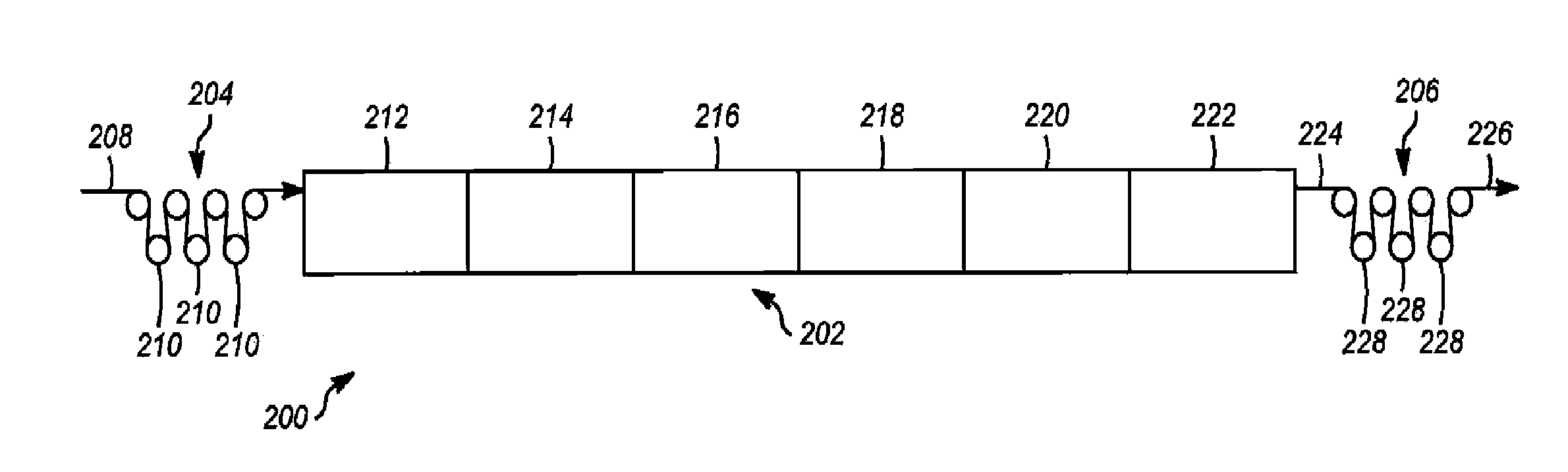

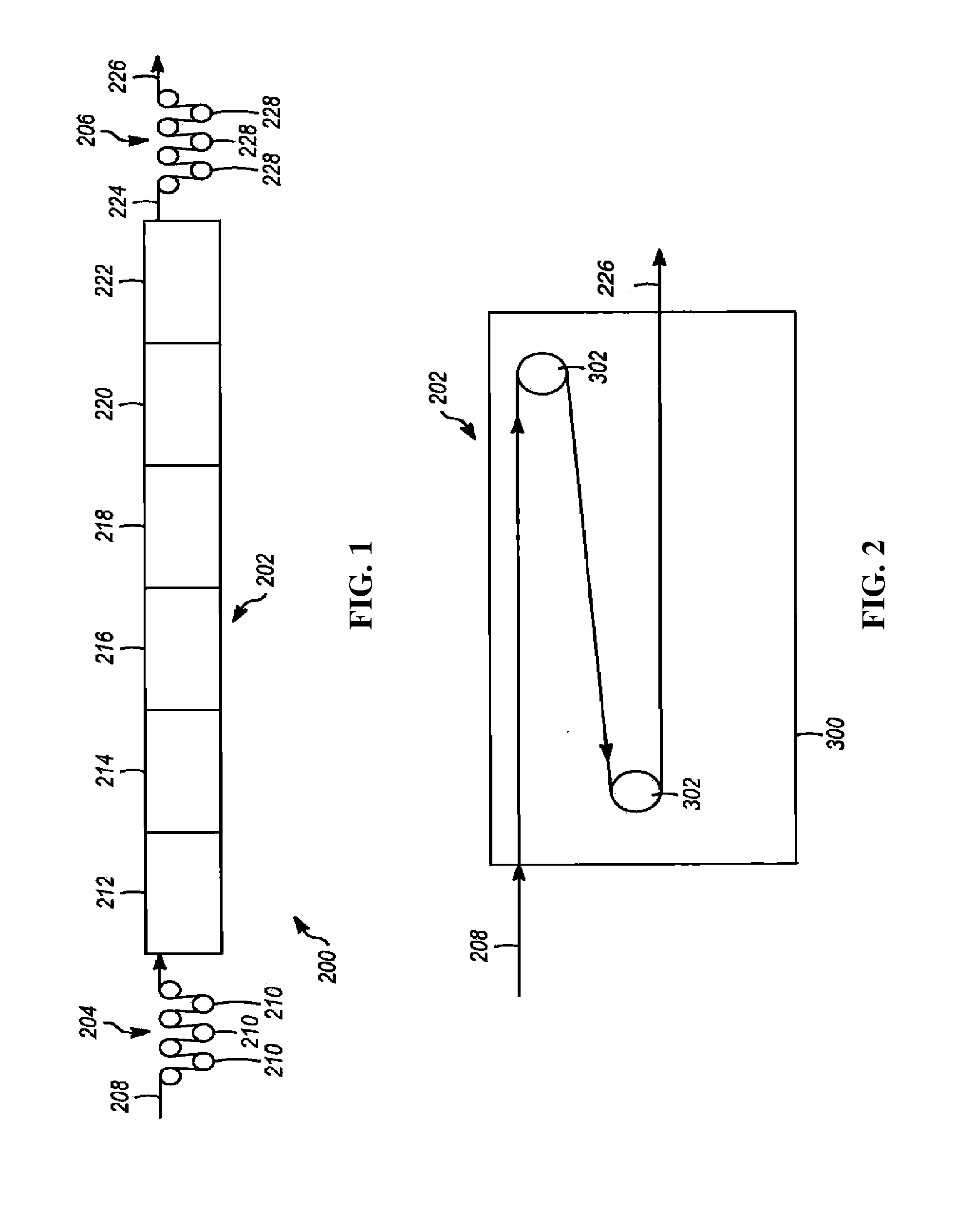

Automated process control using manometric temperature measurement

ActiveUS6971187B1Simple processDrying solid materials without heatDrying machines with progressive movementsFreeze-dryingControl system

Owner:PURDUE RES FOUND INC +1

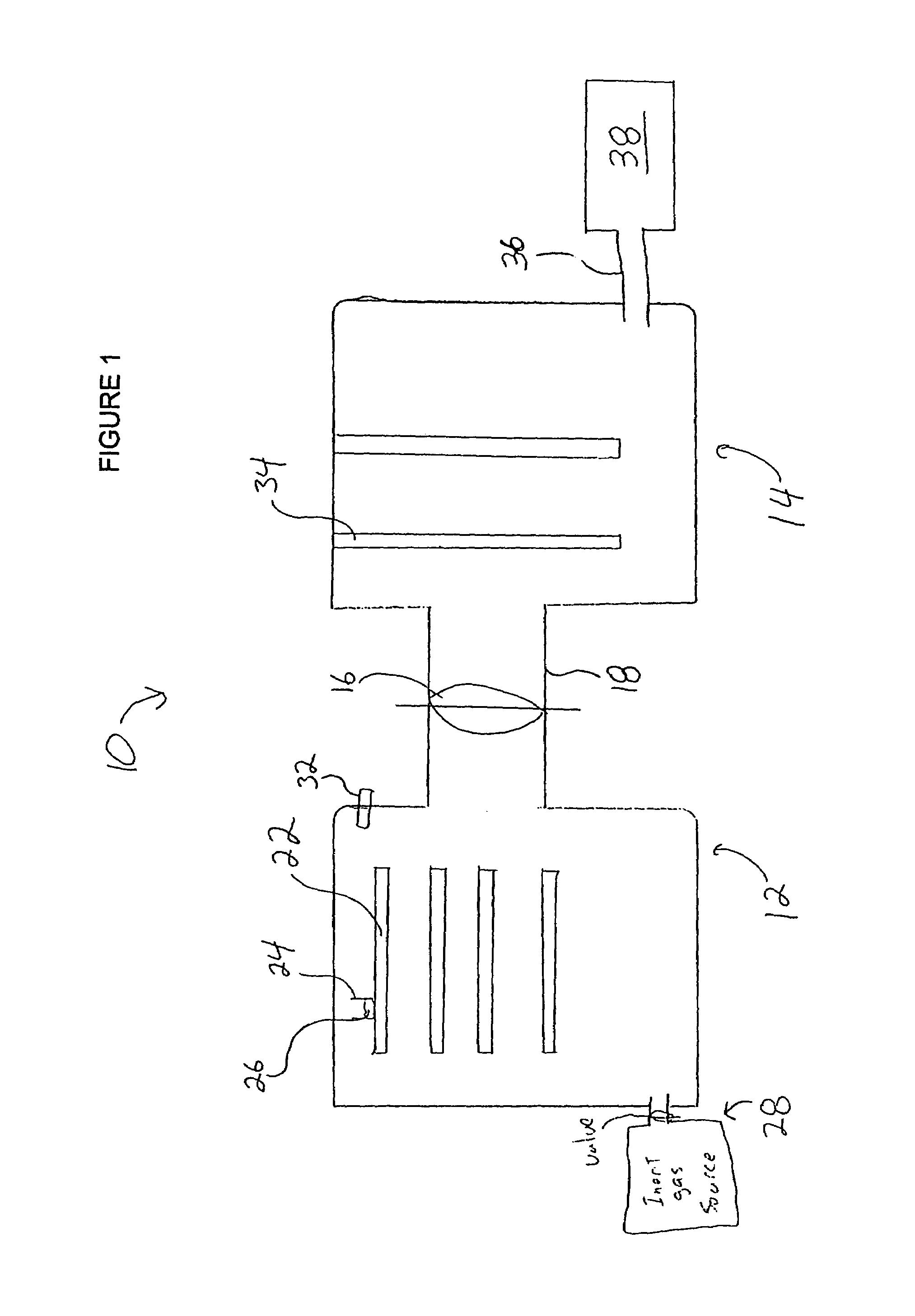

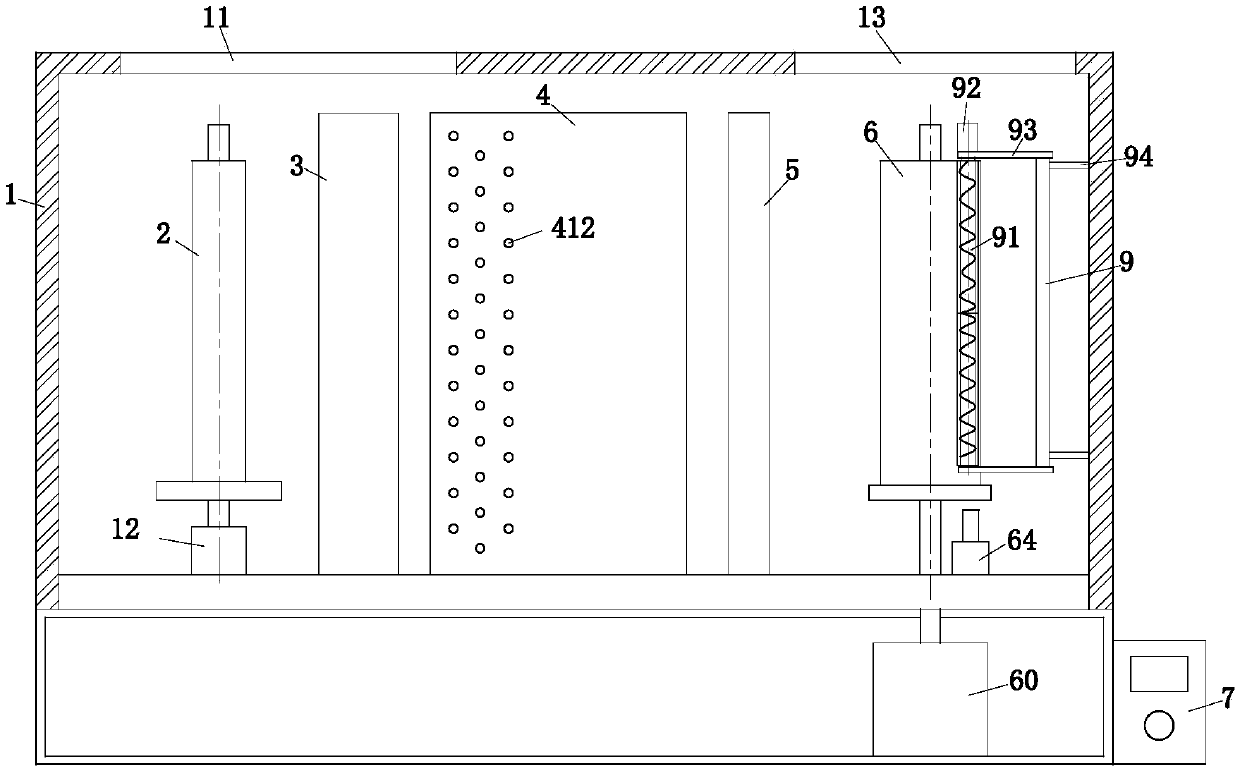

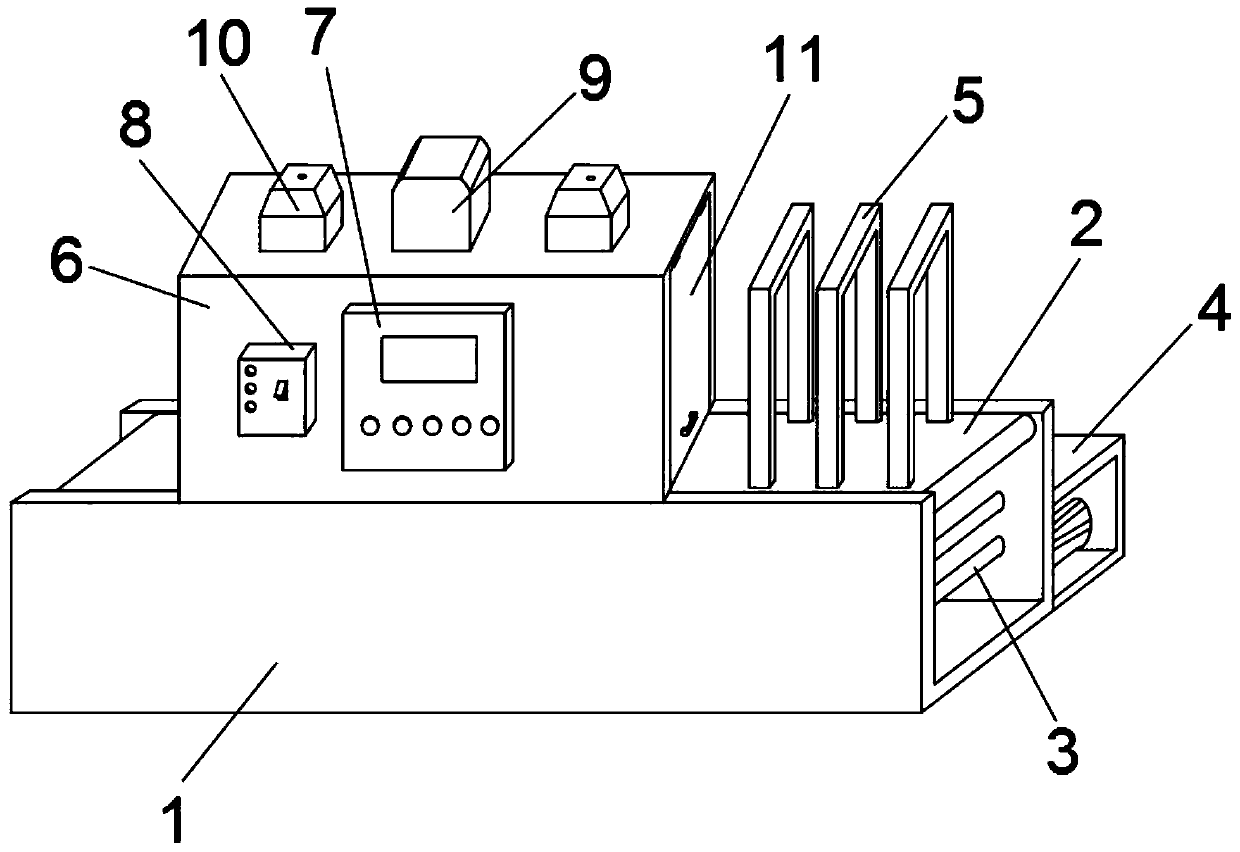

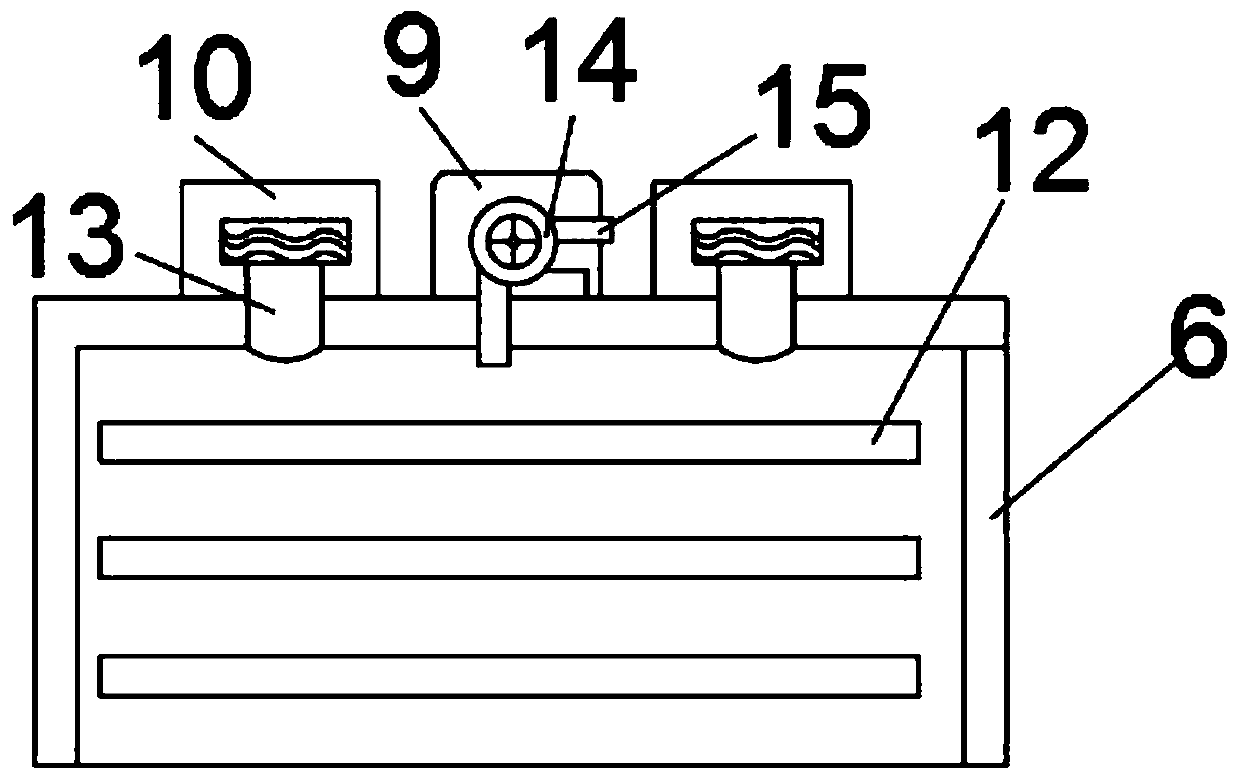

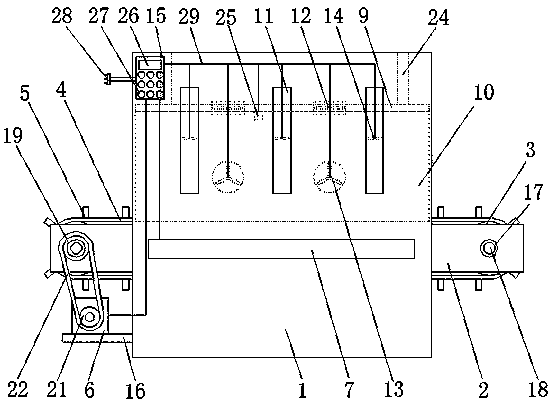

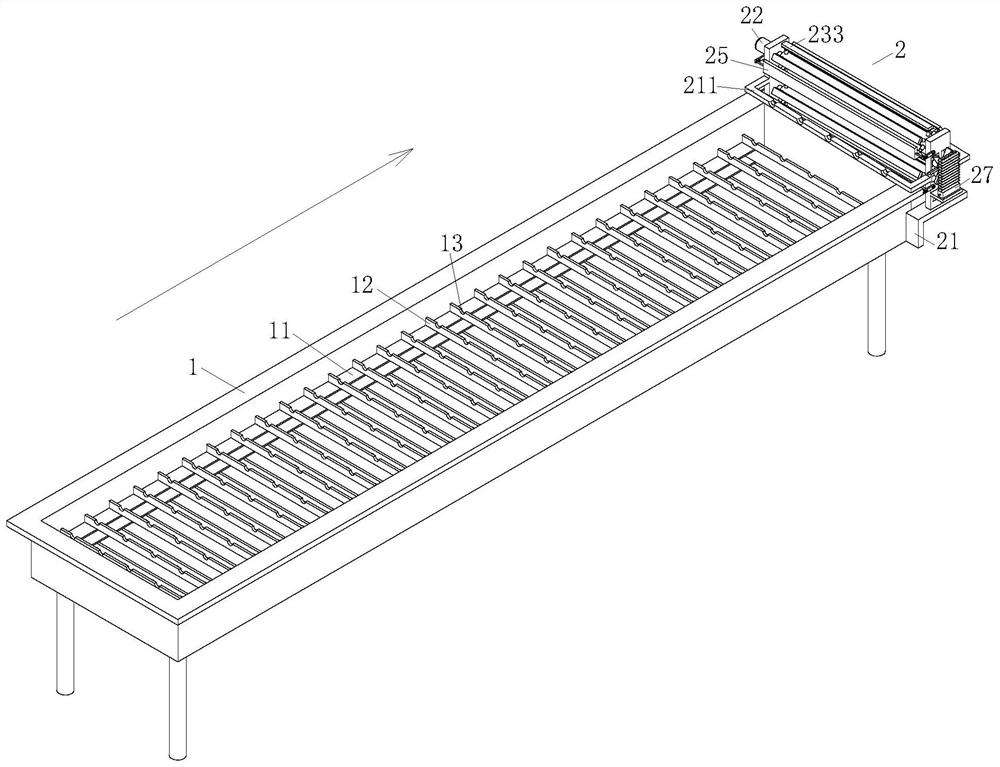

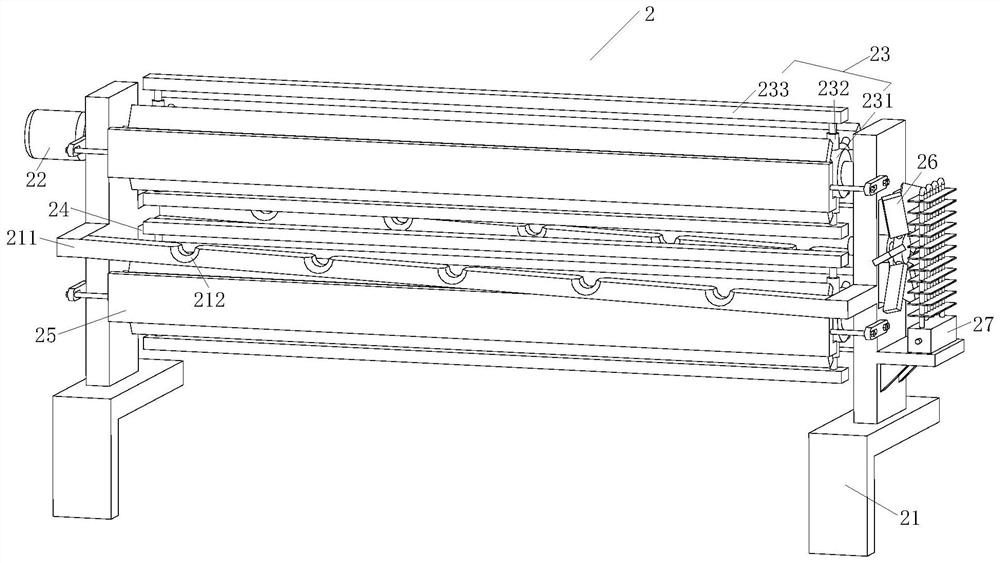

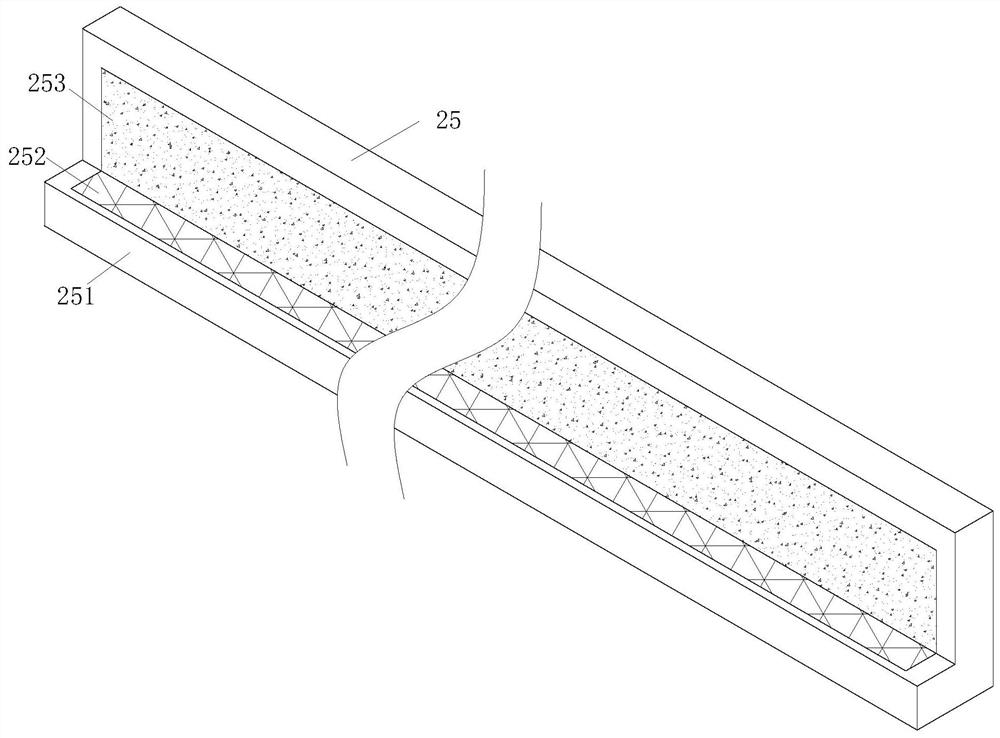

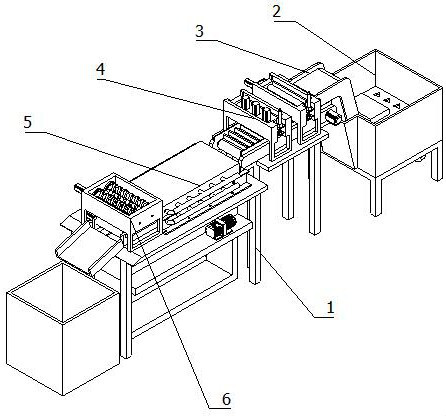

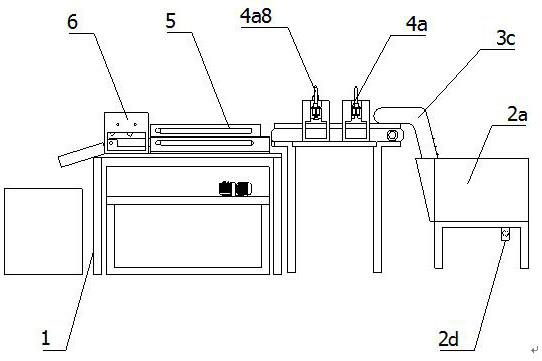

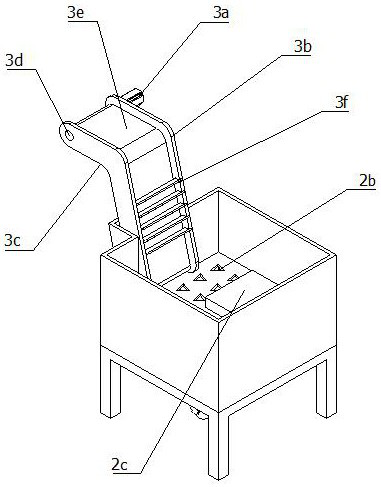

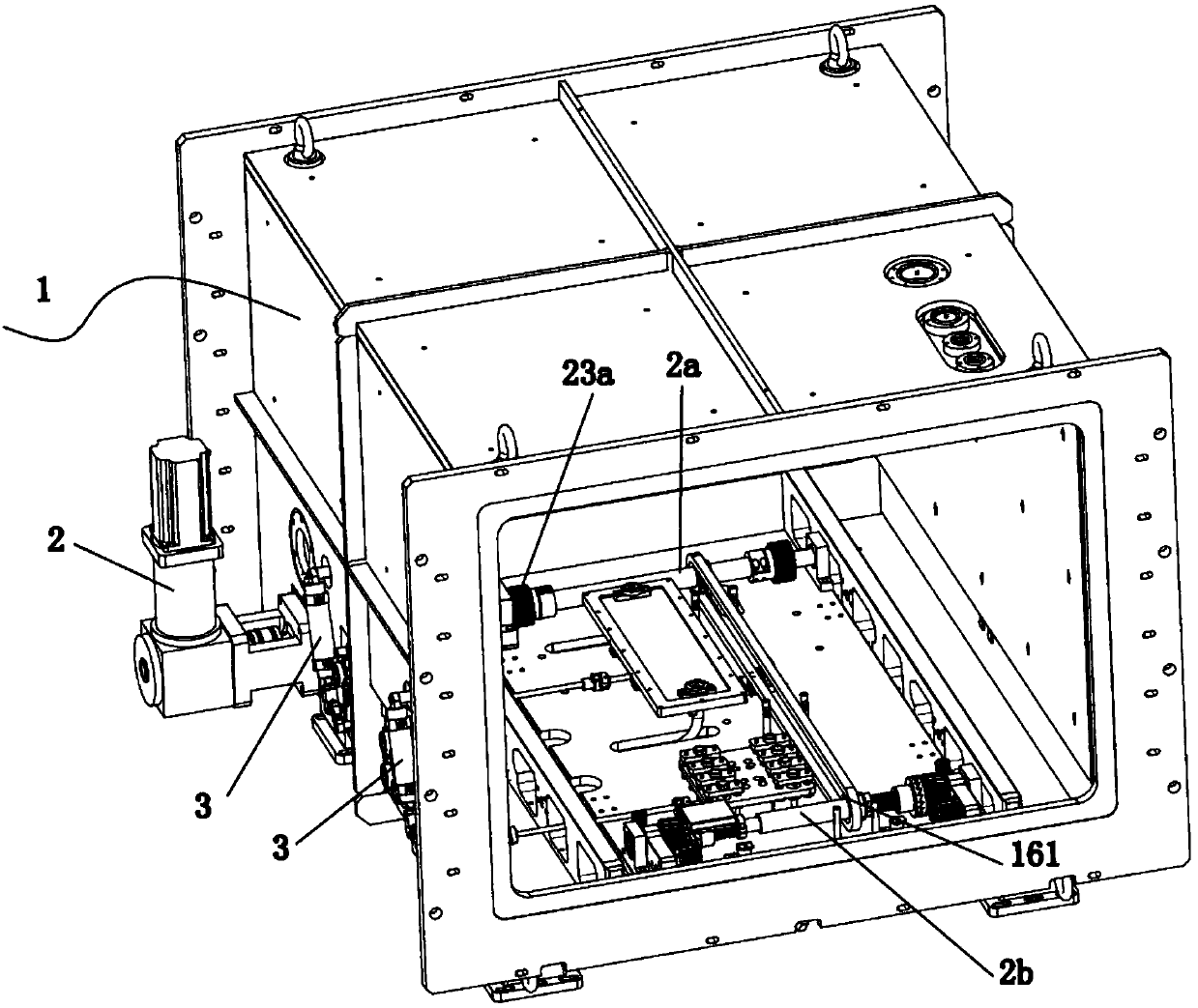

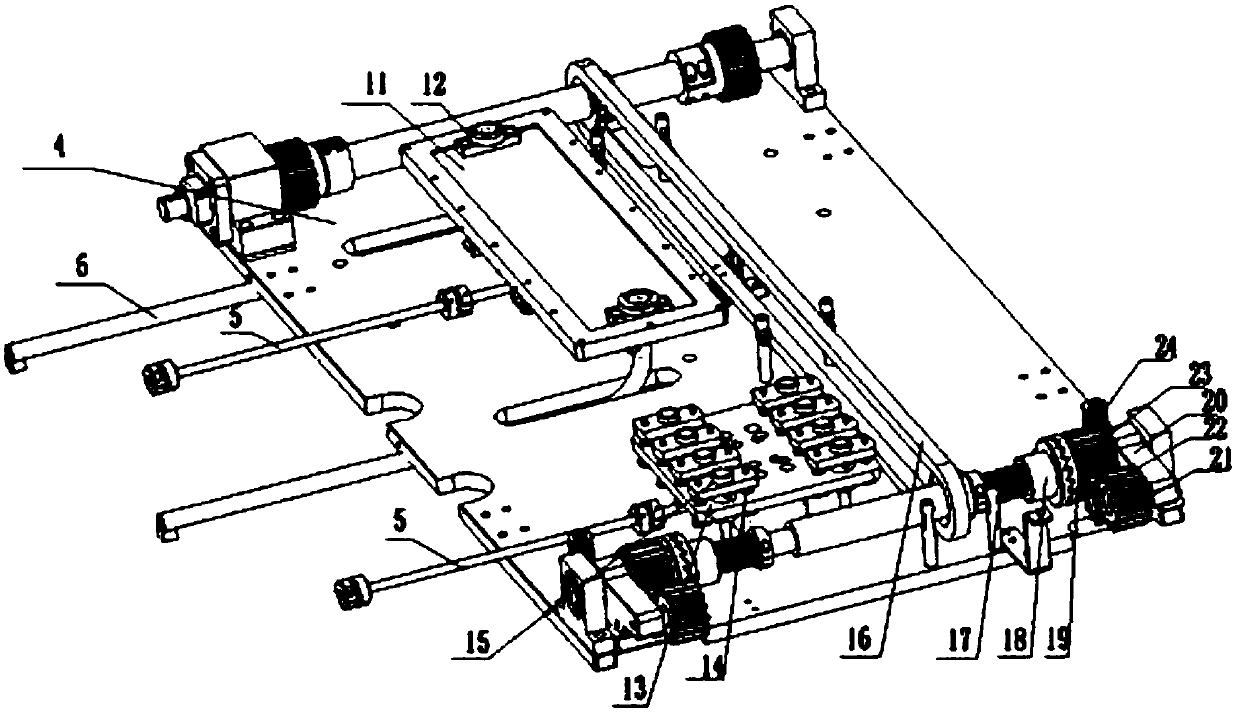

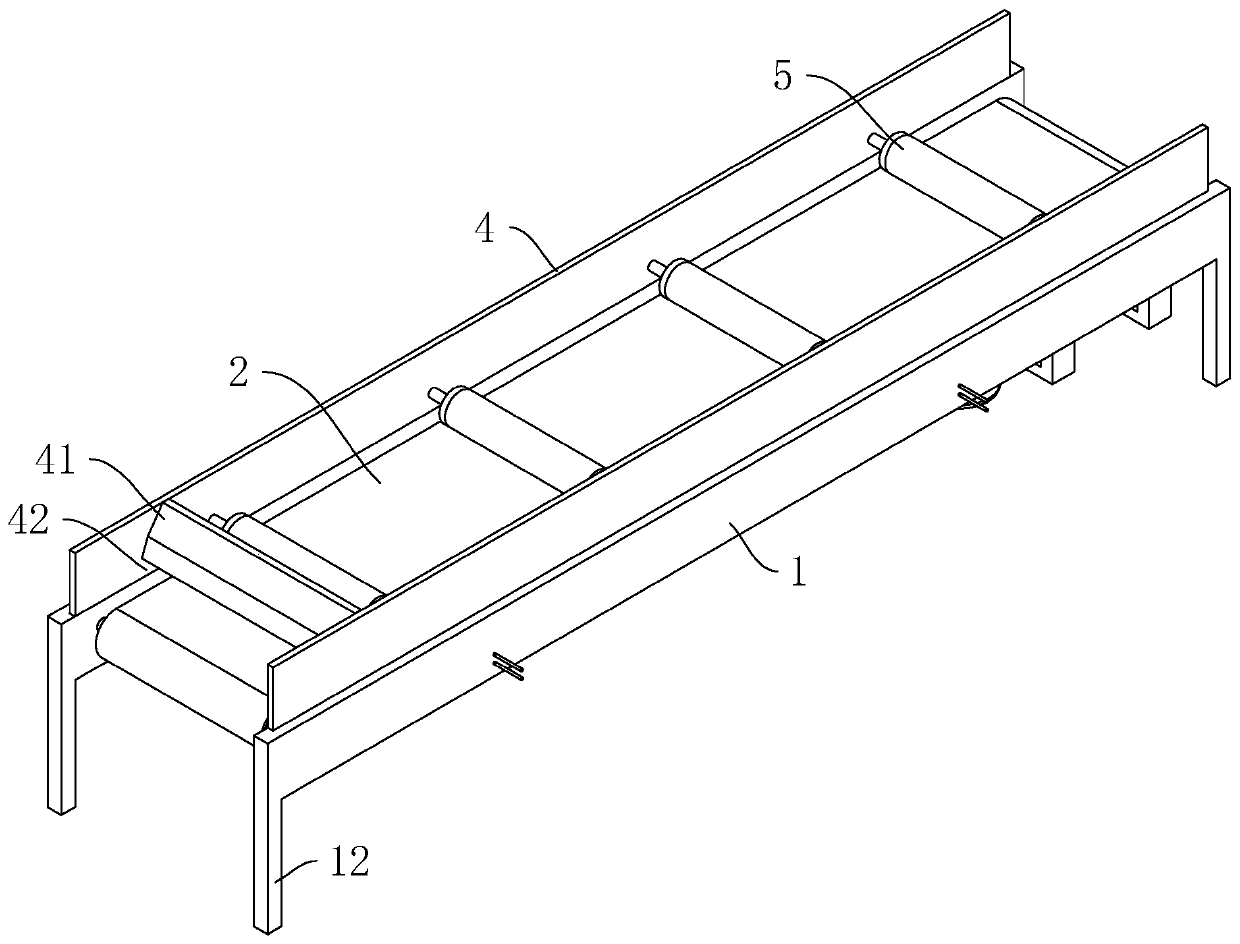

Online chip cleaning and drying equipment

ActiveCN102820242ASimple structureIngenious designDrying using combination processesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

The invention discloses online chip cleaning and drying equipment which comprises an automatic feeding mechanism, a spray type cleaning device, vacuum drying equipment and a positioning table. The vacuum drying equipment comprises a frame; a pair of drying conveying belts which are connected with a cleaning machine, support the two sides of a chip and horizontally move are arranged in the middle of the frame; a push plate which controls and supports the chip to move up and down through mechanical power is arranged on the frame below the part between the drying conveying belts; a first vacuum chamber provided with a vacuum sucker and an infrared heating tube is arranged right over the push plate; a second vacuum chamber which is movably connected with the first vacuum chamber through a connecting rod mechanism and provided with a sealing structure matched with the lower end of the first vacuum chamber is arranged on one side of the first vacuum chamber; and a vacuum adsorption hole corresponding to the chip is formed on one side of the second vacuum chamber corresponding to the first vacuum chamber and provided with the sealing structure. The equipment is simple in structure and skillful in design, automatically picks up chips, performs spray type cleaning and vacuum drying on the chip, dries the chip through thermal power in the vacuum environment, and prevents the chips from being damaged.

Owner:TONGLING TAIYANGDAO AGRI TECH CO LTD

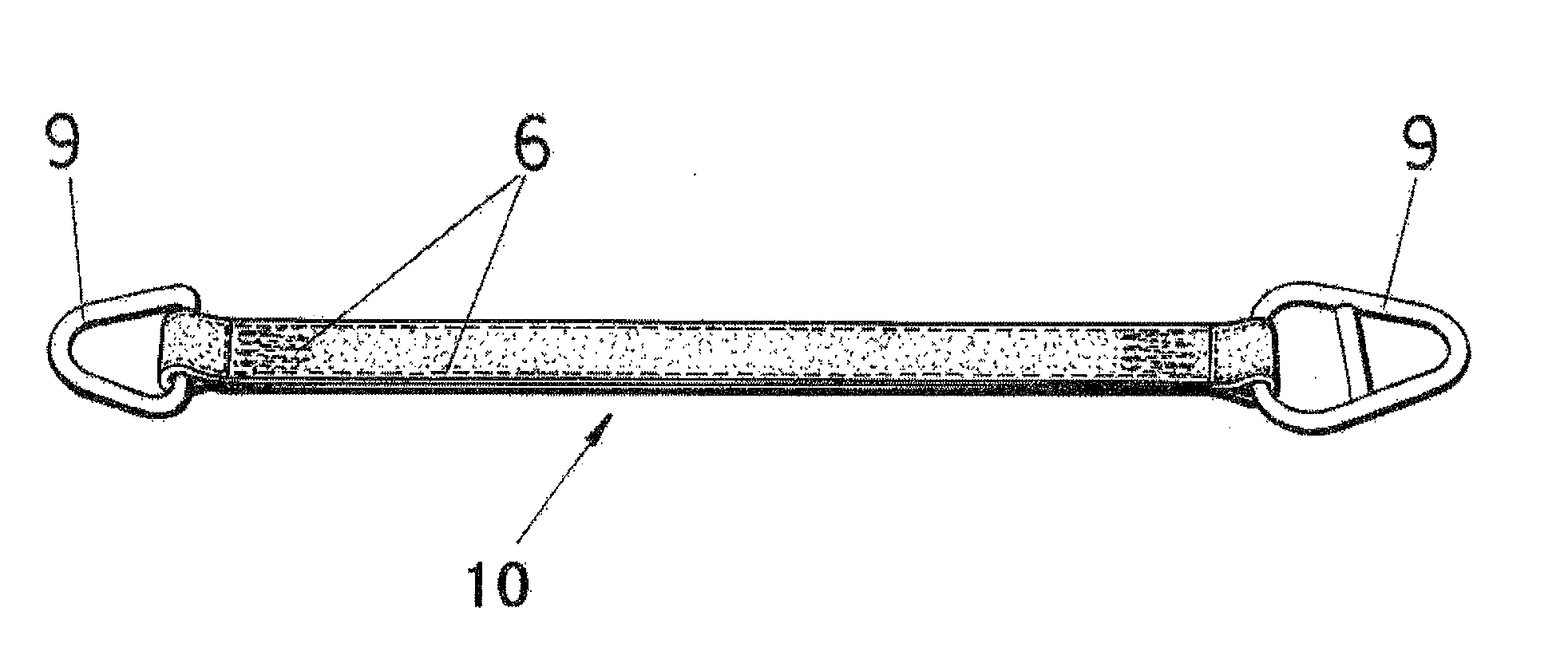

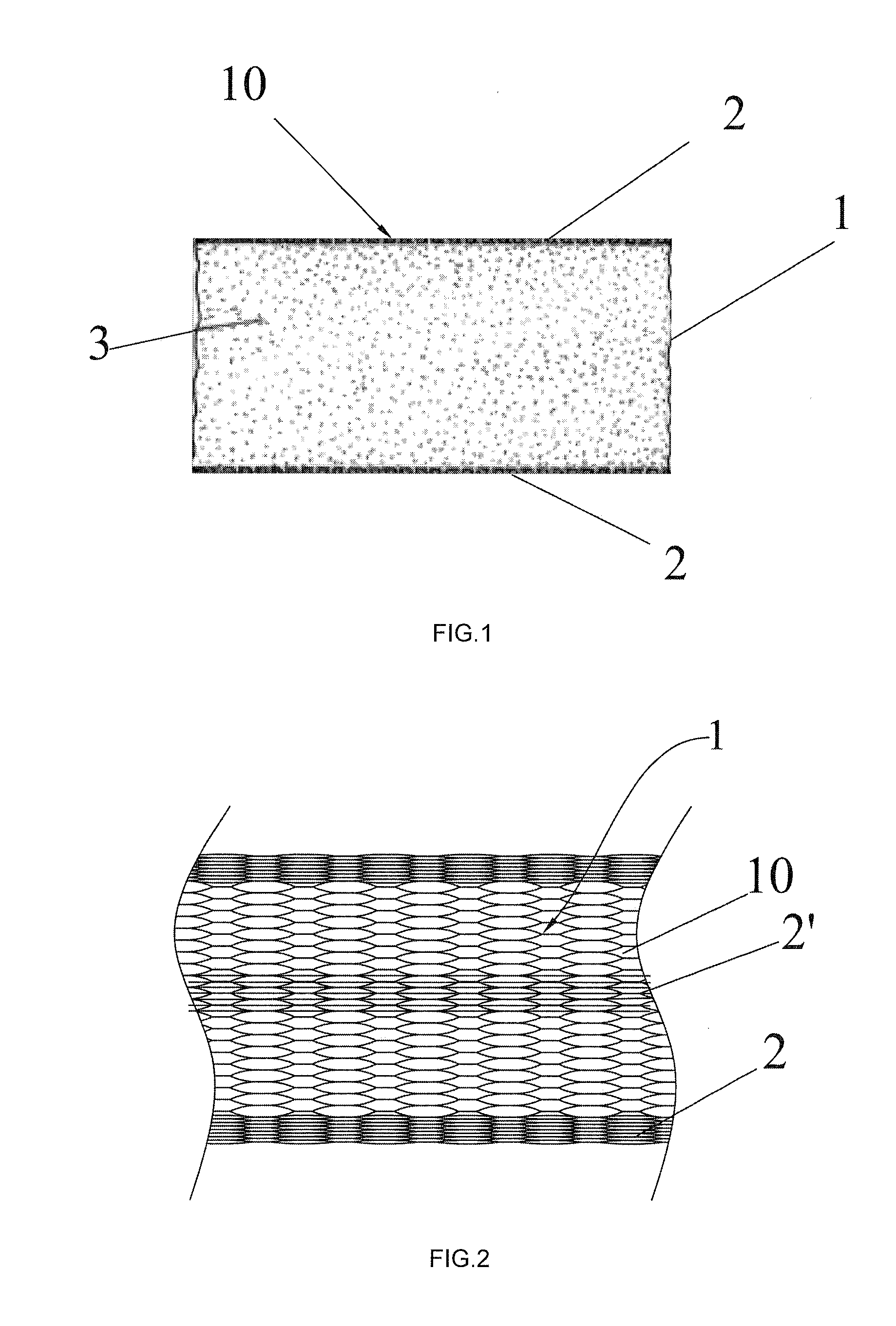

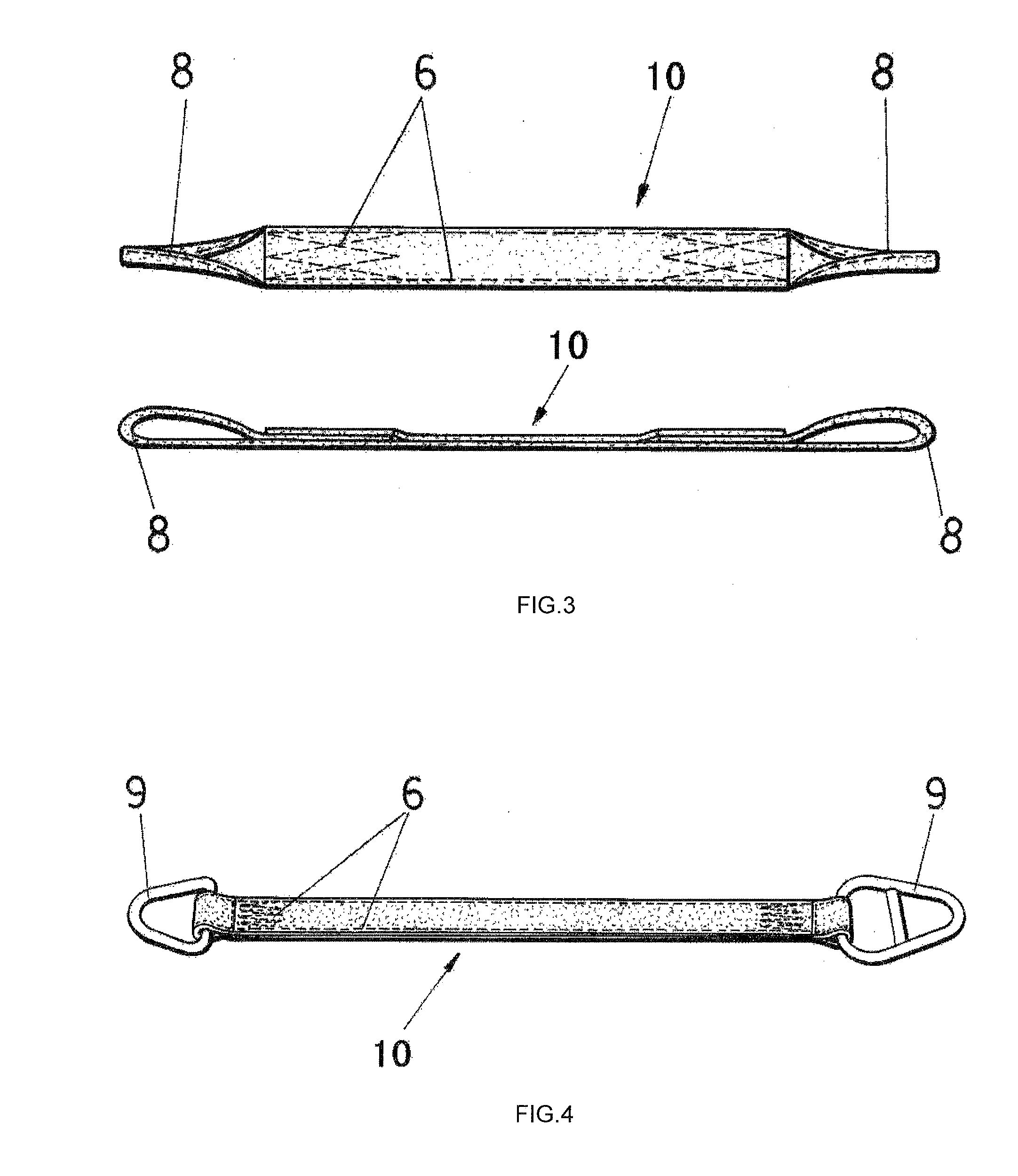

Textile sling and method of manufacturing same

InactiveUS20100327615A1Tough to abrasionTough to cutLoomsDrying machines with progressive movementsYarnPolyurethane dispersion

Owner:DONGGUAN PONSA TEXTILE

Novel uhmwpe fiber and method to produce

Owner:HONEYWELL INT INC

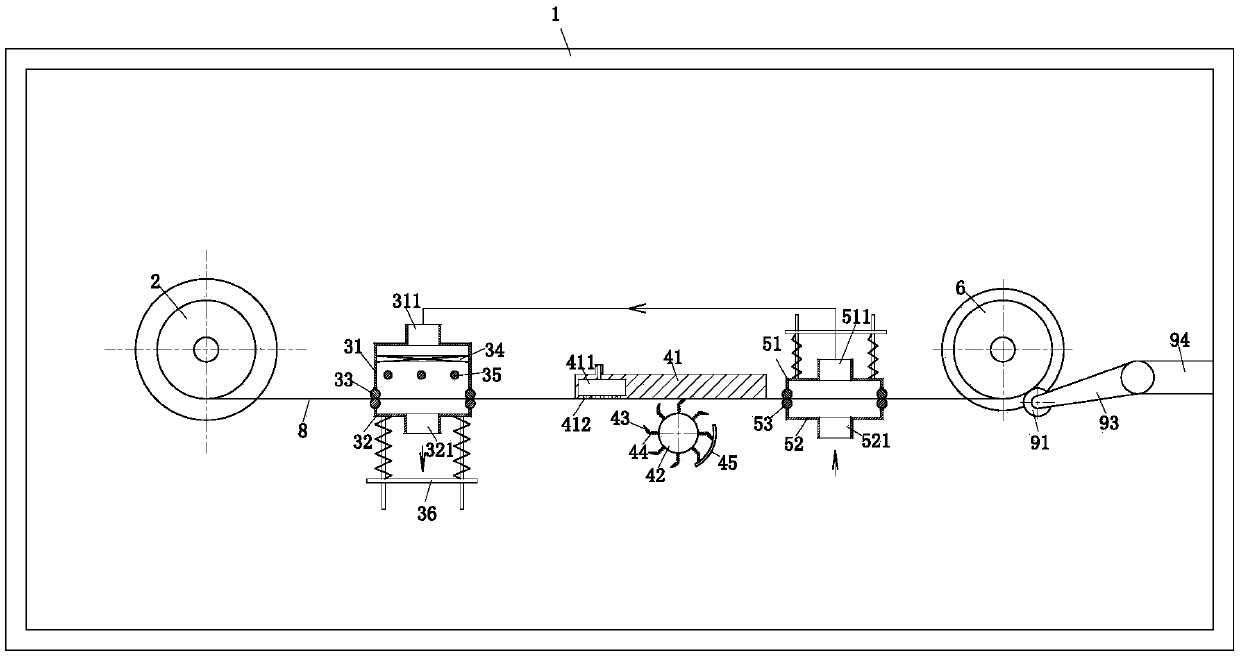

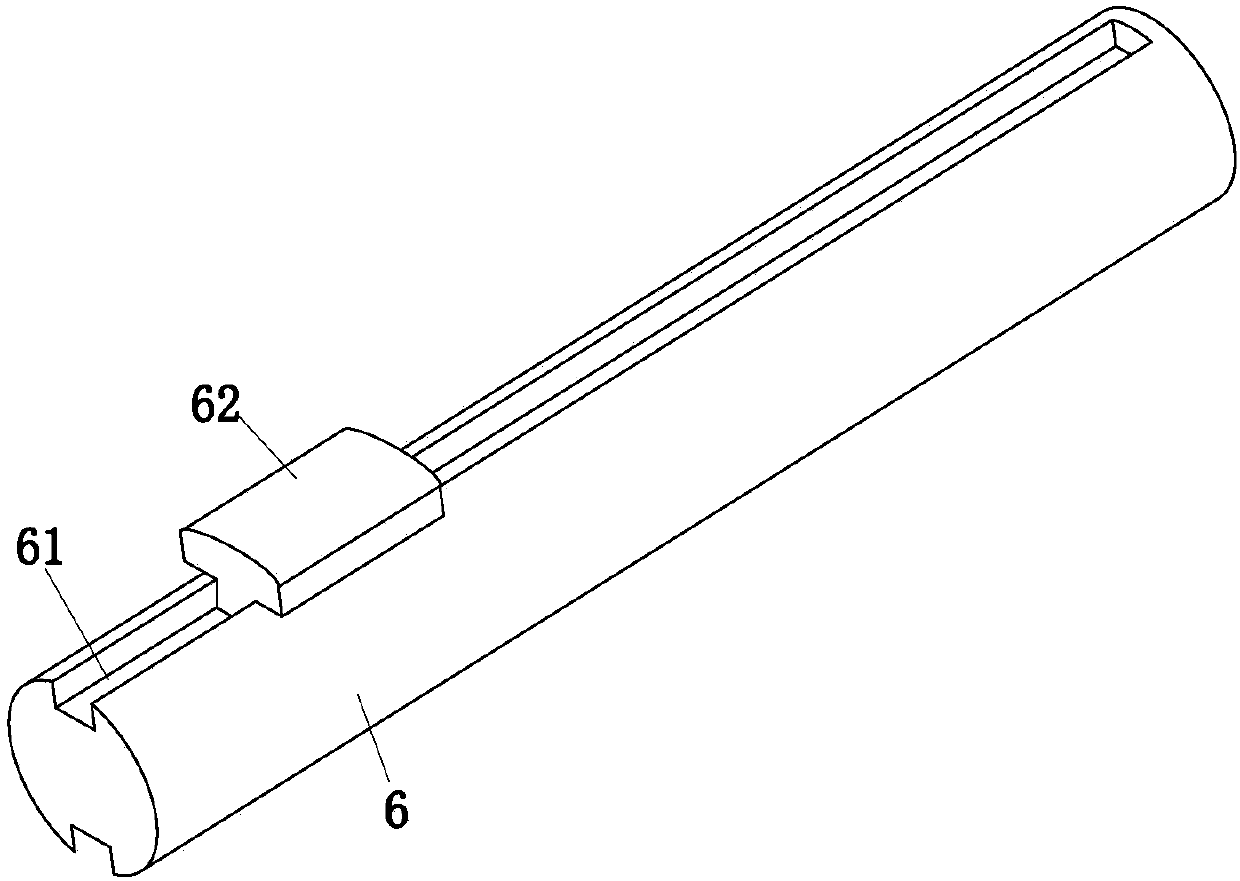

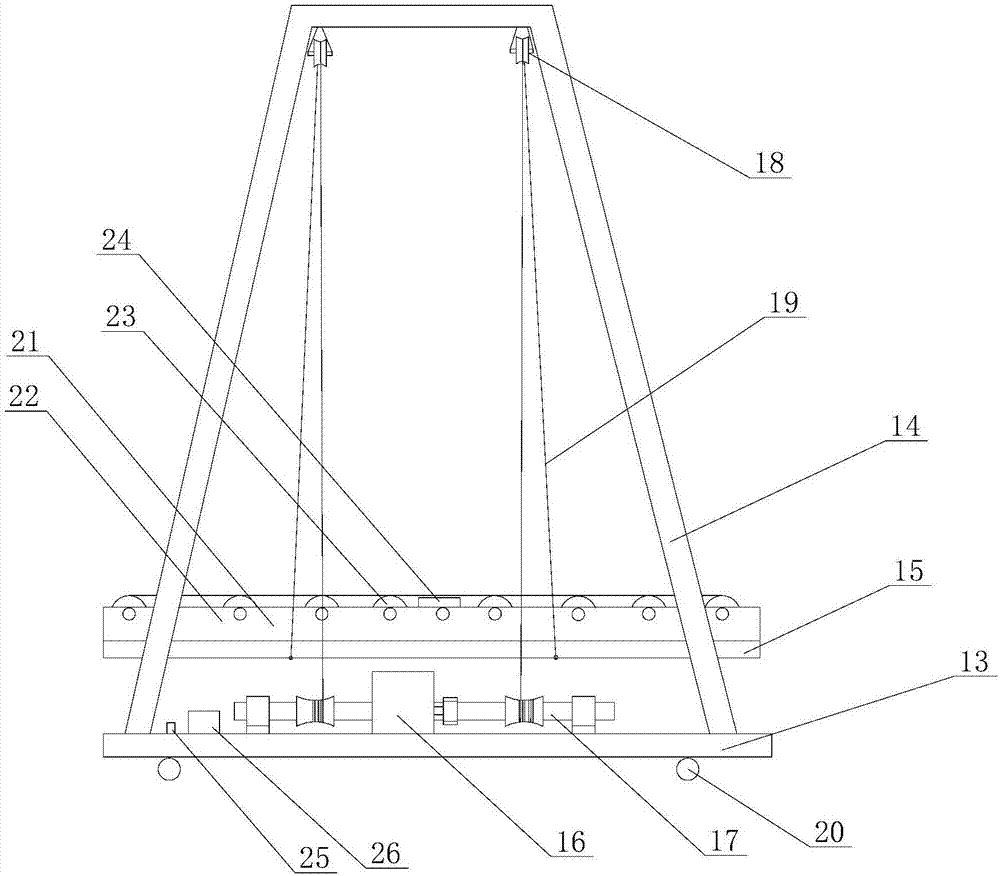

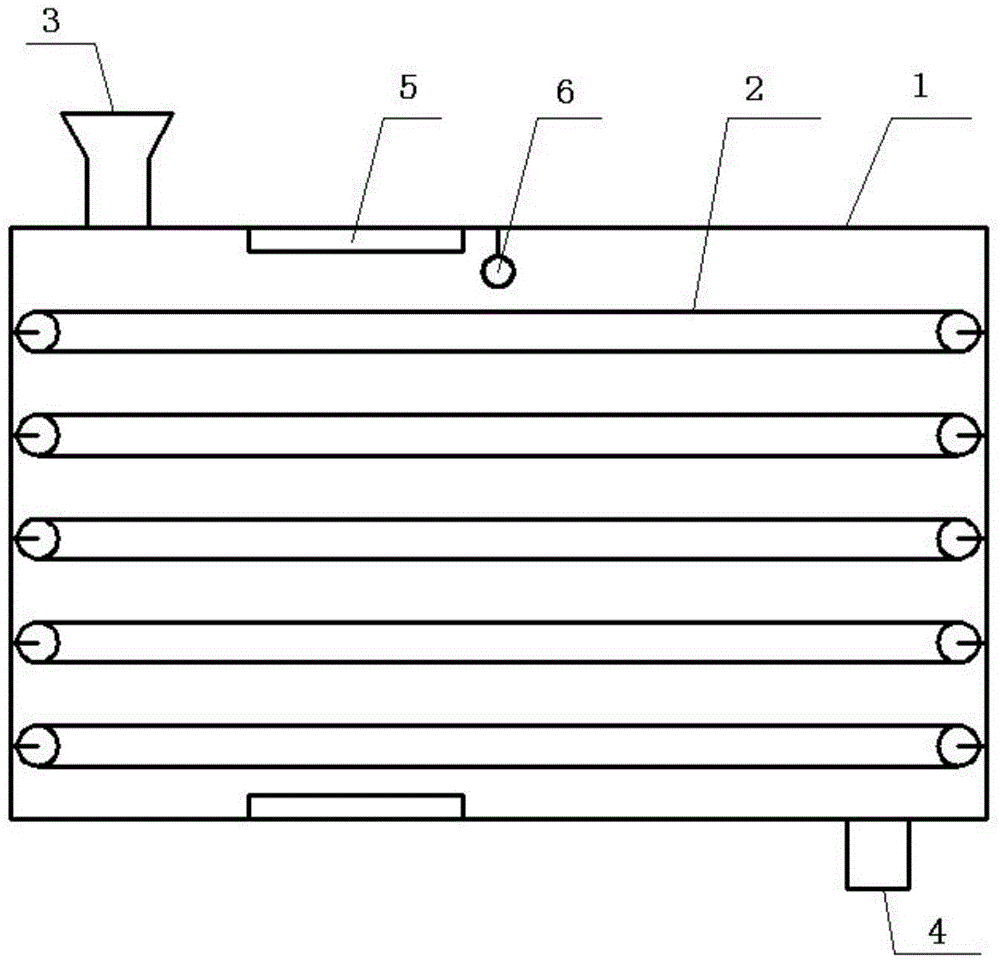

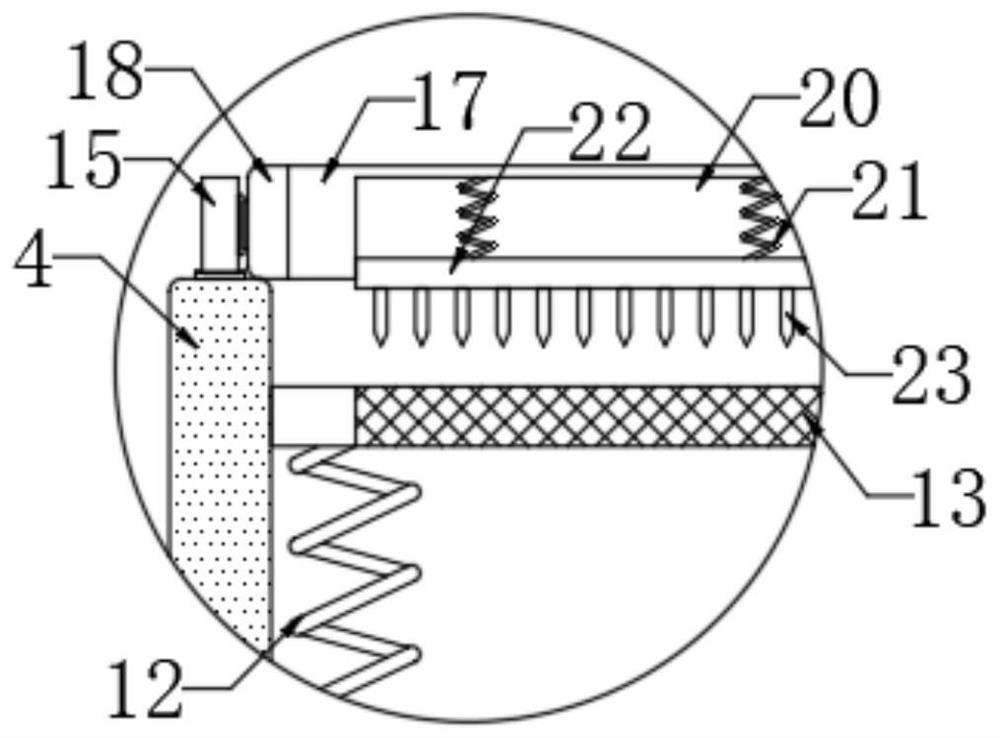

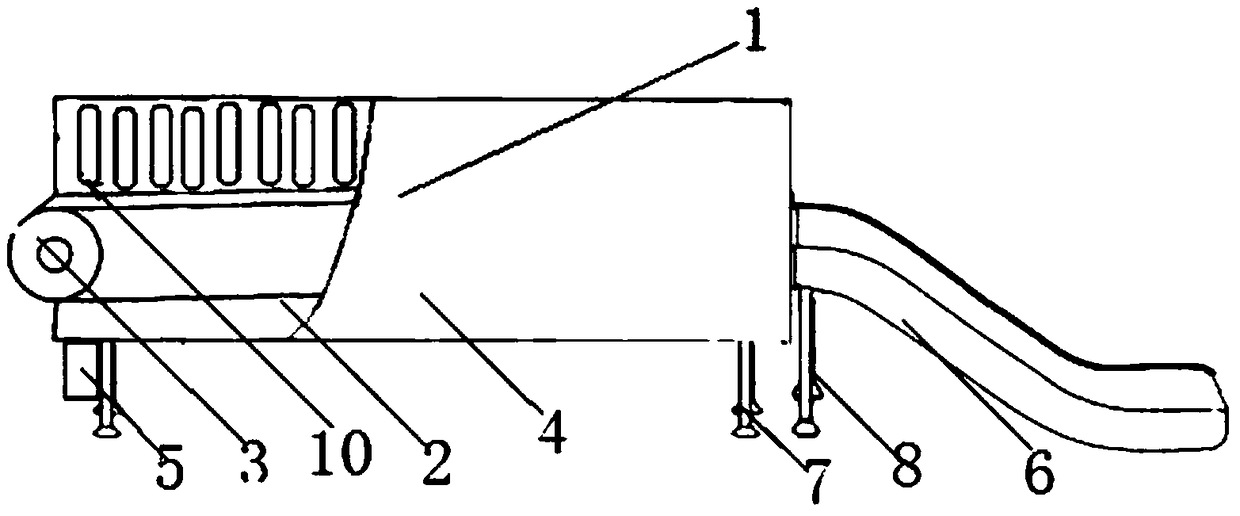

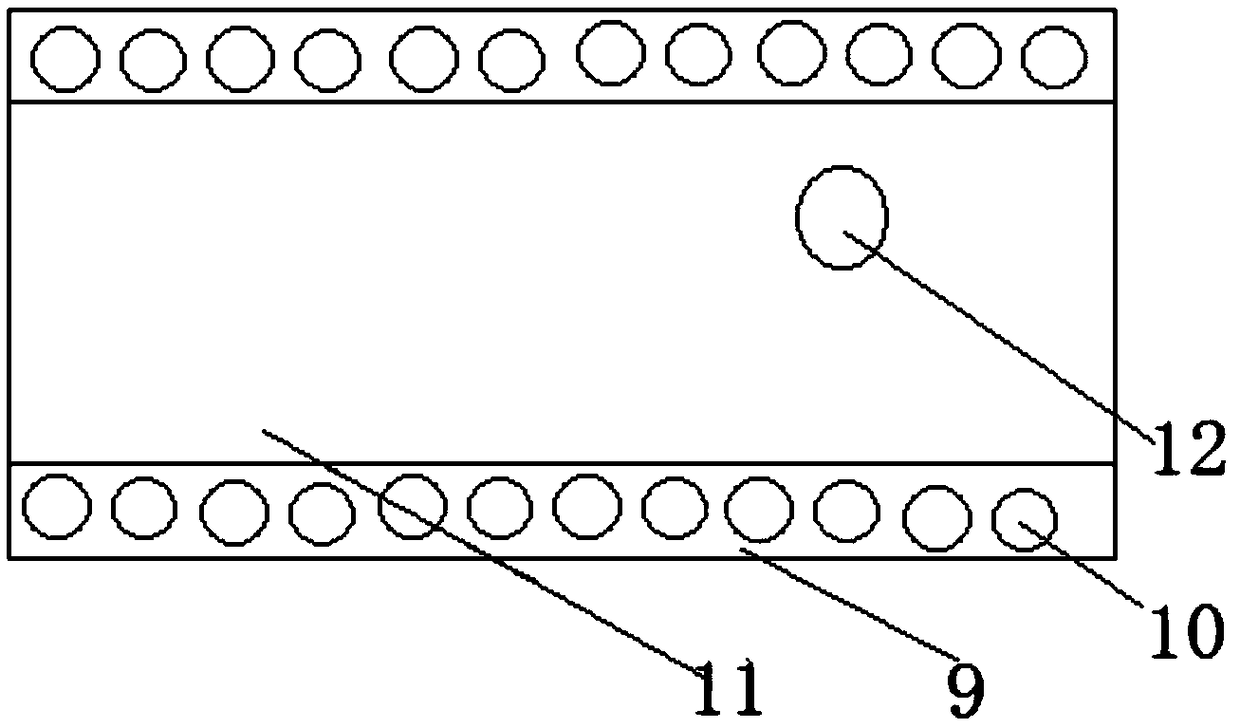

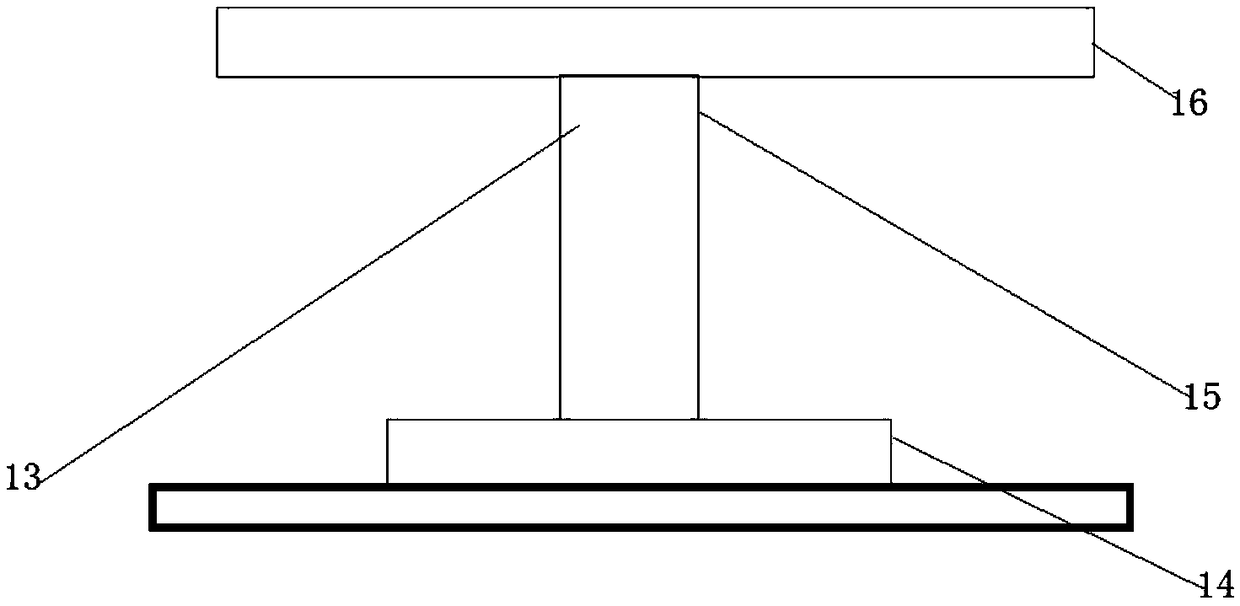

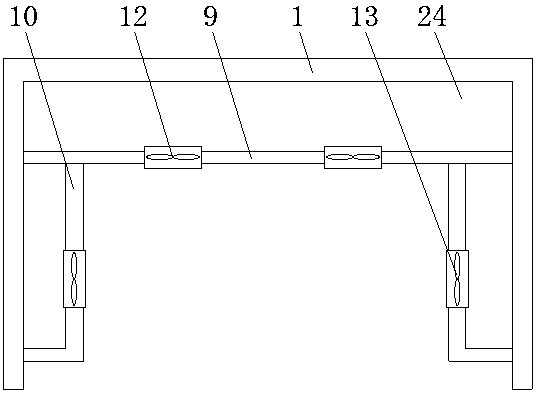

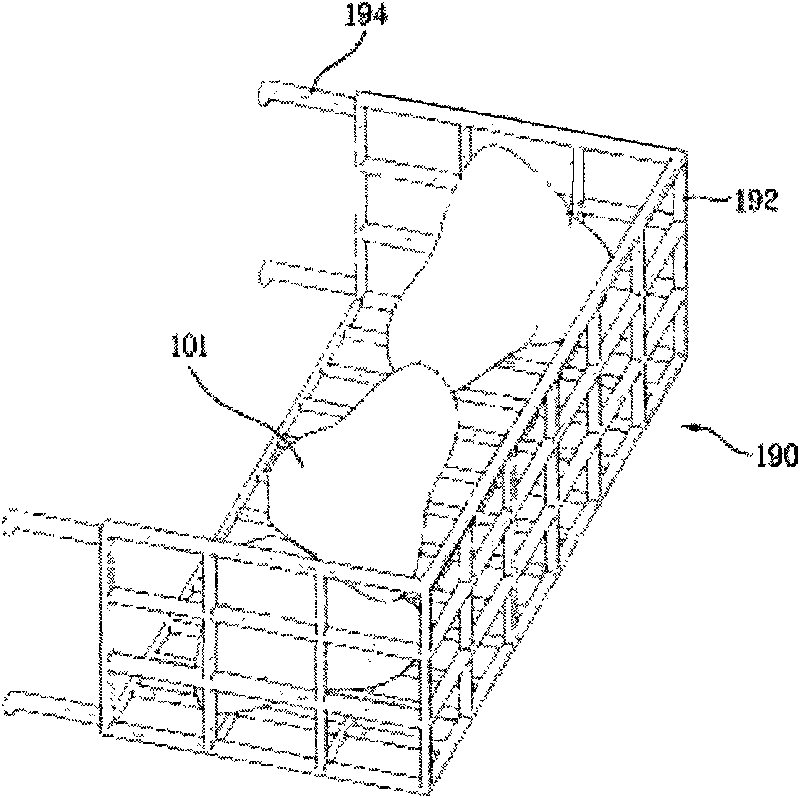

Cylinder-moving conveying type packaging bag drier

InactiveCN106564662AEasy to moveEasy to installDrying gas arrangementsDrying machines with progressive movementsEngineering

The invention discloses a cylinder-moving conveying type packaging bag drier which comprises a rack and a main board. A transverse moving through groove is formed in the middle of a top plate of the rack, rodless cylinders are fixed to the bottom face of the top plate of the rack, and guiding connection plates are fixed to sliding blocks of the rodless cylinders. Each guiding connection plate upwards stretches out of the transverse moving through groove, and an upper horizontal plate is fixed to each guiding connection plate. Guiding slide blocks are fixed to the left side and the right side of the bottom face of each upper horizontal plate, guiding rails are fixed to the left side and the right side of the top face of the top plate of the rack, sliding grooves are formed in the top faces of the guiding rails, and the guiding slide blocks are inserted into the sliding grooves. Movable connecting blocks are fixed to the left ends and the right ends of the front and back sides of the main board. The rodless cylinders push the upper horizontal plates to move rapidly and stably; meanwhile, heating pipes are fixed to the main board, the main board can move up and down to adjust the vertical positions of the heating pipes, so that heat is adjusted; and the heating pipes are fixed in an insertion mode through mounting blocks and limiting blocks, and the heating pipes are convenient to dismount and mount.

Owner:SHAOXING LITAI TEXTILE TECH CO LTD

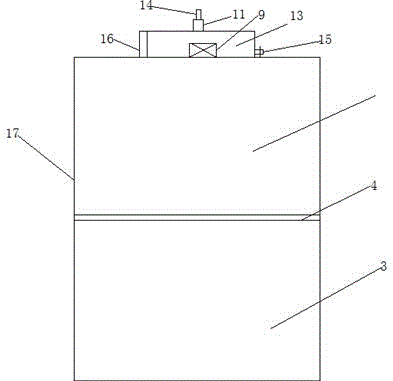

Clothing cloth drying equipment

ActiveCN107677084AEasy to acceptSmall footprintDrying gas arrangementsDrying machines with progressive movementsAir dryingEnergy consumption

The invention relates to the technical field of drying equipment, in particular to clothing cloth drying equipment. The clothing cloth drying equipment comprises a box body, a discharging shaft for discharging cloths, a drying module, an ironing module, an air-drying module, a rolling shaft for rolling the cloths and a controller. The top of the left side of the box body is provided with a storinghole for storing the cloths, a damping piece mounted at the bottom of the box body is arranged under the storing hole, and the discharging shaft is vertically mounted on the damping piece. The dryingmodule is used for drying the cloths, the ironing module is used for ironing the cloths, and the air-drying module is used for air-drying the ironed cloths. The rolling shaft is located on the rightside of the air-drying module, a material taking hole for taking out the cloths is formed in the top of the box body over the rolling shaft, the rolling shaft is driven through a rolling motor, and the rolling motor is electrically connected with the controller. The clothing cloth drying equipment is mainly suitable for being used in a clothing manufacturing shop and has the characteristics that the size is small, the weight is small, the price is low, and energy consumption is little.

Owner:安徽衣信纺织科技有限公司

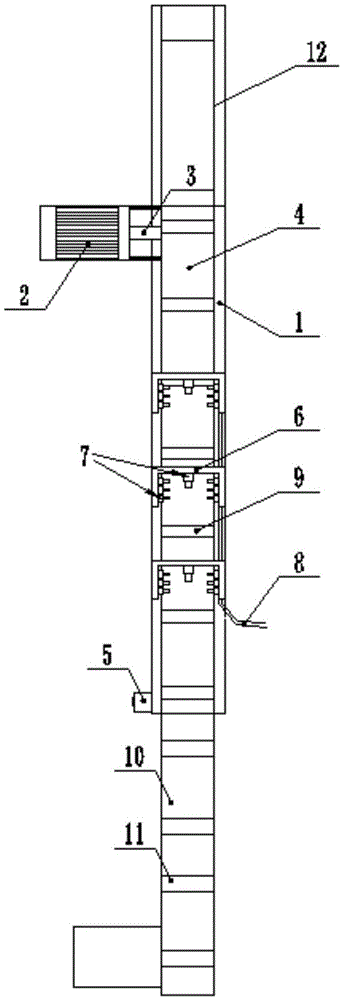

Matching drying equipment for dyeing clothing cloth

InactiveCN109654856AConvenient and fast windingFully heatedDrying gas arrangementsDrying machines with progressive movementsEngineeringCopper

The invention provides matching drying equipment for dyeing clothing cloth. The matching drying equipment comprises lower guide rollers, upper guide rollers, guide roller mounting plates, a cloth passing frame, a positioning plate and a top plate. A drying box is integrally arranged in a rectangular shape. The bottom of the drying box is provided with a water receiving tank. A group of pressing rollers driven by a motor are supported and welded to openings in the front end of the drying box. The middle of the bottom of the outer wall at the front end of the water receiving tank is provided with a drain copper ball valve in a threaded locking mode. Two electric heating fans are symmetrically locked and installed on the top plate of a hot air box. The three groups of lower guide rollers arearranged and supported at bottom positions of the left and right side walls of the drying box at equal intervals. Four electric push rods are symmetrically and vertically supported on the left side and right side of the water receiving tank. Piston rods of the four electric push rods are connected with screws of the two guide roller mounting plates in a screw locking mode. Due to the arrangement of the four positioning rods, the left-and-right swinging of the three upper guide rollers can be limited by the four positioning rods, and the piston rods of the four electric push rods are preventedfrom being broken by conveying and drawing force of cloth.

Owner:FO SHAN SHI TAO LIAN RAN ZHENG DING XING YOU XIAN GONG SI

Wood board drying equipment

InactiveCN107976046AImprove drying efficiencyFully contactedDrying gas arrangementsDrying machines with progressive movementsControl systemEngineering

Owner:广西桂林林博士家具有限公司

Vegetable noodle production process and microwave drying device thereof

InactiveCN109751838AIncreased versatilityMeet drying needsDrying solid materials with heatDrying chambers/containersMicrowaveWater vapor

Owner:ANHUI QINGSONG FOOD

Medicine heating and drying device

InactiveCN105021006ADrying machines with progressive movementsDrying solid materialsElectric heatingEngineering

Owner:蒋魏

Efficient drying machine for spinning

ActiveCN112696902AAutomatic deliveryDry thoroughlyDrying gas arrangementsDrying machines with progressive movementsSpinningWorkbench

Owner:新疆金大禹环境科技有限公司

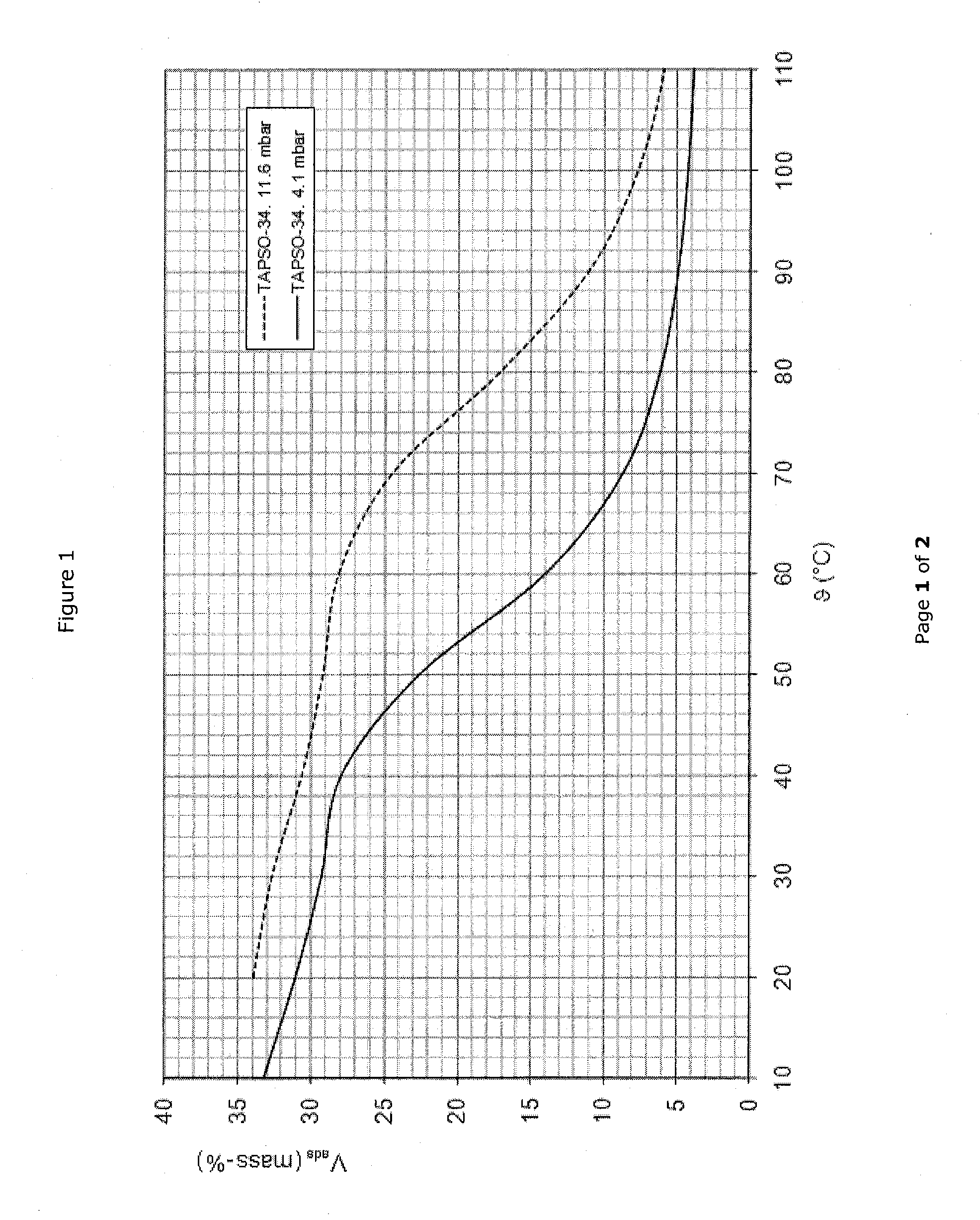

Drying device containing a titanium aluminum phosphate

InactiveUS20120159804A1Low costWeaken energyAluminium compoundsSilicon halogen compoundsSodium aluminium phosphatePhosphate

Owner:CLARIANT INT LTD

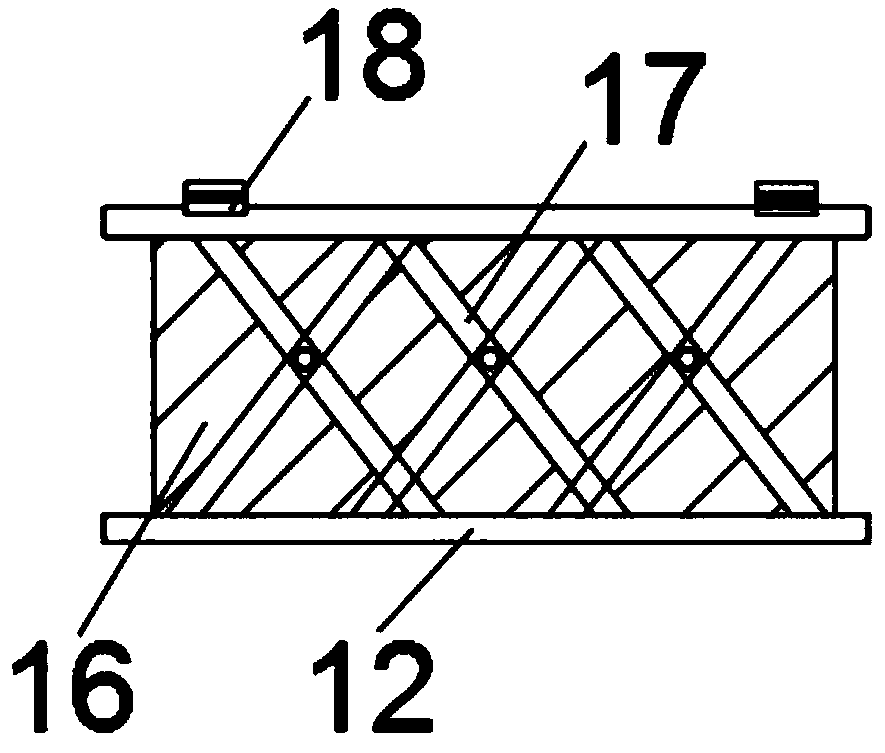

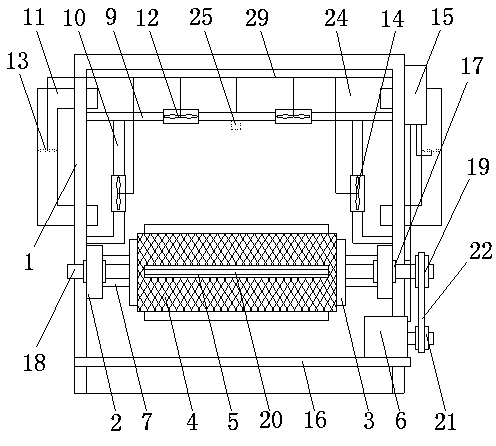

Textile cleaning and drying integrated machine

InactiveCN108035102AReduce cost inputEasy to integrateMechanical cleaningPressure cleaningAgricultural engineeringProcessing cost

The invention discloses a textile cleaning and drying integrated machine and relates to the technical field of textile processing equipment. The textile cleaning and drying integrated machine includesa box body, a filtering mechanism, a lifting mechanism, a material guiding mechanism, a water inlet pipe, a water outlet pipe, a partition plate, a long hole, strip-shaped holes, mounting plates, bearings, rotating shafts, mounting holes, connecting rods, motors, bobbins, a hot air fan, a three-way pipe, air outlet pipes, air exhaust pipes, a box door and a water tank. The middle of the front face of the box body is movably connected to the box door through hinges, and the water tank is fixedly installed in the inner bottom wall of the box body. According to the textile cleaning and drying integrated machine, the box body can be divided into two spaces for cleaning and drying through the partition plate fixedly connected in the box body, the cleaning and drying operation in the same machine can be conducted, the integration degree is high, the processing cost of the machine can be effectively saved, and accordingly the cost input of manufacturers is reduced.

Owner:SHAOXING KEQIAO CHENGXIN PRECISION CASTING CO LTD

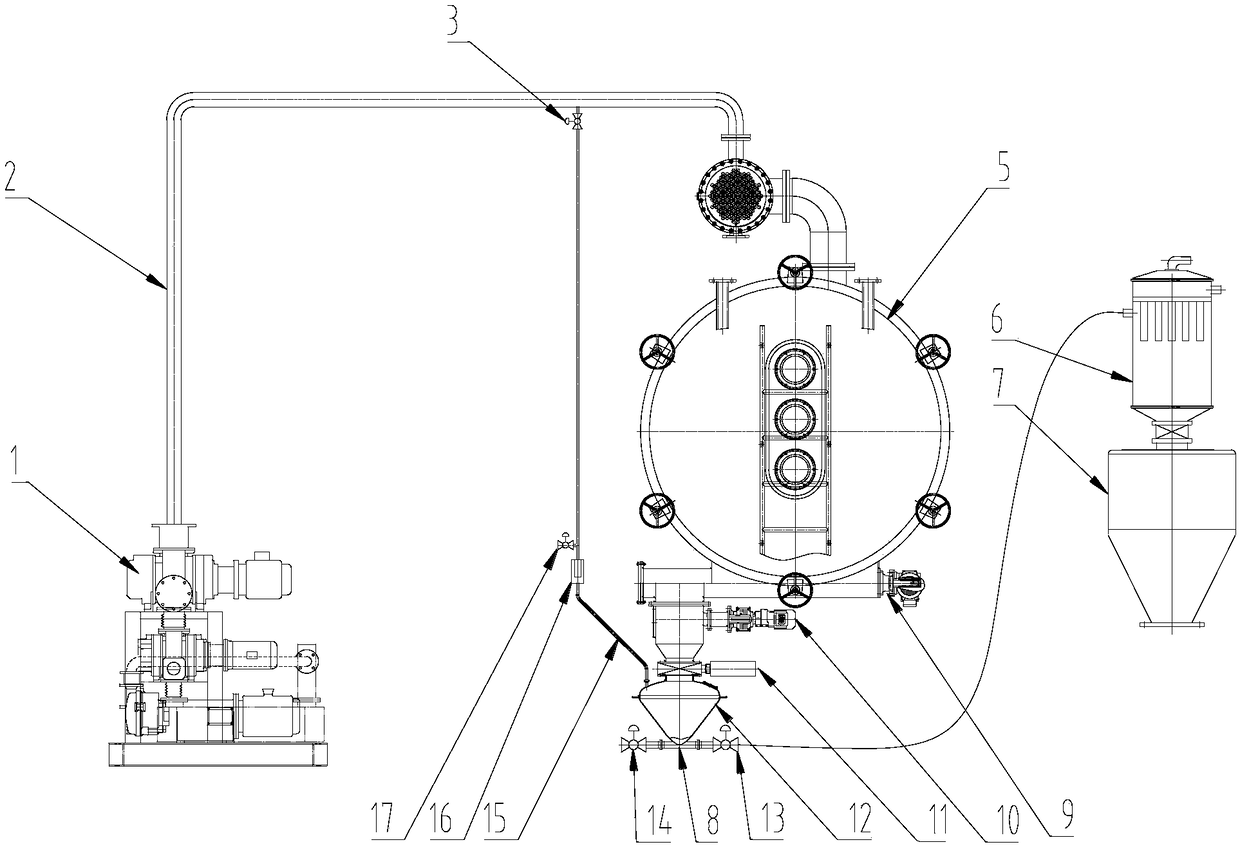

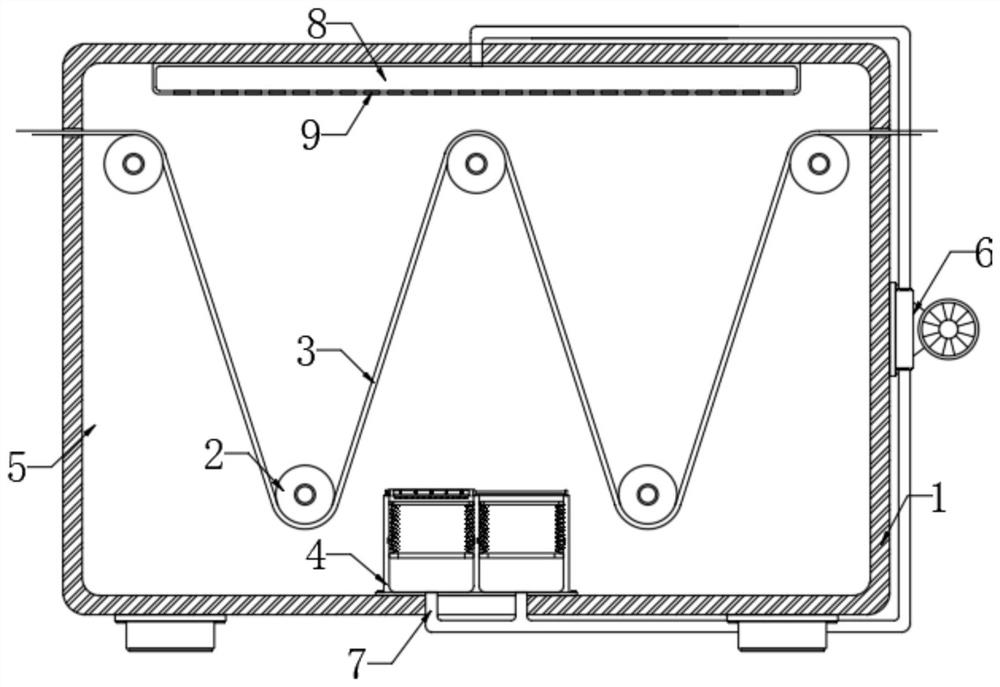

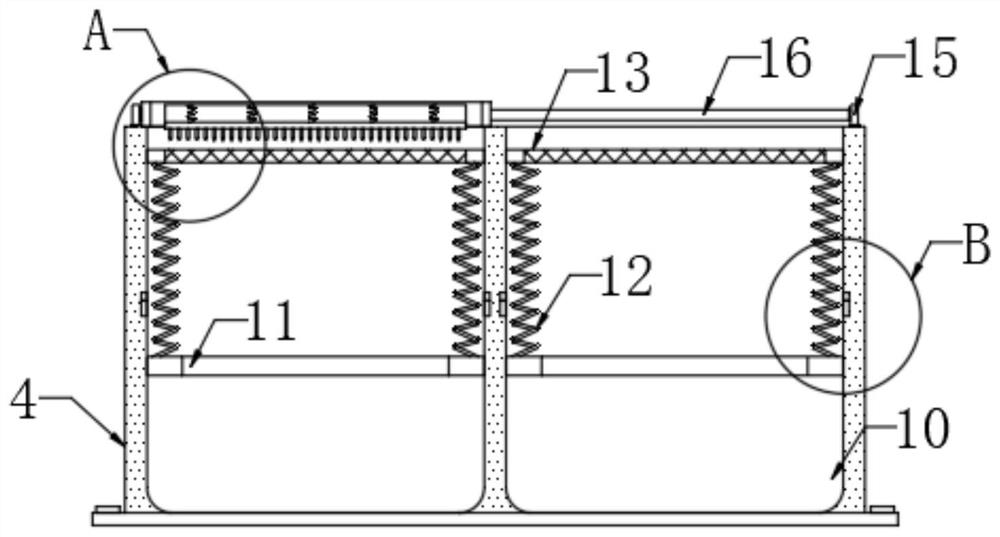

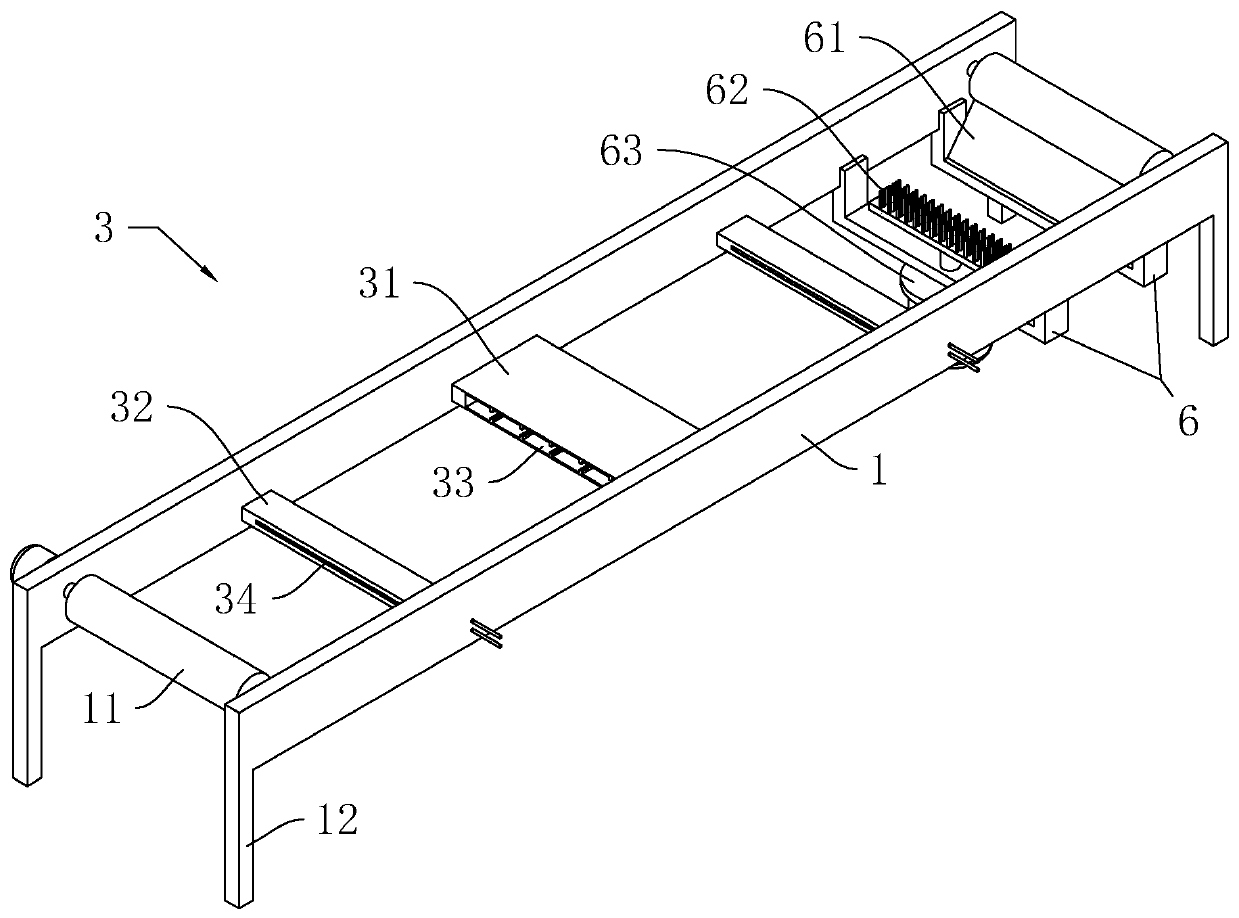

Vacuum belt type dryer material dust continuous discharge system

PendingCN108946175AGuaranteed filter effectImprove drying recoveryDrying solid materials without heatDrying machines with progressive movementsBuffer tankInlet valve

Owner:常州朗脉洁净技术有限公司

Continuous operation type energy-saving drying device for textile production

PendingCN113251775AWon't wasteTake advantage ofDrying gas arrangementsLiquid/gas/vapor removal by gas jetsProcess engineeringAir blower

Owner:杨干英

Cable cleaning device

ActiveCN108405441ACleaning using toolsDrying machines with progressive movementsLiquid wasteEngineering

The invention provides a cable cleaning device which comprises a cleaning tank, a cleaning part in the cleaning tank, a liquid waste pool located below the cleaning tank, and a cable inlet formed in the side face of the cleaning tank. The cleaning part comprises cleaning devices arranged in the cleaning tank and spraying devices connected with a water tank. The cleaning devices comprise mounting seats arranged on the inner walls of the side faces of the cleaning tank and connected with a cleaning liquid tank, supporting devices and cleaning wheels. Cleaning grooves sunken towards the centers of the cleaning wheels are formed in the cleaning wheels, and cleaning sponge layers are arranged on the cleaning grooves. According to the cable cleaning device, a cable is cooled through the sprayingdevices, the cable is wetted preliminarily, the mounting seats connected with the cleaning liquid tank provide cleaning liquid for cable cleaning when the cable passes through the cleaning wheels, the cable is sufficiently cleaned when passing through the cleaning grooves with the cleaning sponge layers, the service life of the cable is prolonged, and the manpower cost is reduced.

Owner:LONGYOU COUNTY POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

Bus umbrella drying system

InactiveCN109059507AEasy to take umbrellaBatteries circuit arrangementsElectric powerHeat conductingConveyor belt

Owner:SHAANXI UNIV OF SCI & TECH

Heat cycle type wood plank drying device suitable for furniture processing

InactiveCN108518958AReduce wasteImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsWater vaporFixed frame

Owner:萧县智鑫知识产权运营有限公司

Spinning gauze lossless drying equipment

InactiveCN106766791AAcceptance balanceAvoid lossDrying gas arrangementsDrying machines with progressive movementsInternal pressureWater vapor

Owner:响水县嘉禾纺织制衣有限公司

Preparation system of biodegradable composite material

PendingCN113478674ADry fastFully contactedDrying gas arrangementsDrying machines with progressive movementsSurface cleaningWater resources

Owner:李文干

Direct combustion type hot air penetration internal circulation drying device for non-woven fabric production

PendingCN110500865AAchieve cycleEasy drying processDrying gas arrangementsDrying machines with progressive movementsFiberCombustor

Owner:ZHEJIANG WANGJIN NONWOVENS CO LTD

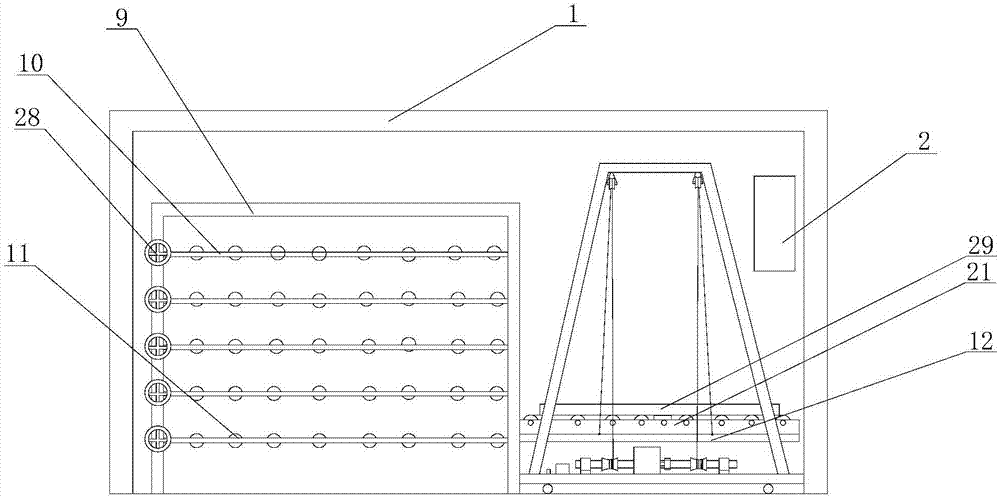

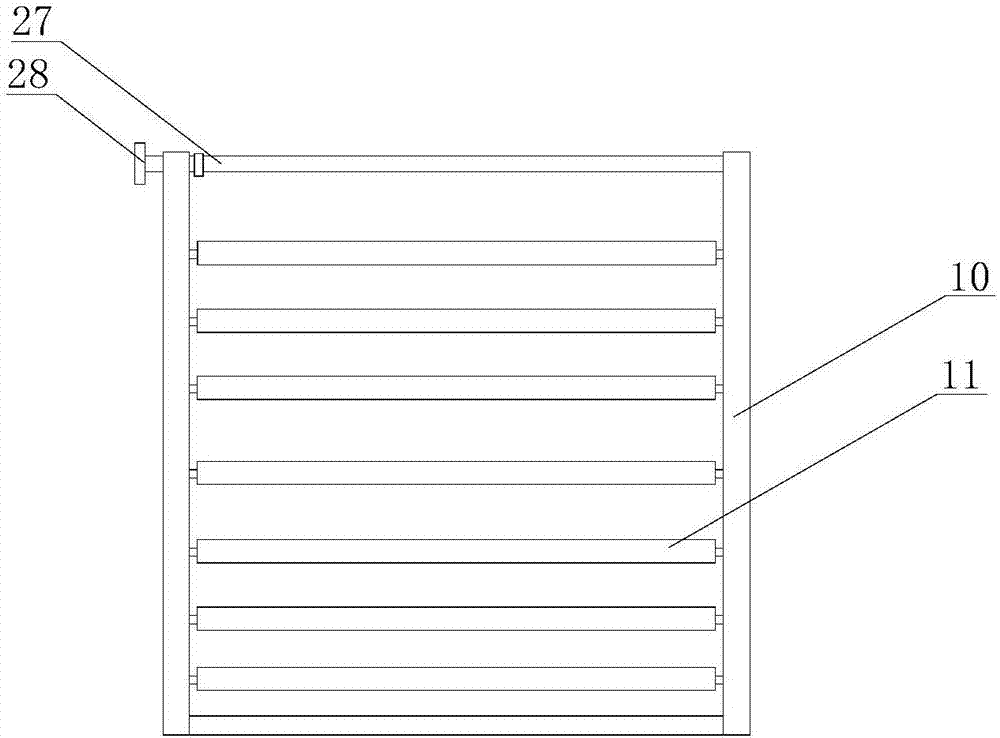

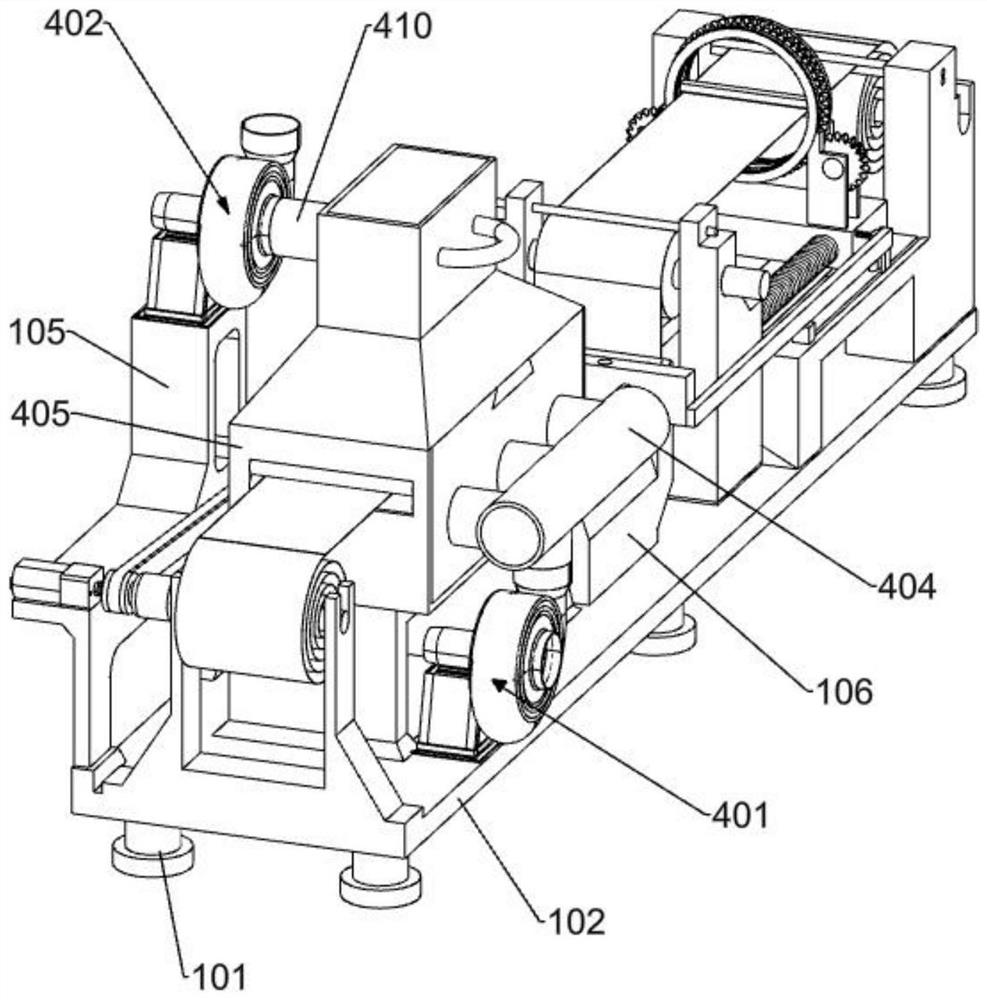

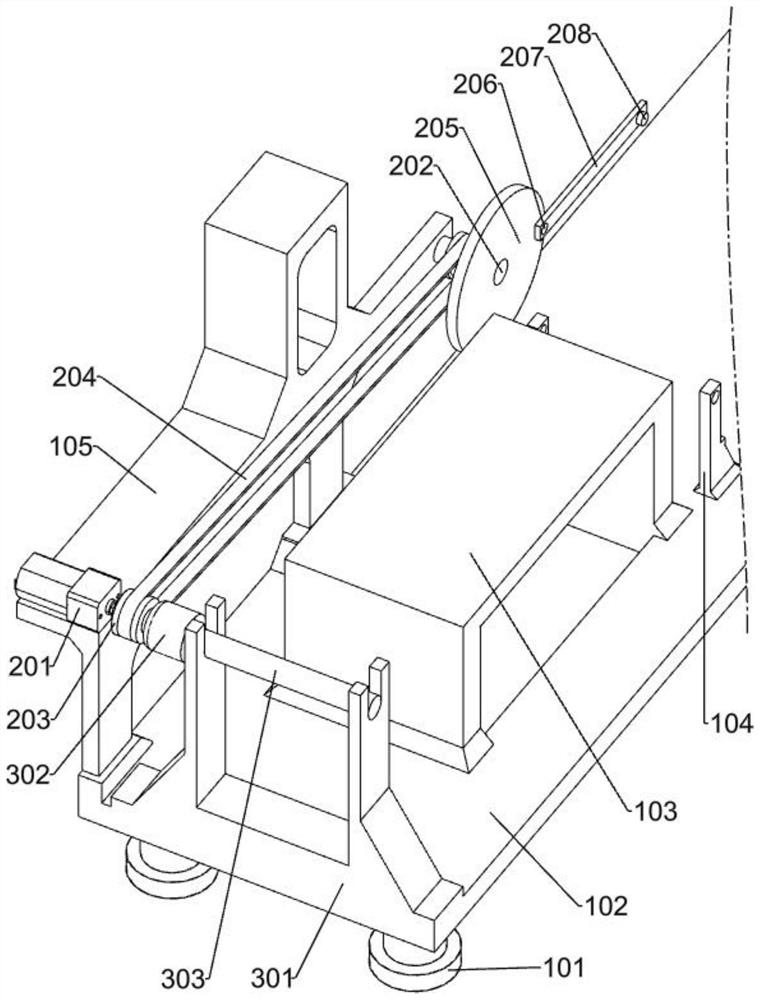

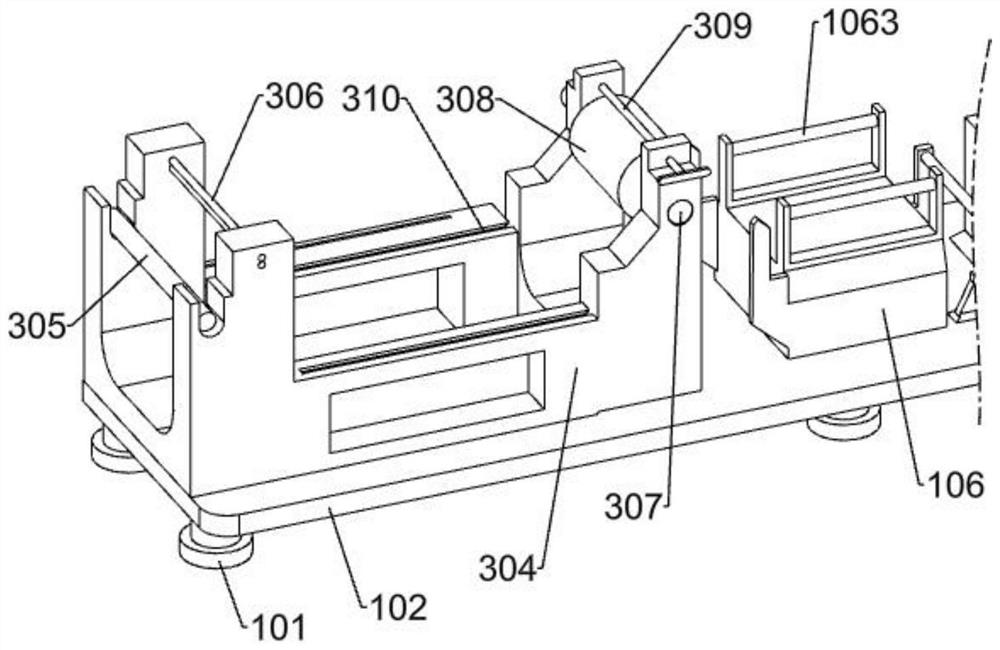

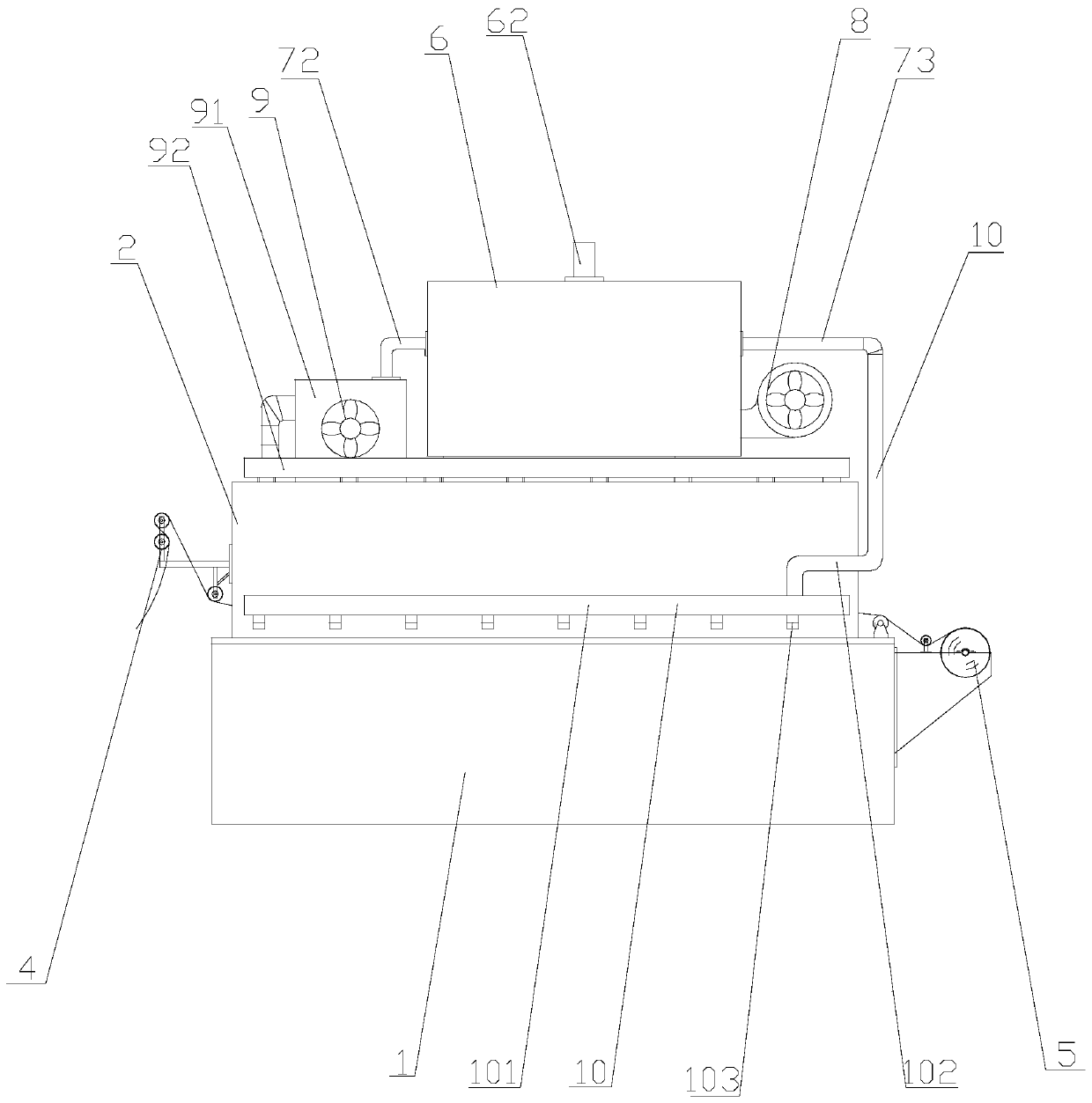

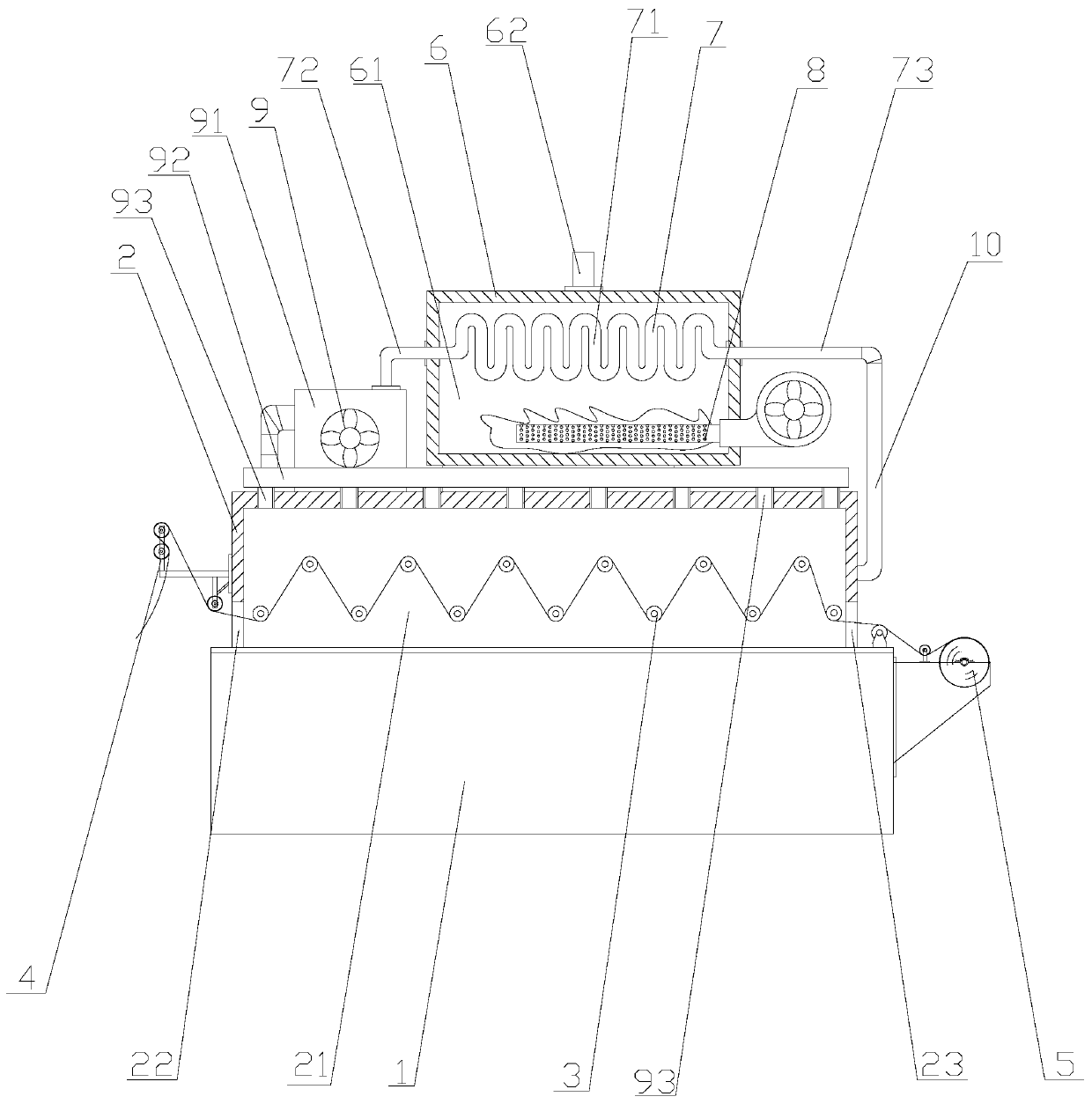

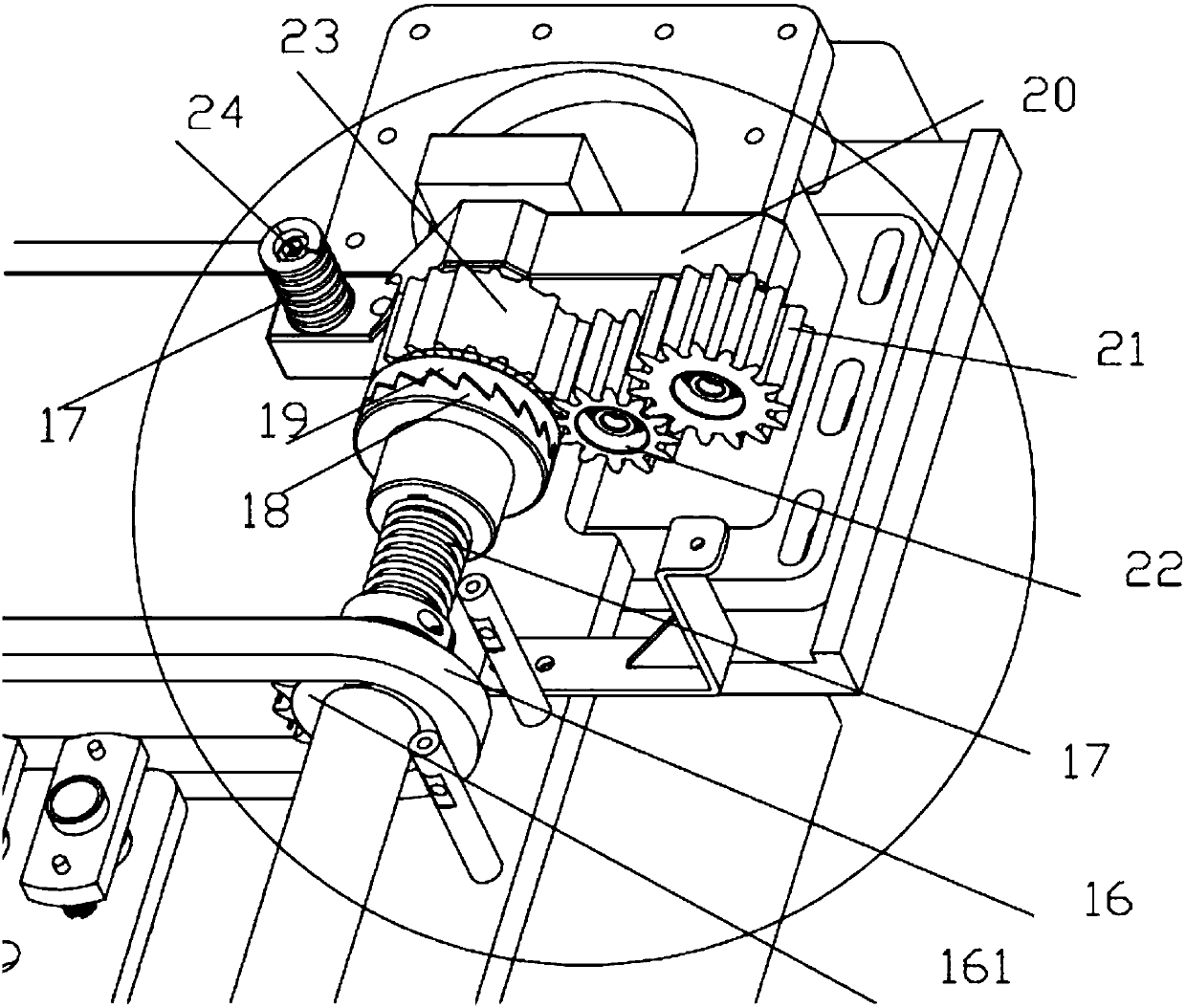

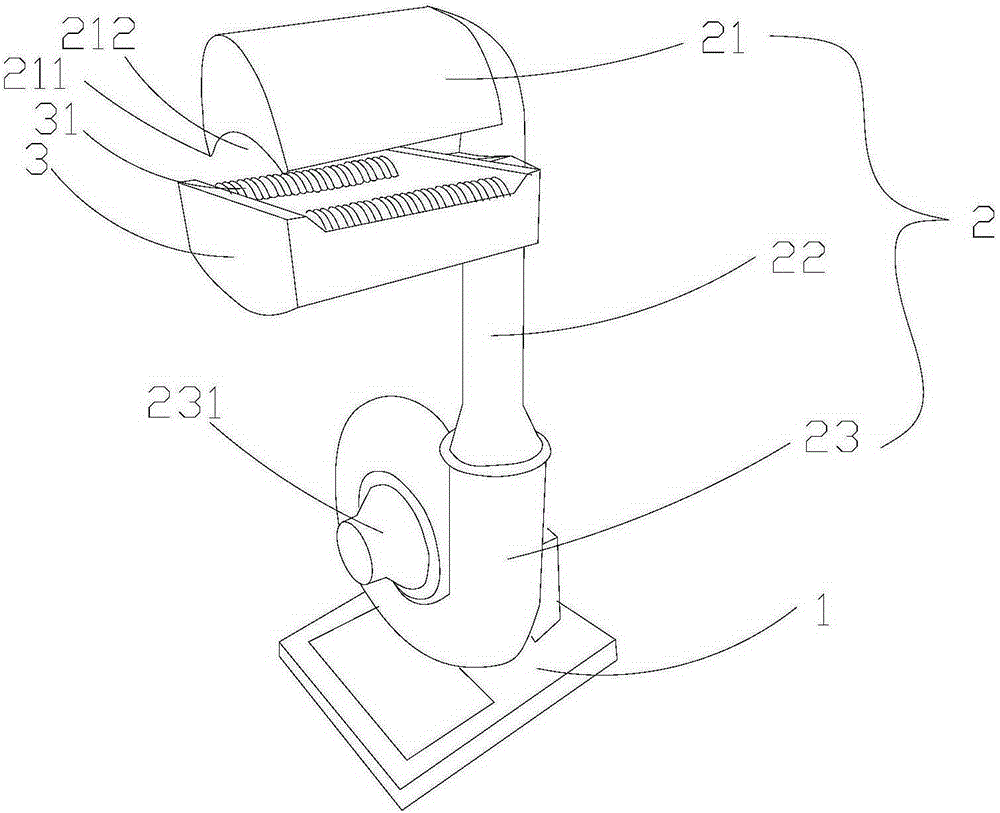

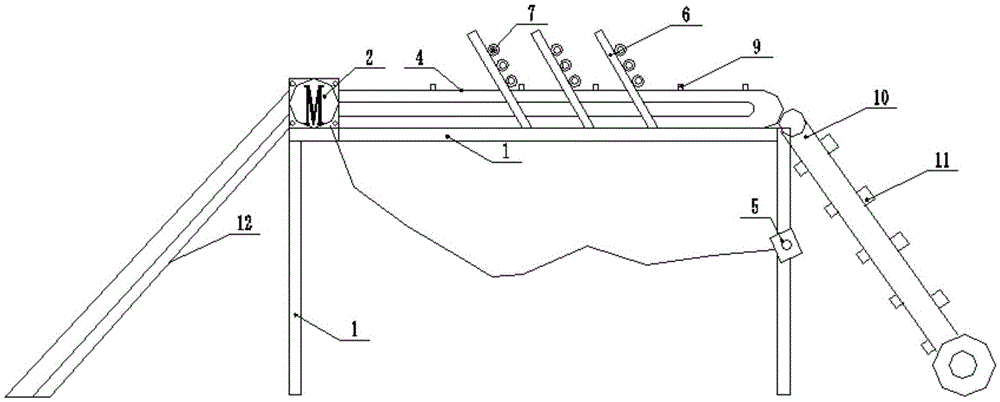

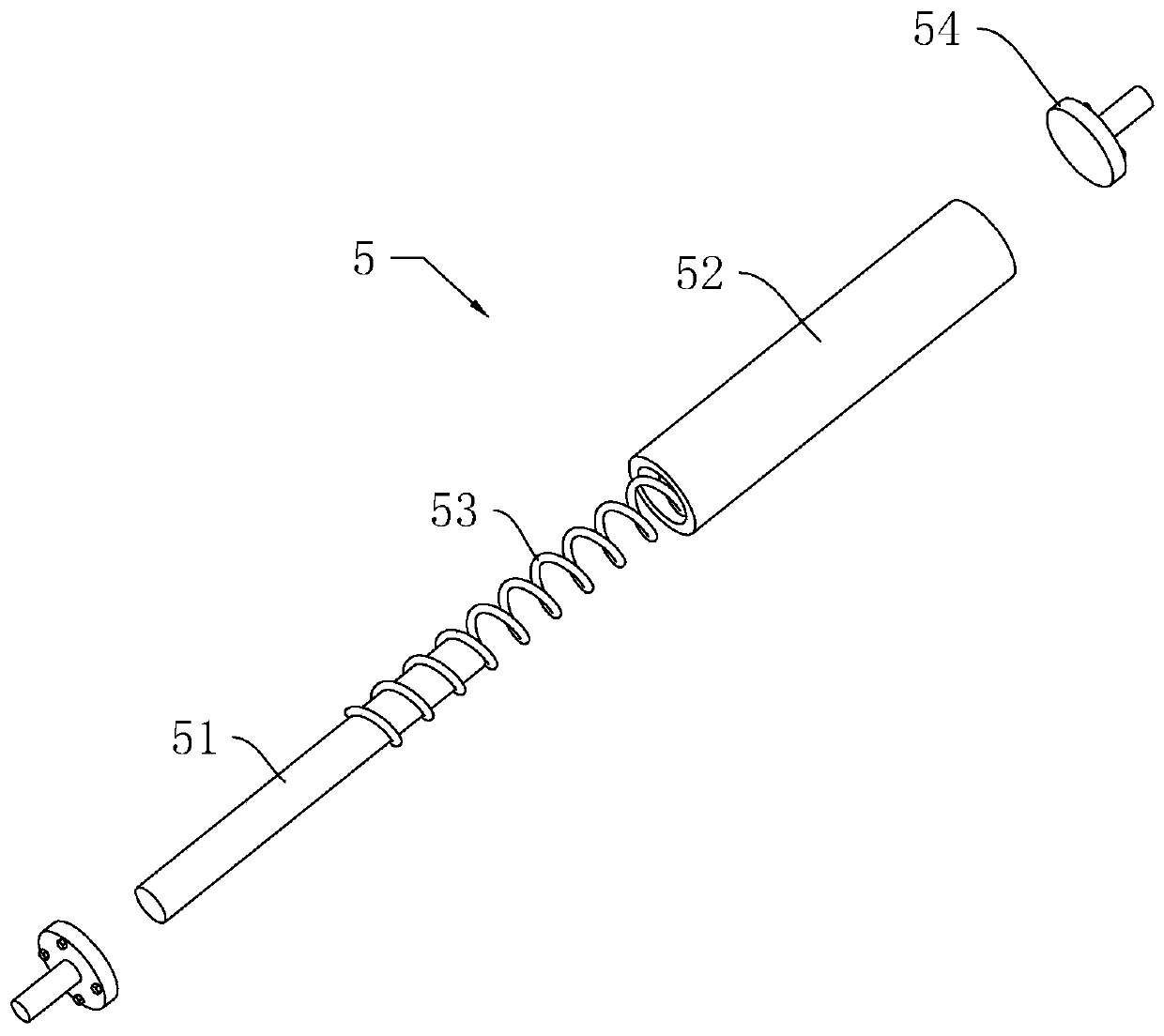

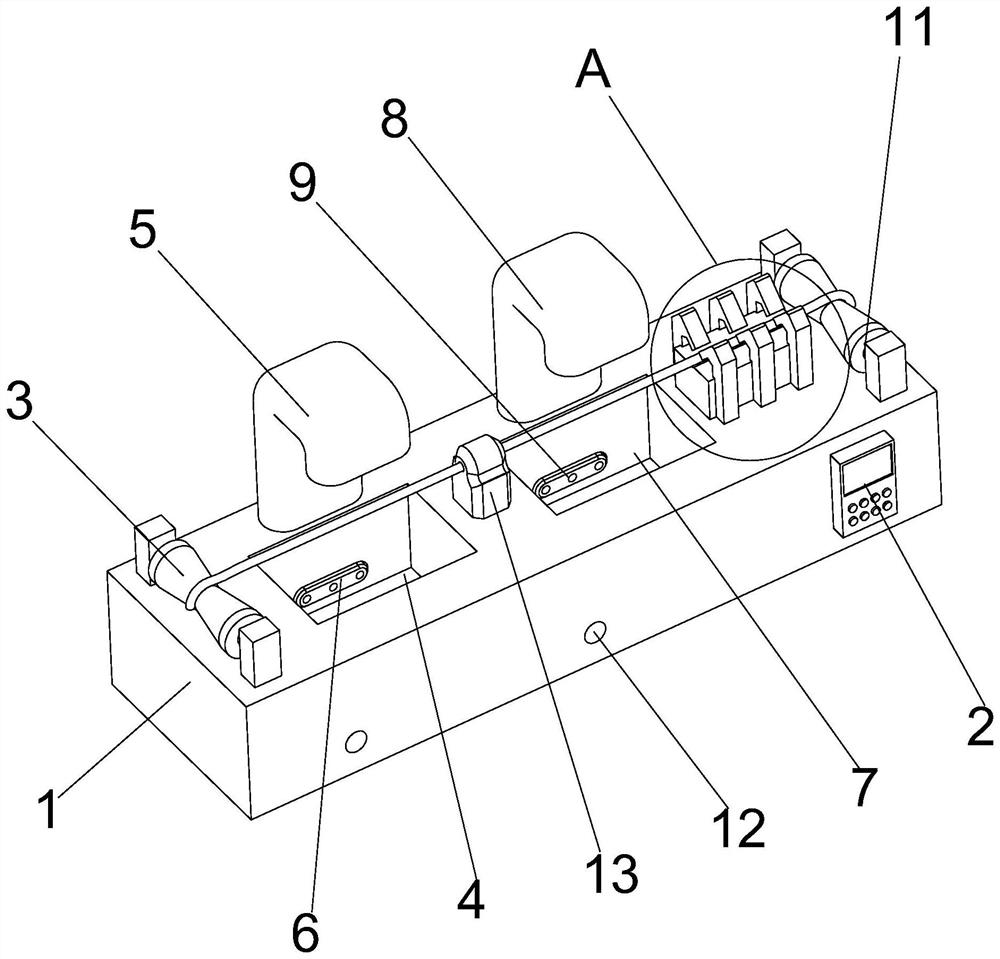

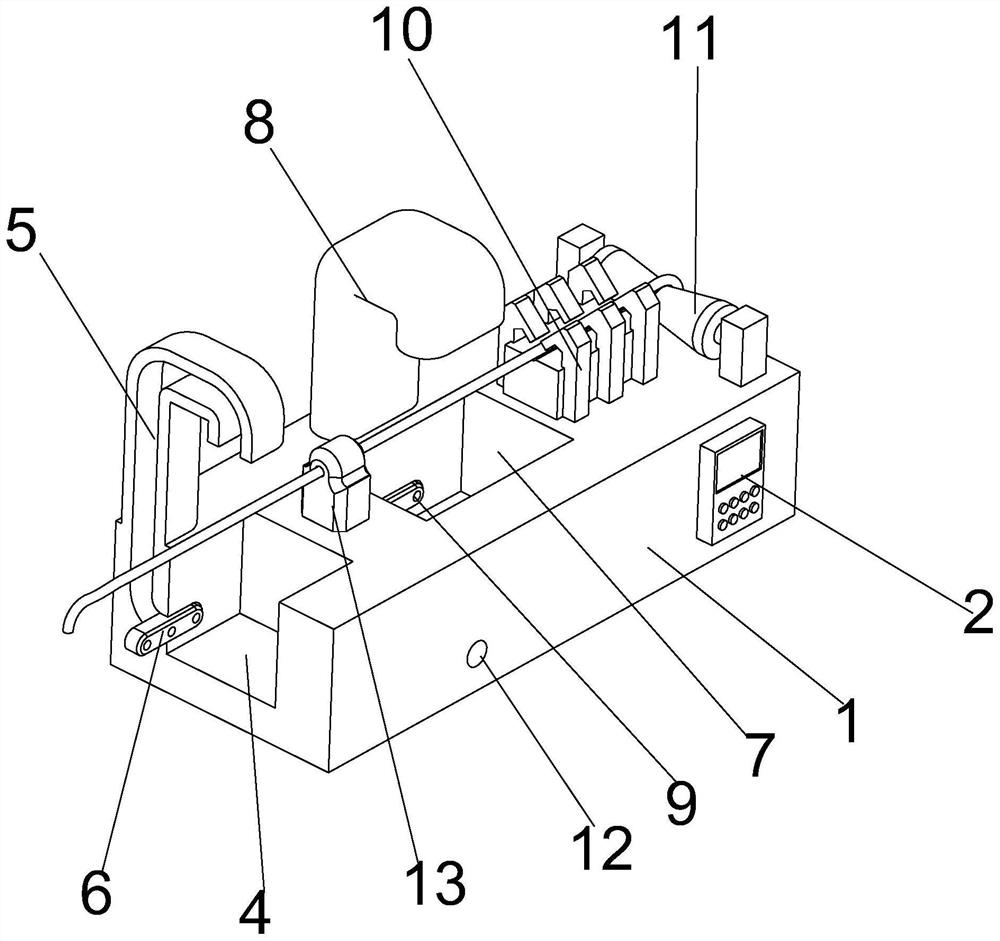

Separated dynamic contact system having heating and cooling functions

PendingCN107642967ASmall footprintRealize separate dynamic heatingDrying machines with progressive movementsDrying solid materialsRotated toothEngineering

The invention discloses a separated dynamic contact system having heating and cooling functions. The separated dynamic contact system comprises a cavity body, a servo motor, a cooling mechanism, a poking tooth mechanism and a heating movable contact mechanism, the cooling mechanism, the poking tooth mechanism and the heating movable contact mechanism are arranged on a transmission baseplate at thebottom of an inner cavity of the cavity body, an output shaft of the servo motor is connected with a main rotating shaft, driving big gears sleeve two ends of the main rotating shaft, and rotating teeth are fixedly connected in the middle section of the main rotating shaft; the separated dynamic contact system further comprises a driven rotating shaft and a chain, driven big gears sleeve two endsof the driven rotating shaft, rotating teeth, a first ratchet wheel, a second ratchet wheel and an axial compression spring are fixedly connected in the middle section of the driven rotating shaft, the first ratchet wheel and the second ratchet wheel are meshed with each other, the axial compression spring sleeves the driven rotating shaft, the second ratchet wheel is fitted to a driving big gear, and the chain sleeves the rotating teeth of the main rotating shaft and the driven rotating shaft. The system has the advantage that power transmission is smooth and free of clamping stagnation.

Owner:SHENZHEN DACHENG PRECISION EQUIP CO LTD

Air blower

InactiveCN105276942ADrying gas arrangementsDrying machines with progressive movementsWater collectionControl engineering

Owner:FENGHUA XURI HONGYU

Dryer

InactiveCN101701414AImprove drying efficiencyDrying solid materials without heatDrying machines with progressive movementsPulp and paper industryExhaust gas

Owner:NANJING LG PANDA APPLIANCES

Rapid workpiece oil and water removing system

InactiveCN105486060ADrying gas arrangementsDrying machines with progressive movementsAssembly lineNozzle

Owner:CHONGQING JINCHEN MACHINERY MFG

Adsorption and water removal device for gypsum

InactiveCN110345719AAchieve reuseReduce the use effectDrying solid materials without heatDrying machines with progressive movementsPulp and paper industryGypsum

Owner:常州华伦热电有限公司

Pretreatment device and method before wire tinning

PendingCN114250429AHot-dipping/immersion processesDrying machines with progressive movementsPre treatmentSmart control

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

Activated carbon preparation process

ActiveCN111874904AReduce processing efficiencyReduce air pressureCarbon compoundsDrying gas arrangementsActivated carbonHoneycomb

The invention belongs to the technical field of activated carbon preparation, and particularly relates to an activated carbon preparation process which comprises the following steps: step 1, drying and grinding: carbonizing and grinding sawdust after drying to obtain dried carbon powder; step 2, processing and forming: processing the carbon powder into a cylindrical carbon block by using a mold, and forming a plurality of honeycomb-shaped through holes; step 3, cleaning of the carbon block: washing the formed carbon block with water to remove impurities on the surface of the carbon block; step4, drying of the carbon block: drying the cleaned carbon block to remove moisture in honeycomb-shaped through holes of the carbon block, wherein the drying process of the cleaned carbon block in thestep 4 is completed by adopting an activated carbon preparation machine in a matching manner. The invention solves the problems that at present, when the interiors of cylindrical activated carbon honeycomb holes are dried, part of moisture on the inner walls of the honeycomb holes permeates into the surface layers of activated carbon, sufficient drying is difficult, and moisture residues are likely to be caused, and conveying and drying cannot be conducted synchronously, and the machining efficiency is low.

Owner:JIANGSU QIANHUIHE ENVIRONMENTAL REGENERATION CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap