PCB non-metallic material steel-plastic compound plate tray, preparing production line and preparing method

A non-metallic material, composite board technology, applied in sustainable manufacturing/processing, container, packaging recycling, etc., can solve the problems of high cost, low strength, poor impact resistance, etc. The effect of high bending resistance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

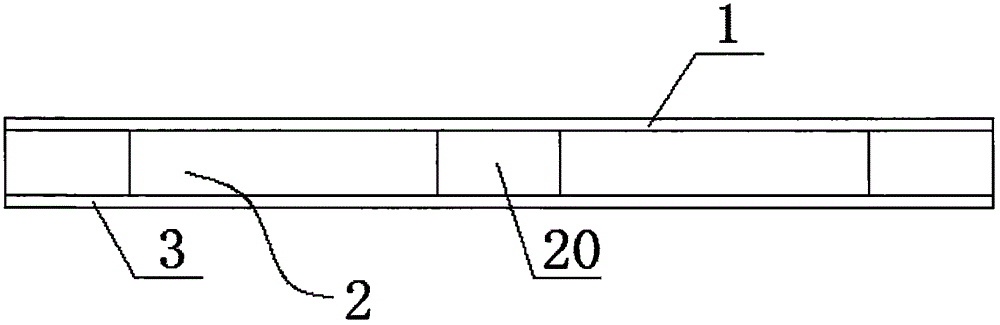

[0092] Such as figure 1 and figure 2 As shown, the PCB non-metal material steel-plastic composite board tray is characterized in that it is composed of a first steel-plastic composite board 1, a support layer 2 and a second steel-plastic composite board 3 arranged in sequence from top to bottom, and the support layer 2 is composed of several vertical columns 20, the first steel-plastic composite board 1 is fixedly connected to the top of the column 20, and the second steel-plastic composite board 3 is fixedly connected to the bottom end of the column 20, so Both the first steel-plastic composite board 1 and the second steel-plastic composite board 3 are composed of a first plastic layer 10, a reinforcement layer 11 and a second plastic layer 12 arranged in sequence from top to bottom.

[0093] Preferably, the column 20 is a solid cylinder made of polyvinyl chloride foam. The polyvinyl chloride uprights 20 can play the role of support and buffering, and on the other hand, it is

Embodiment 2

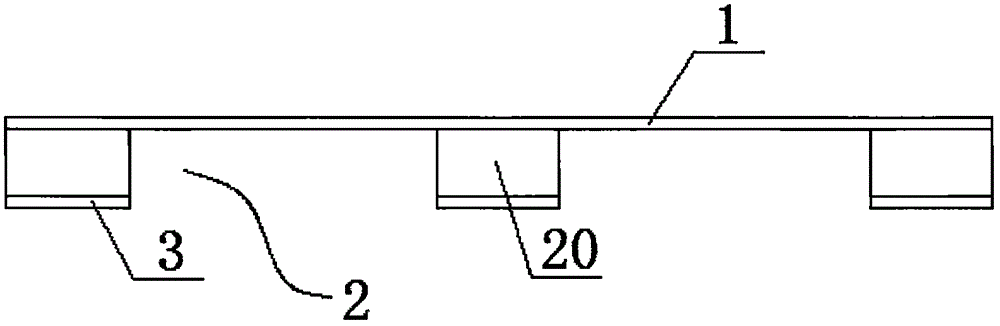

[0101] Such as image 3 and Figure 4 As shown, the PCB non-metal material steel-plastic composite board tray is characterized in that it is composed of a first steel-plastic composite board 1, a support layer 2 and a second steel-plastic composite board 3 arranged in sequence from top to bottom, and the support layer 2 is composed of several vertical columns 20, the first steel-plastic composite board 1 is fixedly connected to the top of the column 20, and the second steel-plastic composite board 3 is fixedly connected to the bottom end of the column 20, so Both the first steel-plastic composite board 1 and the second steel-plastic composite board 3 are composed of a first plastic layer 10, a reinforcement layer 11 and a second plastic layer 12 arranged in sequence from top to bottom.

[0102] Preferably, the column 20 is a solid cylinder made of polyvinyl chloride foam. The polyvinyl chloride uprights 20 can play a supporting and buffering role, and at the same time facilitat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap