Separated dynamic contact system having heating and cooling functions

A dynamic contact and separation technology, used in lighting and heating equipment, progressive dryers, drying solid materials, etc., can solve problems such as unreasonable drying objects, and achieve the effect of saving equipment space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

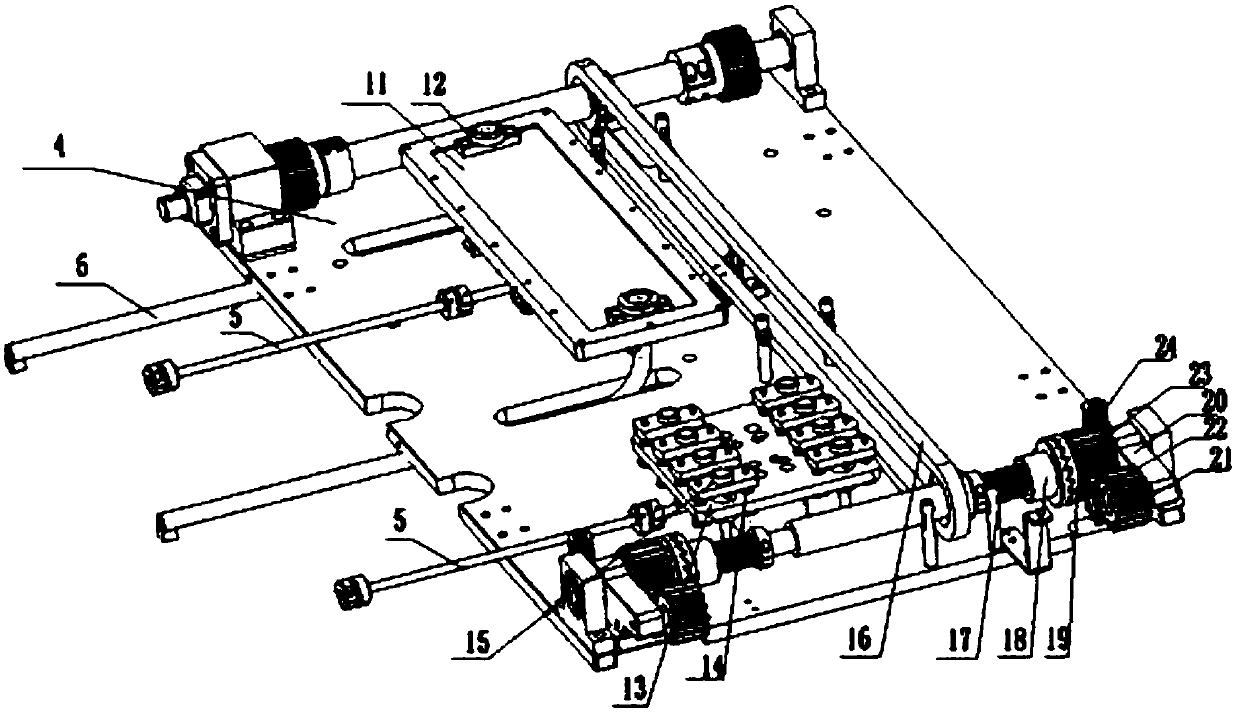

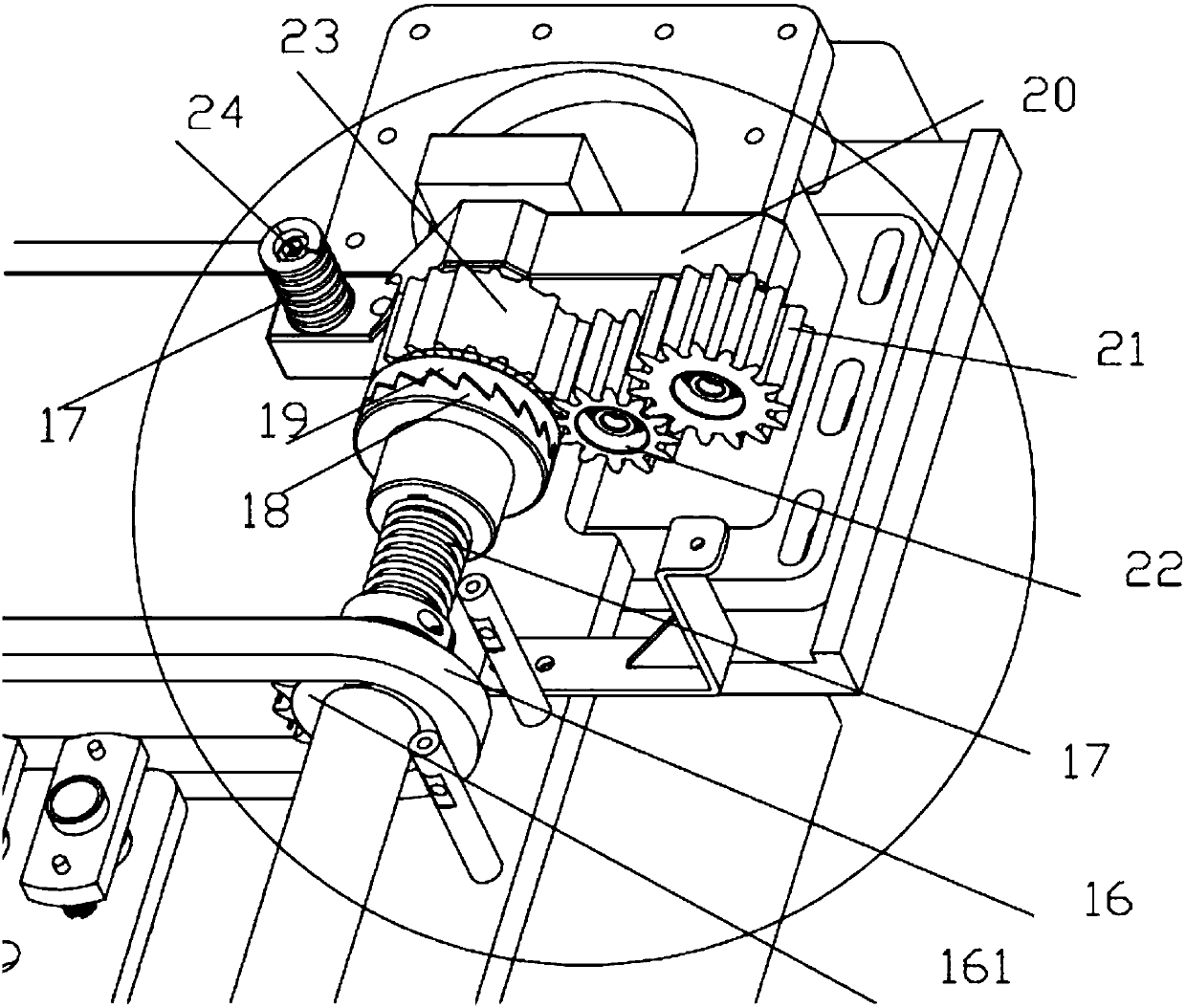

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

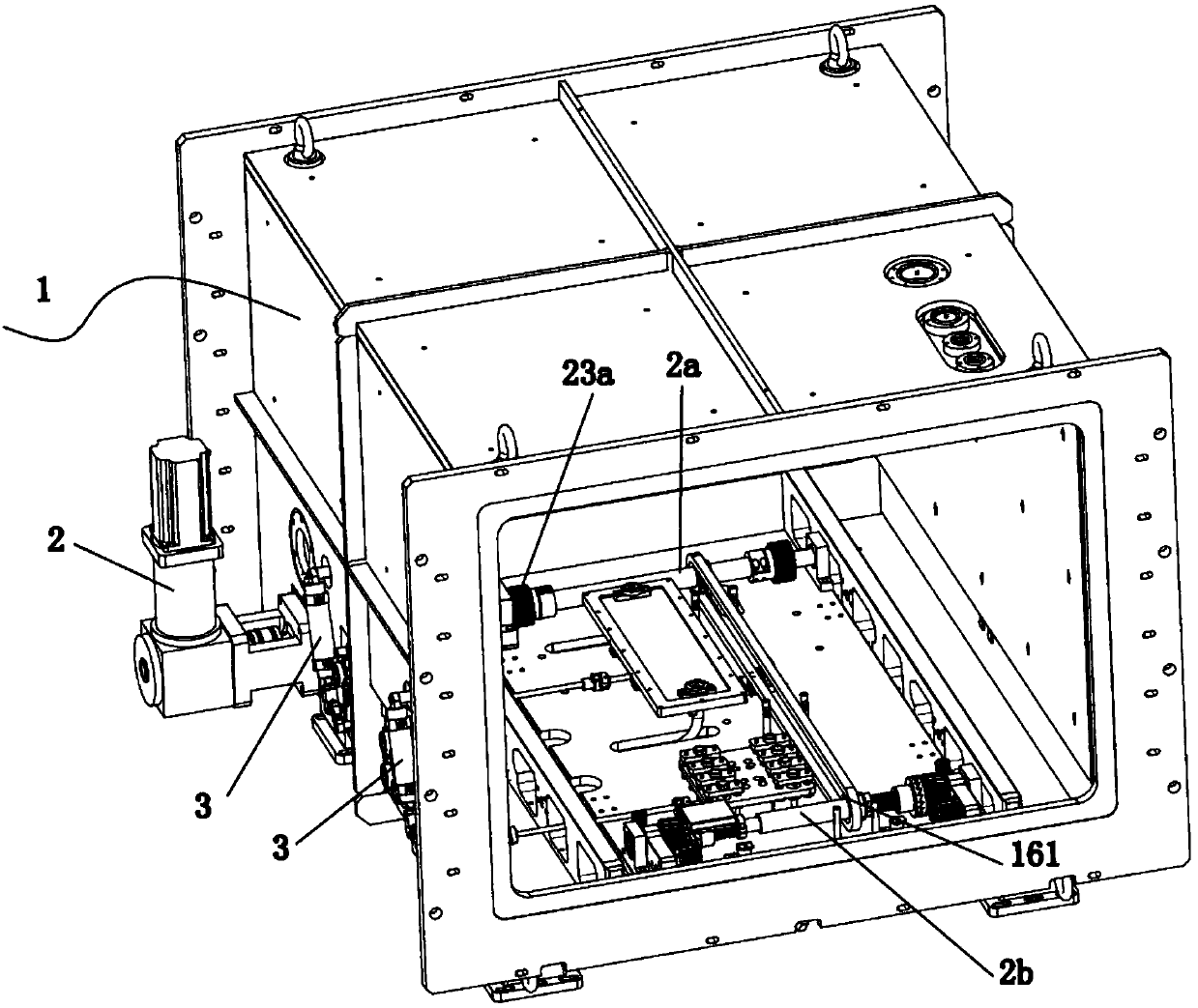

[0030] Such as Figure 1-Figure 3 As shown, a separate dynamic contact system with heating and cooling functions, including a cavity body 1, a servo motor 2 and a cylinder 3, a cooling mechanism, a gear shifting mechanism and a heating movable contact mechanism,

[0031] The cavity main body 1 is a rectangular cavity with openings on both sides and through, and the remaining surfaces are sealed;

[0032] The cooling mechanism, the shifting gear mechanism and the heatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap