Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal expansion is the tendency of matter to change its shape, area, and volume in response to a change in temperature. Temperature is a monotonic function of the average molecular kinetic energy of a substance. When a substance is heated, the kinetic energy of its molecules increases. Thus, the molecules begin vibrating/moving more and usually maintain a greater average separation. Materials which contract with increasing temperature are unusual; this effect is limited in size, and only occurs within limited temperature ranges (see examples below). The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of thermal expansion and generally varies with temperature.

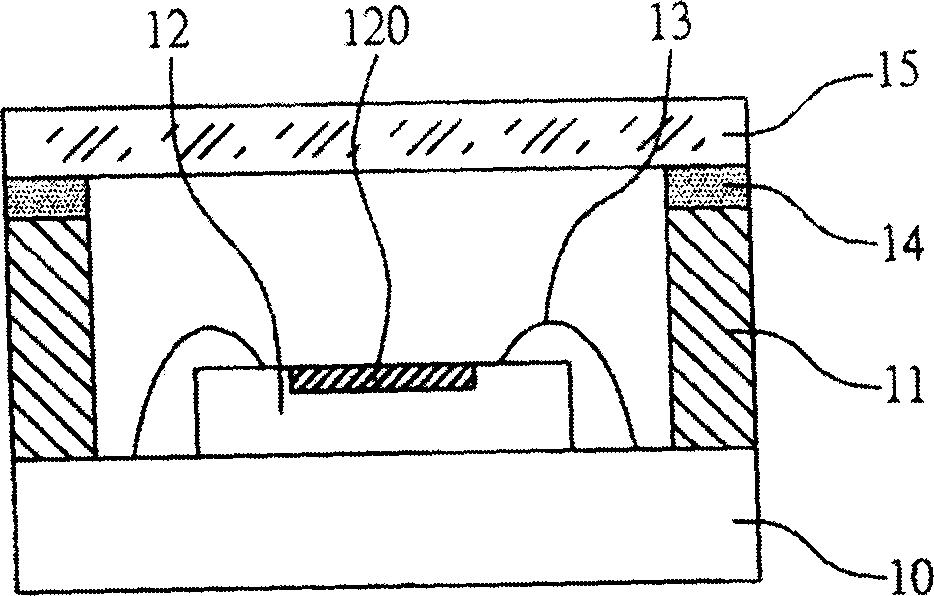

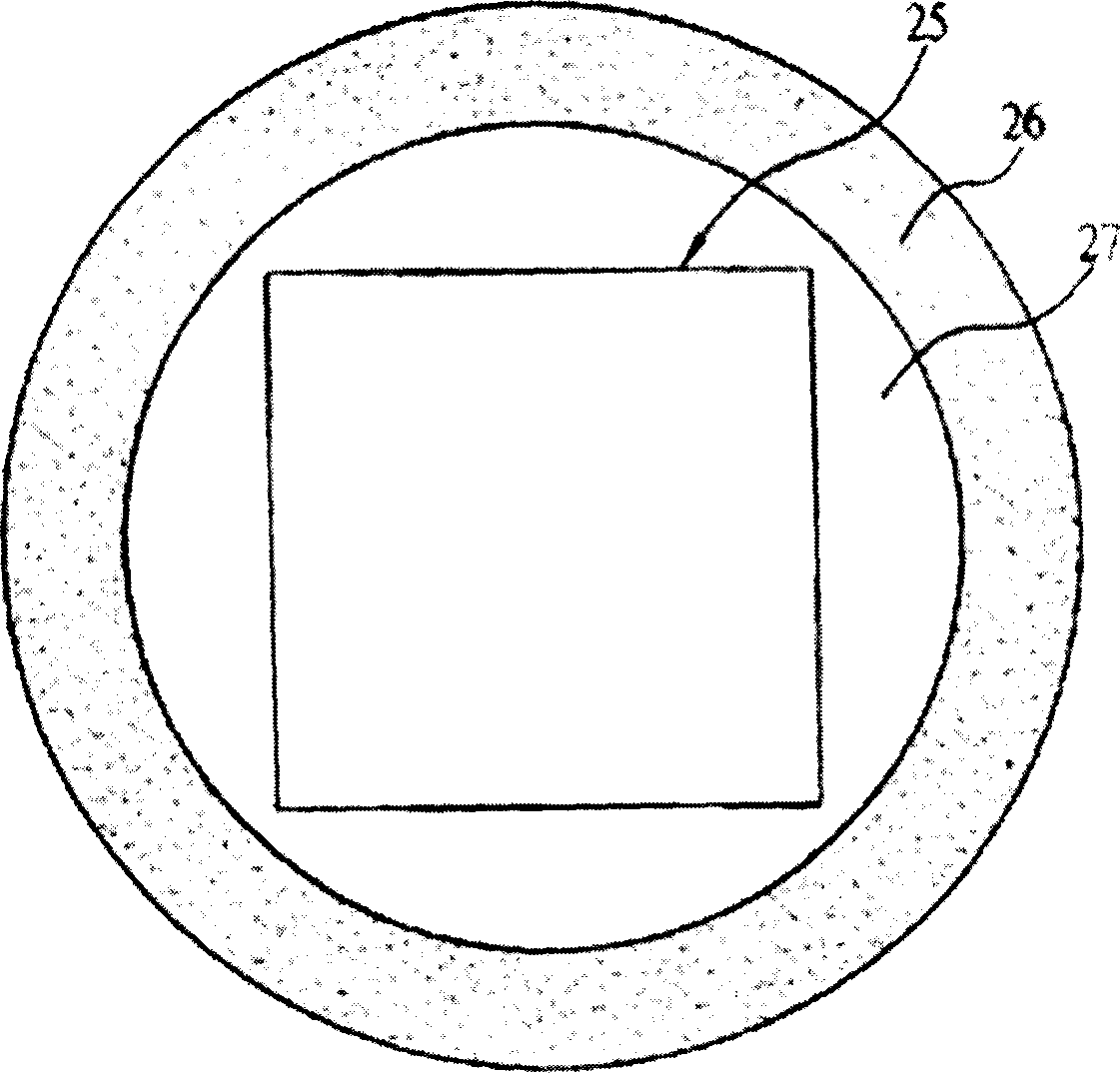

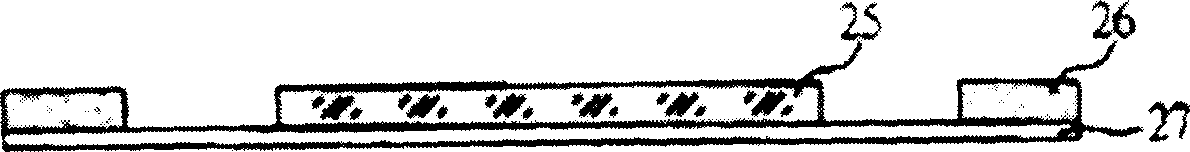

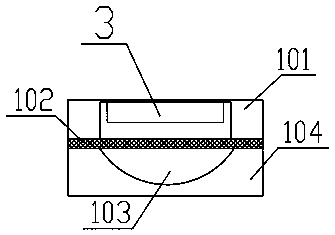

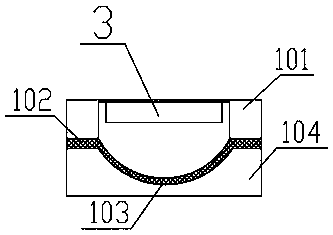

Light emitting device and sealing material

InactiveUS20050173708A1Semiconductor/solid-state device detailsSolid-state devicesRefractive indexThermal expansion

A light emitting device has: a light emitting element; a conducting portion to supply power to the light emitting element; an element housing portion that houses the light emitting element therein; and a sealing material that seals the light emitting element housed in the element housing portion. The sealing material contains a transparent resin material and a transparent filler with a thermal expansion coefficient smaller than the transparent resin material, and the transparent filler has a refractive index nearly equal to the transparent resin material.

Owner:TOYODA GOSEI CO LTD

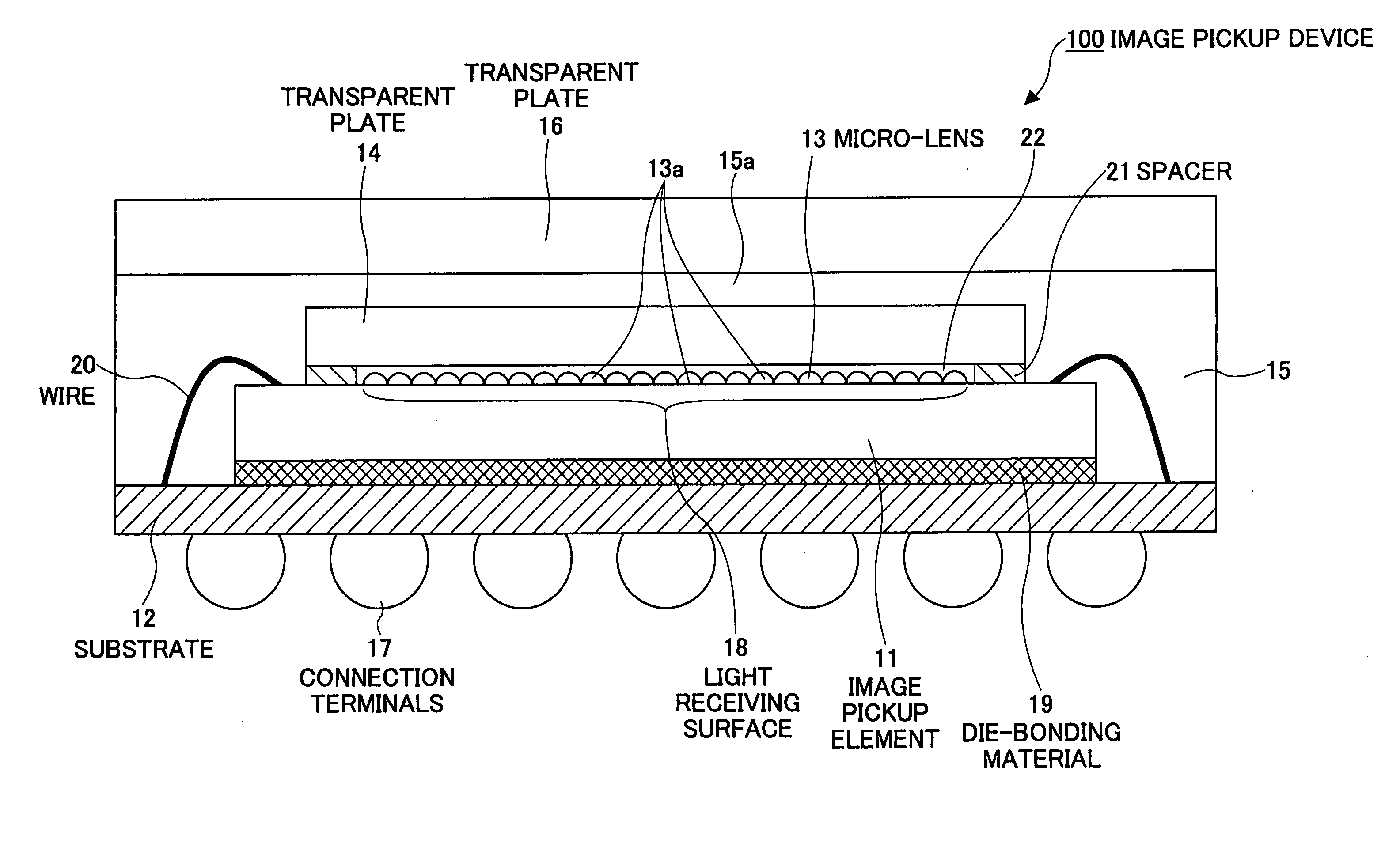

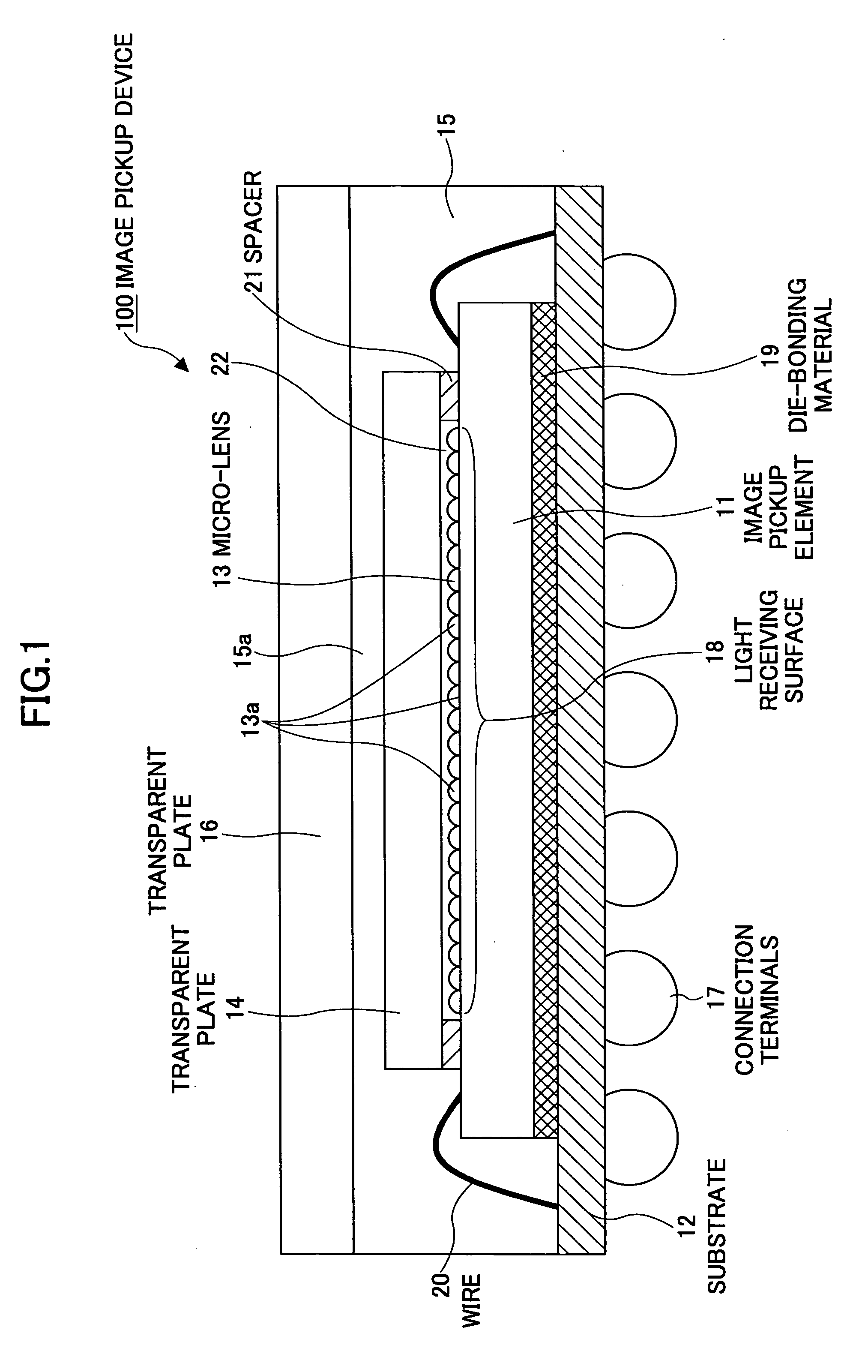

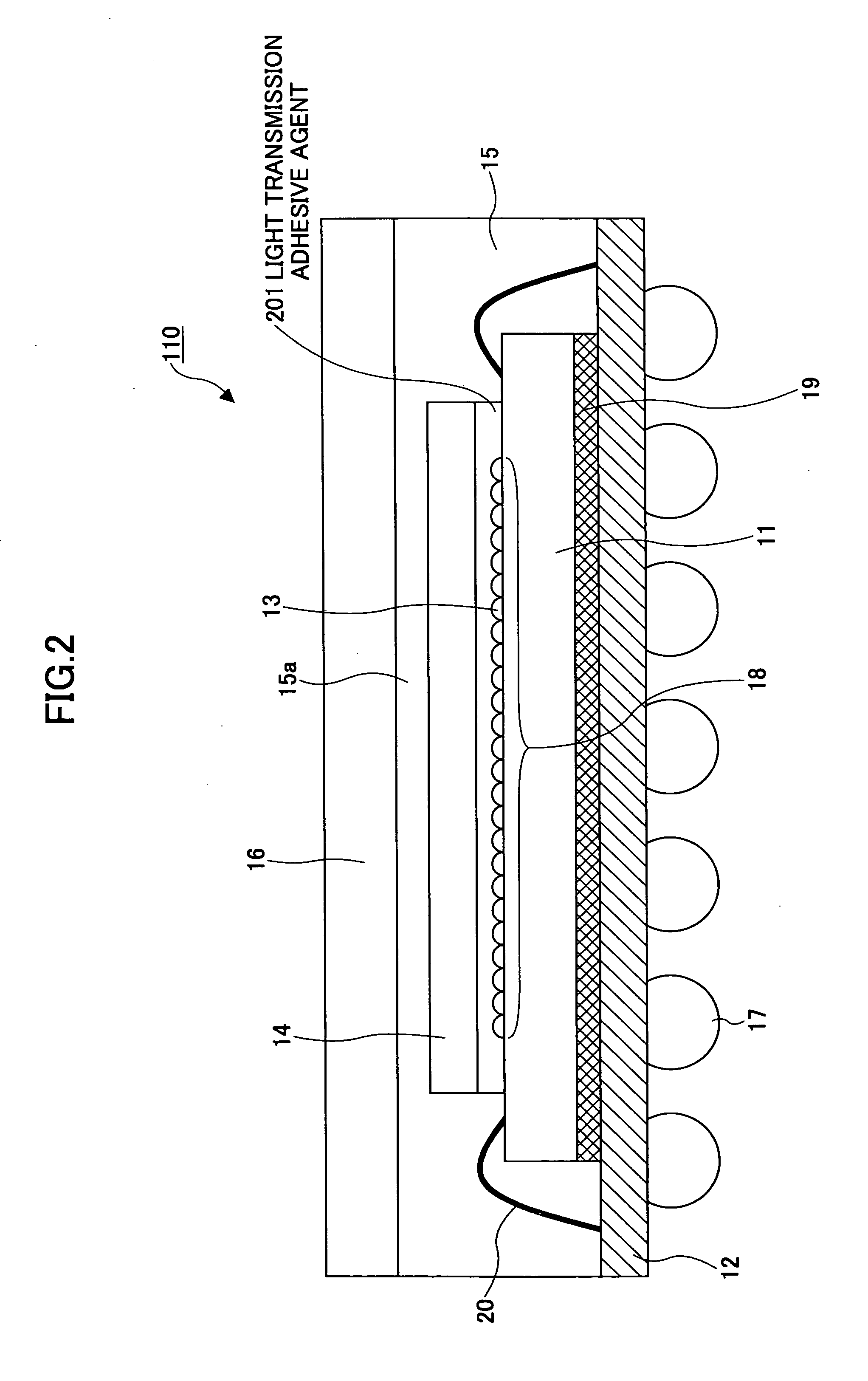

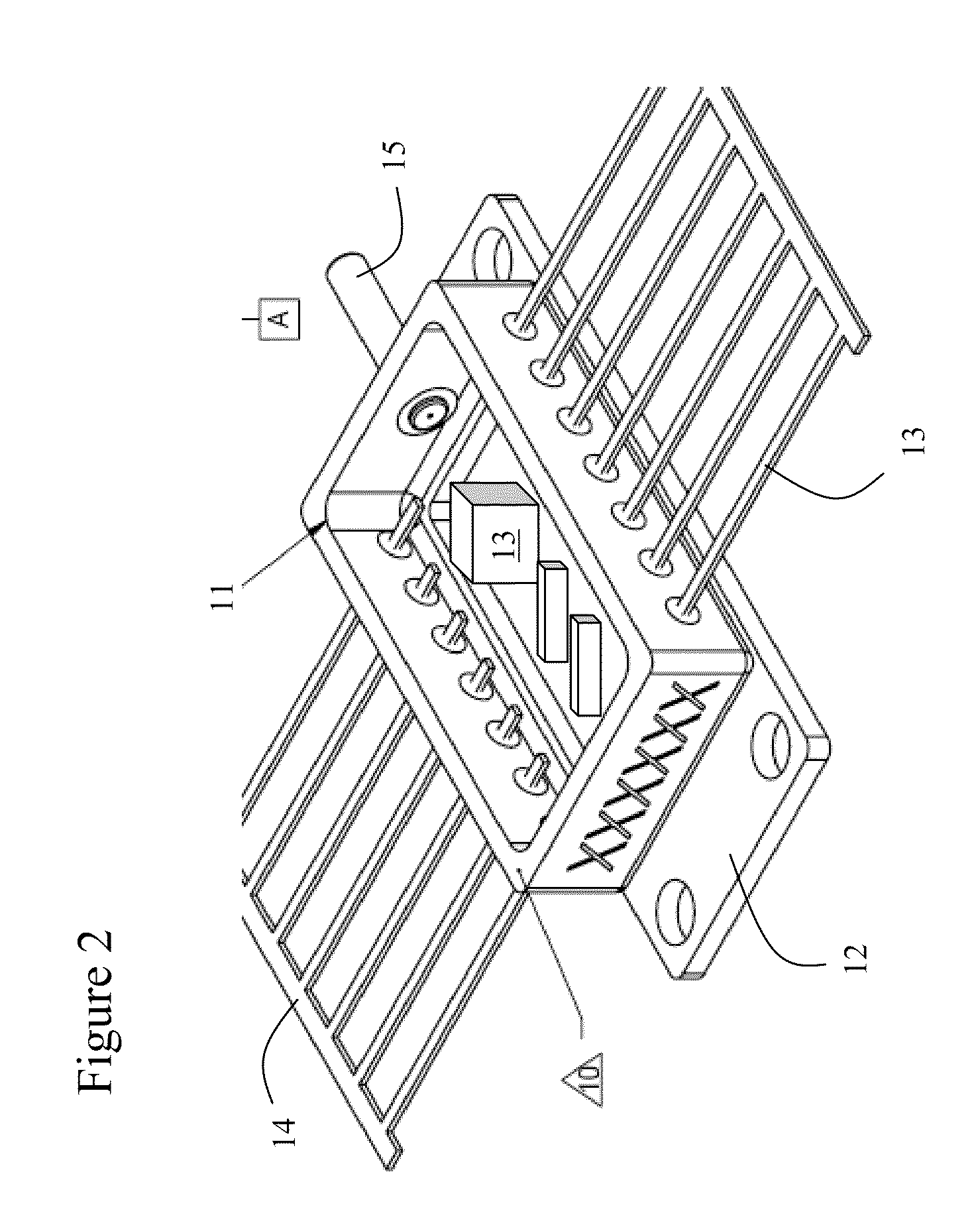

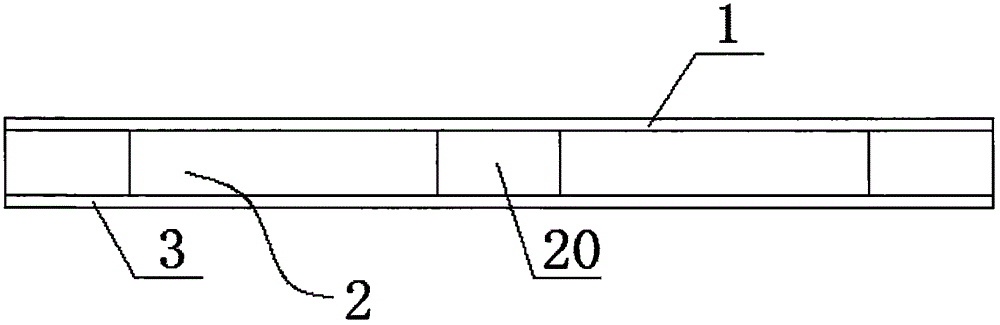

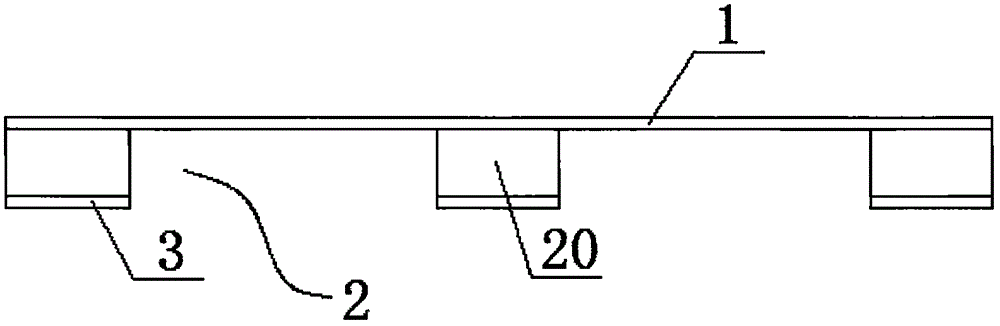

Image pickup device and production method thereof

InactiveUS20050275741A1Good lighting performanceSmall overall deformationTelevision system detailsSemiconductor/solid-state device detailsThermal expansionComputer science

Owner:SOCIONEXT INC

Aluminum-based composite material for composite pan bottom of stainless steel pan and preparation method thereof

The invention relates to an aluminum-based composite material for the composite pan bottom of a stainless steel pan and a preparation method thereof. The aluminum-based composite material consists of an aluminum-based body and reinforced particles, wherein the aluminum-based body is pure aluminum or an aluminum alloy; the reinforced particles are any one of SiC, Al2O3, B4C or SiO2 particles; the particle diameter is between 30 and 100 mu m; the volume fraction is between 5 and 30 percent; and the reinforced particles are uniformly distributed in the aluminum-based body and has good combination with the interface of the aluminum-based body. The preparation method comprises the following steps of: smelting aluminum in a resistance furnace, adding proper active elements into the resistance furnace after refining, adding a certain amount of treated particles into the resistance furnace under the protection of atmosphere, stirring, pouring and molding. A product has high specific stiffness, good composite matching with stainless steel (thermal expansion coefficient is close to that of stainless steel) and high heat conductivity; and the prepared composite pan bottom has the characteristics of light weight, difficult deformation, uniform heat transfer and the like.

Owner:NANJING TECH UNIV

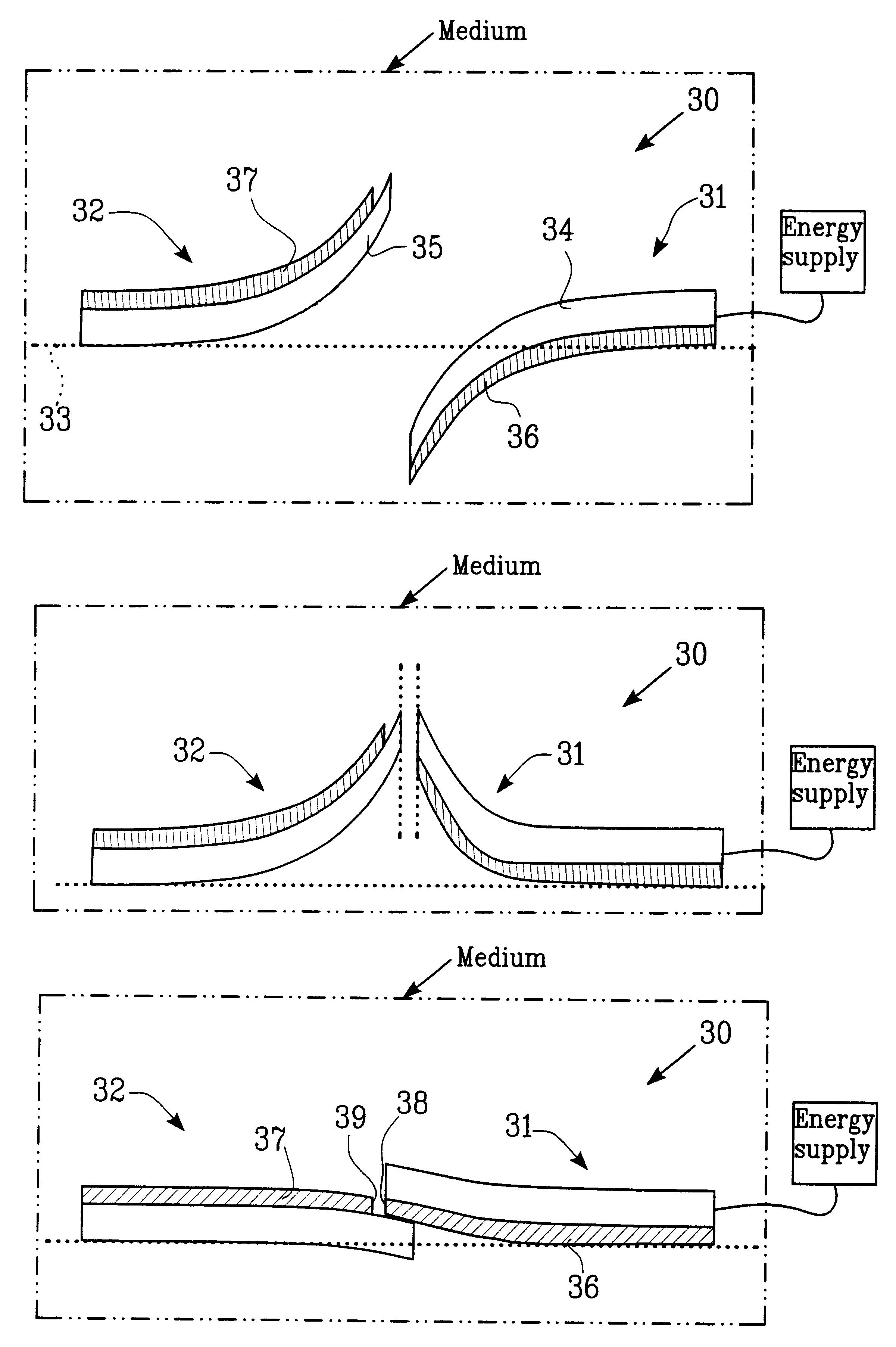

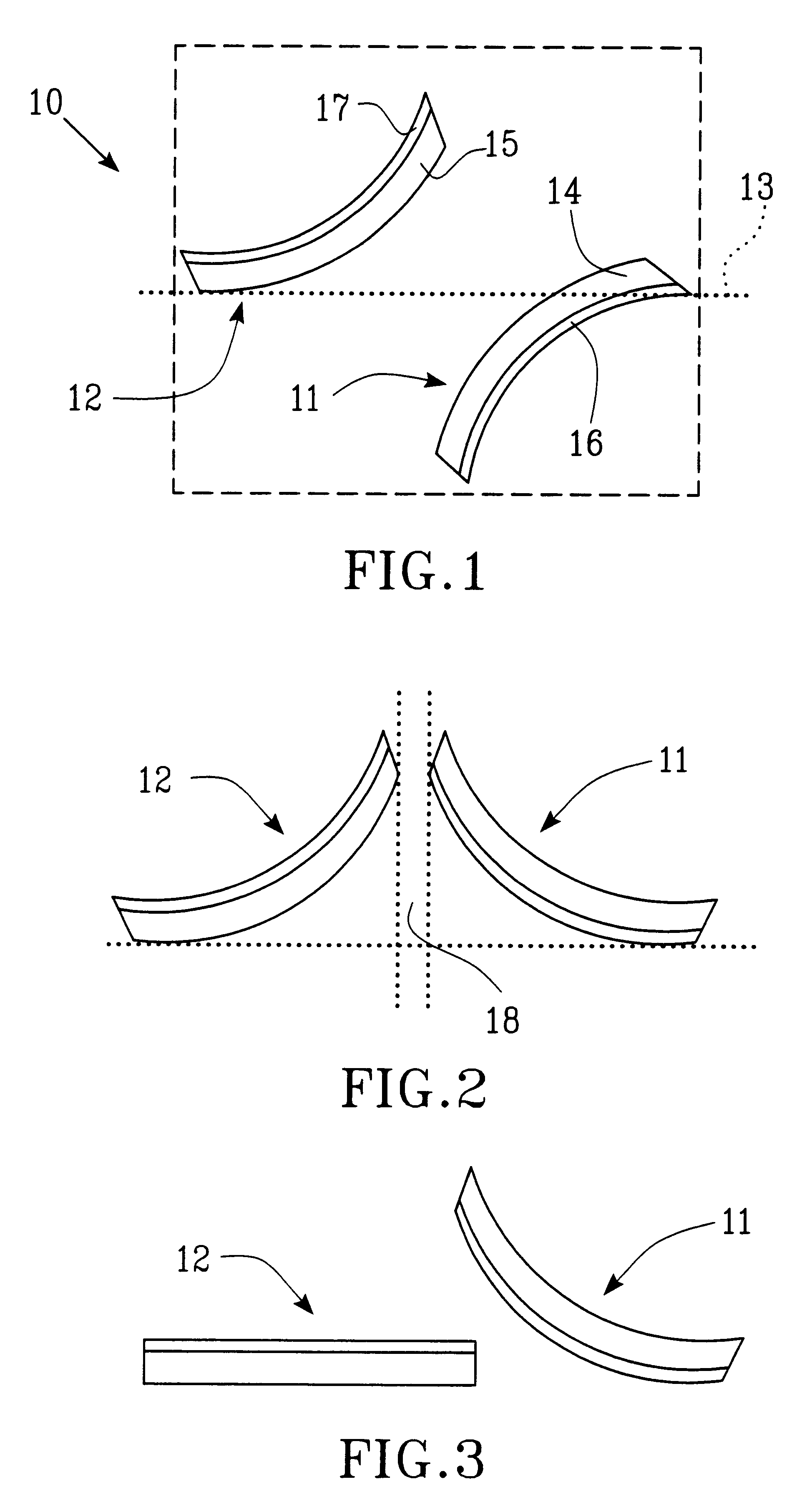

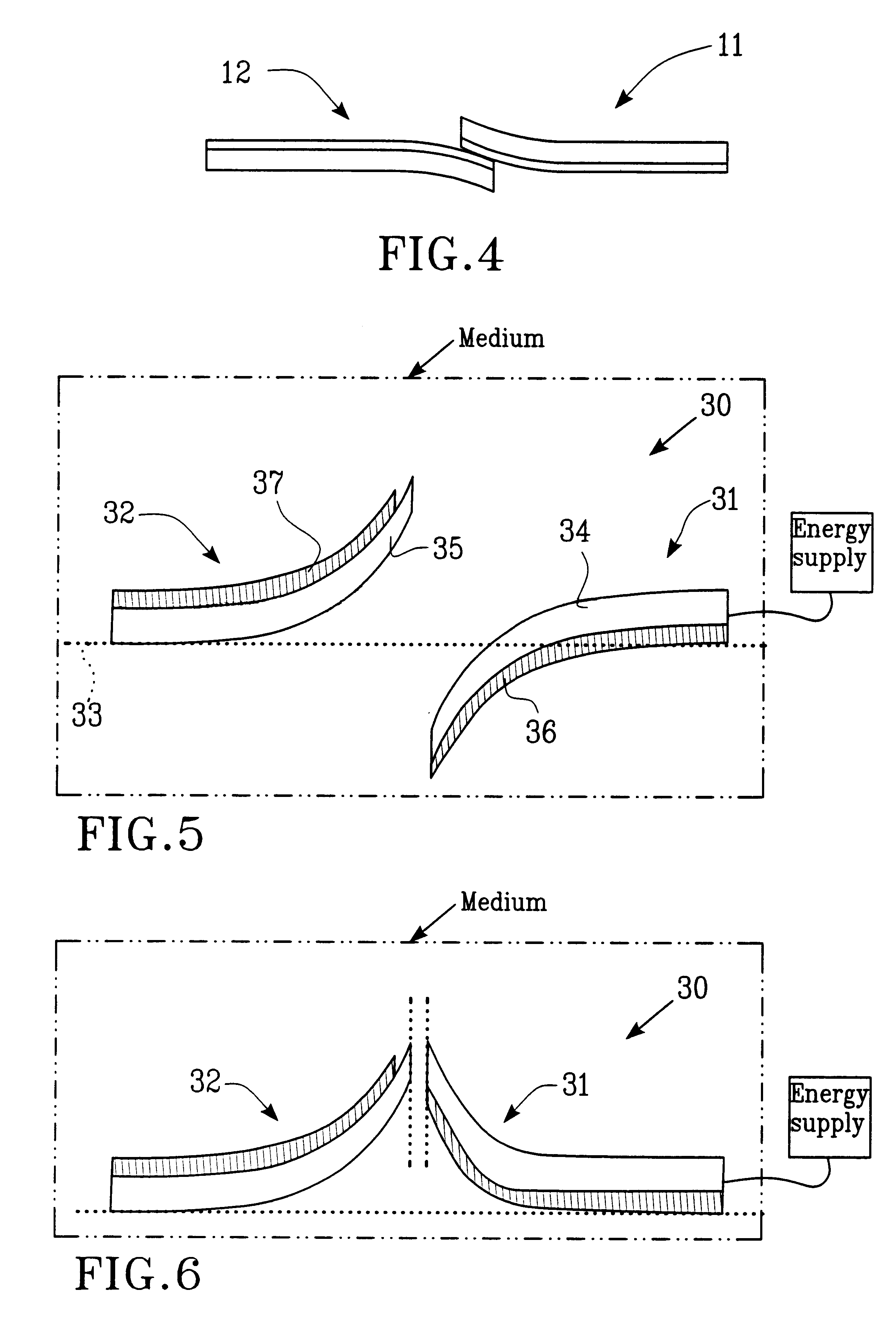

Device for micromechanical switching of signals

InactiveUS6456190B1Reduce power consumptionElectrothermal relaysThermal micromechanical switchesEngineeringThermal expansion

Owner:IMEGO

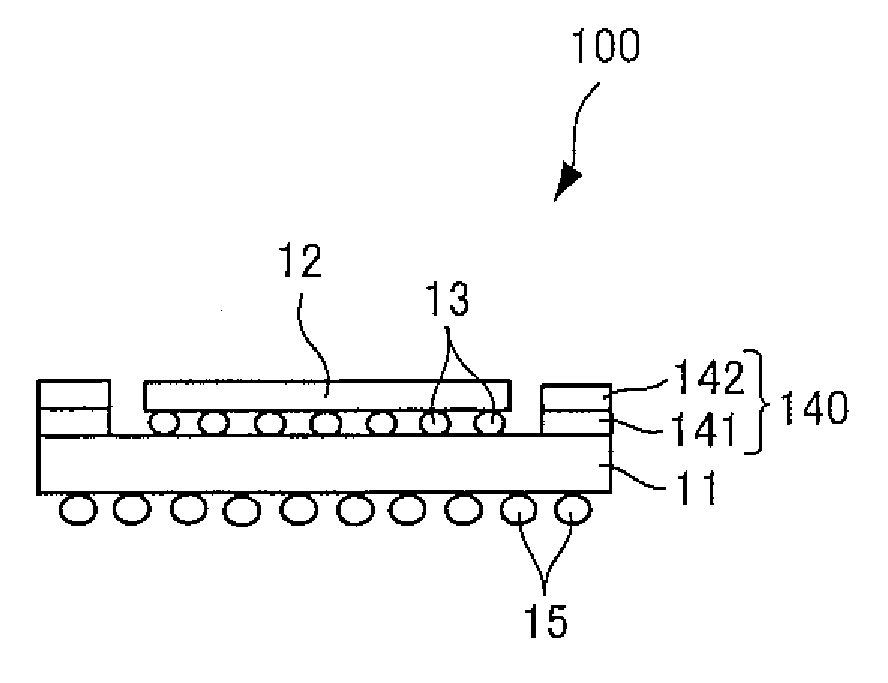

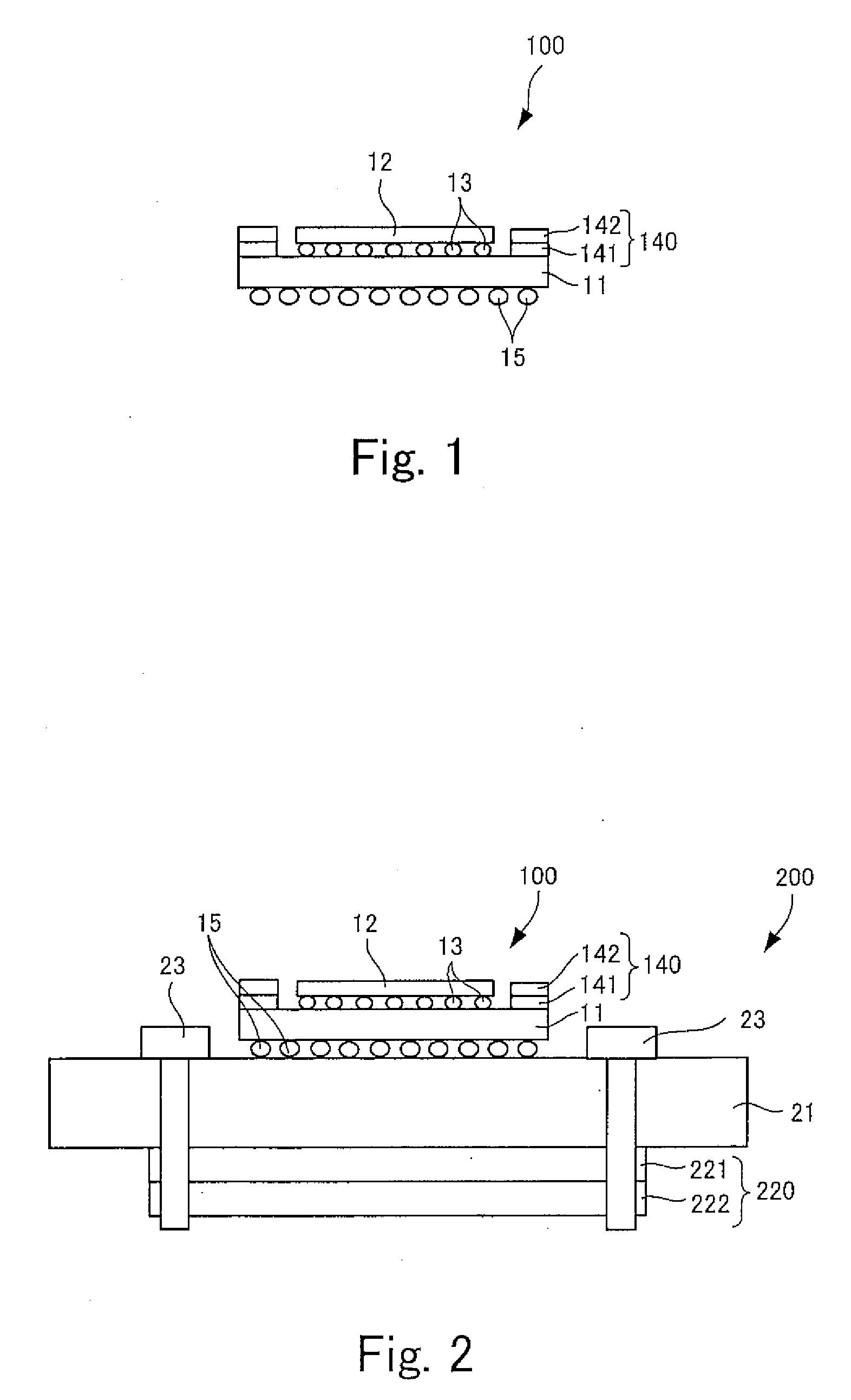

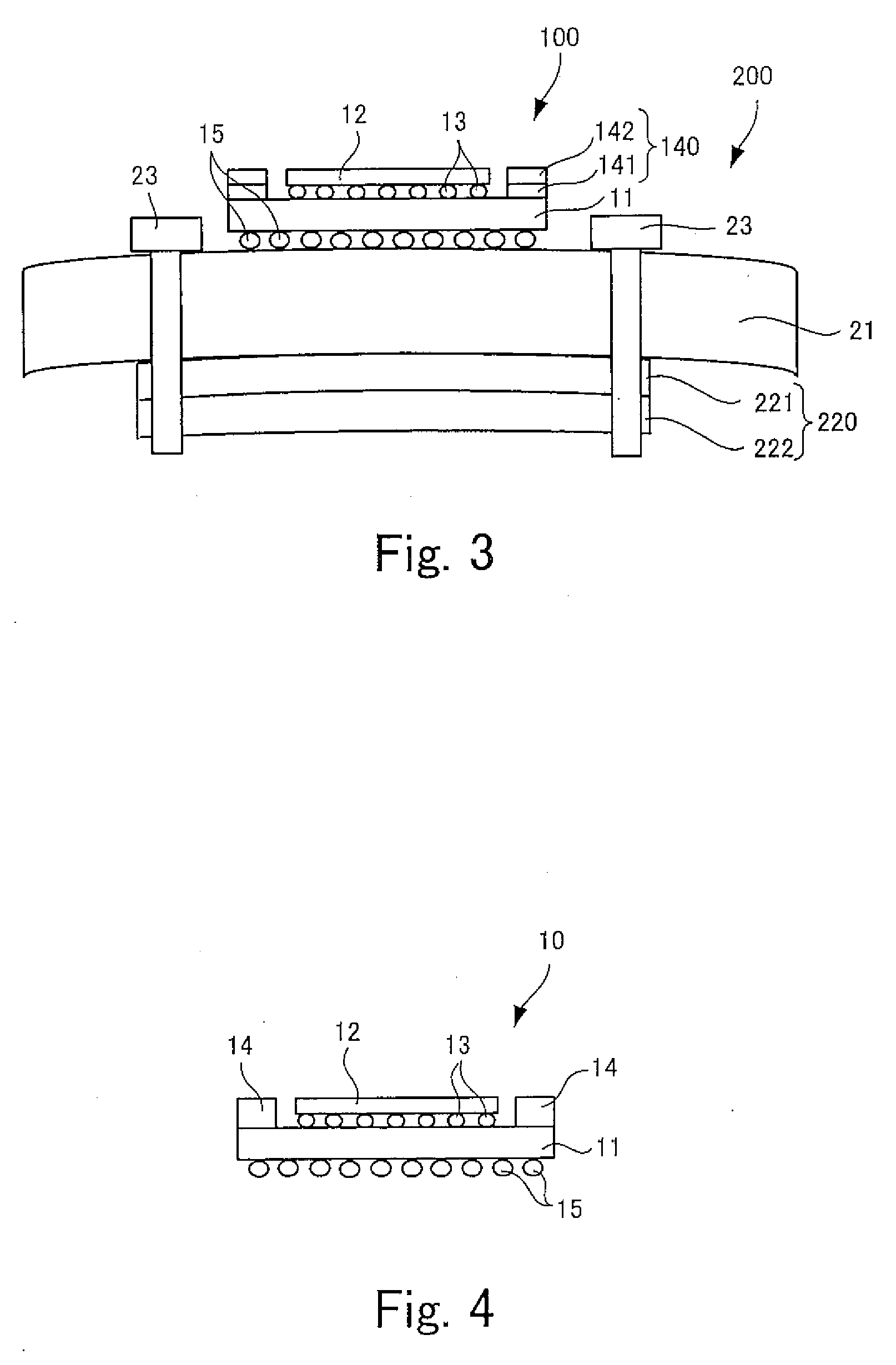

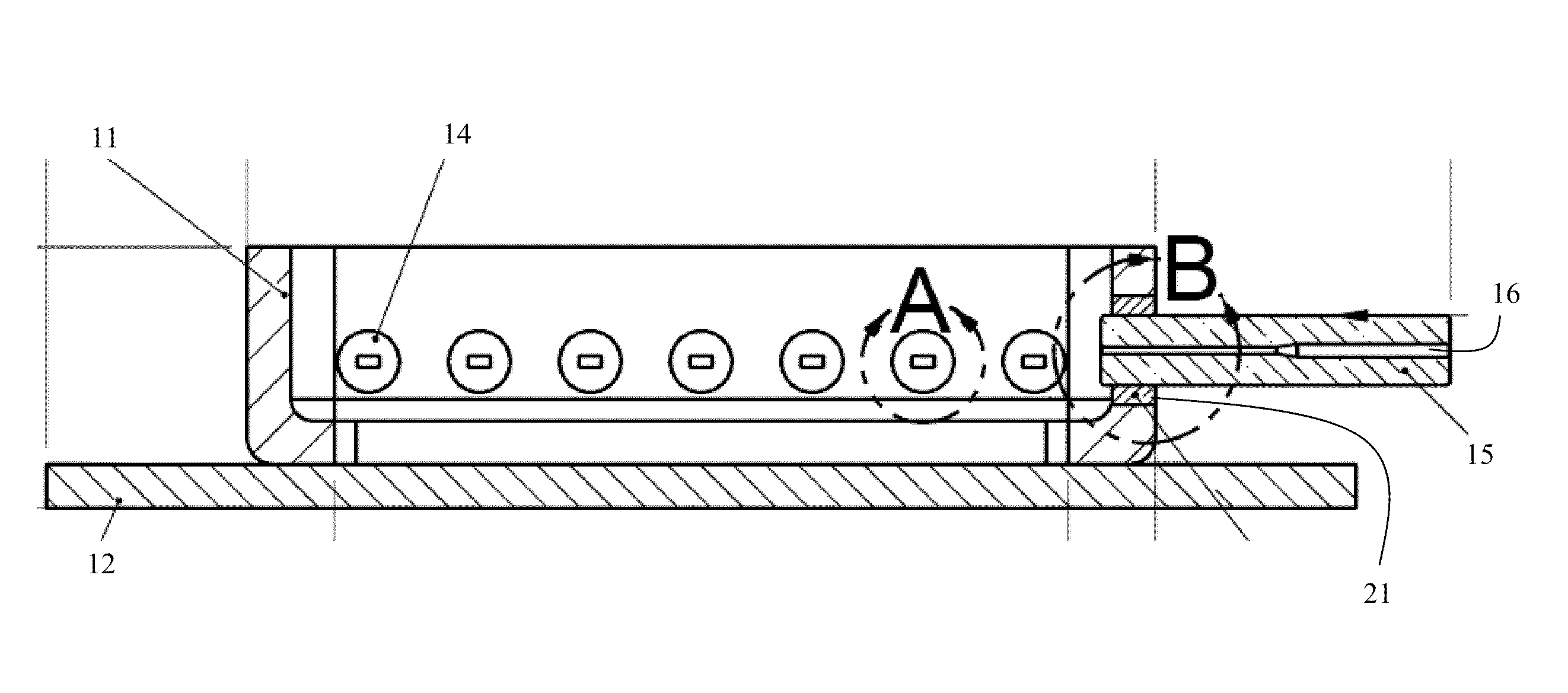

Package mounted module and package board module

InactiveUS20070278647A1Relieve stressMaintain reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:FUJITSU LTD

Optical module with fiber feedthrough

Owner:LUMENTUM OPERATIONS LLC

Non-alkali glass and method for producing same

The present invention relates to a non-alkali glass having a strain point of from 710° C. to lower than 725° C., an average thermal expansion coefficient at from 50 to 300° C. of from 30×107 to 43×10−7 / ° C., a temperature T2 at which glass viscosity reaches 102dPa.s of 1710° C. or lower, a temperature T4 at which the glass viscosity reaches 104 dPd.s of 1320° C. or lower, and containing, indicated by mol % on the basis of oxides, SiO2 66 to 70, Al2O3 12 to 14, B2O3 exceeding 0 to 1.5, MgO exceeding 9.5 to 13 (or 5 to 9.5), CaO 4 to 9 (or 4 to 11), SrO 0.5 to 4.5, BaO 0 to 0.5 and ZrO 0 to 2.

Owner:AGC INC

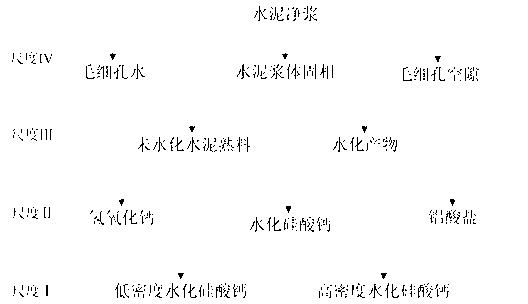

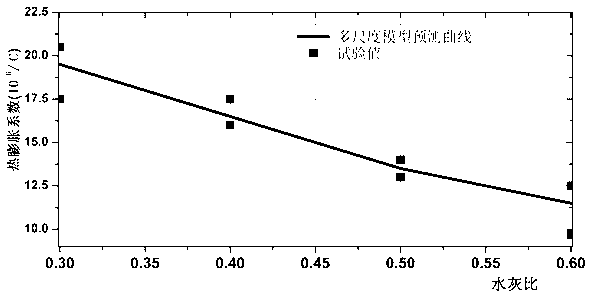

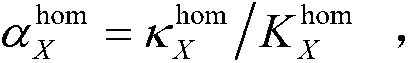

Hardened ordinary cement paste thermal expansion coefficient multiscale predication method

InactiveCN103105485ASolve the many factors affecting macro performanceSolve the problem of large dispersion of test dataMaterial testing goodsPredictive methodsThermal expansion

Owner:HOHAI UNIV

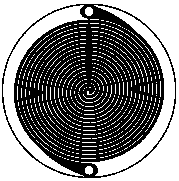

Image sensor package, optical glass therefor and processing method

InactiveCN1905140AEnsuring the ability to receive optical signalsPrevent intrusionSemiconductor/solid-state device detailsFinal product manufactureRough surfaceOptoelectronics

Owner:SILICONWARE PRECISION IND CO LTD

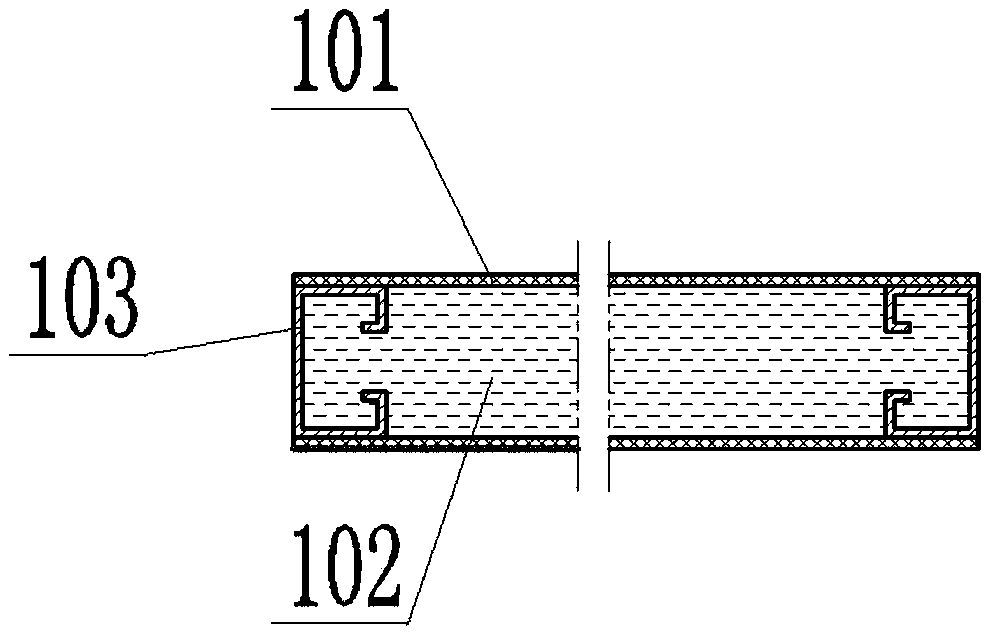

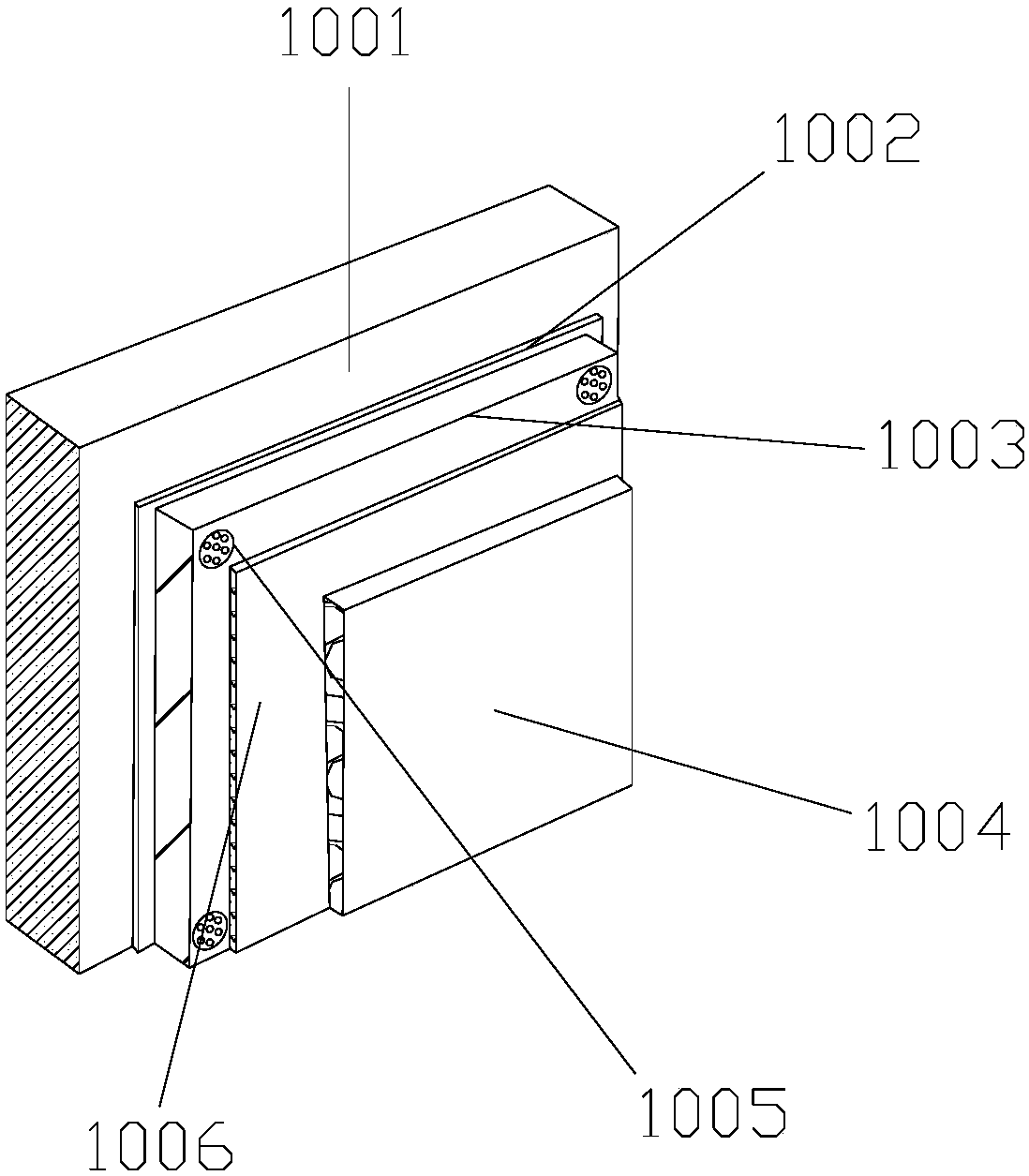

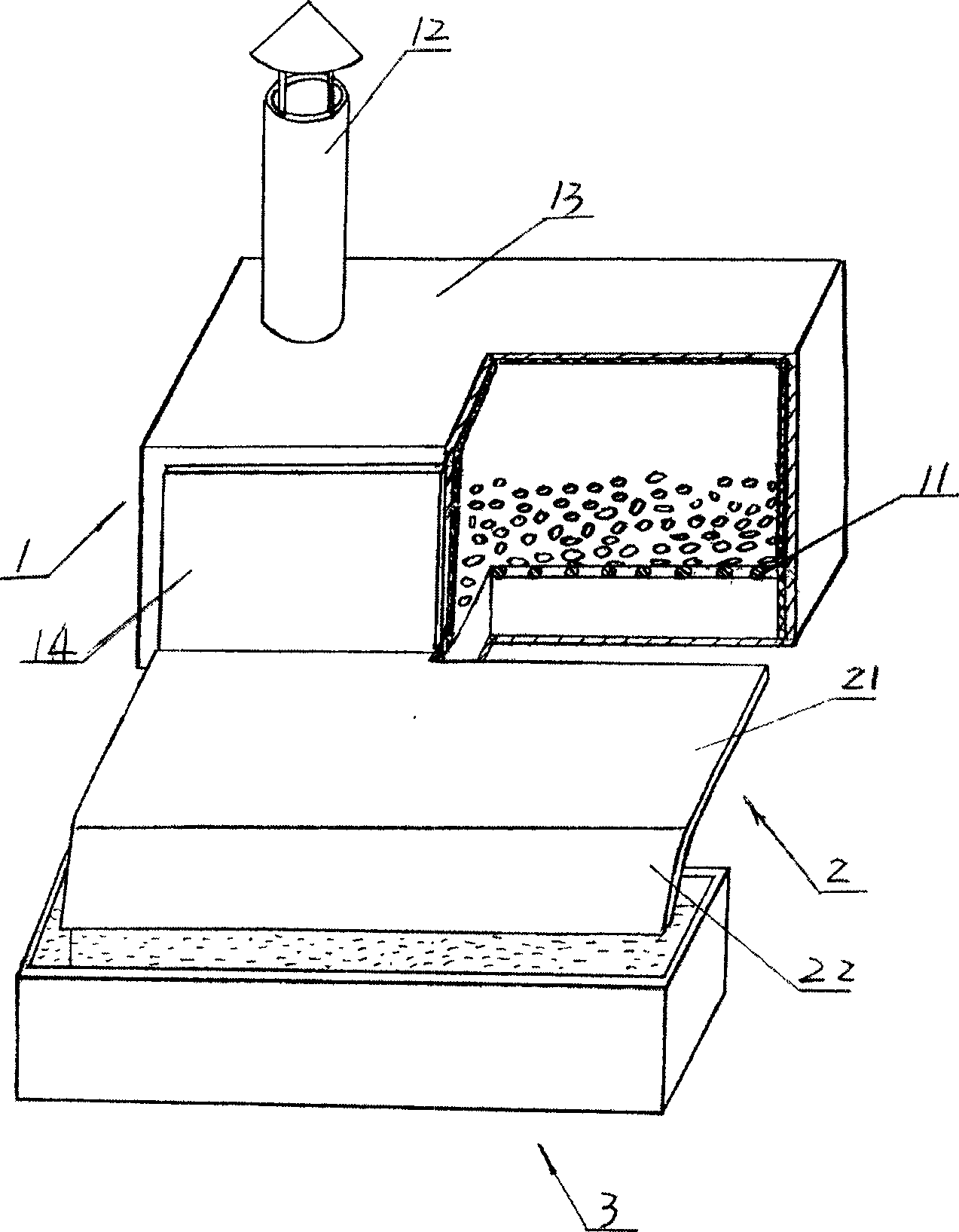

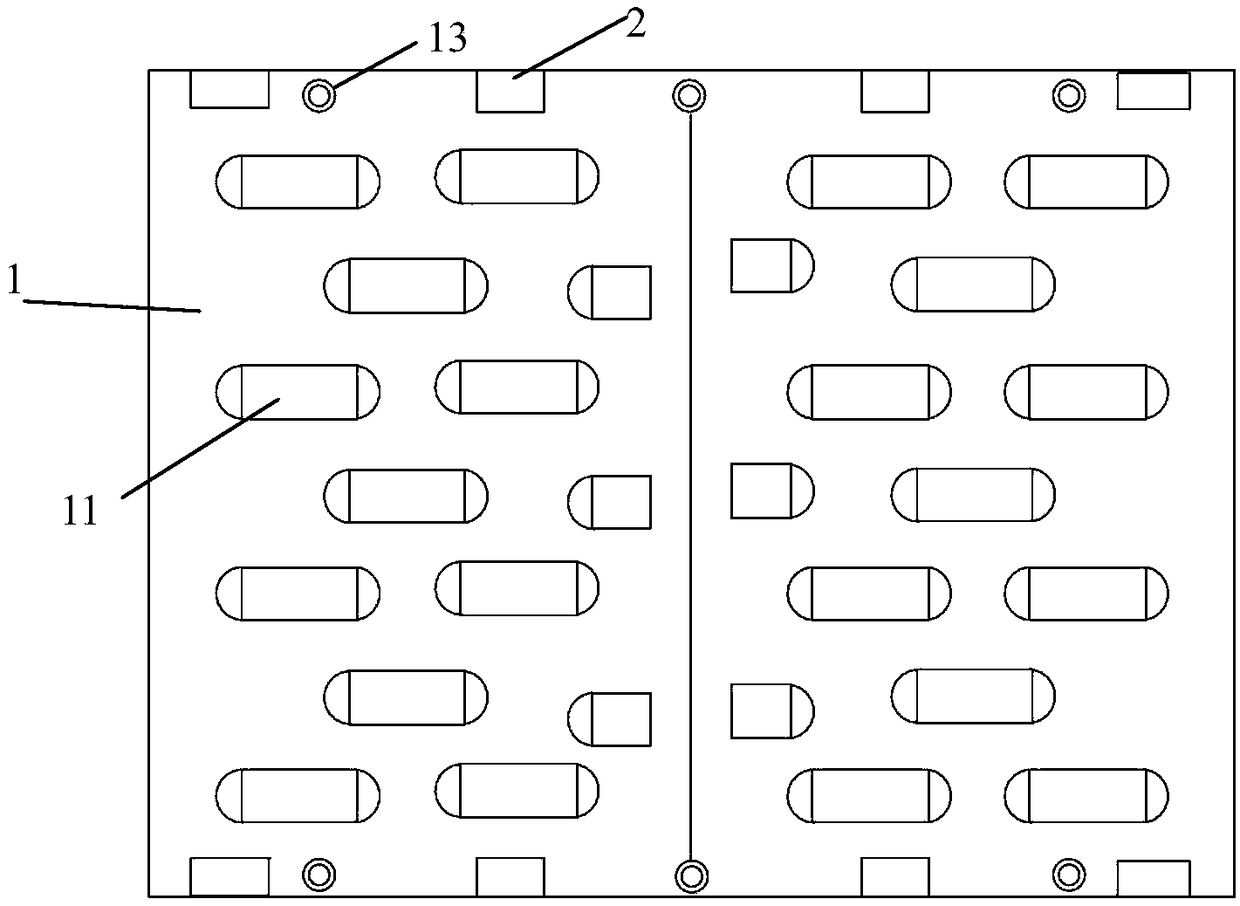

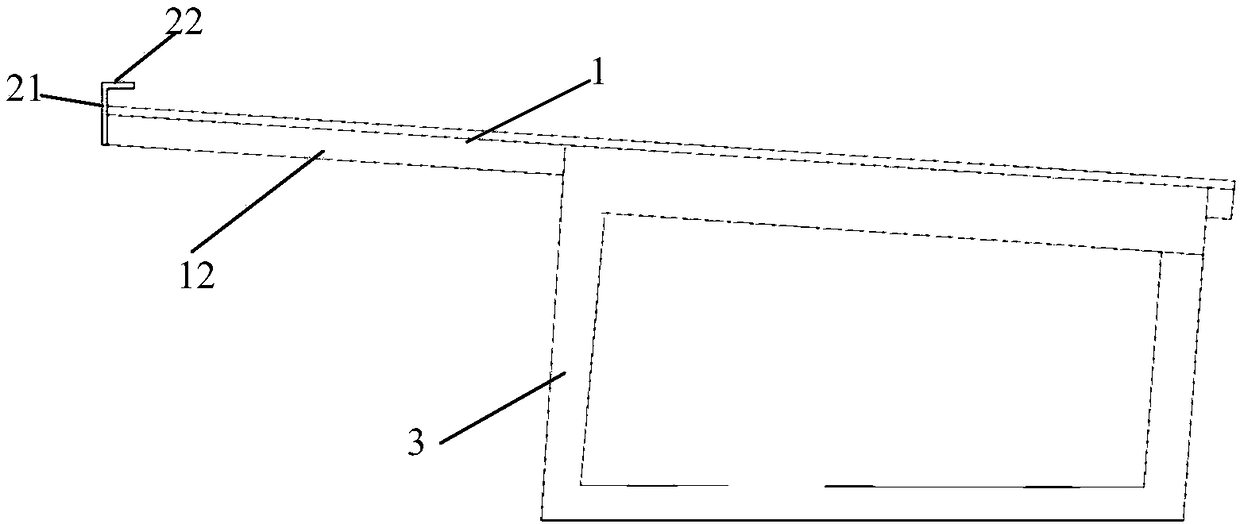

Laminating device and method applied to large-size battery assembly

PendingCN110370778ADistribute stressReduce shockLaminationLamination apparatusElectrical batteryThermal expansion

The invention relates to a laminating device and method applied to a large-size battery assembly. The laminating device comprises a laminating cavity, a curing cavity, pre-cooling cavities and a cooling cavity which are connected sequentially, and the temperature in the pre-cooling cavities is higher than the temperature in the cooling cavity; and in the laminating process, the assembly is sequentially subjected to the four steps of laminating, curing, pre-cooling and cooling, wherein in the pre-cooling process, the assembly is cooled from 130-160 DEG C to 50-80 DEG C firstly and then placed into the cooling cavity to be cooled to 20-50 DEG C. The laminating device and method have the beneficial effects that the laminating device including the one or more pre-cooling cavities is adopted, through a stepped cooling method, the influences of quick cooling on large-size battery pieces are reduced, stress, caused by thermal expansion and cold contraction phenomena in the cooling process, ofthe surface of a silicon wafer is dispersed, impact borne by the surfaces of the battery pieces is buffered, the phenomena of laminating fragments and subfissure of the battery pieces are obviously reduced, the efficiency of assembly preparation is improved, and the qualified rate of assembly preparation is increased.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

Thermal expansion valve

InactiveCN101988585AAvoid shakingAvoid throttling differencesOperating means/releasing devices for valvesValve members for absorbing fluid energyThermal expansionEngineering

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

PCB non-metallic material steel-plastic compound plate tray, preparing production line and preparing method

InactiveCN106005678AHigh tensile strengthImprove bending abilityPackage recyclingDomestic articlesProduction lineShrinkage rate

Owner:王传华

Microfluidic chip and microfluidic drive and control system thereof

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

Method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions

ActiveCN106316397AHigh purityQuality improvementLayered productsCooling/ventilation/heating modificationsHeat conductingGranularity

The invention discloses a method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions. The method includes the steps of raw material preparing, pre-crushing, pre-screening, deironing, secondary crushing, secondary screening, mixing, profiling and heating, graphitizing at high temperature, back film preparing, heat conducting tank pressing and cutting. The machining process is scientific and reasonable in step, the machining process in the prior art is improved, the raw material is processed in a refined mode, the granularity of the graphite flakes is more uniform, the qualification rate of the finished product is increased, and electrical conductivity and heat conductivity of the heat conducting graphite flakes are improved; by means of the process, the chemical stability of the graphite flakes can be improved, thermal expansion is reduced, and the graphite flakes are easy to machine and shape.

Owner:DONGGUAN KAIDI CARBON CO LTD

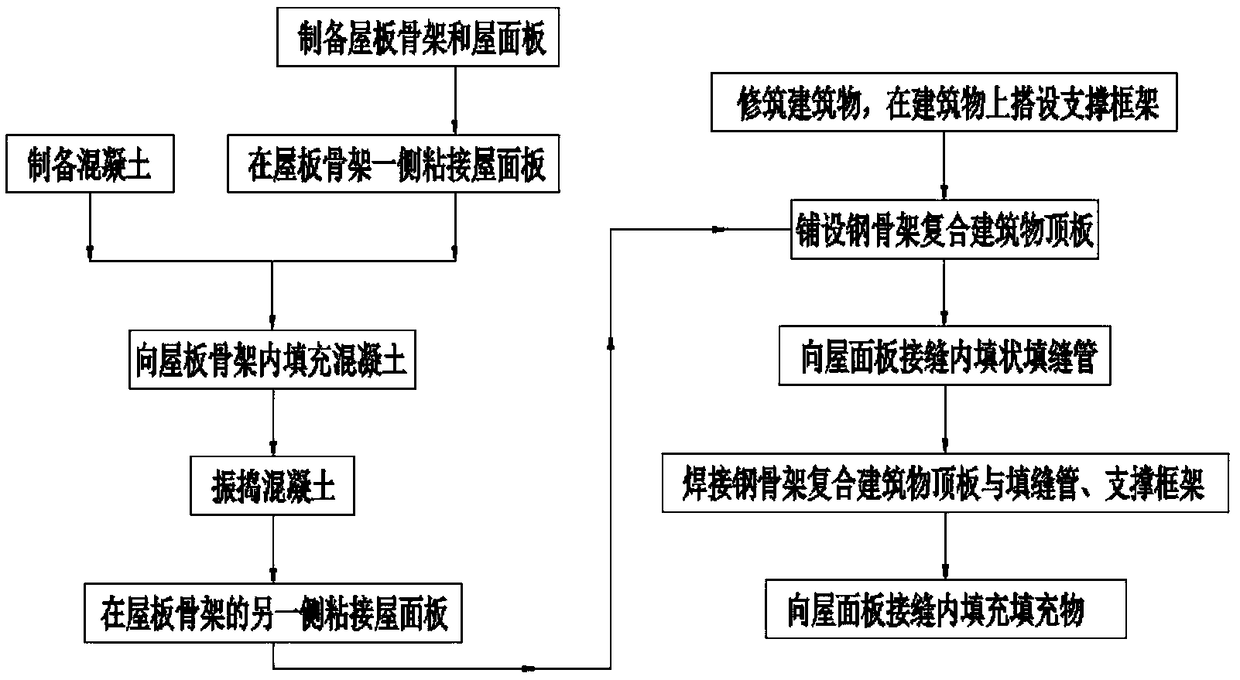

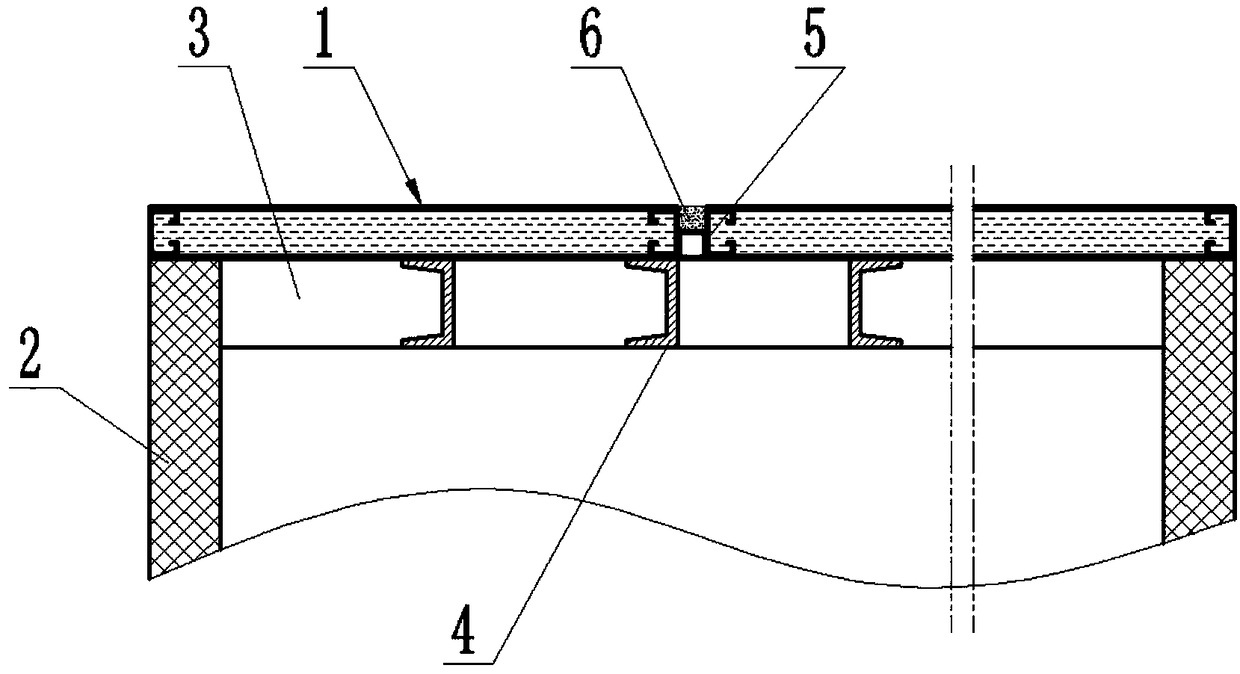

Paving construction process for roofs of steel framework composite building

ActiveCN108824810AUniform and consistent expansionSame expansion rateBuilding material handlingBraced frameArchitectural engineering

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

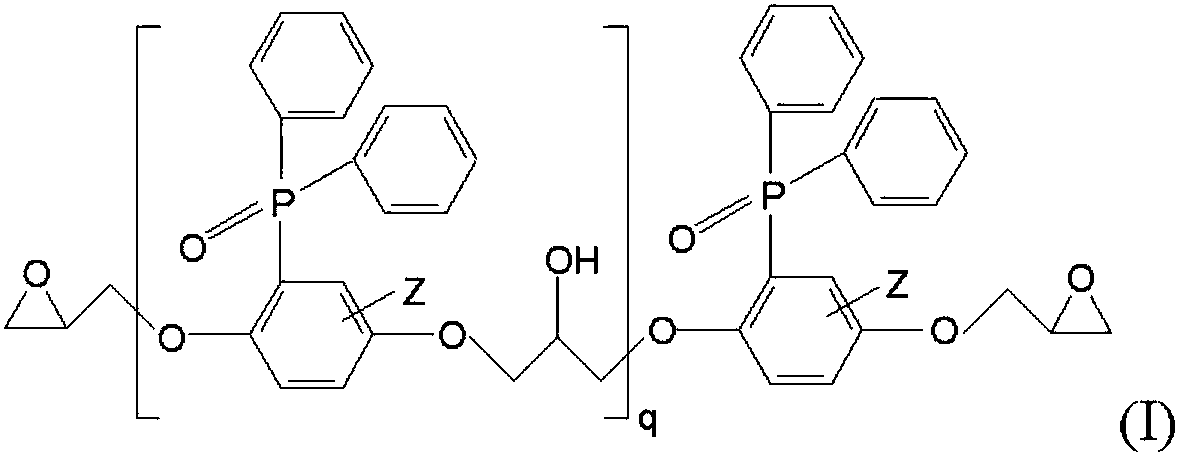

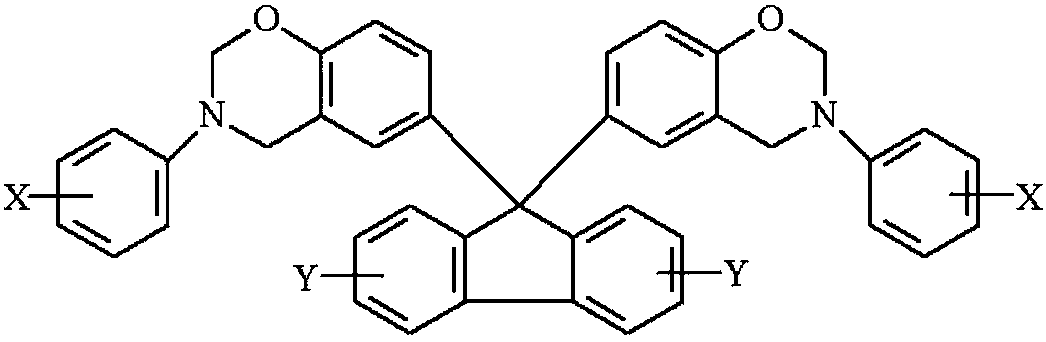

Halogen free thermosetting resin composition, and prepreg, laminated board, metal foil layer-coated laminated board and printed circuit board using halogen free thermosetting resin composition

ActiveCN108192281ALow water absorptionImprove heat resistanceLaminationLamination apparatusEpoxyMetal foil

Owner:江西生益科技有限公司

Flat ceramic membrane formulation carrying nano copper oxide and preparation method thereof

The invention a flat ceramic membrane formulation carrying nano copper oxide and a preparation method thereof. The flat ceramic membrane comprises a carrier and a separation membrane layer; the carrier incudes a main materials and auxiliary materials; the main materials of the carrier include one or more of alumina, mullite, dolomite, and bauxite; the auxiliary materials of the carrier include a sintering aid, a plasticizer, a pore-forming agent and a binder; the separation membrane layer is made with adhesive, nano copper oxide particles, a dispersing agent and a plasticizer. The flat ceramicmembrane carrying nano copper oxide has the advantages that the materials of the carrier are simple and easily accessible, the materials have antibacterial and catalytic functions, the pore size is flexibly controllable, and the materials have good features, such as excellent mechanical properties and low thermal expansion coefficient.

Owner:CHANGZHOU SUNAN WATER ENVIRONMENT RES INST CO LTD

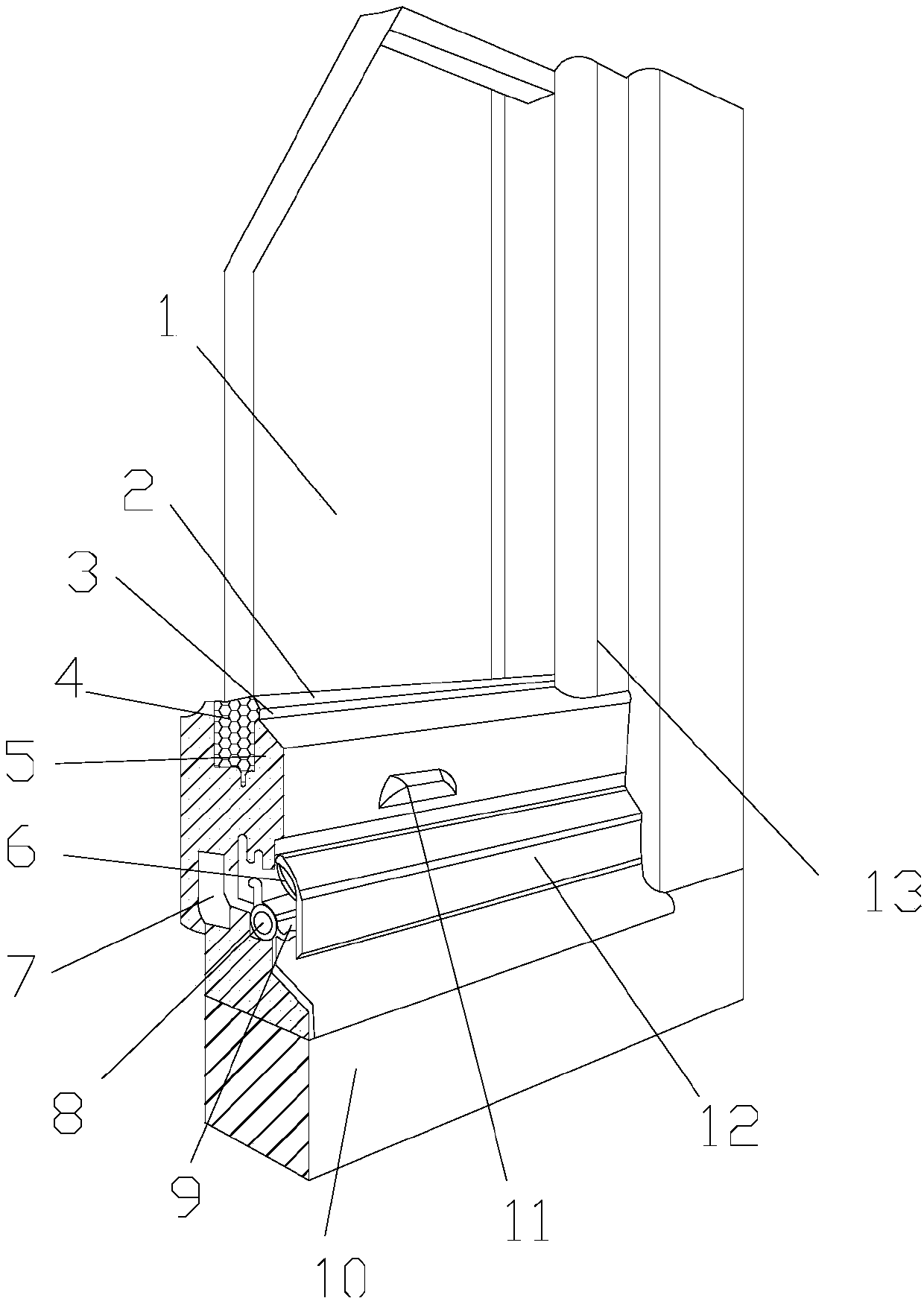

Aluminum alloy window mounting structure

InactiveCN107724865AReduce maintenanceAvoid breakingWindow/door framesCondensed water drain-offAluminum canMoisture permeation

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

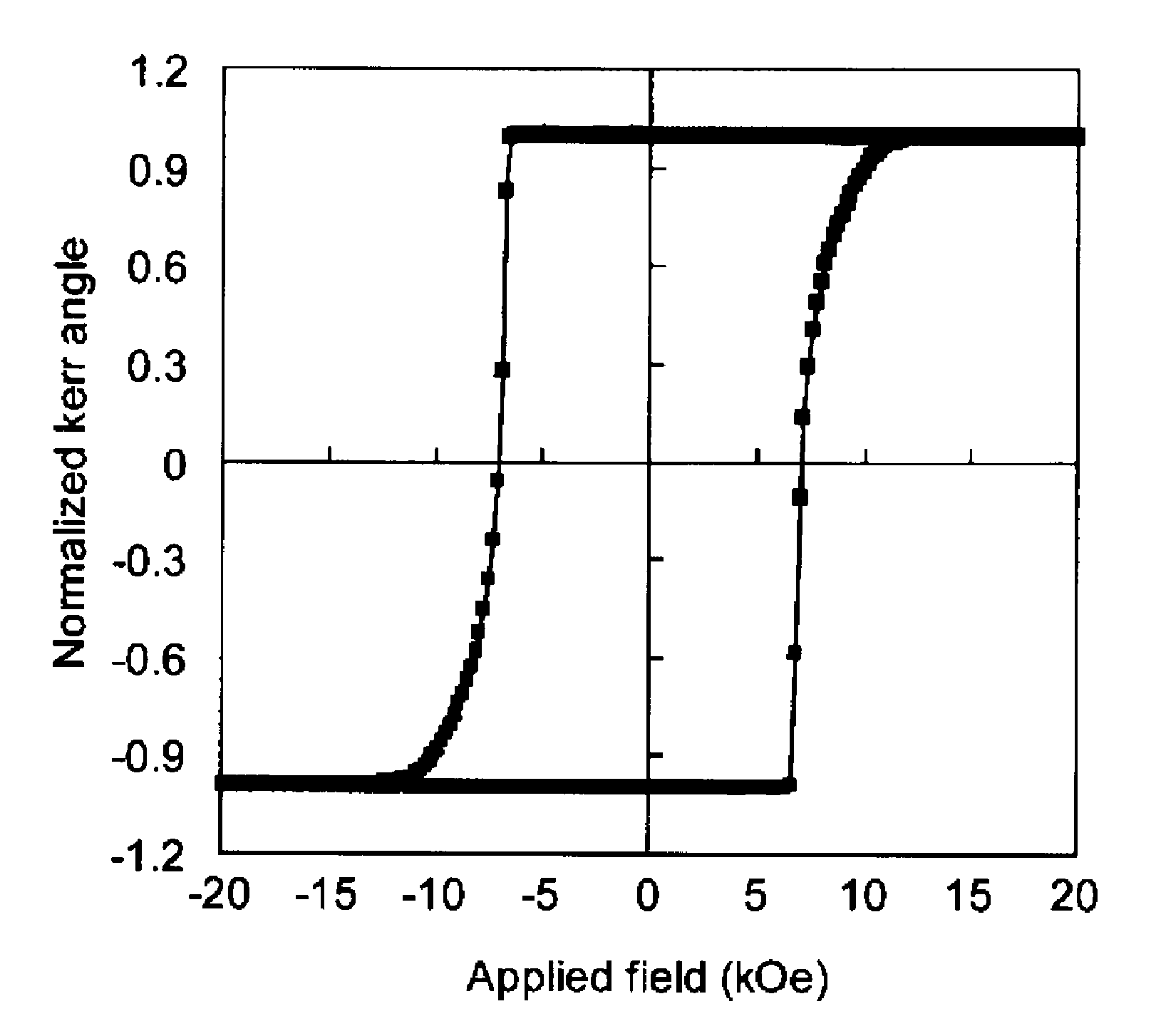

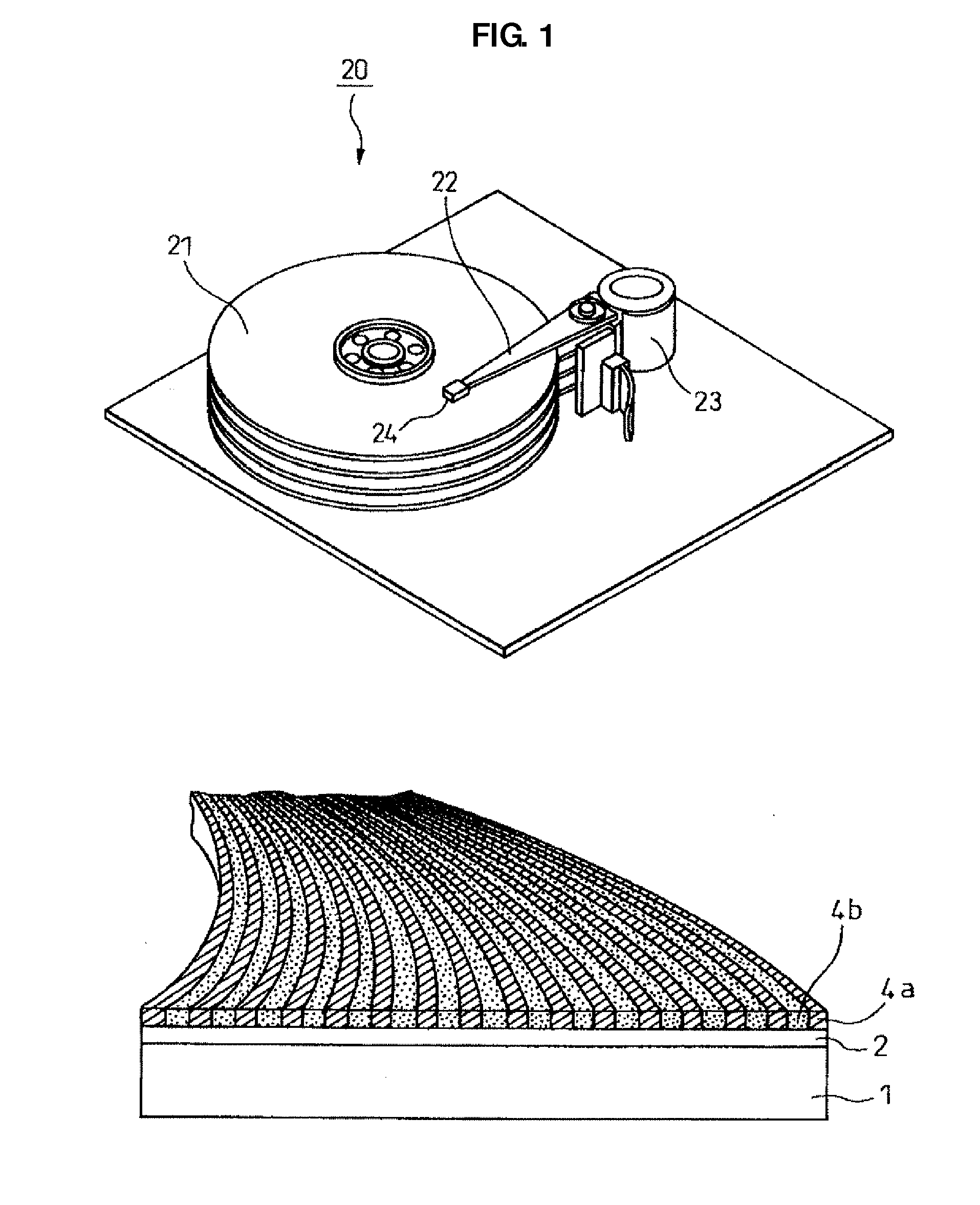

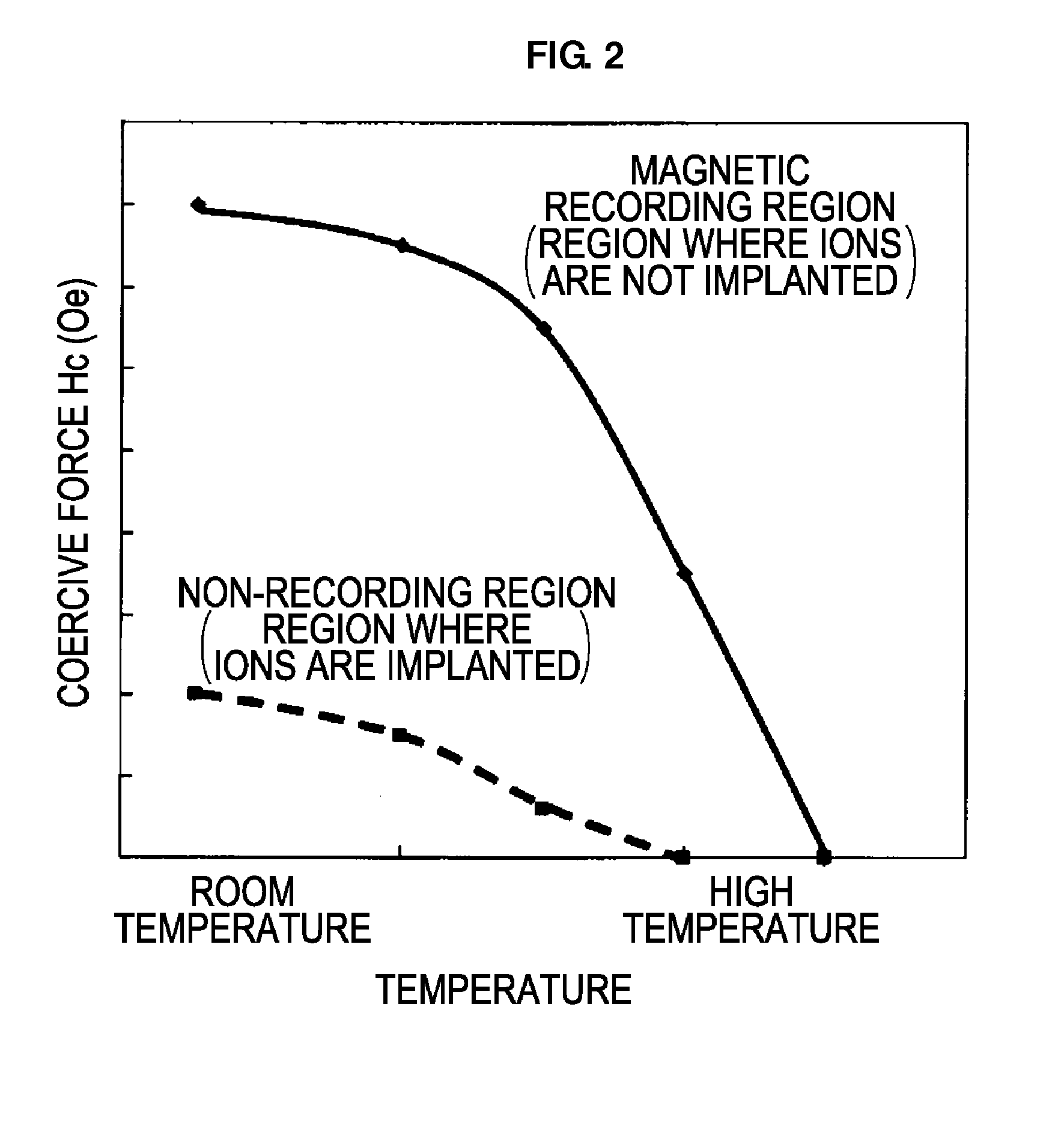

Thermally Assisted Magnetic Recording Disk, Manufacturing Method Thereof, And Magnetic Recording Method

ActiveUS20120075740A1Low coercivitySmall coercive forceNanoinformaticsPatterned record carriersHeat-assisted magnetic recordingCurie temperature

Owner:WESTERN DIGITAL TECH INC

Semi-automatic sample feeding needle

ActiveCN109452985AAvoid thermal expansion and contractionAutomatic syringesMedical devicesMedicineSemi automatic

The invention discloses a semi-automatic sample feeding needle, which comprises a needle tube, a needle head and a cylinder-shaped body, wherein one end of the needle tube is connected with the needlehead, the other end of the needle tube is connected with the cylinder-shaped body, the outside of the cylinder-shaped body is connected with an upper quick pressing rod through a balance bracket, thequick pressing rod is arranged above the needle tube and the cylinder-shaped body and is parallel to the needle tube and the cylinder-shaped body, the front end of the quick pressing rod is providedwith a braking spring which acts downwards on the outer wall of the cylinder-shaped body, the rear end of the quick pressing rod is provided with a speed regulating guide rod, the lower end of the speed regulating guide rod acts on the inner side of the cylinder-shaped body, and the cylinder-shaped body is internally provided with a liquid quantity pull rod used for drawing liquid medicine. The needle is a semi-automatic sample feeding needle and can trigger a device to quickly feed samples after the needle is inserted, hands do not directly contact the tube wall, and the reagent can be prevented from expanding with heat and contracting with cold. The semi-automatic sample feeding needle can be used, by one researcher, to independently complete the fixed-point, positioning, fixed-speed andquantitative medicine feeding operation for an animal experiment body.

Owner:JIANGSU FANBANG SEMICON MATERIAL TECH CO LTD

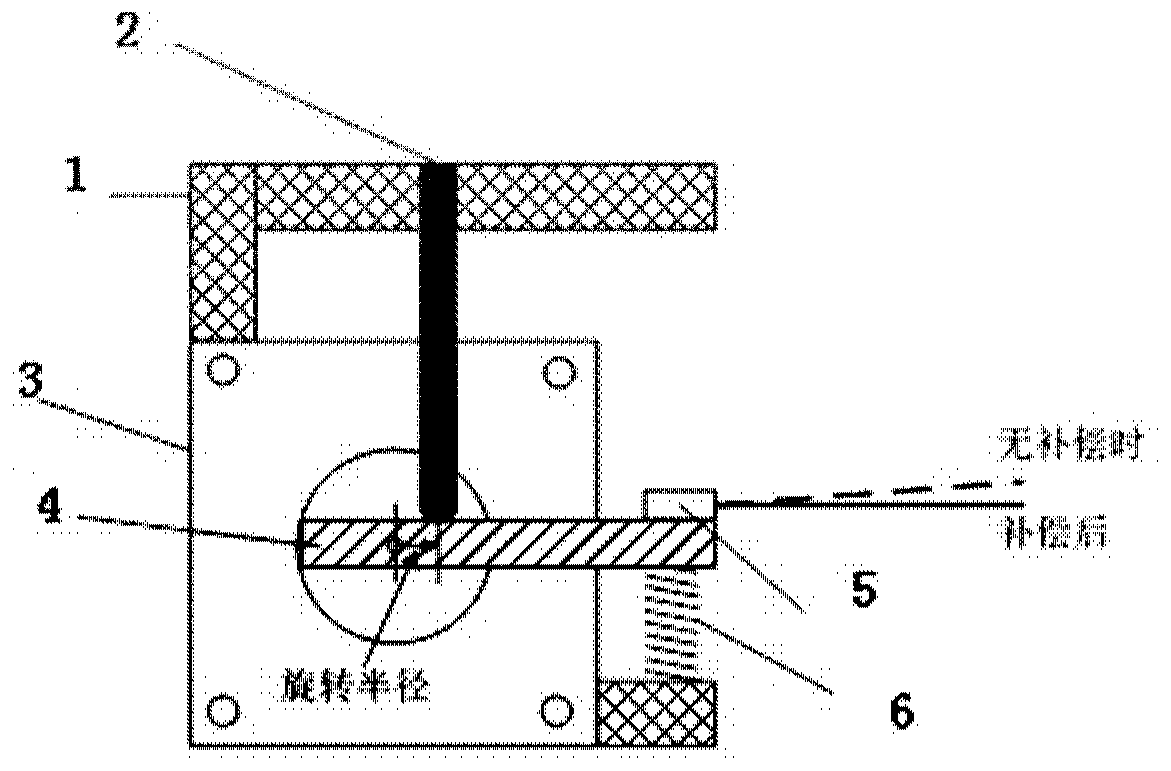

Adaptive compensation device for horizontal imaging field pitch angle of laser radar

InactiveCN109828263ADrift is reduced or substantially eliminatedImprove reliabilityWave based measurement systemsRadarThermal expansion

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Injection mould device with spray nozzle self-centering device

The invention discloses an injection mould with a spray nozzle self-centering device. The injection mould with the spray nozzle self-centering device comprises a fixed mould, a moving mould, a mould line cavity, a flow distribution plate and a spray nozzle device, wherein the spray nozzle self-centering device is arranged at the upper end of the spray nozzle device; the spray nozzle self-centering device comprises a connecting part, a protective ring, and a guide ring part which are arranged outside a spray nozzle main body from the top to the bottom; and the spray nozzle main body is fixed to the bottom surface of the flow distribution plate axially through the connecting part by the protective ring. By rotating the guide ring part forwards or reversely, a first central guide surface and a second central guide surface are matched and then are separated to finish the self-centering of the spray nozzle device and keep the centers of related components aligned. A radial sliding clearance is formed between the protective ring and the connecting part to counteract horizontal movement of the protective ring caused by thermal expansion of the flow distribution plate, wherein the bottom surfaces of the protective ring and the connecting part are in sliding contact, so that the spray nozzle main body cannot be influenced by the thermal expansion and deformation and a centering state is remained.

Owner:HOTSYS CO LTD

Machine tool, its manufacture method and welding plate therefor

InactiveCN100415434CContains inhomogeneityTool workpiece connectionReaming toolsVolumetric Mass DensityThermal expansion

The invention relates to a machine tool with a tool shank (10) and a cutting head (12) made from different materials, which are joined to each other on opposite joint surfaces (14,16) in a positive material fit by means of a joint layer (18') made of a ductile solder material. According to the invention, in order to obtain a solder connection which is substantially stress-free, powder particles (31) made of a temperature-resistant material with a thermal expansion coefficient which is lower than the solder material (30) are embedded into the joint layer (18') and the density of the powder particles (31) varies along the entire thickness of the joint layer (18').

Owner:KOMET GROUP GMBH

Nickel-copper alloy seamless tube

The invention discloses a nickel-copper alloy seamless tube. The nickel-copper alloy seamless tube comprises the following components: copper, iron, manganese, silicon, silicon, sulfur and the balance of nickel; the manufacturing steps of the nickel-copper alloy seamless tube comprise the following steps of: (1), preparing blank and checking the performances of the blank; (2), heating up the ingredients and punching; (3), polishing the blank; (4), carrying out thermal expansion molding treatment on the blank; (5), heating up the blank; (6), carrying out straightening, internal grinding, external grinding and flaw detection on the blank; and (7), carrying out checking, spraying, packaging, weighing and stock removal on the finished product. According to the nickel-copper alloy seamless tube disclosed by the invention, the surface corrosion performances of the product are improved, the performance standards are better, and the manufacturing cost is lowered; and moreover, the production process is simple.

Owner:SUZHOU BEST METAL PROD

Separating preventing hard alloy maintenance tool

ActiveCN106403610AReduce pressure coefficientImprove protectionMaintainance of heating chambersThermal expansionAlloy

Owner:南通盟鼎新材料有限公司

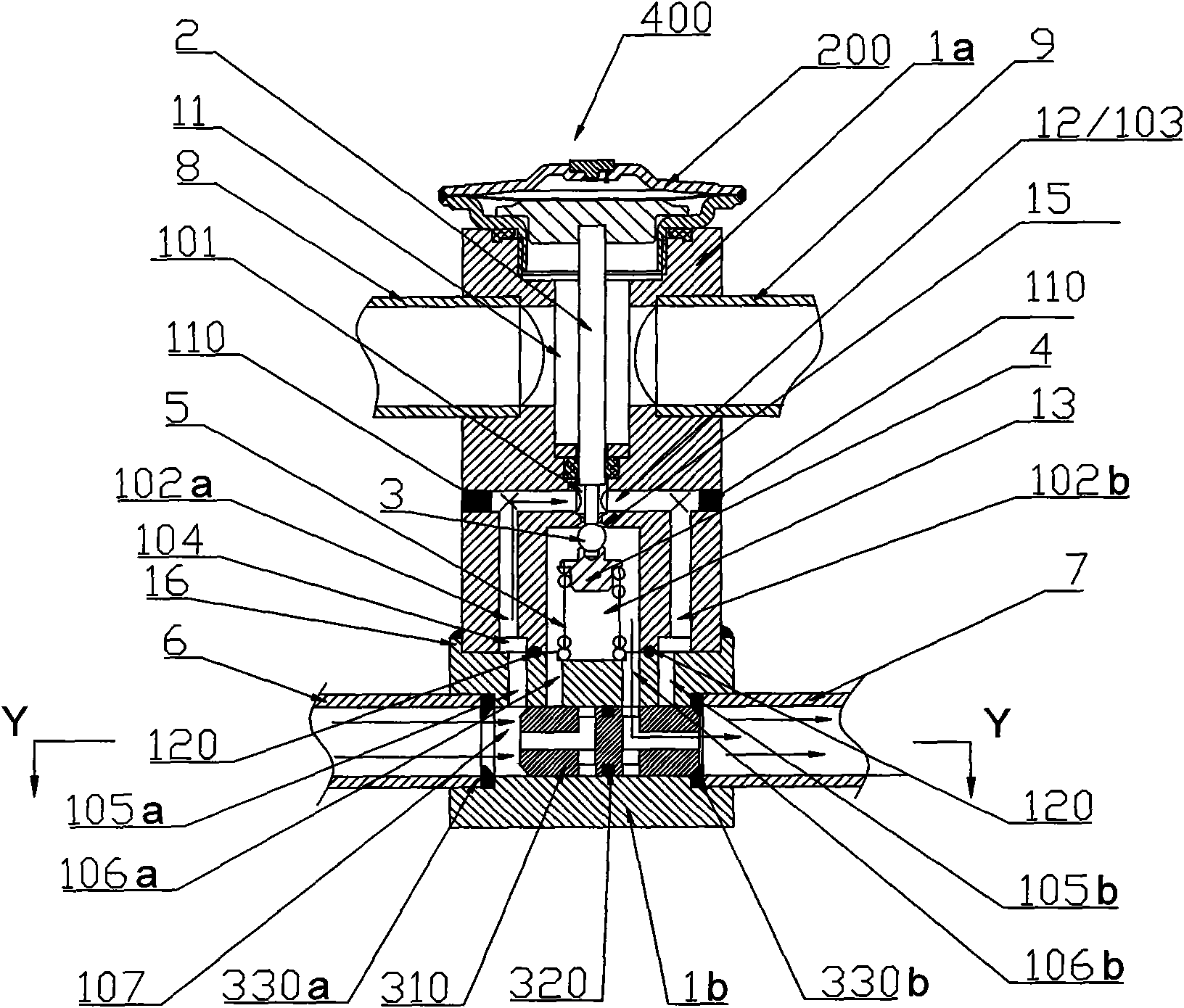

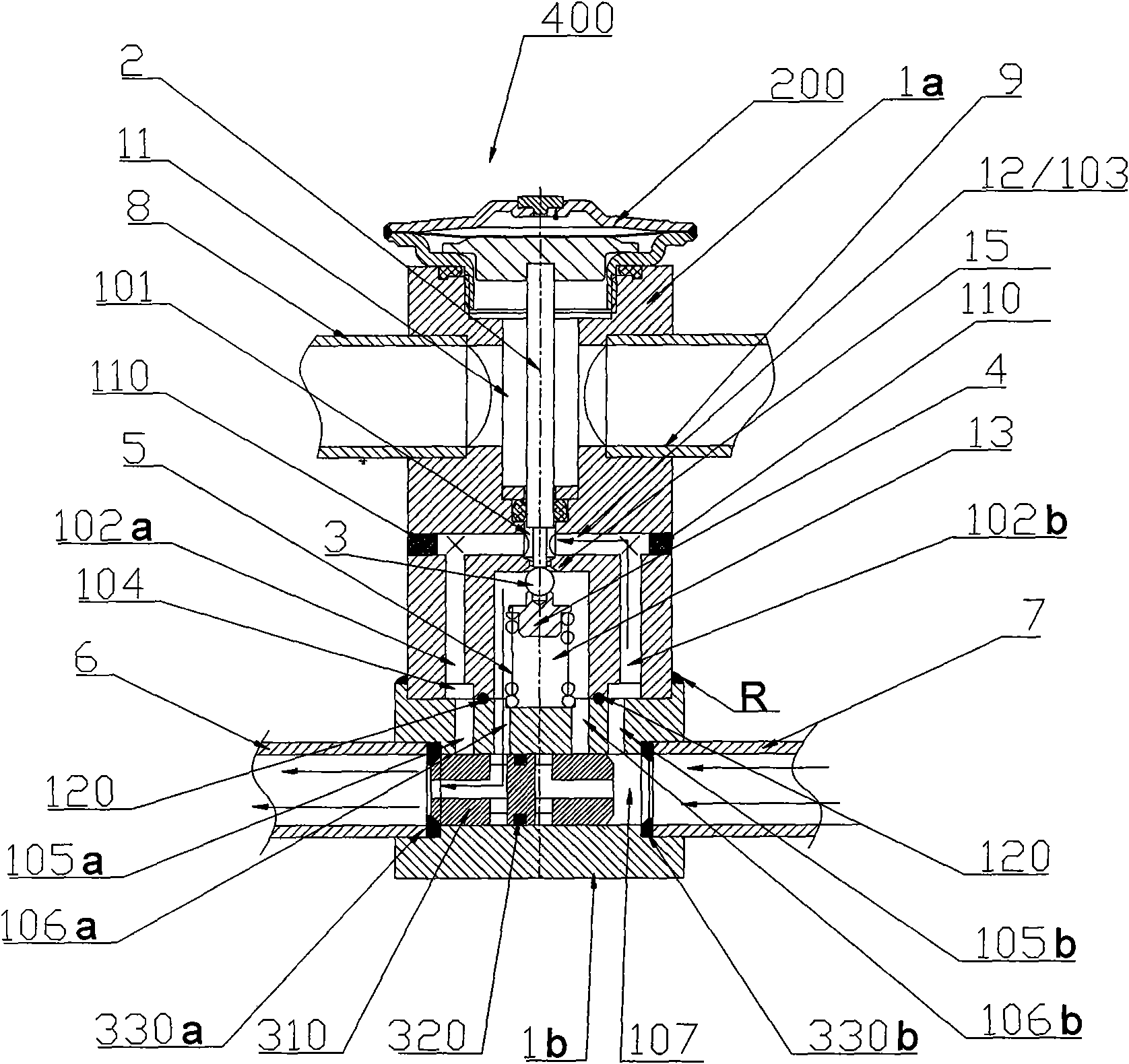

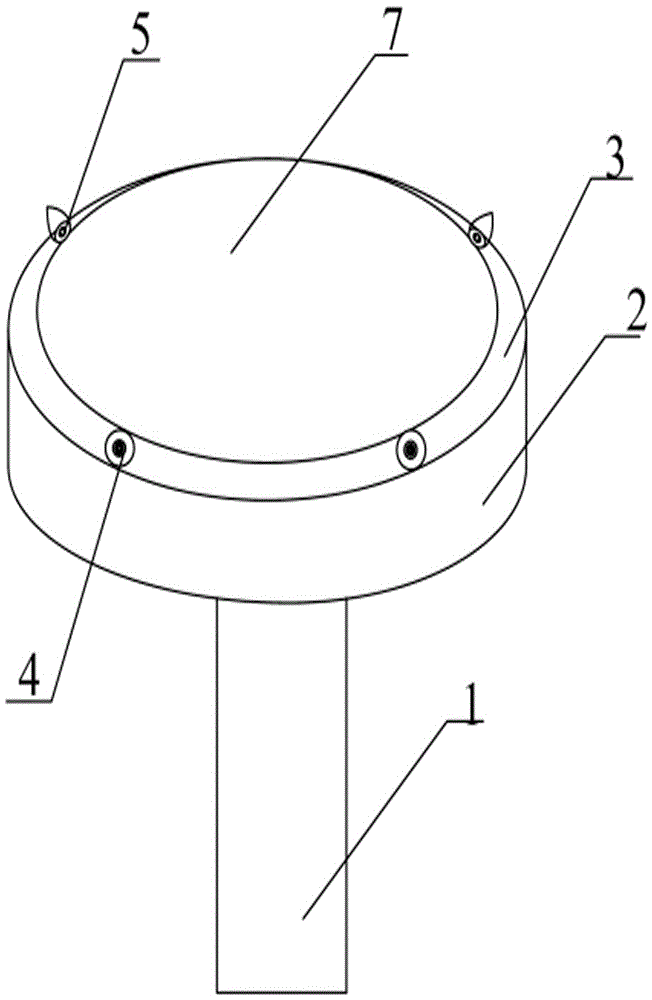

A mechanical device that obtains power from temperature differences and utilizes natural laws to realize automatic operations

ActiveCN105298775BGood thermal expansion and contraction performanceGuaranteed service lifeMachines/enginesMechanical power devicesControl systemMechanical energy

A mechanical device obtaining power from a temperature difference to realize automated operation. In the present invention, two type of liquids being sensitive to a temperature difference change are sealed in a container, and are separated with an isolating membrane. The device utilizes thermal expansion and contraction to convert kinetic energy generated by thermal expansion of the liquids into mechanical energy, and drives an operating apparatus with the mechanical energy. The device utilizes laws of nature and saves energy.

Owner:贾二芳

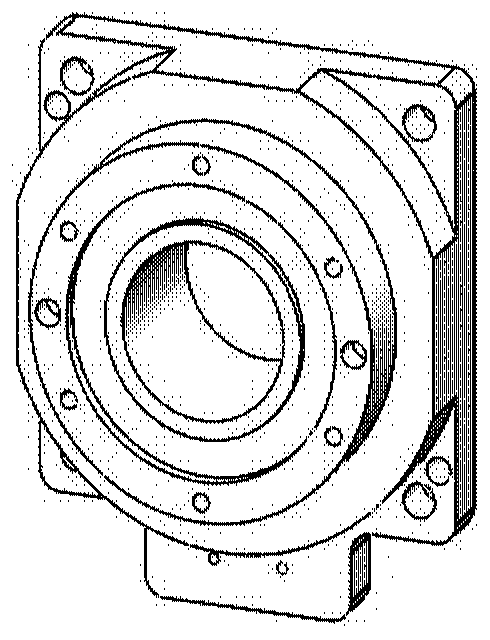

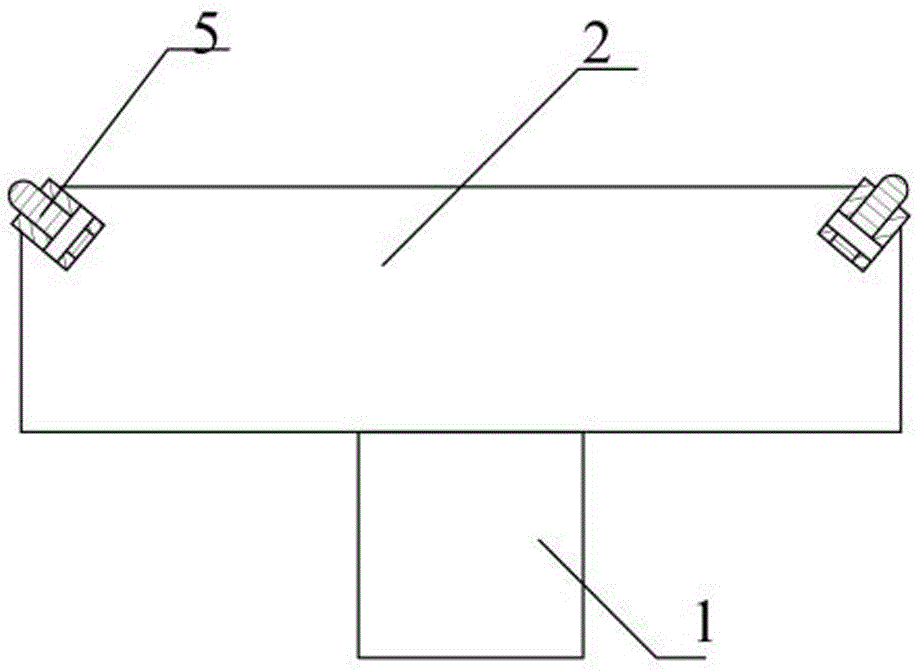

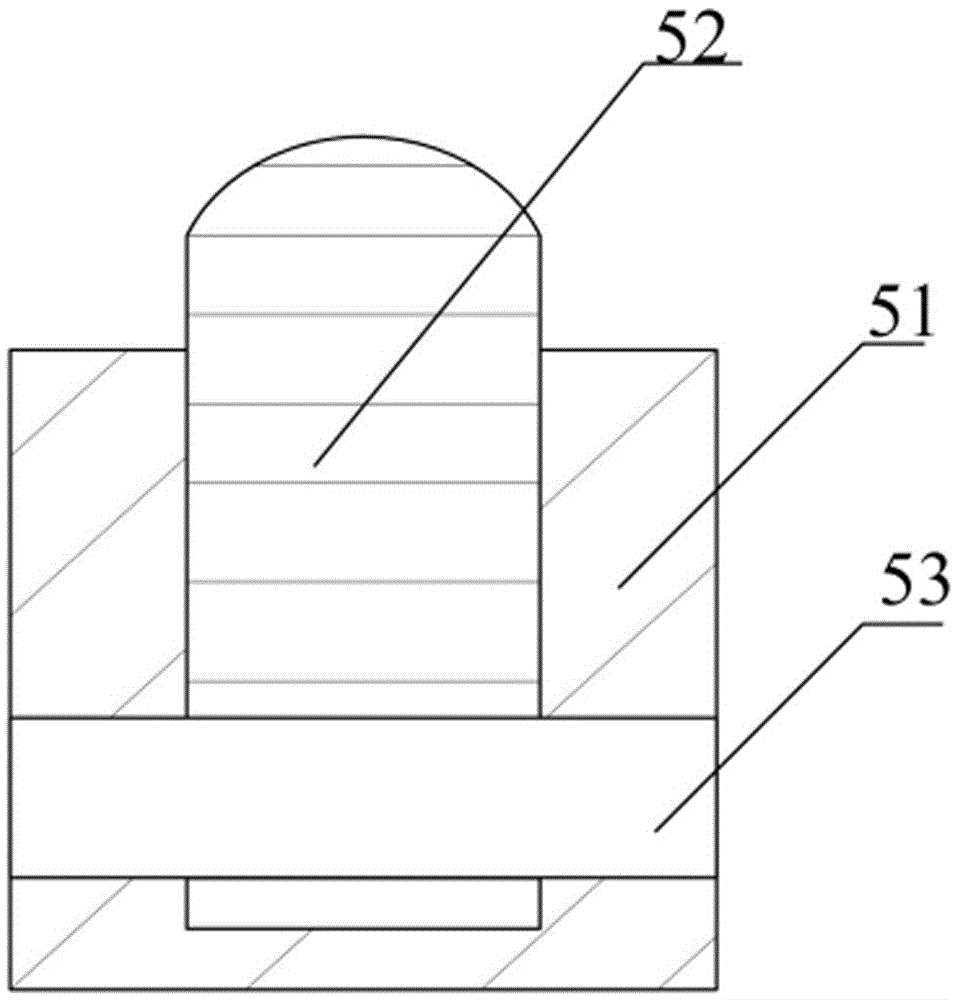

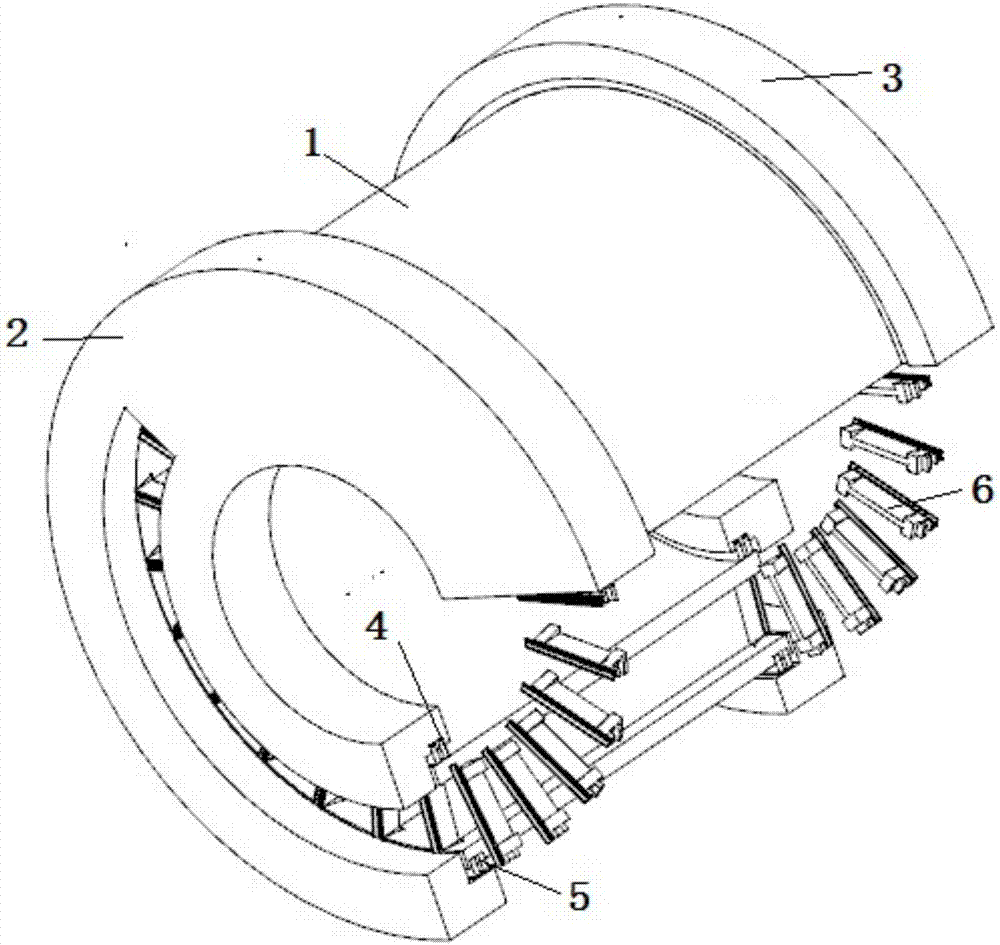

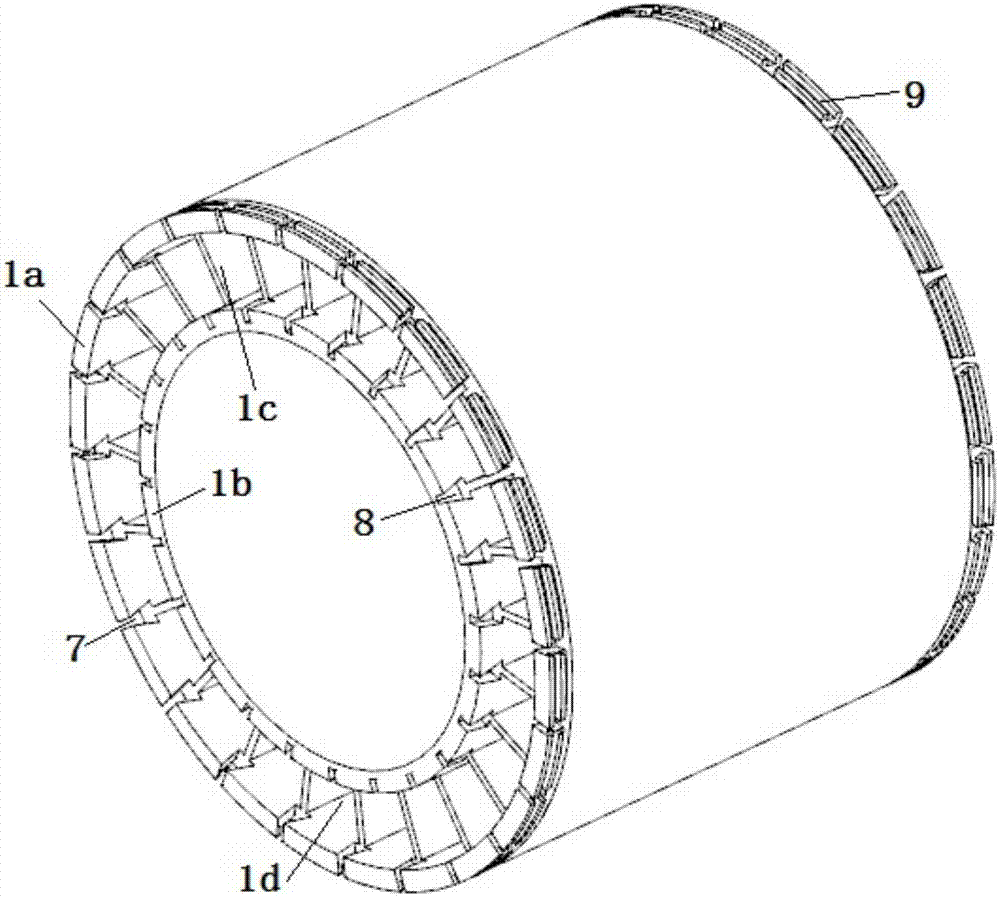

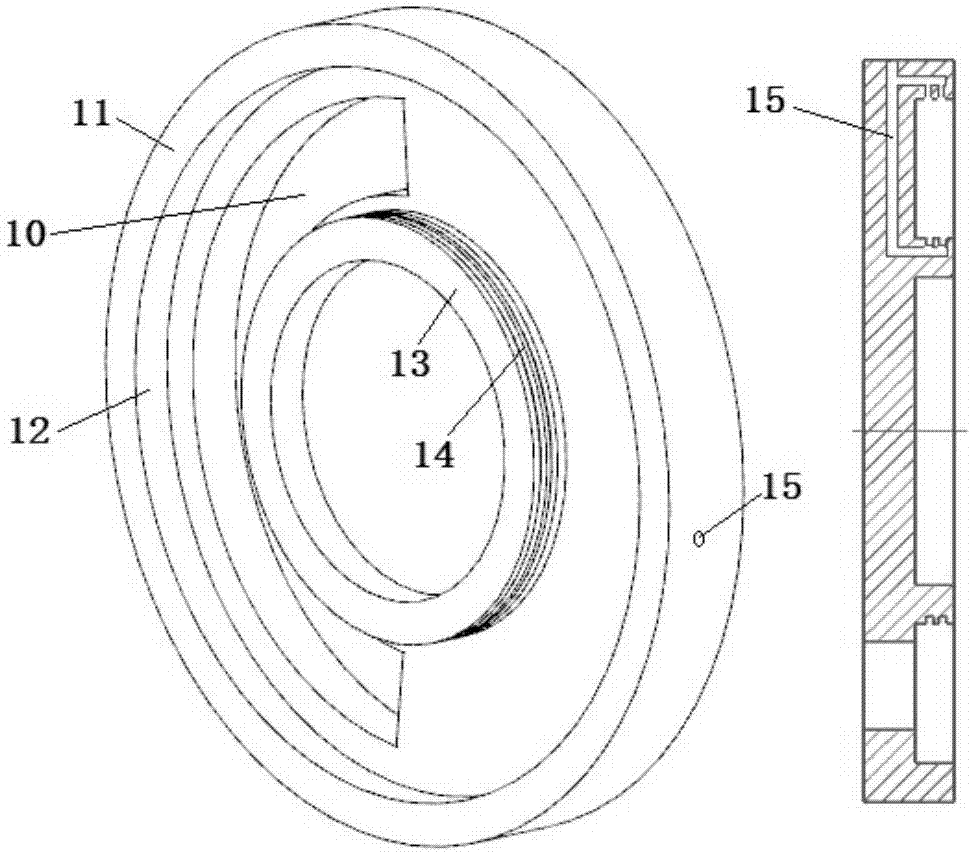

Expansion ring and sealing brush combined internal combustion wave rotor

ActiveCN106930839AImprove sealingReduce frictionEngine sealsGas turbine plantsAviationCombustion chamber

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

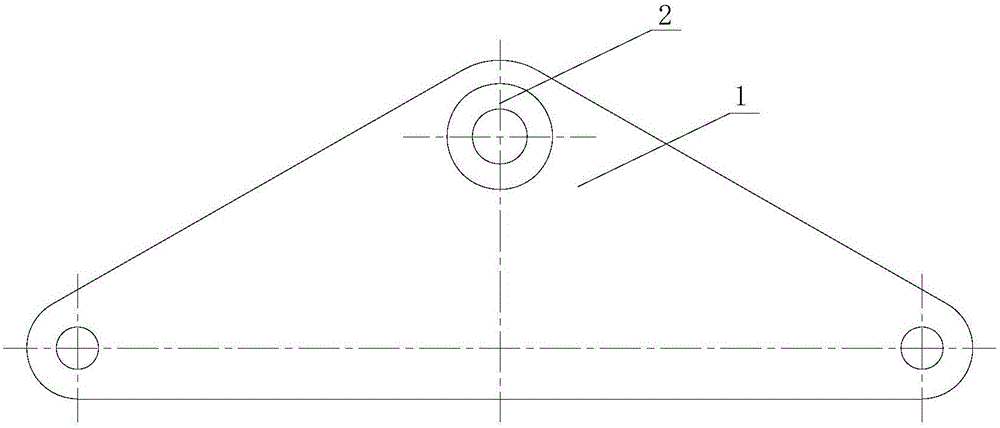

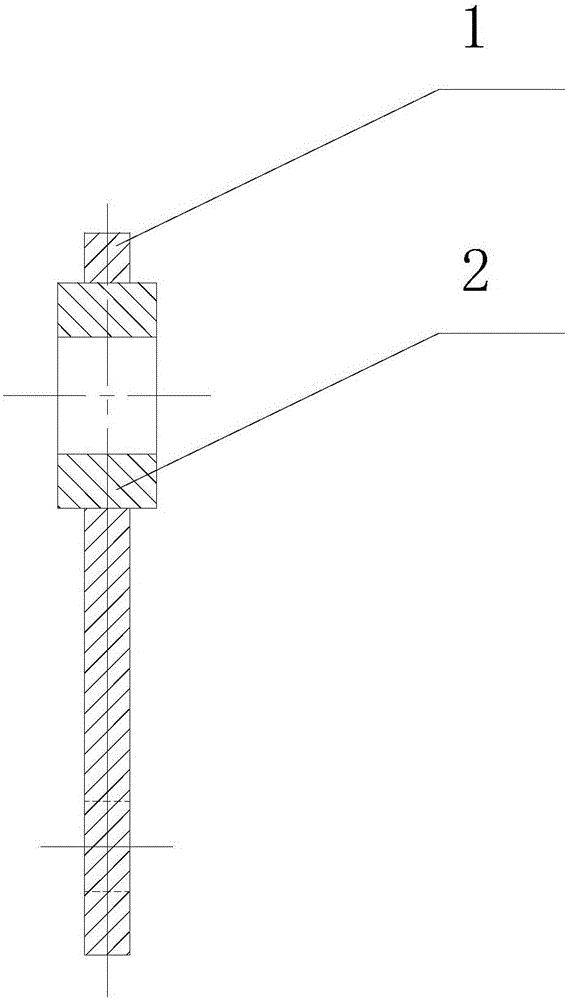

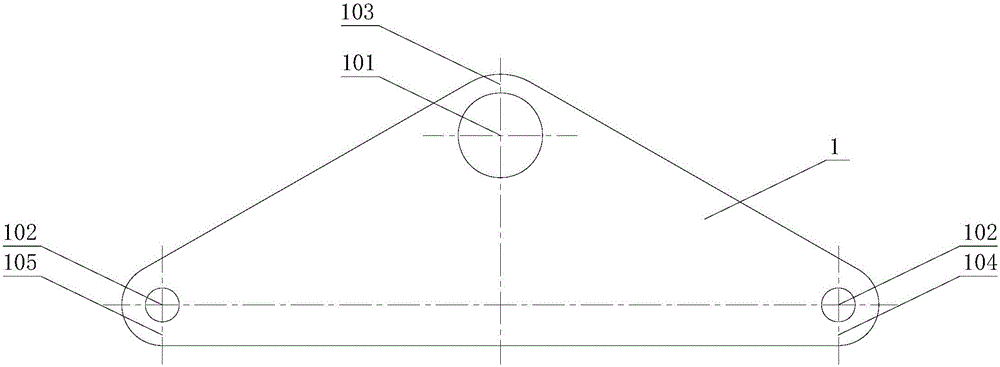

Nested reinforcing yoke plate and processing method thereof

InactiveCN106438598AAvoid problems such as reduced strengthAvoid intensitySecuring devicesMetal working apparatusInterference fitSteel jacket

Owner:JIANGSU SHUANGHUI FUTAI ELECTRIC

Method and equipment for crashing steel piece in large size

InactiveCN1695815AEasy to operateReduce crushing costsGrain treatmentsThermal expansionHeating furnace

Owner:范培友

Alloy type silver mirror backboard, reflector, solar power generation reflector and manufacturing method

PendingCN109239822APrecise positioningImprove stabilitySolar heating energyMirrorsThermal expansionSolar power

Owner:TIANJIN BINHAI LIGHT & HEAT REFLECTING TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap