Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24 results about "Accelerant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Accelerants are substances that can bond, mix or disturb another substance and cause an increase in the speed of a natural, or artificial chemical process. Accelerants play a major role in chemistry—most chemical reactions can be hastened with an accelerant. Accelerants alter a chemical bond, speed up a chemical process, or bring organisms back to homeostasis. Accelerants are not necessarily catalysts as they may be consumed by the process.

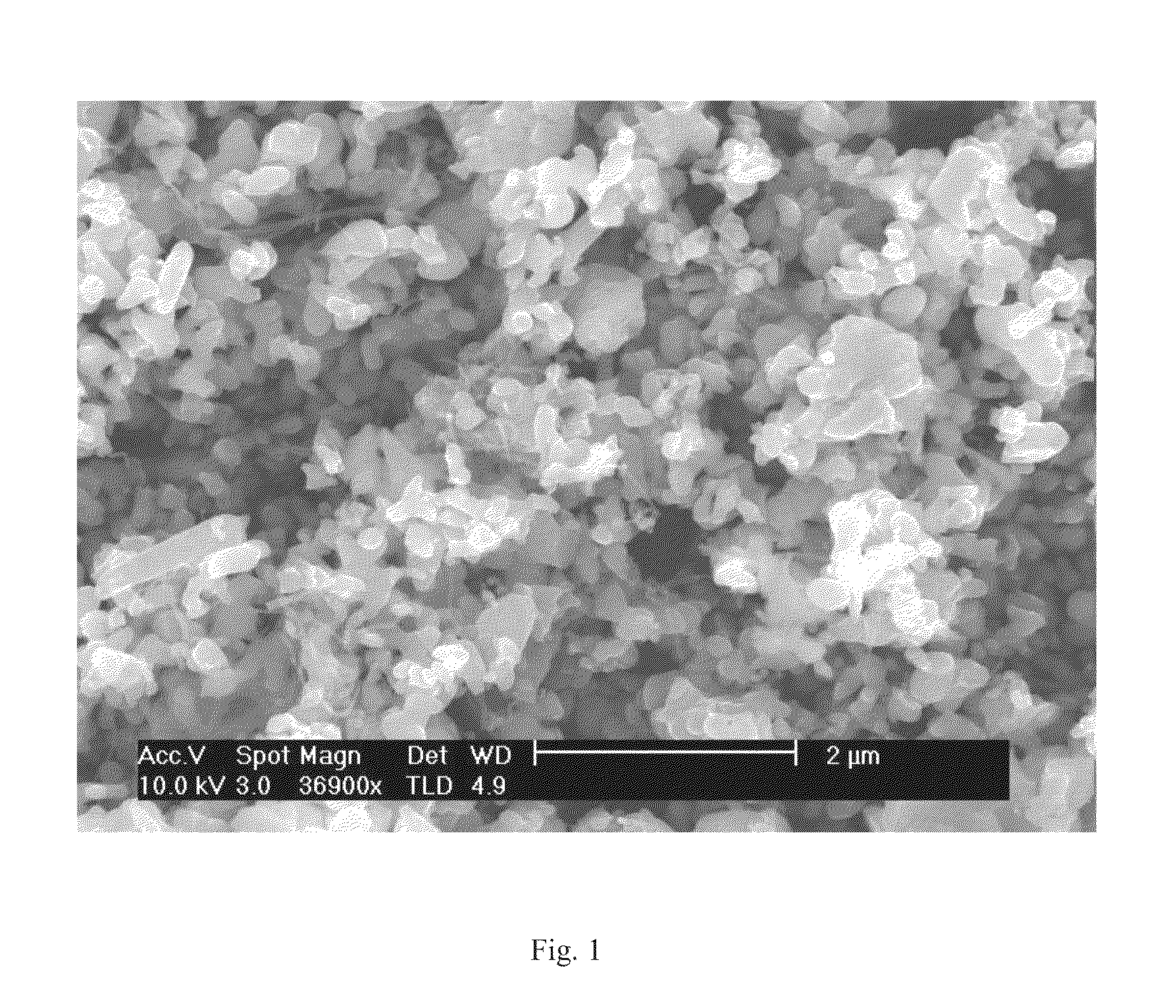

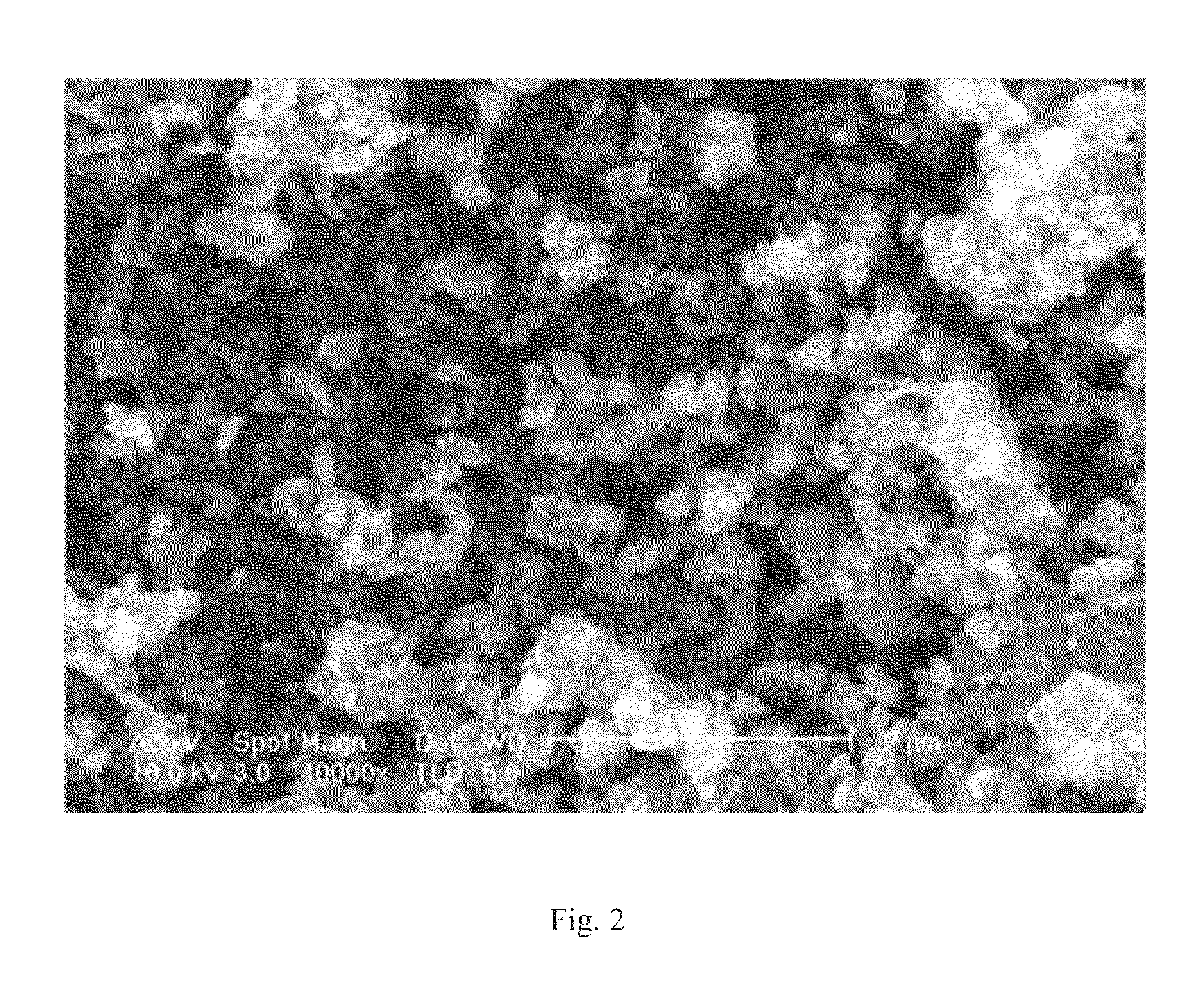

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

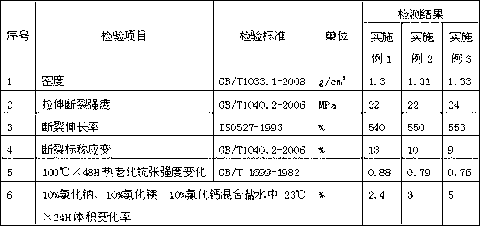

Formula of highly anti-fatigue automobile brake chamber rubber diaphragm material

ActiveCN101302311ASolve the blending problemImprove thermal stabilityPolytetramethylene terephthalateRubber material

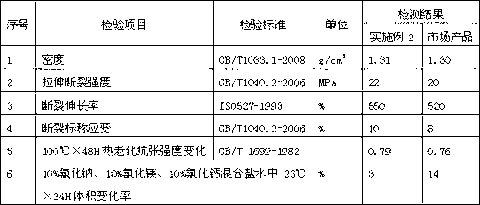

The invention provides a rubber material formulation for a high fatigue resistant rubber diaphragm of an automobile brake chamber, which is mainly prepared by natural rubber (NR), styrene butadiene rubber (SBR), polybutylene terephthalate (PBT), vulcanizing agent, zinc oxides, stearic acid, anti-aging agent, dispersant, accelerant, carbon black, aromatic oil and white carbon black. The physical mechanical properties of the rubber diaphragm of the automobile brake chamber prepared by the rubber formulation all reach the novel standard drafted by the Society of Automotive Engineering (SAE) of America; the service life of a platform of the rubber diaphragm reaches over 2 million times; the platform has the advantages of high stress at definite elongation, strength and elongation property, compression fatigue resistivity, flexural deformation resistance and attrition resistance, and maintenance of small variation of the material characteristics within the wide use temperature between 55 and 100 DEG C when the material is used; and the service life of the platform is basically the same as that of an air brake assembly, and resource conservation is greatly promoted simultaneously, thereby realizing conversion of the platform from 'a wearing part' to 'a permanent part'.

Owner:GUIZHOU JINGZHONG RUBBER & PLASTIC IND CO LTD

Wear resistant sole material

InactiveCN103483677ADoes not affect elasticityDoes not affect resilienceSolesEnvironmental resistanceFoaming agent

The invention relates to a wear resistant sole material. The wear resistant sole material comprises, by weight, 35-45 parts of EVA, 4-8 parts of styrene butadiene rubber, 1-8 parts of butadiene rubber, 1-4 parts of a vulcanizing agent, 2-5 parts of a reinforcing agent, 1-4 parts of an activator, 1-4 parts of an accelerant and 0.5-3 parts of a foaming agent. The wear resistant material greatly improves the wear resistance of a sole without influencing the elasticity, the resilience, the portability or the like of the sole, and also has the advantages of non-toxicity, no pollution, safety and environmental protection.

Owner:KUNSHAN CHUNBAI PRECISE HARDWARE CO LTD

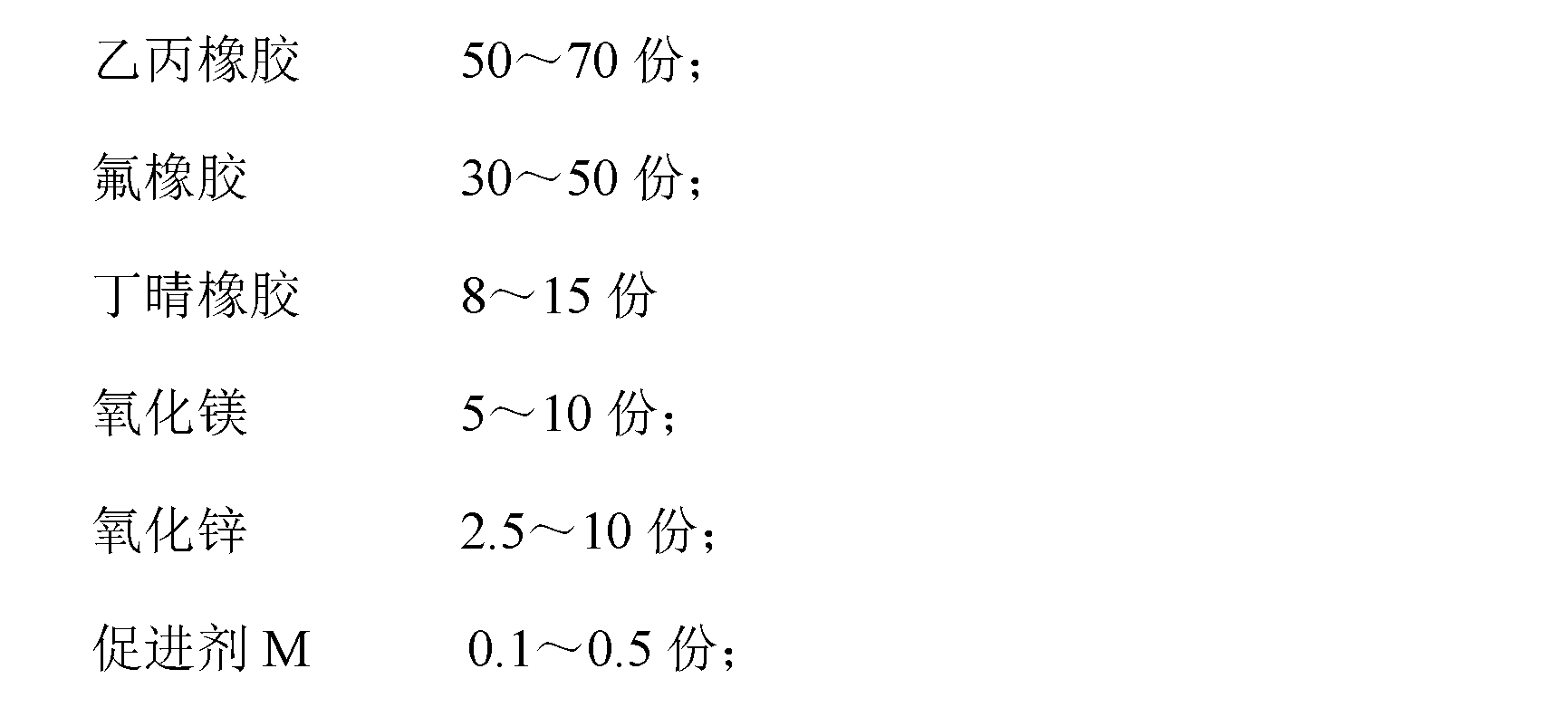

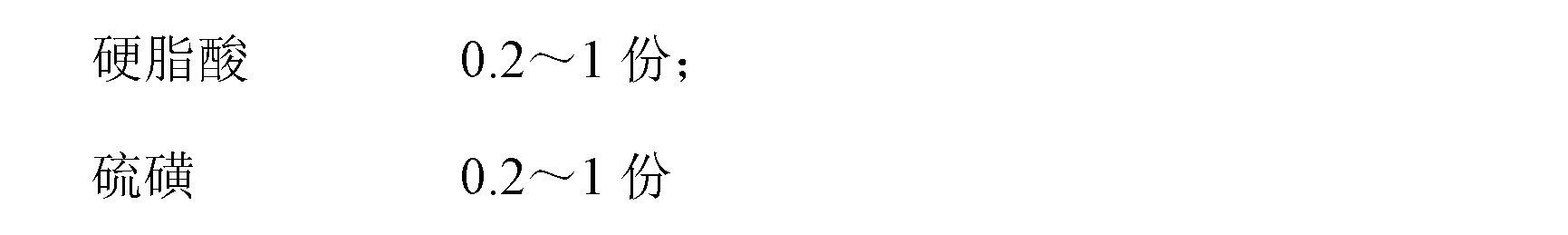

Formula of fluororubber-ethylene propylene rubber mixing rubber compound

ActiveCN103232643AImprove media resistanceImprove low temperature resistancePolymer scienceStearic acid

Owner:扬中市橡胶塑料厂有限公司

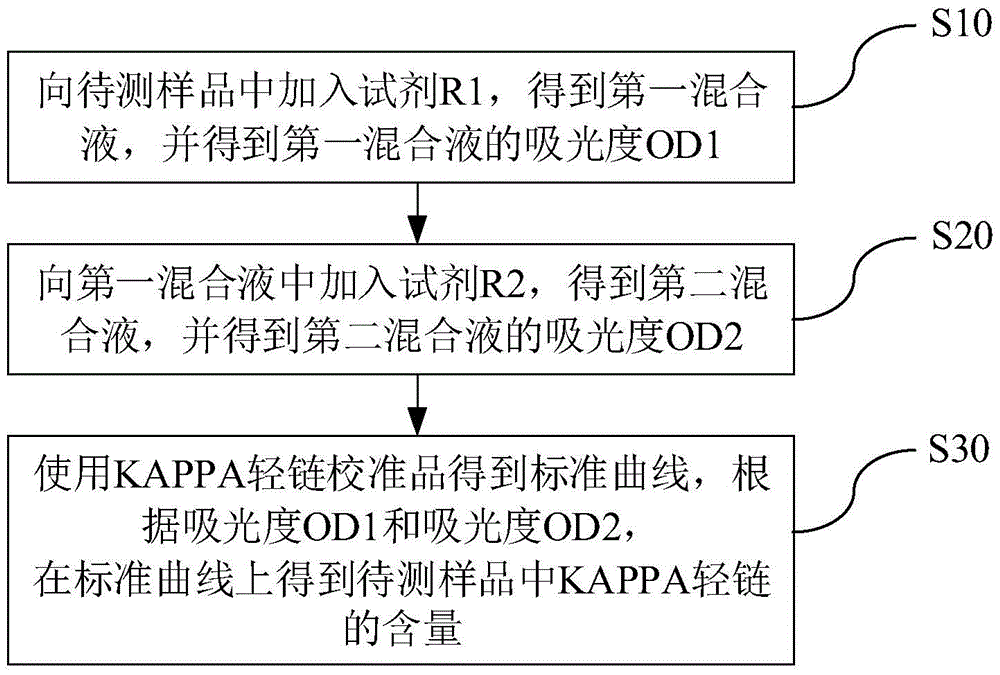

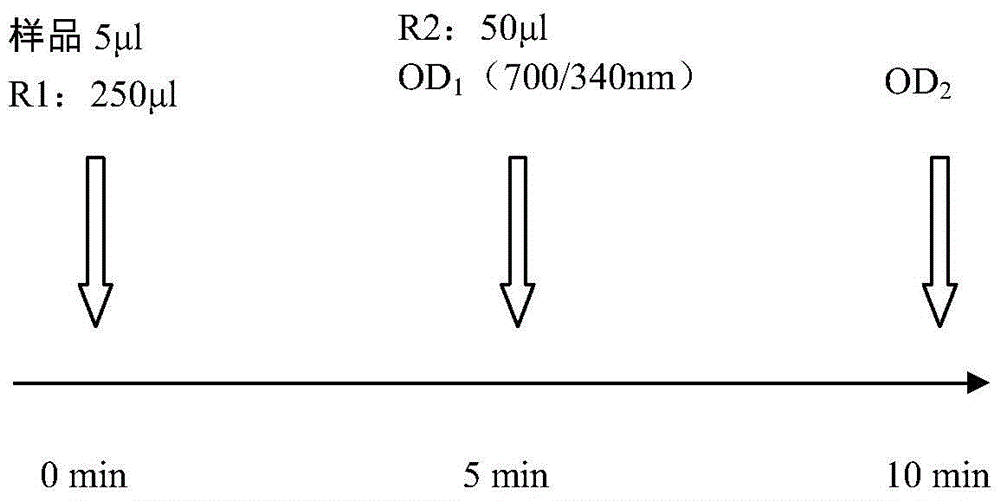

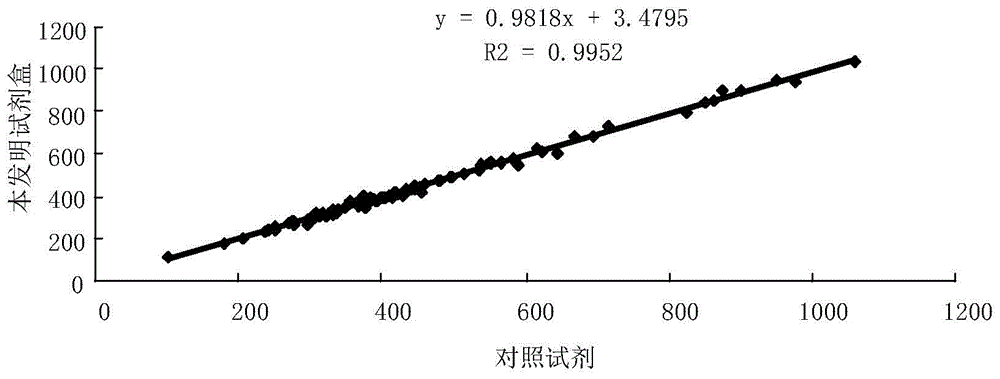

Kit and method for detecting content of KAPPA light chain and application of kit

ActiveCN105738300ADetection is simple and fastEasy to useDisease diagnosisColor/spectral properties measurementsAntigenC1-inhibitor

Owner:潍坊三维生物工程集团有限公司

Tire inner liner rubber and preparation method thereof

Owner:DEZHOU LINGLONG TIRE

High-strength marine rubber fender

InactiveCN103012863AImprove tensile strength at breakRubber materialSulfide

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

Desulfurization additive as well as applications and using method of same

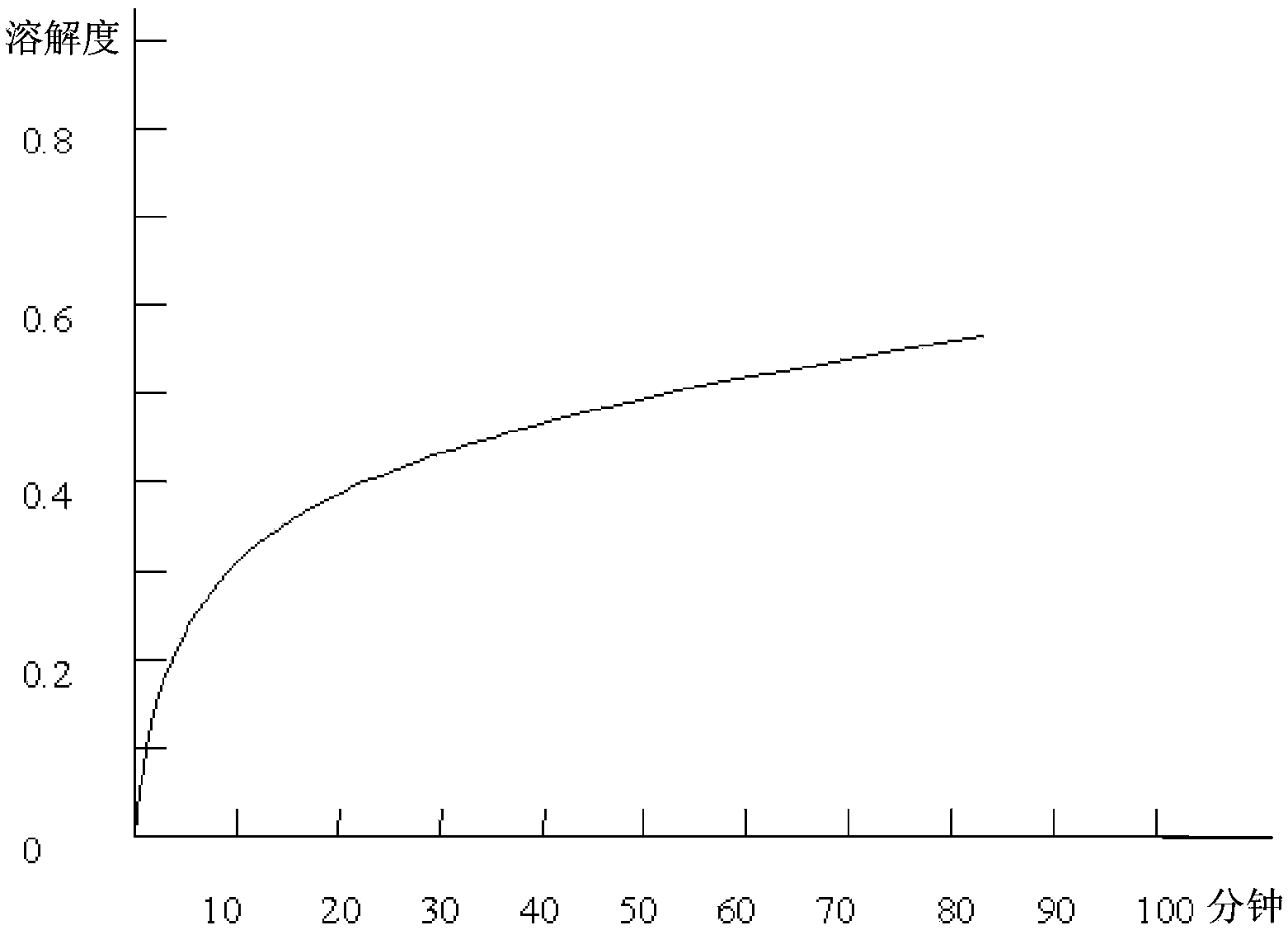

InactiveCN103446870ABuffer pH dropHigh reactivityDispersed particle separationChemical industryReaction rate

Owner:BEIJING HUADIAN ZHUOYUE TECH CO LTD

Nano conductive ink and preparation method, RFID antenna and application thereof

InactiveCN108641487AReduce dosageLow resistivityAntenna supports/mountingsInksOrganic solventAccelerant

Owner:佛山市瑞联福电子科技有限公司

Rubber roll sheet of rubber roll for drawing frame or combing machine

InactiveCN103628196AEasy to transportReduce installationCombing machinesDrafting machinesAcrylonitrileEngineering

The invention relates to a drafting component used in the technical field of textile accessories, in particular to a rubber roll sheet of a rubber roll for a drawing frame or combing machine. The rubber roll sheet is formed by bonding an iron arc-shaped plate with the radian of 120 degrees to an adhesive material the same with a bonding surface of the iron arc-shaped plate. Five holes are evenly drilled in the rubber roll sheet. The adhesive material is prepared by 90-110 parts of butadiene-acrylonitrile rubber, 3-5 parts of sulphur, 1-2 parts of accelerant DM, 10-15 parts of zinc oxide, 3-5 parts of coupling agent, 1.2-3.8 parts of age resister, 30-60 parts of white carbon black, 8-25 parts of titanium dioxide, 4-20 parts of electrostatic agent and 5-20 parts of auxiliary powder.

Owner:TAIZHOU YAMEI RUBBER PROD

Rubber formula for inner tube-splicing dies

Owner:XIAMEN CHENGSHIN ENTERPRISE CO LTD

Flame-retardant outlet nozzle for air conditioner motor

InactiveCN105418990AFlame retardantRestorativeMicrocrystalline waxAging resistance

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

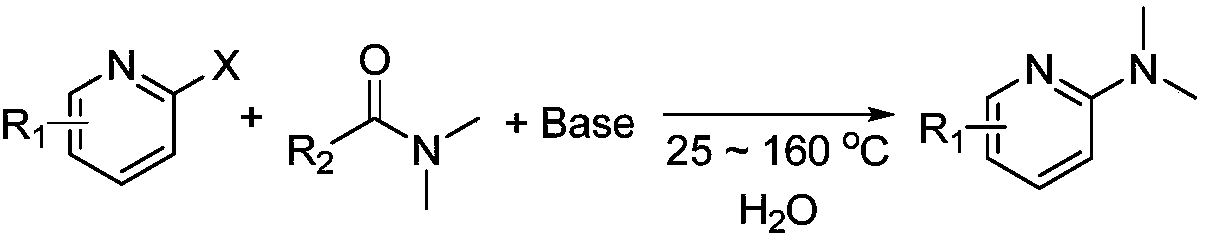

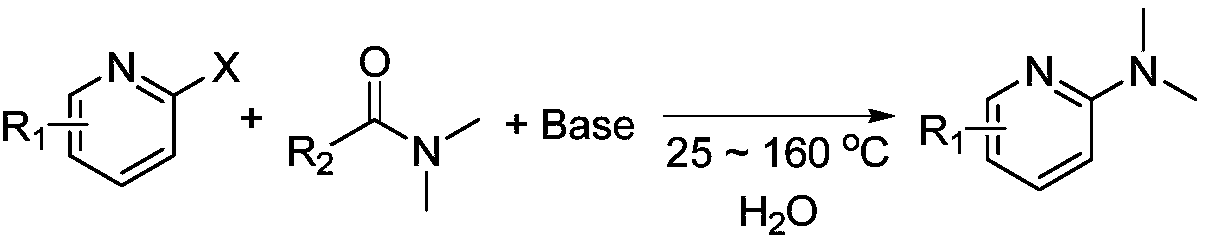

Novel green and practical synthesis method of N,N-dimethyl pyridine compound

ActiveCN108689923APromoting the dehaloamination reaction to generateOrganic chemistryN dimethylformamideSynthesis methods

Owner:TAIZHOU UNIV

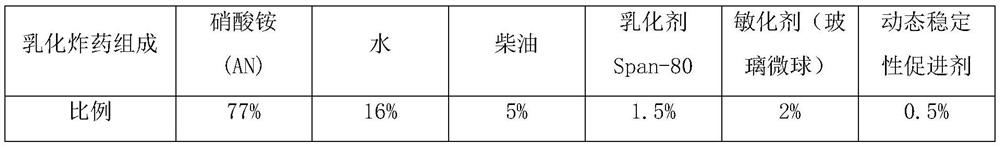

Dynamic stability accelerant for emulsion explosive

ActiveCN114057530ASimple preparation processRaw materials are easy to getNon-explosive stabilisersPolymer scienceExplosive Agents

Owner:NANJING XIAOZHUANG UNIV

Polytrifluoropropyl-methyl-siloxane-coated titanium dioxide composite material as well as preparation method and application thereof

ActiveCN110934776AHigh whitenessGood weather resistanceCosmetic preparationsBody powdersOrganic filmWeather resistance

The invention discloses a polytrifluoropropyl-methyl-siloxane-coated titanium dioxide composite material as well as a preparation method and application thereof. The titanium dioxide composite material comprises TiO2 ultrafine particles. The surfaces of the TiO2 ultrafine particles are coated with a polytrifluoropropyl methyl siloxane organic film layer to form a core-shell structure. In addition,the preparation method comprises the following steps: preparing a fluorosilanol alkali metal prepolymer; adding TiO2 ultrafine particles, the remaining 1, 3, 5-trimethyl-1, 3, 5-tri (3, 3, 3-trifluoropropyl) cyclotrisiloxane and an accelerant to prepare the titanium dioxide composite material. The titanium dioxide composite material having advantages of high whiteness, good weather resistance, good dispersity, strong ultraviolet absorption capacity, hydrophobicity, oleophobicity and the like can be applied to cosmic product preparation widely and has the great application value and broad application prospects; moreover, the preparation method is simple and is operated conveniently; the reaction is controllable; the titanium dioxide composite material is suitable for large-scale preparation; and the polytrifluoropropyl-methyl-siloxane-coated titanium dioxide composite material is suitable for industrial production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

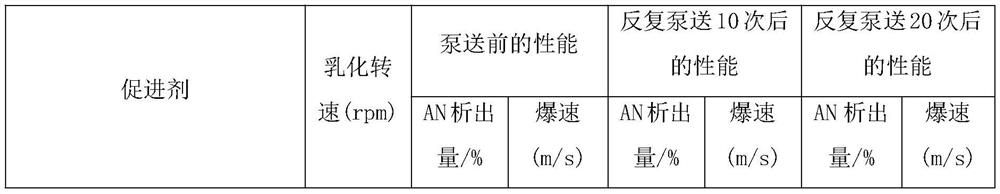

Chemical-Mechanical Polishing Compositions Containing Aspartame And Methods Of Making And Using The Same

InactiveUS20080314872A1Low rateOther chemical processesDecorative surface effectsCompound (substance)Slurry

Owner:FERRO CORP

Method for improving corrosion resistance of vinyl resin

ActiveCN114316750AHigh barrierImprove hydrophobicityAnti-corrosive paintsEpoxy resin coatingsOctanoic AcidsResin coating

Owner:广东美亨新材料科技有限公司 +1

Rubber composition for improving performance of tire on ice and snow field and tire

ActiveCN113321856AIncrease contact areaImprove comfortSpecial tyresRolling resistance optimizationPolymer scienceVulcanization

Owner:CHENG SHIN RUBBER CHINA

Preparation method for composite material of corrugated pipe of natural gas pipeline

Owner:江苏三水企业孵化器有限公司

Rubber cable insulating layer

InactiveCN106893209AGood physical and mechanical propertiesImprove tear resistanceRubber insulatorsWeather resistanceSulfur

Owner:烟台鑫海耐磨胶业有限公司

Tear-resistant sole material and manufacturing method thereof

InactiveCN111171393AMeet the needs of anti-slipImprove tear resistanceSolesFoaming agentTear resistance

The invention discloses a tear-resistant sole material and a manufacturing method thereof. The tear-resistant sole material comprises the following components in parts by weight: 55-65 parts of natural rubber; 35 to 45 parts of EPDM; 4-6 parts of a compatilizer; 40-50 parts of a filler, 3-4 parts of activated zinc oxide; 1.5 to 2 parts of stearic acid; 2-4 parts of a foaming agent; 2.5 to 3 partsof vulcanizing agent; 0.3 to 0.6 part of an accelerant; and 0.2 to 0.4 part of an anti-aging agent; a preparation process of the compatilizer comprises the following steps: mixing 10-12 parts by weight of brominated butyl rubber and 0.2-0.3 part by weight of BPO, heating to 60-70 DEG C, mixing for 15-20 minutes, adding 0.5-0.7 part by weight of octadecyltrimethoxysilane, heating to 110-120 DEG C,continuously mixing for 10-15 minutes, cooling, and discharging to obtain the compatilizer. The tear-resistant sole material can meetthe anti-skid requirements ofsoles ondry surfaces andwet surfaces,the quality far exceeds the national standard, and the prepared soles are good in tear resistance and wear-resistant compared with other types of anti-skid soles, and wearing durability is achieved.

Owner:WENZHOU RUNBANG SHOES CO LTD

Permanent-compression-resistant sealing ring for carrier roller and preparation method of permanent-compression-resistant sealing ring

PendingCN114805965AExcellent resistance to permanent compressionGuaranteed tightnessPolymer scienceStearic acid

Owner:SHANGYU HUAYUN CONVEYING EQUIP CO LTD

Transport vehicle crown rubber

Owner:QINGDAO SANHUI RUBBER MACHINERY MFG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap