Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116 results about "Mechanical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of mechanical property. : a property that involves a relationship between stress and strain or a reaction to an applied force.

Method and apparatus for the control and monitoring of shape change in tissue

ActiveUS7416550B2Surgical instruments for heatingShape changeOptical property

A method of electroforming tissue comprises creating stress in the tissue; and causing a direct current to flow in the tissue to change the stress, strain, or intrinsic mechanical properties including shape of the tissue. Force is mechanically applied to the tissue to create external stresses or material parameters of the tissue are used to create internal stresses in the tissue by causing a current to flow in the tissue. The method further comprises the step of monitoring the stresses in the tissue and controlling the current flowing in the tissue according to the stresses therein by monitoring impedance, the optical properties, the pH, acoustic properties of the tissue, the gas formation in the tissue, the color of the tissue as caused by a chemical dye disposed therein or as caused by electroplating a material thereon.

Owner:RGT UNIV OF CALIFORNIA

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

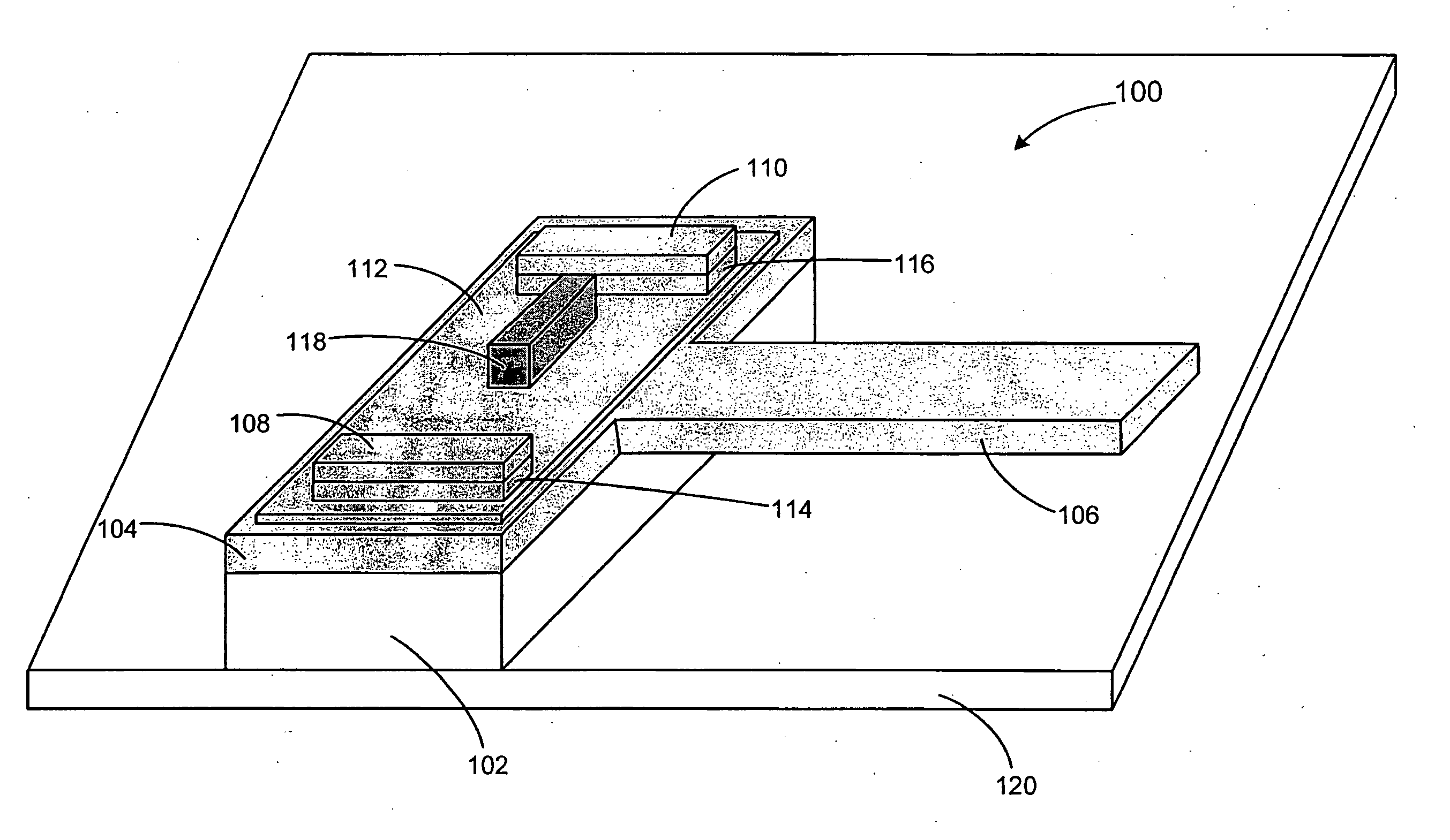

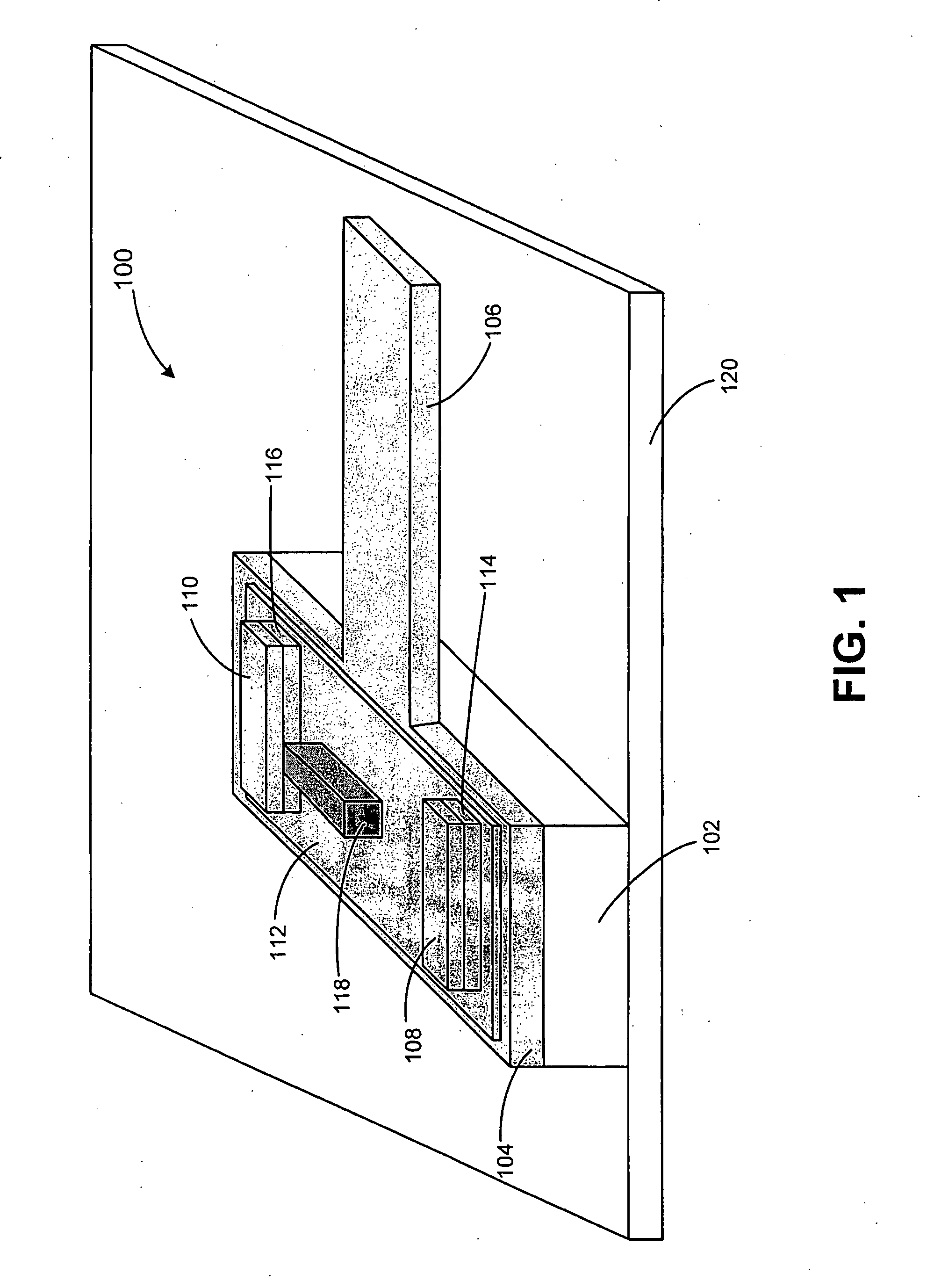

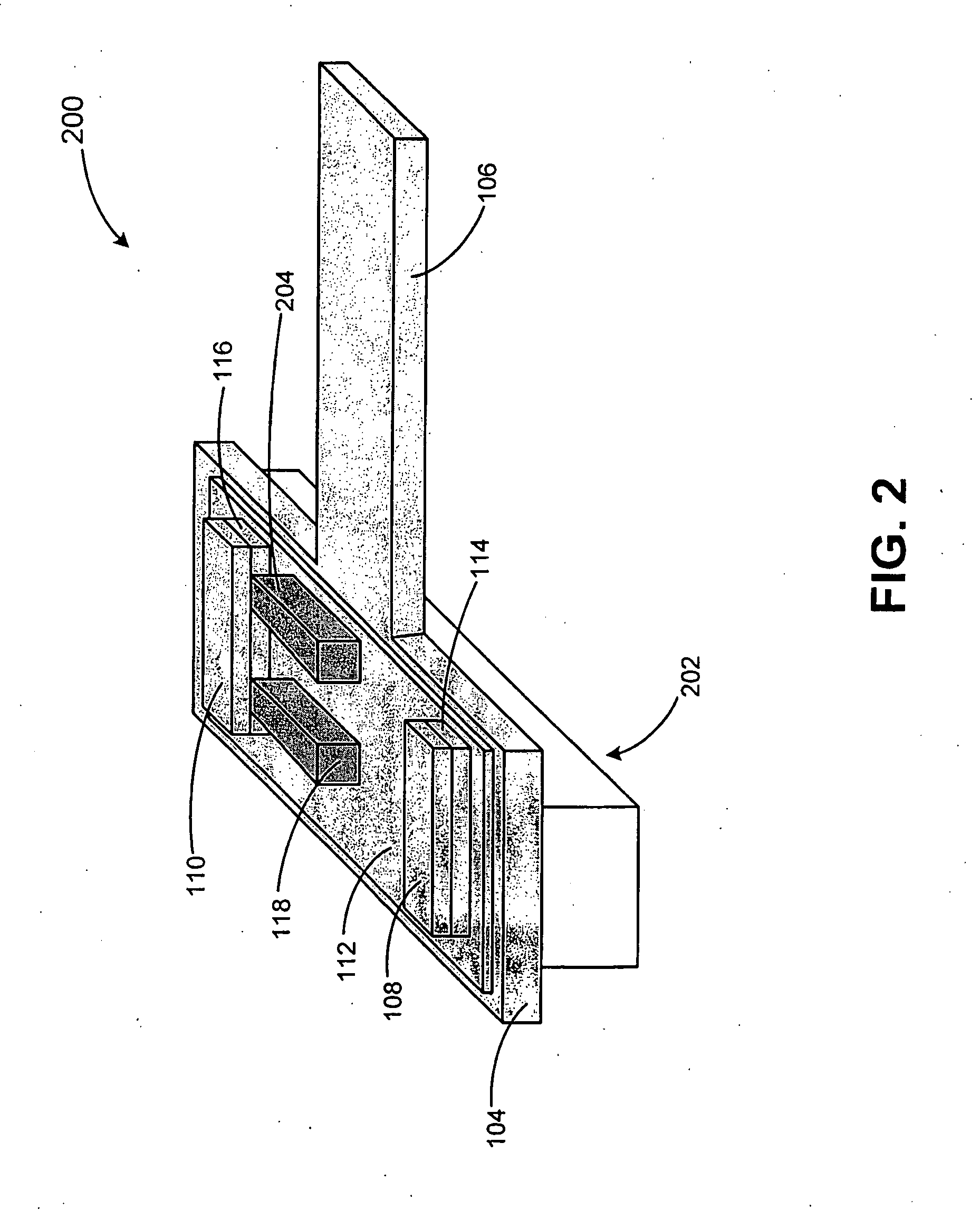

Microelectromechanical structures, devices including the structures, and methods of forming and tuning same

InactiveUS20050225413A1Simple structureImpedence networksSemiconductor/solid-state device manufacturingElectrical conductorEngineering

Owner:AXON TECH

Manufacture method of slip sheet of air conditioner compressor

InactiveCN102251166AImprove the lubrication effectImprove wear resistanceFoundry mouldsSolid state diffusion coatingCarbideSlip sheet

Owner:乐金电子(秦皇岛)有限公司 +1

Asphalt modified thermoplastic polyolefin water-proof coiled material and preparation method thereof

InactiveCN101550729AImproves UV resistanceExcellent ozone resistanceRoof covering using flexible materialsBuilding insulationsPolymer sciencePolyolefin

Owner:胜利油田大明新型建筑防水材料有限责任公司

Insulation rubber for longitudinal water-tight demagnetization cable used for ship, and manufacture method for insulation rubber

InactiveCN102746587AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsGas phaseAging resistance

The invention discloses an insulation rubber for longitudinal water-tight demagnetization cables used for ships and a manufacture method for the insulation rubber, belonging to the field of cables. The raw materials of the rubber are 15 parts of terpolymer EP rubber K21, 5 parts of terpolymer EP rubber 4045M; 0.5-0.6 parts of a vulcanizing agent DCP, 0.2-0.3 parts of a vulcanizing agent TAIC, 0.7-0.9 parts of an antioxidant MB, 0.2-0.3 parts of an antioxidant RD, 1.0-2.0 parts of paraffin oil, 1-2 parts of chlorinated paraffin-52, 0.5-1.0 parts of microcrystalline paraffin, 1.0-2.0 parts of zinc oxide, 0.3-0.5 parts of eleaostearic acid, 8-11 parts of powdered talcum, 1.0-1.5 parts of gas phase method silica, and 7-9 parts?of calcined pottery clay. First, mixing the raw rubbers of the terpolymer EP rubbers K21 and 4045 in an internal mixer; then adding the rest of the raw materials except the vulcanizing agents in sequence and mixing for 14-16 minutes, and after the obtained mixture being mixed uniformly, loading the obtained product on an open mill to make triangular bags eight times, followed by rubber sieving and sheets making. The insulation rubber has the advantages of good insulative and mechanical properties, aging resistance and oil resistance, which can satisfy the usage requirements of the longitudinal water-tight demagnetization cables used for ships.

Owner:JIAXING JUNHONG OPTICAL CO LTD

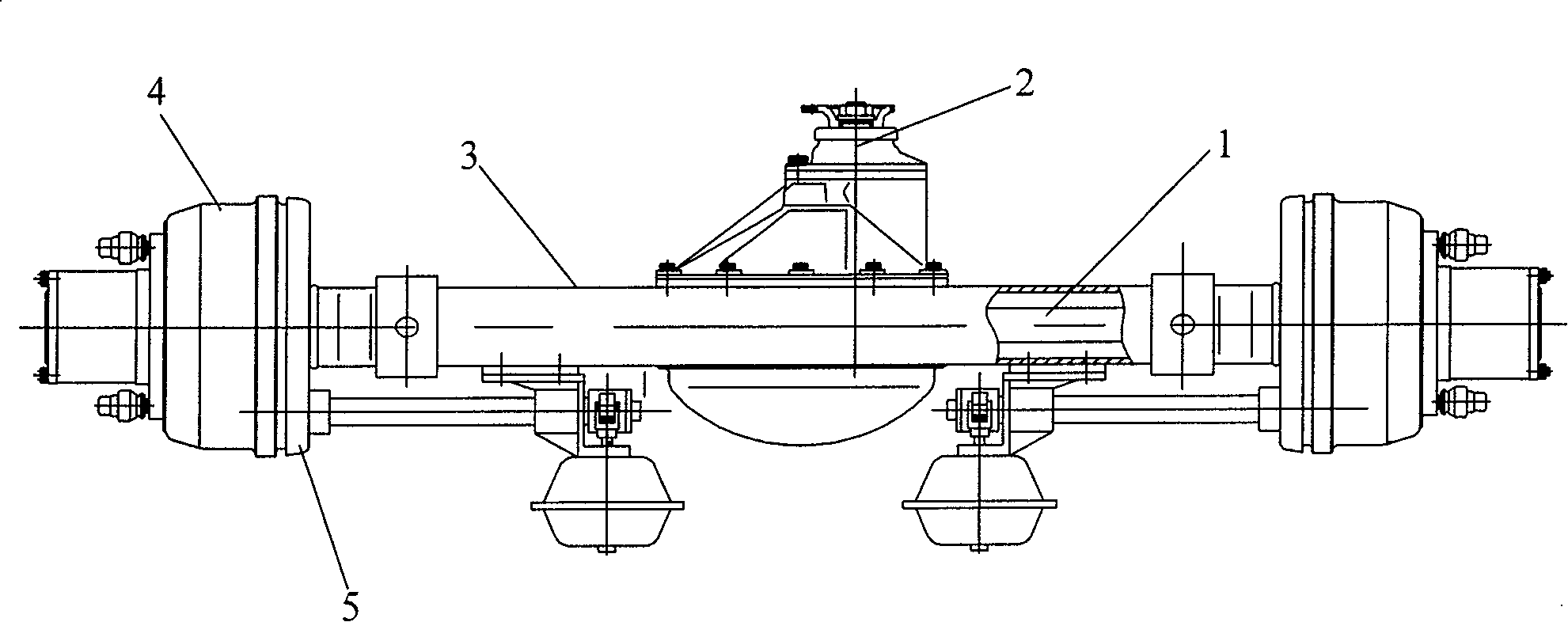

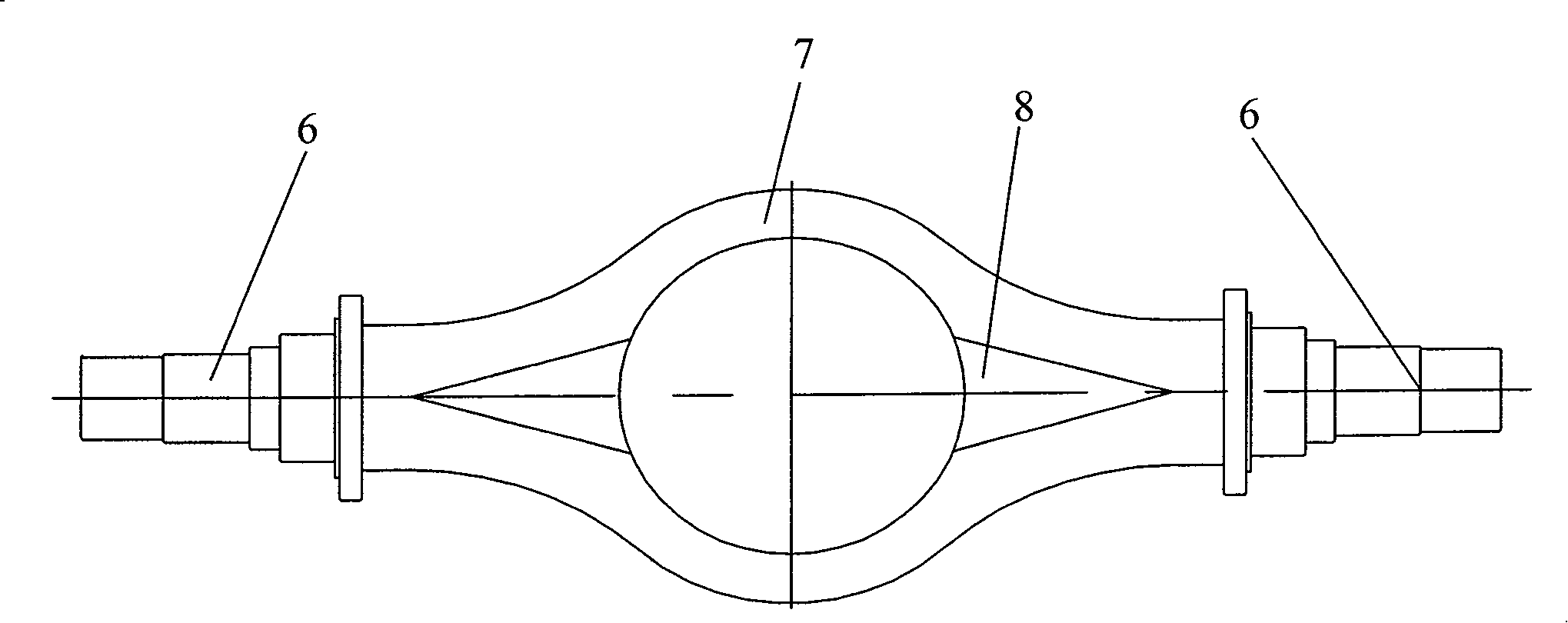

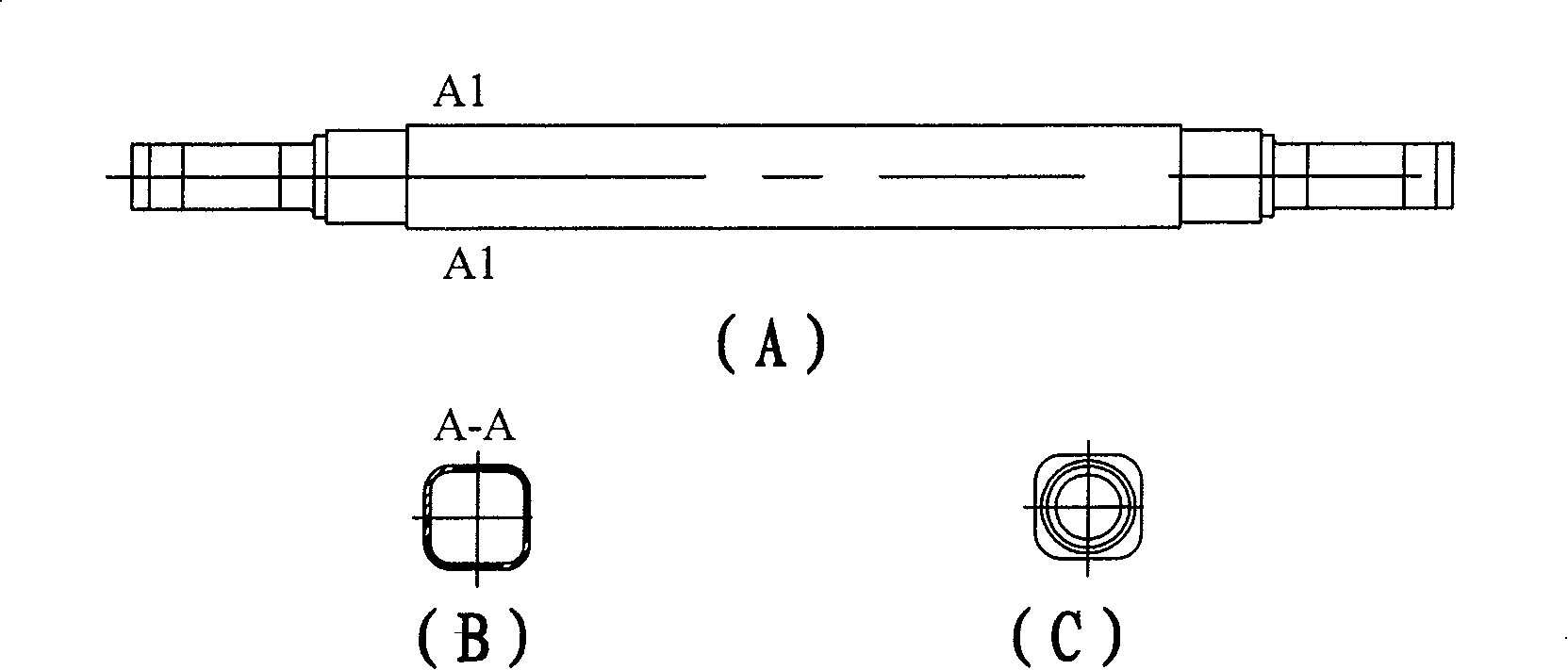

Roll type cold pressing processing method and device for vehicle driving axle housing

InactiveCN101185946ASimple structureHigh mechanical strengthExtrusion control devicesRams/plungersAxial pressureEngineering

Owner:梅利红

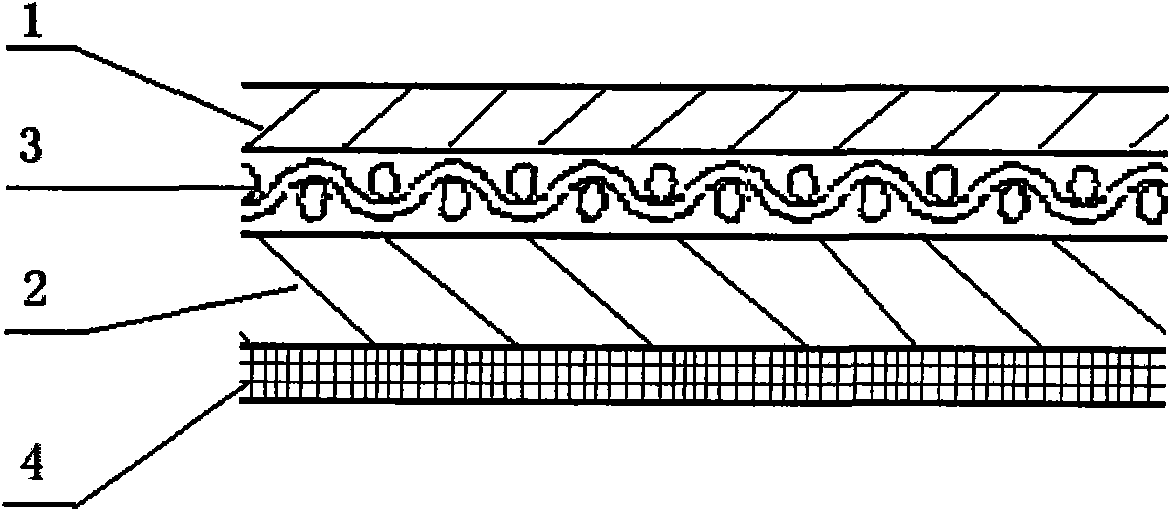

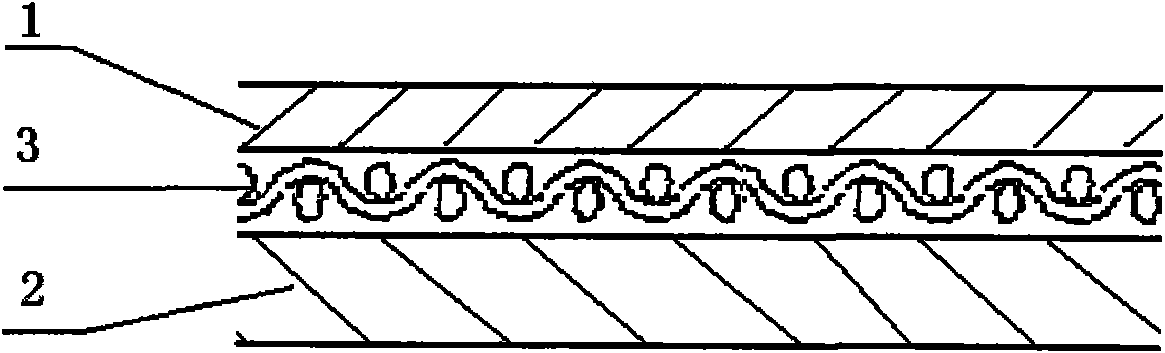

Processing technology for super-imitated-cotton/fine-denier damp conduction polyester comfortable mercerized velvet warp knitting fabric

ActiveCN103859664AEasy to takeGood flexibilitySucessive textile treatmentsWarp knittingHeat resistanceEngineering

Owner:ZHEJIANG QINGSONG TEXTILE

Method for preparing silicon carbide ceramic material with low residual silicon by adopting multi-step reaction sintering method

ActiveCN106478105ASolve the mechanical propertiesSolving Elasticity ProblemsHeat conductingYoung's modulus

Owner:咸阳瞪羚谷新材料科技有限公司

Method for raising fluidity of thermoplastic cross-linked rubber

Owner:SHANDONG DAWN POLYMER CO LTD

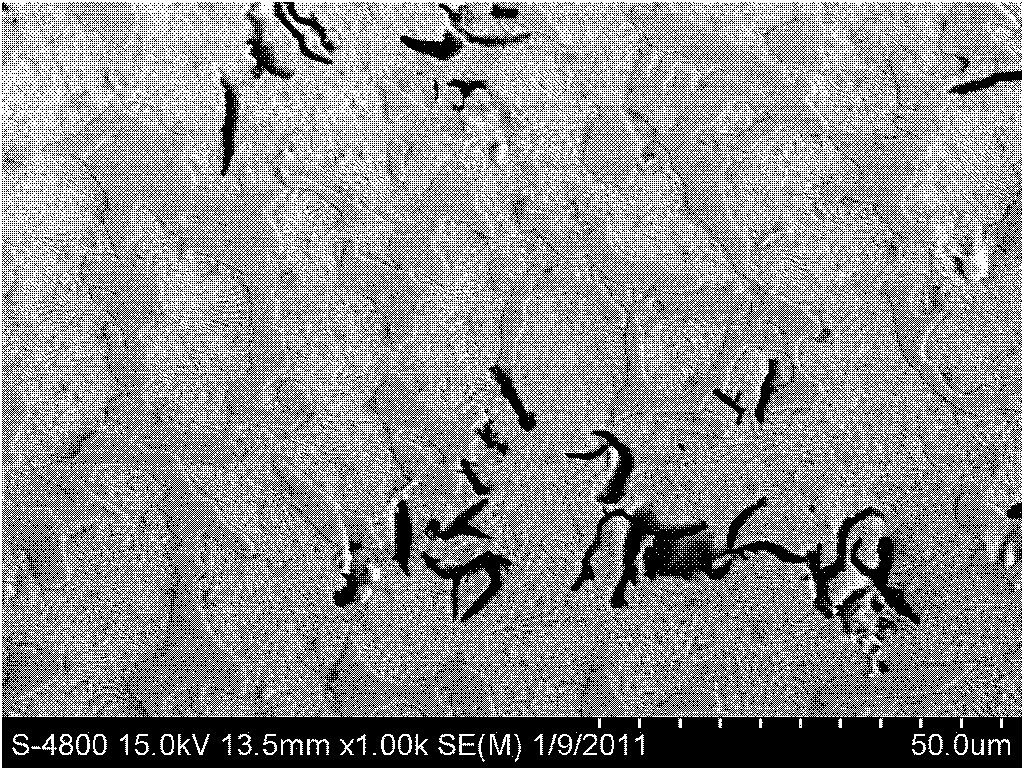

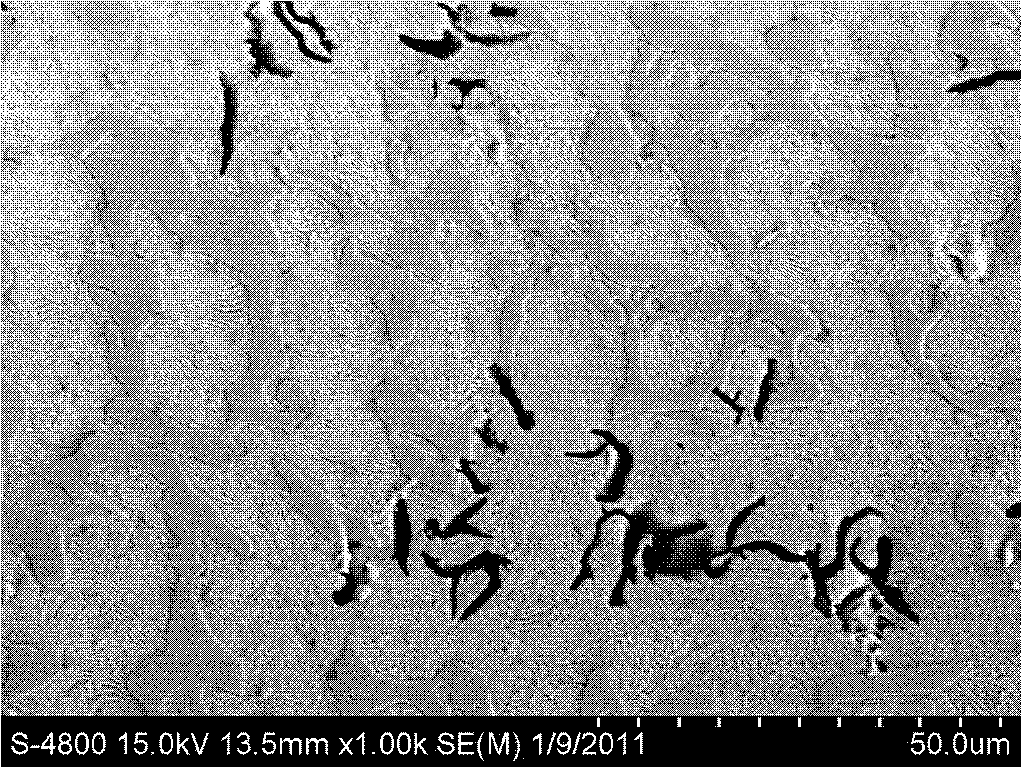

Method for metallizing ceramic surface and method for connecting ceramic with aluminum

ActiveUS20120121896A1Hot-dipping/immersion processesSoldering apparatusMicrometerAlloy thin film

A process for metalizing a ceramic surface or attaching a ceramic to a metal is provided. The process may comprise: immersing the ceramic into an aluminum or aluminum alloy melt, making the ceramic move or stay still relative to the melt to adhere the melt to the ceramic; and then removing the ceramic from the melt to unaffectedly cool the film adhered thereto. The process can attach an aluminum or aluminum alloy thin film having a thickness of several to tens of micrometers on a ceramic surface. The thin film is formed by solidification, and does not have microscopic faults such as oxide film inclusions or pores, therefore having proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.This invention discloses a process for metalizing the surface of a ceramic and a process for attaching a ceramic to a metal. A process for attaching an aluminum or aluminum alloy thin film to a ceramic surface comprises the steps of: immersing a ceramic surface to be metalized into a aluminum or aluminum alloy melt, and making the ceramic move or stay still relative to the melt to adhere the melt of the aluminum or aluminum alloy to the metalizing surface of the ceramic; and then removing the metalizing surface of the ceramic from the melt to unaffectedly cool the aluminum or aluminum alloy liquid film adhered thereto to obtain a ceramic having the aluminum or aluminum alloy thin film attached to the surface. The process to attaching aluminum or aluminum alloy thin film on the surface of a ceramic of the present invention can attach an aluminum or aluminum alloy thin film having a thickness of several micrometers to tens of micrometers on the surface of a ceramic. The thin film is formed by the solidification of the aluminum of aluminum alloy liquid film attached on the surface of a ceramic, and it does not have the microscopic faults such as oxide film inclusions or pores, therefore having the proper physical of mechanical properties of aluminum. Ceramics or a ceramic and a metal can be brazed via the surface metalizing film, the bonding strength of their interface can over the strength of aluminum itself.

Owner:TSINGHUA UNIV

Shoulder wedge composite material and manufacturing method thereof

The invention discloses a shoulder wedge composite material and a manufacturing method thereof. The shoulder wedge composite material consists of the following raw materials in part by weight: 100 parts of natural rubber, 10 to 50 parts of carbon series nano thermal conducting filler, 10 to 35 parts of coarse particle size carbon black, 2 to 6 parts of octyl phenolic resin, 2 to 4 parts of surfactant, 1 to 8 parts of silane coupling agent, 1.5 to 9 parts of vulcanizing agent and the balance of other common aids. The preparation method comprises the following steps of: plasticating the rubber in an internal mixer, adding the coarse particle size carbon black, the carbon series nano thermal conducting filler, the octyl phenolic resin, the surfactant and the other aids into the internal mixer, mixing and controlling the temperature to be between 80 and 120 DEG C; adding the silane coupling agent into the mixture, controlling the temperature to be between 120 and 160 DEG C, and discharging the sizing material; adding a master batch and the vulcanizing agent into the internal mixer and discharging products until the temperature is 80 to 120 DEG C, wherein if the other aids contain scorch retarder, the scorch retarder and the vulcanizing agent are added together. The shoulder wedge composite material provided by the invention meets the requirements of mechanical properties, and is low in themogenesis, high in thermal conductivity, and excellent in machinability.

Owner:BEIJING UNIV OF CHEM TECH +1

Carbon nanotube filled polycarbonate Anti-curl back coating with improved electrical and mechanical properties

Transparent or semi-transparent, electrically conductive anti-curl back coating composite for electrophotographic imaging member comprising a carbon nanotube complex and a polycarbonate binder are described along with processes for preparing them.

Owner:XEROX CORP

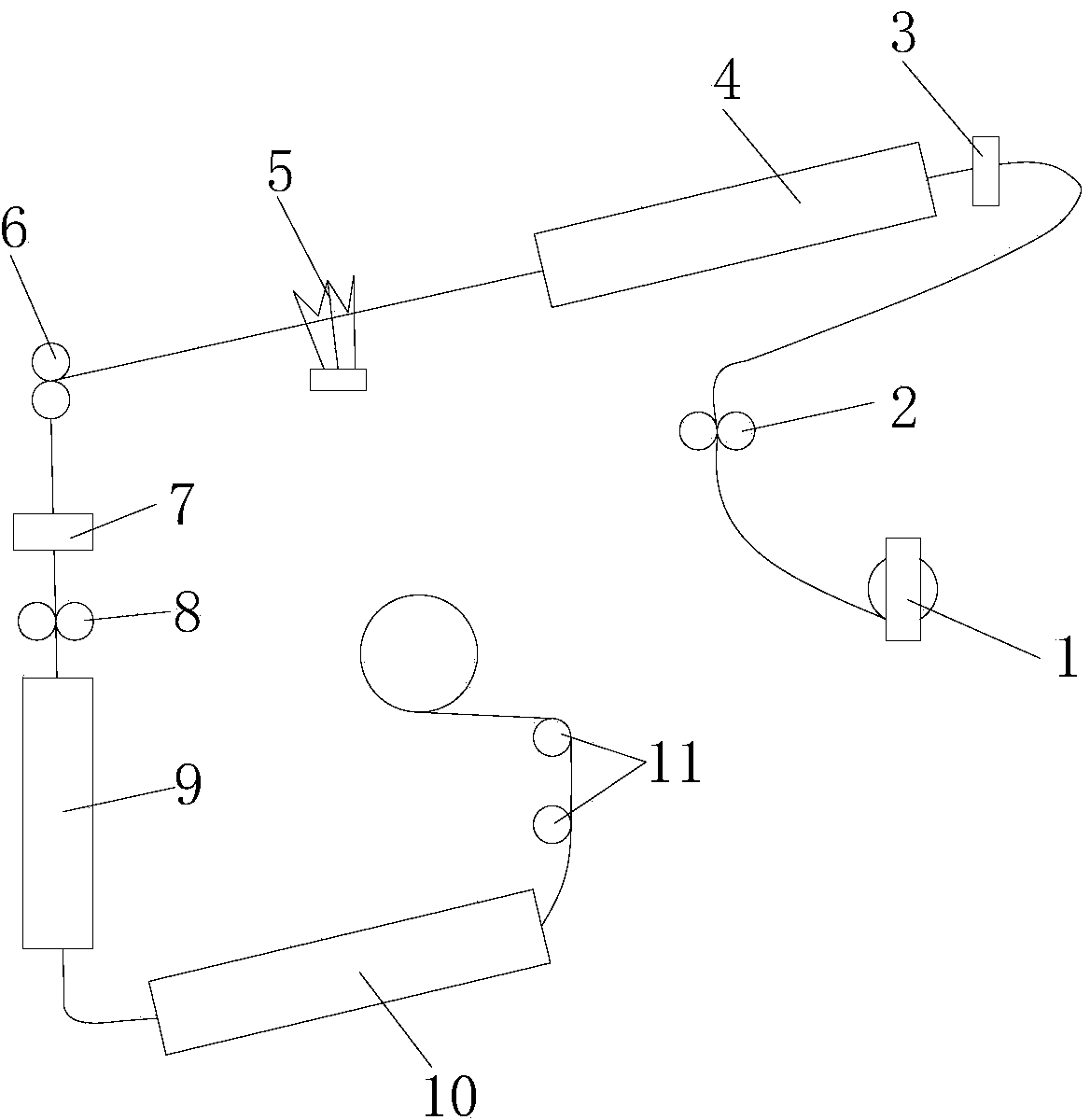

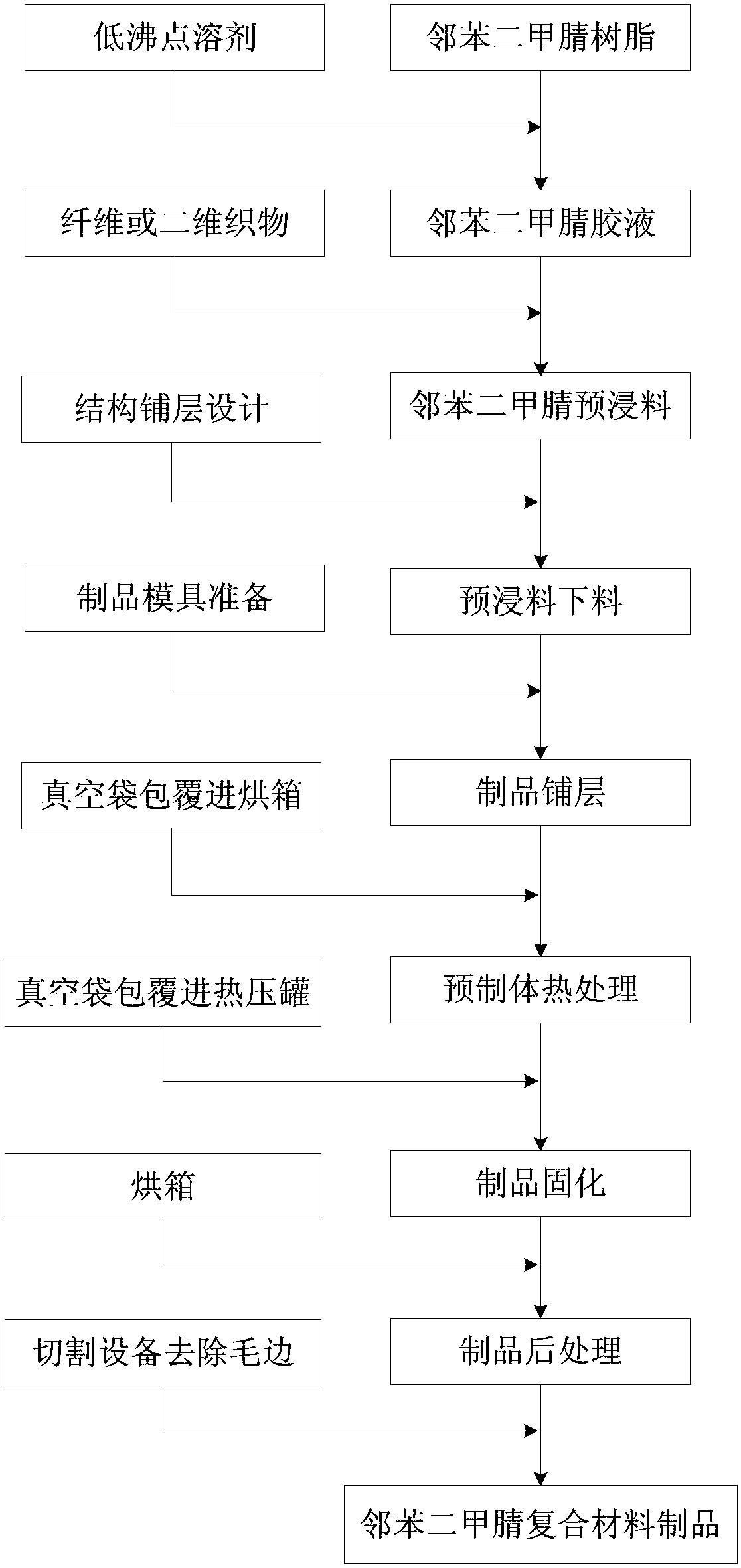

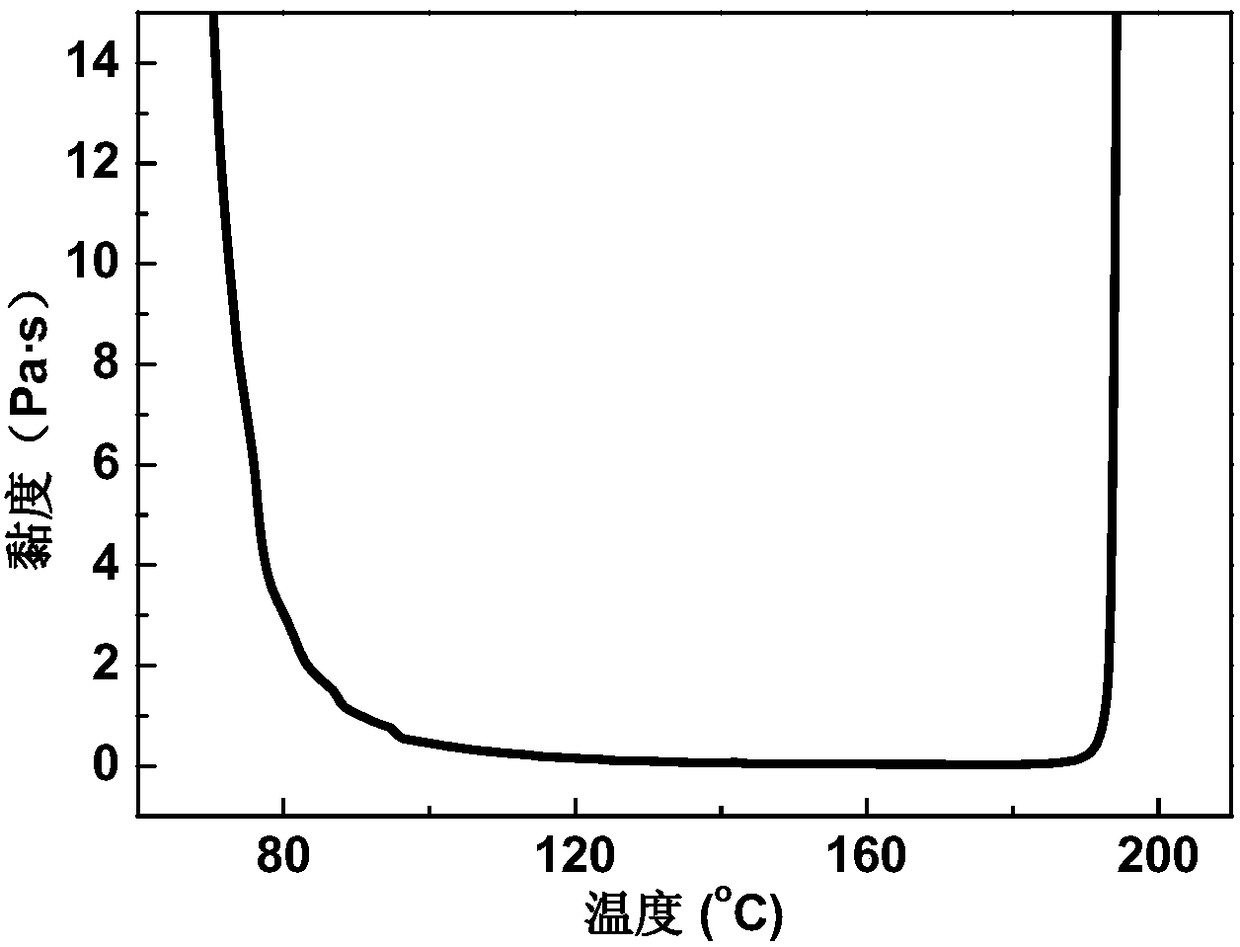

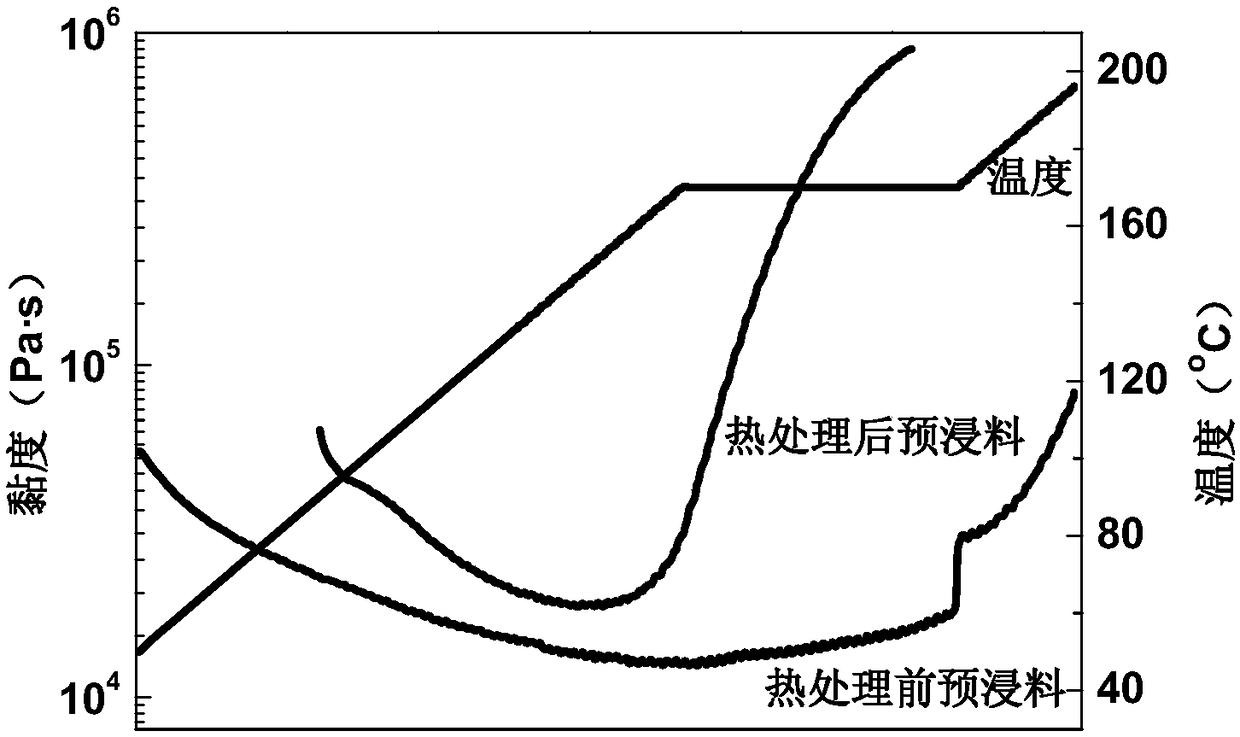

Phthaphthalonitrile resin prepreg, composite material and preparation method of composite material

ActiveCN108454135AGood mechanical propertiesImprove molding qualityPhthalonitrileTemperature resistance

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

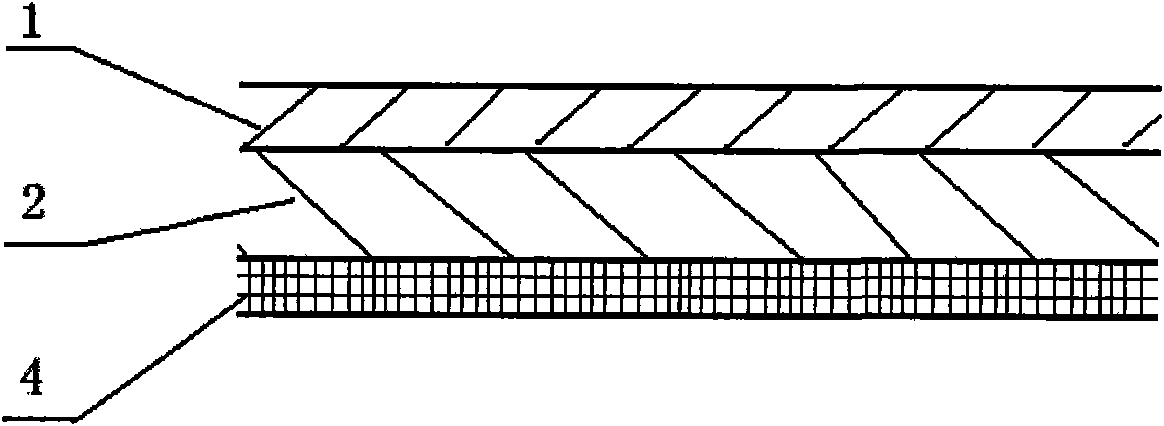

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

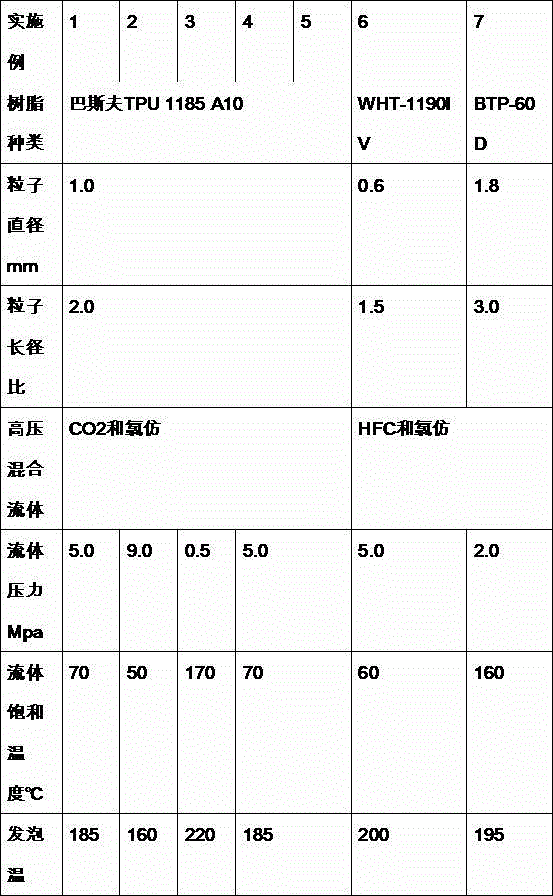

Method for preparing high-resilience thermoplastic polyurethane foamed particles and molded body thereof

Owner:茂泰(福建)新材料科技有限公司

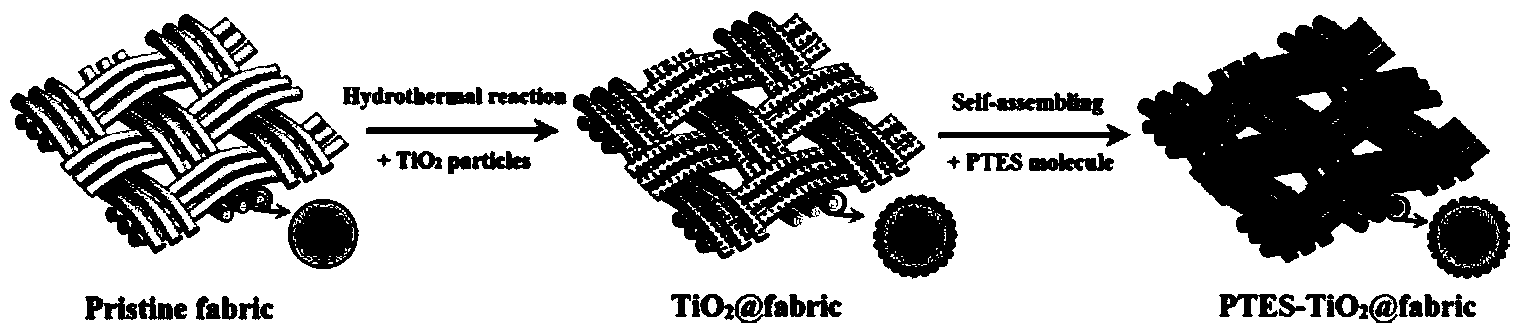

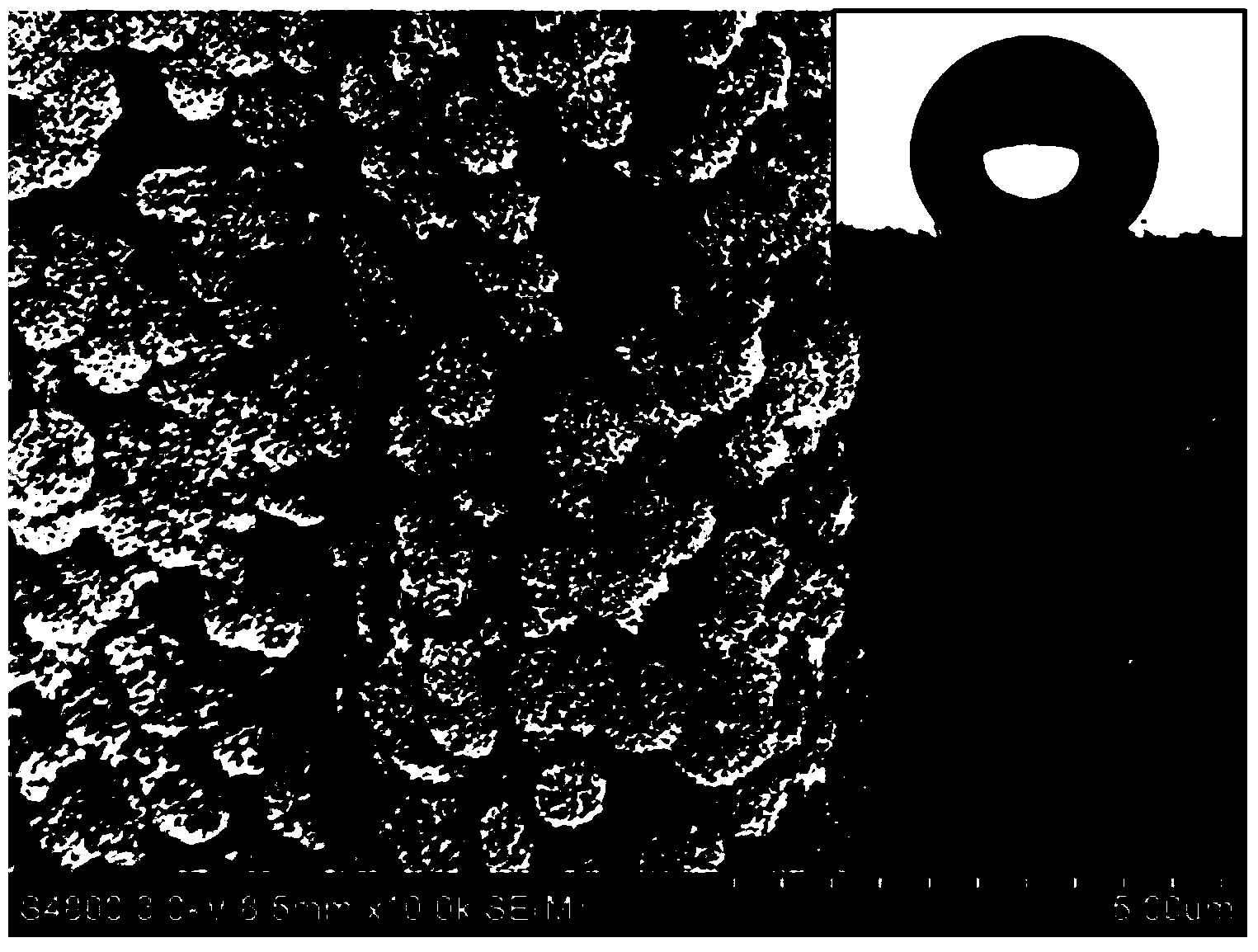

Preparation method of special-infiltration functional fabric surface with self-cleaning and oil-water separation functions

Owner:SUZHOU UNIV

Formula of highly anti-fatigue automobile brake chamber rubber diaphragm material

ActiveCN101302311ASolve the blending problemImprove thermal stabilityPolytetramethylene terephthalateRubber material

The invention provides a rubber material formulation for a high fatigue resistant rubber diaphragm of an automobile brake chamber, which is mainly prepared by natural rubber (NR), styrene butadiene rubber (SBR), polybutylene terephthalate (PBT), vulcanizing agent, zinc oxides, stearic acid, anti-aging agent, dispersant, accelerant, carbon black, aromatic oil and white carbon black. The physical mechanical properties of the rubber diaphragm of the automobile brake chamber prepared by the rubber formulation all reach the novel standard drafted by the Society of Automotive Engineering (SAE) of America; the service life of a platform of the rubber diaphragm reaches over 2 million times; the platform has the advantages of high stress at definite elongation, strength and elongation property, compression fatigue resistivity, flexural deformation resistance and attrition resistance, and maintenance of small variation of the material characteristics within the wide use temperature between 55 and 100 DEG C when the material is used; and the service life of the platform is basically the same as that of an air brake assembly, and resource conservation is greatly promoted simultaneously, thereby realizing conversion of the platform from 'a wearing part' to 'a permanent part'.

Owner:GUIZHOU JINGZHONG RUBBER & PLASTIC IND CO LTD

Preparation method and application of surface artemisinin molecule imprinting adsorbing material of vegetable sponge

InactiveCN102600813ASpecific recognition abilityHigh selectivityIon-exchange process apparatusOrganic chemistryCross-linkN dimethylformamide

Owner:UNIV OF JINAN

Aluminum plastic plate flame-retardant core layer and aluminum-plastic plate

ActiveCN109111617AReduce corrosionExtended service lifeSynthetic resin layered productsMetal layered productsLow-density polyethyleneAntioxidant

Owner:台州市佳信新材料科技有限公司

High heat resistant non-skid coatings

InactiveUS20110224327A1Efficient use ofAcceptable mechanicalFireproof paintsOther chemical processesMechanical propertyHigh heat

Owner:AKZO NOBEL COATINGS INT BV

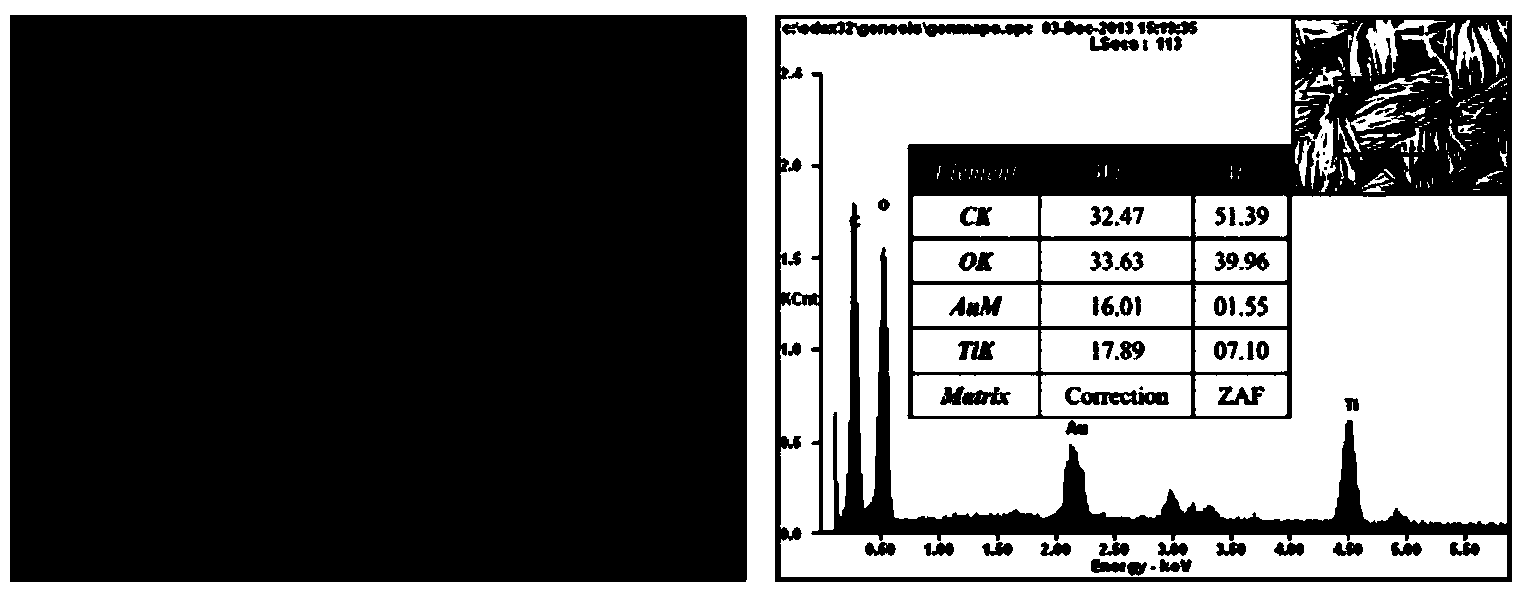

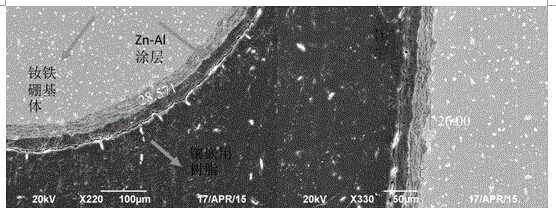

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Molybdenum fibre reinforced resin concrete material

InactiveCN101759397AGood physical and mechanical propertiesHigh compressive strengthKinetosomesResin-Based Composite

Owner:SHANDONG UNIV

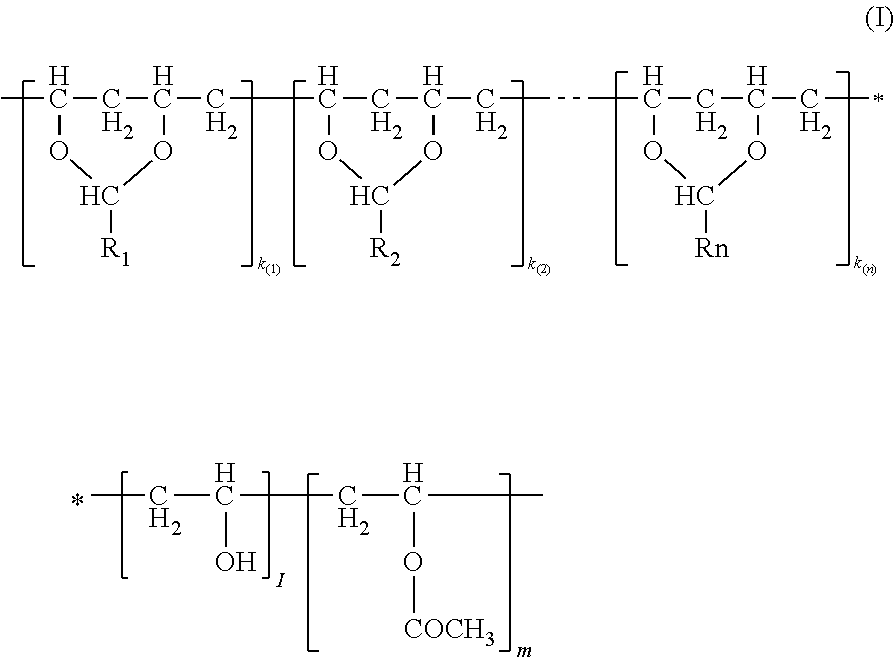

Thermoplastic polymer composition and molded article

InactiveUS20130122289A1Excellent in flexibility propertyImprove mechanical propertiesNon-fibrous pulp additionNon-macromolecular adhesive additivesPolyvinyl alcoholGlass transition

Owner:KURARAY CO LTD

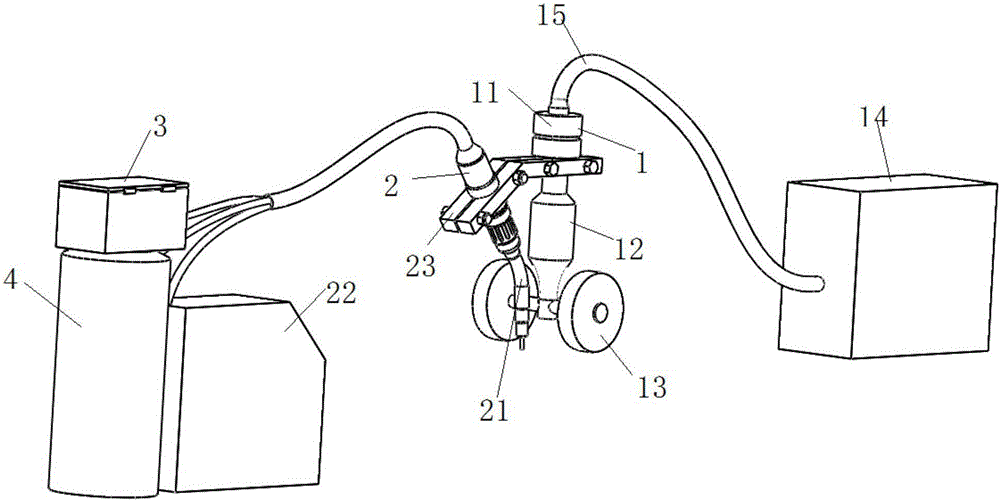

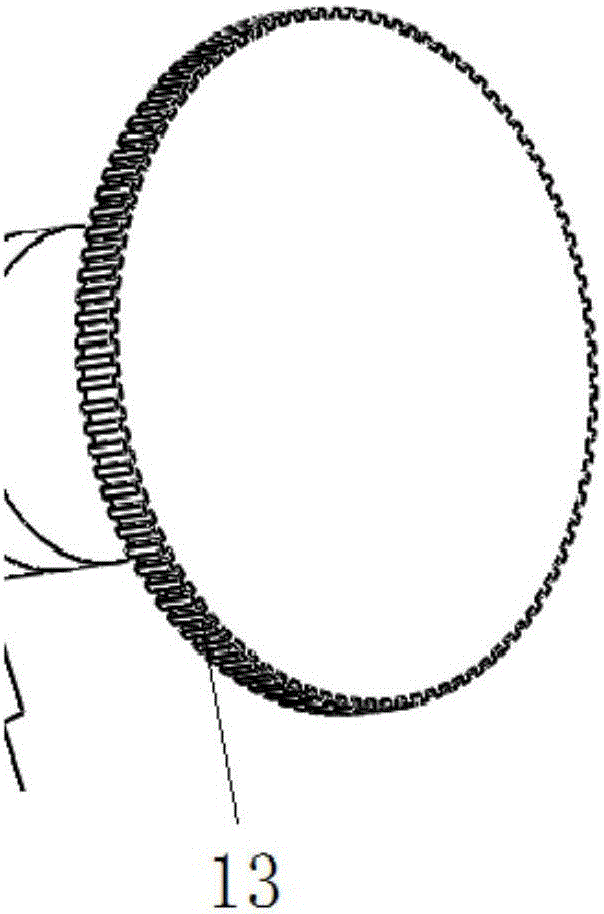

Rolling type ultrasonic arc composite welding device

PendingCN106624401AGrain refinementImprove weld structureWelding apparatusMechanical propertyHigh frequency vibration

Owner:GUANGDONG INST OF INTELLIGENT MFG

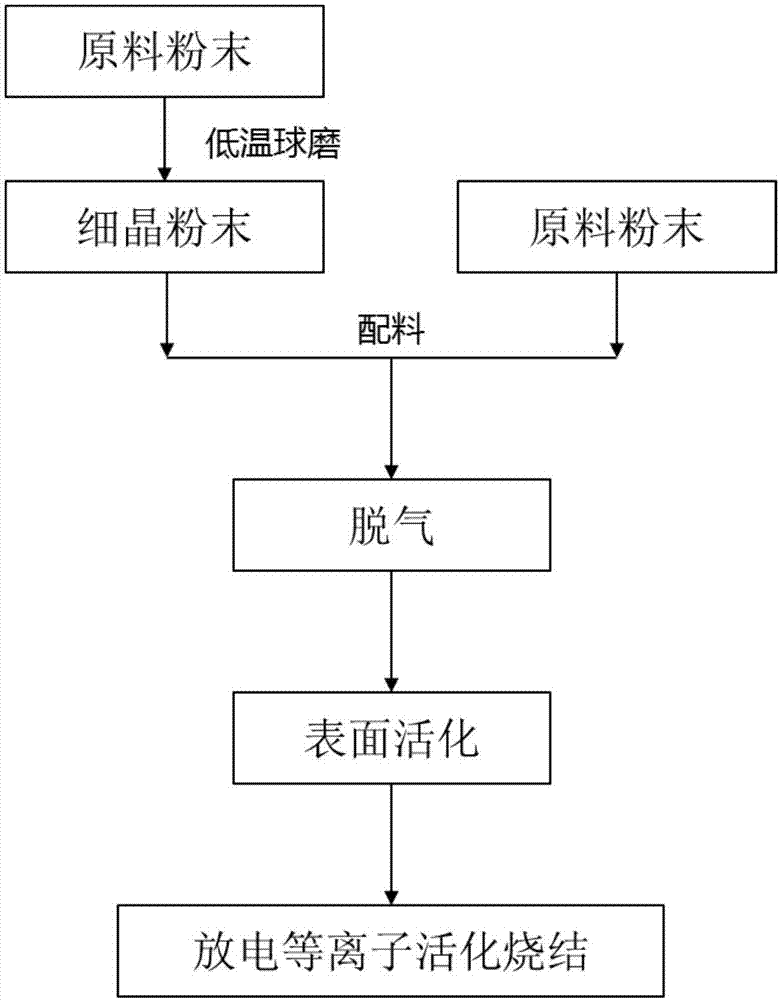

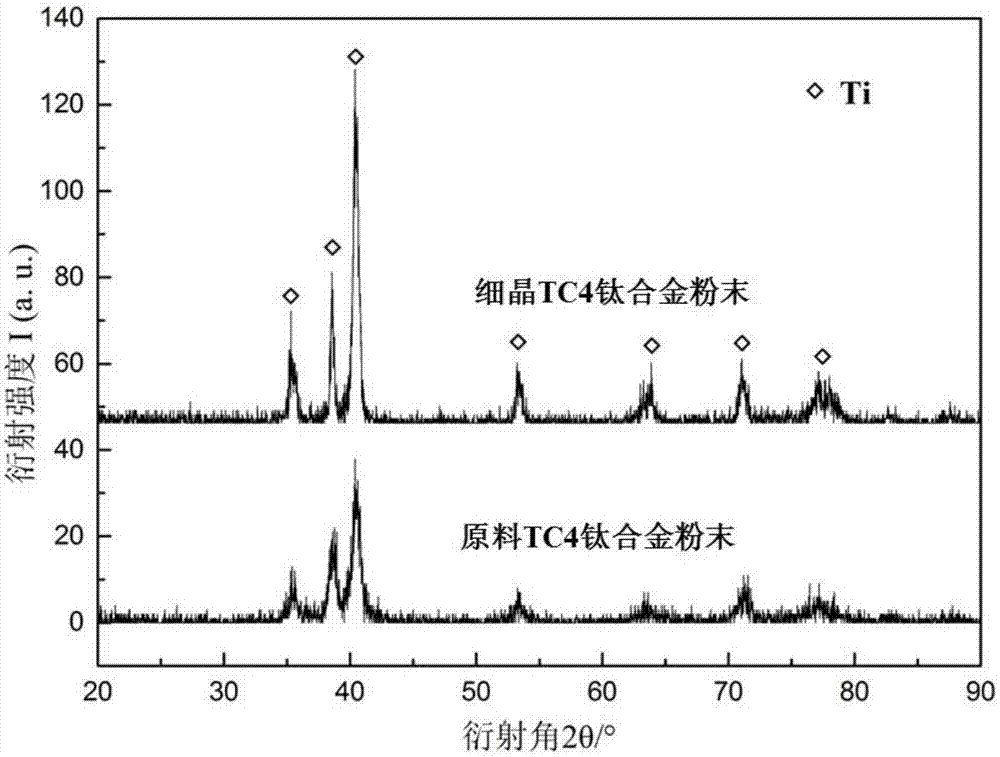

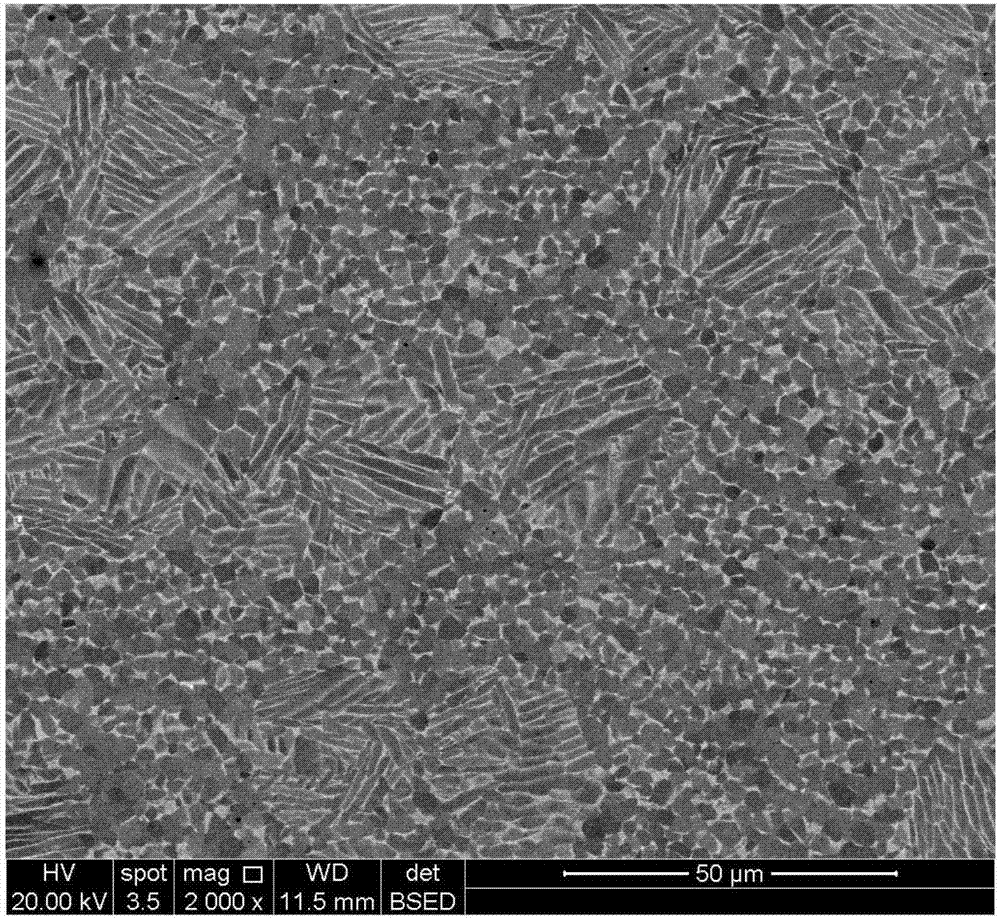

Preparation method of dual-scale titanium alloy material

Owner:WUHAN UNIV OF TECH

Fiber-enhanced epoxy resin composition for quickly forming automobile part and preparation method thereof

ActiveCN106674900AMeet heat resistance requirementsPromote infiltrationDiethylenetriamineFiber-reinforced composite

Owner:芜湖天道绿色新材料有限公司

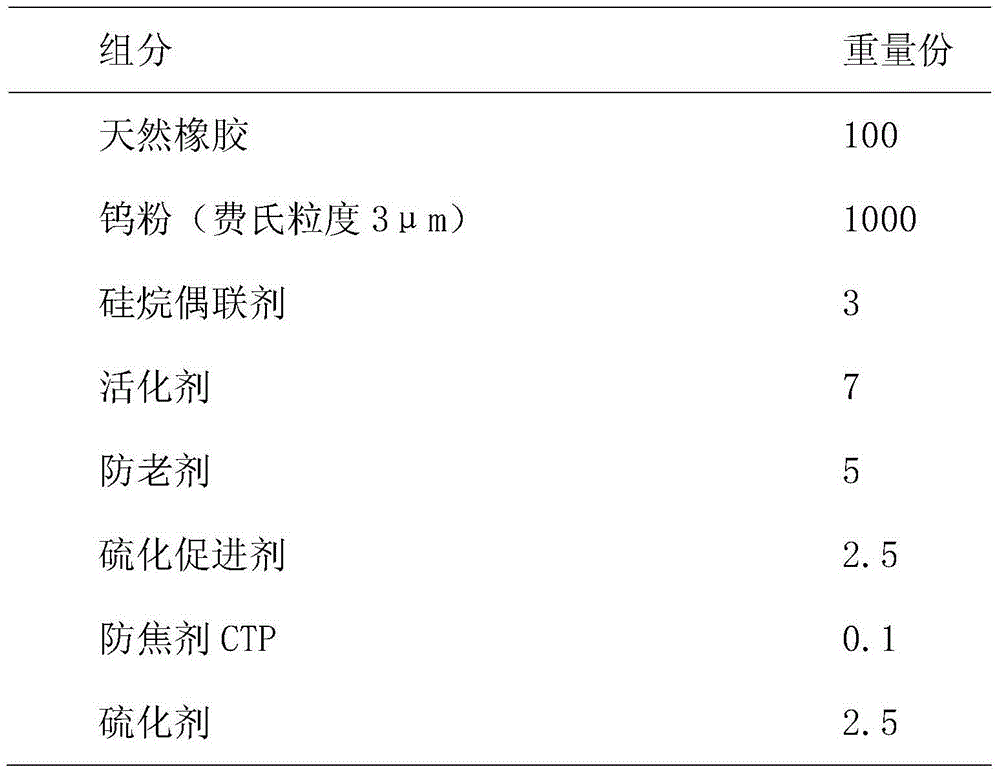

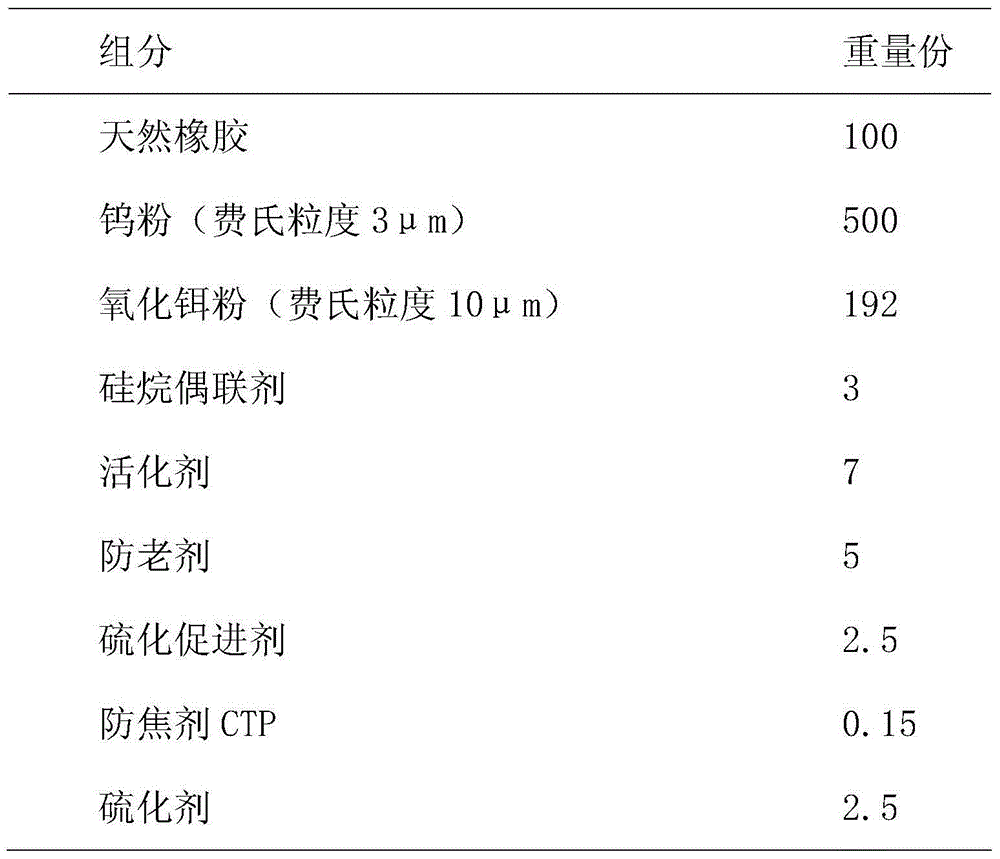

Tungsten-base composite material applied to ray shielding and preparation method thereof

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Polyamide toughening agent as well as preparation method and use thereof

InactiveCN104177825AImprove impact resistanceImprove low temperature impact resistanceElastomerPolyolefin

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

Method for enhancing anti-freeze and tensile properties of cellulose ion hydrogel, anti-freeze stretchable cellulose ion hydrogel and application

The invention provides a method for enhancing the anti-freeze and tensile properties of cellulose ion hydrogel, anti-freeze stretchable cellulose ion hydrogel and application, relating to the technical field of ion hydrogel. The method for enhancing the anti-freeze and tensile properties of the cellulose ion hydrogel comprises steps as follows: enabling the cellulose ion hydrogel to be immersed into a chlorinated metal salt solution, and dipping for 10-40min to obtain the anti-freeze stretchable cellulose ion hydrogel. Current cellulose ion hydrogel has the technical problems that the tensileproperty is poor and tensile and wire properties can lose at low temperature as well. According to the method, by enabling the cellulose ion hydrogel to be immersed in the chlorinated metal salt solution, metal ions and chloride ions in chlorinated metal salt enter the cellulose ion hydrogel, so that the anti-freeze property of the cellulose ion hydrogel is effectively improved, and the prepared anti-freeze stretchable cellulose ion hydrogel still has good mechanical property and chemical property at the low temperature.

Owner:SOUTH CHINA UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap