Coaxiality testing tool

A technology of coaxiality and checking tools, which is applied in the direction of manufacturing tools, angle/taper measurement, mechanical roughness/irregularity measurement, etc., can solve the problems of low efficiency and achieve high detection accuracy, safe performance and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The details and working conditions of the specific device proposed according to the present invention will be described below in conjunction with the accompanying drawings.

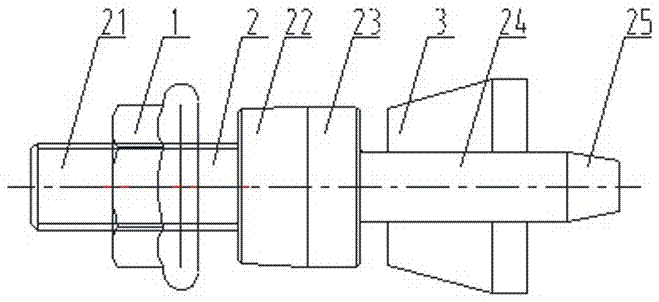

[0017] The device is composed of a hexagonal flange nut 1 , a measuring column 2 and a detection sleeve 3 , the hexagonal flange nut 1 cooperates with the threaded column 21 ; the detection sleeve 3 cooperates with the detection column 24 .

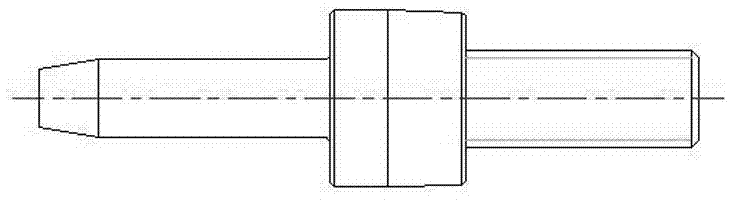

[0018] Measuring column 2 includes threaded column 21, cone 22, cylinder 23, detection column 24 and guide cone 25 five parts; threaded column 21 is on the left side of cone 22, cylinder 23 is on the right side of cone 22, and detection column 24 is on the right side of the cylinder 23, and the guide cone 25 is on the right side of the detection column 24.

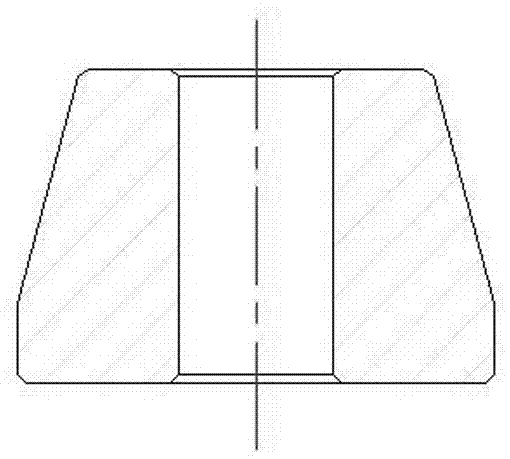

[0019] The diameter of the inner hole of the detection sleeve 3 is ΦA, and the tolerance is (0, +0.003) mm; the runout of the outer cone surface relative to the central axis of the inner hole is 0.005 mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap