Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Servo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Servos (also RC servos) are small, cheap, mass-produced servomotors or other actuators used for radio control and small-scale robotics. Most servos are rotary actuators although other types are available. Linear actuators are sometimes used, although it is more common to use a rotary actuator with a bellcrank and pushrod. Some types, originally used as sail winches for model yachting, can rotate continuously.

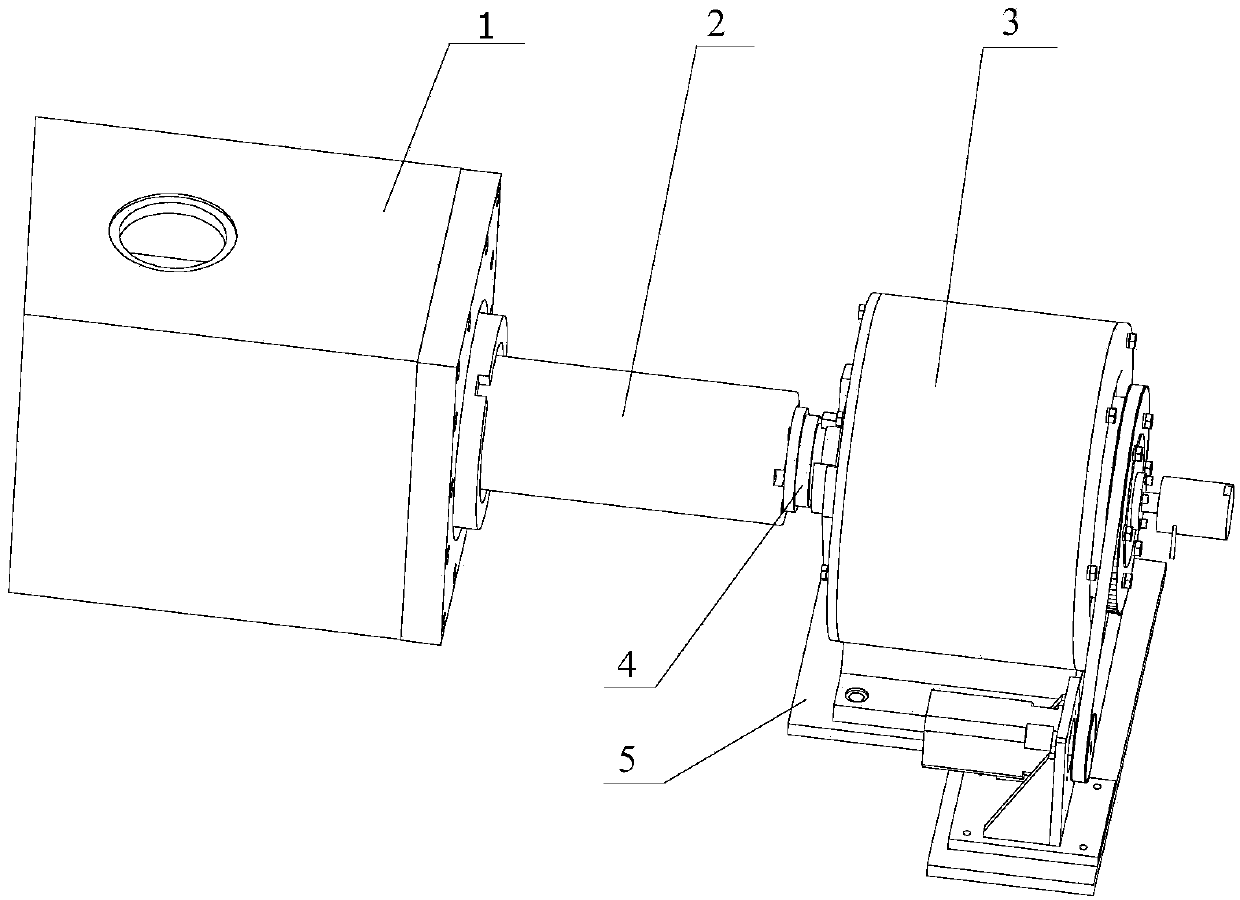

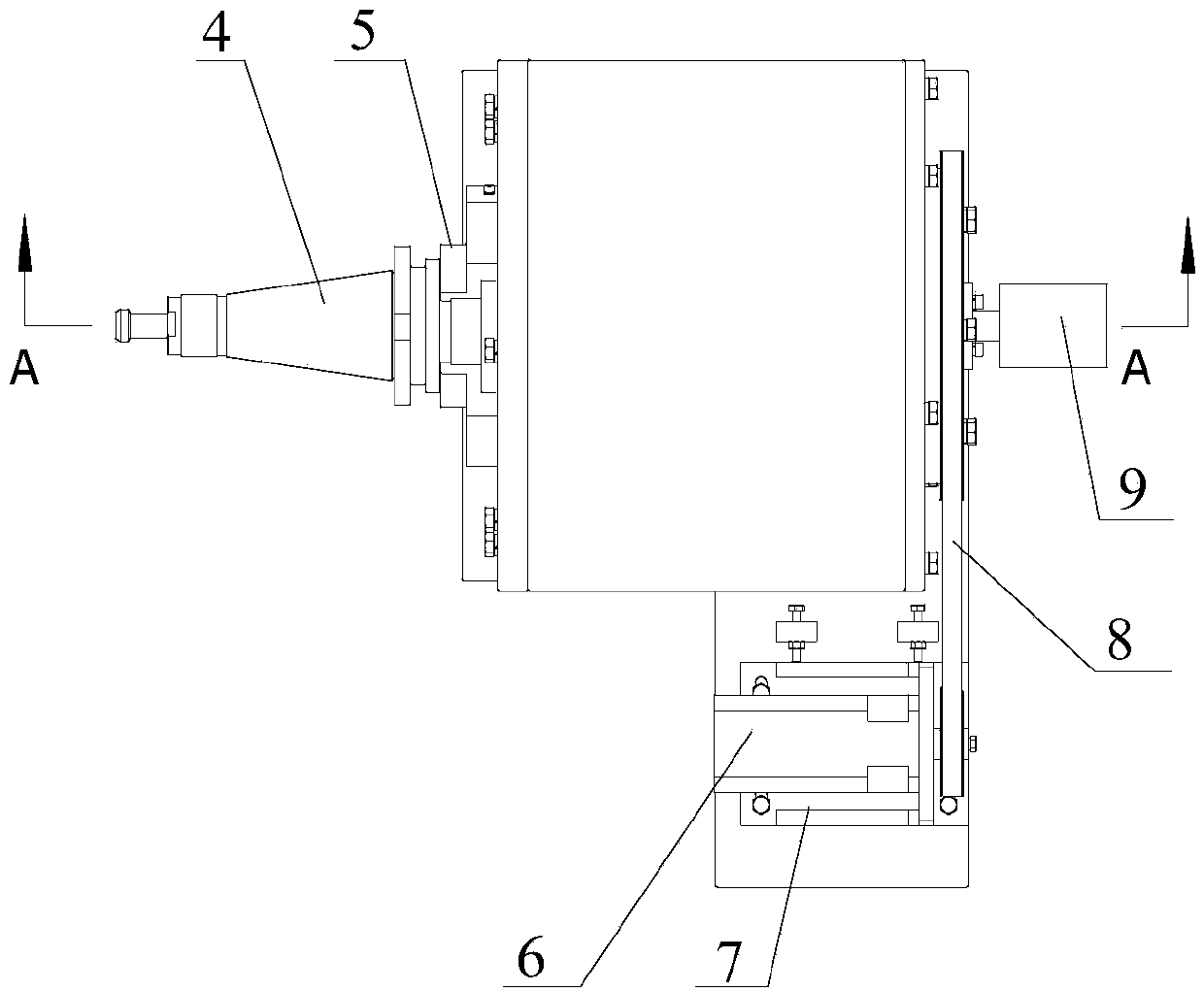

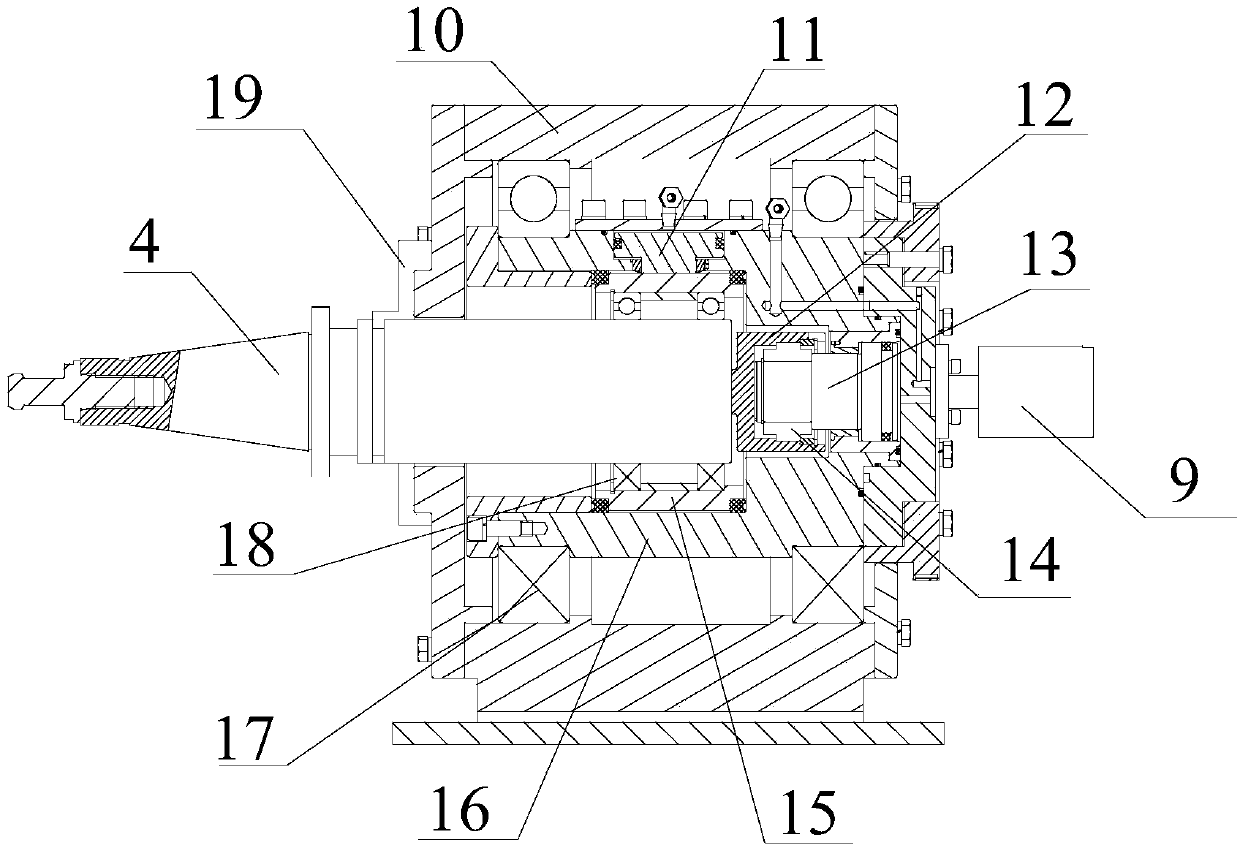

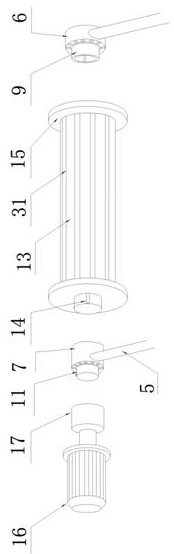

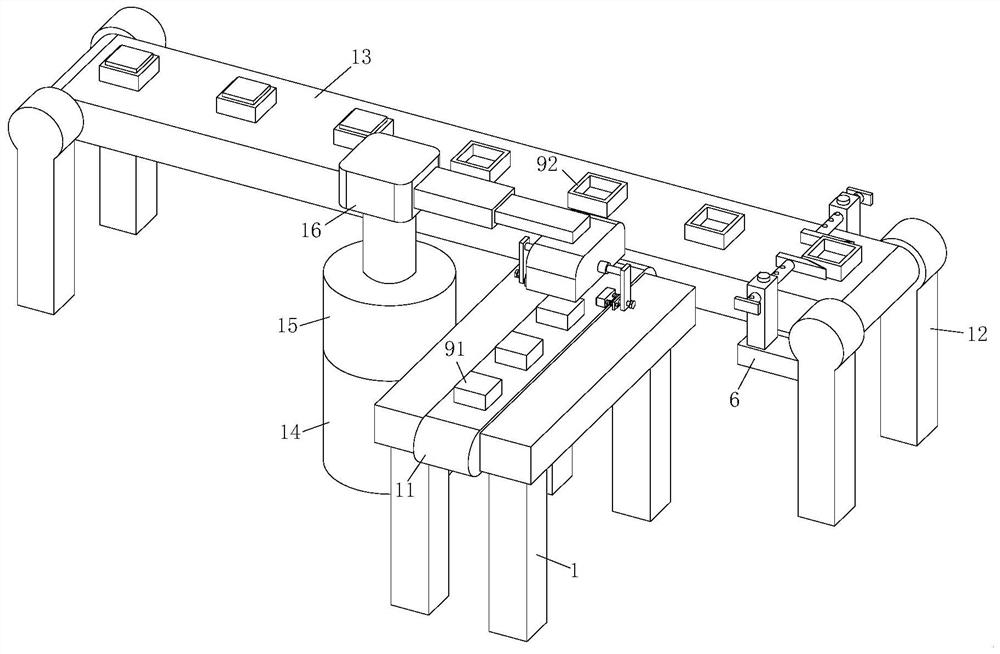

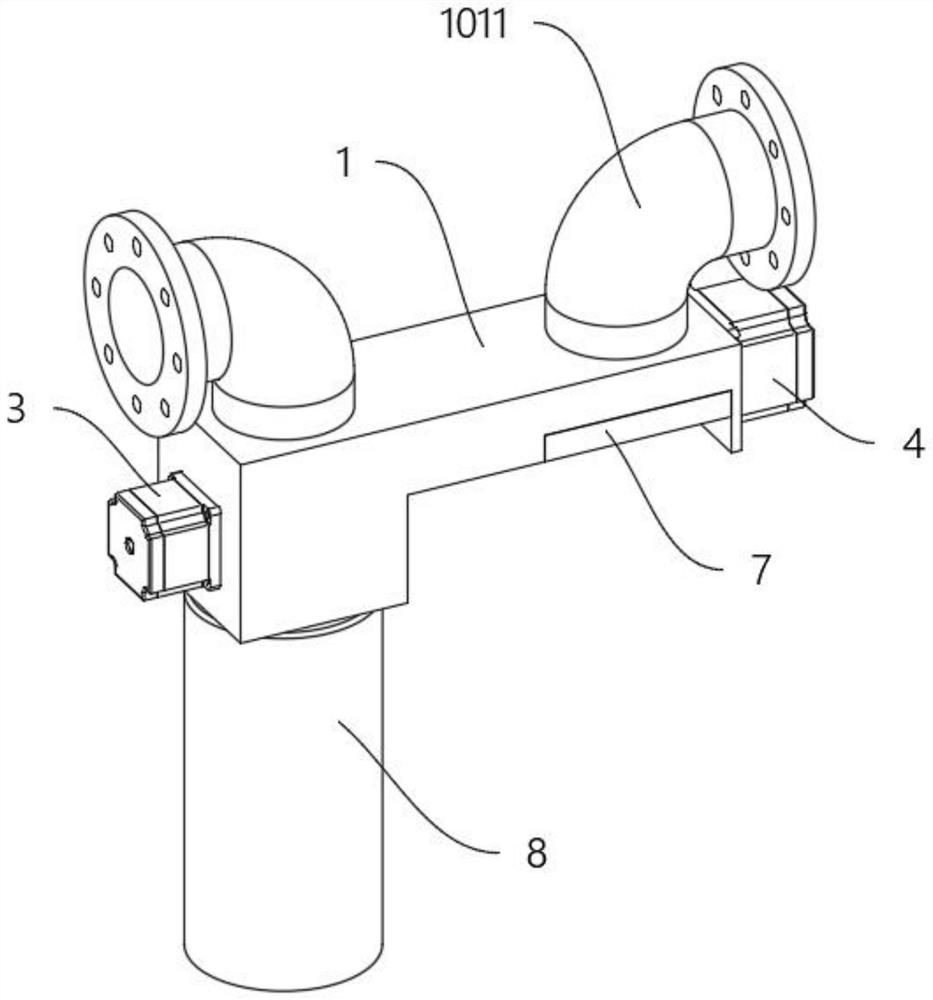

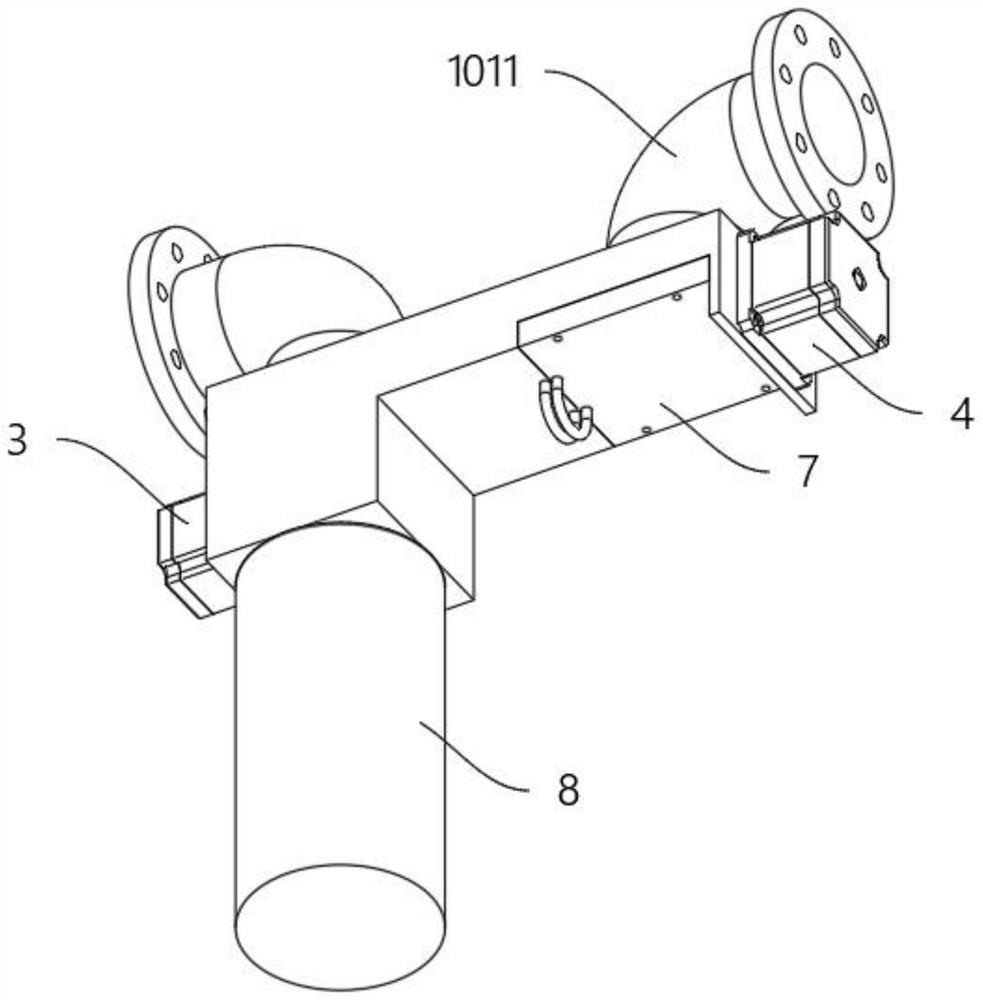

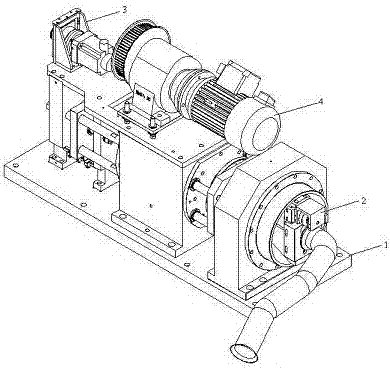

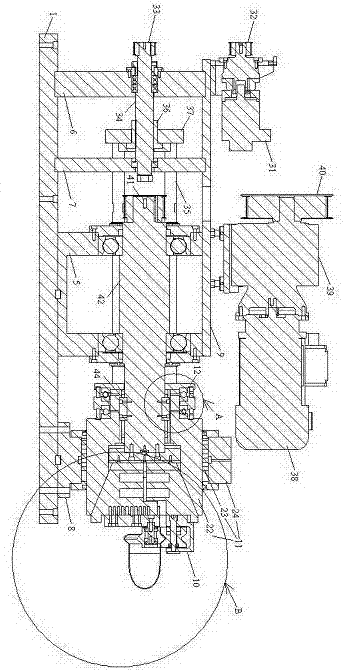

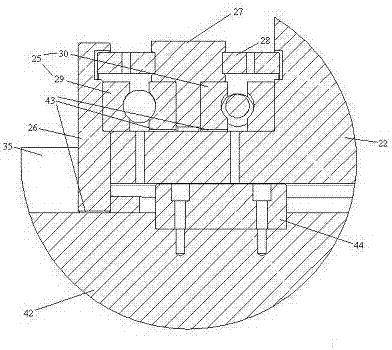

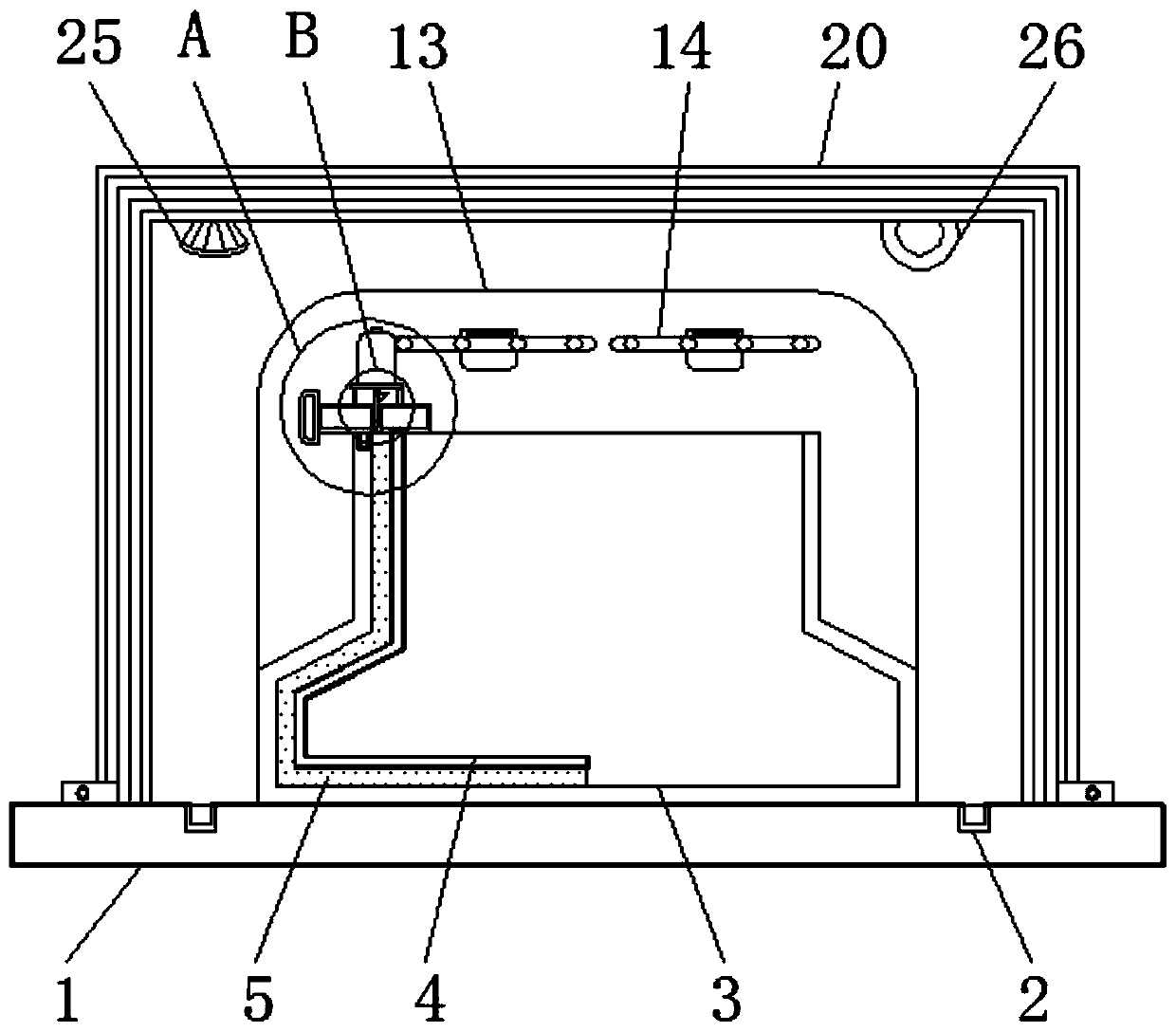

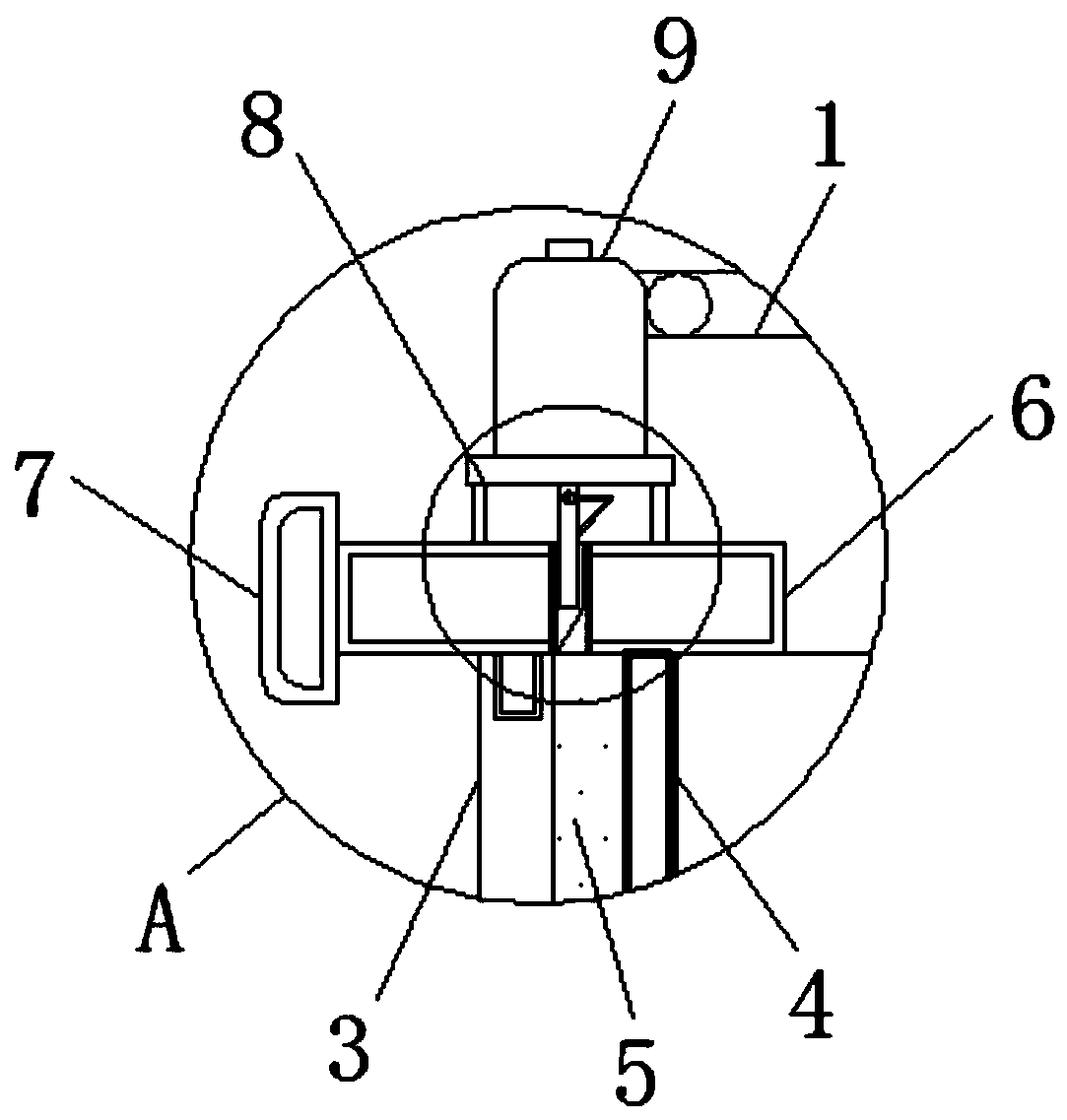

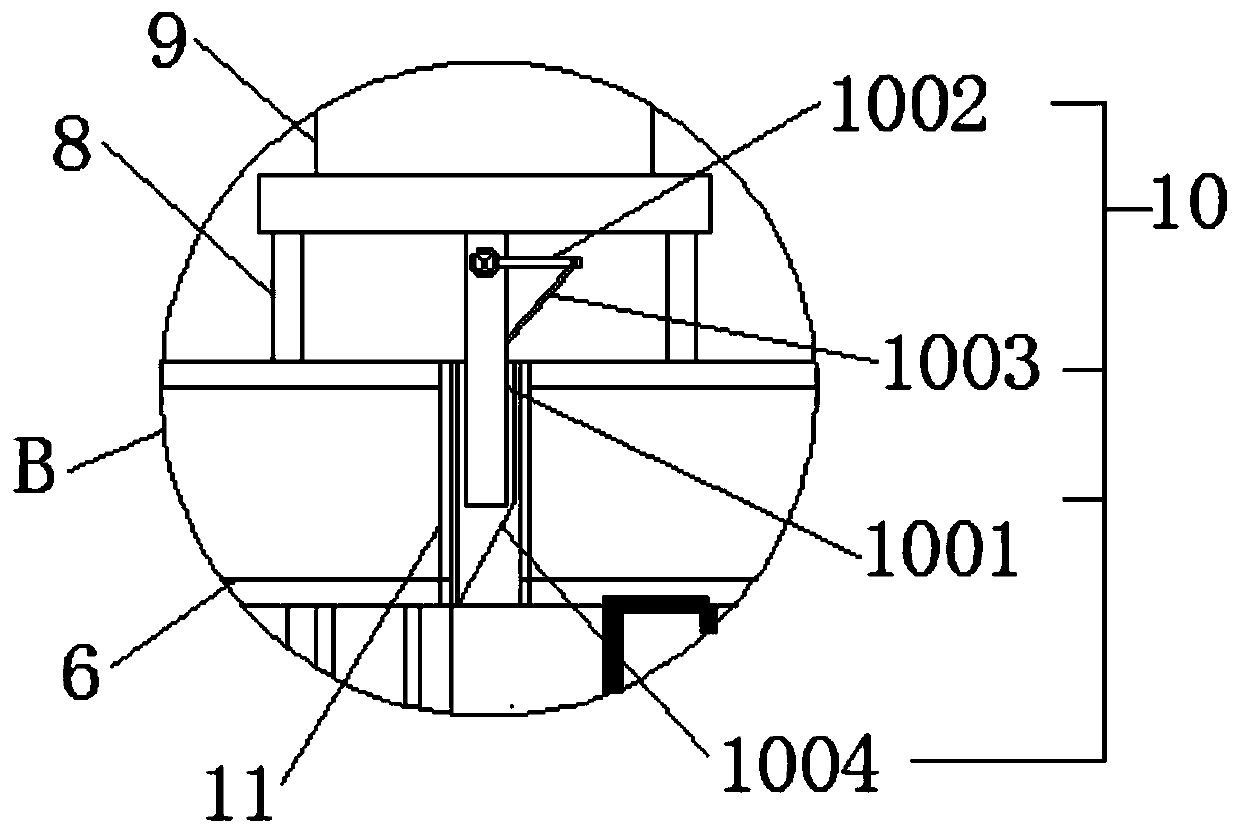

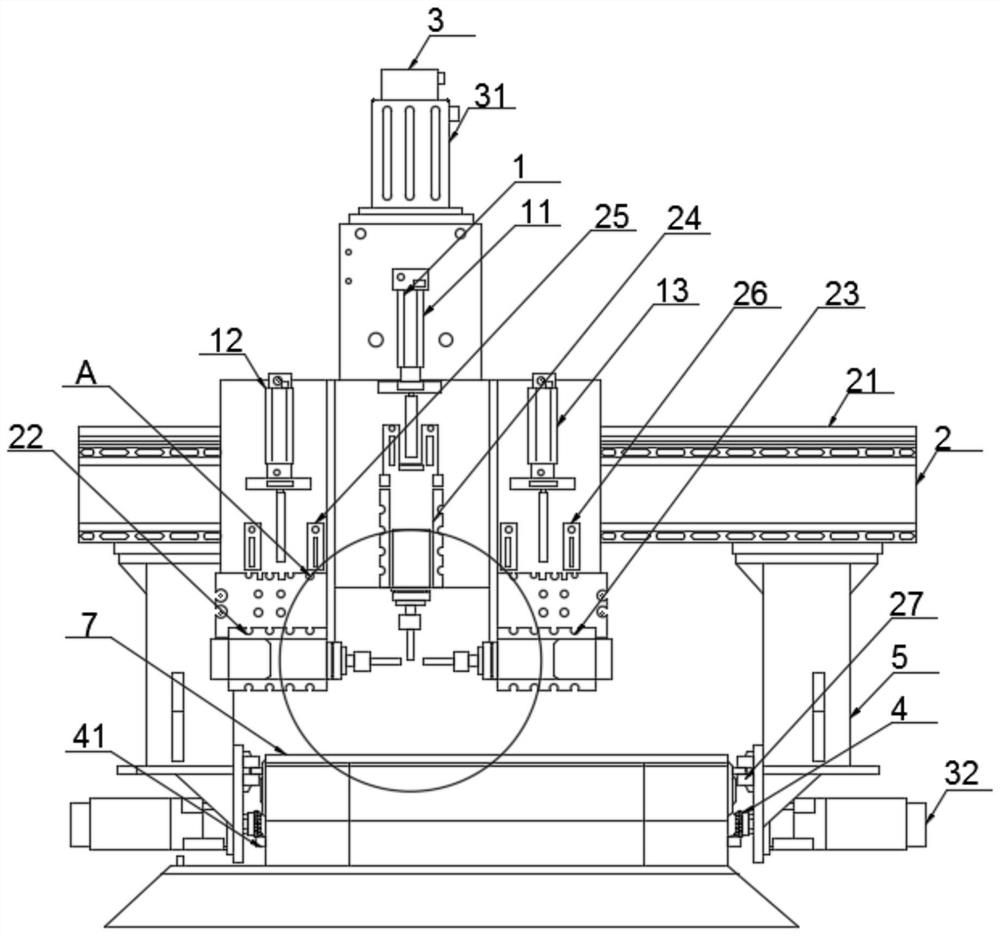

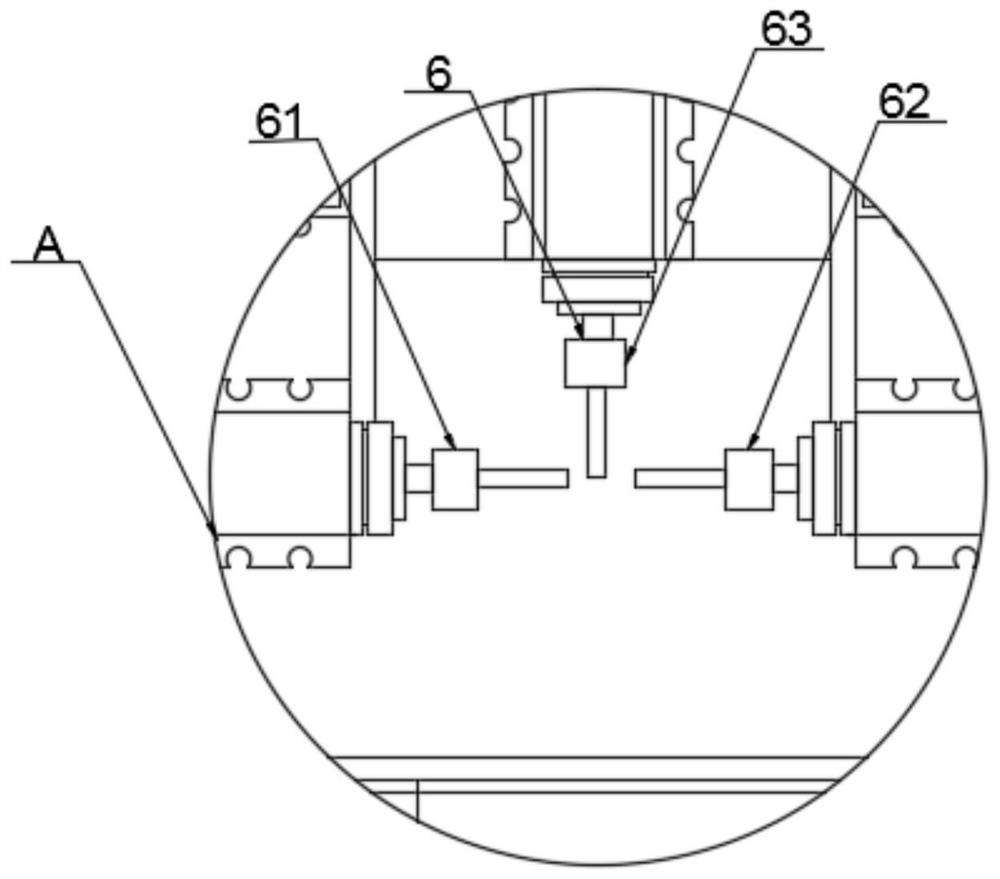

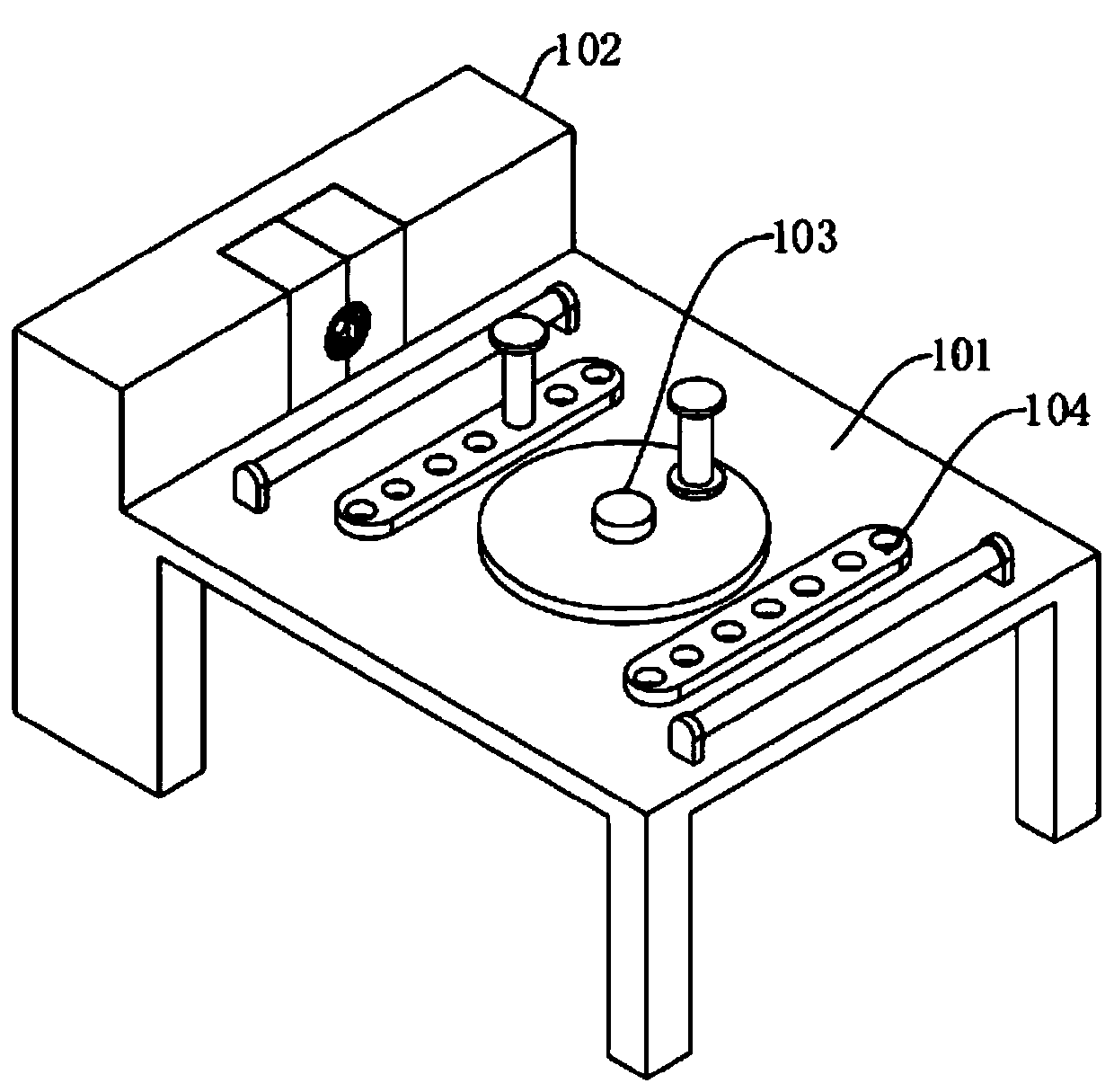

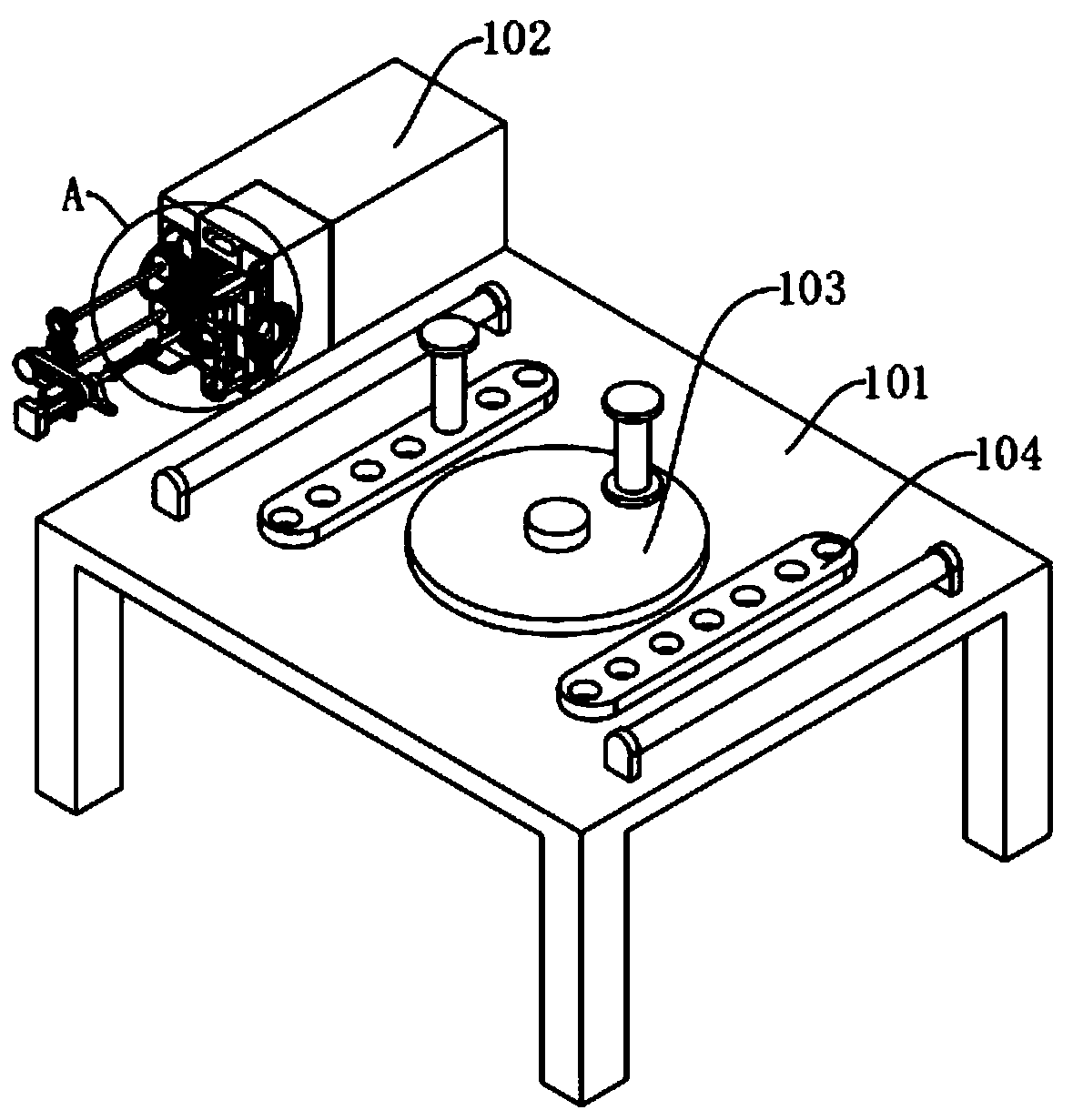

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

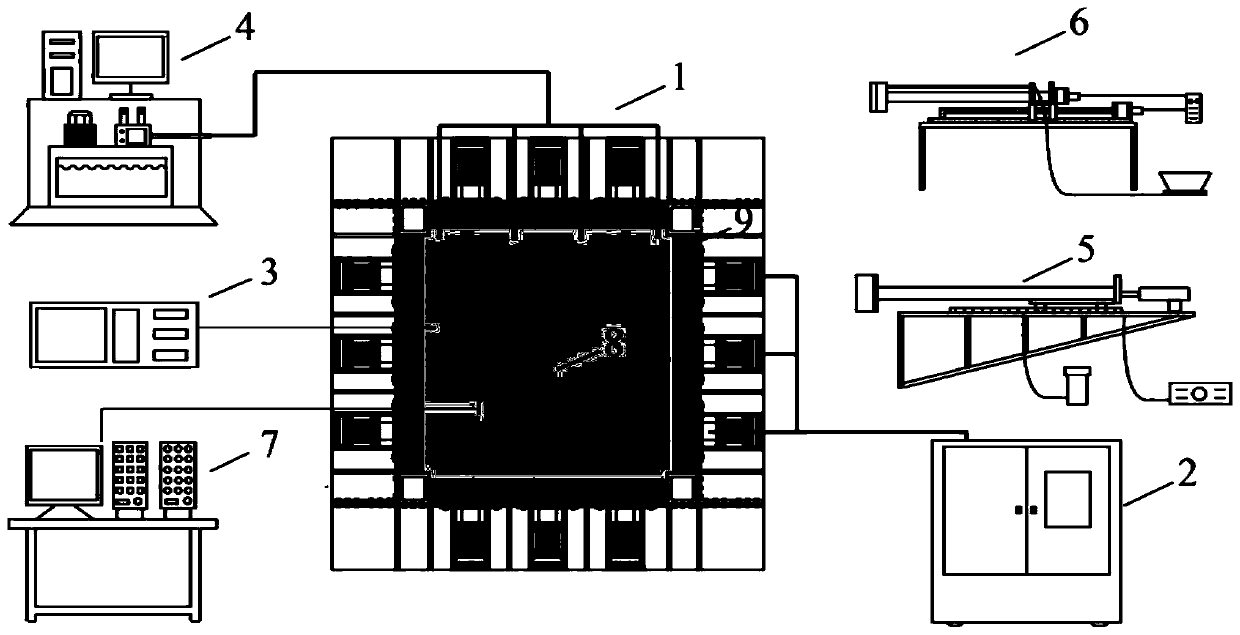

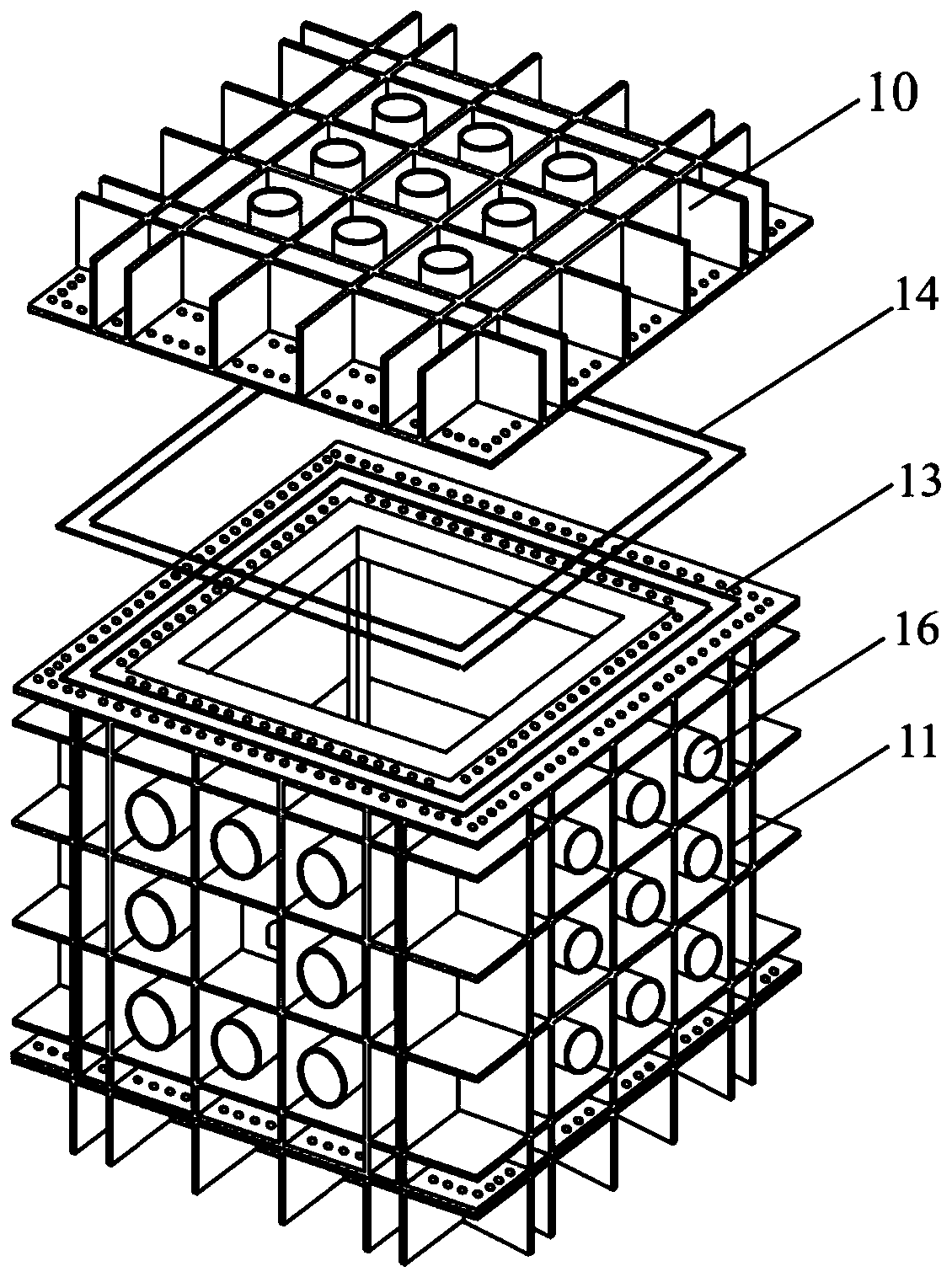

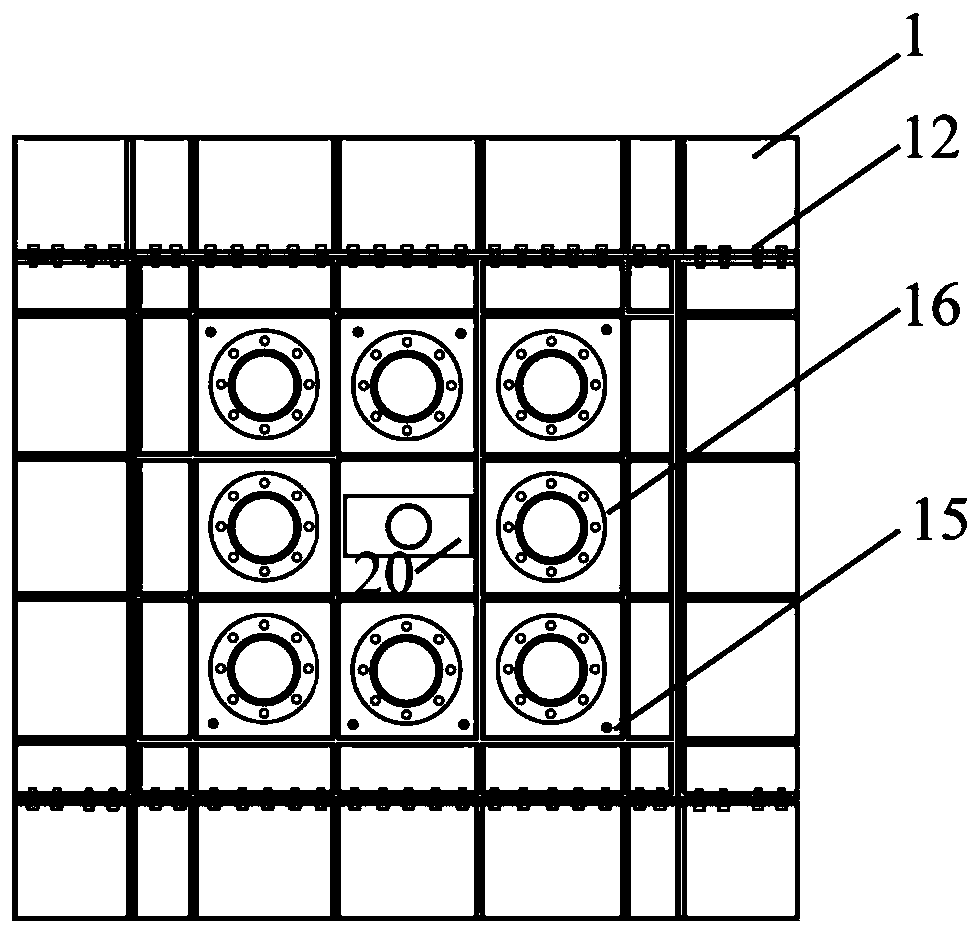

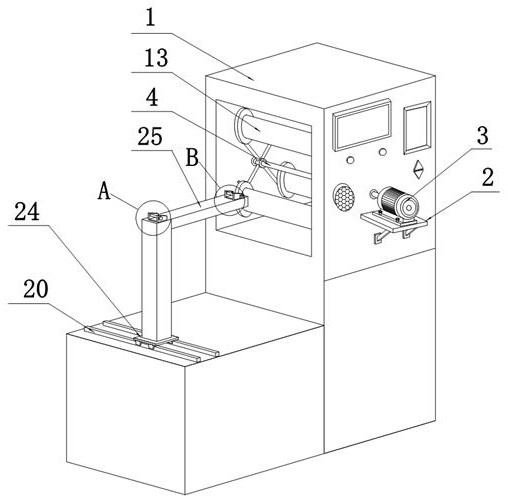

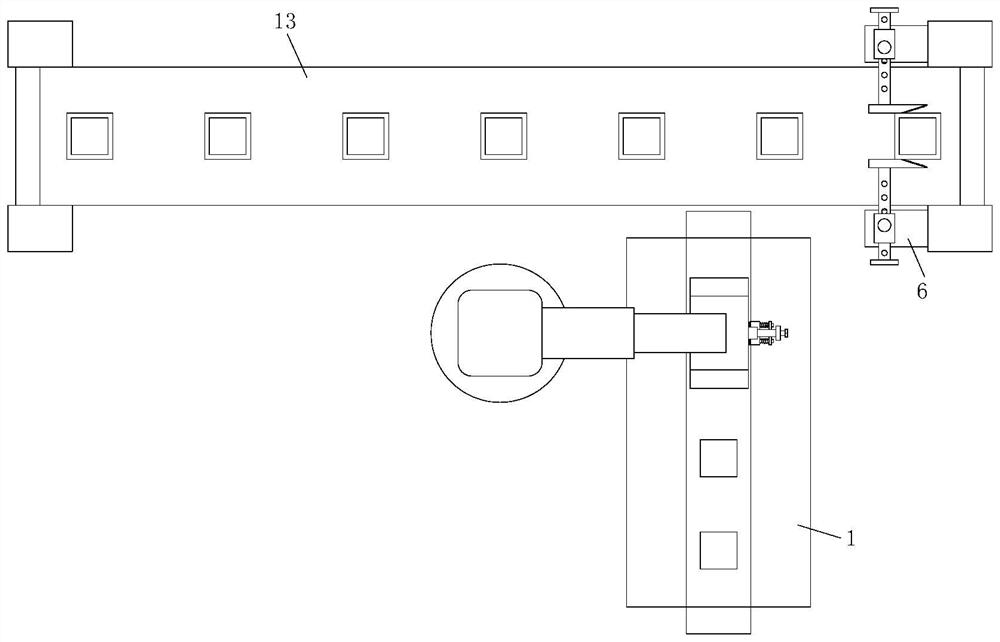

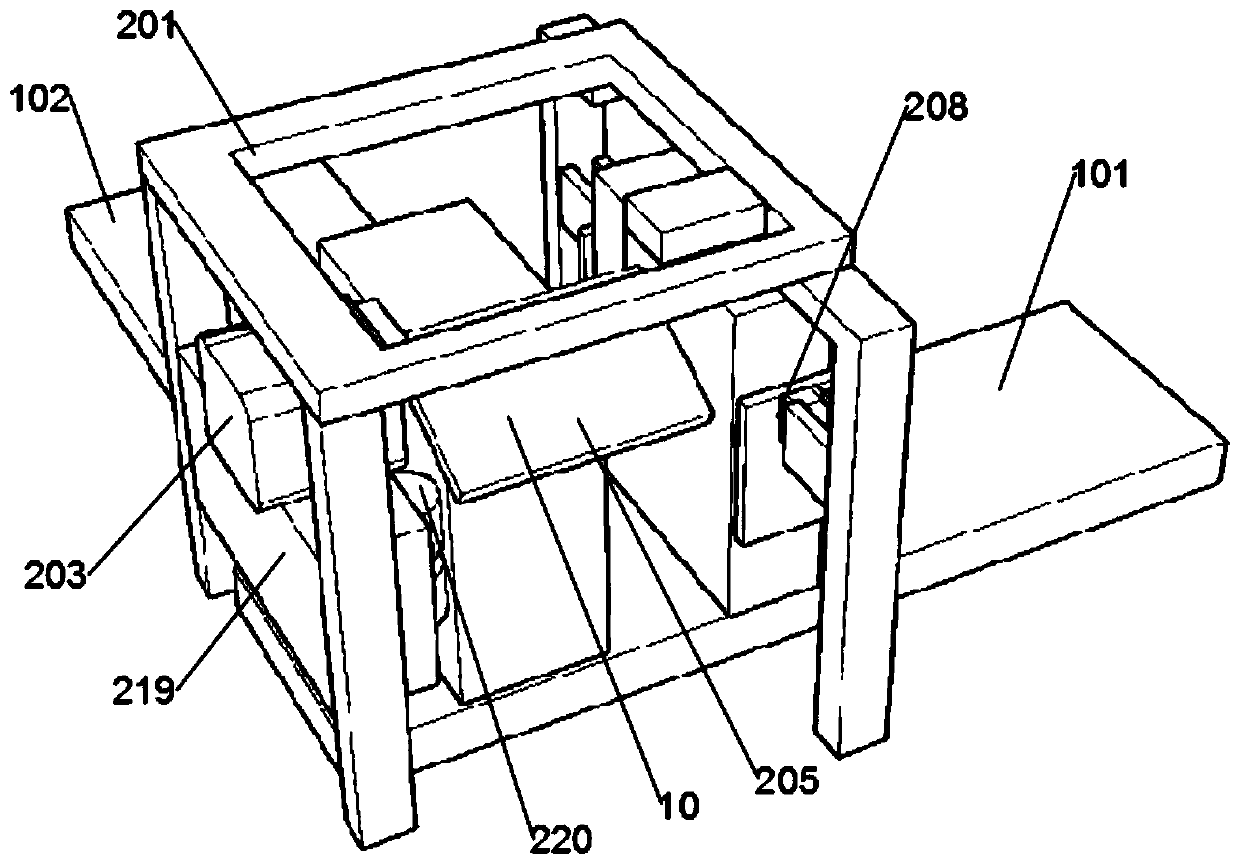

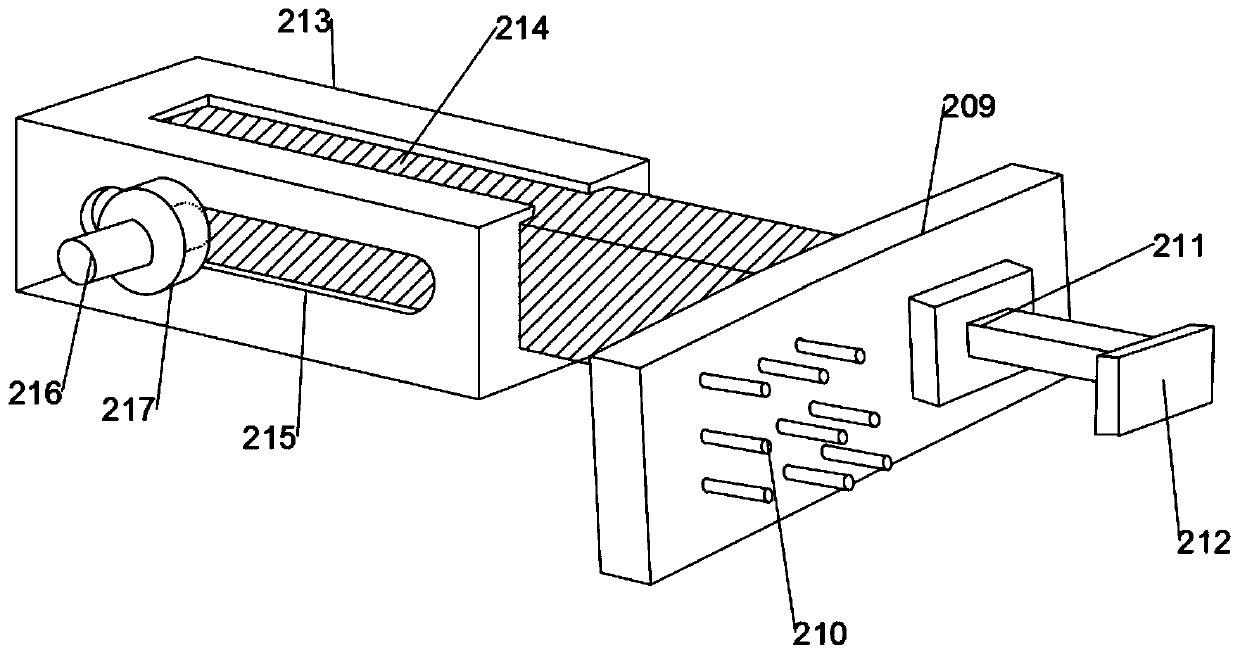

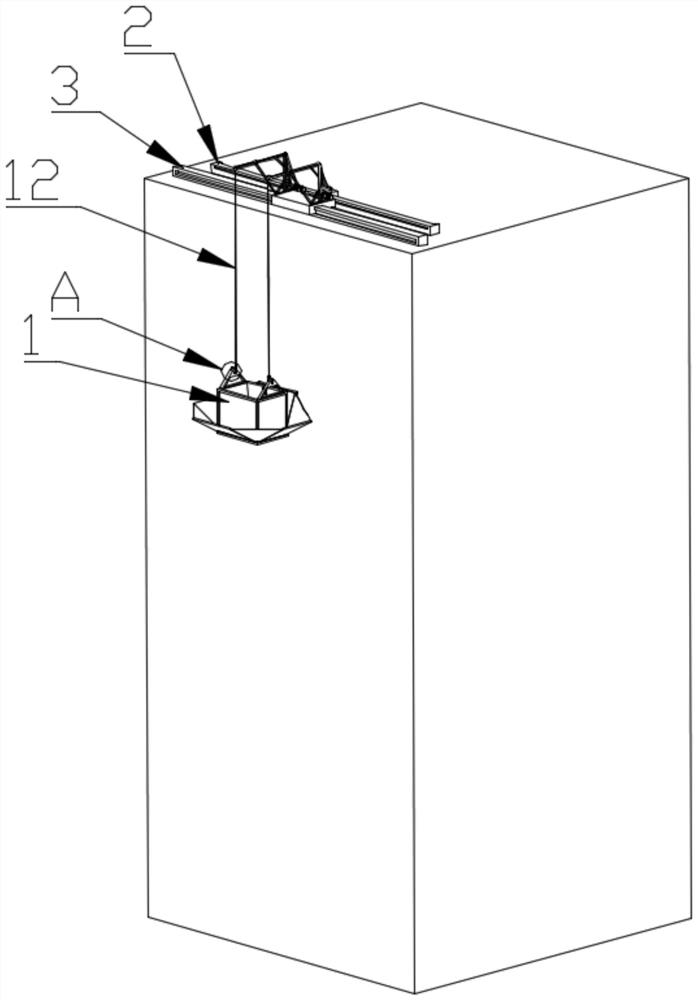

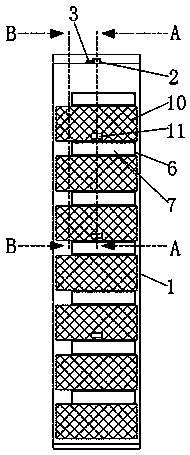

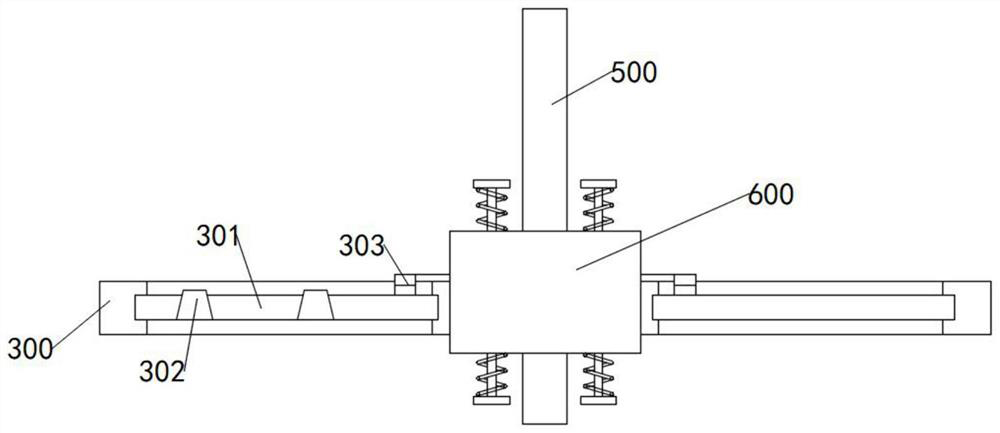

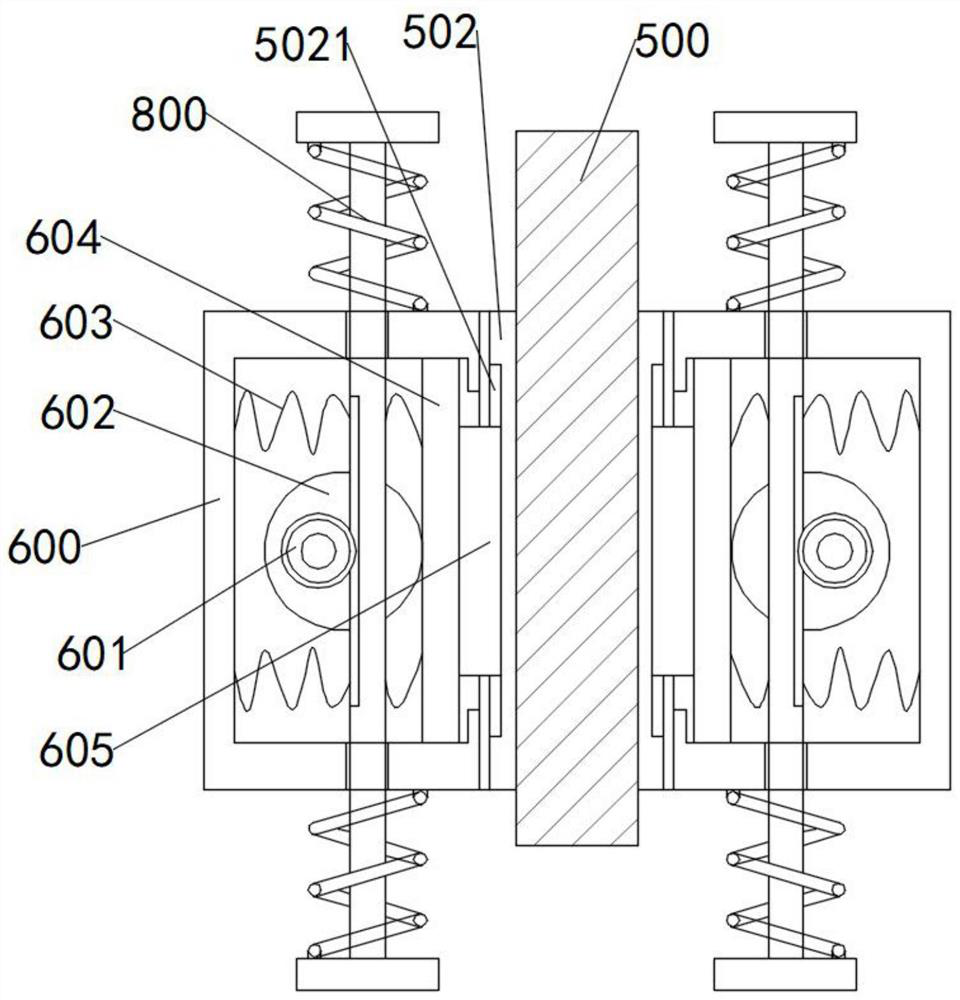

Large-burial-depth tunnel surrounding rock stabilization and support model test system under complex conditions

ActiveCN111208015AMaterial strength using tensile/compressive forcesStructural/machines measurementServoCrustal stress

Owner:SHANDONG UNIV

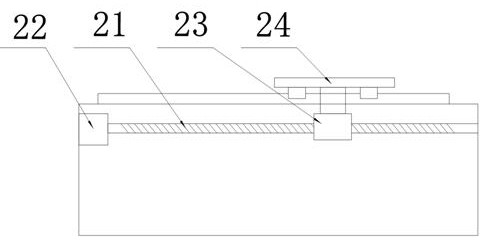

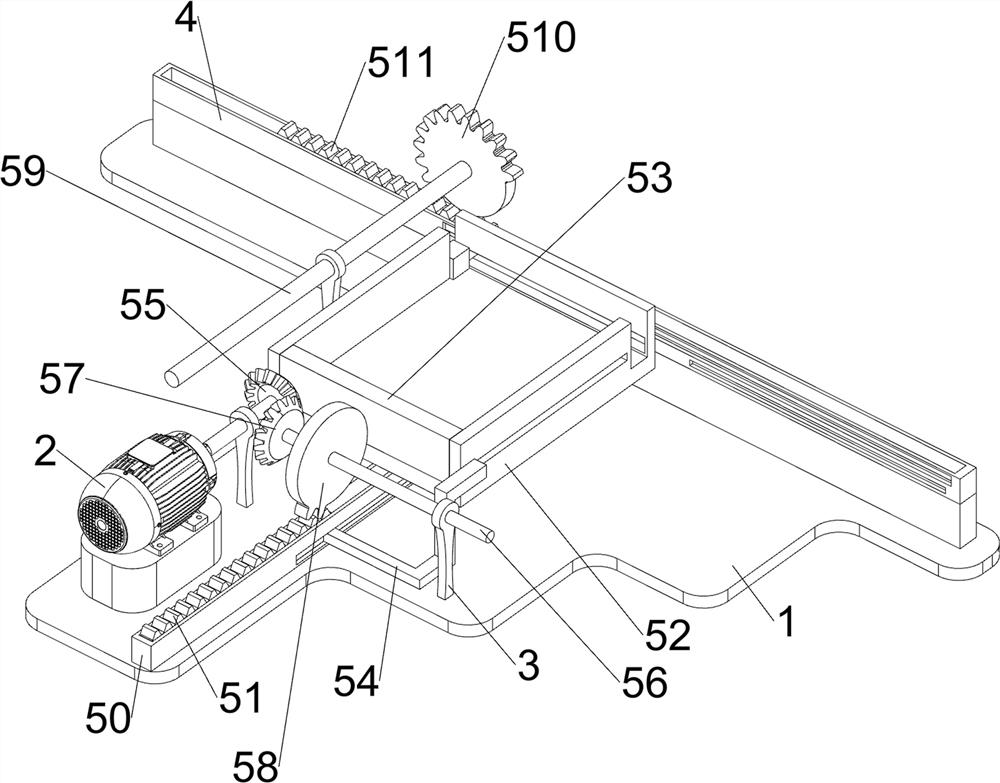

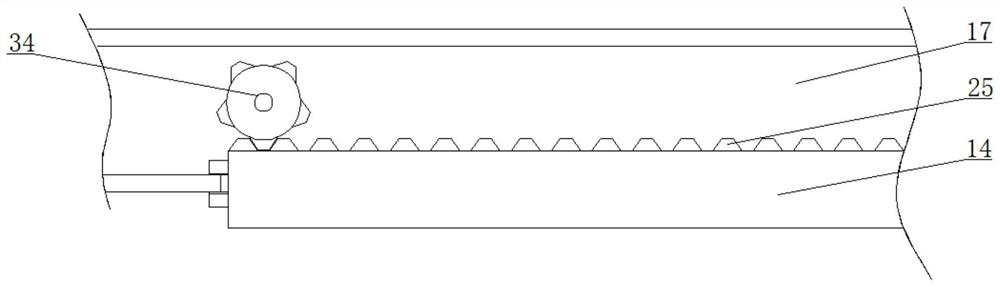

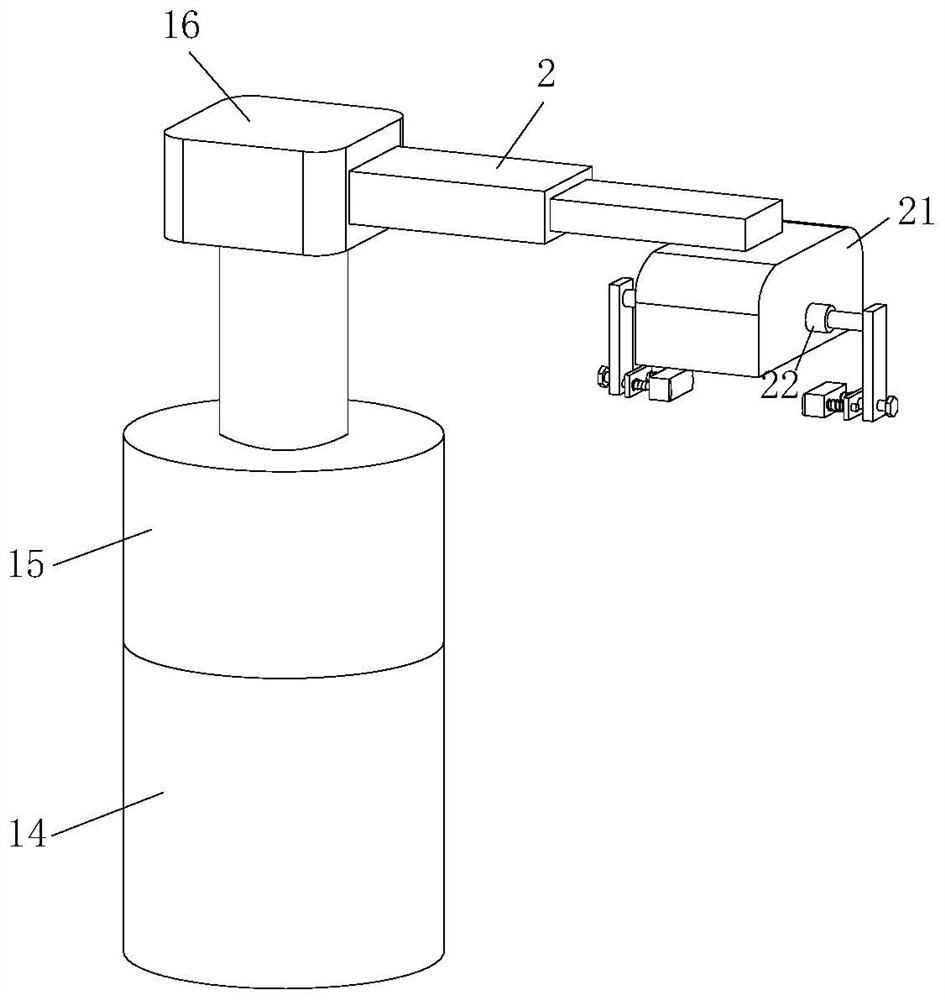

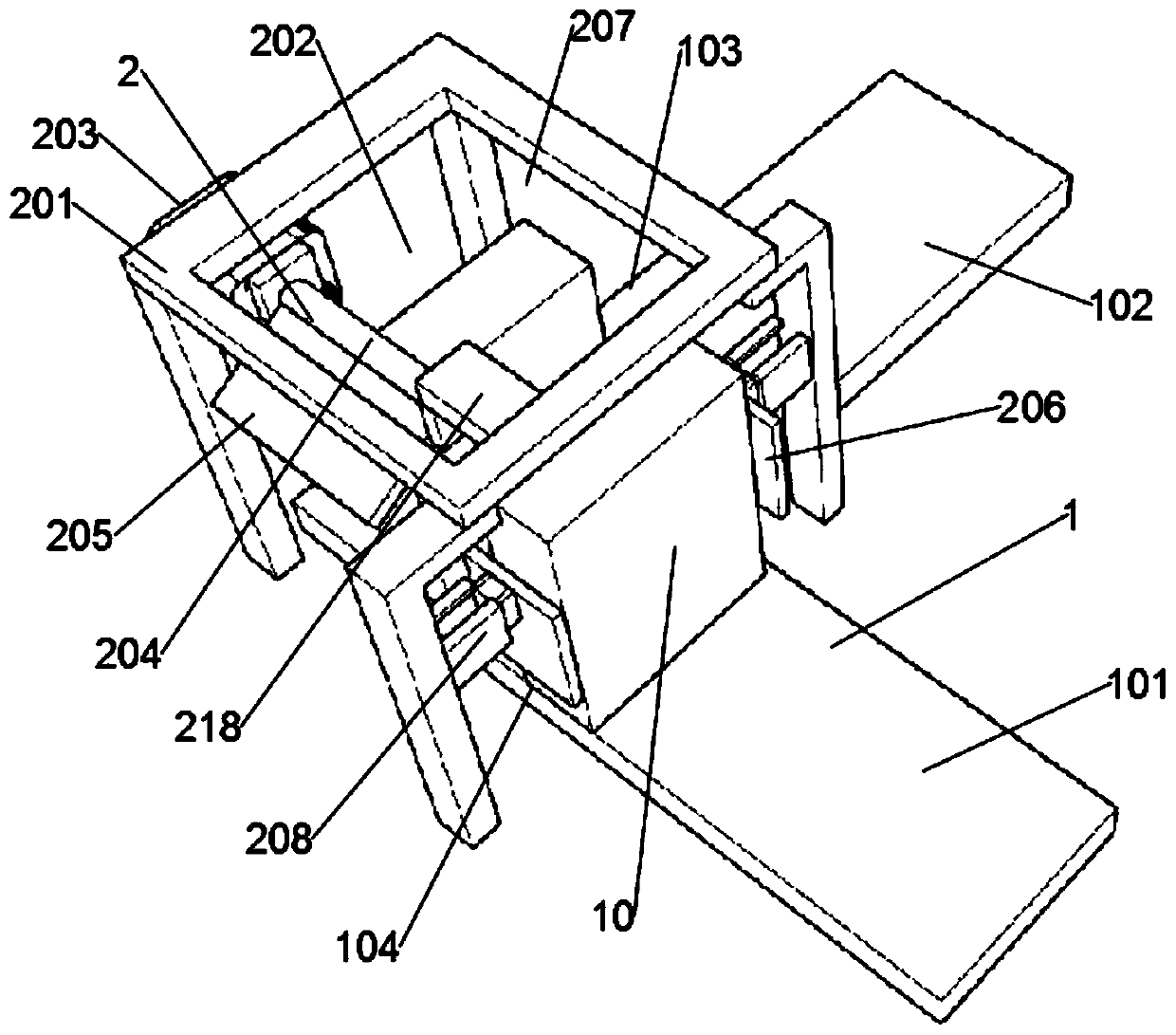

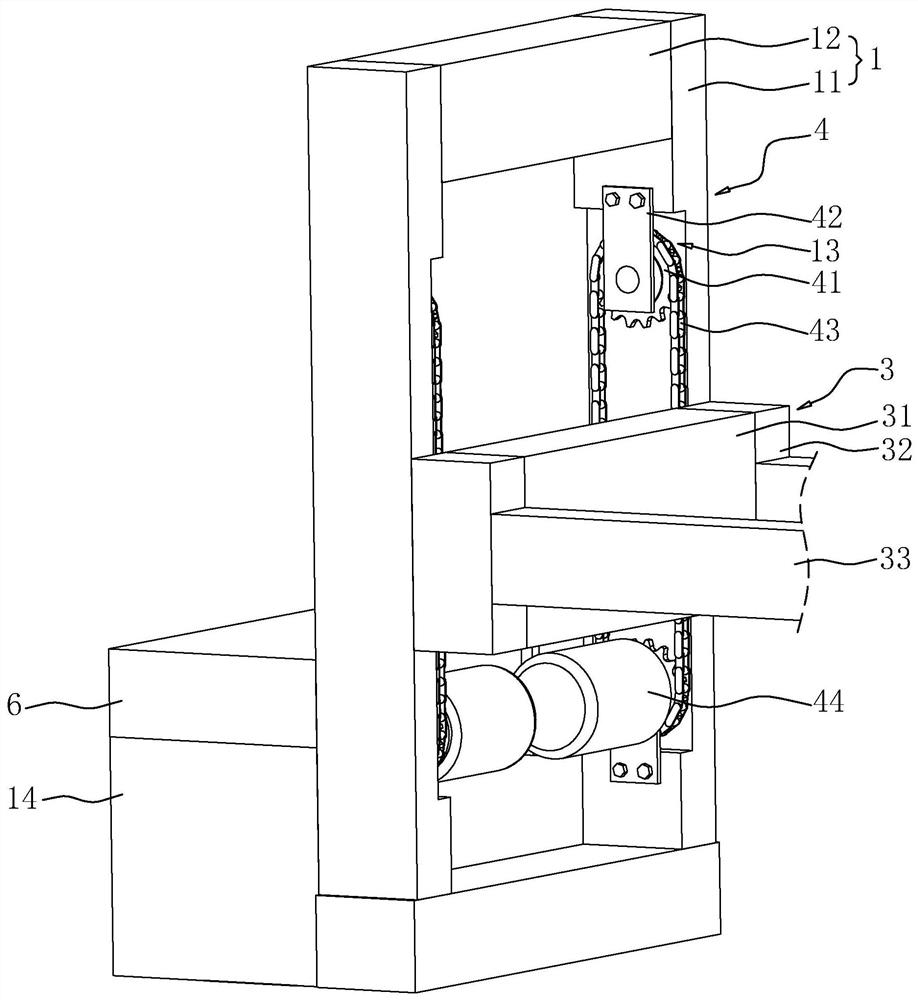

Supporting plate feeding system of numerical-control scraping rolling machine

InactiveCN112476011AAssisted movementReduce the impact of movementFeeding apparatusMaintainance and safety accessoriesGear wheelControl engineering

The invention relates to the technical field of oil cylinder machining, and discloses a supporting plate feeding system of a numerical-control scraping rolling machine. The supporting plate feeding system comprises a rack, wherein guide rails are fixedly mounted on the left side and the right side of the top end of the rack, fixed frames are movably mounted at the top ends of the guide rails, andracks are fixedly mounted at the ends, close to each other, of the two guide rails; and fixed seats are fixedly mounted on sides of the back surfaces of the fixed frames. According to the supporting plate feeding system of the numerical-control scraping rolling machine disclosed by the invention, the bottom ends of the output shafts of servo motors are fixedly sleeved with the gears, the racks arearranged on the side surfaces of the guide rails and connected to the gears in a meshed mode; and when the fixed frames need to be moved, the gears at the bottom ends of the servo motors can be driven to rotate at the moment by starting the servo motors; the gears can be driven by the racks to move relative to the guide rails and drive the fixed frames to move relative to the guide rails, so thatthe influence of sliding friction on movement of the fixed frames is reduced, and therefore, the advantage of assisting movement of the fixed frames is achieved.

Owner:LOUDI DINGLI HYDRAULIC TECH CO LTD

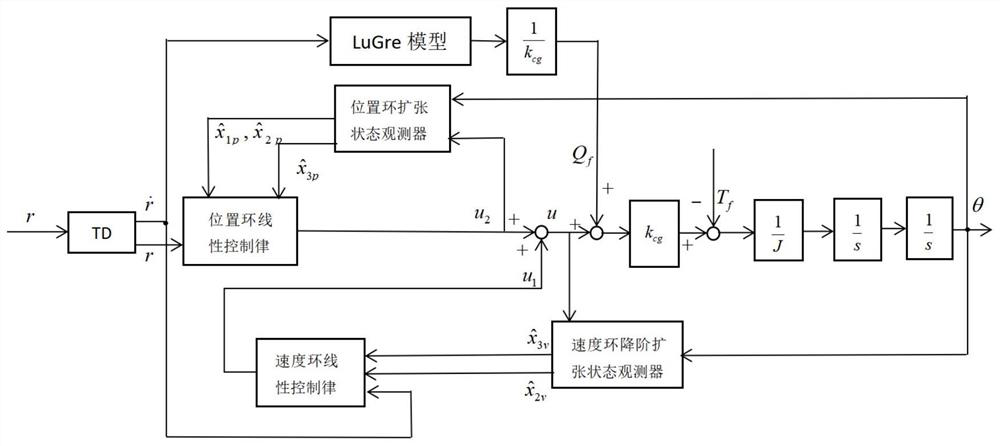

Active-disturbance-rejection controller and design method thereof

ActiveCN113325805AAvoid influenceImprove dynamic performanceNumerical controlLinear controlFriction torque

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Convenient-rectifying winding device for producing zippers

Owner:四会市世经拉链制品有限公司

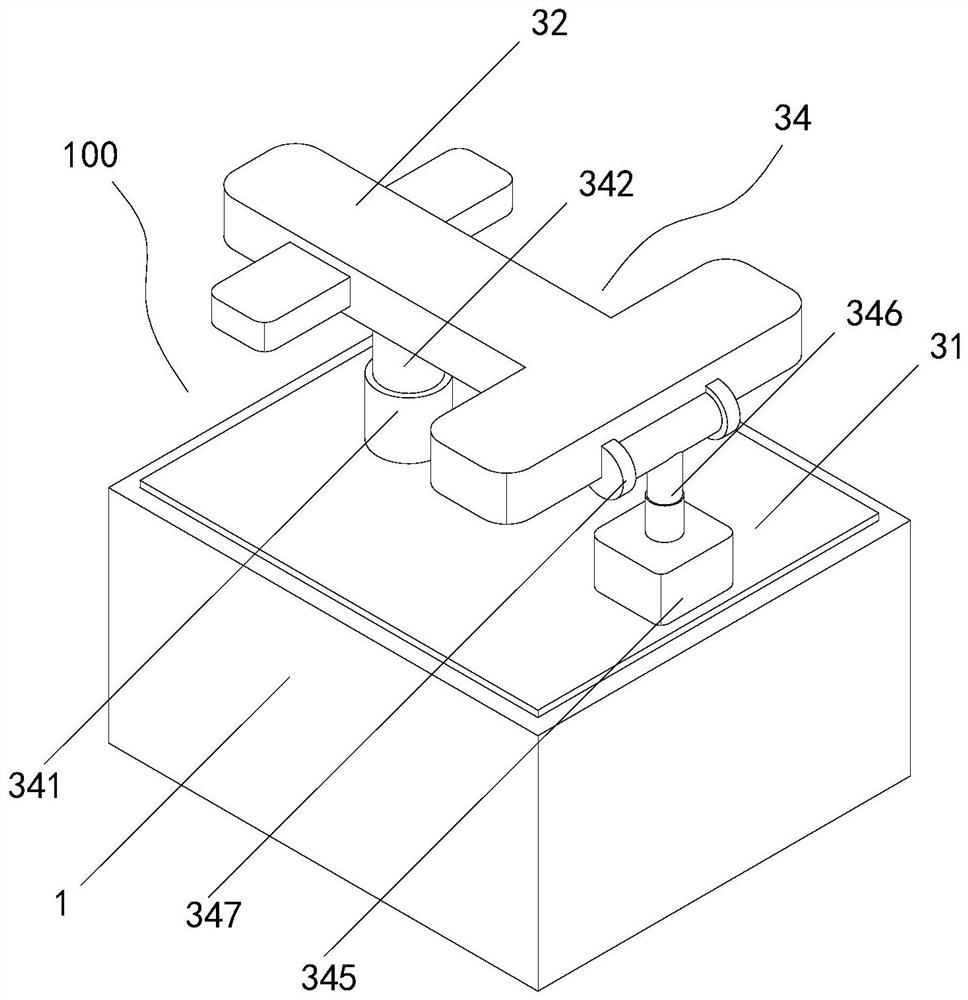

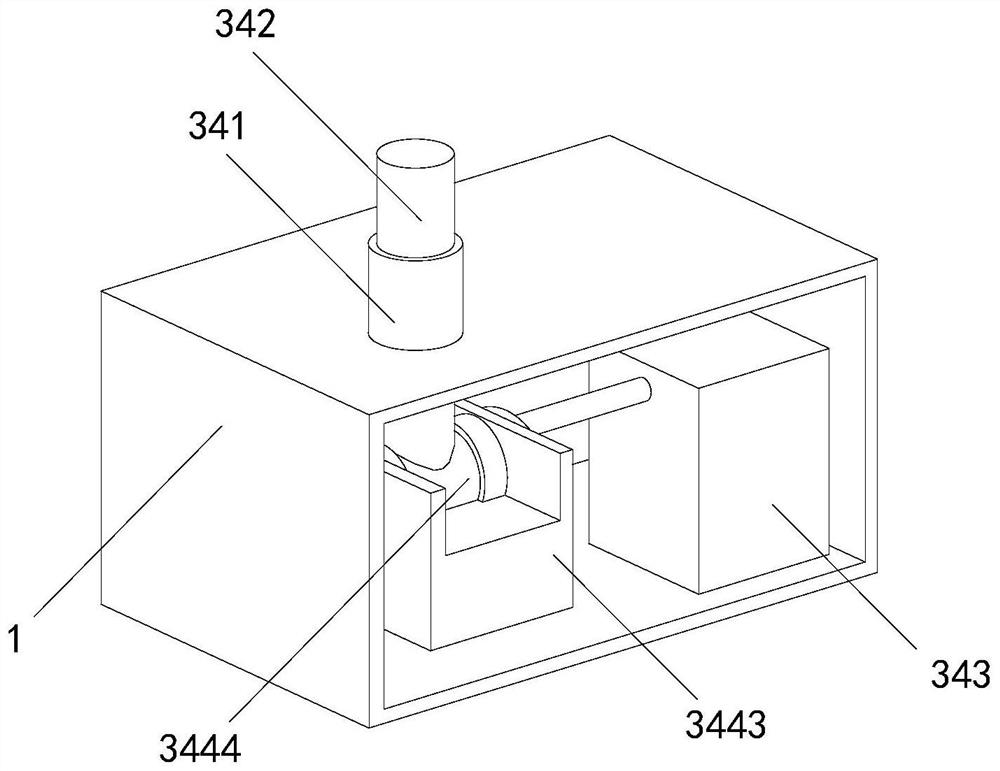

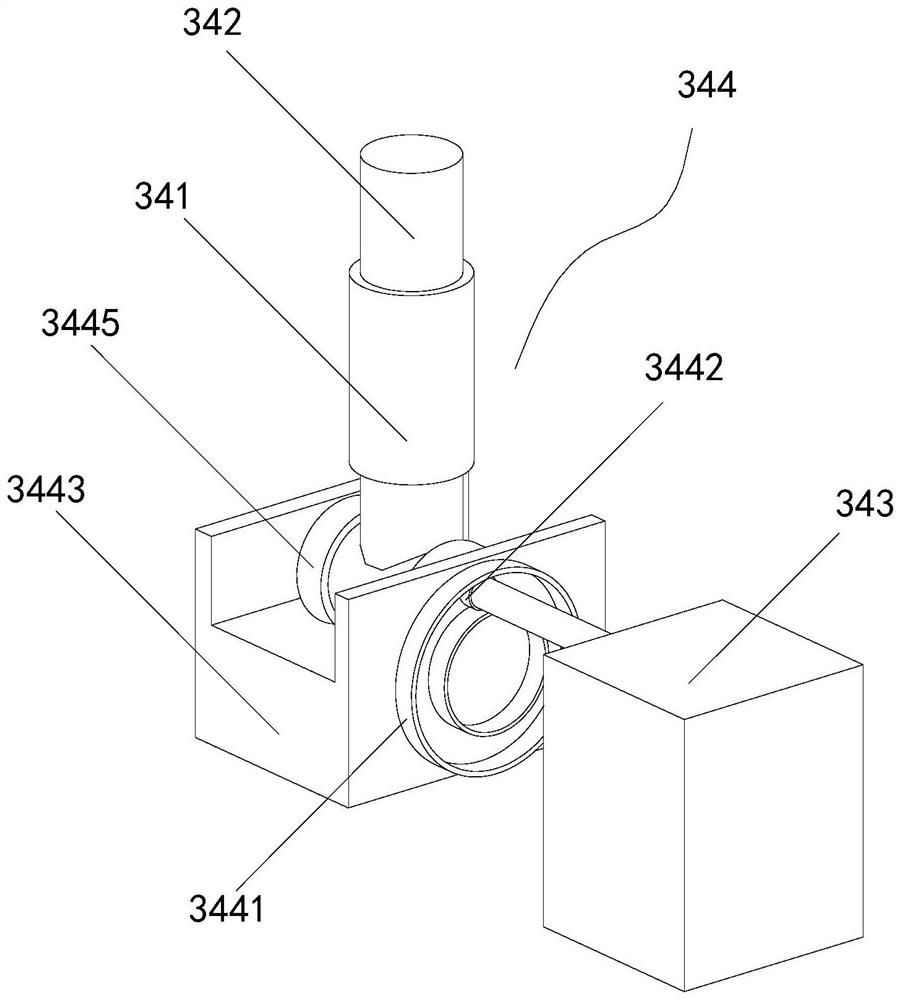

Civil automatic brick making device

InactiveCN112297194AConvenient collection workNo need for manual extrusionCeramic shaping apparatusBrickArchitectural engineering

The invention relates to a brick making device, in particular to a civil automatic brick making device. According to the civil automatic brick making device, slime is mechanically and automatically extruded into the shape of a brick, so that the surface layer of the slime is very smooth. The civil automatic brick making device comprises a bottom plate, a feeding mechanism, a rotating mechanism andan ejection mechanism, wherein a servo motor is arranged on one side of the top of the bottom plate; the feeding mechanism is arranged on one side, close to the top of the servo motor, of the bottomplate; the rotating mechanism is arranged on the other side of the top of the bottom plate; and the ejection mechanism is arranged in the middle of the top of the bottom plate. Slime can be automatically conveyed to an ejection mechanism part through the feeding mechanism, and workers only need to fill new slime used for making bricks when a feeding frame moves at intervals every time; and throughthe arranged rotating mechanism, the slime can be automatically extruded, manual extrusion is not needed, the extrusion force is consistent, and the formed bricks are smoother.

Owner:杨金鑫

Soft geological foundation pit excavation construction method for existing line station

InactiveCN113152476AImprove construction efficiencyAutomatic monitoring effect is goodArtificial islandsExcavationsAutomatic controlArchitectural engineering

The invention relates to the technical field of foundation pit excavation construction, and provides a soft geological foundation pit excavation construction method of an existing line station. The soft geological foundation pit excavation construction method comprises the following steps that S1, construction is prepared; S2, a foundation pit to be excavated is monitored; S3, a main body of the station is excavated; S4, a steel support servo system is arranged on the main body of the station, construction monitoring is performed on excavation of the main body of the station through the steel support servo system, data is automatically monitored, a deformation rule is analyzed and automatic control is performed; and S5, the excavated foundation pit is subjected to leakage water stopping treatment. The construction efficiency of the foundation pit can be improved, the automatic monitoring effect is good, the construction safety is high, and the application range is wide.

Owner:CHINA RAILWAY NO 9 BUREAU GRP NO 1 CONSTR CO LTD

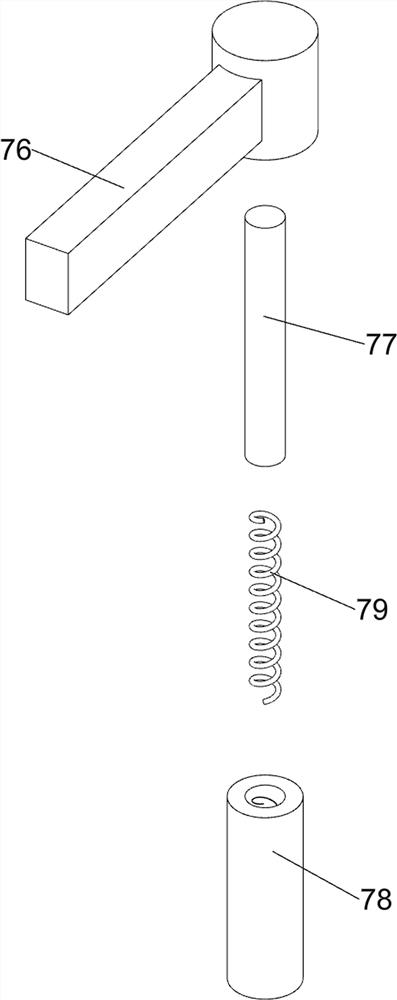

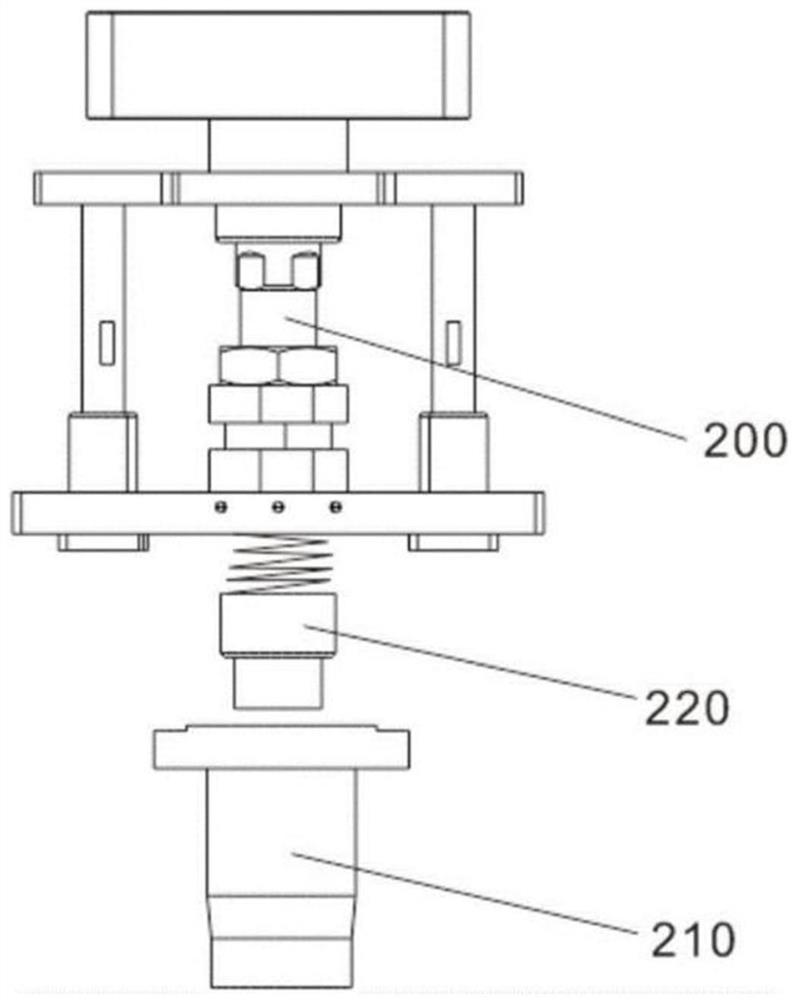

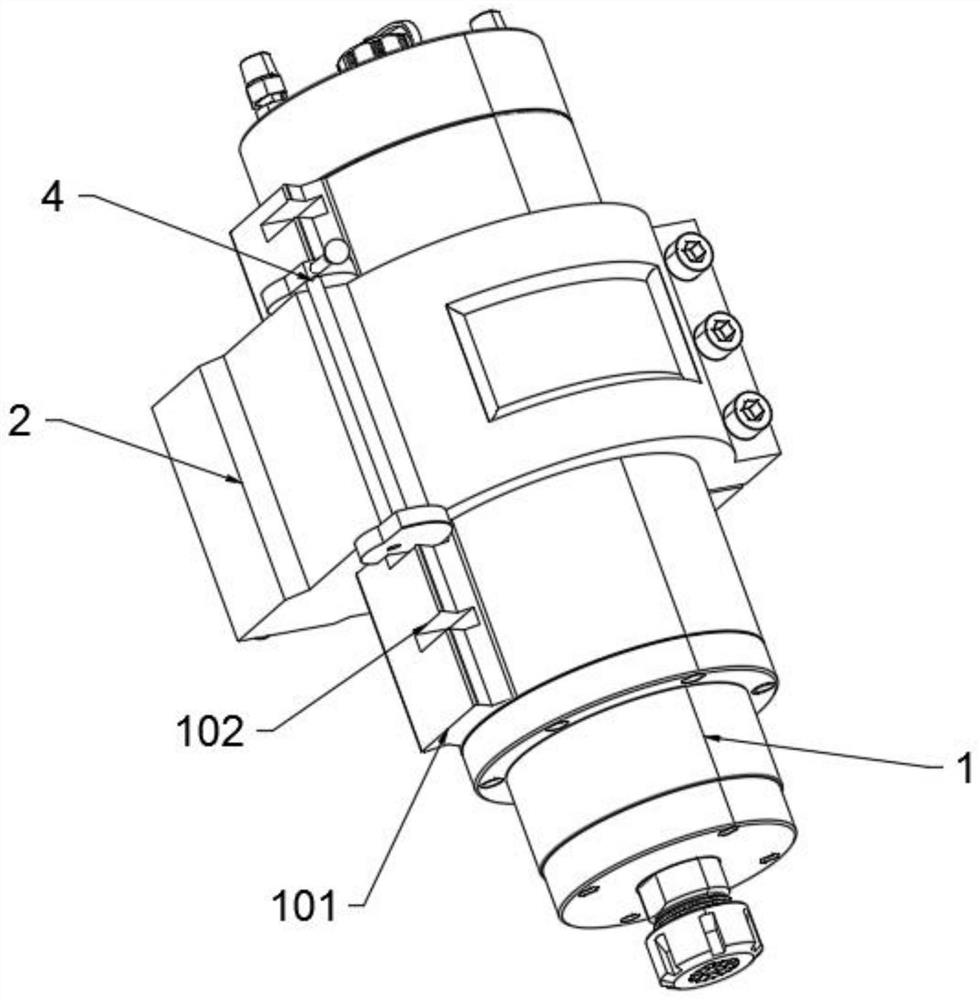

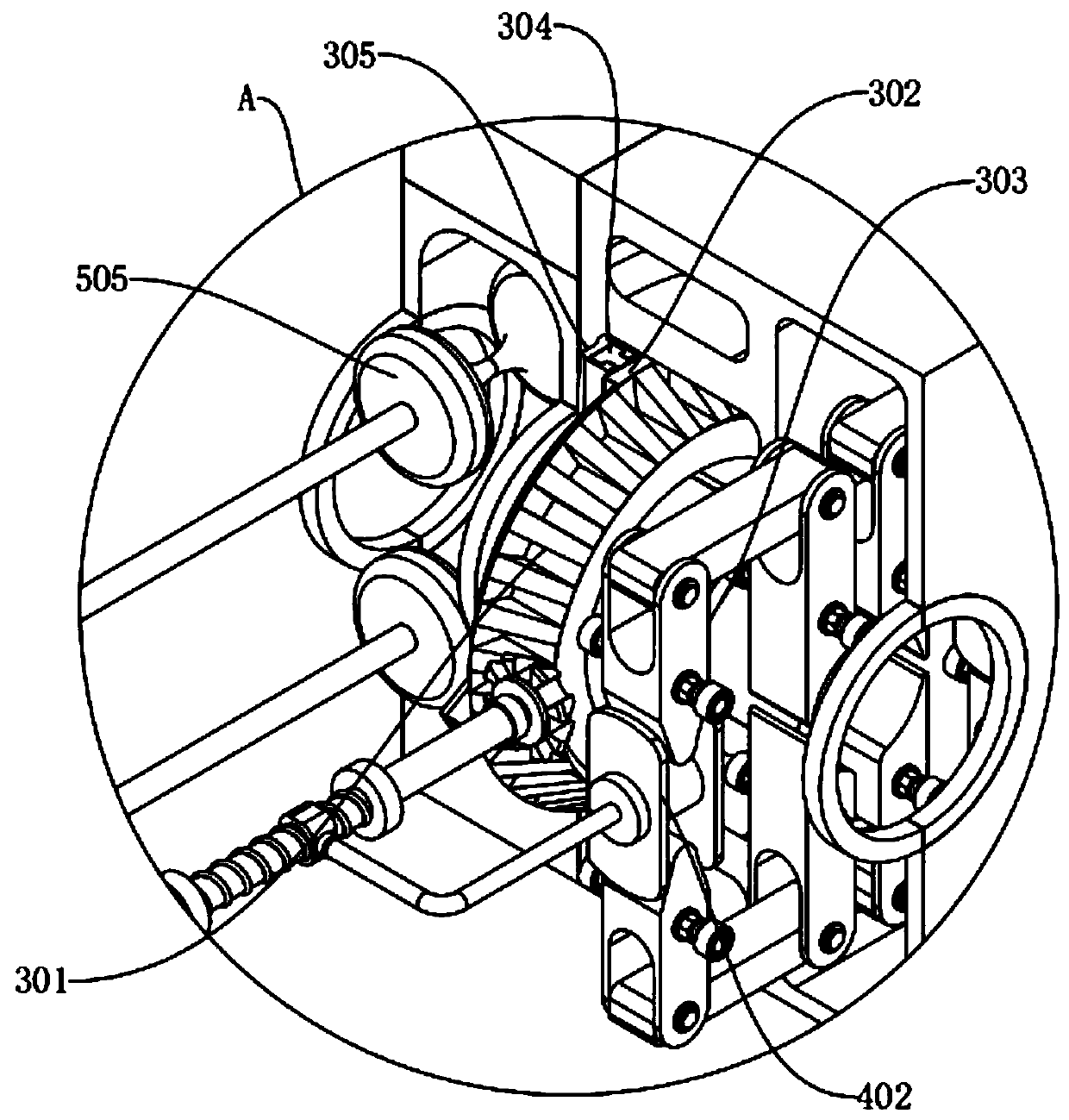

Push rod device with force control

InactiveCN111697752ANo loss of force detection accuracyHigh speed transmissionAssociation with control/drive circuitsGearingCommunication interfaceBall screw

The invention provides a push rod device with a force control function. The push rod device comprises a push rod device body and an independent base, wherein the push rod device body is fixed on the independent base through a plunger knob, a power supply access box and a control box are both installed on the push rod device body, a direct-current brushless servo motor, a ball screw and a nut sleeve are arranged in an inner cavity of the push rod device body, a nut sleeve is arranged on the front portion in the cavity, a ball screw is arranged in the nut sleeve in a penetrating mode, a linear push rod extending out of the cavity is fixed to a front end of the ball screw, a pressure sensor is installed at a front end of the linear push rod, the pressure sensor is sleeved with a pressure head, and a rear end of the ball screw is connected with a direct-current brushless servo motor, and a pressure sensor transmitting module and a motor driving controller are arranged in the control box. The push rod device is advantaged in that the force control function is achieved through linear extension and contraction, the force control function and the stress state maintaining function are achieved, a high-speed real-time bus communication interface is achieved, the structure is light, and installation is convenient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

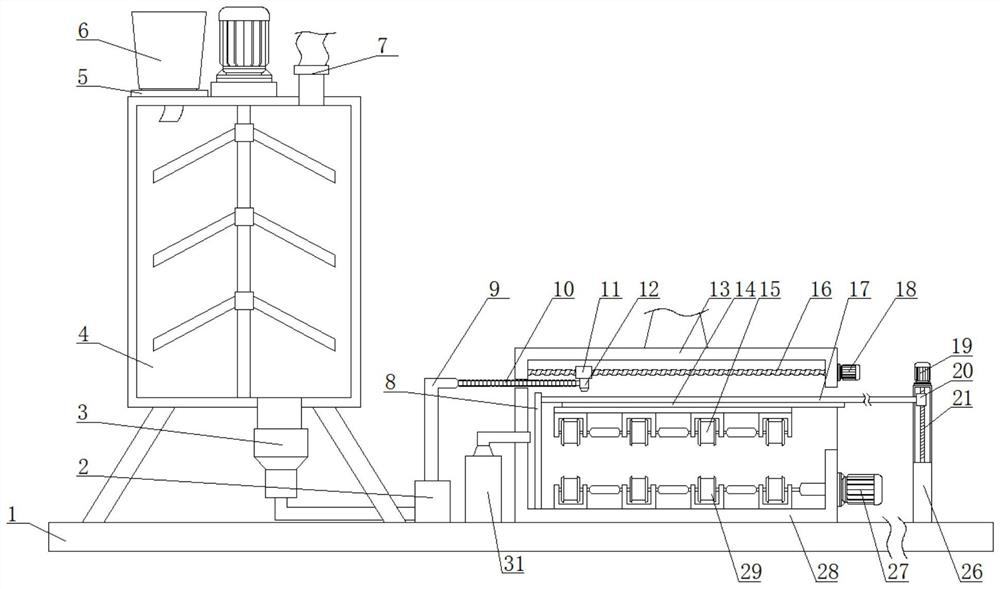

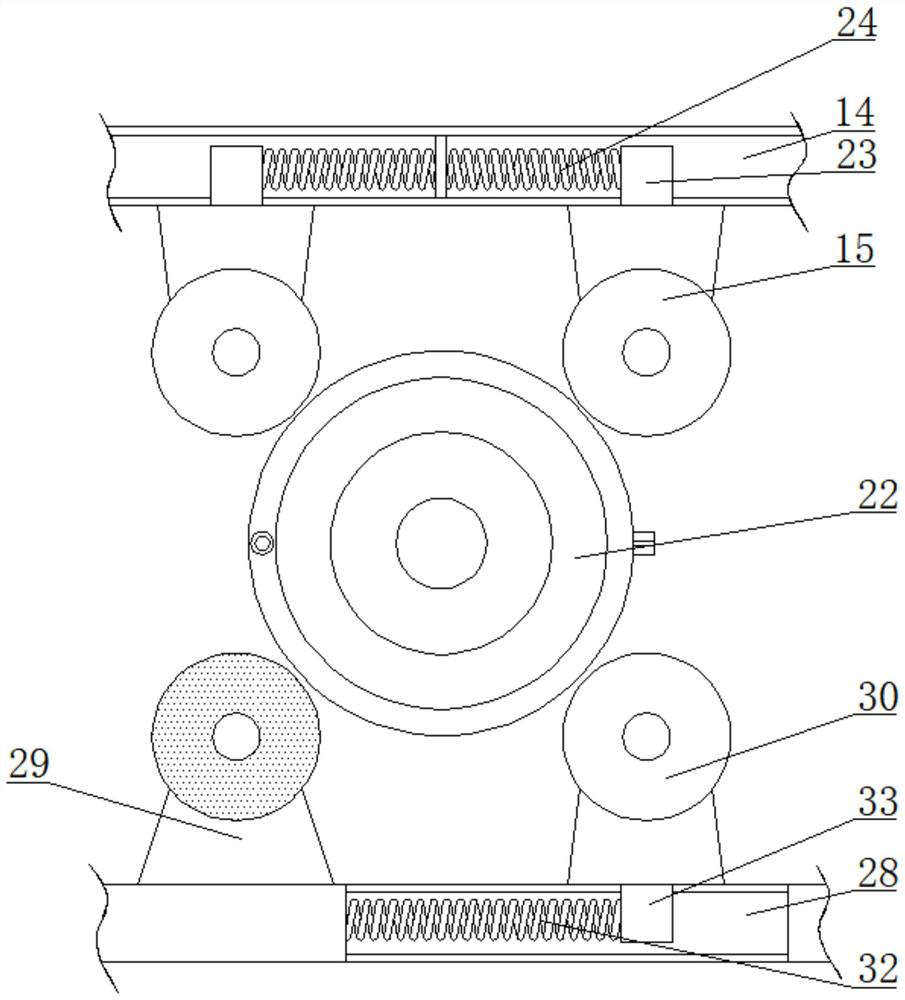

Concrete pole automatic production line

PendingCN112677308APrevent throwing outEasy to fixMixing operation control apparatusFeeding arrangmentsGear wheelEngineering

Owner:广东新荣荣电力科技有限公司

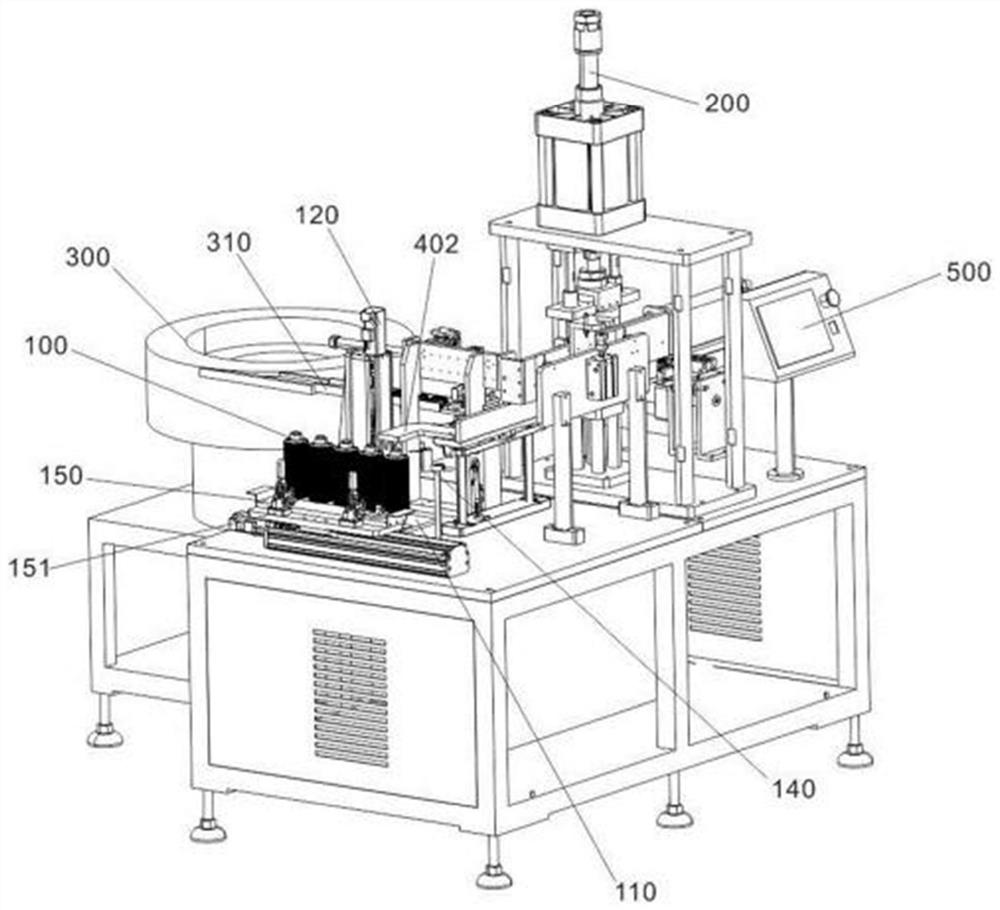

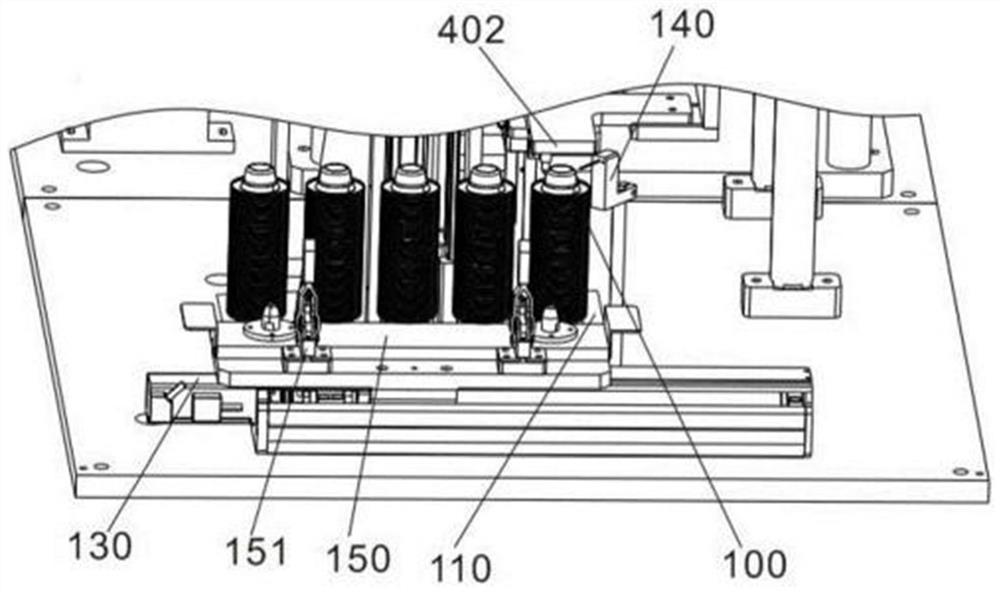

Pushing device for assembly of micro-size parts of intelligent robot

Owner:DONGGUAN UNIV OF TECH

Feeding and plate arranging equipment

PendingCN114162387AHigh speedImprove compactnessIndividual articlesMachine partsStructural engineering

Owner:ZHEJIANG BUSINESS TECH INST

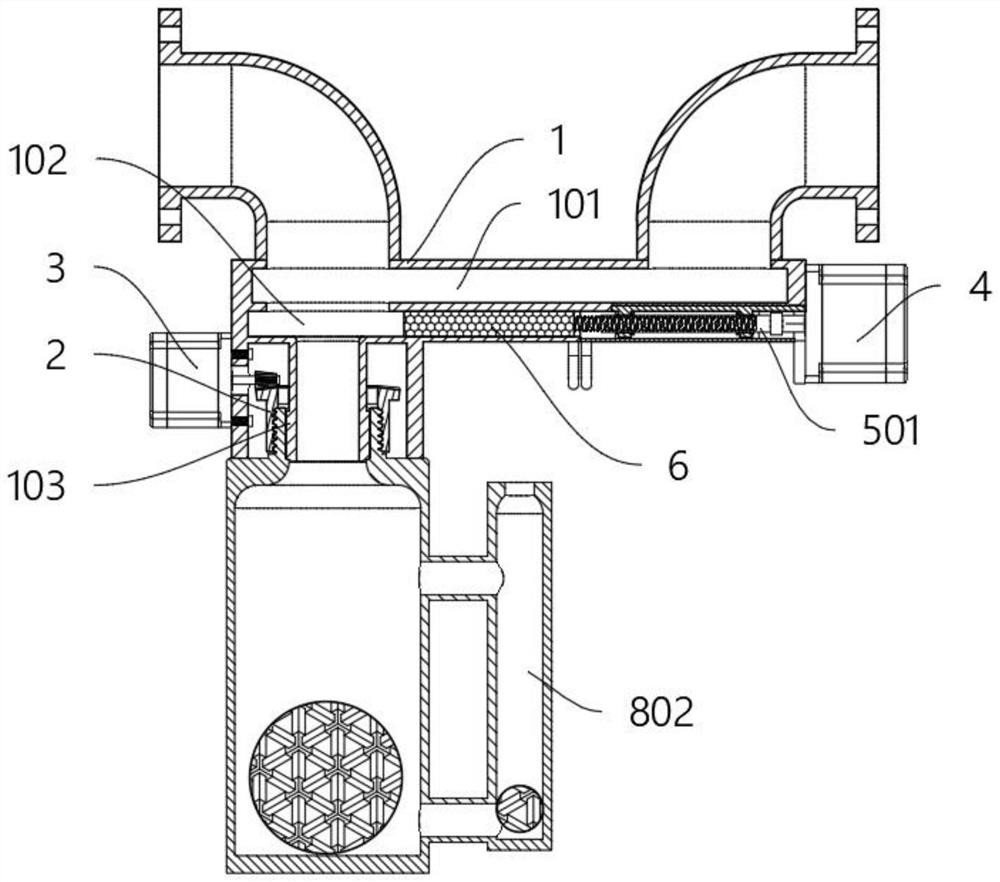

Sampling valve based on intelligent automatic theft prevention

ActiveCN114427604AOperating means/releasing devices for valvesWithdrawing sample devicesServoSampling valve

Owner:浙江金新流体控制股份有限公司

Processing mode of conical surface of pipe fitting and spinning device

Owner:ZHENJIANG HENGYUAN AUTOMOBILE COMPONENTS

Aviation lead experiment workbench

Owner:中国人民解放军海军航空大学青岛校区

Water-saving type intelligent control concrete prefabricated piece manufacturing device

Owner:杭州钱神商品混凝土有限公司

High-speed servo motor side pushing mechanism of intelligent box supply assembly line and side pushing method

Owner:SHAN DONG DONG E E JIAO

Full-automatic intelligent drilling and milling integrated equipment

Owner:沈阳市永特佳尔机电科技有限公司

Driving mode self-adaptive switching platform

InactiveCN114248776AInstruments for road network navigationElectrical steeringDriver/operatorGear wheel

The invention relates to a driving mode self-adaptive conversion platform, which comprises a steering control machine, a driving mechanism, a driving mechanism, a steering control mechanism and a steering control mechanism, and is characterized in that the steering control machine comprises a steering pivot, a rear steering gear box, a servo motor, a rear steering tie rod, a connecting rod, a connecting shaft, an input gear, an output gear, a steering wheel, a steering controller, a steering angle ratio sensor and a driving motor; the mode switching mechanism is used for switching the current driving mode of the vehicle from a conventional driving mode to a moving driving mode when the longest completion duration is longer than the historical completion duration; and the priority of the mode switching based on the personnel information is greater than the priority of the mode switching based on the longest completion duration. According to the invention, whether the current driving road section needs top-speed driving or not can be determined based on the feedback result of the navigation APP, the driving personalized demand of the current driver can be determined based on the visual identification result of the driver, and the self-adaptive setting of the current driving mode of the vehicle can be realized based on the two parameters and the setting modes with different priorities.

Owner:刘广富

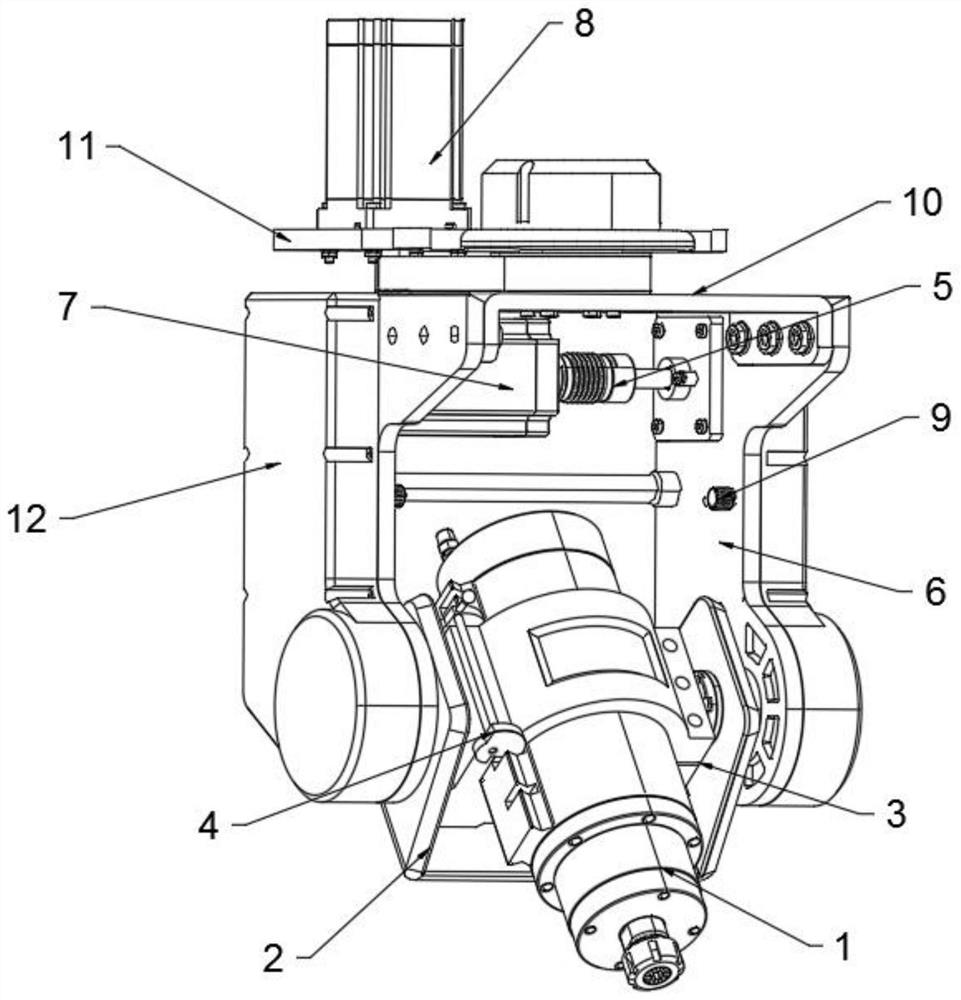

Angle milling head of numerical control machine tool

InactiveCN114770144AEasy to adjustSatisfy processing useLarge fixed membersMilling equipment detailsNumerical controlRatchet

Owner:张先中

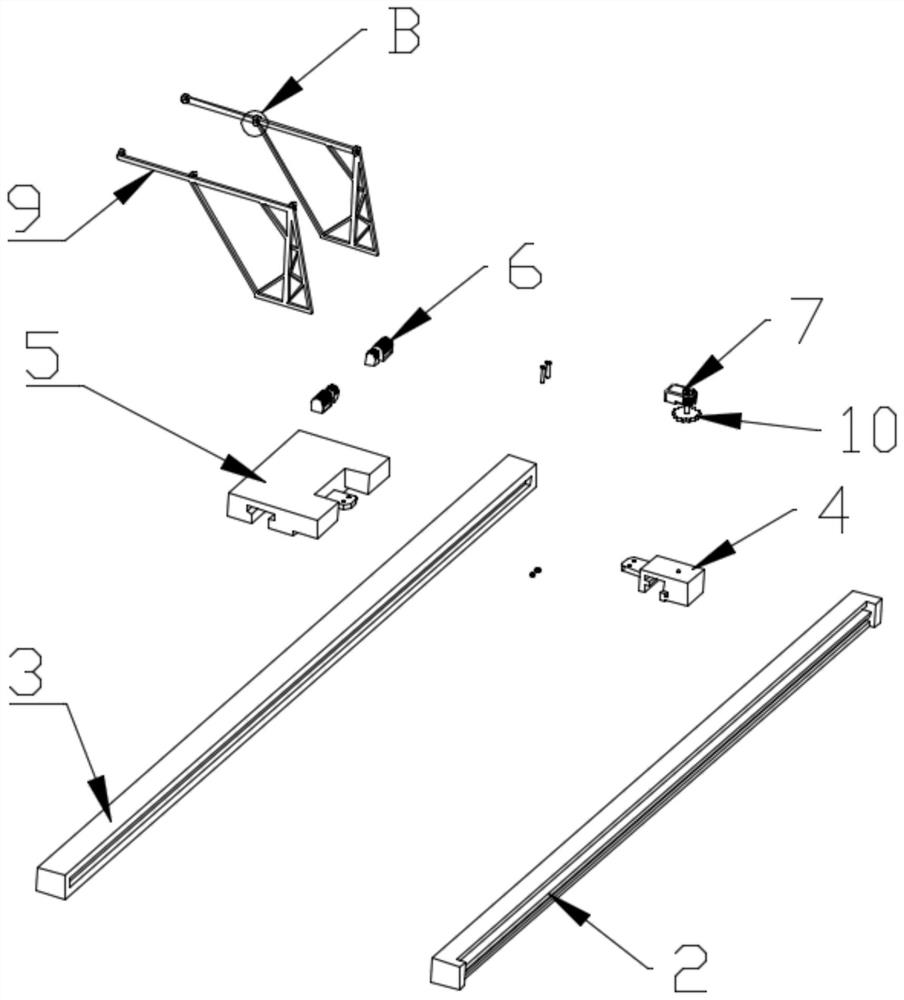

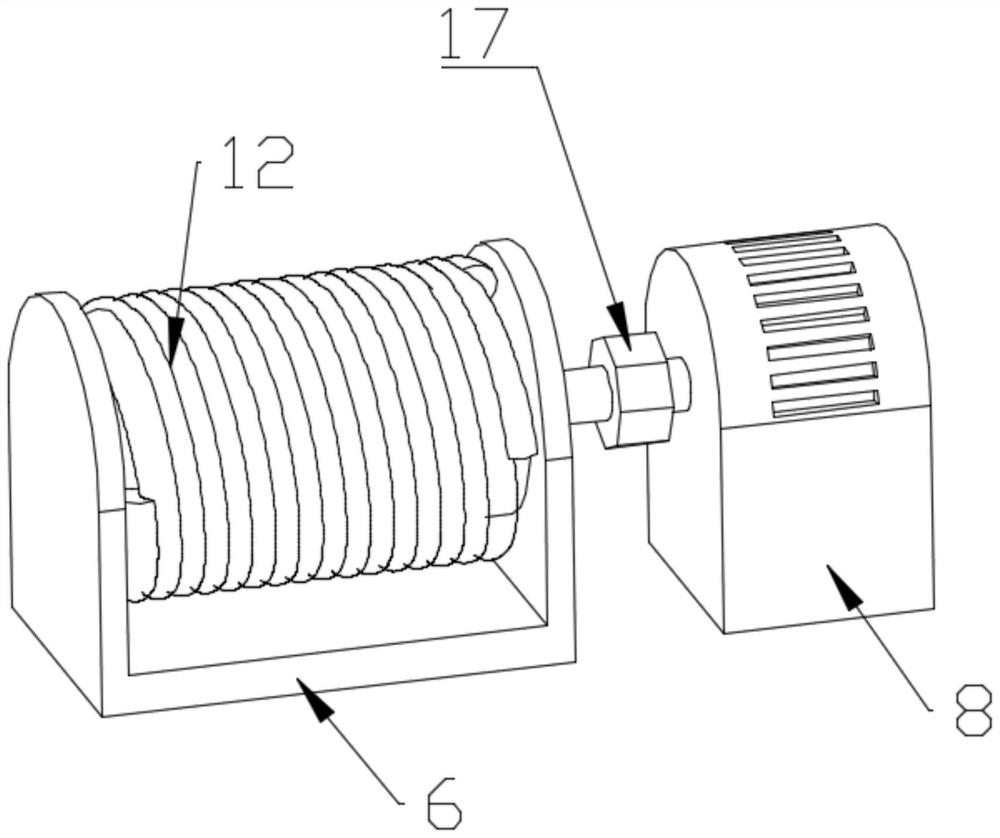

Novel corner removing mode and structure used for removing corner seams of plastic doors and windows

The invention discloses a novel corner removing mode and structure used for removing corner seams of plastic doors and windows, and mainly relates to the technical field of corner removing of the plastic doors and windows. The structure comprises a corner removing structure, the corner removing structure comprises a supporting frame body, a tool set adjusting and controlling structure, a corner removing servo motor and a corner removing tool combination, the tool set adjusting and controlling structure comprises an X1-axis displacement adjusting structure, a Z1-axis displacement adjusting structure and an A main shaft rotating mechanism, the X1-axis displacement adjusting structure achieves linear displacement of the corner removing servo motor and the corner removing tool combination along an X1 axis, the Z1-axis displacement adjusting structure achieves linear displacement of the corner removing servo motor and the corner removing tool combination along a Z1 axis, and the A main shaft rotating mechanism realizes the rotation adjustment of the corner removing servo motor and the corner removing cutter combination along the X1 axis. The novel corner removing mode and structure usedfor removing the corner seams of the plastic doors and windows have the beneficial effects that the mechanical mechanism is simple, removing can be carried out on the frame corner corner seams of theplastic doors and windows at a time by adopting one cutter combination, and therefore the corner seam removing efficiency is greatly improved.

Owner:JINAN LUNQU NUMERICAL CONTROL ELECTRICAL

Steel bar forming mechanical equipment for building

The invention discloses steel bar forming mechanical equipment for a building, and belongs to the field of steel bar forming. According to the steel bar forming mechanical equipment for the building,steel bars are placed in a feeding bin and conveyed to a steel bar bending rotary plate, then a driving mechanism is started to drive a primary limiting mechanism and a secondary limiting mechanism tofix the steel bars, due to the fact that a rotating wheel set rotates in a one-way mode, a feeding mechanism cannot move at the moment, and after bending is completed, a servo motor is started to rotate reversely to drive the primary limiting mechanism and the secondary limiting mechanism to rotate to loosen the steel bars, the feeding mechanism is synchronously driven to operate, and the steel bars are driven to move forwards. The device can complete automatic feeding, fixing and other operations of the steel bars, when the device is used, an operator only needs to control the steel bar bending rotary plate to rotate, the steel bars are bent under operation, the steel bar forming device is convenient to use, manual operation is greatly reduced, and the steel bar forming device is suitable for being used in a construction site.

Owner:CHINA MCC17 GRP

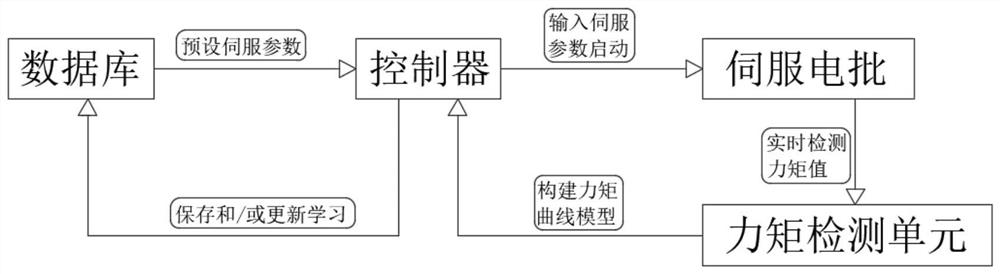

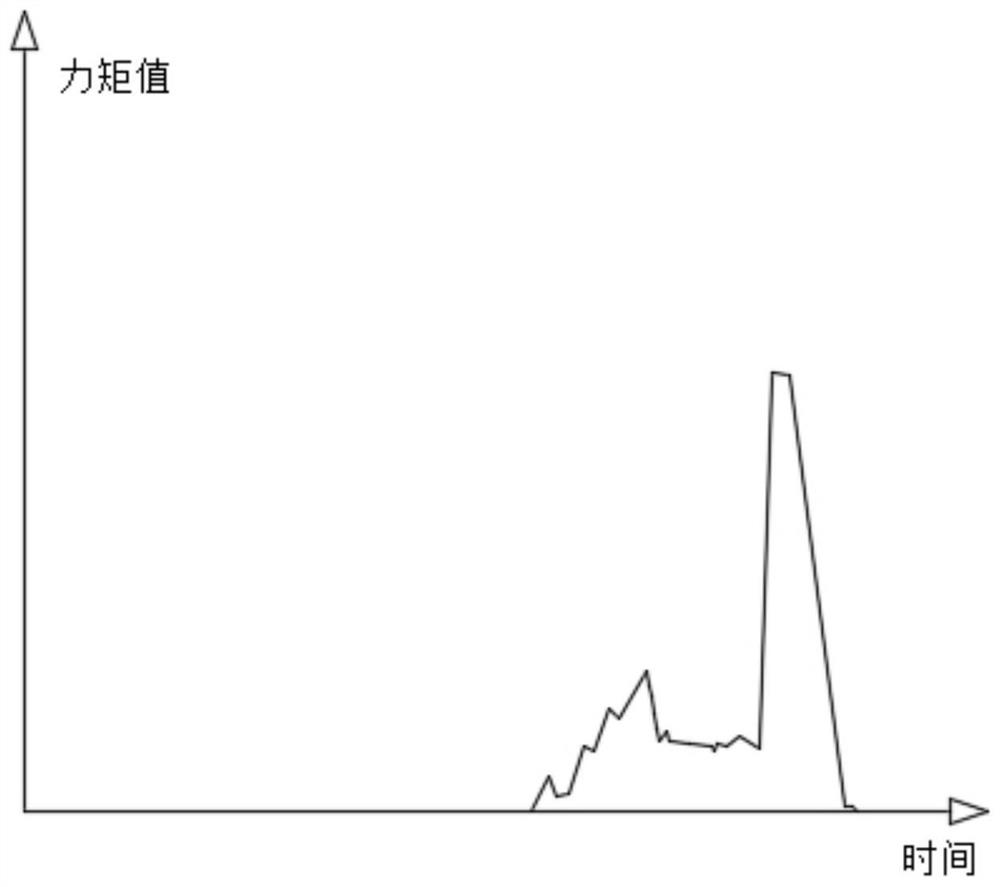

Control method and control system of servo electric screwdriver

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Hanging basket for constructional engineering

ActiveCN113982243ACenter of gravity balanceAvoid falling objectsProgramme control in sequence/logic controllersScaffold accessoriesGyroscopeClassical mechanics

Owner:广东九为新材料科技有限公司

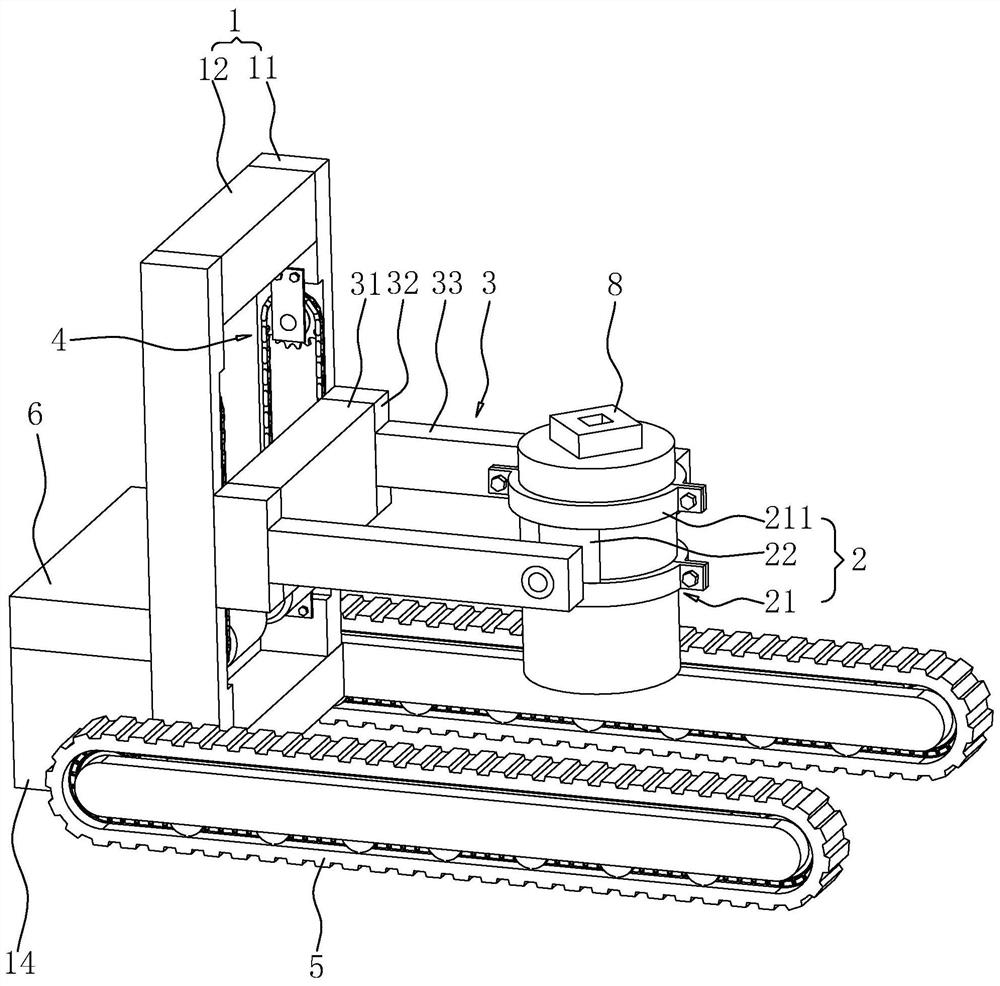

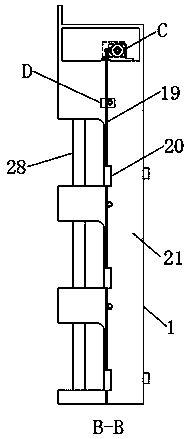

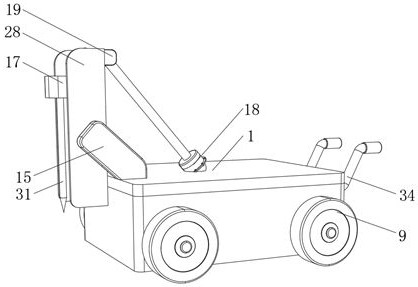

Auxiliary device for maintaining rotary excavating drill bit and construction method of auxiliary device

PendingCN112267840AReduce security risksReduce maintenance timesDrilling rodsDrilling casingsControl engineeringChain link

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

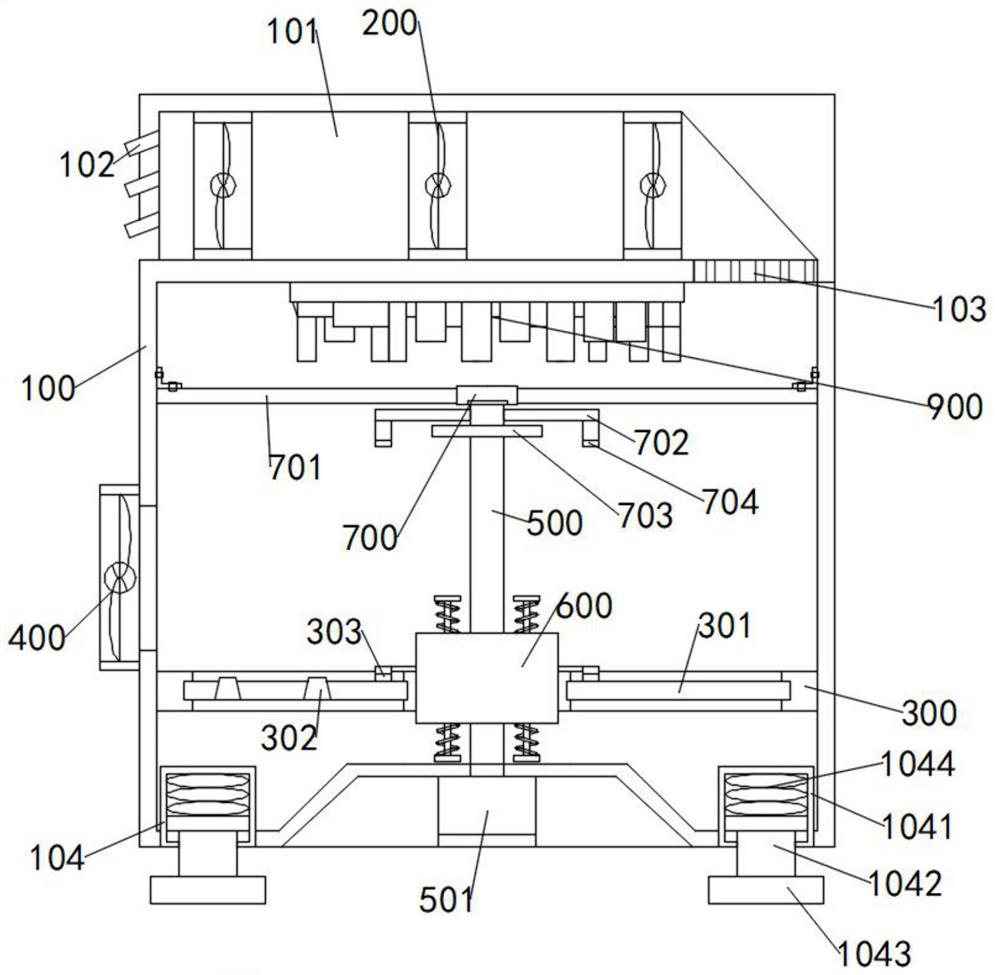

Built-in automatic temperature regulation and control mechanism of high-low voltage power distribution cabinet

ActiveCN111564775AImprove temperature control effectSolve the problem of oversupplySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPhysicsServo

The invention discloses a high-low voltage power distribution cabinet built-in automatic temperature regulation and control mechanism, which comprises an adjusting box, an electromagnetic valve, a dryer, temperature sensors, a servo motor and an electric push rod, wherein gas guide fins and wind exhaust nets are arranged on the outer surface of the front end of the adjusting box, and are arrangedin an up-down staggered manner, the temperature sensors are fixed to the outer surfaces of the front ends of the wind exhaust nets through screws, a gas inlet pipe is welded to the top end of the adjusting box, the outer surface of the gas inlet pipe is sleeved with the electromagnetic valve, a partition plate is fixed to the inner side of the adjusting box through screws, a cold gas transition bin is arranged on one side of the partition plate, partition sheets are arranged on the inner side of the cold gas transition bin, a connecting shaft is arranged in the centers of the partition sheetsin a penetrating mode, and one end of the connecting shaft is rotationally connected with the inner wall of the adjusting box through a bearing. According to the invention, the high-low voltage powerdistribution cabinet built-in automatic temperature regulation and control mechanism is provided with the point-dividing regulation and control mechanism, can conveniently and rapidly regulate and control the cold gas supply amount at different positions in the cabinet and improve the temperature regulation and control effect, and is energy-saving and environmental protection.

Owner:甘肃嘉瑞电力工程有限公司

Information processing device for campus computer education

Owner:GUANGDONG NEW WAY EDUCATIONAL TECH CO LTD

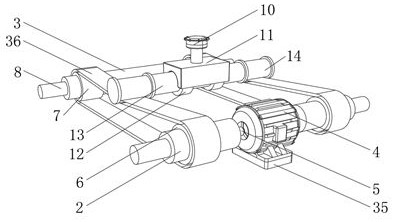

Precise shallow hole drilling machine for engineering geological exploration

InactiveCN112031651AEasy to moveAdjustable tightnessConstructionsRotary drillingBall bearingDrive motor

Owner:湖南福格森装备科技有限公司

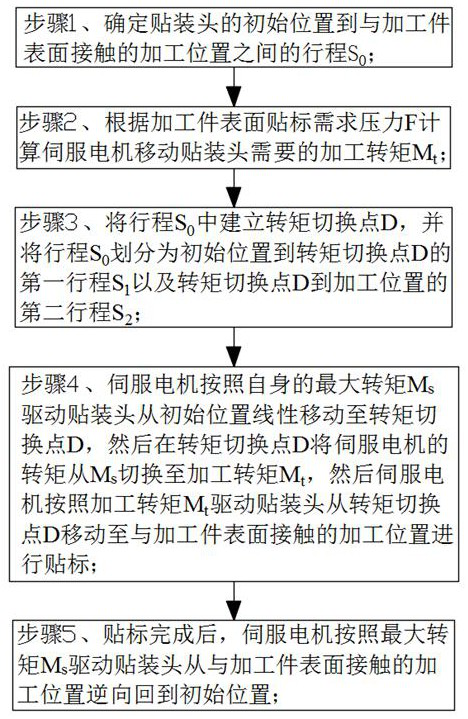

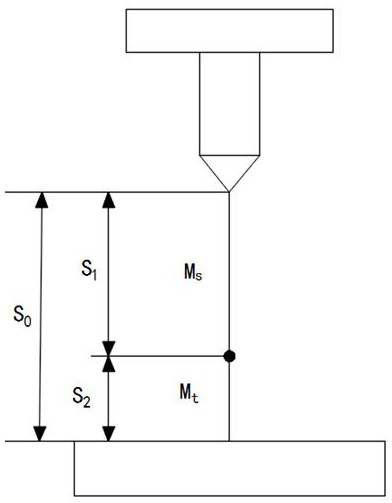

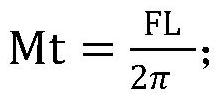

Method for controlling labeling pressure of servo labeling machine

Owner:成都乐创自动化技术股份有限公司

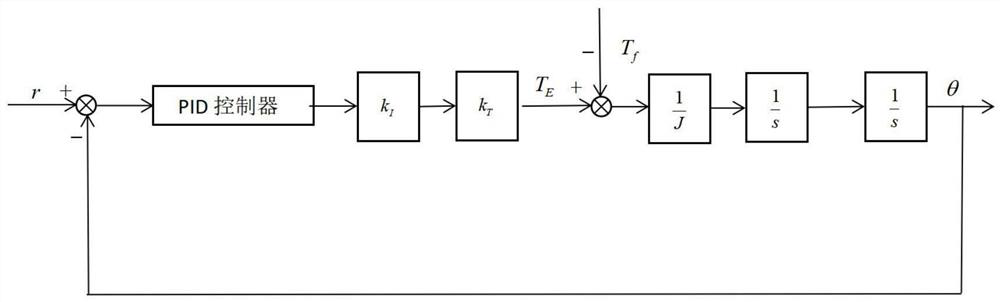

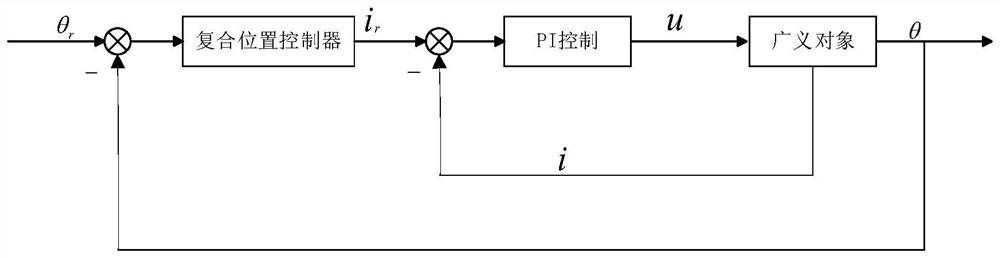

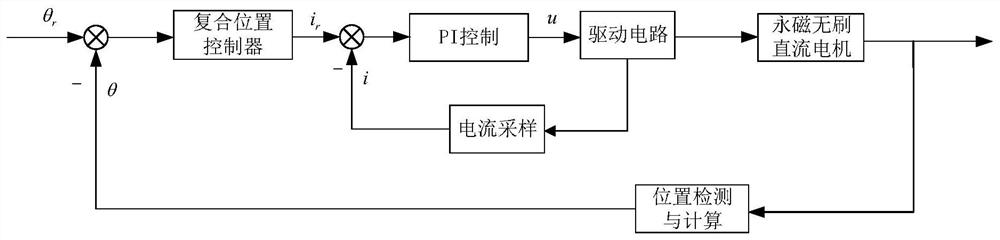

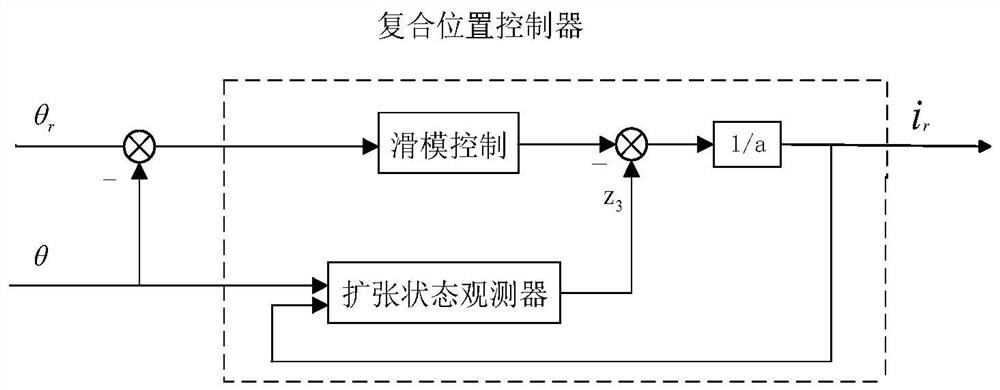

Permanent magnet brushless direct current motor position servo system based on composite position controller

PendingCN112600474AElectronic commutation motor controlElectric motor controlComposite controllerServo

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap