Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about "Measurement/indication equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

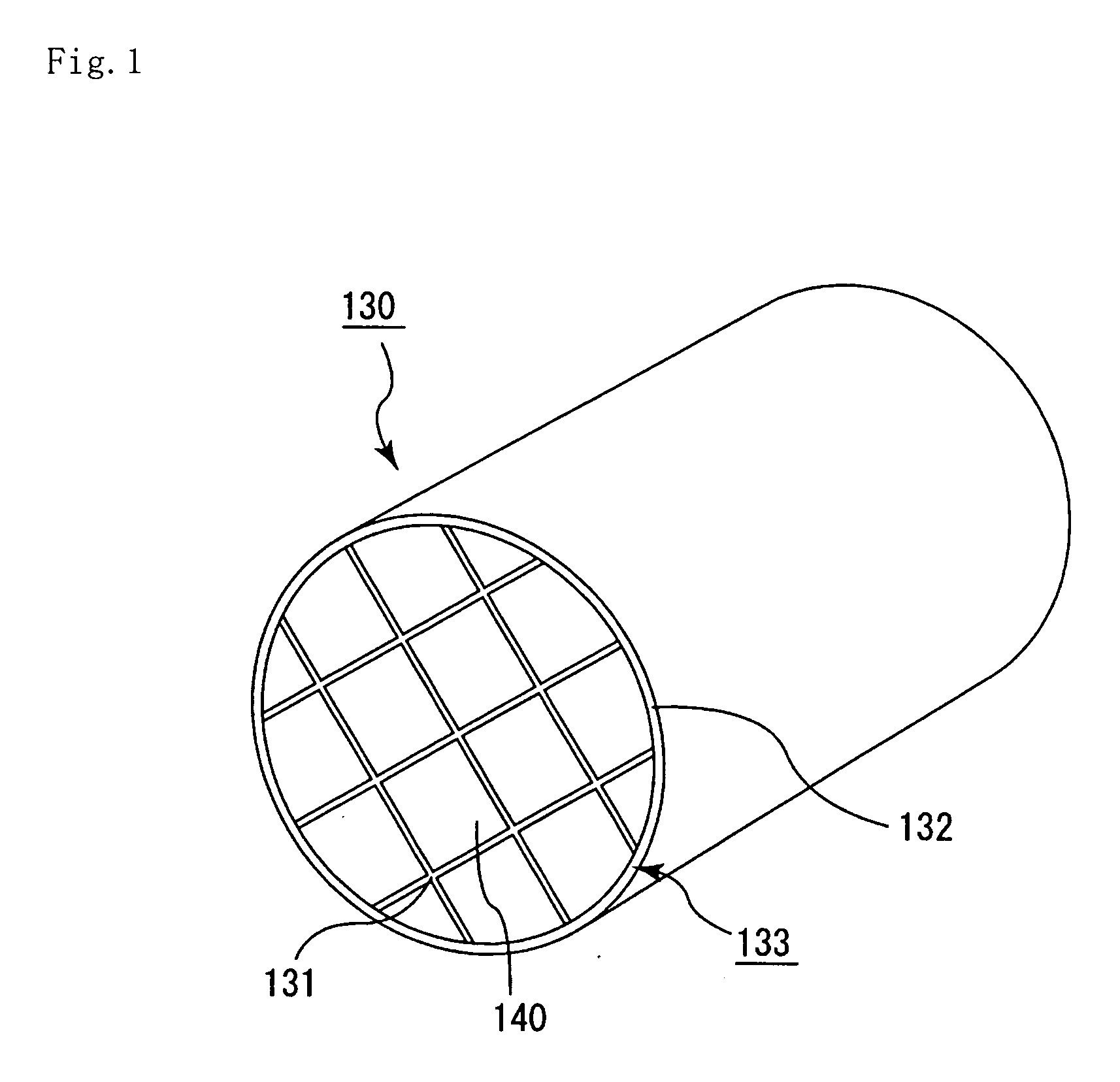

Method for inspecting honeycomb structured body and method for manufacturing honeycomb structured body

InactiveUS20070175060A1Good informationShort timeWalking sticksInternal combustion piston enginesEngineeringCell wall

Owner:IBIDEN CO LTD

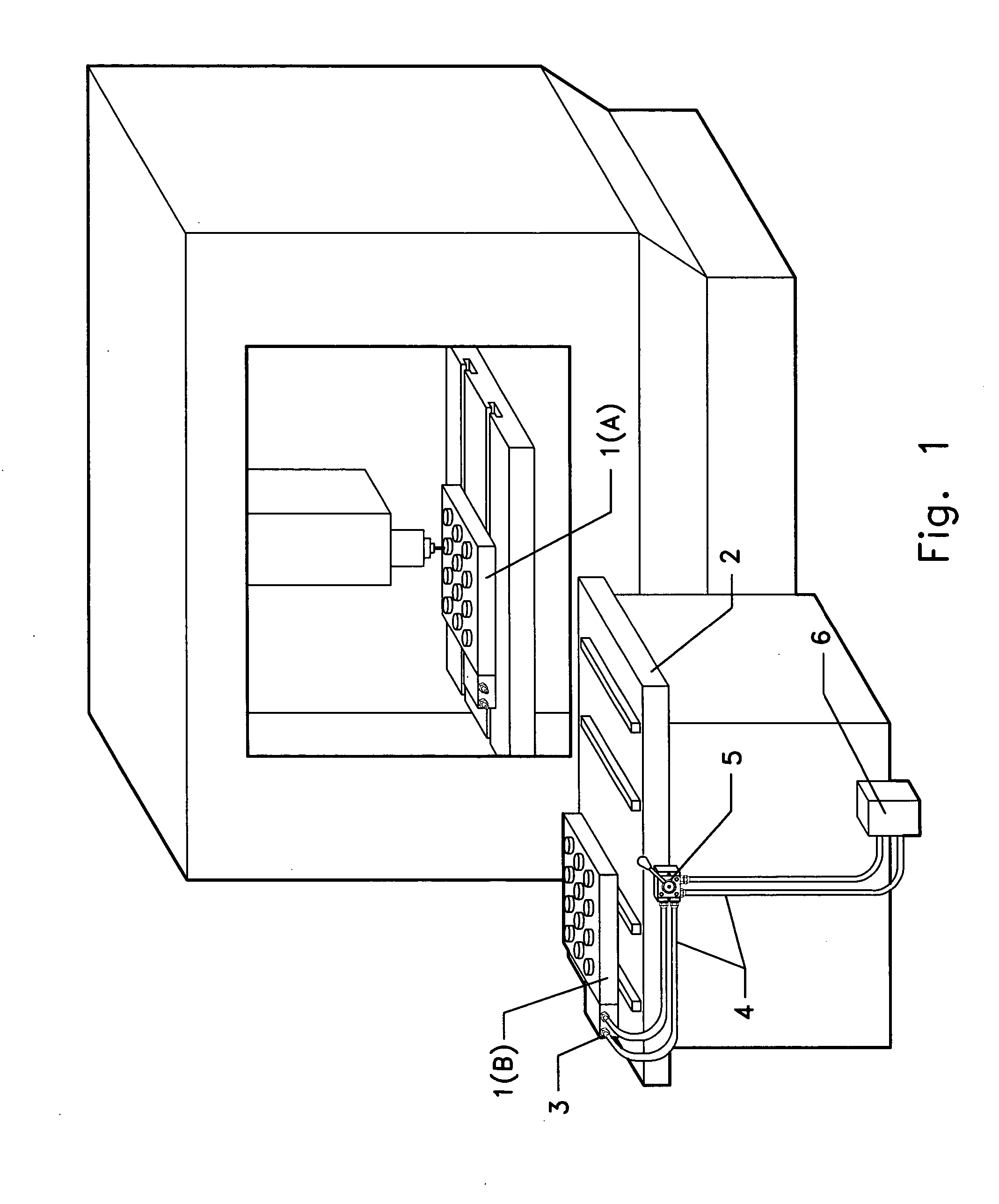

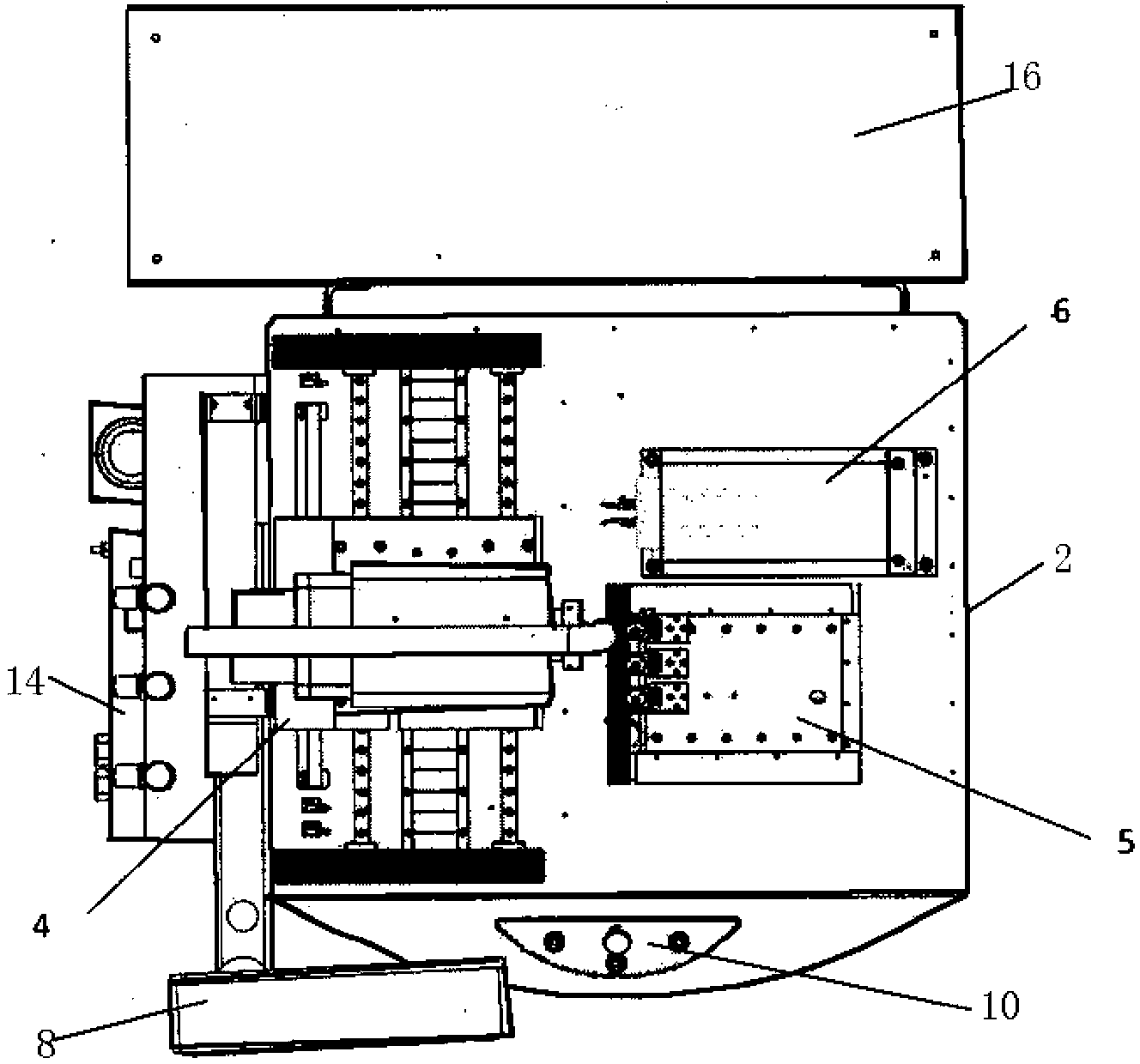

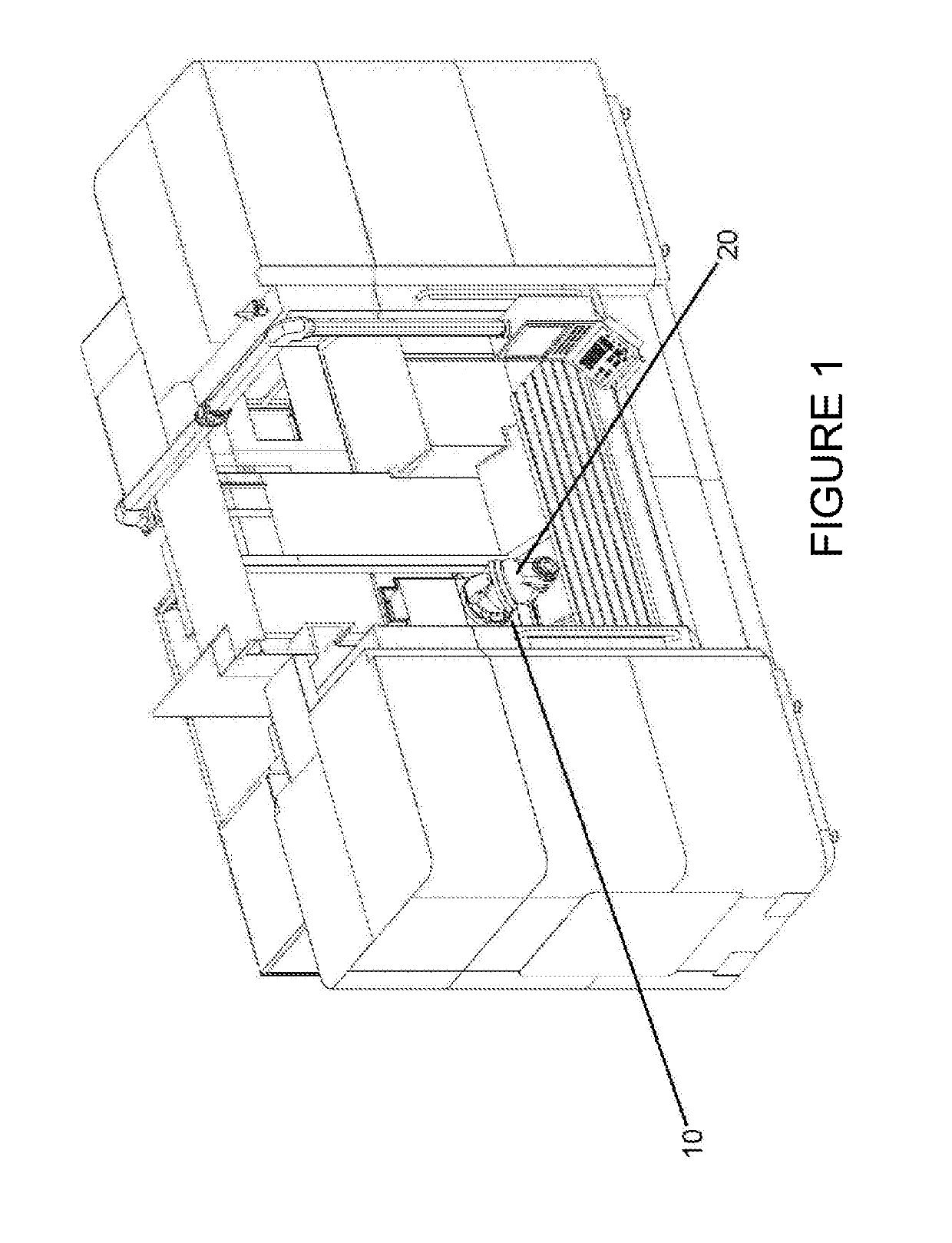

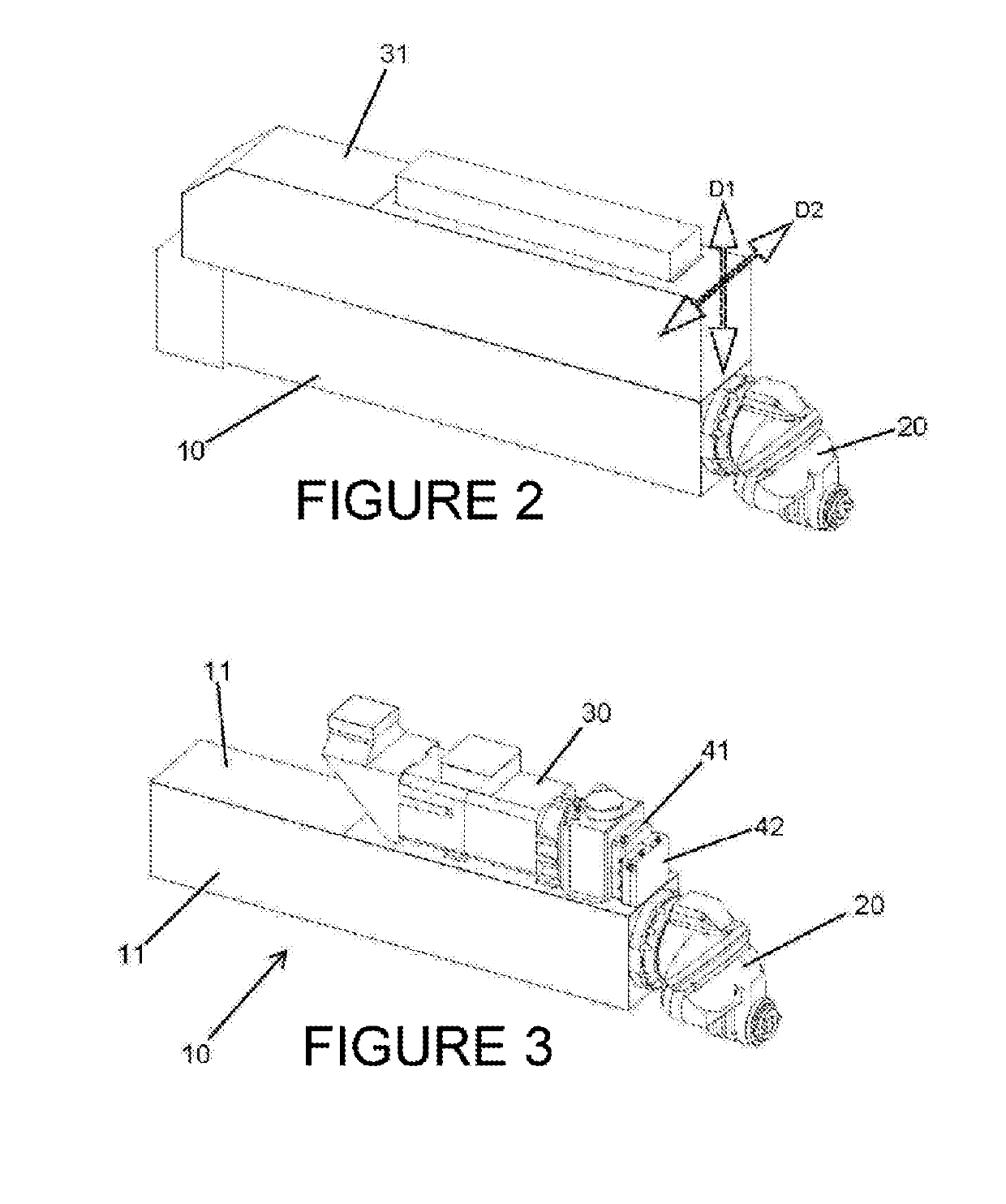

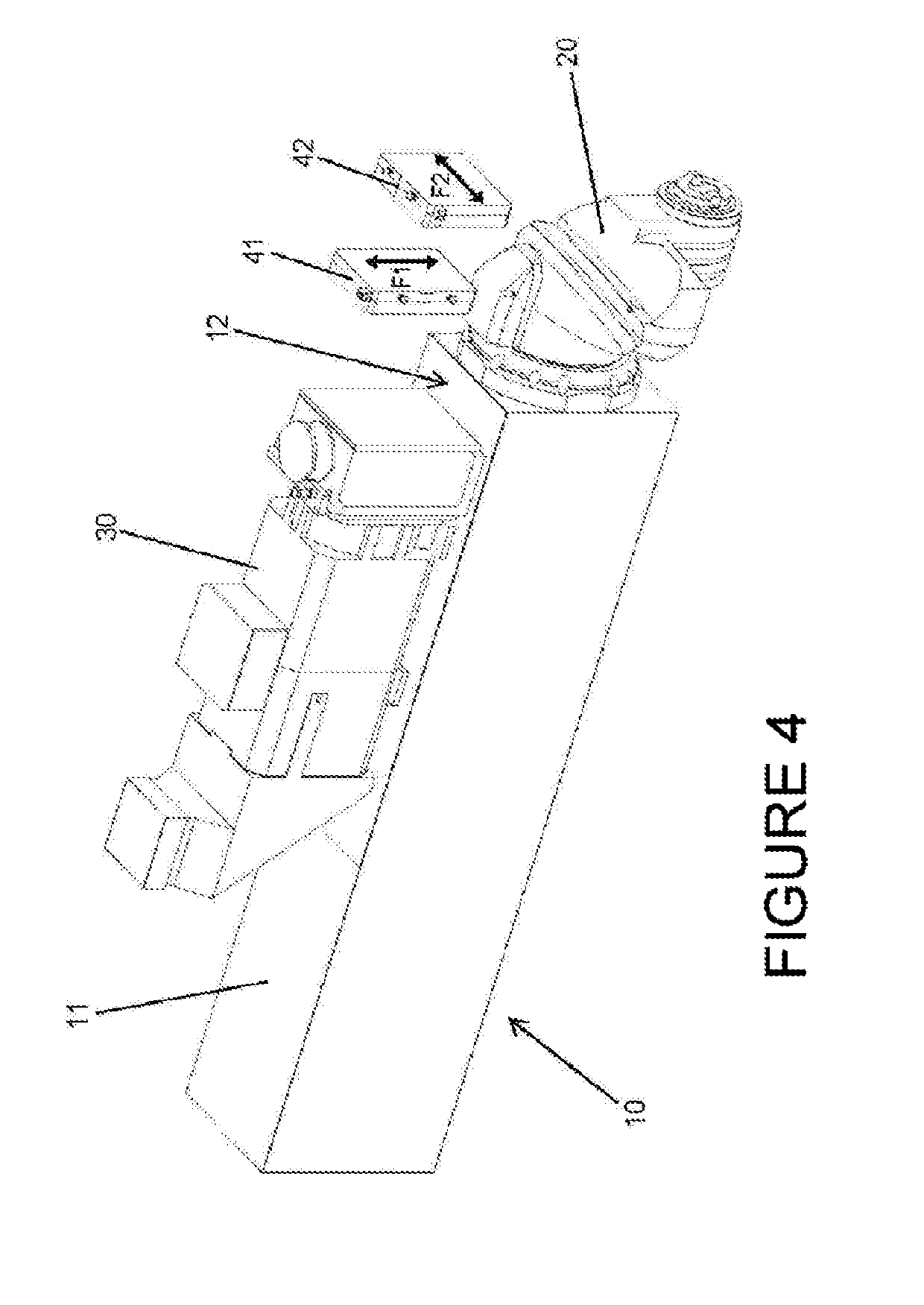

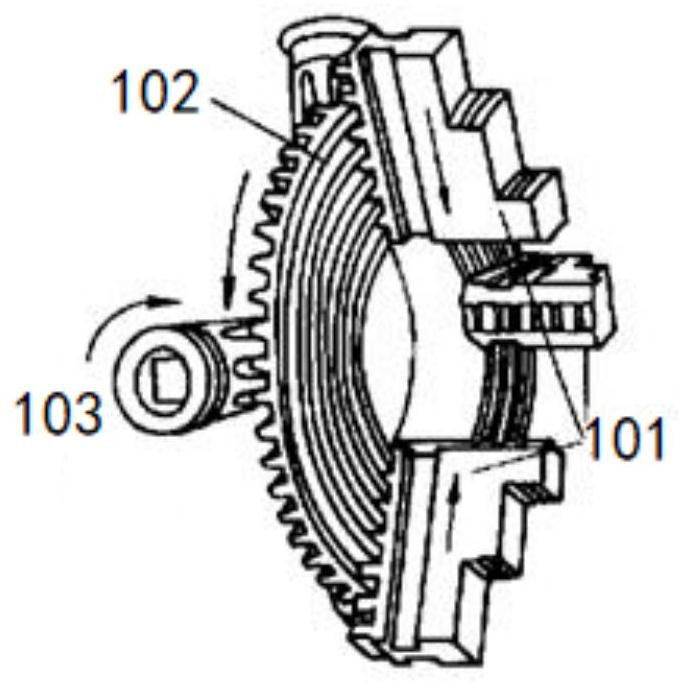

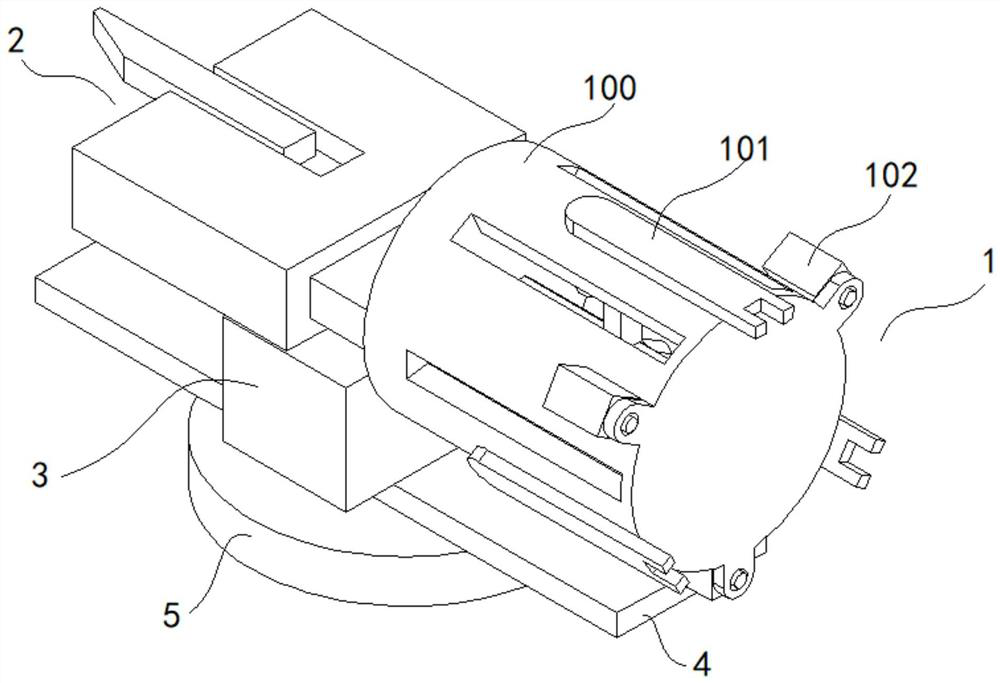

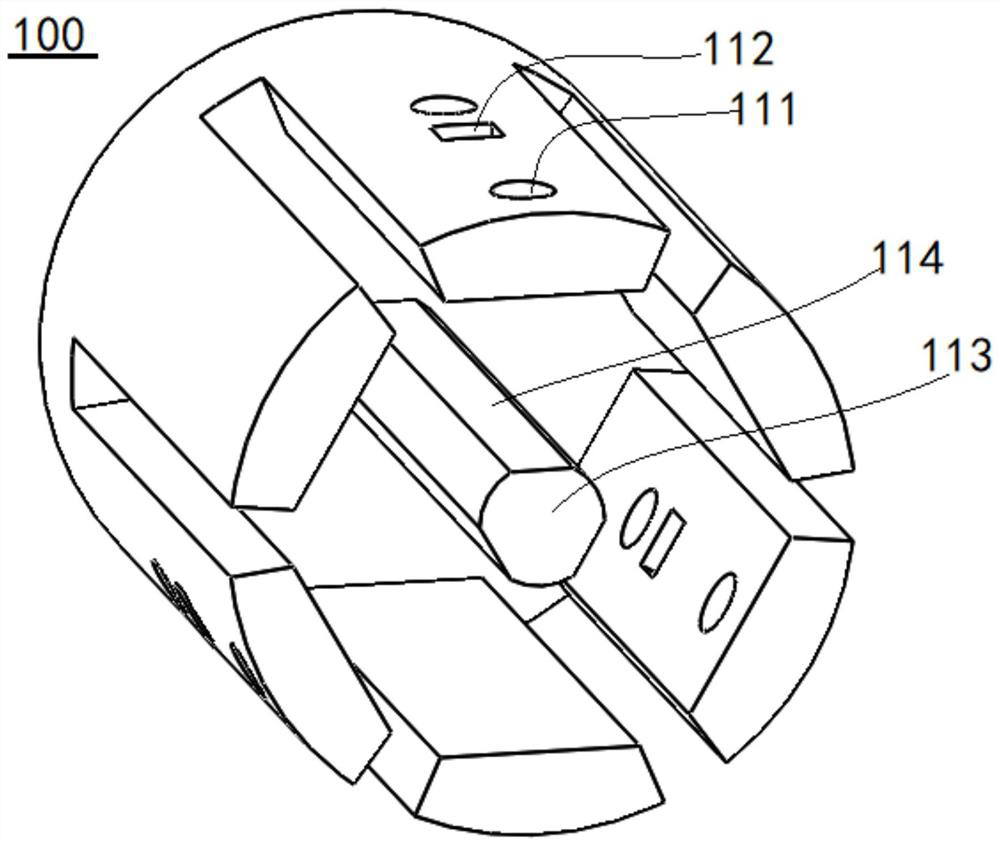

Pallet replacing device

InactiveUS20060130311A1Reduced footprintReduced space required for installationMeasurement/indication equipmentsMetal working apparatusEngineeringVertical axis

A pallet P held in a vertical position is moved from a pallet mounting surface, formed to extend vertically on a table 115 of a machine tool 101, to a pallet mounting surface formed vertically on a pallet support member 17 of a pallet changer 11. After rotationally indexing a swivel base 15 by 180 degrees about a vertical axis, a pallet P′ is moved from the pallet support member 17 to the table 115.

Owner:MAKINO MILLING MASCH CO LTD

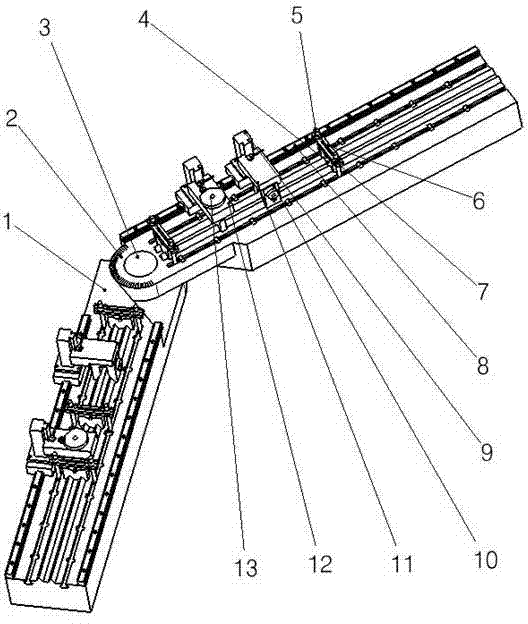

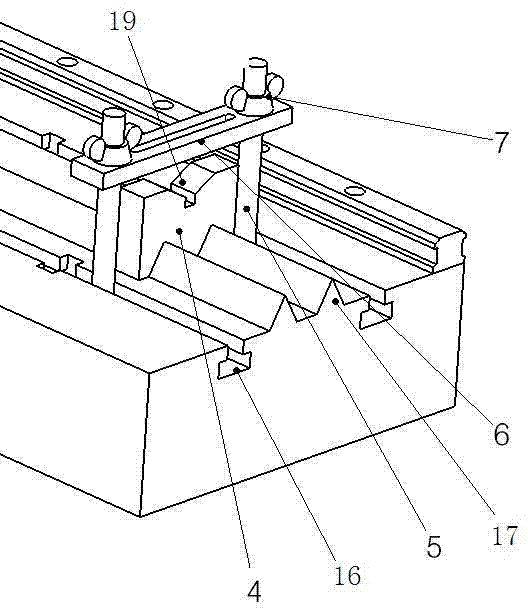

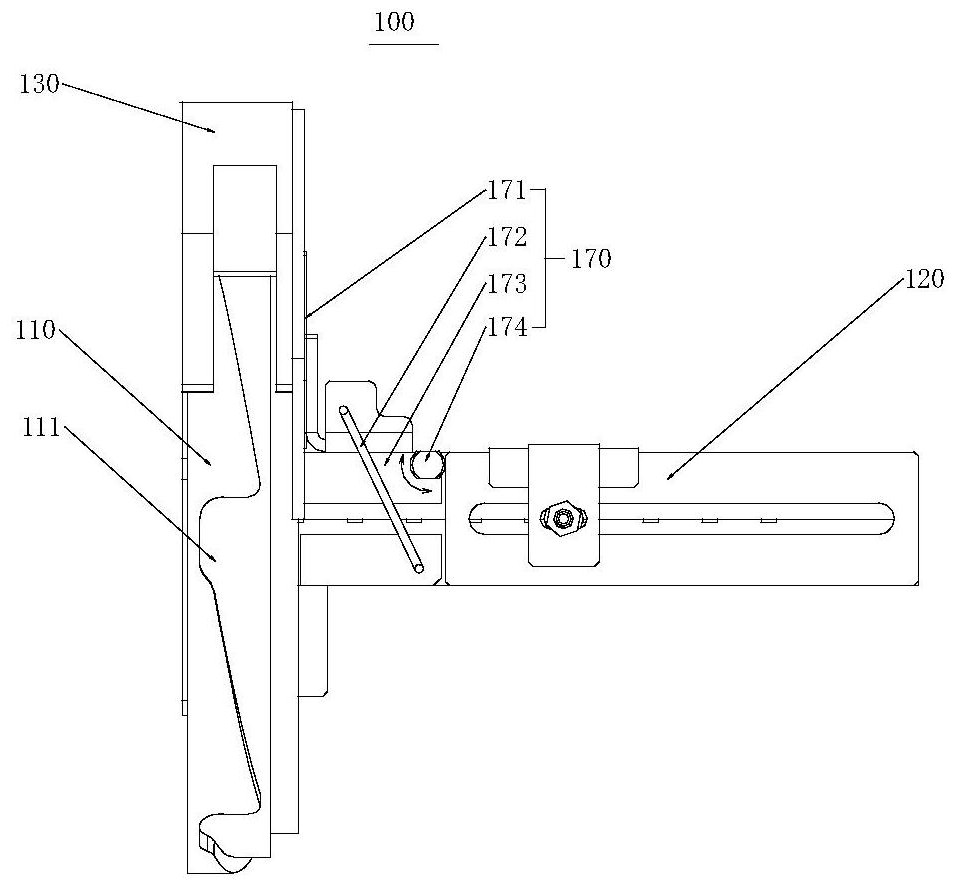

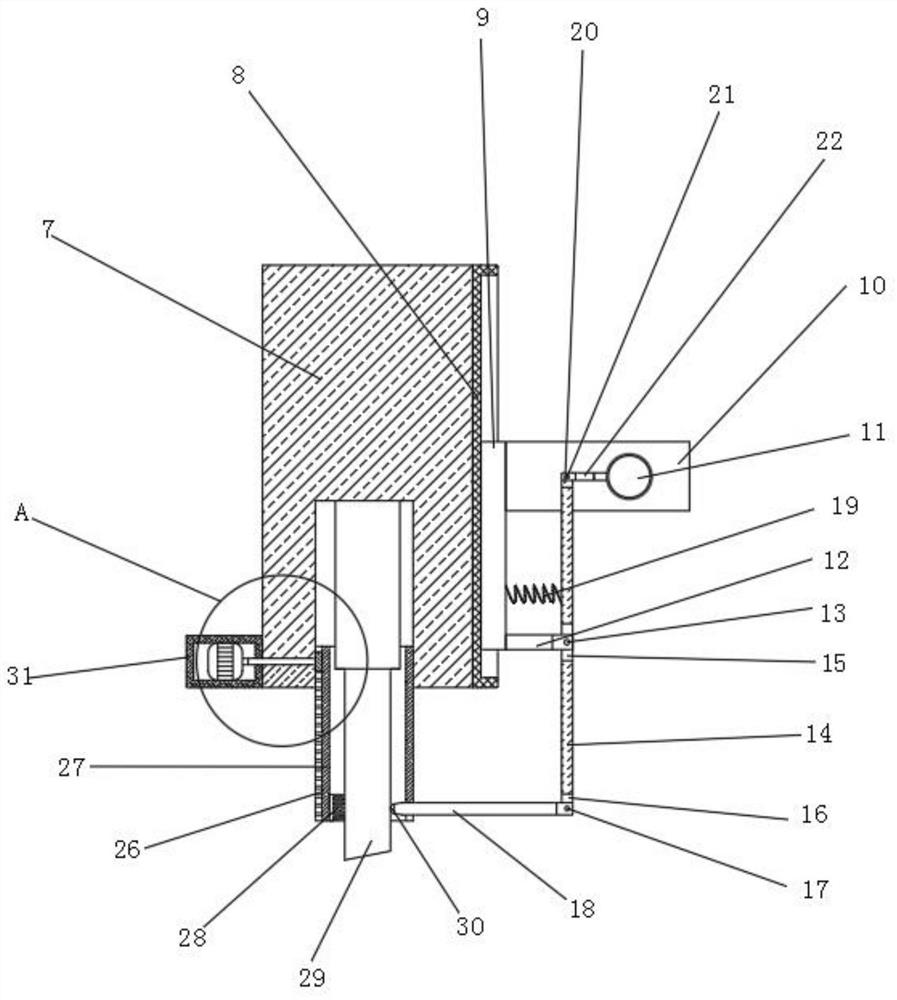

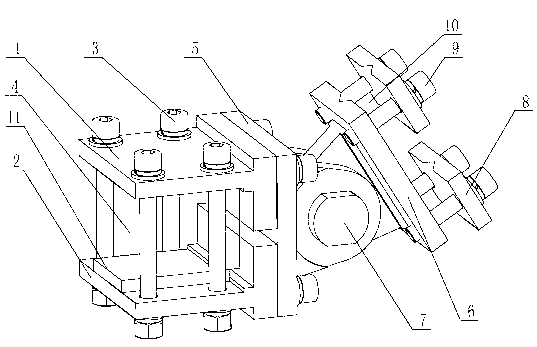

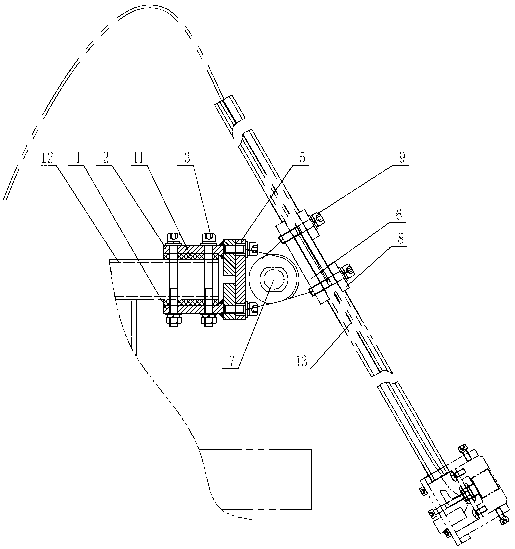

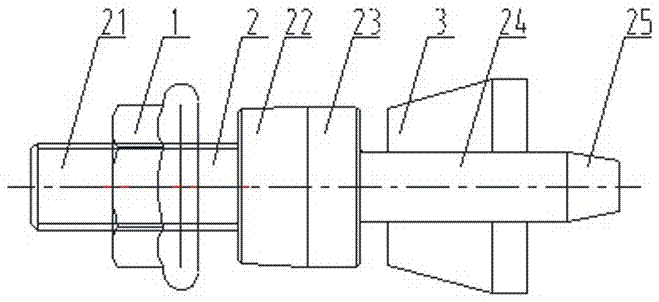

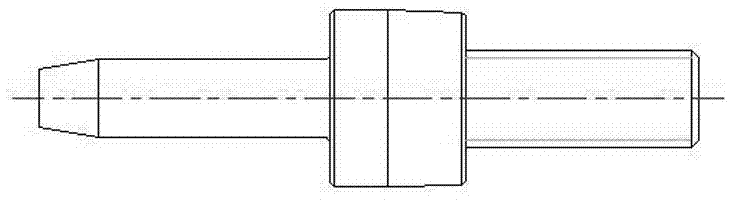

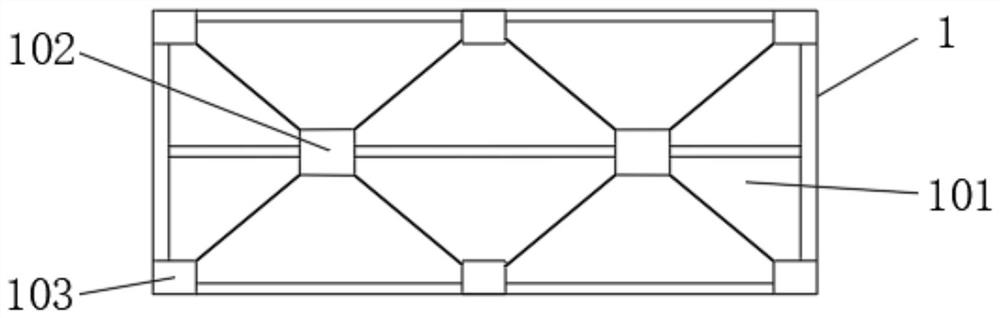

Cylindrical part bending angle measuring and horizontal and vertical surface drilling jig

InactiveCN103692251APrecise positioningConvenient bending angle measurementMeasurement/indication equipmentsPositioning apparatusHorizontal and verticalDrill

Owner:SHENYANG AEROSPACE UNIVERSITY

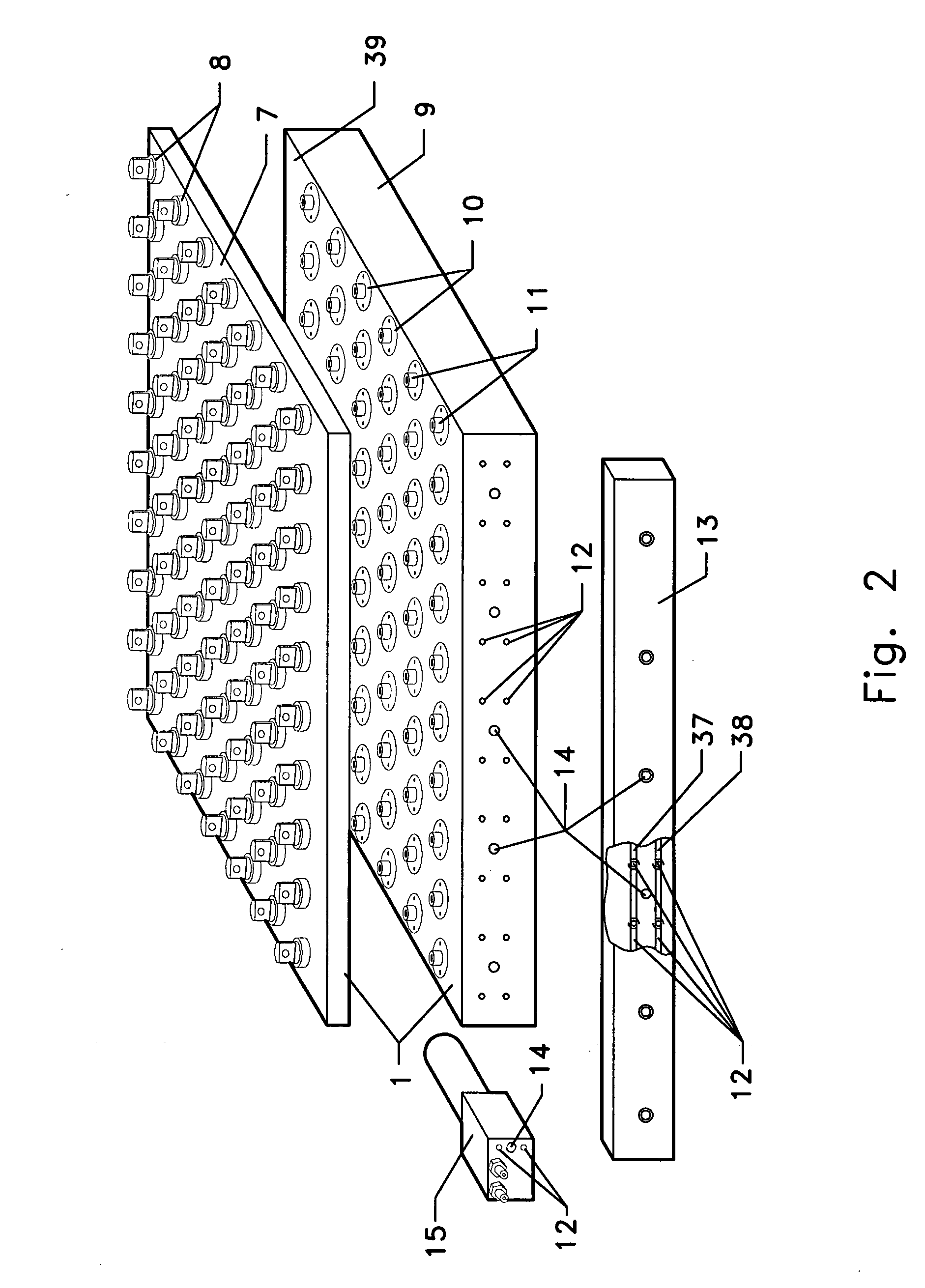

Versatile palletized work holding system

InactiveUS20040113345A1Measurement/indication equipmentsPositioning apparatusPistonMultiple function

Owner:MONTAGUE TOOL & MFG

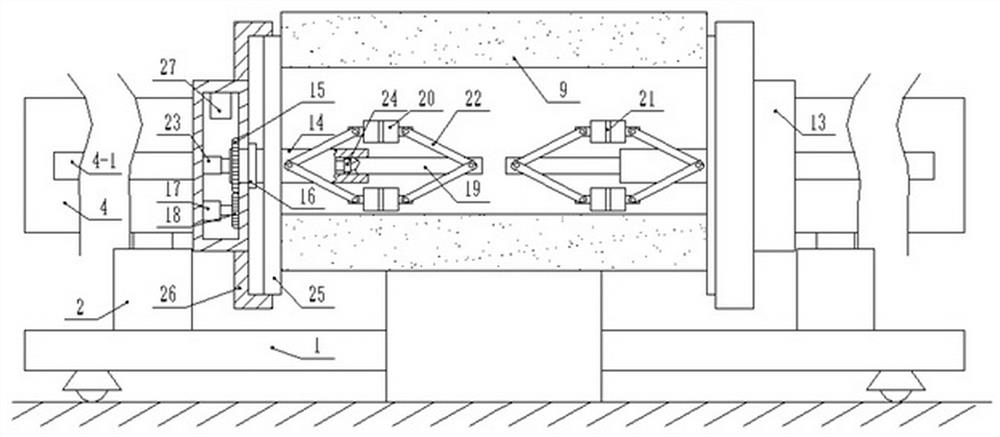

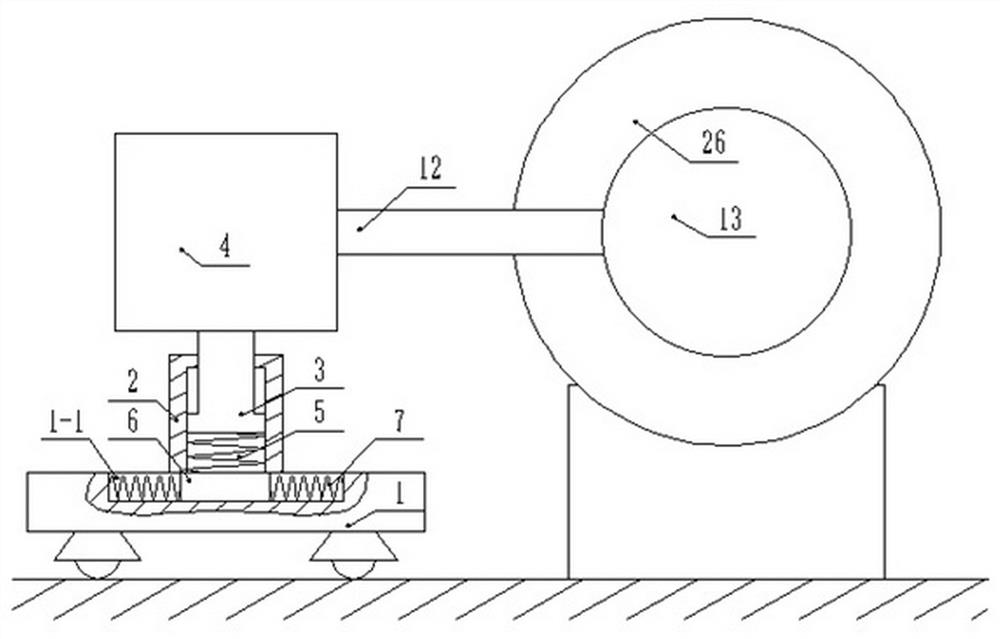

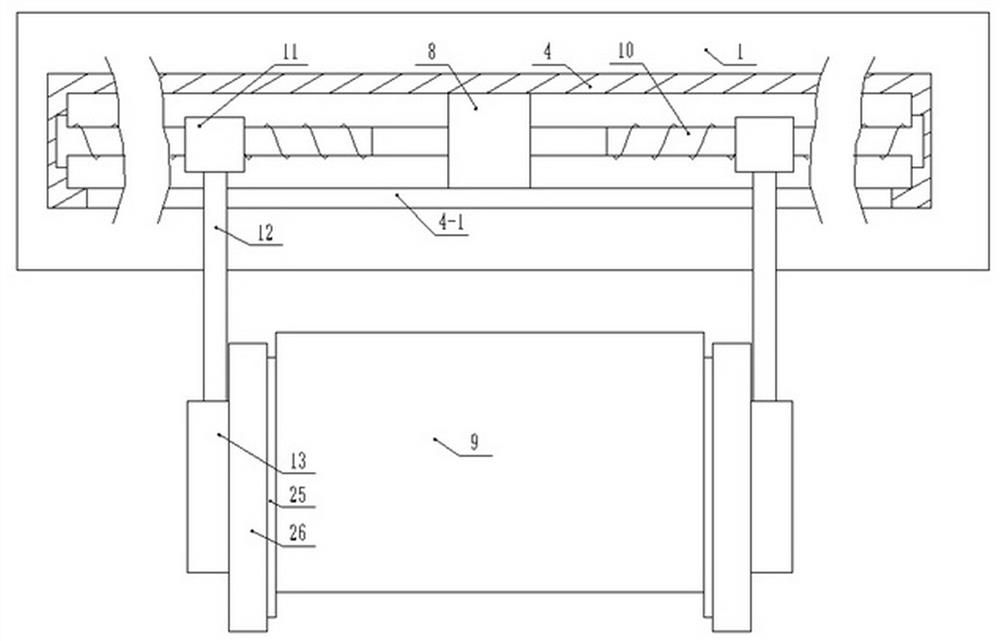

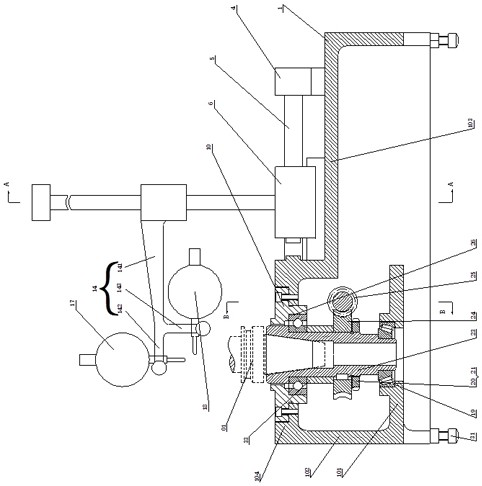

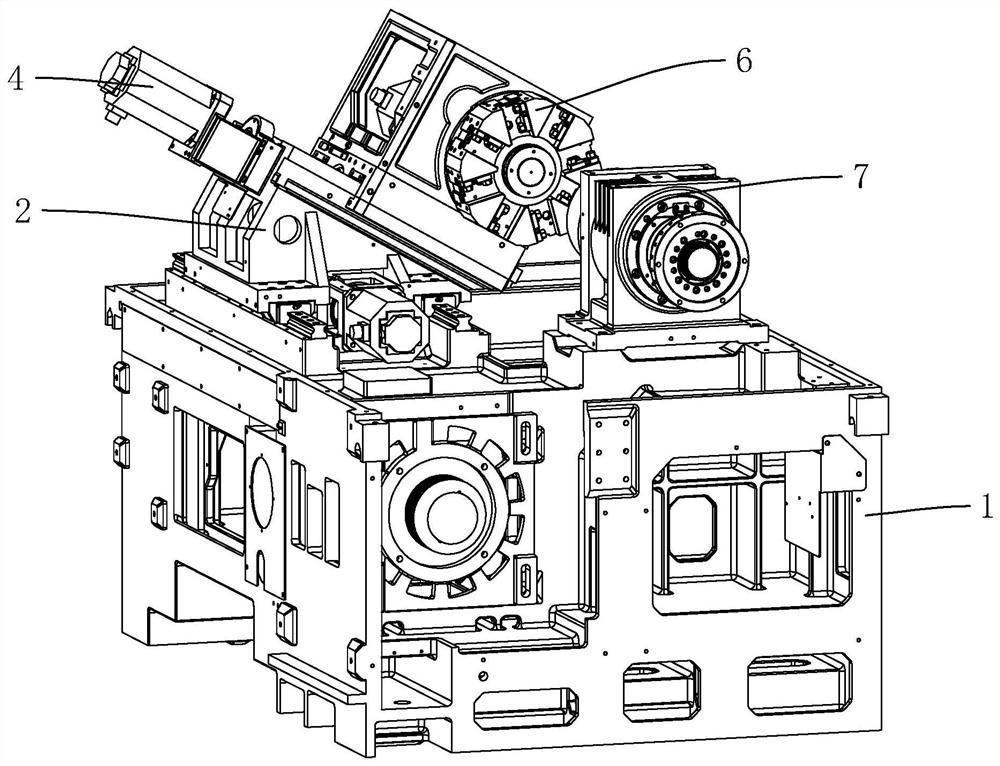

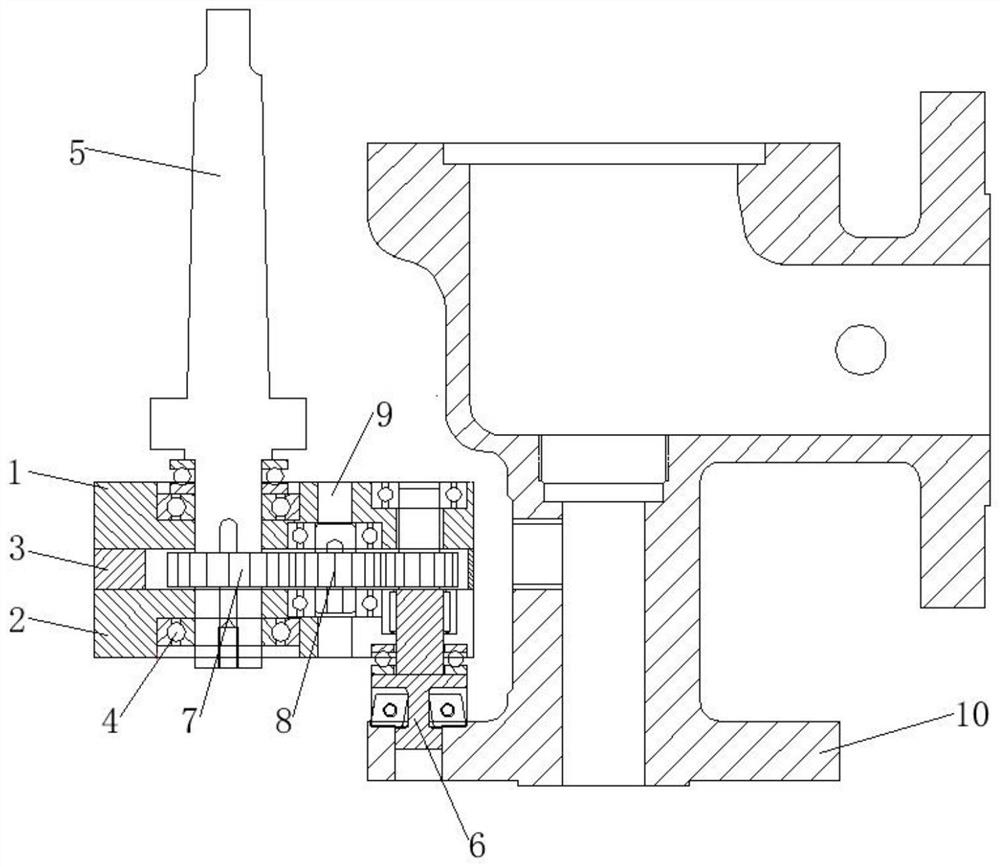

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

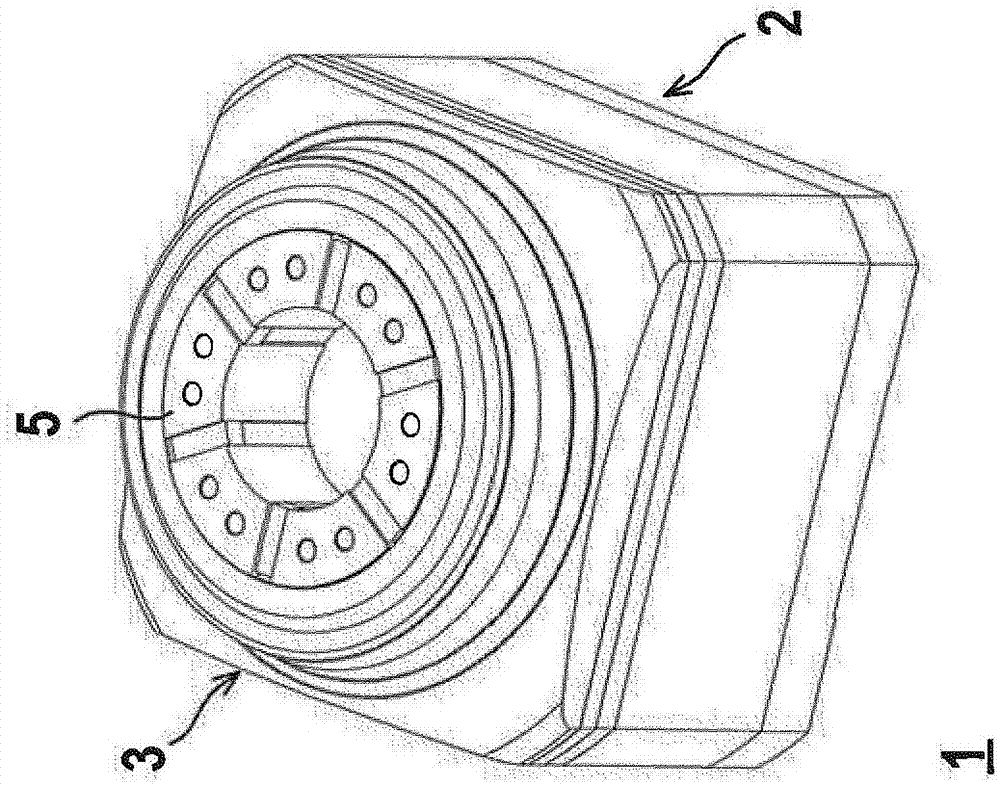

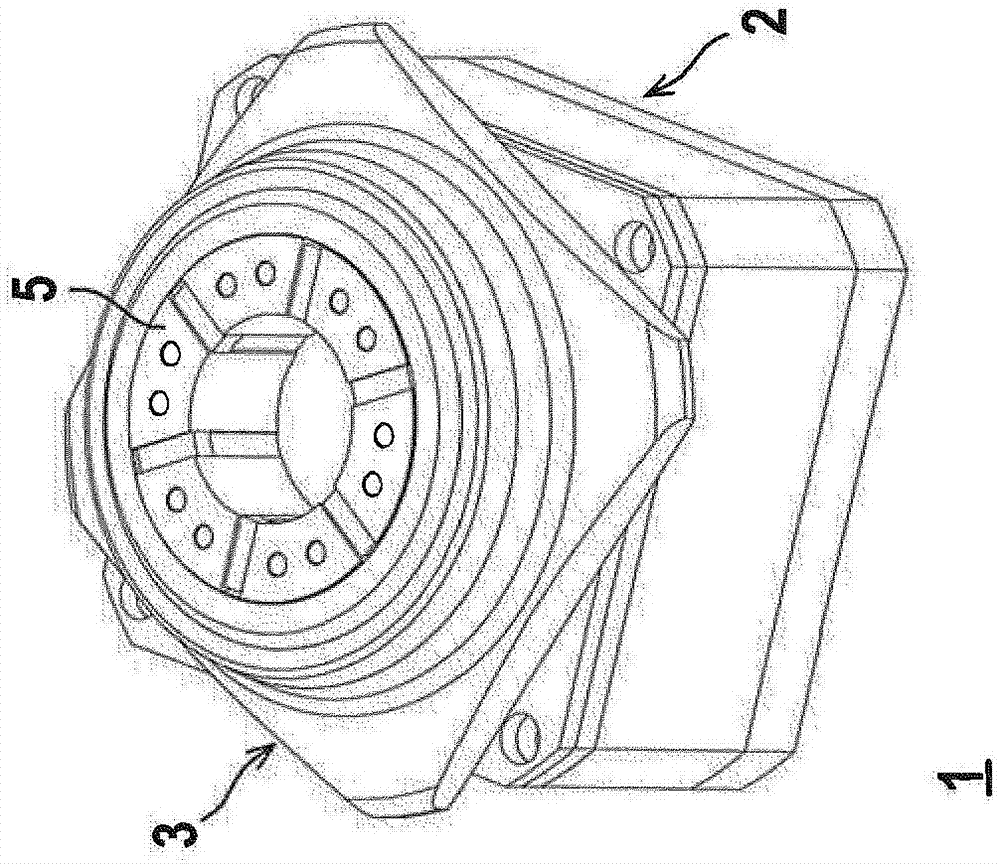

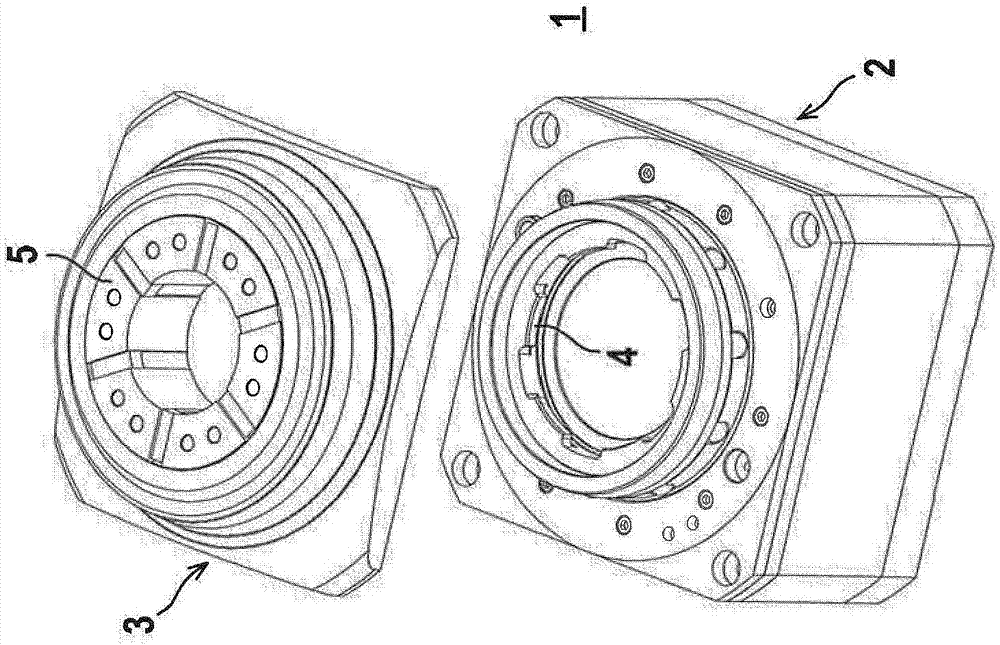

Machine tool and machine tool unit

ActiveUS20170326697A1No errors or impairmentsEasy to operateElectric/magnetic position measurementsMeasurement/indication equipmentsElectric power transmissionMotor drive

A motor-driven machine tool unit having a stator unit and at least one rotor unit having a rotor shaft that is rotatable about an axis of rotation. The rotor unit includes at least one first bearing unit arranged in the end region of a tool and / or workpiece receptacle, and a second bearing unit arranged at the opposite end region for mounting the rotor shaft in the stator unit. At least one electrical power transmission unit for transmitting electrical power between the stator unit and the rotor unit is provided. The problem addressed by the invention is that of better satisfying the increasing demands on modern machine tools or machine tool units. This problem is solved by the electrical power transmission unit is arranged in the end region opposite the tool and / or workpiece holder and / or on the second bearing unit.

Owner:FRANZ KESSLER GMBH

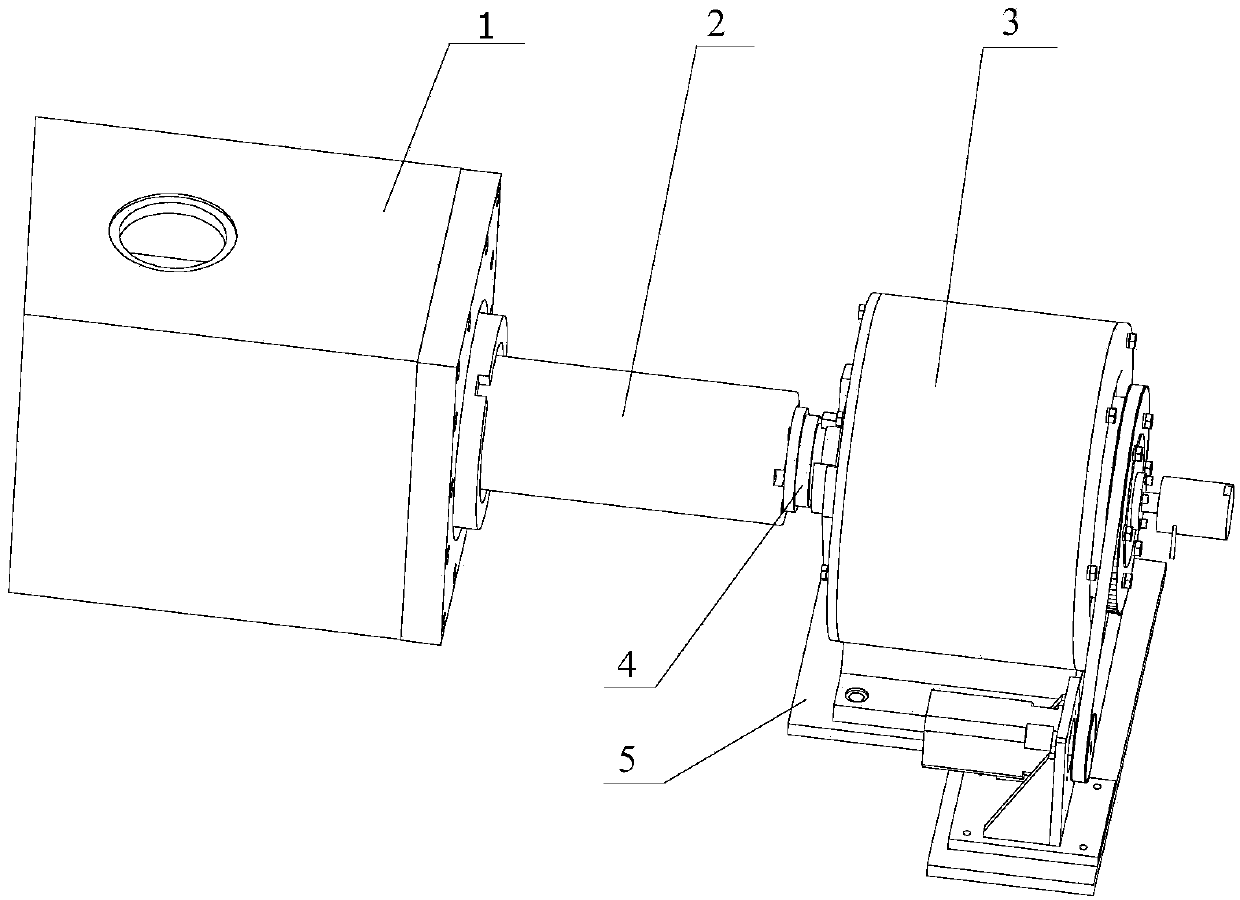

Lathe used for processing hard contact lenses

ActiveCN103231075AAuxillary equipmentMeasurement/indication equipmentsElectrical controlControl table

Owner:SCHOOL OF OPHTHALMOLOGY & OPTOMETRY WENZHOU MEDICAL COLLEGE

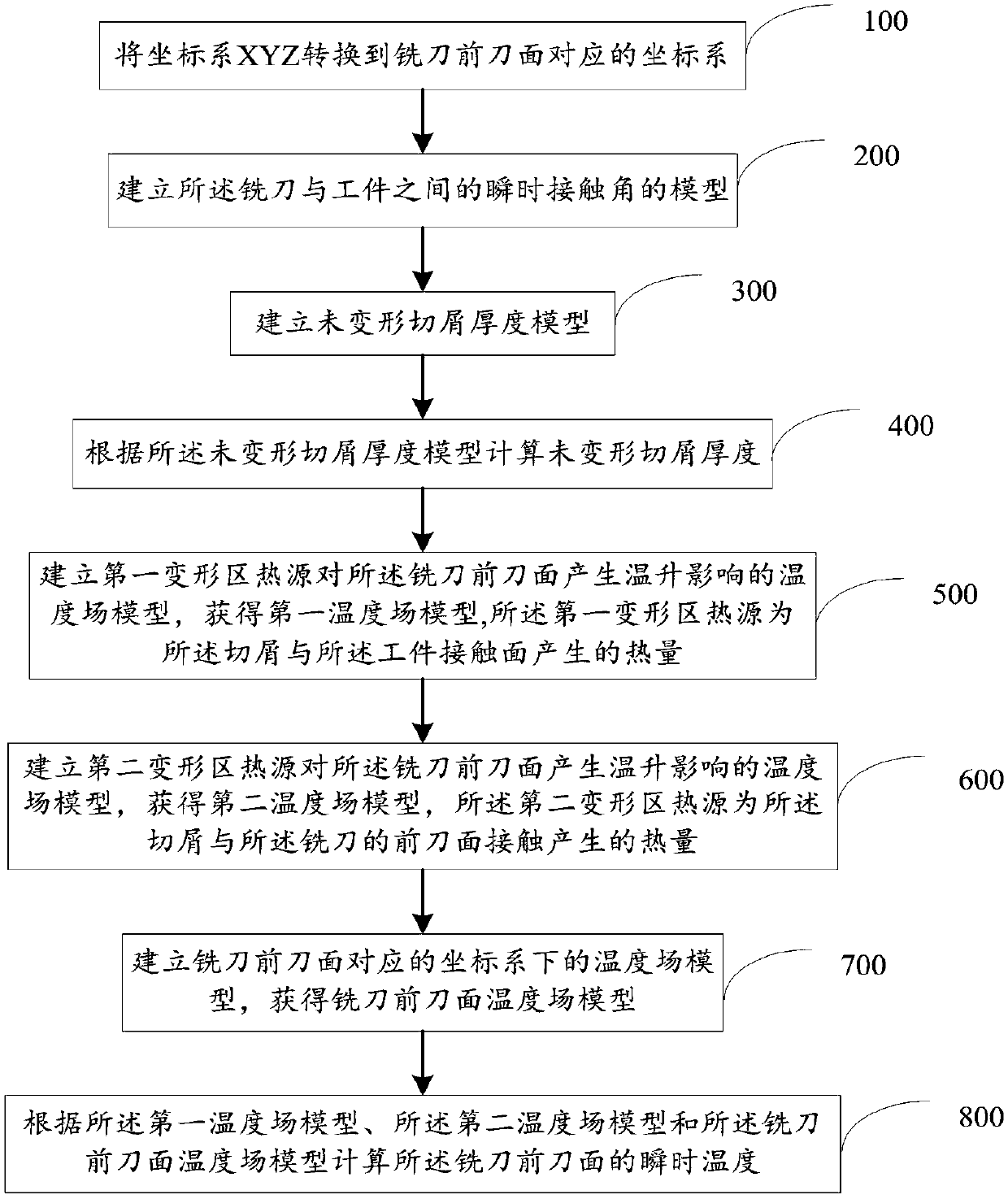

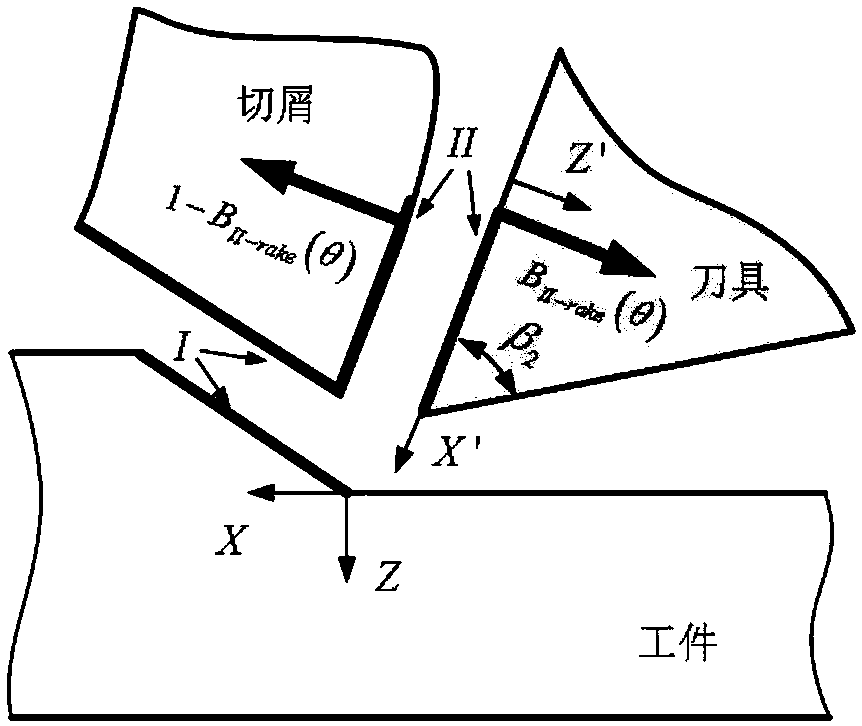

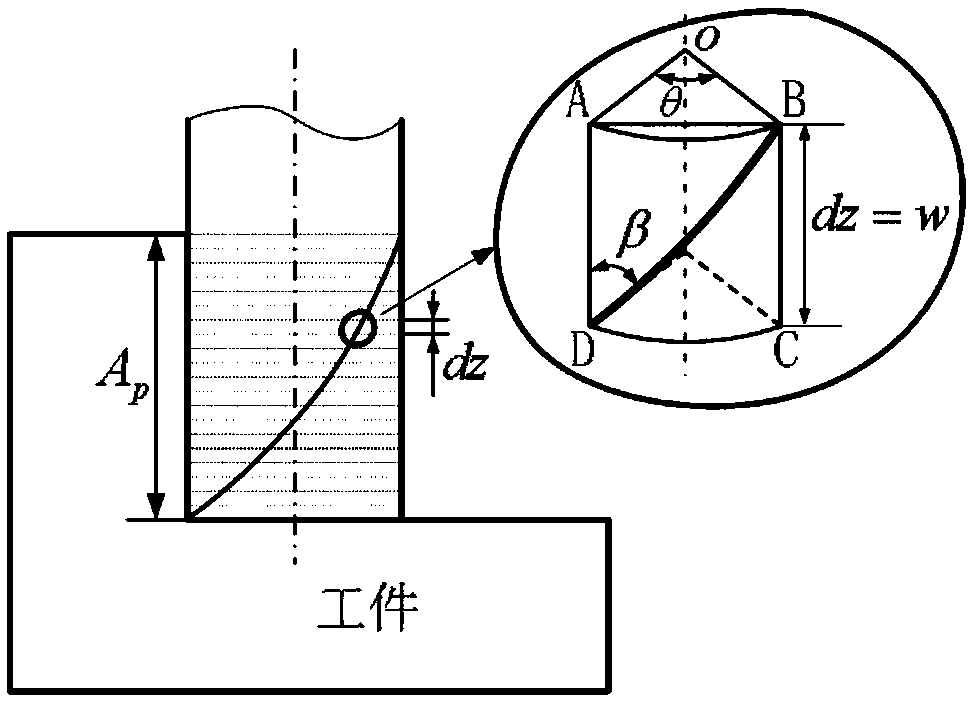

Determining method and determining system for instantaneous temperature of front cutter face of integral type flat-end milling cutter

Owner:HARBIN UNIV OF SCI & TECH

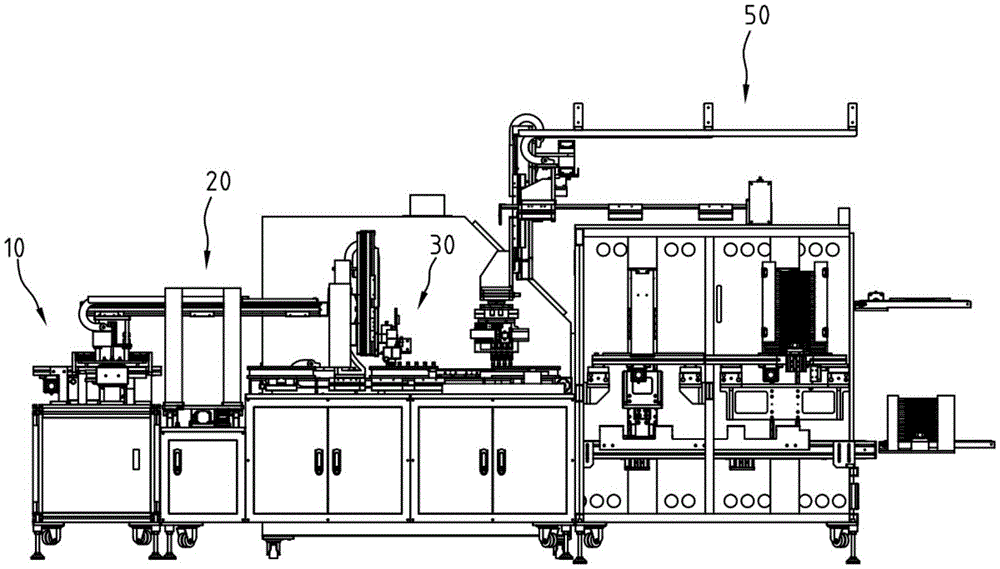

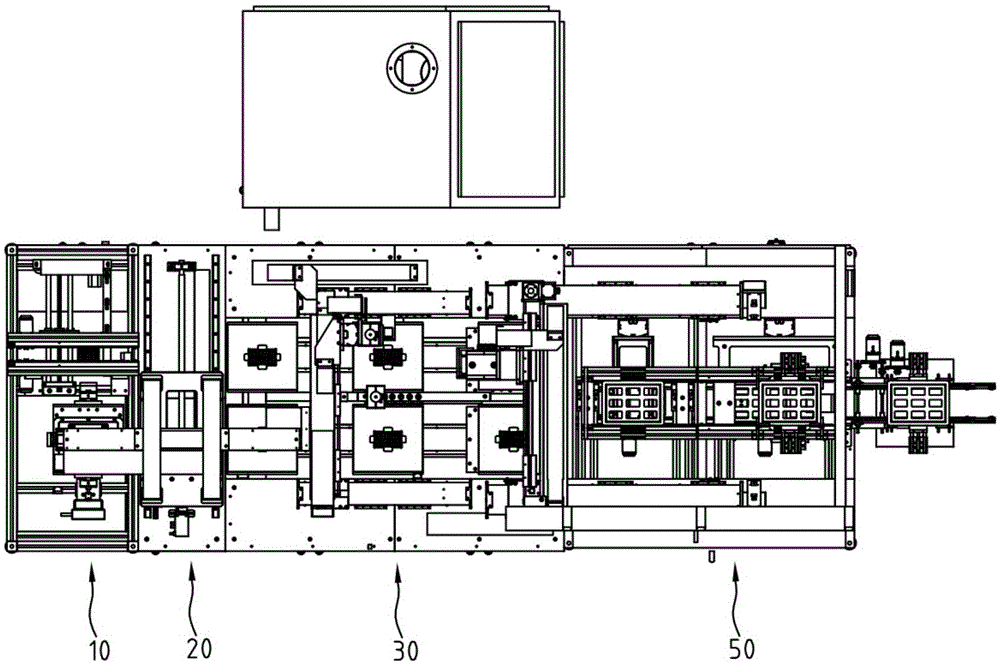

PCB (Printed Circuit Board) connection sheet dividing machine provided with jig returning lifting platform

InactiveCN105458364AMeasurement/indication equipmentsMilling equipment detailsTelescopic cylinderPrinted circuit board

Owner:SUZHOU HEROIC AUTOMATION TECH

Digital controlled drilling machine capable of automatically adjusting depth of hole

InactiveCN103157821AReasonable designLow costAutomatic control devicesMeasurement/indication equipmentsElectricityControl system

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

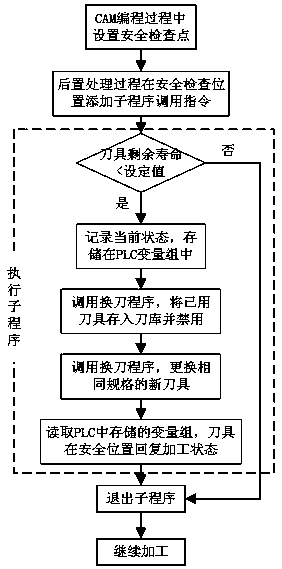

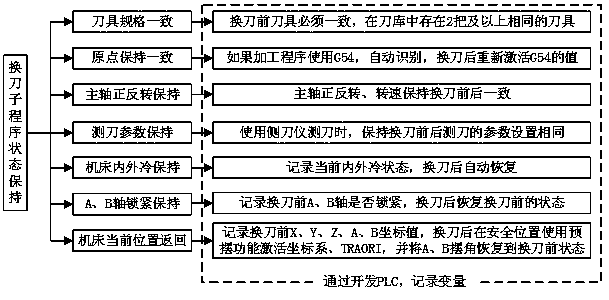

Safe tool replacing method based on tool life application mode

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Clamping unit

Owner:纳尔合伙有限责任公司

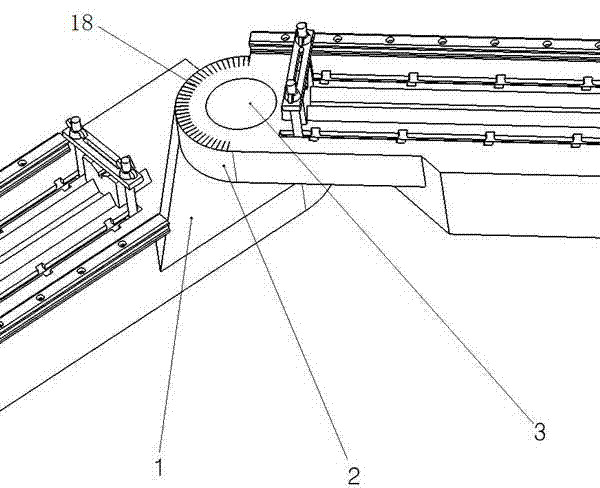

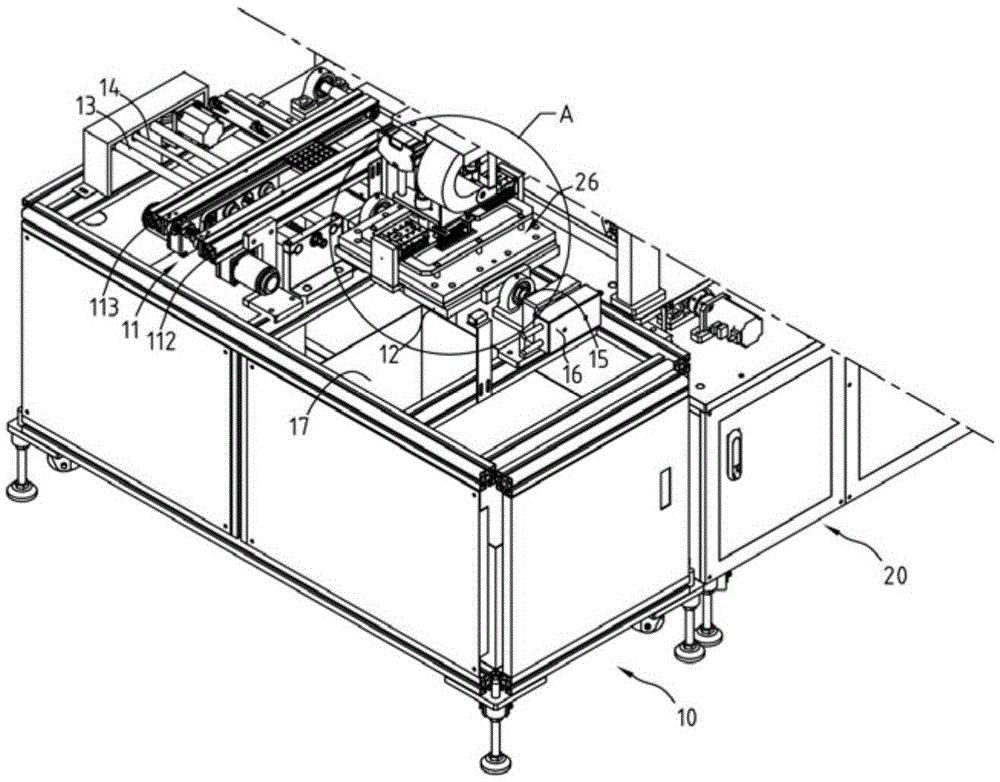

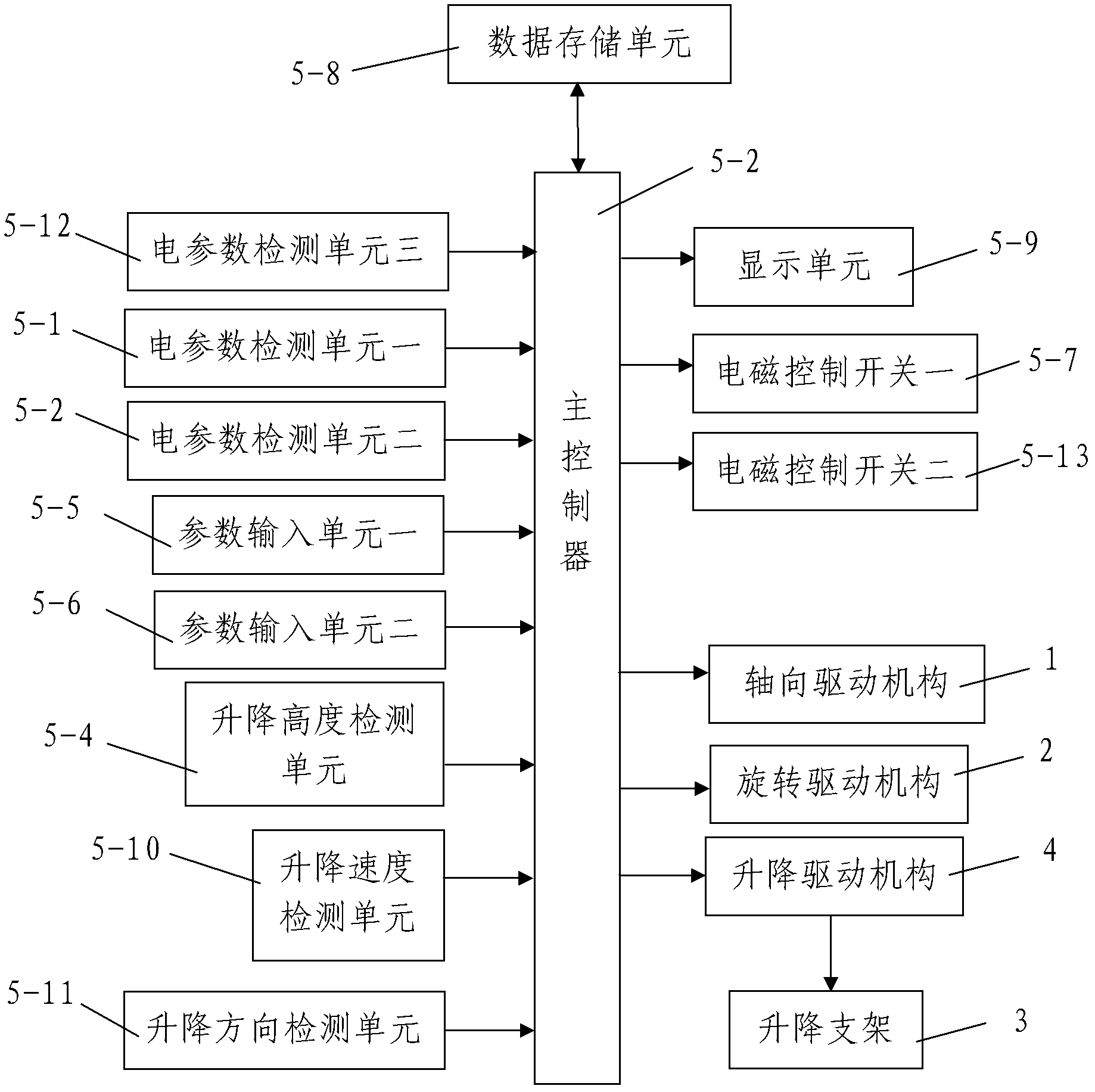

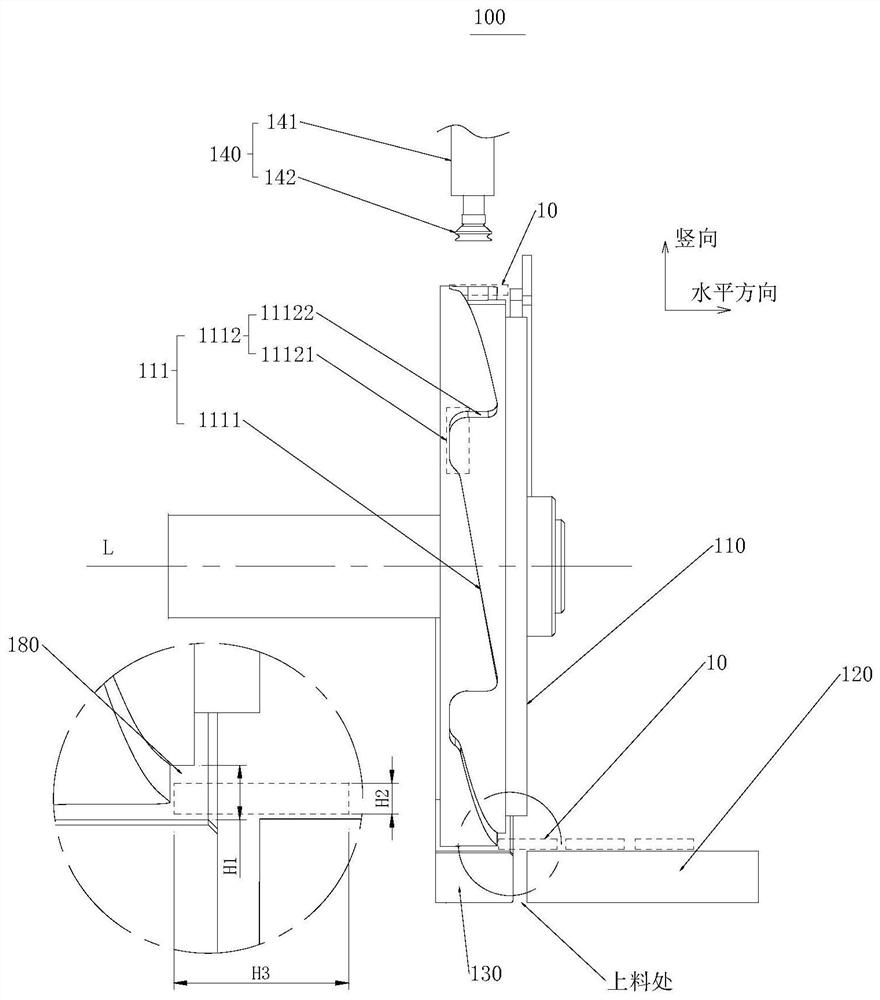

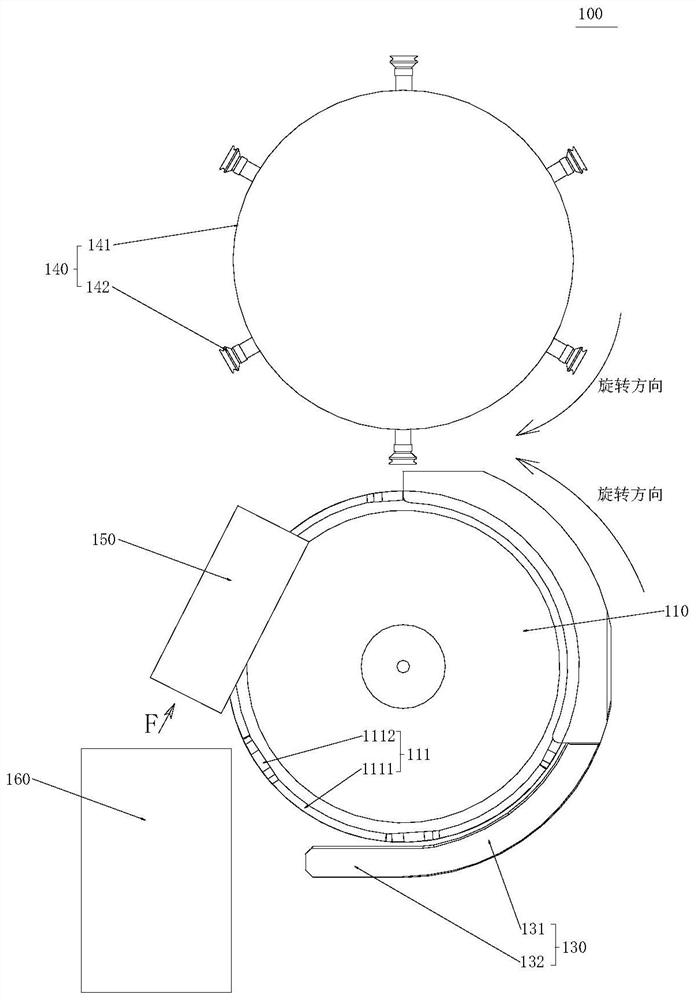

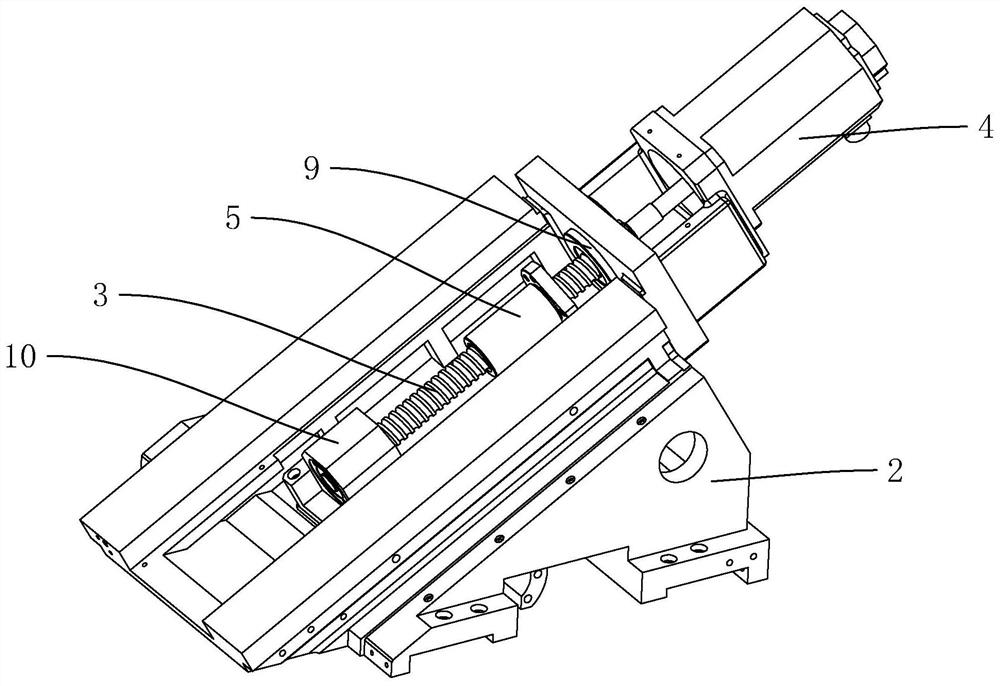

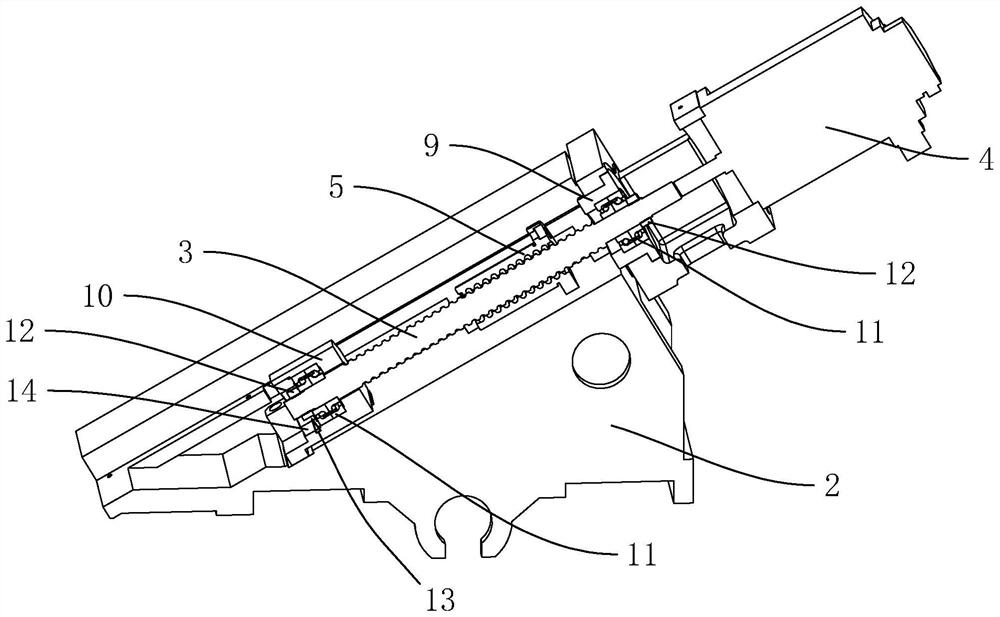

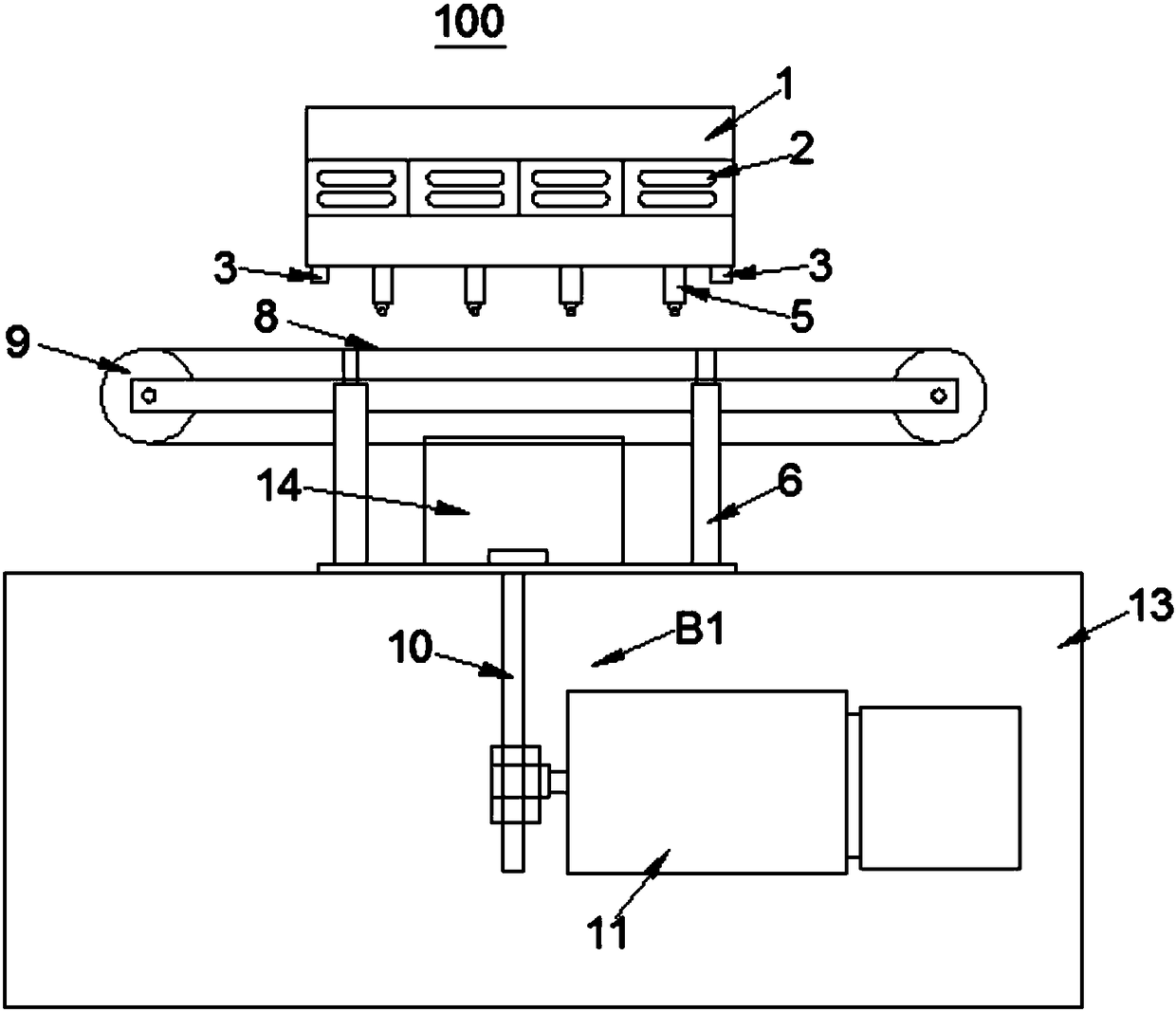

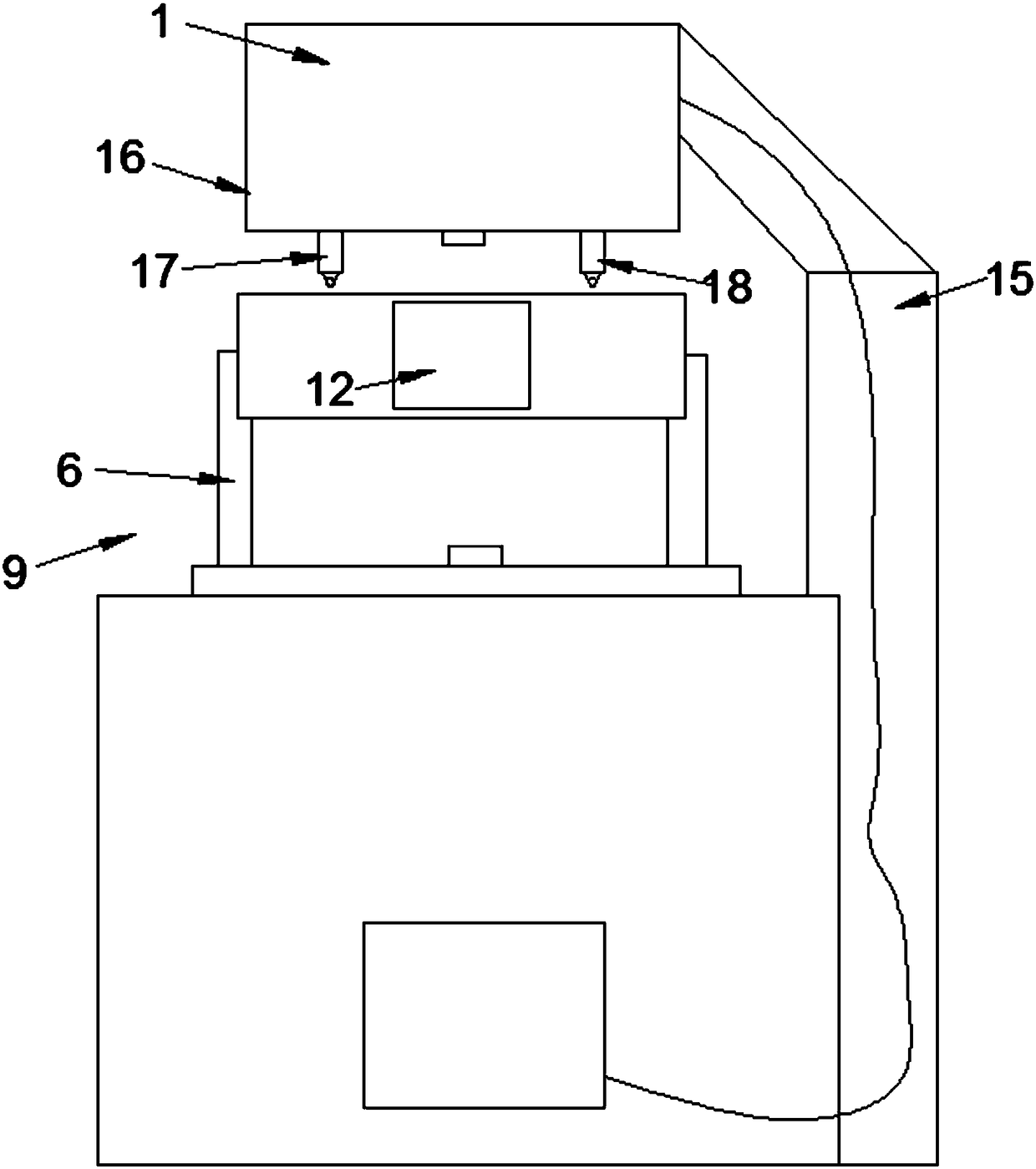

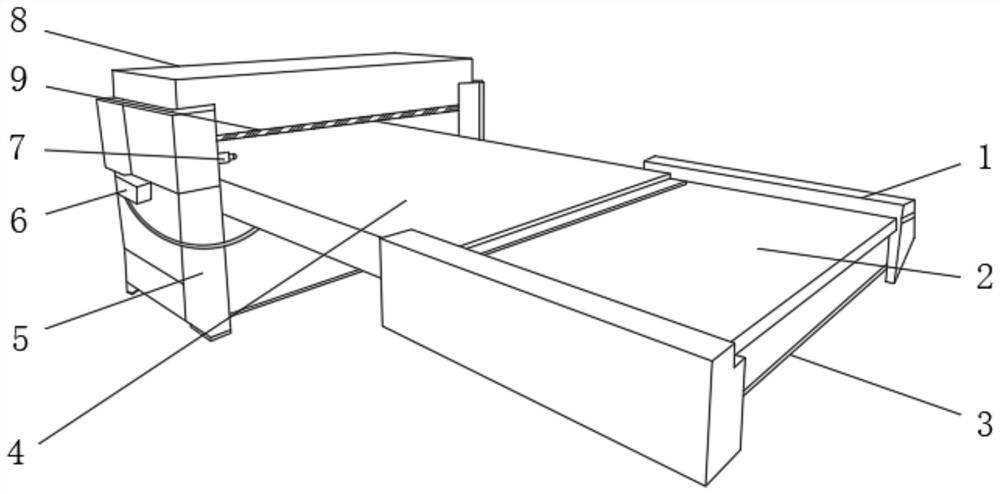

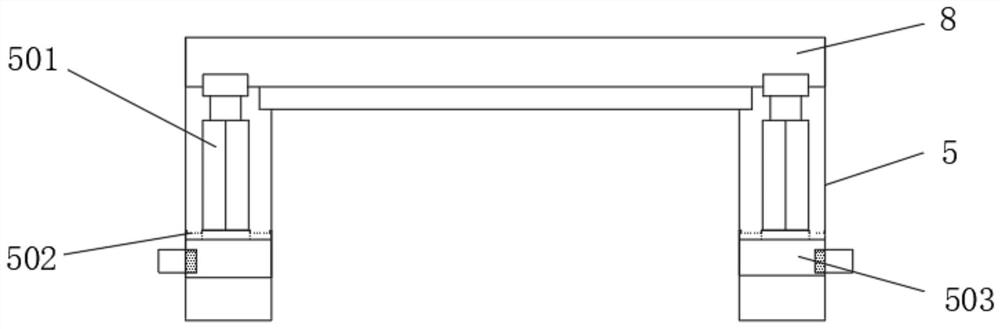

Feeding mechanism

PendingCN112171357AAvoid material jamsImprove feeding efficiencyMeasurement/indication equipmentsMetal working apparatusEngineeringMechanical engineering

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

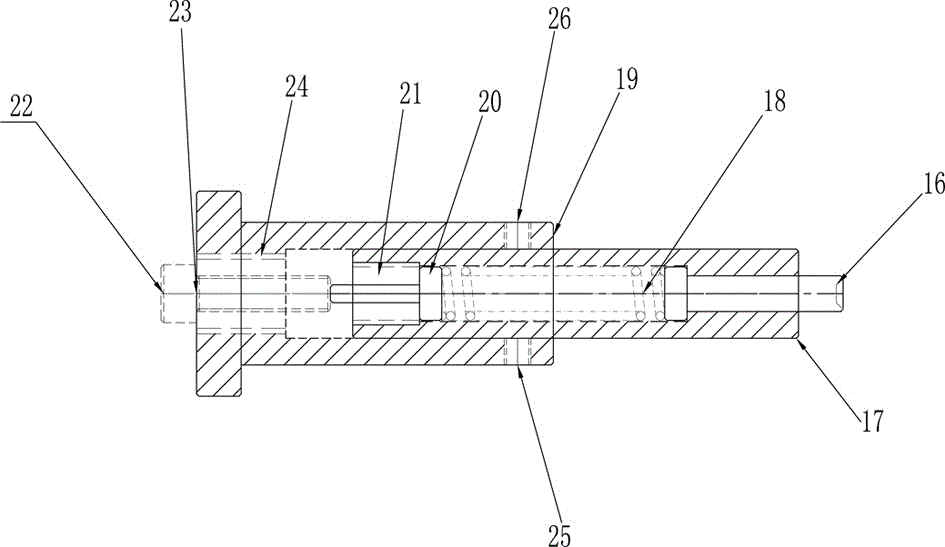

Dynamic calibration system for propeller shaft hole boring

ActiveCN107116398AAvoid Quality AccidentsMeasurement/indication equipmentsMeasurement devicePropeller

The invention discloses a dynamic calibration system for propeller shaft hole boring. The dynamic calibration system comprises two transmitting, receiving and alarming integrated machines, two positioning hole units, a position detecting unit and a system host; and the two transmitting, receiving and alarming integrated machines are installed at one ends of two boring rods, the two positioning hole units are installed at the other ends of the two boring holes, the position detecting unit is installed on a supporting bearing of the boring rods, and the system host is connected to a servo motor controller. According to the dynamic calibration system for propeller shaft hole boring, two different measurement devices are used, real time monitoring of the two or more boring rods in one shaft system can be achieved, the boring rods stop running after alarming and can run after resetting, and quality accidents are prevented.

Owner:DALIAN LIAONAN SHIPYARD 4801 FACTORY

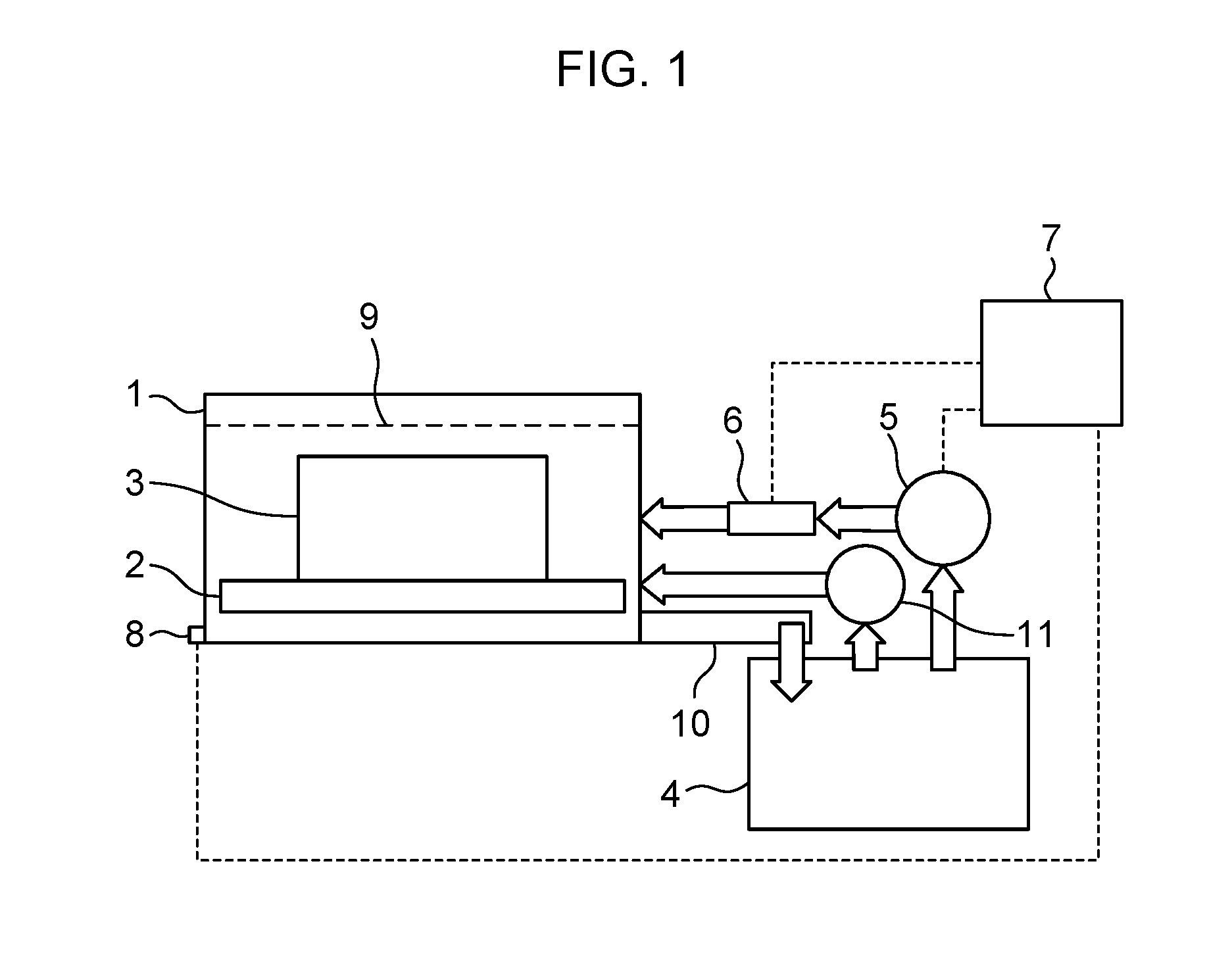

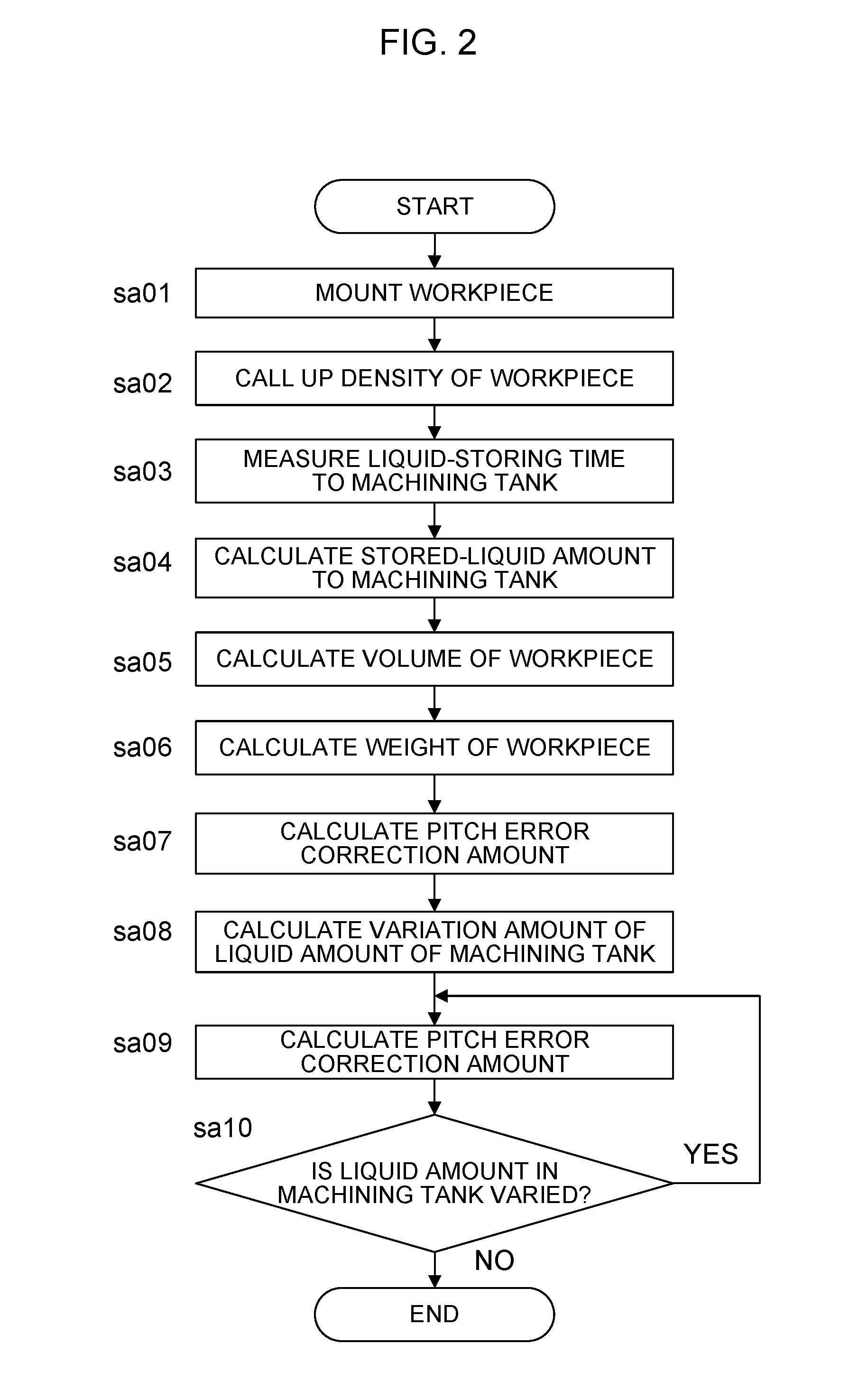

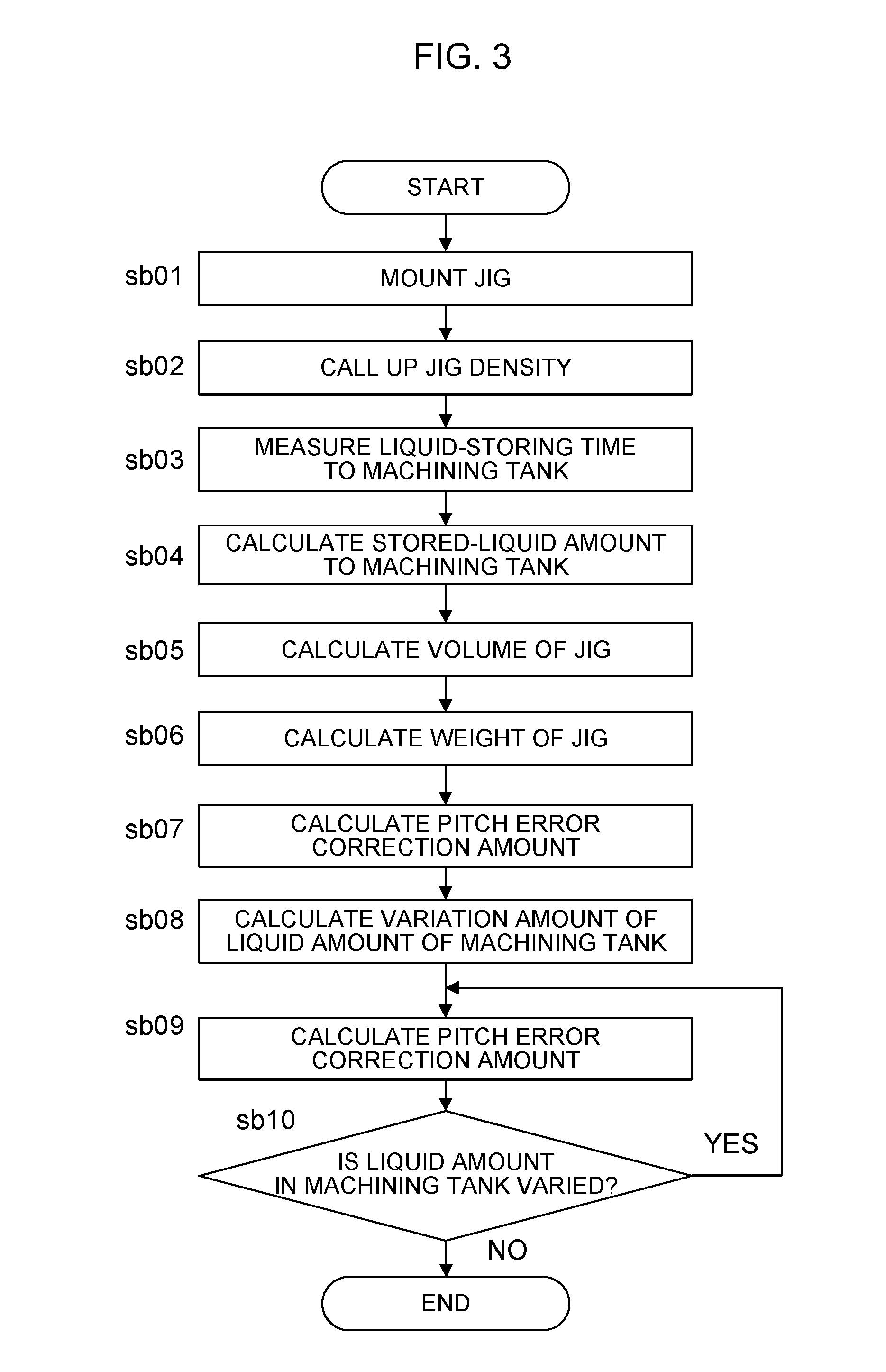

Electric discharge machine

ActiveUS20170030762A1Automatically calculatingWithout usingProgramme controlMeasurement/indication equipmentsEngineeringMechanical engineering

Owner:FANUC LTD

Control device for judging whether machining is possible

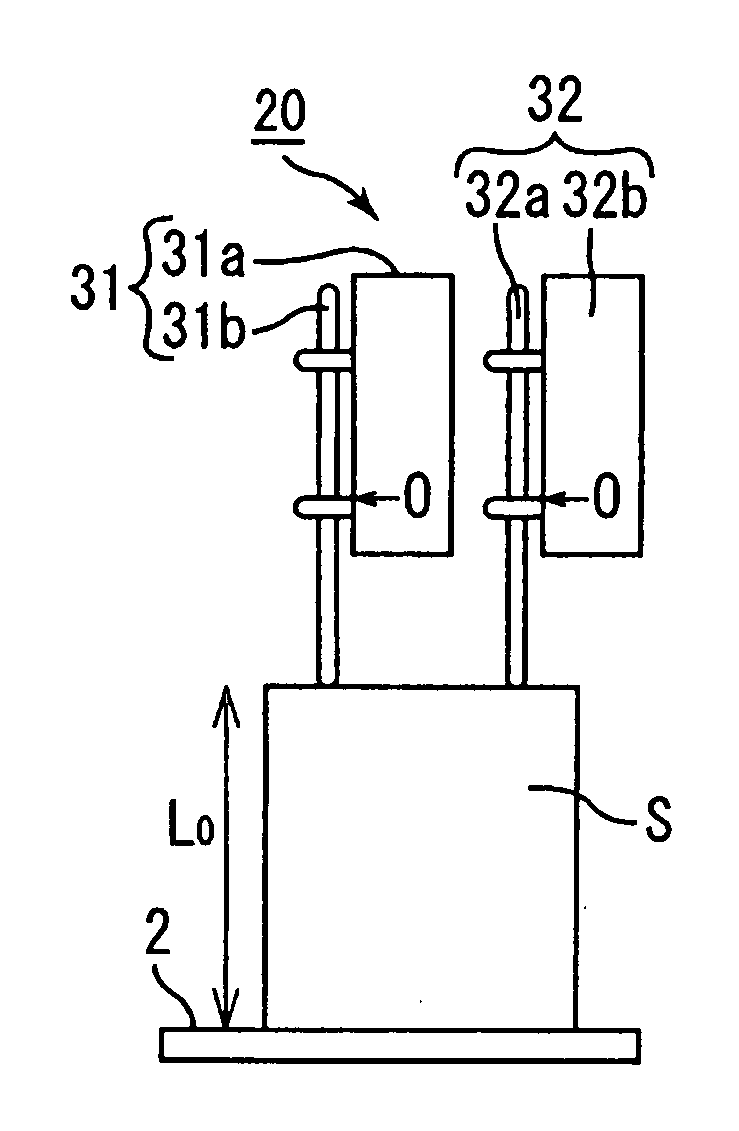

The invention provides a control device for judging whether machining is possible. The control device (20) comprises a first ratio calculating unit (24) that calculates a maximum output value corresponding to the speed of a motor (11) , which is detected by a speed detecting unit (13) based on a first relationship, and calculates a first ratio of an actual output in relative to the maximum output value; a second ratio calculating unit (25) that calculates a continuous nominal output value corresponding to the speed of the motor (11) , which is detected by the speed detecting unit (13) based on a second ratio , and calculates a second ratio of the actual power in respect to the continuous rated output value; and a judging unit (26) that uses the first ratio and the second ratio as a basis to judge whether at least one of an intermittent machining and a continuous machining of a workpiece is possible.

Owner:FANUC LTD

Machine tool with active damping

ActiveUS20190299349A1Easy and efficient solutionMachine tool componentsMeasurement/indication equipmentsEngineeringMachine tool

Owner:SORALUCE S COOP

Hot rolled steel curled edge burr trimming and shoveling device

InactiveCN113042825ASimple structureFunction increaseMeasurement/indication equipmentsElectric machinePolyvinyl chloride

Owner:XINJIANG BAYI IRON & STEEL

Tool deformation monitoring system for numerical control fixed beam type plano-boring and milling machine

Owner:QIQIHAR JINGGONG WEIYE MACHINE TOOLS CO LTD

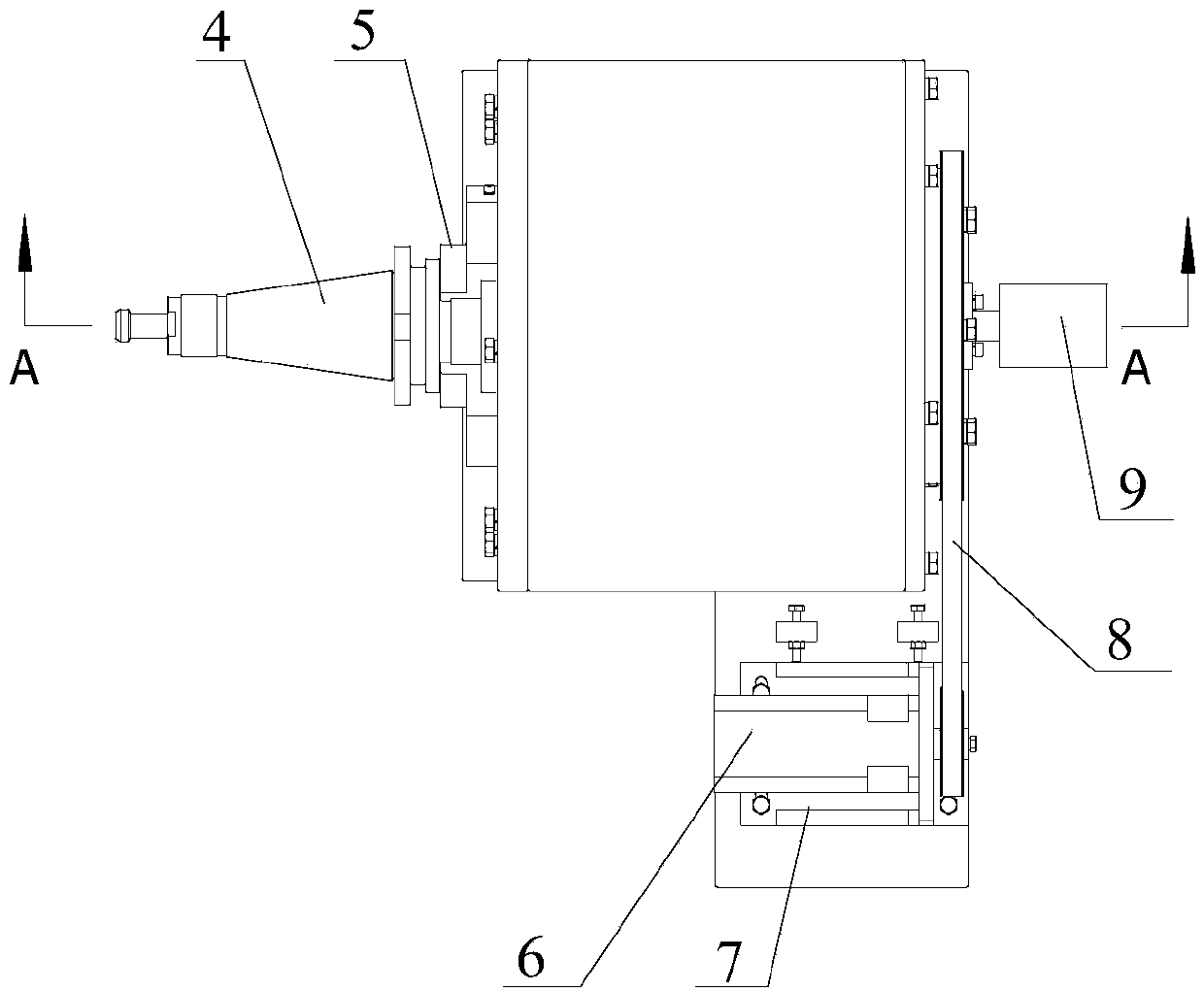

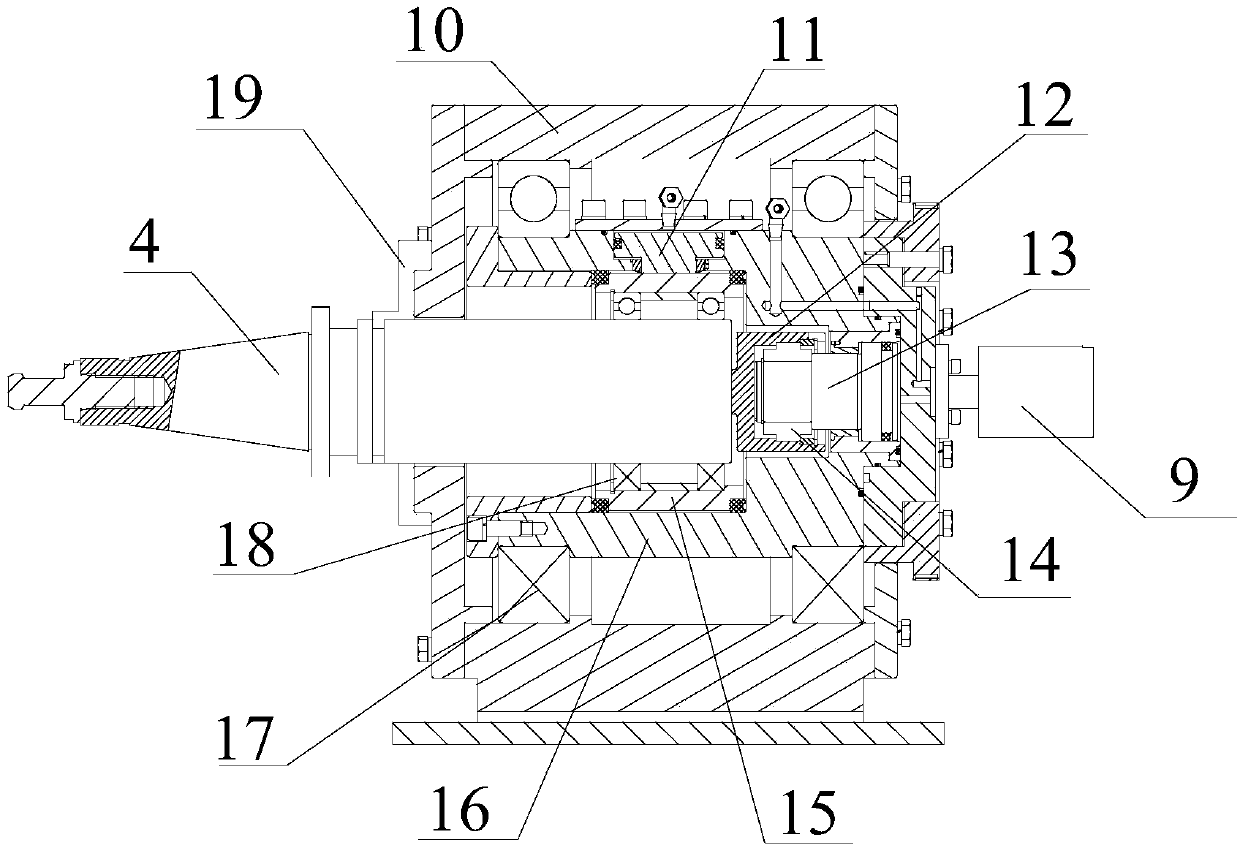

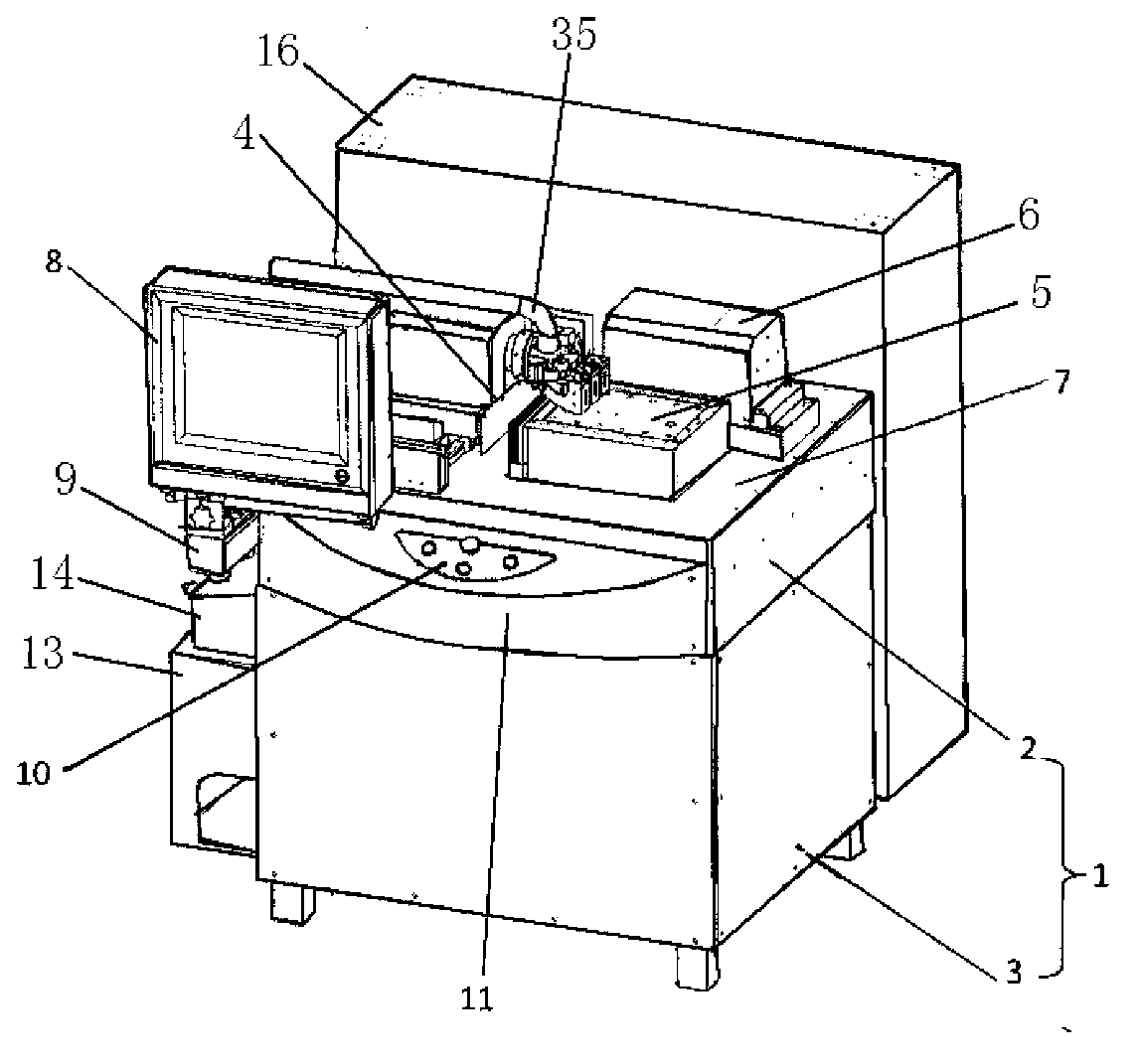

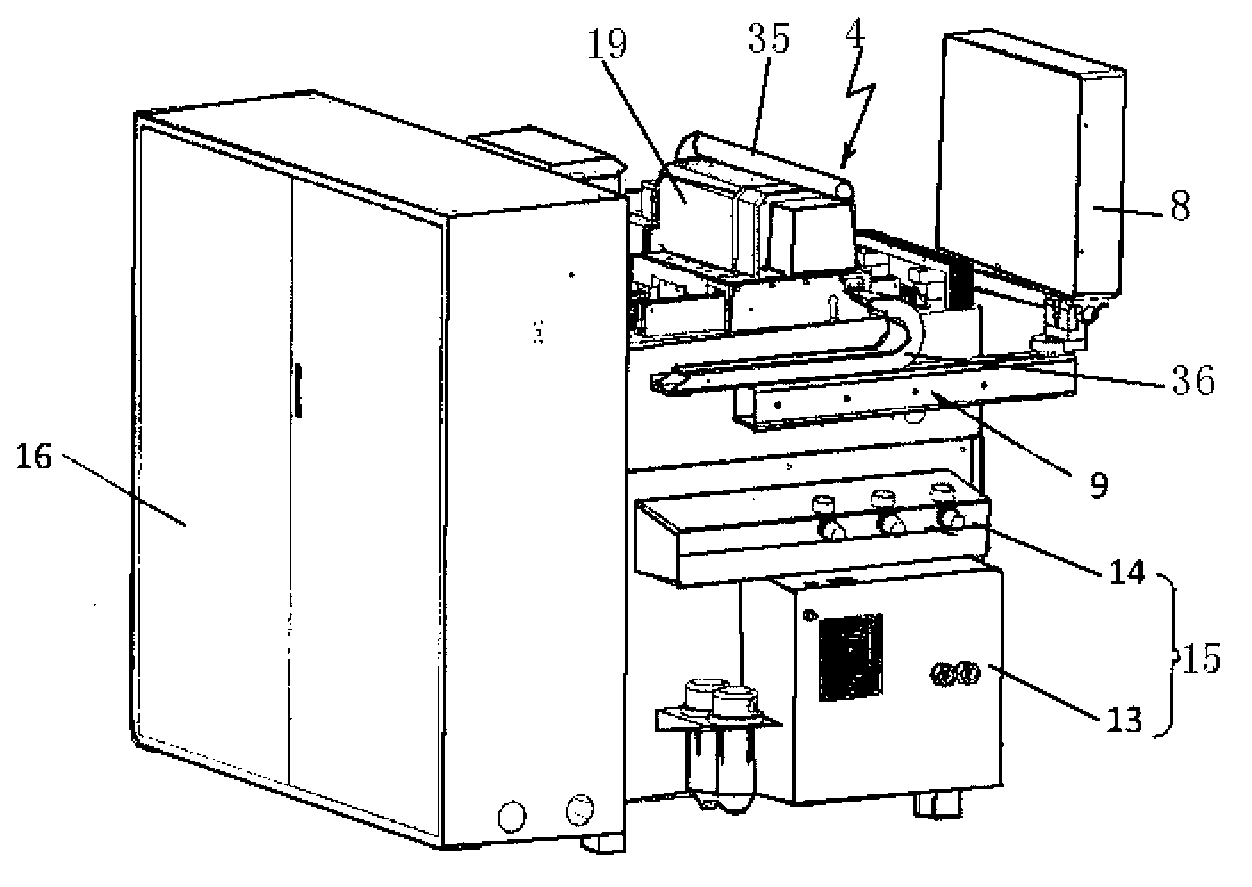

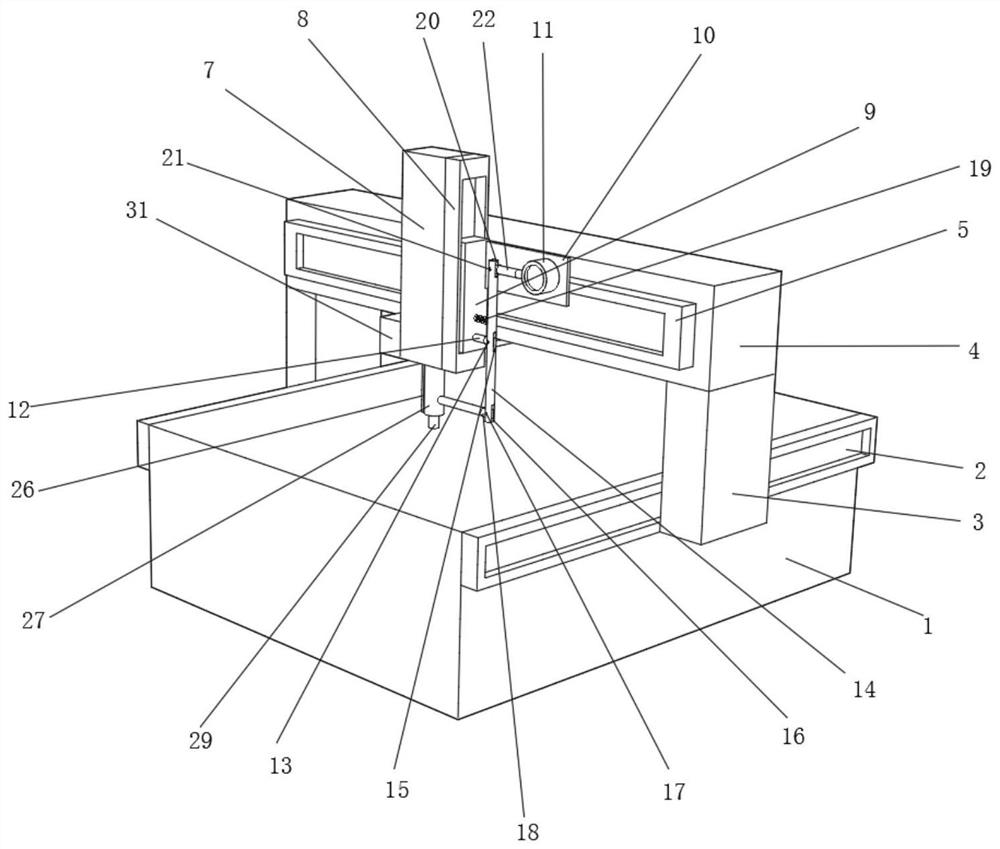

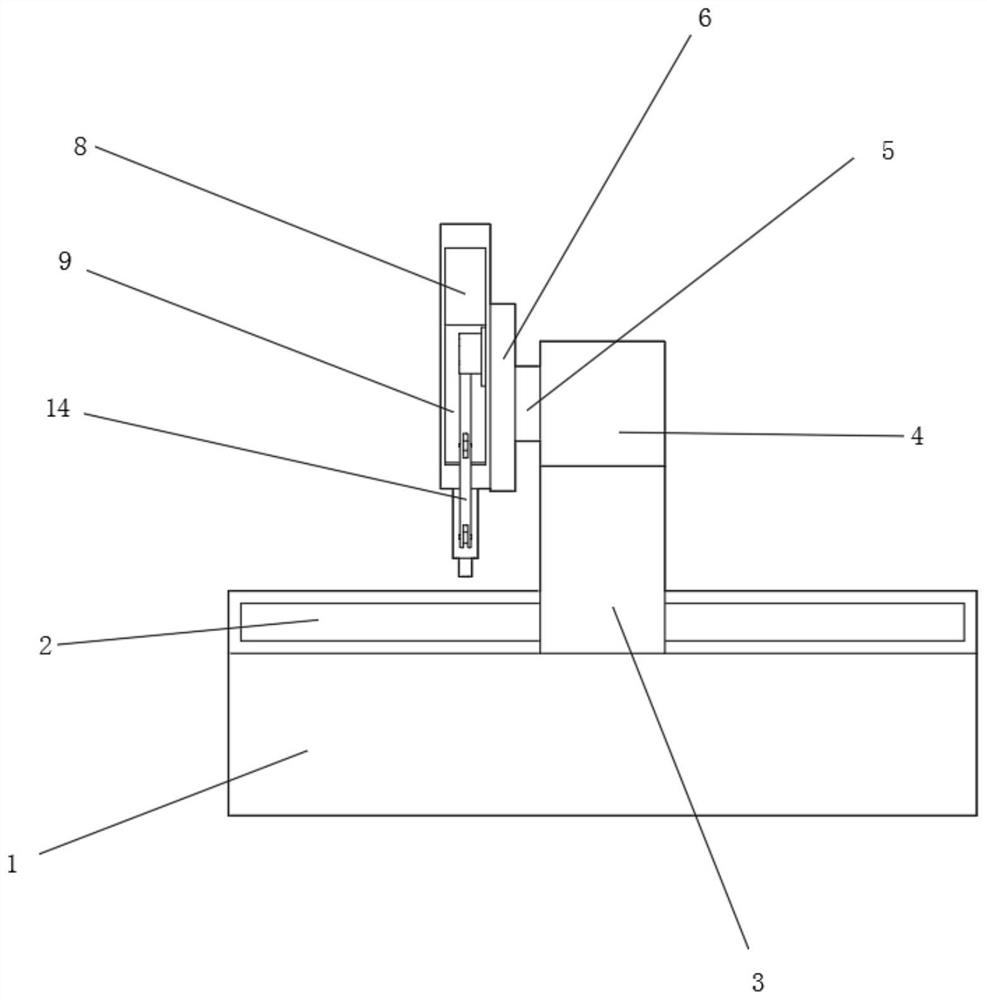

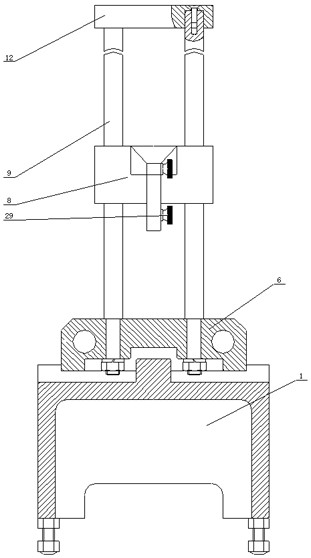

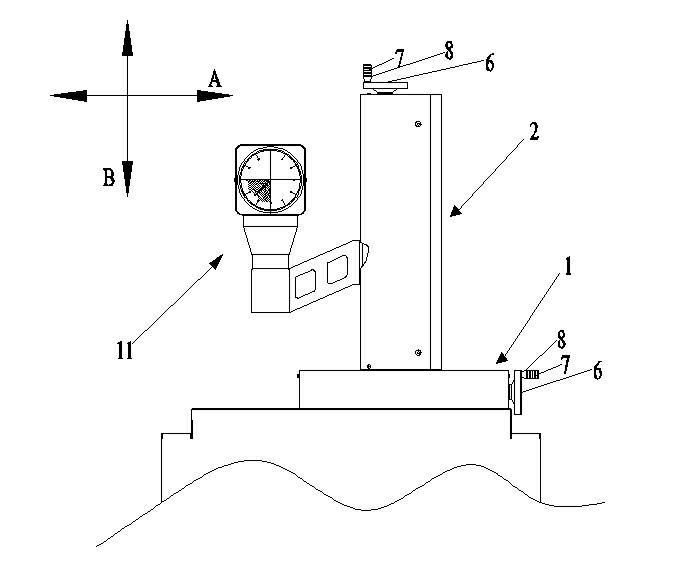

Convenient-to-use mechanical tool measuring instrument for measuring tool holder and tool tip

InactiveCN112296758ALow costMeet the precision requirementsMeasurement/indication equipmentsEngineeringTool holder

The invention discloses a convenient-to-use mechanical tool measuring instrument for measuring a tool holder and a tool tip. The upper side of a base is connected with a rotating device, the upper side of the base is slidably connected with a horizontal adjusting device, and the upper side of the horizontal adjusting device is slidably connected with a vertical adjusting device. The upper end of the rotating device is detachably connected with the tool holder of a to-be-measured tool. A main shaft of the rotating device is arranged in the base, a tool holder connector is arranged at the upperend of the main shaft, the outer wall of the main shaft is connected with a driving part, and the lower end of the main shaft is connected to the bottom of the base in a supported mode through a supporting part, so that the main shaft rotates under driving of the driving part. The defects that in the prior art, the requirement for precision is low, and the requirement for low-cost, rapid and simple tool measurement cannot be met are overcome. According to the convenient-to-use mechanical tool measuring instrument for measuring the tool holder and the tool tip, the overall structure is simple,the requirement for measurement precision can be met, the measurement effect of multiple dimensions can be facilitated, and the requirement for rapid, low-cost and simple measurement is met.

Owner:湖州永盛机械铸造有限公司

Mounting structure and method for reducing thermal deflection of tool tower crane

InactiveCN113478273AAvoid thermal expansionReduce mistakesMeasurement/indication equipmentsOther manufacturing equipments/toolsThermal dilatationElectric machinery

Owner:津上精密机床(浙江)有限公司

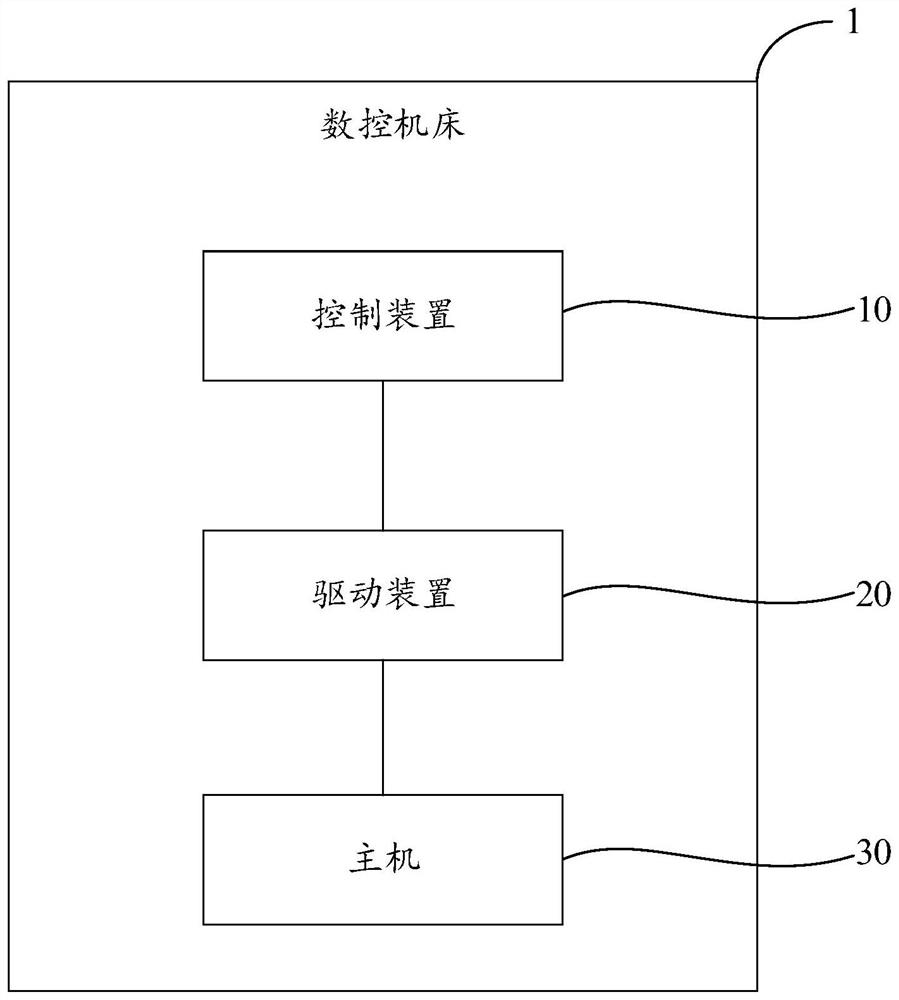

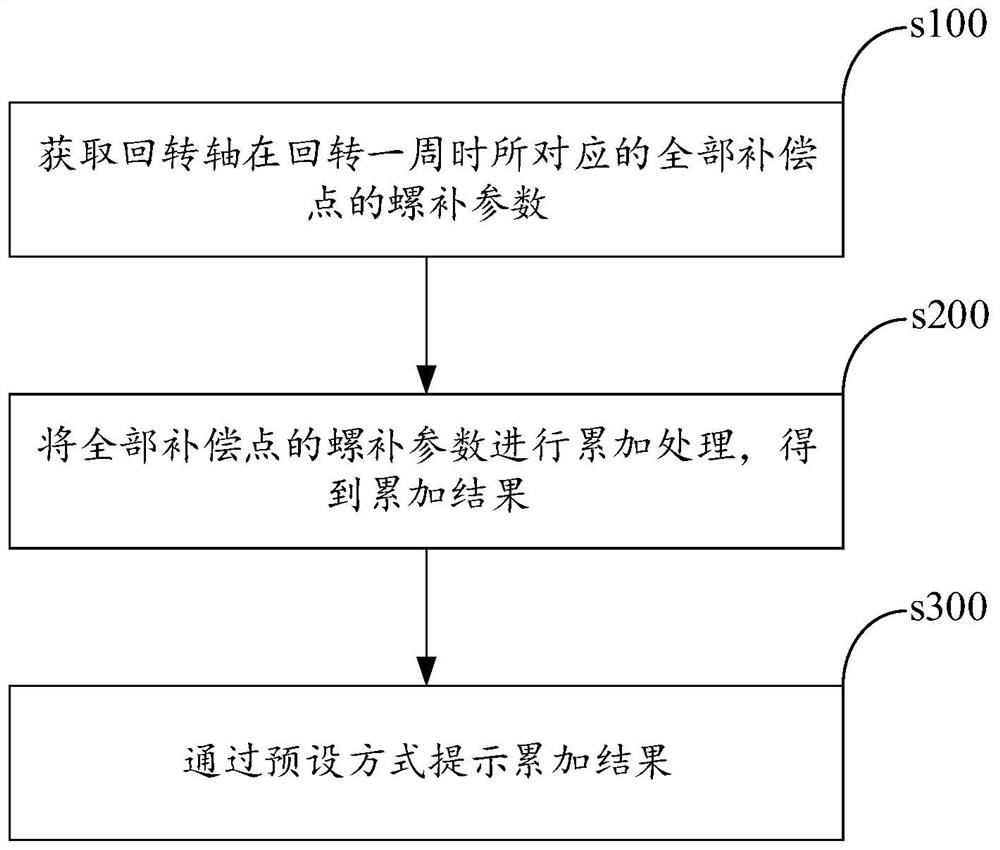

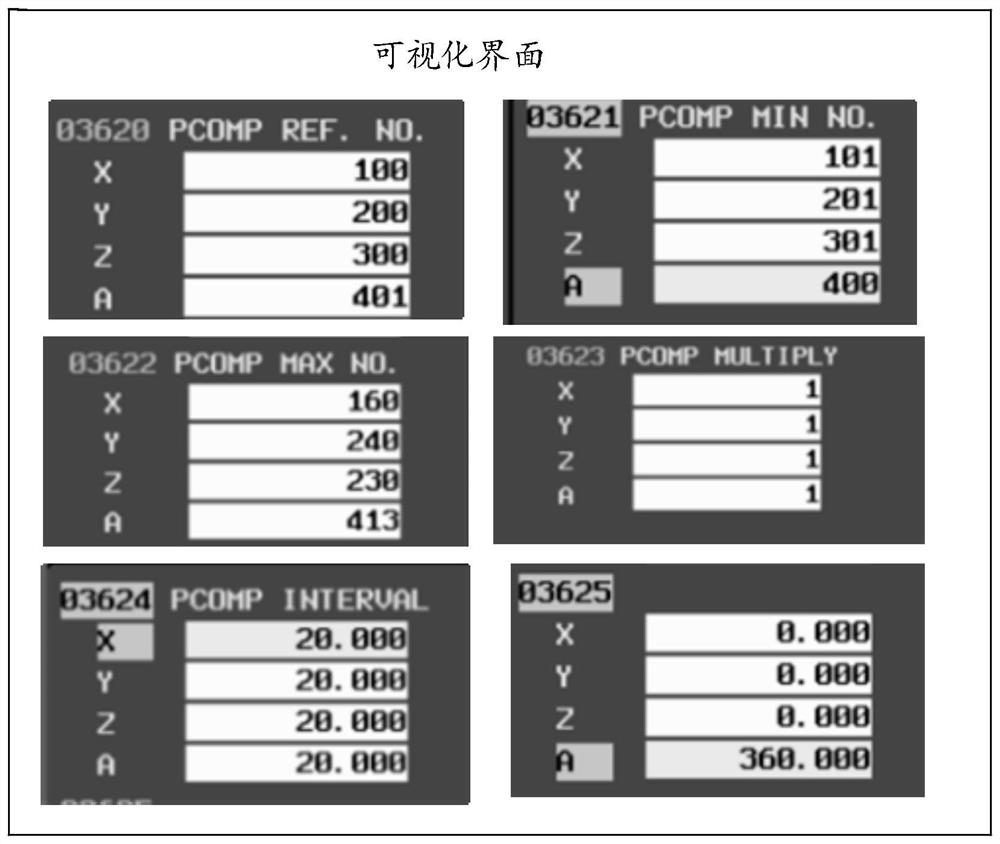

Numerical control machine tool and rotating shaft pitch error detection method thereof

PendingCN114770222AReduce mistakesMeasurement/indication equipmentsNumerical controlControl engineering

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

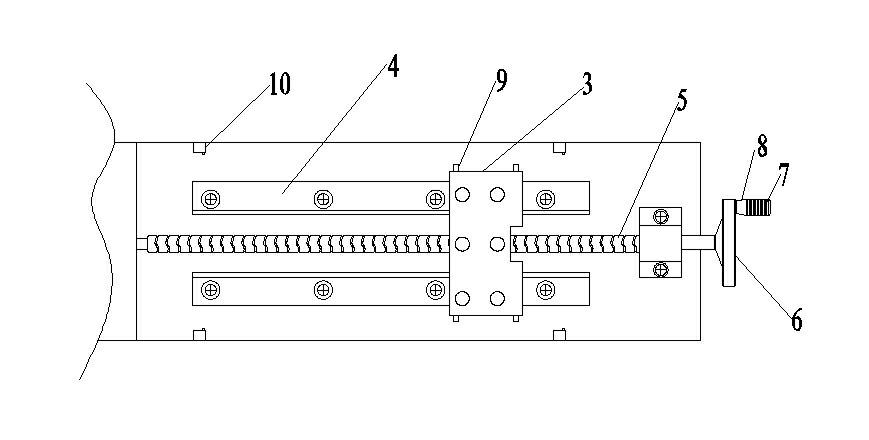

Position adjusting device for optical tool setting gauge projection system

InactiveCN102658505AFlexible adjustmentEasy to adjustMeasurement/indication equipmentsEngineeringProjection system

Owner:SUZHOU EASSON OPTOELECTRONICS

Sensor installation structure in circular seam back-chipping edge milling machine

Owner:WUXI HUALIAN PRECISION MACHINERY

Coaxiality testing tool

PendingCN106959068AAngles/taper measurementsMeasurement/indication equipmentsEngineeringConical surface

Owner:CITIC DICASTAL

Tool holder module and machine tool

PendingCN112620669ARealize the clamping centering adjustment functionEasy to operateAuxillary equipmentMeasurement/indication equipmentsEngineeringMachine tool

Owner:GUANGZHOU ROVMA AUTO PARTS

Auxiliary device for shearing and forming amorphous alloy iron core and auxiliary forming method

PendingCN108284249AQuality assuranceMeasurement/indication equipmentsShearing machine accessoriesElectricityAlloy

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

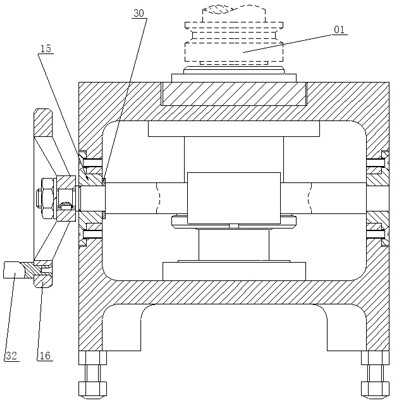

Internal flexible precise high-speed hydraulic machine tool with infrared sensing device

PendingCN113500444AMeasurement/indication equipmentsMetal working apparatusHydraulic equipmentEngineering

Owner:XUZHOU AOBO MACHINERY TECH

90-degree transmission shaft counter bore machining device

Owner:南平市建阳区湛卢精密制造有限公司

Servo motor driven type in-die variable-speed tapping machine with screw tap detection device

ActiveCN106041228AThread cutting machinesMeasurement/indication equipmentsMaterial hardnessMotor drive

Owner:DONGGUAN FOUROCEAN MACHINERY TOOLS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap