Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Polyvinyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl chloride (/ˌpɒlivaɪnəl ˈklɔːraɪd/; colloquial: polyvinyl, vinyl; abbreviated: PVC) is the world's third-most widely produced synthetic plastic polymer, after polyethylene and polypropylene. About 40 million tonnes are produced per year.

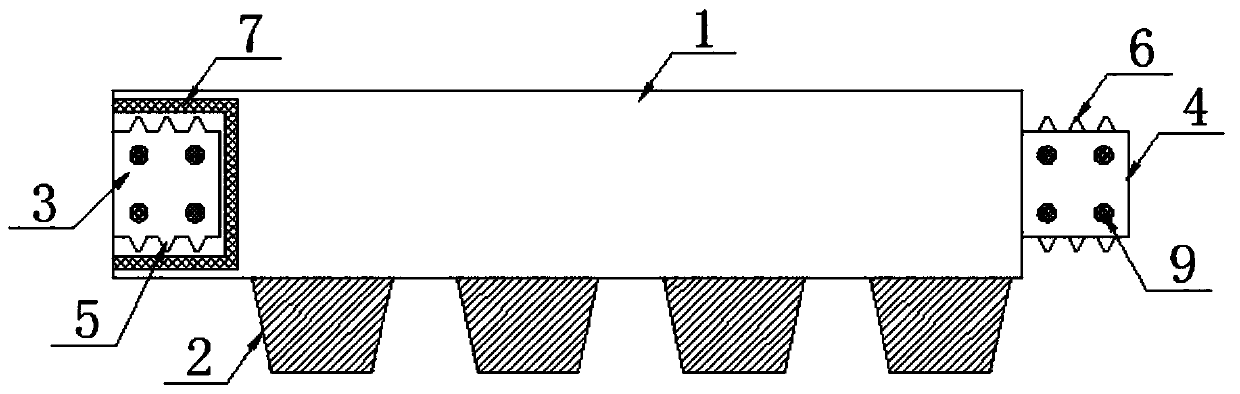

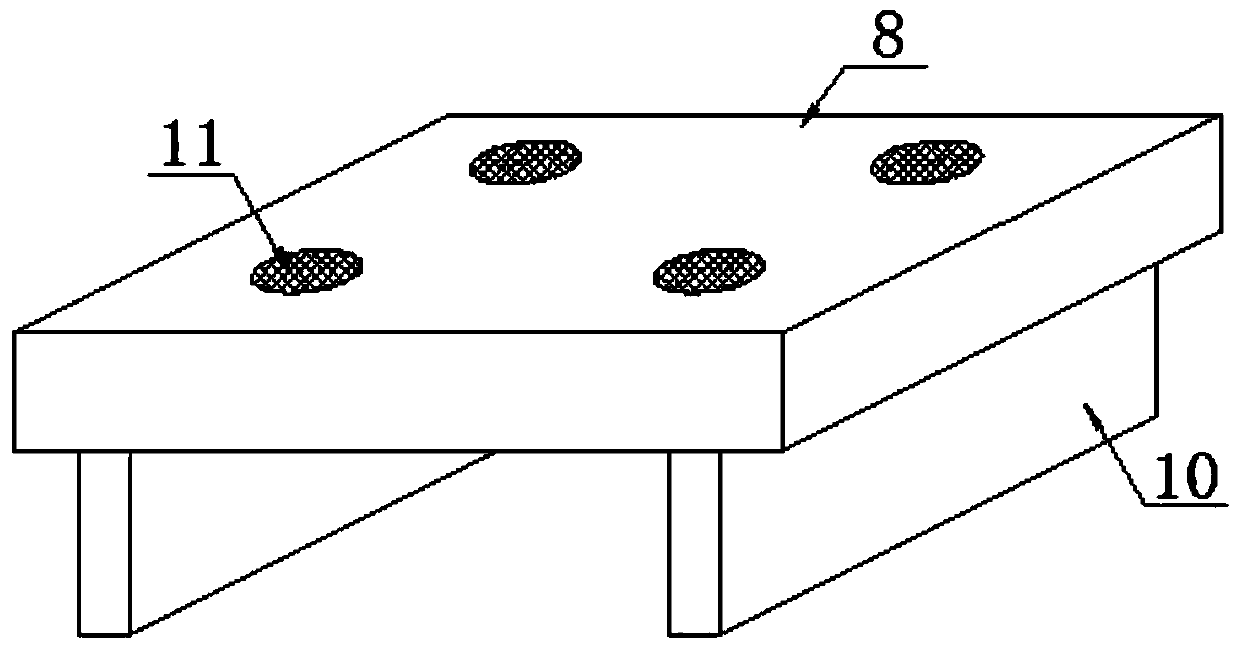

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

Plasticizers Derived From Renewable Feedstock

Owner:GALATA CHEM LLC

High-thixotropic poly(vinyl chloride) plastic sol

Owner:上海理日化工新材料有限公司

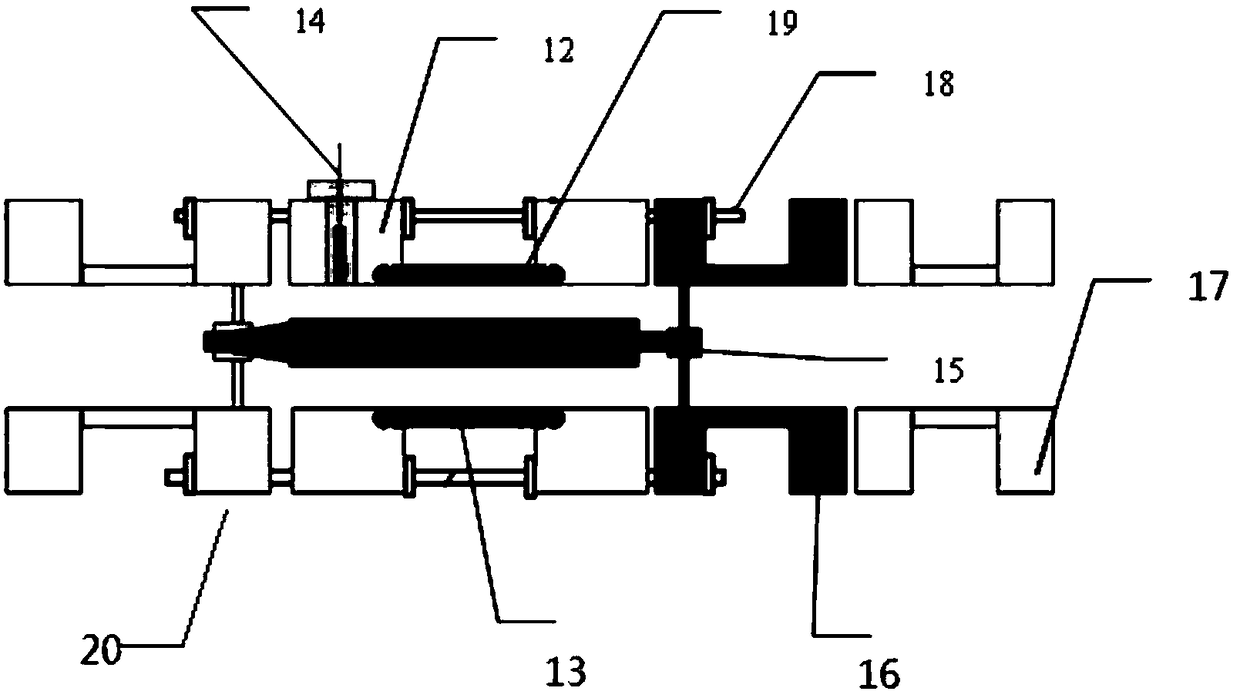

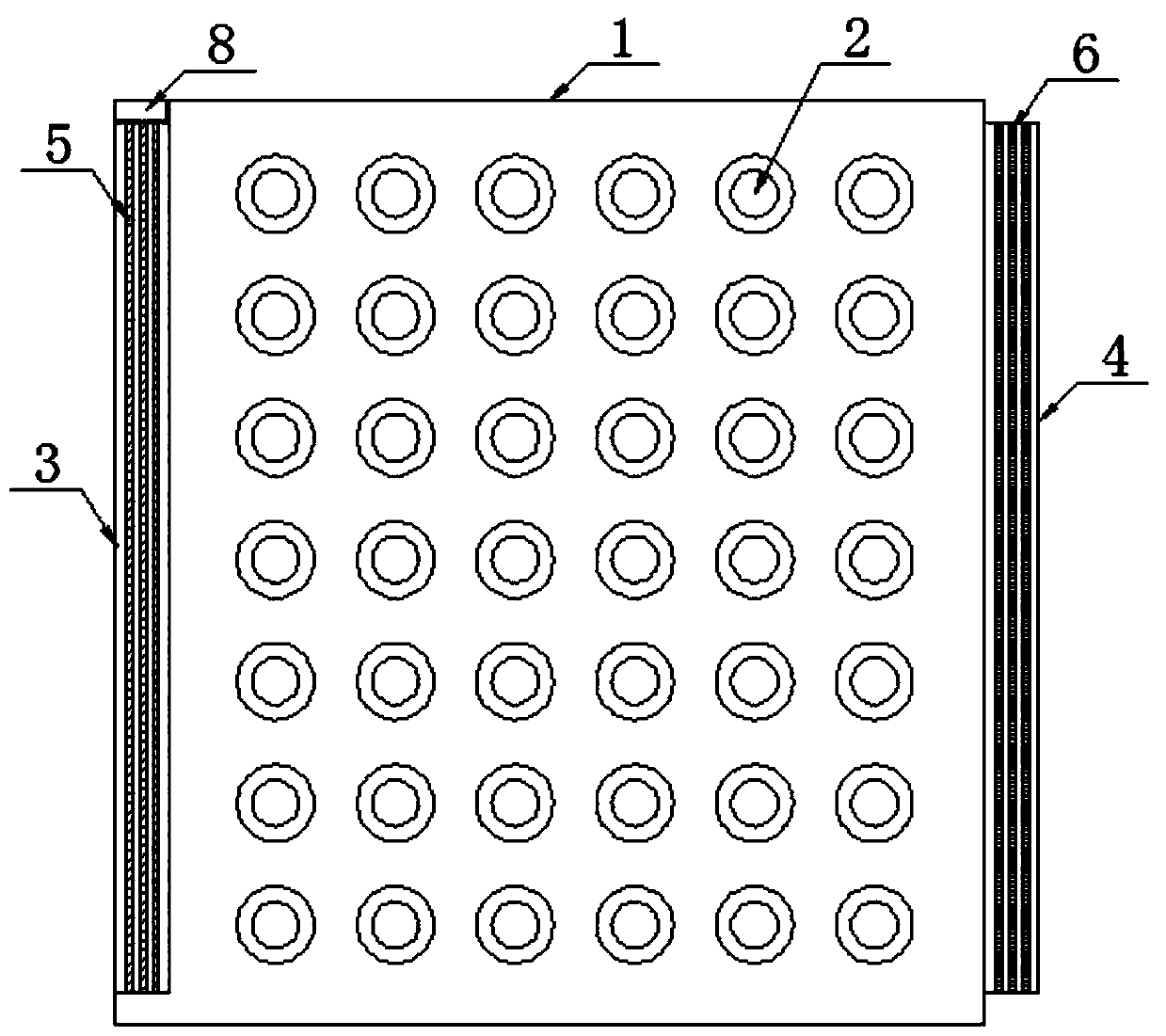

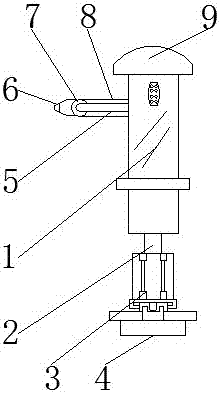

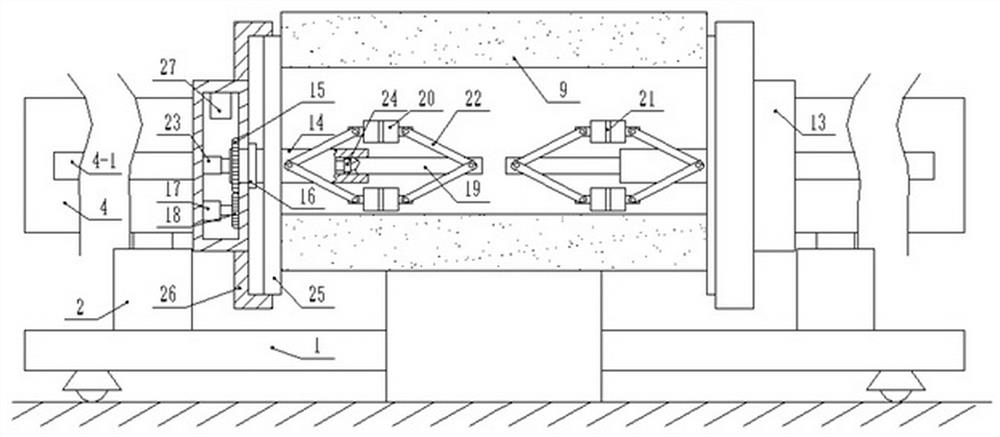

Electrochemical pipeline erosion corrosion testing device

ActiveCN109444236AEnables electrochemical measurementsEasy to analyzeMaterial electrochemical variablesTest efficiencyMaterial Erosion

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

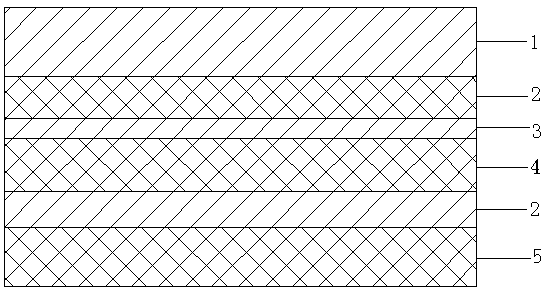

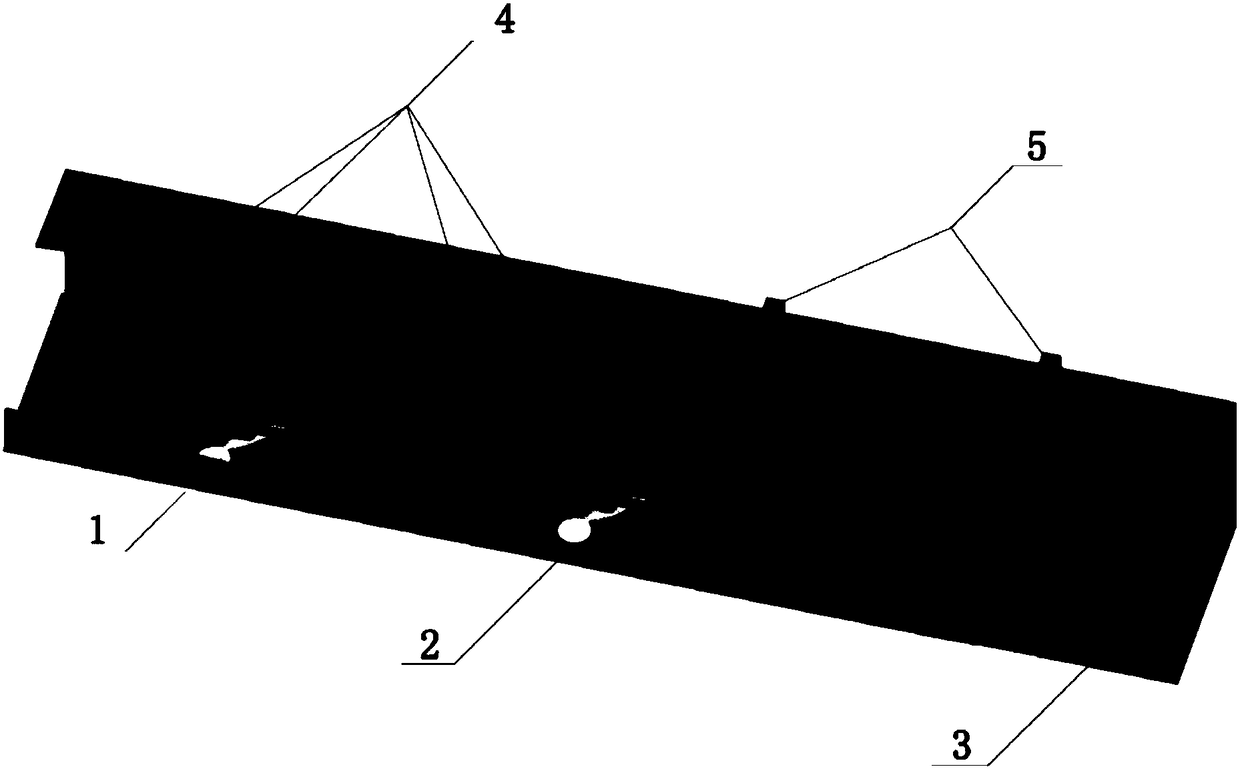

Combined fatigue resistant pad and manufacturing method thereof

InactiveCN101292833AReduce manufacturing costEffective protectionLayered productsDomestic articlesFoaming agentPolyvinyl chloride

Owner:TAICANG ALL MATS PLASTIC IND

Novel acrylic pressure-sensitive adhesive

ActiveCN108192019AWide range of bondingGood adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolyester

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

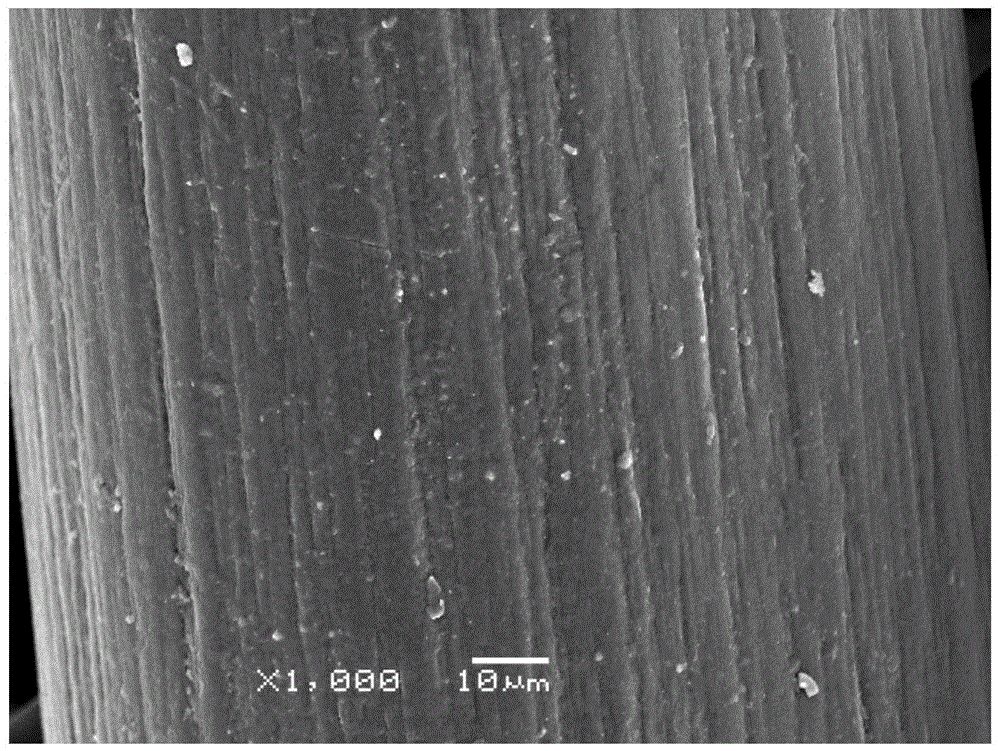

Production method for preparing polyvinyl chloride fibers for hair by melting method

ActiveCN104611781ALow shrinkageSmall shrinkageWigsMonocomponent halogenated hydrocarbon artificial filamentPlasticizerBoiling point

Owner:邵阳美丽来发制品有限公司

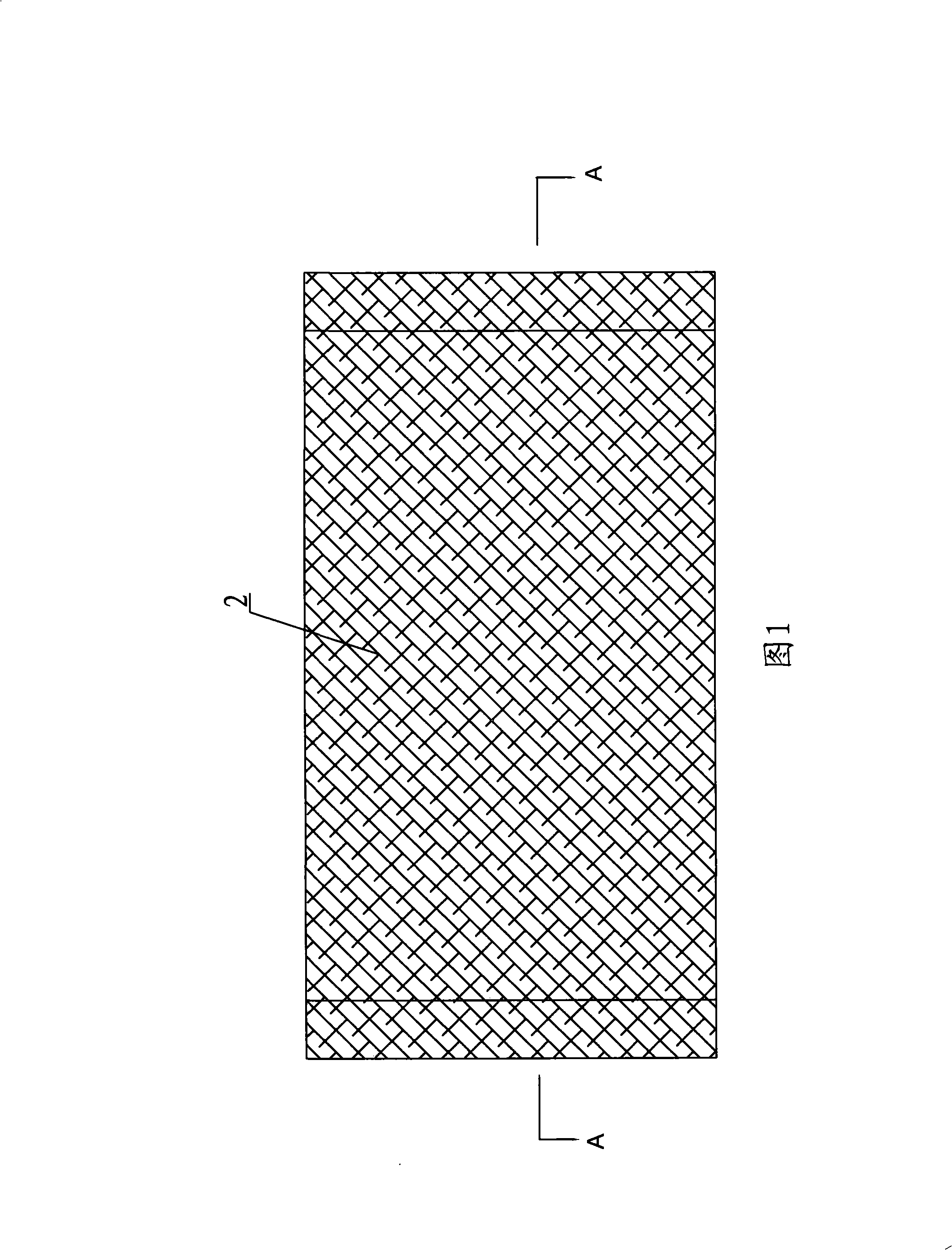

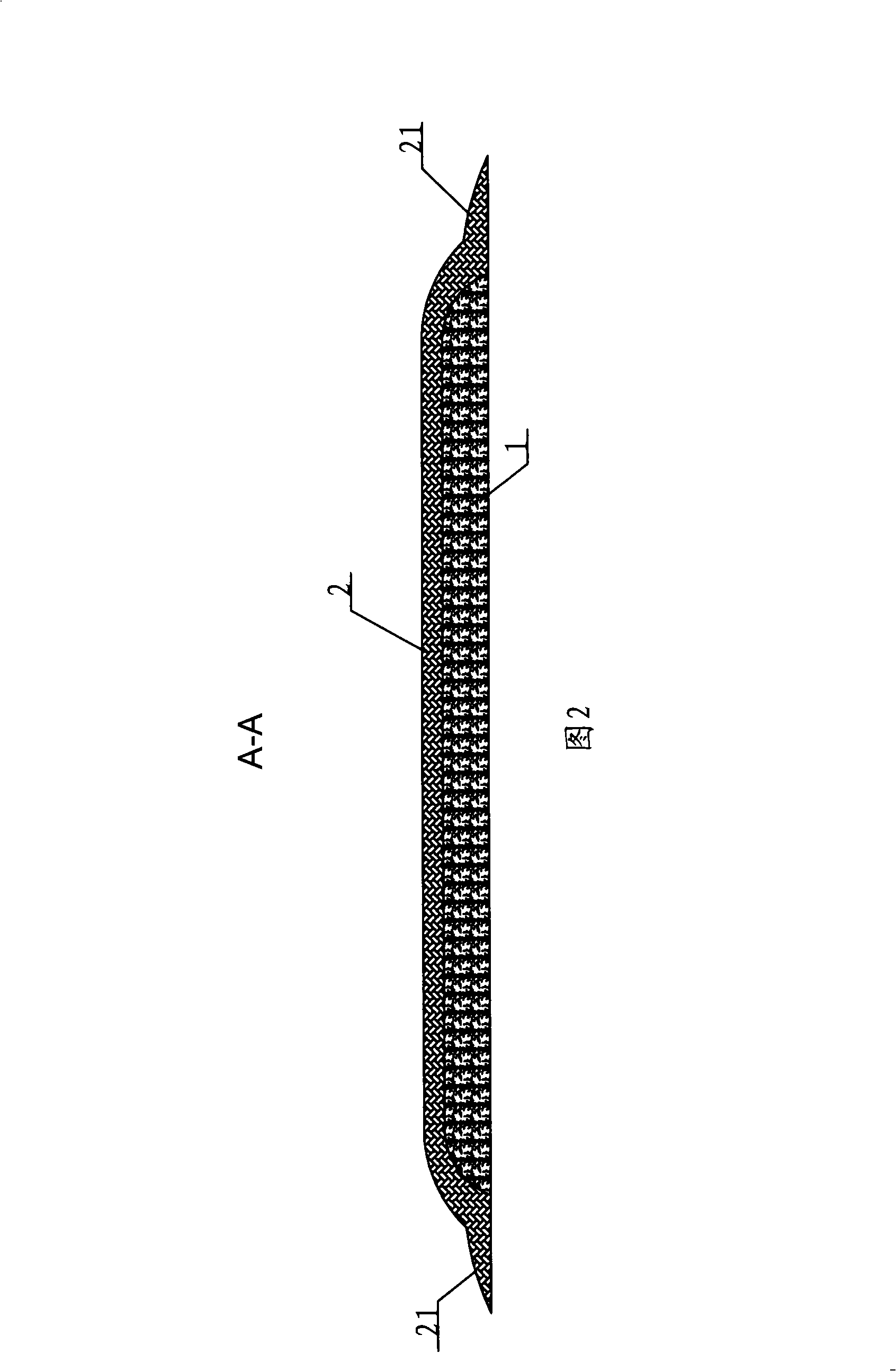

High-efficiency filter sheets for air microfiltration membrane filters

InactiveCN108031209AHigh mechanical strengthIncreased mechanical toughnessDispersed particle filtrationFiltration separationPolyvinyl chlorideFilter effect

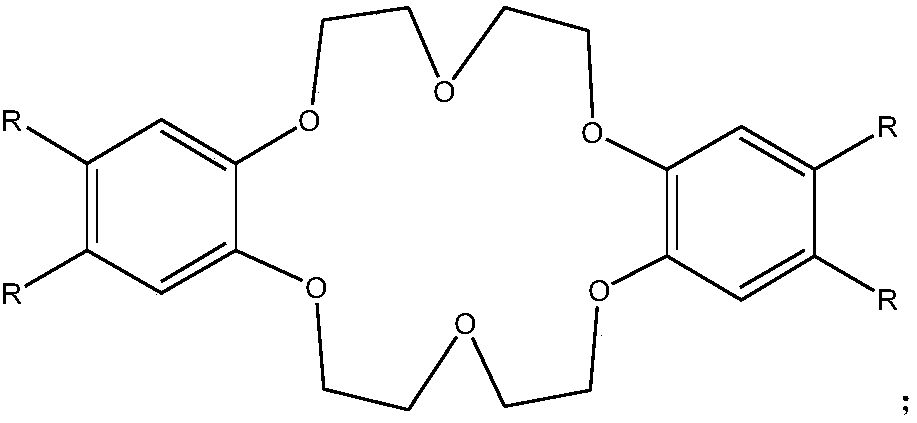

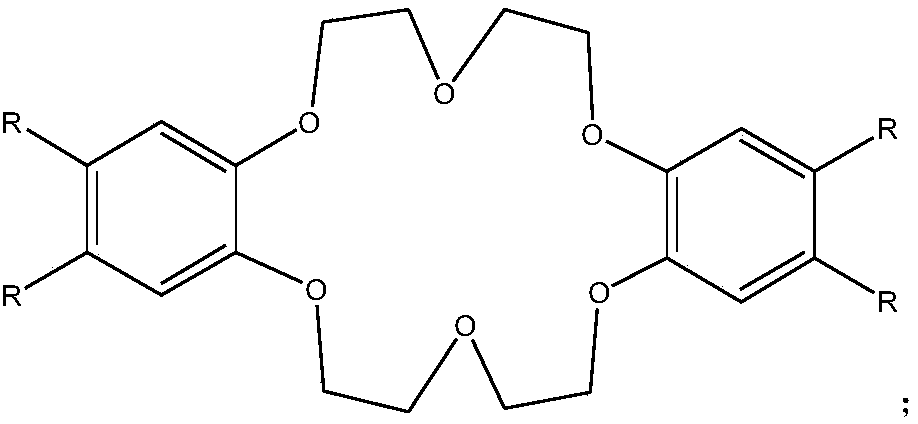

The present invention relates to a high-efficiency filter sheet for air microfiltration membrane filters. The high-efficiency filter sheet comprises a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively in a unidirectional arrangement, and an included angle between the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer is 60-65 DEG. According to the high-efficiency filter sheet, a double layer combination of the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer is used, and a specific angle between the fiber filaments is set, so that windage resistance and filtering effect of the filter sheet are improved; the introduced polytetrafluoroethylene fiber layer has superhigh mechanical strength and structural toughness, so that vibration caused by strongwind can be effectively suppressed, and airflow in a dust collection chamber of a vacuum cleaner is stabilized; and a filling layer is additively arranged, so that the filtering effect of the filter sheet is further improved.

Owner:SUZHOU QINGRUI AIR SYST

Aluminum-plastic compositedoor and window section bar

InactiveCN103216176AComposite installation is simpleImprove thermal insulationWing framesPolyvinyl chlorideEngineering

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

Aging-resistant polyvinyl chloride plastic

Owner:湖南凯誉电气科技有限公司

Insulated fireproof coating for optical cables

InactiveCN105567024AExcellent physical and chemical propertiesDry fastFireproof paintsEpoxy resin coatingsFiberEpoxy

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +1

Foaming material with modifying filler

InactiveCN103613836AIncrease elasticityStrong sound insulationLinear low-density polyethylenePolyvinyl chloride

The invention discloses a foaming material with modifying filler. The foaming material is characterized by being prepared from the following raw materials in parts by weight: 80-90 parts of linear low density polyethylene, 12-16 parts of SG-5 polyvinyl chloride, 20-24 parts of calcium carbonate powder, 2-3 parts of stearic acid, 2-3 parts of zinc oxide, 4-5 parts of azodicarbonamide, 5-7 parts of chlorinated paraffin, 3-5 parts of polyethylene terephathalate, 4-6 parts of titanium dioxide powder, 2-3 parts of triphenyl phosphite and 6-8 parts of modifying filler. Due to addition of the modifying filler, the foaming material has excellent flame retardant effect, and is further endowed with excellent mechanical property, good rebound resilience and strong sound insulation performance. The polyvinyl chloride foaming material simultaneously has the characteristics of heat insulation, light weight, low water absorption and the like. The foaming material also has the advantages that the operation is simple, the raw materials are easily available, and the cost is low.

Owner:ANHUI AOLO DOOR & WINDOW SYST ENG CO LTD

Shell plastic for computer display screens and preparation method of shell plastic

InactiveCN107163494AGood acid and alkali resistanceGood high temperature resistancePolyvinyl chlorideEngineering

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Anti-corrosion power protection pipe

Owner:安徽盛华管业有限公司

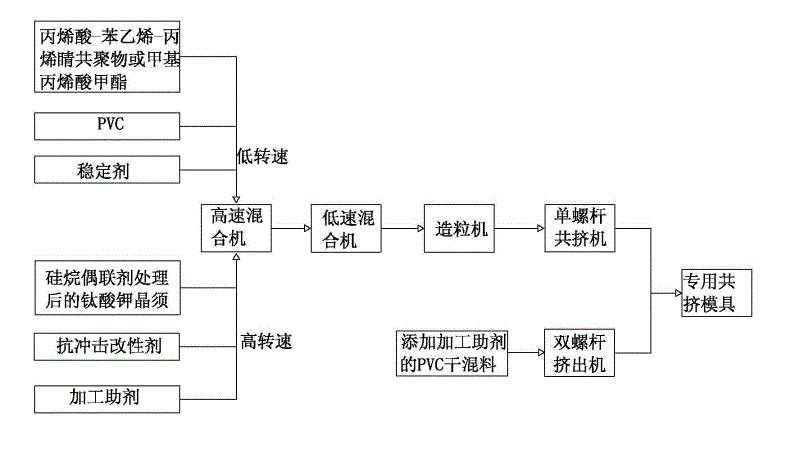

Color bending-resistant co-extruded section bar reflecting infrared rays and preparation method thereof

ActiveCN102617962AWith reflective infrared functionWith heat insulation functionInfraredPolyvinyl chloride

Owner:新疆蓝山屯河型材有限公司

Anti-ultraviolet PVC (Polyvinyl Chloride) gloves and preparation method thereof

InactiveCN108164883ADoes not affect initial colorabilityImproves UV resistanceGlovesProtective garmentEmulsionBenzotriazole

The invention discloses anti-ultraviolet PVC (Polyvinyl Chloride) gloves and a preparation method thereof. The anti-ultraviolet PVC gloves are prepared from the following raw materials in parts by weight: 100 parts of PVC, 78 to 82 parts of DOP, 10 to 15 parts of TXIB, 10 to 15 parts of D70, 2 to 2.5 parts of stabilizer, 2 to 2.5 parts of epoxidized soybean oil and 5 to 10 parts of anti-ultraviolet aid, wherein the anti-ultraviolet aid is prepared from the following raw materials in parts by weight: 12 to 15 parts of a fluorocarbon emulsion, 2 to 5 parts of 2-(2'-hydroxy-3'-tert-butyl-5'-methyl phenyl)-5-chloro-benzotriazole, 5 to 8 parts of 2-hydroxyl-4-methoxybenzophenone and 3 to 4 parts of a ceramic powder. The anti-ultraviolet PVC gloves disclosed by the invention have the advantagesof good anti-ultraviolet performance, long duration time, comfortableness in wearing and low cost; the adopted anti-ultraviolet agent does not affect the transparency of a product and also has no effects on the initial coloring of the PVC gloves; the production process of the anti-ultraviolet PVC gloves is simple and easy to operate.

Owner:JIANGSU HUAYUAN GLOVE

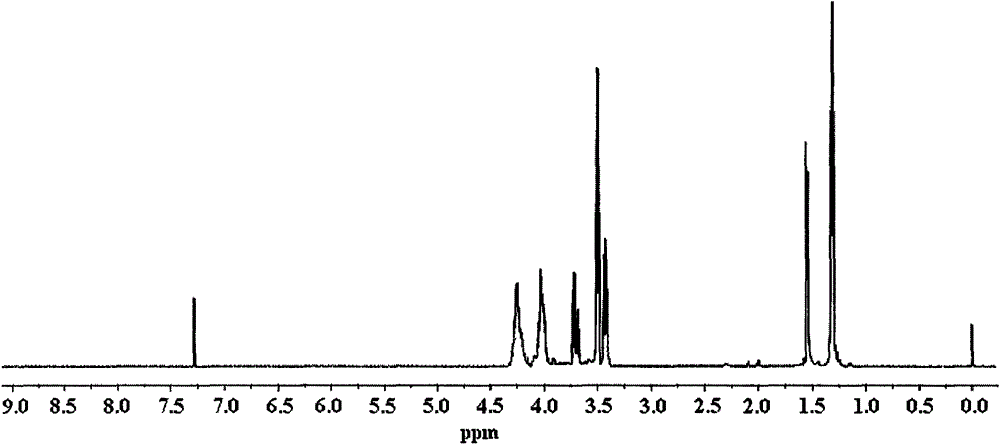

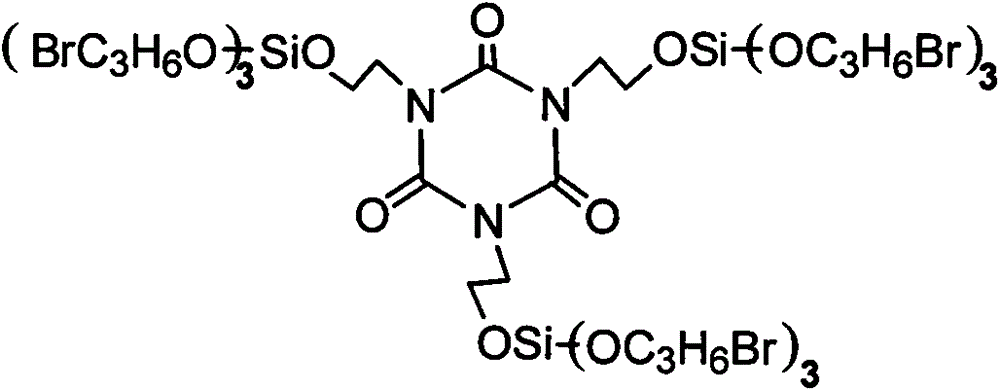

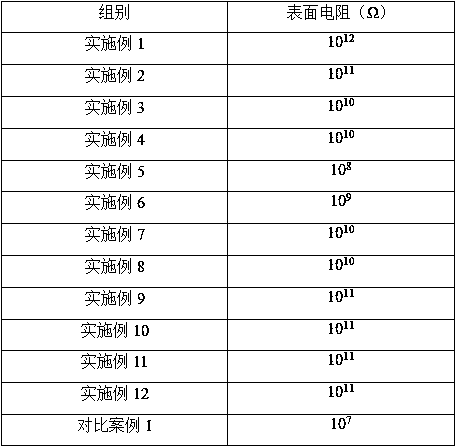

Flame retardant tris(hydroxyethyl) isocyanurate trisilicate propyl bromide compound and preparation method thereof

ActiveCN103554147APrevent secondary combustionHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyPropyl bromide

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Insulating PVC (polyvinyl chloride) glove and preparation method thereof

ActiveCN108047606AImprove insulation performanceSimple production processCoatingsDomestic articlesPlasticizerPolyvinyl chloride

Owner:BLUE SAIL MEDICAL

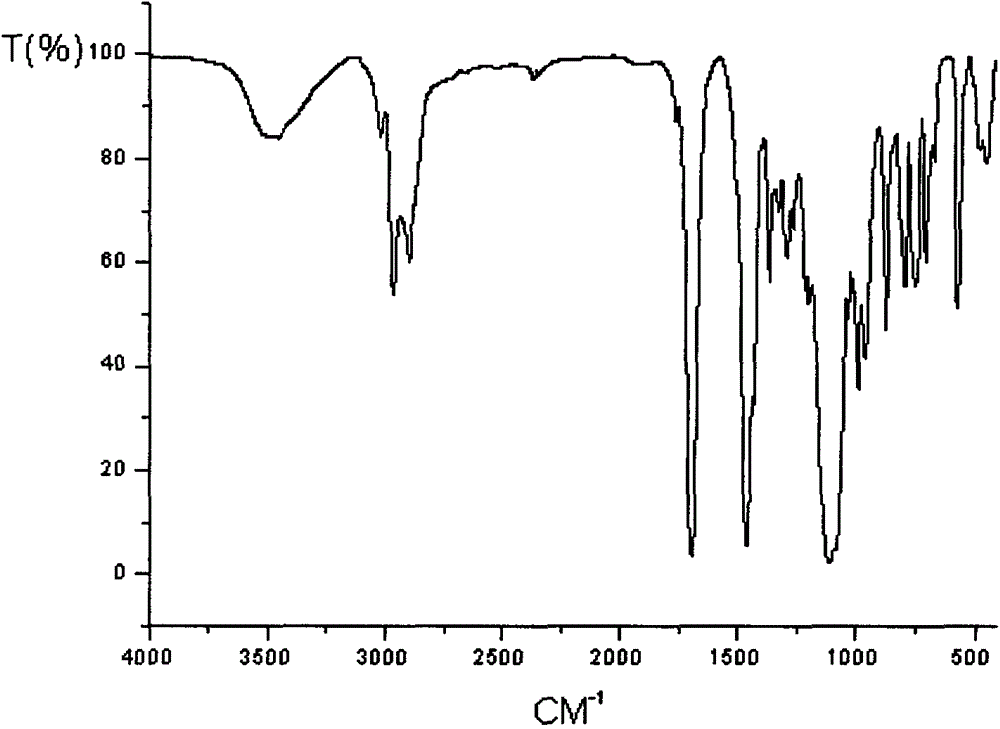

Modified PVC (Polyvinyl Chloride) composite material and preparation method thereof

InactiveCN107474428AImprove creep resistanceImprove low temperature impact performancePlastic/resin/waxes insulatorsActive agentPolyvinyl chloride

The invention discloses a PVC (Polyvinyl Chloride) composite modified material and a preparation method thereof, relates to a PVC modified material and a preparation method thereof, and aims to solve the problems that a product surface is rough and lusterless as a conventional PVC modified material has a certain amount of unsaturated double bonds on a molecular chain, an active center can be formed and thus the ductility is low and a melt is easily crushed. The PVC composite modified material is prepared from the following components in parts by weight: a PVC resin, a low-temperature flexibilizer, an impact modifier, processing aids, a surfactant, a composite stabilizer, a covering agent, an initiator and a cross-linking agent. The preparation method comprises the following steps: I, weighing; II, premixing so as to obtain a premix; III, mixing at different steps so as to obtain mixtures of different steps; IV, performing final mixing so as to obtain a final mixture; and V, performing extrusion pelletizing, thereby obtaining the PVC composite modified material. The invention aims to prepare the PVC composite modified material.

Owner:WUHU PILOT NEW MATERIAL TECH CO LTD

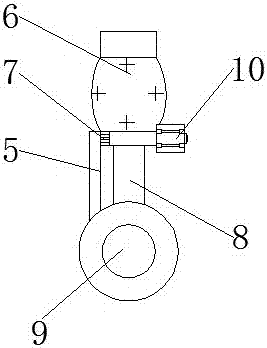

Automated sprinkling irrigation device

InactiveCN107409957AEasy to adjust the angleEasy to adjustWatering devicesCultivating equipmentsWater resourcesPolyvinyl chloride

Owner:TAICANG MIX MACHINERY EQUIP CO LTD

70 degrees centigrade insulation grade flexible polyethylene plastic

The invention discloses a 70 degrees centigrade insulation grade flexible polyethylene plastic, comprising the following raw materials by weight: 37-40 parts of low-density polyethylene, 23-26 parts of PVC resin, 12-15 parts of polyvinyl chloride, 1.1-1.4 parts of stearic acid, 15-18 parts of ultra-dispersed graphene reinforcement filler, 0.5-0.8 part of paraffin, 1-3 parts of polyethylene wax, 2.6-2.9 parts of calcium stearate, 0.9-1.2 parts of butyl benzyl phthalate, 1.4-1.7 parts of epoxidized butyl oleate, 0.4-0.6 part of anti-aging agent, and 1.4-1.7 parts of diisooctyl phenyl phosphite.

Owner:ANHUI YANGTIAN PLASTIC IND TECH

Anti-static warning tape base material

InactiveCN103497447AImprove waterproof performanceImprove moisture resistanceFilm/foil adhesivesAntistatic agentPolyvinyl chloride

Owner:SUZHOU HUAZHOU TAPE

Method for preparing ardealite filler for producing PVC (PVC) material

InactiveCN105348863AReduce corrosionGood optical performancePigment treatment with macromolecular organic compoundsPolyvinyl chlorideSlurry

Owner:GUIZHOU KAILIN GRP CO LTD

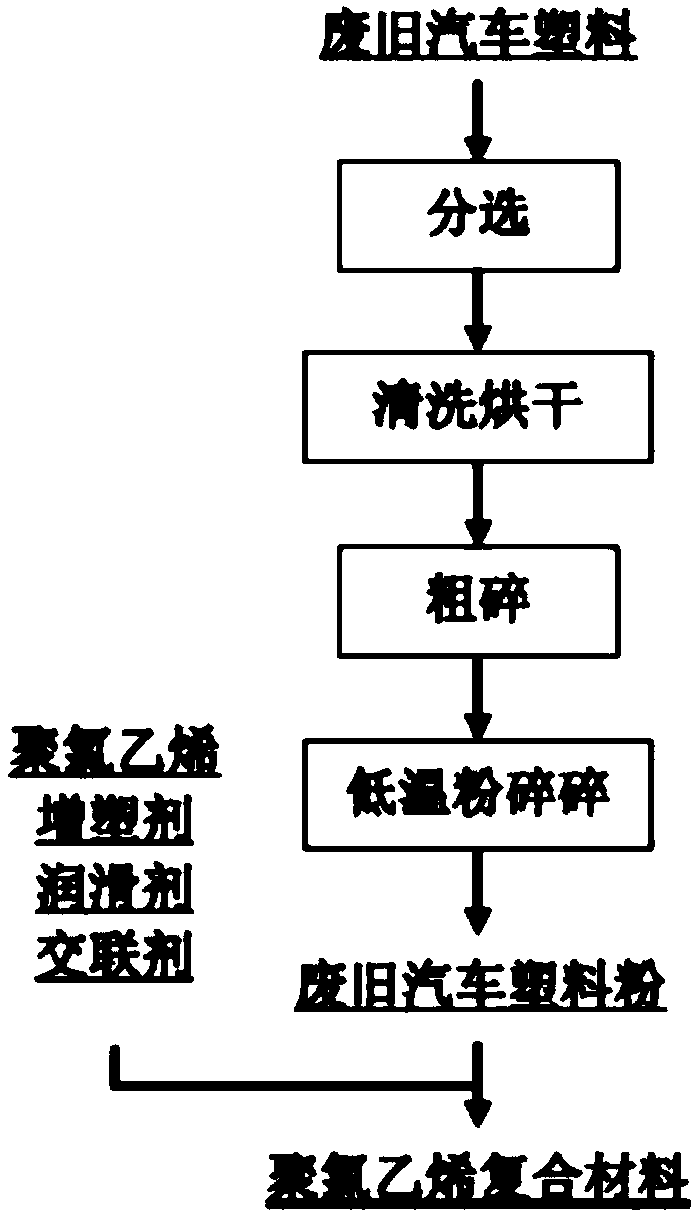

Polyvinyl chloride composite material realizing reutilization of waste plastic and preparation method thereof

InactiveCN108659377ALow costImprove mechanical propertiesPlastic recyclingMechanical material recoveryPlasticizerPolyvinyl chloride

Owner:湖北天霖新材料有限公司

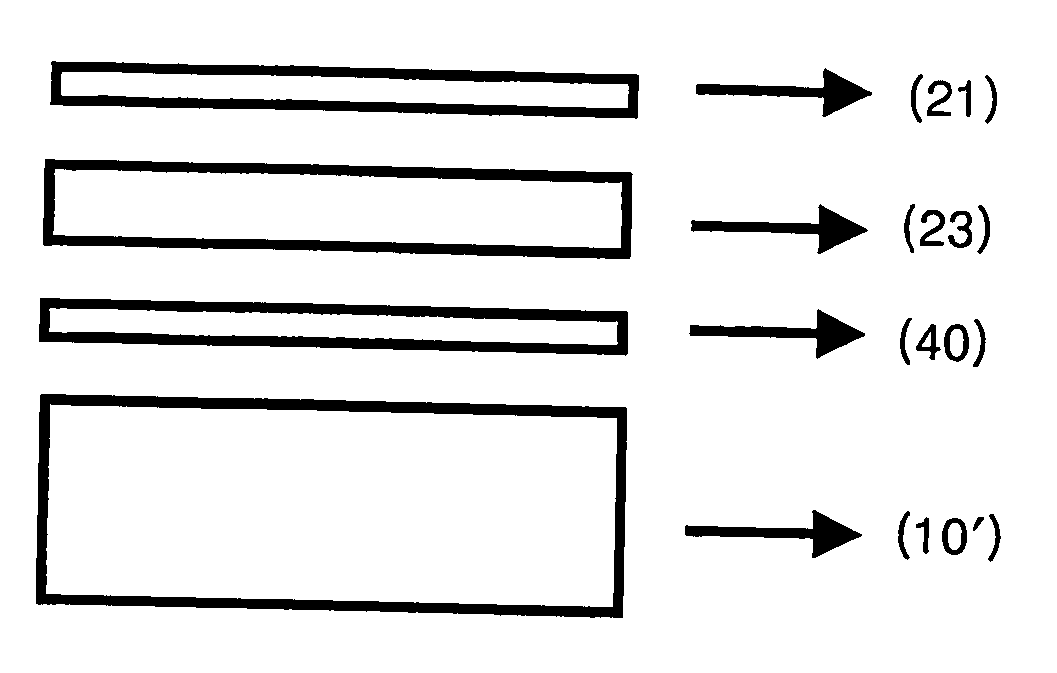

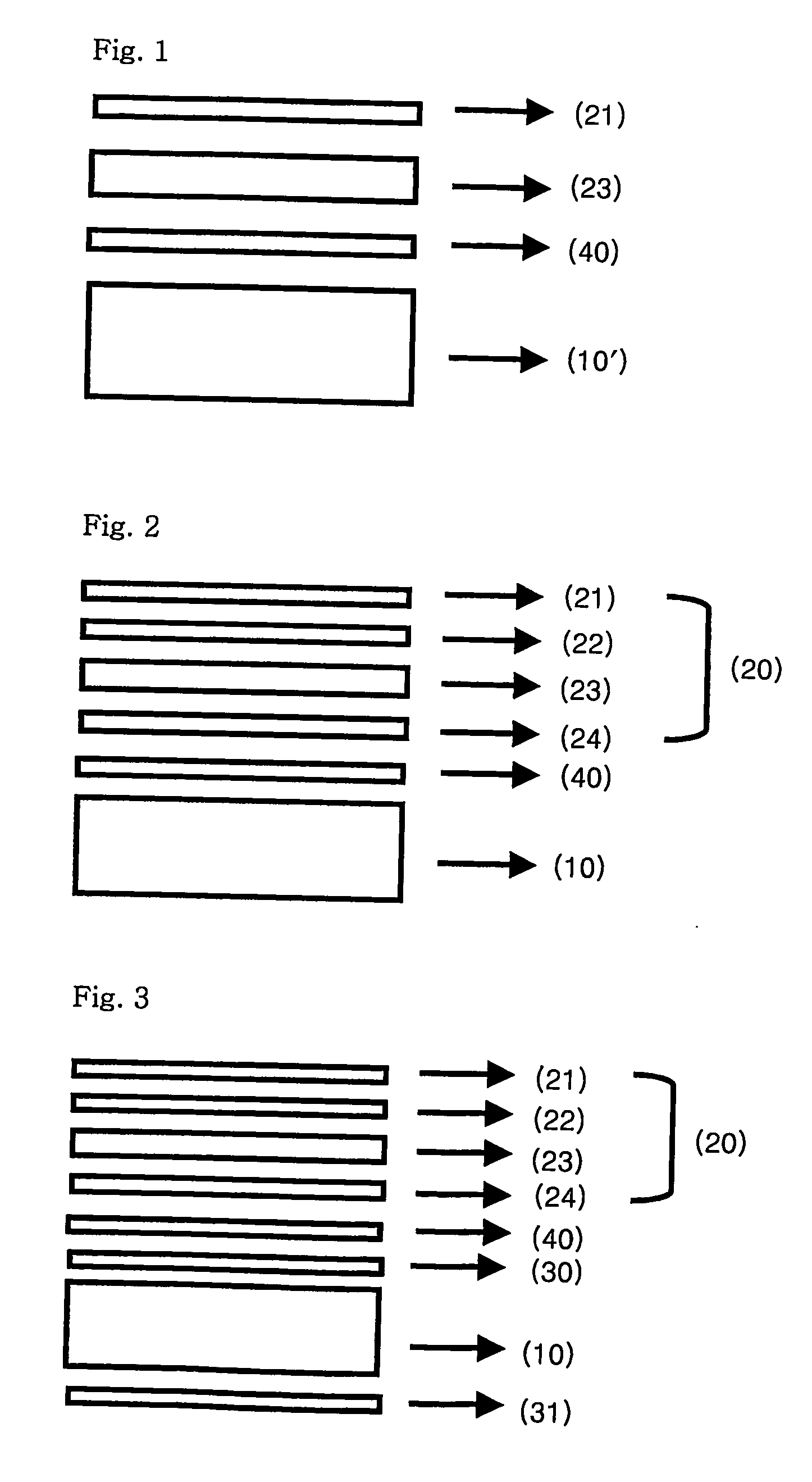

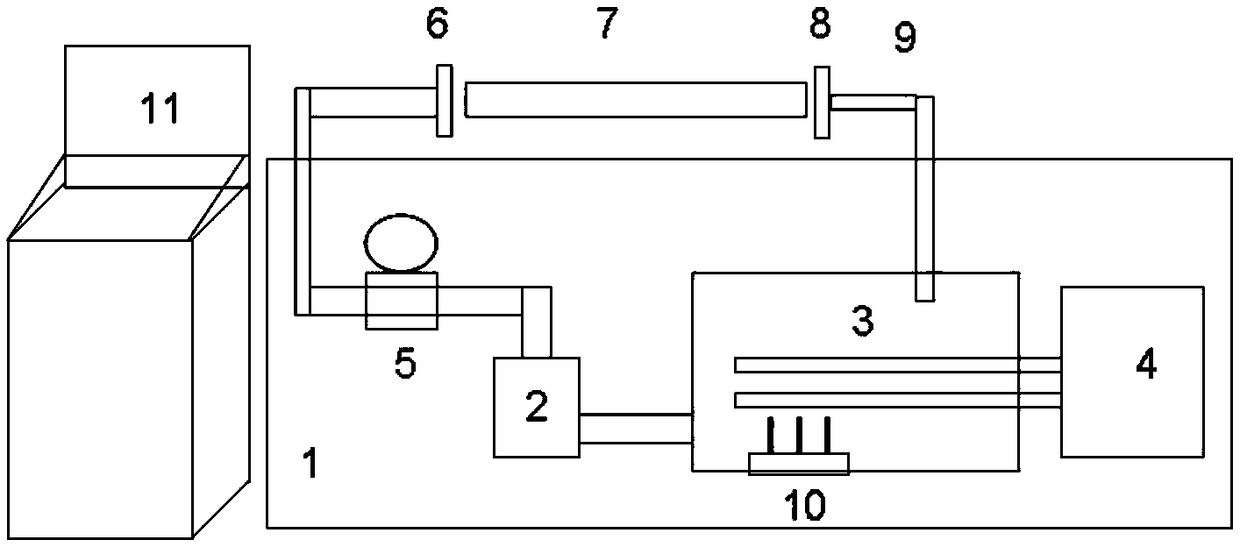

PMMA/PC-based high-performance polaroid

InactiveCN113093323AReduce manufacturing costImprove performancePolarising elementsCoatingsGlass fiberPolymer science

Owner:SOUTHWEAT UNIV OF SCI & TECH

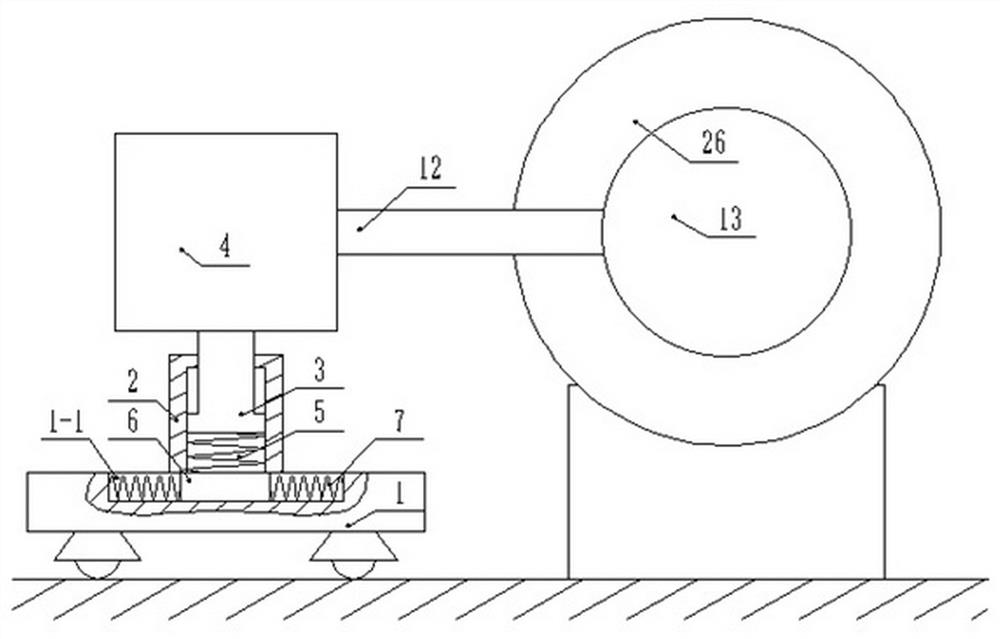

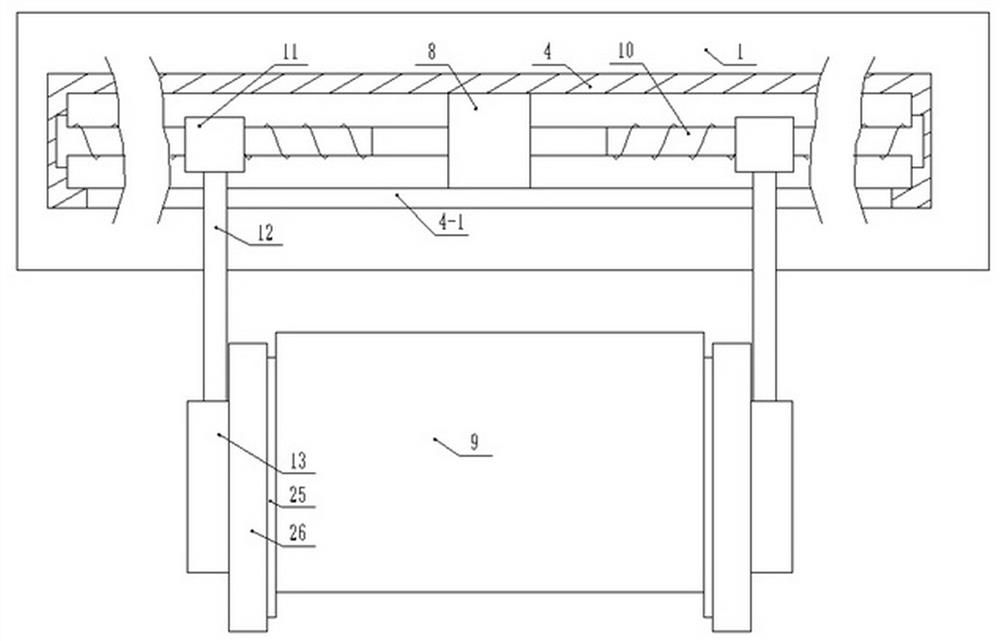

Hot rolled steel curled edge burr trimming and shoveling device

InactiveCN113042825ASimple structureFunction increaseMeasurement/indication equipmentsElectric machinePolyvinyl chloride

Owner:XINJIANG BAYI IRON & STEEL

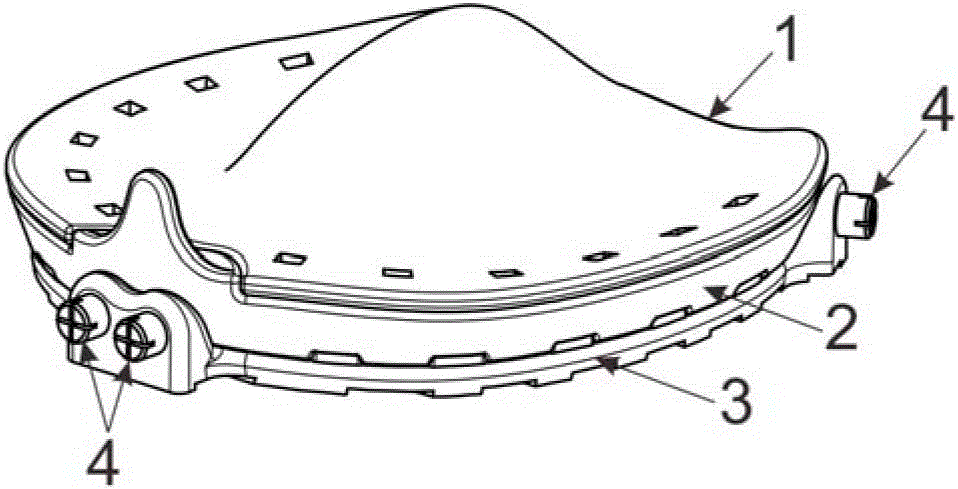

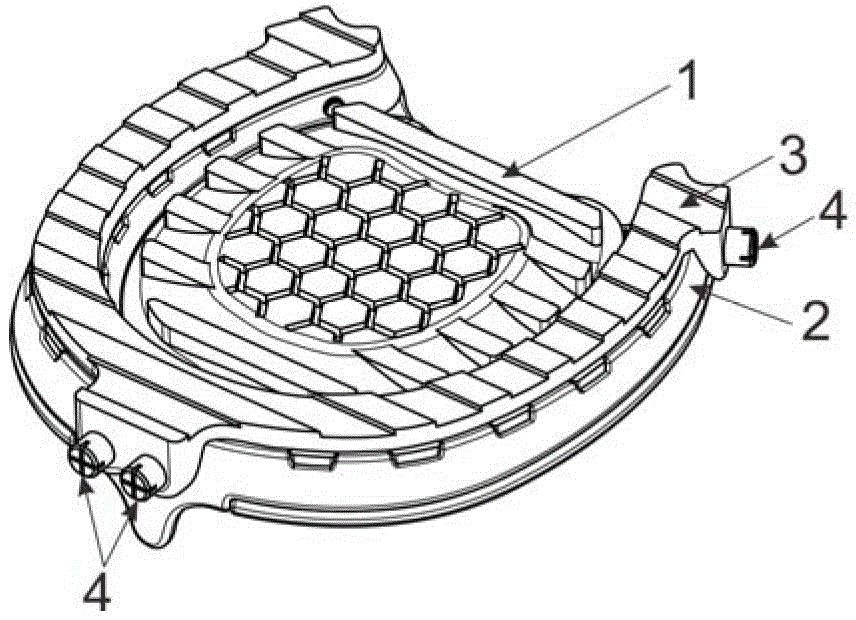

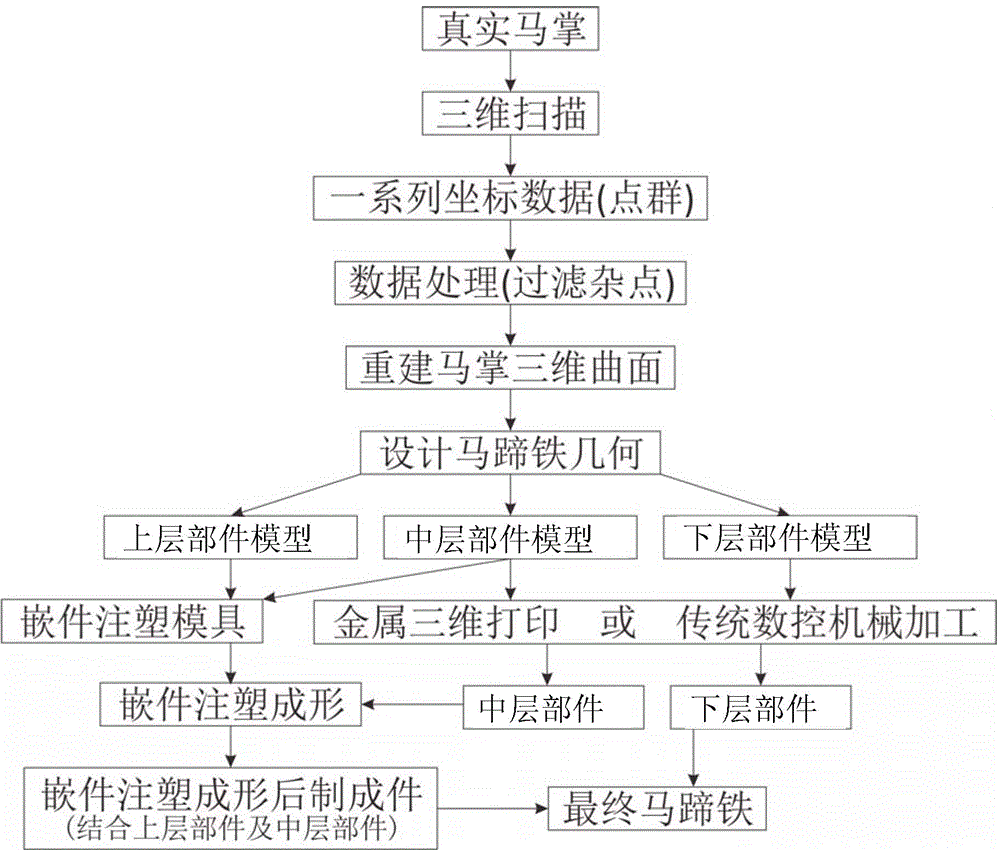

Shock-proof and easily-replaceable horseshoe and manufacturing method thereof

Owner:HONG KONG PRODUCTIVITY COUNCIL

Cement nanometer toughening agent for natural gas well cementation

Owner:CNPC BOHAI DRILLING ENG

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap