Auxiliary device for shearing and forming amorphous alloy iron core and auxiliary forming method

An amorphous alloy and auxiliary device technology, applied in shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve problems such as uneven thickness and affect product performance, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

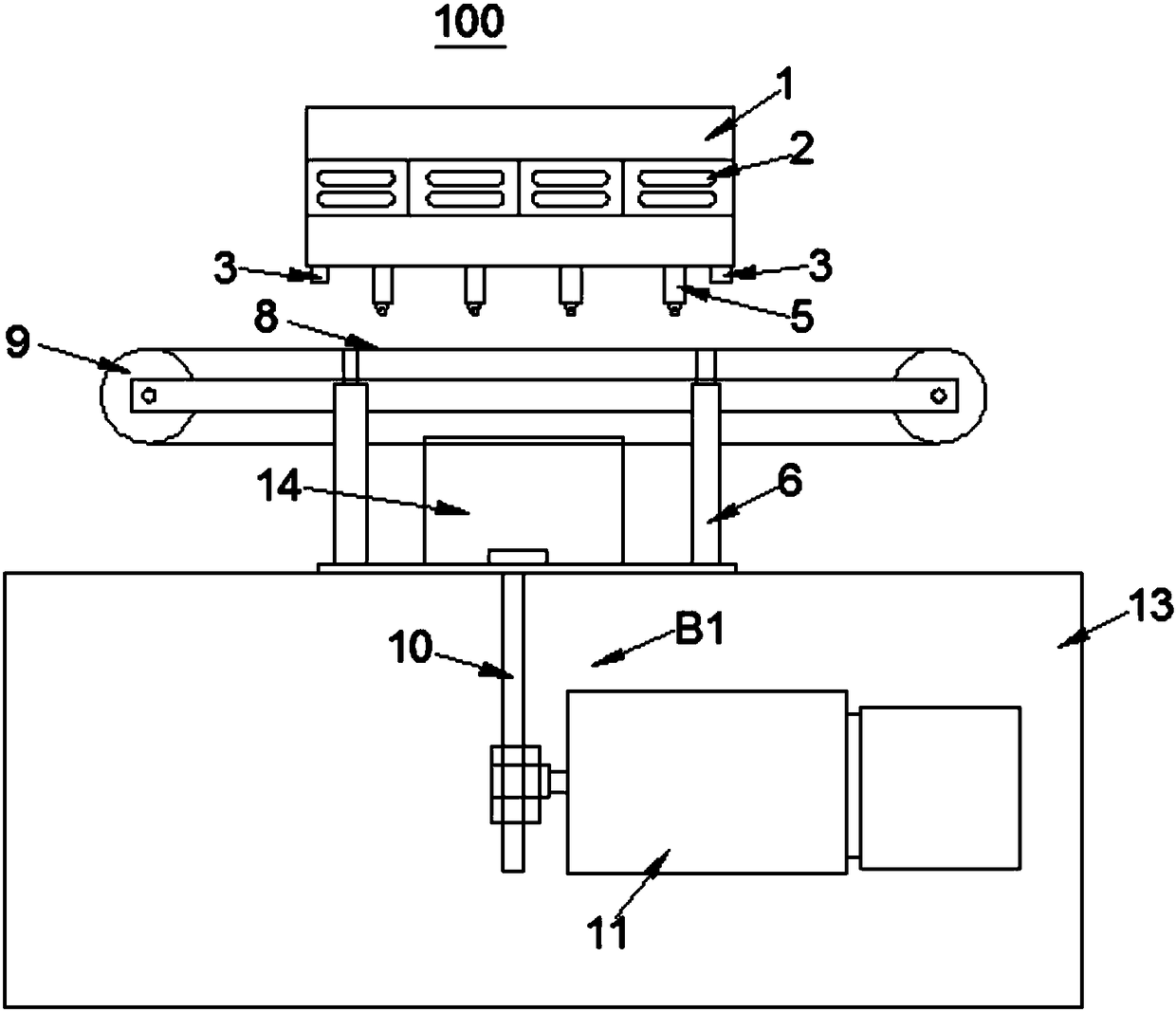

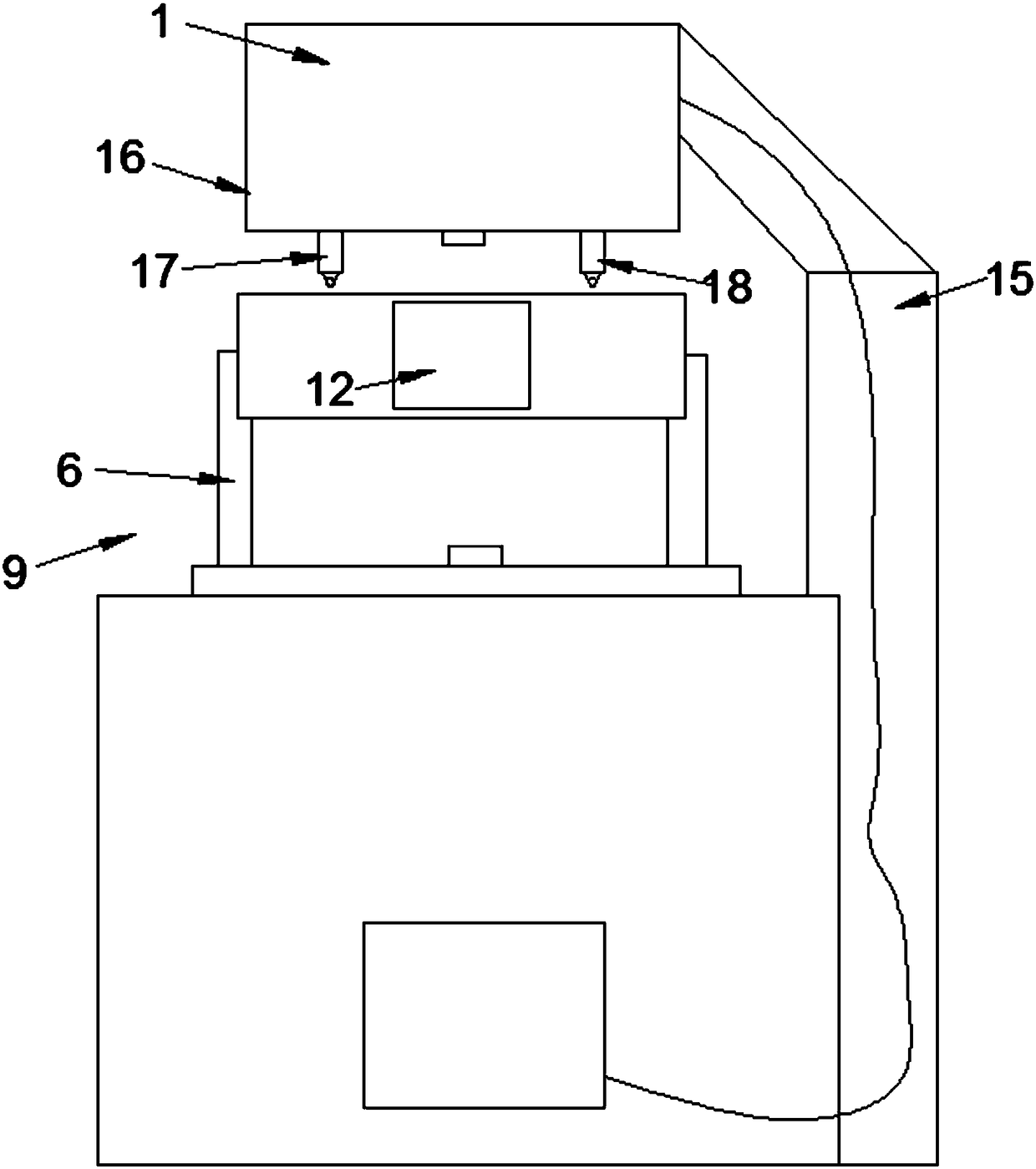

[0050] figure 1 It is a structural schematic diagram of the auxiliary device 100 for shearing and forming of an amorphous alloy core in an embodiment of the present invention. figure 2 Yes figure 1 Another perspective view. see figure 1 , figure 2 , the embodiment of the present invention provides an auxiliary device 100 for shearing and forming of an amorphous alloy core, which includes a rotating mechanism B1 , a transfer table 9 , a thickness measuring structure 5 , and a position sensor 3 . The transfer table 9 is driven by the first driver 12, and the transfer table 9 can be controlled to transfer objects placed thereon in the forward or reverse direction. The position sensor 3 is electrically connected to the first driver 12 , and can be activated and control the first driver 12 to stop driving the conveying action of the conveying table 9 when sensing that the amorphous alloy strip conveyed by the conveying table 9 is in place. Thickness measuring structure 5 vertic

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap